Patents

Literature

111results about How to "Reduce hole size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sulfonium salt having polymerizable anion, polymer, resist composition, and patterning process

ActiveUS20080102407A1Feature size of to decreaseSmall feature sizeOrganic chemistryPhotosensitive materialsResistHigh energy

A sulfonium salt having a polymerizable anion generates a strong sulfonic acid upon exposure to high-energy radiation so that it facilitates effective scission of acid labile groups in chemically amplified resist compositions. It is useful as a monomer from which a base resin for use in radiation-sensitive resist compositions is derived.

Owner:SHIN ETSU CHEM IND CO LTD

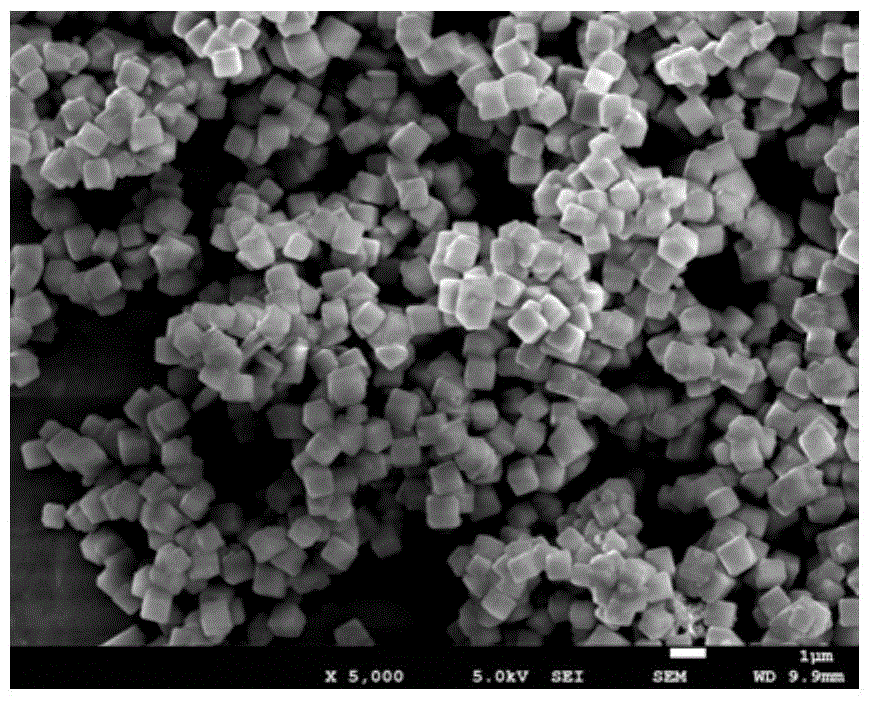

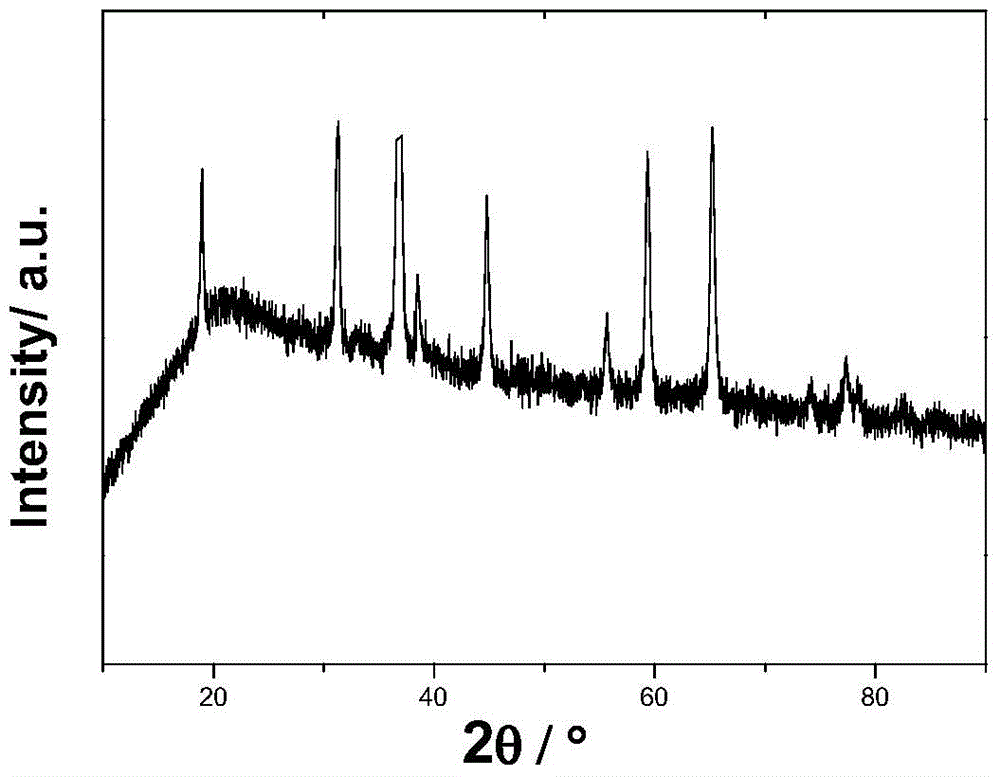

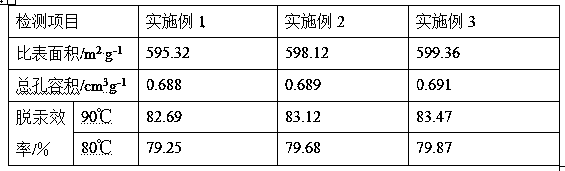

Homogeneous-phase multi-element porous oxide material, preparation method and application thereof

ActiveCN104445079ALarge specific surface areaEasy to prepareOxide/hydroxide preparationIron oxides/hydroxidesChemical compoundOrganic component

The invention relates to a homogeneous-phase multi-element porous oxide material, a preparation method and application of the homogeneous-phase multi-element porous oxide material. The method comprises the following steps: preparing solutions by metal organic ligands; optionally adding deprotonation agents; adding mixed salts of at least two metals; stirring at a constant temperature and reacting for a certain time to obtain a multielement metal organic frame compound; performing suction filtration, washing and drying; and roasting at a certain temperature and performing ablation on organic components in the metal organic frame to obtain the homogeneous-phase multi-element porous oxide material. The method is simple in process, high in yield, low in cost and free of pollution; the homogeneous-phase multi-element porous oxide material has uniformly-distributed metal elements and is high in specific surface area. The multi-element porous oxide material has wide application prospects in the fields of adsorption, catalysis, sensing, energy storage and the like.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

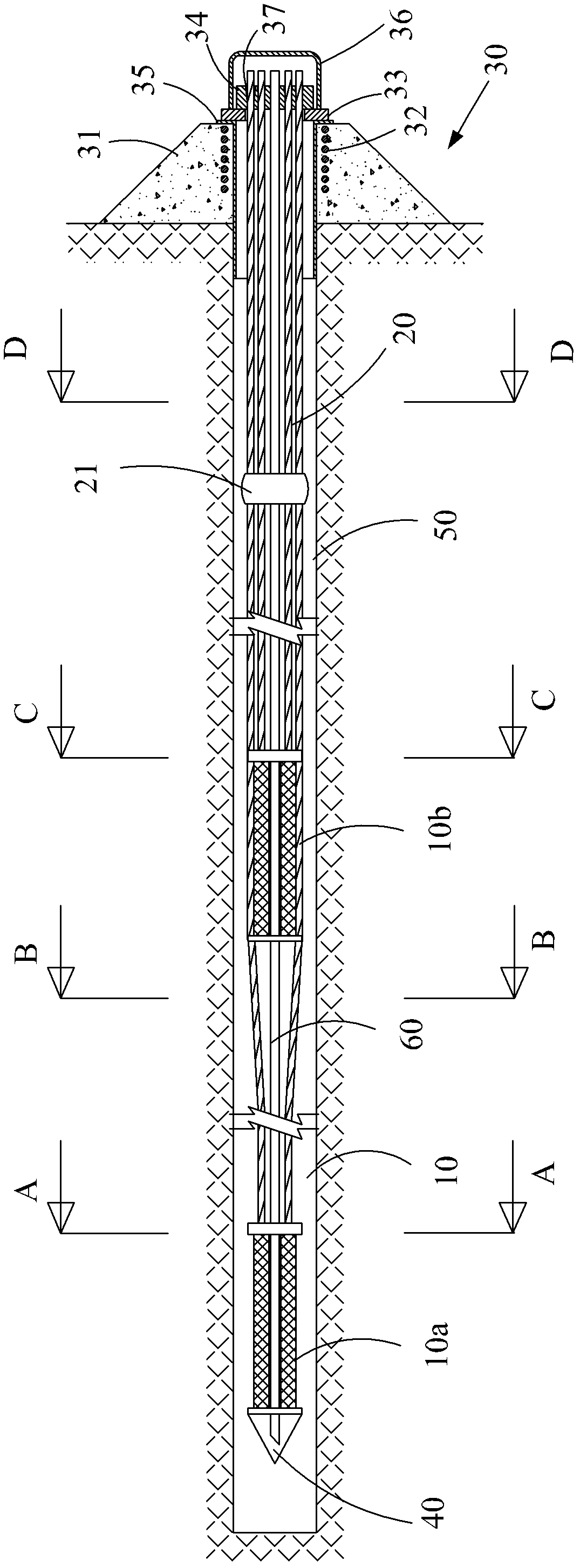

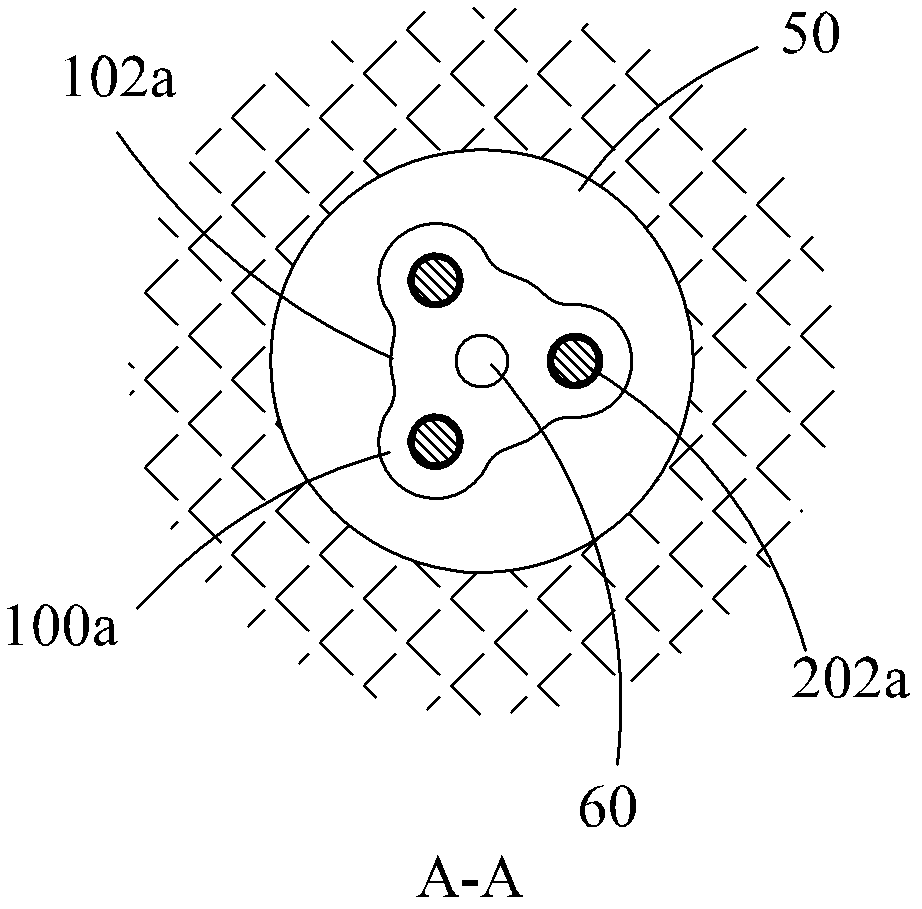

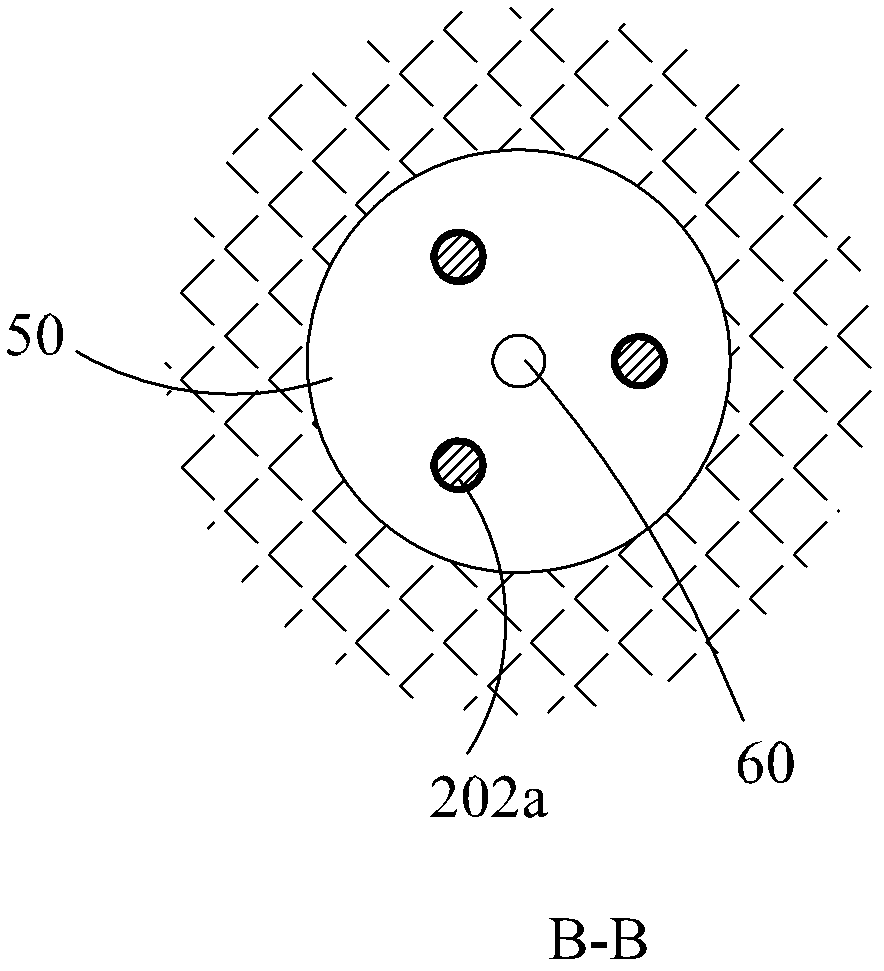

Pressure dispersion type yielding anchor cable

ActiveCN102619226AAvoid breakingPlay the role of earthquake resistanceBulkheads/pilesHigh pressureMechanical engineering

