Forming technology and preparation method for double-color and double-hardness sole

A molding process and dual-hardness technology, applied in the field of molding technology and preparation of two-color dual-hardness soles, to achieve the effect of simple process, long service life and fast foaming molding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention can be further understood through the embodiments of the present invention given below, but the protection of the present invention is not limited thereto.

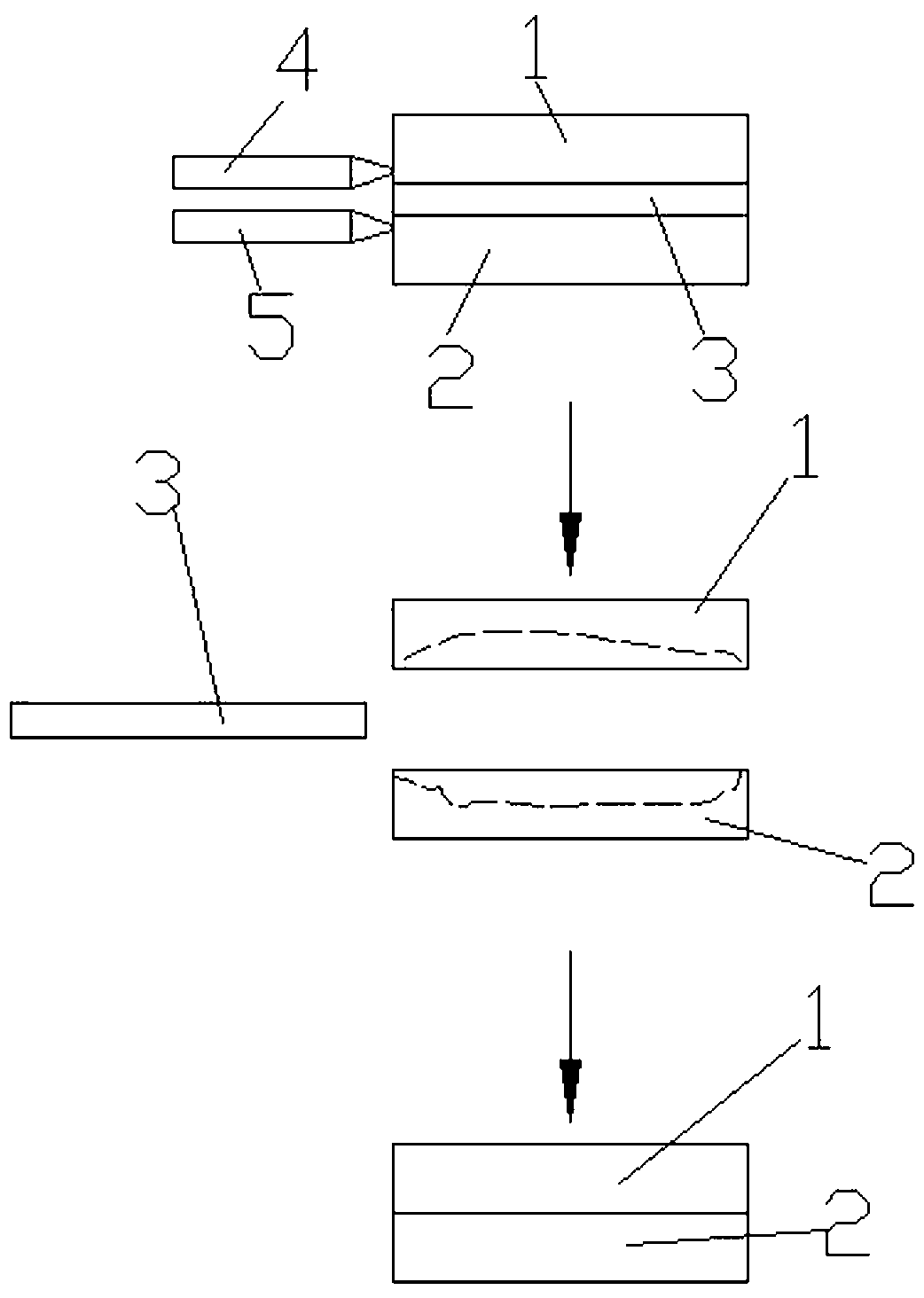

[0022] Refer to as figure 1 As shown, a molding process and preparation method of a dual-color dual-hardness shoe sole is characterized by including the following steps:

[0023] (1) Preparing the mold: Prepare a set of injection molds including upper mold 1 and lower mold 2. The upper mold 1 and the lower mold 2 are separated by a partition 3, and the upper mold 1 and the lower mold 2 are respectively used for the injection outsole And the midsole, the upper mold 1 and the lower mold 2 are provided with molding cavities, the temperature of the upper mold 1 and the lower mold 2 is 175°C, and the temperature of the partition 3 is 90°C;

[0024] (2) Injection preparation: Preliminarily store the wear-resistant rubber-plastic composite material in the injection molding hopper of the injection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com