Patents

Literature

280 results about "Bearing design" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

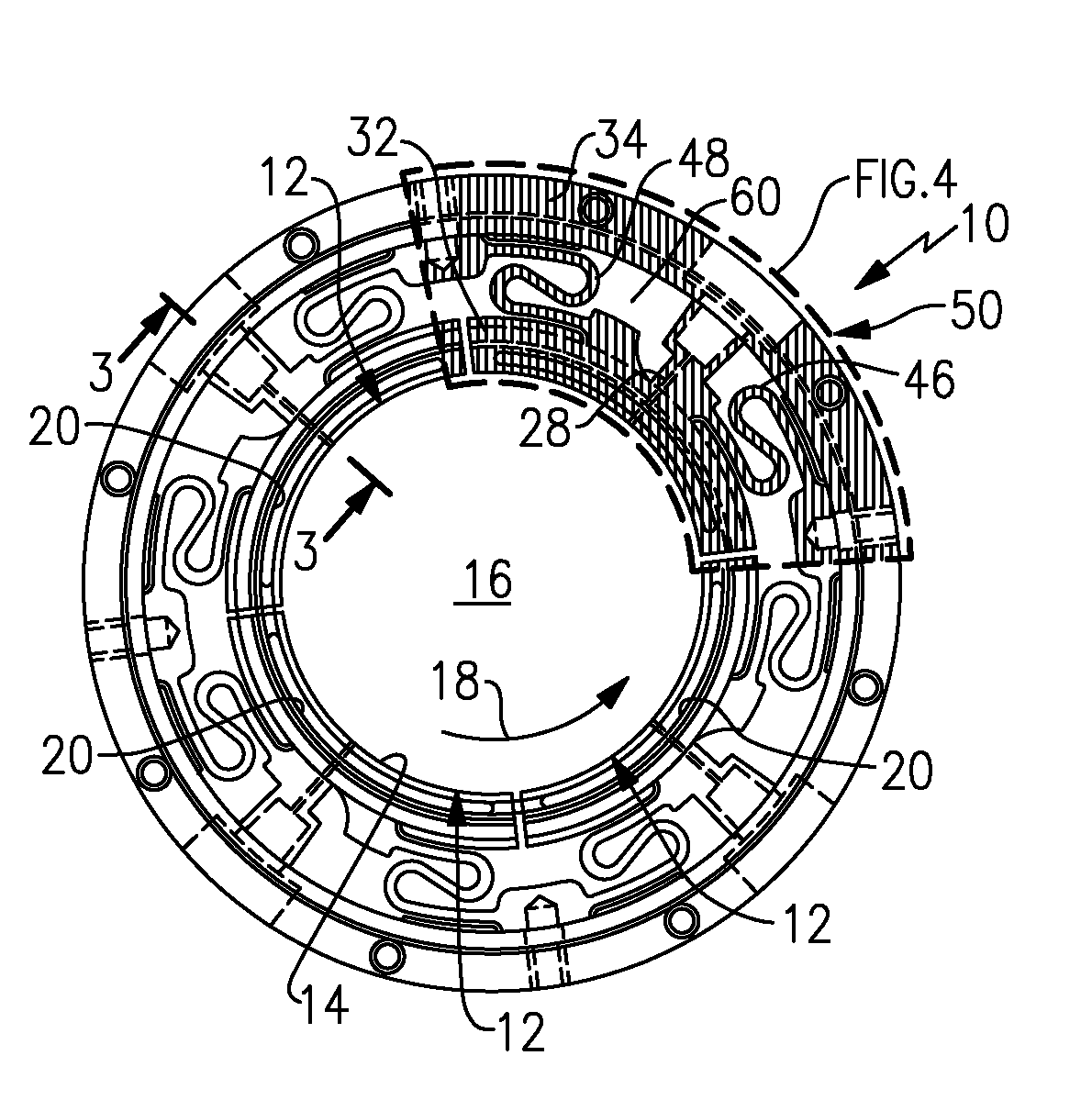

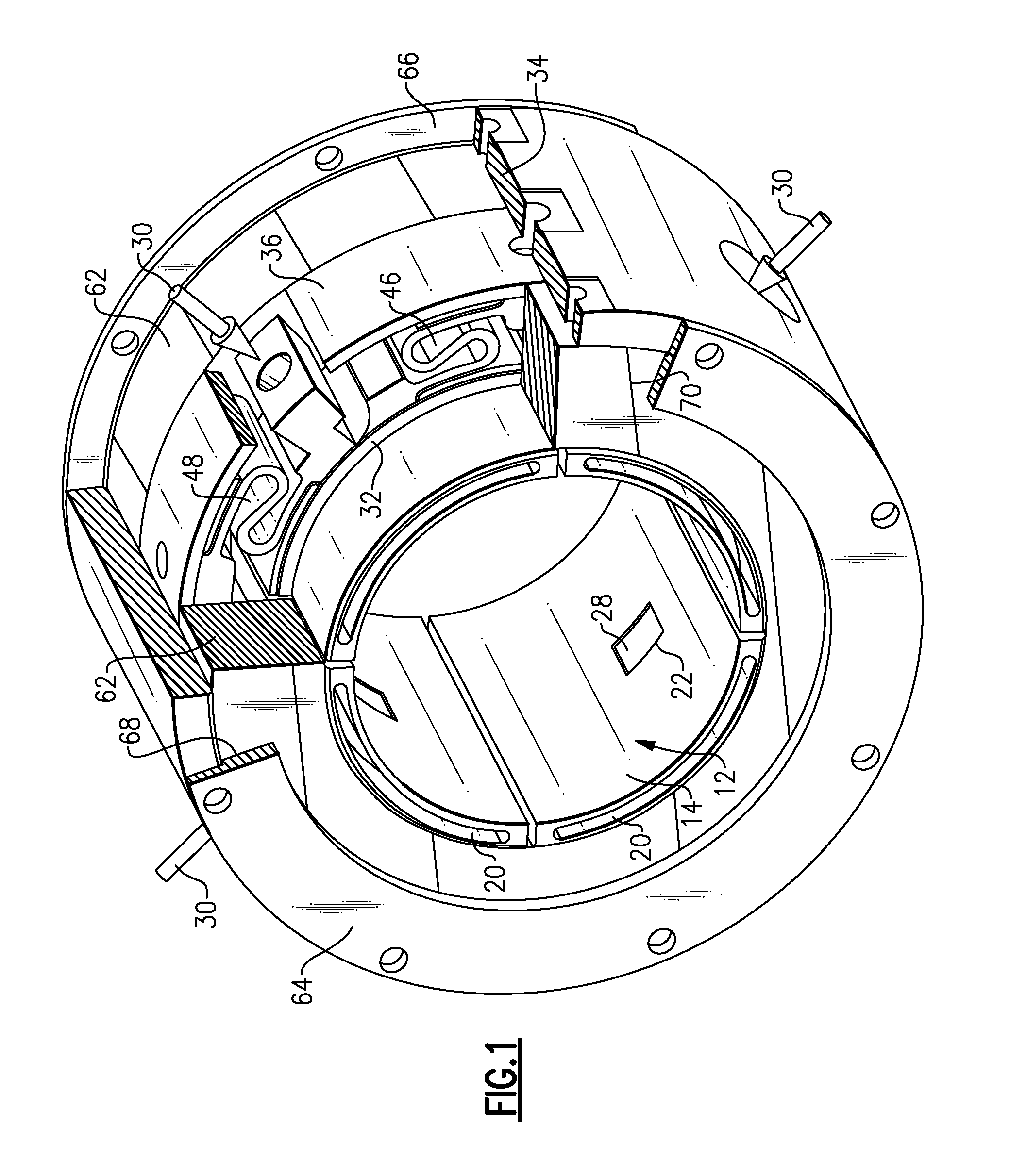

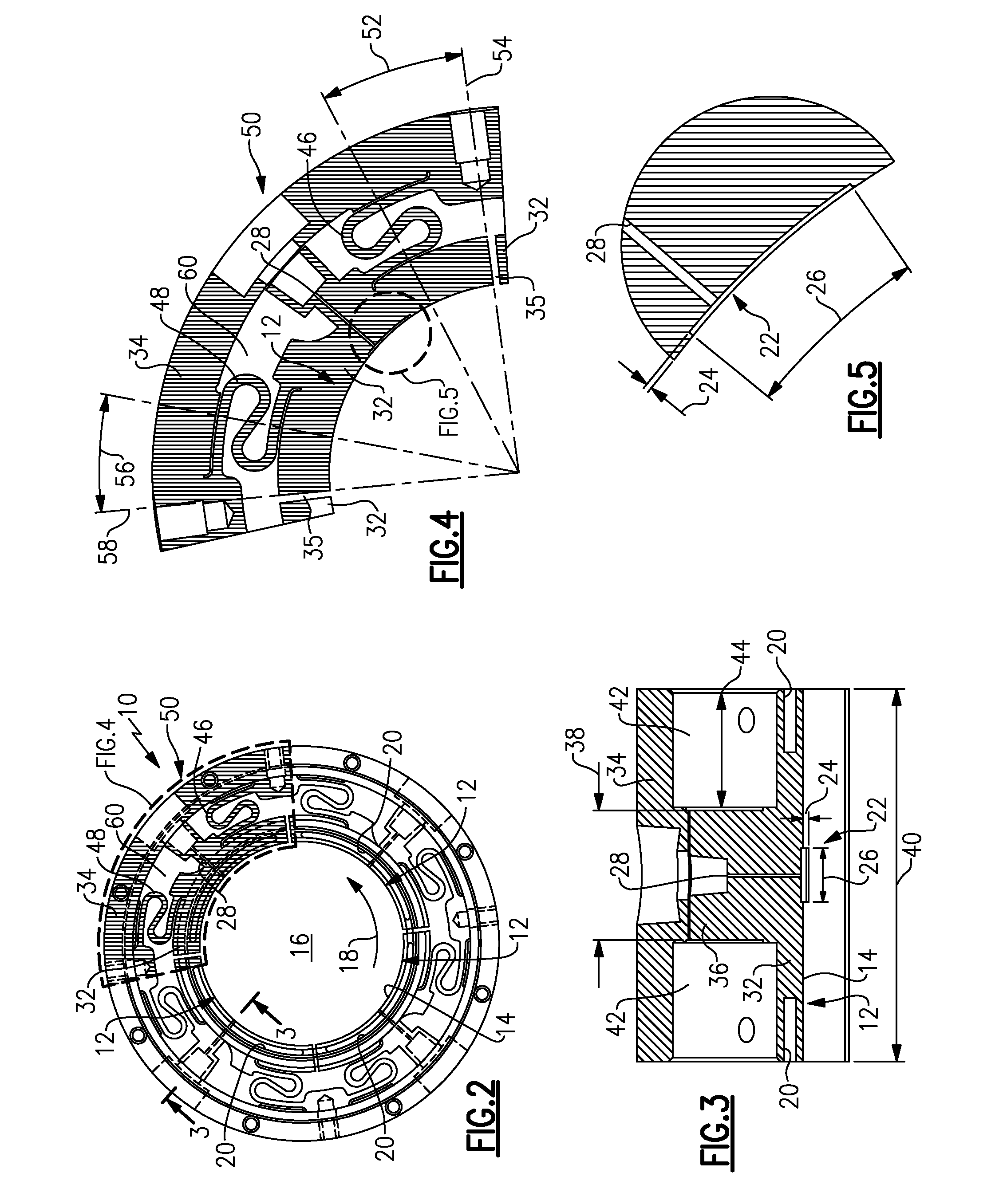

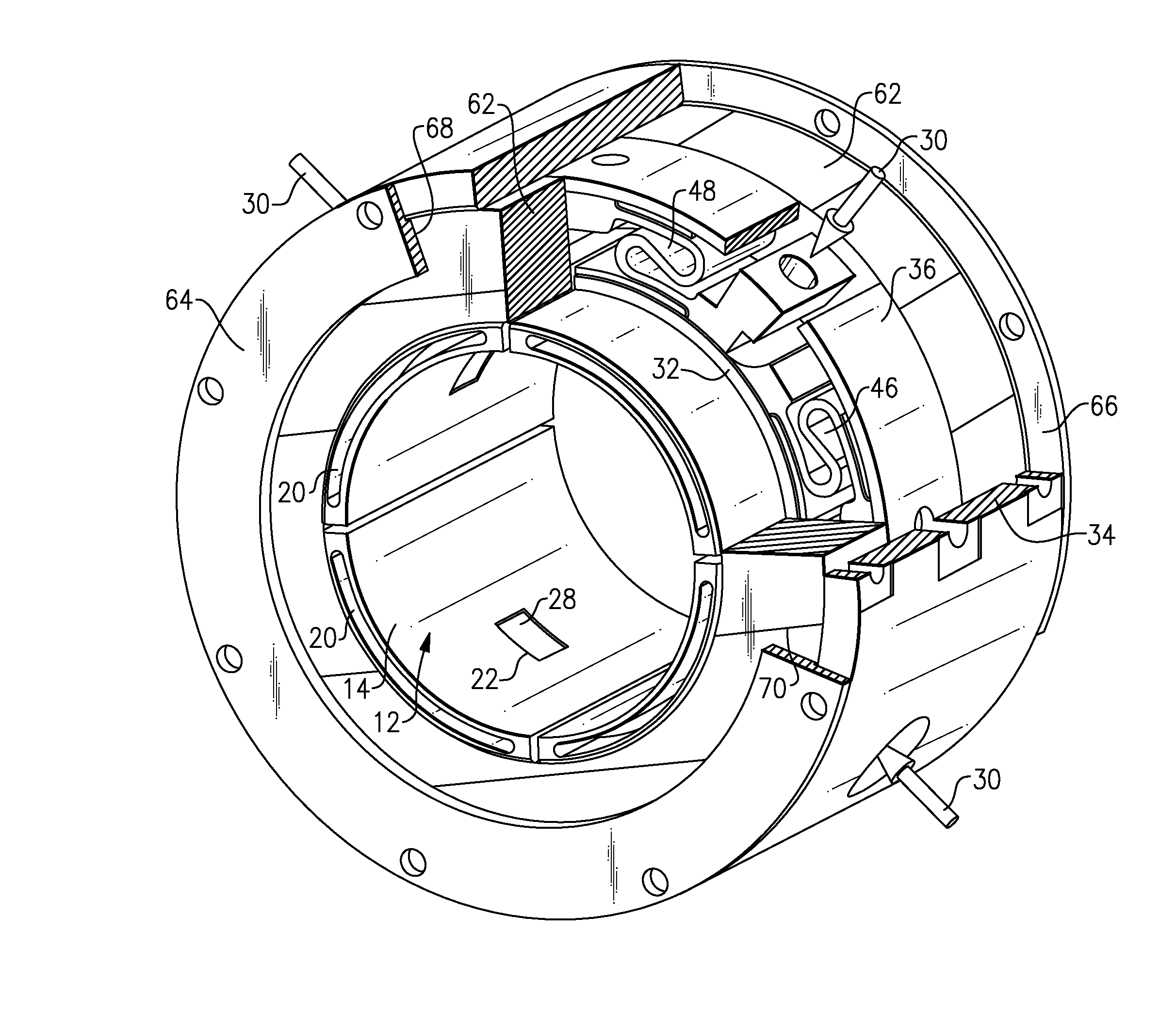

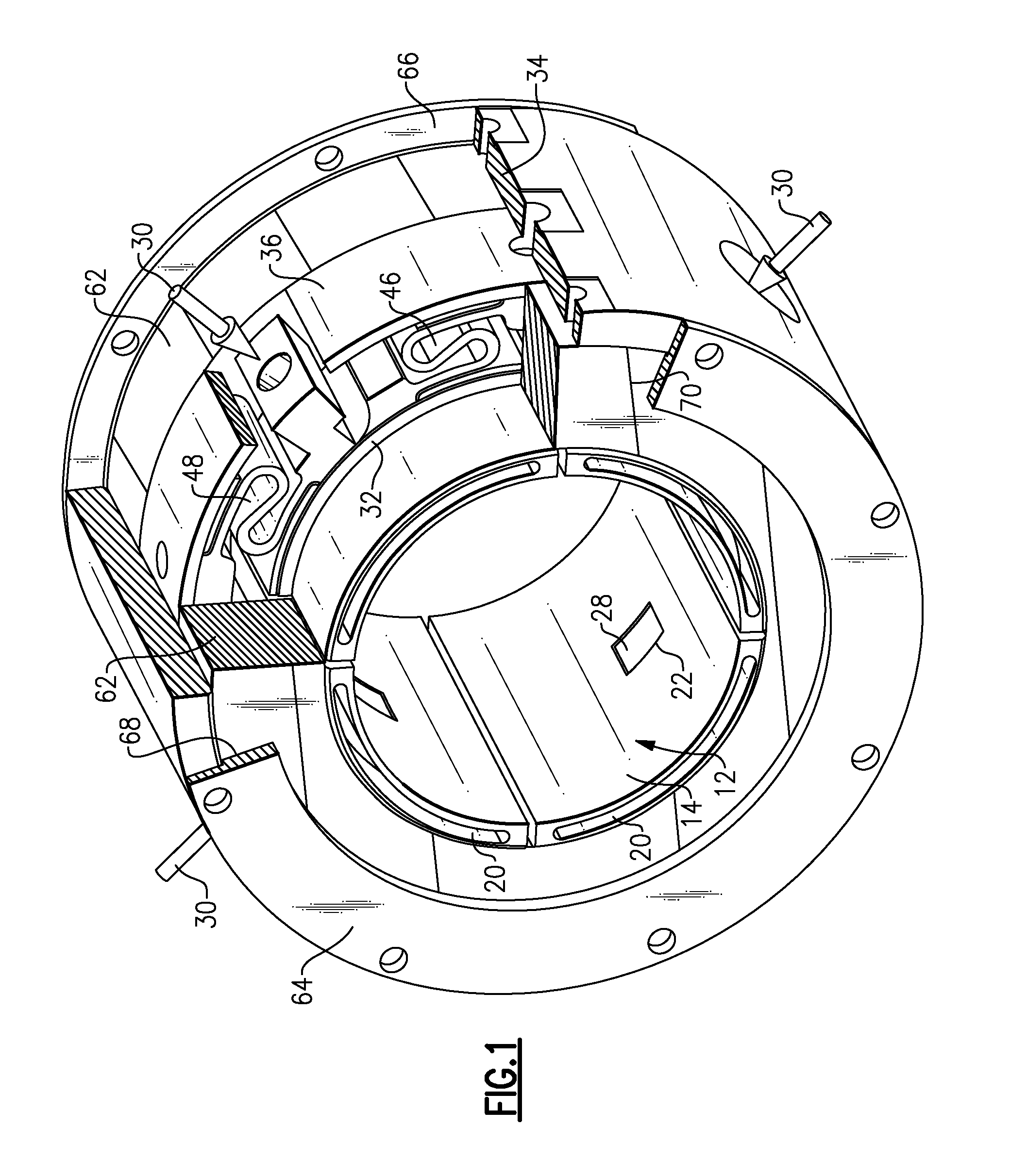

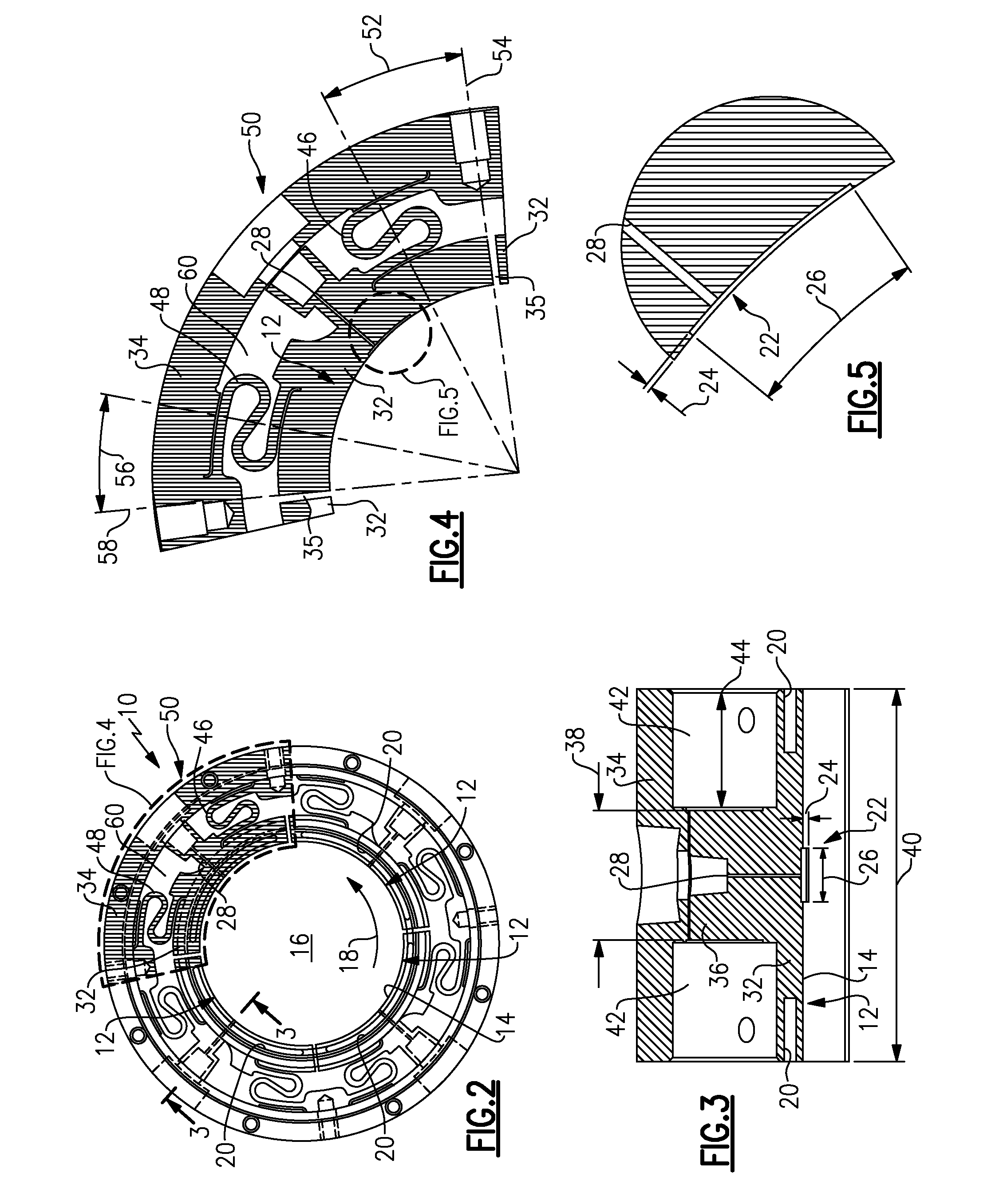

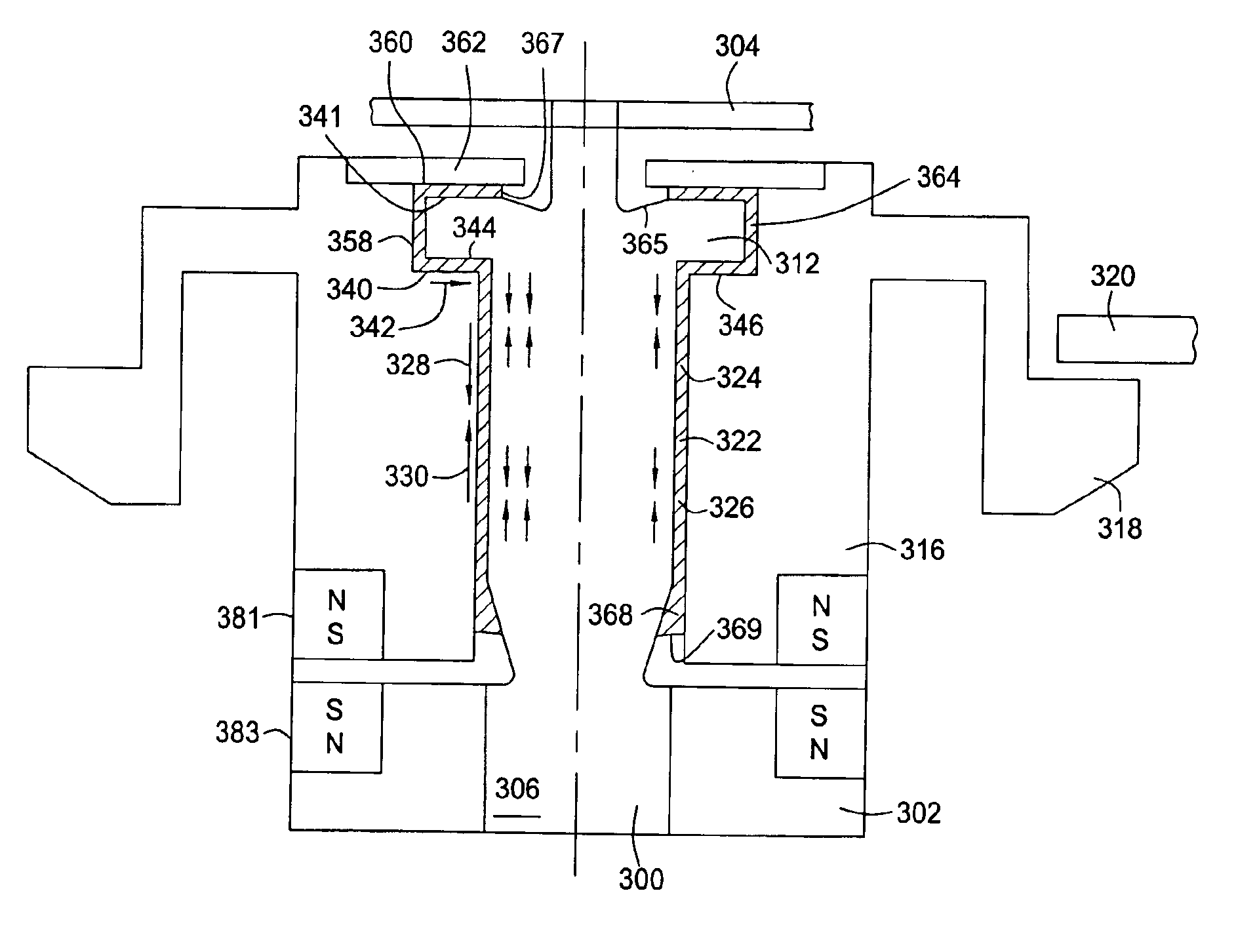

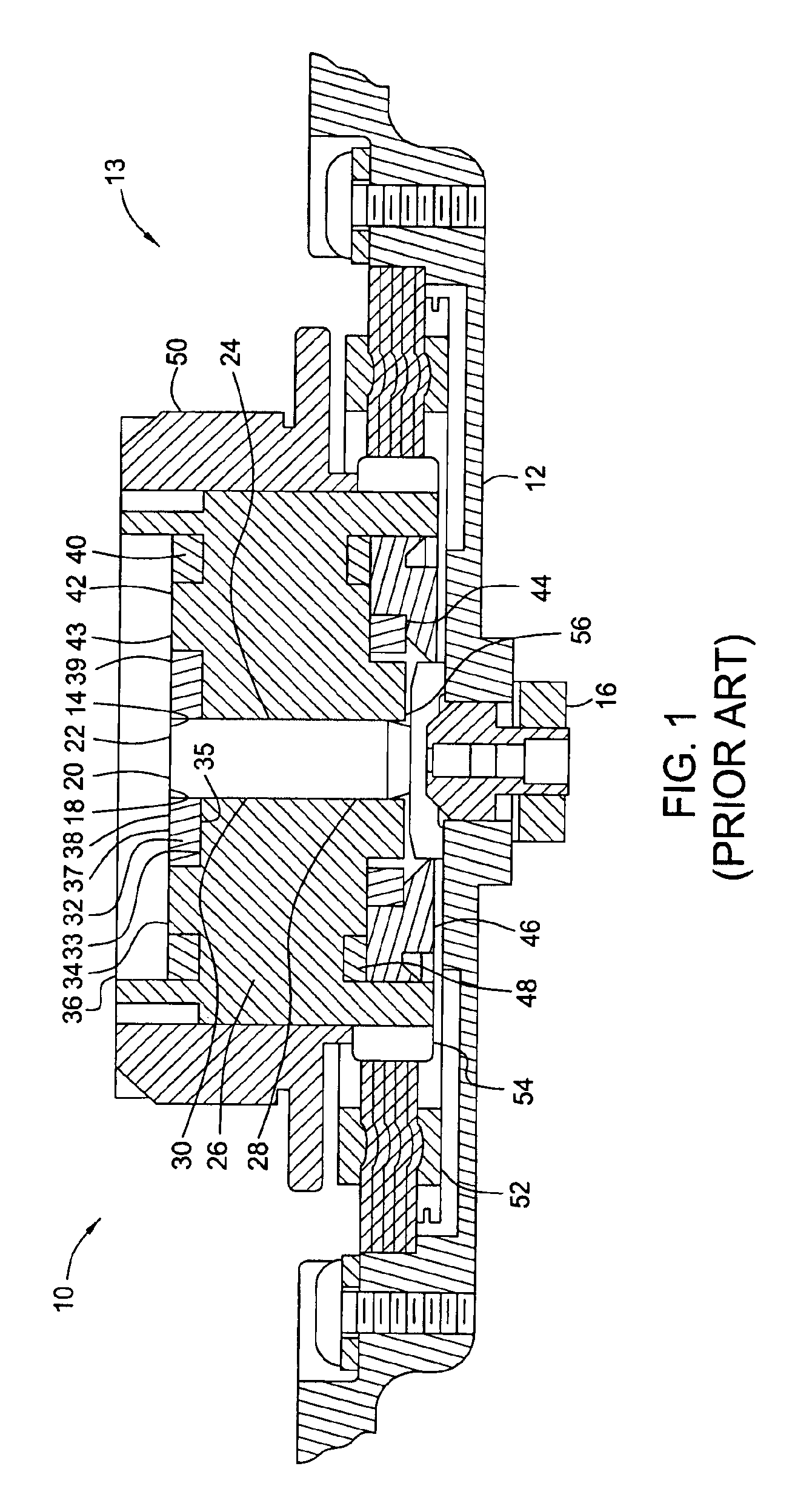

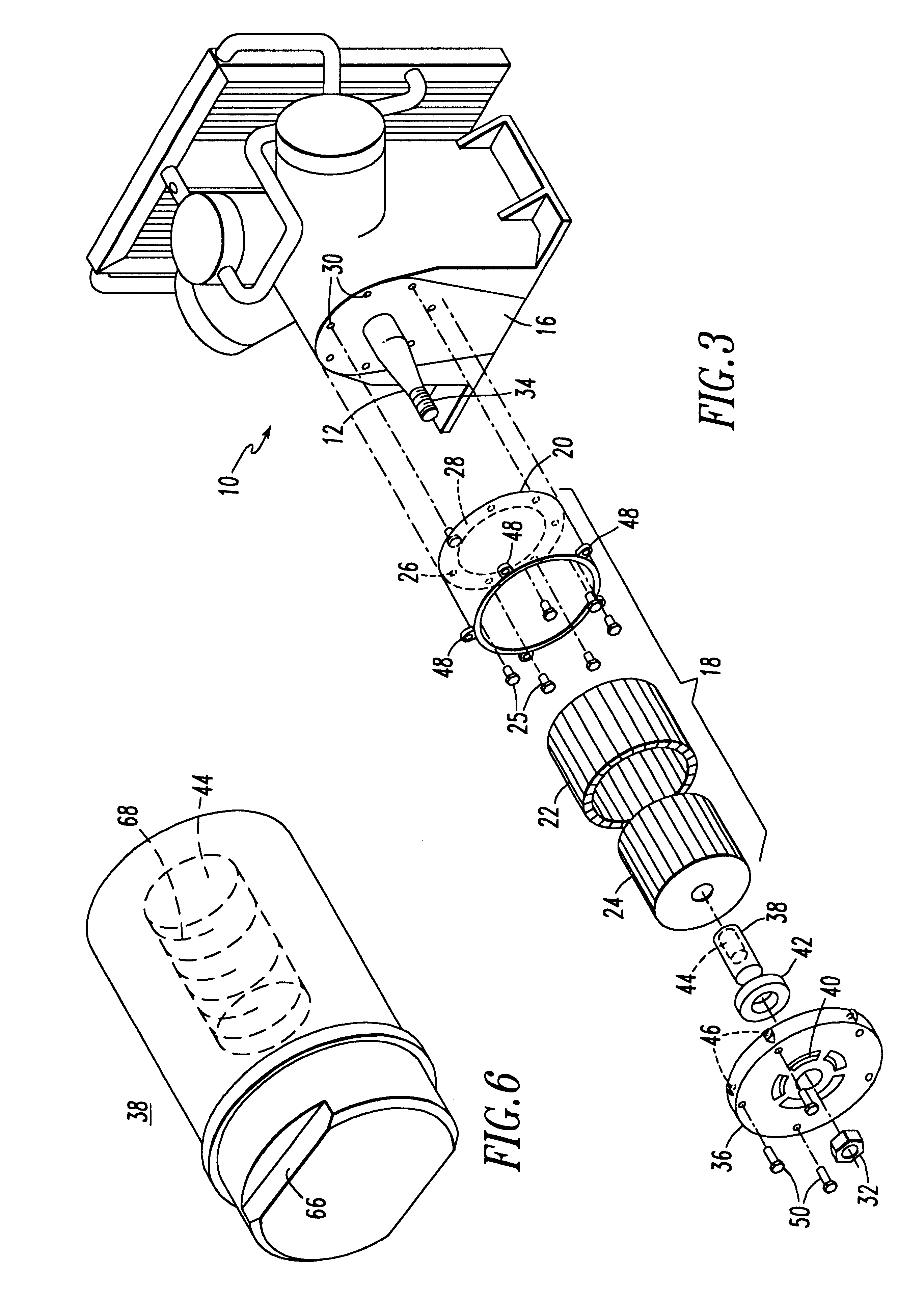

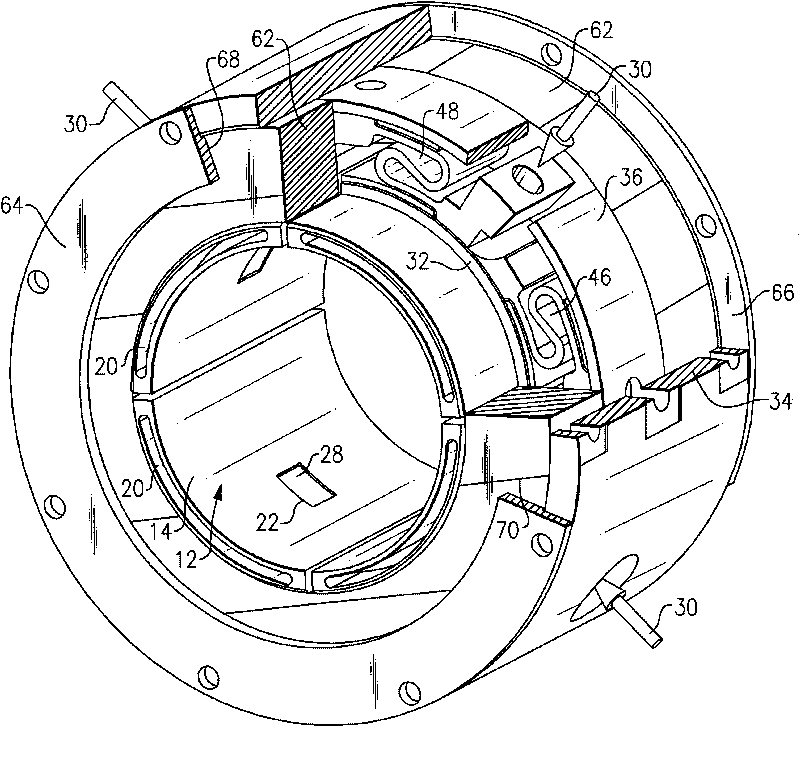

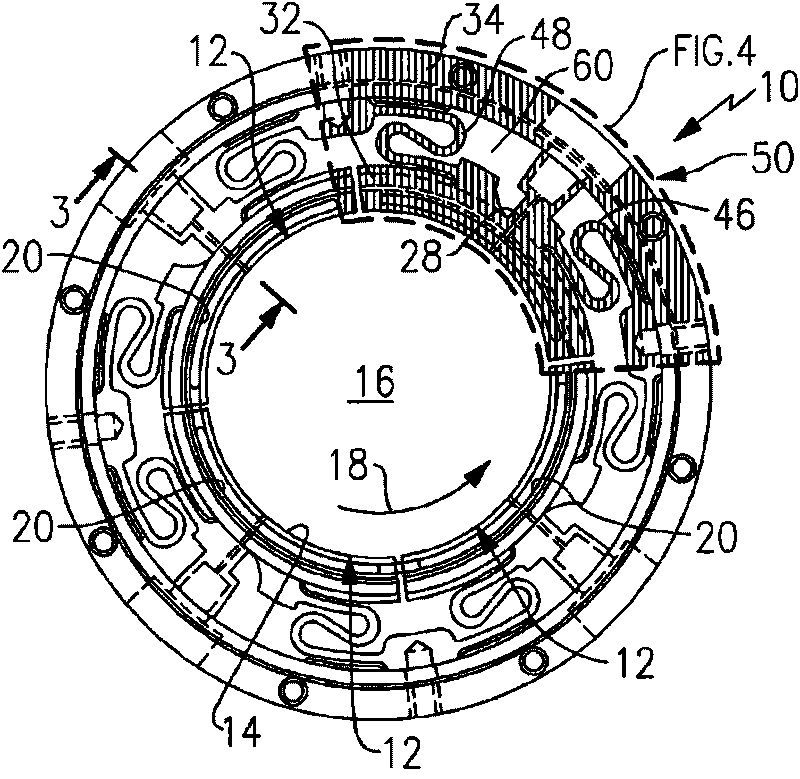

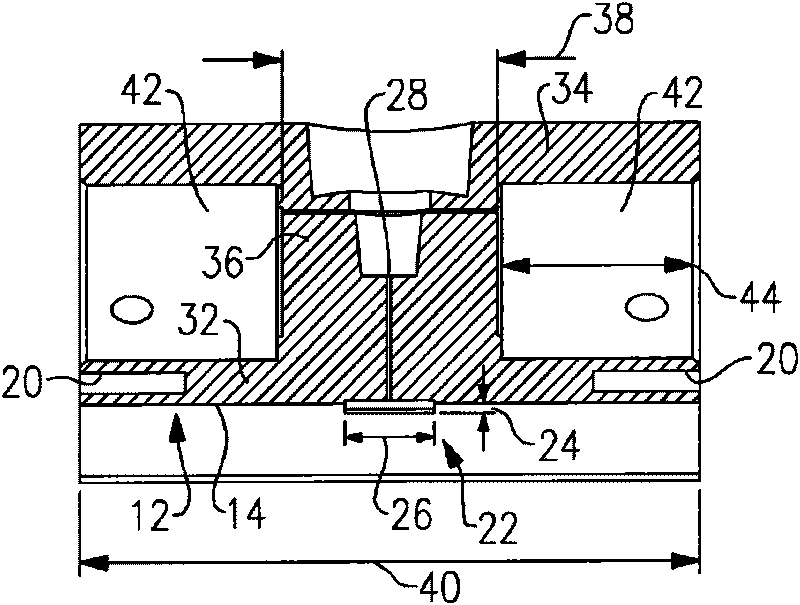

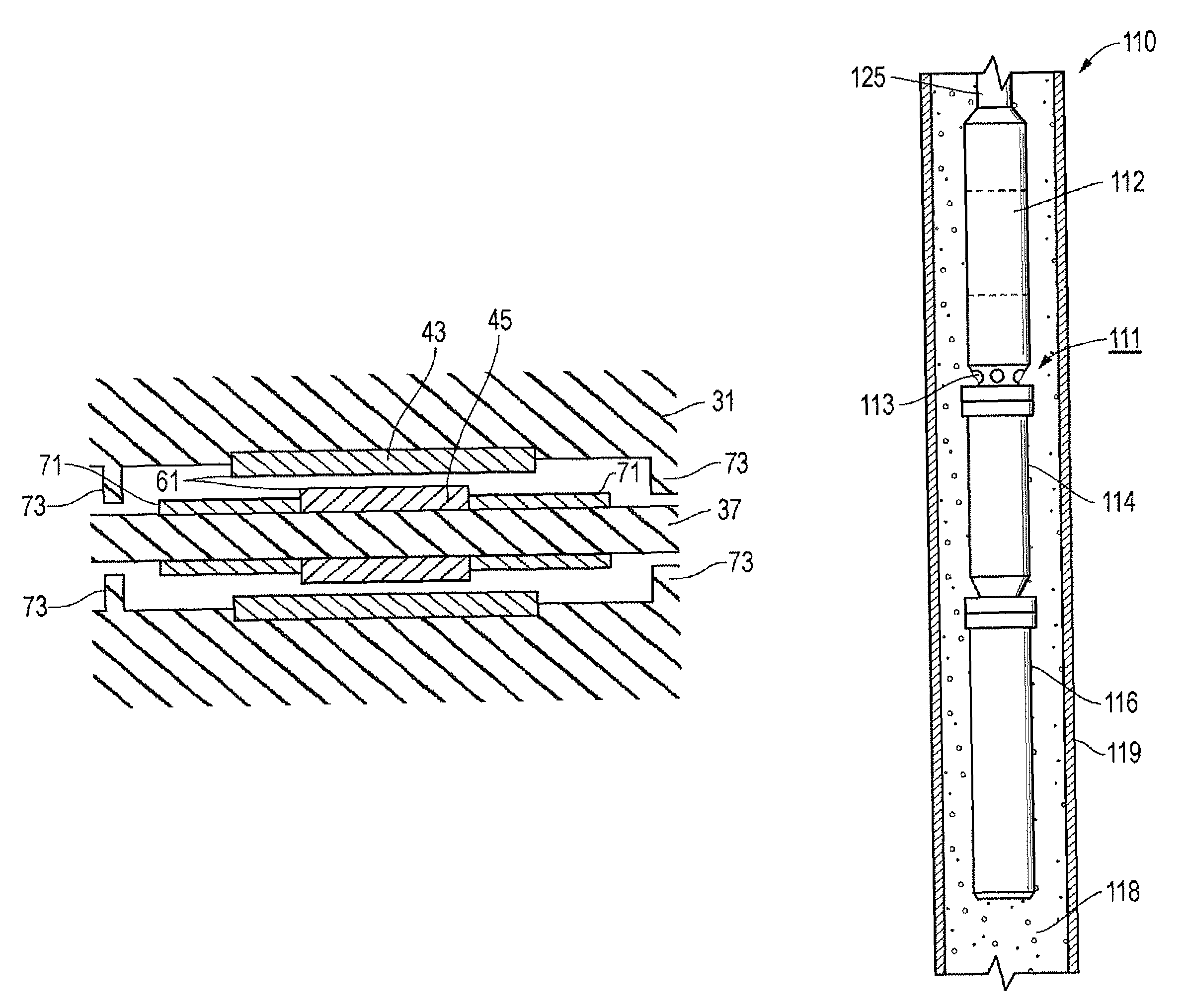

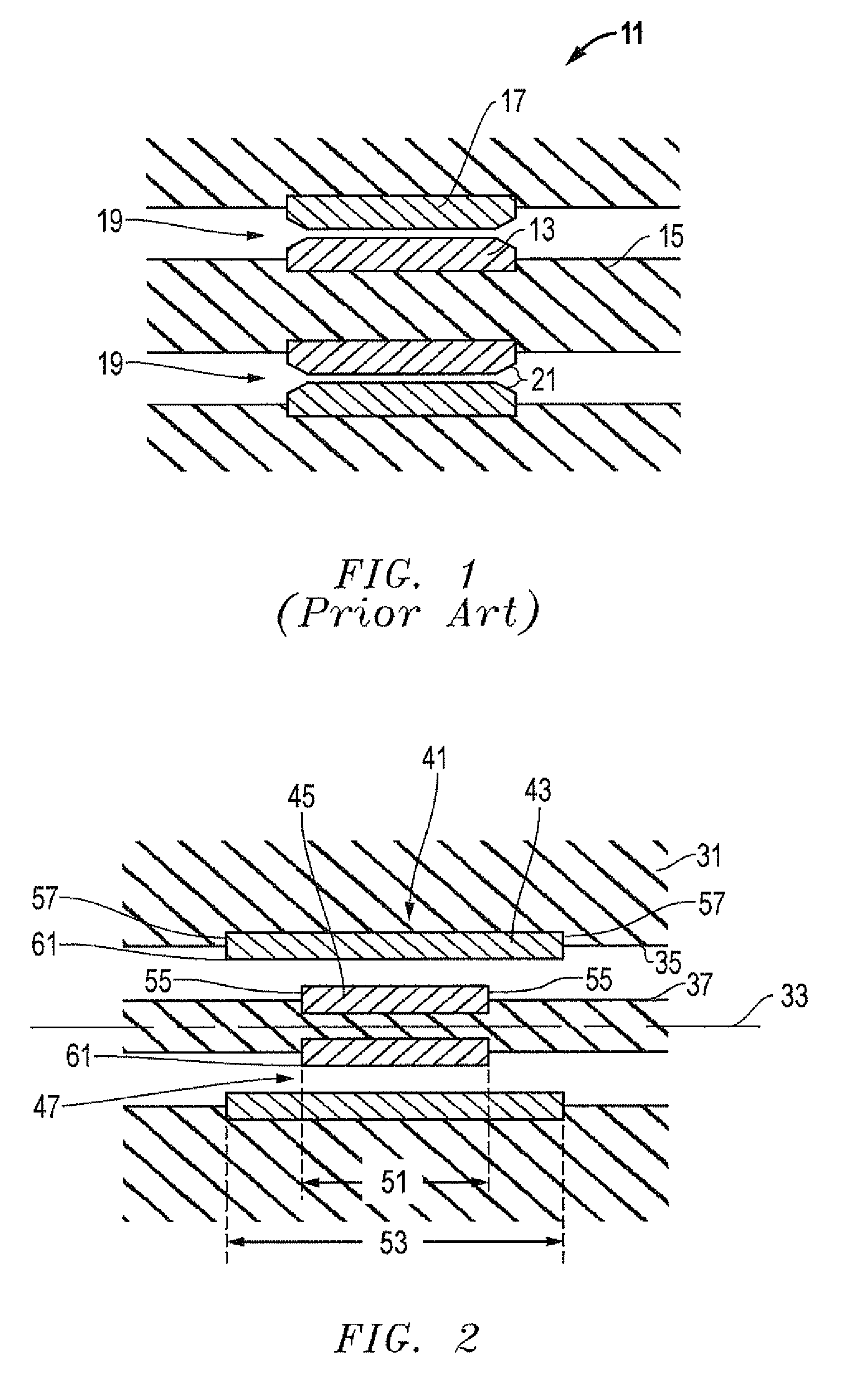

Compliant hybrid gas journal bearing using integral wire mesh dampers

A compliant hybrid gas journal bearing includes compliant hybrid bearing pads having a hydrostatic recess and a capillary restrictor for providing a flow of pressurized gas to the bearing. The bearing also includes an inner rim adjacent the bearing pads, an outer rim and a damper bridge between the inner and outer rims. The damper bridge has an axial length that is less than an axial length of the bearing pads and the outer rim to form a damper cavity on each side of the damper bridge. An integral wire mesh damper is situated within the damper cavity on each side of the damper bridge. Integral centering springs are located between the inner and outer rims to provide radial and rotational compliance to the bearing pads. The oil-free bearing design addresses the low damping and low load capacity characteristics that are inherent in present day compliant air foil bearing designs, while retaining the compliance to changes in rotor geometry.

Owner:GENERAL ELECTRIC CO

Compliant hybrid gas journal bearing using integral wire mesh dampers

A compliant hybrid gas journal bearing includes compliant hybrid bearing pads having a hydrostatic recess and a capillary restrictor for providing a flow of pressurized gas to the bearing. The bearing also includes an inner rim adjacent the bearing pads, an outer rim and a damper bridge between the inner and outer rims. The damper bridge has an axial length that is less than an axial length of the bearing pads and the outer rim to form a damper cavity on each side of the damper bridge. An integral wire mesh damper is situated within the damper cavity on each side of the damper bridge. Integral centering springs are located between the inner and outer rims to provide radial and rotational compliance to the bearing pads. The oil-free bearing design addresses the low damping and low load capacity characteristics that are inherent in present day compliant air foil bearing designs, while retaining the compliance to changes in rotor geometry.

Owner:GENERAL ELECTRIC CO

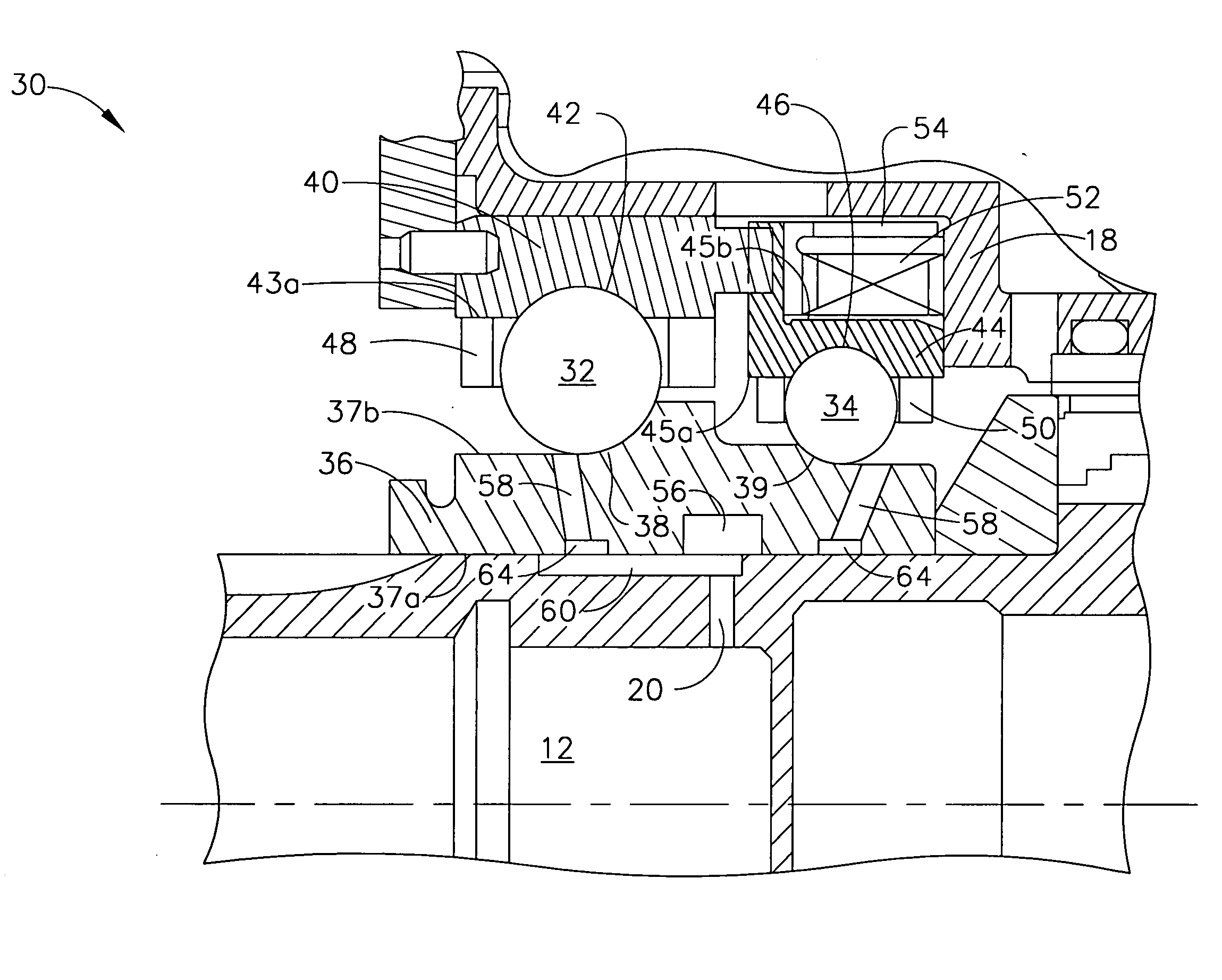

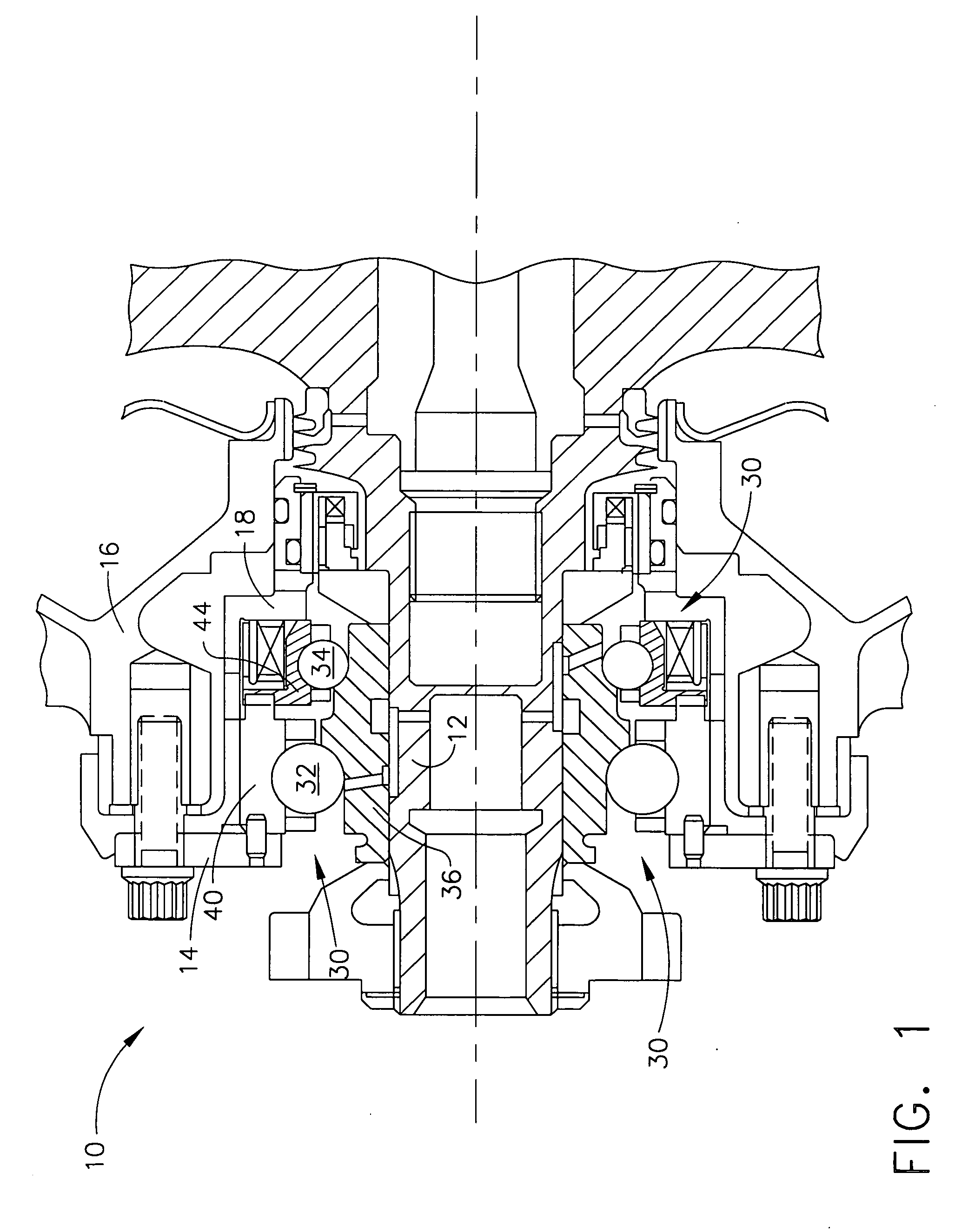

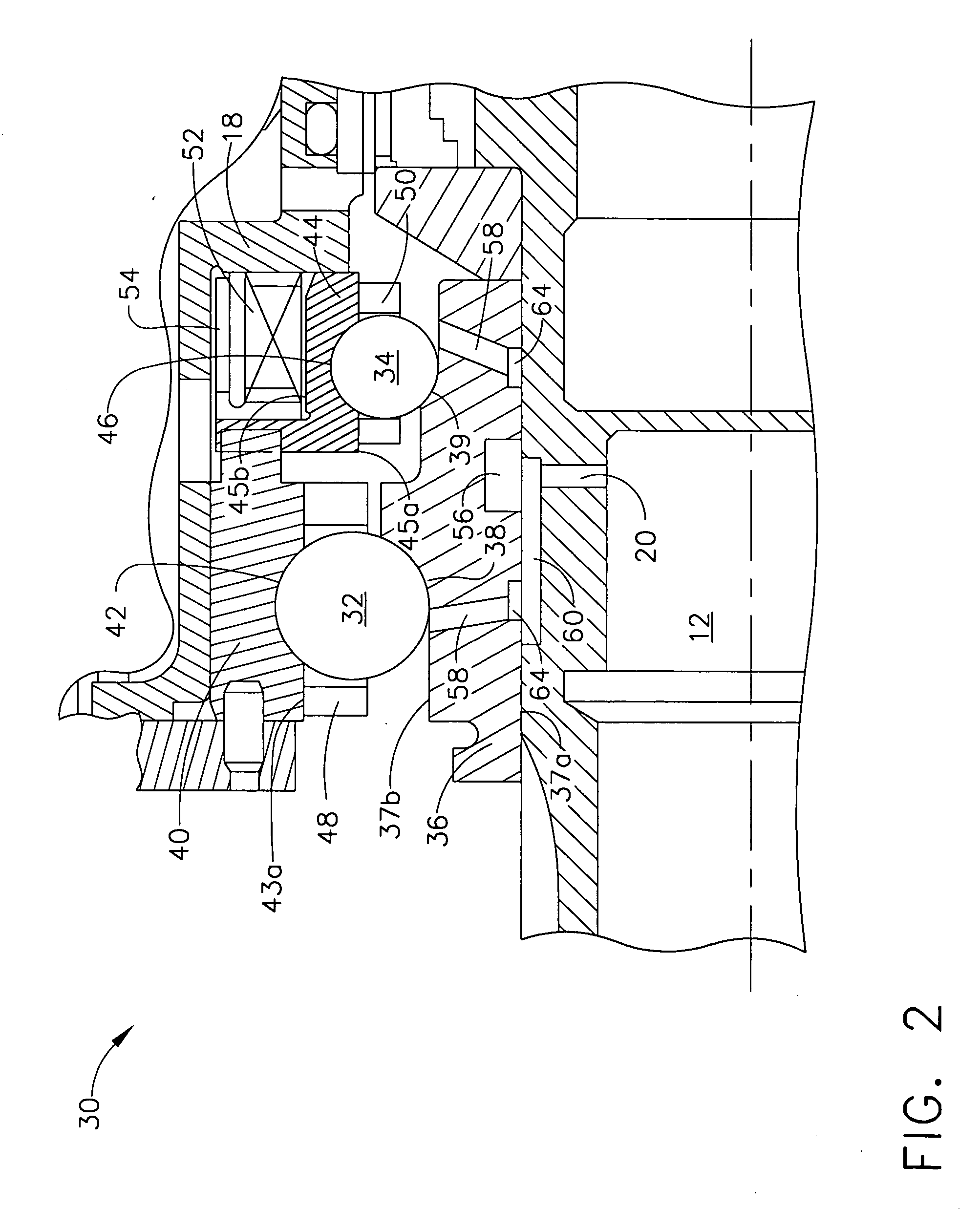

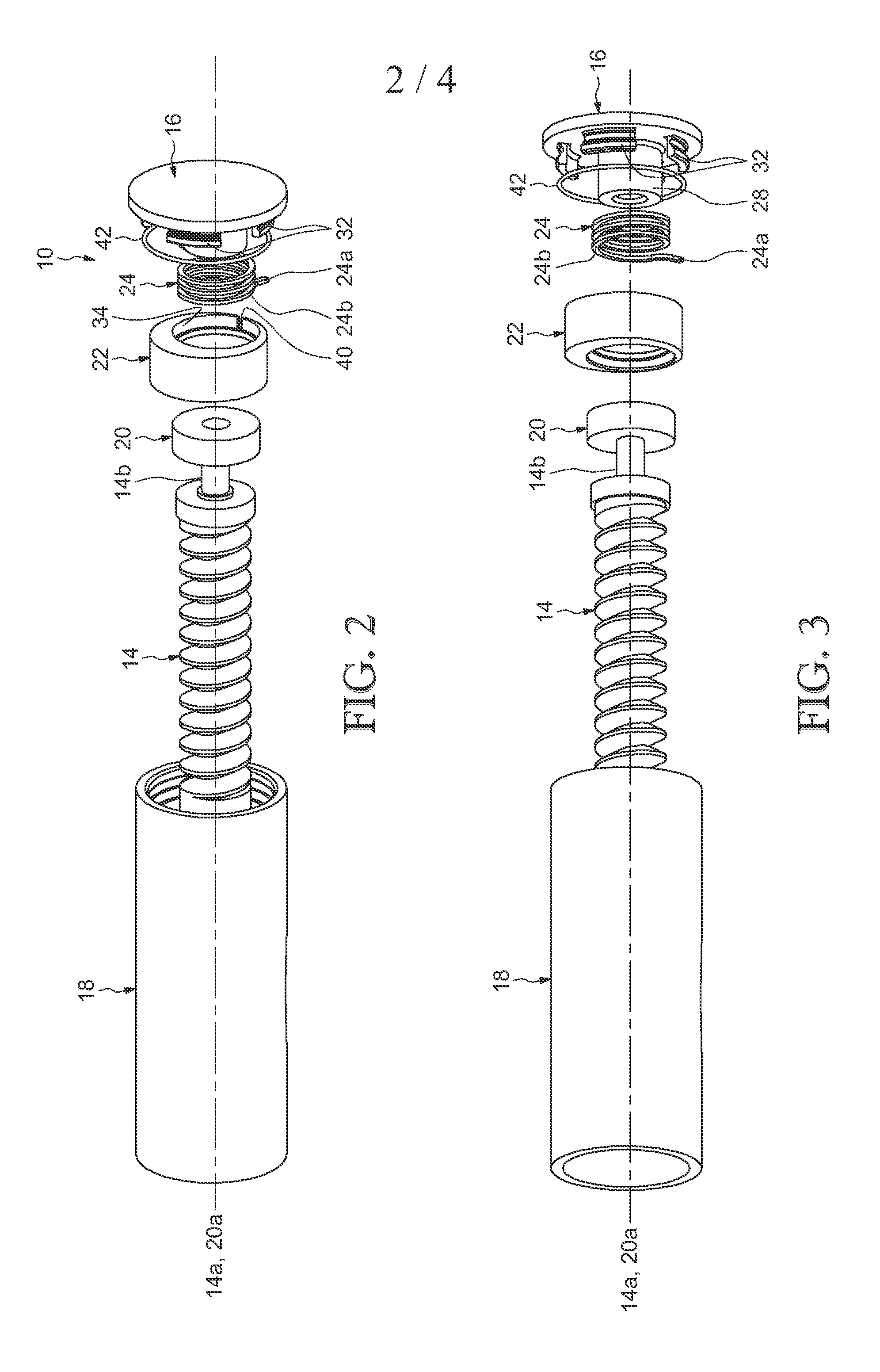

Bearing system for a turbocharger

ActiveUS7189005B2Easy to assembleReduce friction and wearEngine fuctionsShaftsTurbochargerStructural engineering

