Patents

Literature

51results about How to "Improve calendering effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

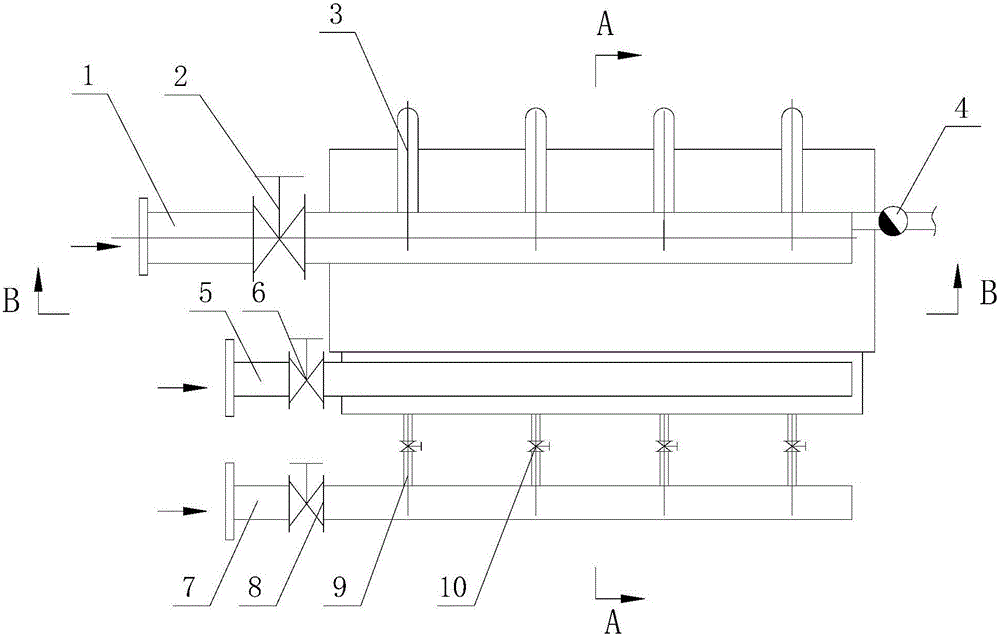

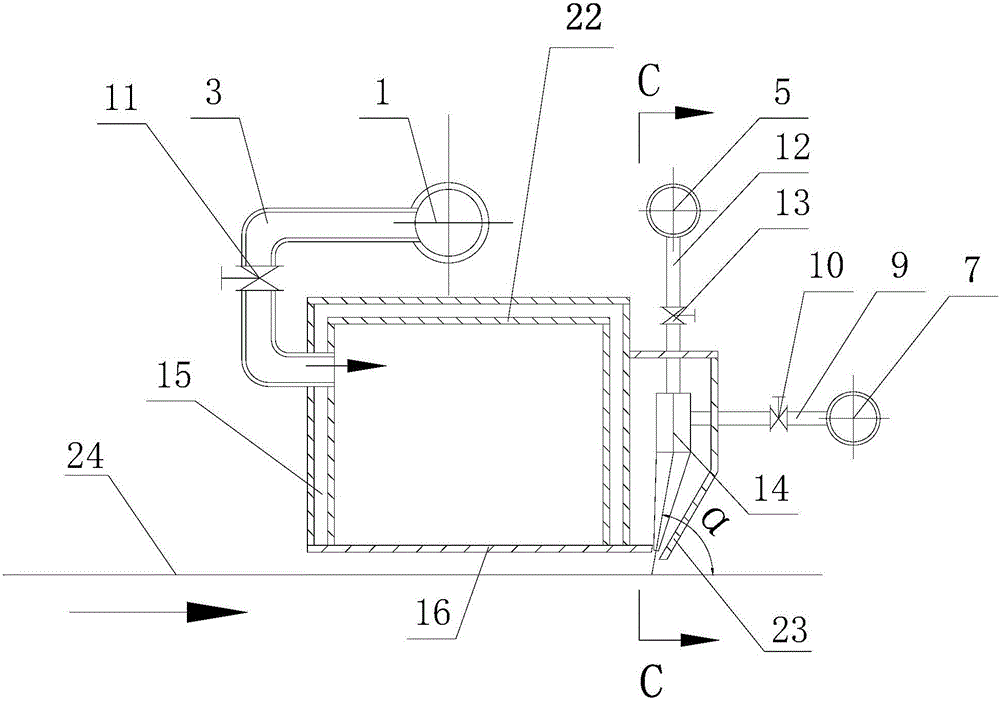

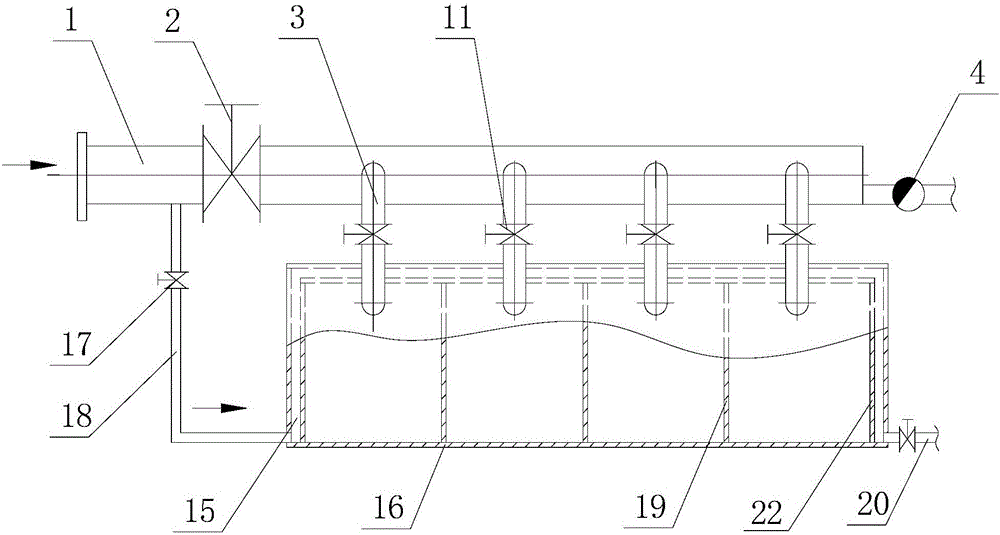

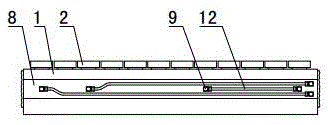

Steam device of supercalender and paper sheet moisture regulation method therefor

InactiveCN104988786APrevent spillageReduce dosageCalendersDamping devicesPulp and paper industryMoisture

The invention discloses a steam device of a supercalender and a paper sheet moisture regulation method therefor. In the steam device, a steam box and a spray box are arranged sequentially along paper sheet conveying direction, air atomizers are arranged in the spray box, a steam header pipe is connected with the steam box through steam branch pipes, a compressed air header pipe is connected with the air atomizers through compressed air branch pipes, and a low-pressure water header pipe is connected with the air atomizers through low-pressure water branch pipes. According to the paper sheet moisture regulation method, steam is conveyed into the steam box by the steam header pipe through the steam branch pipes and is sprayed to the surface of a paper sheet through through holes in a bottom plate; and meanwhile, compressed air is conveyed into the air atomizers by the compressed air header pipe through the compressed air branch pipes, low-pressure water is conveyed into the air atomizers by the low-pressure water header pipe through the low-pressure water branch pipes, and water mist is formed by the compressed air and the low-pressure water in the air atomizers and is sprayed to the surface of the paper sheet so as to further regulate the temperature and humidity of the paper sheet. According to the steam device of the supercalender and the paper sheet moisture regulation method therefor, the temperature and humidity of the paper sheet can be effectively regulated so as to improve the calendering effect.

Owner:SOUTH CHINA UNIV OF TECH

Process for preparing SBS water emulsion

