Patents

Literature

112results about How to "Not easy to degumming" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for detecting potential inherent toxicity of organic pollutants in water body

InactiveCN101570785AHigh enrichment factorProtect healthMicrobiological testing/measurementMaterial analysis by electric/magnetic meansResearch ObjectGel electrophoresis

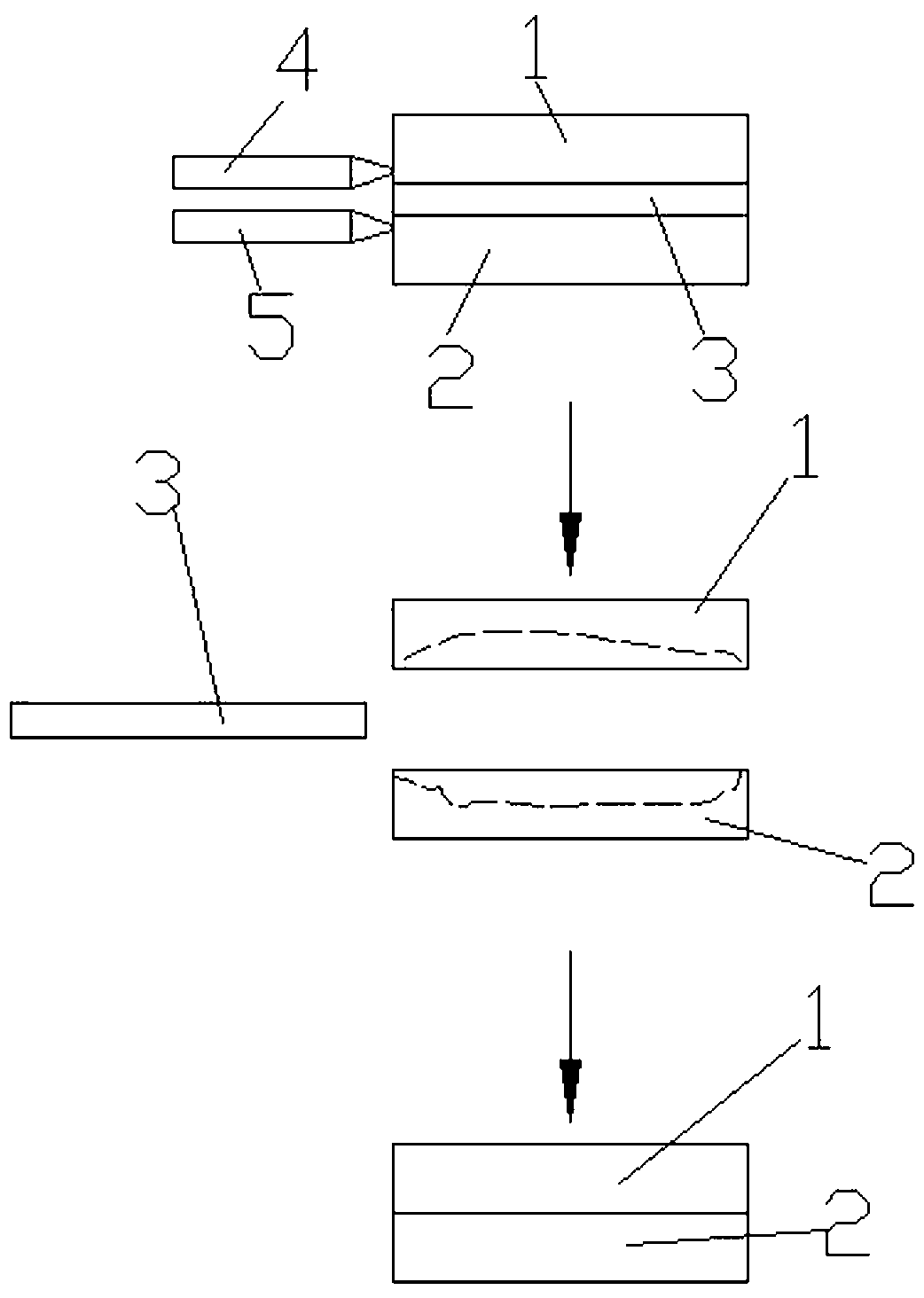

The invention discloses a method for detecting potential inherent toxicity of organic pollutants in a water body, which comprises the following steps: using resin to perform enrichment of water samples first; and applying a comet assay of Euglena gracilis to research the inherent toxicity of the organic pollutants in the water body. The key technique lies in the innovation of glue manufacturing process, namely adopting fractioning at a first layer, then adopting the conventional 'sandwich' glue manufacturing method, and manufacturing the glue by using a normal melting point glue with a higher melting point at a third layer, thus the defect that a rubber plate in the conventional method is easy to damage is overcome. By performing optimization research on cracking time and electrophoresis conditions of algae comets, a perfect image result is obtained. At present, the method for detecting the potential inherent toxicity of the organic pollutants in the water body through algae single cell gel electrophoresis (SCGE) is not reported, and algae are applied to the SCGE to widen the research objects of the SCGE.

Owner:NANJING UNIV

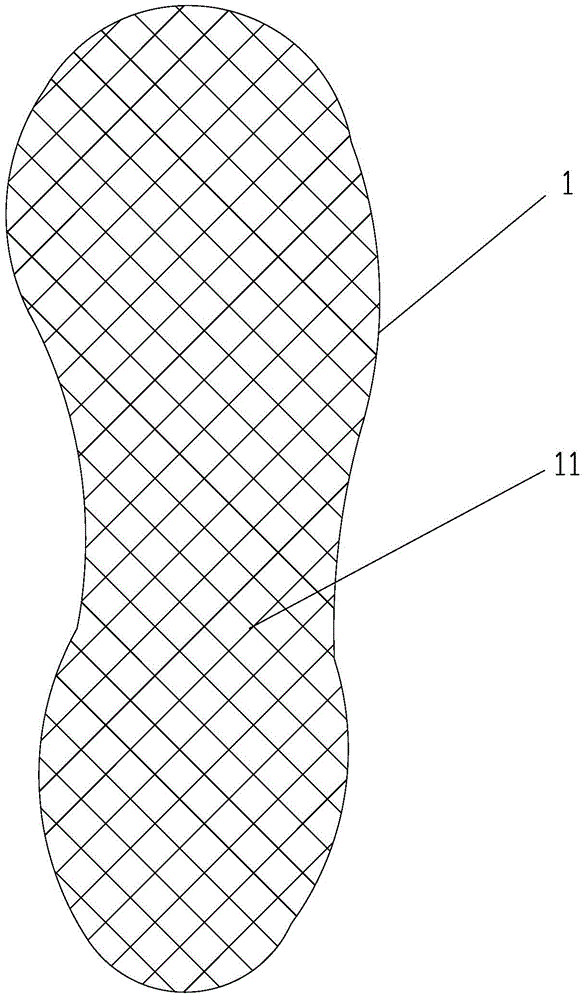

Forming technology and preparation method for double-color and double-hardness sole

ActiveCN103128978AEliminates manual hand gluing stepsSimple processDomestic articlesPlastic injection moldingHardness

The invention discloses a forming technology and a preparation method for a double-color and double-hardness sole. The forming technology and the preparation method for the double-color and double-hardness sole mainly includes the following steps: step 1, a mold is prepared, wherein a set of plastic injection mold is prepared; step 2, a plastic injection molding process is prepared, wherein a plastic injection molding machine is provided with two injection gun barrels which can be used for injecting plastics into the plastic injection mold simultaneously; step 3, the plastic injection molding process is carried out, wherein the plastic injection mold is placed on a mold frame of the plastic injection molding machine, the plastic injection molding machine is started, the two injection gun barrels are used for injecting the plastics into an upper mold body and a lower mold body of the plastic injection mold simultaneously, then the plastic injection mold is pre-pressed through a partition plate and then opened, the upper mold body and the lower mold body are separated, and then the partition plate is drawn out; and step 4, a bonding and cross-linked foaming forming process is carried out, wherein the upper mold body and the lower mold body are closed again, an upper-layer composite material and a lower-layer composite material are subjected to bonding and cross-linked foaming forming in a closed mold cavity, then the plastic injection mold is opened, and the double-color and double-hardness sole is obtained. According to the double-color and double-hardness sole produced through the preparation method, a shoe outsole portion and a shoe middle sole portion are not degummed when meeting water, do not separate from each other and are long in service live, the foaming forming process is fast, and a color bleeding phenomenon cannot happen.

Owner:JINJIANG CHENGCHANG SHOES

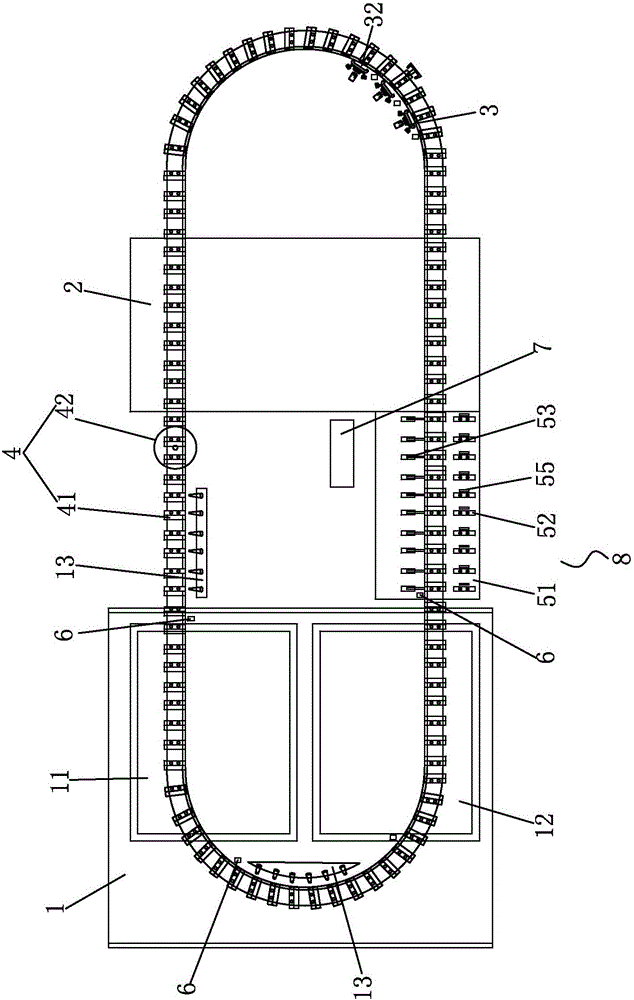

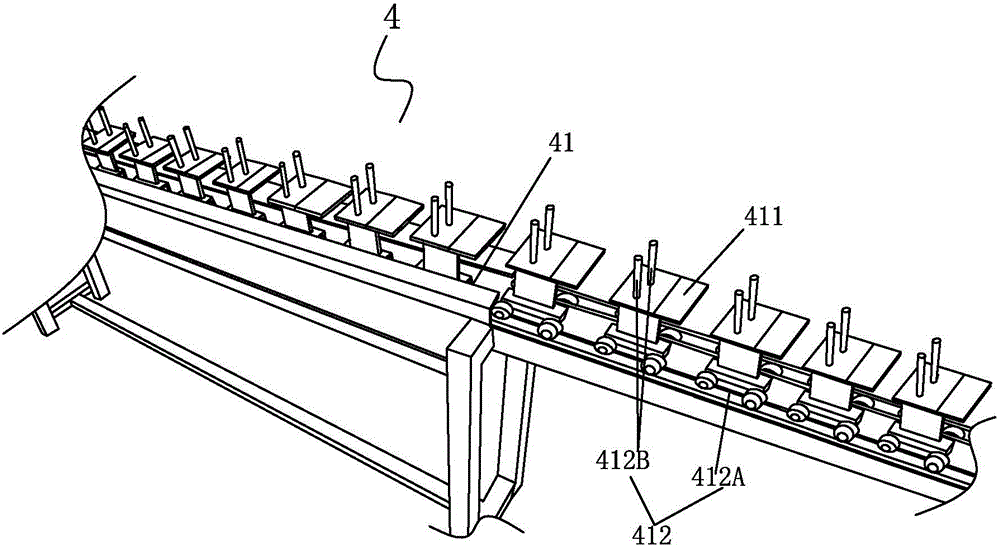

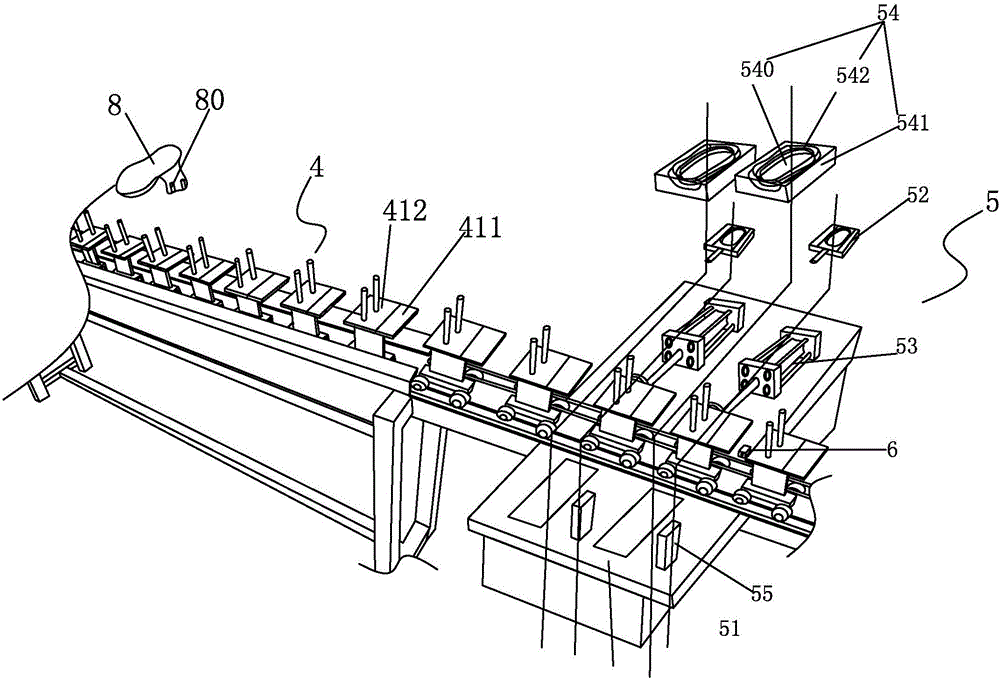

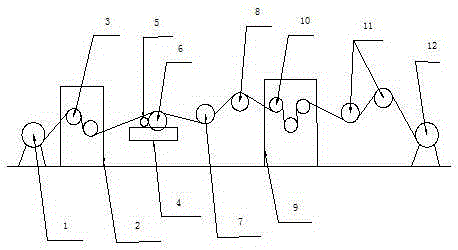

Shoemaking device and operating method

The invention discloses a shoemaking device.The shoemaking device comprises a drying device, a cooling device and a delasting mechanism.The shoemaking device further comprises a conveying mechanism, a press fitting mechanism, an induction unit and a control unit.The conveying mechanism is arranged on the drying device, the press fitting mechanism, the cooling device and the delasting mechanism in a penetrating mode to define an annular conveying mechanism.The conveying mechanism comprises an upper track, a lower track and a driving motor used for driving the upper track and the lower track to generate horizontal annular displacement, wherein the upper track is used for carrying soles, and supports used for positioning and supporting lasts are formed on the lower track.The press fitting mechanism is arranged between the drying device and the cooling device and comprises pressure bearing tables, auxiliary clamping components, driving air cylinders and pressure applying units, wherein the pressure bearing tables are arranged on one or two sides of the conveying mechanism and used for supporting the lasts.According to the shoemaking device, various devices needed in the shoemaking process are combined into a whole, automatic operation is achieved under driving of the control unit, and thus manual cost is substantially lowered.

