Method for preparing ultra-filtration membranes with high selectivity and high permeability

A high-permeability, high-selectivity technology, applied in ultrafiltration, semi-permeable membrane separation, chemical instruments and methods, etc., can solve problems such as limiting the simultaneous improvement of ultrafiltration membrane permeability and selectivity, and achieve high selectivity and permeability, reducing pore size, increasing pore density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1, prepare ultrafiltration membrane with high selectivity and high permeability concurrently, the steps are as follows:

[0021] Step 1. Configuration of the casting solution: add 160mg of polyethersulfone (6020P type), 160mg of Pluronic F127 and 680mg of dimethylformamide into a round bottom flask, heat and stir in a water bath at 70°C for 4h, then statically defoam for 2h ,stand-by.

[0022] Step 2, configuration of the coagulation bath: add an aqueous solution of tannic acid with a mass volume concentration of 10 g / L into a beaker, stir at room temperature for 1 hour, and set aside.

[0023] Step 3. Solidify and form a film: Cool the casting solution configured in step 1 to room temperature, pour it on a glass plate and scrape it into a liquid film with a thickness of about 200 μm, and put it in the coagulation bath configured in step 2 at a constant temperature of 25°C to continue 10 minutes to solidify into a film.

[0024] Step 4, post-treatment: imme...

Embodiment 2

[0026] Embodiment 2, preparation has the ultrafiltration membrane of high selectivity and high permeability concurrently, and its preparation process is basically the same as embodiment 1, and difference only is: in step 2, the mass volume concentration of tannic acid aqueous solution is 20g / L, and final preparation Obtain ultrafiltration membrane 2.

