Patents

Literature

116results about How to "High hole density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

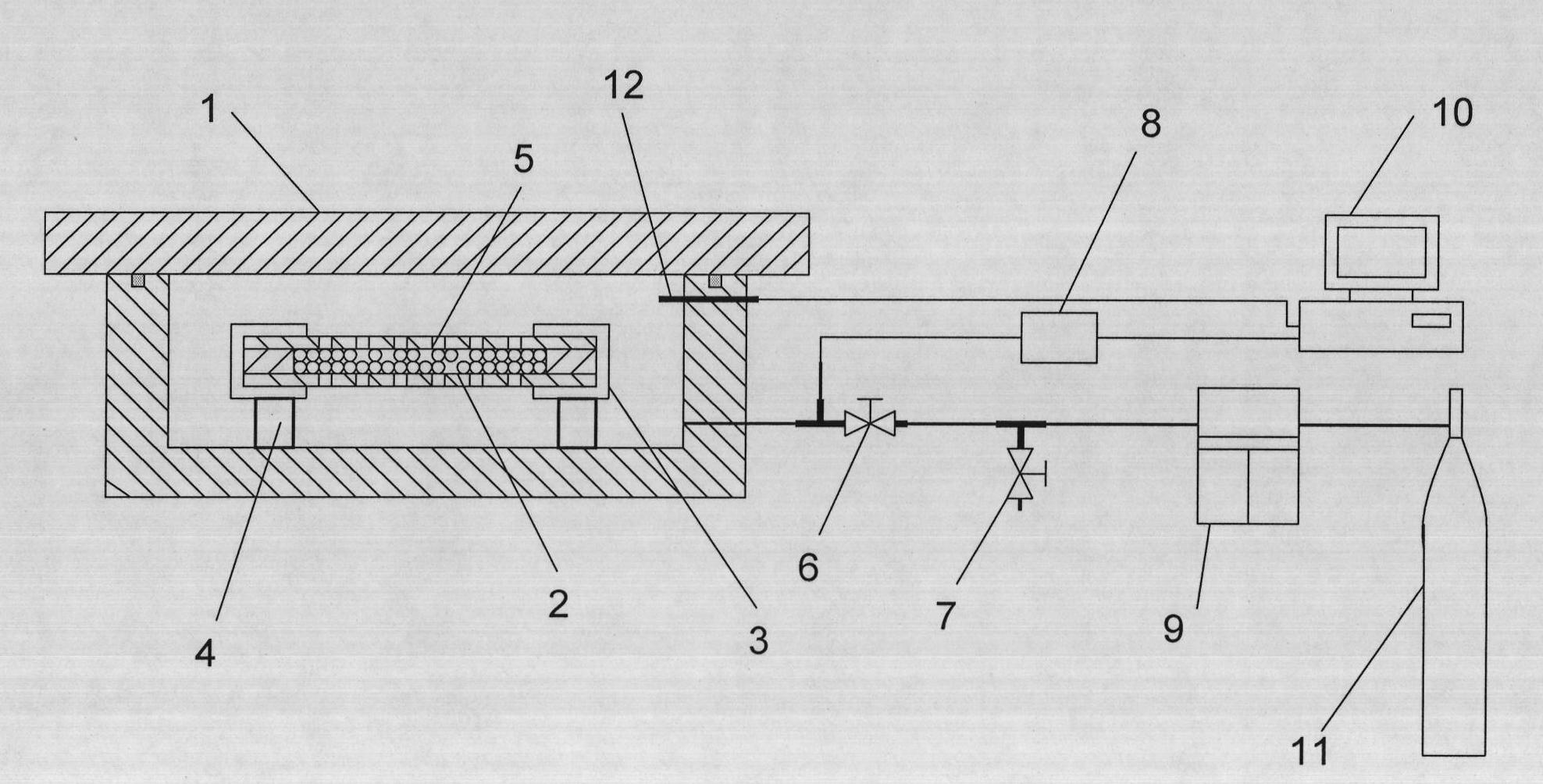

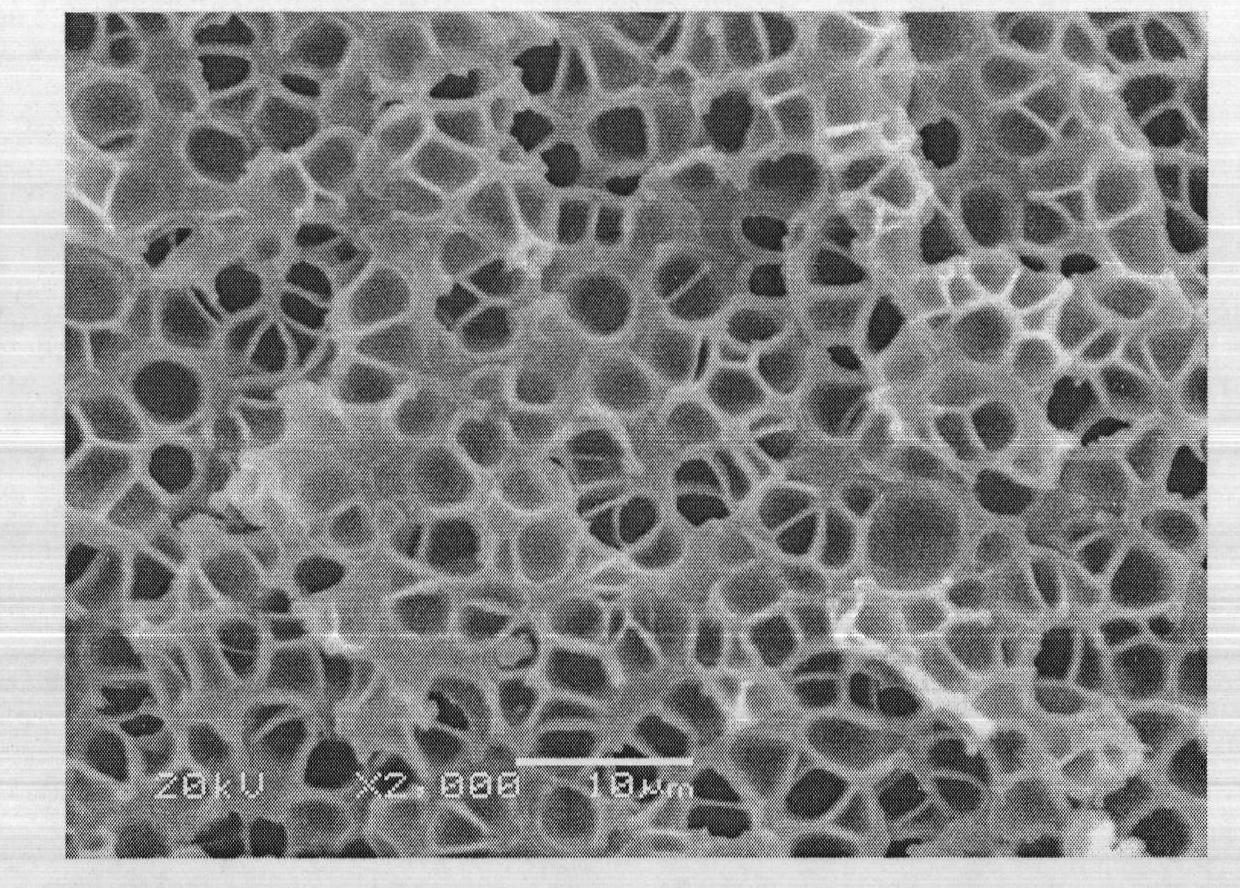

Method for preparing polymer microporous foaming material by supercritical mould foaming

The invention provides a method for preparing a polymer microporous foaming material by supercritical mould foaming. The method comprises the following steps of: heating a foaming mould on a mould press to the foaming temperature; placing a polymer into the mould; closing the mould by using the mould press; sealing the mould; introducing supercritical fluid, which swells and diffuses to the polymer, into the mould; and opening the mould by using the mould press to release pressure and foam to obtain the polymer microporous foaming material. Compared with the prior art, the method has the advantages that: the high-temperature and high-pressure supercritical fluid is used for swelling the polymer, so the moulding cycle is greatly shortened; the limit that only microporous foaming sheet material with lesser thickness can be manufactured in the prior art is broken through, so a polymer microporous foaming plate with greater thickness can be manufactured; when the mould is opened, the pressure-releasing speed is high and the foaming pore core-forming speed is high, so the formed microporous foaming material has smaller foaming pores, higher pore density and more excellent performance; and multiple layers of moulds can be placed on one mould press, so the method is suitable for industrialized scale production.

Owner:常州福源科技新材料有限公司

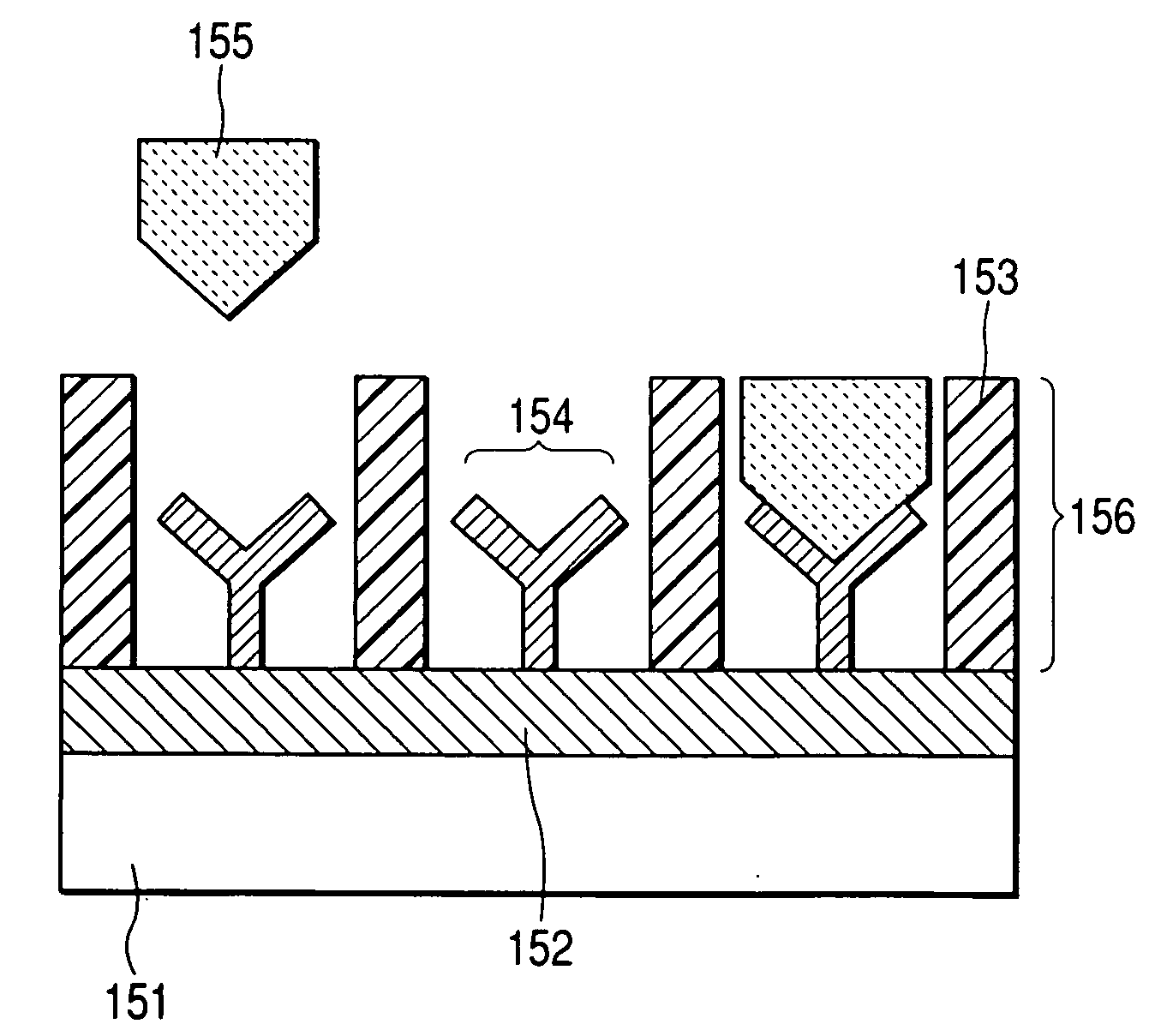

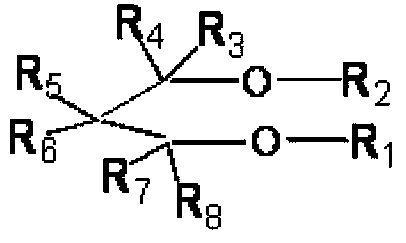

Customized polishing pads for CMP and methods of fabrication and use thereof

ActiveCN101166604AHigh hole densityLapping machinesFlexible-parts wheelsChemical-mechanical planarizationSurface engineering

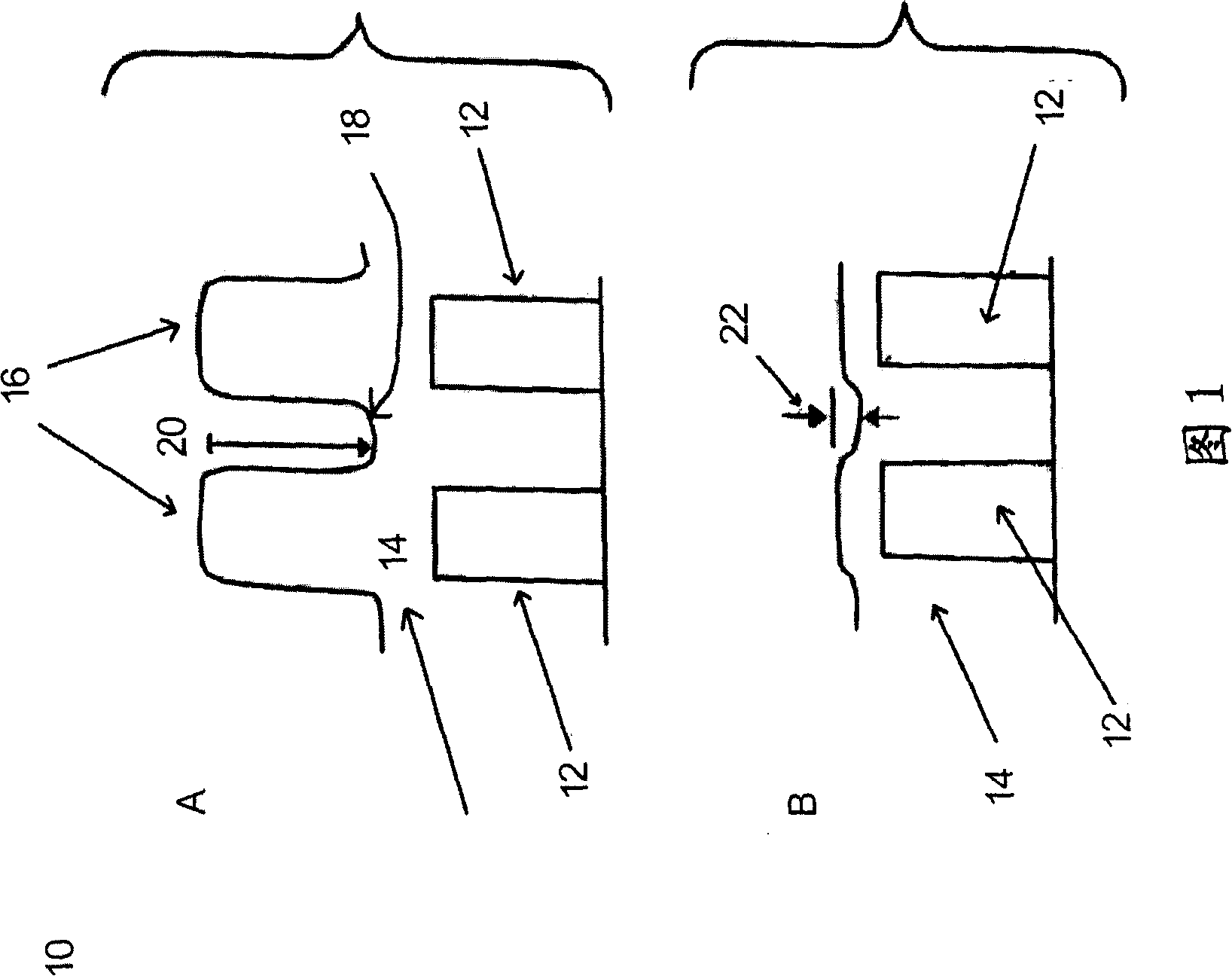

The present application relates to polishing pads for chemical mechanical planarization (CMP) of substrates, and methods of fabrication and use thereof. The pads described in this invention are customized to polishing specifications where specifications include (but not limited to) to the material being polished, chip design and architecture, chip density and pattern density, equipment platform and type of slurry used. These pads can be designed with a specialized polymeric nano-structure with a long or short range order which allows for molecular level tuning achieving superior themo-mechanical characteristics. More particularly, the pads can be designed and fabricated so that there is both uniform and nonuniform spatial distribution of chemical and physical properties within the pads. In addition, these pads can be designed to tune the coefficient of friction by surface engineering, through the addition of solid lubricants, and creating low shear integral pads having multiple layers of polymeric material which form an interface parallel to the polishing surface. The pads can also have controlled porosity, embedded abrasive, novel grooves on the polishing surface, for slurry transport, which are produced in situ, and a transparent region for endpoint detection.

Owner:CMC MATERIALS INC

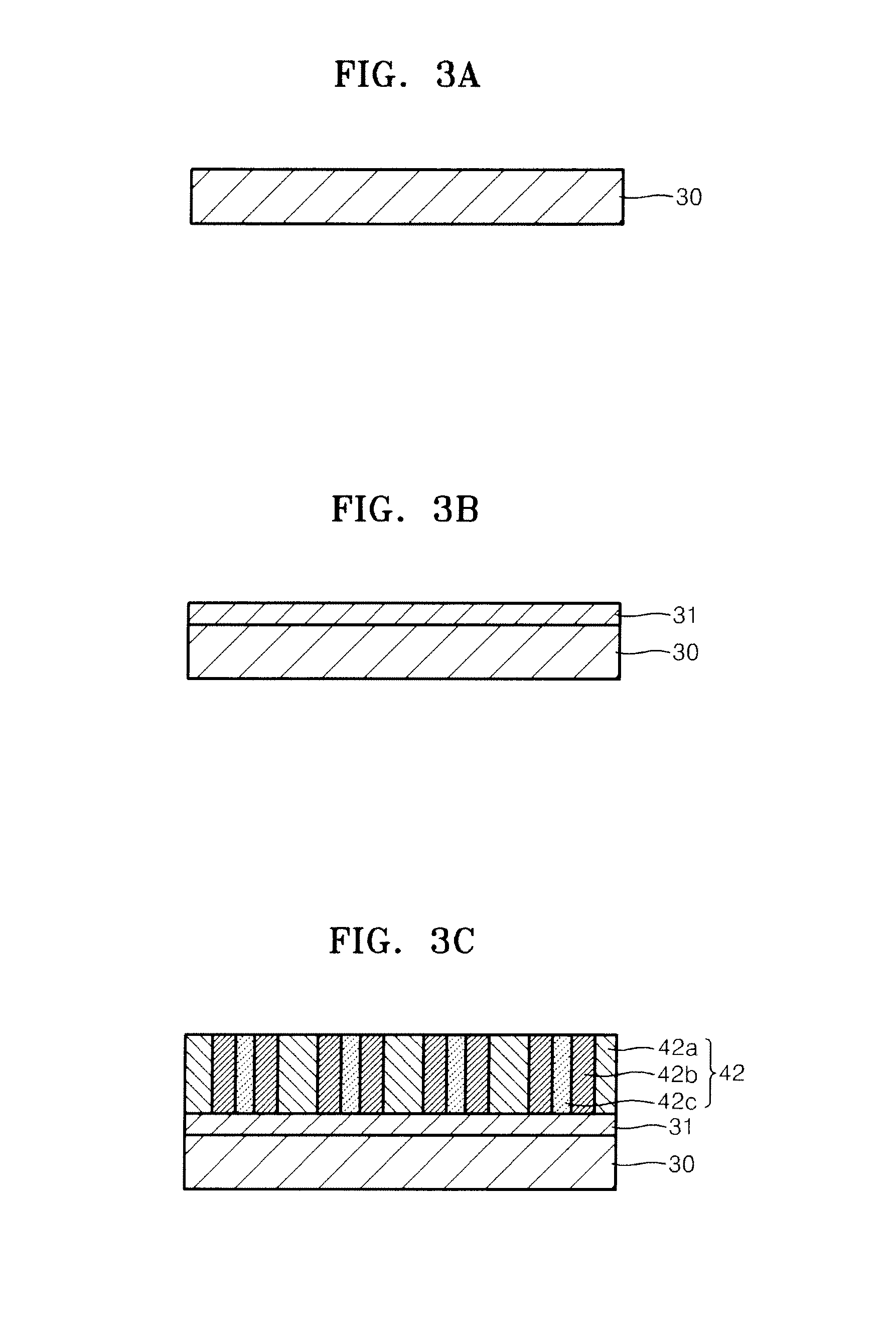

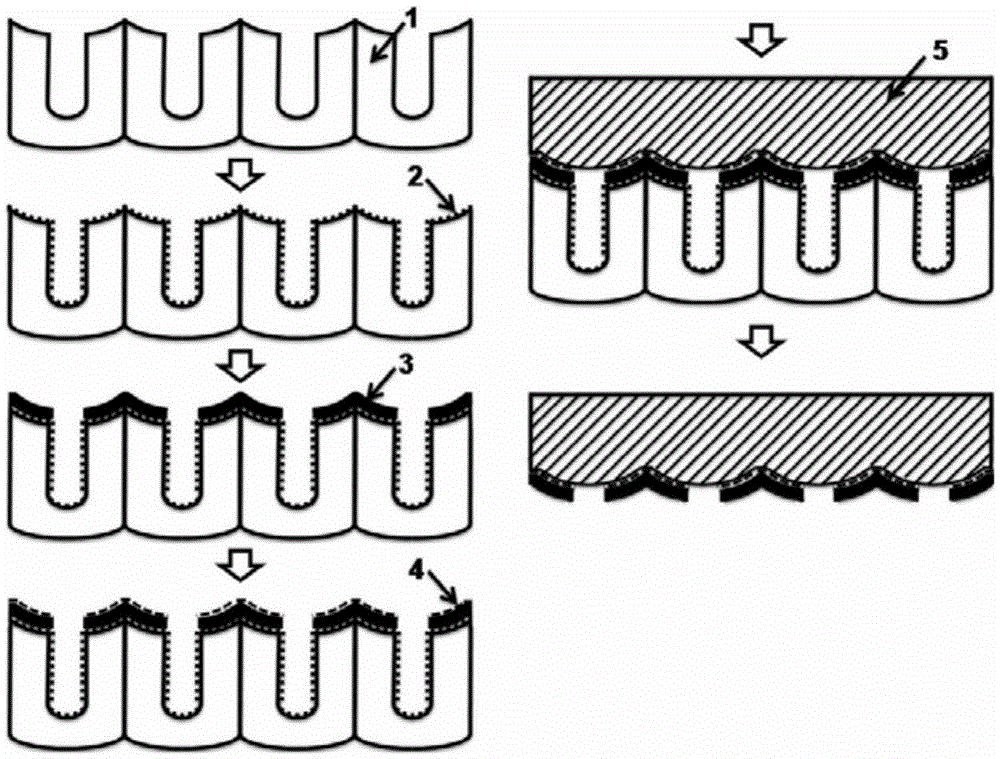

Nanoporous membrane, process of fabricating the same and device for controlled release of biopharmaceuticals comprising the same

InactiveUS7935416B2High hole densityUniform pore sizeSemi-permeable membranesMembranesControl releaseNanoporous membrane

Provided are a nanoporous membrane including a support; a first separation layer with a plurality of first nano-sized pores and a first matrix; and a second separation layer having a plurality of second pores respectively corresponding to the plurality of first pores of the first separation layer and a second matrix, and formed on the first separation layer, wherein a density of the plurality of the first pores and the second pores is equal to or greater than 1010 / cm2, and a diameter of each of the second pores is less than that of the corresponding first pore, a process of fabricating the same, and a device for a controlled release of biopharmaceuticals including the nanoporous membrane. The device for a controlled release of biopharmaceuticals including the nanoporous membrane can release biopharmaceuticals at a constant rate for a long period of time regardless of the concentration of the biopharmaceuticals including in pharmaceuticals, and high flex and selectivity.