Owner:杭州图强工程材料有限公司

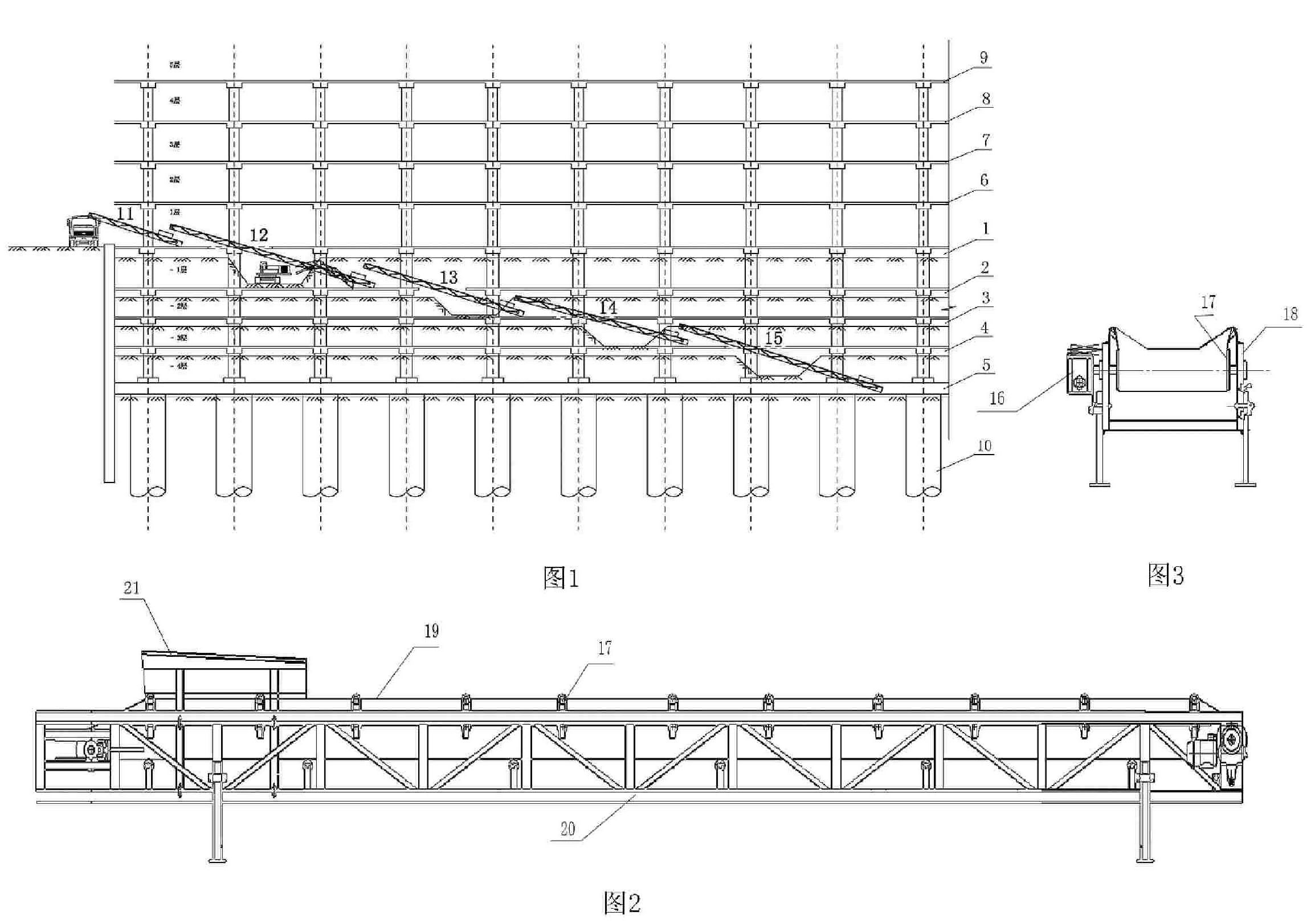

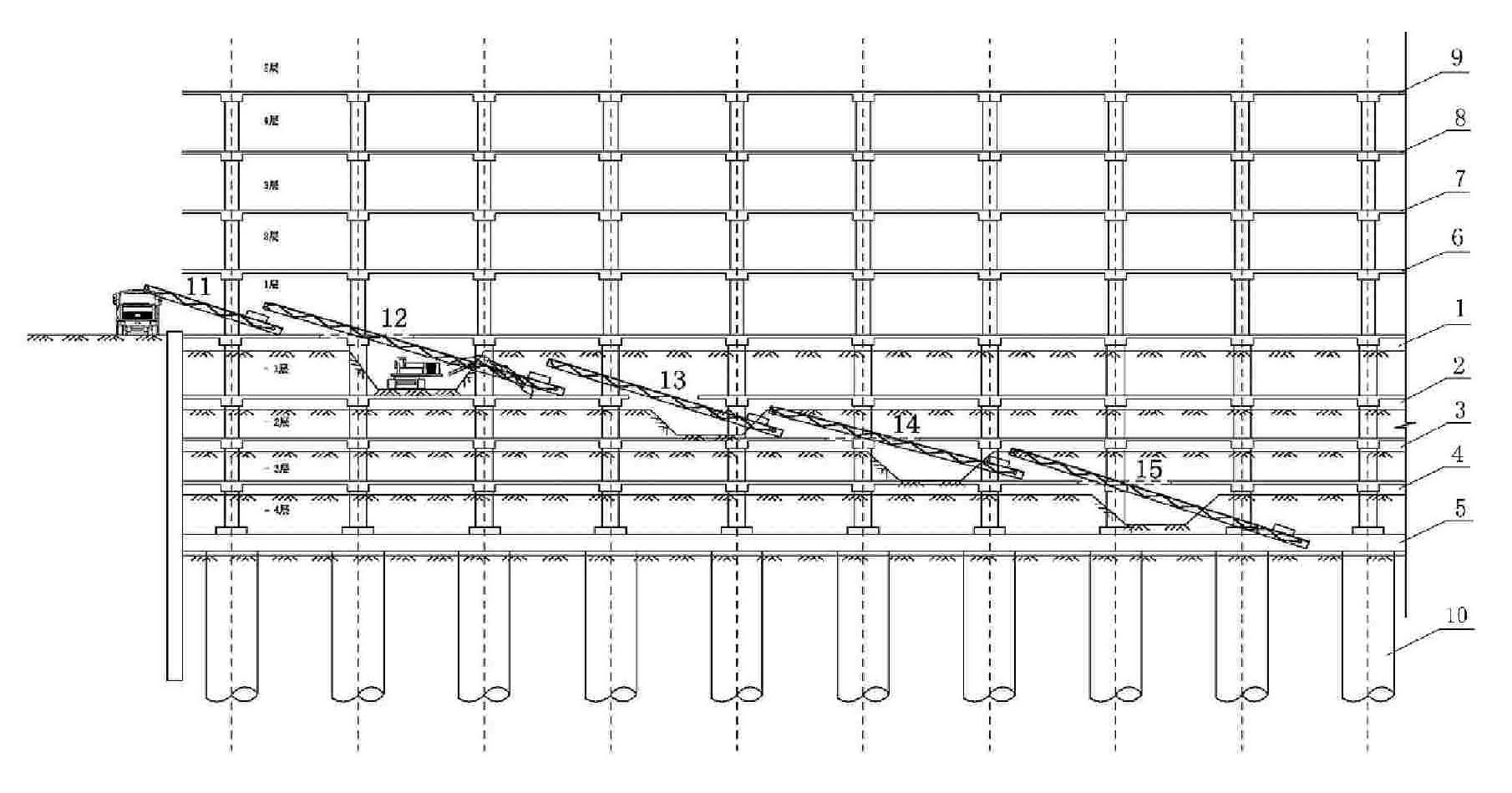

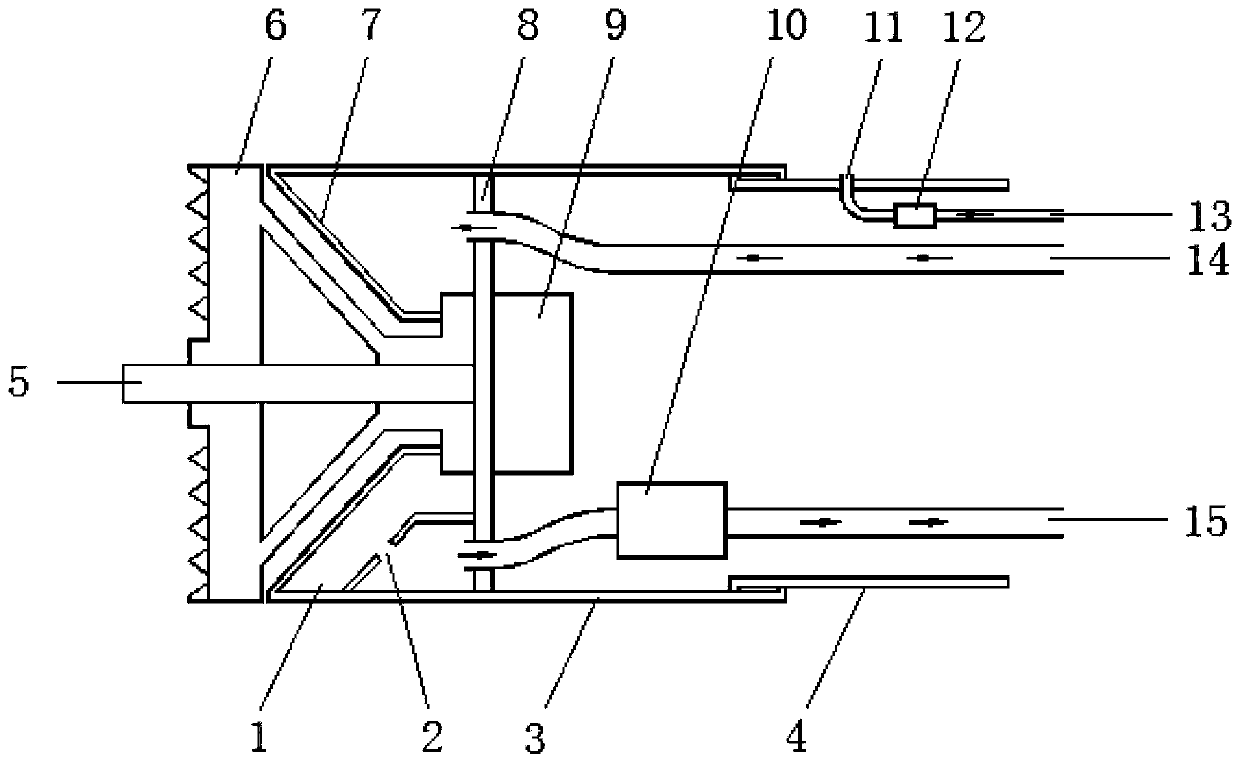

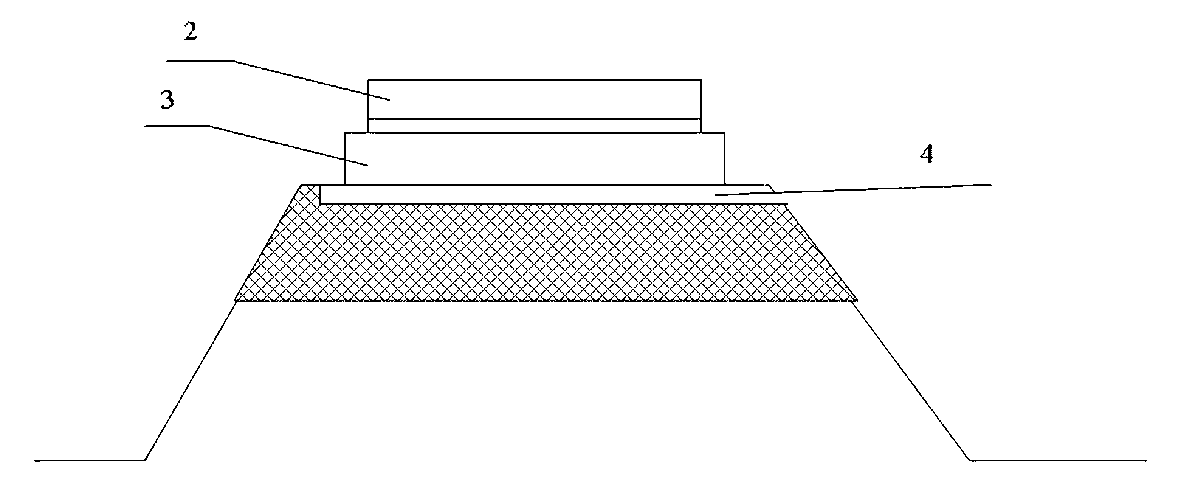

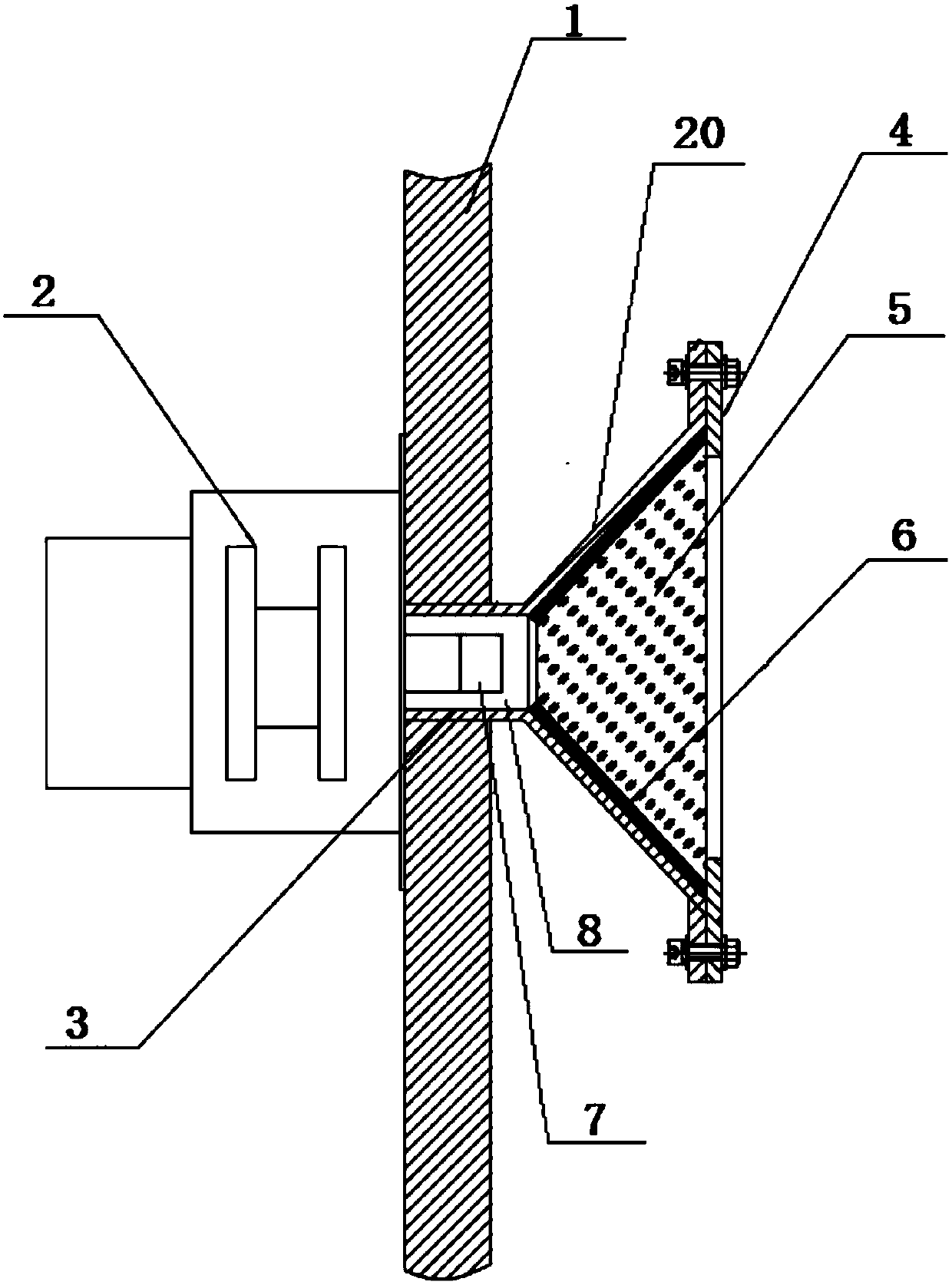

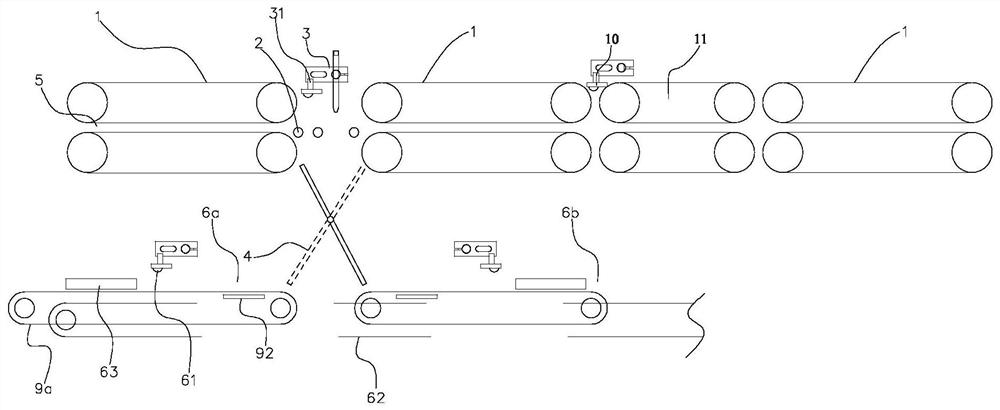

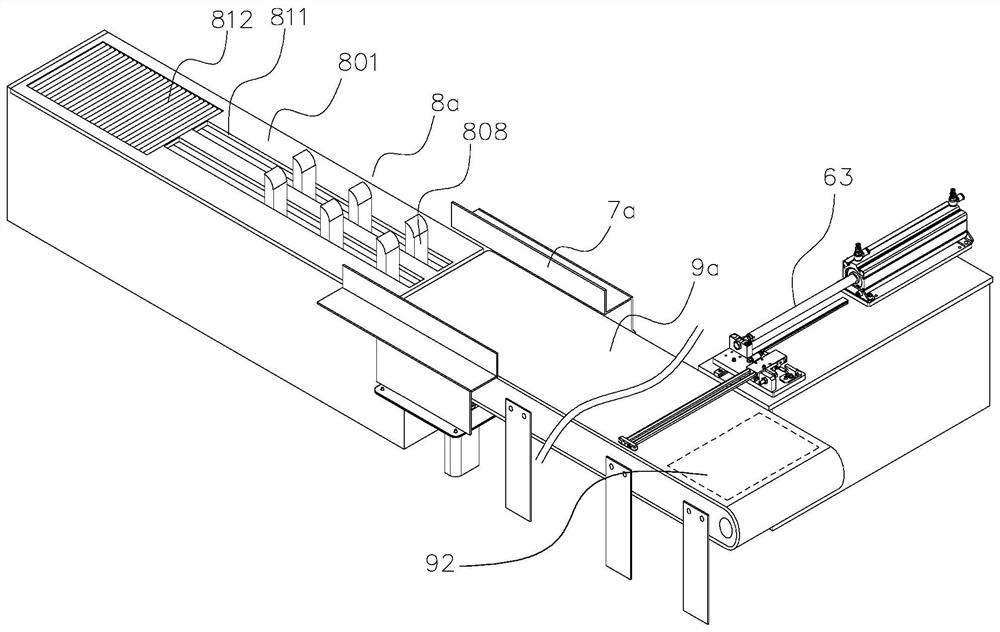

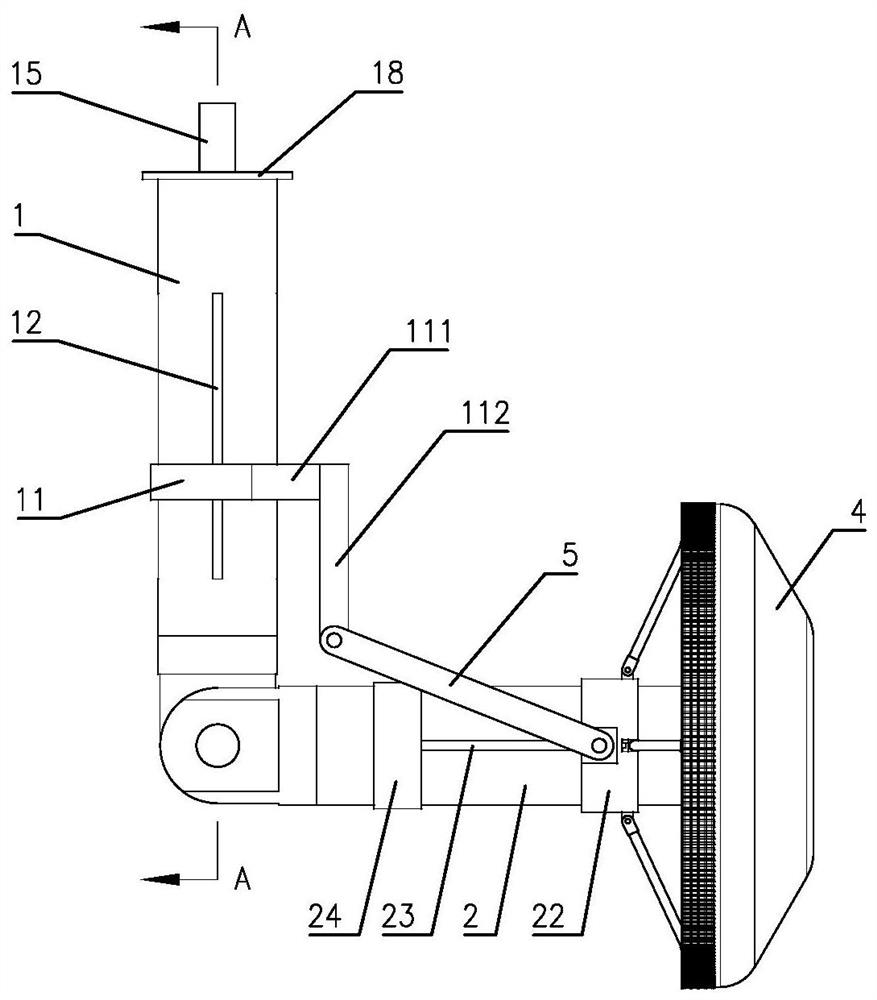

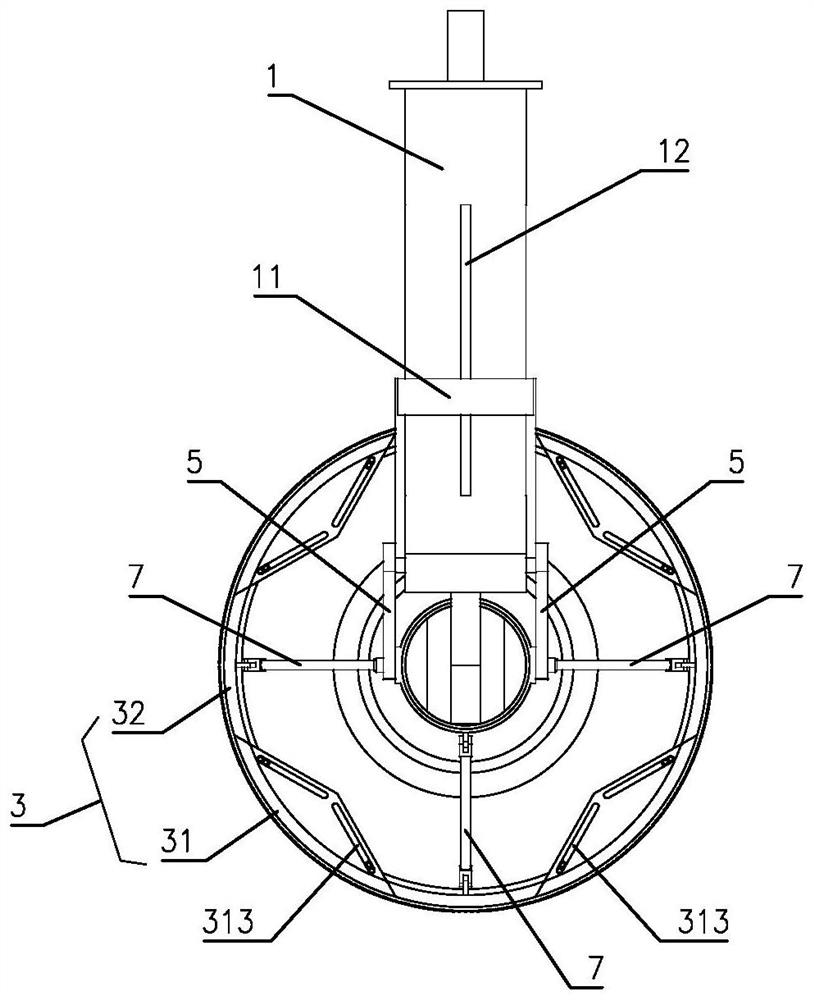

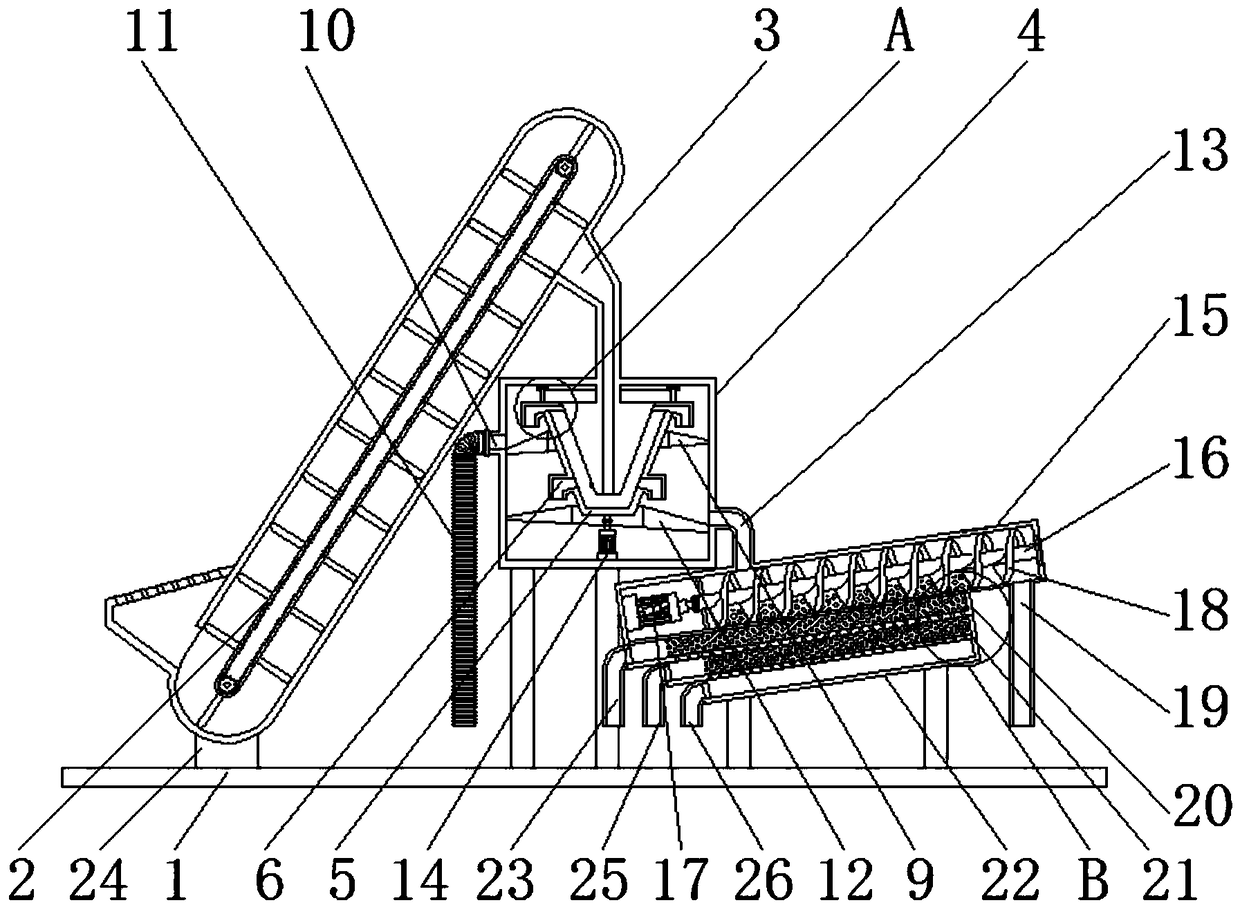

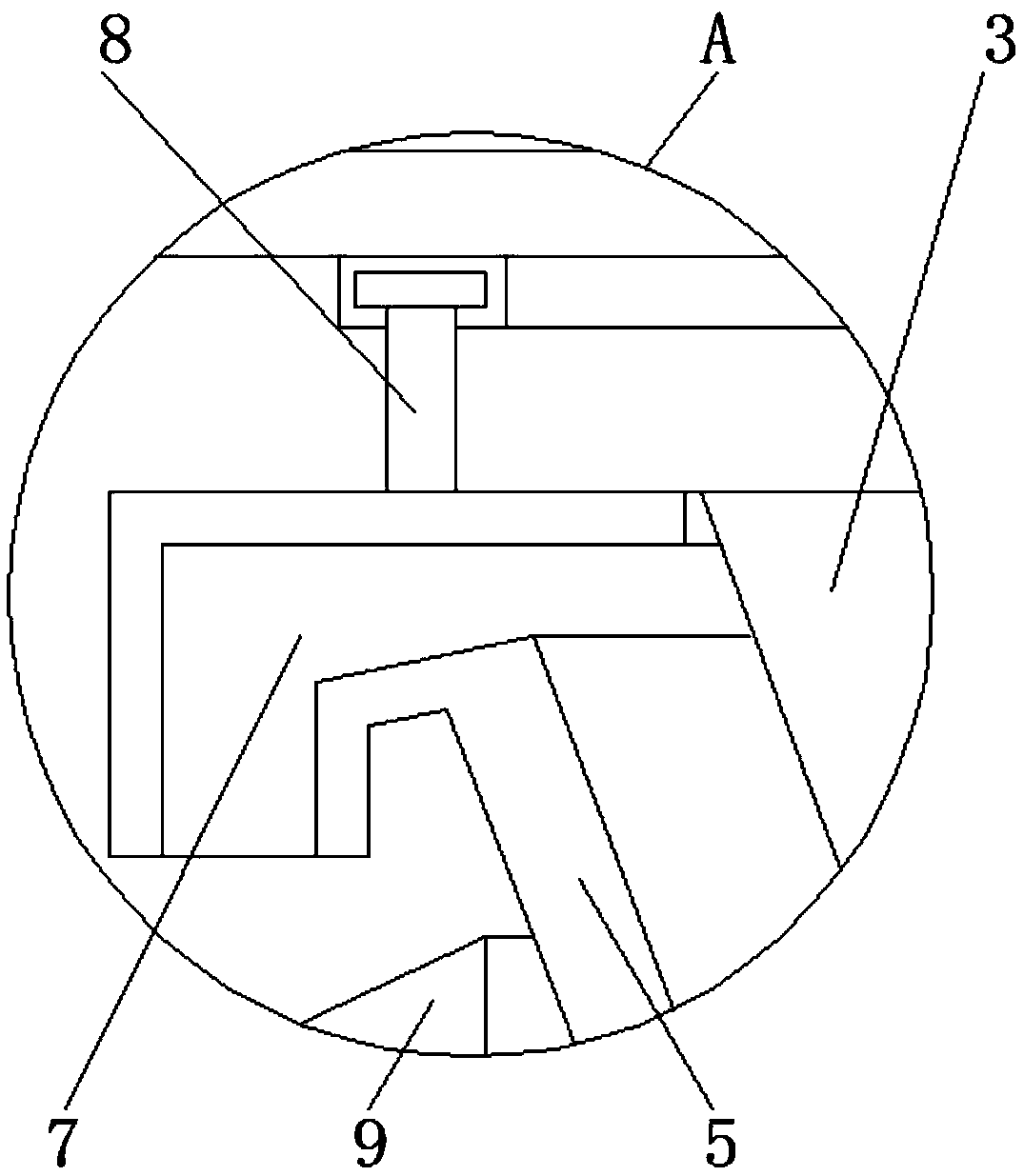

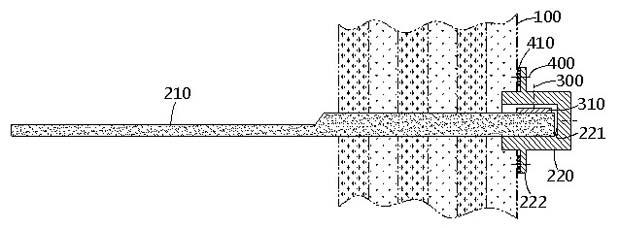

Device and method for vertically transporting earthwork by reverse construction method

InactiveCN101775821AImprove digging efficiencyReduce hole sizeSoil-shifting machines/dredgersExcavationsFloor slabConveyor belt

The invention relates to a device and a method for vertically transporting earthwork by a reverse construction method, which belong to the field of civil construction. In the device, segmental belt-type conveyor belts are adopted as earthwork transporting tools in a deep foundation pit; the conveyor belts pass through reserved holes of floor slabs on each floor; and the earthwork is transported to a dump truck obliquely from the bottom to the top by the conveyor belts. The device is formed by connecting independently segmented and obliquely arranged belt-type conveyor belts end to end; and each floor is provided with at least one conveyor belt which consists of an electric motor, a conveyor belt rack, an unloading tank, a scraping plate, a roller wheel, a roller wheel shaft bracket, a belt, a feeding funnel and an emergency brake device. The device and the method for vertically transporting the earthwork by the reverse construction method can effectively increase the earth volume in single vertical transport, effectively improve excavation efficiency, reduce excavation machines, reduce excavation cost, and simultaneously, reduce the influence of the construction of underground excavation on the simultaneous construction of an upper structure to the minimum.

