Microwave pressure sintering furnace

A technology of pressure sintering and microwave, applied in furnaces, muffle furnaces, cooking furnaces, etc., can solve problems such as difficult to meet the scale-up production, reduce the influence of weakening reaction effect, reduce the difficulty of pressure design and processing, uniform heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

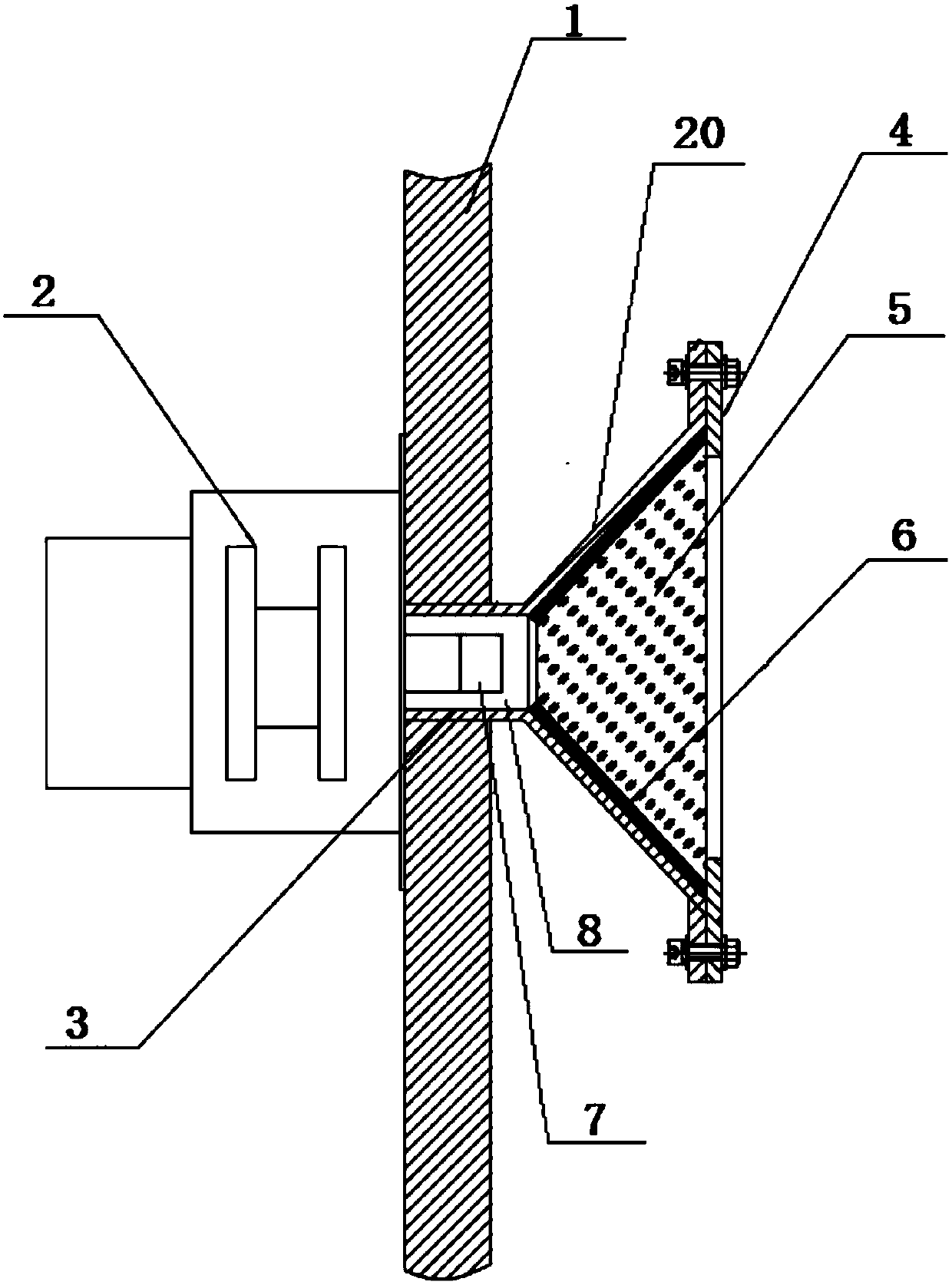

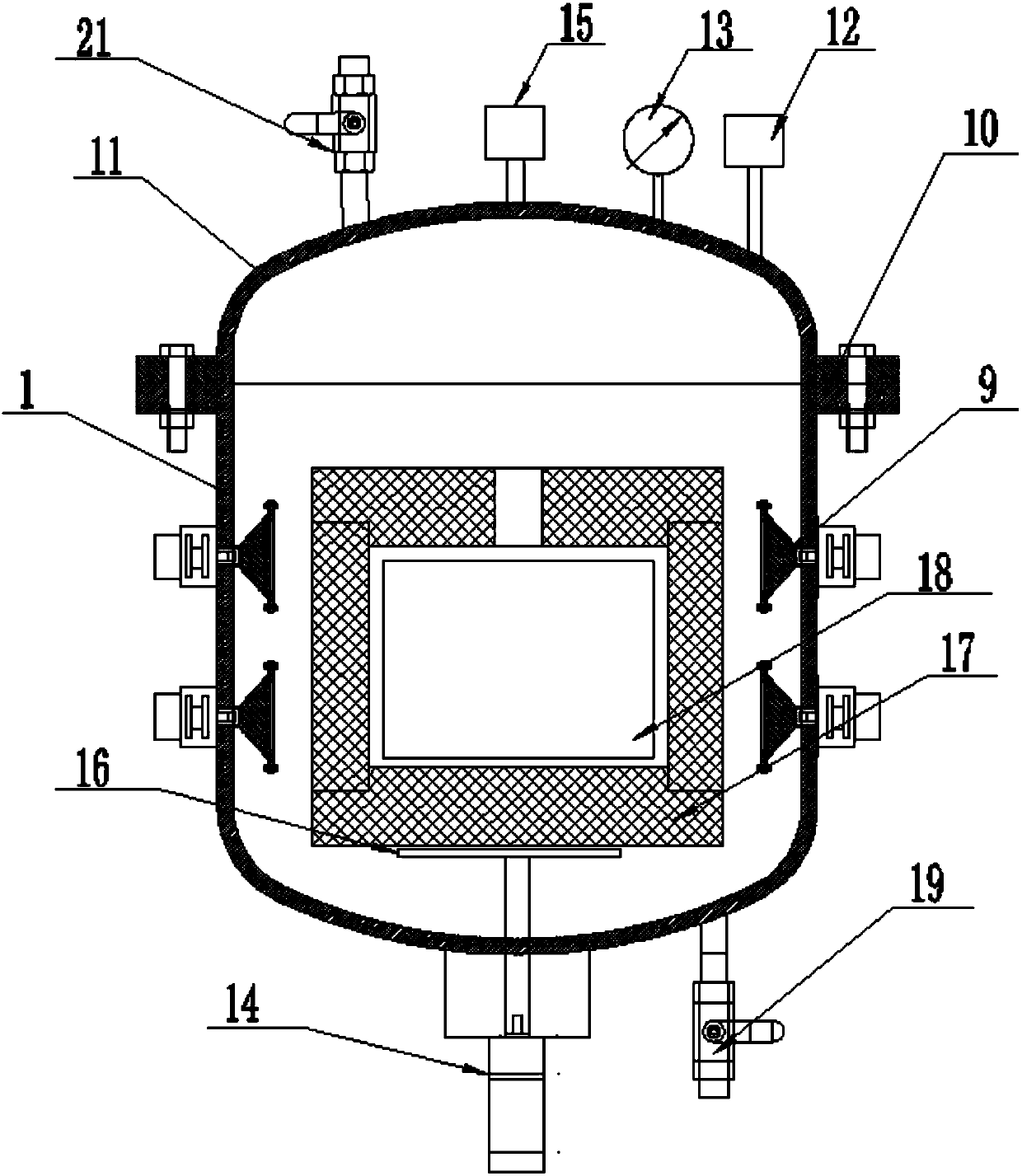

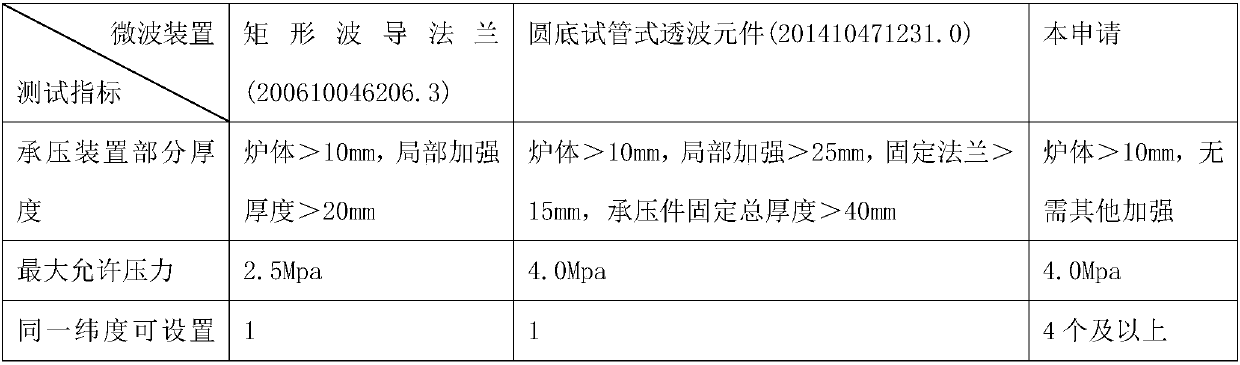

[0033] Such as figure 1 and figure 2 As shown, the present invention comprises a furnace body 1, a furnace cover 11 sealedly connected with the opening of the furnace body 1, a heat preservation device 17 and a microwave energy feeding device 9, and the microwave energy feeding device 9 includes a magnetron 2 and a microwave excitation feeding pressure bearing device;

[0034] The microwave excitation feeding pressure-bearing device includes a circular tube 3 arranged on the furnace body 1, a horn 20 located inside the furnace body 1, a conical pressure-bearing member 5 located in the cone 20, and a conical pressure-bearing member 5 that restricts the movement of the cone. The wave-transparent fixture 4;

[0035] The antenna 7 of the magnetron 2 is located in the circular tube 3, the antenna 7 and the circular tube 3 form a coaxial resonant cavity 8, and the coaxial resonant cavity 8 and the horn 20 form a microwave excitation device.

[0036] Both the furnace body 1 and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com