Owner:ANTA CHINA

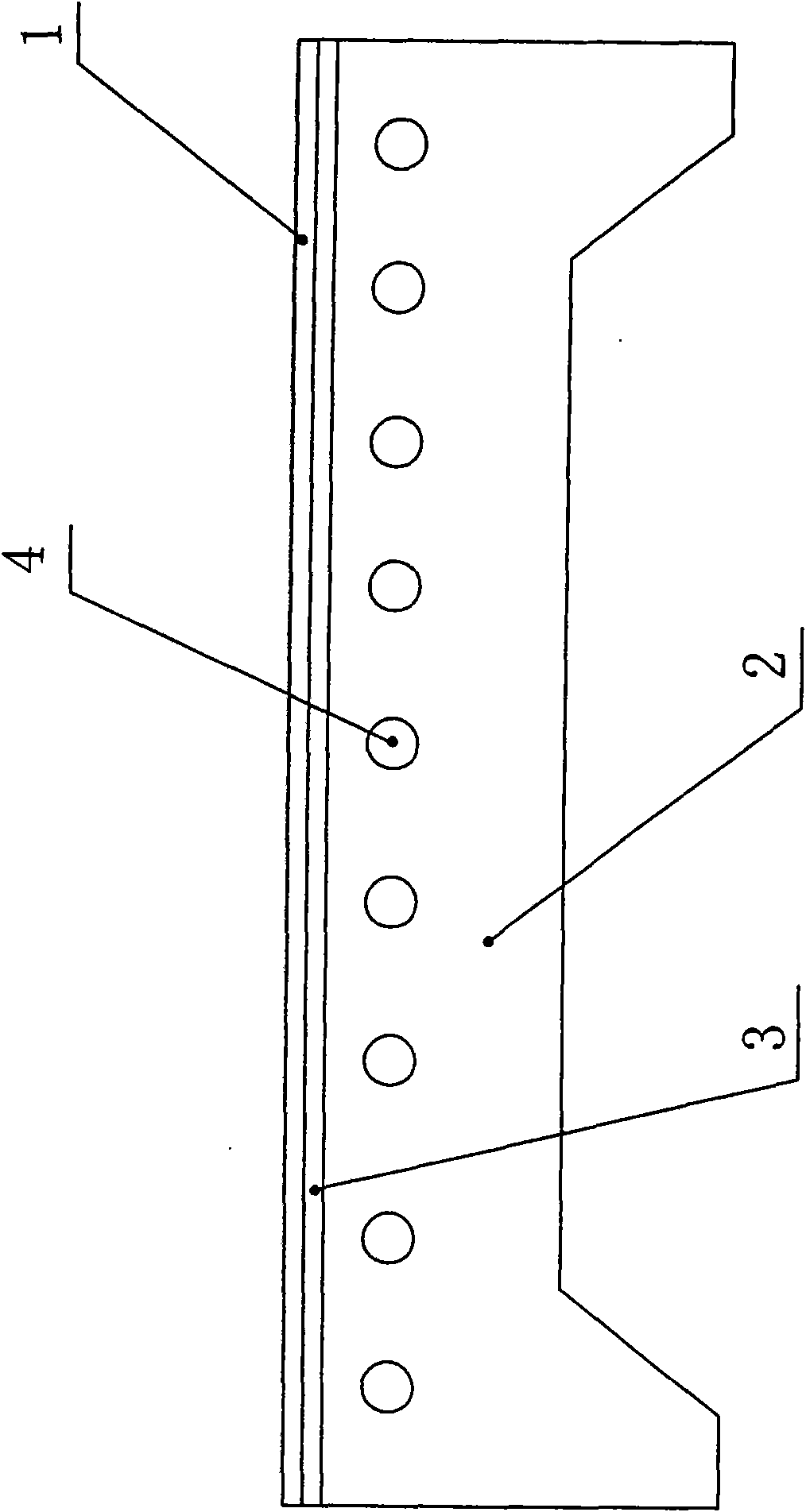

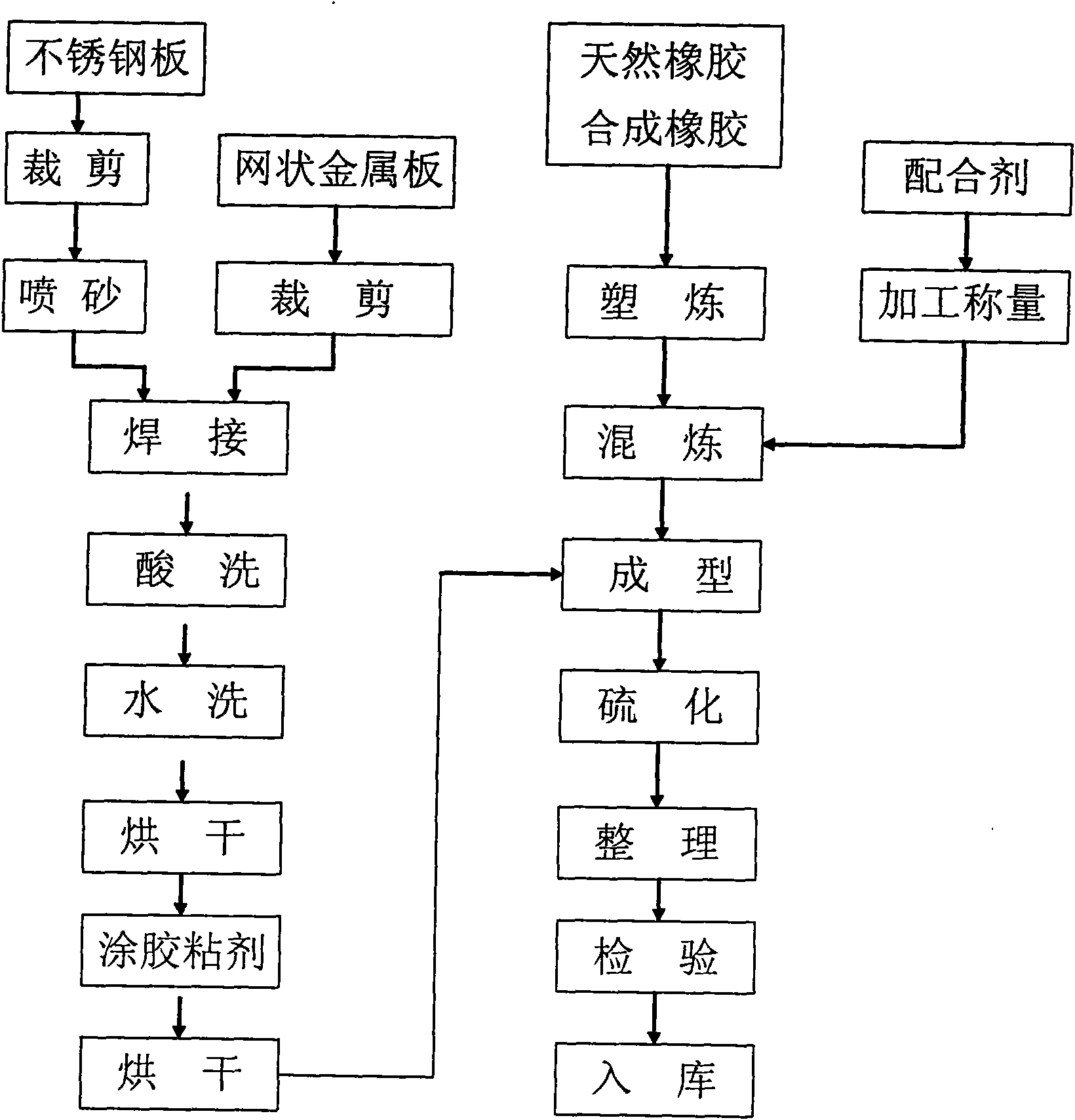

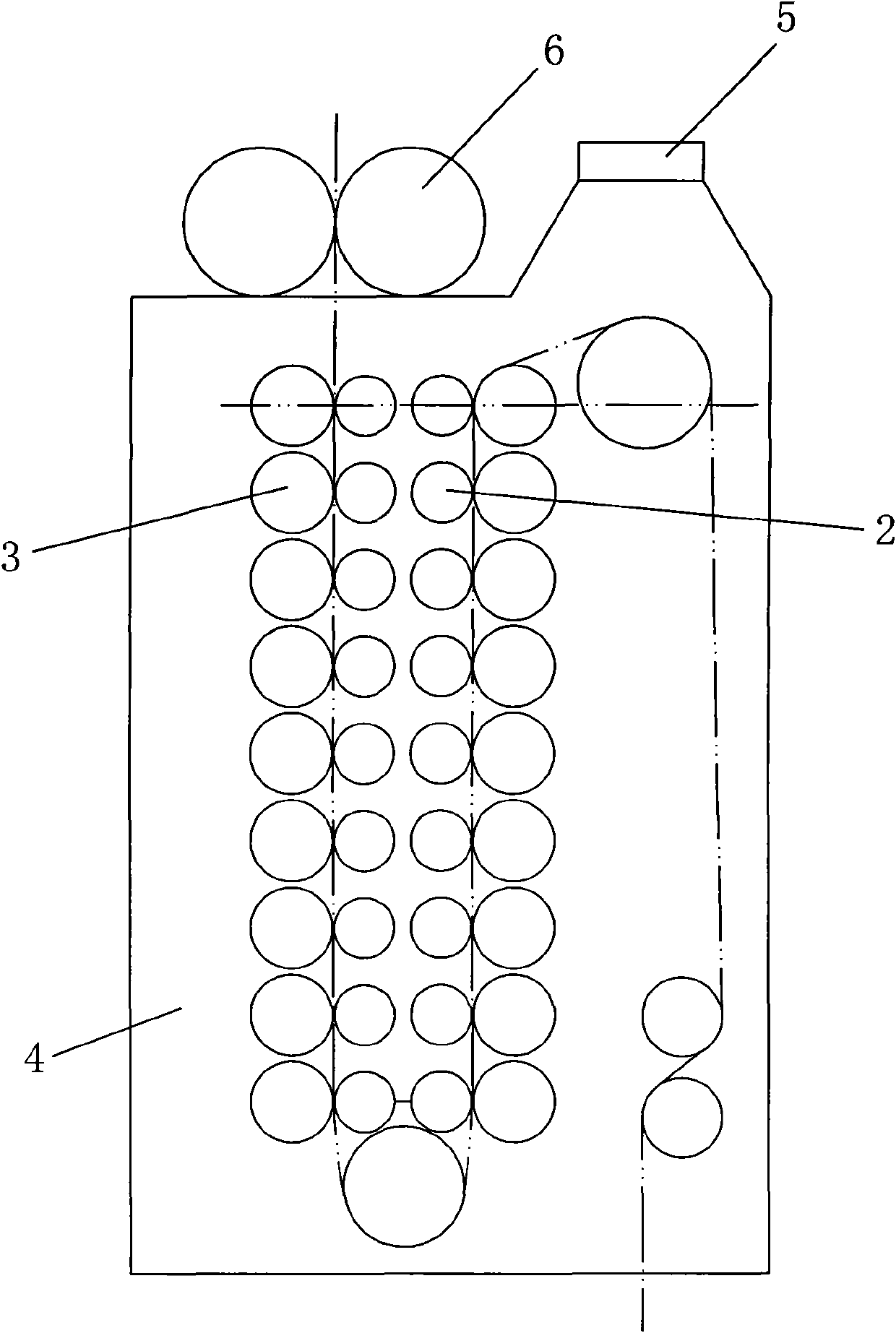

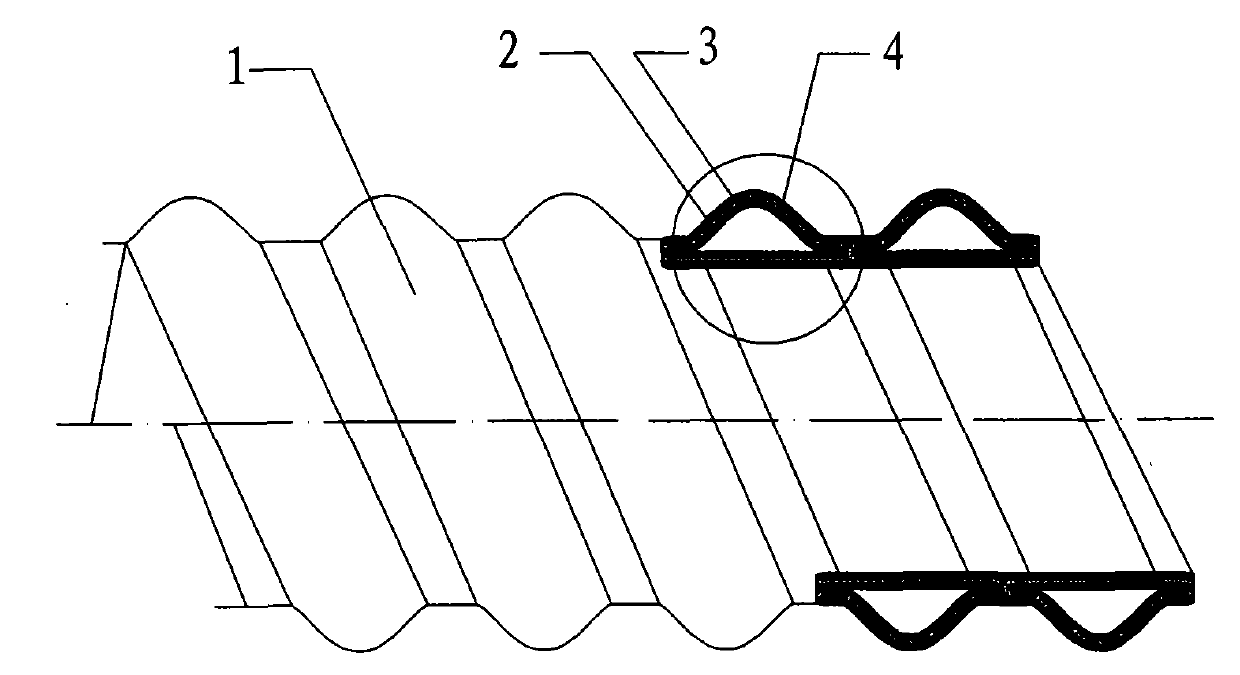

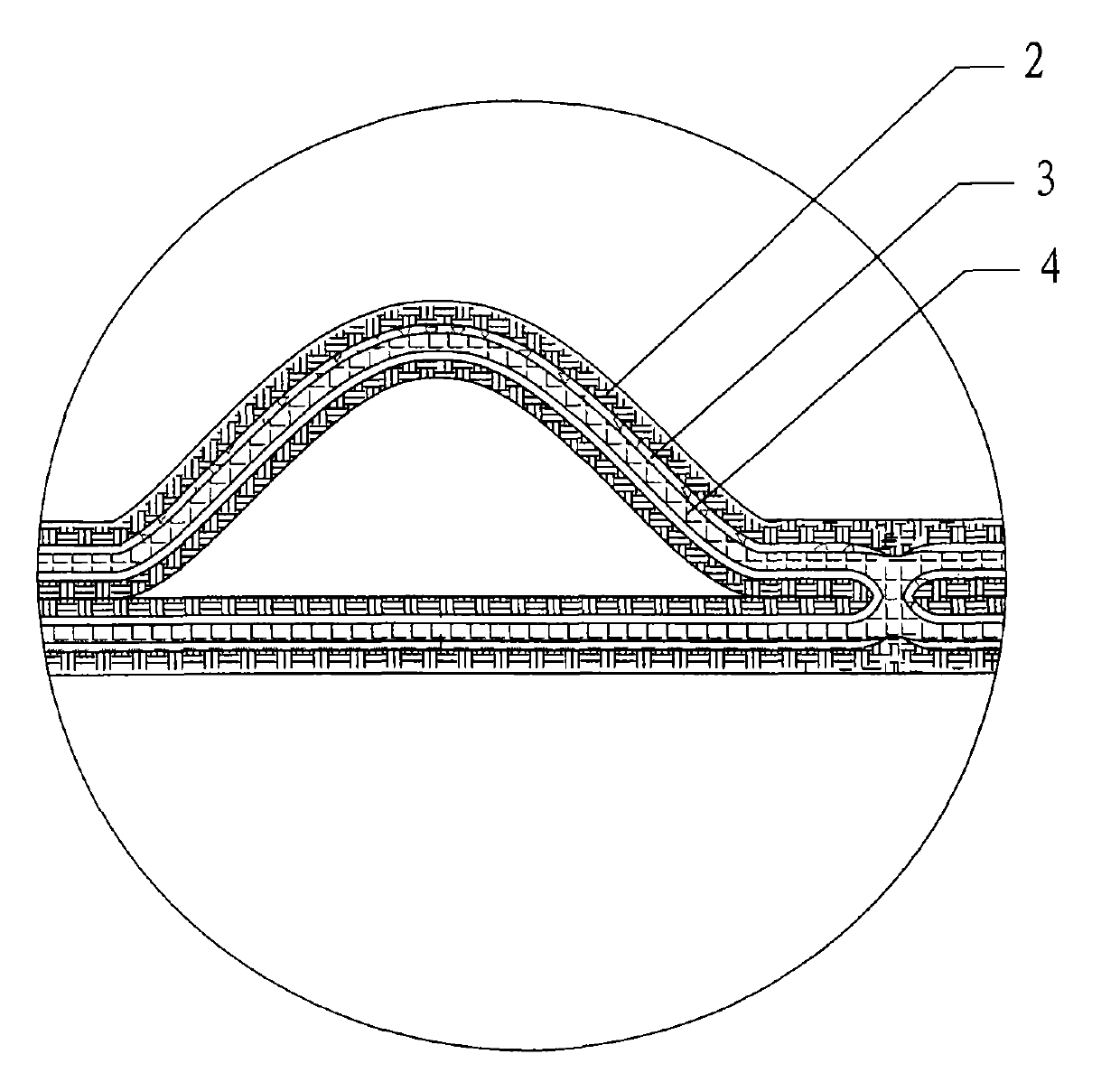

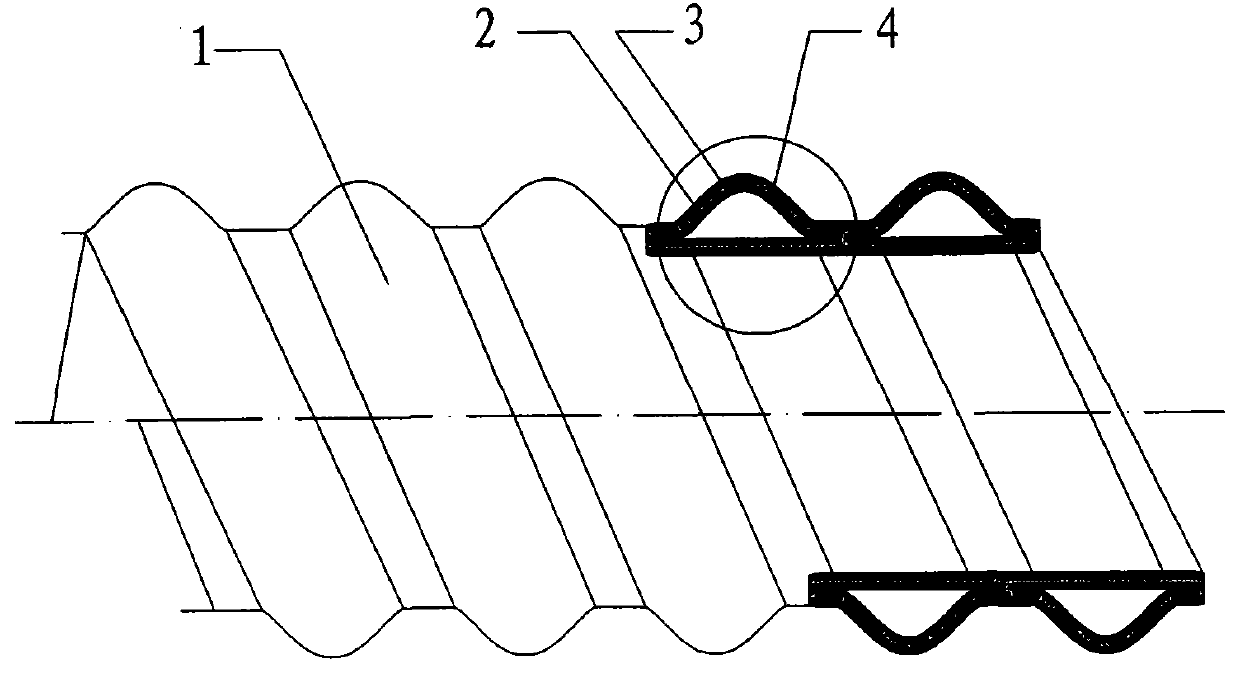

Vibration damping composite rubber mat plate used under railway rail and preparation method thereof

InactiveCN101555674AAvoid aestheticsImprove adhesionRail fastenersResistance welding apparatusAgricultural engineeringRubber sheet

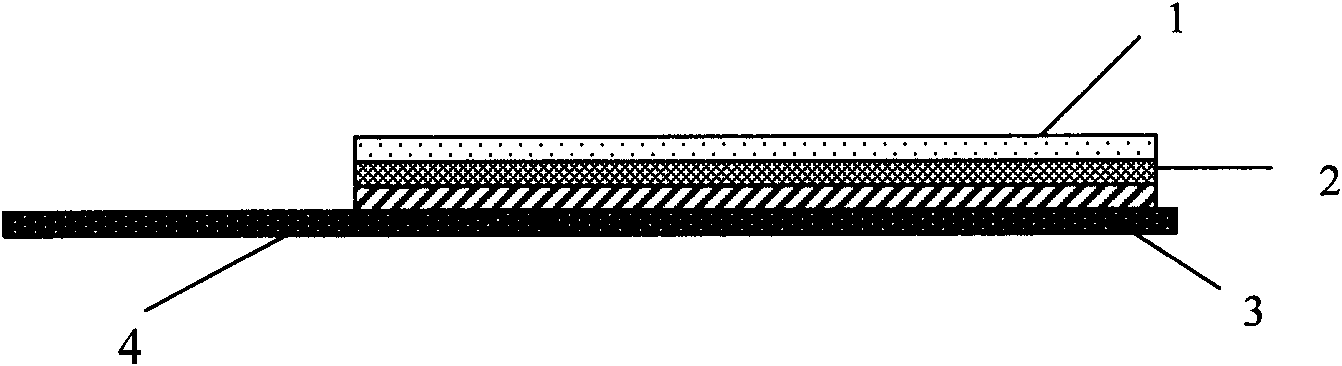

The invention relates to a vibration damping composite rubber mat plate used under a railway rail and a preparation method thereof. The rubber mat plate comprises a stainless steel plate (1) and a rubber plate (2), wherein, the stainless steel plate (1) is stuck on the upper surface of the rubber plate (2); the rubber mat plate is characterized in that the lower surface of the stainless steel plate (1) is welded with a metal screen plate (3), and the stainless steel plate (1) and the metal screen plate (3) are connected on the upper surface of the rubber plate (2). The stainless steel plate of the composite rubber mat plate is stuck and integrated with the rubber plate by the metal screen plate, so that the aesthetic property of the stainless steel surface is ensured, and the adhesive attraction between the stainless steel plate and the rubber can be greatly improved; therefore, the stainless steel plate and the rubber are well stuck with each other and not easy to deglue, the service life is prolonged, and the preparation process is simpler. The rubber mat plate can be used for buffering the high speed vibration and impact extrusion force which are generated when vehicles pass through the steel rail, thus protecting a roadbed and a rail bearing of the steel rail and making electric insulation for a signal system.

