Design method of water lubrication step tile dynamic pressure thrust bearing

A technology of thrust bearing and design method, applied in the direction of sliding contact bearing, rotating bearing, bearing, etc., can solve the problems of high rigidity of water film, etc., and achieve the effect of large load bearing and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following descriptions are only preferred embodiments embodying the principles of the present invention, and do not therefore limit the protection scope of the present invention.

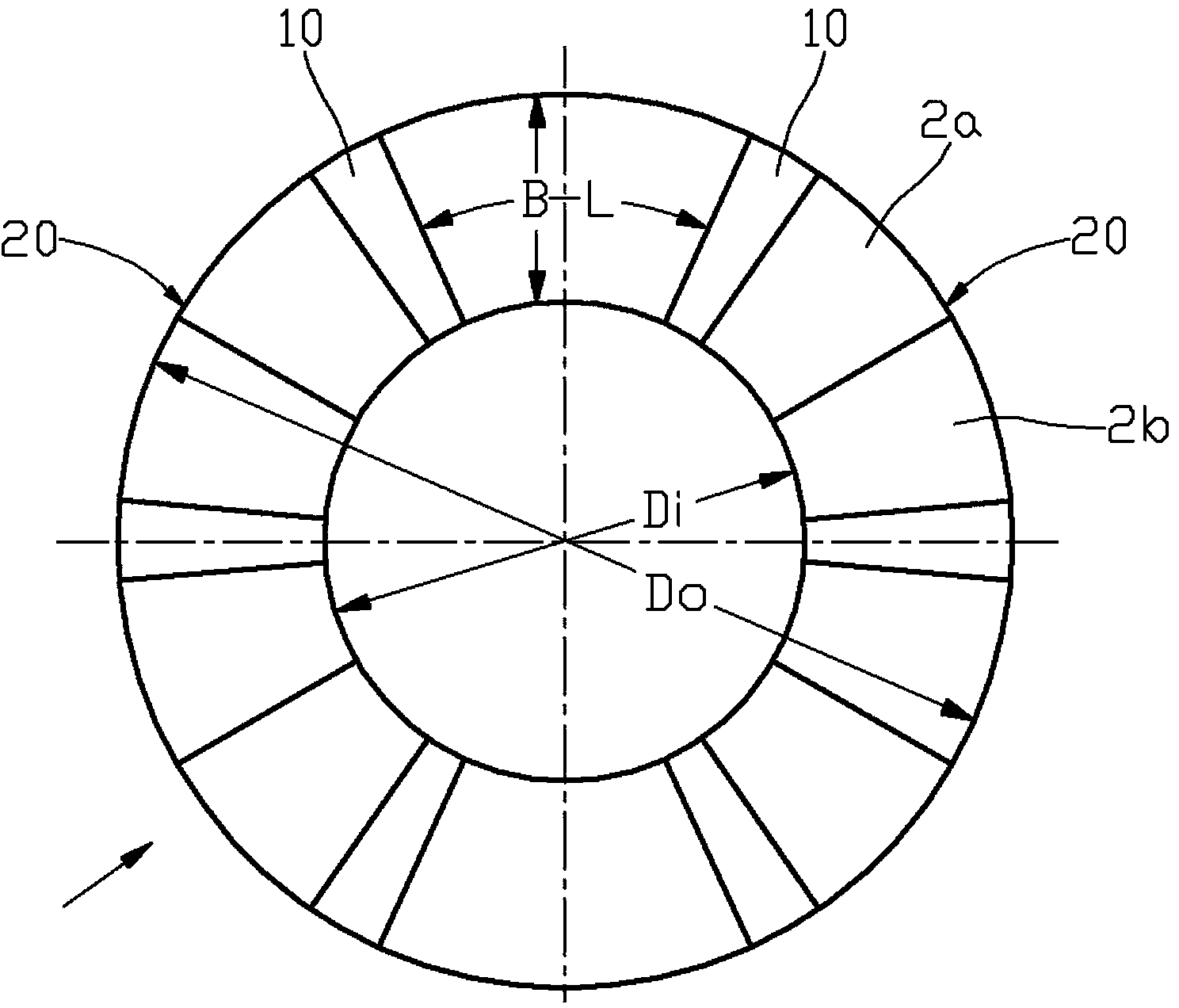

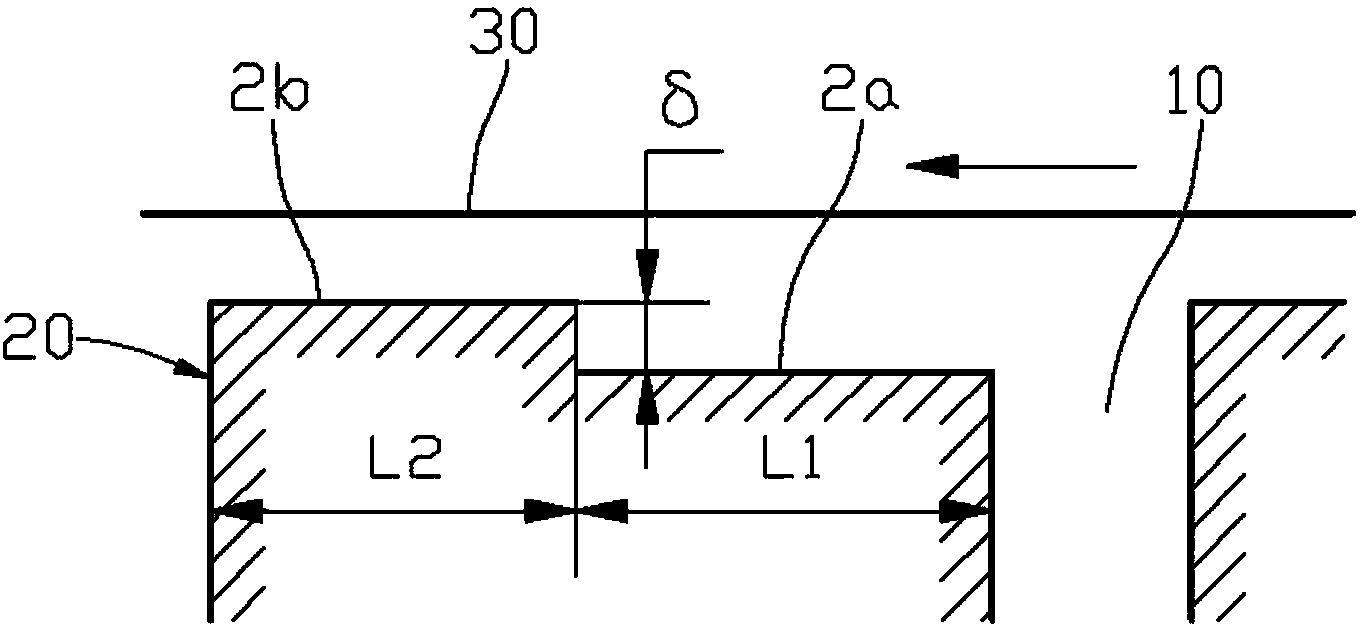

[0030] refer to Figure 1 to Figure 7 Shown: the design method of a kind of water-lubricated step shoe dynamic pressure thrust bearing of the present invention comprises the following steps:

