Porous environment-friendly material

An environmentally friendly material and porous technology, applied in ceramic products, other household appliances, household appliances, etc., can solve the problems of not achieving reduction, stabilization, harmlessness, recycling, secondary pollution, etc., and achieve soil Water retention and breathability, avoid pollution, facilitate purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: A porous environmental protection material, the specific gravity of the porous environmental protection material is 0.6 ~ 1.1, and the water absorption is below 15%; the porous environmental protection material is obtained by the following steps:

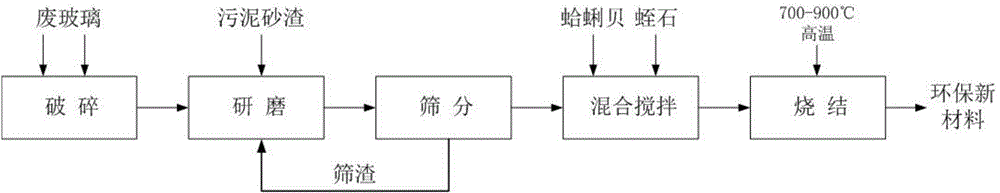

[0022] Step 1. Put the waste glass into the glass crusher and crush it into 5~10mm glass fragments;

[0023] Step 2. Grinding the glass shards in step 1 to produce glass powder with a particle size of micron;

[0024] Step 3, mixing the glass powder in step 2 with the sludge and sand slag produced after dehydration, drying and incineration from the sewage treatment plant according to the weight ratio of 80:5 and grinding to form a primary powder mixture;

[0025] Step 4, sieving the primary powder mixture from step 3, and then adding the sieved primary powder mixture composed of glass powder and sludge sand slag into a mixing and stirring device;

[0026] Step 5, 10 parts of clam shells and 5 parts of vermiculi...

Embodiment 2

[0031] Embodiment 2: A porous environmental protection material, the specific gravity of the porous environmental protection material is 0.6~1.1, and the water absorption is below 15%; the porous environmental protection material is obtained by the following steps:

[0032] Step 1. Put the waste glass into the glass crusher and crush it into 5~10mm glass fragments;

[0033] Step 2. Grinding the glass shards in step 1 to produce glass powder with a particle size of micron;

[0034] Step 3, mixing the glass powder in step 2 with the sludge and sand slag produced after dehydration, drying and incineration from the sewage treatment plant according to the weight ratio of 60:10 and grinding to form a primary powder mixture;

[0035] Step 4, sieving the primary powder mixture from step 3, and then adding the sieved primary powder mixture composed of glass powder and sludge sand slag into a mixing and stirring device;

[0036] Step 5, 15 parts of clam shells and 15 parts of vermiculi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com