Owner:CHINA CONSTR FIRST BUILDING GRP CORP LTD +2

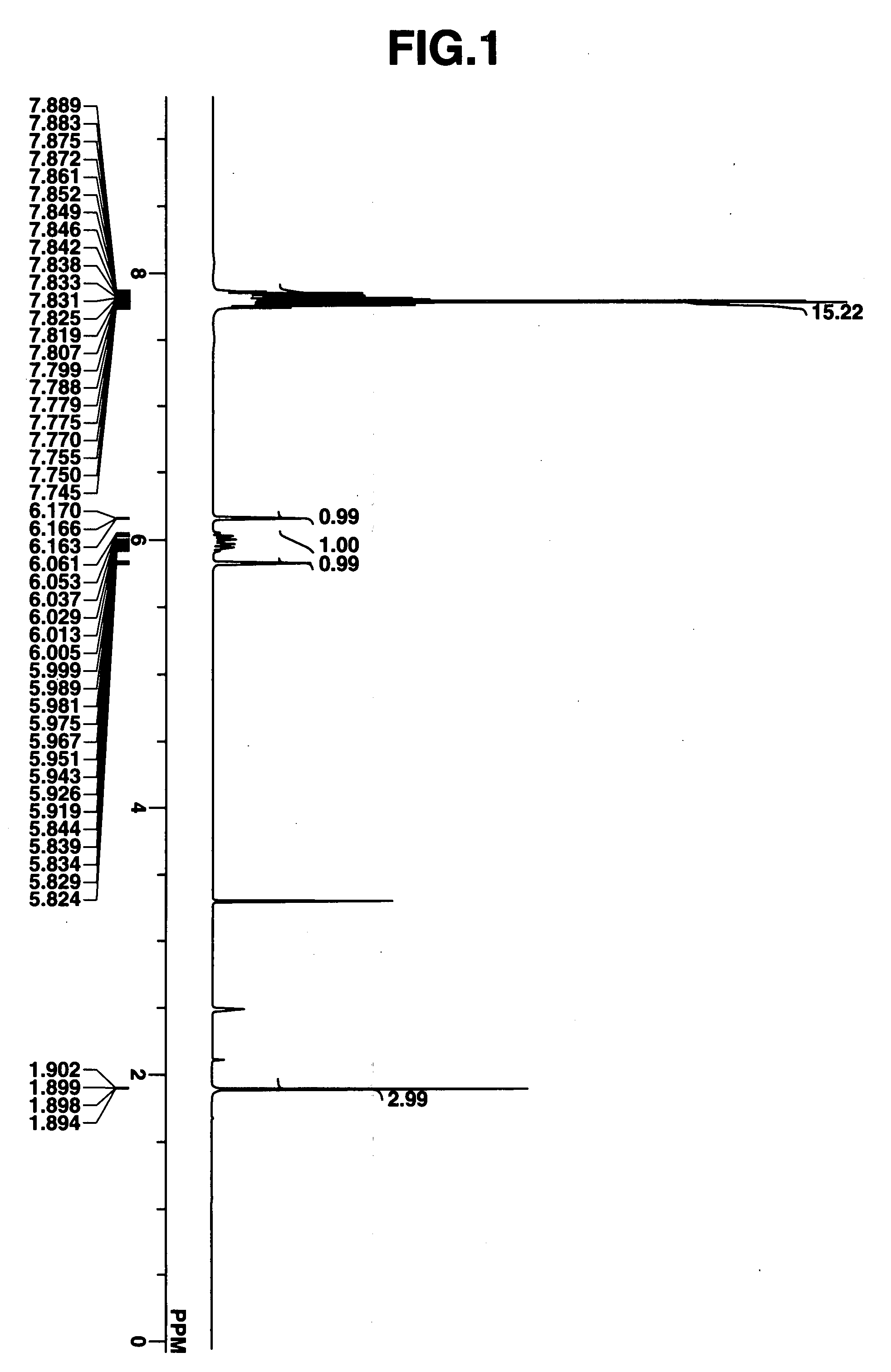

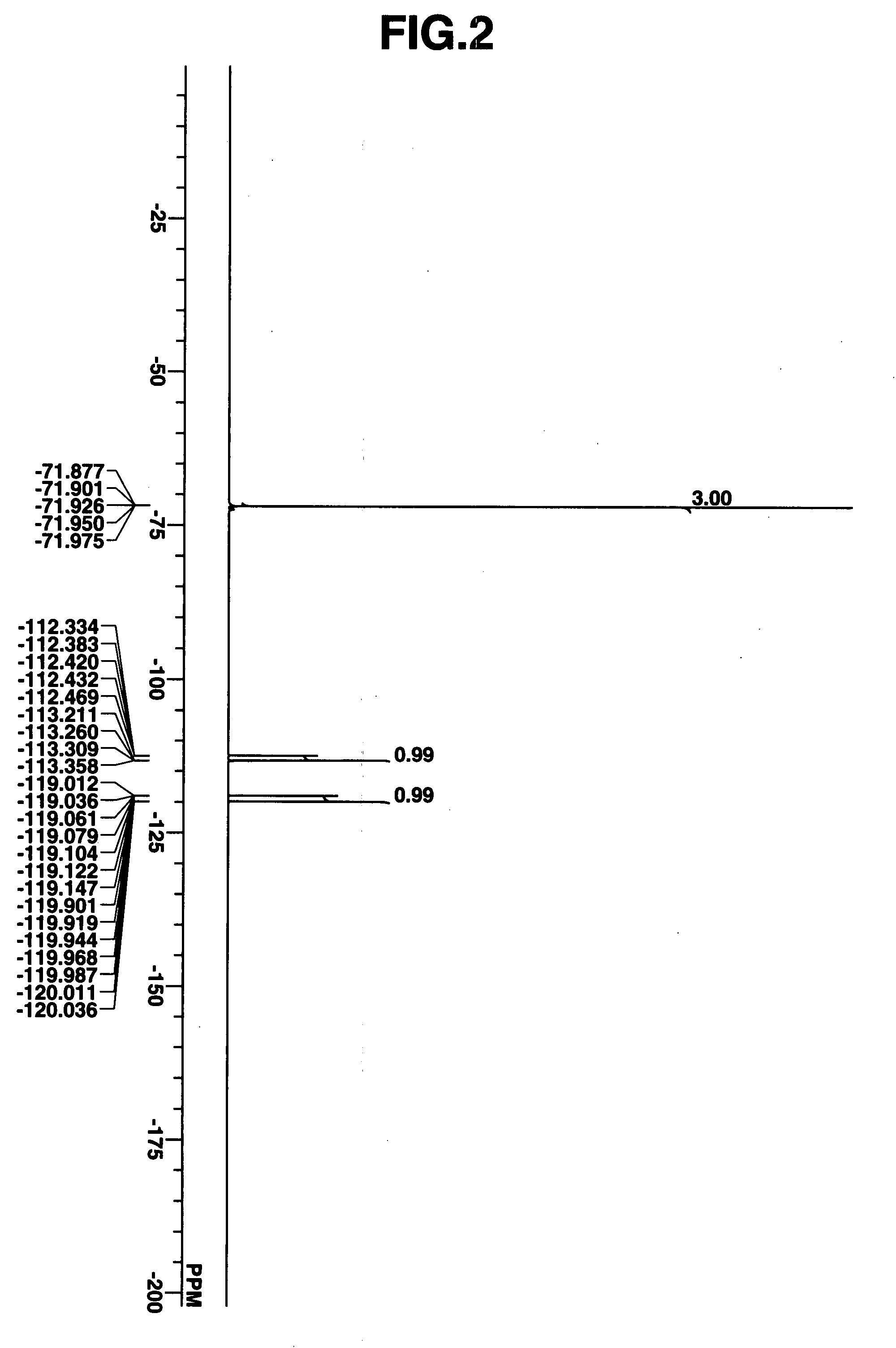

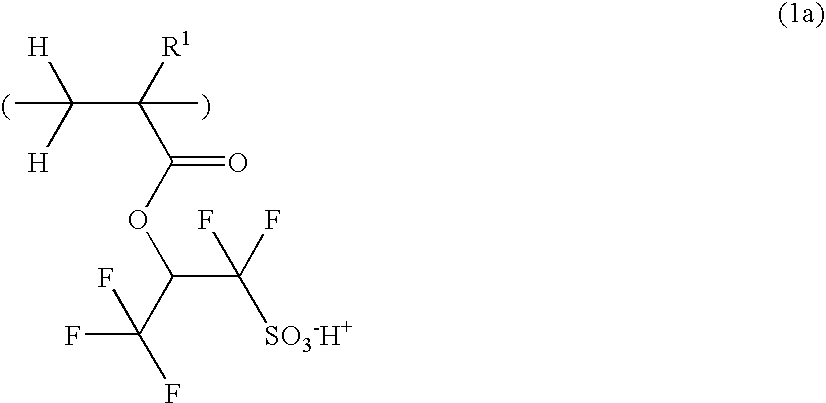

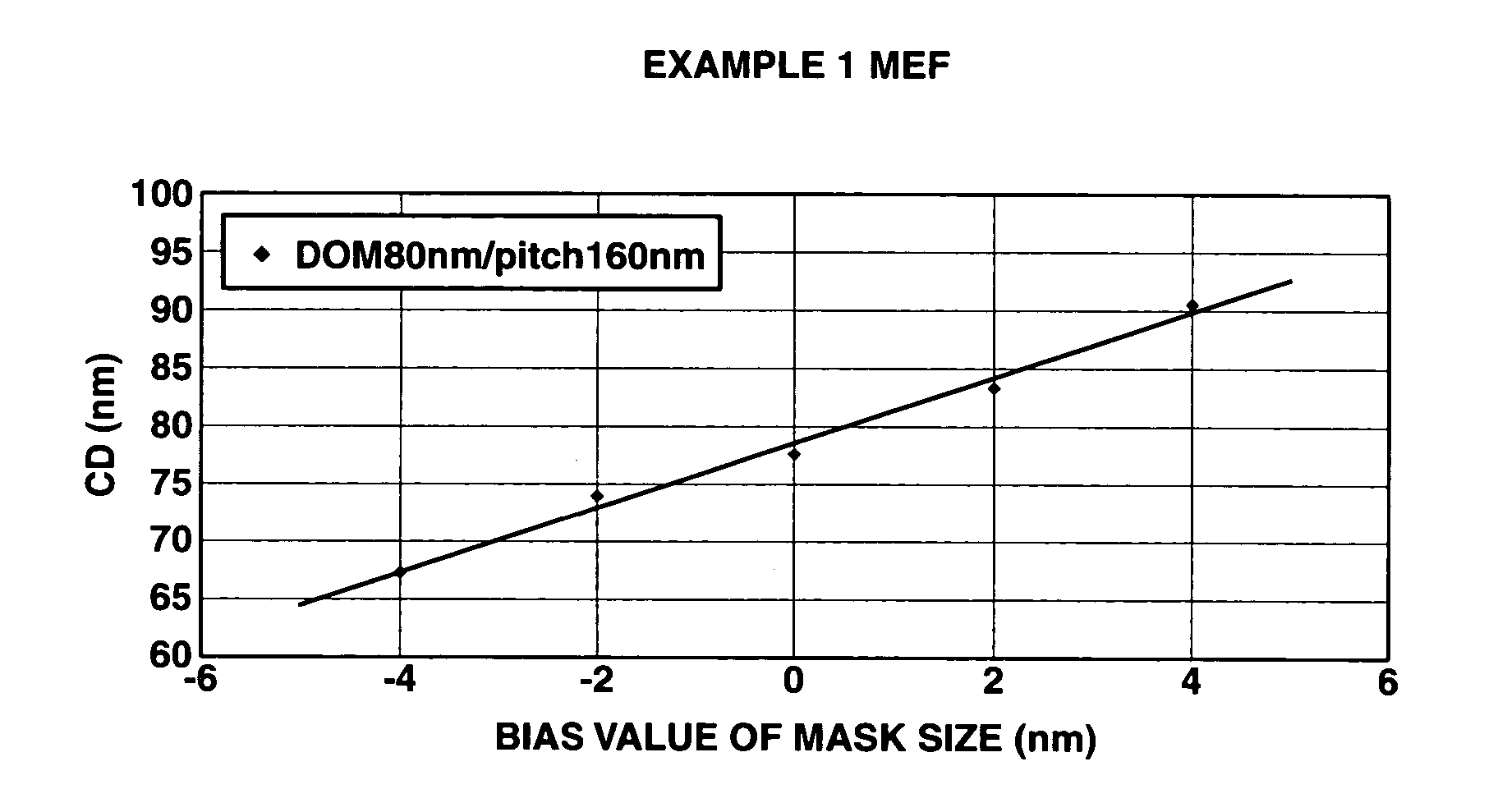

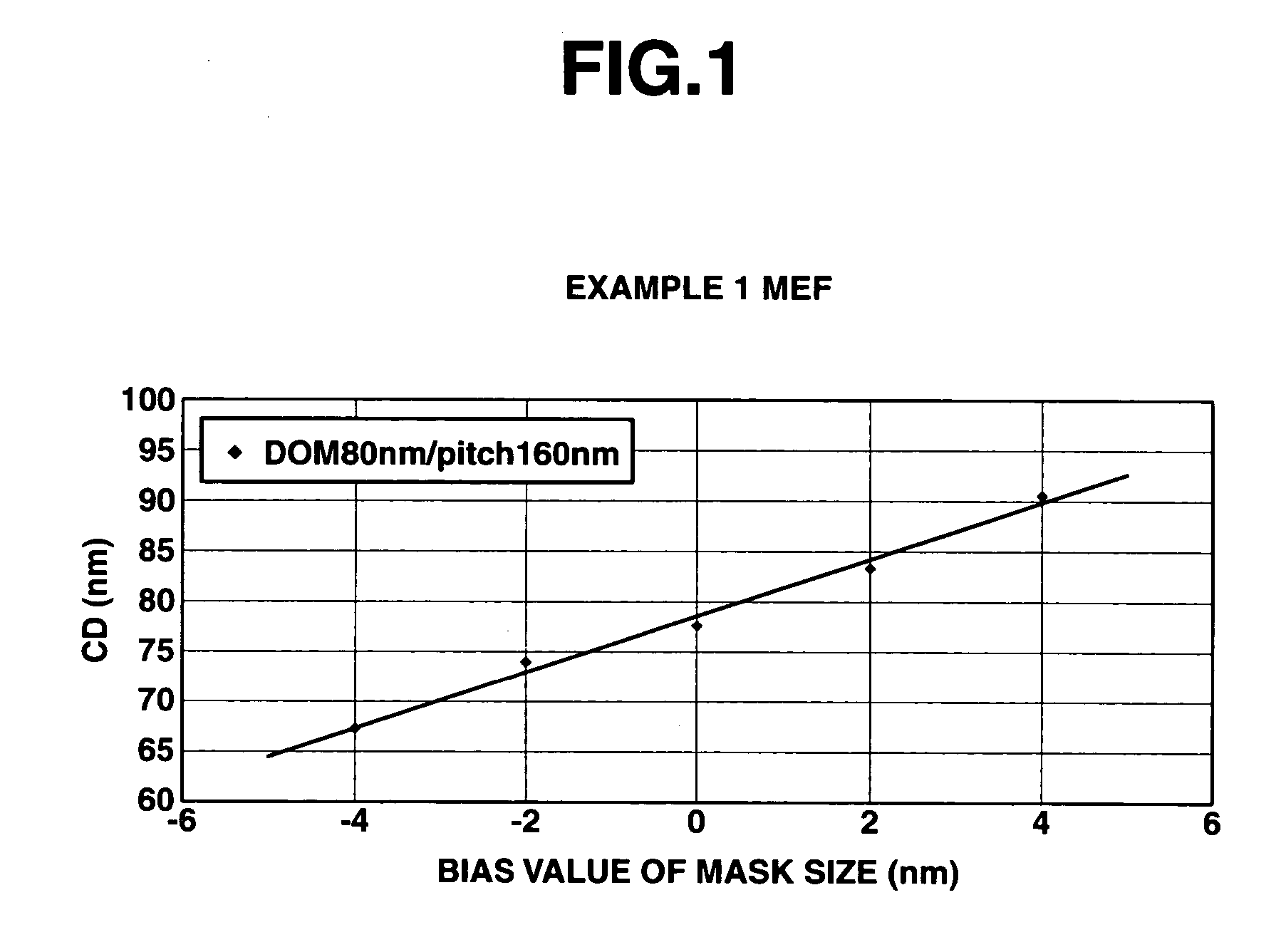

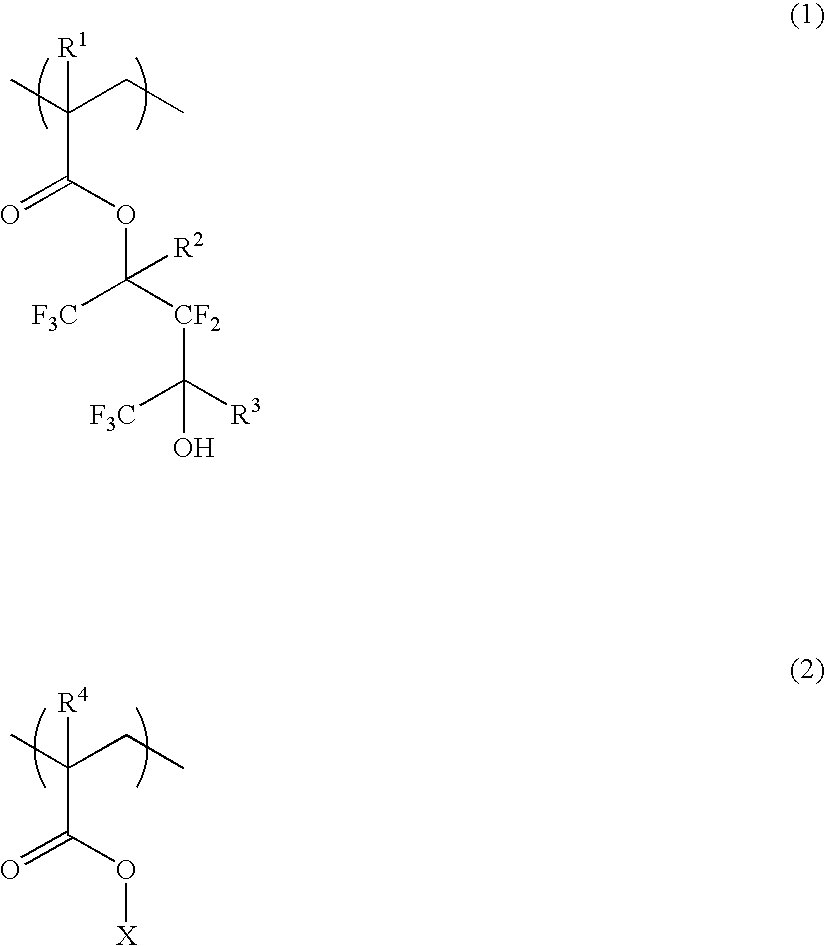

Polymer, resist composition and patterning process

ActiveUS20070099114A1High affinityWeak affinityPhotosensitive materialsPhotomechanical apparatusResistImage resolution

A polymer of which dissolution rate in an alkaline developer increases under the action of acid comprises recurring units having formulae (1) and (2) wherein R1, R2, and R4 are H or methyl, R3 is difluoromethyl or trifluoromethyl, and X is tertiary alkyl. A resist composition comprising the polymer has a high sensitivity and resolution, decreased pattern collapse during development, and minimized MEF and is best suited as micropatterning material for the VLSI manufacture.

Owner:SHIN ETSU CHEM IND CO LTD

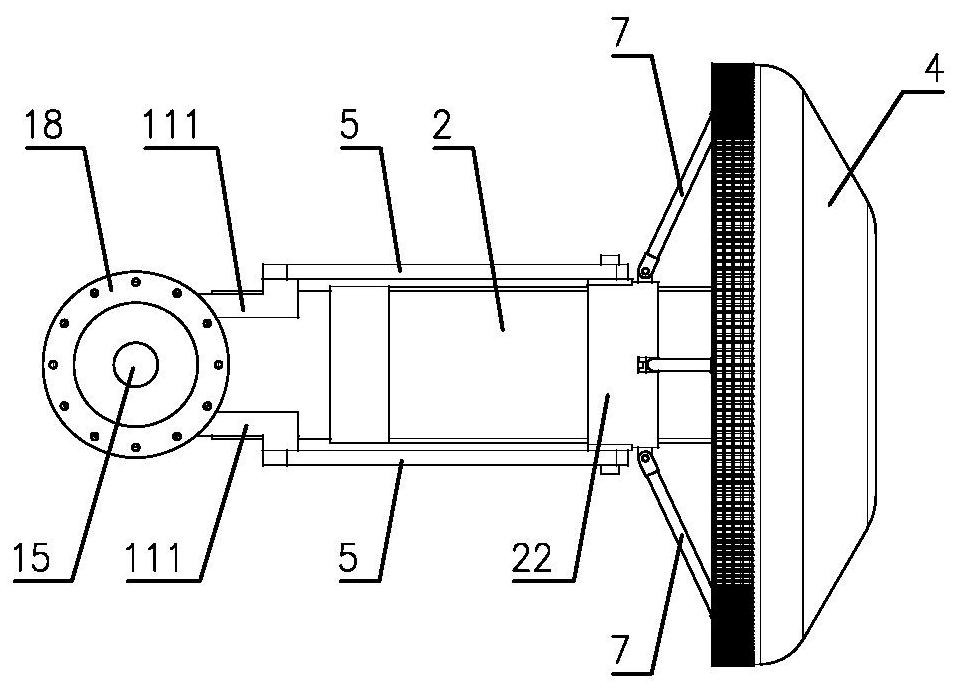

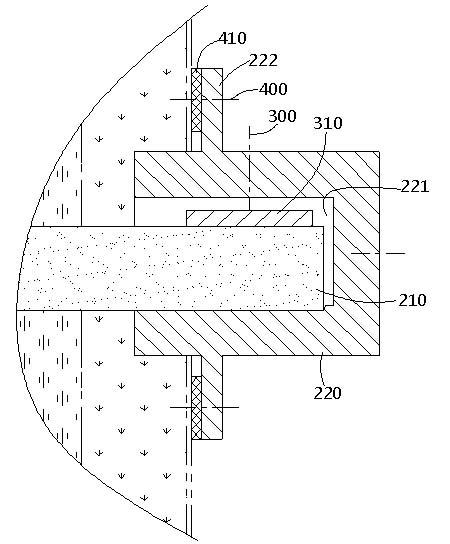

Horizontal directional drilling crossing construction method and horizontal directional drilling crossing drilling device

ActiveCN104213833AReduced displacement requirementsReduce dosageDirectional drillingFlushingWater dischargeDirectional drilling

The invention discloses a horizontal directional drilling crossing construction method and a horizontal directional drilling crossing drilling device, wherein the method and the device are designed for improving stability of the hole wall of the drilled hole and reducing the crossing construction risk. The front portion of the cabin wall in a drilling device body is connected with a main shaft, a conical breaking mechanism, a cutterhead and a horizontal directional drilling machine traction drill stem, and the rear portion of the cabin wall is connected with a cutterhead driving mechanism, a water supply pipe and a water discharge pipe. The rear end of the body is connected with and provided with an injected hole and internally provided with a dragging pipe short section of an injection pipe. The rear end of the dragging pipe short section is connected with a crossing pipeline. The method and the device are used for horizontal directional drilling crossing of pipelines with the diameter of 400 mm or larger, and can expand the drilled hole to the size of a finished hole at a time, and directly drag the pipeline back into the drilled hole so that pavement can be completed; meanwhile, a gap between the inner wall of the drilled hole and the crossing pipeline is filled, and drilling chips are discharged to the soil outlet end. By means of the method and the device, stability of the hole wall of the drilled hole can be improved, the construction risk caused by hole collapsing is reduced, construction cost is reduced, the environment is protected, the large-diameter and long-distance pipeline crossing under the loose stratum conditions and the hard rock stratum conditions can be achieved, and the application range of the horizontal directional drilling method is enlarged.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

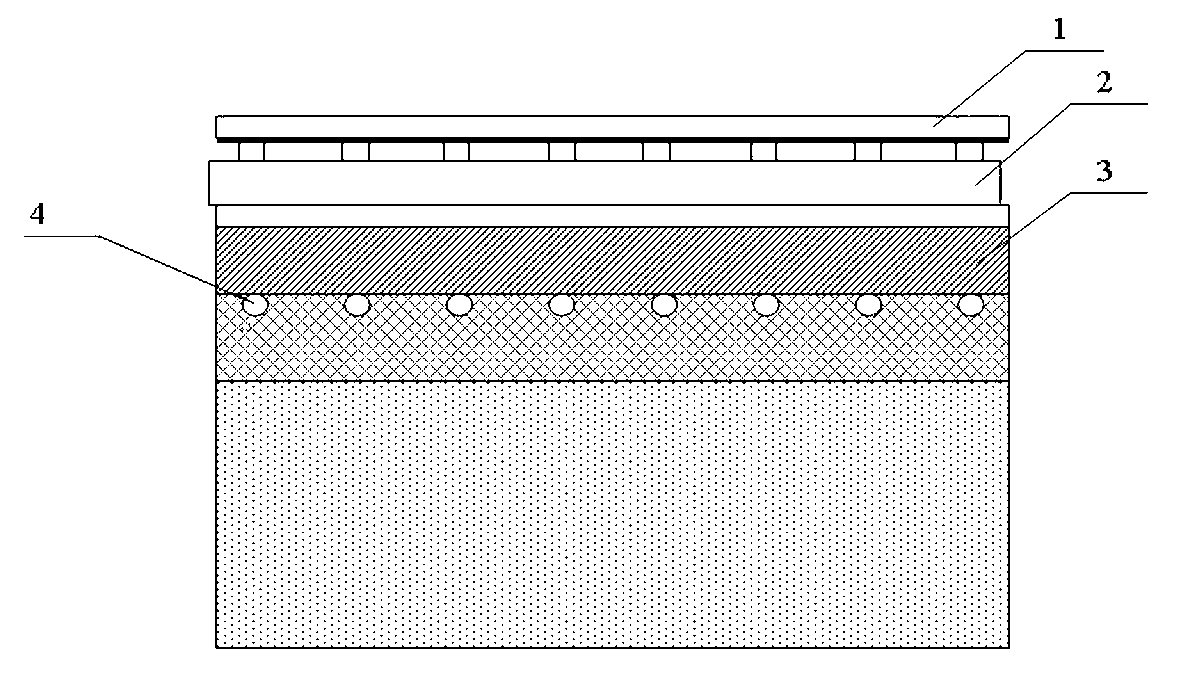

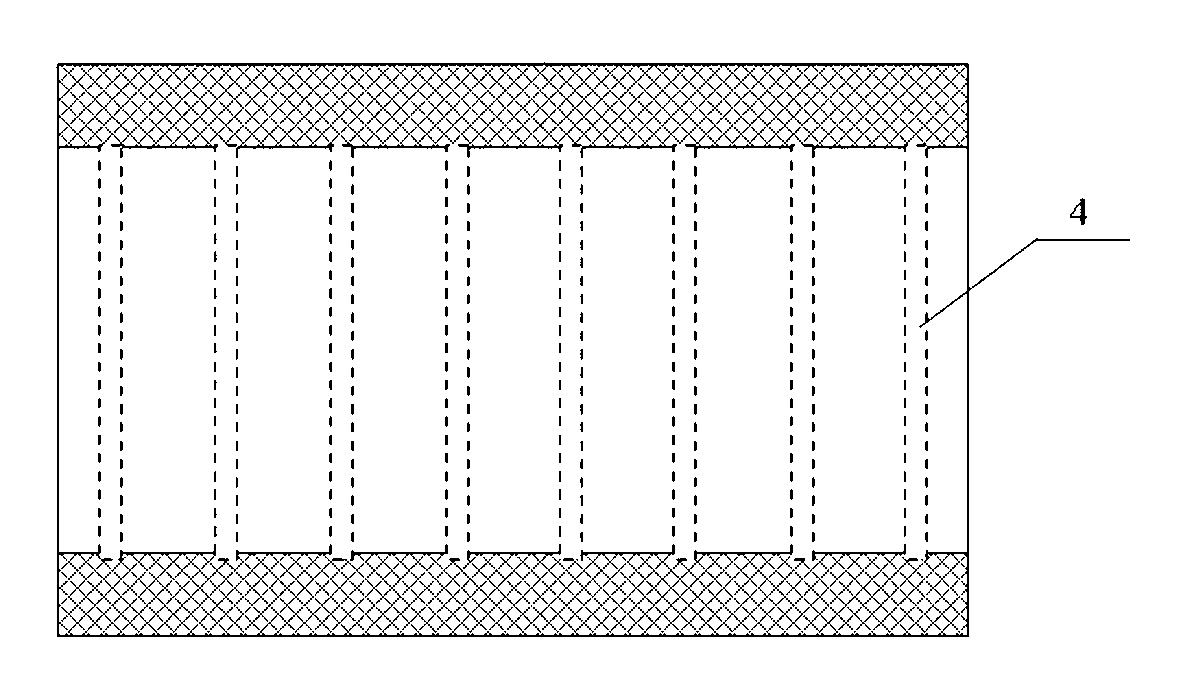

High polymer grouting method for lifting ballastless track of high speed railway

ActiveCN103215863AAchieve liftingGuaranteed smoothnessRailway track constructionSocial benefitsEngineering

The invention relates to a high polymer grouting method for lifting a ballastless track of a high speed railway. The method comprises the following steps that (1) grouting holes are drilled; (2) geotextile bags are manufactured, and in addition, the geotextile bags and grouting pipes are bound; (3) the geotextile bags are tied up; (4) the geotextile bags are placed; (5) the grouting is carried out in the geotextile bags; (6) the track is lifted; (7) the grouting is filled; and (8) the lifting quantity is monitored: a laser gradienter is used for monitoring the vertical lifting height in real time, and the grouting stops when the lifting requirement is reached. The method has the advantages of high speed, little damage, light weight, high tenacity, economy, endurance and the like, the lifting of the ballastless track of the high speed railway can be fast realized, and a novel, advanced, efficient, economic and practical method is provided for the subgrade settlement repair of a high-speed rail. The method is successfully applied to multiple ballastless track lifting projects, and huge economic and social benefits and wide development and application prospects are realized.