Owner:POSTECH ACAD IND FOUND

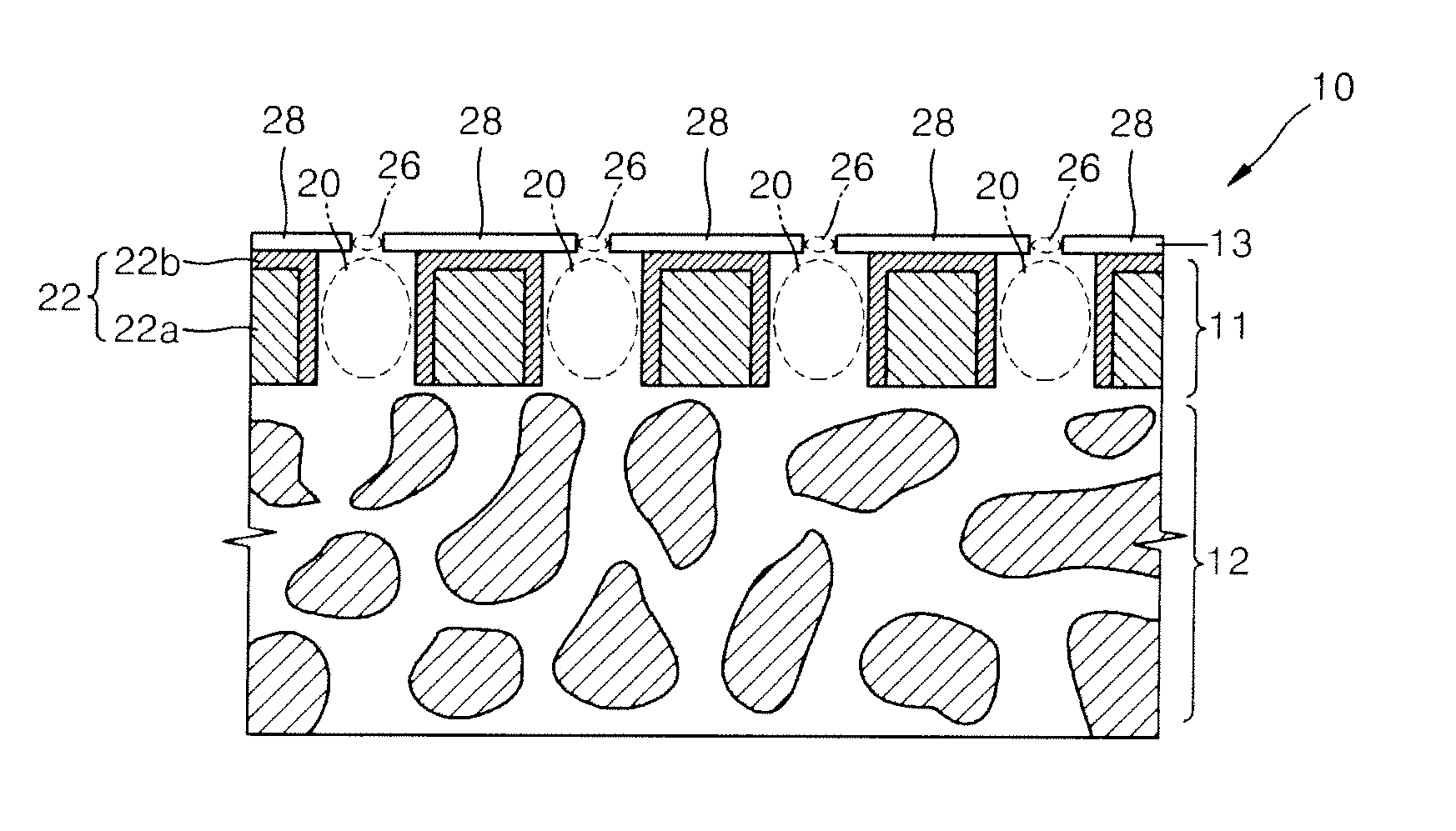

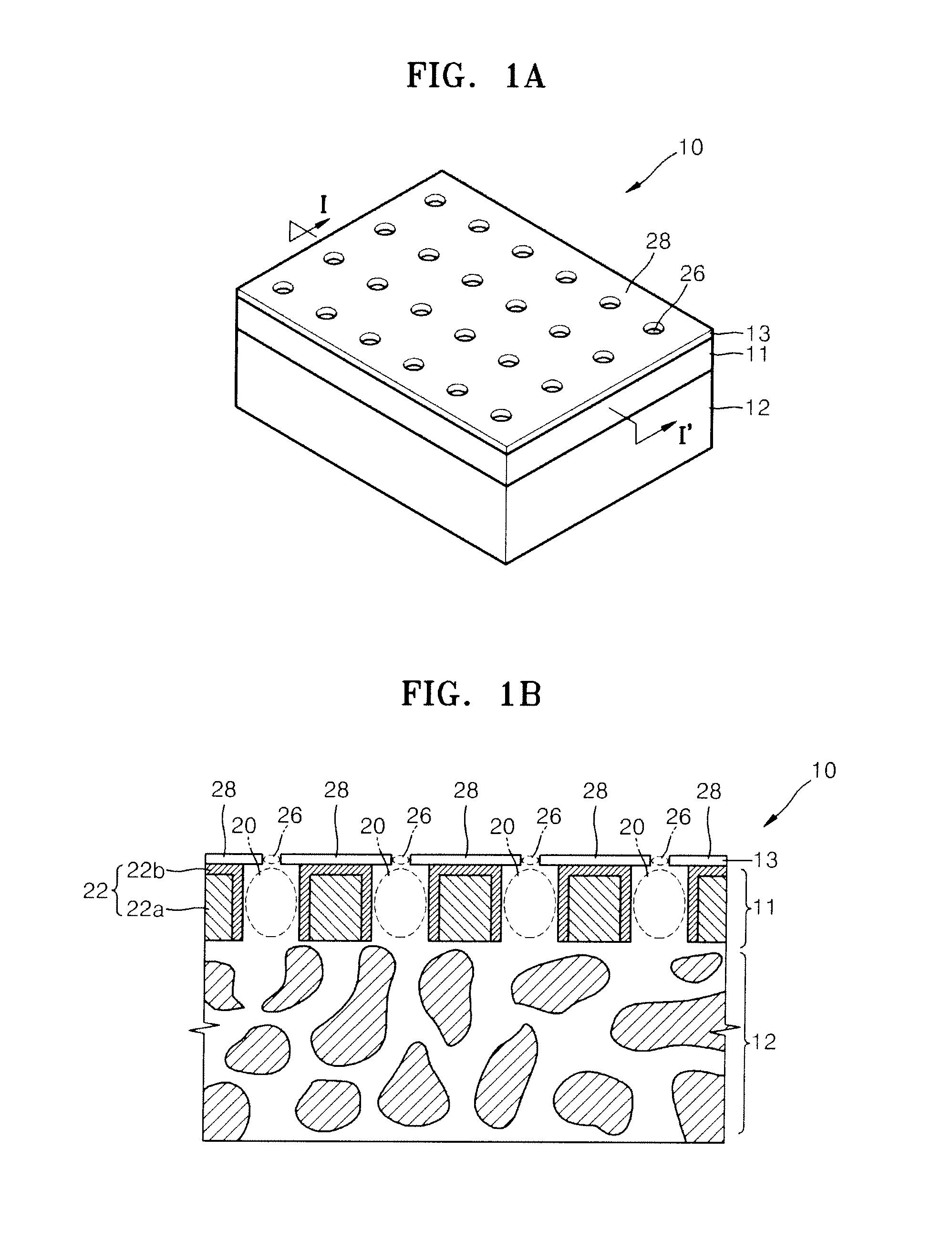

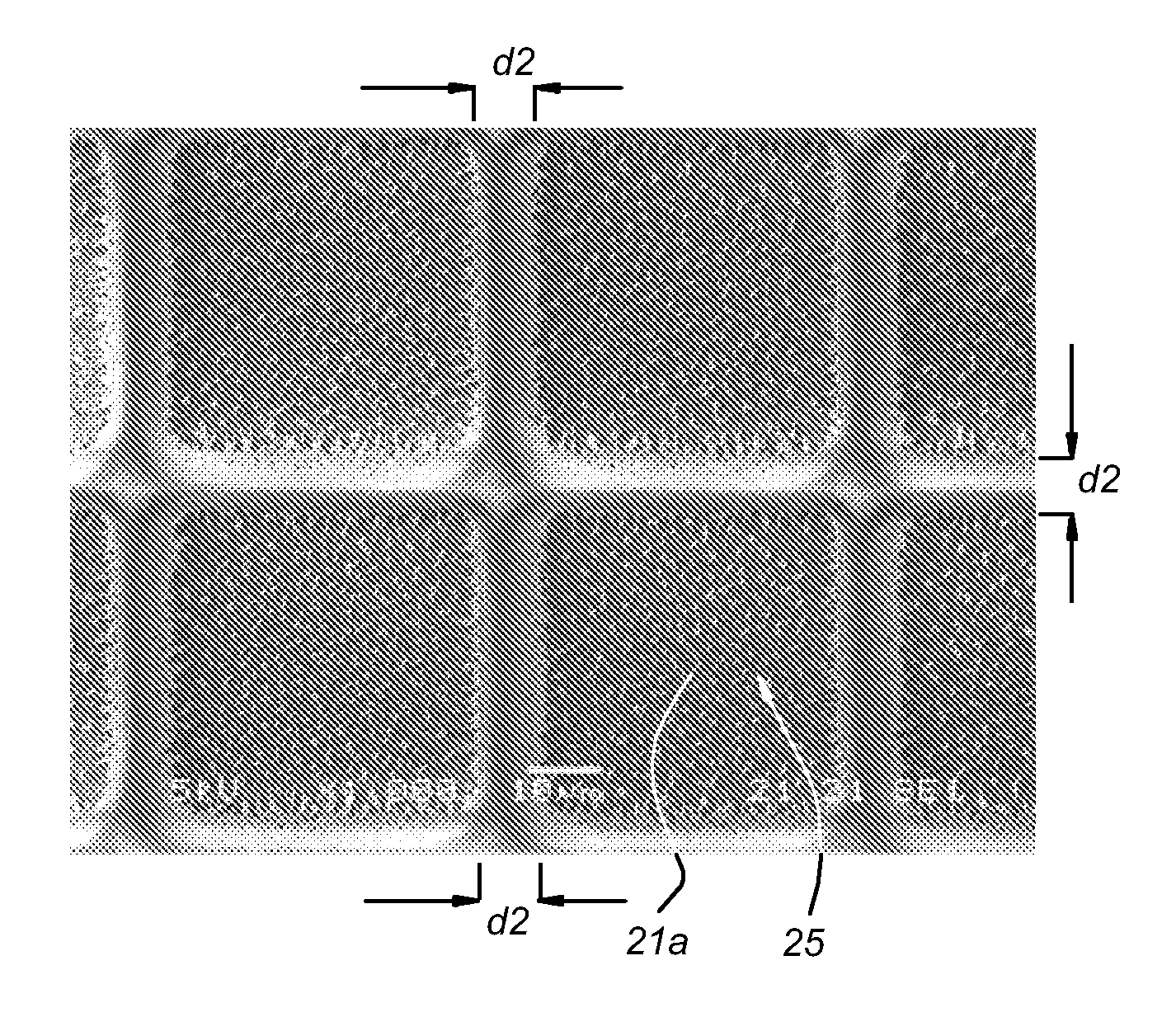

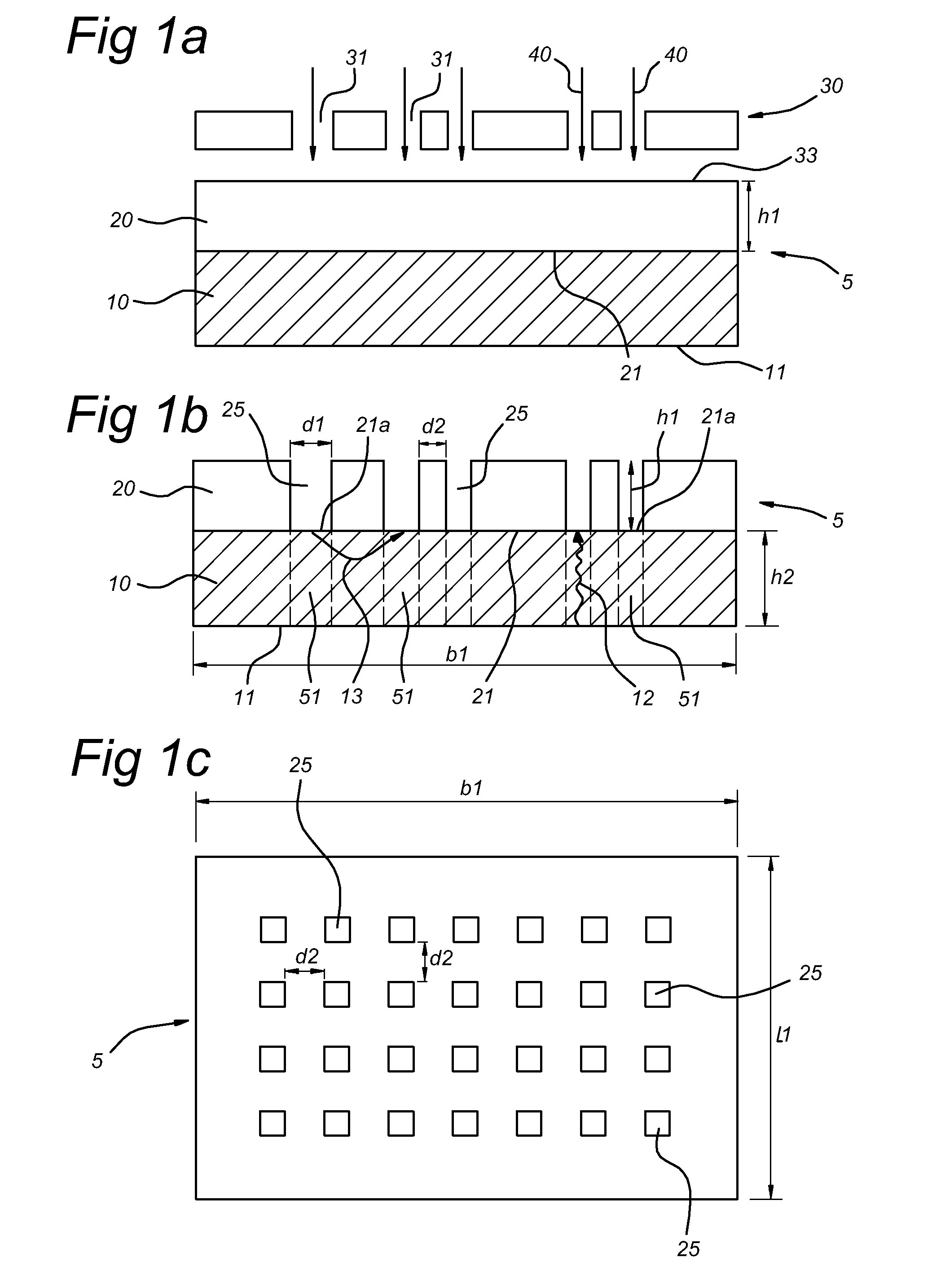

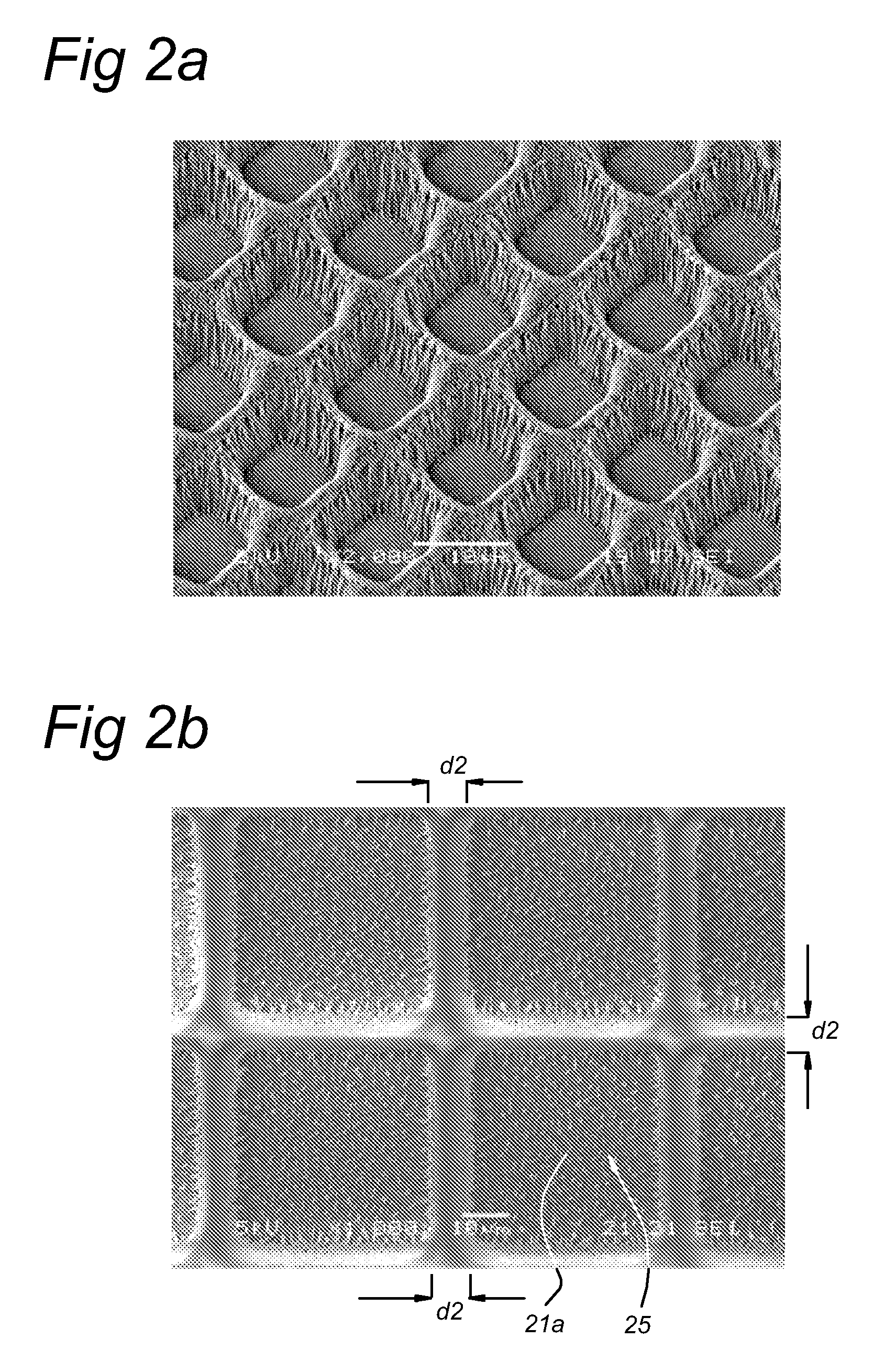

Biochip and process for the production of a biochip

InactiveUS20090042736A1High hole densityReduce adhesionSequential/parallel process reactionsMicrobiological testing/measurementCoated surfacePolymer coatings

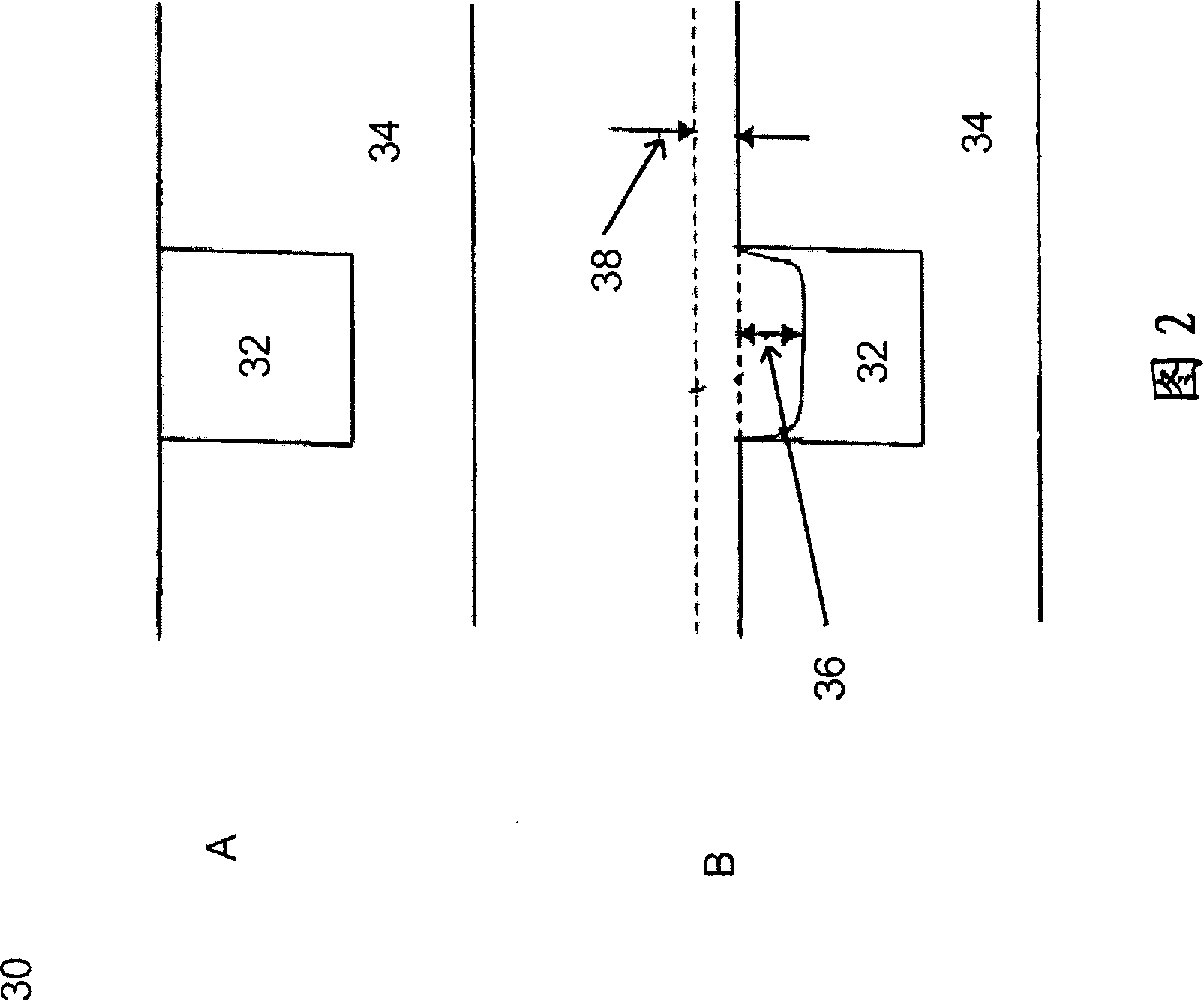

The invention relates to a biochip (5) comprising a porous support (10), wherein the porous support (10) comprises at least one surface coated with a coating, preferably a polymer coating (20), wherein the coating is patterned with a micro compartments (25) pattern, with the support providing a bottom surface to the compartments and the coating providing edges to the compartments, and wherein the pattern comprises at least 400 compartments per mm2. The biochip (5) can be obtained by a process comprising providing a porous support (10); coating at least one surface of the support with a coating (20); arranging between the coated surface and an ion etching device a shadow mask with a predetermined hole pattern; and ion etching at least part of the coating such that a patterned coating with micro compartments (25) is obtained.