Owner:刘浩杰

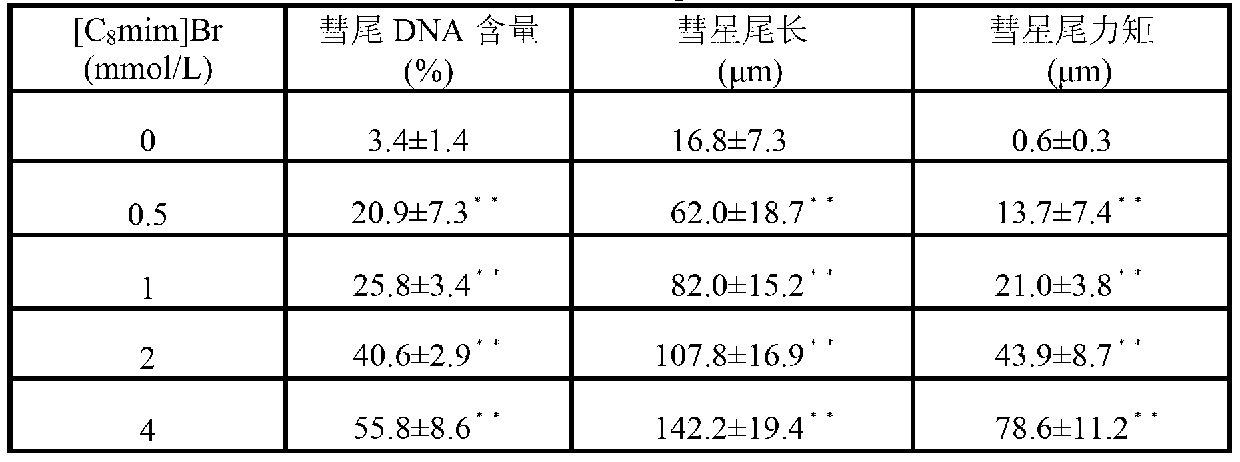

Preparation method of sample for conveniently and rapidly detecting deoxyribonucleic acid (DNA) cell damage and kit using same

InactiveCN103276048ANot easy to degummingEasy to operateMicrobiological testing/measurementFluorescenceA-DNA

The invention discloses a preparation method of a sample for conveniently and rapidly detecting deoxyribonucleic acid (DNA) cell damage. The method mainly comprises a gel sheet-making step, a cell lysis step, a DNA melting step, an electrophoresis step, a neutralizing step and a dyeing step, wherein in the gel sheet-making step, two layers of gels need to be spread; and in the dyeing step, a GelRed nucleic acid gel dye with high sensitivity and low toxicity is used. The invention also provides a kit using the method. The kit comprises normal melting-point agarose, low melting-point agarose, a cell lysis solution, an electrophoretic buffer solution, the DNA gel dye and a frosted edgeglass slide. According to the method, fluorescence dyeing is carried out by using the GelRed nucleic acid gel dye, and the GelRed nucleic acid gel dye is high in sensitivity, low in toxicity and stable, and environment pollution cannot be caused by wastes, so that the method is safe and environment-friendly; and because of only two layers of the spread gels, compared with a sandwich gel-spreading method used in the traditional comet assay, the preparation method is easy to operate and difficult to degum, and is uniform in dyeing; and moreover, the obtained electrophoresis image is relatively clear and objective.

Owner:JIANGSU UNIV

Forming technology and preparation method of bicolor sole

The invention relates to the field of soles, and provides a forming technology and preparation method of a bicolor sole which has simple forming technology and high production efficiency. According to the bicolor sole which is produced by utilizing the forming technology, the bicolor sole is free from debonding and delaminating as the shoe undersole and the shoe insole are combined firmly, and the service life is long. The forming technology and preparation method of the bicolor sole, provided by the invention, relates to the following steps of: material preparing-pelleting-injection-forming preparing-injection forming-foaming-punching-milling expanding-oil pressing.

Owner:晋江市五里艇源鞋塑有限公司 +1

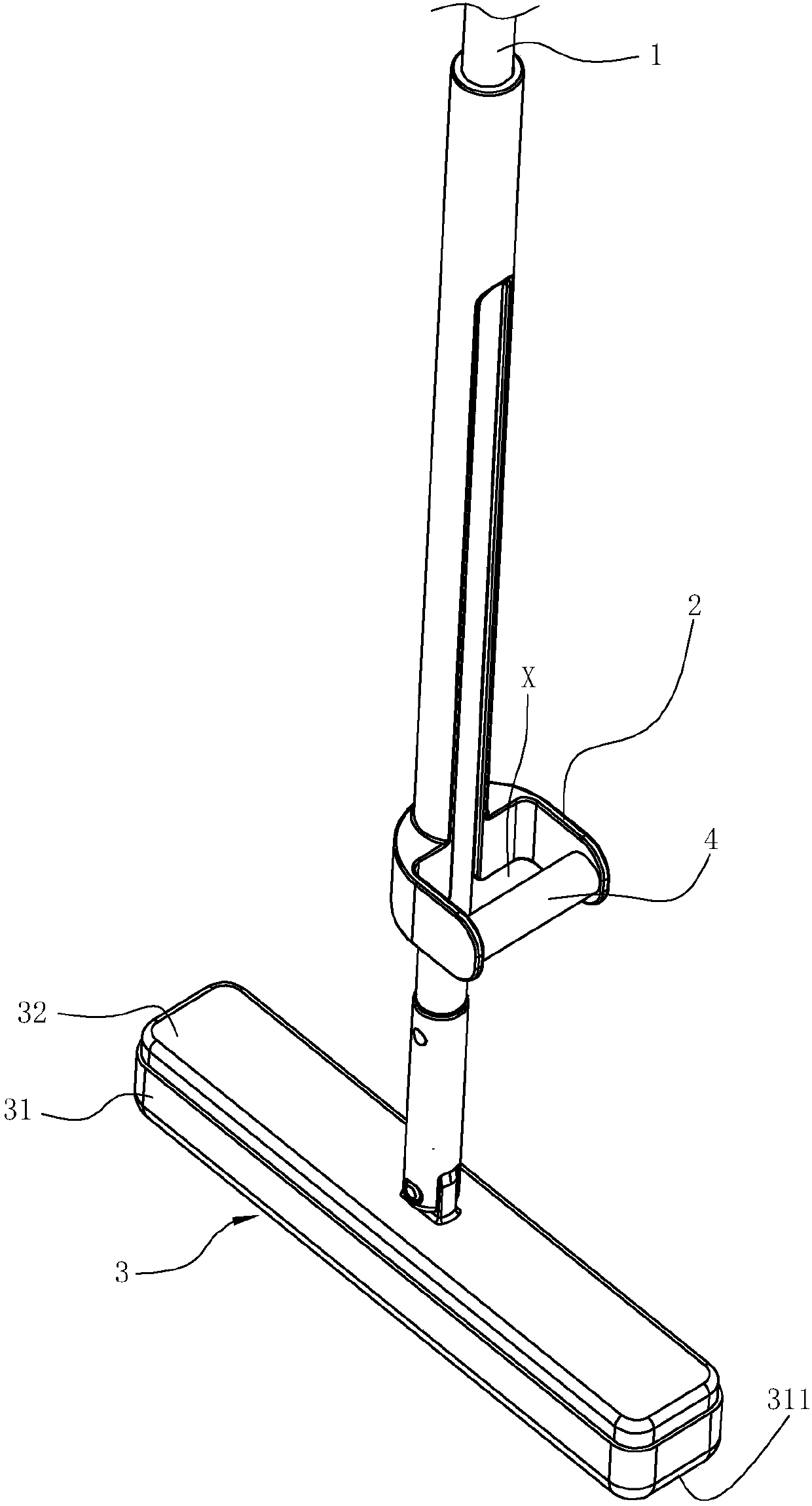

Extruding structure of foaming cotton mop

ActiveCN107865620ANot easy to degummingShort contact distanceCarpet cleanersFloor cleanersEngineeringMechanical engineering

The invention relates to an extruding structure of a foaming cotton mop. The extruding structure comprises a mop rod, a foaming cotton mop head and a water extruding frame, and is characterized in that the foaming cotton mop head is provided with a foaming cotton part and an installation plate part; the foaming cotton part is arranged on the installation plate part; the installation plate part ismovably connected with the lower end of the mop rod; the water extruding frame is provided with an extruding port through which the end surface of the foaming cotton part can pass, an extruding part is arranged in the extruding port and is used for extruding the bottom surface of the foaming cotton part via the extruding port, and the foaming cotton mop head is turned to the end surface aligned with the extruding port and passes through the extruding port in the water extruding process; the end surface of the foaming cotton part and the bottom surface of the foaming cotton part are connected by a transition surface; the foaming cotton part is provided with a gradually thickened guide section along the water extruding direction. The extruding structure has the advantages that the extrudingstructure can smoothly pass through the extruding port of the extruding frame without damage in the initial phase of water extruding; in the extruding operation, the labor intensity is decreased, andthe easiness in damage to the foaming cotton part is avoided.

Owner:宁波蓝小鱼家居科技有限公司

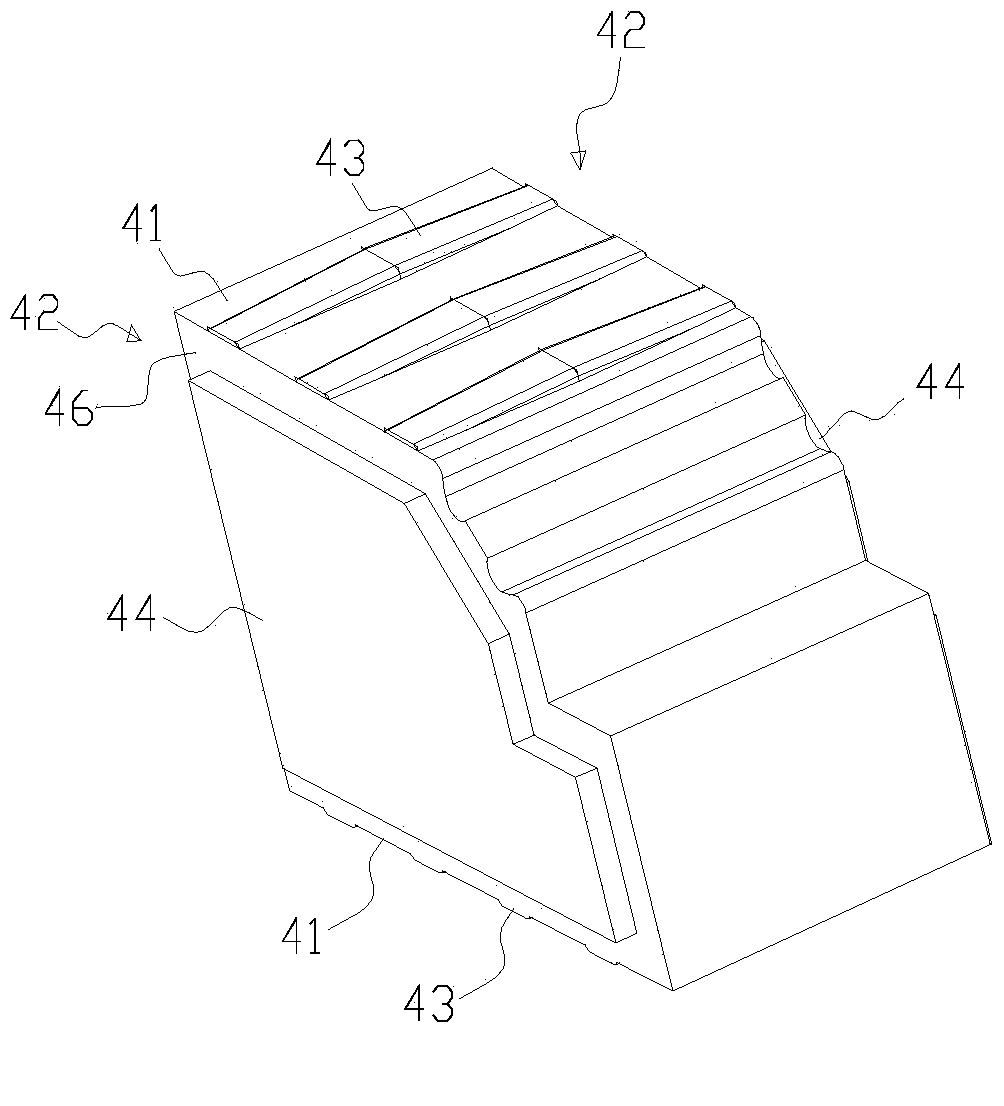

Production method for edge sealing type hidden buckle rock wool laminboard

InactiveCN101403248ANot easy to degummingNot easy to deformRoof covering using slabs/sheetsWater leakageEngineering

The invention relates to the technical field of construction materials, in particular to a manufacture method of an edge-sealed type hidden-fastening rock wool laminboard, which comprises the steps as follows: A. two side edges of a panel are subjected to moulding by pressing and folding respectively so as to form a tile hidden fastner and a tile fastening edge; B. the upper end and the lower end of an edge-sealed side board are subjected to moulding by pressing and folding respectively so as to form an upper connecting edge and a lower connecting edge; C. the panel and the edge-sealed side board are subjected to fastening-mouding by pressing and folding and connected together; D. the rock wool core materials are arranged between the panel and a bottom board; and E. the bottom board and the edge-sealed side board are tightly fixed and connected, wherein, the panel, the bottom board and the edge-sealed side board are combined together to form a sealed border, the clearances of the panel and the two sides of the bottom board are sealed by the edge-sealed side board, and therefore water can not permeate from the edge-sealed side board between the panel and the bottom board easily and can not leak into the rock wool materials, thus preventing water leakage effectively and prolonging the service life; moreover, the rock wool laminboard manufactured by using the method has stable structure of the sealed boarder, and therefore the phenomena such as degumming, deforming, dispersing and the like do not occur on the panel and the bottom board easily.

Owner:DONGGUAN HONGFA STEEL STRUCTURE MATERIAL

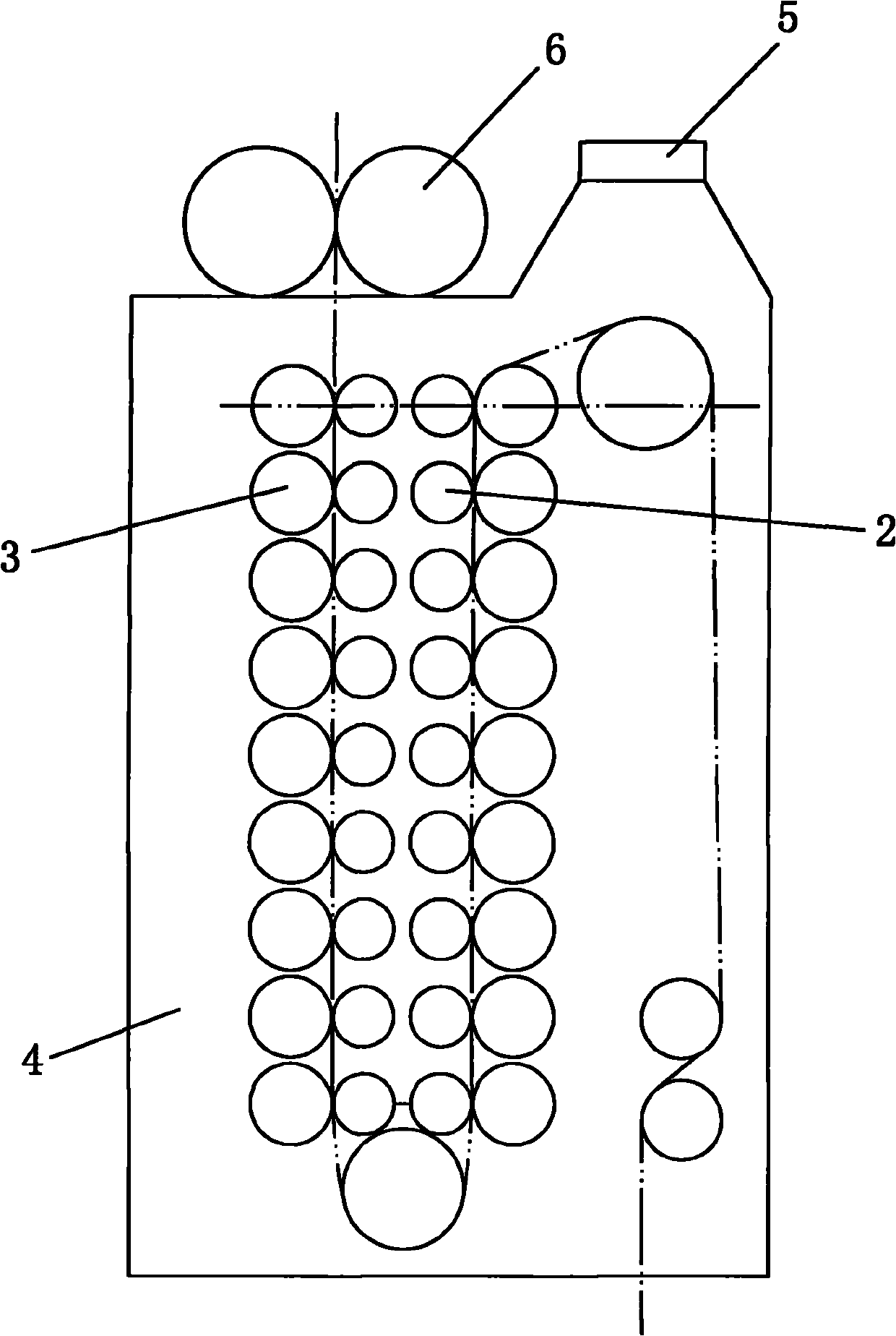

Oil-seepage-prevention coating device

InactiveCN105234042AImprove appearance qualityWill not cause product surface contaminationLiquid surface applicatorsCoatingsEngineeringSealant

The invention discloses an oil-seepage-prevention coating device and relates to coating devices. The oil-seepage-prevention coating device comprises an unrolling mechanism, a preheating device, preheating rolls, a material groove, a scraping roll, a coating roll, an expanding roll, a guide roll, an oven, heating rolls, cooling rolls and a rolling mechanism. The unrolling mechanism is fixed to the ground. The preheating device is arranged behind the unrolling mechanism and connected with the unrolling mechanism. The two preheating rolls are arranged in the preheating device. The other side of the preheating device is provided with a material groove. The material groove is filled with a prepared sealant. The coating roll is arranged above the material groove. The bottom of the coating roll falls into the material groove. The scraping roll is arranged above the material groove. The expanding roll and the guide roll are arranged behind the coating roll. The oven is arranged on the right side of the guide roll. The three heating rolls are arranged in the oven. The cooling rolls are arranged behind the oven. The rolling mechanism is arranged behind the cooling rolls. The impermeable oil coating device has the beneficial effects that when glue coating is conducted, the coating amount can be controlled by adjusting pressure among the rolls, even glue coating is achieved, the coating quality is guaranteed, fastness is good after coating, and debonding is not likely to happen.