Owner:南方工程检测修复技术研究院

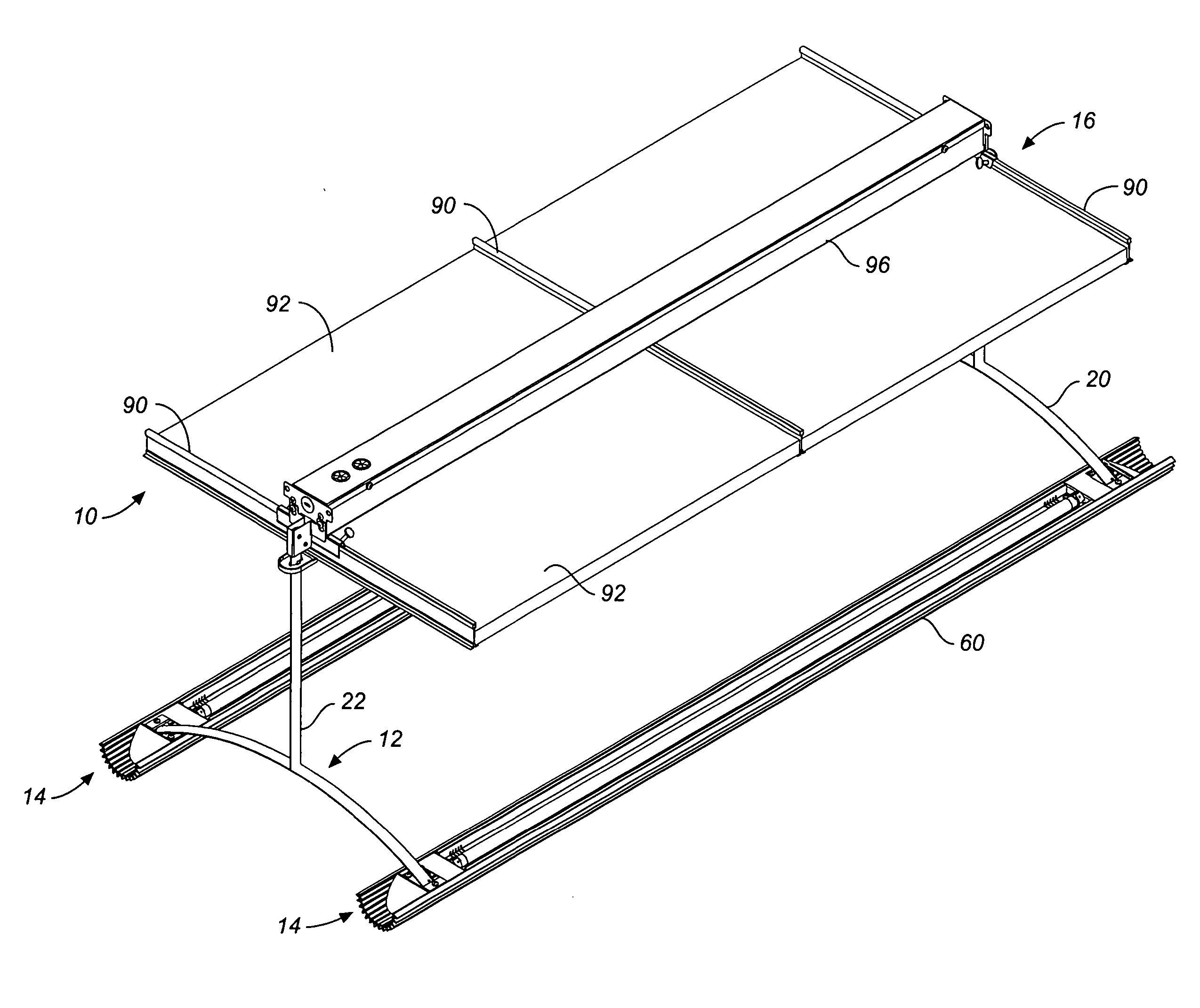

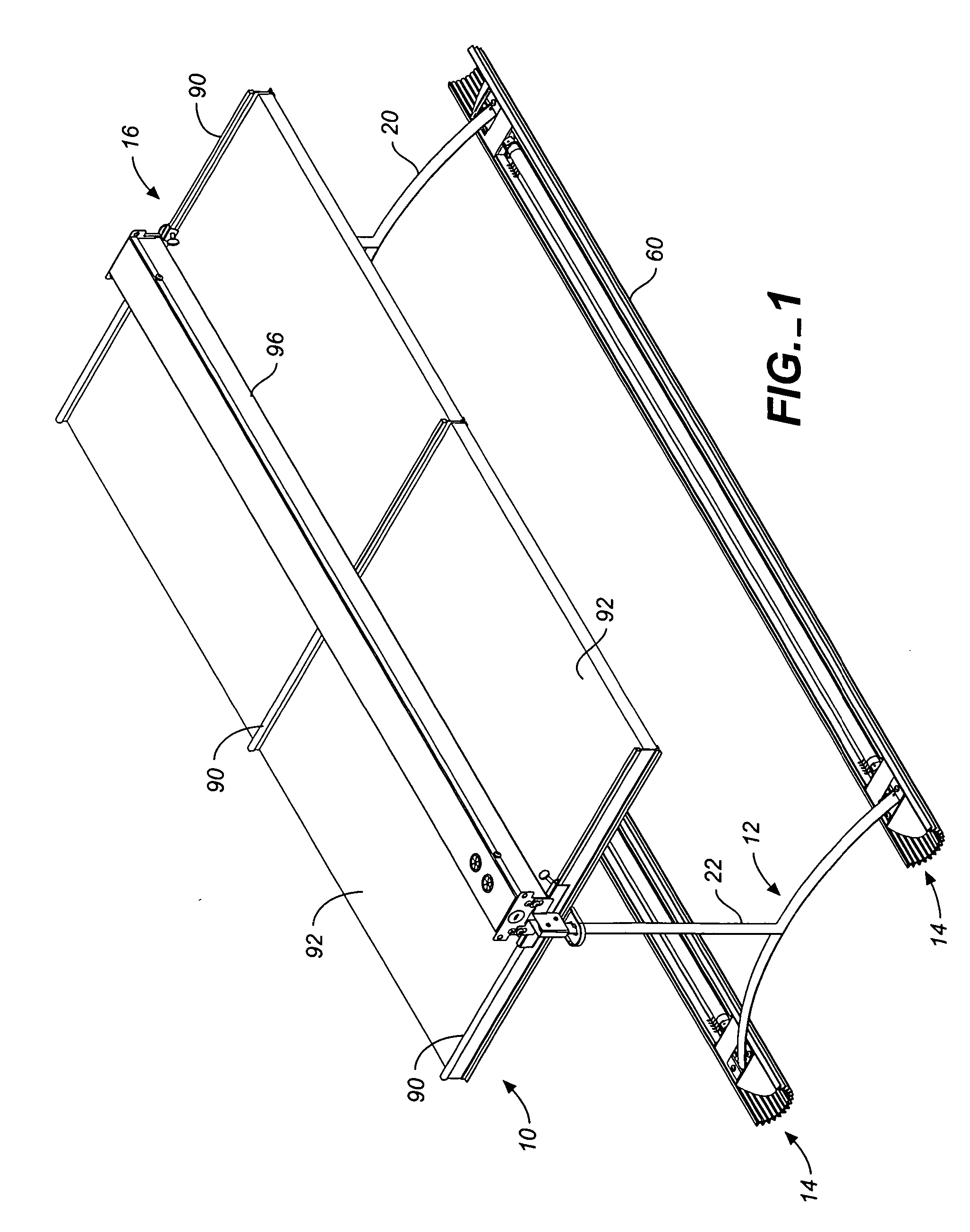

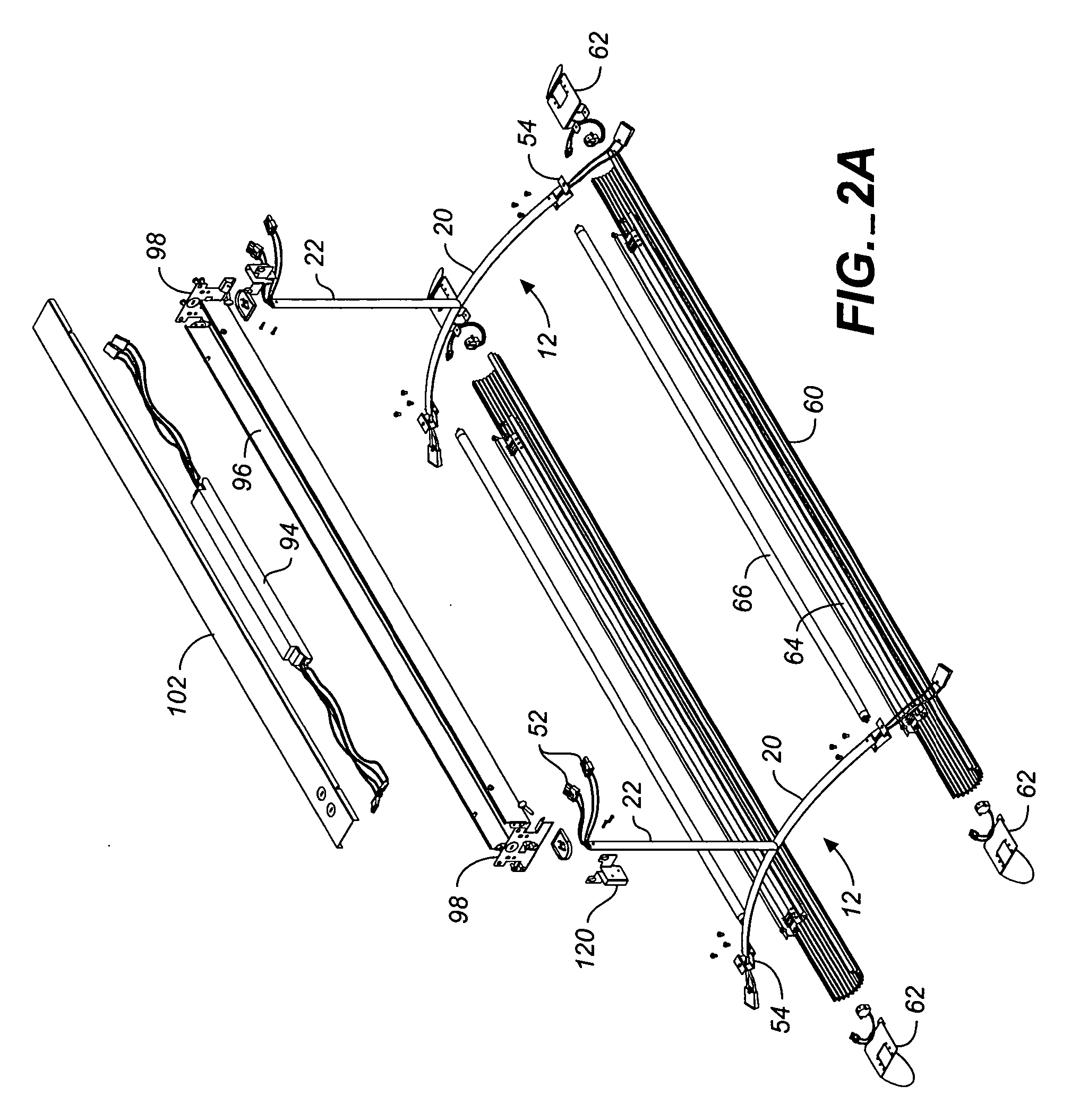

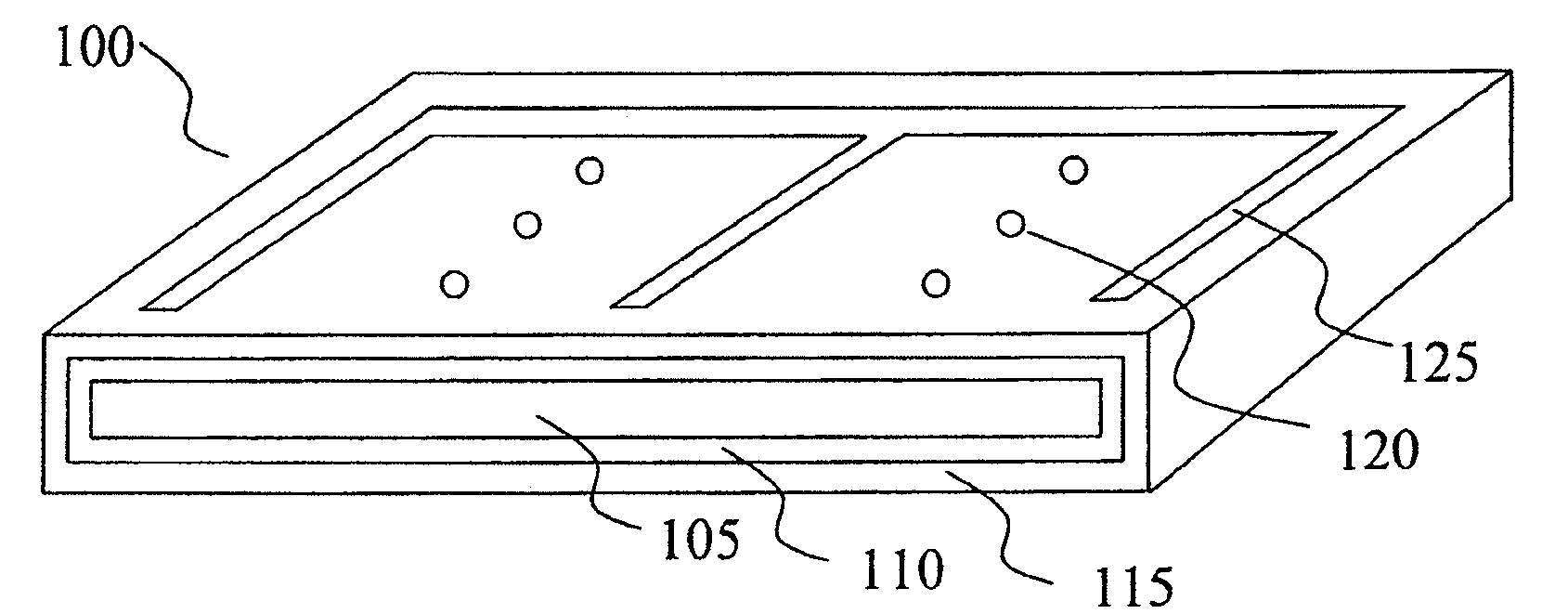

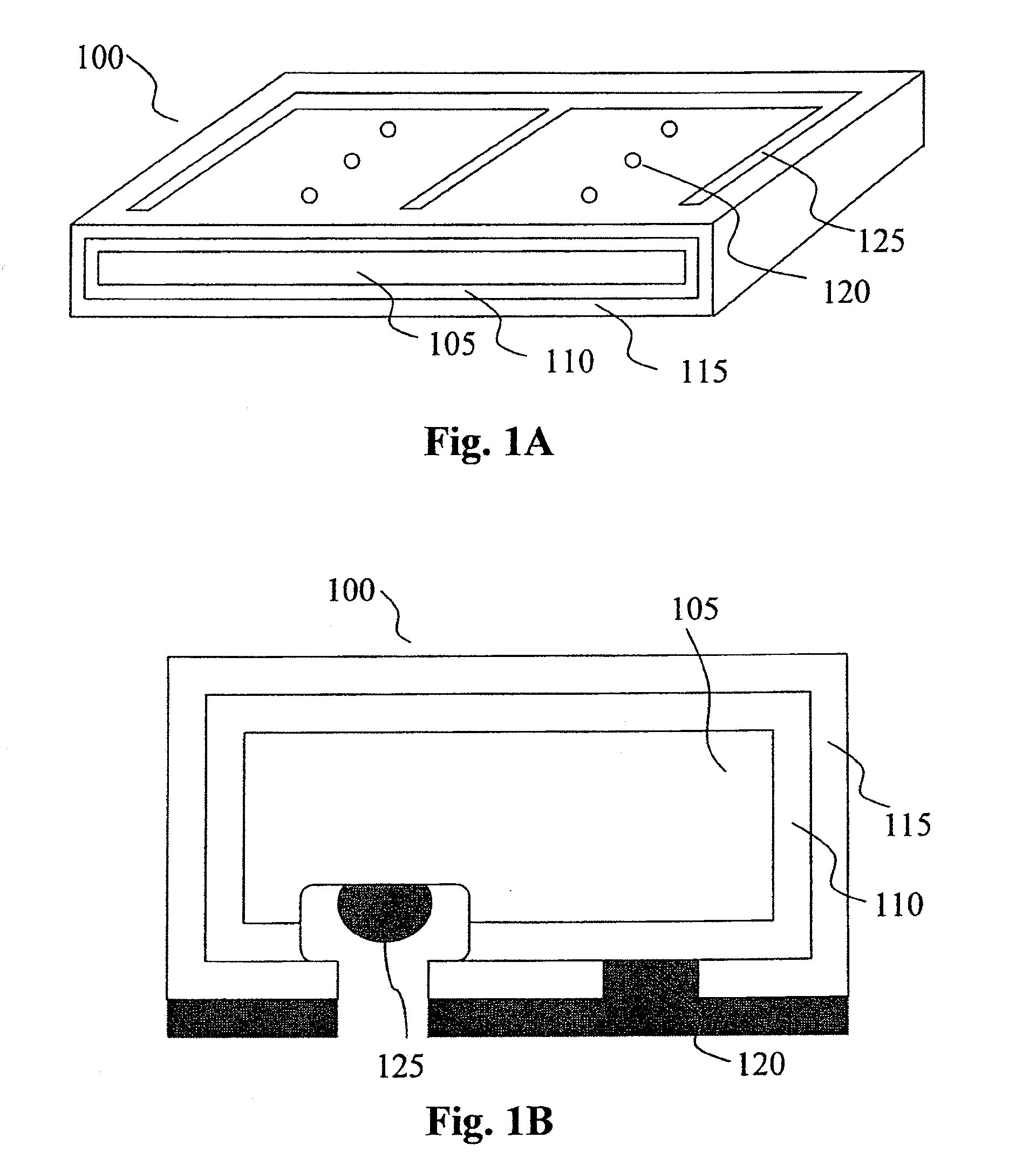

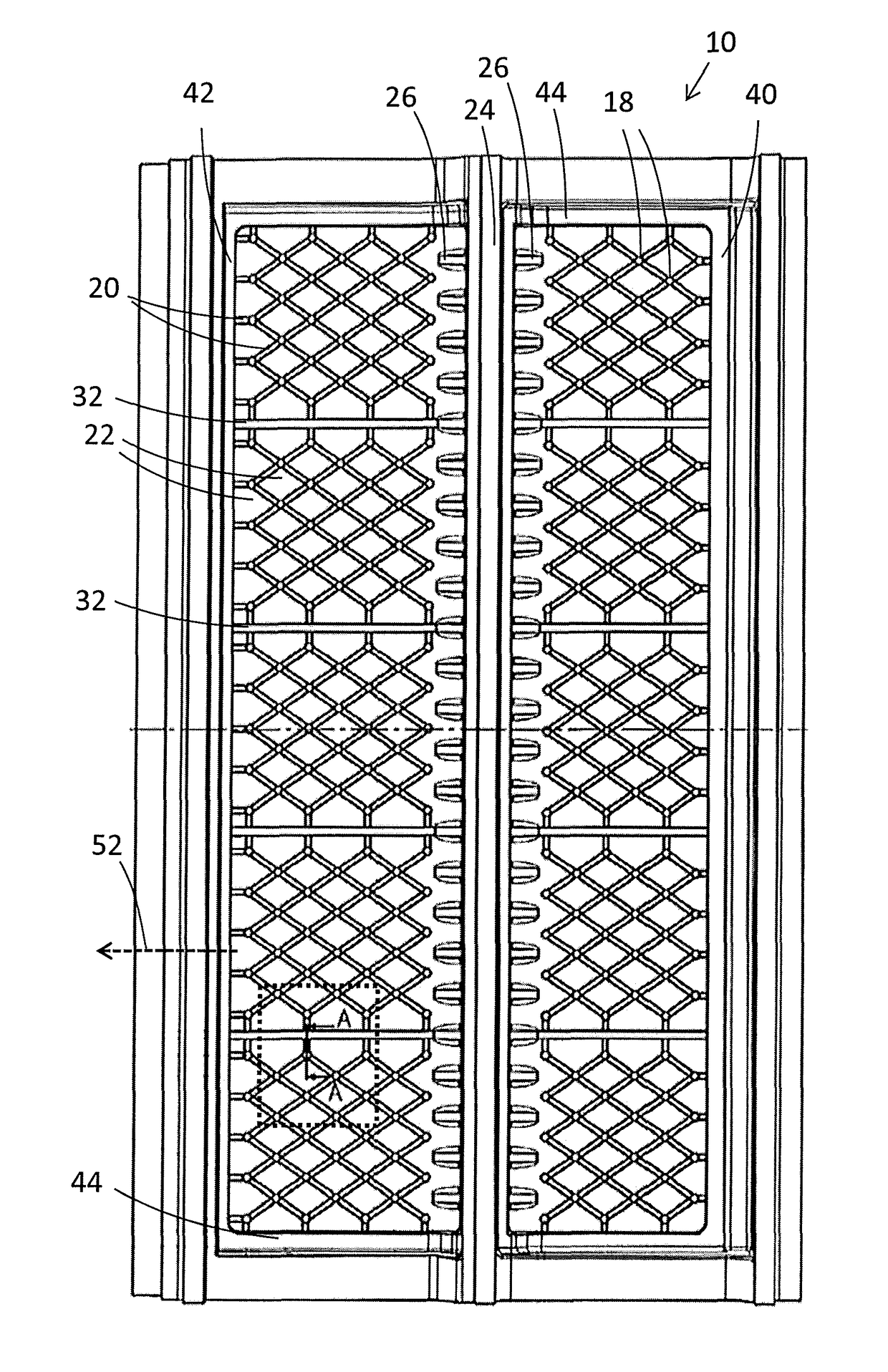

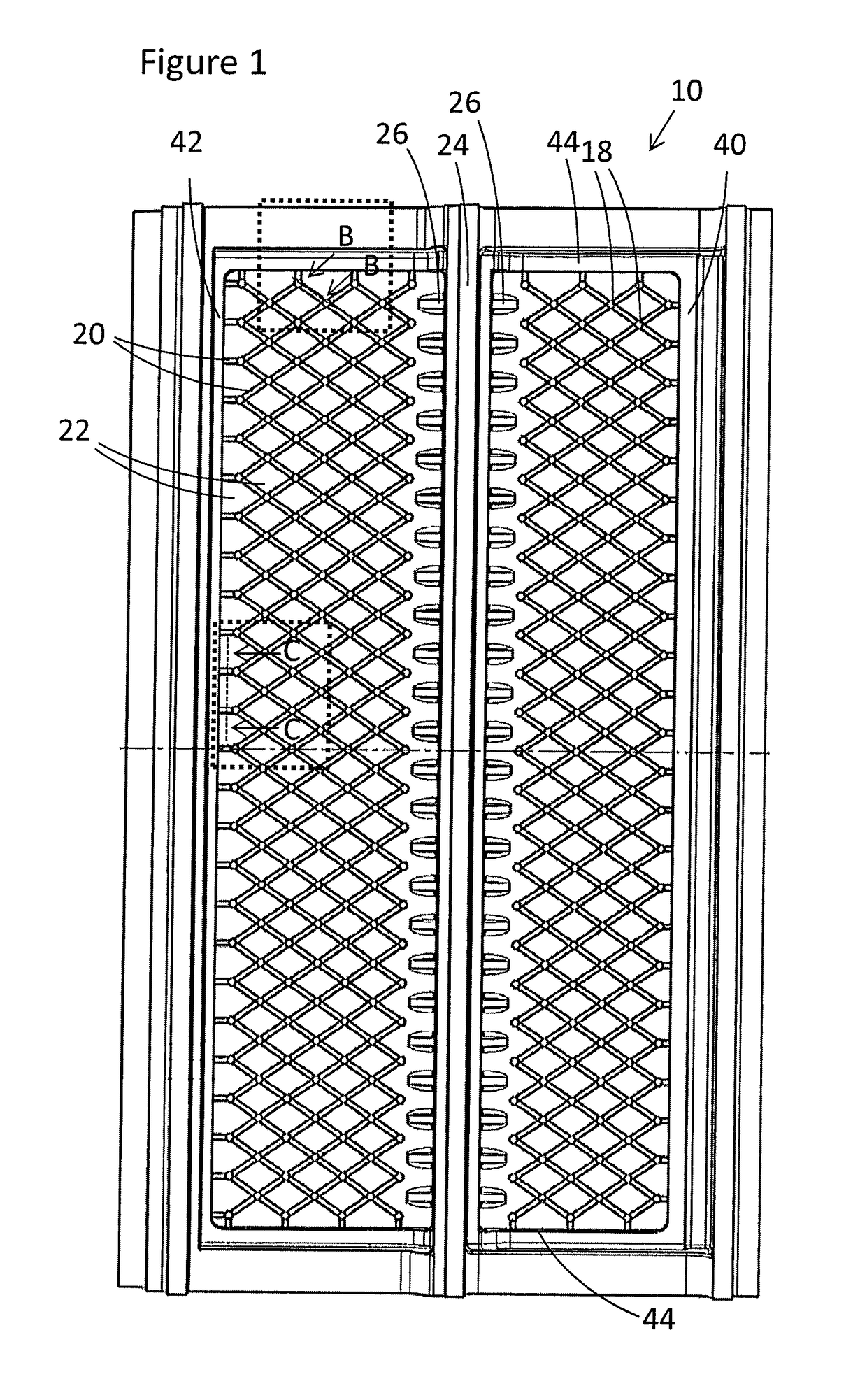

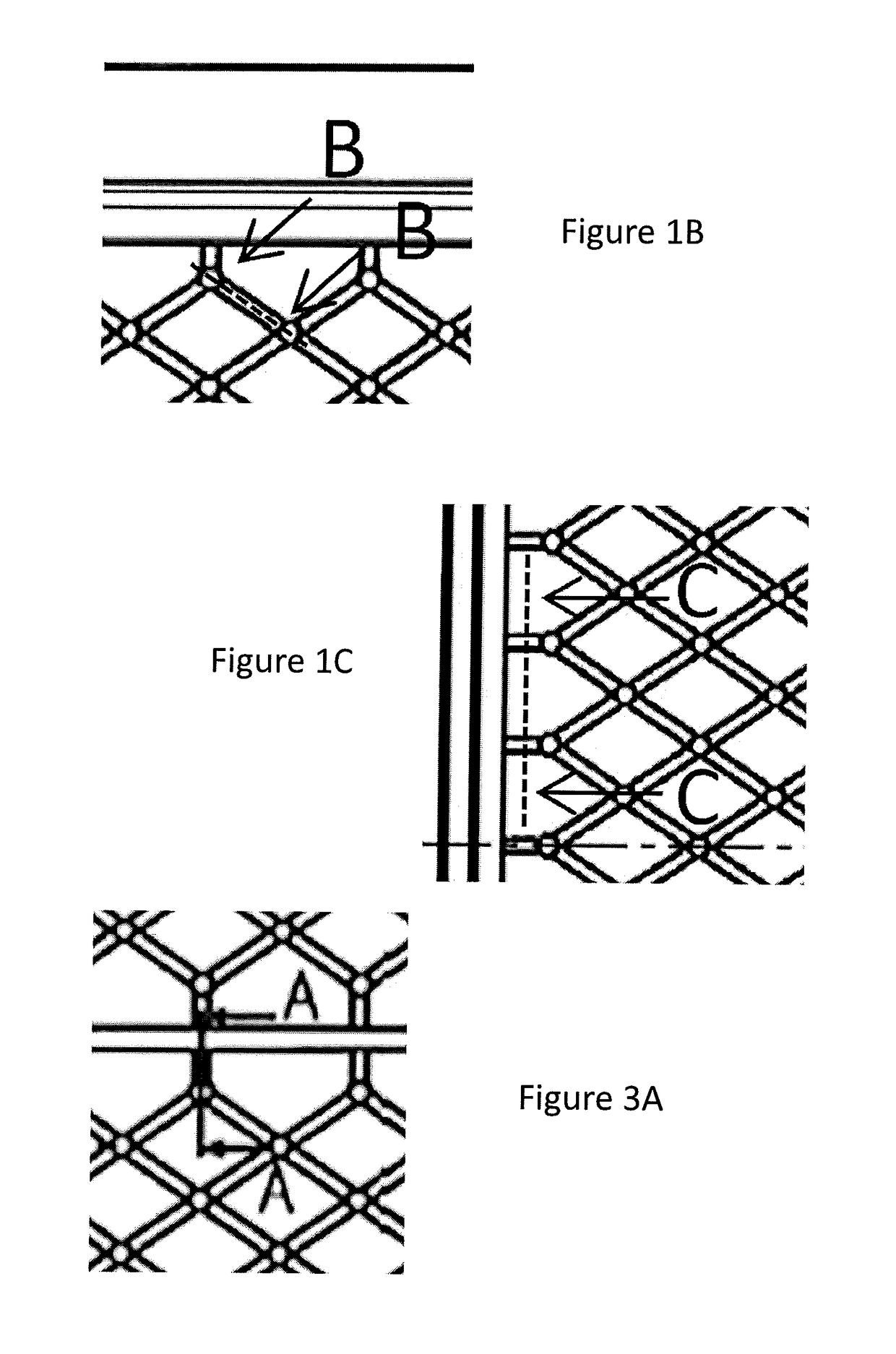

Small profile hanger system for ceiling suspended lighting fixtures

InactiveUS20050286256A1High strengthReduce hole sizeCeilingsLighting support devicesEngineeringBallast

An improved small profile hanger system for ceiling suspended lighting fixtures comprises a plurality of hanger assemblies having a support stem and a downwardly arced crossbar. The support stem and crossbar have a relatively small elliptical profile have two sets of wire holes, each set of wire holes having an inner hole and an outer hole overlapping the inner hole, the inner and outer holes defining an intervening gap narrower than the dimension of either hole. The holes are sized to receive an insulated wire; the intervening gap preventing the wire from crossing over into the adjacent hole. The wire holes of the support stem are in communication with the wire holes of the crossbar providing a fully enclosed wiring passage from a ballast box assembly installed above a suspended ceiling to energize a lamp in a diffuser depending from a pair of the crossbars.