The SBS water emulsion is prepared with SBSM 20-60 wt%, non-ionic emulsifier 0.2-0.5 wt%, ionic emulsifier 0.5-1.0 wt%, electrolyte 0.2-0.4 wt% and defoaming agent 0.1-0.3 except water. The preparation process includes dissolving polarized SBS (SBSM) in organic solvent; adding water solution of emulsifier, defoaming agent and electrolyte slowly under stirring of 3000-5000 rpm to obtain O / W type emulsion; stirring in raised rotation speed of 8000-10000 rpm to crush the particles to under 1 micron; heating and decompressing to eliminate solvent via pumping to obtain stable SBS water emulsion. The SBS water emulsion has small particle size, high stability, solidified matter content of 1-4 %, good compatibility with stuffing and has high stuffing capacity.

Owner:BALING PETRO CHEM CO LTD SINOPEC +1

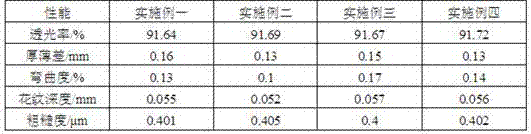

Ultrathin photovoltaic rolled glass

InactiveCN107162407AReduce glass expansion coefficientIncrease glass refractive indexExpansion factorOxide

The invention discloses ultrathin photovoltaic rolled glass. The ultrathin photovoltaic rolled glass comprises the following oxides by mass percentage: 71.0-73.18% of SiO2, 8.0-8.50% of CaO, 3.50-4.50% of MgO, 1.35-2.8% of Al2O3, 13.30-14.0% of Na2O, 0.6-1.0% of B2O3, 0.05-0.18% of Sb2O3, 0.05-0.1% of CeO2 and 0.01-0.012% of Fe2O3. According to the content of the oxides, the raw materials are compounded, and the photovoltaic rolled glass of which the thickness is less than 2.0 mm is prepared by founding, rolling forming and annealing processes; a glass component system is optimized, the B2O3 is introduced to reduce the glass expansion factor and increase the glass refractive index so as to play the fluxing action; the CeO2 and nitrate perform the combined action, so the clarification and decoloration effects are improved, the drawability of the glass is enhanced, and the plasticity of the photovoltaic rolled glass is improved; and the content of the Al2O3 and MgO is high, and the frit performance is improved. The final performance can satisfy the high-transparent and high-speed formability requirements of the industrial production of the photovoltaic glass of which the thickness is less than 2.0 mm, the production cost is saved, and the industrial production of the light and thin photovoltaic glass is realized.

