Manufacturing method of heat pipe and heat pipe

A production method and technology of heat pipes, which are applied in indirect heat exchangers, lighting and heating equipment, etc., can solve the difficulties of processing, the thinness of flat heat pipes, the difficulty in further improving the performance and stability of mass production, and the uneven distribution of capillary particles and other issues to achieve the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

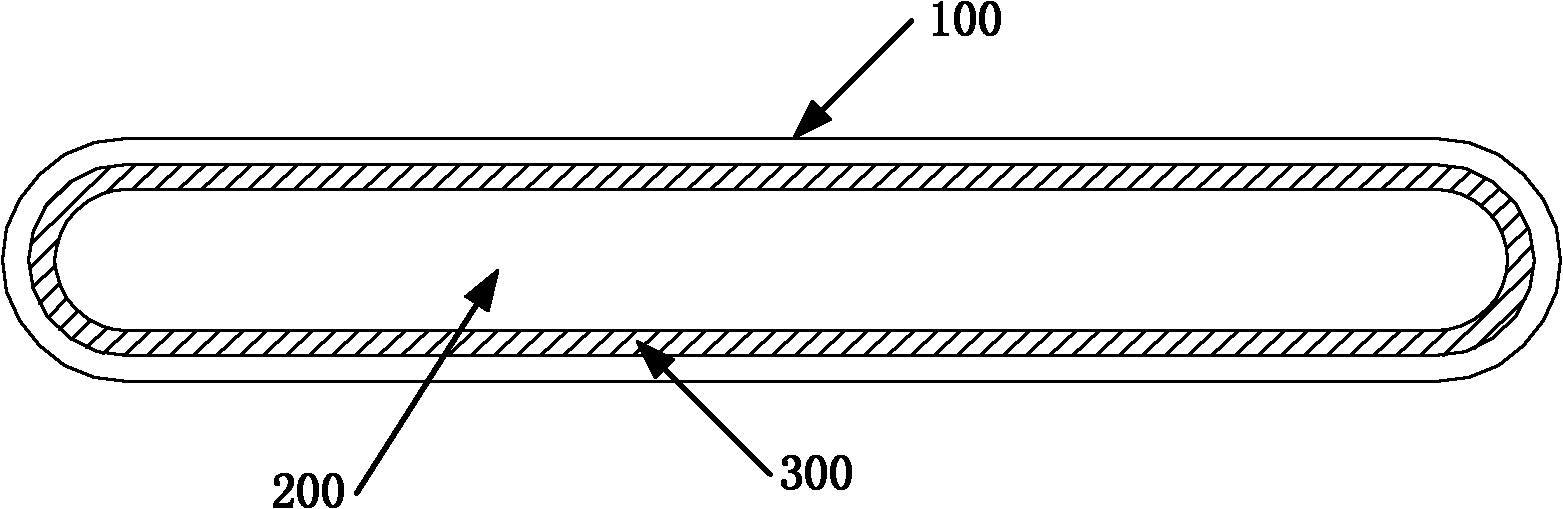

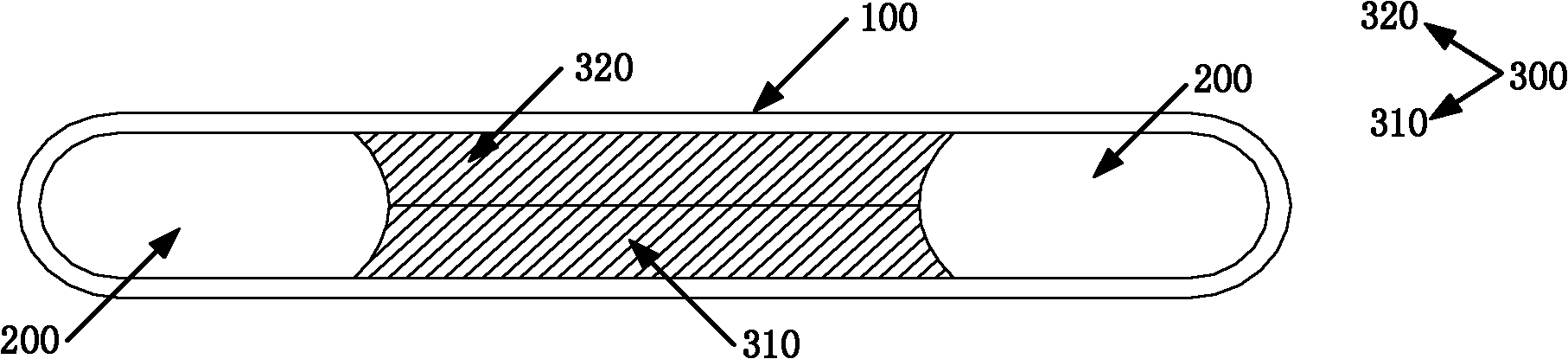

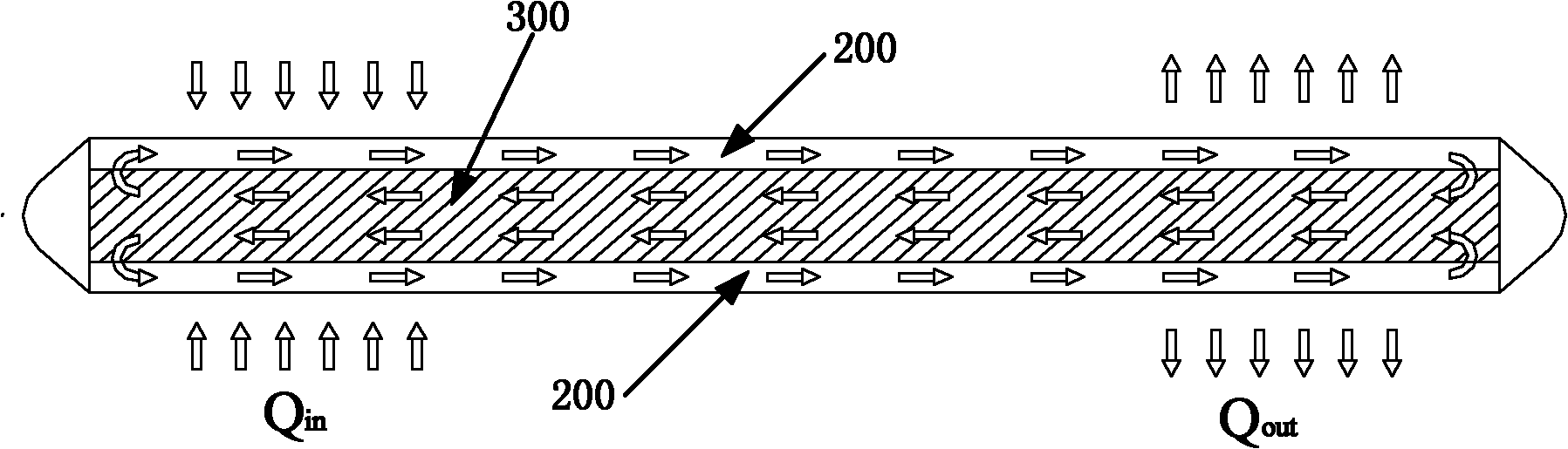

[0033] Below in conjunction with accompanying drawing, preferred embodiment of the present invention is described in further detail:

[0034] Such as Figure 4 As shown, a manufacturing method of a heat pipe includes the following steps.

[0035] Step 1 as Figure 4 As shown in (a), the rod body 900 with a circular cross section is inserted into the tube body 100 with a circular cross section, the tube body 900 is pre-flattened, and then capillary particles 390 are filled in the spaces left at both flattened ends.

[0036] Step 2 as Figure 4 As shown in (b), the rod body 900 is pulled out, and the tube body 100 is expanded.

[0037] Step 3 as Figure 4 As shown in (c), mark the position where the capillary particles 390 are filled, apply pressure to the tube body that is filled with the capillary particles 390, and flatten the tube body 100 until they are respectively distributed on the inner wall of the tube body 100 The capillary particles 390 at opposite positions are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com