Owner:JIANGSU LEATER GREEN PACKAGING CORP LTD

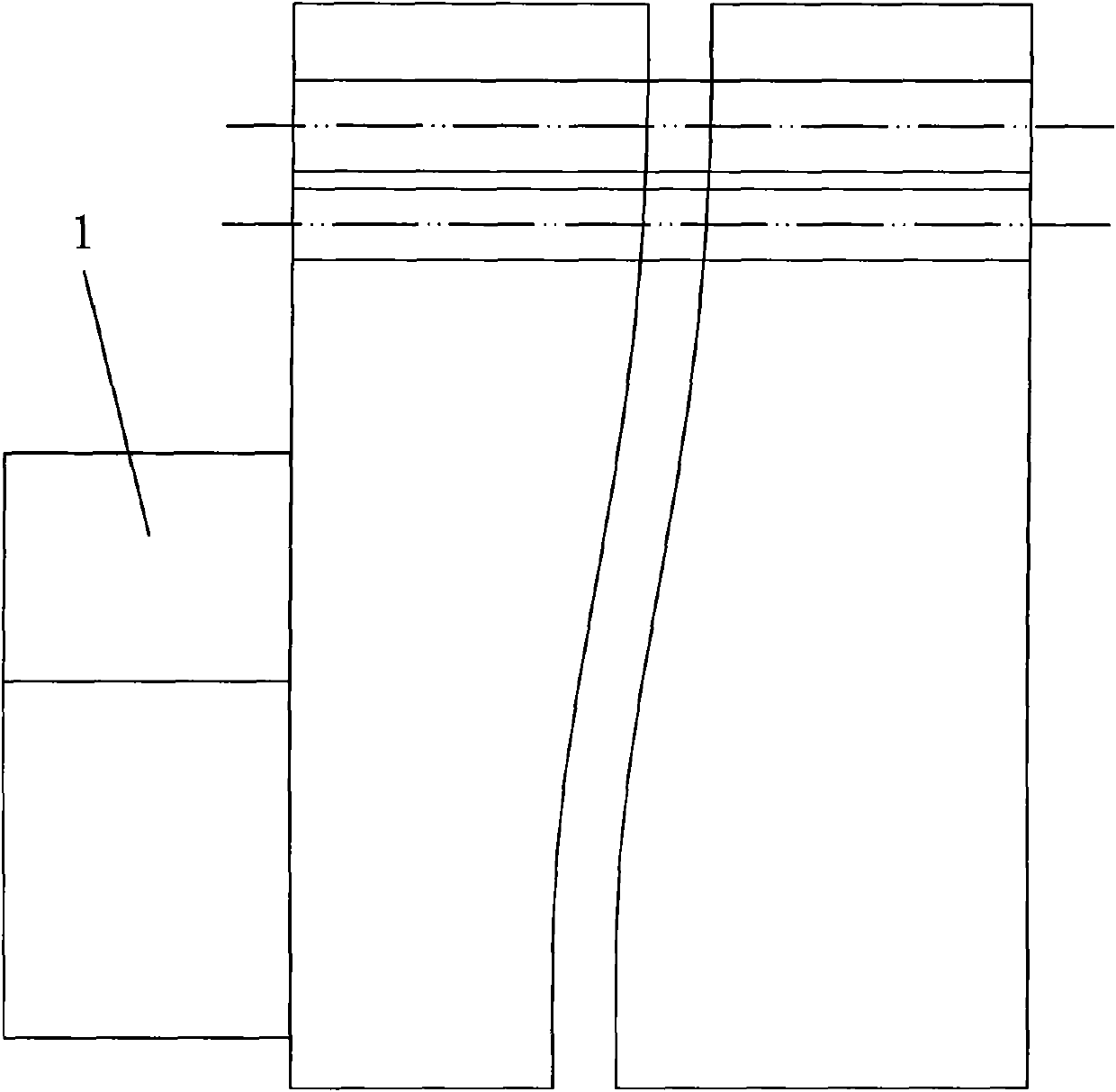

Method and device for after-finishing of various textiles and non woven fabrics through plasma treatment technology

InactiveCN102021814AChange propertiesProduce adhesionUltrasonic/sonic fibre treatmentTextile printerPlasma generator

The invention discloses a method and a device for after-finishing of various textiles and non woven fabrics through the plasma treatment technology. Various textiles and non woven fabrics are fed in through a group of fabric clamping rollers, and electro discharge treatment is carried out through a carrier roller rotating electrode fixed on a stand and a discharge channel of a plasma generator connected with an electric control box. Under the action of electric ions, the molecular characteristics of the textiles are changed, hydrophilcity, adhesiveness and proportionality of the textiles are increased, and the after-finishing process is carried out. For after-finished textiles through the plasma electro discharge treatment, the color fastness and the colorfulness of textile printing are increased. During coating, because the textiles have no dirt or dust, the adhesiveness is strong, the coating is even and is not easy to degum. The adhesion degree is increased during compounding, the textiles are not easy to degum and scale off and not easy to blister. According to the process, the quality of the textiles is greatly improved, and the economic benefit is increased. A large amount of ozone gas generated during the electro discharge treatment process of the various textiles and the non woven fabrics is absorbed through an ozone collector.

Owner:FUCHENG CHINA

Preparation method of high-strength and quick-drying type carton box binder

PendingCN107118709AIncrease the degree of cross-linkingImprove compactnessNon-macromolecular adhesive additivesProtein adhesivesCross-linkAluminum Ion

The invention discloses a preparation method of a high-strength quick-drying type carton adhesive. The compounding of borax and aluminum ions is used as a cross-linking agent, and the compounding of soybean protein / silicon dioxide hybrid sol and oxidized starch is used as an adhesive. Network skeleton, through cross-linking mixing reaction to obtain carton adhesive. The preparation method of the invention can effectively ensure the crosslinking and bonding strength between the raw materials, prevent the invasion of water molecules, and the prepared carton adhesive has the advantages of environmental protection, water resistance, high strength and fast drying speed, and meanwhile, the adhesive layer has good flexibility, Not easy to be brittle, degummed, long service life, good appearance quality, strong practicability.

Owner:天长市天达纸箱纸品厂

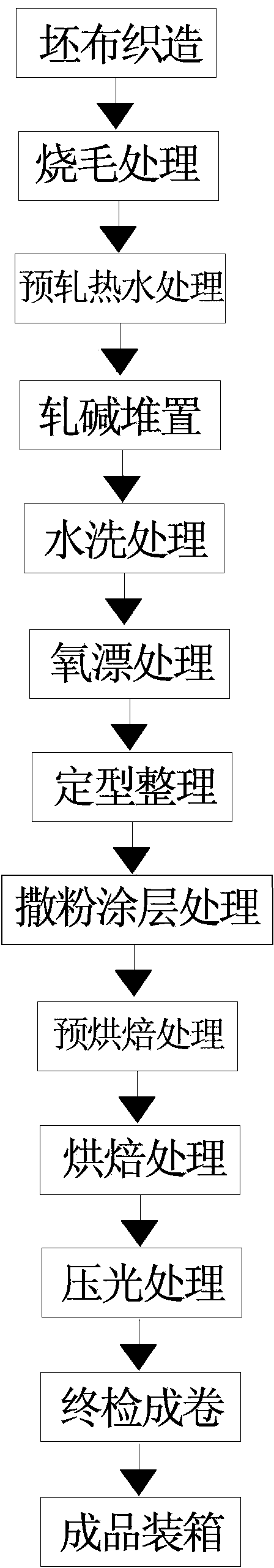

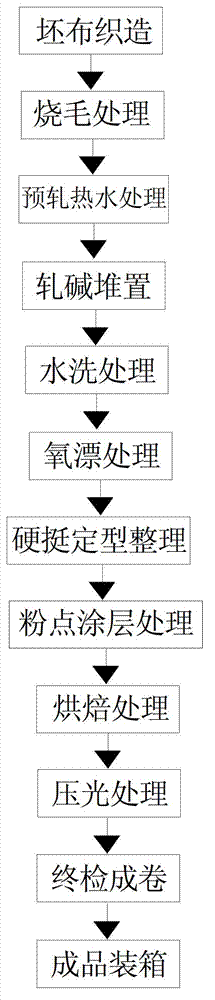

Shoe lining production process

InactiveCN102797156BIncrease thicknessImprove adhesion fastnessBiochemical fibre treatmentBleaching apparatusCooking & bakingHigh stiffness

The invention discloses a shoe lining production process, which comprises gray fabric weaving, singeing treatment, pre-rolling hot water treatment, rolling alkali and piling, washing treatment, oxygen bleaching, setting and finishing, powder scattering coating, pre-baking, baking, calendaring, performing final inspection and coiling, and packaging the finished product. The shoe lining has good handfeel, high stiffness, dimensional stability, low shrinkage rate and a lasting retention effect; and after the shoe lining is arranged for a long time, the stiffness is not reduced, and the shoe lining is high in thickness, high in adhesive firmness, good in a calendaring effect, long in service life and environment-friendly and is difficult to degum.

Owner:温州鸿马科技有限公司

Anticorrosive rubber lining and preparation method thereof

InactiveCN107383442ASolve the problem of anti-corrosion performanceExtend effective lifeChemical industryPolymer science

The invention belongs to the technical field of rubber linings, in particular to an anti-corrosion rubber lining and its preparation method, which solves the shortcomings of the prior art such as the lining falling off, fast aging, loose fit, especially high water absorption and easy moisture regain, and proposes An anti-corrosion rubber lining and its preparation method, and the preparation method is widely used, involving petroleum, chemical, fertilizer, metallurgy, electric power acid-base storage tanks, reactors, pure steel equipment used in floor isolation layers, etc. Used in many industrial productions, it includes 20-40 parts of natural rubber, 8-16 parts of styrene-butadiene rubber, 0.5-1.5 parts of peptizer, 8-16 parts of high styrene, 10-20 parts of graphite powder, 20-20 parts of sulfur 30 parts, 0.5-2 parts of high-speed accelerator, 2-4 parts of dispersant. The anti-corrosion rubber lining of the invention has high hardness, strong tensile capacity, good ductility and simple manufacturing process, can be constructed in workshops or on site, and is easy to realize.

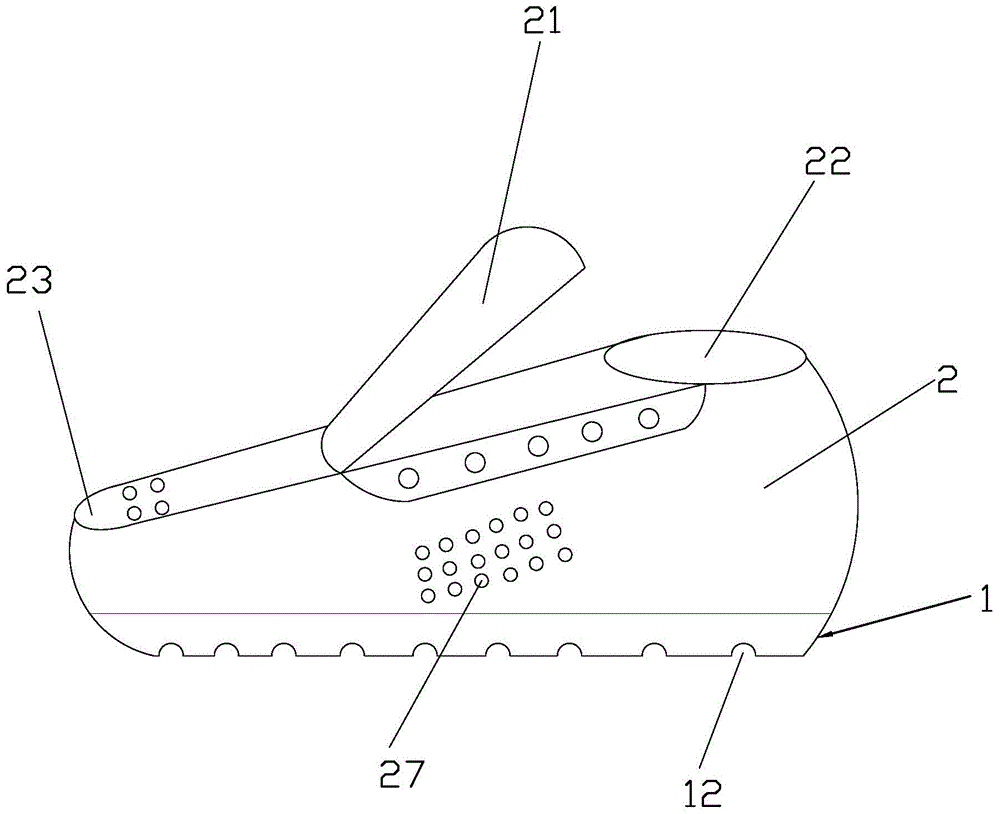

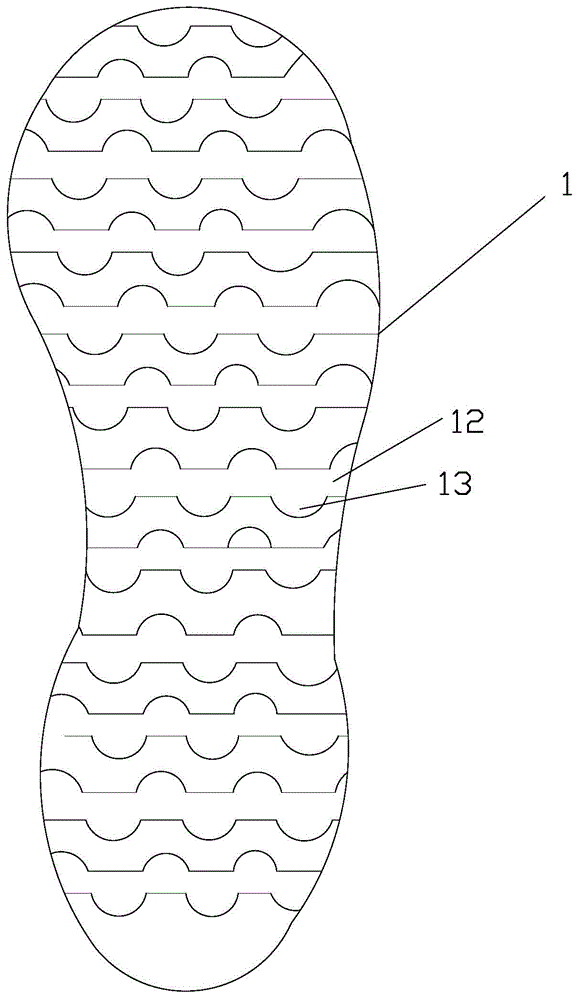

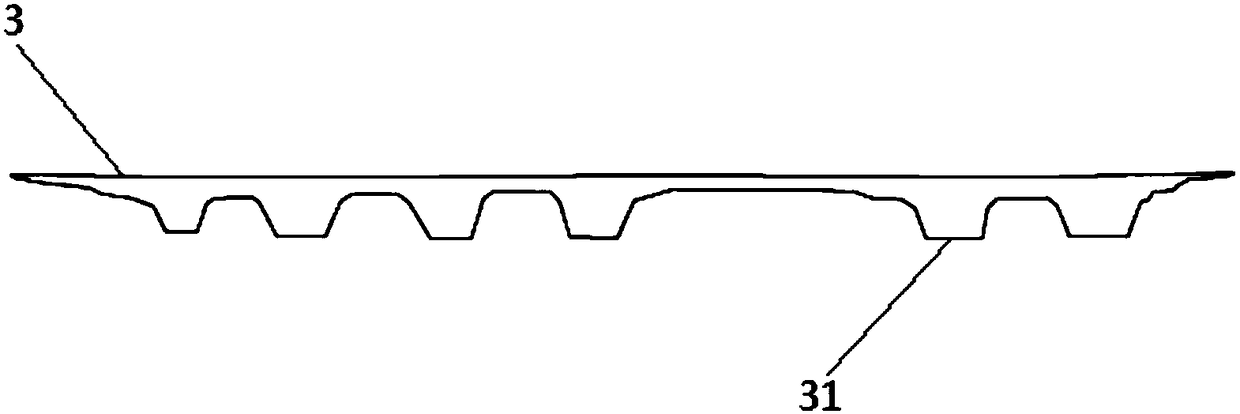

Preparation method for high-elastic rubber foamed shoe sole and application thereof to foamed shoe

The invention provides a preparation method for a high-elastic rubber foamed shoe sole. The raw materials comprises, in parts by weight, 250-500 parts of natural rubber, 20-40 parts of talcum powder, 2-5 parts of an anti-ageing agent, 2-4 parts of a rubber promoter M, 2-6 parts of zinc stearate, 2-6 parts of a rubber promoter DM, 4-8 parts of zinc oxide, 5-15 parts of sodium bicarbonate, 5-10 parts of polyethylene glycol, and 2-6 parts of AC foaming agent. Also, the shoe sole is applied to prepare a rubber foamed shoe, and the rubber foamed shoe comprises the sole and a vamp which are in adhesive connection. The thickness of the sole is 0.2-1.2 cm, the top surface of the sole is provided with an antiskid thread, the bottom surface of the sole is provided with water-discharging grooves which are distributed at equal intervals and run through the left and right ends of the sol, the distance of adjacent water-discharging grooves is 0.1-0.5 cm, and the wall of the water-discharging groove is provided with a groove gradually oblique from the top to the bottom of the water-discharging groove. The sole possesses good elastic effect, is resistant to wear and is not easy to deform. The shoe prepared by using the sole is comfortable to wear, and the preparation technology is simple.

Owner:NANAN FANKE BEARING DETECTION TECH CO LTD

Binder for wood plate

InactiveCN106479415AHigh bonding strengthImprove water resistanceMonocarboxylic acid ester polymer adhesivesMineral oil hydrocarbon copolymer adhesivesEpoxyParaffin wax

The invention discloses a binder for a wood plate. The binder is prepared from 0 to 500 parts by weight of epoxy resin, 1 to 200 parts by weight of a paraffin emulsion, 1 to 300 parts by weight of white latex, 1 to 200 parts by weight of a curing agent, 50 to 100 parts by weight of ultra-fine cellulose powder and 0 to 10 parts by weight of cellulase. The binder is prepared from the above raw materials dissolved in an organic solvent and is jelly. Through synergetic bonding of epoxy resin and white latex, bonding strength is improved so that the binder does not easily fall off in long-term use. The paraffin emulsion is used and the paraffin emulsion with fine particle sizes can naturally penetrate into a wood plate so that the wood plate has water resistance after drying. The cellulose has good absorptivity, has hydrophily under cellulase action and realizes moisture prevention.

Owner:重庆市开州区庆宁木业有限公司

Reactive type modified asphalt and production method therefor

InactiveCN105238080AExtended service lifeEasy constructionTextiles and paperBuilding insulationsPolymer chemistryEngineering

The present invention aims to provide reactive type modified asphalt and a production method therefor, and particularly relates to reactive viscosity modified asphalt that can perform chemical cross-linking and physical tenon connection with concrete. The reactive type viscosity modified asphalt is prepared by raw materials comprising asphalt, a rubber modifier, and a waterproof bridging agent. The modified asphalt provided by the present invention can be used as an adhesive layer of a waterproof roll or directly used as a waterproof material to build a waterproof bridge, and generates very strong adhesion force with a cement base surface.

