Stiff waist liner production process

A production process and waist lining technology, applied in the field of waist lining, can solve the problems affecting the grade and price of trousers and skirts, short service life of waist lining, low stiffness of waist lining, etc., achieving good calendering effect and strong adhesion The effect of large degree and not easy to degumming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

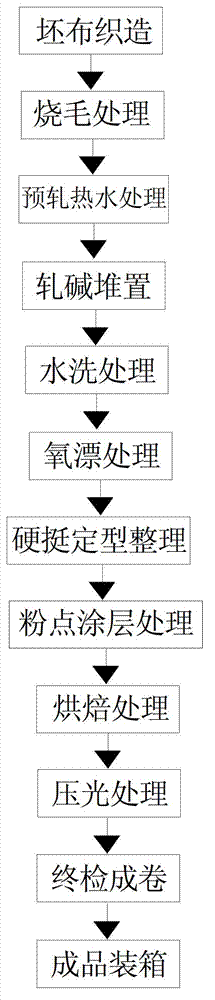

[0026] refer to figure 1 , a kind of waist lining production technique of the present invention, comprises the following steps successively:

[0027] A) Gray fabric weaving: The warp yarn of the woven base fabric is a 28Tex yarn formed by a mass ratio of 65% polyester and 35% cotton, and the weft yarn is a double-ply cotton 59Tex yarn. cm × 141.5 threads / 10 cm weave to form waist lining gray fabric;

[0028] B) singeing treatment: perform singeing treatment on the waist lining gray cloth, and the temperature is 51°C;

[0029] C) pre-rolling hot water treatment: the padding hot water treatment is performed on the waist lining gray cloth that has undergone B) singeing treatment, and the temperature of the padding hot water is 59 ° C;

[0030] D) Alkali padding and stacking: Pad and pad light lye (NaOH) on the waist lining gray cloth that has completed C) pre-rolling hot water treatment, and then stack for 2.1 hours;

[0031] E) Washing treatment: carry out desizing and washin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com