Owner:CNBM YIXING NEW ENERGY CO LTD

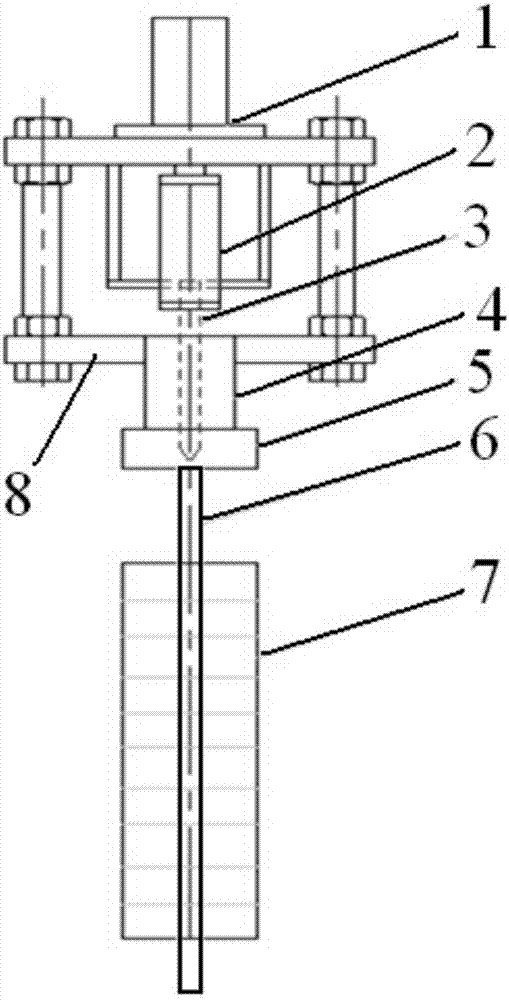

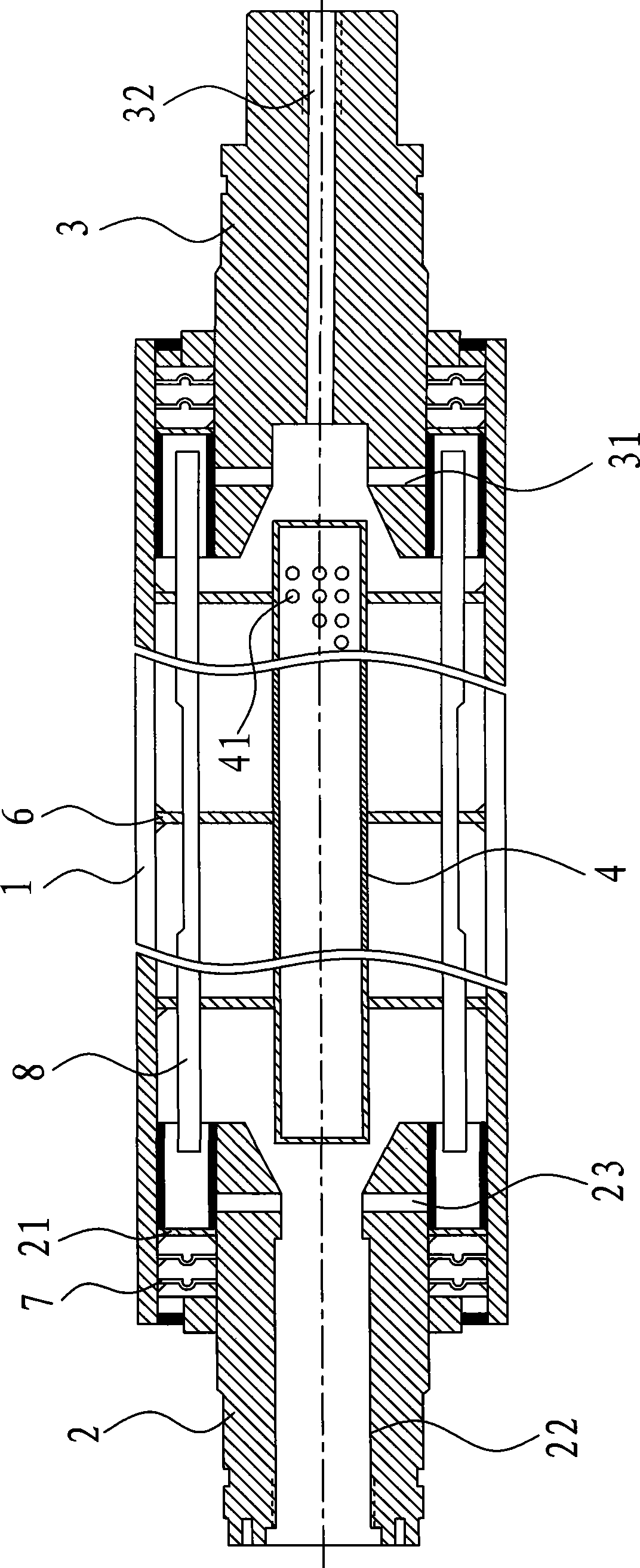

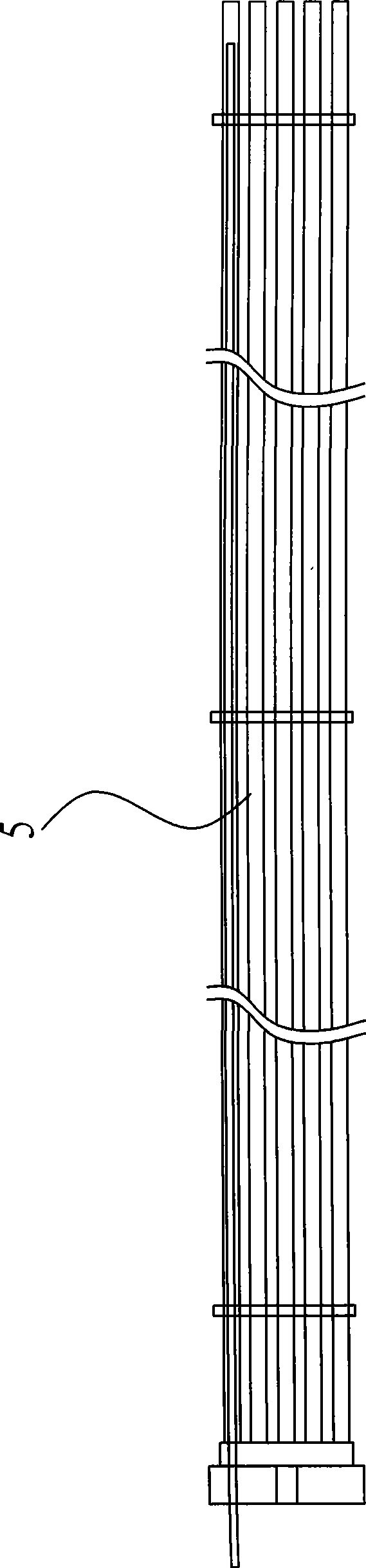

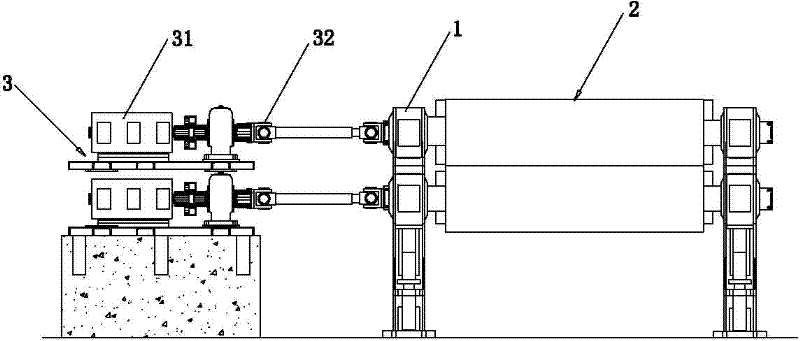