Owner:ABL IP HLDG

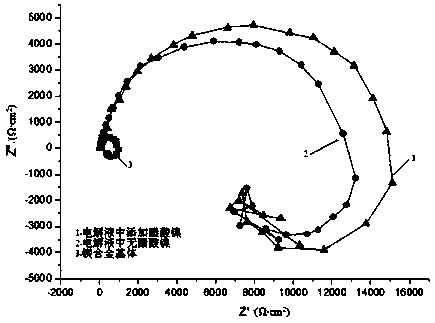

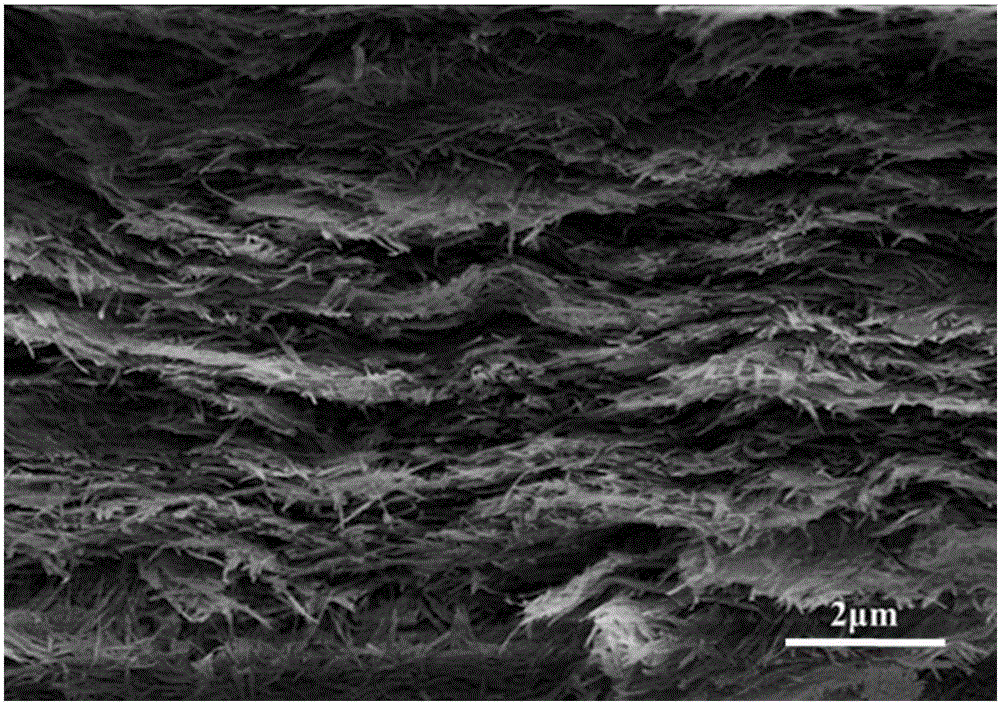

Method of adopting environment-friendly nickel-containing electrolyte to prepare microarc oxidation film layer on surface of magnesium alloy

ActiveCN103726093AReduce hole sizeImprove corrosion and wear resistanceAnodisationPlasma electrolytic oxidationNickel salt

The invention discloses a method of adopting an environment-friendly nickel-containing electrolyte to prepare a microarc oxidation film layer on surface of a magnesium alloy, and belongs to the technical field of metal finishing. The method comprises the following steps: taking the magnesium alloy as an anode, and a phosphorus and fluorine-free nickel salt-containing aqueous solution electrolyte; performing microarc oxidation processing under the process conditions so as to generate a ceramic microarc oxidation film layer on the surface of the magnesium alloy material; performing routine plugging processing on the ceramic microarc oxidation film layer so as to form a high erosion-resistant and wear-resistant microarc oxidation film layer on the surface of the magnesium alloy, wherein the aqueous solution electrolyte comprises the following components: 0.5-1.5 g / L nickelous acetate or nickel sulfate, 15-30 g / L sodium silicate, 20-40 g / L sodium borate, 10-30 g / L sodium hydroxide or potassium hydroxide, 10-20 mL / L triethavolamine, and 5-10 mL / L ethylene diamine. The electrolyte contains the nickel salt, but not the phosphorus and fluorine, and is environment-friendly. The microarc oxidation film layer on the surface of the magnesium alloy is a nickeliferous ceramic film with relatively small film hole size, and has relatively high wear resistance, corrosion resistance and binding force, and therefore is wide in application.

Owner:WUHAN RES INST OF MATERIALS PROTECTION

Hydrophilic polyvinylidene fluoride-based hollow-fiber separation membrane, and method for manufacturing same

ActiveCN103857462AHigh mechanical strengthReduce hole sizeSemi-permeable membranesMembranesHollow fibreFiber

In general, a process manufacturing for polyvinylidene fluoride-based separation membrane and a membrane manufactured using same employ a non-solvent induced phase separation method and a thermally induced phase separation method. However, the hydrophilic polyvinylidene fluoride-based hollow-fiber separation membrane according to the present invention is manufactured using a spinning solution that contains a predetermined hydrophilic polymer and a poor solvent for excellent mechanical strength, and has small pores, a high permeation flow rate, and high membrane contamination resistance. Also, when a separation membrane for water treatment is manufactured, predetermined post-processing processes for providing porosity and hydrophilicity are eliminated, such that the separation membrane may be manufactured economically and efficiently.

Owner:LG CHEM LTD

Graded porous polyvinylidene fluoride hollow-fiber composite film and production method thereof

InactiveCN108079795AThe production process is simple and controllableReduce manufacturing costSemi-permeable membranesMembranesFiberWater baths

The invention relates to the technical field of water treatment and particularly relates to and discloses a graded porous polyvinylidene fluoride hollow-fiber composite film. The graded porous polyvinylidene fluoride hollow-fiber composite film comprises a graded porous macroporous middle layer, an outer separation layer and an inner separation layer which cover the two sides of the macroporous middle layer, wherein the three-layer structure is integrally made from the same material, pores of adjacent two layers communicate with one another, and structures of the outer separation layer and theinner separation layer are denser than that of the macroporous middle layer. The invention further discloses a production method of the composite film. The method comprises the steps: (1) preparing apolyvinylidene fluoride casting solution; (2) subjecting the casting solution to composite forming, so as to prepare complex type hollow fibers; (3) carrying out air spacing, then, carrying out water-bath coagulating forming, and carrying out traction winding, thereby obtaining the polyvinylidene fluoride hollow-fiber composite film. According to the graded porous polyvinylidene fluoride hollow-fiber composite film and the production method thereof, disclosed by the invention, the graded porous polyvinylidene fluoride hollow-fiber composite film has the advantages of small pore size, high flow rate, high strength and pollution resistance. The production method has the advantages that production procedures are simple and controllable, and the production cost is low.

Owner:ZHEJIANG CHANGXING CREFLUX MEMBRANE TECH CO LTD

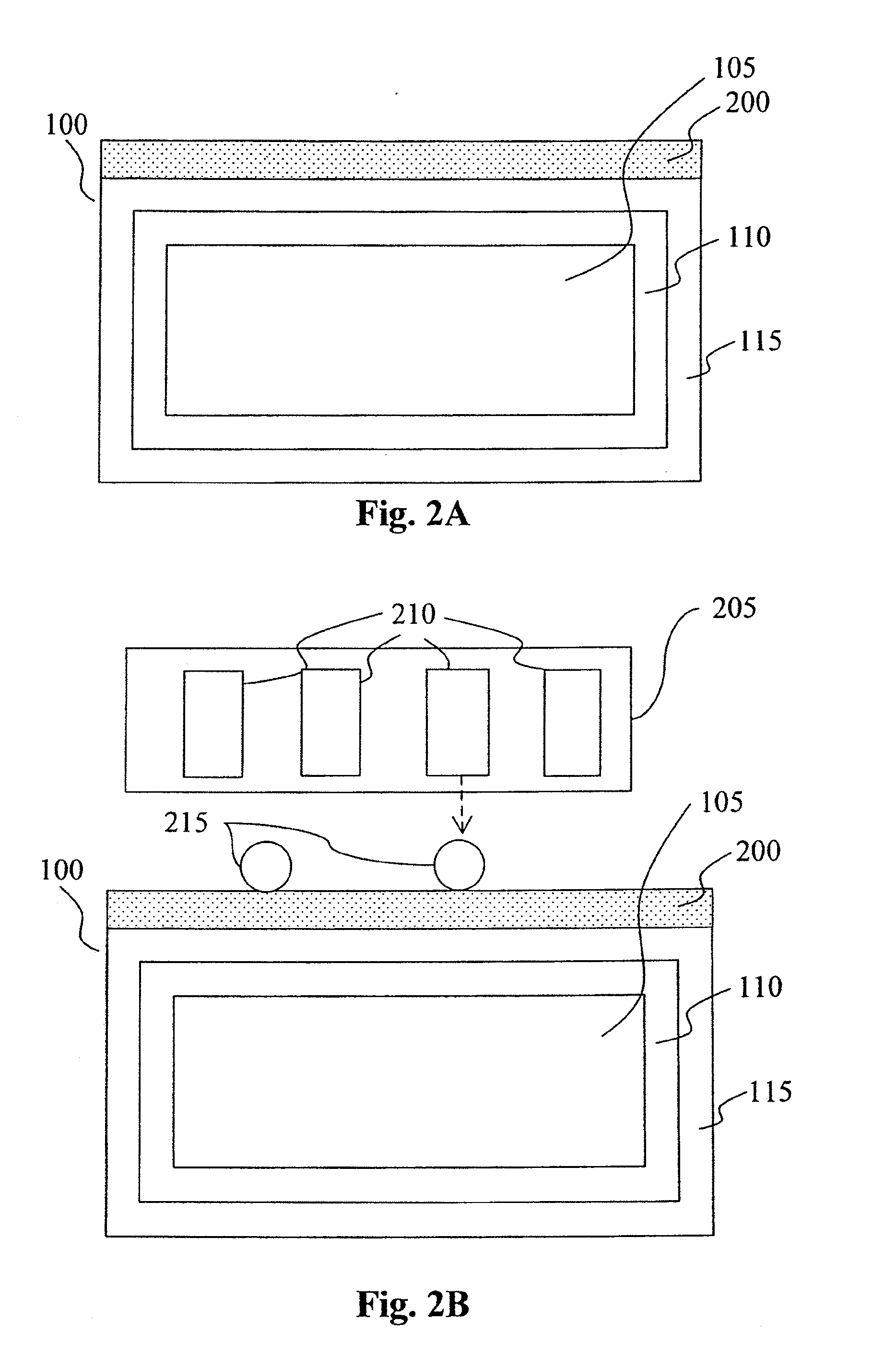

Method of forming openings in selected material

InactiveUS20100047721A1Small feature sizeReduce the permeable areaDecorative surface effectsSemiconductor/solid-state device manufacturingResistPolymer science

A method is provided for forming an opening in a layer of a selected material. The method comprises, forming a polymer resist layer over said selected material and plasticising areas of the resist where openings are to be formed. The plasticising is performed by depositing a first solution onto the surface of said polymer resist layer, where the first solution is a plasticiser selected to increase permeability of the polymer resist layer to a second solution, in an area which has absorbed the first solution. The second solution is selected to be an etchant or solvent for the selected material. After the resist layer has been selectively plasticised, it is contacted with the second solution, which permeates the polymer resist layer in the area of increased permeability and forms an opening in the selected material.

Owner:NEWSOUTH INNOVATIONS PTY LTD

Composite membrane as well as preparation method and the application thereof in gas separation and purification

ActiveCN108283889AMake up selectivityMake up for permeabilitySemi-permeable membranesDispersed particle separationChemical physicsPorous membrane

The invention provides a composite membrane. A porous carrier is adopted as a support body, an organic-inorganic porous material is adopted as a transition layer on the surface of the support body, and a polymer membrane is arranged on the surface of the transition layer. When the composite membrane is applied to gas separation, purification, and the like, a gas penetrates through the polymer membrane and is subjected to secondary separation in the organic-inorganic porous transition layer, compared with the polymer membrane, the composite membrane is excellent in permeability and relatively good gas selectivity, compared with a conventional inorganic porous membrane, the composite membrane is capable of improving gas separation and purification performance. Therefore, the composite membrane has relatively good application prospects in industrial fields such as gas separation, purification, and the like.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

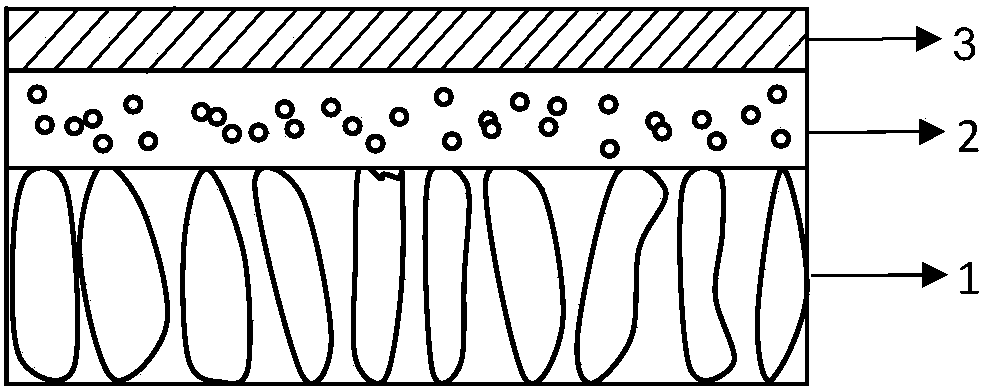

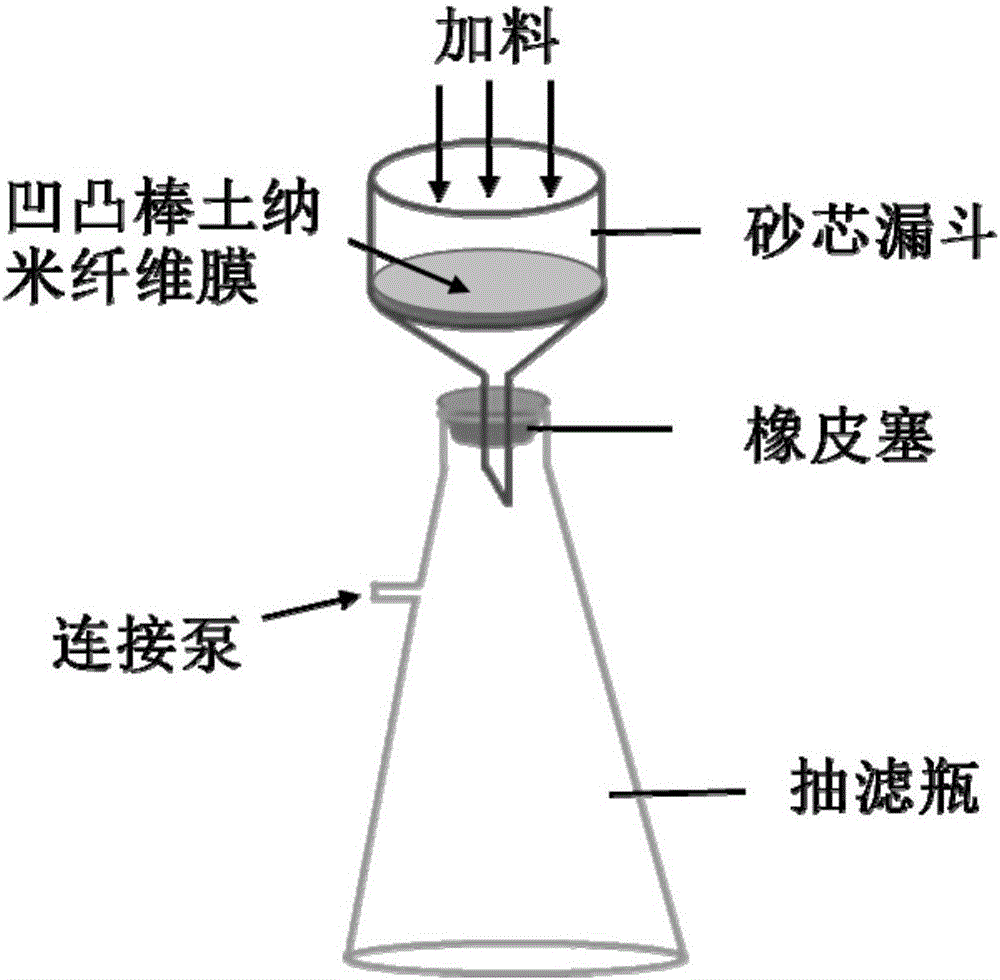

Self-supported attapulgite nanofiber membrane, and preparation method thereof

InactiveCN106390773AAbundant raw materialsGreat potential for industrializationMembranesSemi-permeable membranesFiltrationUltrafiltration

The invention relates to a self-supported attapulgite nanofiber membrane, and a preparation method thereof. The self-supported attapulgite nanofiber membrane is a nanofiber membrane with a three-dimensional net structure, and is formed via combination of attapulgite with a water-soluble polymer. The preparation method comprises following steps: attapulgite colloid and a solution of the water-soluble polymer are mixed and concentrated so as to obtain a mixed slurry; the mixed slurry is subjected to suction filtration so as to obtain a membrane; and the membrane is dried, and is subjected to step sintering in an inert atmosphere so as to obtain the finished product. The self-supported attapulgite nanofiber membrane possesses uniformly distributed nano-scaled pores and chemical corrosion resistance, is high in mechanical strength, and excellent in adsorption performance, and can be applied to the field of ultrafiltration.

Owner:DONGHUA UNIV

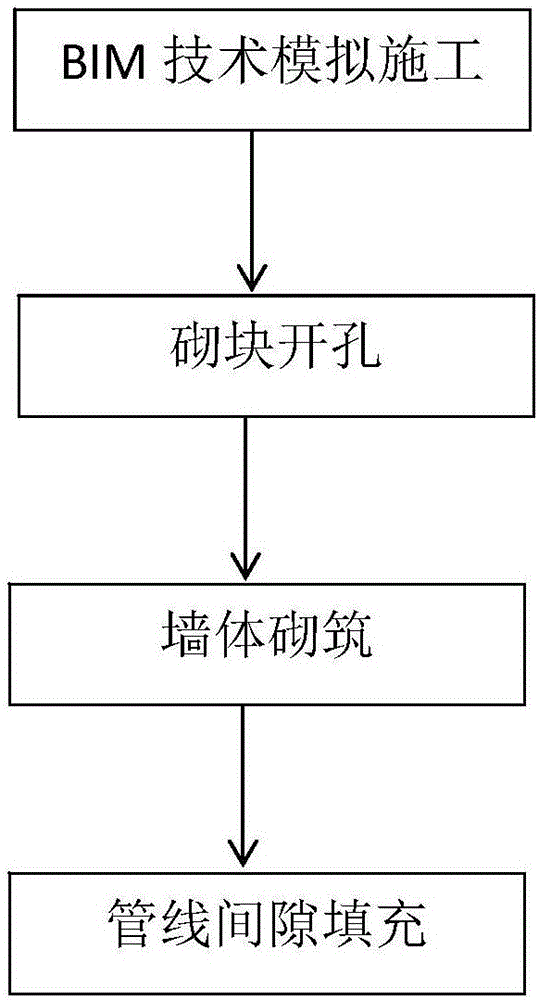

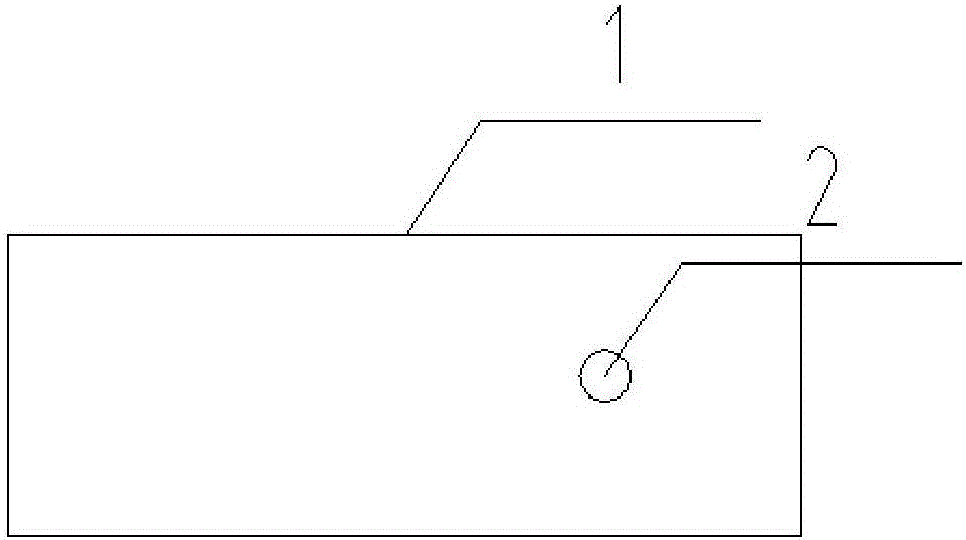

Improving method for pipeline burying construction of infilled wall

InactiveCN106703279ASimple buried operationConvenience in concealed operationWallsBuilding material handlingUltimate tensile strengthGap filling

The invention discloses an improving method for pipeline burying construction of a block wall body. The improving method comprises the following four procedures: I, BIM (Building Information Modeling) technology simulated construction; II, building block tapping; III, wall body building; IV, pipeline gap filling. A pipeline position is located accurately by the BIM technology simulated construction, a small quantity of infilled wall building blocks are tapped by a tapper, a pipeline is inserted into the block wall body, the pipeline is arranged firstly, and the infilled wall is built secondly. The improving method has the advantages of easiness and convenience in pipeline burying operation, high efficiency and low cost. The improving method has the beneficial effects that hole sizes are reduced, so that damage to the building blocks is lowered, and the strength of the block wall body is ensured effectively.

