Corrosion and wear resistant alloy

A wear-resistant and corrosion-resistant technology, applied in the field of tool steel alloy products, can solve problems such as corrosion resistance is not helpful

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

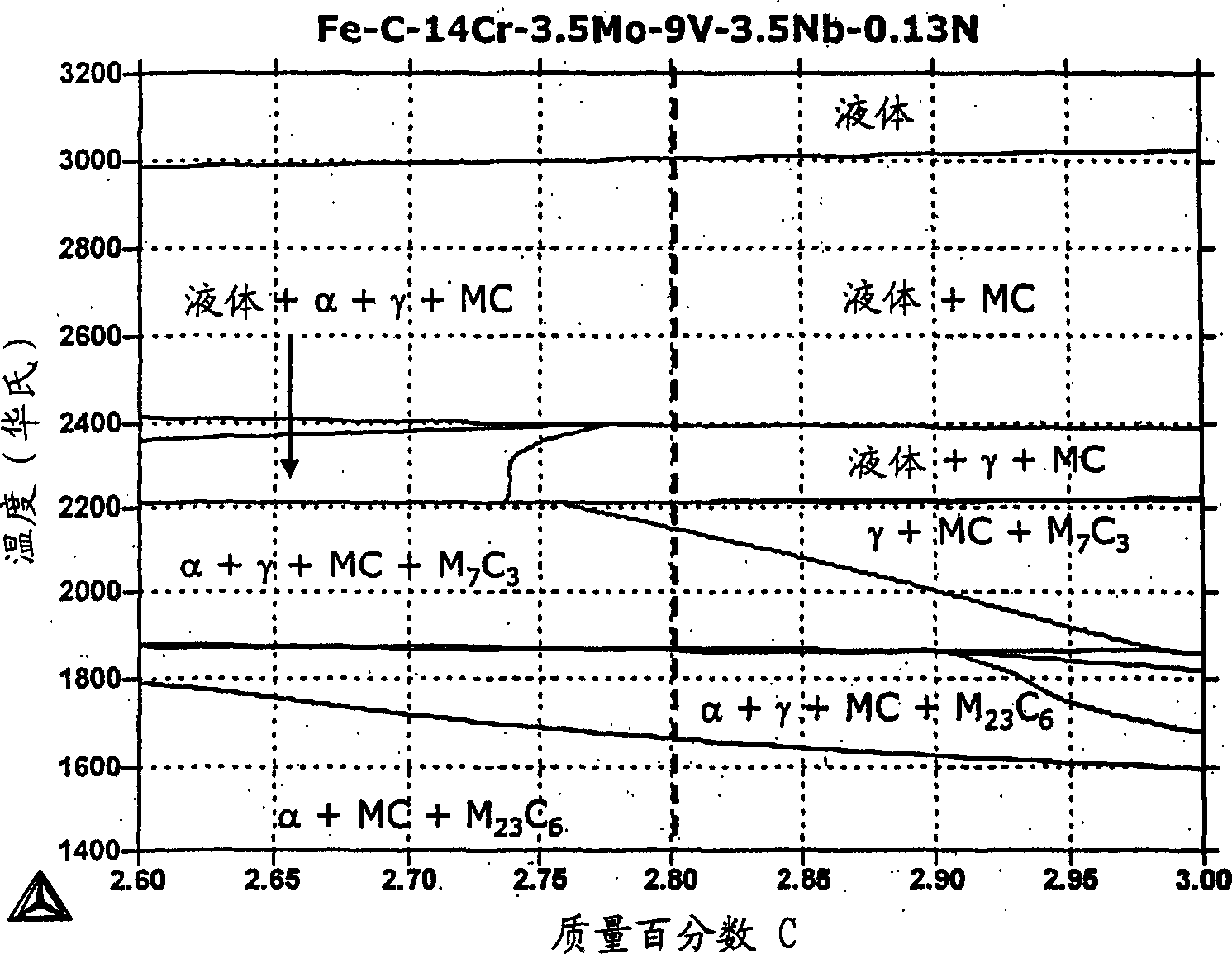

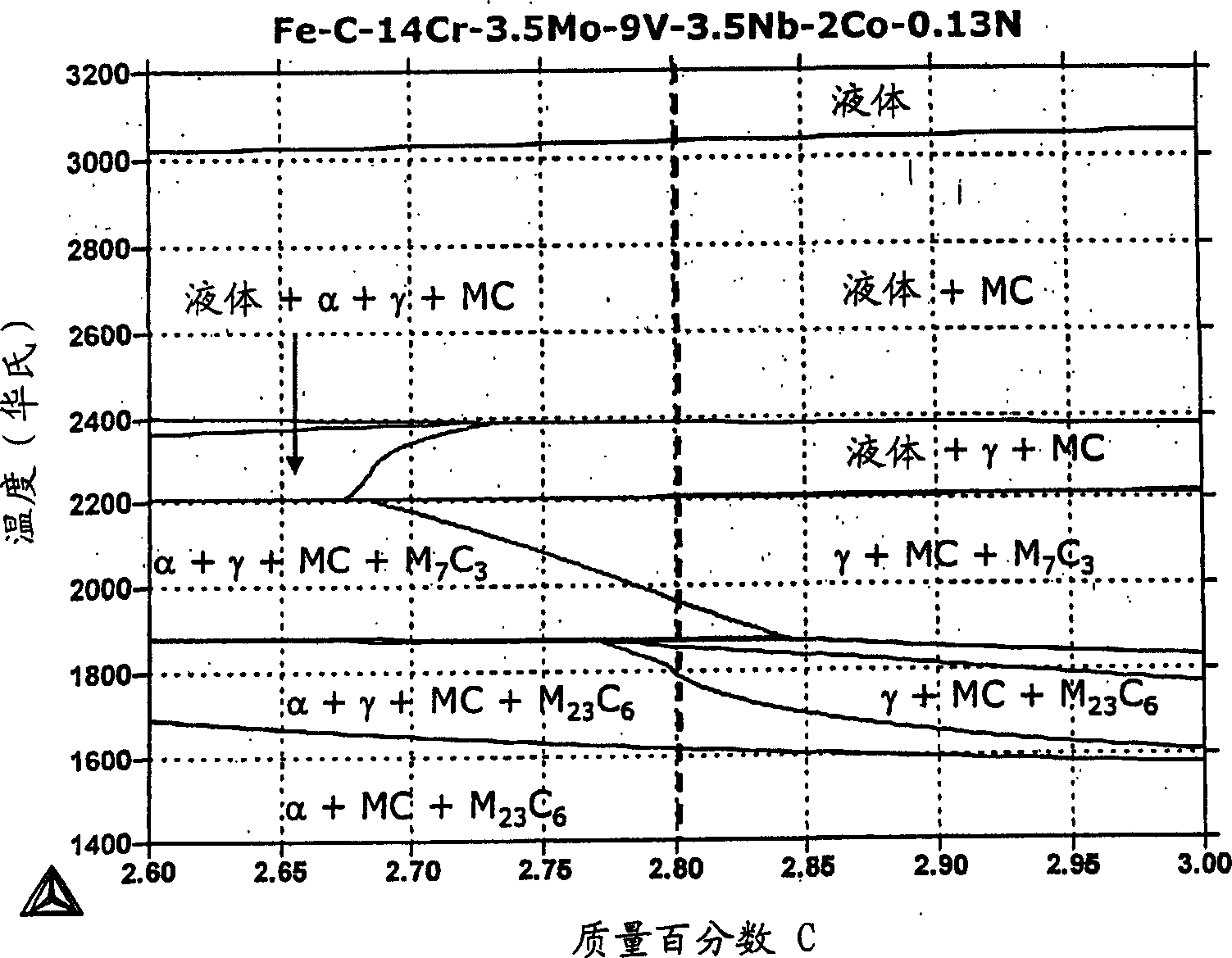

[0023] Chemical Composition Test

[0024] Table 1 presents the chemical compositions tested experimentally to achieve the improved combination of corrosion resistance and wear resistance of the alloy articles of the present invention. The reported alloys 03-192 to 04-099 are obtained according to the present invention.