Owner:卢桂才

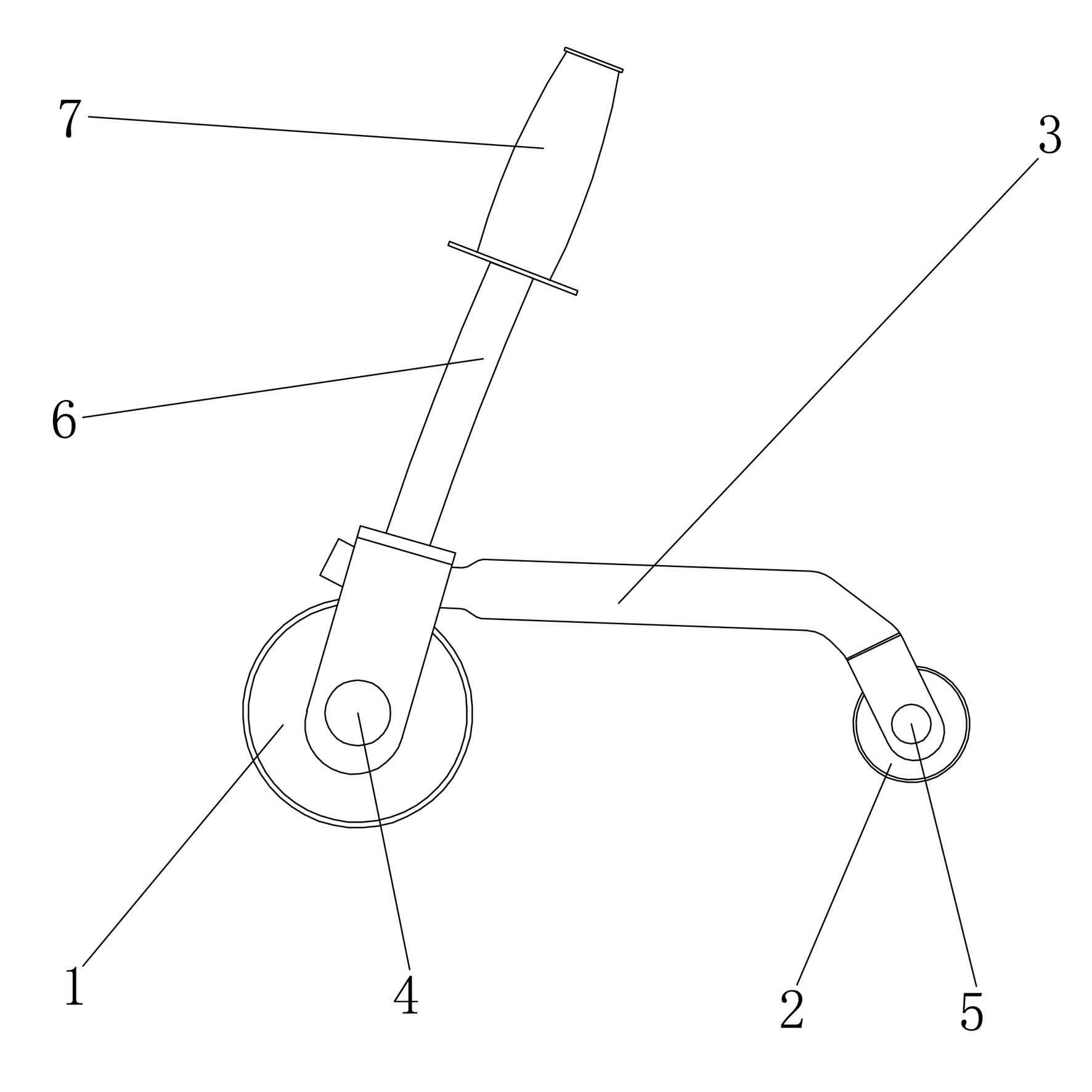

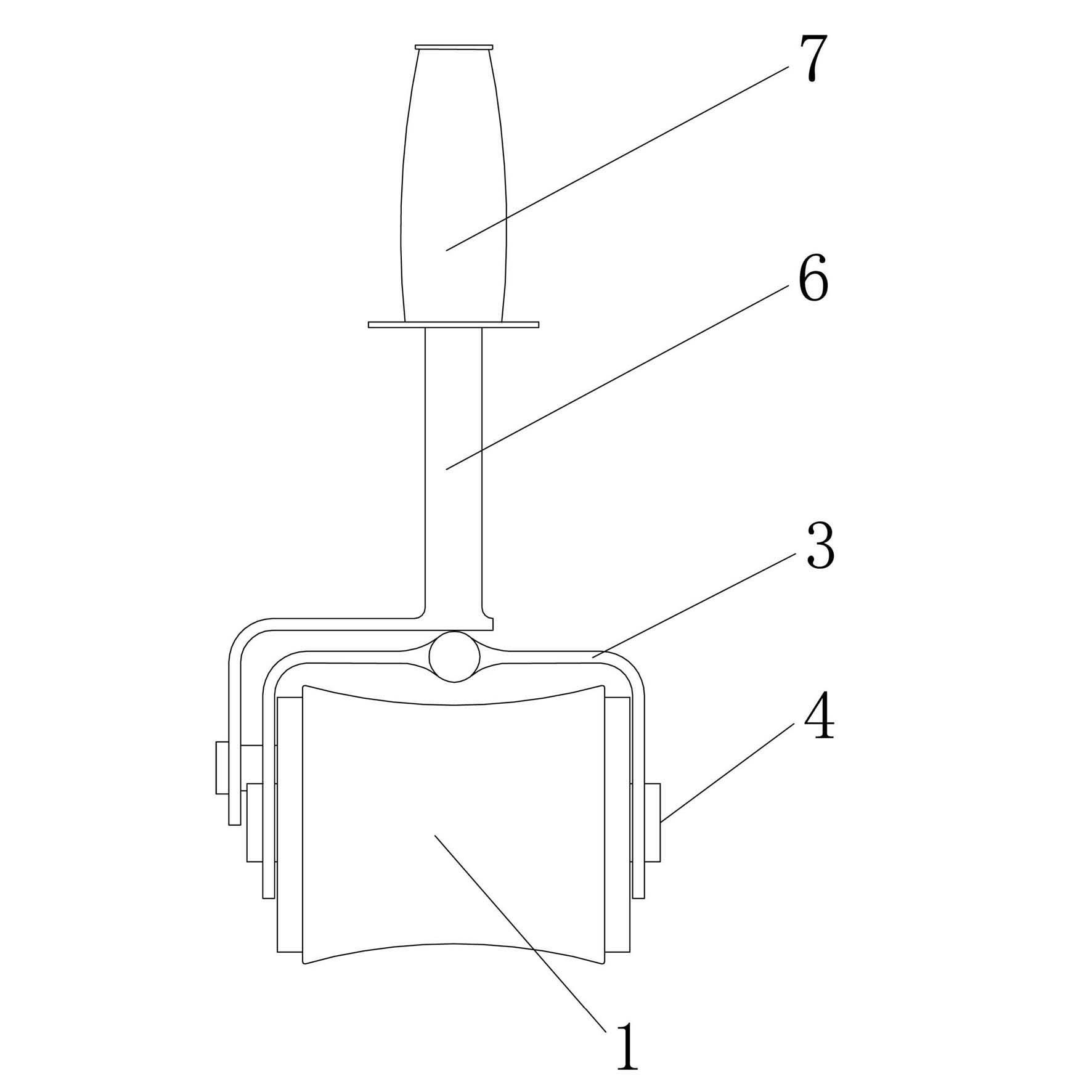

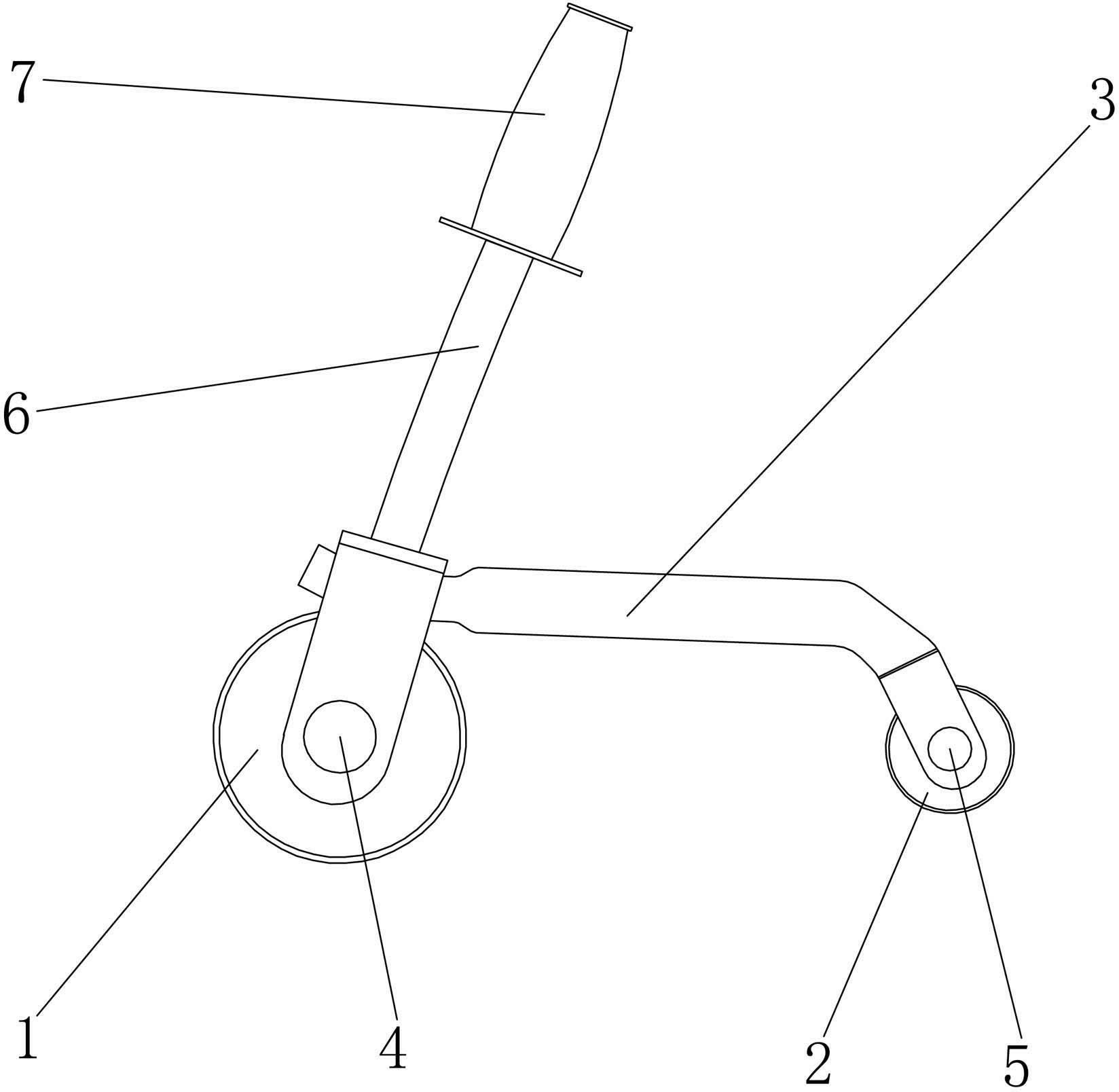

Disposable compaction tool for automobile decoration strip

InactiveCN102205528AEven by forceNot easy to degummingMetal-working hand toolsVehiclesEngineeringMechanical engineering

The invention relates to an auxiliary operating tool in the automobile production industry, in particular to a disposable compaction tool for an automobile decoration strip. The disposable compaction tool for the automobile decoration strip comprises a handle and a roller for compacting the decoration strip; the roller comprises a driving roller and a driven roller; the driving roller is connected with the driven roller through a force application handle; the motion traces of roller slots of the driving roller and the driven roller are overlapped; and the force application handle is connected with the driving roller and the driven roller through a driving roller shaft and a driven roller shaft. In the disposable compaction tool, the decoration strip is compacted by two rollers twice, and the motion traces of the roller slots of the two rollers are overlapped, so the phenomenon of too large or too small partial pressure can be avoided and the stress is uniform; as a guide handle guides the decoration strip, deflected rolling can be avoided and the surface of painting cannot be damaged; and by adoption of the decoration strip compacted by the compaction tool, the debonding problem can be solved basically.

Owner:JIANGLING MOTORS

Handle-free frame type solid wood composite kitchen cabinet door sheet and manufacturing method thereof

PendingCN110331921AAvoid deformationAvoid anisotropyCorner/edge jointsWood working apparatusSolid woodEngineering

The invention discloses a handle-free frame type solid wood composite kitchen cabinet door sheet and a manufacturing method thereof. The door sheet comprises a door frame and a door core panel, wherein the door frame comprises a handle side frame and a non-handle side frame; the handle side frame comprises a solid wood plate strip; a handle model is arranged on the solid wood plate strip; the non-handle side frame comprises a second multi-layer plate base material; the outer side, away from the center of the door frame, of the side frame is coated with an outer side solid wood edge-sealing strip; the side frame and the side wall of the door core panel are simultaneously coated by the outer side solid wood edge-sealing strip; and a groove which is adaptive to the handle model is formed in the door core panel. The door sheet adopts solid wood plate facing and solid wood strip edge-sealing, saves wood resources, is environmentally friendly and reduces cost, so that the effects of achieving wood anisotropism, not cracking and not warping are solved. The manufacturing process for splicing and compounding two different materials on a plate splicing machine is provided, and thus the problem of product simplification is solved.