Owner:DSM IP ASSETS BV

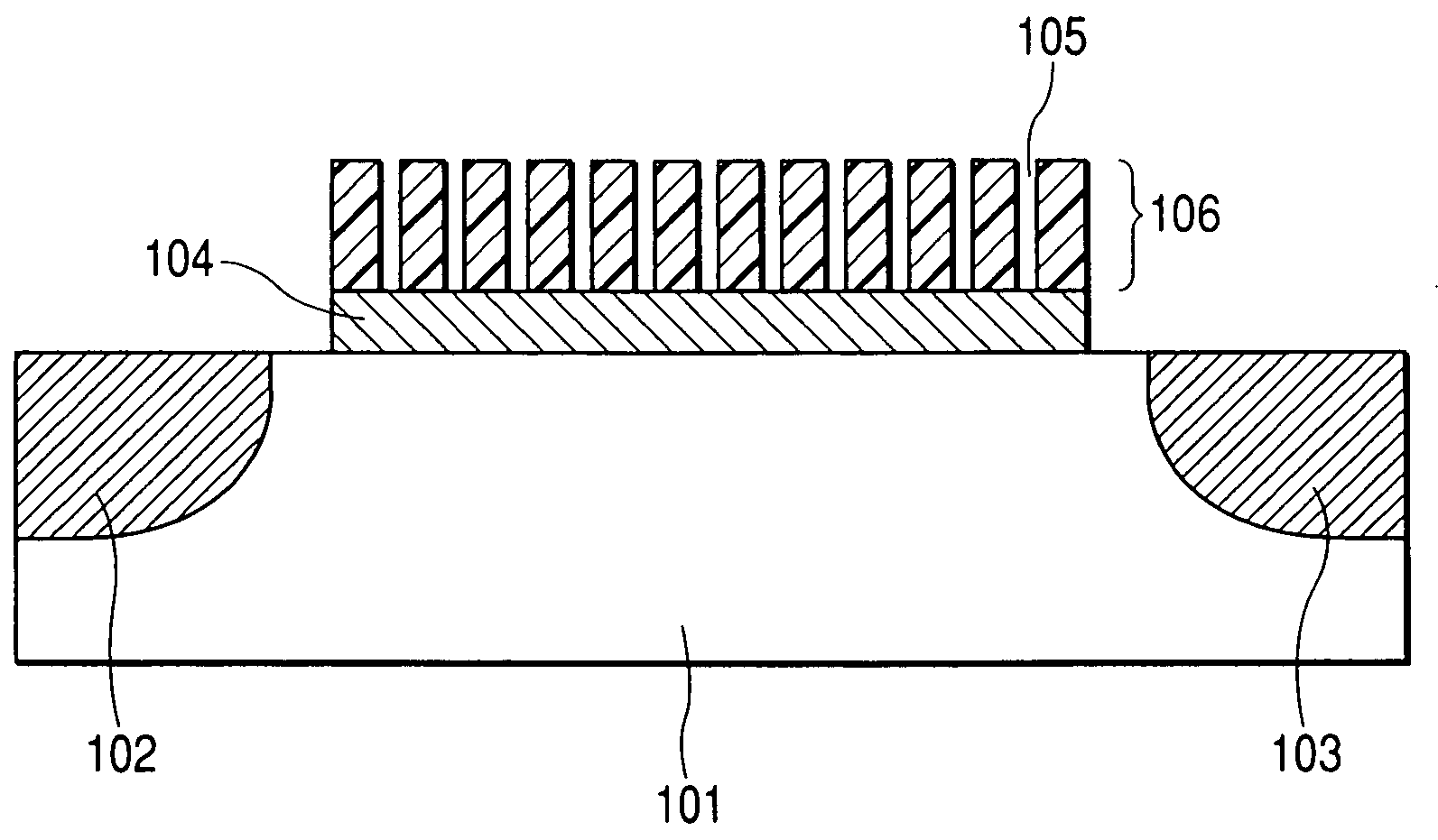

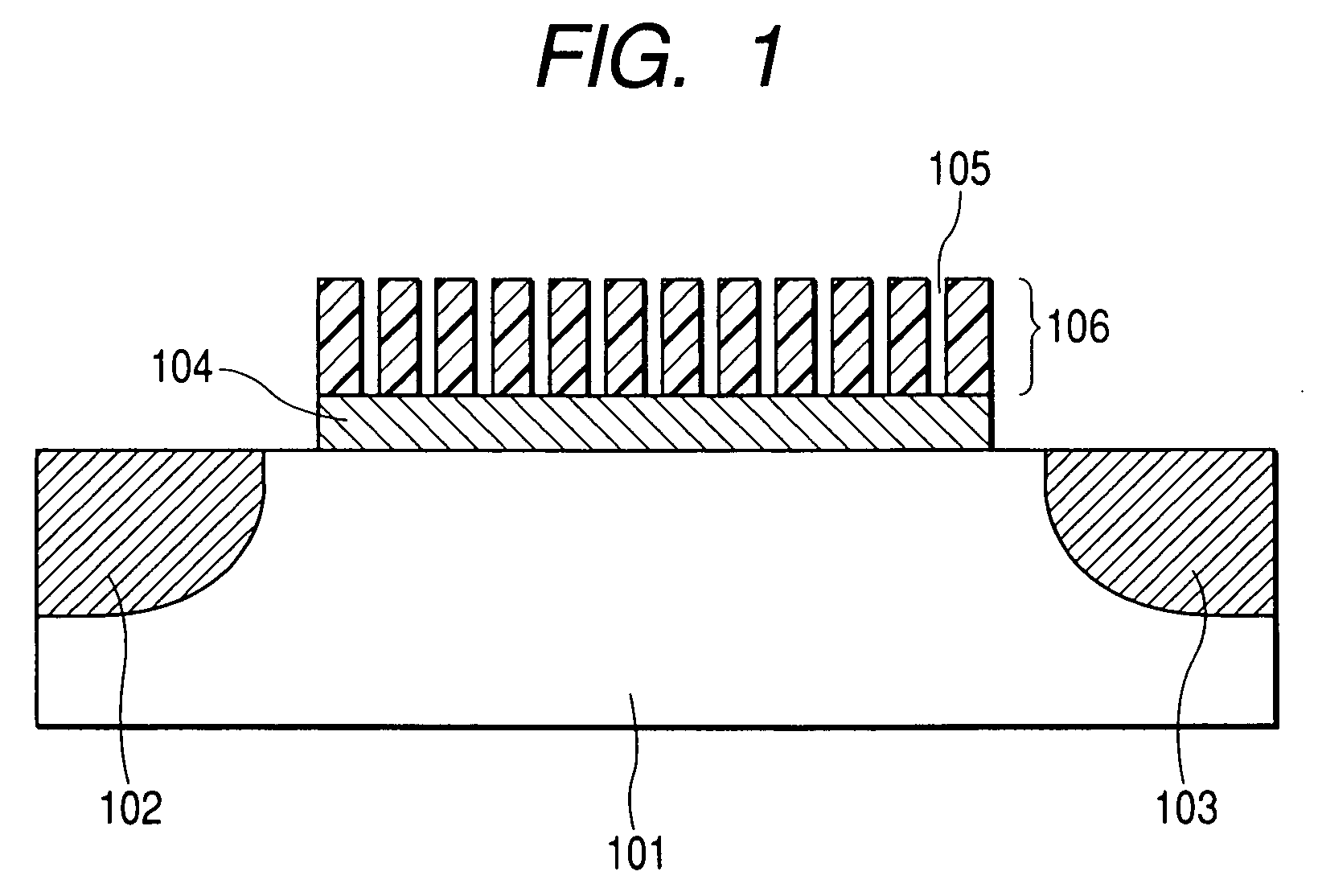

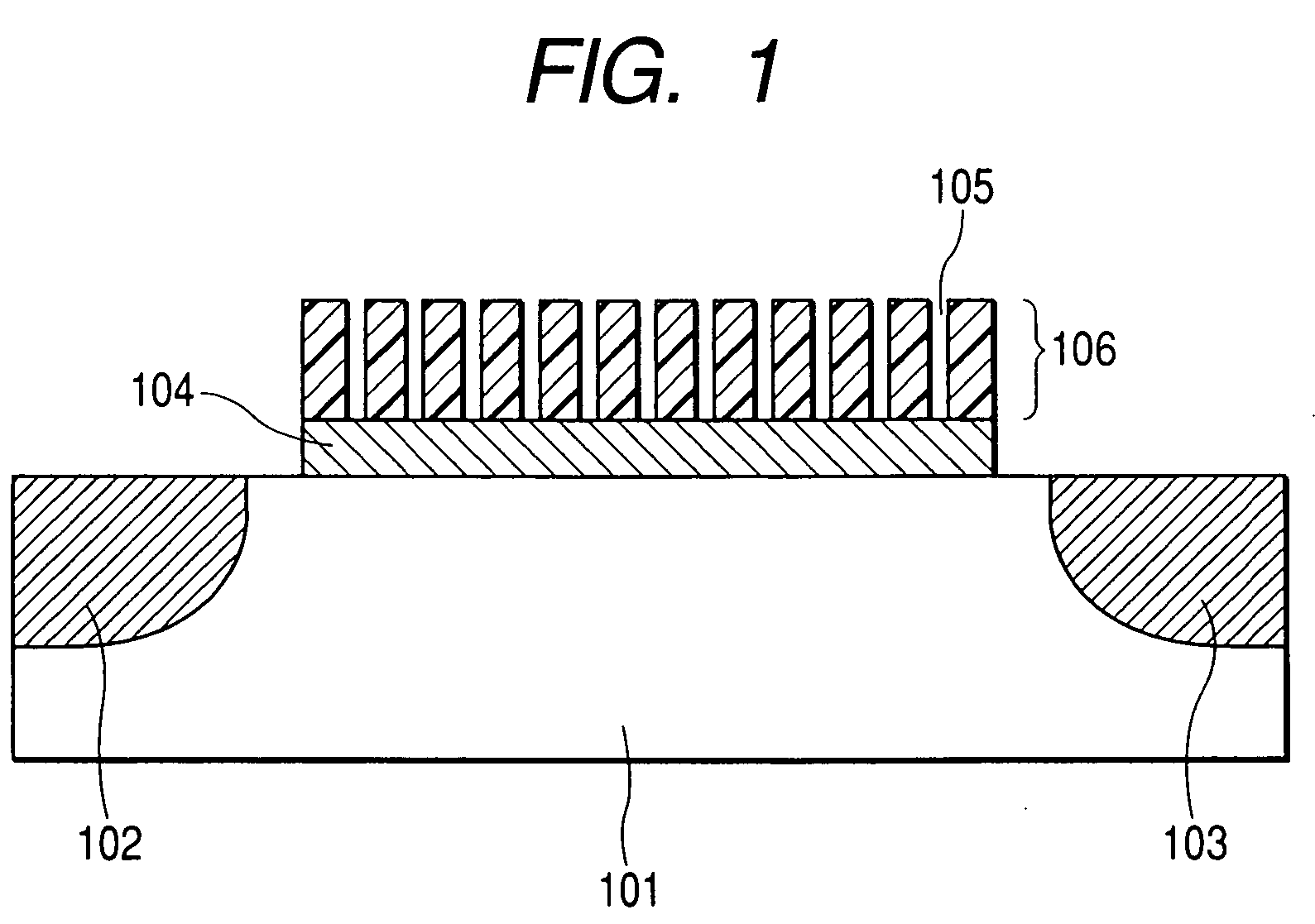

Field-effect transistor, sensor using it, and production method thereof

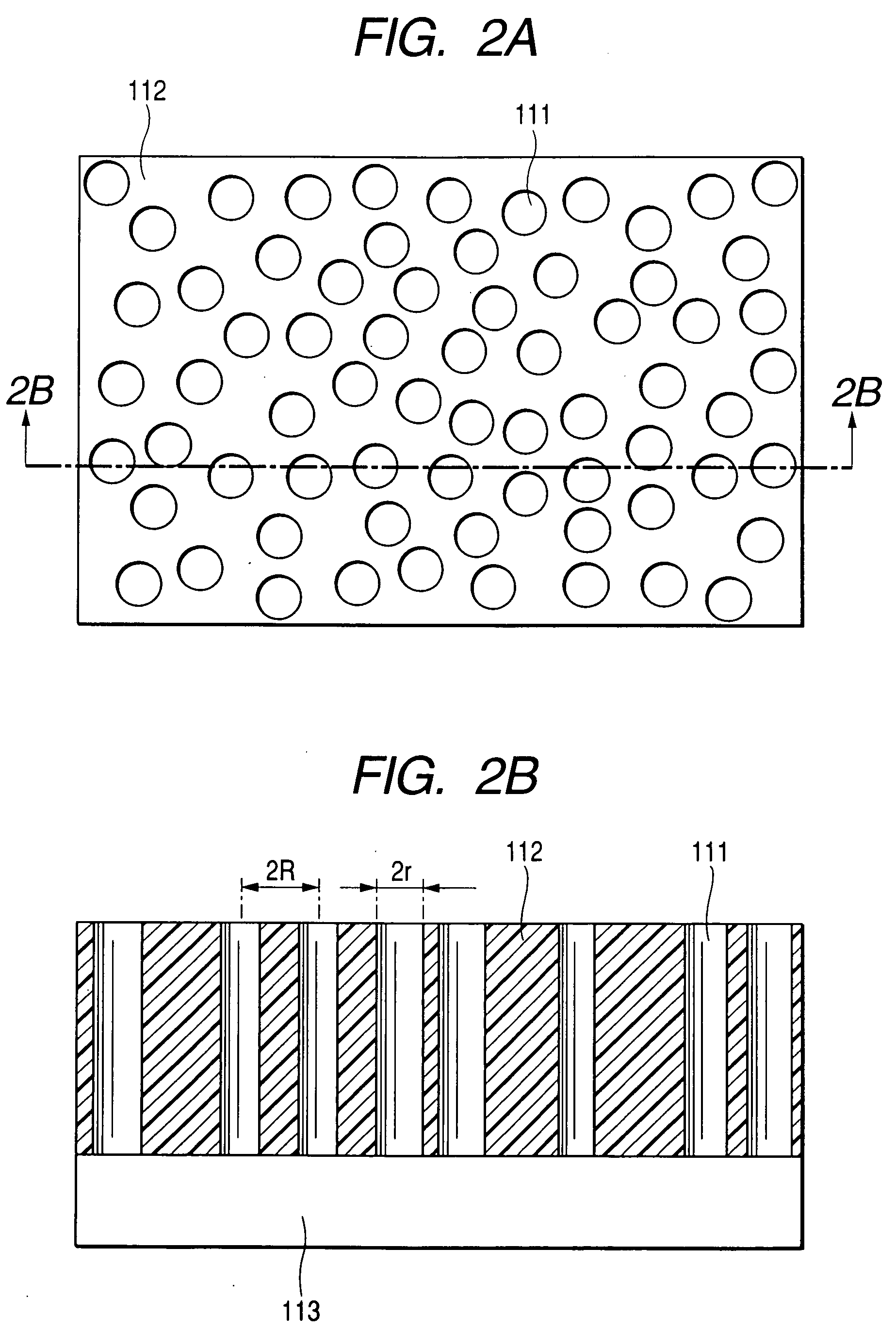

InactiveUS7329387B2High hole densityExcelled in responseTransistorMaterial analysis using wave/particle radiationSemiconductor materialsSilicon oxide

A sensor which has high measuring sensitivity and is excellent in response is provided by forming a porous film in a sensitive section of a field-effect transistor. It comprises a porous body, which is formed on a sensitive section (here, a gate insulating film) of the field-effect transistor and has cylindrical pores which are formed almost perpendicularly to a substrate, and the field-effect transistor. It uses as a porous film a porous film which is made of a semiconductor material whose main component (except oxygen) is silicon, germanium, or a composite of silicon and germanium, or a porous film made of an insulation material whose main component is silicon oxide, which has pores perpendicular to the substrate.

Owner:CANON KK

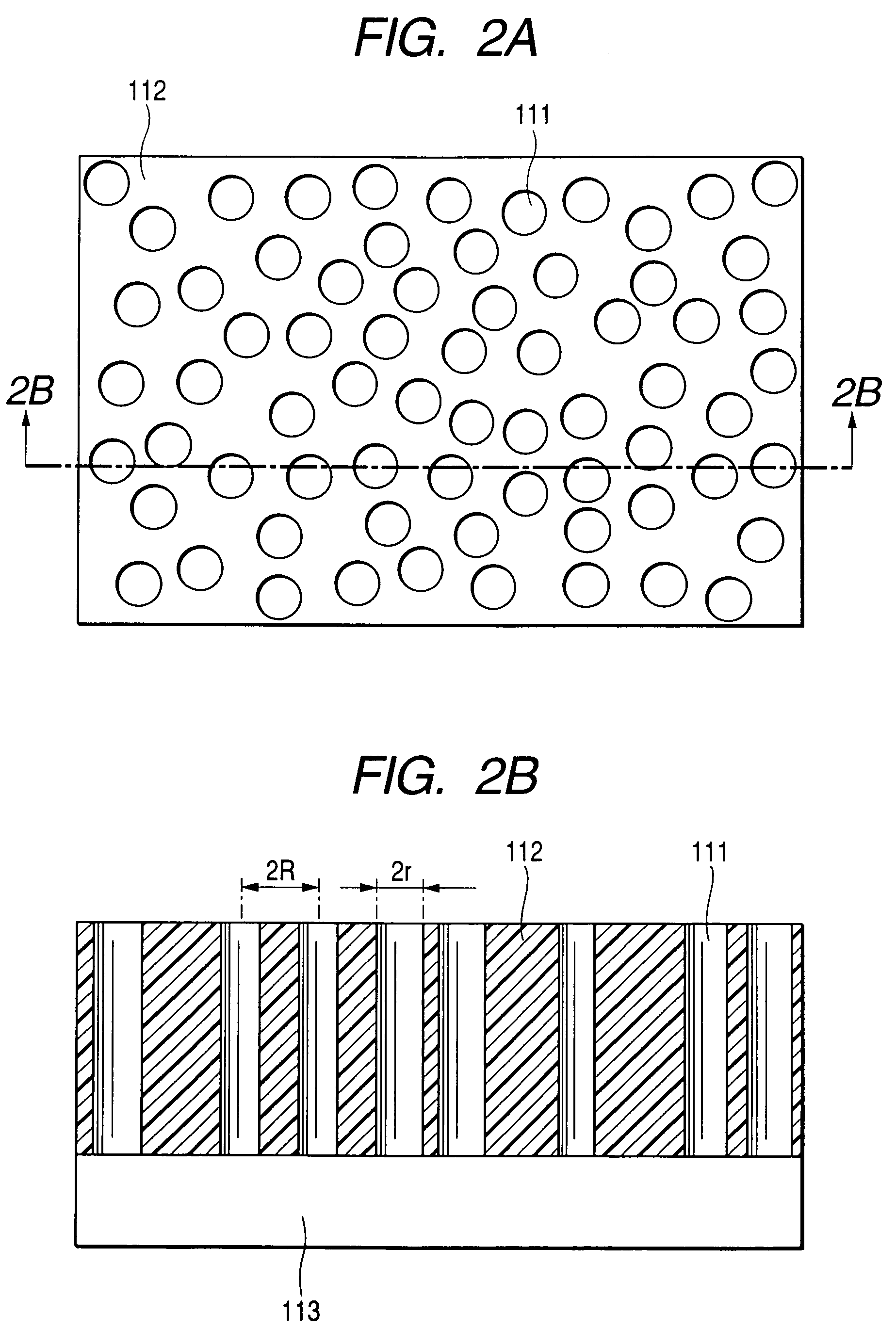

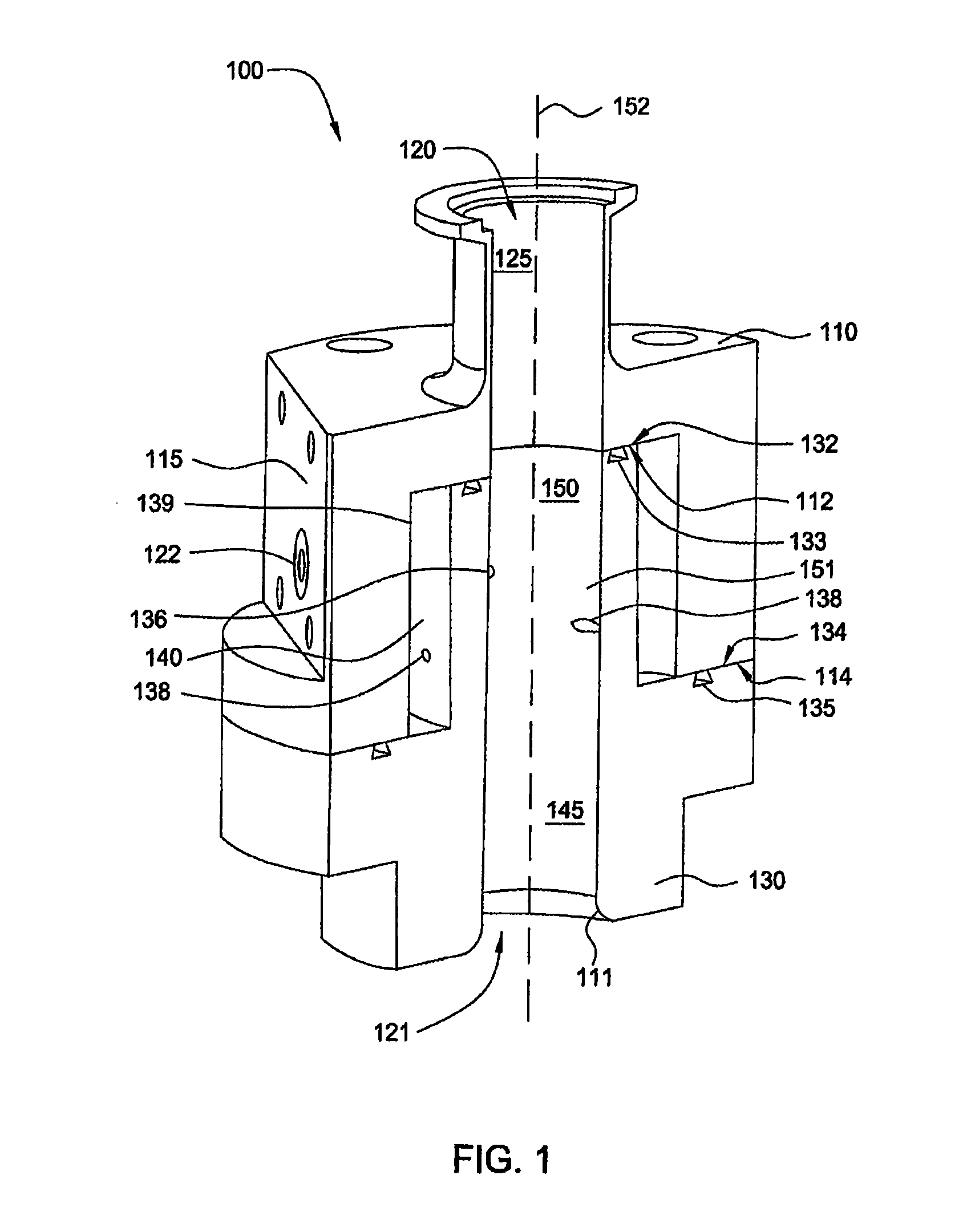

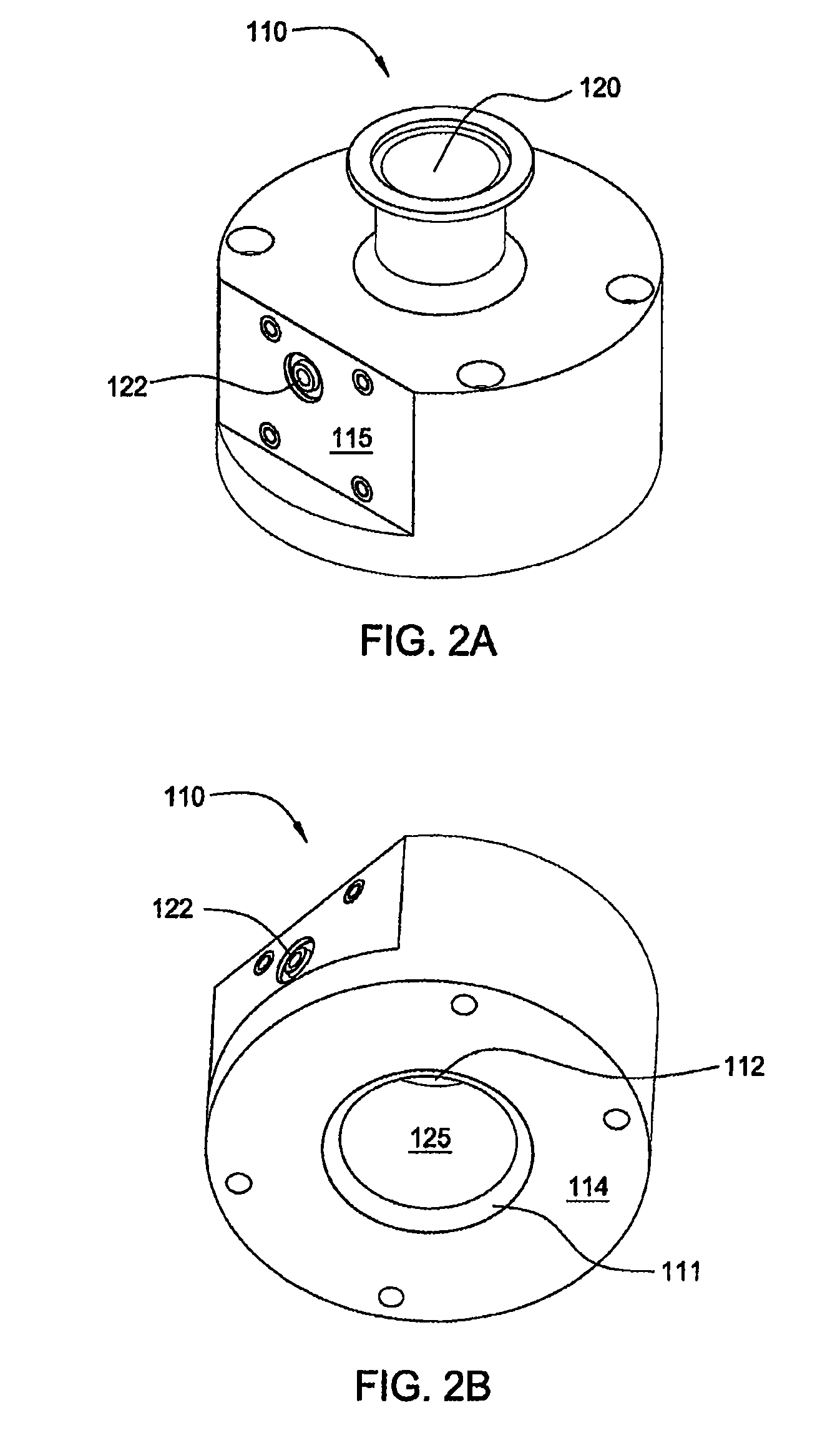

Apparatuses and methods for atomic layer deposition

ActiveUS20120000422A1Low densityHigh hole densityElectric discharge tubesSemiconductor/solid-state device manufacturingRemote plasmaEngineering

Embodiments of the invention provide apparatuses and methods for atomic layer deposition (ALD), such as plasma-enhanced ALD (PE-ALD). In some embodiments, a PE-ALD chamber is provided which includes a chamber lid assembly coupled with a chamber body having a substrate support therein. In one embodiment, the chamber lid assembly has an inlet manifold assembly containing an annular channel encompassing a centralized channel, wherein the centralized channel extends through the inlet manifold assembly, and the inlet manifold assembly further contains injection holes extending from the annular channel, through a sidewall of the centralized channel, and to the centralized channel. The chamber lid assembly further contains a showerhead assembly disposed below the inlet manifold assembly, a water box disposed between the inlet manifold assembly and the showerhead assembly, and a remote plasma system (RPS) disposed above and coupled with the inlet manifold assembly, and in fluid communication with the centralized channel.