A bearing system for a turbocharger, simple in design and easy to manufacture, having desired rotational dynamics of a three piece bearing design, yet having the superior vibration damping characteristics of a one piece bearing design. The inboard end of each journal bearing includes an axial recess for receiving an outboard end of a cylindrical bearing spacer, thereby axially locating the journal bearings as well as axially and radially locating the bearing spacer.

Owner:BORGWARNER INC

Preloaded duplex ball bearing design

A bearing assembly comprising a centrifugal debris trap for removing contamination debris from lubrication fluid prior to lubrication of the bearing assembly components is provided. The centrifugal debris trap comprises an annular groove on an inner race such that with sufficient centrifugal force, contamination debris in the lubrication oil is forced into the groove and held there. Removal of contamination debris from the lubrication oil prevents damage to bearing balls and races of the bearing assembly, thus reducing bearing fatigue. A method for lubricating bearing assembly components using the bearing assembly of the present invention is also provided.

Owner:HONEYWELL INT INC

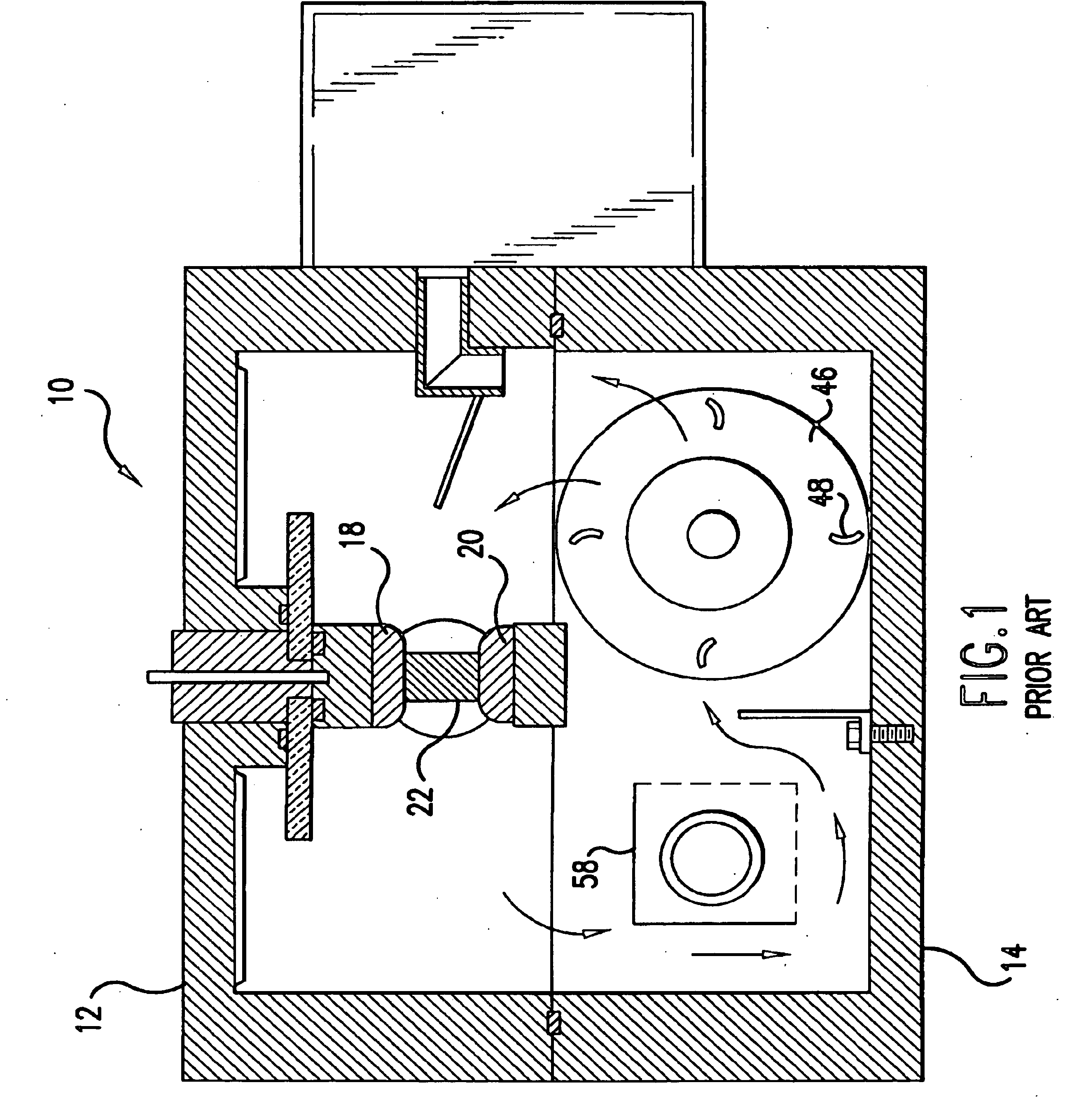

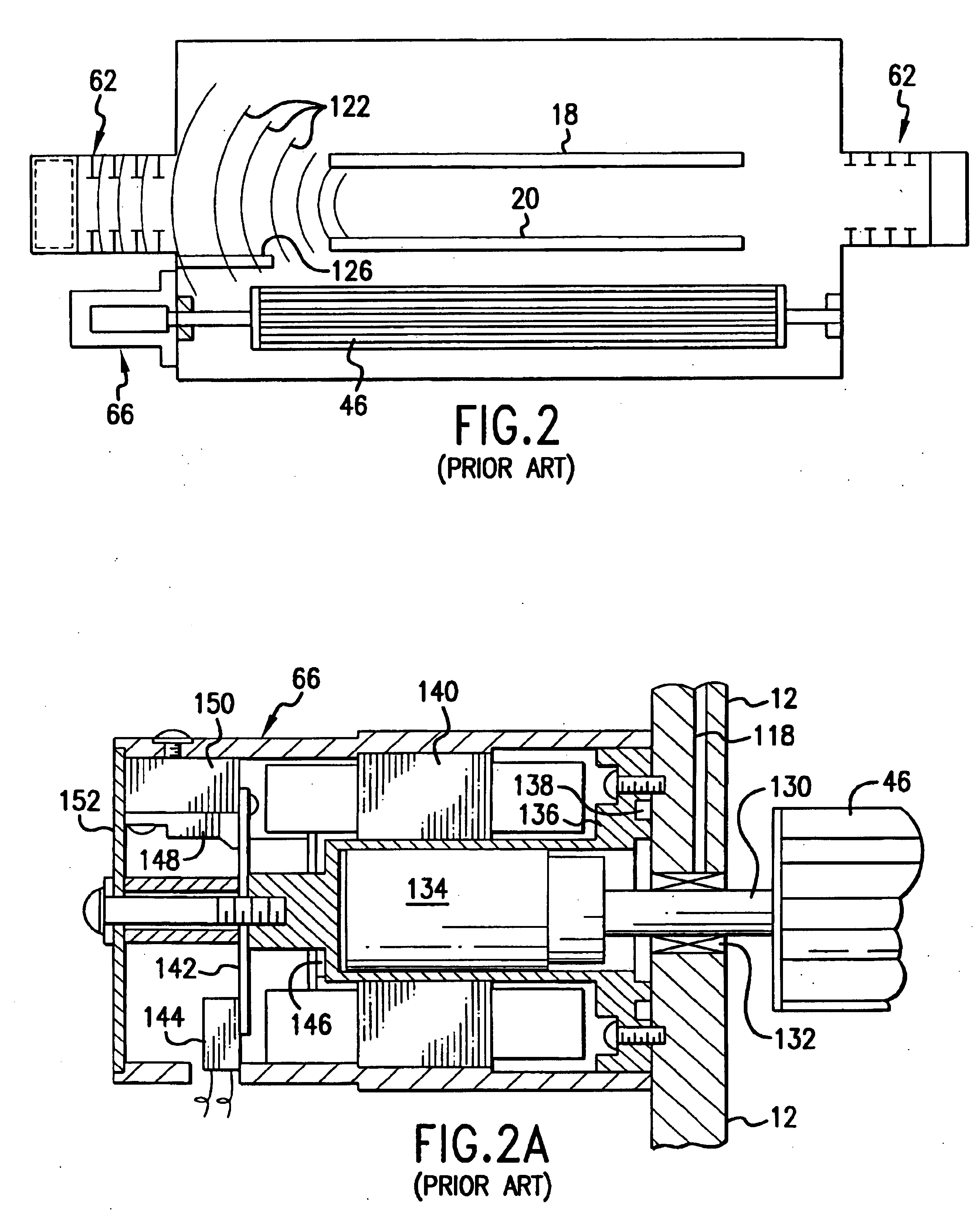

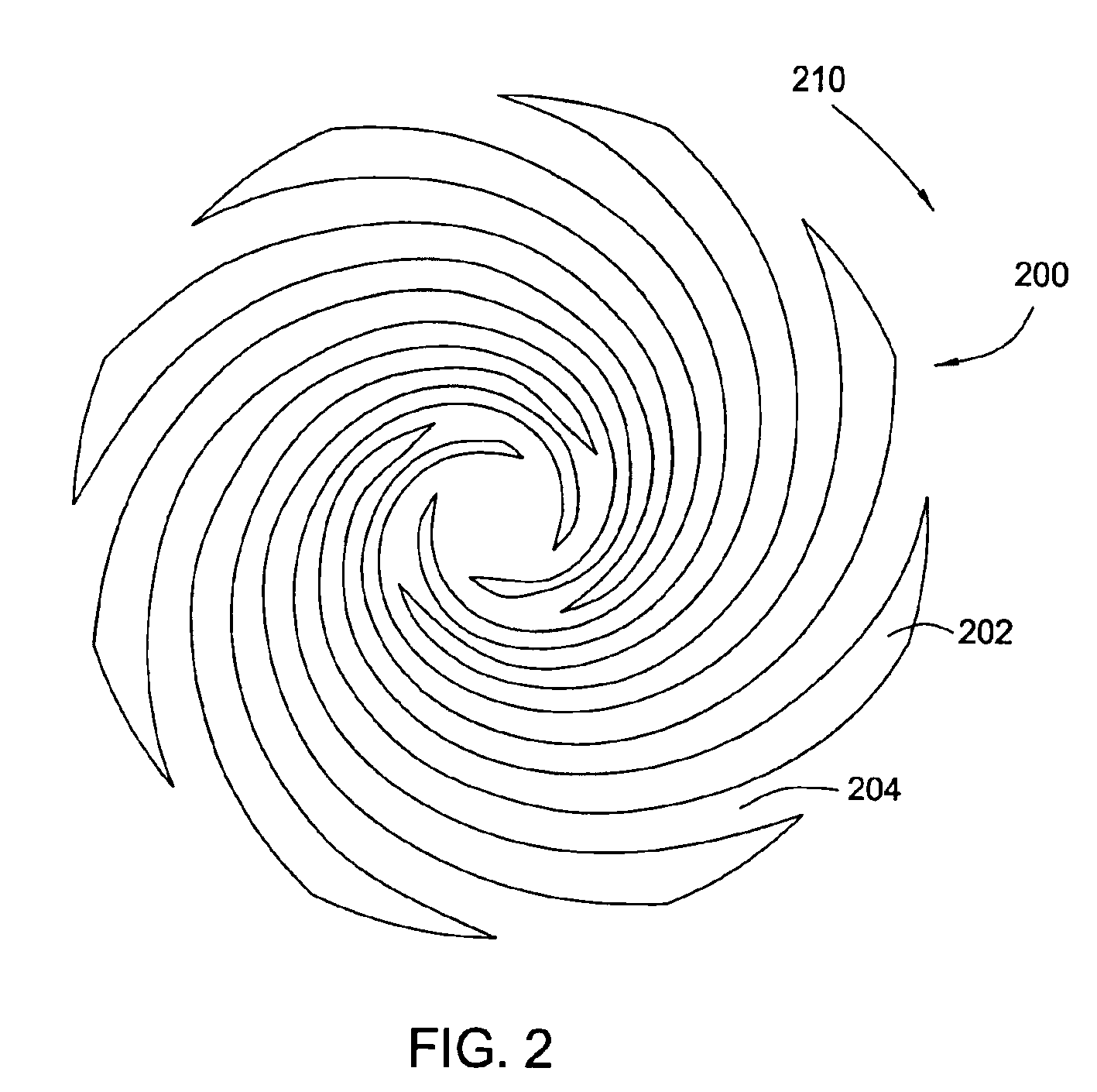

Six to ten KHz, or greater gas discharge laser system

InactiveUS6914919B2Reliable long-term operationSpeed up the gas flowOptical resonator shape and constructionLaser arrangementsMagnetic bearingSystems design

The present invention provides gas discharge laser systems capable of reliable long-term operation in a production line capacity at repetition rates in the range of 6,000 to 10,0000 pulses power second. Preferred embodiments are configured as KrF, ArF and F2 lasers used for light sources for integrated circuit lithography. Improvements include a modified high voltage power supply capable for charging an initial capacitor of a magnetic compression pulse power system to precise target voltages 6,000 to 10,0000 times per second and a feedback control for monitoring pulse energy and determining the target voltages on a pulse-by-pulse basis. Several techniques are disclosed for removing discharge created debris from the discharge region between the laser electrodes during the intervals between discharges. In one embodiment the width of the discharge region is reduced from about 3 mm to about 1 mm so that a gas circulation system designed for 4,000 Hz operation could be utilized for 10,000 Hz operation. In other embodiments the gas flow between the electrodes is increased sufficiently to permit 10,000 Hz operation with a discharge region width of 3 mm. To provide these substantial increased gas flow rates, Applicants have disclosed preferred embodiments utilize tangential forms of the prior art but with improved and more powerful motors and novel bearing designs. New bearing designs include both ceramic bearings and magnetic bearings. In other embodiments, some or all of the gas circulation power is provided with a blower located outside the laser chamber. The outside blower can be located in the laser cabinet or in separate location.