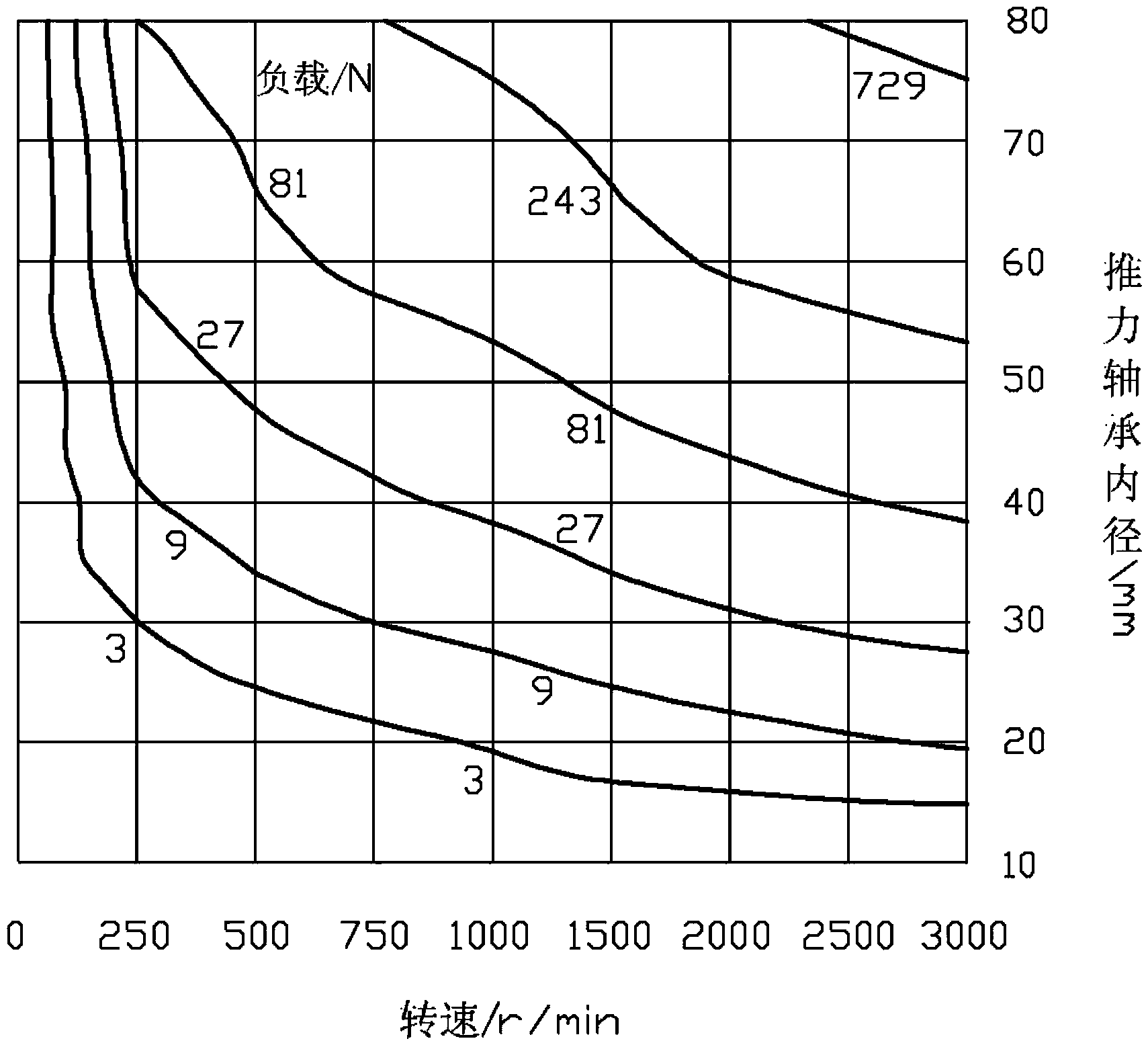

[0031] (1) Clarify the operating conditions (speed, load) and installation dimensions of water-lubricated thrust bearing applications, refer to figure 2 Select the inner diameter of the bearing, and the outer diameter of the bearing is generally 1.5 to 3 times the inner diameter;

[0032] (2) According to the determined inner diameter of the thrust bearing, the number of thrust pads can be selected according to the following table. The larger the size of the bearing, the more pads should be, so that there are more water tanks to fully form the dynamic pressure water film on the bearing surface. R...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com