Owner:APPLIED MATERIALS INC

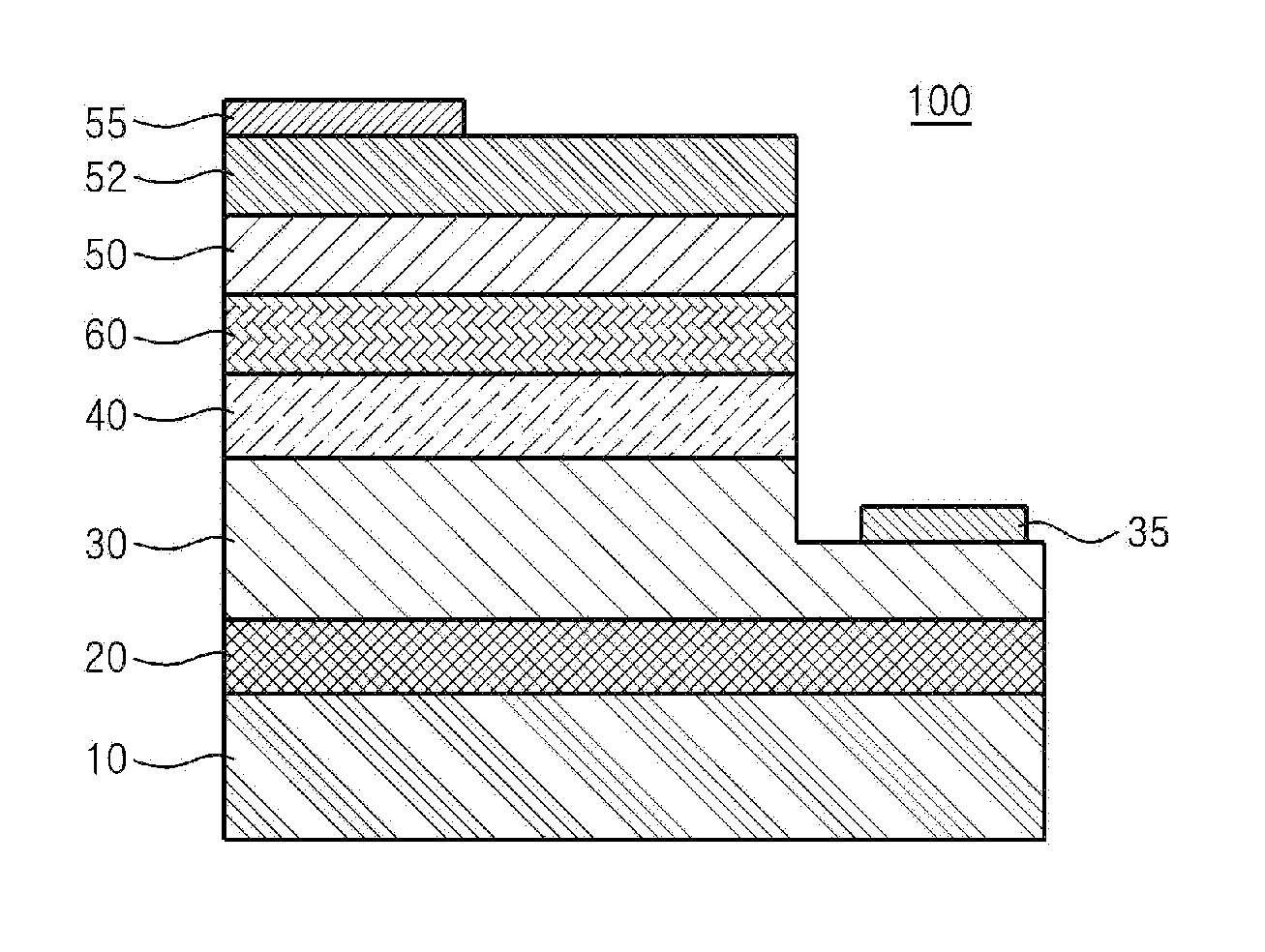

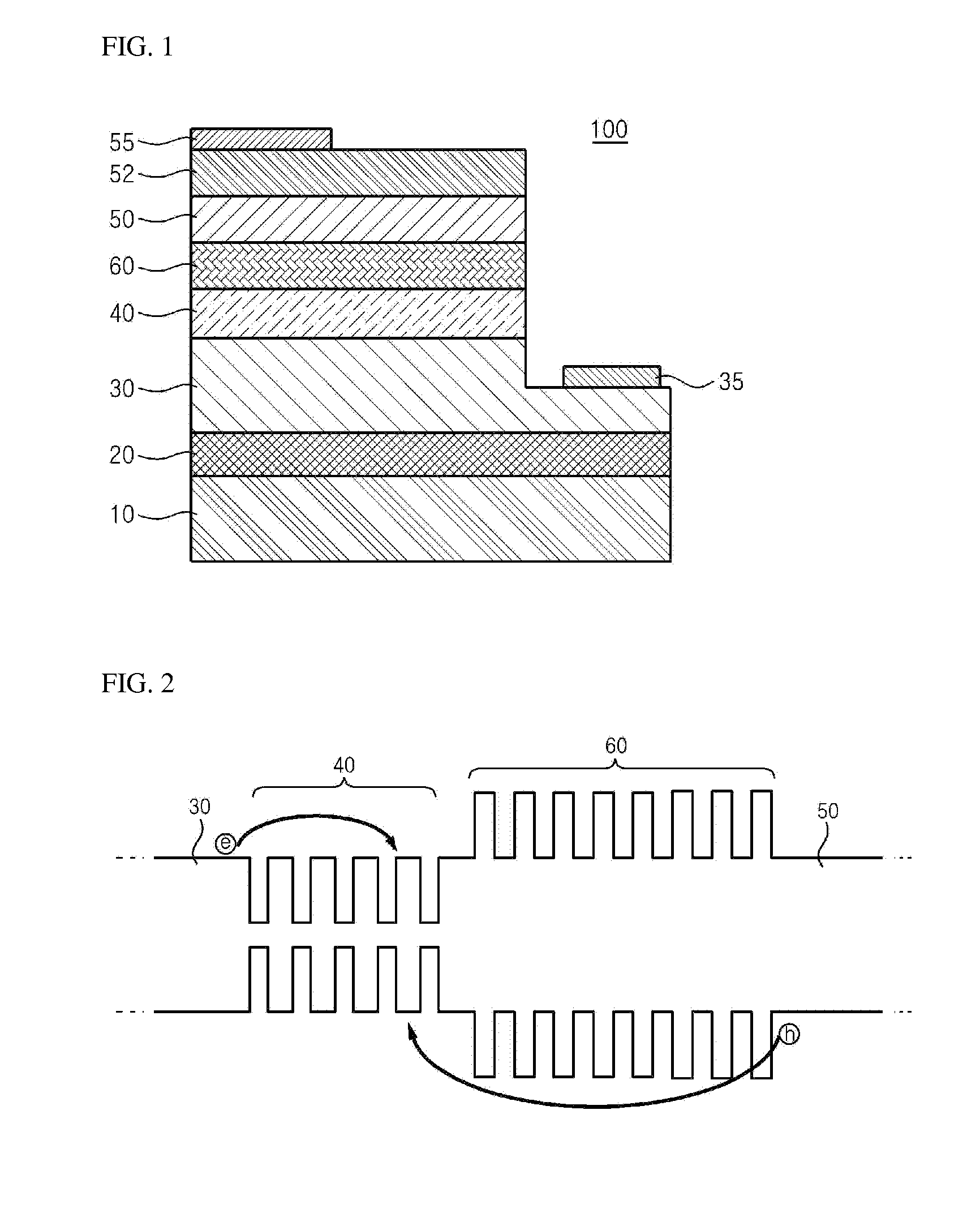

Nitride semiconductor light emitting device

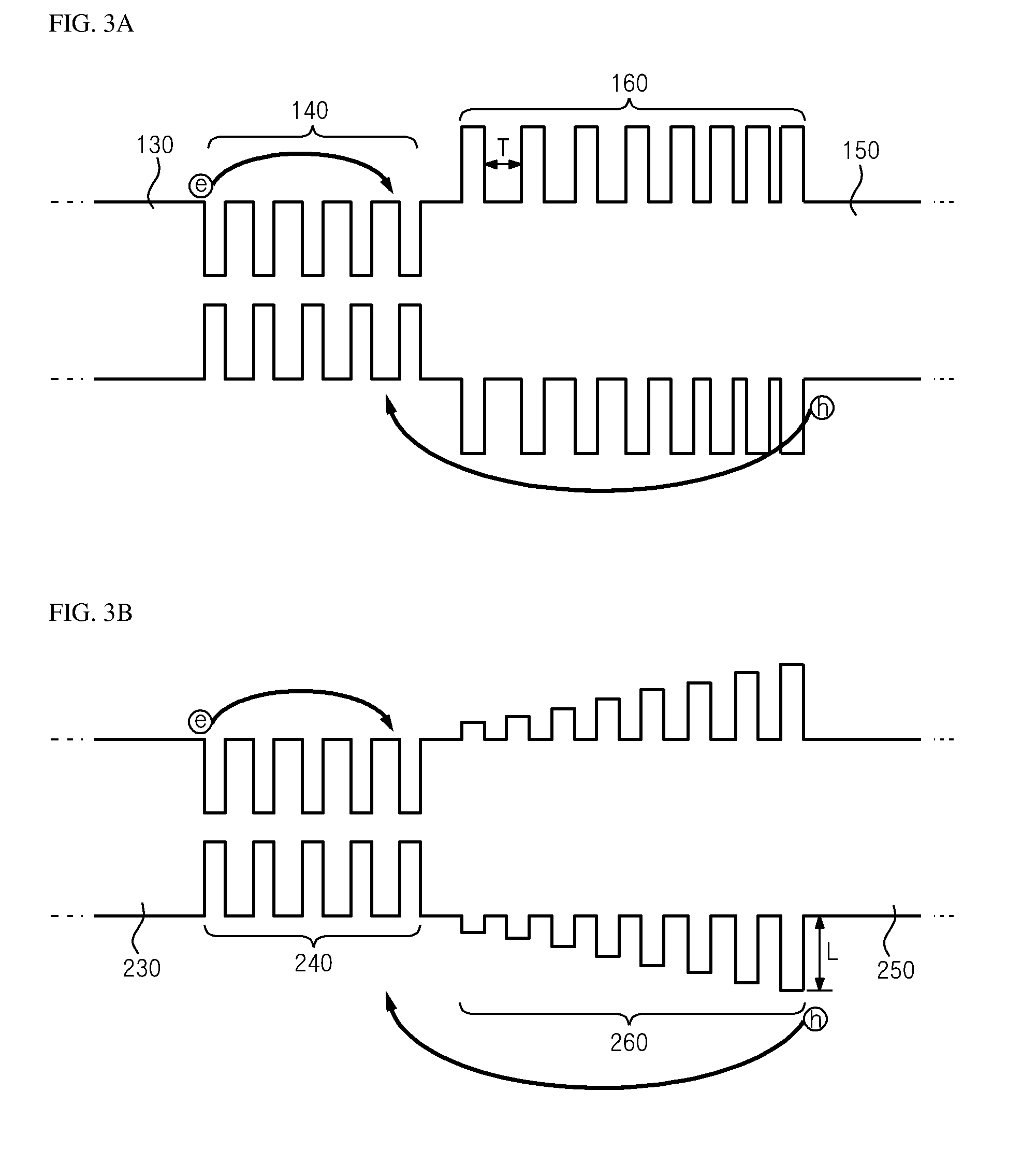

ActiveUS20140319454A1Improve lighting efficiencyIncrease hole injectionSemiconductor devicesMultiple quantumSuperlattice

The present invention discloses a nitride semiconductor light emitting device with improved light efficiency. The nitride semiconductor light emitting device includes a n-type nitride layer and p-type nitride layer, an active layer disposed between the n-type and p-type nitride layers and with a multiple quantum well structure wherein a plurality of quantum well layers and a plurality of quantum barrier layers are stacked alternatively in the active layer, and a superlattice layer between the active layer and the p-type nitride layer with asymmetric structure. Herein, a thickness of a well layers gradually increases from the p-type nitride layer to the active layer and the height of the barrier layers gradually increases from the active layer to the p-type nitride layer and therefore, an injection efficiency of a hole supplied from p-type nitride layer to an active layer is increased.

Owner:INTELLECTUAL DISCOVERY CO LTD

Heat Sink and Electronic Device and Heat Exchanger Applying the Same

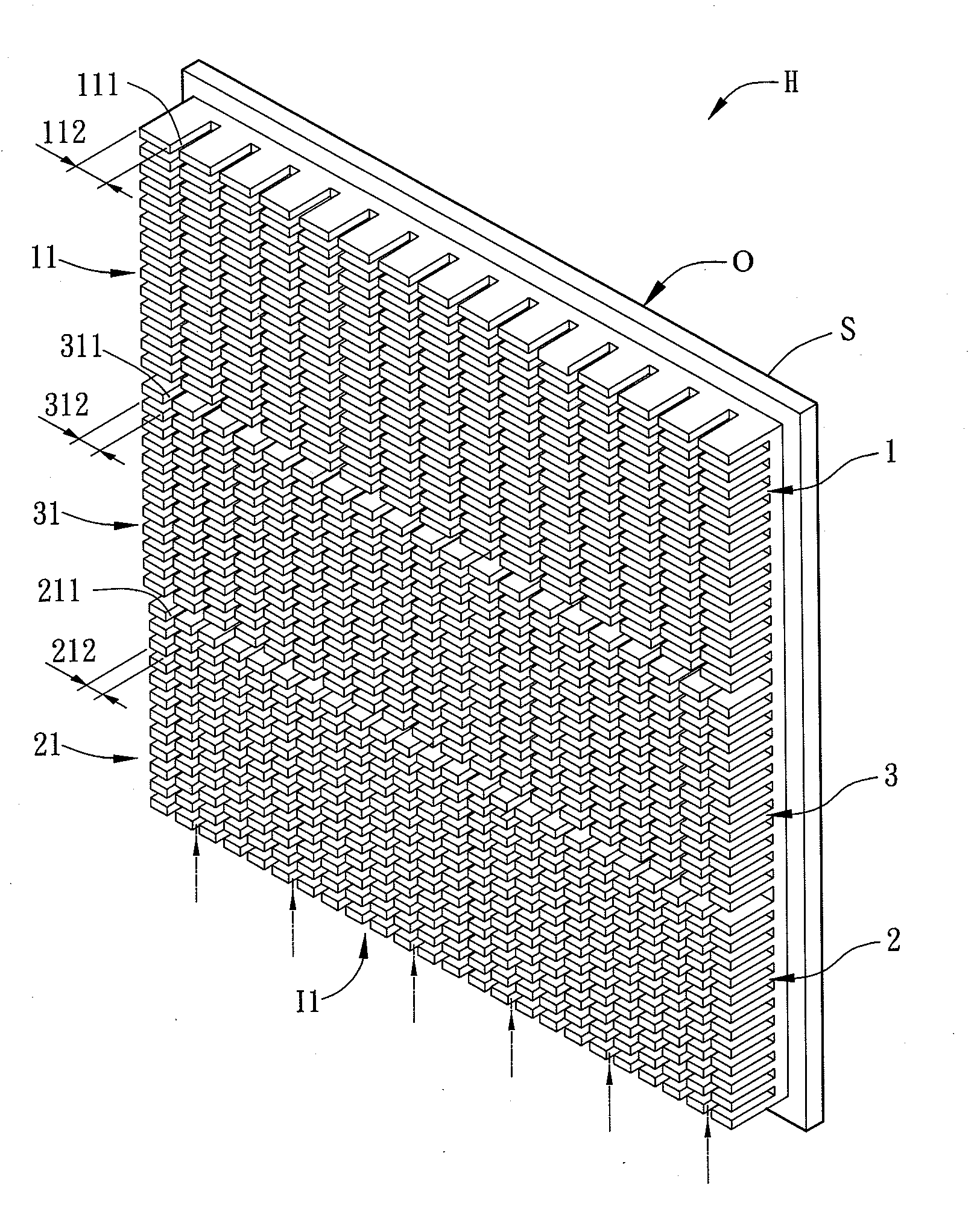

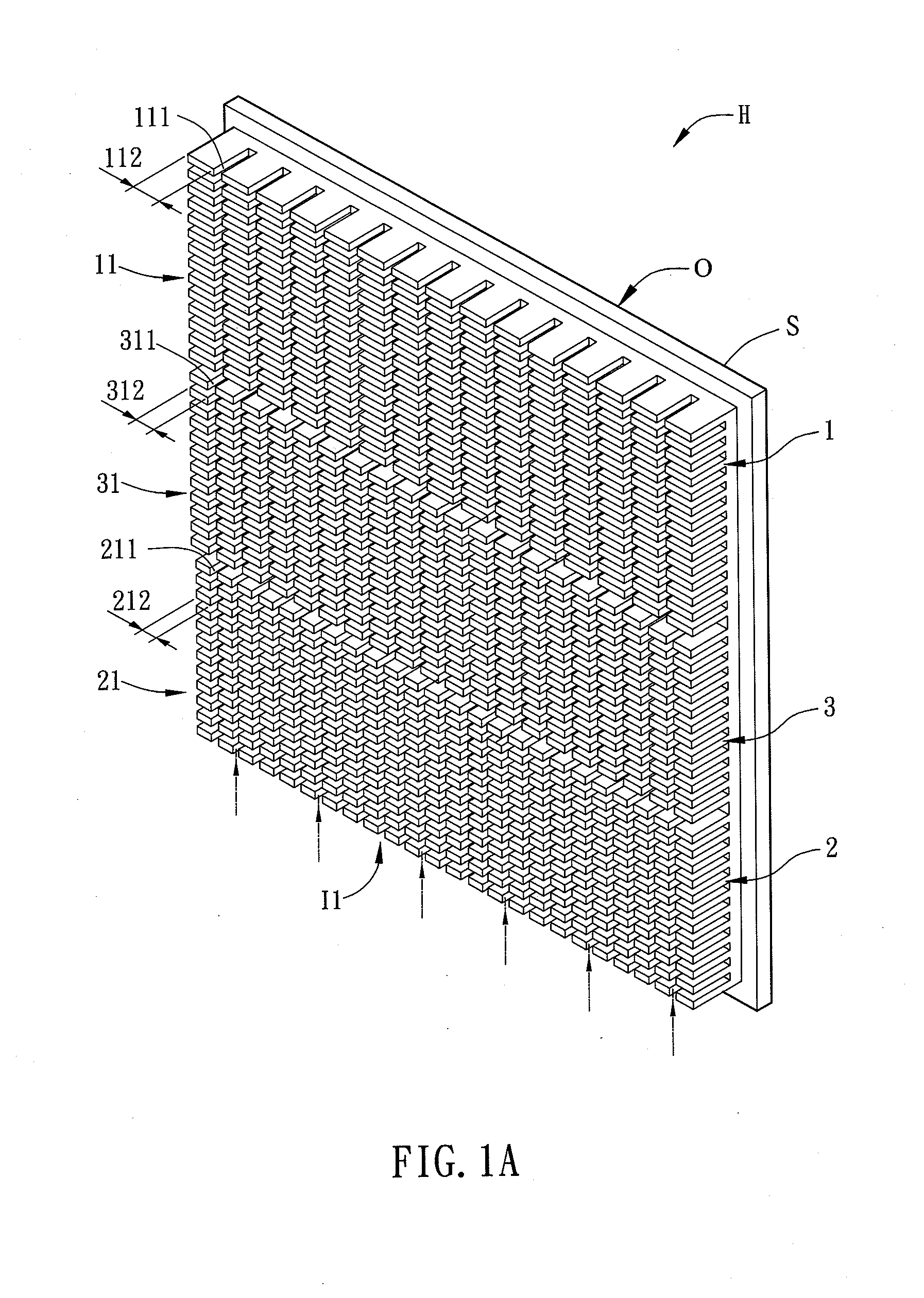

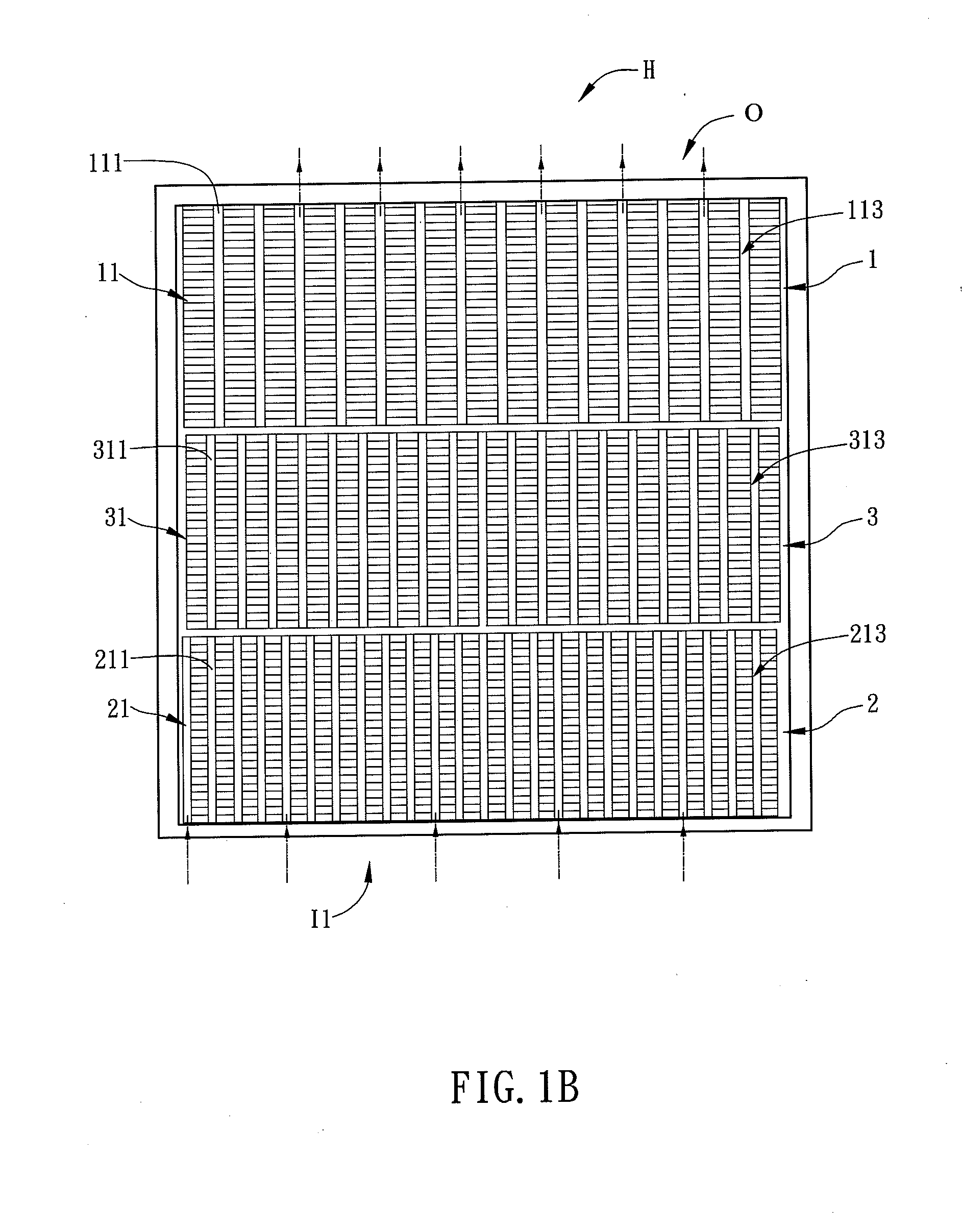

InactiveUS20140014308A1Improve cooling efficiencyHigh hole densityHeat exhanger finsElectrical apparatus contructional detailsHeat sinkEngineering

A heat sink includes a substrate, at least a first fin set and at least a second fin set. The first fin set is disposed on the substrate and has a plurality of first fins, and the first fin has a plurality of first holes. The second fin set is disposed on the substrate and has a plurality of second fins, and the second fin has a plurality of second holes. The total area of the second holes is larger than that of the first holes. An electronic device and a heat exchanger which are configured with the heat sink are also disclosed. The structure and configuration of the heat fins can increase the wind guiding effect, and thus improve the heat-dissipation efficiency.

Owner:DELTA ELECTRONICS INC

Foaming composite material with high thermal conductivity

ActiveCN103818075AOvercoming thermal conductivityOvercome functionNon-macromolecular adhesive additivesSynthetic resin layered productsAntioxidantPlasticizer

The invention relates to a resin foaming composite material, especially to a foaming composite material with high thermal conductivity. The foaming composite material is prepared by the following steps: primary mixing: 8-12 parts by weight of a heat conduction material is added into 40-100 parts by weight of matrix resin to obtain a primary mixed object; plasticization and granulation: 2-8 parts by weight of a fire retardant, 6-10 parts by weight of a softening plasticizer, 3-7 parts by weight of a flexibilizer, 1-4 parts by weight of a coupling agent and 0.6-1.2 parts by weight of an antioxidant are added into the primary mixed object for blending modification and plasticization, and extrusion and granulation are carried out to obtain a first granule; remixing and foaming: 15-25 parts by weight of one or more selected from fatty alcohol polyoxyethylene lauryl ether sulfate sodium or an azo-compound are mixed with one or more selected from the first granule and 30-70 parts by weight of the matrix resin, extrusion and foaming are conducted to prepare a foaming material, and a full-open foaming material layer is compounded on the foaming material through glue to form the foaming composite material with high thermal conductivity. The material provided by the invention has high thermal conductivity and is waterproof and shock-absorbing.

Owner:ZHEJIANG RUNYANG NEW MATERIAL TECH

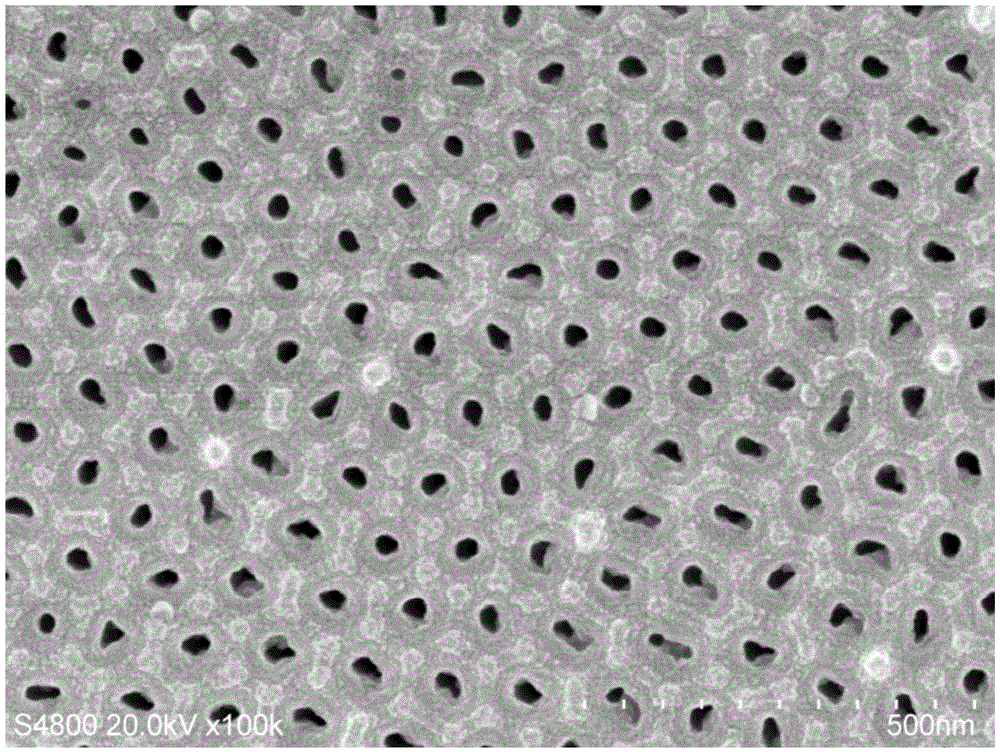

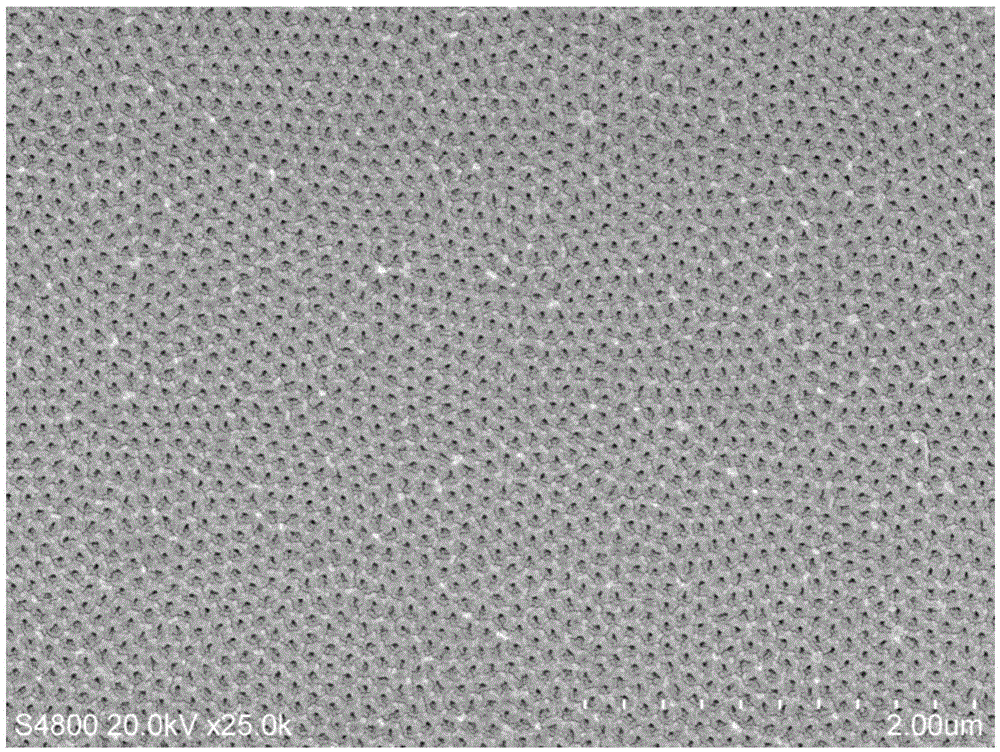

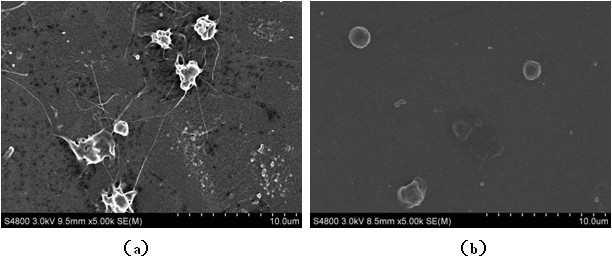

Preparation method of flexible surface enhanced Raman spectrum substrate and application thereof

ActiveCN105424676AHigh strengthRegular uniform porous structureRaman scatteringSurface-enhanced Raman spectroscopyMetallic materials

The invention discloses a preparation method of a flexible surface enhanced Raman spectrum substrate and application thereof. The method comprises the steps that the surface of an anodic aluminum oxide template is coated with a layer of anti-adsorption material, an active metal material layer is deposited, a supporting layer is formed through in-situ solidification or by adhering a layer of organic material, the supporting layer is removed from the surface of the anodic aluminum oxide template, and the active metal material layer with a structure is obtained to serve as the surface enhanced Raman substrate. In addition, in order to achieve successful transfer, a material layer capable of enhancing adsorption can be additionally arranged on the active metal material layer or the organic material layer, and the integrity of the structure transfer is guaranteed. The prepared flexible surface enhanced Raman spectrum substrate with a porous structure is good in uniformity and high in repetitive rate, the structure is easy to control, the template can be reused, and the method is low in cost and suitable for large-scale industrial application.