Owner:เซี่ยเหมิน โกลเด้นโฮม โค

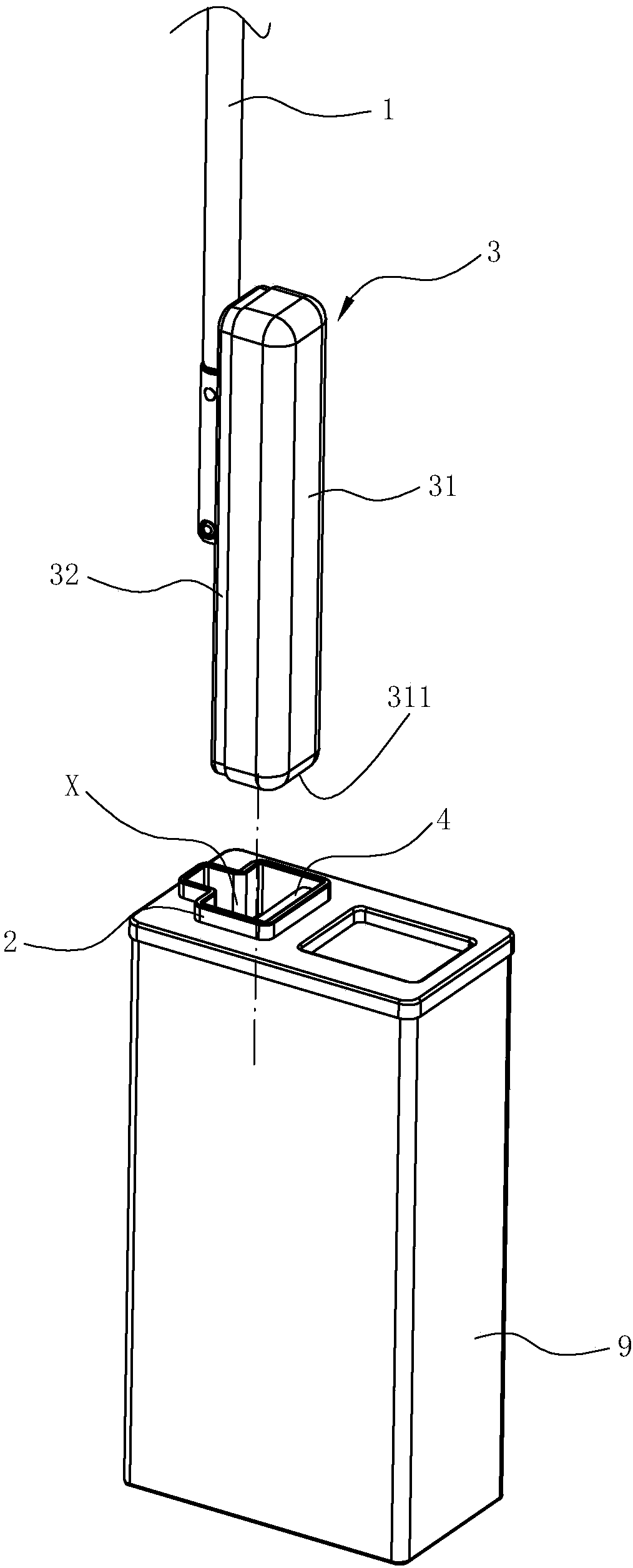

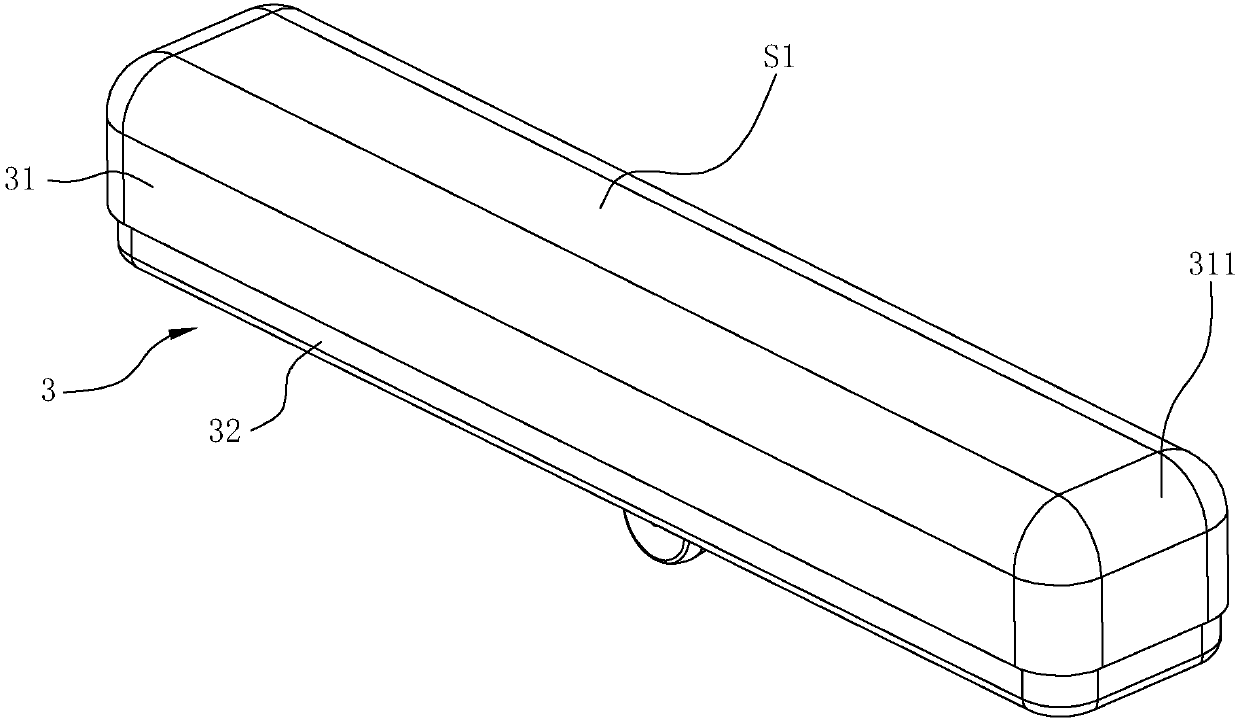

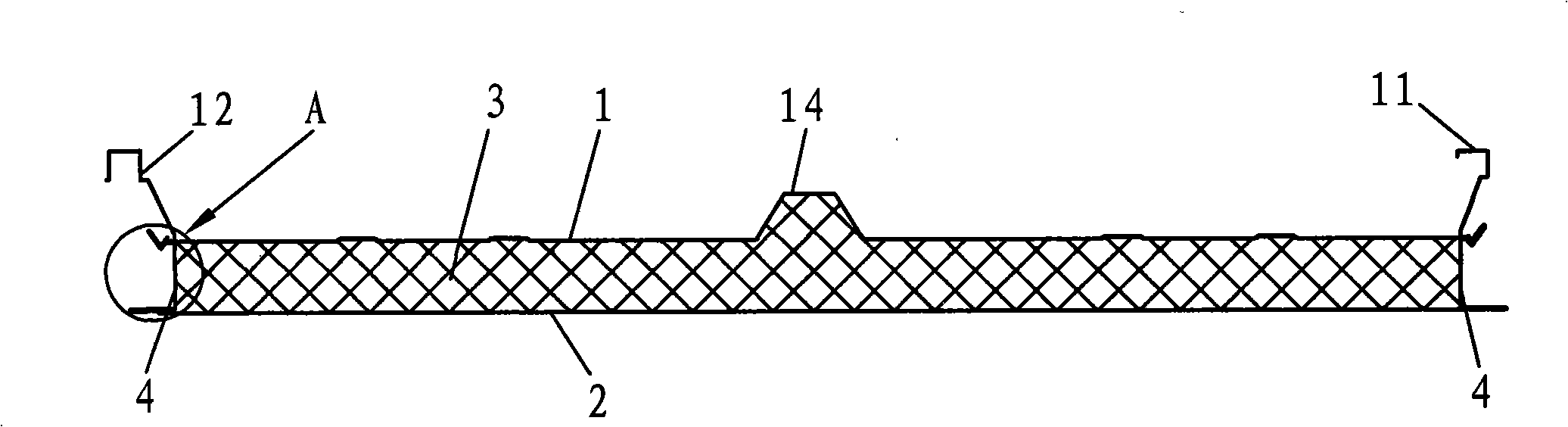

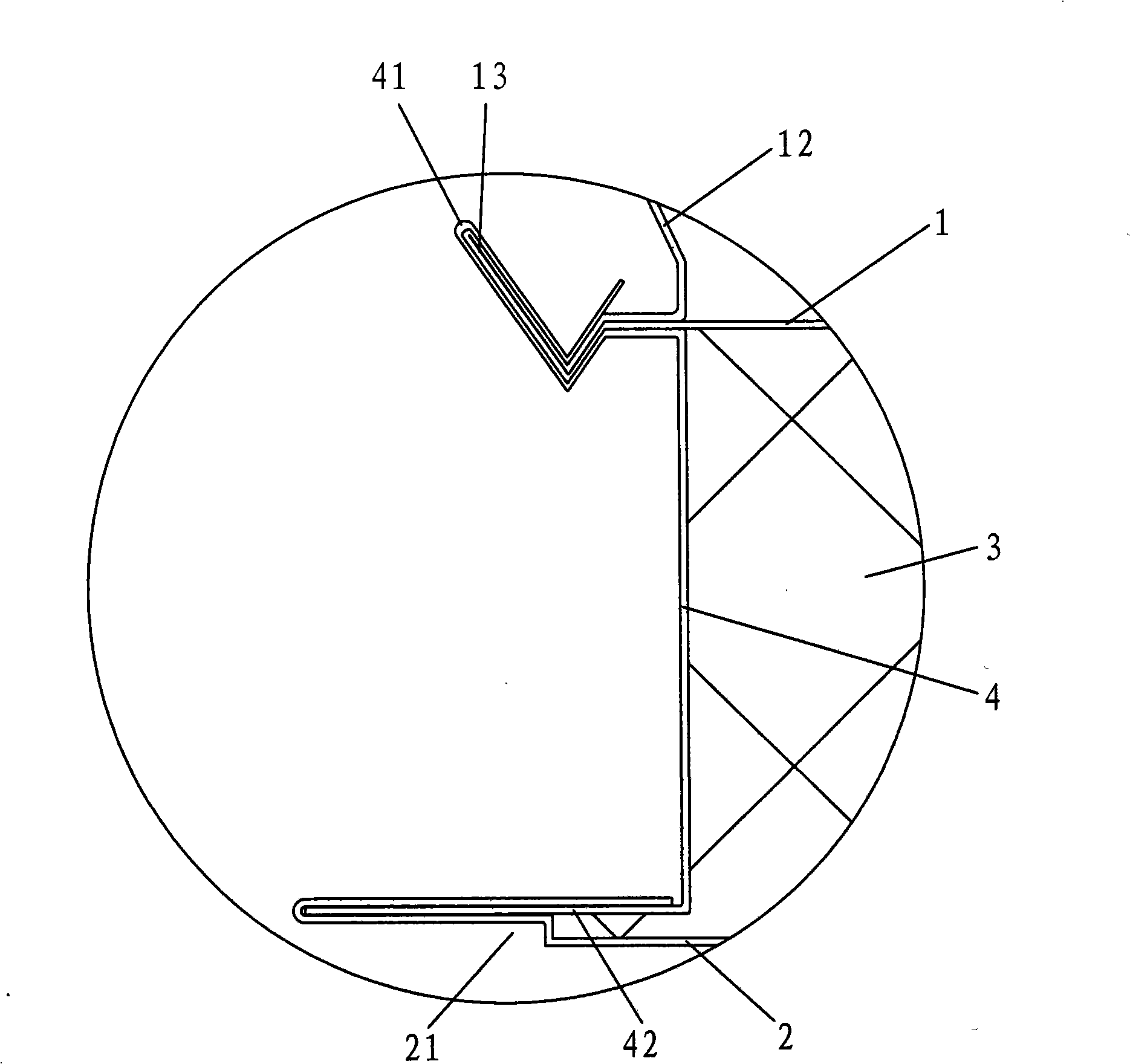

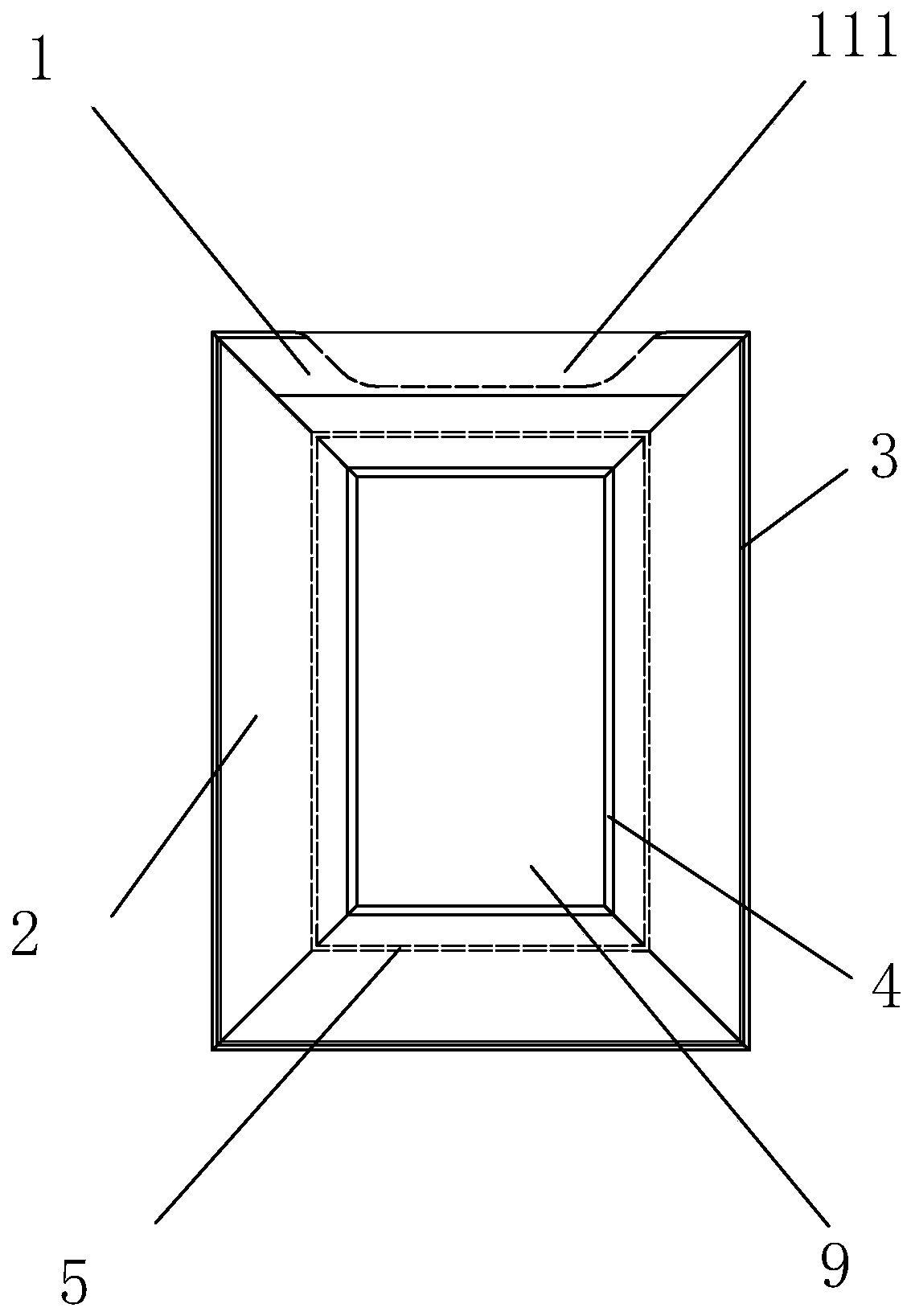

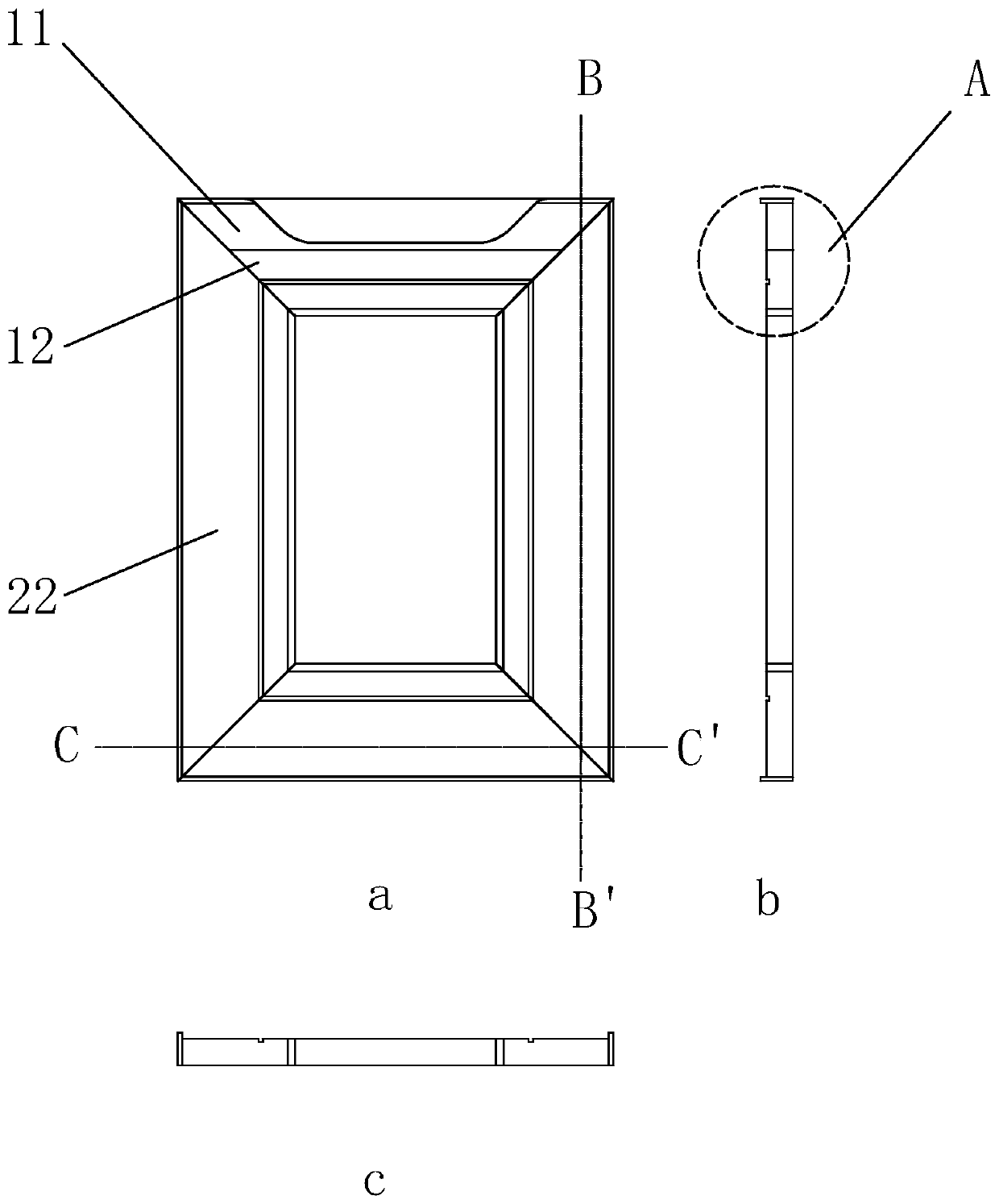

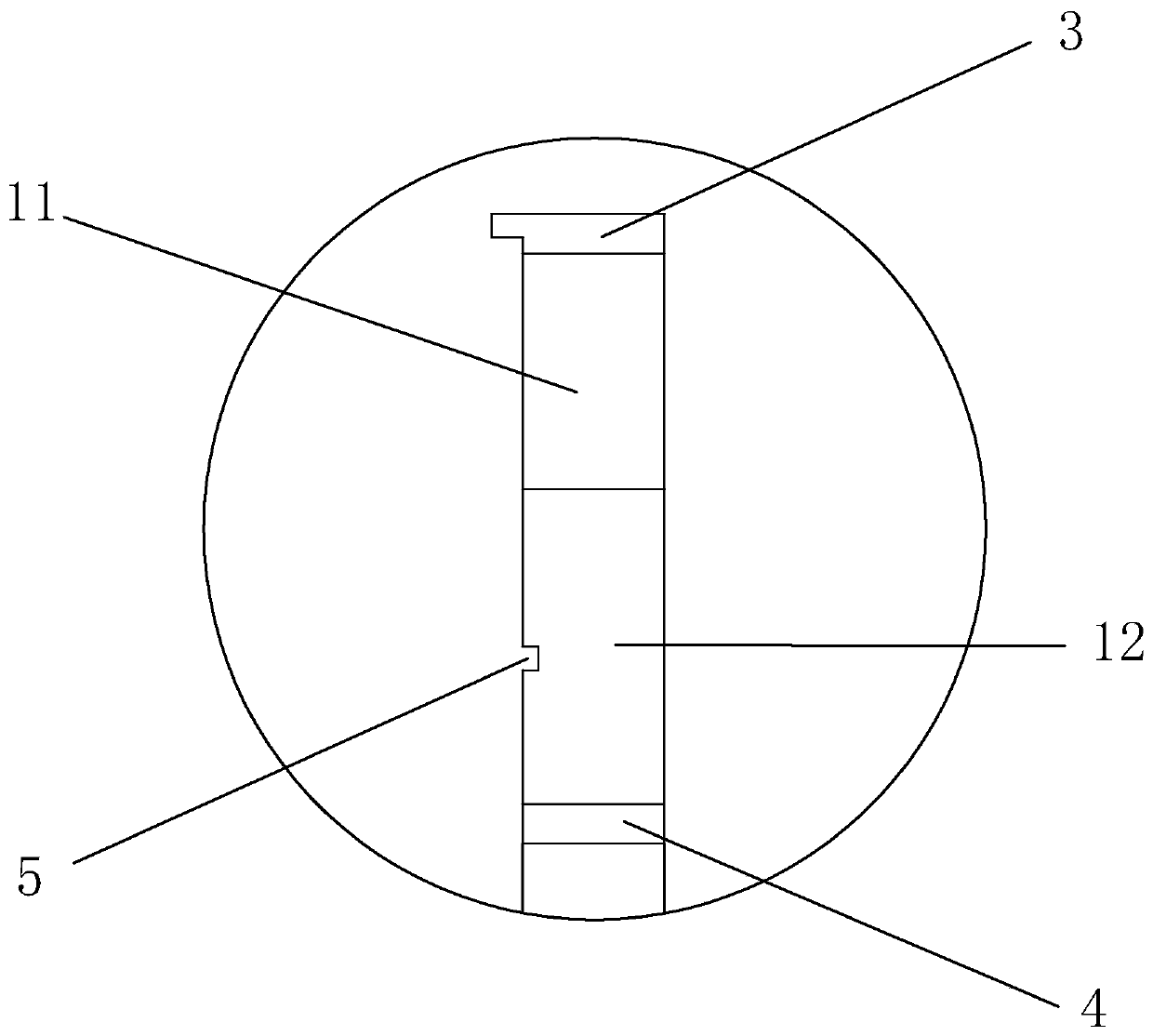

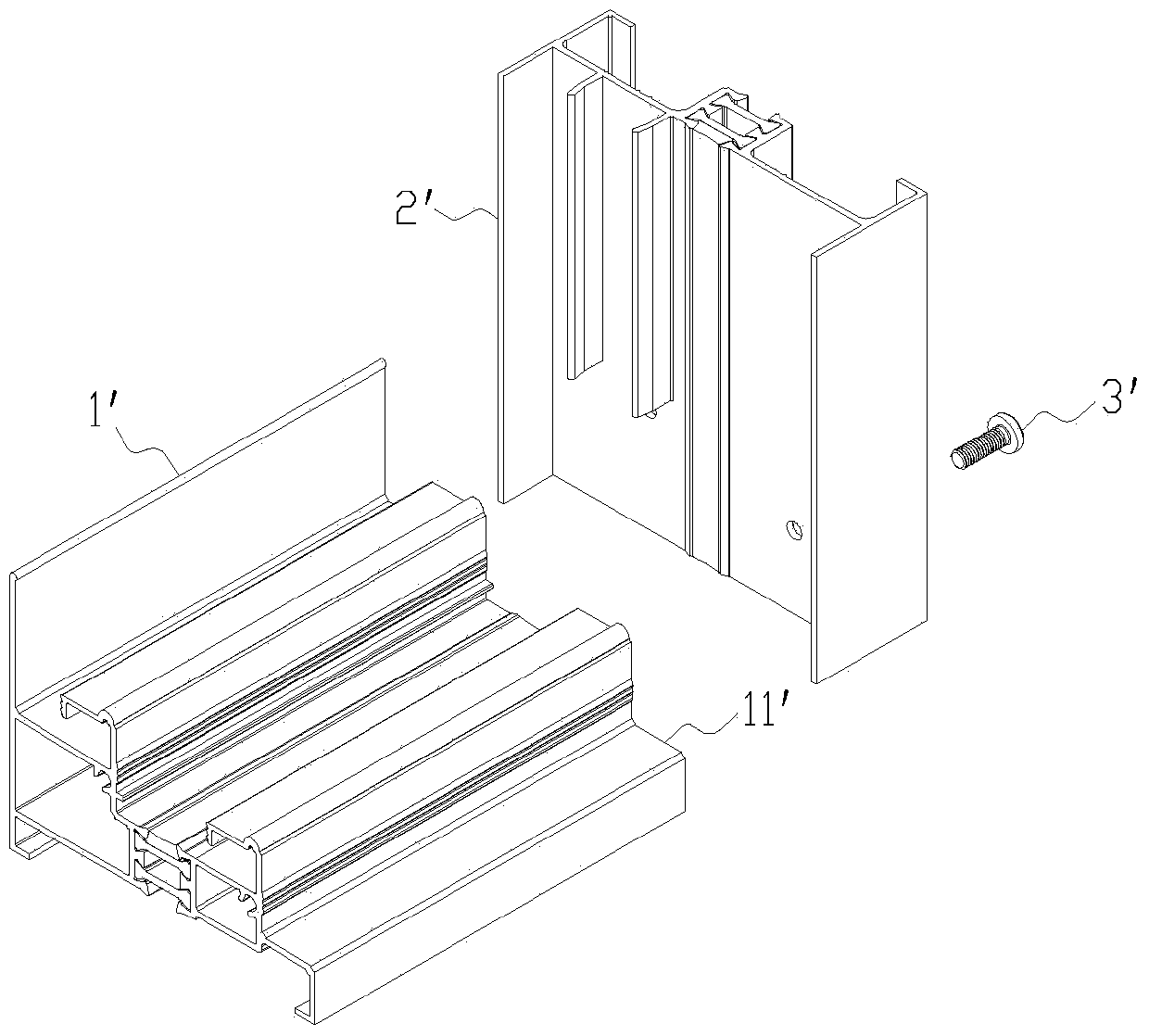

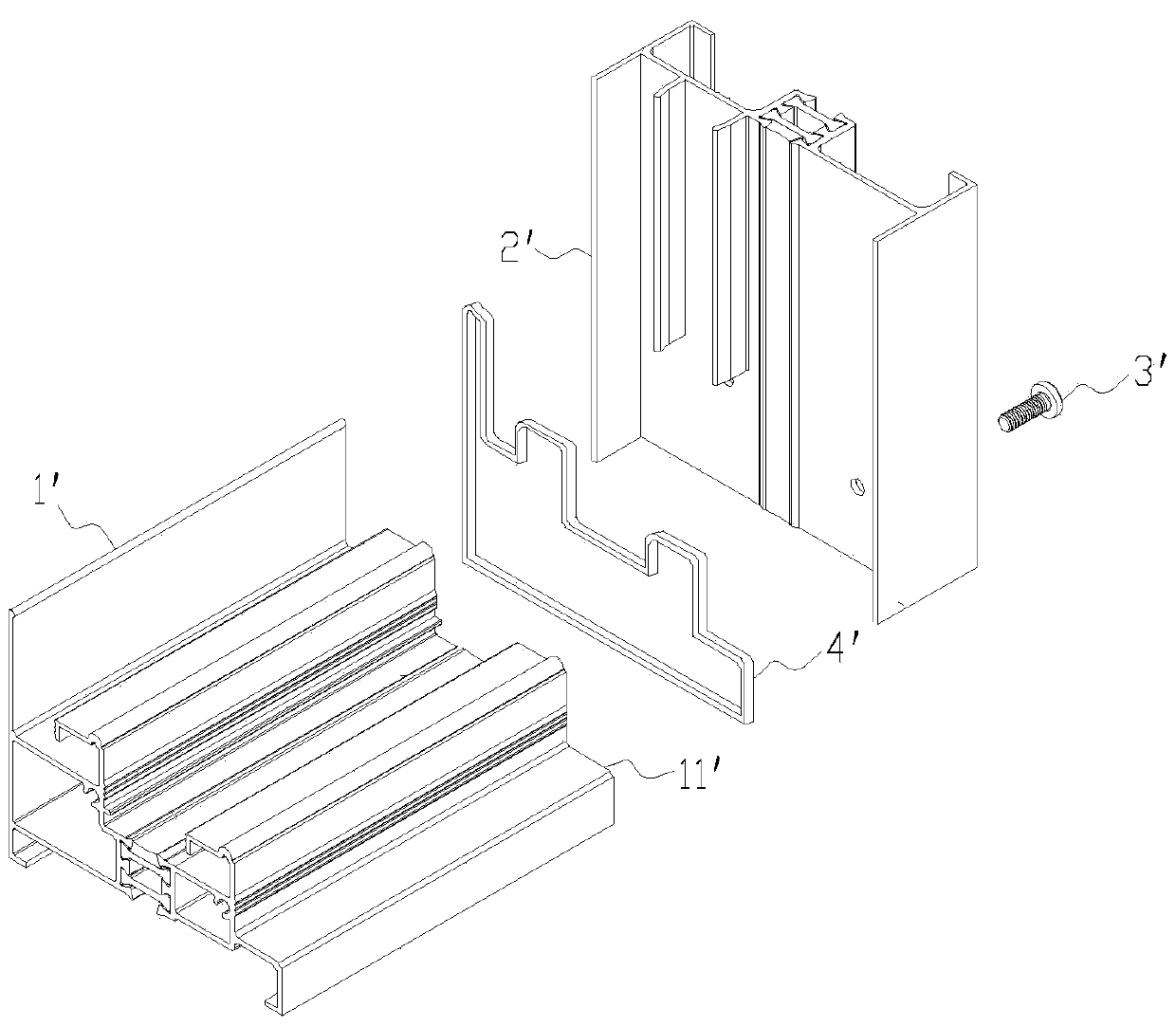

Connecting piece with cavity sectional material

ActiveCN103437666AIncrease profitOvercome water seepage gapsDoors/windowsUltimate tensile strengthMachining