Owner:TIANJIN SANJIAN CONSTR ENG

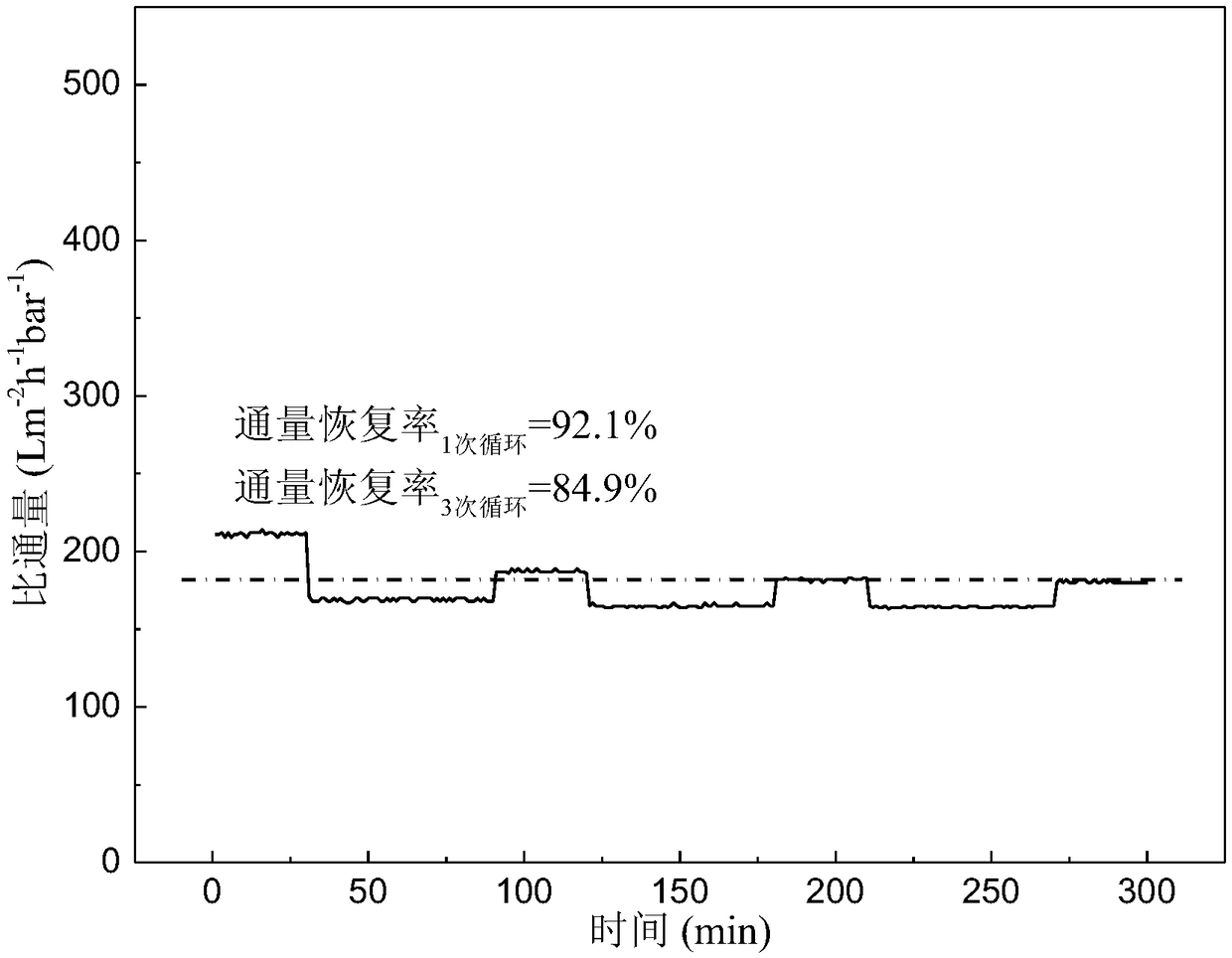

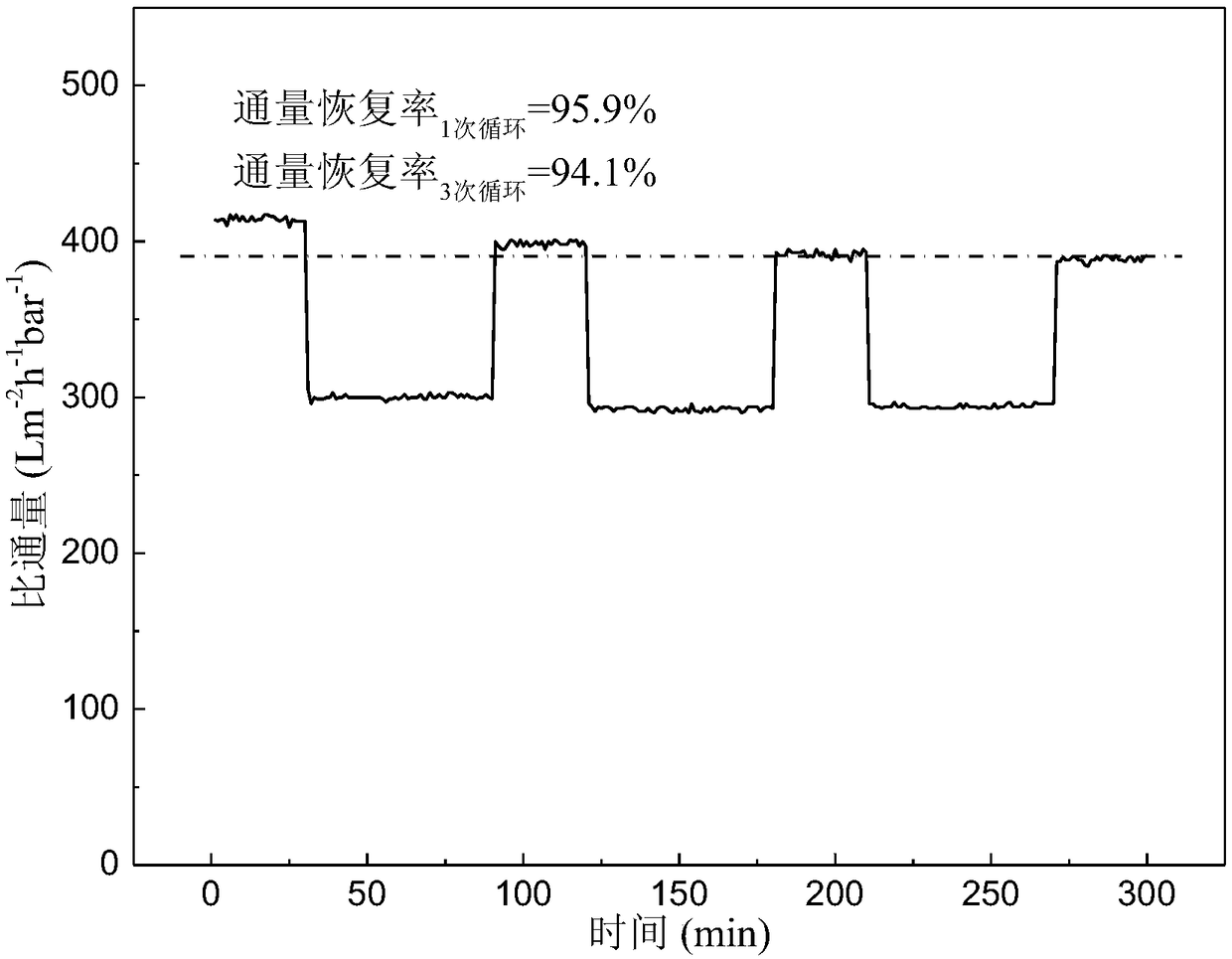

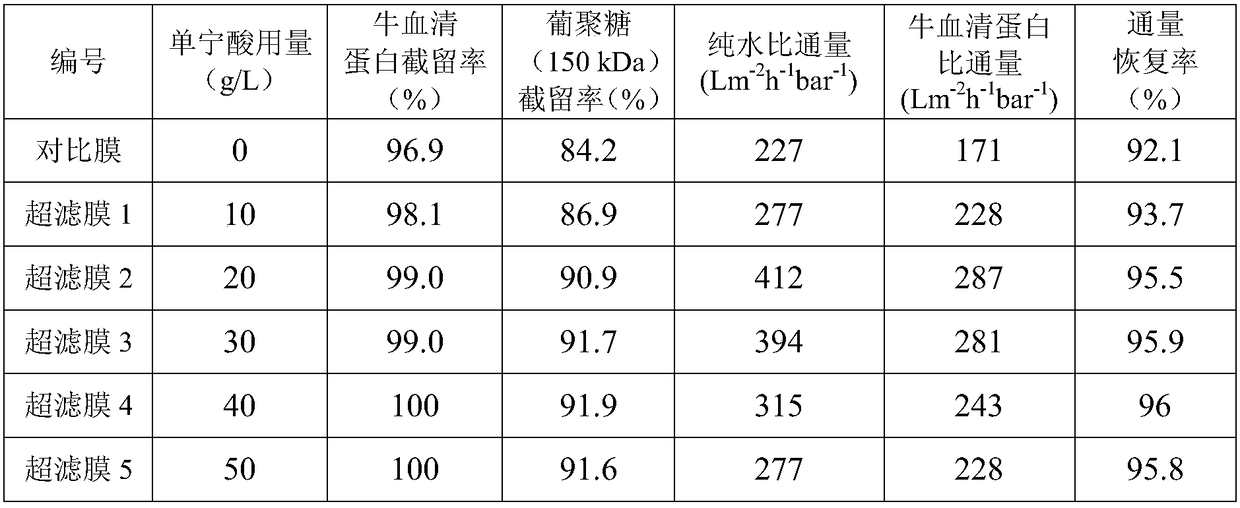

Method for preparing ultra-filtration membranes with high selectivity and high permeability

InactiveCN108654385AHigh selectivityImprove permeabilityMembranesUltrafiltrationWater bathsFiltration membrane

The invention discloses a method for preparing ultra-filtration membranes with high selectivity and high permeability. The method includes heating and stirring polyethersulfone, pluronic F127 and dimethylformamide in water bath at the temperature of 70 DEG C according to a mass ratio of 20:20:85 for 4 h, and carrying out static defoaming for 2 h to obtain casting membrane solution; adding tannic acid aqueous solution with certain concentration into a beaker, and stirring the tannic acid aqueous solution at the room temperature for 1 h to be used as coagulating bath; cooling the casting membrane solution until the temperature of the casting membrane solution reaches the room temperature, then pouring the casting membrane solution on glass plates, forming liquid membranes with the thicknesses of approximately 200 micrometers by means of scraping, placing the liquid membranes in the coagulating bath at the constant temperature of 25 DEG C and carrying out continuous solidification and membrane formation for 10 minutes; continuously immersing obtained membranes in sodium hydroxide solution for 12 h, and continuously immersing the membranes in ionized water for 24 h to obtain the ultra-filtration membranes with the high selectivity and the high permeability. The potential of hydrogen of the sodium hydroxide solution is 12. The method has the advantages that hole parameters of the ultra-filtration membranes can be optimized by the aid of interfacial assembly of tannic acid and the pluronic F127 in membrane formation procedures, in other words, the hole density can be increased, and the hole sizes can be reduced, so that the ultra-filtration membranes prepared by the aid of the method are high in selectivity and permeability.

Owner:TIANJIN UNIV

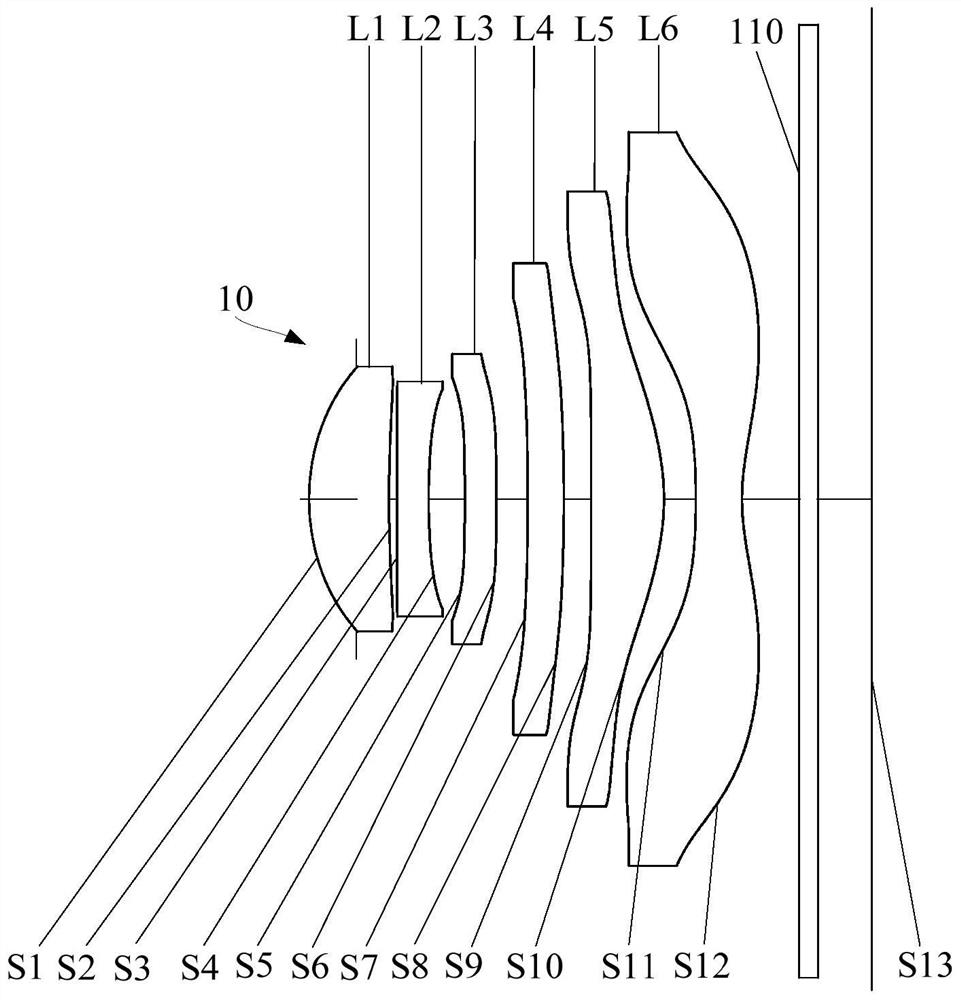

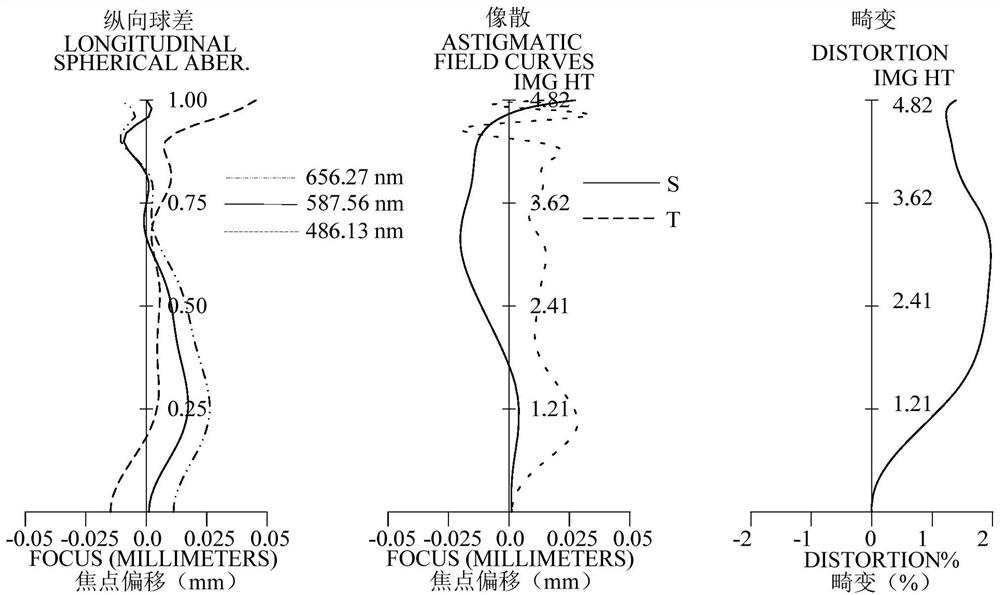

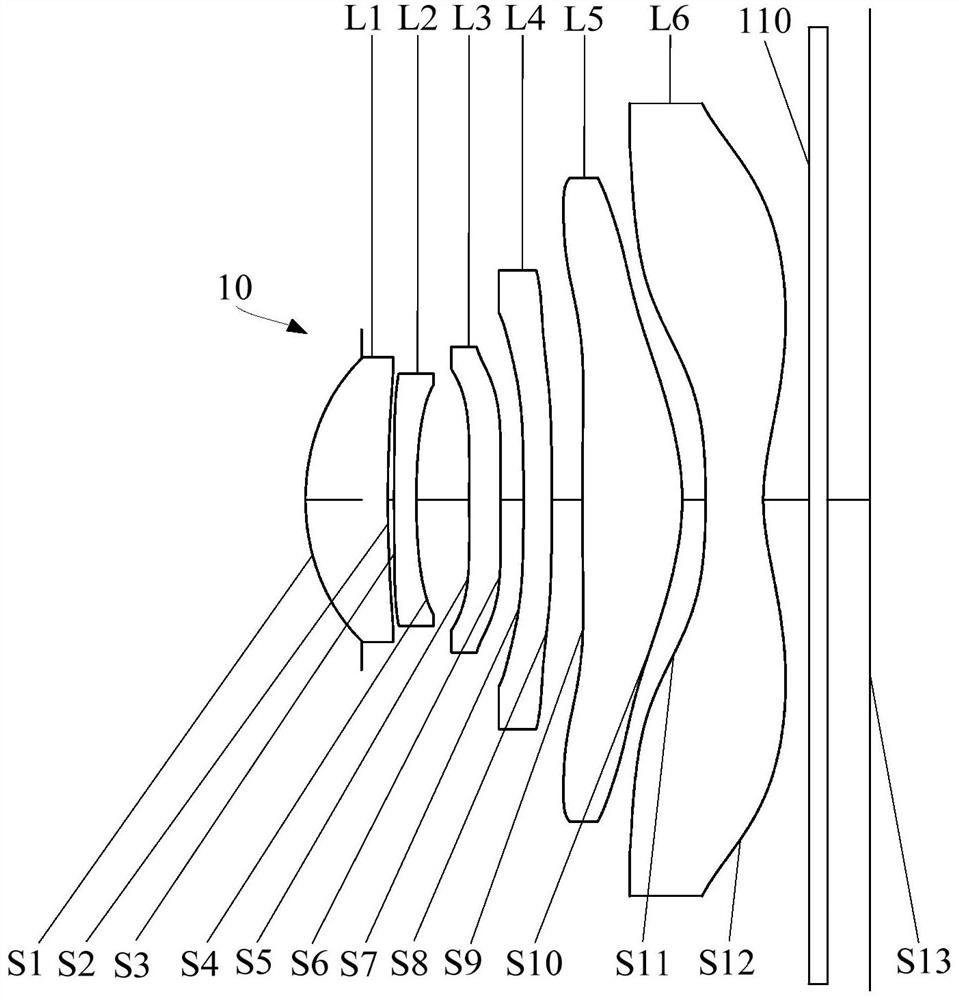

Optical system, camera module and electronic equipment

ActiveCN112363302AReduce hole sizeIncrease the screen ratioOptical elementsCamera moduleOptic system

The invention relates to an optical system, a camera module and electronic equipment. The optical system includes, in order from an object side to an image side: a first lens element with positive refractive power; a second lens element with negative refractive power; a third lens element with positive refractive power; a fourth lens element with a concave object-side surface at a paraxial regionand a convex image-side surface at a paraxial region; a fifth lens element with positive refractive power, wherein both the object-side surface and the image-side surface of the fifth lens element areaspheric; and a sixth lens with negative refractive power, wherein the object side surface and the image side surface of the sixth lens are aspheric surfaces, and at least one of the object side surface and the image side surface is provided with an inflection point. The optical system satisfies the following relationship: 0.25 < SD11 / ImgH < 0.35; sD11 is the maximum effective radius of the object side surface of the first lens, and ImgH is half of the image height corresponding to the maximum field angle of the optical system. The optical system can achieve small-head design, so that the screen-to-body ratio of equipment can be improved.

Owner:JIANGXI JINGCHAO OPTICAL CO LTD

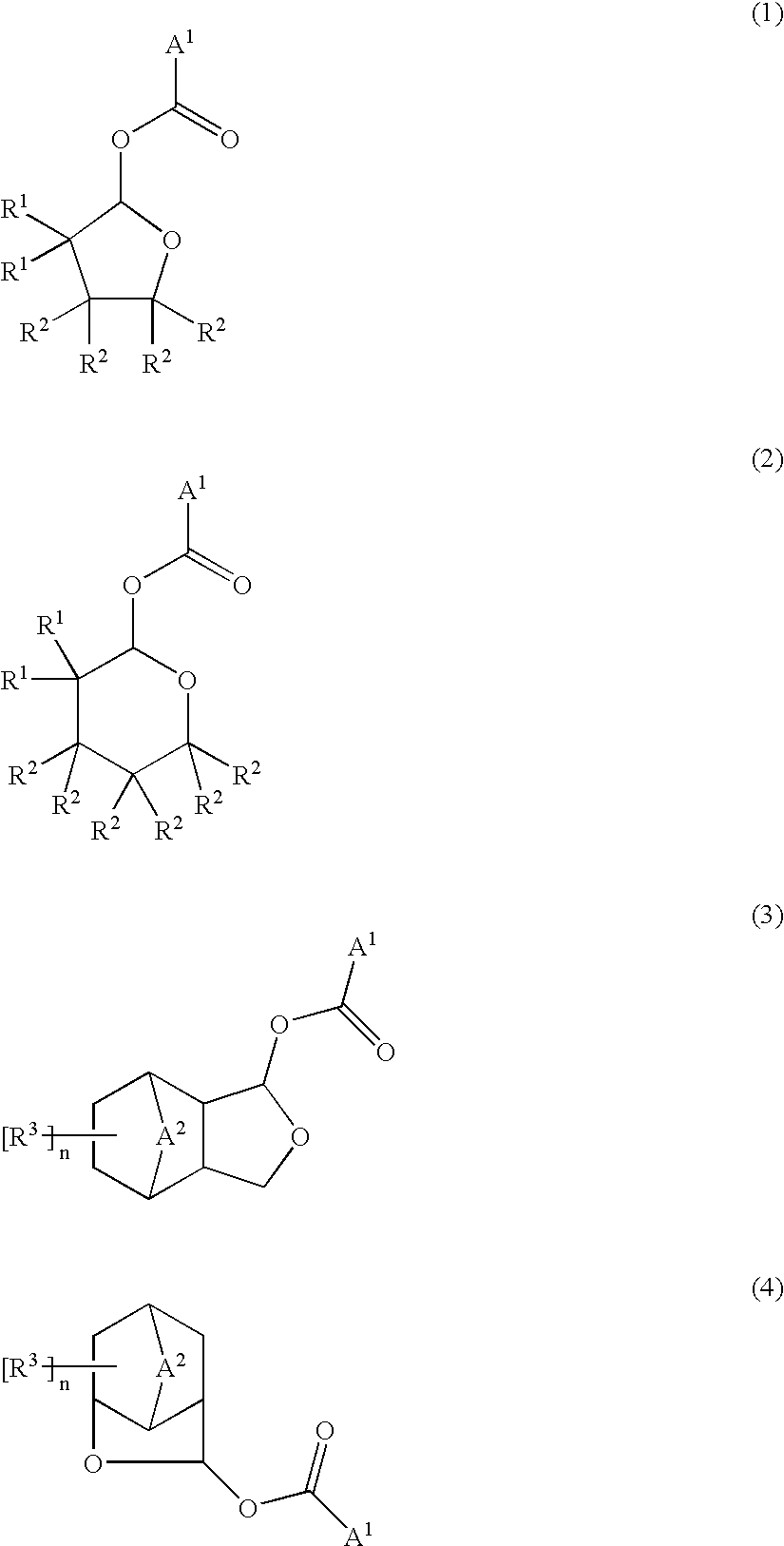

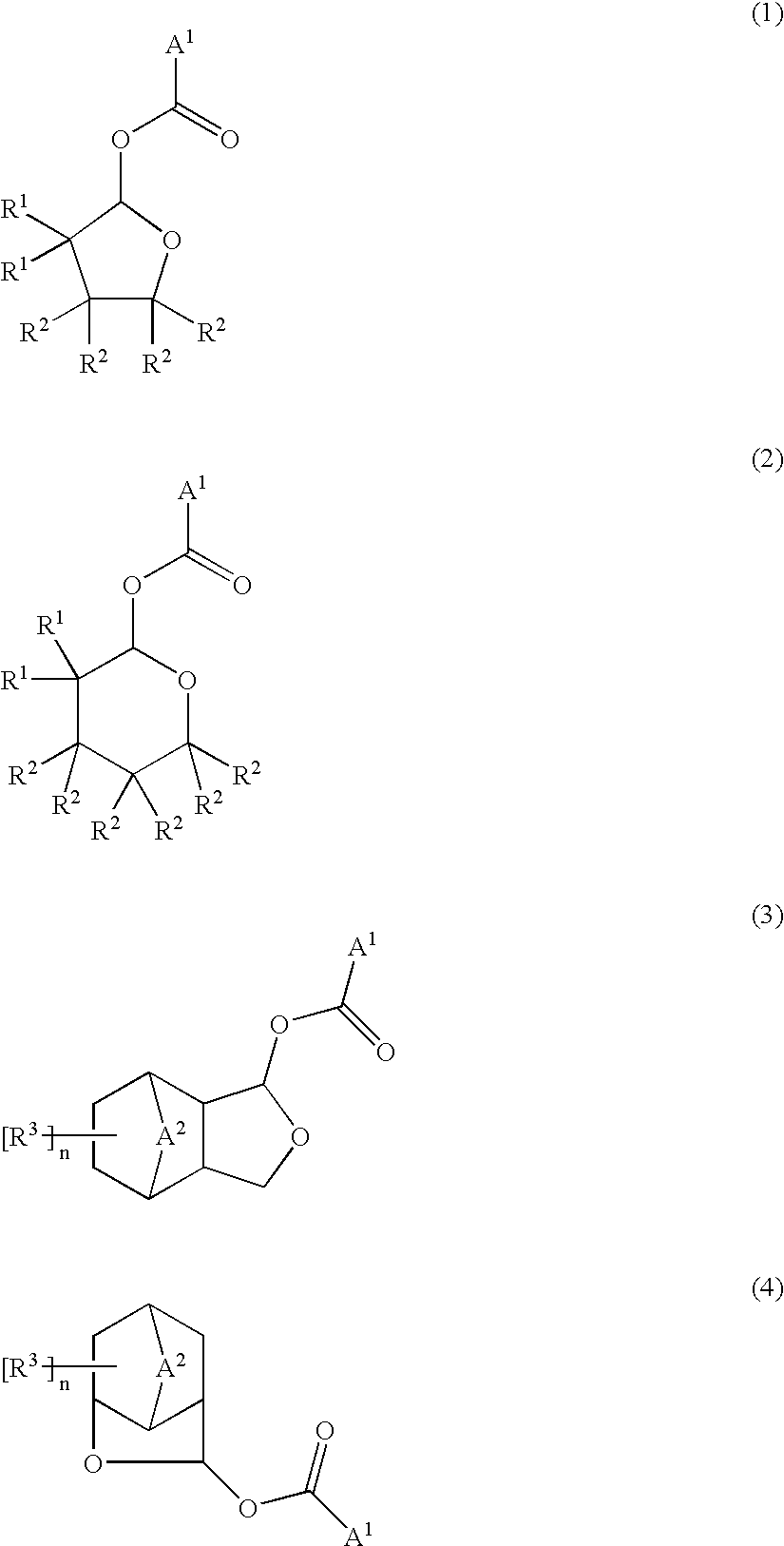

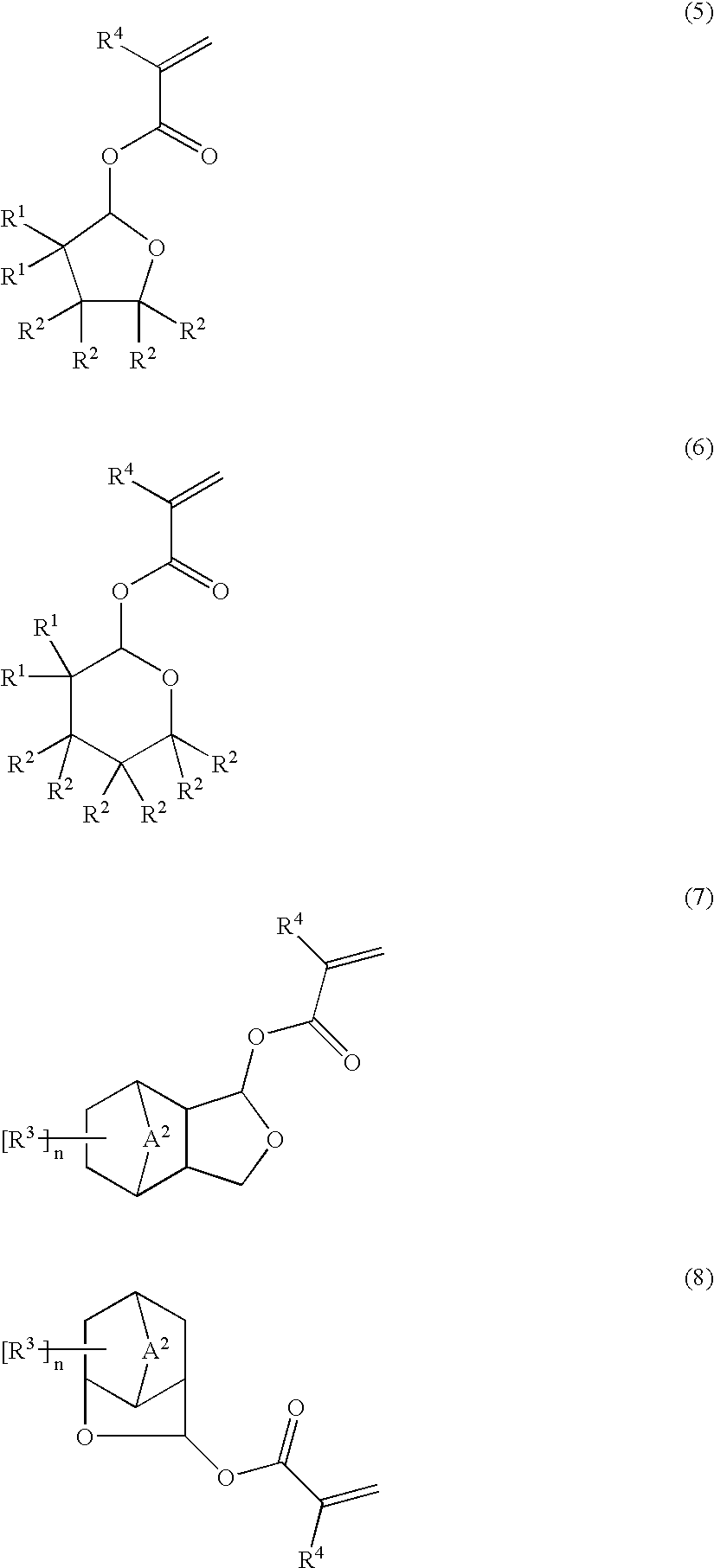

Ester compounds and their preparation, polymers, resist compositions and patterning process

ActiveUS20080008965A1Feature size of to decreaseSmall feature sizeOrganic chemistryElectric discharge tubesResistHigh energy

Novel ester compounds having formulae (1) to (4) wherein A1 is a polymerizable functional group having a carbon-carbon double bond, A2 is oxygen, methylene or ethylene, R1 is a monovalent hydrocarbon group, R2 is H or a monovalent hydrocarbon group, any pair of R1 and / or R2 may form an aliphatic hydrocarbon ring, R3 is a monovalent hydrocarbon group, and n is 0 to 6 are polymerizable into polymers. Resist compositions comprising the polymers as a base resin are thermally stable and sensitive to high-energy radiation, have excellent sensitivity and resolution, and lend themselves to micropatterning with electron beam or deep-UV.