Owner:CYMER INC

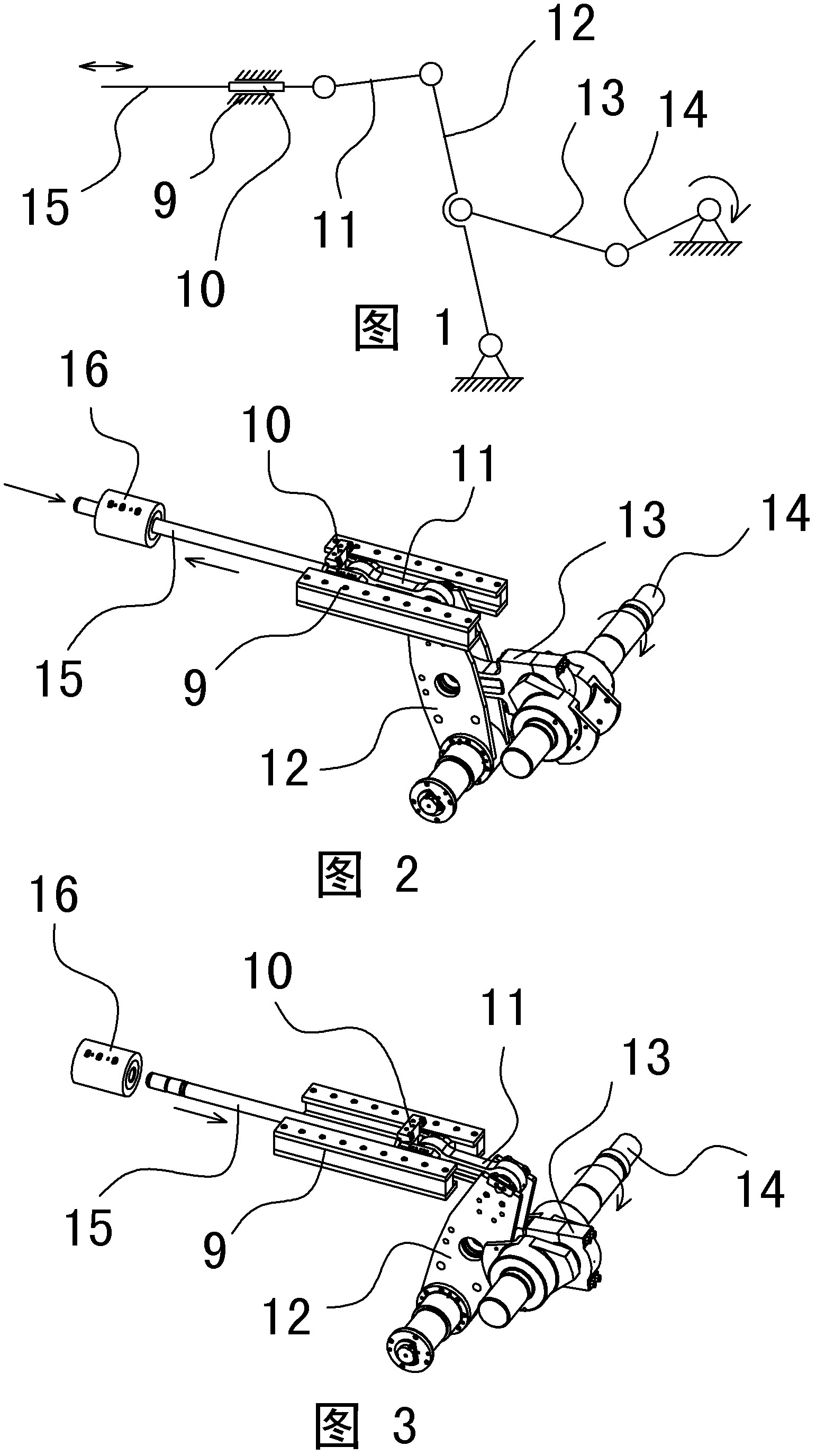

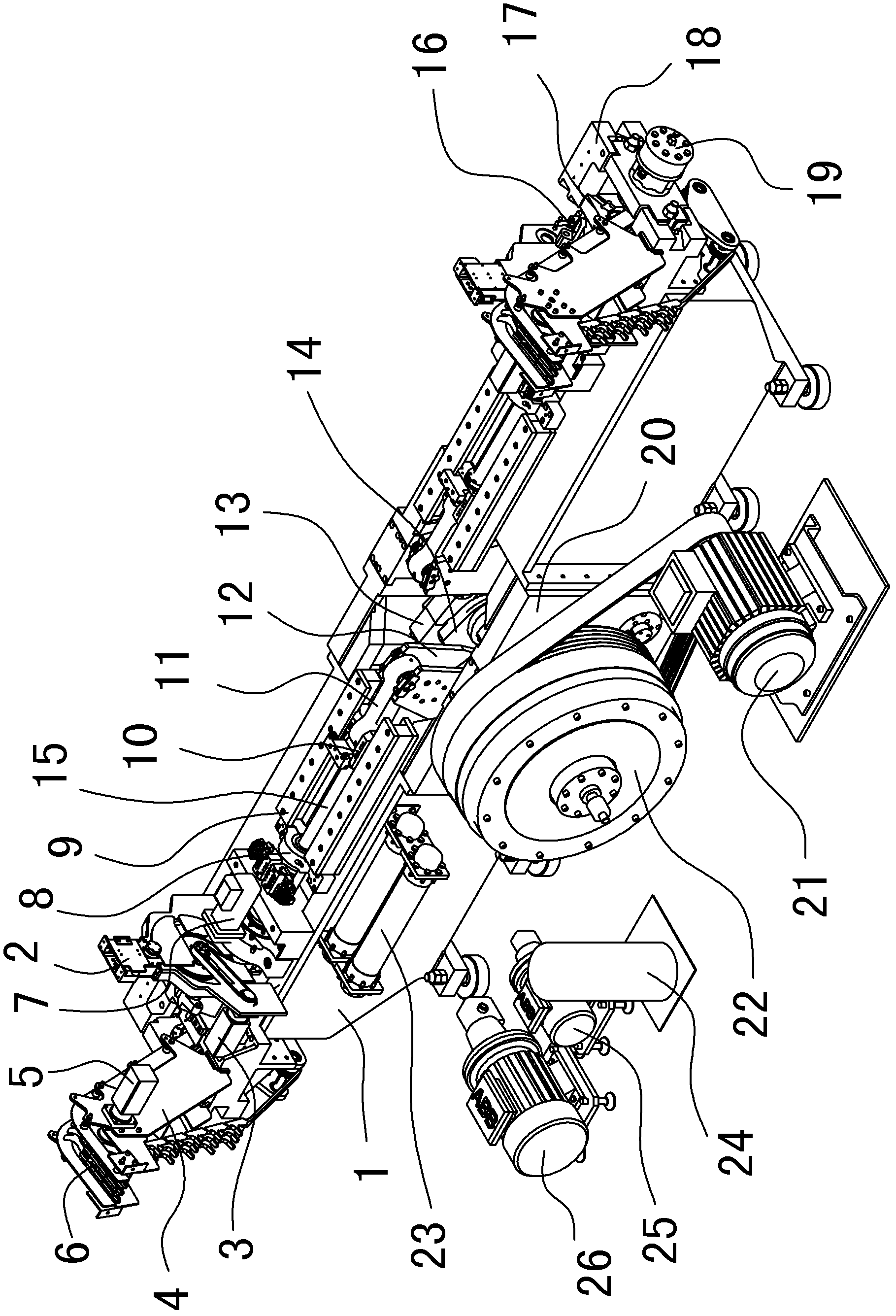

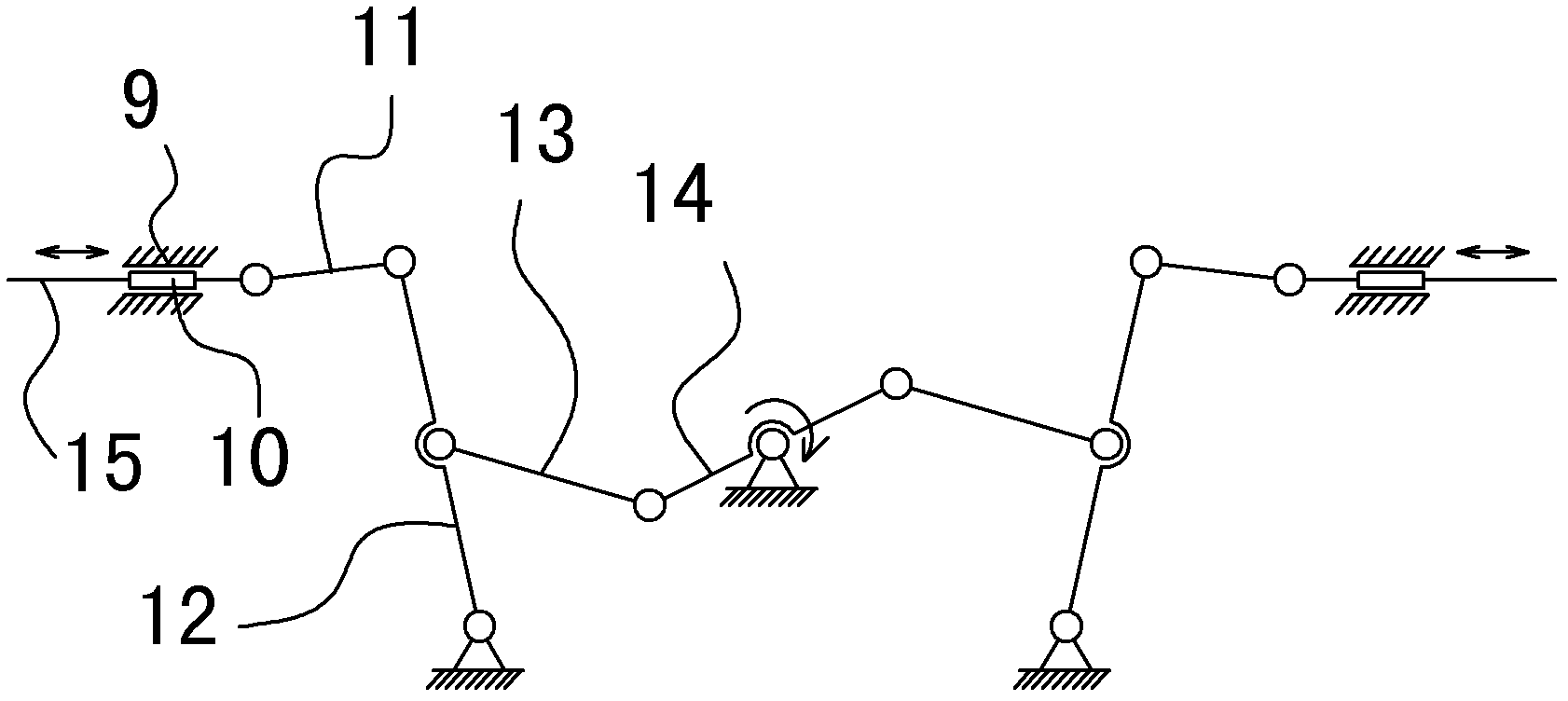

Bidirectional double-punching can body drawing machine

The invention discloses a bidirectional double-punching can body drawing machine. The machine is characterized in that: in a structural design, two same sets of punching rod driving mechanisms are used to form a bidirectional double-punching structural pop can body drawing machine by using a crankshaft designing scheme commonly. By the scheme, the two sets of punching rod driving mechanisms are symmetrically arranged after sharing one crankshaft, so that the inertial force of an oscillating rod, a sliding block, a punching rod and other parts in the moving process and the reverse action force of the parts in the can body molding process can be balanced; therefore, the load of a crankshaft supporting bearing is obviously reduced, the designing and processing requirements of the bearing are reduced, and the service life of the drawing machine is prolonged; in addition, the yield of two conventional can body drawing machines can be realized by one bidirectional double-punching can body drawing machine; and compared with the two conventional can body drawing machines, the bidirectional double-punching can body drawing machine has the advantages that the manufacturing cost is saved, and the energy consumption is reduced.

Owner:SUZHOU SLAC PRECISION EQUIP CO LTD

Top cover attachable fluid dynamic bearing motor

InactiveUS6917130B2Reduce power consumptionShaftsRecord information storageConstant forceClassical mechanics

A single thrust bearing fluid dynamic bearing (FDB) design, including a typical dynamic bearing design which has a ring-shaped or circular thrust plate mounted at or near the end of a shaft, wherein the shaft defines together with the surrounding sleeve a journal bearing by providing grooves on one of the two surfaces facing the gap between the shaft and sleeve. On the thrust plate, only one of the two surfaces is grooved to establish an active thrust bearing. The rotor is then biased against the single active thrust bearing with a constant force generated by a magnetic circuit.

Owner:SEAGATE TECH LLC

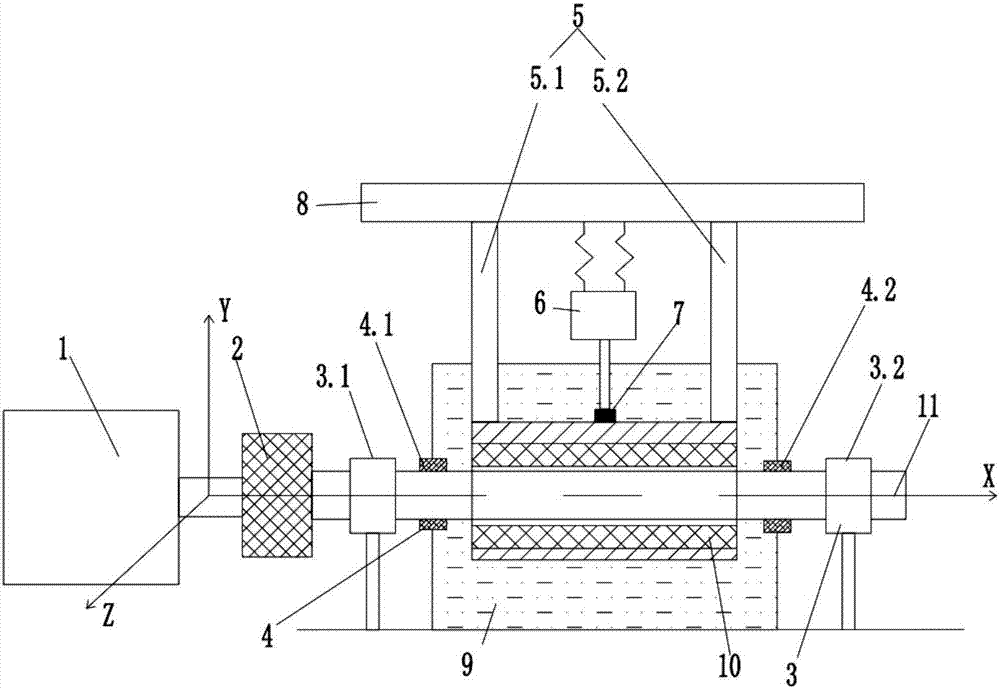

Water lubrication bearing dynamic characteristic parameter test device

ActiveCN107084842ARealize simulationComprehensive and real actual operationMachine bearings testingMeasurement deviceVibration acceleration

The invention relates to a water lubrication bearing dynamic characteristic parameter test device. The device is formed by a driving device, a loading and measuring device, an auxiliary device and a water lubrication bearing, the driving device mainly comprises a driving motor, a high-elastic coupling and a coupling shaft segment, the loading and measuring device mainly comprises a static force loading device, a dynamic force loading device and a dynamic force and response measurement device, the dynamic force and response measurement device can be used for measuring a vibration acceleration and a dynamic force, and the auxiliary device mainly comprises a roller bearing and support, a dynamic sealing device, a loading device support frame, and a water tank etc. According to the device, under the loading effect of the static force and the dynamic force, direct measurement of the radial rigidity and damping of the water lubrication bearing is realized, the structure is simple, measurement data is reliable, measuring results can provide reliable input parameters for calculation and assessment of the shafting vibration characteristics employing the water lubrication bearing and provide experiment bases for the design of the water lubrication bearing.

Owner:CHINA SHIP SCIENTIFIC RESEARCH CENTER (THE 702 INSTITUTE OF CHINA SHIPBUILDING INDUSTRY CORPORATION)

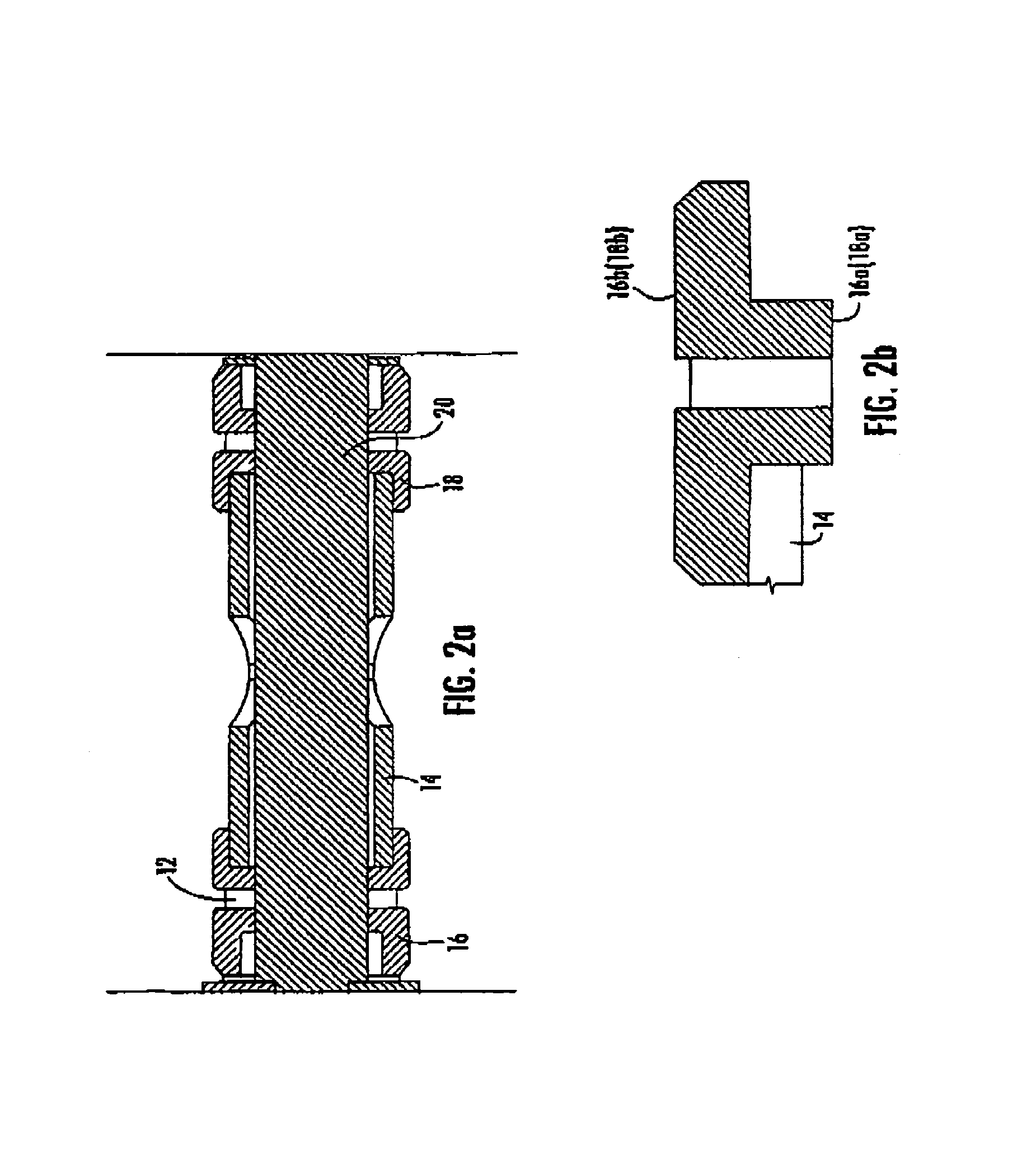

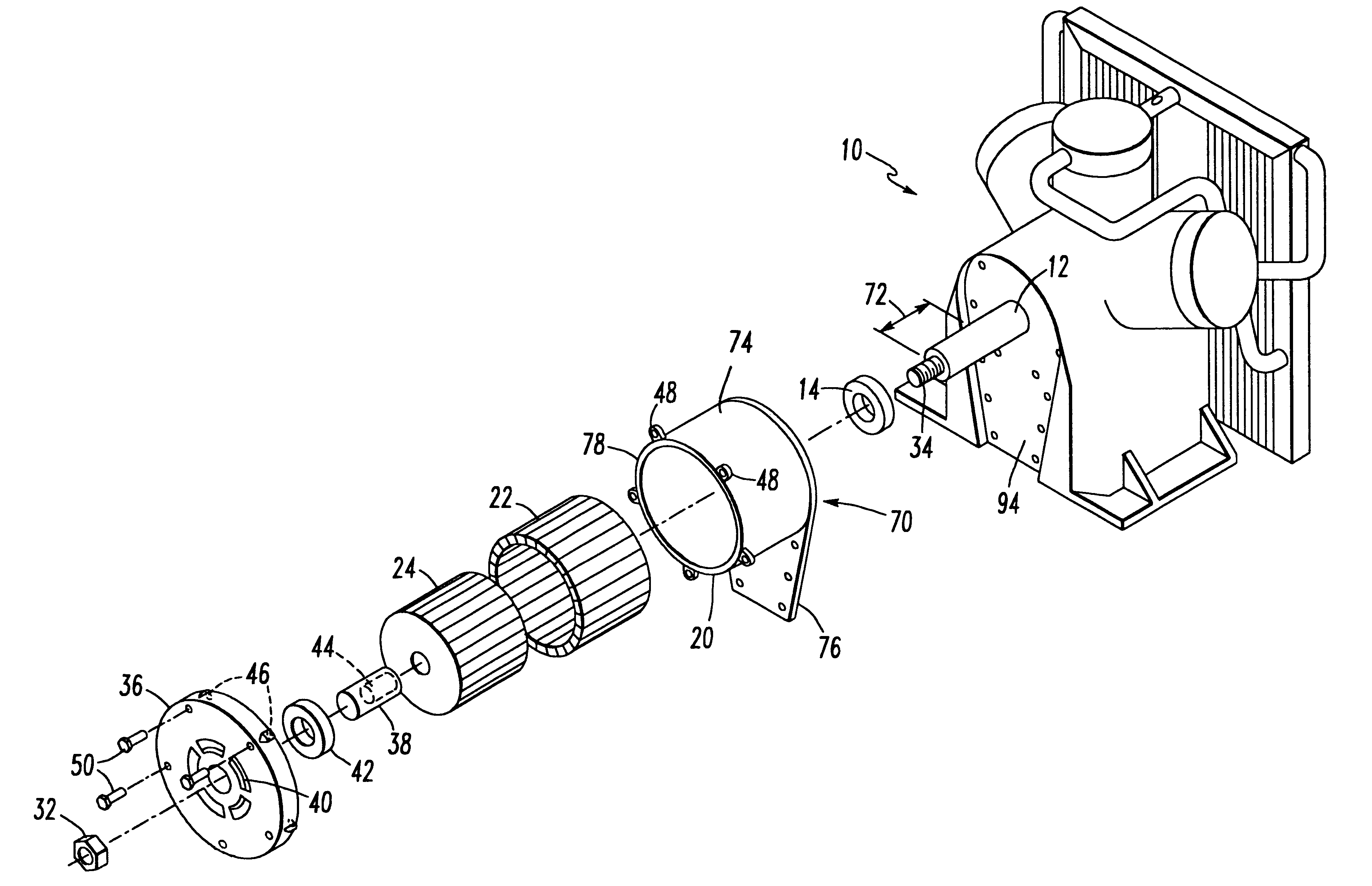

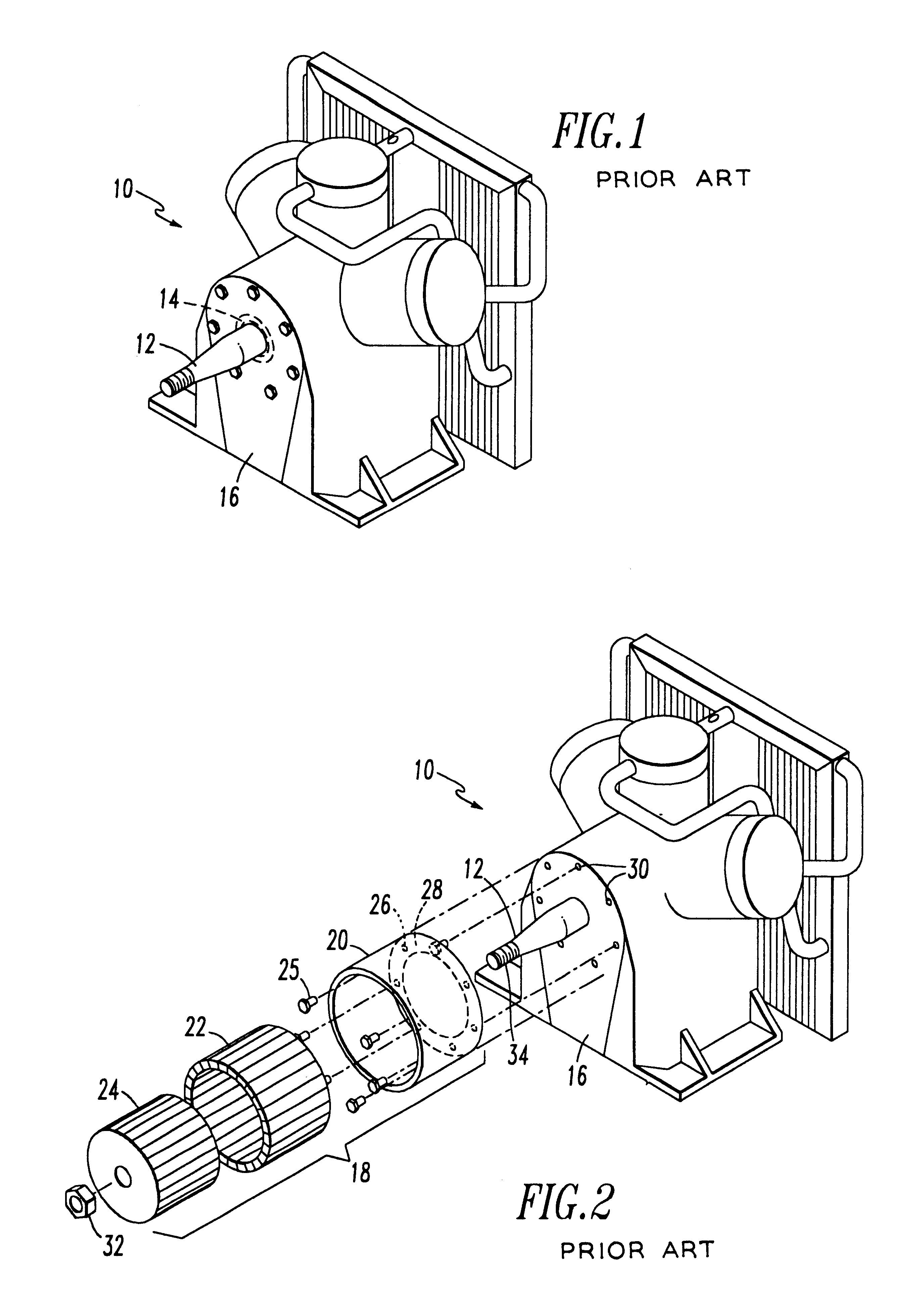

Shaft extension for use with outboard bearing designs

InactiveUS6419465B1Reduce failureLower performance requirementsPositive displacement pump componentsPiston pumpsStub axleAir compressor

A shaft extension for attachment to a crankshaft of an electric motor driven air compressor to axially extend the crankshaft for engagement with an outboard rotational bearing. The electric motor driven air compressor includes a bearing plate, an inboard rotational bearing mounted on the bearing plate, the crankshaft projecting through both of the inboard rotational bearing and the bearing plate and terminating in a distal end disposed exterior of the bearing plate. The air compressor also includes an electric motor, the electric motor having a stator frame, a stator fixedly mounted within the stator frame, and a rotor fixedly mounted to the crankshaft for rotation therewith and disposed interior of the stator. The air compressor further includes the outboard rotational bearing disposed axially outboard of the stator frame, the stator, and the rotor. The shaft extension includes an extension member having an extended major axis and a minor axis extending substantially transverse to the extended major axis and a connection mechanism for connecting the extension member to the distal end of the crankshaft.

Owner:WESTINGHOUSE AIR BRAKE TECH CORP

Dynamic monitoring system for operating condition of thrust bearing of hydro-generator

InactiveCN102967462AGuaranteed uptimeReduce volumeMachine bearings testingOriginal dataDynamic monitoring

The invention discloses a dynamic monitoring system for an operating condition of a thrust bearing of a hydro-generator. The system comprises a temperature sensor, a pressure sensor, an oil film thickness sensor, a host machine and a remote computer, wherein the sensor is arranged on a mirror plate of the thrust bearing for outputting lubricating parameter data such as oil film thickness, oil film pressure, oil film temperature and the like with the rotation of the mirror plate; and the data can be used for reflecting the operating condition of the thrust bearing. Data is exchanged between the remote computer and the system host machine by using wi-fi wireless communication; the host machine is used for carrying out high-speed acquisition under the control of programs; the acquired data is uploaded to the computer by the wi-fi network for displaying, storing and analyzing in the remote computer; if the thickness of the oil film of a thrust pad is excessively small or the temperature increase is excessively quick, alarm prompting is carried out to avoid a pad burning accident, thereby ensuring the safe operation of the thrust bearing of the hydro-generator. The data can be used for optimizing the design of the thrust bearing of the hydro-generator, and can be used as the original data of the expert thrust bearing analysis system.

Owner:HARBIN ELECTRIC MASCH CO LTD

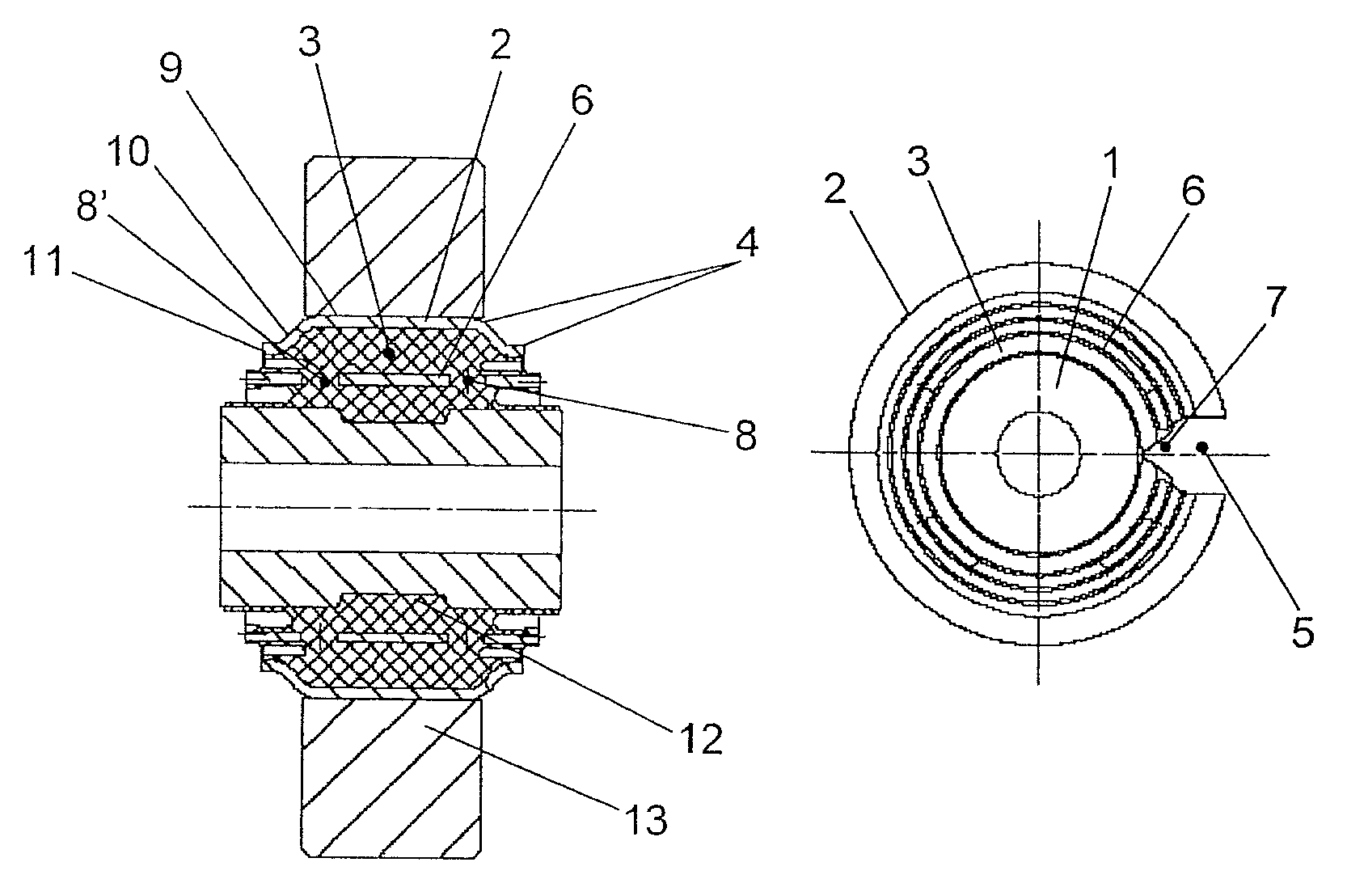

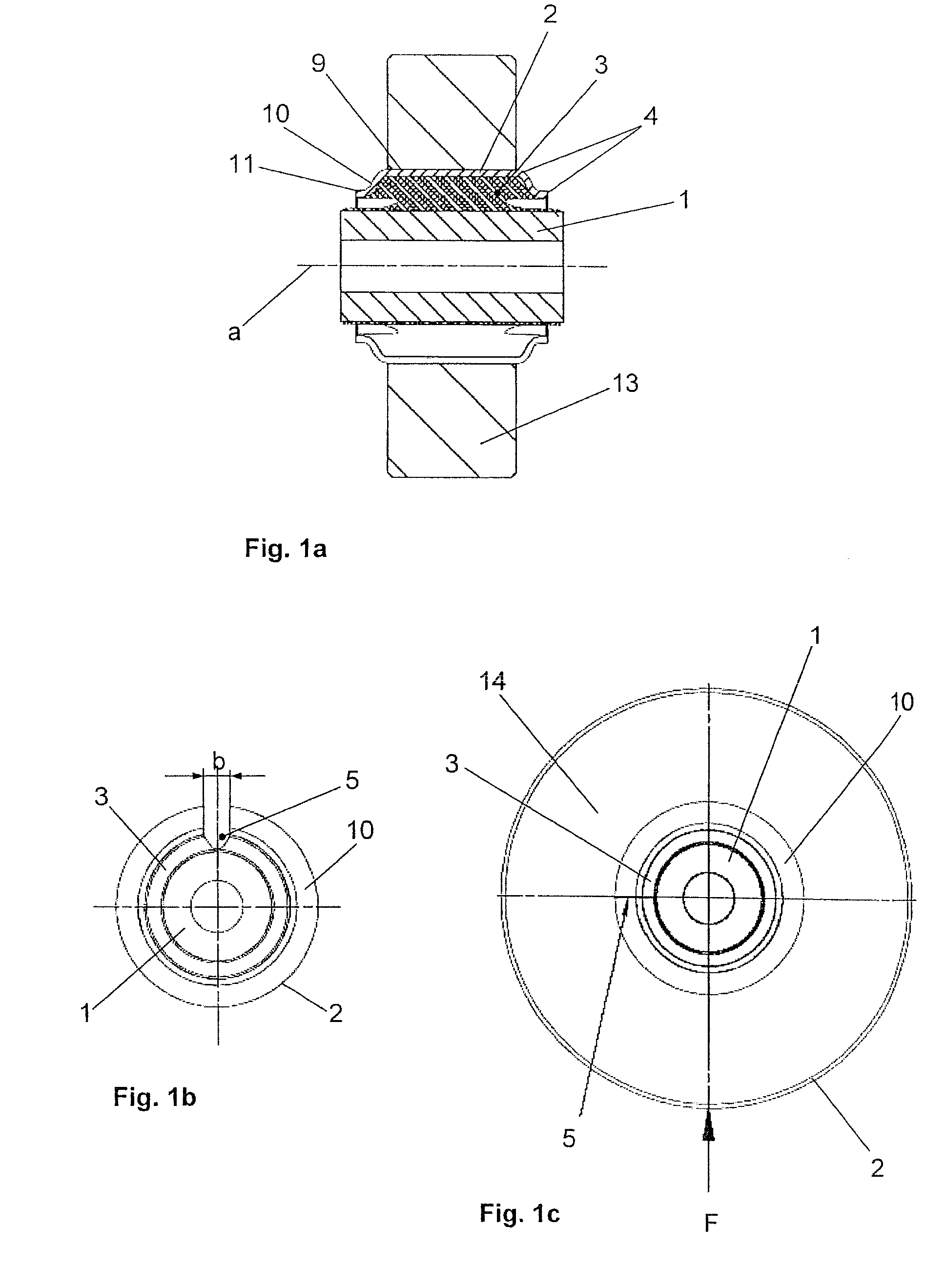

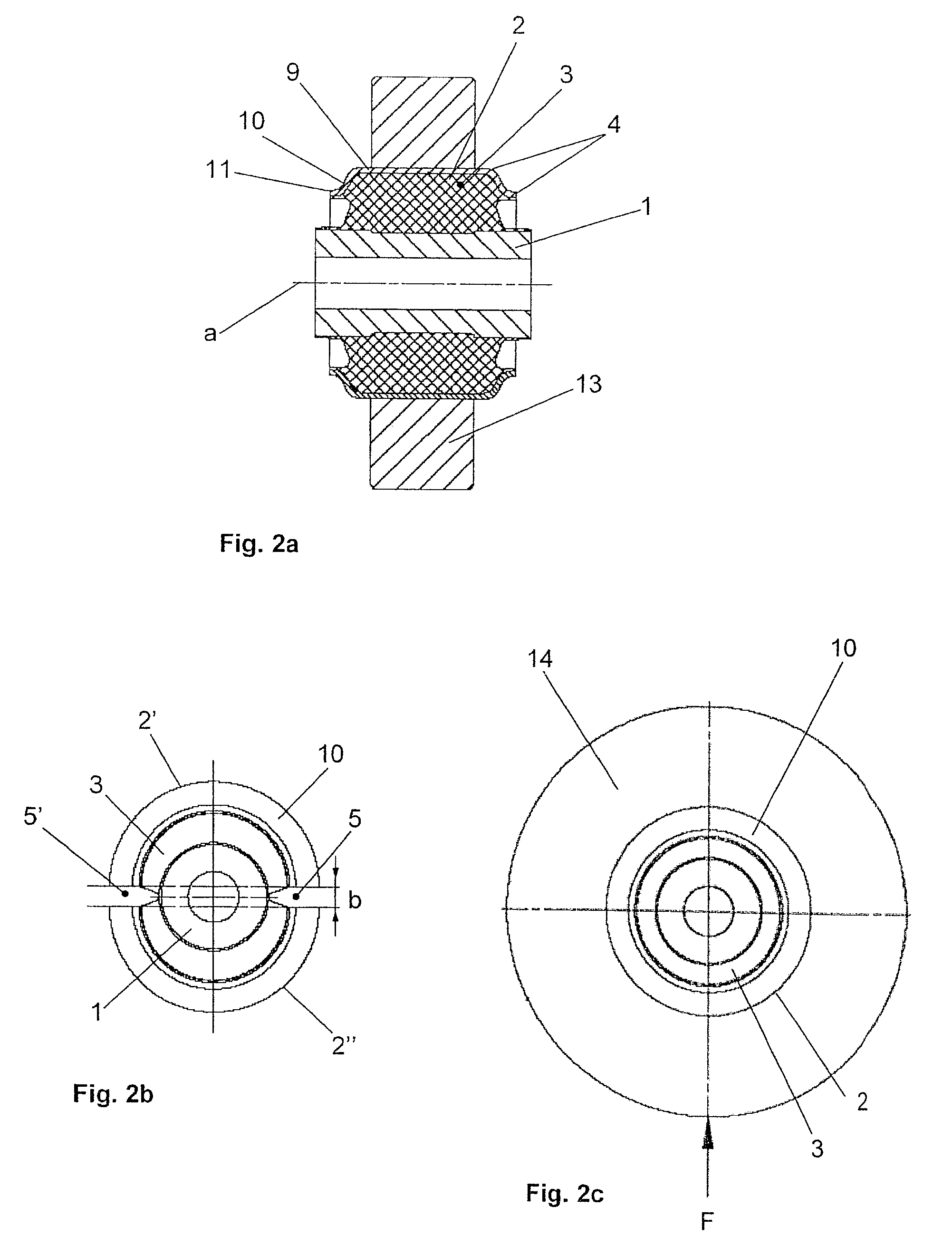

Elastomeric bush bearing and process for manufacturing same

InactiveUS7441759B2Improve radial stiffnessEvenly distributedSprings/dampers functional characteristicsResilient suspensionsElastomerGeometric design

An elastomeric bush bearing is designed as a slotted bush. To reach a high ratio of static radial stiffness to torsion spring rate along with a high axial stiffness at the same time, a beading is formed at least at one axial end but preferably at both axial ends of the slotted bush. In case of an especially advantageous embodiment, a slotted bush with additional intermediate parts inserted into the elastomeric bearing body, two encapsulated rubber packets are created by the simultaneous special geometric design of the inner part. The individual stiffnesses of the two rubber packets are thus compensated and thus there is a homogeneous increase in the overall stiffness of the bush. The beadings are prepared before the components of the bearing are assembled and vulcanized to the parts of the later outer sleeve.