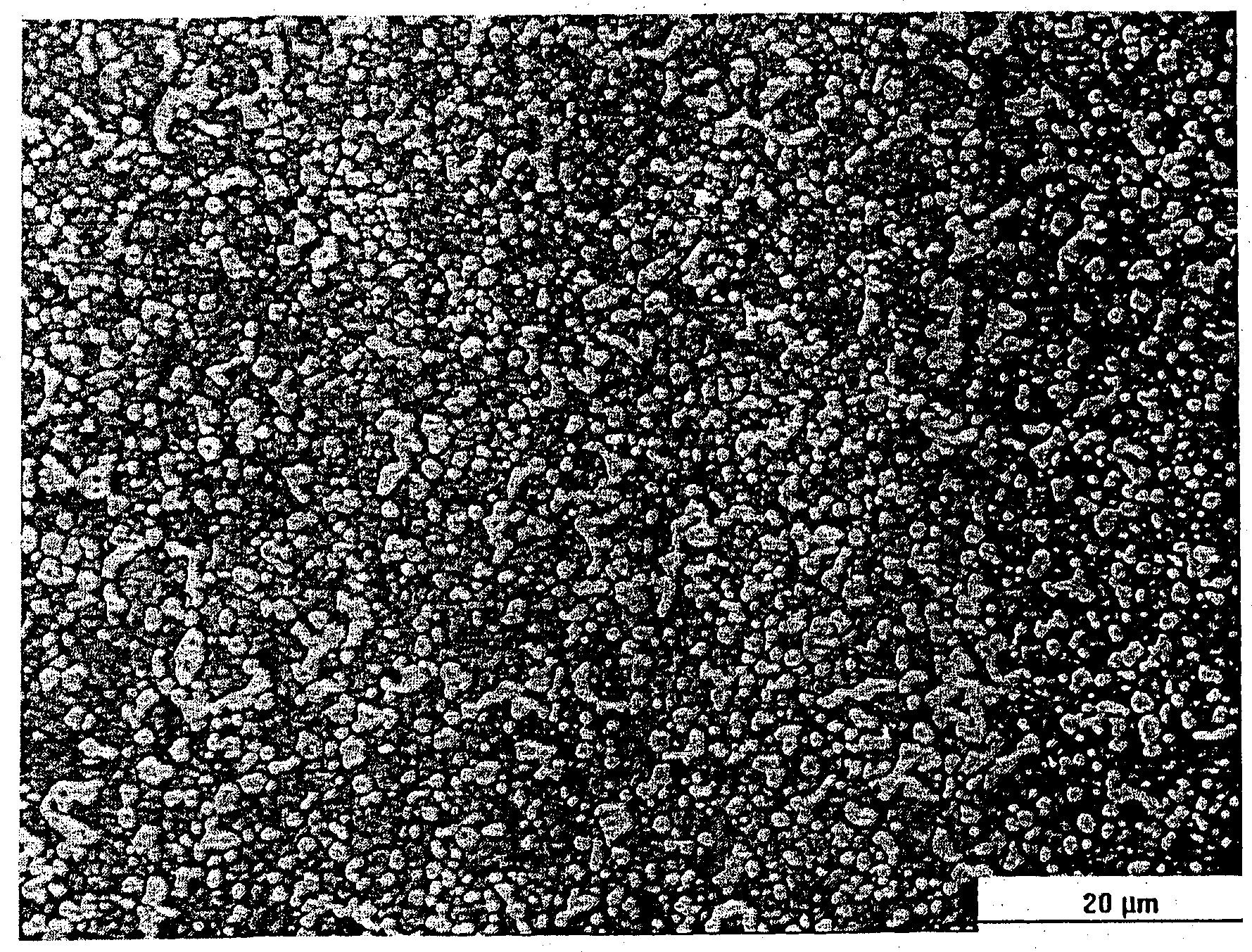

[0025] All examined composites were made using the Crucible Particle Metallurgy (CPM) technique. Each grade of pre-alloyed tool steel of different chemical composition given was melted in a nitrogen atmosphere, atomized with nitrogen gas, and hot isostatic pressed (HIP) at a temperature of 2150°F and a pressure of 14.5 ksi for four hours.

[0026] The various alloying elements involved in the wear and corrosion resistant tool steel satisfy the following conditions.

[0027] Carbon is present in an amount of at least 2.0%, although a maximum amount of carbon can be equal to 3.5%, and is preferably between 2.7% and 3.0%. It is important to carefully control t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com