Owner:SHENZHEN TOPMEMBRANES INC

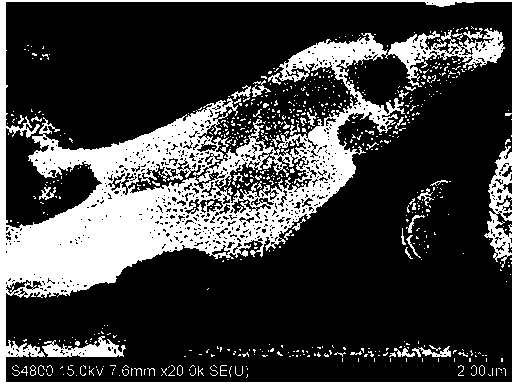

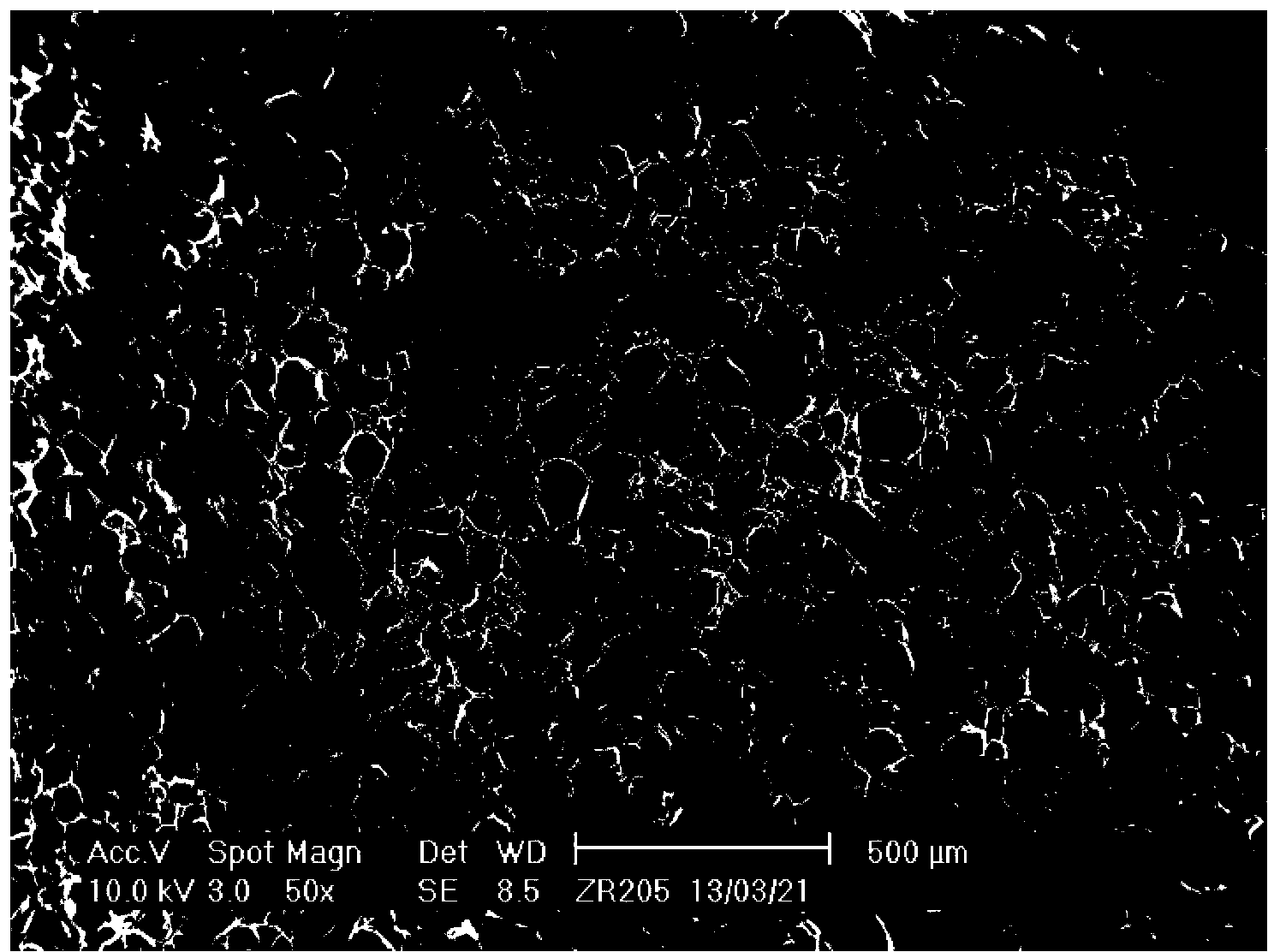

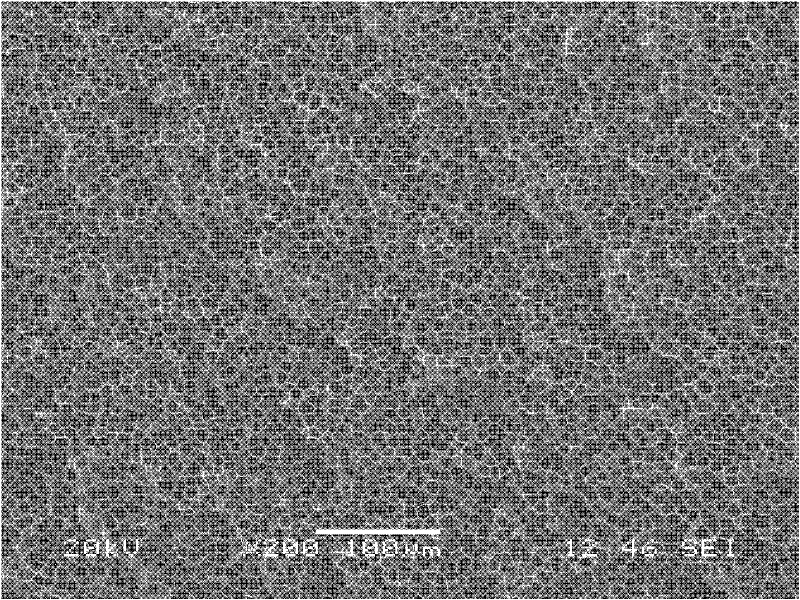

Method for preparing nano porous silicon by utilizing doped silicon particles

ActiveCN103985848AIncrease concentrationHigh hole densityCell electrodesSecondary cellsHydrofluoric acidReaction temperature

The invention discloses a method for preparing nano porous silicon by utilizing doped silicon particles. The method comprises the following steps: selecting silicon particles with a certain doping concentration, washing with hydrofluoric acid, then enabling the silicon particles to react in a solution which is prepared by selecting nitrate, hydrofluoric acid and oxidant with assistance of ultrasonic process centrifugally washing the silicon particles, and finally washing the silicon particles by using dilute nitric acid to obtain the three-dimensional nano porous silicon. The optimal process parameters such as best constitution of chemical etching corrosive agent, volume ratio and specific concentration of a reaction reagent, reaction time, reaction temperature, ultrasonic frequency, processing time and the like are screened out through a great number of experiments, and the prepared high-purity three-dimensional doped porous silicon is regular in pore shape, uniform in distribution and applicable to the fields such as lithium batteries, solar batteries, semiconductors and sensors. The method is strong in process maneuverability, low in cost, high in yield and applicable to industrialized mass production.

Owner:南京卓胜自动化设备有限公司

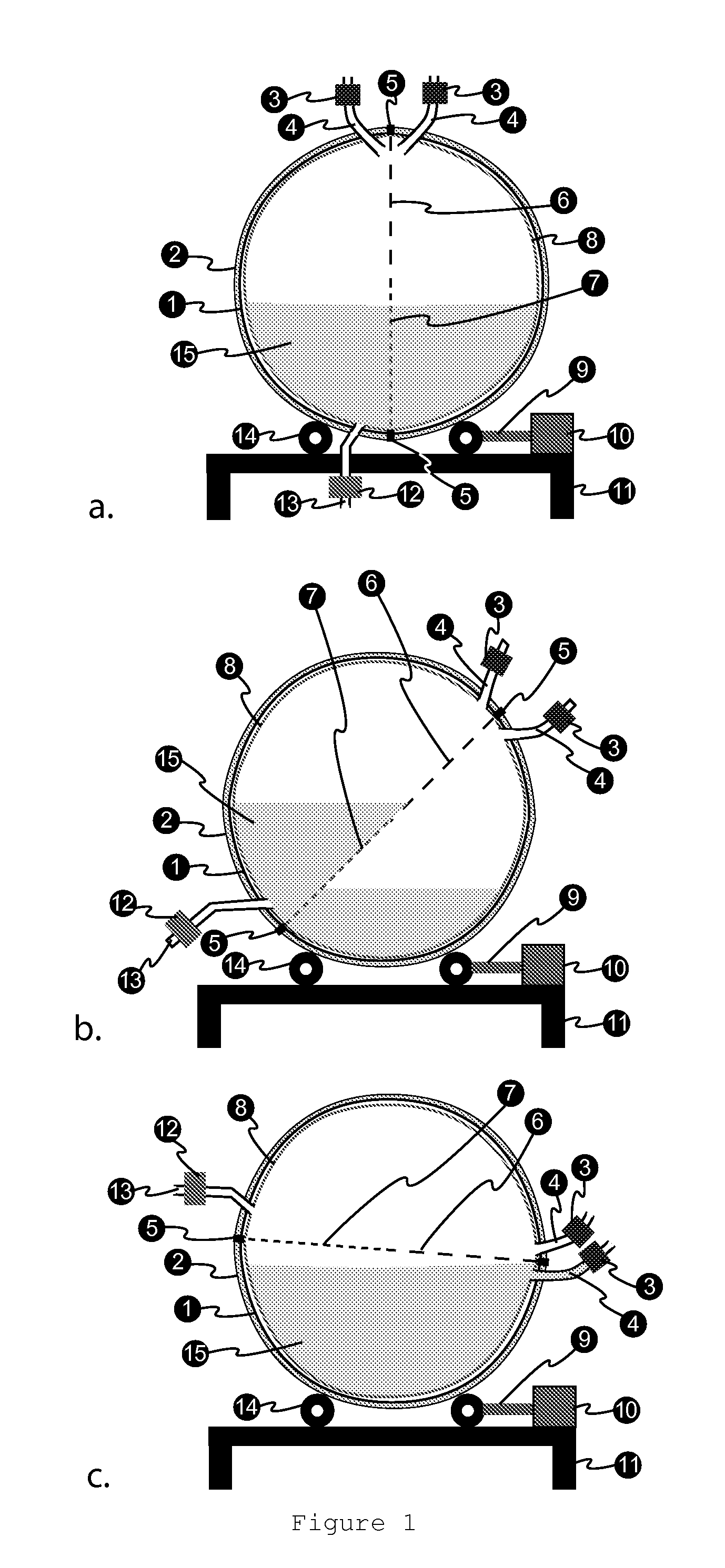

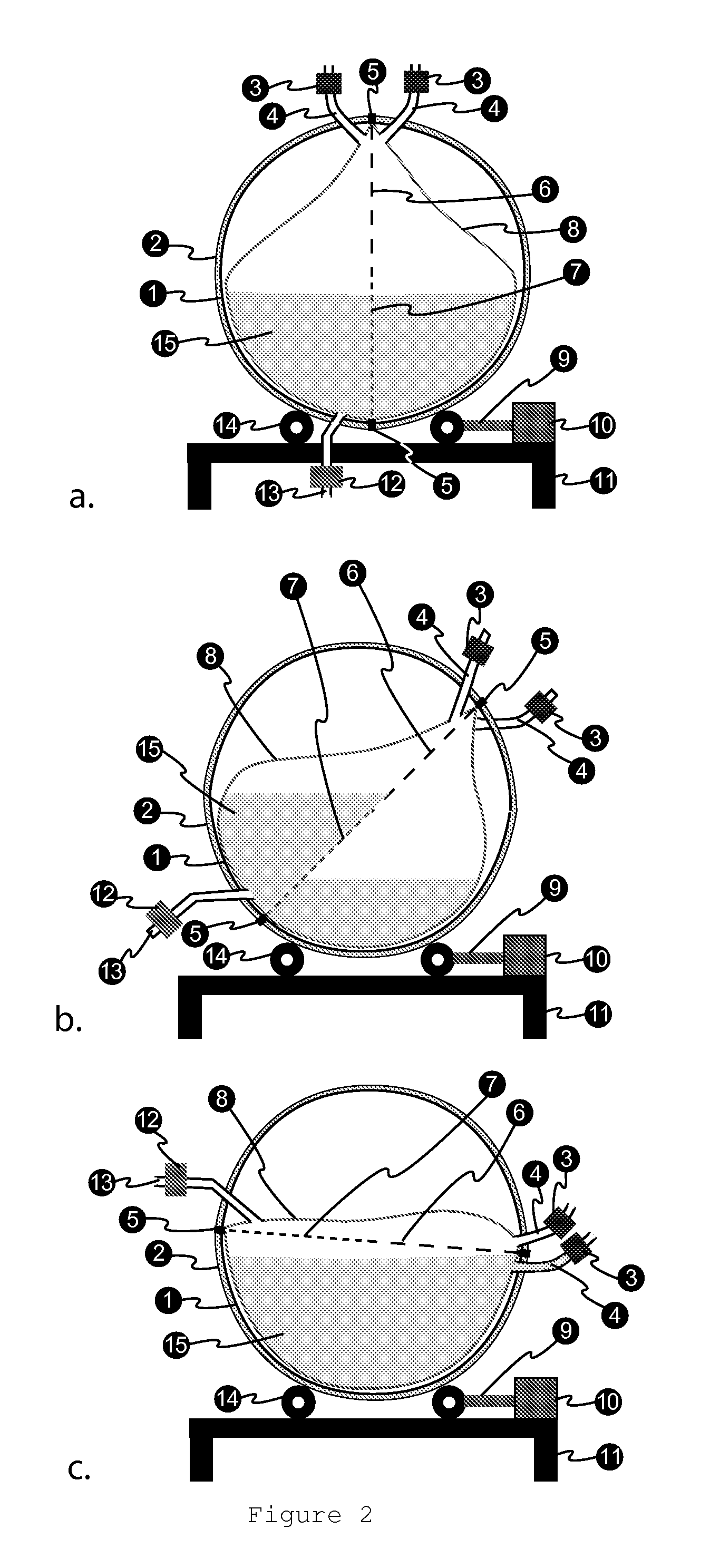

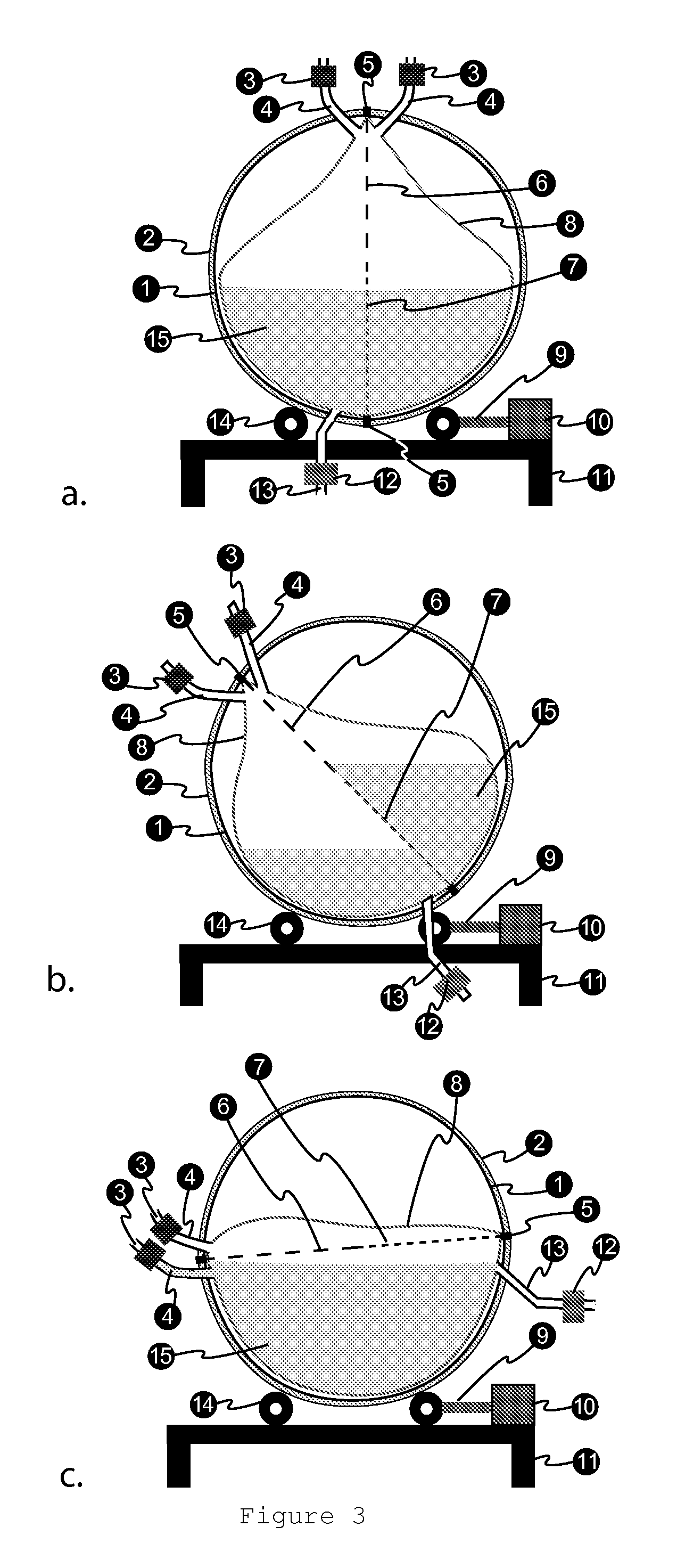

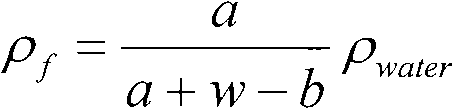

Pivoting pressurized single-use bioreactor

InactiveUS20130171616A1Efficient mixingWell mixedRotating receptacle mixersTransportation and packagingBiomedical engineeringCell culture

Pressurized hermetically sealed bags disposed inside a cylindrical support and containing a septum with variable density of porosity and dividing the bag into two chambers are used to provide optimal mixing and gasification of nutrient media to grow a variety of biological cultures, particularly the cell cultures to produce a multitude of pharmaceutical and biotechnology products in a disposable system.

Owner:NIAZI SARFARAZ K

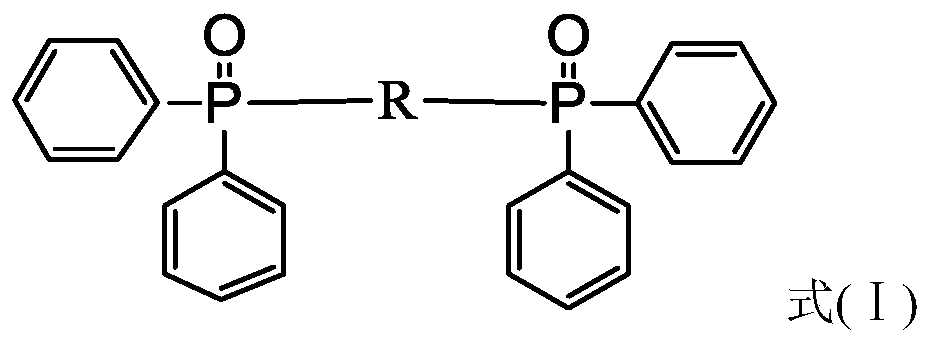

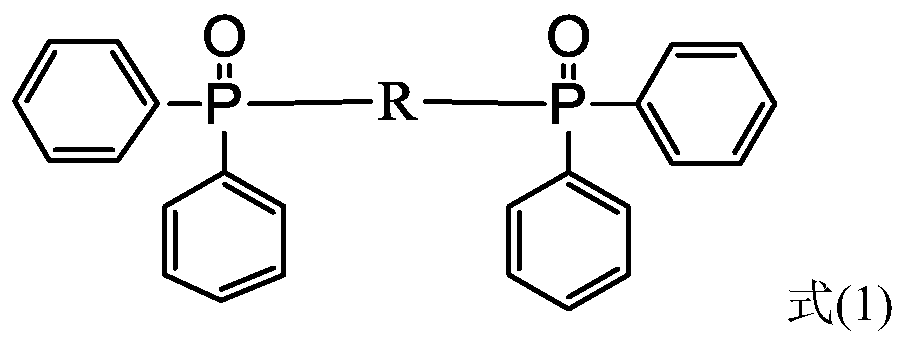

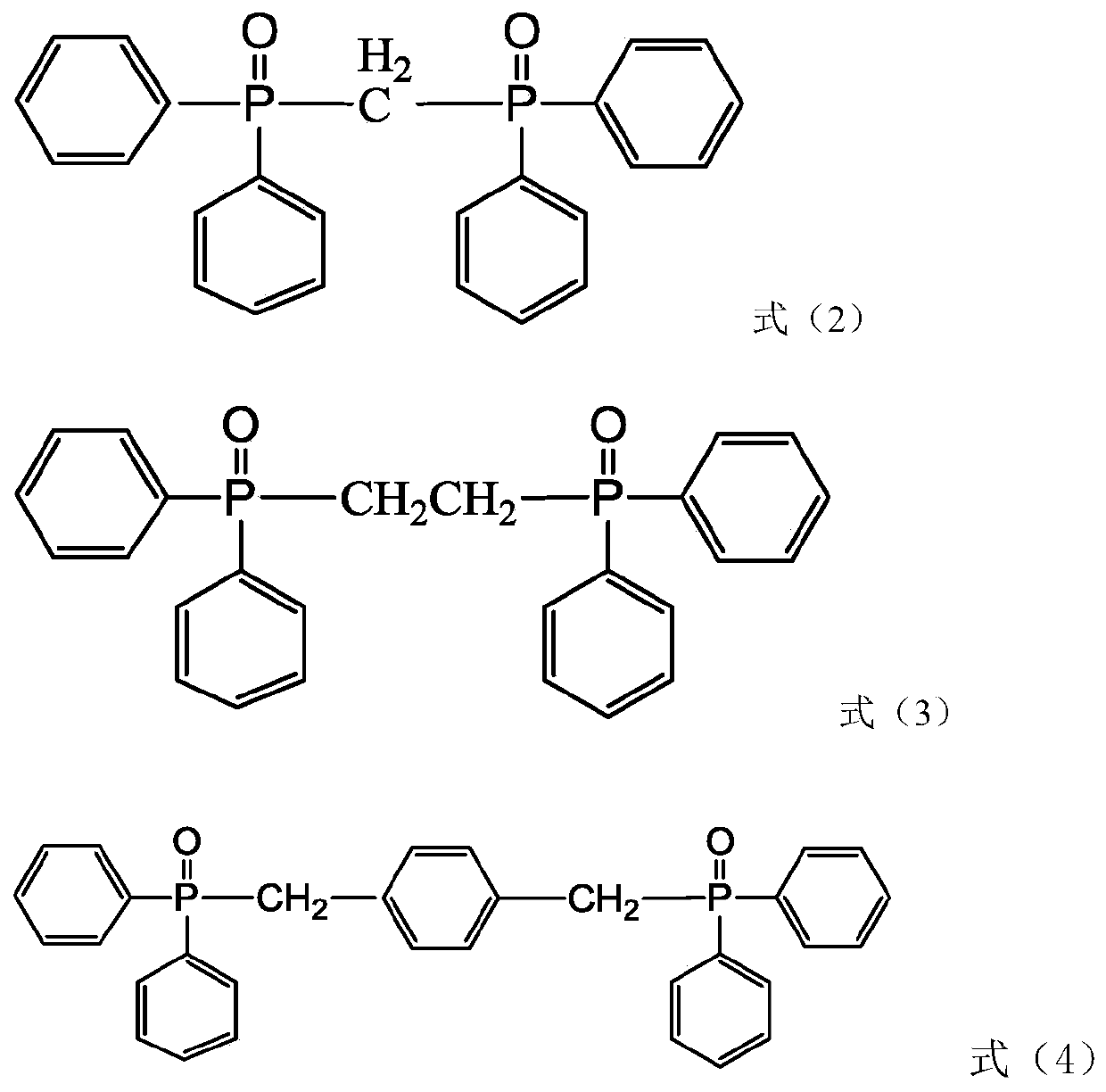

Halogen-free flame-retardant epoxy resin composition and application thereof

The invention relates to the field of high molecular materials, in particular to a halogen-free flame-retardant epoxy resin composition and application thereof. The composition comprises 100 parts ofepoxy resin, a halogen-free composite flame retardant provided with diphenylphosphine oxide flame-retardant groups, 5-15 parts of a main flame retardant, 0-10 parts of an auxiliary flame retardant, 2-30 parts of a curing agent and 0-1 part of a curing accelerating crosslinking agent. The composition further comprises a mixture of at least two of reinforced fibers, a flexibilizer, a filler, a silane coupling agent and a solvent. The composite flame retardant containing the diphenylphosphine oxide groups is high in flame-retarding efficiency and small in adding amount and has excellent compatibility and dispersity with the epoxy resin; and in the curing process, intermolecular dispersion with the epoxy resin can be realized, and the original transparent state of the epoxy resin is maintained. The finally cured flame-retardant resin composition has the advantages of low cost, high transparency, low water absorption rate, high glass conversion temperature, high thermal stability, low dielectric constant and dielectric loss, high flame retarding and the like.