Owner:ZF FRIEDRICHSHAFEN AG

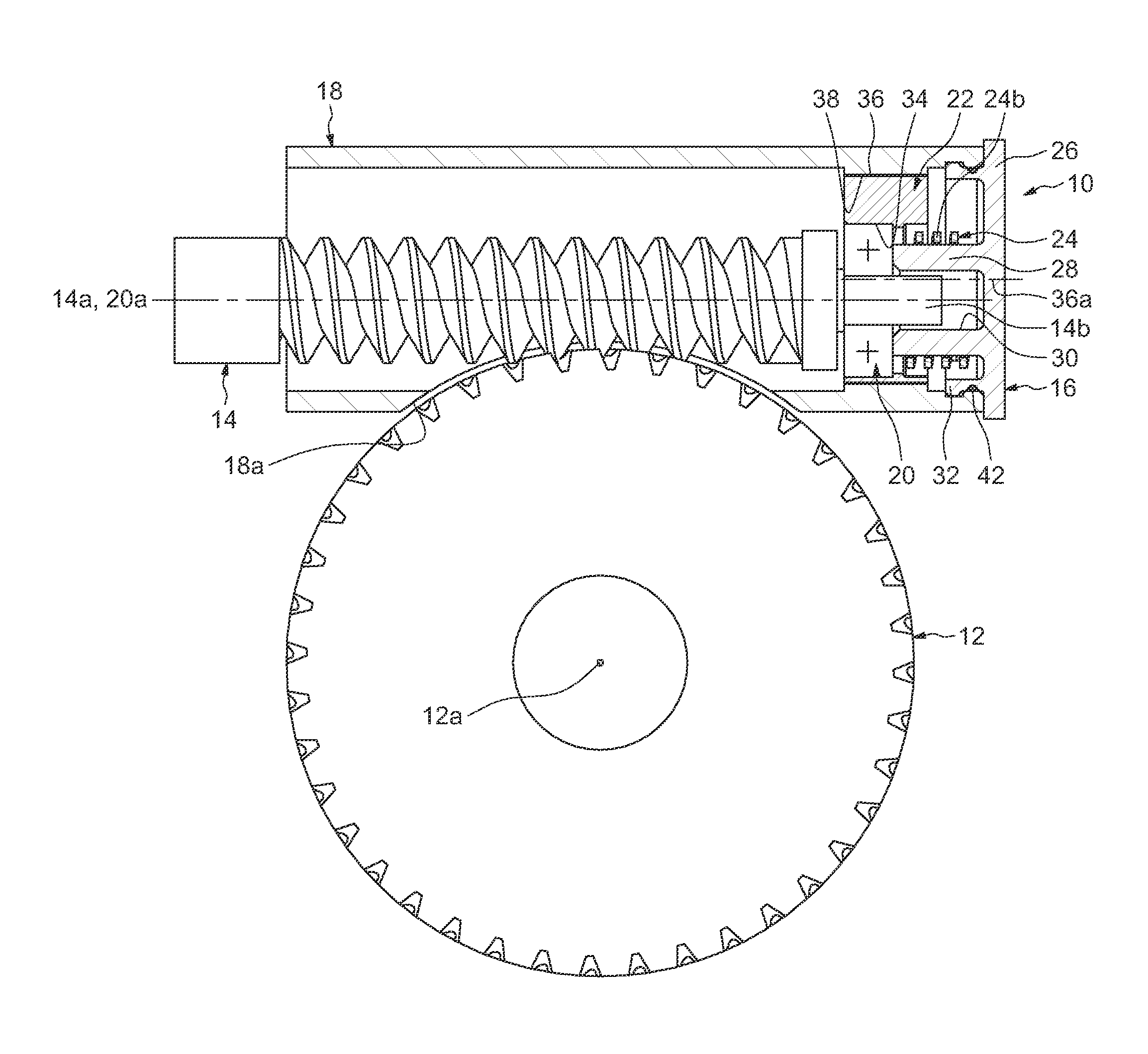

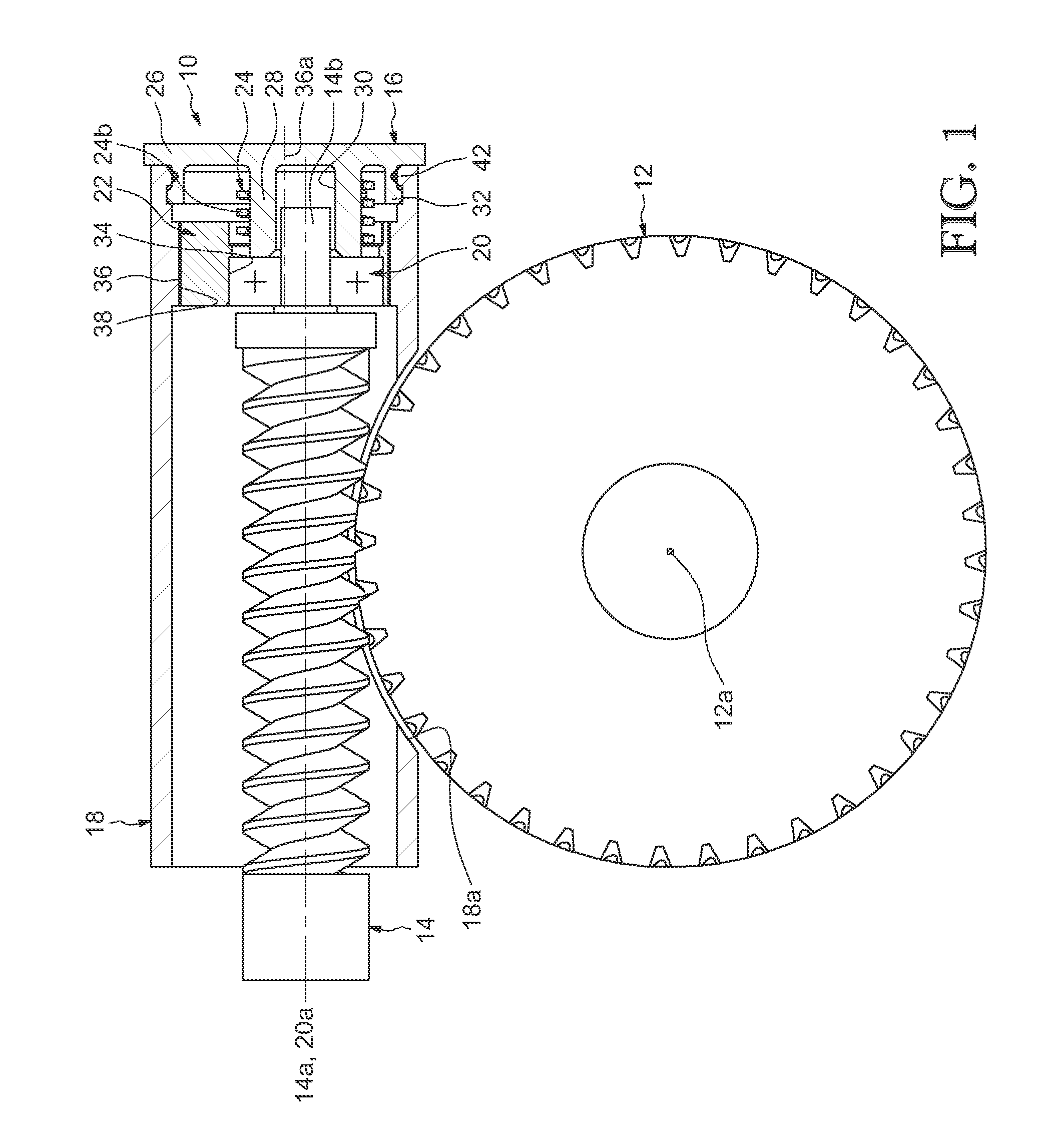

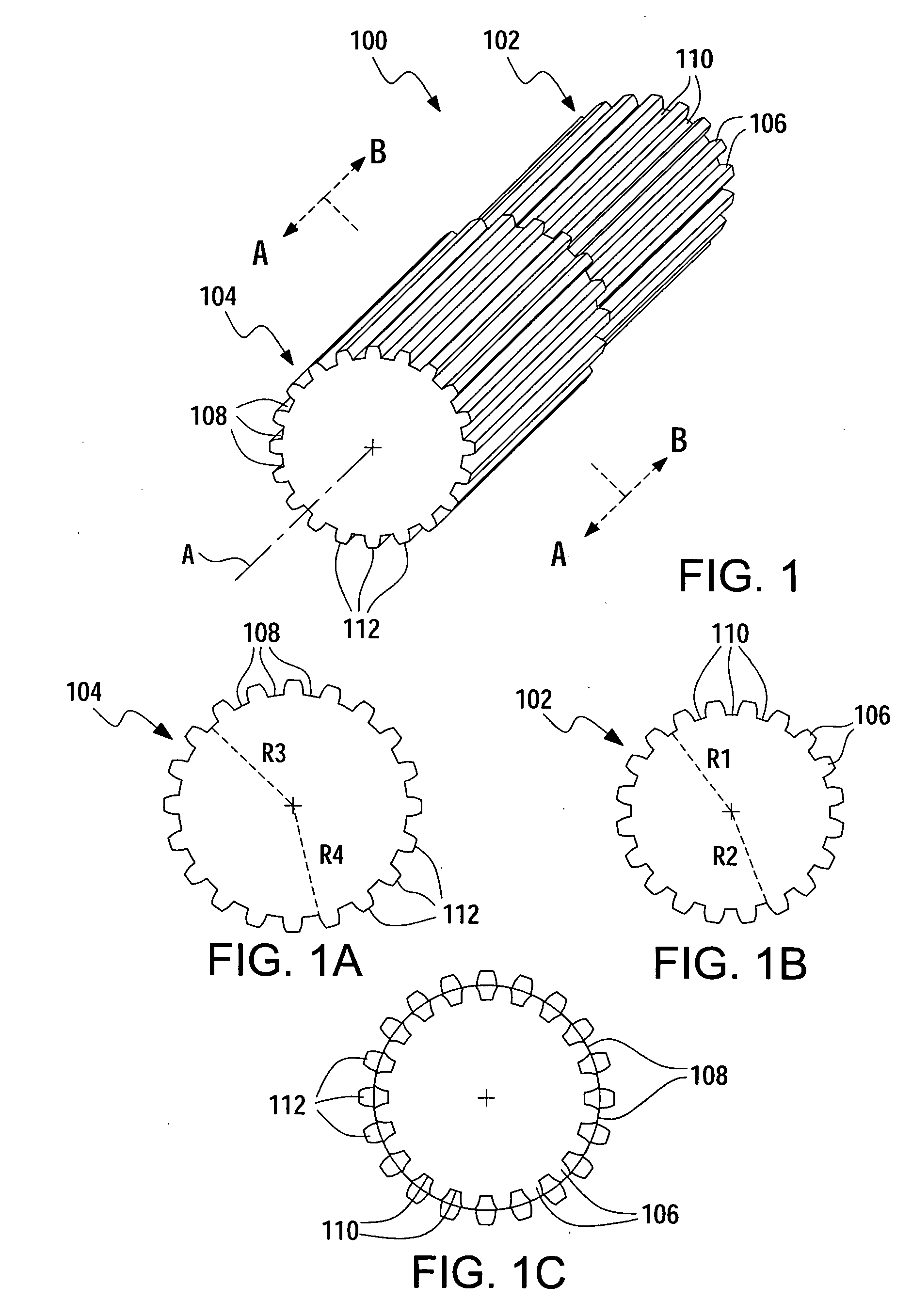

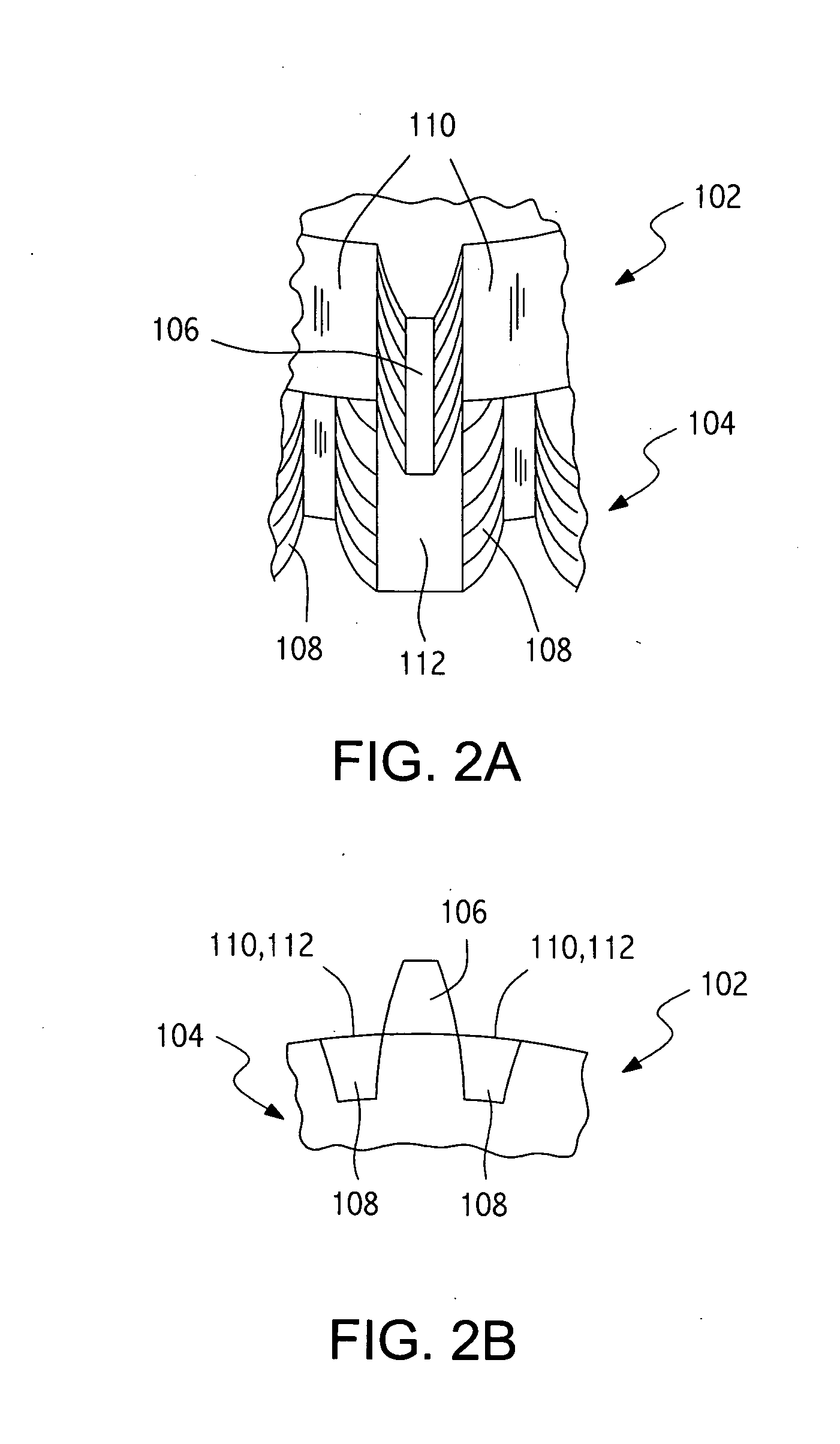

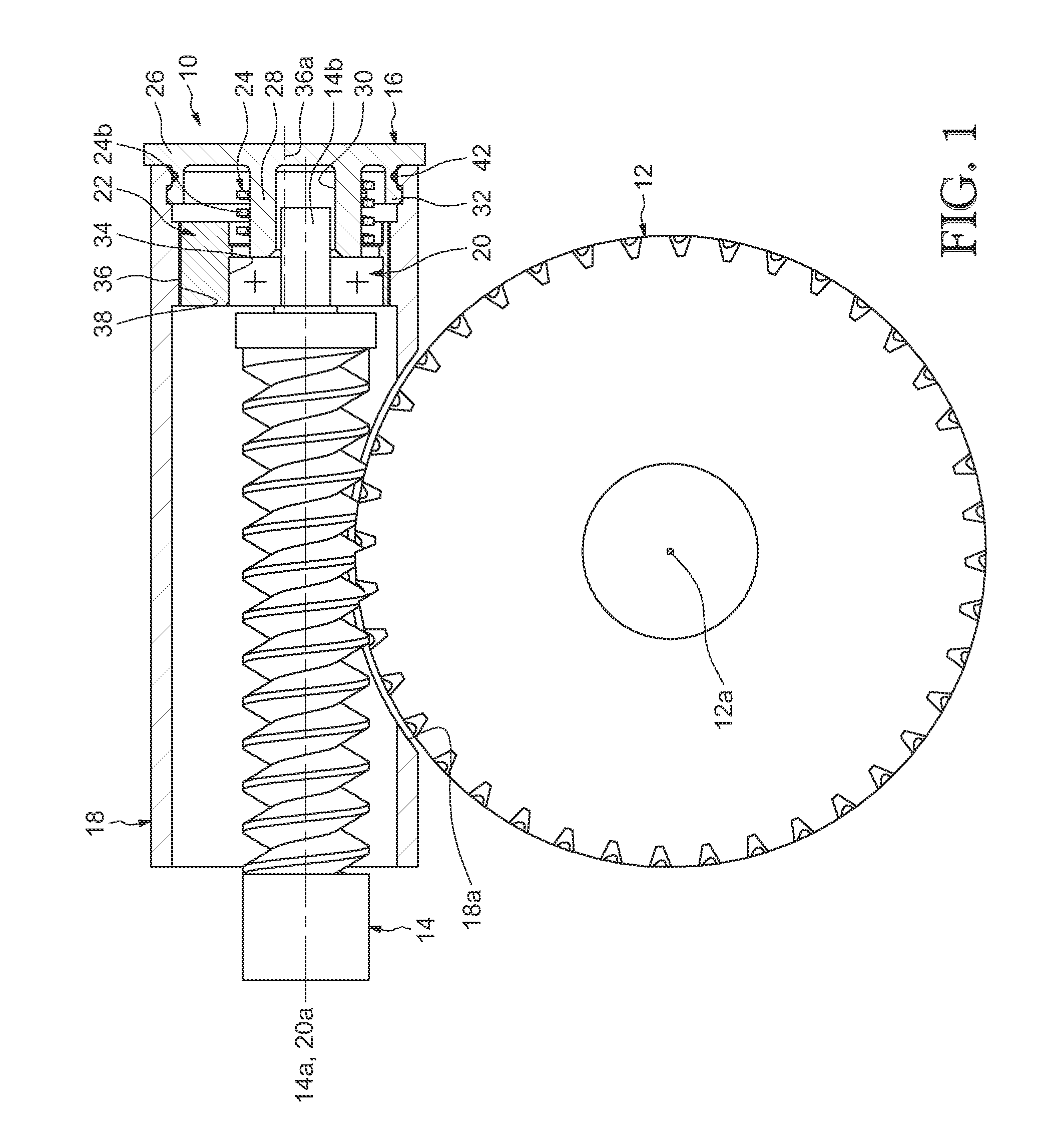

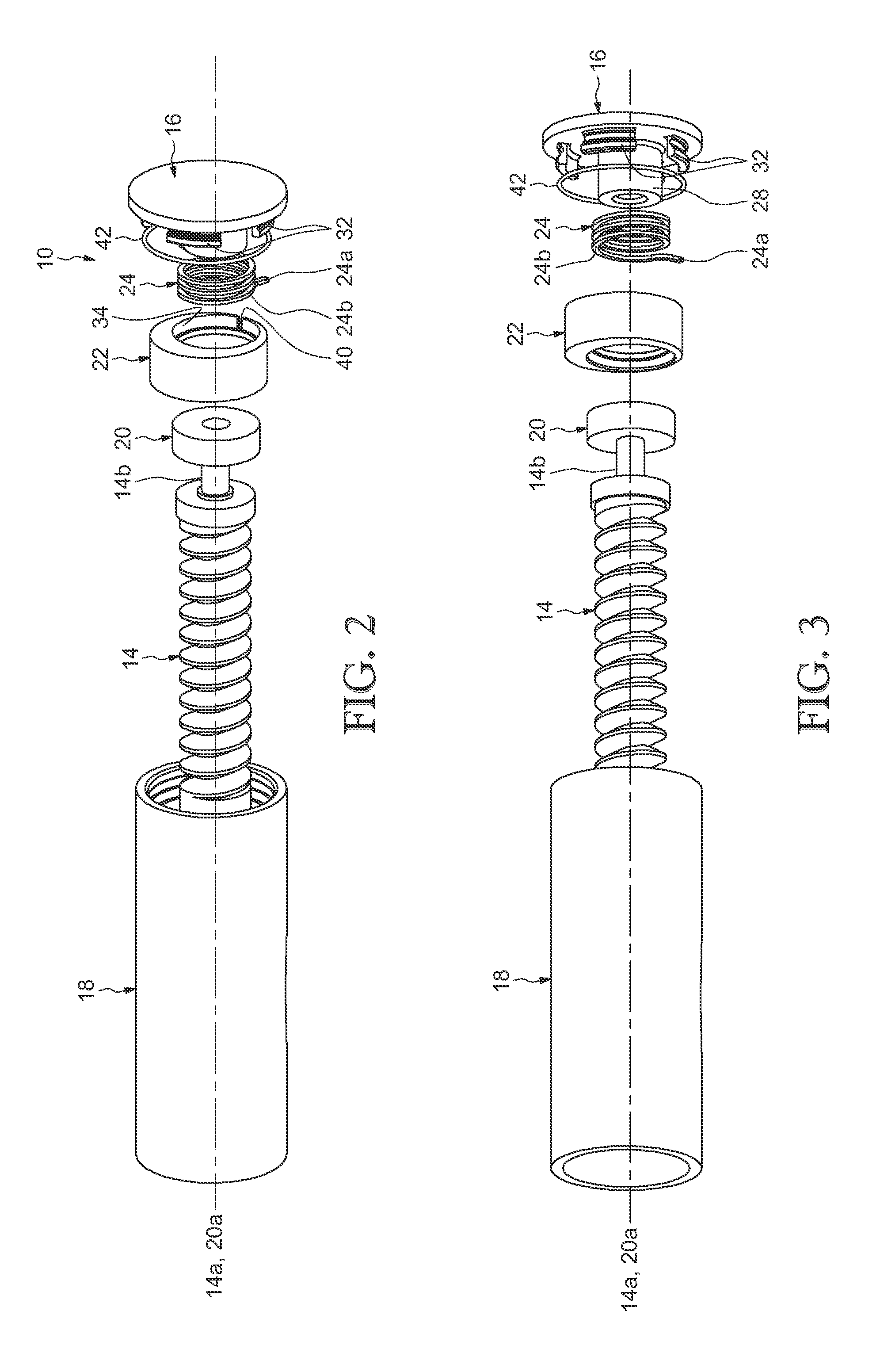

Wear-Compensation Device For A Gear

ActiveUS20120227526A1Limit wearEasy to installToothed gearingsGearing detailsGear wheelTorsion spring

The wear-compensation device for a gear comprises a fixed support capable of being fixed axially on an external element in order to keep the device on the said external element, a bearing designed to be mounted on a shaft comprising one of the wheels of the gear, an eccentric mounted on the bearing and designed to be in contact with the external element, the said eccentric being able to move angularly relative to the fixed support. The device also comprises a torsion spring mounted axially between the fixed support and the eccentric and capable of exerting a circumferential preload force on the said eccentric, the said spring comprising a first end mounted inside a recess of the eccentric and a second end interacting with the fixed support.

Owner:AB SKF

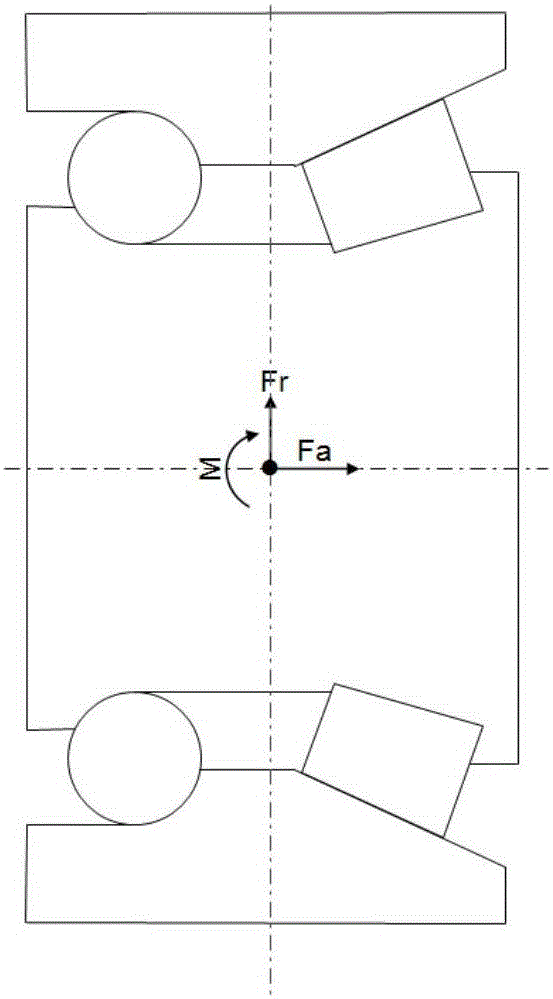

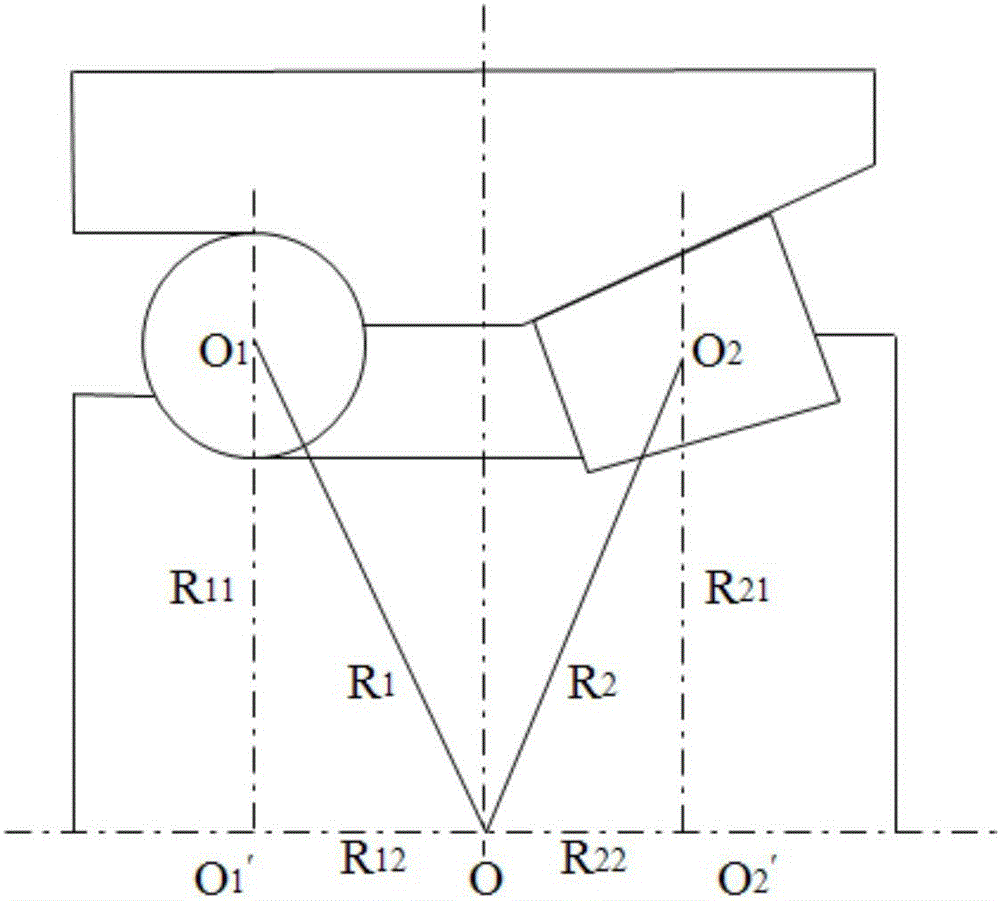

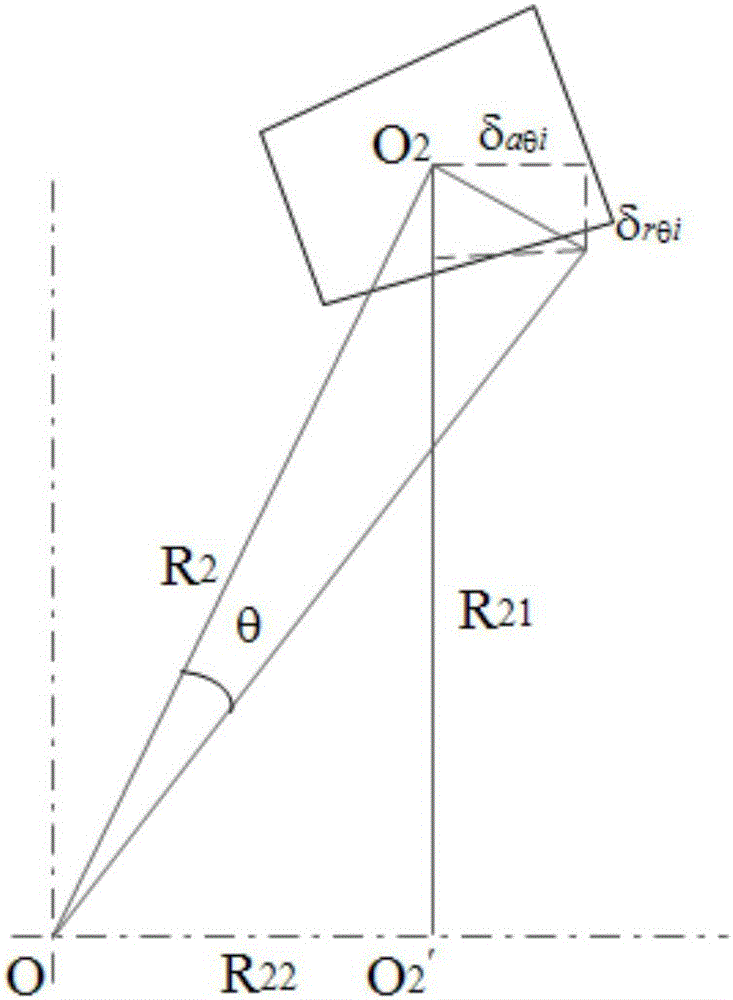

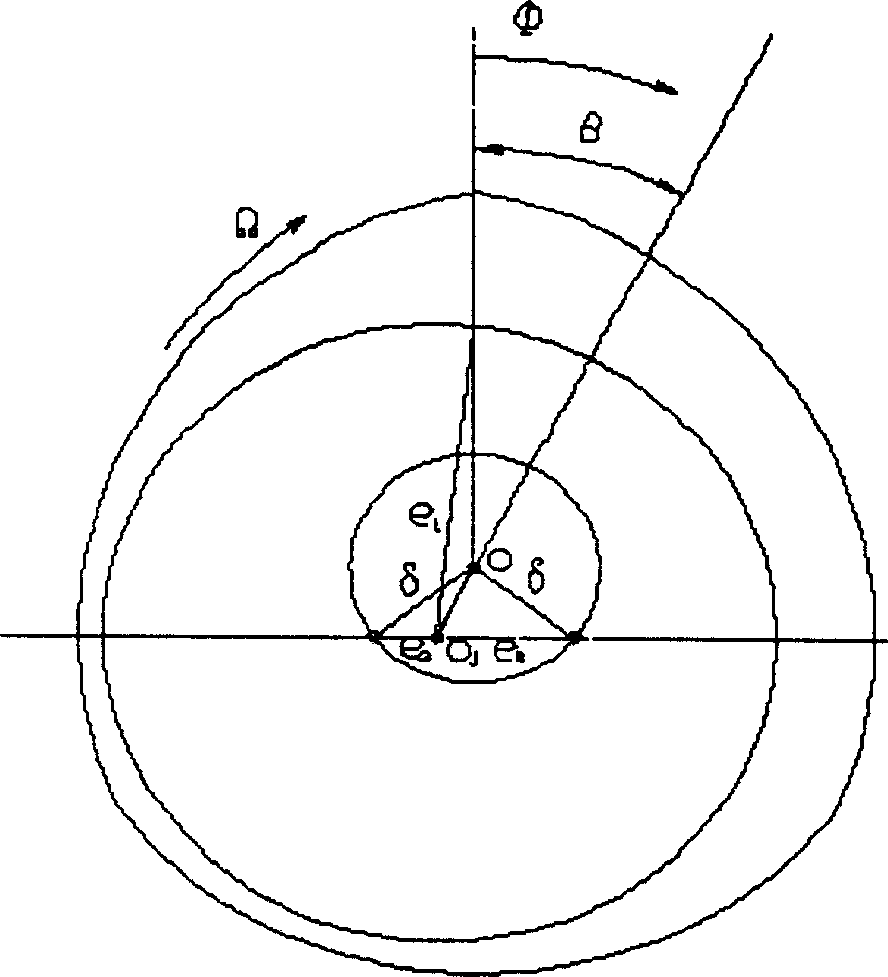

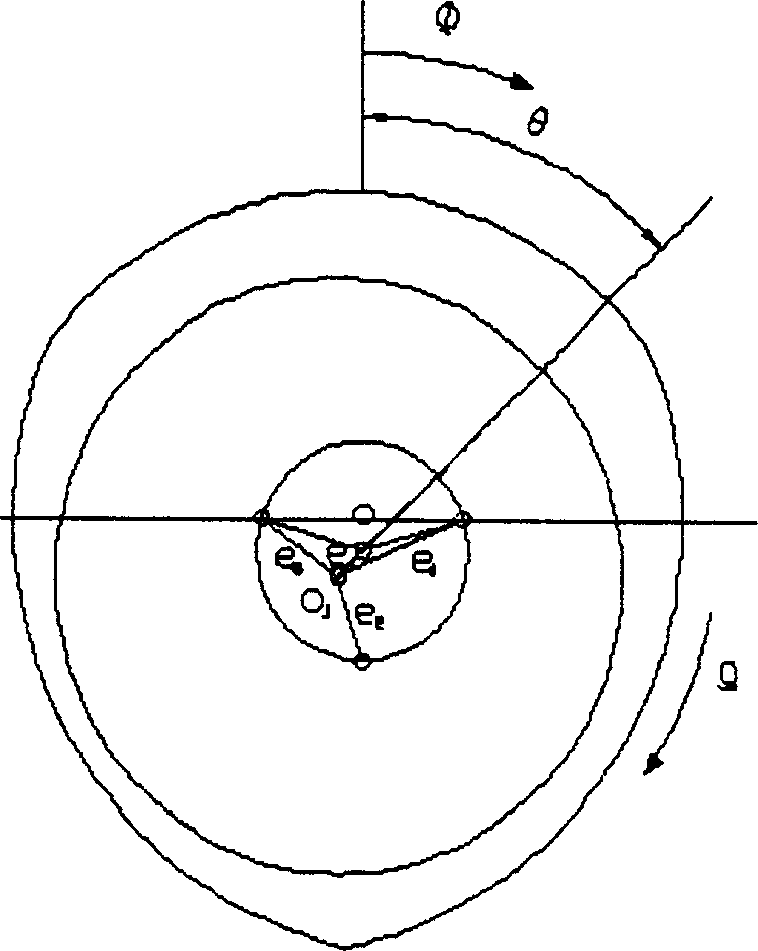

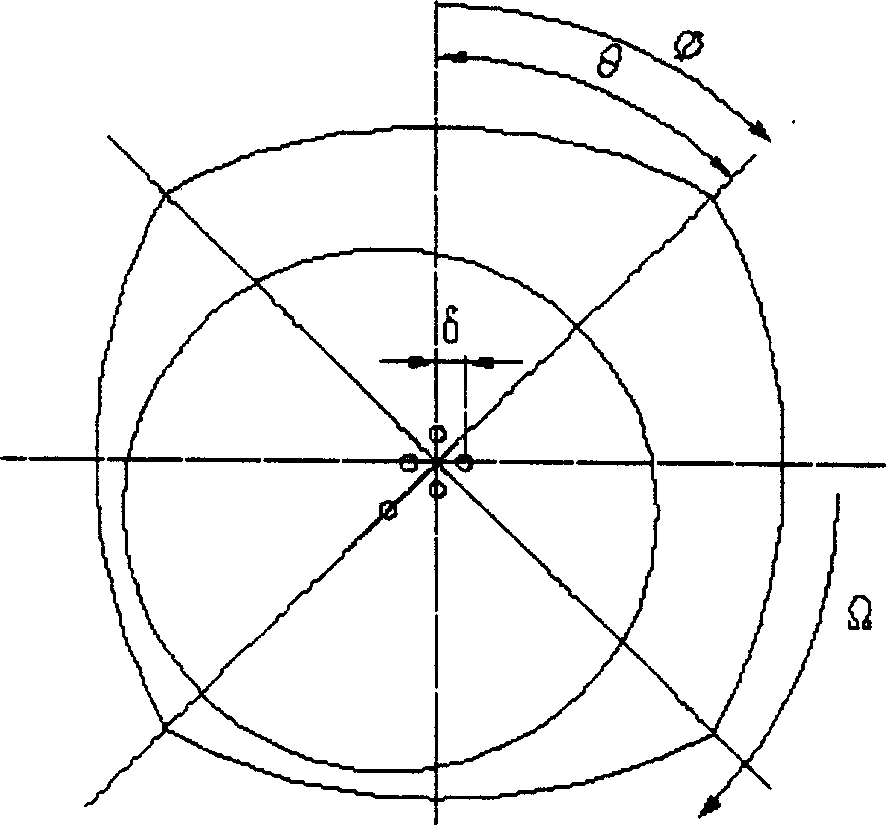

Method and device for obtaining load distribution of ball-cone mixed double-row hub bearing

ActiveCN106089993AQuickly obtain accurate bearing characteristic parametersImprove rationalityGeometric CADBall and roller bearingsAxial displacementPosition angle

The invention relates to a method and a device for obtaining load distribution of a ball-cone mixed double-row hub bearing. Firstly, a normal contact load Q1i in any position angle wi of a steel ball and a normal contact load Q2i in any position angle phi i of a conical roller with an outer ring are derived; then, total radial force Q1r, axial force Q1a and resistance torque M1 generated to the inner ring by the steel ball and total radial force Q2r, axial force Q2a and resistance torque M2 generated by the conical roller to the inner ring are obtained; a mechanical balance equation of the inner ring of the ball-cone mixed double-row hub bearing with delta r, delta a and theta as unknown quantities is built; and a Newton iteration method is applied to solve the balance equation to obtain a radial displacement delta r, an axial displacement delta a and an angular displacement theta of the inner ring of the bearing so as to obtain the load distribution conditions in each row of the bearing. The method can quickly obtain precise bearing characteristic parameters of the ball-cone mixed double-row hub bearing, can directly judge if the structural design of the ball-cone mixed double-row hub bearing is reasonable, and improves the design rationality and accuracy of the ball-cone mixed double-row hub bearing.