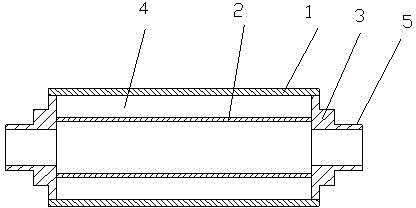

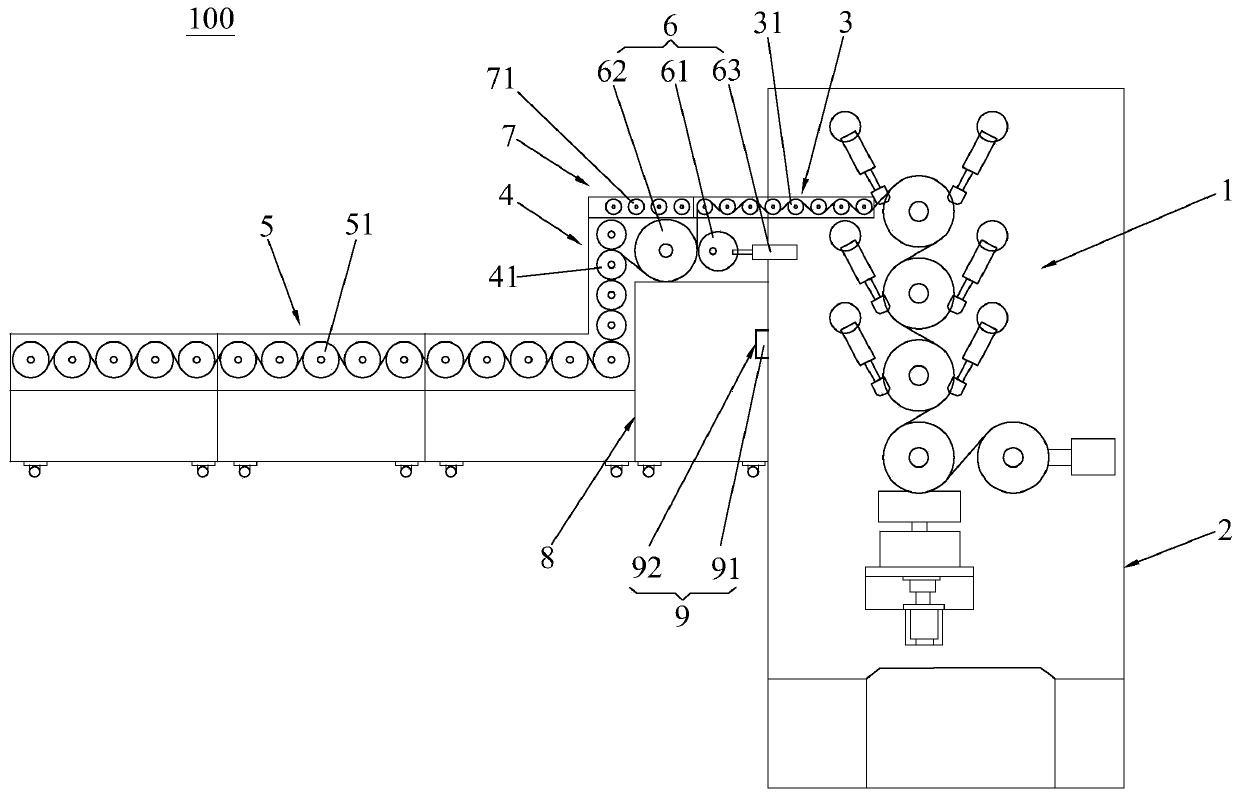

Extrusion preparation method and extrusion equipment for extra-large-orifice PTFE pipe fitting paste