The invention discloses a connecting piece with a cavity sectional material, and solves the defects that the connection of a connecting structure between the existing horizontal sectional material and the vertical sectional material is not firm and the water-proof property is poor. According to the technical scheme, the connecting piece provided by the invention is of a block shape, the outer shape of the connecting piece is matched with a cavity of the sectional material, so that the connecting piece is conveniently placed in the cavity, and the connecting piece comprises at least one inserting surface and a bonding surface which is perpendicular to the inserting surface. The connecting piece provided by the invention has the advantages that the block-shaped connecting piece arranged in the cavity of the horizontal sectional material is used for changing the line connection of a gluing position arranged among the sectional materials into surface connection, the connecting strength is effectively improved, a glue is subjected to extrusion so as to flow from inside to outside so as to rapidly and effectively fill a gap caused by the lower machining precision or sectional material specific structure requirement, the gap after solidifying is blocked, and the waterproof property is good.

Owner:ZHEJIANG BOAO ALUMINUM

Foaming EVA slipper production process

The invention discloses a foaming EVA slipper production process. The process includes the steps of EVA insole irradiation treatment, glue coating and bonding of vamps and EVA insoles, outsole pre-treatment, glue coating and bonding of the outsoles and the EVA insoles and pressing and shaping of the outsoles and the EVA insoles. By adopting the foaming EVA slipper production process, the EVA insoles and the outsoles can be bonded perfectly, the firmness of the produced slippers is high, and the slippers are not likely to be degumed.

Owner:FUJIAN ZHENLONG SHOES

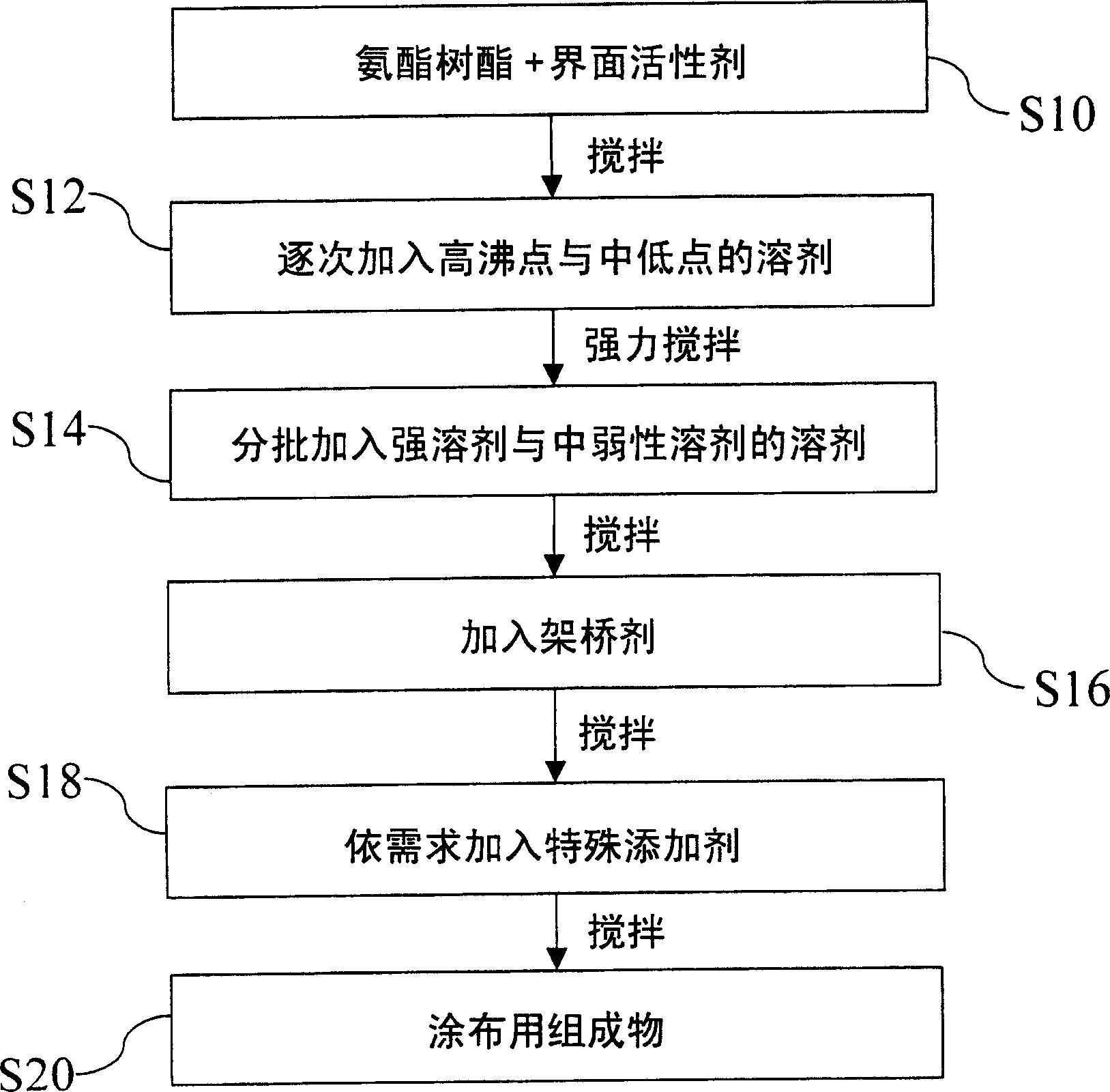

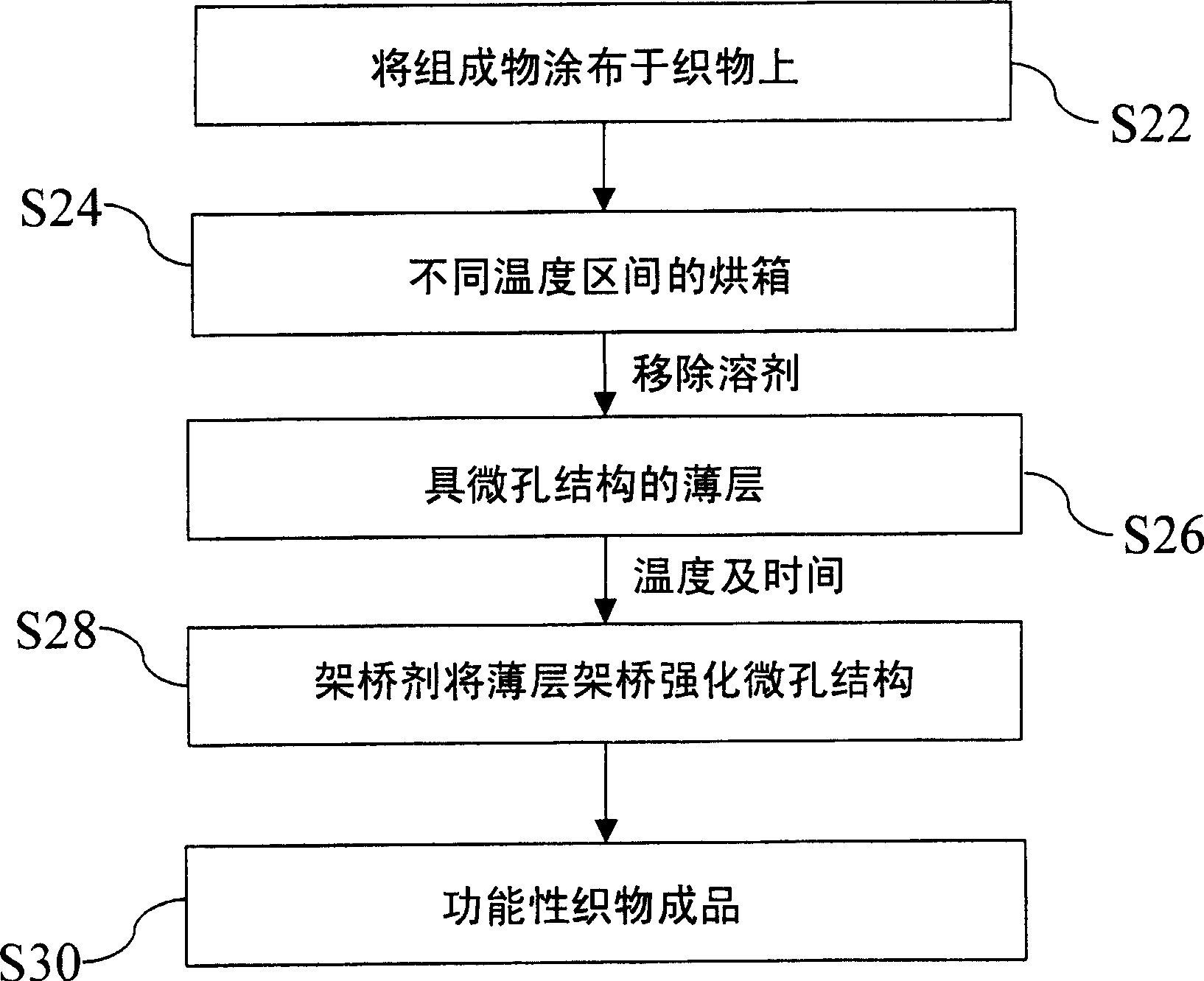

Composition of polyurethane permeable microporous thin layer and method for making same

InactiveCN1844241AExcellent adhesionMeet the requirements of breathable and waterproof functionsTextiles and paperActive agentBoiling point

The invention discloses a polyurethane permeability microporous cave thin layer component and its manufacturing process, which consists of successively adding more than two solvents into the polyurethane resin of 10-50 mass %, in which the solvents consist of mixed solvents of high boiling point solvent and low-and-moderate boiling point solvent and mixed solvents of strong solvent and weak-and-moderate solvent, and stirring them with a mechanical strength; then supplementally treating with interfacial active agent and bridge agent to construct a component. The said component is dried under different thermostages after being applied to prepare the said permeability microporous cave thin layer, which has good air permeable waterproofing and adhesive ability with the textile, and can not expand because of moisture absorption.