Owner:HENAN UNIV OF SCI & TECH

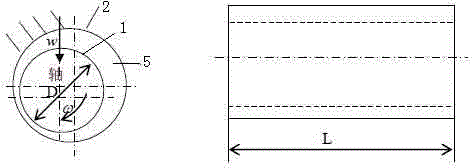

Self-adapting mixed gas radial journal bearing using integral silk net damper

The present invention relates to a self-adapting mixed gas radial journal bearing using an integral silk net damper. The self-adapting mixed gas radial journal bearing (10) comprises a self-adapting mixed bearing pad (12) with a fluid static force convex part (22) and a capillary throttleer (28) for providing pressurized gas flow to the self-adapting mixed gas radial journal bearing (10).The self-adapting mixed gas radial journal bearing (10) also comprises an inner ring (32), an outer ring (34) and a damper bridge (36).Each side of the damper bridge (36) forms a damper cavity (42).the integral silk net damper (62) is located in the damper cavity (42).Integral pair middle springs (46,48) are between the inner ring and the outer ring (32,34) to conveniently provide radial and turning self adaption to the self-adapting mixed bearing pad (12).A bearing design without oil solves the properties of low dumping and low loading ability in the existing self-adapting air chaff bearing design, and meanwhile, the self adaption for the geometry changes of rotors is reserved.

Owner:GENERAL ELECTRIC CO

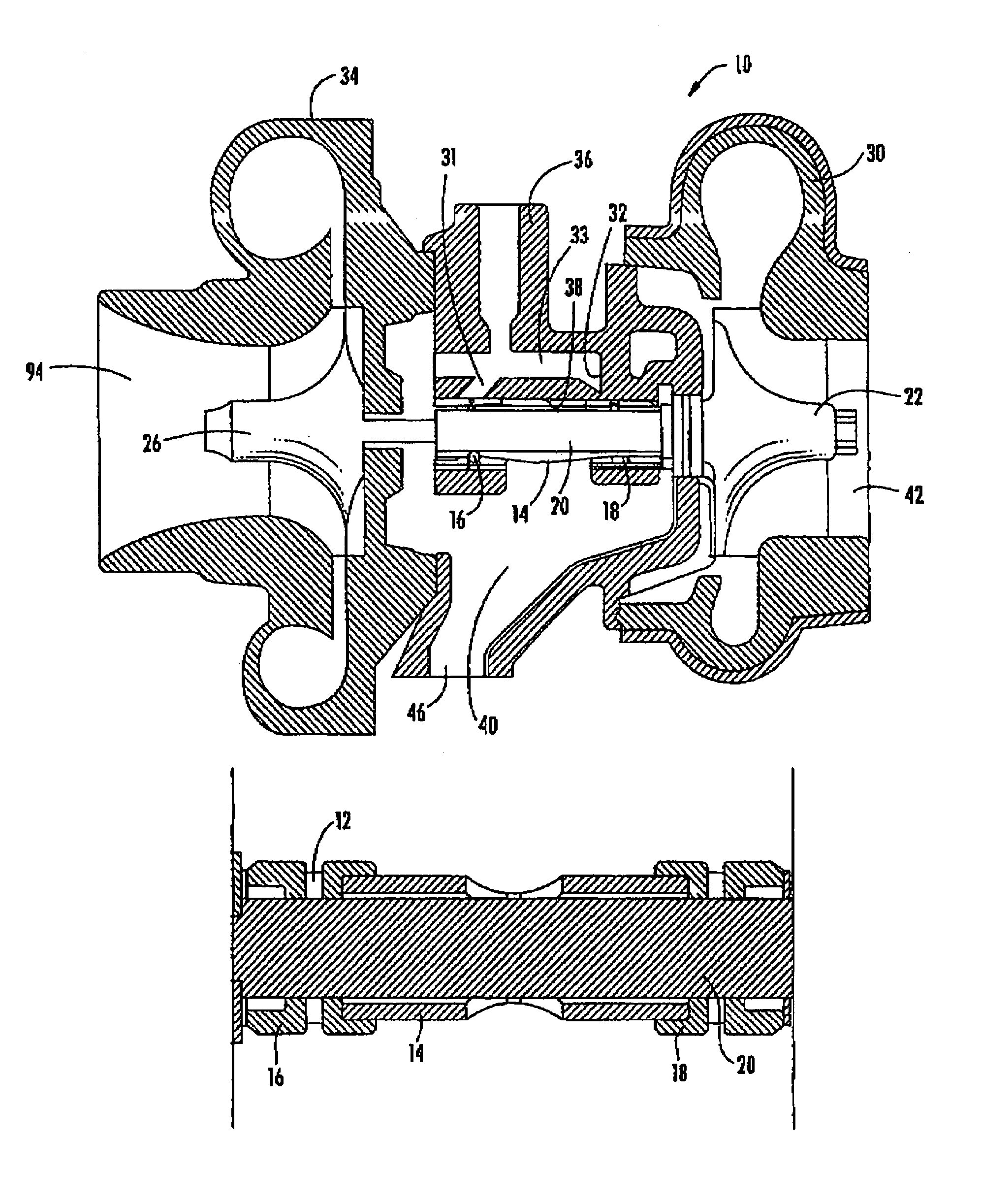

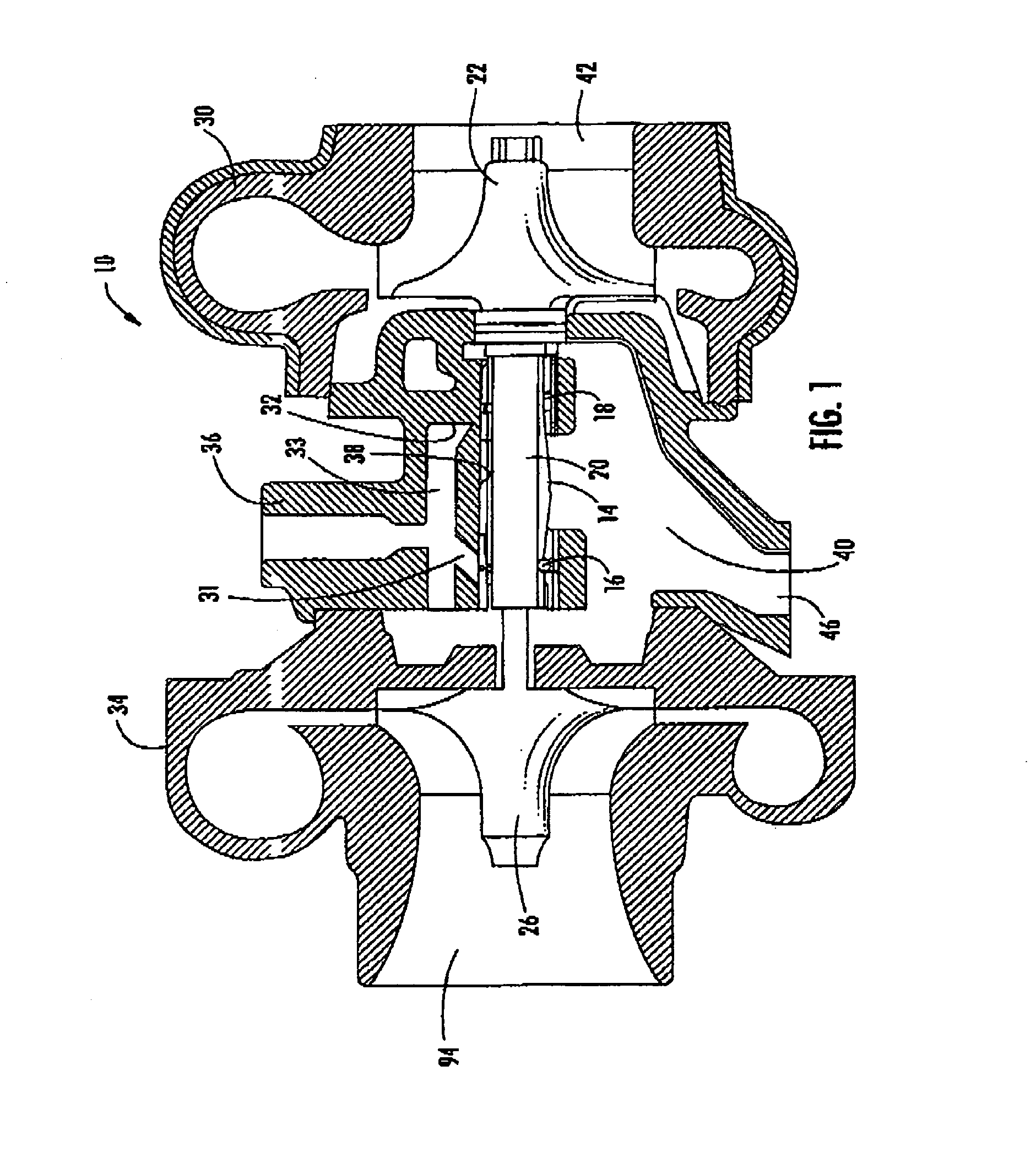

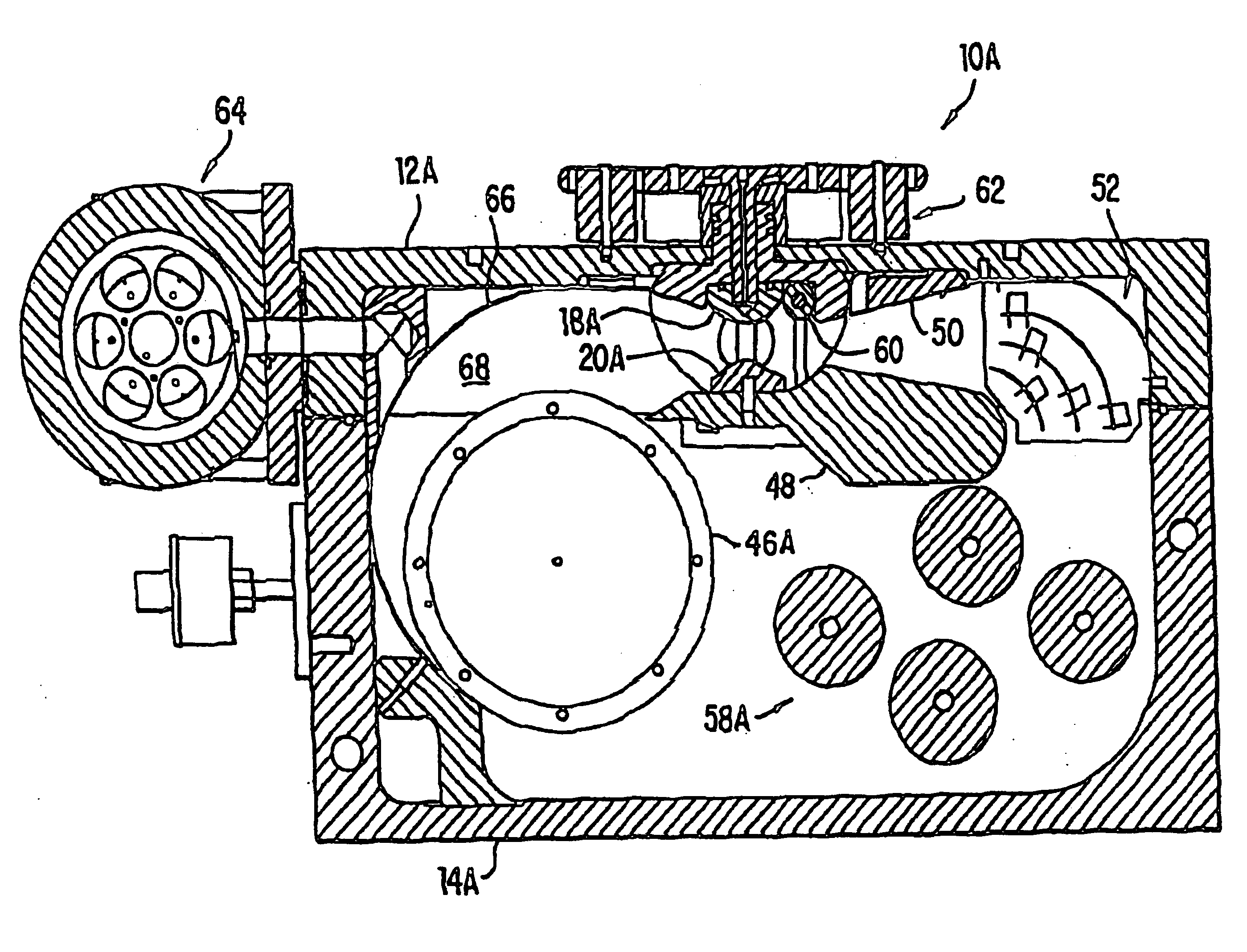

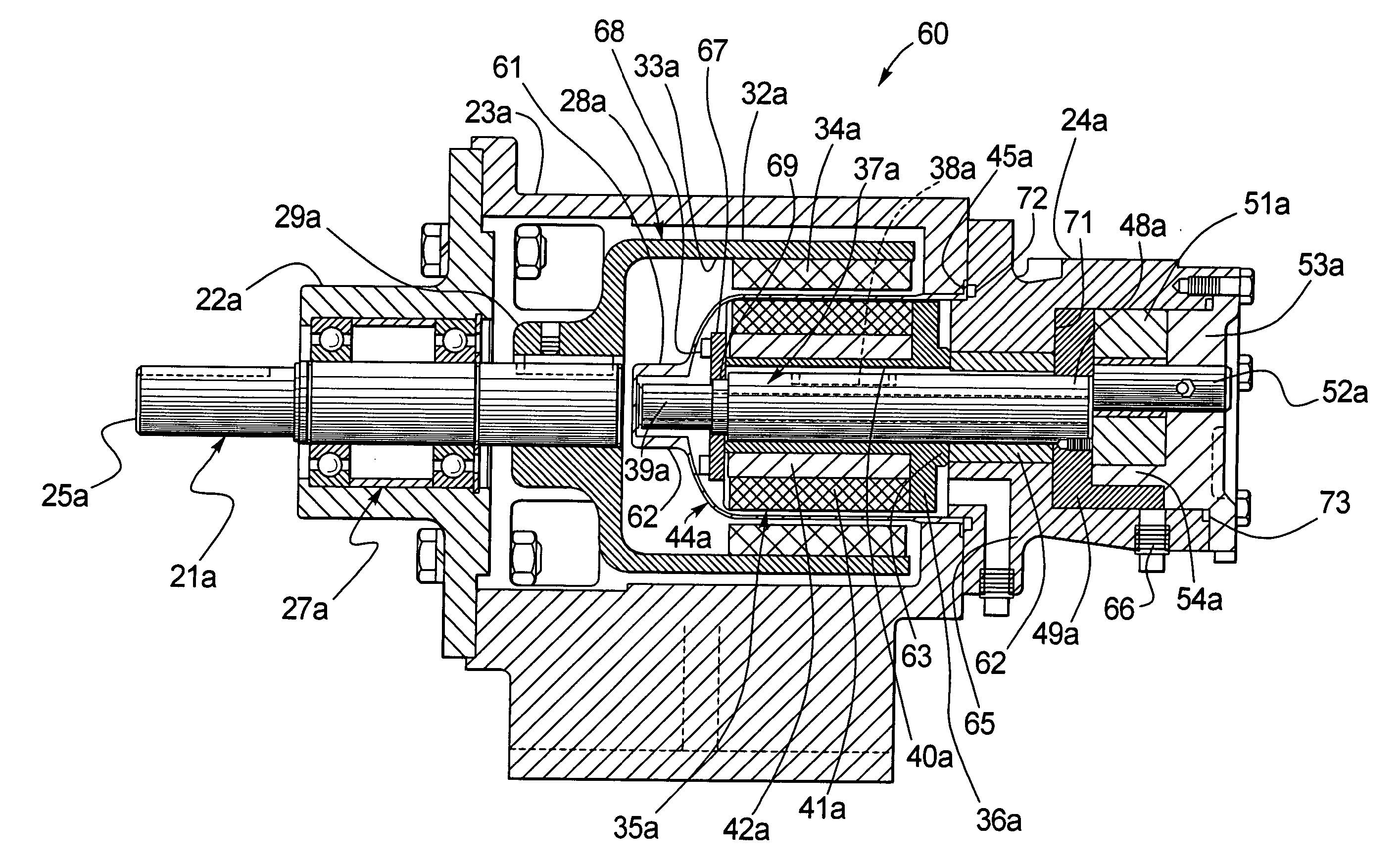

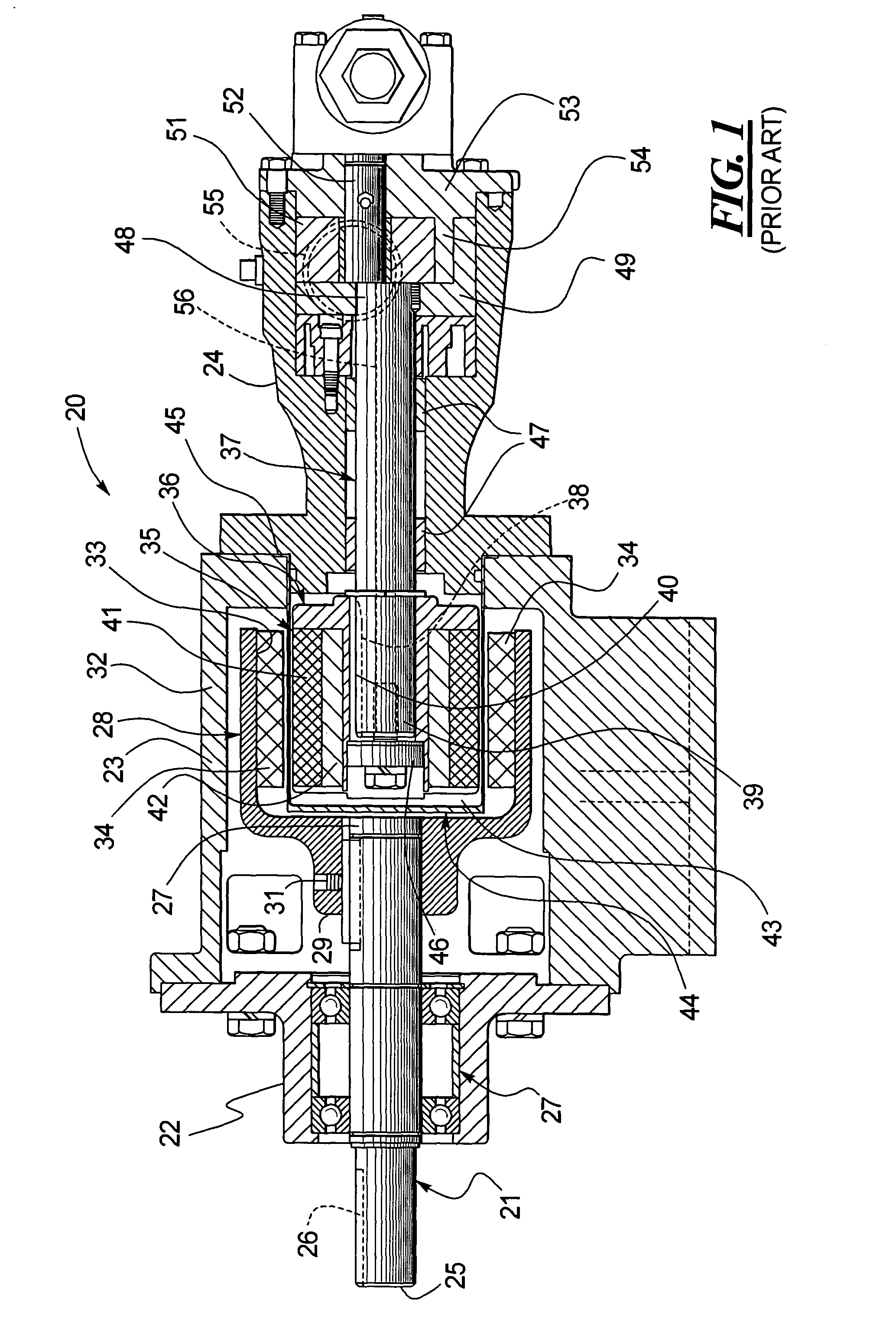

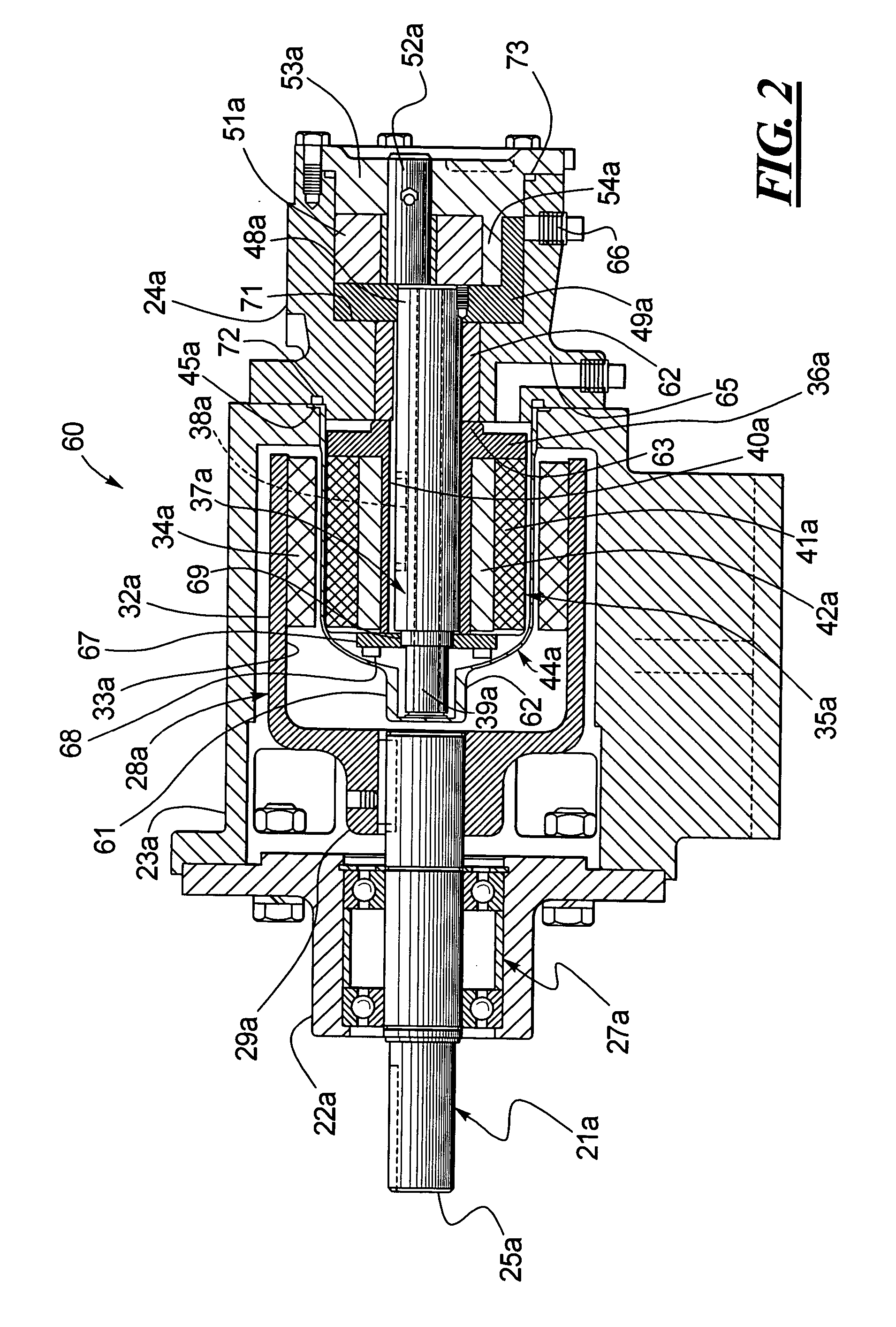

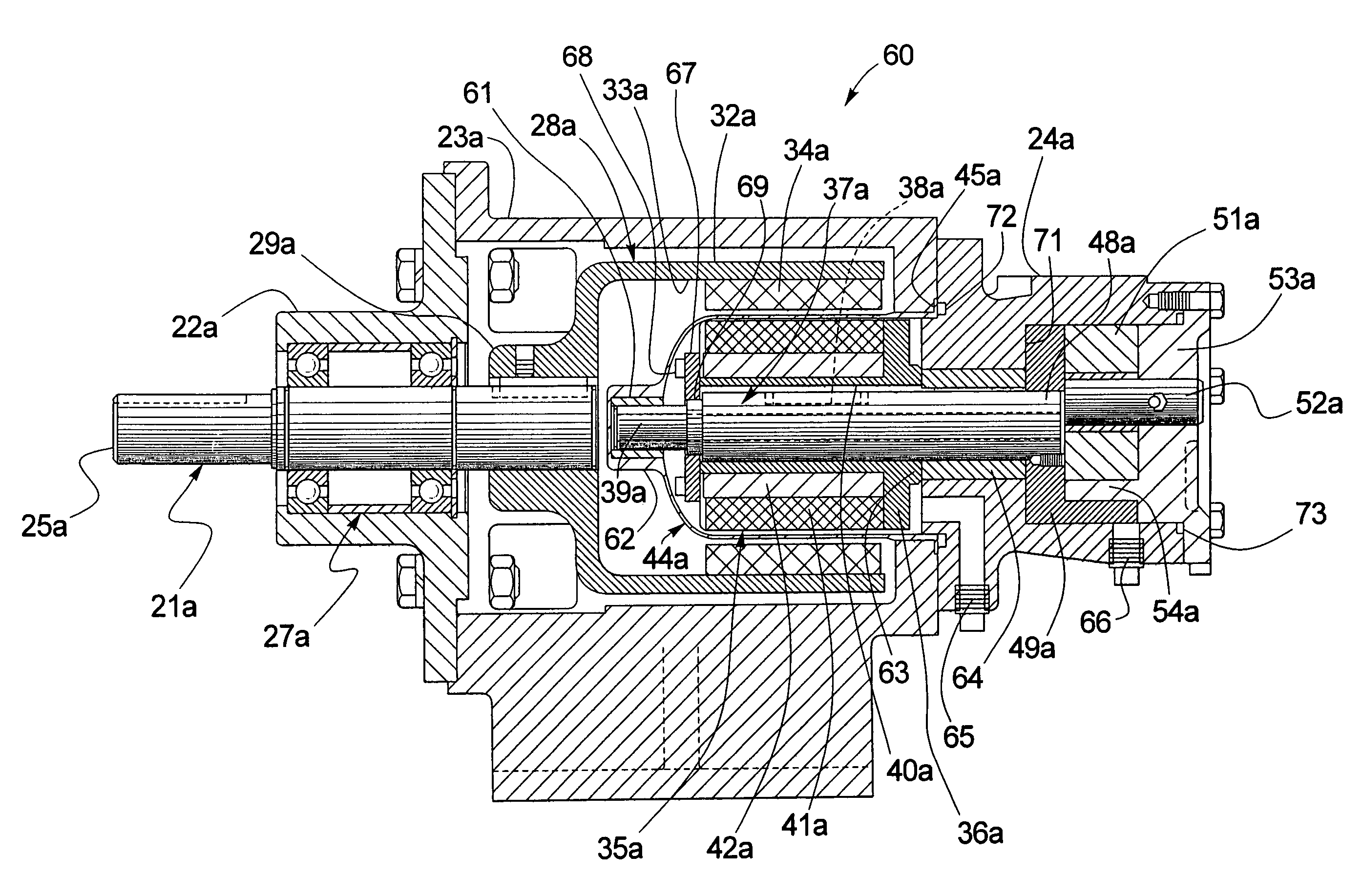

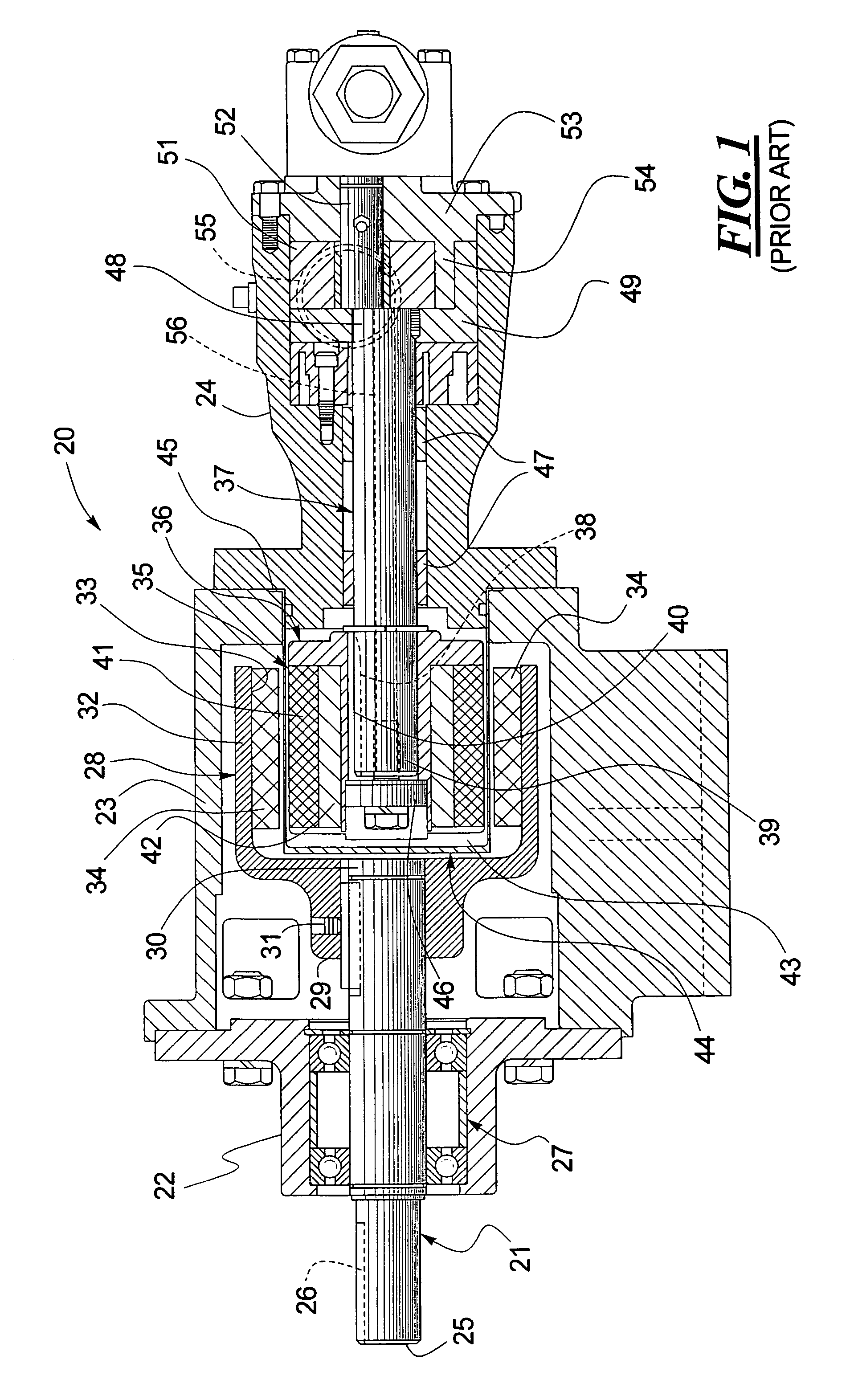

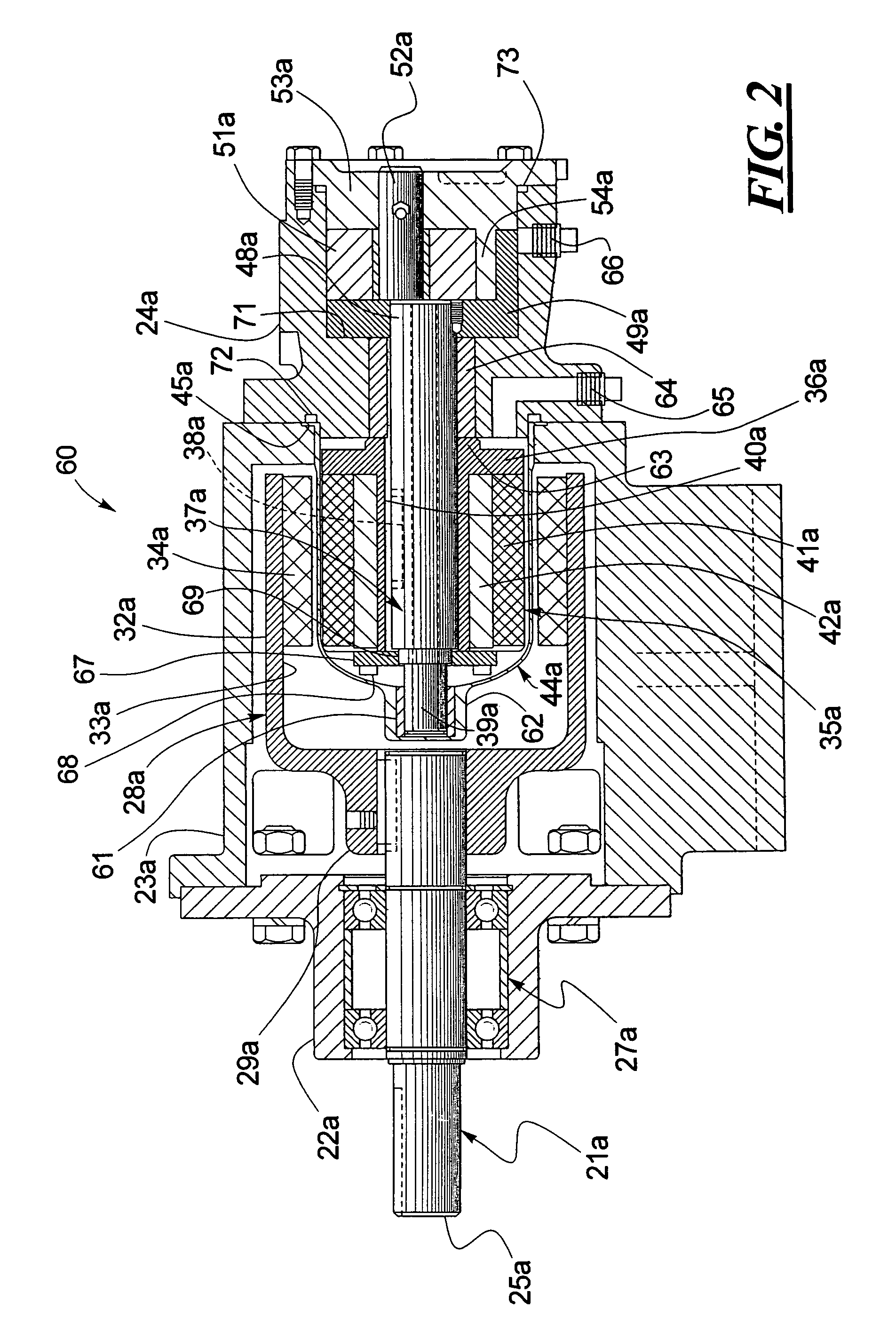

Rotor shaft bearing design and coupling mechanism

ActiveUS20040223864A1Improve stabilityInhibit migrationRotary piston pumpsRotary piston liquid enginesCouplingPump chamber

An improved magnetic drive pump is disclosed with improved bearing support for the proximal and distal ends of the rotor shaft. Further, an improved mechanism to couple the inner magnet assembly to the rotor shaft is also disclosed. Finally a mechanism for sealing the pump chamber from the interior of the canister that surrounds the inner magnet assembly is disclosed which permits a separate supply of coolant to be used for cooling the inner magnet assembly and the proximal end of the rotor shaft wherein such a coolant is not the fluid being pumped in the pump chamber. The pump chamber is isolated from the interior of the canister.