The invention discloses an extrusion preparation method for extra-large-orifice PTFE pipe fitting paste. The extrusion preparation method comprises the following steps of: mixing raw materials; pre-forming the raw materials; extruding and forming the raw materials; tracing extrusion speed and a position of an extruded pipe fitting, controlling an extruder through a feedback signal; sintering and forming; performing position measuring and feedback control on the position of a sintered extra-large-orifice PTFE pipe fitting product; and enabling polytetrafluoroethylene dispersion resin tube to form a product. The invention further discloses extrusion equipment for extra-large-orifice PTFE pipe fitting paste. The extrusion equipment comprises an extrusion drive part, a pushing-pressing assembly, a mandrel assembly, a raw material barrel, an extrusion mould and a thermal forming assembly which are sequentially connected coaxially, wherein the extrusion drive part is mounted on the tail part of the rack; one end of the pushing-pressing assembly is connected with the extrusion drive part; the other end of the pushing-pressing assembly is connected with one end of the mandrel assembly; the raw material barrel is mounted on the front part of the rack; the extrusion mould is mounted at an outlet end of the raw material barrel; the mandrel assembly passes through the center of the raw material barrel and the center of the extrusion mould; and the thermal forming assembly is supported in front of the rack and is concentric with the raw material barrel.

Owner:JIANGNAN FLUOROPLASTIC

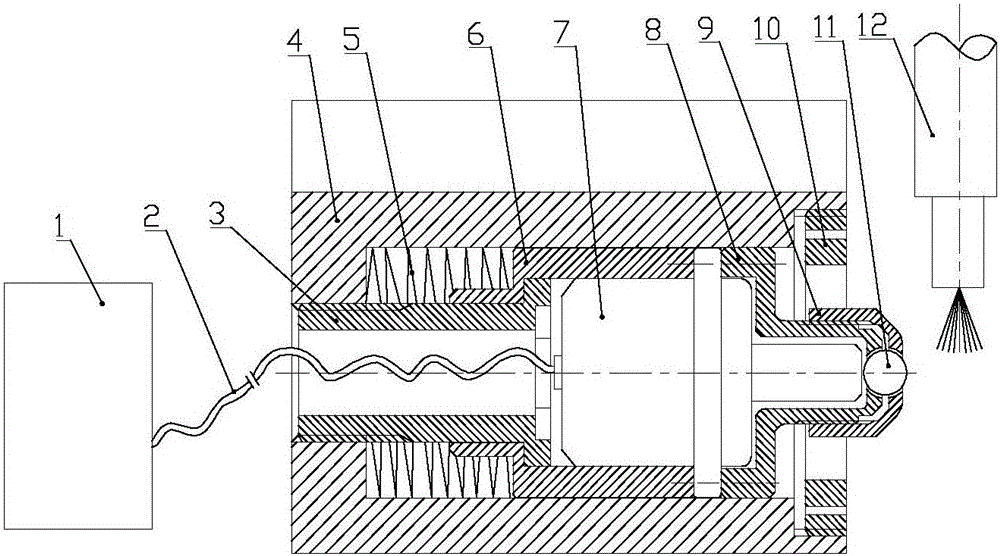

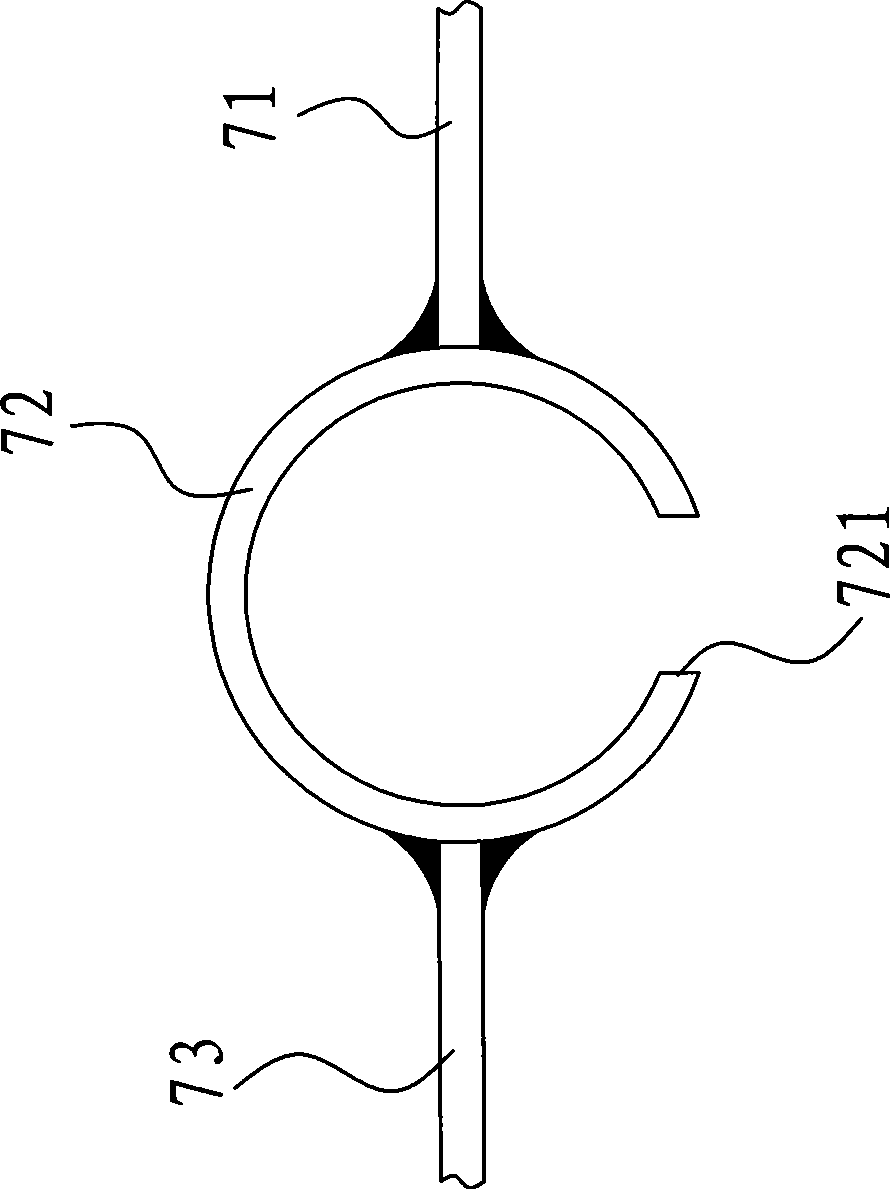

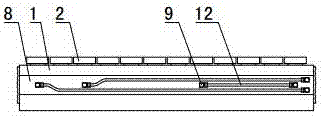

Portable ultrasonic calendering tool

InactiveCN105729042AEasy to replaceCompact structureMaintainance and safety accessoriesEngineeringElectric cables