Owner:FORMOSAN RUBBER GRP

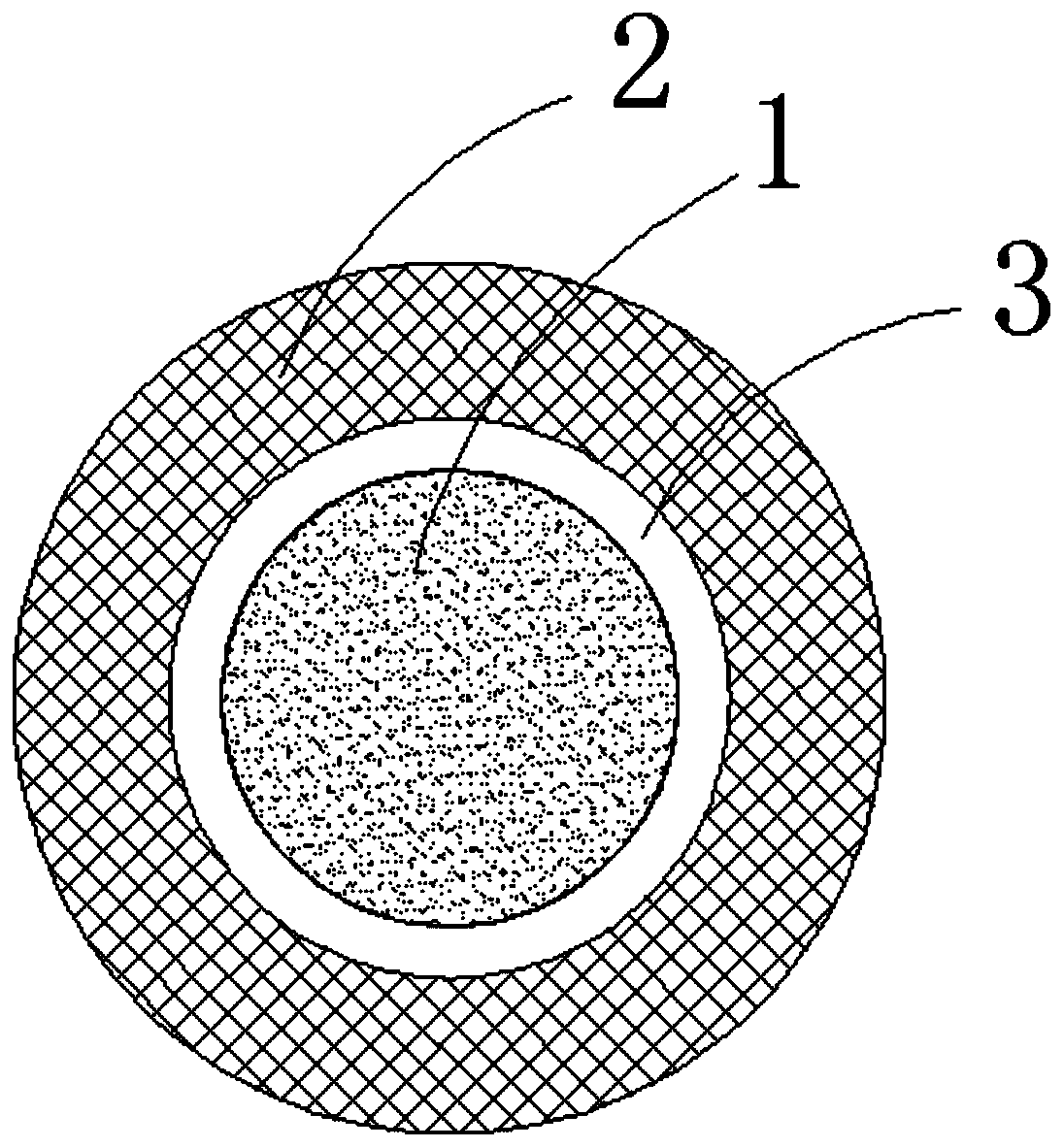

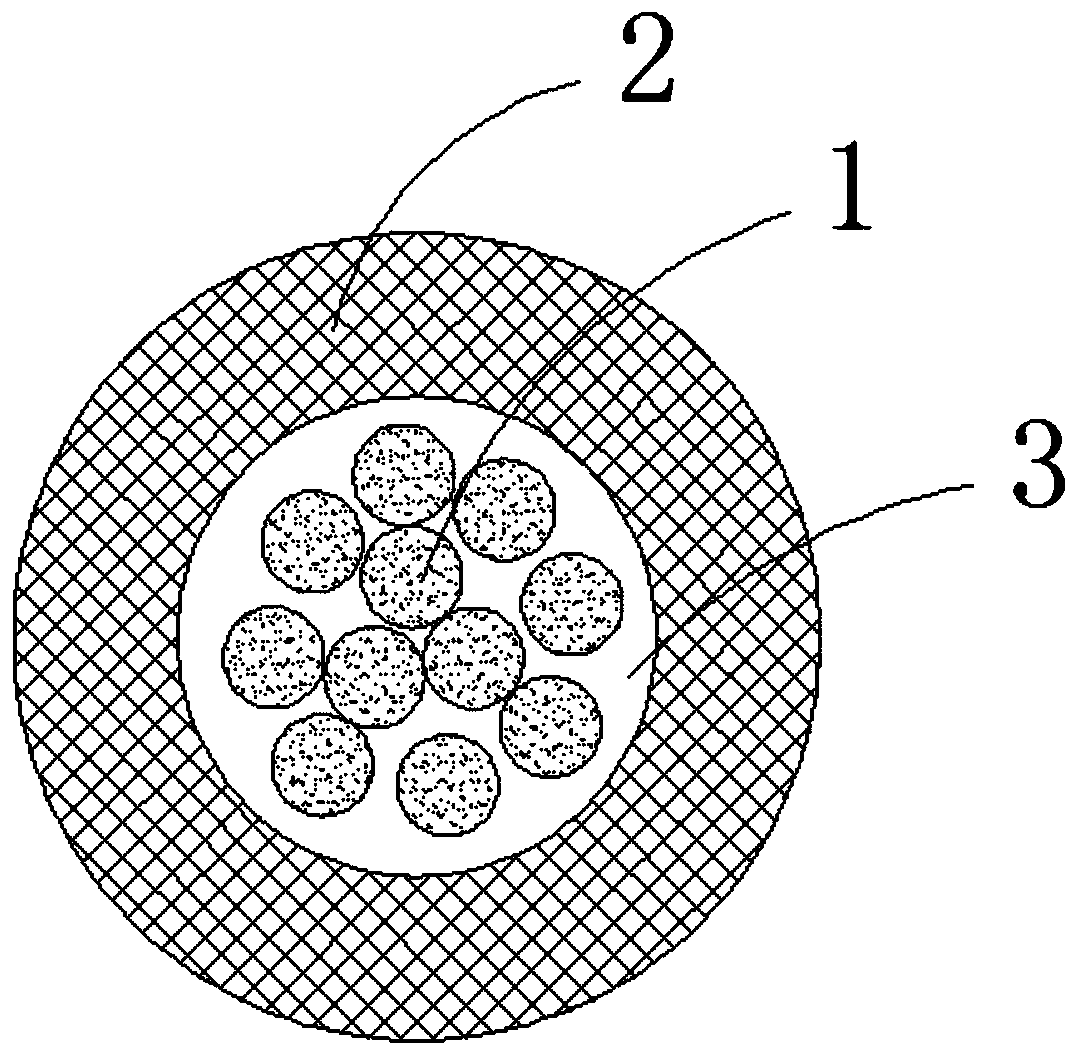

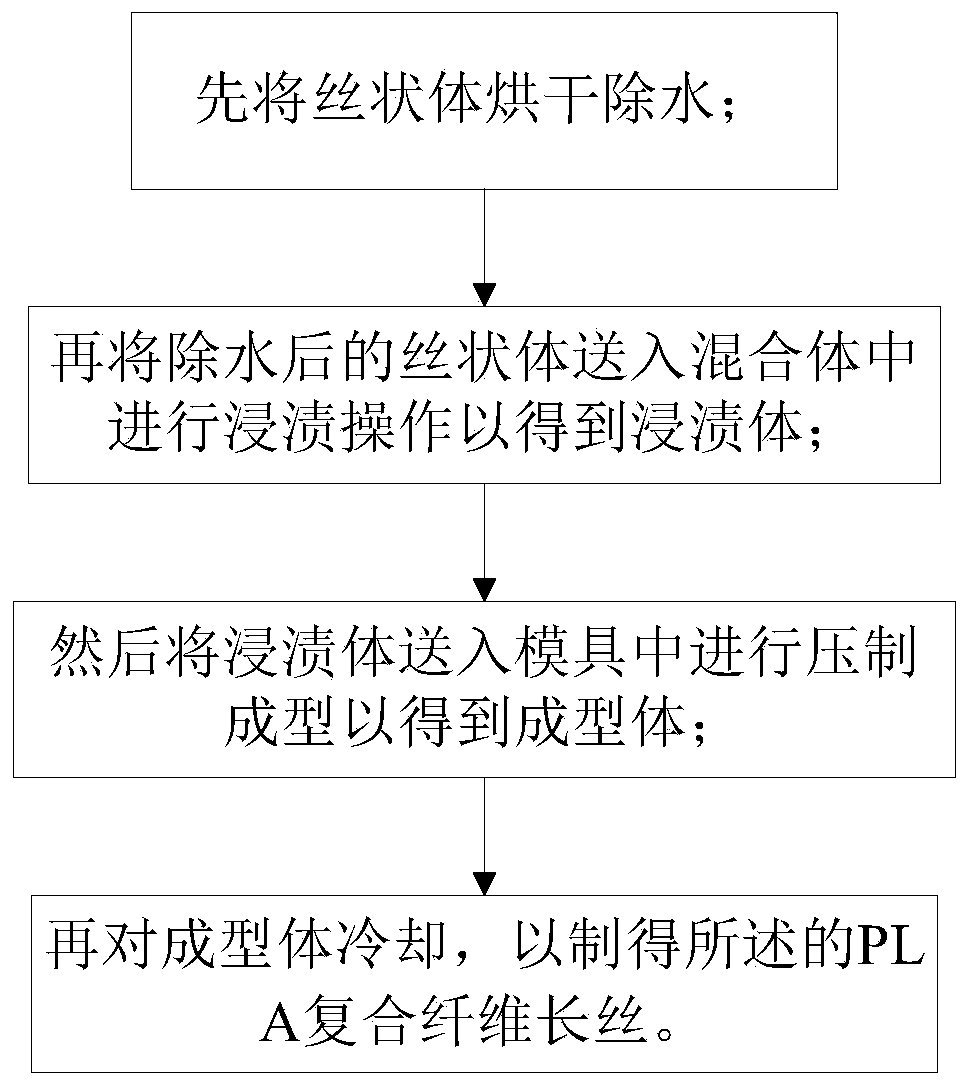

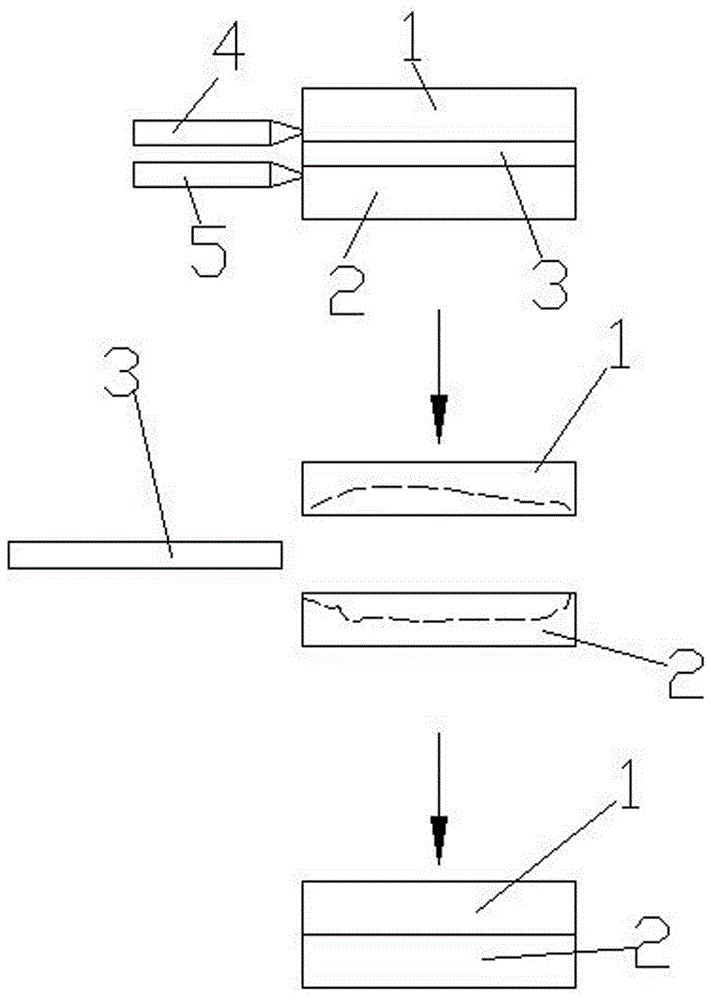

PLA composite fiber filament and making process and application thereof

Owner:WUHAN RED GOLDEN LEAF NEW MATERIAL TECH CO LTD

Preparation method for polyurethane adhesive with high initial bonding strength for fire hose

InactiveCN104745137AHigh bonding strengthGood adhesionPolyureas/polyurethane adhesivesPolymer sciencePolyurethane adhesive

The invention discloses a preparation method for a polyurethane adhesive with high initial bonding strength for a fire hose. The polyurethane adhesive is composed of the following components in percentage by weight: 70-90% of oligomer polyols, 1-5% of micromolecular diol, 8-20% of diisocyanate, 0.1-0.2% of bismuth naphthenate, 0.1-0.5% of an antioxidant, 0.1-0.5% of a light stabilizer and 0.1-0.5% of an ultraviolet absorber, and formed by synthesising and granulating under certain sequential steps. The solid polyurethane adhesive prepared by the preparation method disclosed by the invention is high in initial bonding strength, firm in bonding, excellent in weather resistance and heat resistance, high in melt index, high in tensile strength, suitable for hot-melt processing, convenient to process, safe to transport, easy to use, free from use of an organic solvent, and free from causing pollution to environment.

Owner:洛阳吉明化工有限公司

A molding process of two-color double-hardness sole

ActiveCN103128978BEliminates manual hand gluing stepsSimple processDomestic articlesCross-linkPlastic injection molding

The invention discloses a forming technology and a preparation method for a double-color and double-hardness sole. The forming technology and the preparation method for the double-color and double-hardness sole mainly includes the following steps: step 1, a mold is prepared, wherein a set of plastic injection mold is prepared; step 2, a plastic injection molding process is prepared, wherein a plastic injection molding machine is provided with two injection gun barrels which can be used for injecting plastics into the plastic injection mold simultaneously; step 3, the plastic injection molding process is carried out, wherein the plastic injection mold is placed on a mold frame of the plastic injection molding machine, the plastic injection molding machine is started, the two injection gun barrels are used for injecting the plastics into an upper mold body and a lower mold body of the plastic injection mold simultaneously, then the plastic injection mold is pre-pressed through a partition plate and then opened, the upper mold body and the lower mold body are separated, and then the partition plate is drawn out; and step 4, a bonding and cross-linked foaming forming process is carried out, wherein the upper mold body and the lower mold body are closed again, an upper-layer composite material and a lower-layer composite material are subjected to bonding and cross-linked foaming forming in a closed mold cavity, then the plastic injection mold is opened, and the double-color and double-hardness sole is obtained. According to the double-color and double-hardness sole produced through the preparation method, a shoe outsole portion and a shoe middle sole portion are not degummed when meeting water, do not separate from each other and are long in service live, the foaming forming process is fast, and a color bleeding phenomenon cannot happen.

Owner:JINJIANG CHENGCHANG SHOES

Formaldehyde-free adhesive for sheets

InactiveCN106479413ANo damageHigh bonding strengthMonocarboxylic acid ester polymer adhesivesStarch adhesivesParaffin waxEpoxy

The invention discloses a formaldehyde-free adhesive for sheets. The adhesive comprises the following components in parts by weight: 0 to 500 parts of epoxy resin, 1 to 200 parts of paraffin emulsion, 1 to 300 parts of white latex, 1 to 200 parts of curing agent, and 0 to 400 parts of starch mixed solution; wherein the starch mixed solution is prepared from starch and water according to a ratio of parts by weight of 1:40, and the starch is one or more of corn starch, glutinous rice starch, and wheat starch. The adhesive (jelly like substance) is prepared by dissolving abovementioned raw materials into an organic solvent. Through the cooperative gluing effect of epoxy resin and white latex, the bonding strength is enhanced, degumming is difficult to happen for a long term; due to the adhering effect of starch mixture, the adhering effect of epoxy resin and white latex is enhanced, the overall bonding force is further strengthened; moreover, the raw materials are easily available, the cost is low; furthermore, the adhesive strength is strong, no formaldehyde exists, the environment protection effect is good, and the adhesive is harmless to human body.

Owner:重庆市开州区庆宁木业有限公司

Steel-plastic composite pipe

InactiveCN102086954AIncreased ring stiffnessNot easy to break awayRigid pipesHigh pressureMetallurgy

The invention discloses a steel-plastic composite pipe. The steel-plastic composite pipe comprises a steel strip (4) with a specially-shaped cross section and plastic coatings (2), and is characterized in that: the specially-shaped cross section of the steel strip is hollow and closed; the steel strip is spirally wound to form a tubular body (1); adjacent edges of the steel strip are fixedly welded; and both inner layer and outer layer of the tubular body are provided with the plastic coatings. Since the specially-shaped steel strip has a hollow and closed structure and is wound and welded to form the tubular body, the ring stiffness of a pipeline is obviously improved, high-strength pressure can be born, the pipe is difficultly degummed and squeezed to be broken, and the aims of high strength, high pressure bearing capacity, firm steel-plastic adhesion, difficulty in separating steel from plastic and continuous integral steel strips are fulfilled.

Owner:SICHUAN JINYI PLASTIC PIPE IND

Stiff waist liner production process

InactiveCN103088640AIncrease thicknessImprove adhesion fastnessBleaching apparatusVegetal fibresCooking & bakingShrinkage rate

The invention discloses a waist liner production process which comprises the following steps of: weaving gray fabrics, singeing, performing pre-rolling hot water treatment, alkali rolling stacking, washing, oxygen bleaching treatment, stiff setting and finishing, powder point coating treatment, baking, polishing, final inspection coiling, and finished product boxing. The waist liner is good in handfeel, high in stiffness, stable in size, low in shrinkage rate, lasting in retaining effect, the stiffness is not reduced when the waist liner is arranged for a long time, and the waist liner is high in thickness, high in adhesion firmness, difficult to unglue, good in polishing effect, long in service life and environment-friendly.

Owner:余永生

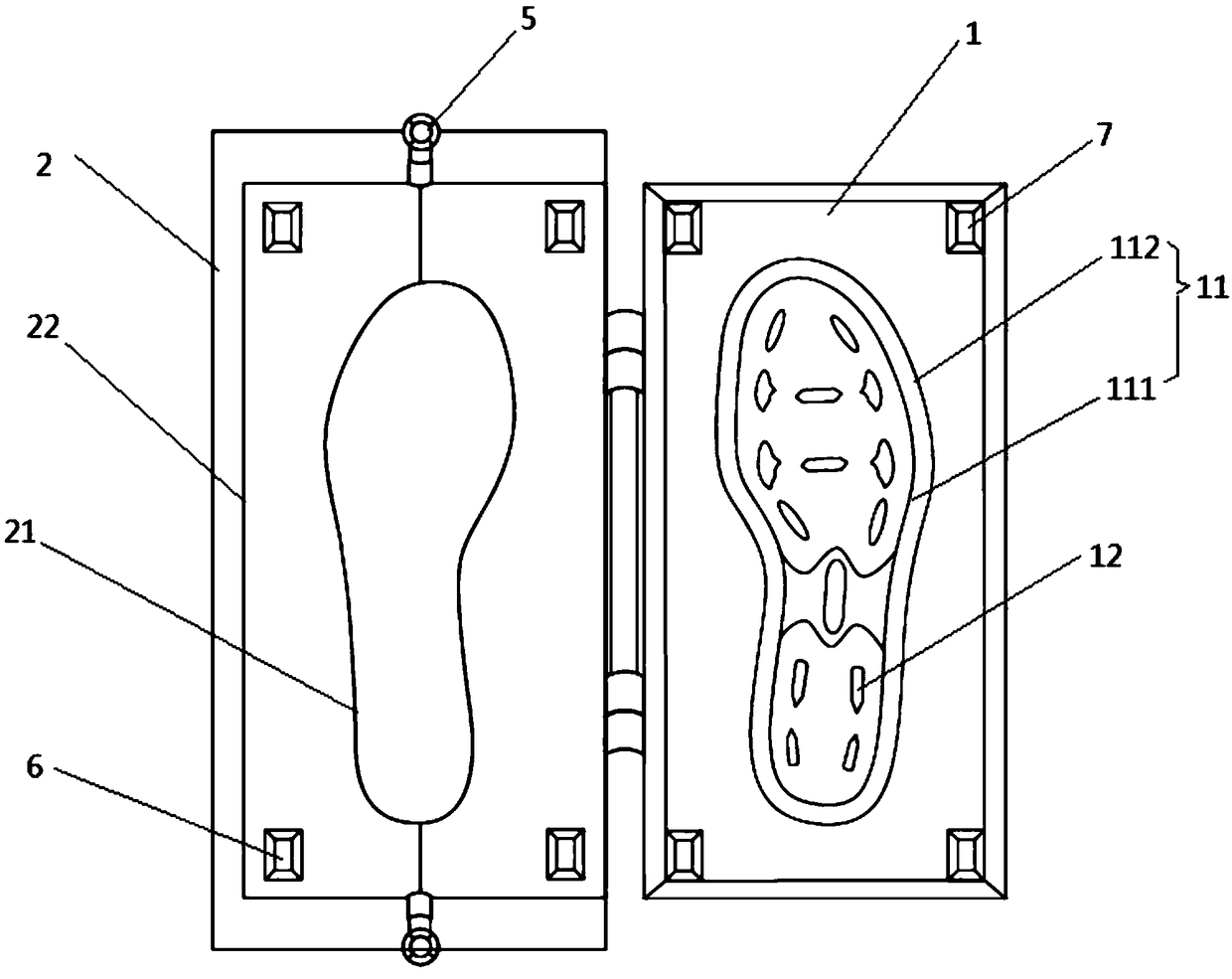

Shoe sole injection mold and injection molding method thereof

PendingCN108437505AOvercome degummingOvercome labor intensityDomestic footwearEngineeringInjection molding machine

The invention provides a shoe sole injection mold and an injection molding method thereof. The shoe sole injection mold is used for a shoe sole where a spiked shoe is integrally formed, and comprisesa lower mold and an upper mold. The lower mold is provided with a shoe sole molding cavity, the bottom face of the shoe sole molding cavity is composed of a shoe sole face and a shoe upper face arranged on the outer side of the shoe sole face in a surrounding manner, grooves matched with spikes are formed in the shoe sole face, and a prefabricated outsole with spikes is fixed in the area of the shoe sole face through inserted connection with the grooves. The upper mold is hinged to one side of the lower mold and is provided with a shoe upper peripheral edge clamping opening. After mold compounding, the shoe upper peripheral edge clamping opening and the shoe sole molding cavity form a shoe sole mold cavity. The method comprises the steps that after the prefabricated outsole is placed in the lower mold, shoe sole molding liquid is injected into the shoe sole molding cavity, then the upper mold and the lower mold are compounded, the shoe sole mold cavity is formed by the shoe upper peripheral edge clamping opening and the shoe sole molding cavity, and after cooling, the prefabricated outsole can be integrally formed on a vamp. According to the shoe sole injection mold and the injection molding method thereof, the manual cost is effectively reduced, the capacity is increased, and the production efficiency is improved.

Owner:SHUANGCHI IND

A kind of medical silicone adhesive tape and preparation method thereof

ActiveCN104491911BWill not affect secondary useImprove fitAbsorbent padsBandagesThermoplastic polyurethaneEngineering

The invention discloses a medical silica gel adhesive tape. The medical silica gel adhesive tape comprises a gelatinous layer and a cloth base material, wherein the cloth base material comprises one of a PE (polyethylene) film, a TPU (thermoplastic polyurethane) film and foam and a non-woven fabric material, and the adhesive tape comprises one of the PET film, the TPU film and the foam, the non-woven fabric material and the gelatinous layer sequentially from outside to inside. The adhesive tape provided by the invention is good in air permeability, good in effect of jointing with skin and less prone to degumming during the use, and can be used repeatedly.

Owner:NANJING 3H MEDICAL PROD CO LTD

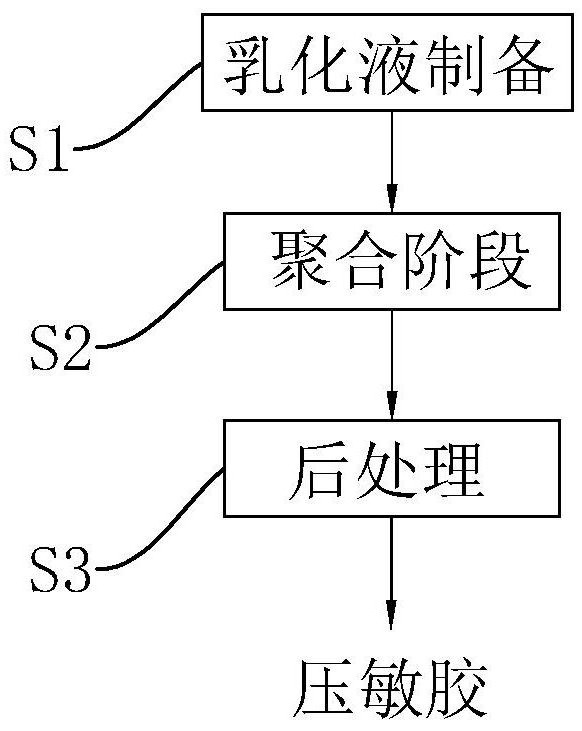

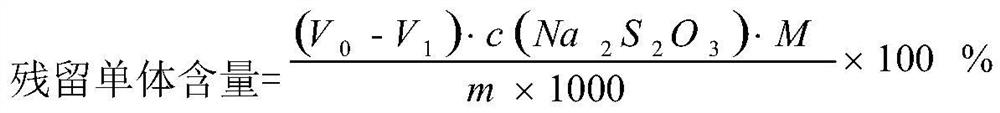

Water-based pressure-sensitive adhesive and preparation method thereof

InactiveCN111607340APolymerization completeResidue reductionNon-macromolecular adhesive additivesEster polymer adhesivesIsooctyl acrylateAdhesive cement

The invention relates to the technical field of adhesives, and discloses a water-based pressure-sensitive adhesive. The water-based pressure-sensitive adhesive is prepared from the following raw materials in parts by weight: 20-60 parts of butyl acrylate, 1-15 parts of an acrylate compound, 2-20 parts of 2-ethylhexyl acrylate, 1-10 parts of an emulsifying agent, 0.1-1 part of an oily initiator, 0.5-5 parts of a thickening agent, 1-5 parts of a buffering agent and 20-60 parts of water. By selecting the oily initiator, the initiator can perform initiation inside emulsion microspheres when a polymerization reaction occurs, so that the polymerization reaction of resin is relatively complete, the monomer residue is reduced, and the waste of raw materials is reduced.

Owner:浙江金科胶材股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com