Preparation method of high adsorption flue gas demercuration adsorbent material

A high-adsorption, adsorbent technology, used in chemical instruments and methods, gas treatment, membrane technology, etc., can solve the problems of poor adsorption performance, large specific surface area of activated carbon, etc., to improve adsorption performance and load strength, excellent structure. performance, the effect of reducing the cost of preprocessing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

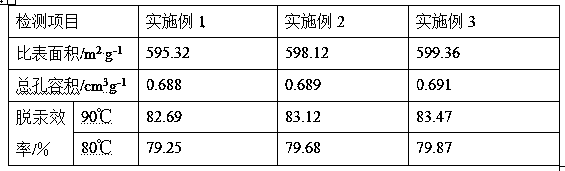

Embodiment 1

[0032] Take bamboo, cut and crush it into bamboo slices with a size of 10mm×1mm, wash them, dry them naturally, and place them in the pre-impregnation solution. After standing for 10 hours, collect the impregnated bamboo slices and place them in a filter press. Press at 25°C and 6MPa until the moisture content of the impregnated bamboo chips is 35%, and the filter bamboo chips are obtained and placed in a steam explosion equipment, and the steam explosion treatment is performed at a pressure of 1.25MPa for 3 minutes. Centrifuge for 10 min under min, collect the lower sediment and rinse with deionized water and wash until the pH of the liquid extruded from the filter press is neutral, then dry to obtain pretreated bamboo fiber; weigh 45 parts by weight and the pH is 4.8 Sodium acetate buffer solution, 10 parts of pretreated bamboo fiber and 25 parts of deionized water were mixed to obtain a base liquid, and cellulase was added to the base liquid at 50 U / g, stirred and mixed, and...

Embodiment 2

[0034] Take bamboo, cut and crush it into bamboo pieces with a size of 10mm×1mm, wash them, dry them naturally and put them in the pre-impregnation solution. After standing for 11 hours, collect the impregnated bamboo pieces and put them in a filter press. Press at 27°C and 7MPa until the moisture content of the impregnated bamboo chips is 37%, and the filter bamboo chips are obtained and placed in the steam explosion equipment, and the steam explosion treatment is performed at a pressure of 1.37MPa for 4 minutes. Centrifuge for 13 minutes under min, collect the lower precipitate and rinse with deionized water and wash until the pH of the liquid extruded from the filter press is neutral, then dry to obtain pretreated bamboo fiber; weigh 47 parts with a pH of 4.8 respectively Sodium acetate buffer solution, 13 parts of pretreated bamboo fiber and 27 parts of deionized water were mixed to obtain a base liquid, and cellulase was added to the base liquid at 50 U / g, stirred and mixe...

Embodiment 3

[0036] Take bamboo, cut and crush it into bamboo slices with a size of 10 mm × 1 mm, wash them, dry them naturally and place them in the pre-impregnation solution. After standing for 12 hours, collect the impregnated bamboo slices and place them in a filter press. Press at 30°C and 8MPa until the moisture content of the impregnated bamboo chips is 38%, and then filter the bamboo chips and put them in the steam explosion equipment. The pressure is 1.5MPa for steam explosion treatment for 5 minutes. Centrifuge for 15 minutes under min, collect the lower precipitate and rinse with deionized water and wash until the pH of the liquid extruded from the filter press is neutral, and then dry to obtain pretreated bamboo fiber; weigh 50 parts by weight and the pH is 4.8 Sodium acetate buffer solution, 15 parts of pretreated bamboo fiber and 30 parts of deionized water were mixed to obtain a base liquid, and cellulase was added to the base liquid at 50 U / g, stirred and mixed, and placed a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com