The invention discloses a portable ultrasonic calendering tool. An inner sleeve (6) is disposed in an outer sleeve (4) to form an elastic telescopic mechanism through a spring (5); an ultrasonic transducer (701) is disposed in the inner sleeve (6) and electrically connected with an ultrasonic generator (1) through a cable (2); a luffing bar (703) is inside a roller supporting sleeve (8) after extending out of the inner sleeve (6), a roller adjusting nut (9) is in threaded connection to the front end of the roller supporting sleeve (8), a roller receiving cavity is formed between the roller supporting sleeve (8) and the roller adjusting nut (9), the front end of the a roller (11) contacts the surface of a workpiece, and the rear end of the roller (11) contacts the front end of the luffing bar (703); the invention has the advantages that finishing after composite ultrasonic treatment with the calendering tool is effective, pressure stress is generated on the surface of a part that is calendered, cutting resistance is greatly reduced and vibrational impact on a machine tool is reduced.

Owner:郭明利 +1

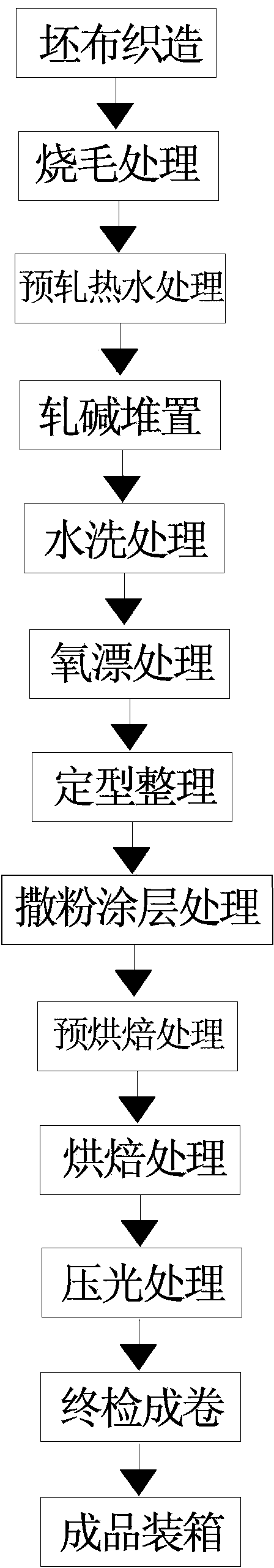

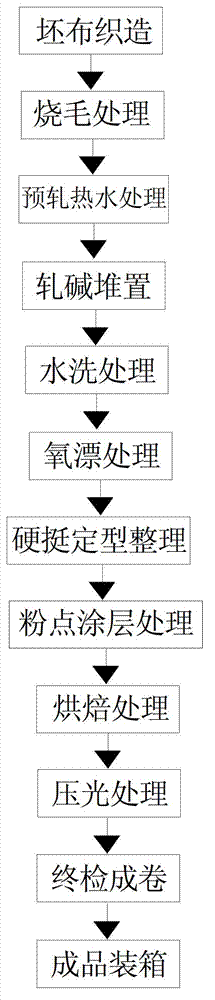

Shoe lining production process

InactiveCN102797156BIncrease thicknessImprove adhesion fastnessBiochemical fibre treatmentBleaching apparatusCooking & bakingHigh stiffness

The invention discloses a shoe lining production process, which comprises gray fabric weaving, singeing treatment, pre-rolling hot water treatment, rolling alkali and piling, washing treatment, oxygen bleaching, setting and finishing, powder scattering coating, pre-baking, baking, calendaring, performing final inspection and coiling, and packaging the finished product. The shoe lining has good handfeel, high stiffness, dimensional stability, low shrinkage rate and a lasting retention effect; and after the shoe lining is arranged for a long time, the stiffness is not reduced, and the shoe lining is high in thickness, high in adhesive firmness, good in a calendaring effect, long in service life and environment-friendly and is difficult to degum.