Owner:VIKING PUMP

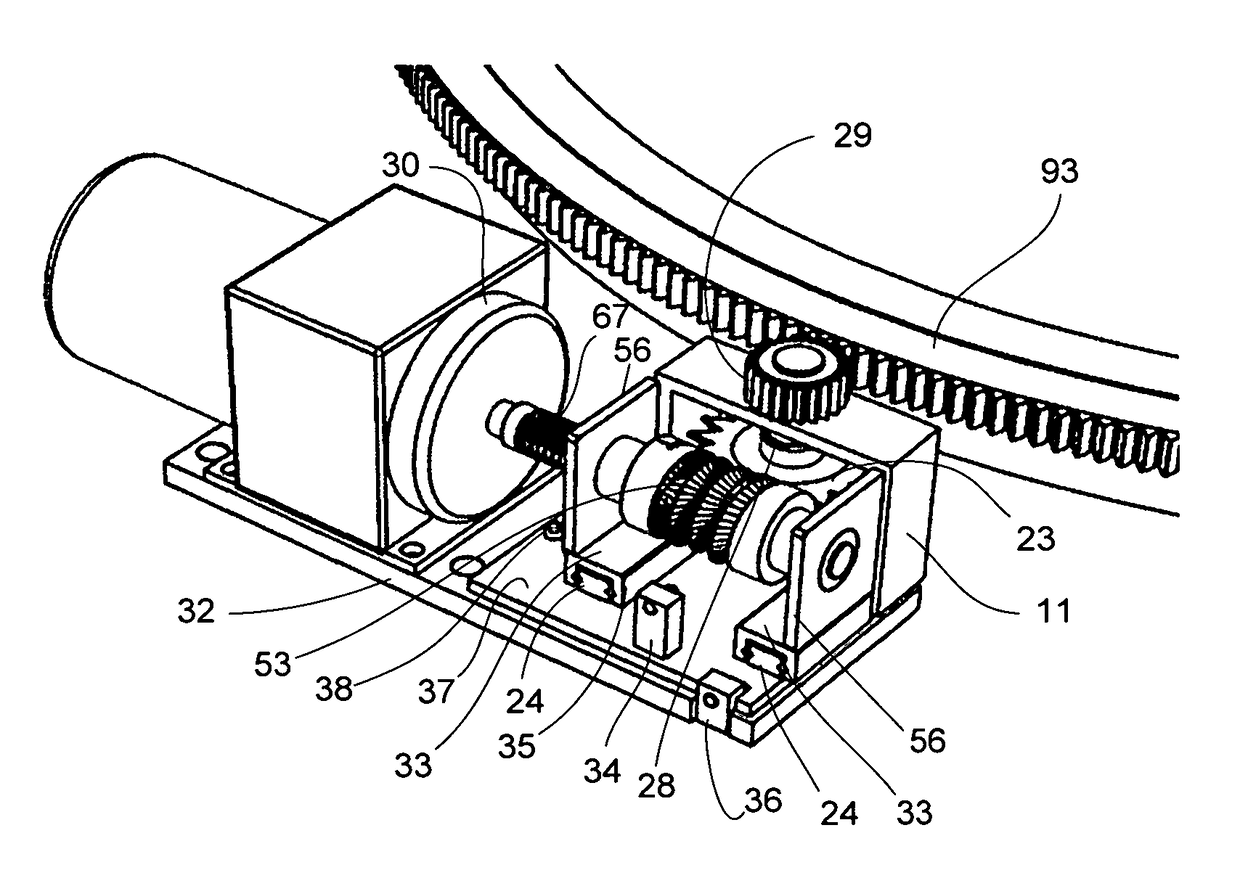

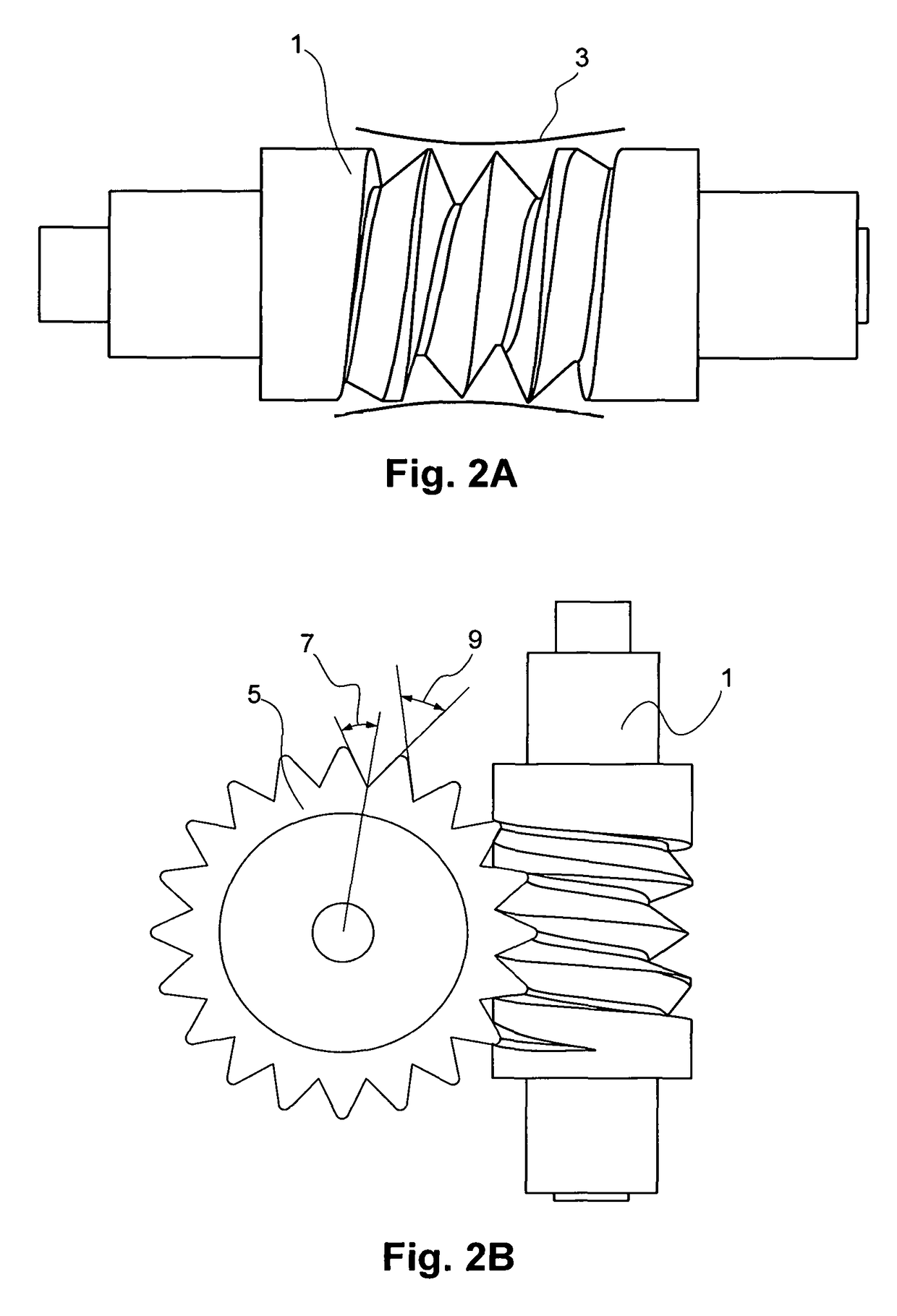

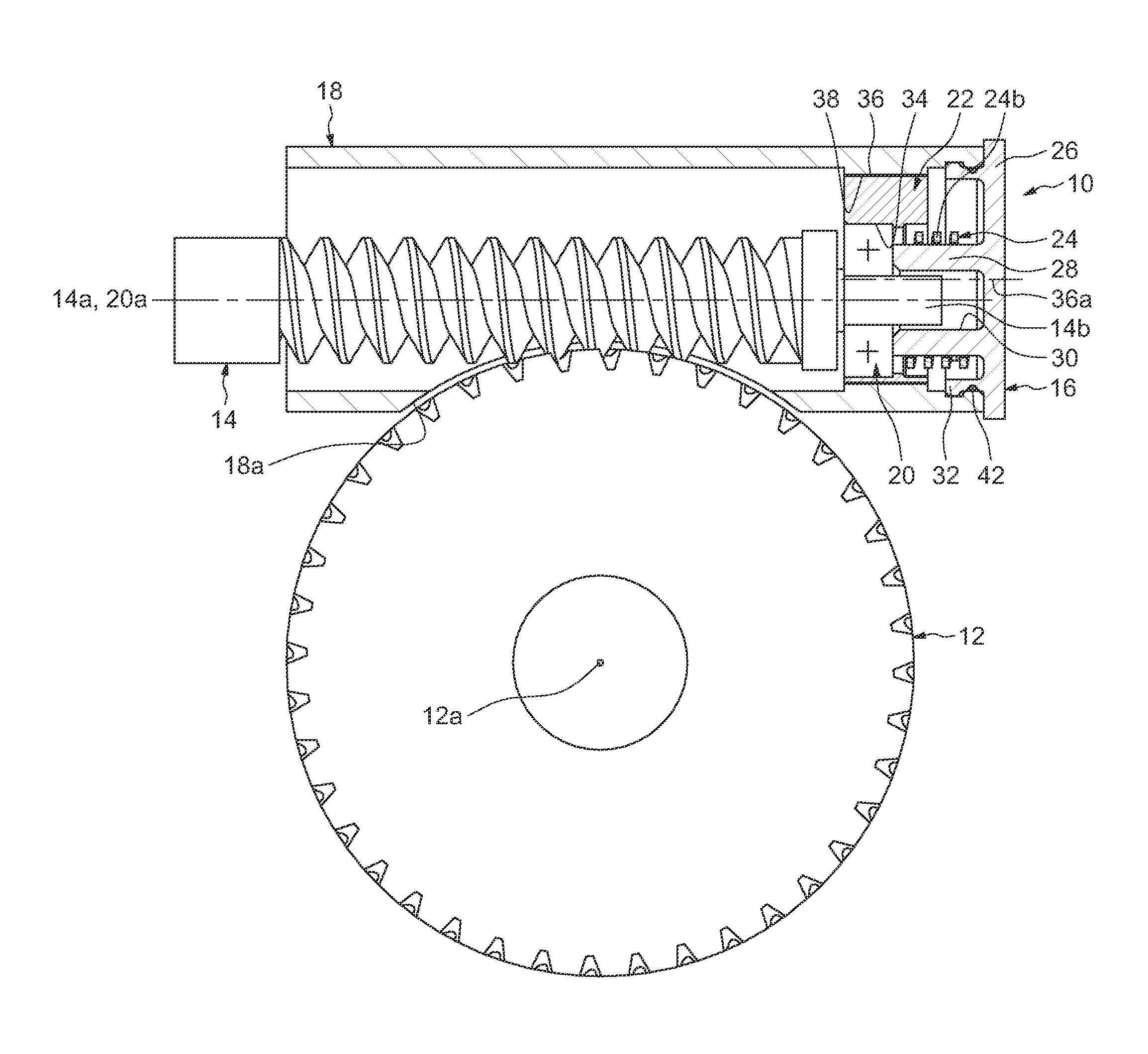

Precision positioning device and stage incorporating a globoid worm and its manufacture

The device is a precision motion right angle drive for use with linear and rotary stages which employs a combination of globoid worm and small diameter star gear. Coaxial with the star gear, on the same shaft, is a spur gear which drives the rotary stage gear or a linear rack. The thin star gear achieves meshing accuracy with the globoid worm permitting a large tooth angle for direct preloading without jamming. This gear combination eliminates backlash, allows a low gear ratio for low globoid worm speed, and enables the use of an ordinary spur gear to engage the stage gear without backdrive or backlash. Further, it allows for gear contact area to compensate for the thinness of the star gear. An embodiment including an integrated bearing rotary stage permits flexibility of application and avoidance of need for custom bearing designs by achieving high motion precision at low cost.

Owner:MAURO COMML IND OF VERO BEACH LLC

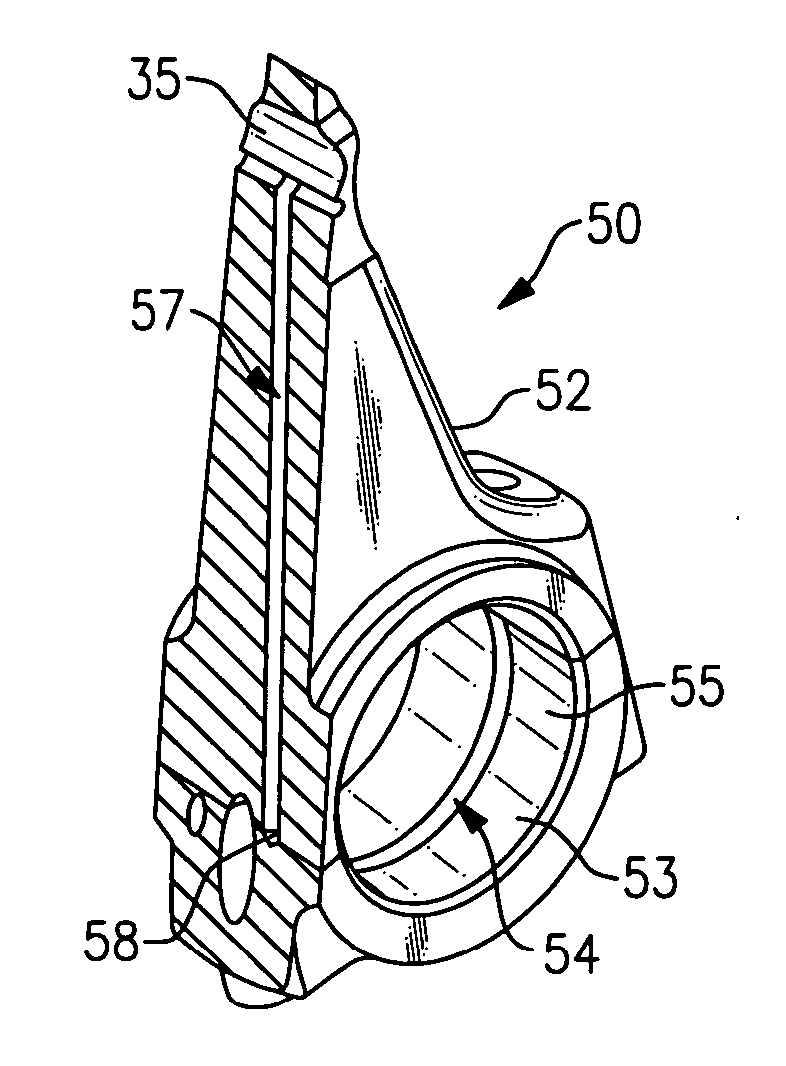

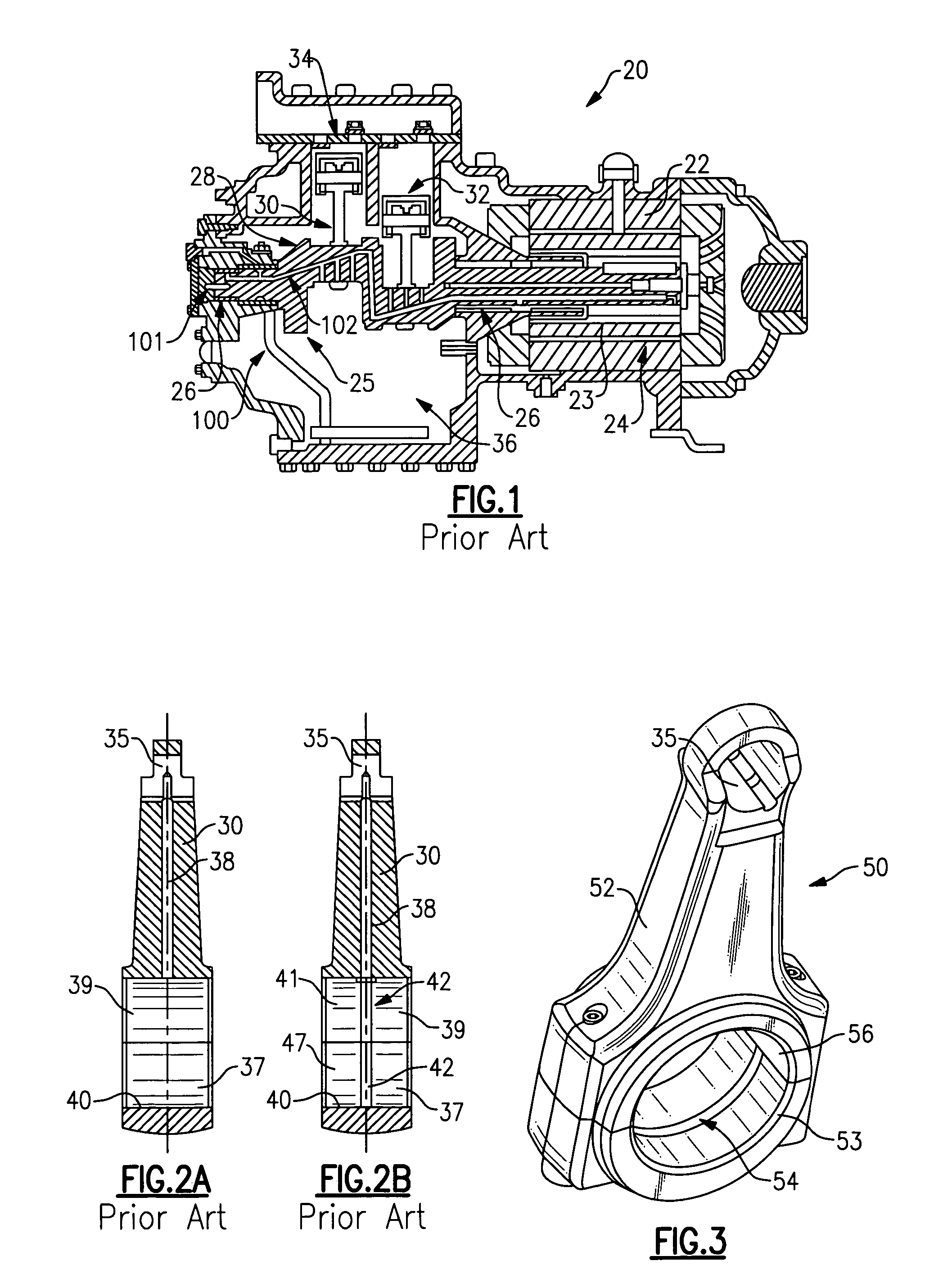

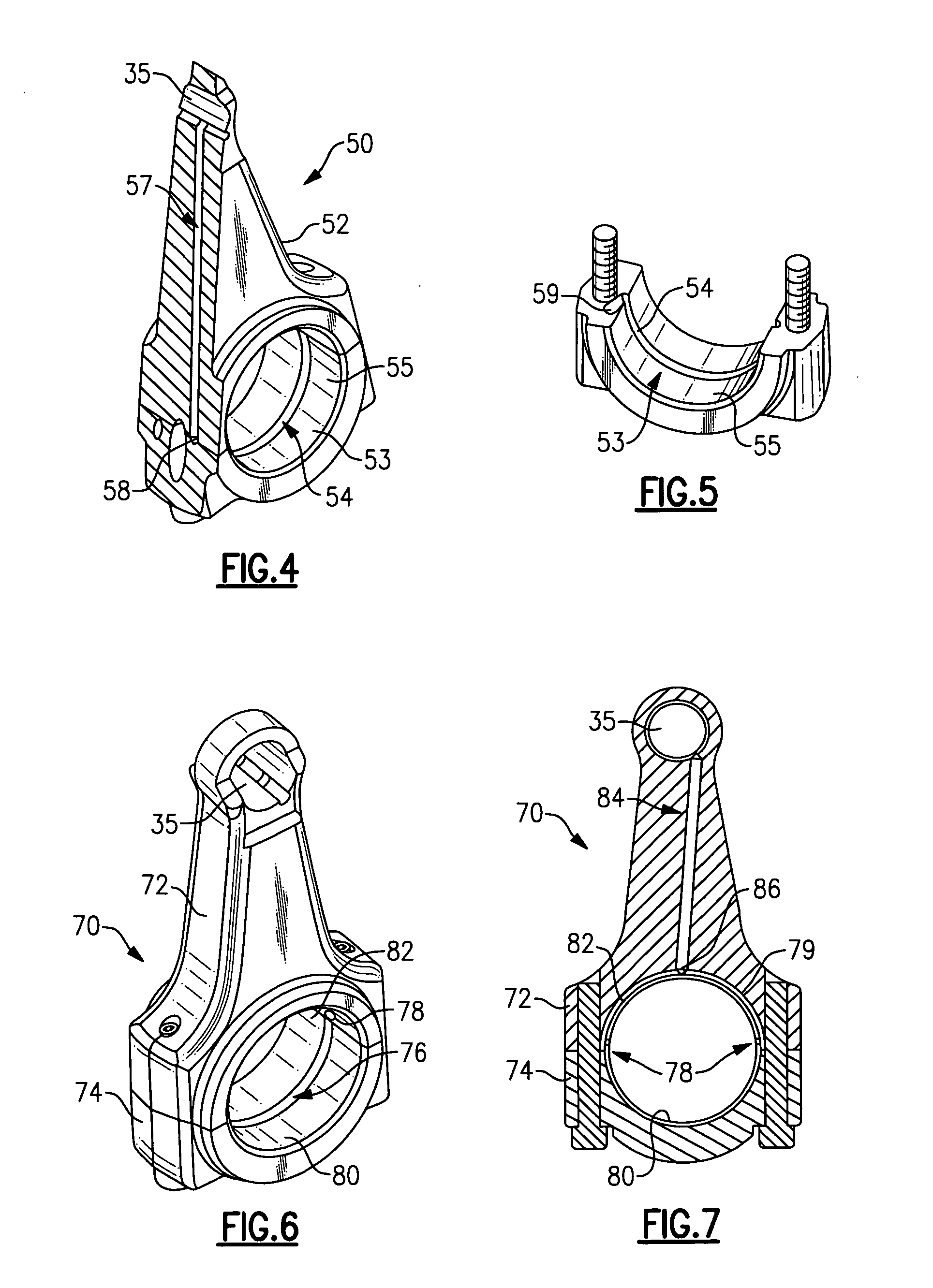

Compressor connecting rod bearing design

An improvement to the oil supply grooves in connecting rods for compressors increases surface area in an upper bearing half. The upper bearing half transmits a force from a driveshaft to the connecting rod. The lower half of the connecting rod includes an oil supply groove that extends over the majority of a circumferential extent of a bearing surface in the lower half that contacts an eccentric. On the other hand, the inner surface of the upper half does not include any large oil supply groove such that the surface area between the upper half and the eccentric is maximized.

Owner:CARRIER CORP

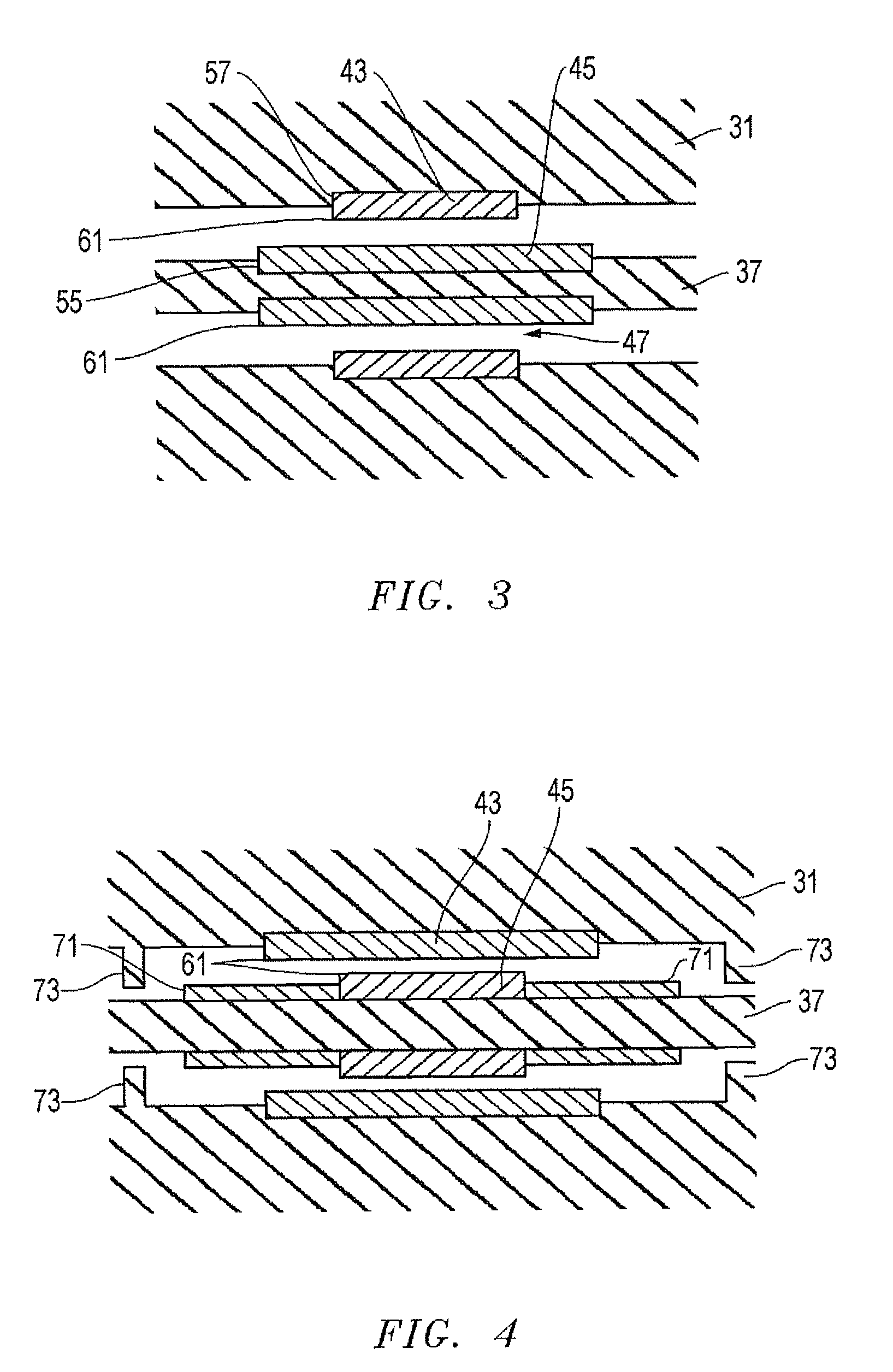

System, method and apparatus for scale resistant radial bearing for downhole rotating tool components and assemblies

Radial bearing designs for electrical submersible pump components and assemblies reduces scale build up on the bearing components. Scale resistant and abrasive resistant sleeves and bushings may be used. The axial lengths of the sleeves are kept within the axial length of the AR bushings, or vice versa, with regard to the axial stroke of one component relative to the other. In addition, sharp corners may be formed on the sleeve or bushing axial faces at their respective interfacing diameters. As the shaft moves axially, the sharp corner on one component scrapes off the scale on the other component. This design discards the scale rather than force it into the clearance between the sleeve and bushing. Small spacer sleeves also may be used adjacent the sleeves so that scale build up on the spacer sleeves is farther away from the bearing to reduce scale-related problems.

Owner:BAKER HUGHES INC

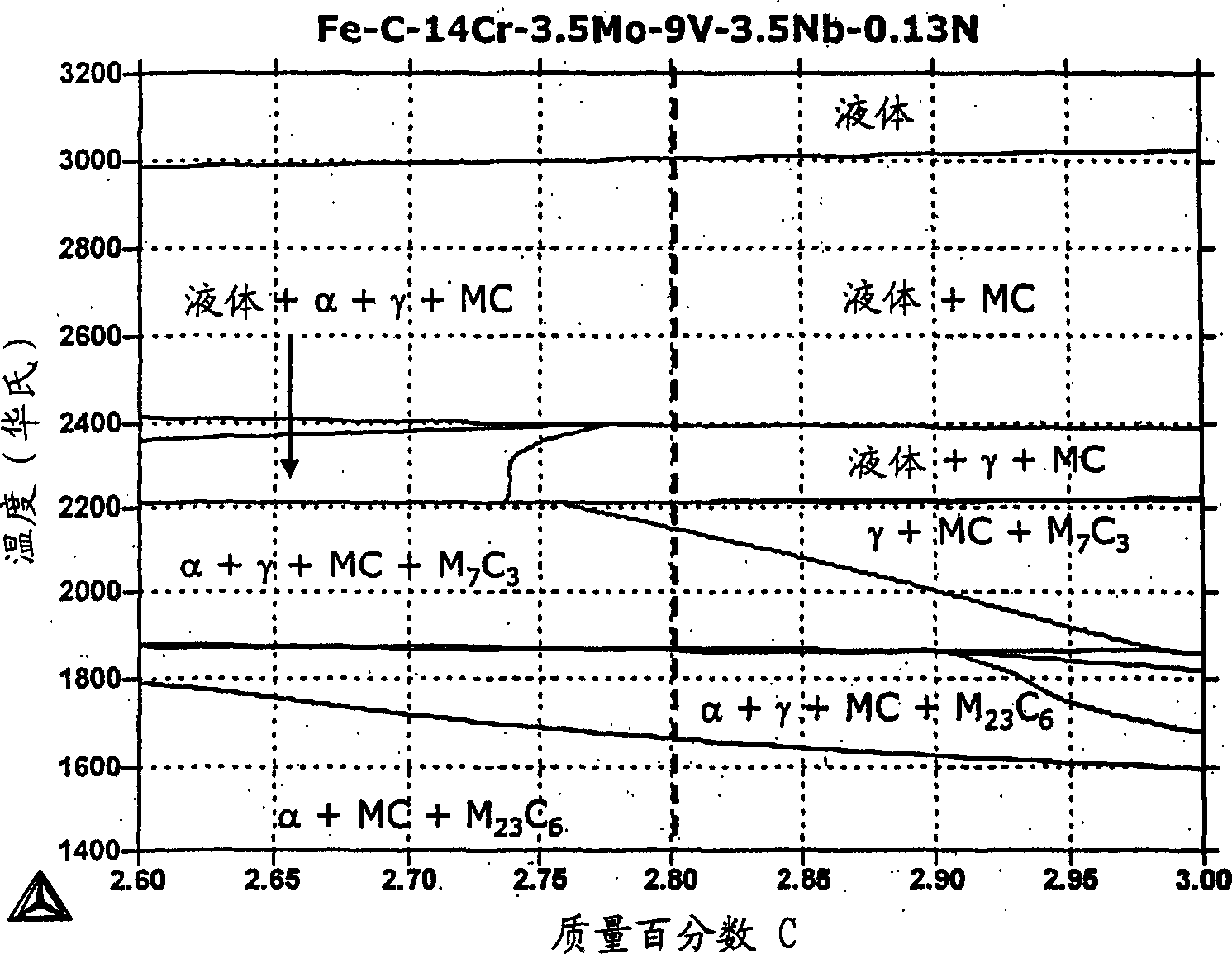

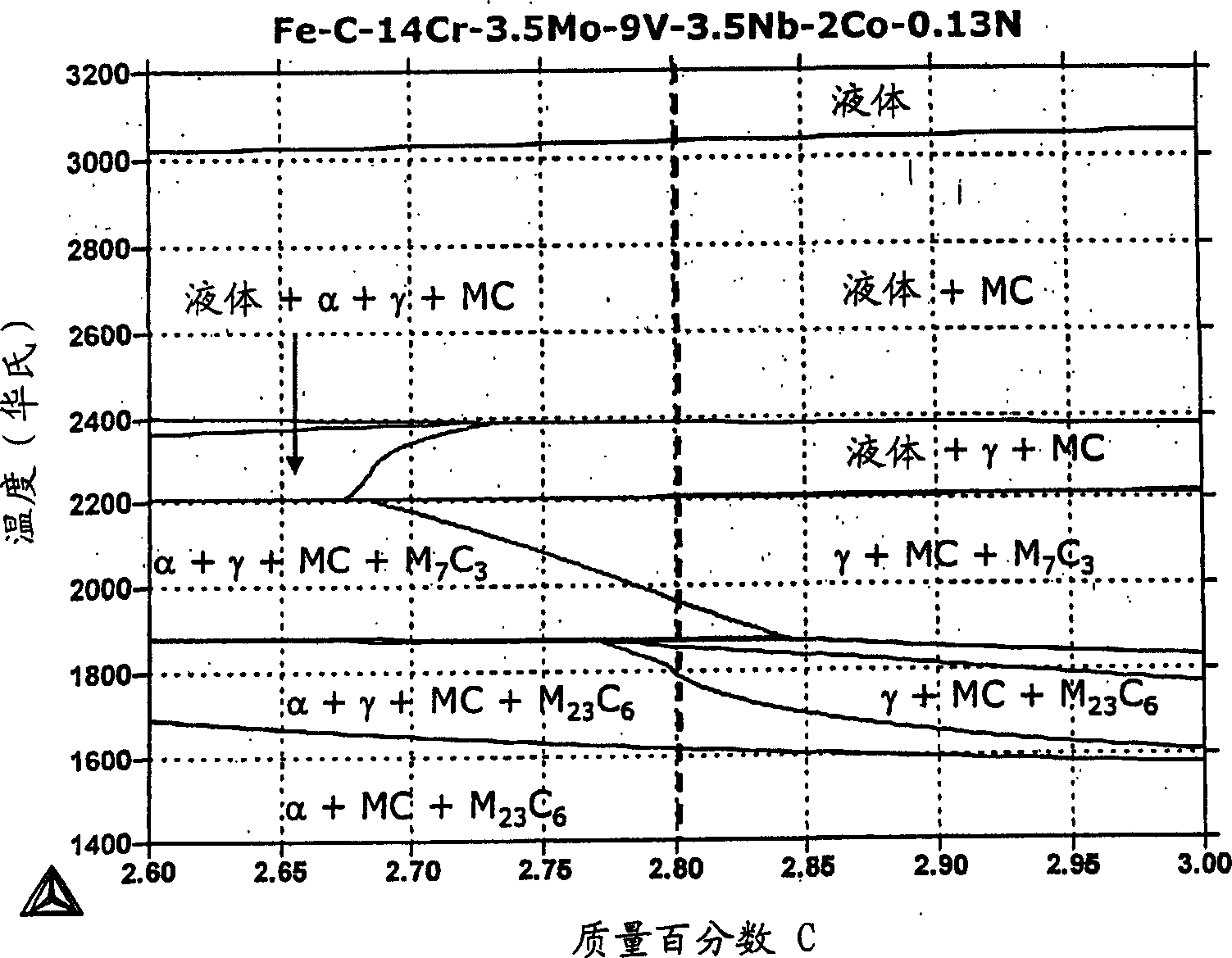

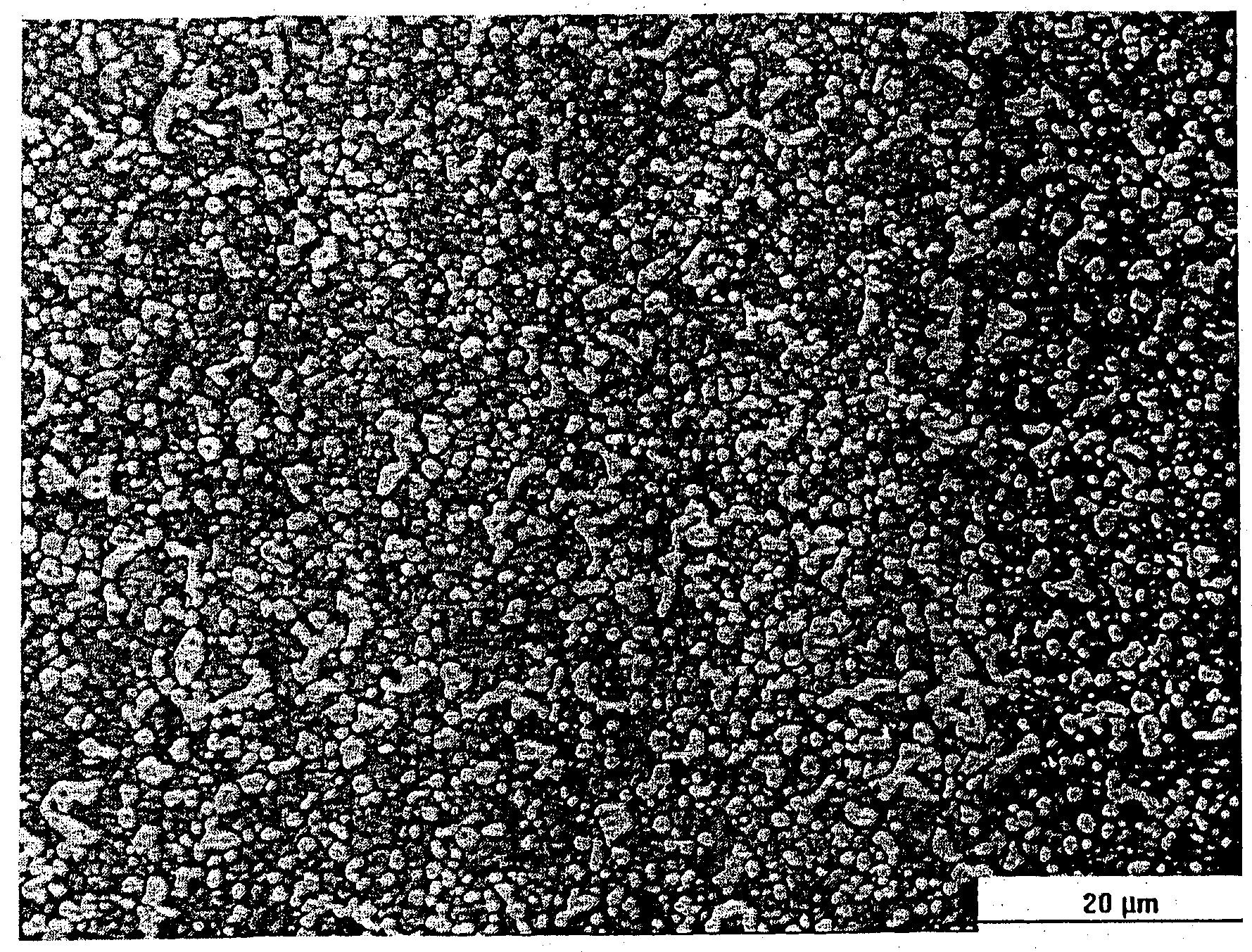

Corrosion and wear resistant alloy

A powder metallurgy corrosion and wear resistant tool steel article, and alloy thereof. The article is manufactured by hot isostatic compaction of nitrogen atomized, prealloyed high-chromium, high-vanadium, high-niobium powder particles. The alloy is characterized by very high wear and corrosion resistance, making it particularly useful for use in the manufacture of components for advanced bearing designs as well as machinery parts exposed to severe abrasive wear and corrosion conditions, as encountered, for example, in the plastic injection molding industry and food industry.