Owner:SHANDONG UNIV OF SCI & TECH

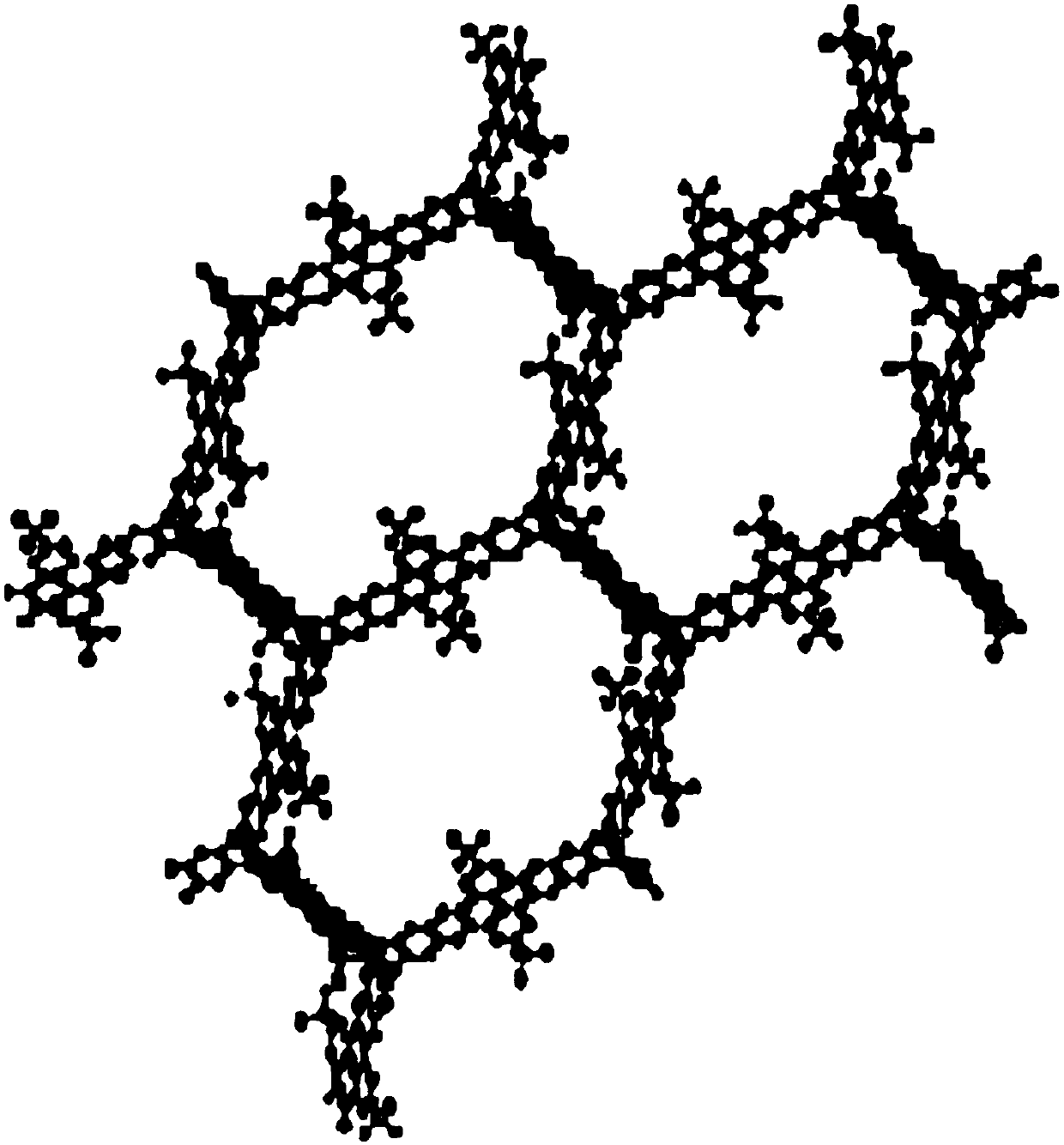

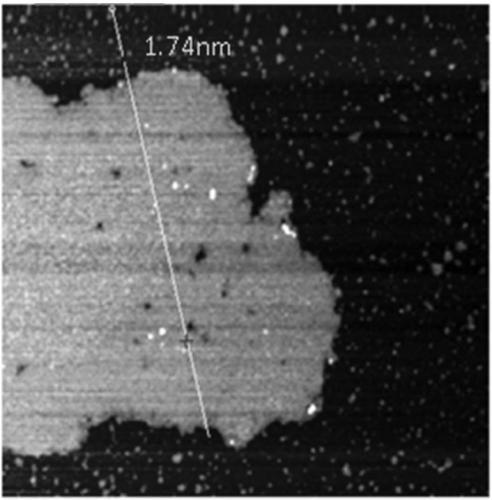

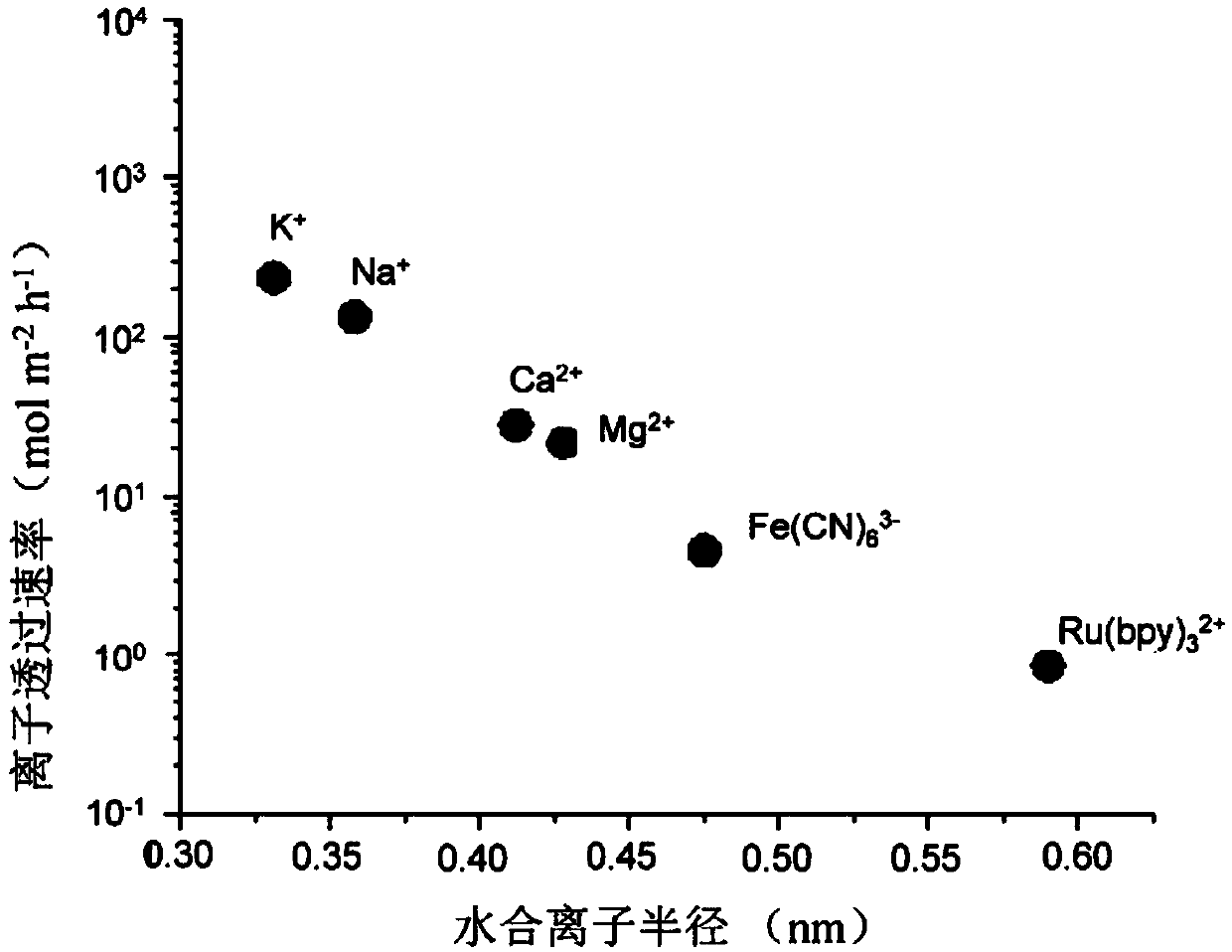

COF film, preparation method, transfer method and application thereof, and chip containing same

ActiveCN111087615AHigh hole densitySignificant separabilitySemi-permeable membranesAnalysis by thermal excitationGraphiteSingle layer graphene

The invention provides a COF film, a preparation method, a transfer method and application thereof, and a chip containing the same. According to the preparation method, the COF film is prepared through polymerization reaction between hexaamino triptycene and pyrene tetraketone; the pi-pi accumulation effect between two-dimensional COF film layers is weakened; the porous COF film with single-layerthickness and extremely high pore density is obtained; and holes do not need to be formed in a plasma bombardment mode like a traditional single-layer graphene film. The COF film has remarkable separation and detection capacity for ions with different hydrated ion radiuses and also has higher ion permeability, and due to the characteristics, the COF film can be used for preparing an ion detectionchip so as to realize ultrafast ion separation and detection.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

Method for forming thermoplastic polyester elastomer closed pore micro-foaming product

The invention discloses a method for forming a thermoplastic polyester elastomer closed pore micro-foaming product, which comprises the following steps of: filling a thermoplastic polyester elastomer into a forming die with capillary through holes, putting the forming die into a high-pressure container, injecting a gas into the high-pressure container to displace air in the high-pressure container, adjusting the temperature of the high-pressure container to between 160 and 220 DEG C and adjusting the pressure to between 8 and 30MPa, keeping the high-pressure container for 10 to 50 minutes at a constant temperature under a constant pressure, then reducing the pressure of the high-pressure container to the atmospheric pressure at the speed of 200 to 700MPa / s, taking the forming die out, and cooling and removing the forming die to obtain the thermoplastic polyester elastomer closed pore micro-foaming product, wherein the gas is nitrogen or carbon dioxide. The method has simple process, is convenient to operate and control, and can obtain the micro-foaming polyester elastomer product with smaller foam pore size, higher foam pore density, more uniform foam pore structure and more excellent damping impact resistance.

Owner:中广核俊尔(上海)新材料有限公司 +1

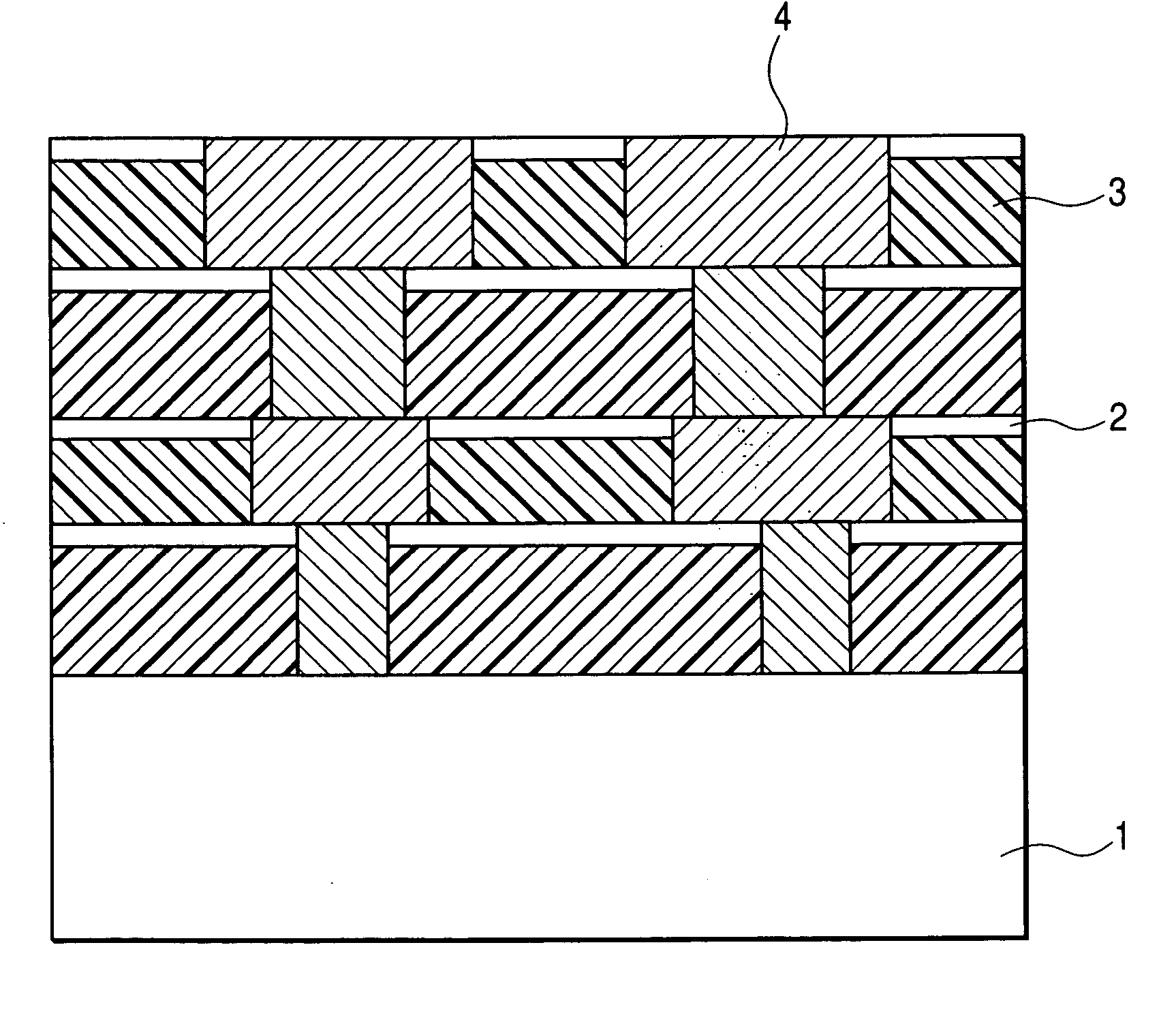

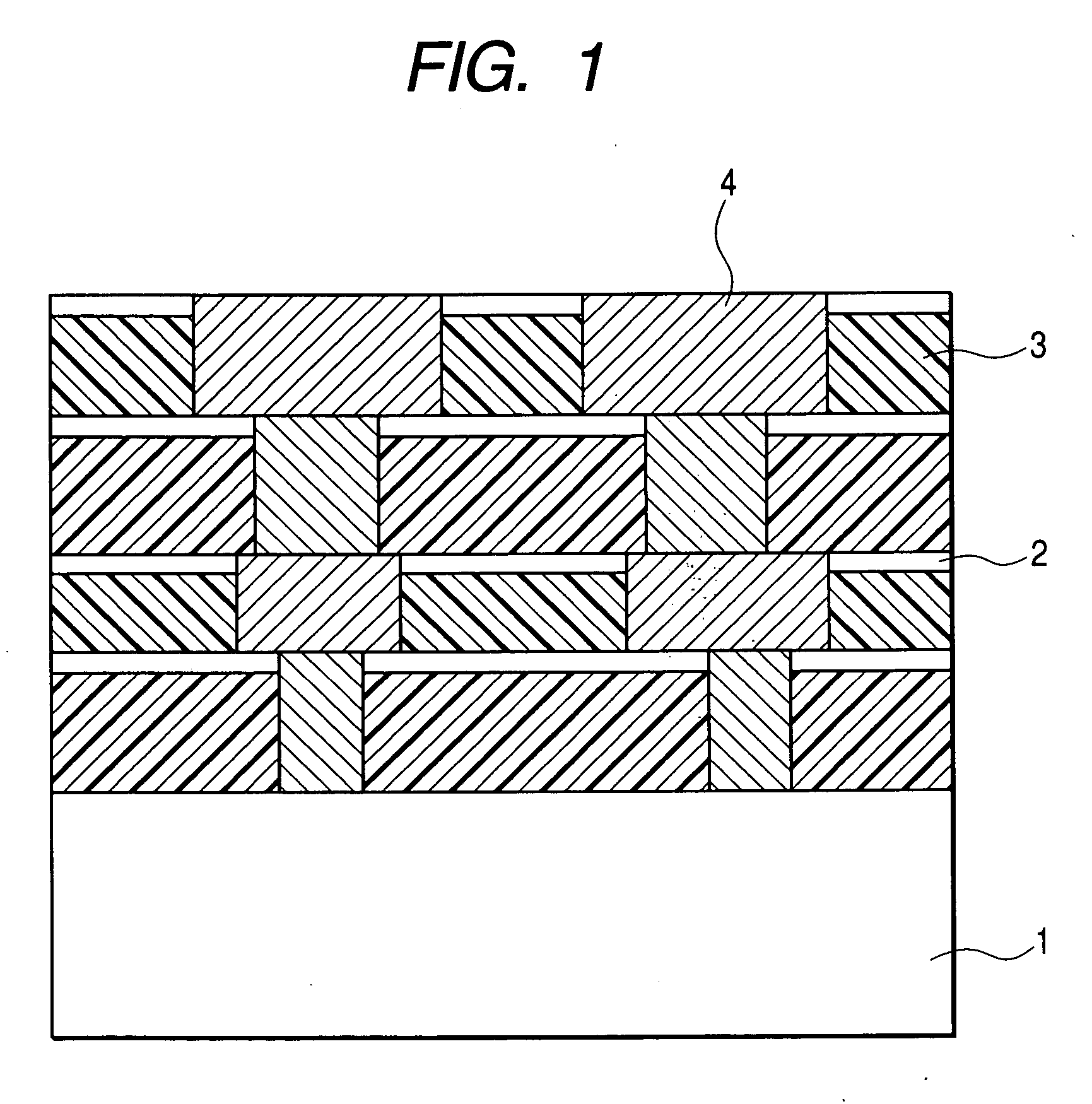

Semiconductor device and method for manufacturing the same

InactiveUS20060022342A1Excels in chemical resistanceExcels in fine processabilityBase layers for recording layersSemiconductor/solid-state device detailsSilicon oxideSemiconductor

A semiconductor device has multi-layered interlayer insulating layers 3 formed on a semiconductor substrate 1, and wirings 4 formed in the interlayer insulating layers 3. The interlayer insulating layers 3 are composed of porous bodies having fine columnar pores and parent-material regions consisting mainly of silicon oxides surrounding the fine pores. The wirings 4 are composed of structures wherein columnar substances containing aluminum are dispersed in a base material containing silicon, or regions wherein an electrically conductive material is introduced in a portion of the porous bodies. The average diameter of the fine pores in the porous bodies is 1 nm or larger and 10 nm or smaller, and the average distance between the fine pores is 3 nm or larger and 15 nm or smaller. The fine pores in the porous bodies is formed perpendicularly, or substantially perpendicularly to the film surface on a semiconductor substrate 1.