Owner:温州鸿马科技有限公司

Novel plating press

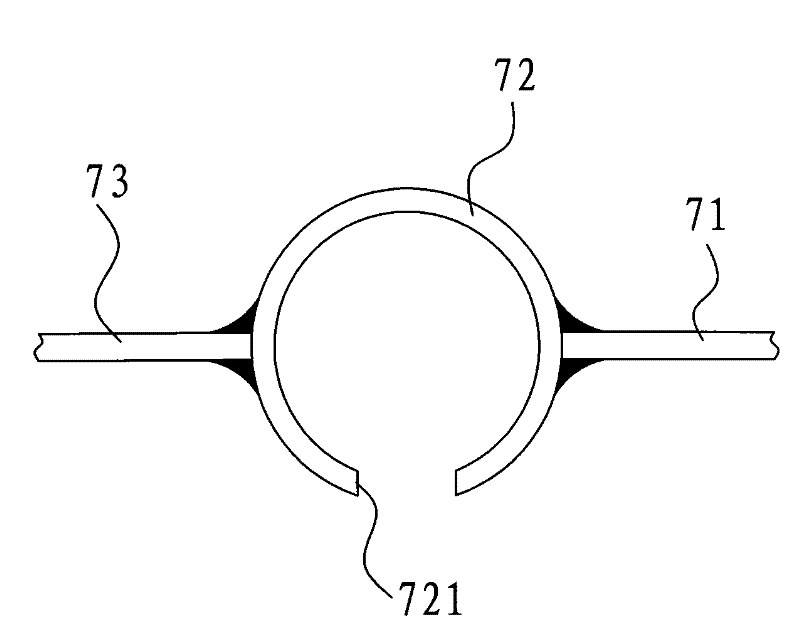

InactiveCN101463543AGood flexibilityReliable sealingTextile shapingPulp and paper industryCopper tubing

The invention provides a novel press-polishing machine which can effectively avoid invalidation of sealing equipment, comprising a frame and hard roller which can rotate and is arranged on the frame; wherein, the hard roller comprises a roller body, two shaft heads, a supporting tube and a heating device, the roller body is of a prismatical hollow structure, the two shaft heads are respectively fixedly arranged at the two ends of a roller body along the axial direction, at least one sealing equipment is arranged between the shaft heads and the roller body, at least two fixed trays are arranged in the roller body along axial direction at intervals, the supporting tube penetrates through the radial central part of the fixed trays, the heating device is arranged in the supporting tube, an input end of the heating device is electrically connected with an external power source by a revolving connector, the sealing equipment comprises an internal tray, a ring-shaped copper tube and an external tray along the axial direction of the roller body, the lateral wall of the ring-shaped copper tube is respectively connected with the adjacent external side of an internal tray and internal side of the external tray and are combined into a whole, the other side of the internal tray and the other side of the external tray are respectively connected with the shaft head and the roller body and are combined into a whole.