Owner:CRUCIBLE IND LLC

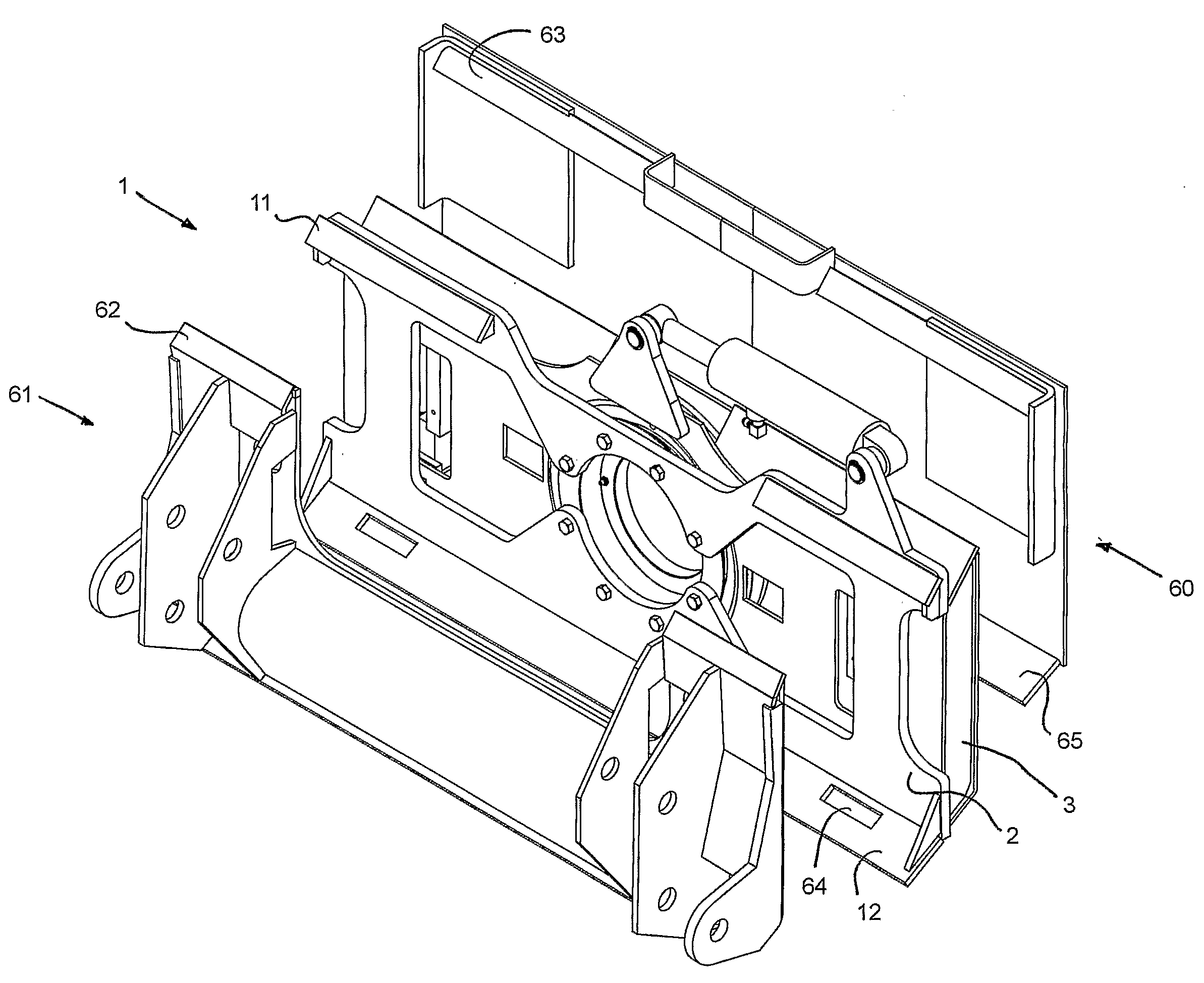

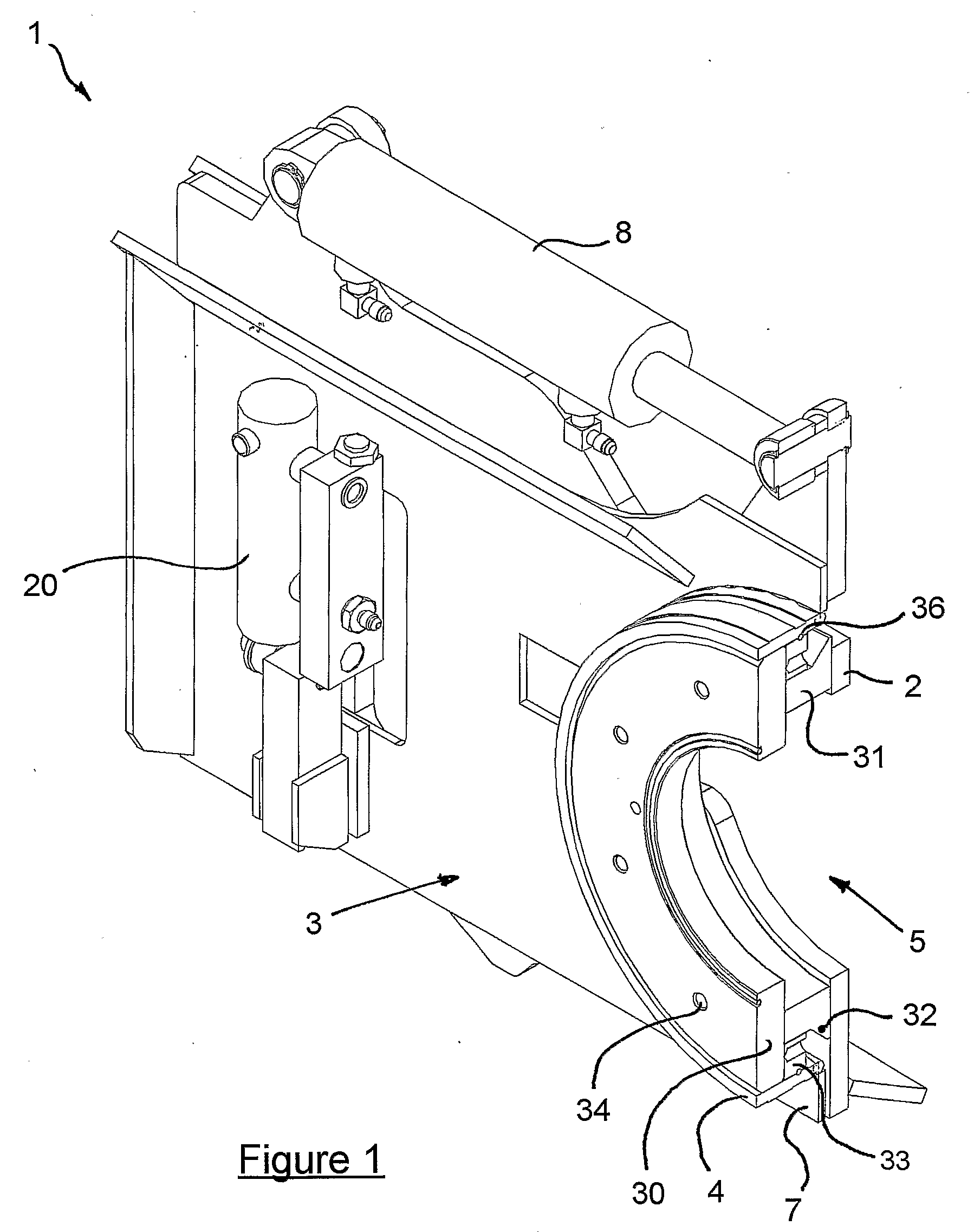

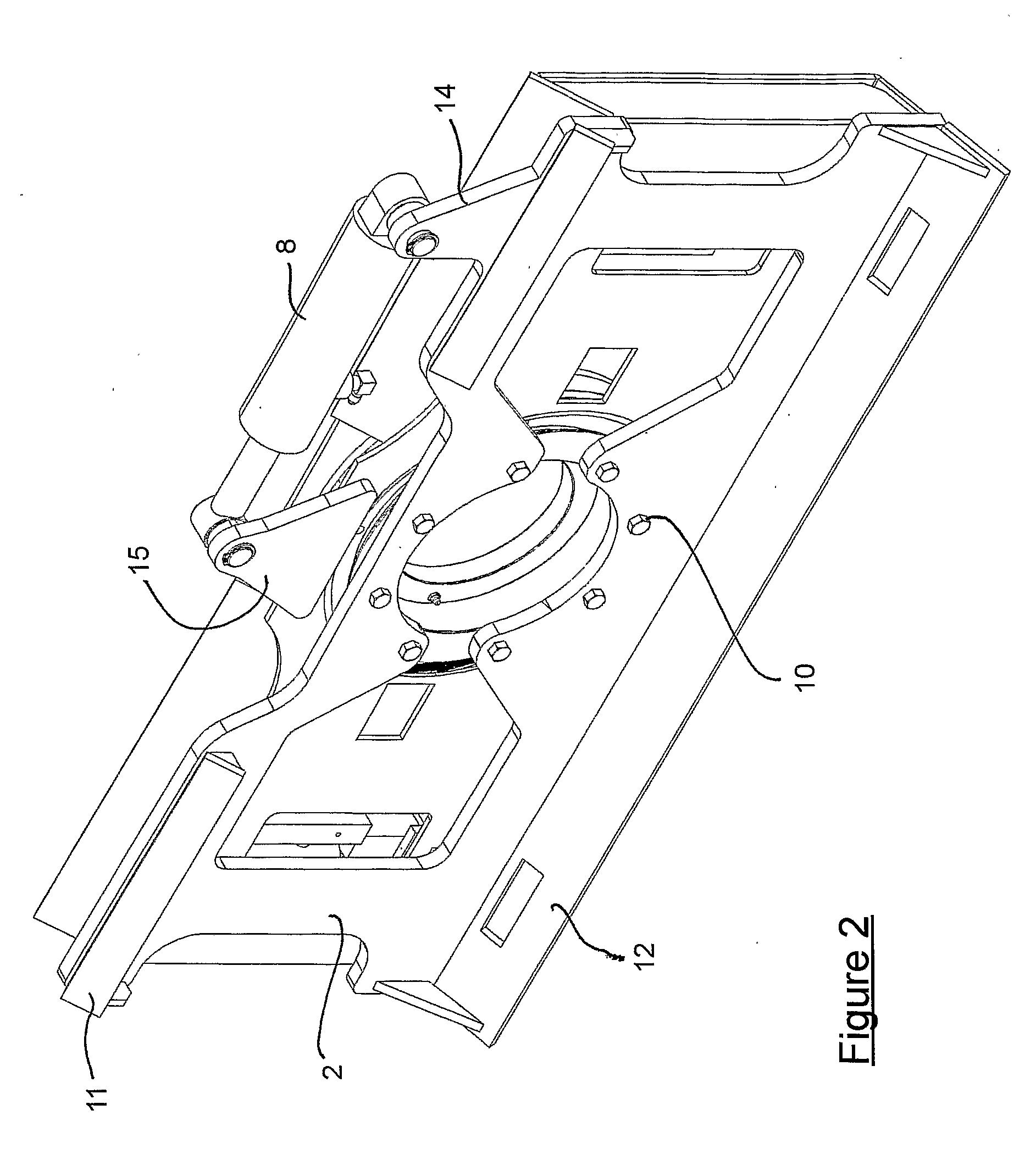

Tilting Accessory Hitch With Specific Bearing Design

InactiveUS20090096190A1Increase load manipulating performanceReduce depthThigh restsPedestrian/occupant safety arrangementAutomatic controlLevelling

A hitch assembly (1) commonly used between an accessory (such as a front end bucket) and a tractor or prime mover (such as a skid steer loader). The hitch assembly (1) includes a bearing arrangement, partly integral with one of two frame members (2, 3), which allows the two frame members (2, 3) to rotate relative to one another. The two frame members (2, 3) are attached to the tractor via adaptor (61) and the rear of the accessory (eg bucket 60). The bearing portion thus enables rotation of the accessory (60) about an axis substantially parallel to the longitudinal axis of the tractor. Automatic control in conjunction with laser type levelling systems or GPS contouring of sloped surfaces is also possible.

Owner:SHARP RODNEY WARWICH

Method for calculating all round properties of bearing of turbo generator in large size

InactiveCN1760511AClear and convenient pre- and post-processingEliminate operating errorsMachines/enginesEngine componentsTurbo generatorEngineering

A method for calculating comprehensive performance of bearing for generator on large ¿C scale turbine includes calling on pretreatment and post ¿C treatment processing module to carry out design pretreatment of bearing for selecting type of bearing and for inputting relevant bearing geometric parameter and single or integrated operation mode parameter , calling on relevant bearing calculation module to calculate parameters of bearing static ¿C dynamic character and bearing stability according to selected type of bearing , returning back to pretreatment and post ¿C treatment module to carry out design post ¿C treatment of bearing.

Owner:SHANGHAI UNIV +1

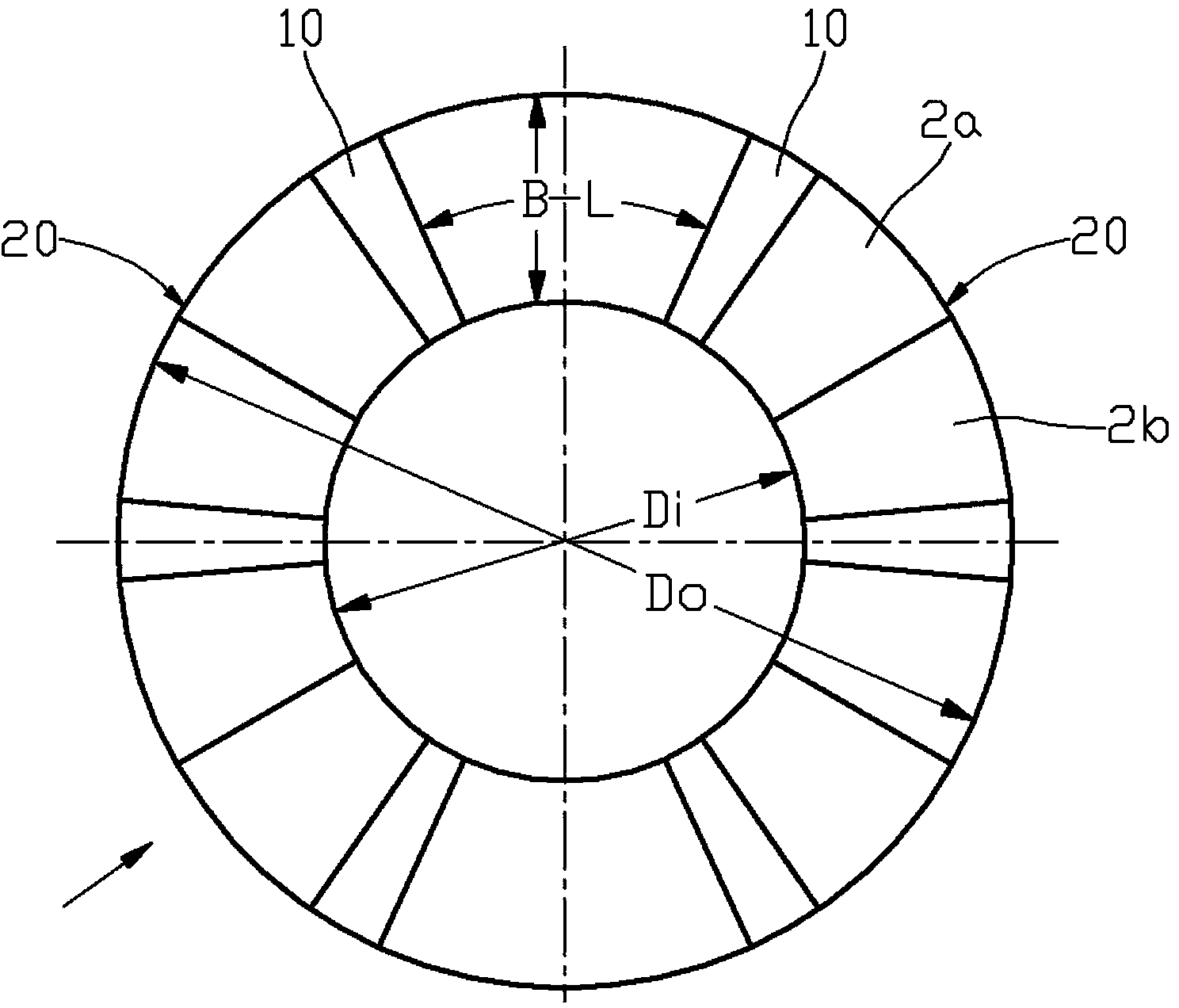

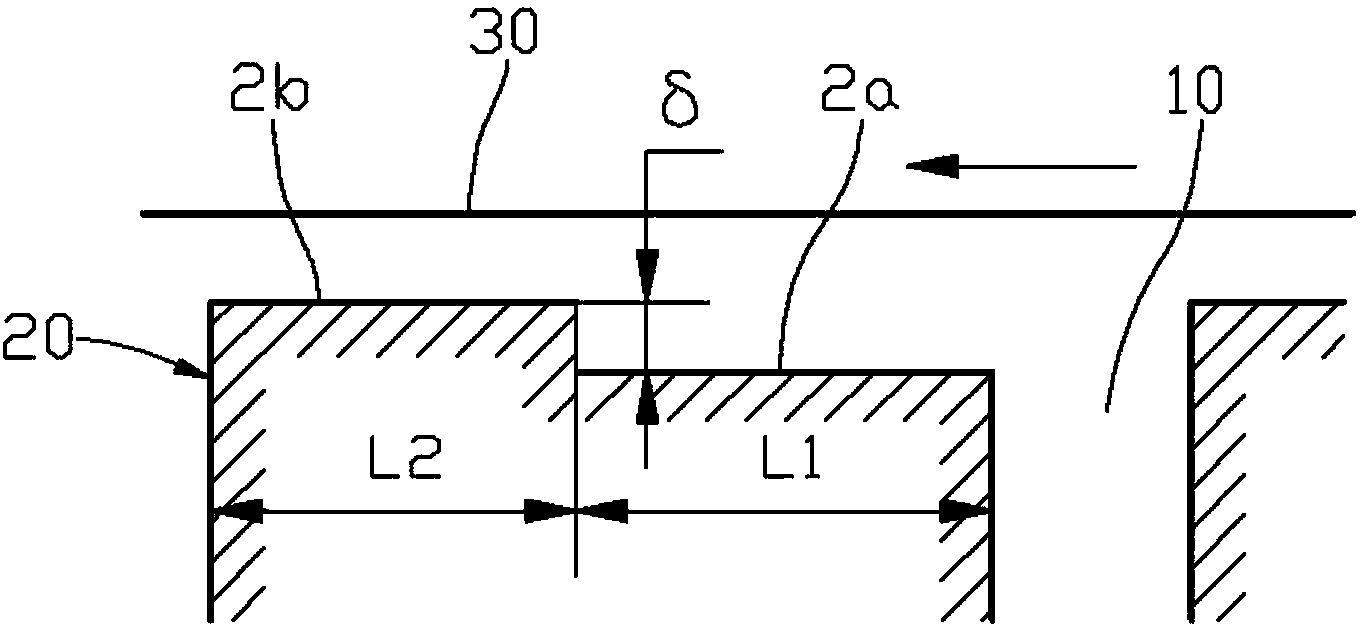

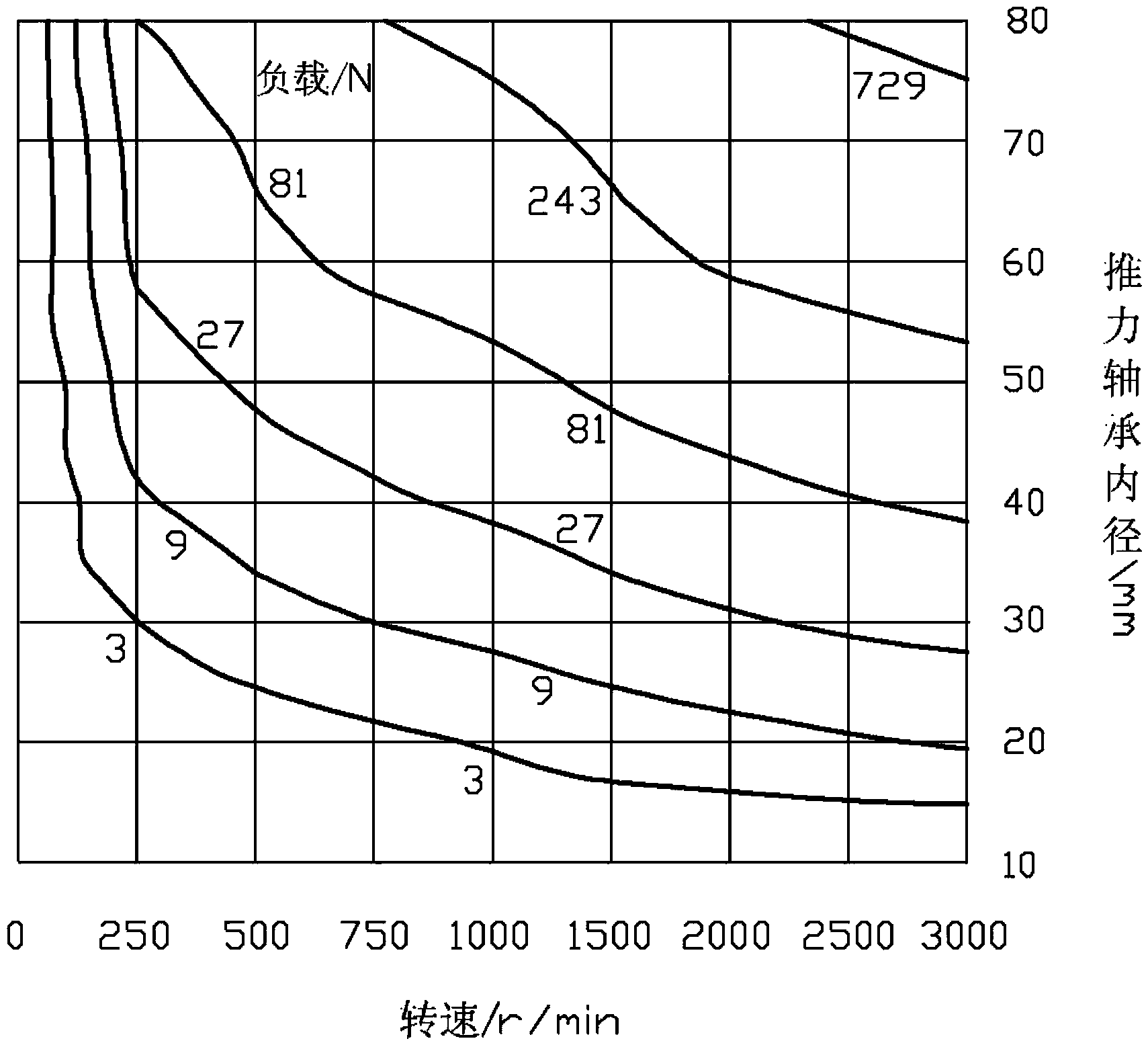

Design method of water lubrication step tile dynamic pressure thrust bearing

InactiveCN103557229AHeavy loadExtended service lifeBearing componentsSliding contact bearingsThrust bearingEngineering

The invention discloses a design method of a water lubrication step tile dynamic pressure thrust bearing. The design method comprises the following steps of (1) determining an inner diameter and an outer diameter of the thrust bearing according to an operating working condition and an installing size of the thrust bearing; (2) determining the number of thrust tiles according to the inner diameter and the outer diameter of the thrust bearing; (3) determining the shape and the size of a water tank; (4) determining positions and sizes of steps on the surfaces of the thrust tiles; and (5) determining the position of a water inlet. According to the method, aiming at the blank of a water lubrication bearing design, by researching a lubrication model of a common-size step tile dynamic pressure thrust bearing under the water lubrication working condition, and analyzing the influence on the bearing capacity of the bearing and the rigidity of a water film caused by the structure size and the operation working condition of the step tile thrust bearing, the most optimized design method is obtained, the water lubrication bearings with same sizes bear large load and are long in service life.

Owner:SHENKE SLIDE BEARING

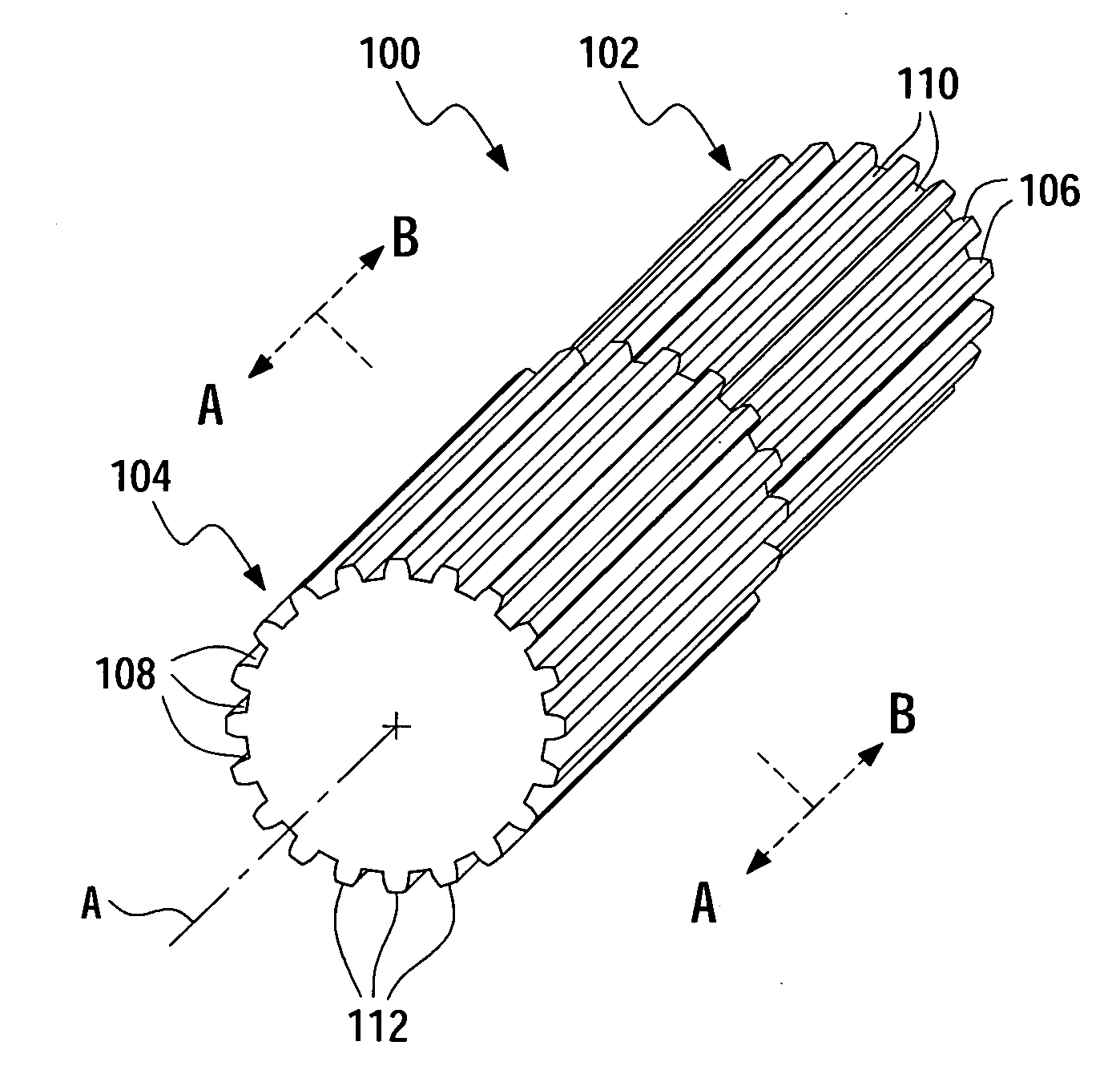

Partial tooth gear bearings

This invention obviates the need for an end roller in the traditional gear bearing design without giving up the desired bearing functions. The preferred embodiment of the partial gear bearing of the invention includes an upper half, comprising peak partial teeth, and a lower, or bottom, half, comprising valley partial teeth. The upper half also has an integrated roller section between each of the peak partial teeth with a radius equal to the gear pitch radius of the radially outwardly extending peak partial teeth. Conversely, the lower half has an integrated roller section between each of the valley half teeth with a radius also equal to the gear pitch radius of the peak partial teeth. The valley partial teeth extend radially inwardly from its roller section. The peak and valley partial teeth are exactly out of phase with each other, as are the roller sections of the upper and lower halves. Essentially, the end roller bearing of the typical gear bearing has been integrated into the normal gear tooth pattern.

Owner:NASA

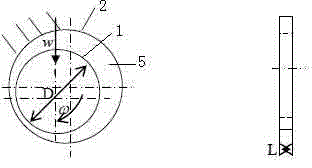

Novel energy-saving radial sliding bearing

ActiveCN104454980AImprove carrying capacityExcellent friction reductionBearing componentsSliding contact bearingsCarrying capacityThin layer

The invention provides a novel energy-saving radial sliding bearing, which is formed by matching a shaft and a bearing sleeve hole or bearing block hole. A bearing sleeve hole wall or bearing block hole wall at an inlet region of a convergent wedge-shaped pore of the bearing is coated by a thin layer material, and the surface-treated bearing sleeve hole wall or bearing block hole wall is paired with the shaft; a gap formed between the bearing sleeve hole wall or bearing block hole wall and the shaft is filled with lubricating oil. The novel energy-saving radial sliding bearing designed by adopting an interface slip technology and adopting a surface coating method has the advantages of great carrying capacity, low coefficient of friction and excellent energy-saving performance. Compared with the traditional interface-slip-free radial sliding bearing, the bearing provided by the invention has the advantages of obviously improved carrying capacity, and obviously improved antifriction and energy-saving performances, thus having an important application value.