Owner:SHIN ETSU CHEM IND CO LTD

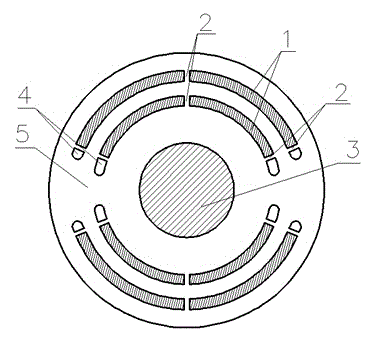

High-speed permanent-magnet motor rotor with layered permanent magnet structure

InactiveCN104868624AReduce quality problemsSmall sizeMagnetic circuit rotating partsElectric machinePermanent magnet motor

The invention relates to the motor rotor, particularly to a high-speed permanent-magnet motor rotor with a layered permanent magnet structure. The rotor is characterized in that the rotor comprises a rotating shaft (3), a rotor iron core (5), permanent magnets (1), reinforced ribs (2), and magnetic isolation bridges (4). The permanent magnets (1) are embedded into the rotor iron core (5) and are in a multi-layer mode, wherein the number of layers is larger than or equal to 2; each layer of permanent magnet (1) unit is divided into multiple segments, wherein the number of segments is larger than or equal to 2; and the reinforced ribs (2) are arranged among all permanent magnet segments. The reinforced ribs (2) and the magnetic isolation bridges (4) are arranged at the two ends of all layers of the permanent magnet (1); a smaller magnetic isolation bridge (4) is arranged at the permanent magnet layer approaching the outermost side of the rotor; and the magnetic isolation bridge (4) arranged at the inner layer of the permanent magnet are gradually increased. According to the invention, a problem that the rotor strenght is reduced due to too large magnetic isolation bridge arranged at the outer layer of the permanent magnet can be solved; and the leakage flux can be reduced with the dimensions of the magnetic isolation bridges at the inner layer of the permanent magnet.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

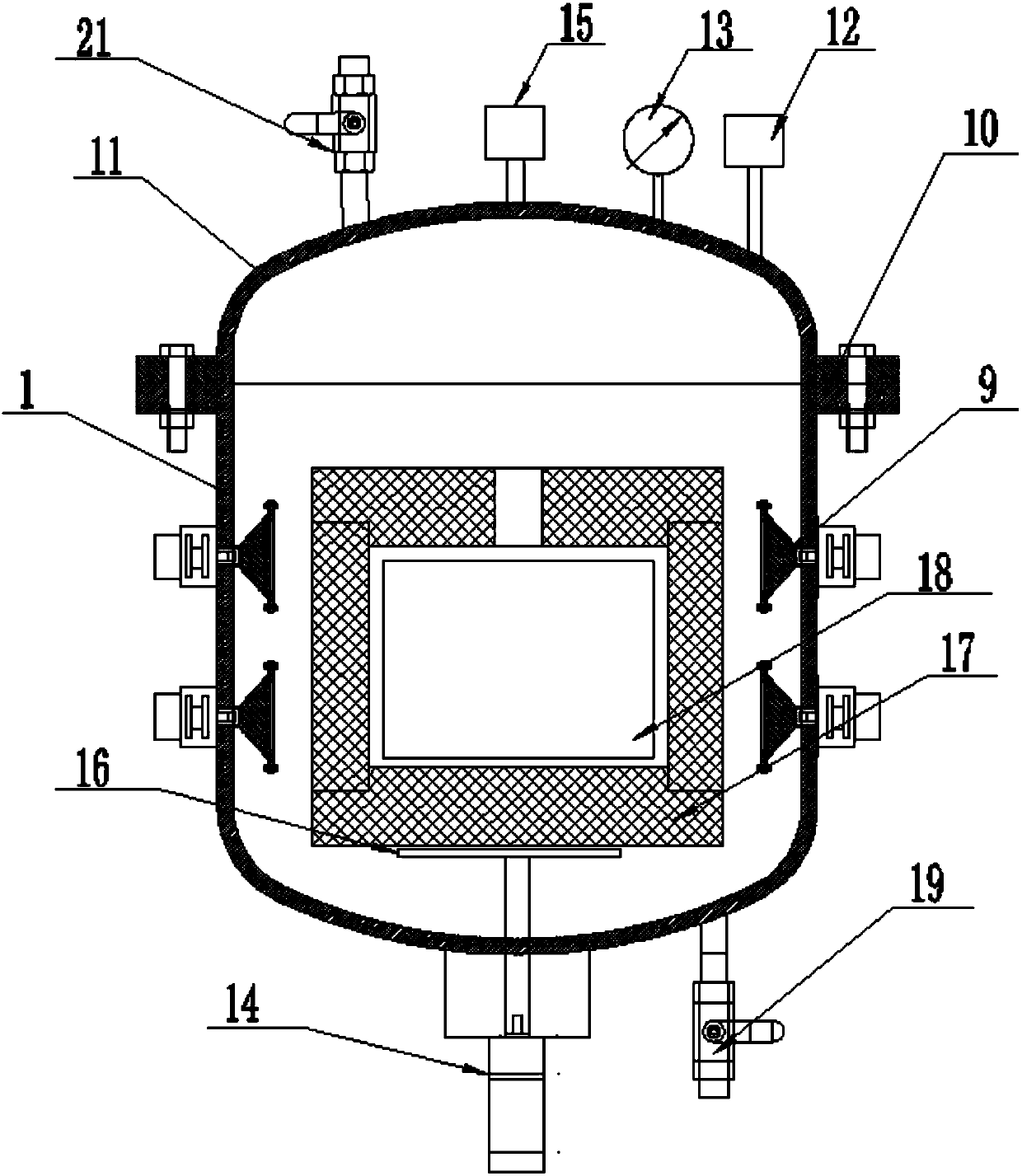

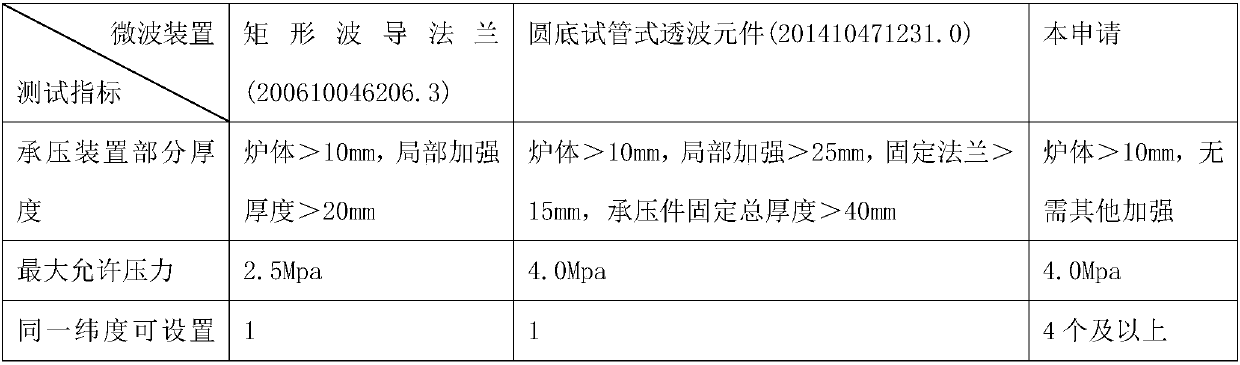

Microwave pressure sintering furnace

ActiveCN107917614AReduce hole sizePrevent leakageMuffle furnacesRetort furnacesResonant cavityMicrowave

The invention discloses a microwave pressure sintering furnace which comprises a furnace body, a furnace lid connected with the opening of the furnace body in a sealing manner, an attemperator and a microwave energy feedback device, wherein the microwave energy feedback device comprises a magnetron and a microwave stimulation feeding pressure-bearing device; the microwave stimulation feeding pressure-bearing device comprises a circular pipe arranged on the furnace body, a loudspeaker in the furnace body, a cone pressure-bearing piece in the loudspeaker, and a wave-transparent fixing part capable of limiting the cone pressure-bearing piece from moving; the antenna of the magnetron is positioned in the circular pipe; and the antenna and the circular pipe form a coaxial resonant cavity. According to the microwave pressure sintering furnace, after being stimulated by the coaxial resonant cavity and the loudspeaker, microwave enters the furnace body by penetrating through the cone pressure-bearing piece to realize microwave energy feedback; the internal diameter of the circular pipe can be reduced to 5-30 mm; the cone pressure-bearing piece fits the inner wall of the loudspeaker and isfixed through the fixing part to effectively prevent pressure leakage, so that the stressed situation of the furnace body and the cone pressure-bearing piece is improved, the pressure-bearing pressuredesigning and processing difficulty of the sintering furnace and the microwave energy feedback device is greatly lowered.

Owner:湖南长仪微波科技有限公司

Material conveying control method

ActiveCN112691949AIncrease delivery speedReduce spacingConveyorsPackaging automatic controlProcess engineeringIndustrial engineering

The invention relates to the field of hygienic product machinery, in particular to a material conveying control method which comprises the following steps: one removed conveyed hygienic product is counted and marked through a high-speed camera, the removed conveyed hygienic product is marked to be red, a detection camera assembly in front of a speed regulation conveying belt scans and counts the hygienic products conveyed after the hygienic products are removed, after the hygienic products are recognized as red marks, the hygienic products conveyed after the hygienic products are removed are conveyed to a next clamping conveying device through the speed regulation conveying belt in an accelerated mode, and the distance between the hygienic products which are removed originally is reduced. The hygienic products input into the next clamping and conveying device can keep the spacing distance between the original rejected hygienic products and the previous hygienic products, and the problem that in the conveying process, the spacing distance between the front materials and the rear materials is caused after waste rejected materials are rejected, as a result, missing packages are likely to exist in packaged products is solved.

Owner:QUANZHOU HANWEI MACHINERY MFG

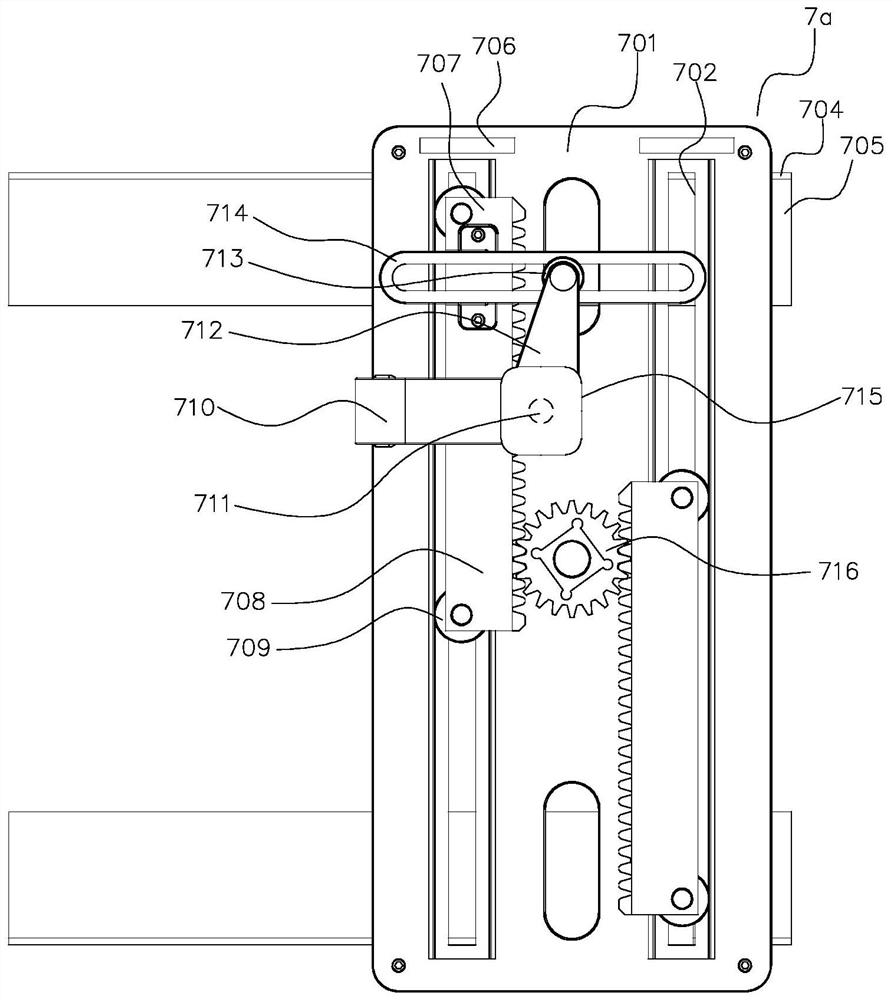

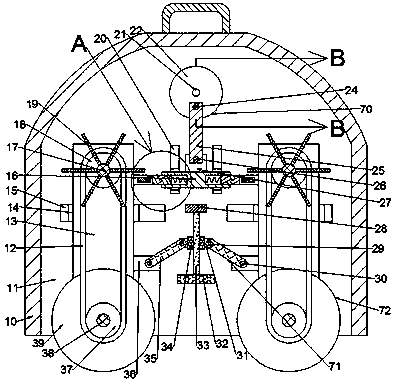

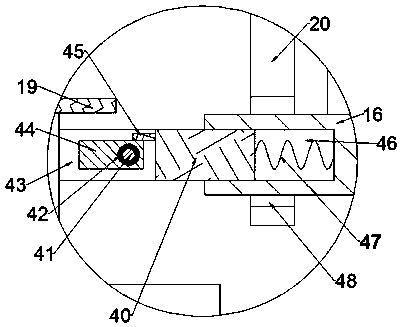

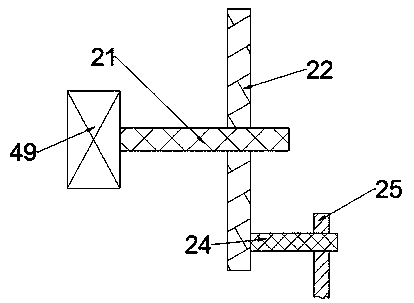

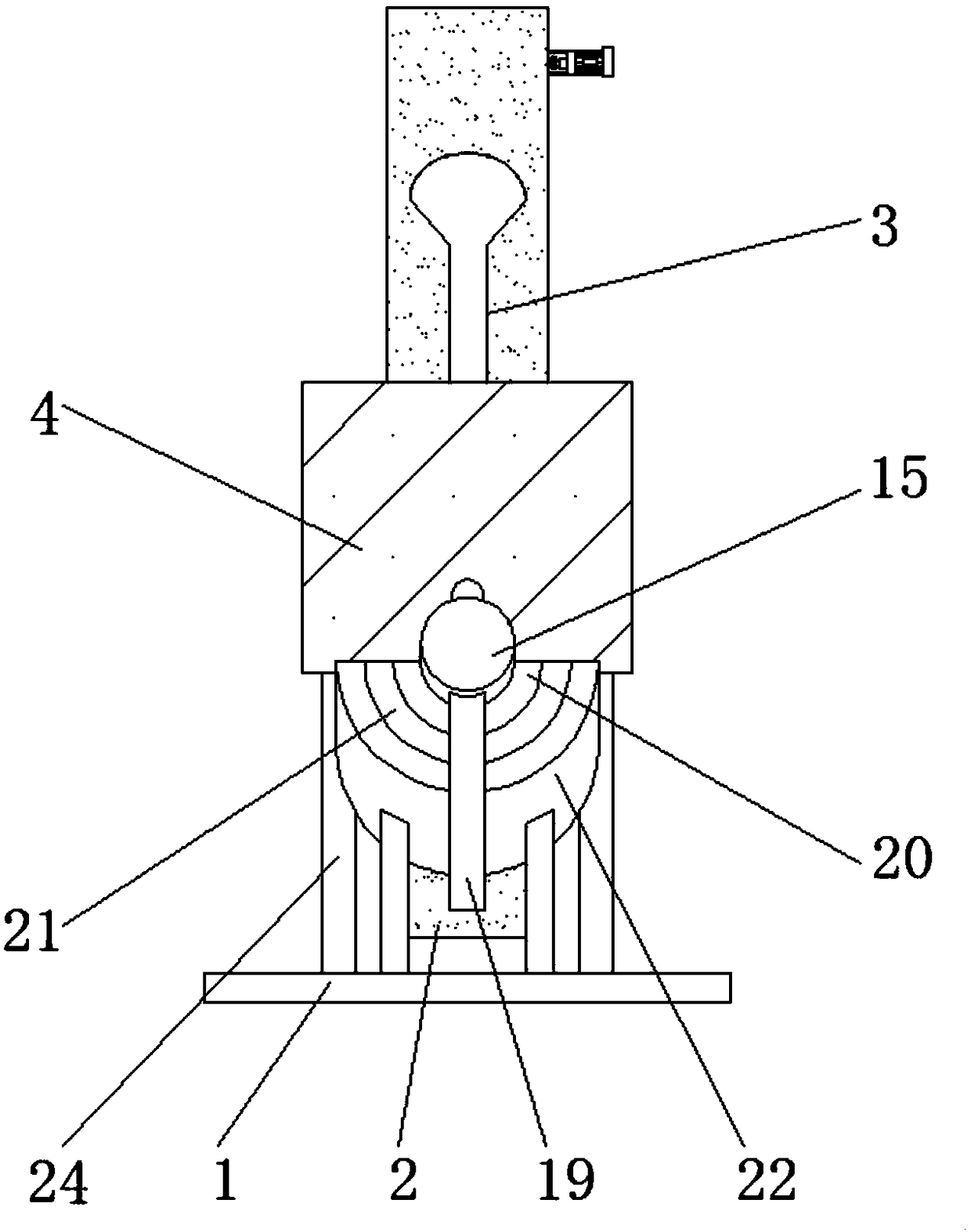

A device for repairing holes on the surface of a leather sofa

ActiveCN110777222BReduce hole sizeHelp complete repairLeather stretching/tensioningSkins/hides/leather/fur manufacturing apparatusStructural engineeringMechanical engineering

The invention discloses a device for repairing holes in a surface of a leather made sofa. The device comprises a repairer box body. A working cavity opened downward is formed in the lower end surfaceof the repairer box body, two repair mechanisms are symmetrically arranged left and right in the working chamber, each repair mechanism comprises a supporting plate capable of moving left and right, an input shaft is rotatably arranged on the front end surface of the supporting plate, six rotating rods are uniformly and fixedly arranged on the input shaft, and repair wheels, the lower ends of which penetrate the lower end wall of the working chamber, are arranged on the lower sides of the rotating rods. For the characteristics of a leather product, leather is softened and stretched by way of extrusion to the center by the two wheels, so that the sizes of holes in the surface of the leather made sofa are reduced, the leather is softened under the circumstance of damaging the physical property of the leather to a less extent, so that the leather is fully repaired subsequently. The distance between the two wheels can be adjusted according to the sizes of the holes in the surface of the leather made sofa, so that the best repair effect is achieved.

Owner:佛山市顺德区腾威家具实业有限公司

Pipeline blocking device

The invention relates to a pipeline blocking device which comprises a first supporting rod, a second supporting rod, an expansion ring and a sealing cover. The first supporting rod is hinged to the second supporting rod. A drive ring, a support and a pull rod are arranged on the first supporting rod. A fixing ring and a sliding ring are arranged on the second supporting rod, and the sliding ring is connected with the pull rod through a transmission rod. The expansion ring comprises first arc parts and second arc parts, wherein the first arc parts and the second arc parts are distributed alternately. Symmetric guide faces are arranged on guide parts of the first arc parts, and sliding grooves and guide holes are formed in the guide faces. The guide holes in the adjacent first arc parts forma splay shape, and supporting lugs are arranged on the second arc parts. The supporting lugs are correspondingly hinged to the fixing ring and the sliding ring through first connecting rods and second connecting rods. Sliding blocks located in the sliding grooves are arranged at the two ends of the second arc parts, and guide pillars located in the guide holes are arranged on the two sides of thesliding blocks. The sealing cover is arranged on the expansion ring in a sleeving manner from right to left and is fixedly connected with the first arc parts. The pipeline blocking device has the beneficial effects that the structure is simple, control is convenient, adaptability is high, and blocking is reliable.

Owner:北京天兴燃气工程有限公司

Wall for a hot gas channel in a gas turbine

ActiveUS10087778B2Control impactControl crackingContinuous combustion chamberTurbine/propulsion engine coolingEngineeringGas turbines

A wall for a hot gas channel in a gas turbine is described, the wall having a back side and a front side and an impingement sheet having impingement cooling holes, the wall being for exposure to a hot fluid at the front side, and the wall having an array of pins attached to the back side and extending between the back side and the impingement sheet, the wall additionally having a plurality of ribs attached to the back side, each rib extending between two pins to delineate an array of cells on the back side, and / or at least one compartment wall attached to the back side to delineate compartments on the back side. Embodiments include an impingement sheet with impingement cooling holes and cooling exit holes. A gas turbine including the wall is also described.