Owner:CANON KK

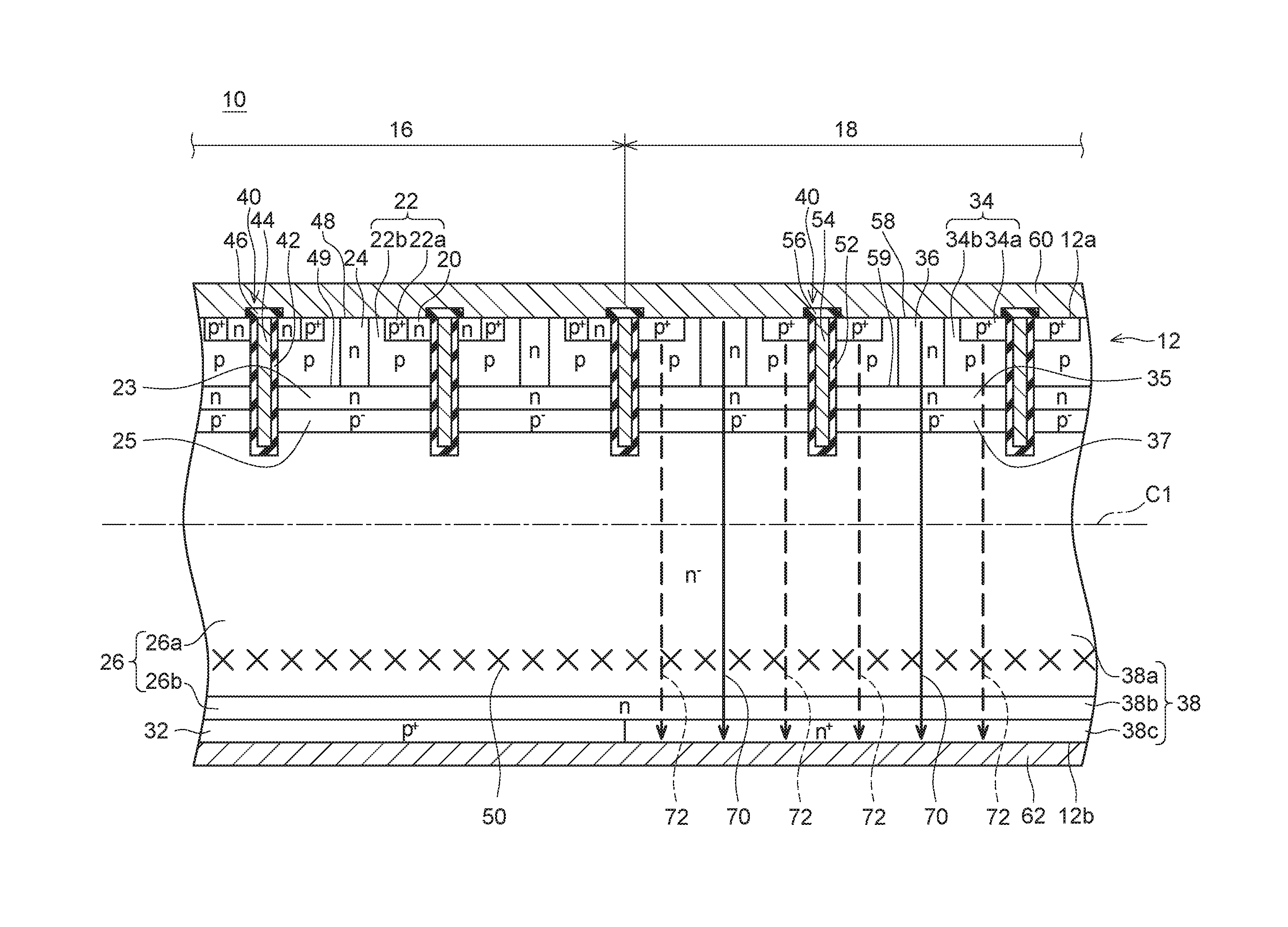

Semiconductor device

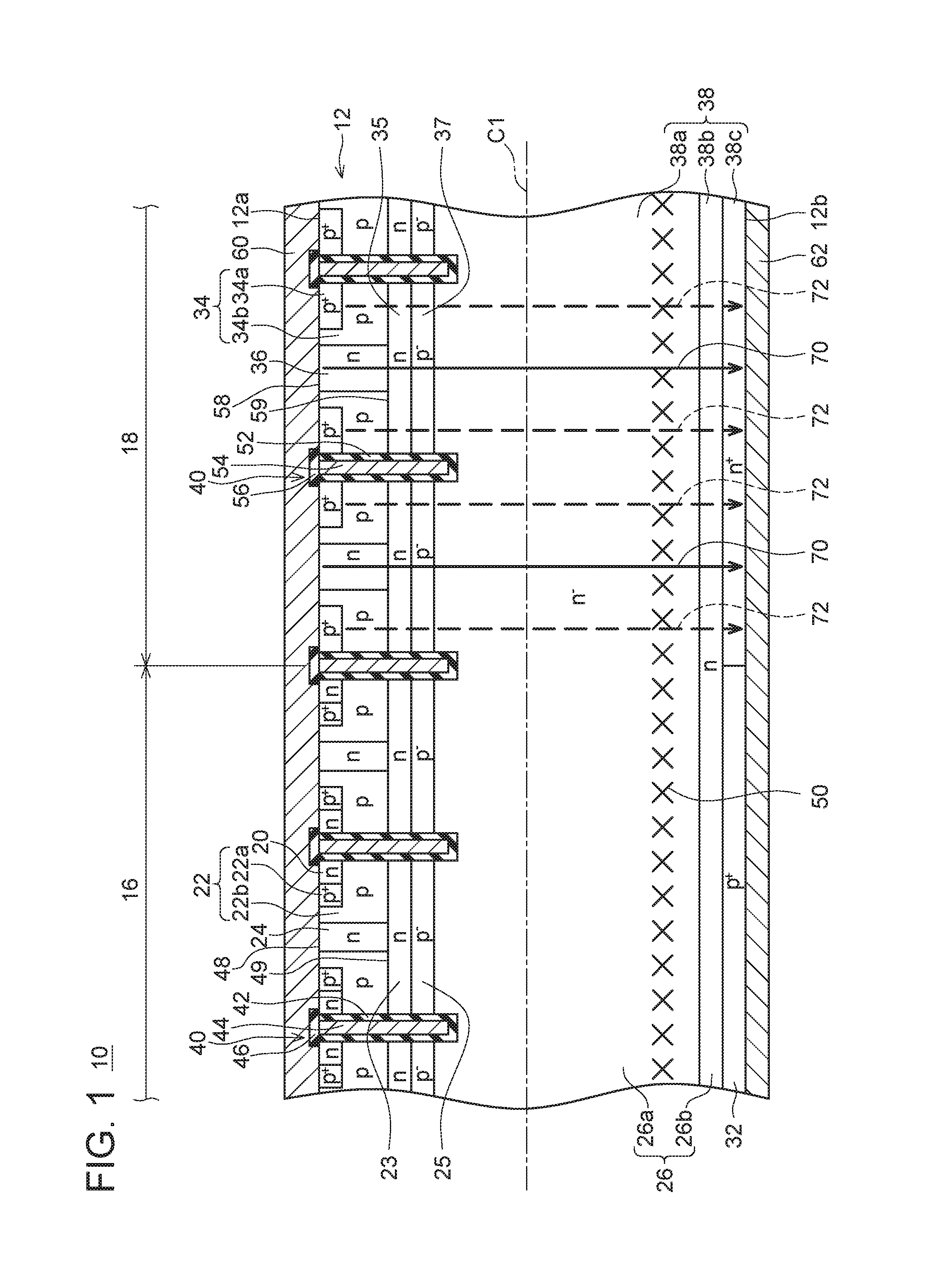

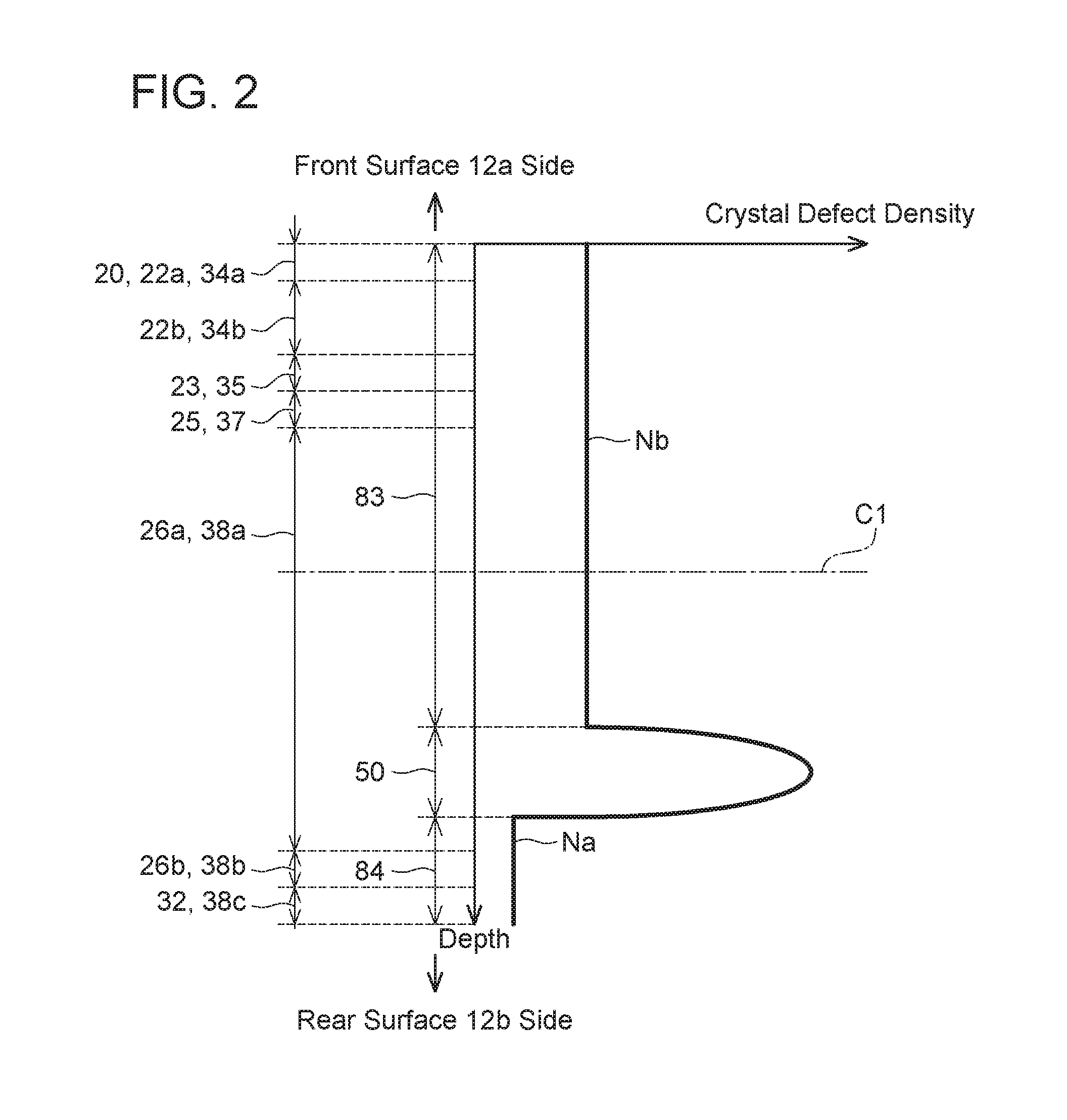

ActiveUS20160260807A1Reverse recovery is improvedHigh hole densityTransistorThyristorControl layerPeak value

A semiconductor device includes a diode and a semiconductor substrate. The diode includes a p-type anode region and an n-type cathode region. A lifetime control layer is provided in an area within the cathode region. The area is located on a back side than a middle portion of the semiconductor substrate in a thickness direction of the semiconductor substrate. The lifetime control layer has crystal defects which are distributed along a planar direction of the semiconductor substrate. A peak value of a crystal defect density in the lifetime control layer is higher than a crystal defect density of a front side region adjacent to the lifetime control layer on a front side of the lifetime control layer and a crystal defect density of a back side region adjacent to the lifetime control layer on a back side of the lifetime control layer.

Owner:DENSO CORP

Method for making silver nano wire using aerogel as template

The preparation method of silver nano wire by using aerogel as form plate includes the following steps: using inorganic oxide aerogel whose pore size is 10-100 nm, porosity is greater than 90% and pore size is concentrated in 30 nm as form plate, then using abrasive paper to sand it and make it into thin sheet whose thickness is 1-3 nm, cleaning it with pure clean water and drying, then soaking it in glucose aqueous solution whose concentration is 10%-60% for 30-40 min., taking out and wipe-drying with filter paper, and soaking it in silver ammonia liquor whose concentration is 3%-5% for 30-40 min. taking out, cleaning with pure clean water, and wipe-drying and removing silver liquor from surface, finally placing it into sodium hydroxide solution whose concentration is 2-5 mol. 1(-1) and soaking it until the form plate is completely dissolved, and the obtained black powder is the invented siler nano wire.

Owner:TONGJI UNIV

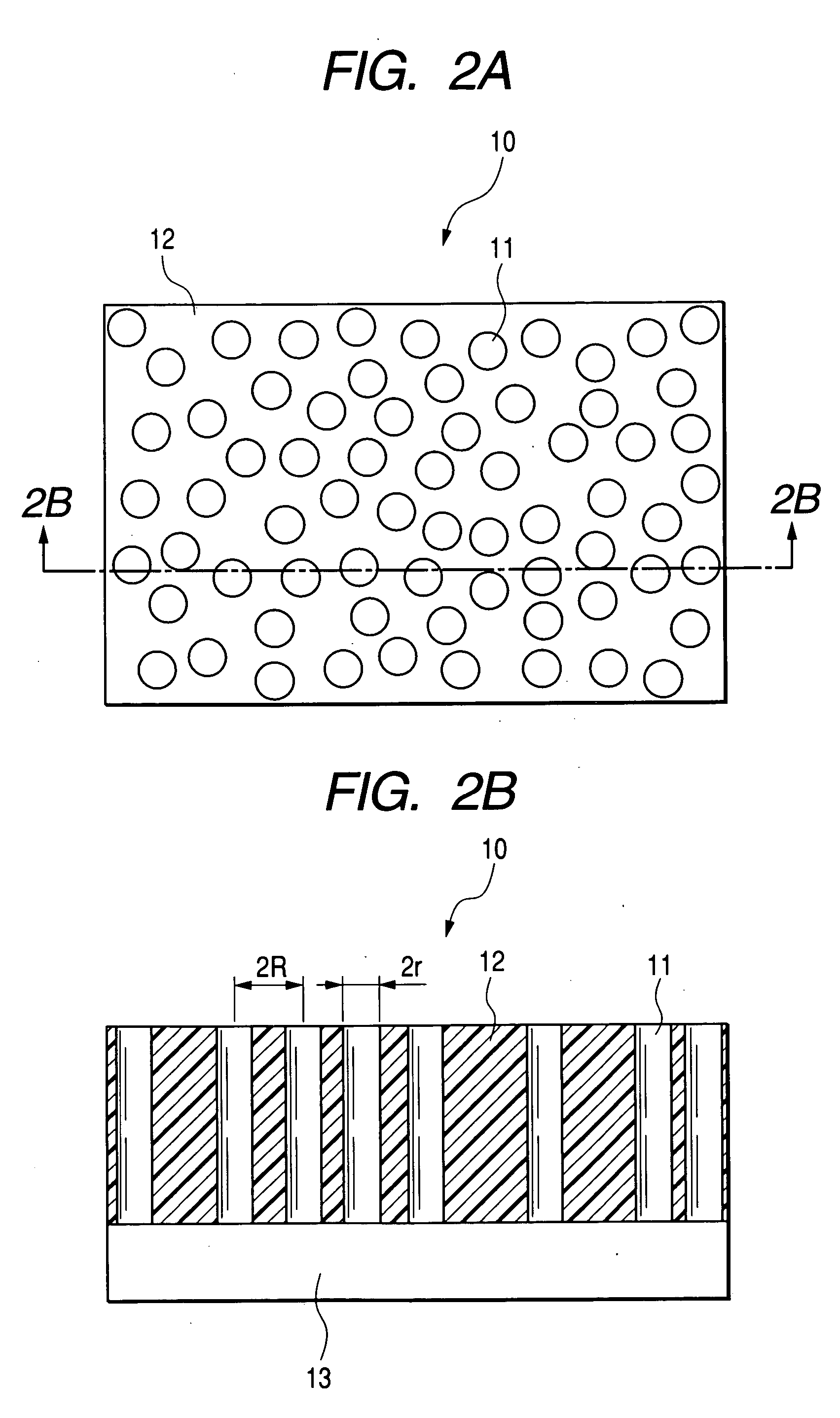

Field-effect transistor, sensor using it, and production method thereof

InactiveUS20060120918A1High sensitivityImprove responseTransistorMaterial analysis using wave/particle radiationSemiconductor materialsSilicon oxide

A sensor which has high measuring sensitivity and is excellent in response is provided by forming a porous film in a sensitive section of a field-effect transistor. It comprises a porous body, which is formed on a sensitive section (here, a gate insulating film) of the field-effect transistor and has cylindrical pores which are formed almost perpendicularly to a substrate, and the field-effect transistor. It uses as a porous film a porous film which is made of a semiconductor material whose main component (except oxygen) is silicon, germanium, or a composite of silicon and germanium, or a porous film made of an insulation material whose main component is silicon oxide, which has pores perpendicular to the substrate.

Owner:CANON KK

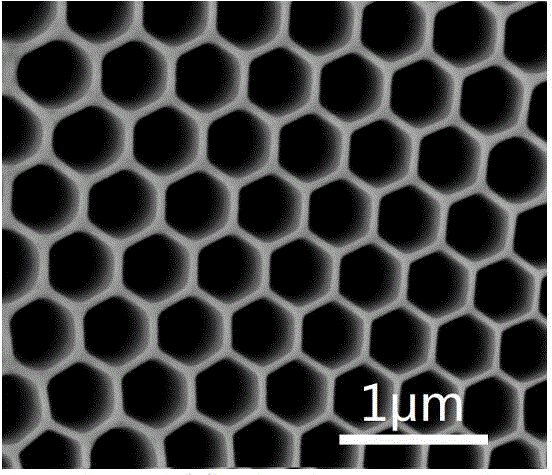

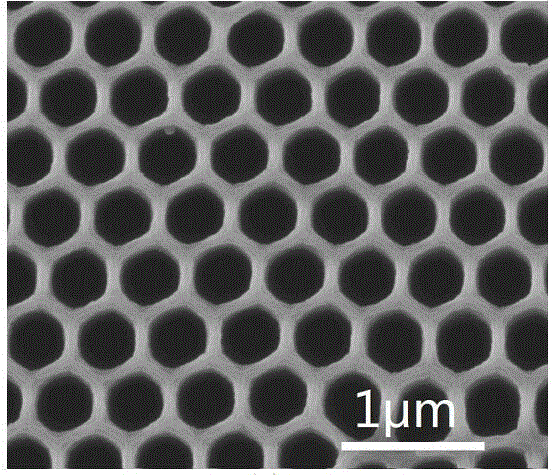

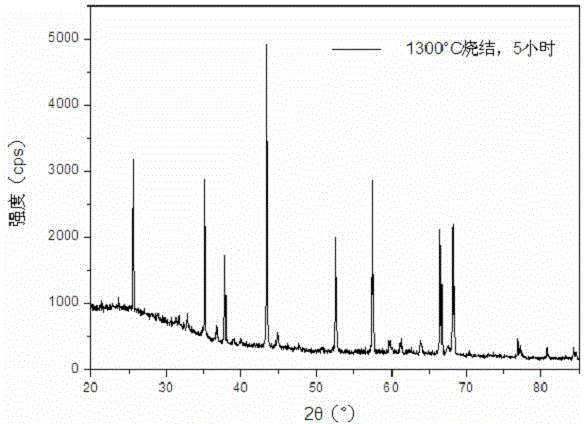

Preparation method of porous alpha-alumina membrane

A preparation method of a porous alpha-alumina membrane comprises the following steps: carrying out an annealing and electric polishing pretreatment on a high purity aluminum foil; taking the processed aluminum foil as the positive electrode, and graphite as the negative electrode, then carrying out two-step positive electrode oxidation in a mixed solution of phosphoric acid and aluminum oxalate to obtain an aluminum-base-containing porous anodic alumina membrane; subjecting the obtained aluminum-base-containing porous anodic aluminum membrane to a pore enlarging treatment; then subjecting the pore-enlarged aluminum-base-containing porous anodic alumina membrane to a water boiling treatment or a hydrothermal treatment; then removing the aluminum base from the aluminum-base-containing porous anodic alumina membrane, which has been treated by water boiling or a hydrothermal treatment; using a sodium citrate solution to remove the baffle layer and alumina hydrate on the external layer of the porous alumina membrane from the aluminum-base-free porous anodic alumina membrane so as to form a periodical hexahedral densely-arranged alumina through hole structure finally; and sintering the prepared alumina membrane with a periodical hexahedral densely-arranged alumina through hole structure in a muffle furnace at a high temperature so as to obtain porous alpha-alumina membrane.

Owner:常毅

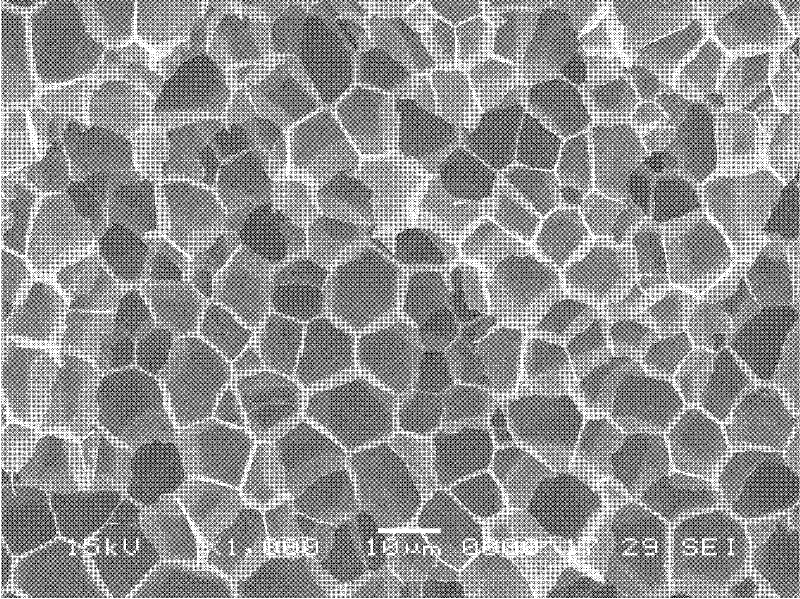

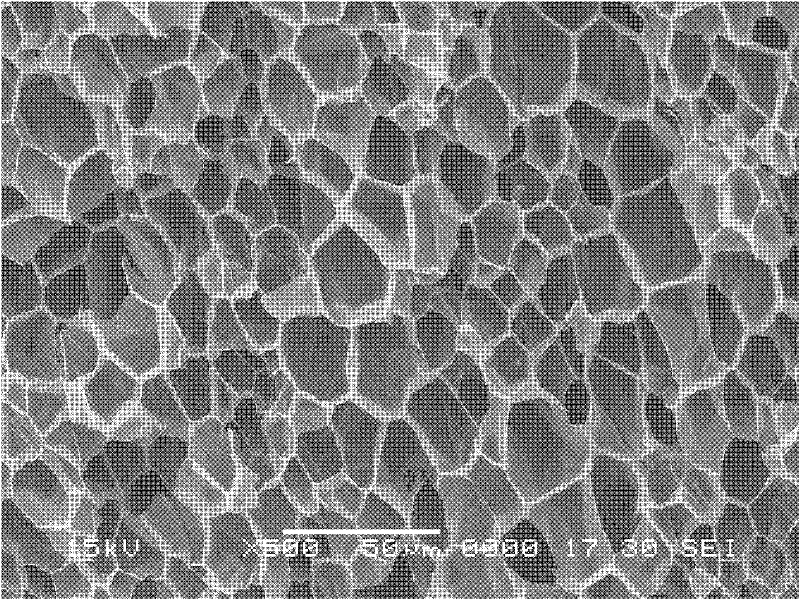

Method for preparing doping porous silicon ball

InactiveCN103979487AAchieving controllable equipmentEasy to operateNanostructure manufactureReaction temperatureOperability

The invention discloses a method for preparing a doping porous silicon ball. The method includes the steps that a silicon ball with certain doping content is selected, after being washed by hydrofluoric acid, the silicon ball is immersed in solutions formed by nitrate and hydrofluoric acid, after ultrasonic processing is carried out, the silicon ball is immersed in solutions prepared by the hydrofluoric acid and oxidizing agents and reacts at a certain temperature for a certain time period, then the silicon ball is washed in a centrifugal mode, and ultimately the nano porous silicon ball is prepared after nitric acid washing and other post-processing procedures. The best variety and the best concentration of reaction solutions, the optimum proportion of components, the best reaction temperature, the best reaction time, best ultrasonic frequency and best ultrasonic processing time are screened out through a large quantity of experiments. According to the whole preparation method, process design is reasonable, operability is high, production cost is low, production efficiency is high, and large-scale industrial production can be achieved. According to the high-purity doping porous silicon ball prepared in the method, the shapes of holes are regular, the holes are uniformly distributed and honeycomb-shaped, the shape of the silicon ball is regular, and the method can be widely used in the field of lithium batteries, solar batteries, semi-conductors, sensors and the like.

Owner:YANCHENG INST OF TECH

Method for preparing organic/inorganic composite nanowire filtering membrane

ActiveCN102585282ASmall apertureHigh hole densitySemi-permeable membranesPorous membraneAqueous solution

The invention discloses a method for preparing an organic / inorganic composite nanowire filtering membrane. The method comprises the following steps of: dissolving metal salt in an aqueous solution of ethanolamine to prepare a metal hydroxide nanowire; adding a heparin solution into a metal hydroxide nanowire solution to prepare a core-shell structured composite nanowire solution; fixing a polymerporous membrane in a filtering container, keeping a membrane surface upward, adding the core-shell structured composite nanowire solution into the filtering container, and filtering under reduced pressure; and drying. Negatively charged heparin is fixed on the surface of the positively charged metal hydroxide nanowire through electrostatic action to form the core-shell structured composite nanowire taking the nanowire as a core and the heparin as a shell, and the composite nanowire is deposited on the surface of the polymer porous membrane by a dynamic membrane preparation method to form the organic / inorganic composite nanowire filtering membrane with antibacterial property and blood compatibility. The nanowire has small diameter, small pore size when loaded, and high pore density, and the preparation process is simple and low in cost.

Owner:ZHEJIANG UNIV

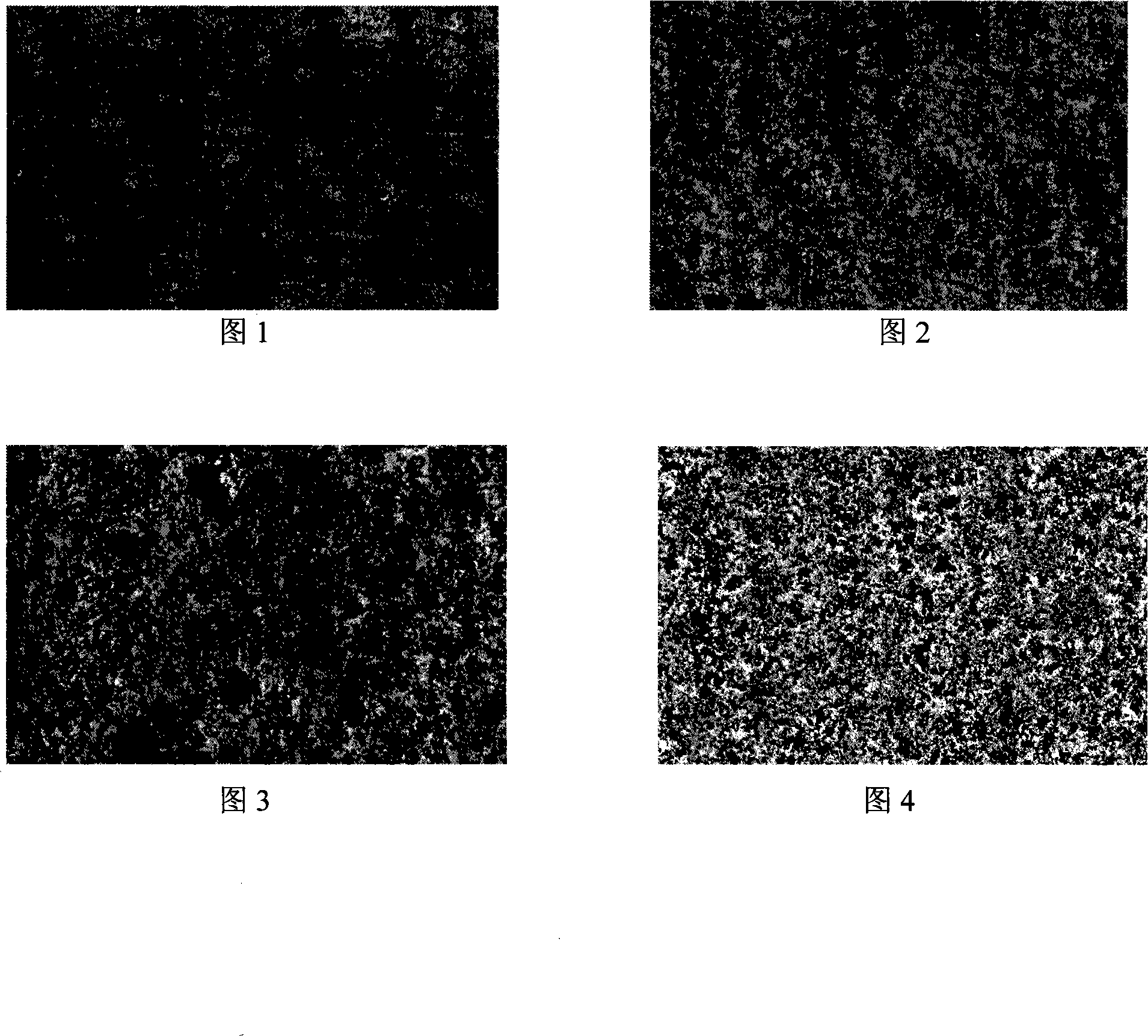

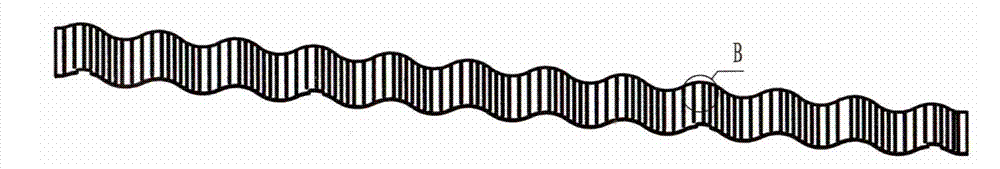

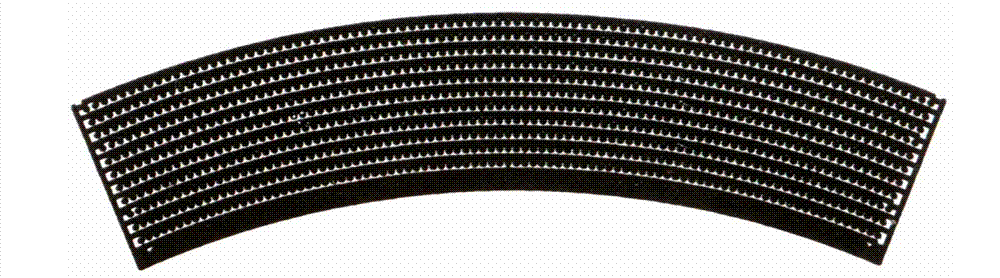

Frequency conversion bore distribution method for low-voltage anodic foil for aluminum electrolytic capacitor

InactiveCN101235533AReduce dispersion rateHigh hole densityElectrolytic capacitorsElectrolysisLow voltage

A method for conversing frequency and distributing holes used in low voltage anode foil of aluminum electrolytic capacitors relates to aluminum electrolytic capacitors, in particular relates to a method which can realize conversing frequency and distributing holes used in low voltage anode foil of the aluminum electrolytic capacitors with high specific volume aluminum electrolytic capacitors and provides a method for conversing frequency and distributing holes used in low voltage anode foil of aluminum electrolytic capacitors, wherein the method comprises the following steps: carrying out conventional oil removal to the aluminum foil, cleaning, and then carrying out hole distribution electrolysis to the aluminum foil, wherein the electrolyte is provided with 0.8-3.8N hydrochloric acid, 0.01-0.5N vitriol oil and 0.1-1.2N alchlor, frequency of the simple-sinusoidal alternating current which is adopted by the electrolysis is 5-80Hz, current density is 0.20-0.37A / cm2, obtaining the etched foil after carrying out conventional hole enlarging, obtaining the aluminum electrolytic capacitors used in low voltage anode foil after carrying out the conventional forming to the etched foil.