Owner:怀宁吉利来精密机械科技有限公司

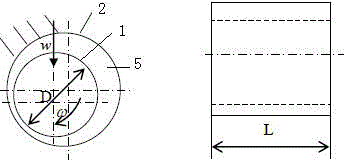

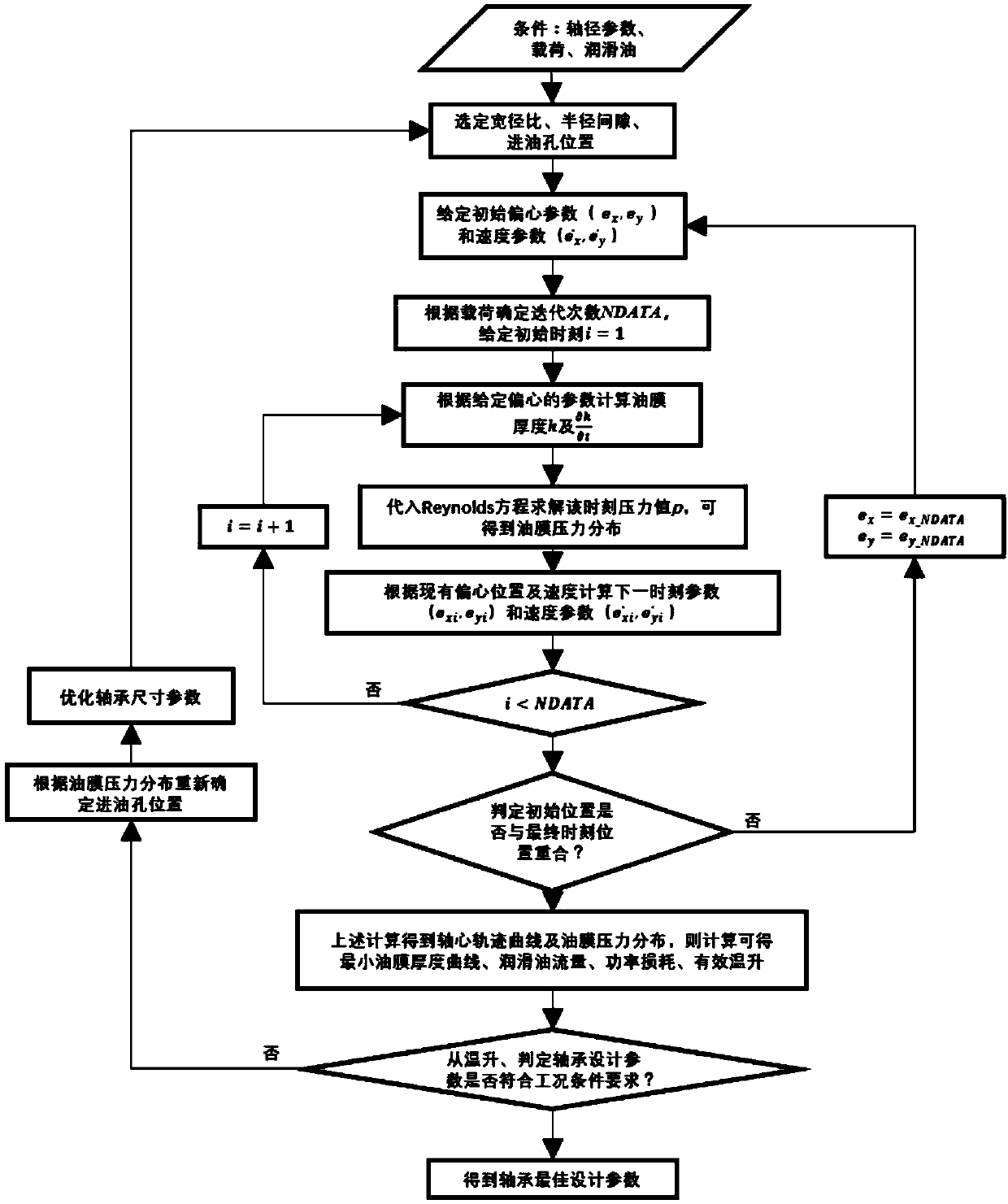

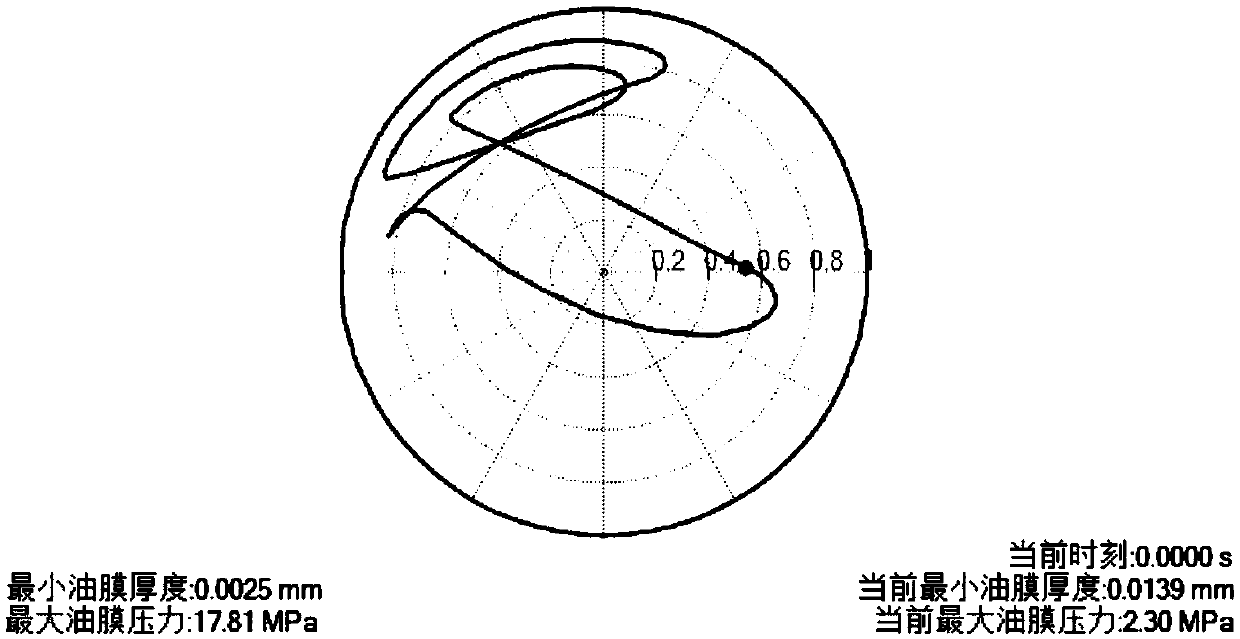

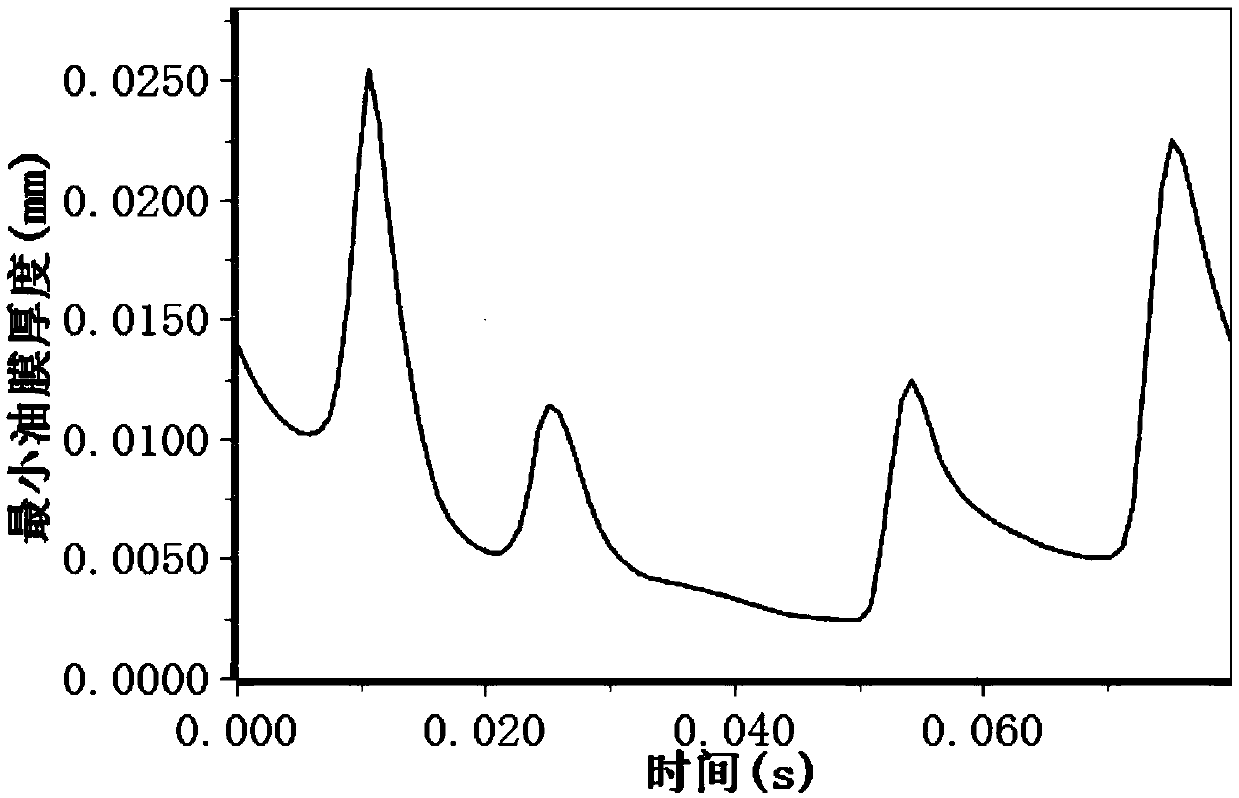

Dynamic load bearing design method applied to reciprocating compressor crankshaft

ActiveCN108799318AFull checkImprove securityGeometric CADCrankshaft bearingsFinite element methodDiameter ratio

The invention discloses a dynamic load bearing design method applied to a reciprocating compressor crankshaft. The method solves the problems that in the traditional dynamic load bearing design process, parameters are difficult to determine, and characteristic parameter calculation is complex. The design method comprises the steps of width-diameter ratio design and radius gap interval computationin the bearing design process, and further comprises the step of calculation of pressure distribution, minimum oil film thickness, oil film pressure, lubricating oil flow, power loses, equivalent temperature rise and the like of a bearing, all parameter indexes of the bearing are checked more comprehensively, and the design objective safety is high. According to the method, a finite element methodis adopted for solving a Reynolds equation, compared with traditional experience formula computing, more parameters can be obtained, as for the bearing, with the complex variable working condition, like the dynamic load bearing, the design steps are simplified, and the design time is saved; and design of a bearing oil inlet hole is carried out by drawing a cloud picture of a pressure crankshaft angle and a bearing circumferential unfolding angle.

Owner:XI AN JIAOTONG UNIV

Rotor shaft bearing design and coupling mechanism

ActiveUS7029246B2Inhibit migrationIncreased axial stabilityRotary piston pumpsRotary piston liquid enginesCouplingPump chamber

An improved magnetic drive pump is disclosed with improved bearing support for the proximal and distal ends of the rotor shaft. Further, an improved mechanism to couple the inner magnet assembly to the rotor shaft is also disclosed. Finally a mechanism for sealing the pump chamber from the interior of the canister that surrounds the inner magnet assembly is disclosed which permits a separate supply of coolant to be used for cooling the inner magnet assembly and the proximal end of the rotor shaft wherein such a coolant is not the fluid being pumped in the pump chamber. The pump chamber is isolated from the interior of the canister.

Owner:VIKING PUMP

Wear-compensation device for a gear

The wear-compensation device for a gear comprises a fixed support capable of being fixed axially on an external element in order to keep the device on the said external element, a bearing designed to be mounted on a shaft comprising one of the wheels of the gear, an eccentric mounted on the bearing and designed to be in contact with the external element, the said eccentric being able to move angularly relative to the fixed support. The device also comprises a torsion spring mounted axially between the fixed support and the eccentric and capable of exerting a circumferential preload force on the said eccentric, the said spring comprising a first end mounted inside a recess of the eccentric and a second end interacting with the fixed support.

Owner:AB SKF

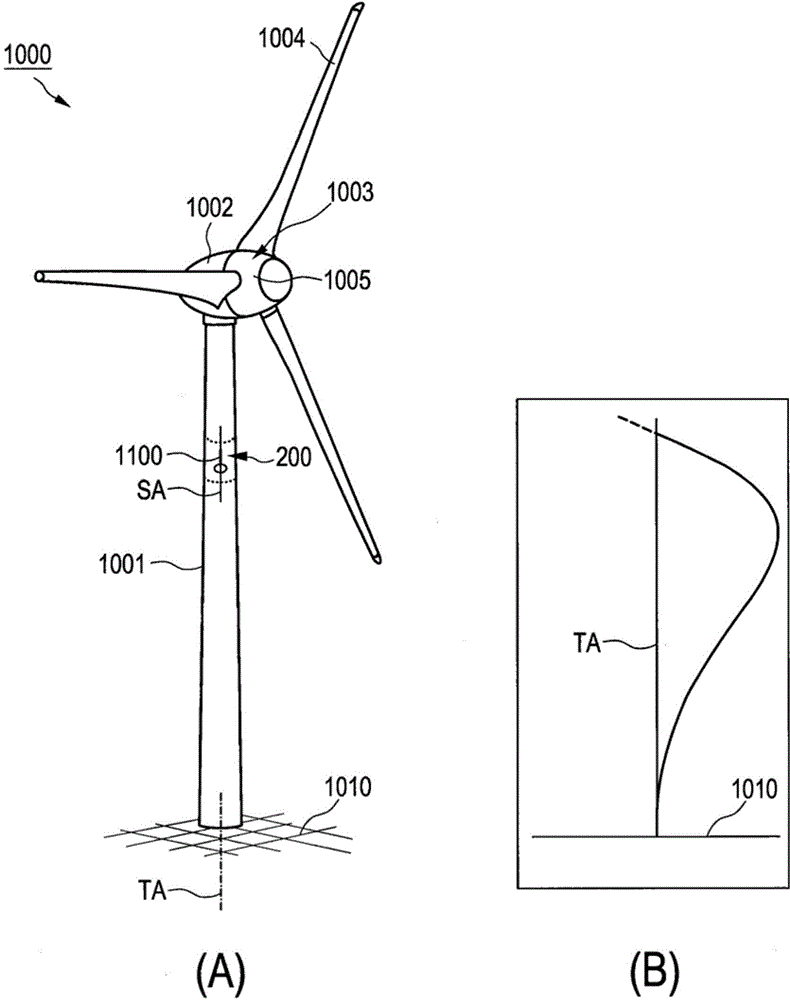

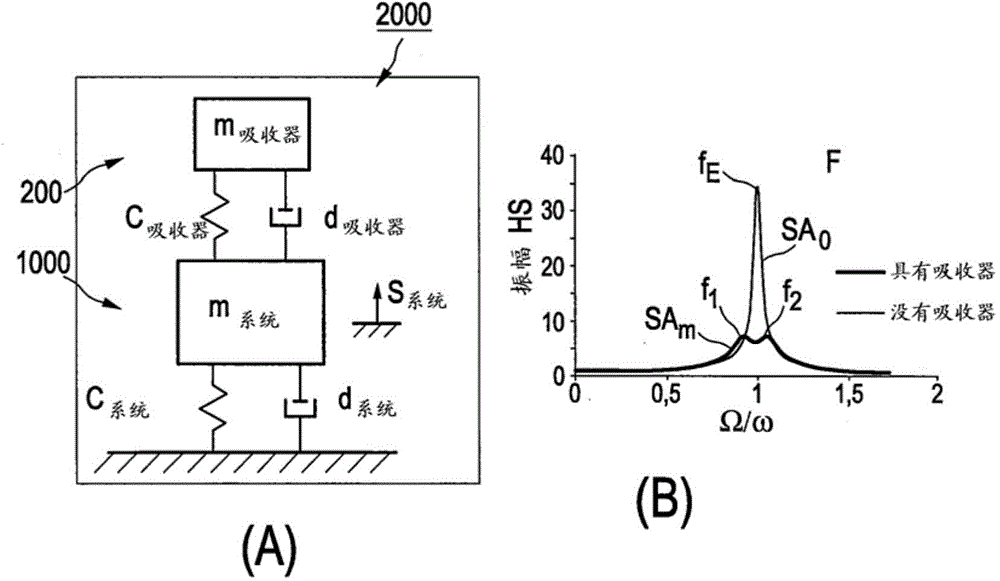

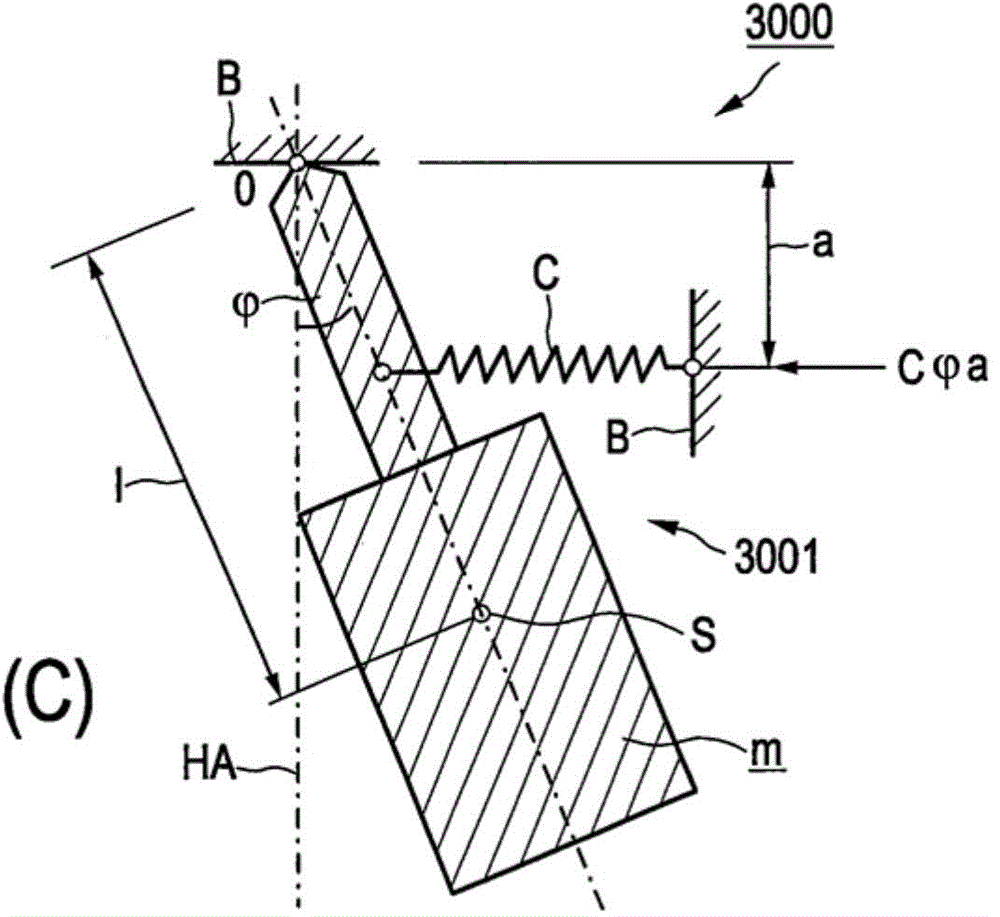

Vibration-limiting module and device, structural segment for structural installation, and wind turbine having vibration-limiting module

InactiveCN104838075AEfficient structure and installationEngine fuctionsWind motor supports/mountsSlider bearingClassical mechanics

Owner:WOBBEN PROPERTIES GMBH

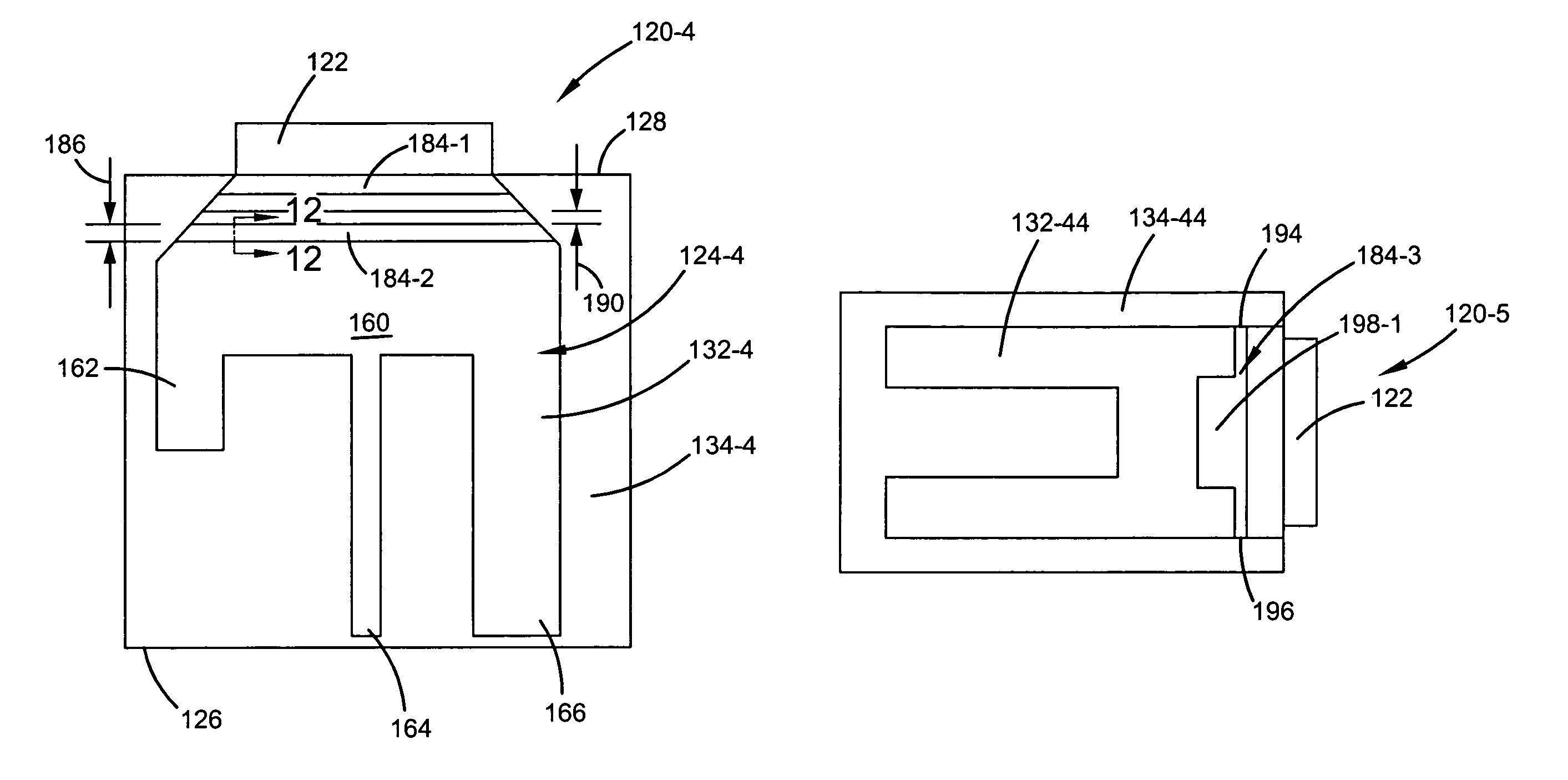

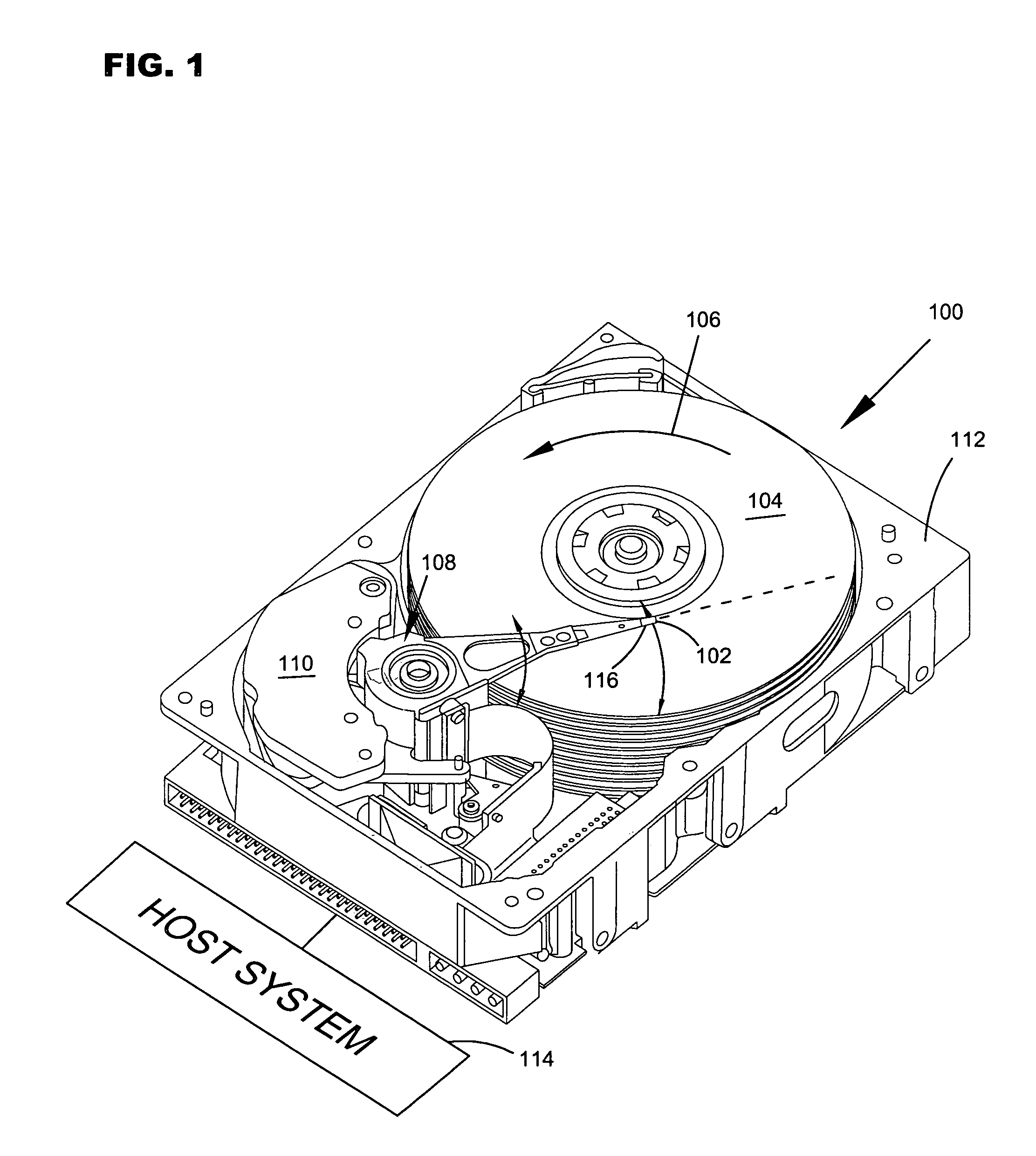

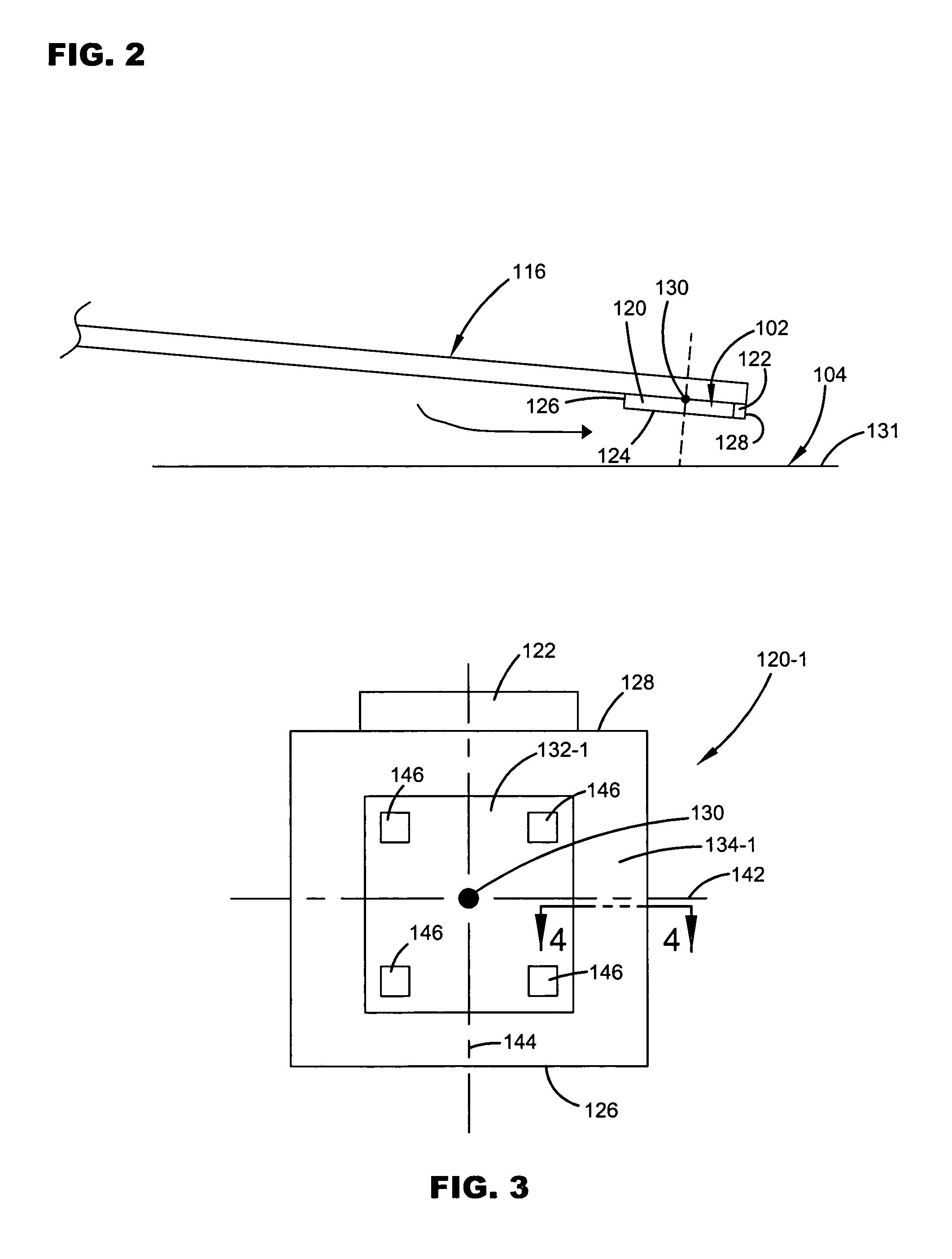

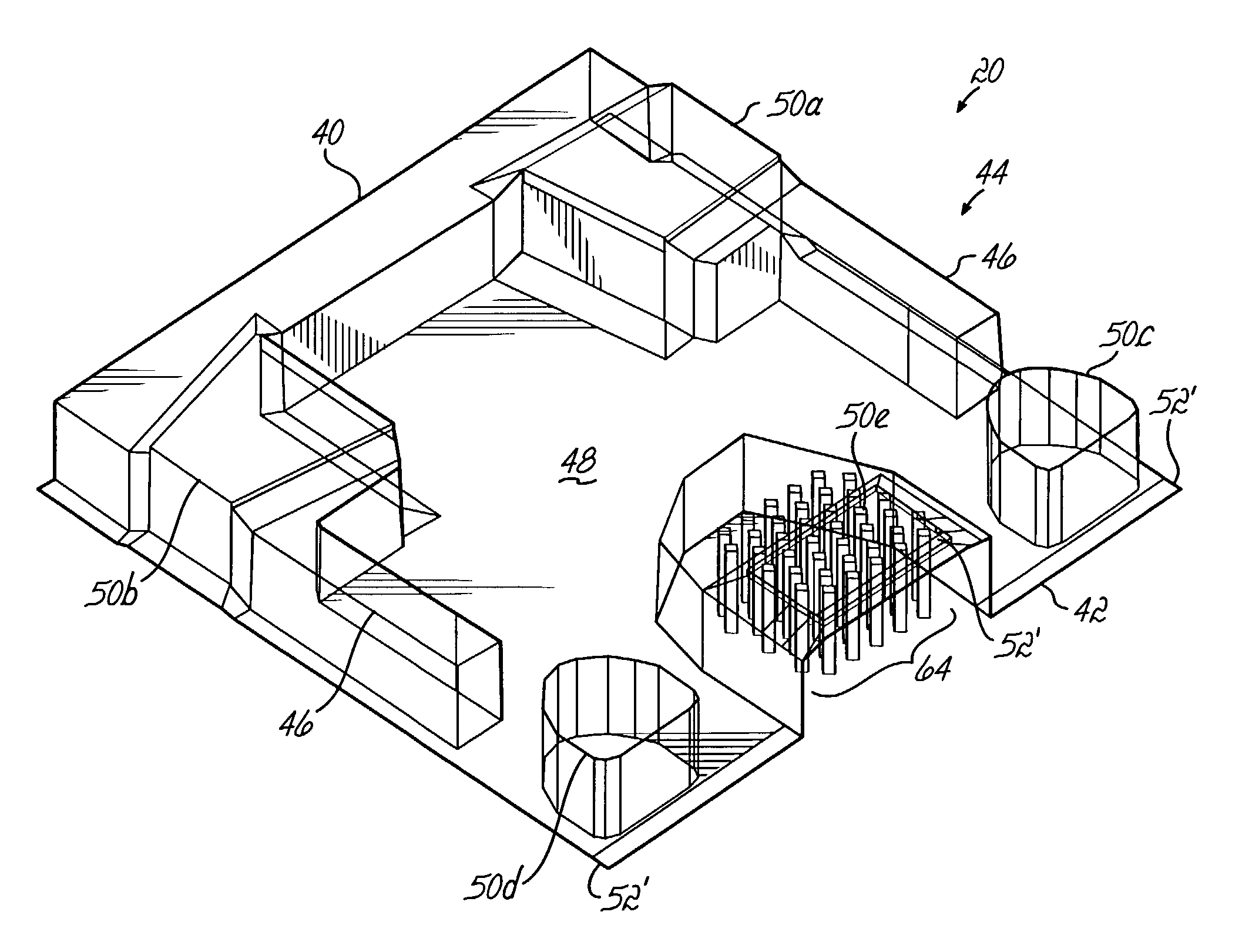

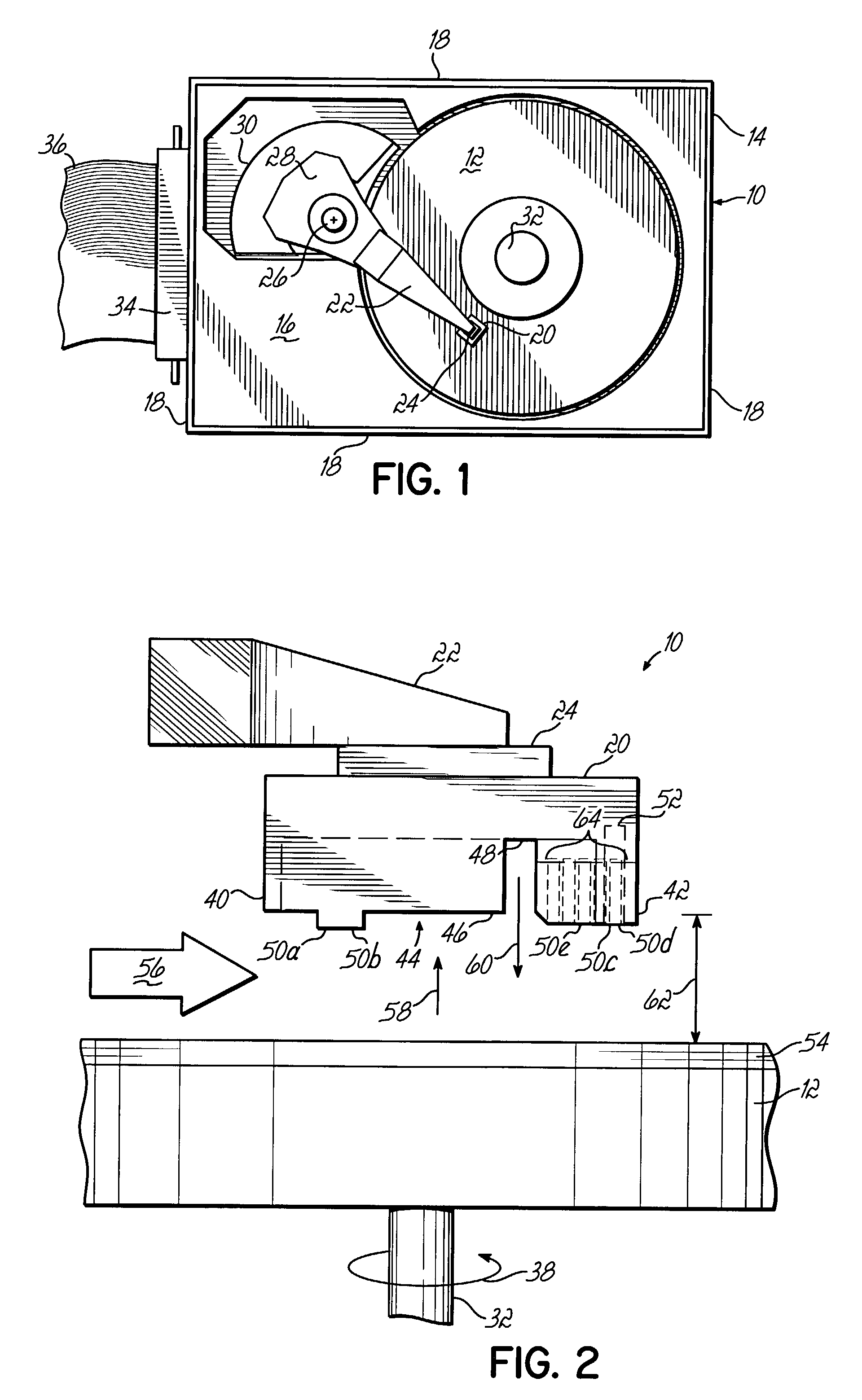

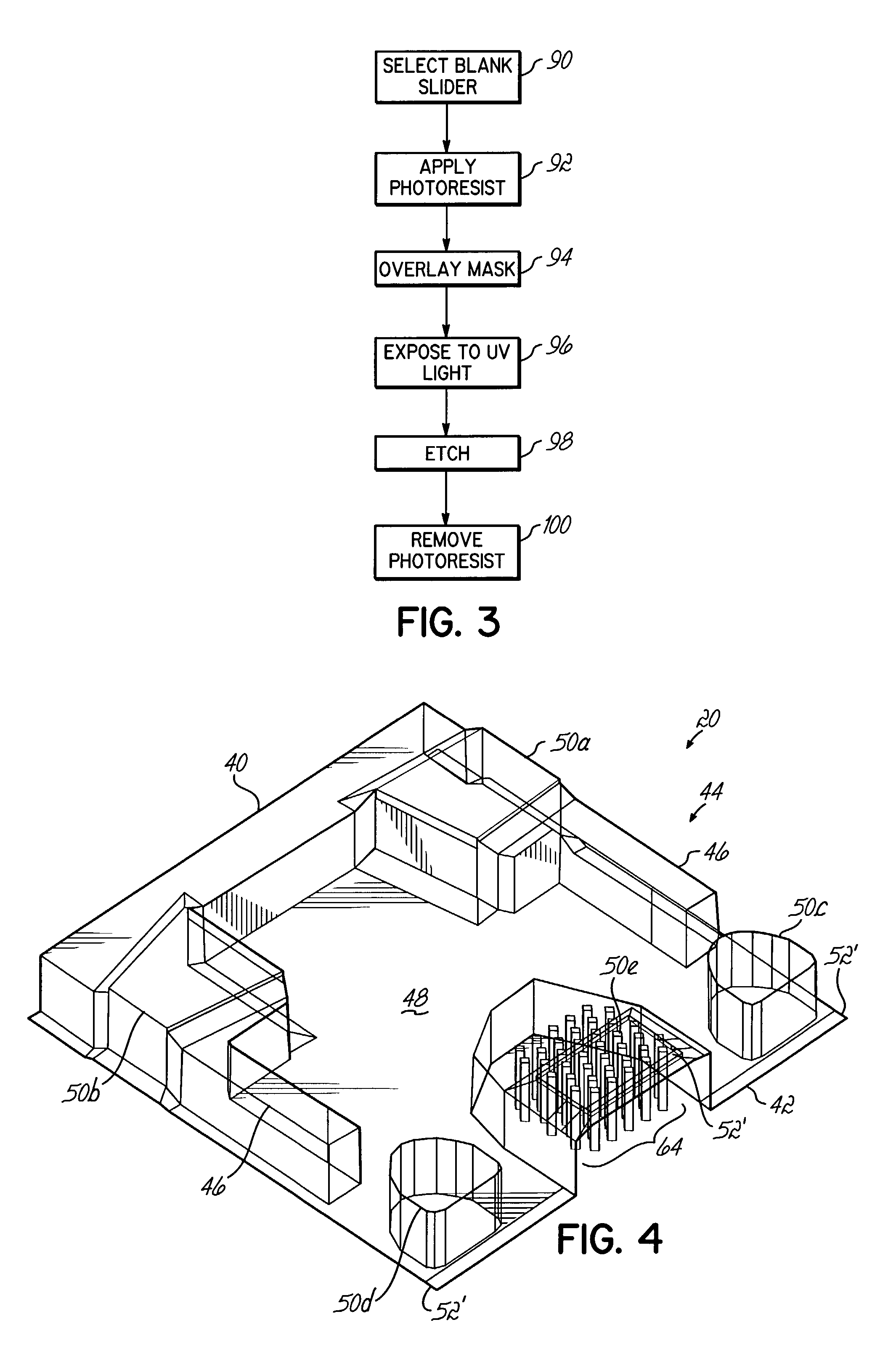

Slider for a data storage device having improved stiction control with reduced interference with air bearing pressurization

InactiveUS7054108B2Reduce creepReduce interferenceRecord information storageFluid-dynamic spacing of headsAir bearingTransducer

A slider for carrying transducers for a data storage device including a stiction control trench. The stiction control trench includes a boundary dimension to reduce creep or interference of the pressurized profile of the raised bearing surface to provide stiction control while limiting interference with the hydrodynamic bearing design.

Owner:SEAGATE TECH LLC

Air bearing designs to reduce external van der waals and electrostatic forces

InactiveUS7023664B2Reduce electrostatic forceReduce van der Waals forcesRecord information storageFluid-dynamic spacing of headsAir bearingAir bearing surface

A slider for a disk drive has an air bearing surface that opposes a rotatable disk of recordable media. The air bearing surface includes one or more interior cavities to reduce van der Waals and electrostatic forces that attract the slider to the disk.

Owner:WESTERN DIGITAL TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com