Owner:ANSALDO ENERGIA SWITZERLAND AG

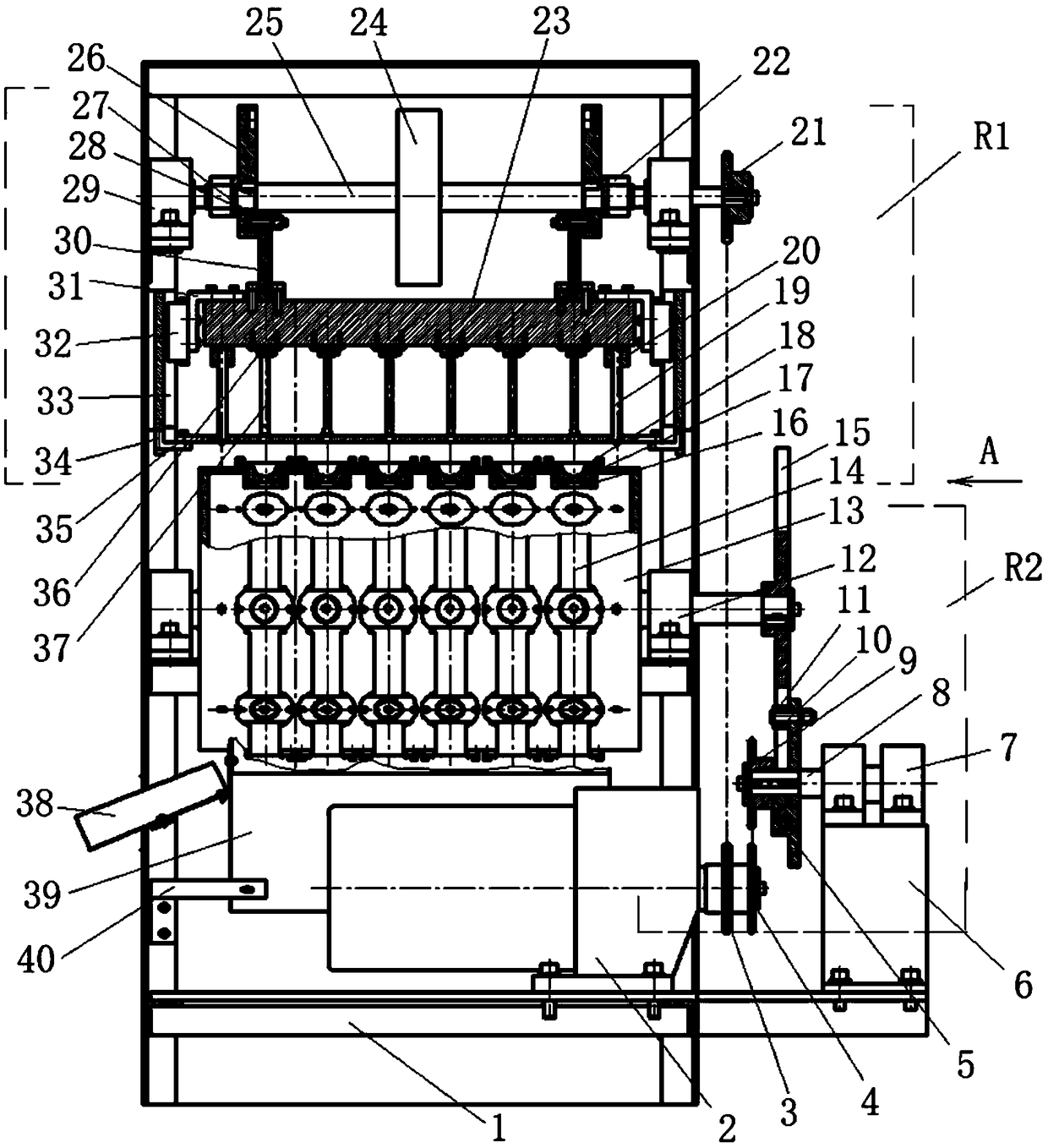

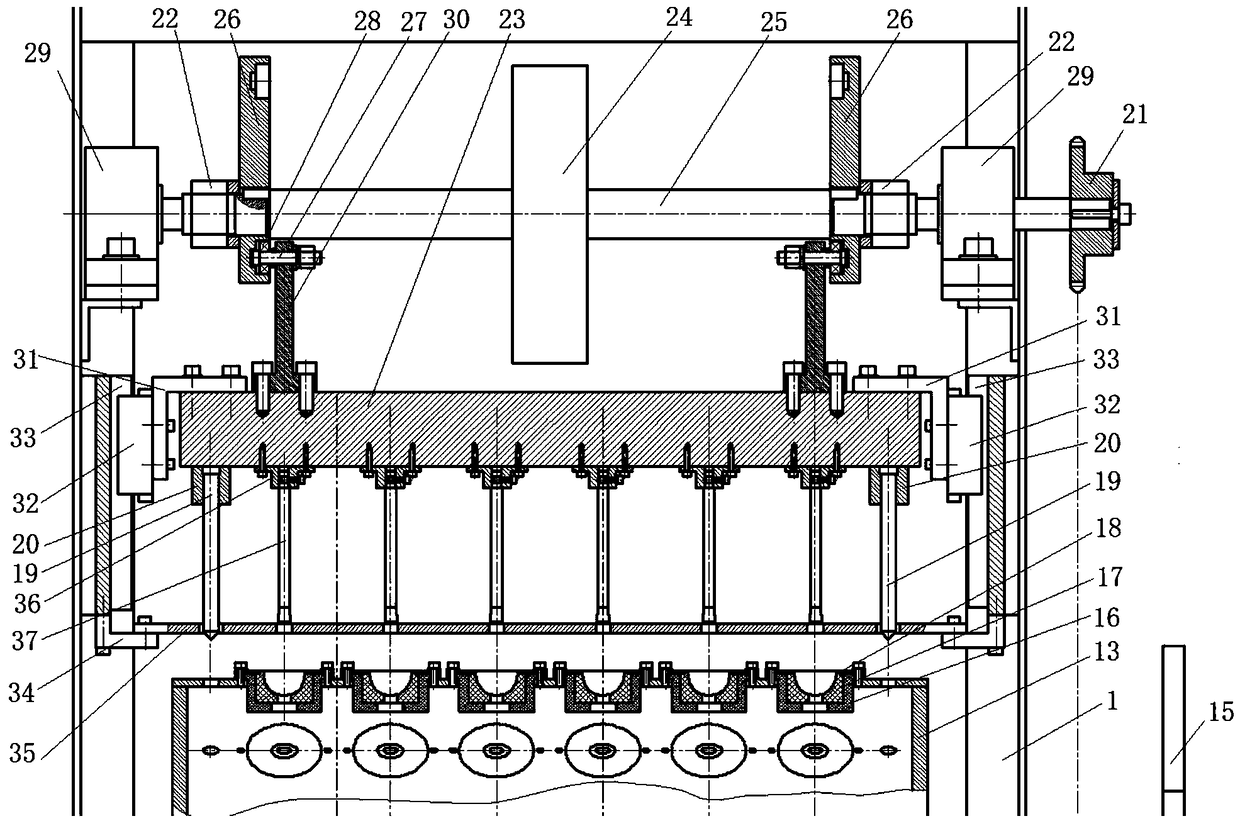

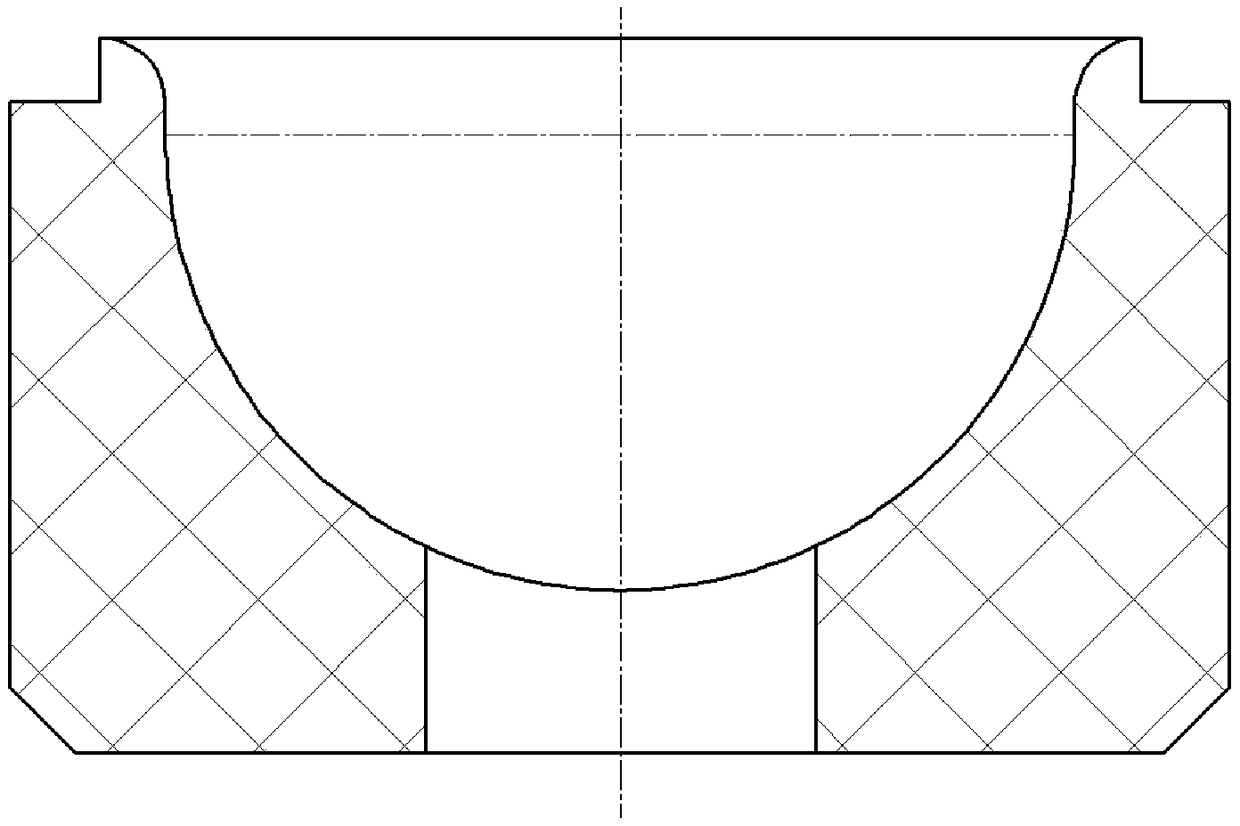

Longan pitting machine

The invention relates to a longan pitting machine. The longan pitting machine comprises a rack, a pitting assembly and a laying-off assembly, wherein the pitting assembly is positioned in front of therack, and the laying-off assembly is positioned at the upper rear part of the rack; the pitting assembly comprises a sliding block, a linear guide rail, a linear guide rail sliding block, a roller, aplurality of arc-shaped fruit guiding blocks, a plurality of core pushing rubber parts and a plurality of core pushing rods; the linear guide rail is vertically installed on the rack, the linear guide rail sliding block is installed on the linear guide rail, the linear guide rail sliding block is connected with a horizontally arranged sliding block, and a plurality of push rods are arranged on the sliding block in a vertical distribution mode; the outer wall of the roller is axially provided with the plurality of rows of core pushing rubber parts distributed at equal intervals, and provided with the plurality of core pushing rubber parts in the circumferential direction, and the arc-shaped fruit guiding blocks are connected with two adjacent core pushing rubber parts which are circumferentially distributed; the plurality of push rods are positioned above the plurality of axially distributed core pushing rubber parts. The longan pitting machine is used for pitting shell-removed core-containing longan fruit, loses less juice, the production efficiency is high, and the quality is stable. The longan pitting machine belongs to the technical field of food machinery manufacturing.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method of high adsorption flue gas demercuration adsorbent material

PendingCN110339815AImprove structural performanceImprove adsorption capacityGas treatmentOther chemical processesTime rangeFlue gas

The invention relates to a preparation method of a high adsorption flue gas demercuration adsorbent material, and belongs to the technical field of adsorbents. According to the technical scheme, a sufficient etching effect can be generated by a plasma on the inner surface and outer surface of bamboo charcoal within a suitable modification time range, so that new undulation and roughness are generated on the inner surface and outer surface of the bamboo charcoal to form many potholes, and the specific surface area is increased. The plasma can react with specific point positions on the inner surface and outer surface of the bamboo charcoal, and a large number of new oxygen-containing groups are generated, the pore size at the positions can be significantly reduced because of the accumulationof the oxygen-containing groups in pores. Etching and group formation can synergistically enhance the pore structure of the bamboo charcoal, and meanwhile the number of the oxygen-containing groups on the surface of the bamboo charcoal is increased. Because parameters such as the specific surface area and pore volume of carbon materials are key factors to determine the adsorption performance, thebamboo charcoal modified by oxygen plasma is obviously improved and enhanced in the specific surface area and the pore volume, the adsorption performance can be better, and the demercuration efficiency of the material is improved.

Owner:贾中辉

Cereal classifying and separating mechanical device beneficial for removing impurities

InactiveCN109261524AGood removal effectLabor saving and uninterrupted feedingSievingGas current separationEngineeringImpurity

The invention discloses a cereal classifying and separating mechanical device beneficial for removing impurities. The mechanical device comprises a bottom frame, an impurity removal separating bucketand a first screening cavity. The left side of the upper surface of the bottom frame is fixedly connected with a feed device through a connecting frame. The lower side of the impurity removal separating bucket is fixedly connected to the middle of the upper surface of the bottom frame through a connecting frame. An impurity removal block is arranged on the outer side of the lower side of an impurity removal connecting pipe. A connecting block is fixedly connected with the upper side of a light impurity discharge port. A heavy material guide plate is arranged on the lower side of a heavy graindischarge port. By means of the cereal classifying and separating mechanical device, feeding can be conveniently and uninterruptedly conducted with lower efforts, work efficiency is improved, the workdifficulty is lowered, different types of impurities can be conveniently removed, and cereal can be separated into different sizes to be collected.

Owner:杨智超

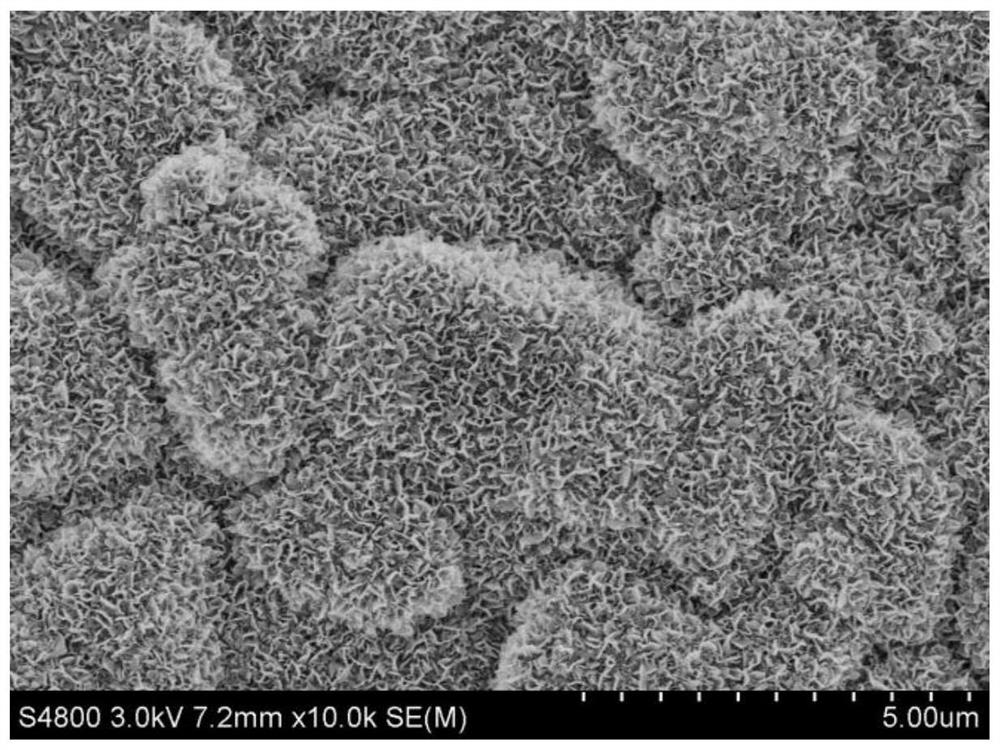

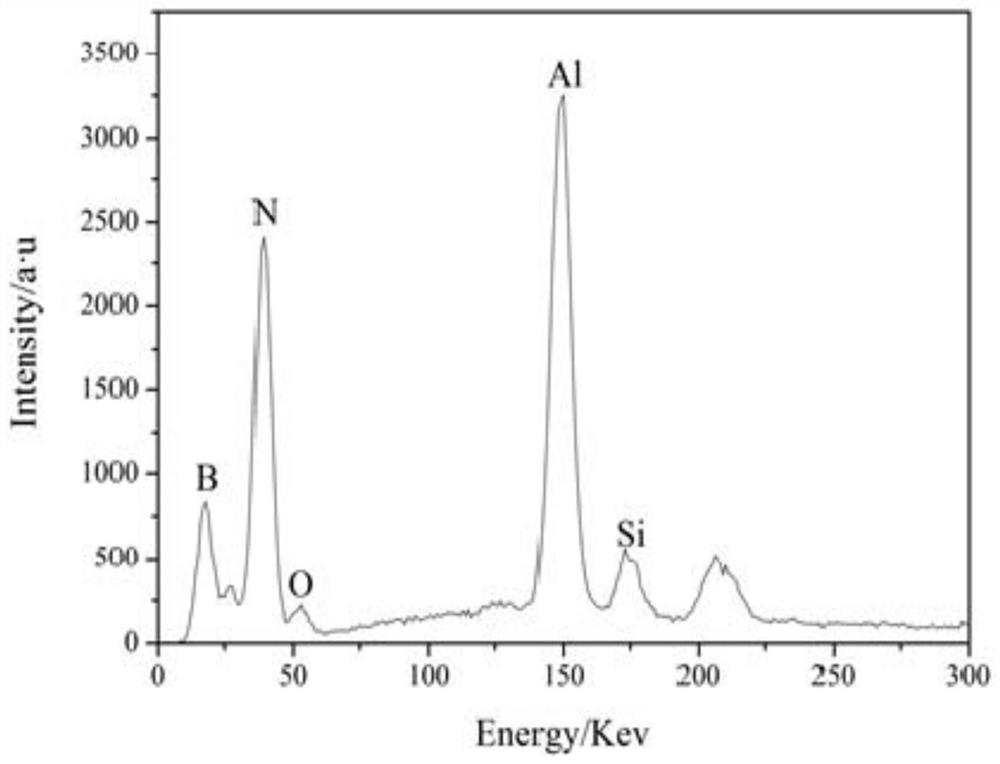

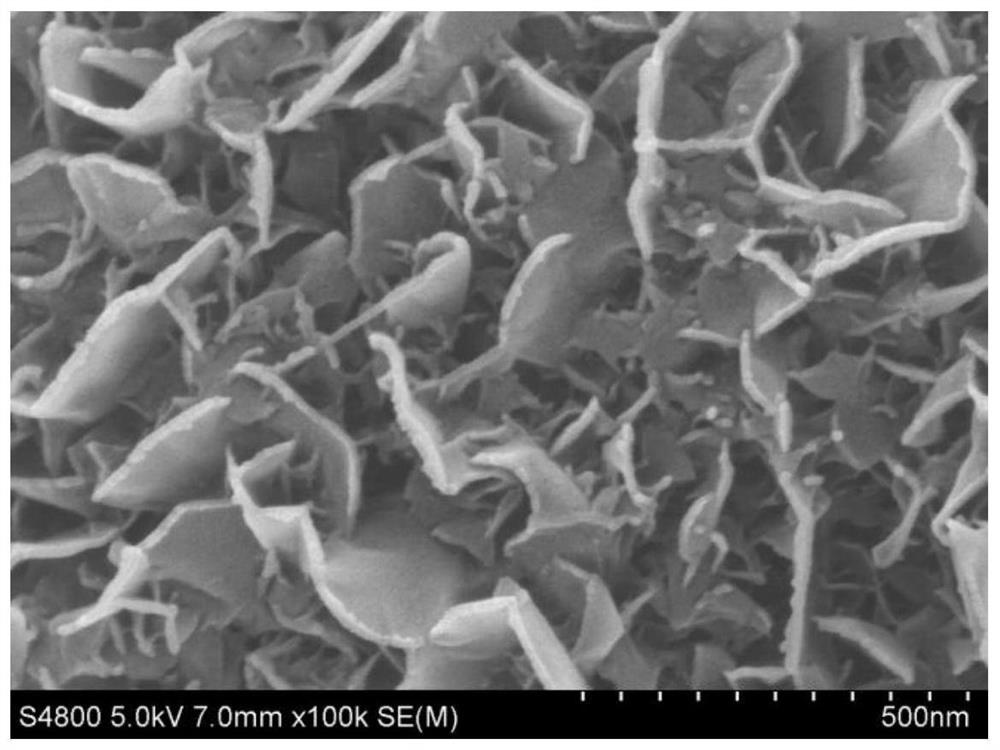

Preparation method of vertically-arranged boron nitride nanosheet film and material with surface provided with vertically-arranged boron nitride nanosheet film

ActiveCN112279683AImprove hydrophobicityHigh temperature resistantOther chemical processesAlkali metal oxides/hydroxidesIron powderBoron nitride

The invention discloses a preparation method of a vertically-arranged boron nitride nanosheet film and a material with the surface provided with the vertically-arranged boron nitride nanosheet film. The method comprises the following steps: mixing cheap boron oxide powder as a boron source with metal iron powder and magnesium powder, carrying out ball milling for 0.5 h or more to prepare a reaction precursor, taking metal , ceramic, silk screen, and porous ceramic as deposition substrates, heating to 1200-1300 DEG C in a high-purity ammonia atmosphere by using a tubular atmosphere protection annealing furnace, and carrying out heat preservation for 1-8 h, so that a layer of off-white BN nanosheet film is deposited on the surface of the substrate, the contact angle of the film to water is 144-146 degrees, and the hydrophobic property is good. The invention can be applied to the fields of self-cleaning surfaces, self-lubricating surfaces, metal protection, oil-water separation and the like, especially high-temperature corrosive environments. The preparation process is simple, the reaction conditions are mild, and the used raw materials are boron oxide powder, iron powder, magnesium powder and ammonia gas, are cheap, easy to obtain, non-toxic and harmless, and are suitable for large-scale industrial production.

Owner:ROCKET FORCE UNIV OF ENG

A novel graphite heater with a single end fixed

InactiveCN102660809AHole cut in halfImprove airtightnessFibre chemical featuresElectric heating for furnacesGraphite electrodeThermal insulation

The invention discloses a novel graphite heater with a single end fixed. The graphite heater comprises a graphite electrode. The graphite electrode extends through a furnace wall thermal insulation layer and is inserted into a heating furnace, wherein the head end of the graphite electrode is located inside the heating furnace, and the tail end of the graphite electrode is located outside the heating furnace. The graphite heater further comprises an electric connection seat, the electric connection seat is clamped at the tail end of the graphite electrode, the electric connection seat is mounted on the outer wall of the heating furnace, and the graphite electrode is fixed in the heating furnace. A clamping slot is arranged in the electric connection seat, the tail end of the graphite electrode is located in the clamping slot. A hold-down bolt is further arranged in the electric connection seat, and the hold-down bolt extends into the clamping slot. Near the tail end of the graphite electrode, a hold-down plate is arranged between the hold-down bolt and the tail end of the graphite electrode, the hold-down bolt abuts against the hold-down plate to enable the clinging of the tail end of the graphite electrode to the inner wall of the clamping slot, so that the tail end of the graphite electrode is fixed. A flange is arranged at the outer edge of the electric connection seat, and the flange is fixedly connected with the heating furnace by using a fixing bolt. The graphite heater extends into the furnace in a suspending manner with a single end fixed, disassembly, assembly and maintenance of the graphite heater are convenient, and mounting space of the graphite heater is reduced.

Owner:SHANGHAI LIANCHUAN AUTOMATION TECH

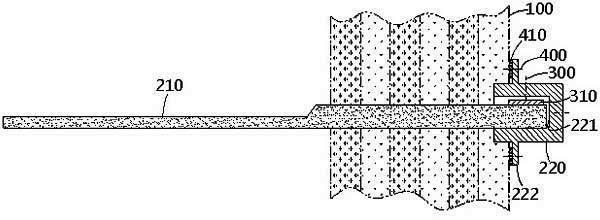

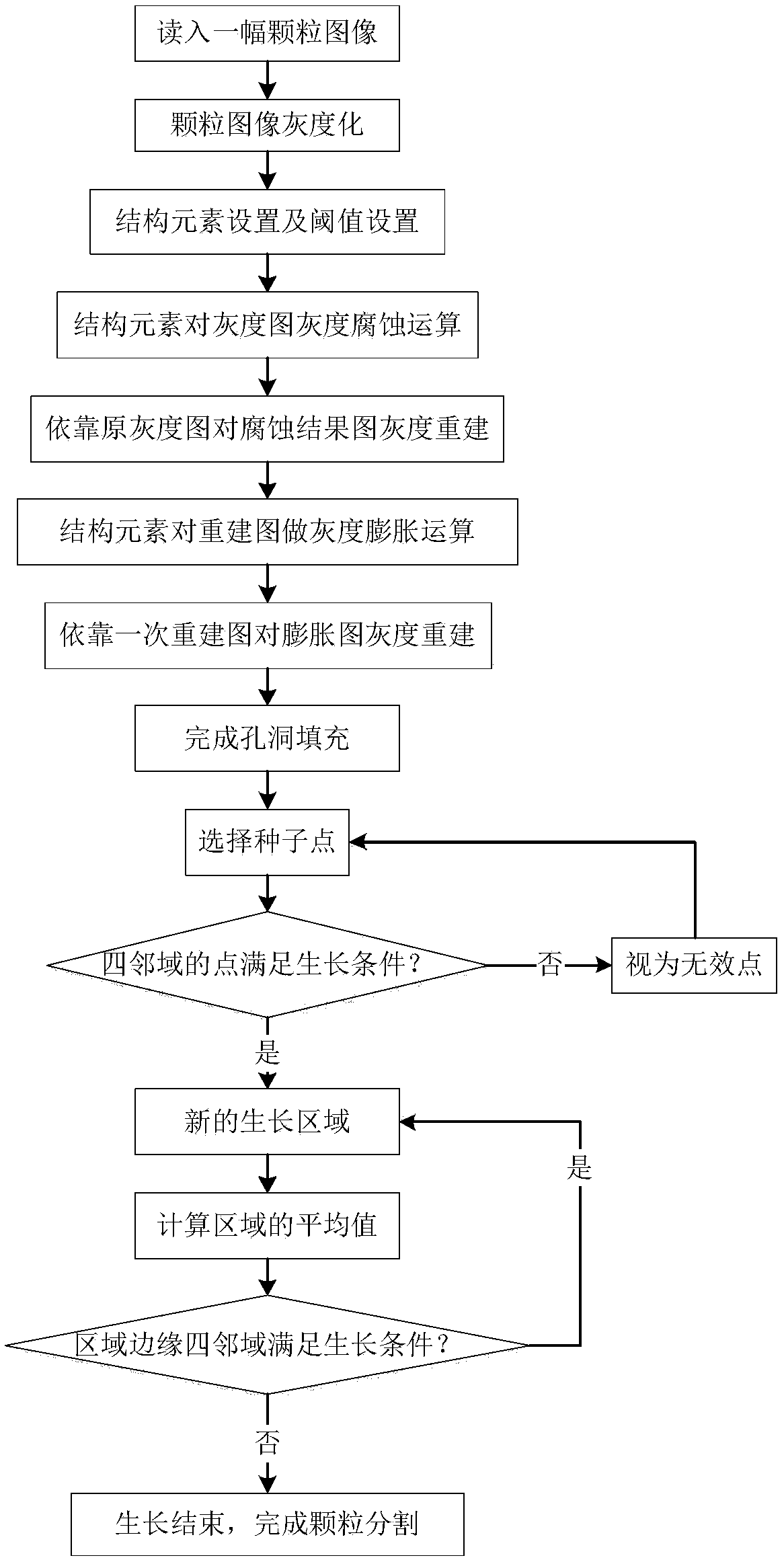

A method of rock particle segmentation based on mathematical morphology

ActiveCN109087308AReduce hole sizeKeep the full shapeImage enhancementImage analysisStone particleClassical mechanics

The invention discloses a rock particle segmentation method based on mathematical morphology, by using gray-scale mathematical morphology to preprocess the rock grain image, the image is filled with tiny holes and the correct boundary of rock grains is preserved so that the rock grains form an effective agglomerate region. Then the pixels with similar properties in each agglomerate region are combined into a single region by the region growth algorithm to complete the segmentation of rock grains. By the invention, the corrosion operation and the dilation operation do not have fuzzy grain boundaries, and the complete shape of the reserved grains is relatively complete, so that the corrosion operation and the dilation operation do not have fuzzy grain boundaries.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com