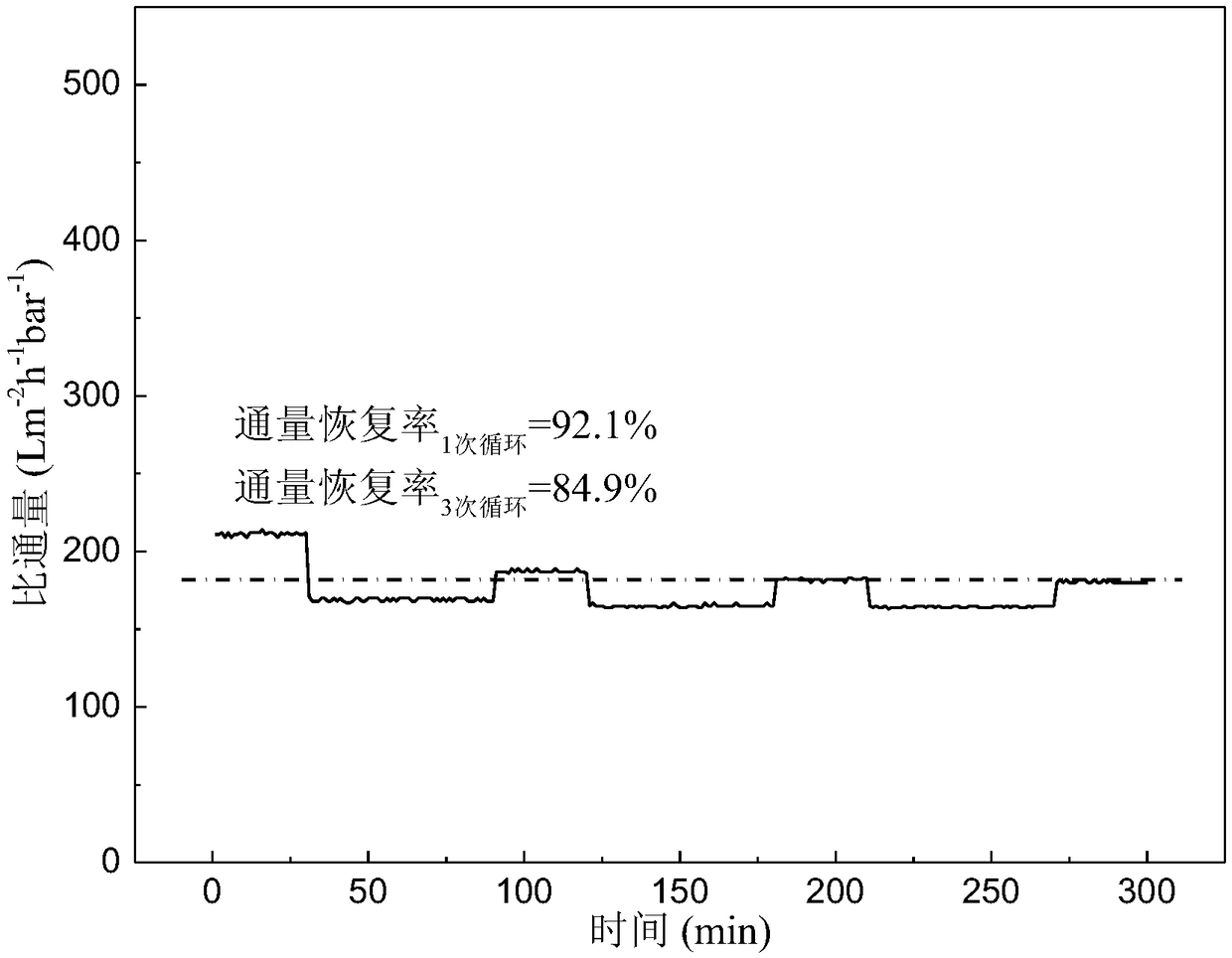

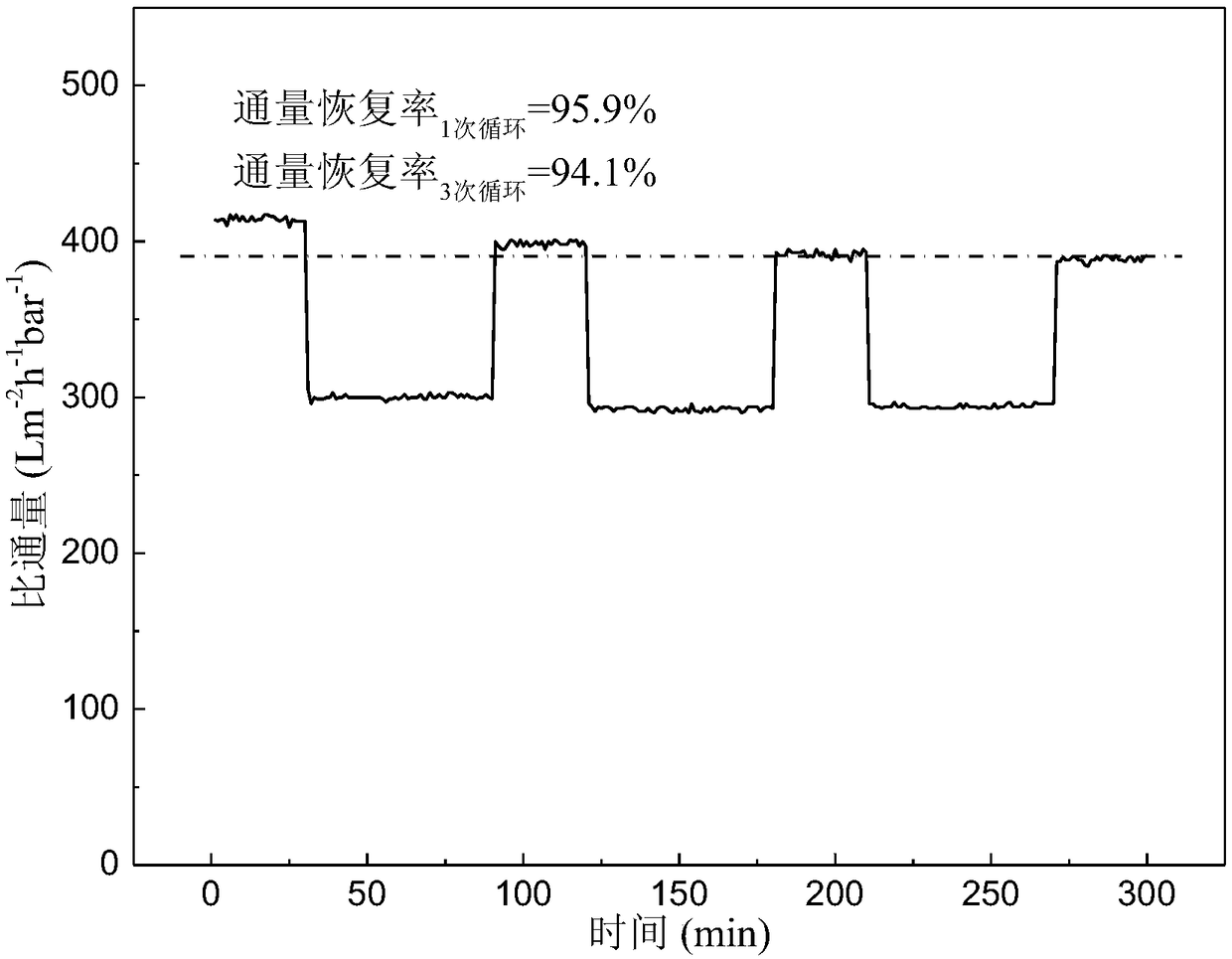

[0027] figure 2 It is the three-cycle flux change diagram of ultrafiltration membrane 2 prepared in Example 2 of the present invention for filtering 1 g / L bovine serum albumin aqueous solution. The content of each cycle is: pure water (30min)-bovine serum albumin aqueous solution (60min)-cleaning (10min, this time is not marked in the figure)-pure water (30min).

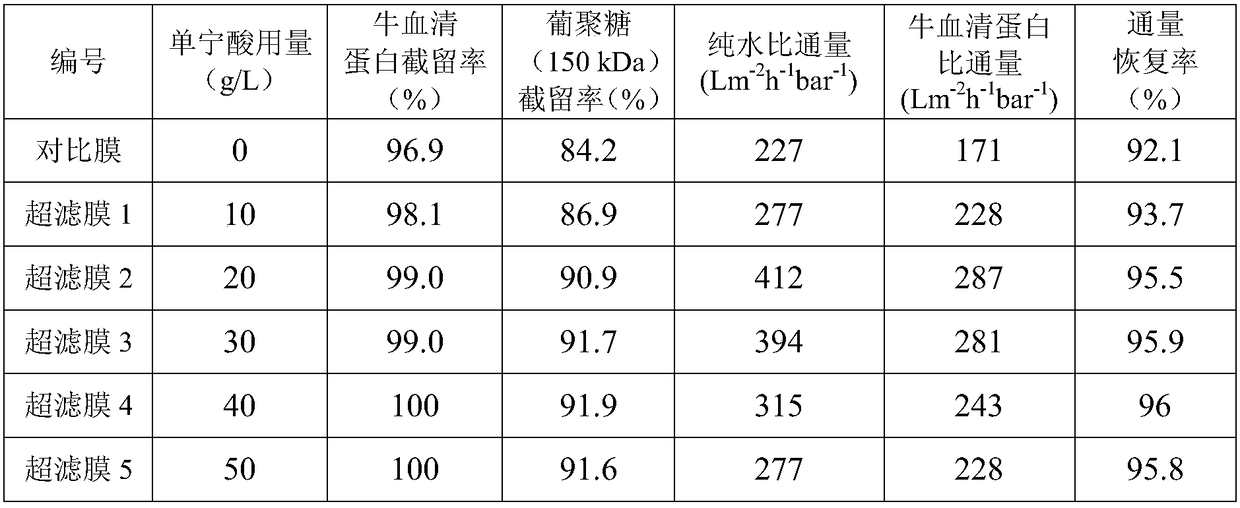

[0028] The ultrafiltration membrane 2 made by embodiment 2 has a rejection rate of 99.0% to bovine serum albumin (1g / L), and a retention rate of 90.9% to dextran (1g / L, molecular weight 150kDa); The specific flux is 412Lm -2 h -1 bar -1 , the specific flux of fil...

Embodiment 3

[0029] Embodiment 3, preparation has the ultrafiltration membrane of high selectivity and high permeability concurrently, and its preparation process is basically the same as embodiment 1, and difference only is: in step 2, the mass volume concentration of tannic acid aqueous solution is 30g / L, and final preparation Obtain ultrafiltration membrane 3.

[0030] The ultrafiltration membrane 3 made by embodiment 3 has a rejection rate of 99.0% to bovine serum albumin (1g / L), and a retention rate of 91.7% to dextran (1g / L, molecular weight 150kDa); The specific flux is 394Lm -2 h -1 bar -1 , the specific flux of filtering 1g / L bovine serum albumin aqueous solution is 281Lm -2 h -1 bar -1 , the flux recovery rate was 95.9% after operating for 60 minutes and washing with pure water shear flow for 10 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com