Owner:XIAMEN UNIV +1

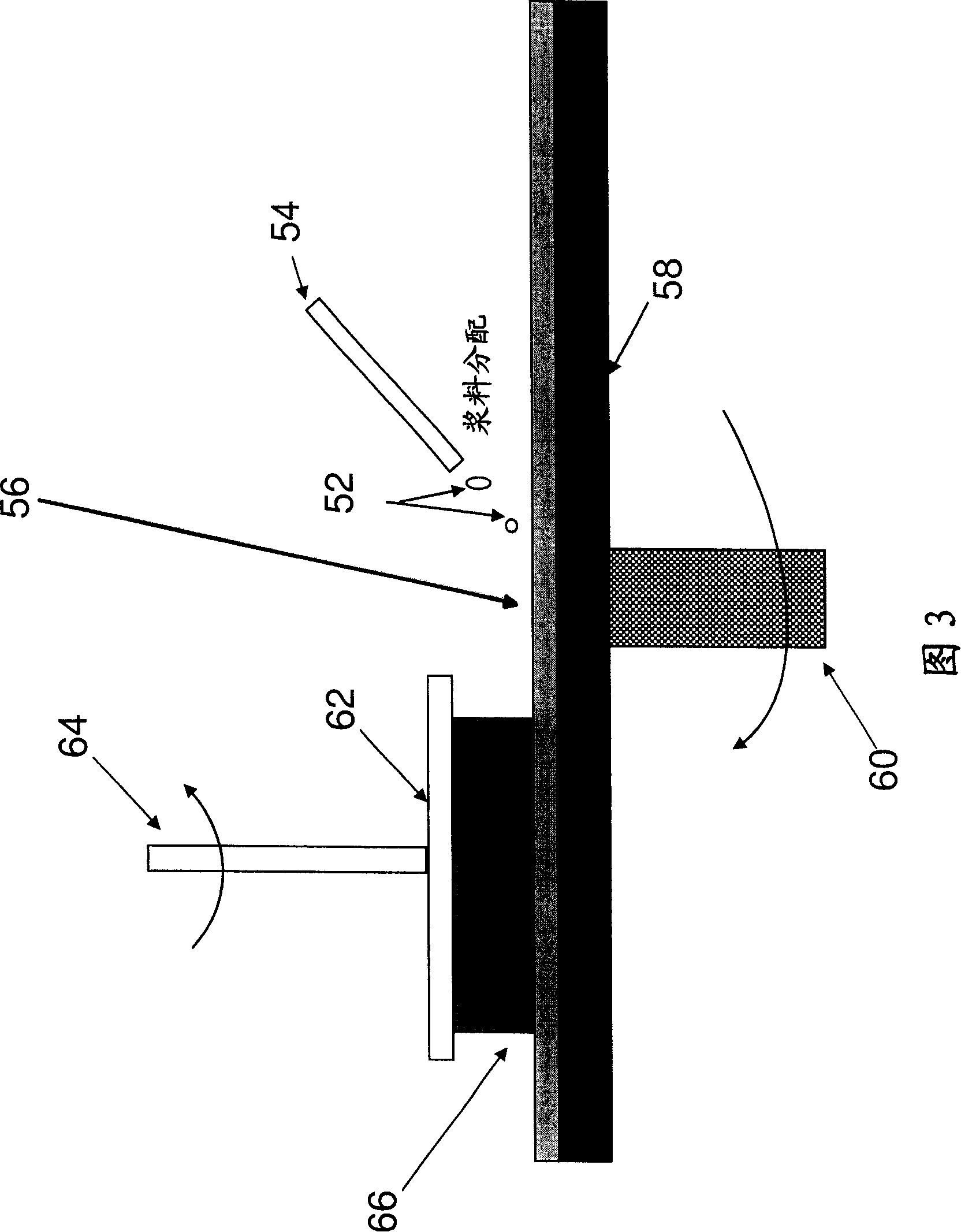

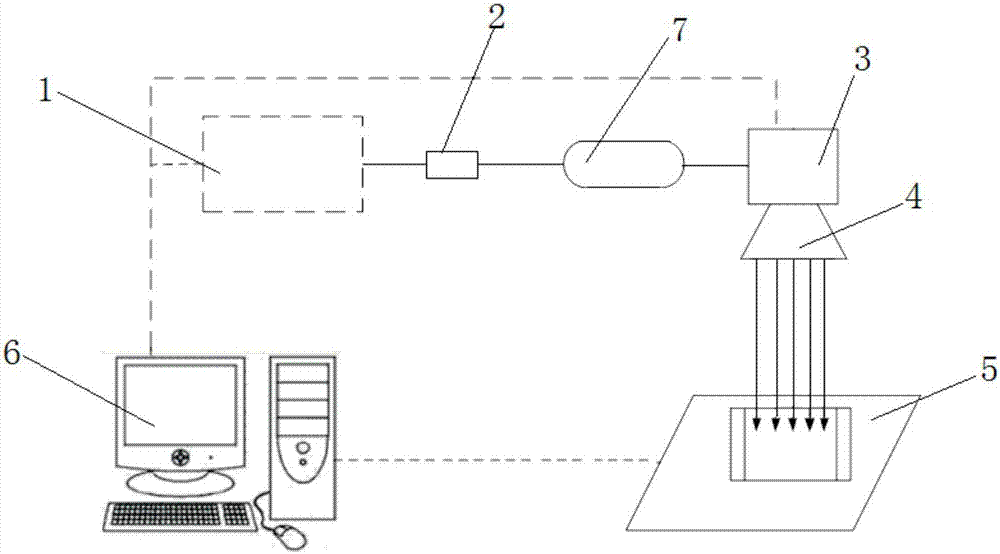

Filtering film processed through laser and laser processing system

InactiveCN106944751AHigh hole densityImprove processing efficiencyDispersed particle filtrationLaser beam welding apparatusLaser processingMicrometer

The invention discloses a filtering film processed through a laser. The filtering film processed through the laser can be used for filtering contamination particles with the dimensions being from hundreds of nanometers to hundreds of micrometers. The filtering film processed through the laser is wide in application range, and effects are better when the hole diameter of the filtering film processed through the laser is smaller than the diameter of the contamination particles. The invention further discloses a laser processing system used for processing the filtering film. The laser processing system comprises a laser device, a beam expanding device, a diffraction optical element, a galvanometer unit, a lens, a carrying mechanism and a corresponding control unit, wherein the laser device, the beam expanding device, the diffraction optical element, the galvanometer unit, the lens, the carrying mechanism and the corresponding control unit are sequentially arranged. Through selection of laser processing parameters, by the adoption of a galvanometer and the carrying mechanism for assistance, an micro-hole array with the hole diameter being from hundreds of nanometers to hundreds of micrometers can be manufactured on the filtering film made of a selected material. The laser processing system can be used for processing the filtering film (net) and is high in work efficiency, low in production cost and free of tool consumption, and the processed filtering film is large in micro-hole density and has a good filtering effect.

Owner:INNO LASER TECH CORP LTD

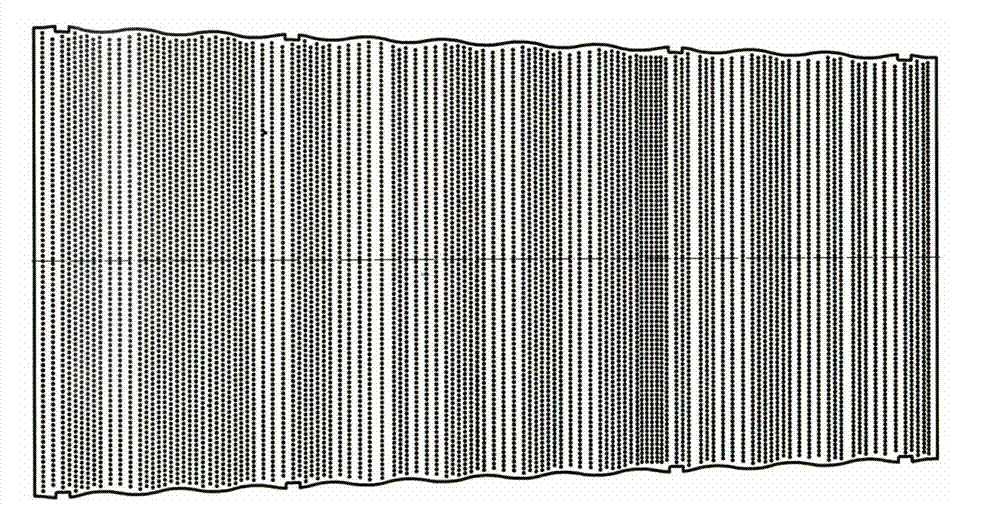

Data acquisition and optimization method for laser processing of multiwave group holes

ActiveCN102880116ASolve efficient programmingSolve processabilityProgramme controlComputer controlLaser processingData acquisition

The invention relates to a data acquisition and optimization method for laser processing of multiwave group holes. The acquisition method comprises the steps of acquiring by the selection modes of all holes on a conducting surface of UG software and storing a file with the extension name of '.txt'. The optimization method comprises the following steps: (1), opening the stored file with the extension name of '.txt' by using WORD software; (2), performing WORD edition for the first time; (3), performing optimal sequencing; (4), performing optimal operation; and (5), arranging into a processing program file. The invention particularly provides the data acquisition and optimization method for laser processing of the multiwave group holes, which solves the problems of high-efficiency programming and high-efficiency processing of the multiwave group hole processing program, successfully finishes multi-ring wave heat screen micro group holes and high-efficiency laser processing, and has the advantages of high processing efficiency and low cost.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Preparation method of polypropylene foaming sheet material

The invention provides a preparation method of a polypropylene foaming sheet material. Homo-polypropylene as base resin and ammonium polyphosphate as a fire retardant undergo foaming in the presence of a supercutical fluid foaming agent so that the polypropylene foaming sheet material is prepared. The preparation method comprises that two or more stages of propylene homopolymerization reactions occur in two or more reactors connected in series, wherein external electron donors used in the two or more stages of reactions respectively are silane and diether compounds. The halogen-free flame-retardation polypropylene foaming sheet material obtained by the preparation method has the advantages of low production cost, short production period, compact foam apertures, uniform aperture distribution and high burning oxygen index and can be used in occasions of automobile parts, steamships and aircraft weight reduction assemblies, and electronic packaging and building decoration having high flame-retardation requirements.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrophilic polyvinylidene fluoride composite material and preparation method thereof

InactiveCN102382404AGood adhesionExcellent anti-fouling and anti-bacterial propertiesPhysical chemistryPolyvinylidene difluoride

The invention discloses a hydrophilic polyvinylidene fluoride composite material and a preparation method thereof. The hydrophilic polyvinylidene fluoride composite material includes, by weight, 70% to 95% of polyvinylidene fluoride resin, 5% to 30% of polymethylmethacrylate, 0.5% to 1.5% of nano particles and 0.5% to 1.5% of surfactant, and the sum of the weight percentages of the above components is 100%. By the aid of the hydrophilic polyvinylidene fluoride composite material and the preparation method, hydrophily of polyvinylidene fluoride is improved, film products produced by the polyvinylidene fluoride and disposed in water have excellent anti-fouling and anti-bacterial property. The preparation method of the hydrophilic polyvinylidene fluoride composite material adopting blending modification is simple in process, convenient in operation and easy to be industrialized.

Owner:SHENZHEN KEJU NEW MATERIAL

Method for preparing polymer microporous foaming material by supercritical mould foaming

The invention provides a method for preparing a polymer microporous foaming material by supercritical mould foaming. The method comprises the following steps of: heating a foaming mould on a mould press to the foaming temperature; placing a polymer into the mould; closing the mould by using the mould press; sealing the mould; introducing supercritical fluid, which swells and diffuses to the polymer, into the mould; and opening the mould by using the mould press to release pressure and foam to obtain the polymer microporous foaming material. Compared with the prior art, the method has the advantages that: the high-temperature and high-pressure supercritical fluid is used for swelling the polymer, so the moulding cycle is greatly shortened; the limit that only microporous foaming sheet material with lesser thickness can be manufactured in the prior art is broken through, so a polymer microporous foaming plate with greater thickness can be manufactured; when the mould is opened, the pressure-releasing speed is high and the foaming pore core-forming speed is high, so the formed microporous foaming material has smaller foaming pores, higher pore density and more excellent performance; and multiple layers of moulds can be placed on one mould press, so the method is suitable for industrialized scale production.

Owner:SHINCELL NEW MATERIAL CO LTD

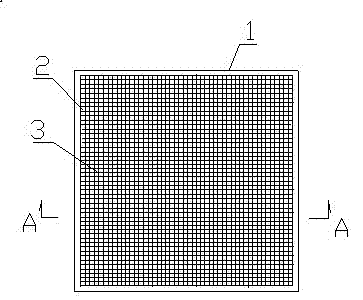

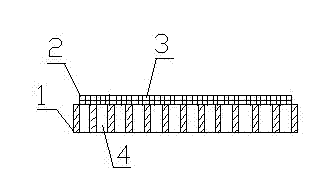

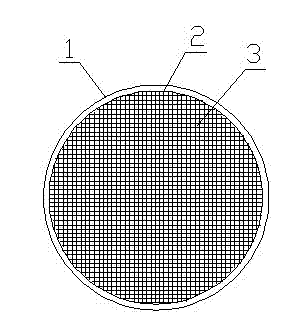

Multilayer casting filter

ActiveCN102350134AShort flow distanceLow flow resistanceFiltration separationPore diameterHoneycomb like

The invention discloses a multilayer casting filter, comprising a support layer (1) made of a ceramic material and a filtering layer (2) made of a ceramic material and arranged on the support layer. The filtering layer contains alveolate filtering holes (3); the support layer contains grid liquid flow holes (4); a hole density of the filtering layer is larger than that of the support layer; an aperture of a filtering hole is smaller than that of a liquid flow hole; a porosity of the support layer is larger than that of the filtering layer (2); and a thickness of the filtering layer is smaller than that of the support layer. The invention can simplify a pouring system, increase produce rate of a cast technology, reduce cast costs, enhance flow velocity and continuity of pouring, facilitate cast mold filling, improve high temperature impact resistance and high temperature bearing capacity of the filter, ensure integrity of the filter in the whole pouring process, facilitate filtering purification of metal liquid and improve inner quality and comprehensive performances of a cast product, and is suitable for pouring of multiple-part mold and large and medium size cast.

Owner:JIANGXI BAOAN NEW MATERIAL TECH

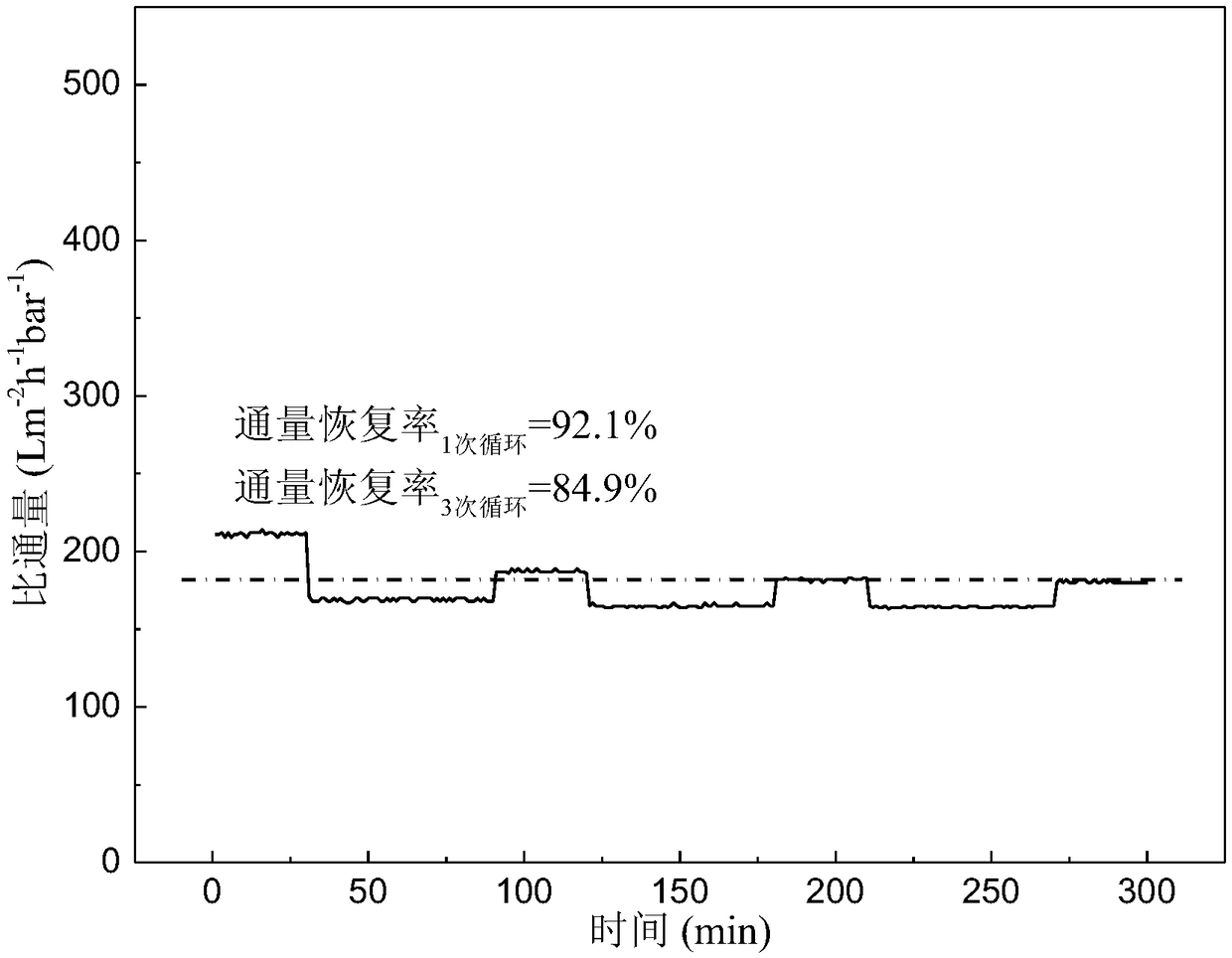

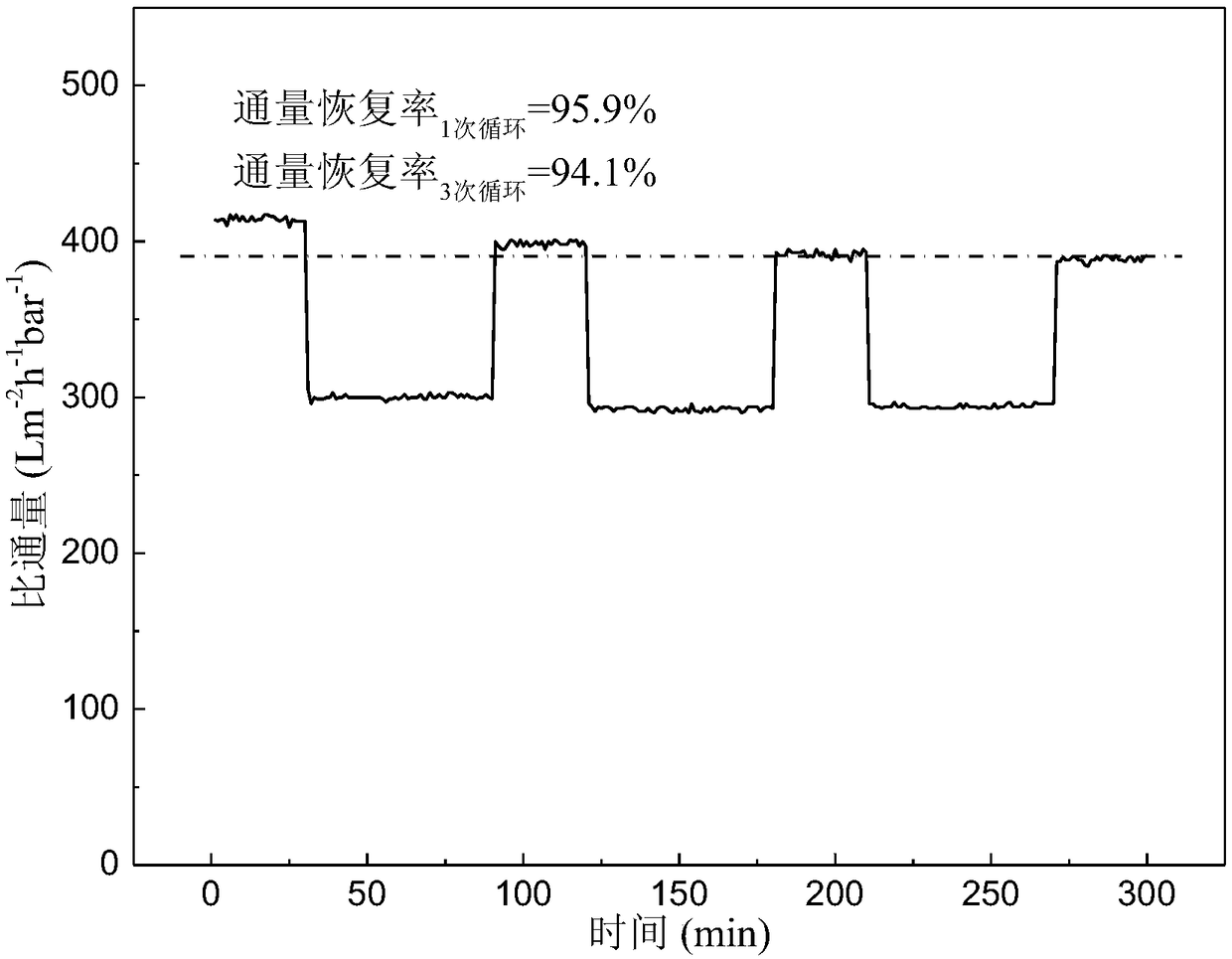

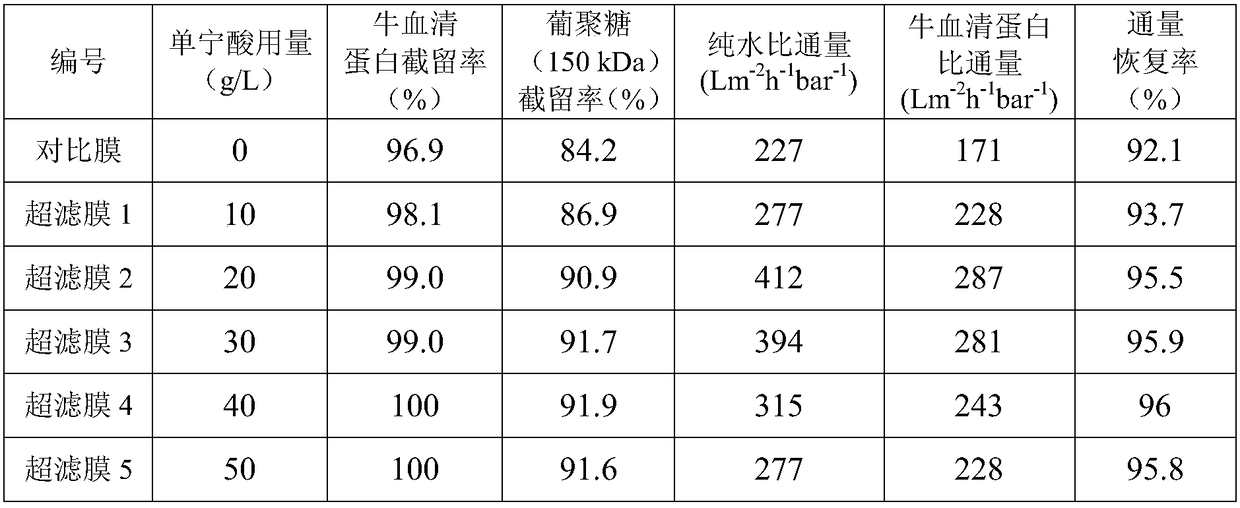

Method for preparing ultra-filtration membranes with high selectivity and high permeability

InactiveCN108654385AHigh selectivityImprove permeabilityMembranesUltrafiltrationWater bathsFiltration membrane

The invention discloses a method for preparing ultra-filtration membranes with high selectivity and high permeability. The method includes heating and stirring polyethersulfone, pluronic F127 and dimethylformamide in water bath at the temperature of 70 DEG C according to a mass ratio of 20:20:85 for 4 h, and carrying out static defoaming for 2 h to obtain casting membrane solution; adding tannic acid aqueous solution with certain concentration into a beaker, and stirring the tannic acid aqueous solution at the room temperature for 1 h to be used as coagulating bath; cooling the casting membrane solution until the temperature of the casting membrane solution reaches the room temperature, then pouring the casting membrane solution on glass plates, forming liquid membranes with the thicknesses of approximately 200 micrometers by means of scraping, placing the liquid membranes in the coagulating bath at the constant temperature of 25 DEG C and carrying out continuous solidification and membrane formation for 10 minutes; continuously immersing obtained membranes in sodium hydroxide solution for 12 h, and continuously immersing the membranes in ionized water for 24 h to obtain the ultra-filtration membranes with the high selectivity and the high permeability. The potential of hydrogen of the sodium hydroxide solution is 12. The method has the advantages that hole parameters of the ultra-filtration membranes can be optimized by the aid of interfacial assembly of tannic acid and the pluronic F127 in membrane formation procedures, in other words, the hole density can be increased, and the hole sizes can be reduced, so that the ultra-filtration membranes prepared by the aid of the method are high in selectivity and permeability.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com