Owner:张贻景

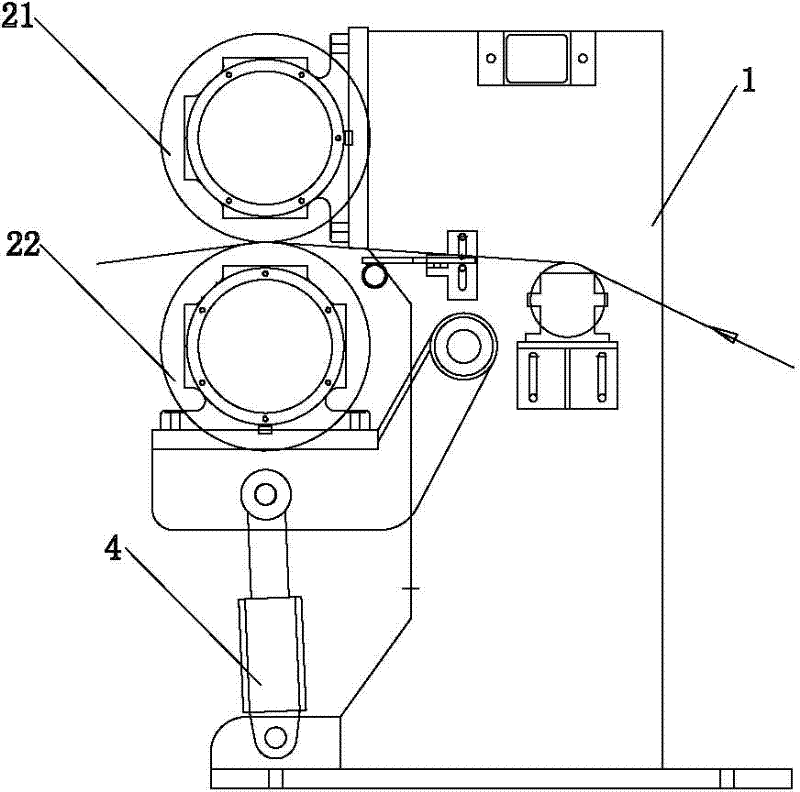

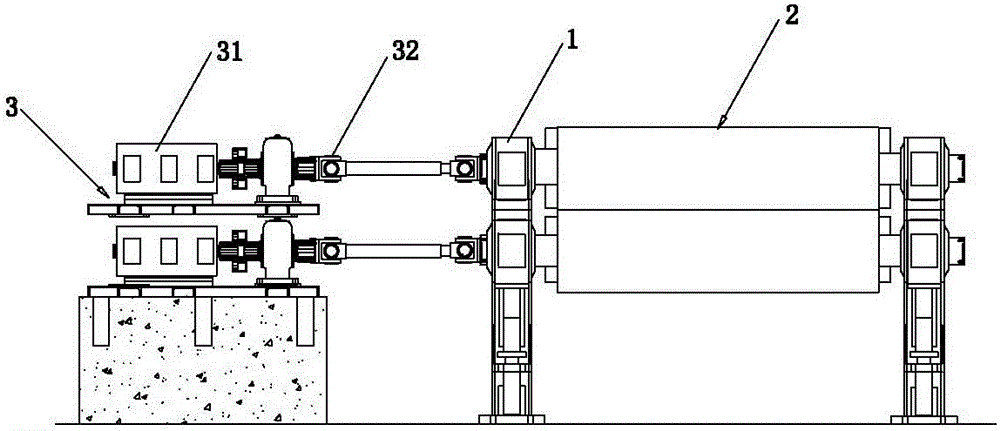

Plating press of improved structure

The invention relates to the technical field of plating presses, especially to a plating press of an improved structure. The plating press comprises a frame and a felt wrapped roll. The felt wrapped roll is connected to the frame. The felt wrapped roll comprises a top roller and a bottom roller. The plating press further comprises a roller gap adjusting system used for adjusting the gap between the top roller and the bottom roller, and a double motor apparatus. The felt wrapped roll is in driven connection with the double motor apparatus. The roller gap adjusting system comprises a PLC control system and a hydraulic pressure station. The hydraulic pressure station is connected with the felt wrapped roll. The PLC control system and the hydraulic pressure station are electrically connected. With the plating press of the improved structure of the invention, paper joints can automatically pass through the pressing zone of the felt wrapped roll, the artificial link of manual operation is decreased, the press polish effect of paper is effectively improved, and the labor intensity is reduced. The plating press of improved structure of the invention is characterized by a high automation degree and high production efficiency. The paper through the roll compacting of the plating press of the improved structure of the invention has a good quality, and the paper smoothness is much higher than the superior grade standard prescribed by national GB / T16797-2008.

Owner:GUANGDONG QIAOSHENG ANTI COUNTERFEITING MATERIALS CO LTD

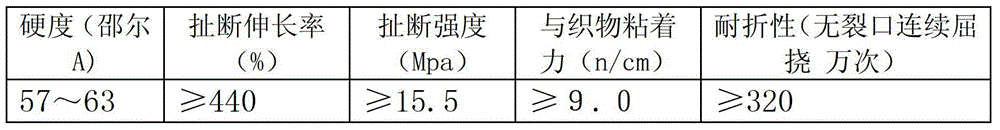

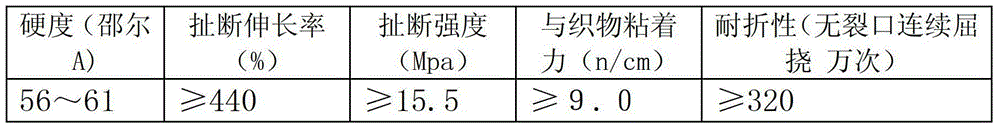

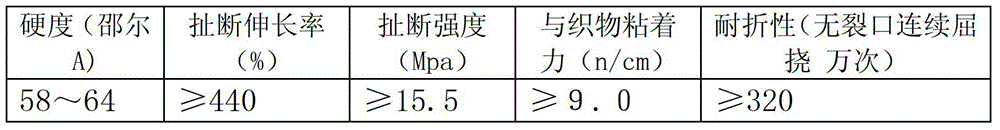

Acid and alkali resistant rubber boot vamp rubber compound and preparation method thereof

ActiveCN103333373AHigh strengthImprove scratch resistanceFootwearComposite indicatorButadiene-styrene rubber

The invention discloses an acid and alkali resistant rubber boot vamp rubber compound comprising Chinese No. 1 smoked sheet, butadiene styrene rubber, an accelerant, sulfur, active zinc oxide, stearic acid, an anti-aging agent, high-abrasion furnace black, general carbon black, barium sulfate, a softening agent and a tackifier. A sizing material of the rubber compound prepared by the preparation method has excellent comprehensive indexes such as high strength, good elongation and good flexing resistance; and the sizing material has small physical and mechanical properties on the basis of meeting the acid-base resistance property, and can meet special requirements of an operating environment. The non-split flexing resistance test of finished-product protective boot made of the mixing rubber in a laboratory shows that the flex times of the protective boots is greater than or equal to 3,200,000, and much higher than that of the common acid and alkali resistant rubber boots sold in the market at present while changes of the hardness, the tensile strength and the elongation at rupture of the sizing material soaked by a chemical agent, and the weigh change are small at the same time; and the acid-base resistance property and the resistance to chemical corrosion of the sizing material are good; the sizing material can effectively resist a poor operating condition of a working space on the basis of meeting the acid-base resistance property; and the service life of the finished-product protective boots made of the sizing material can be up to over six months and is prolonged by over 50% in comparison with that of the ordinary commercial product sold in the market under the identical condition.

Owner:JIHUA 3539 SHOE MAKING

Pitted surface roller machining technology

A pitted surface roller machining technology comprises the machining steps of roller body machining, roller neck machining, shaft head machining, roller neck and shaft head assembling and pitted surface roller assembling. The pitted surface roller machining technology has the advantages that the pitted surface roller production technology is simple, the production cost is low, and the machined pitted surface roller is high in surface hardness, uniform in temperature, good in calendering effect, compact in structure and durable.

Owner:江苏优泽科技有限公司

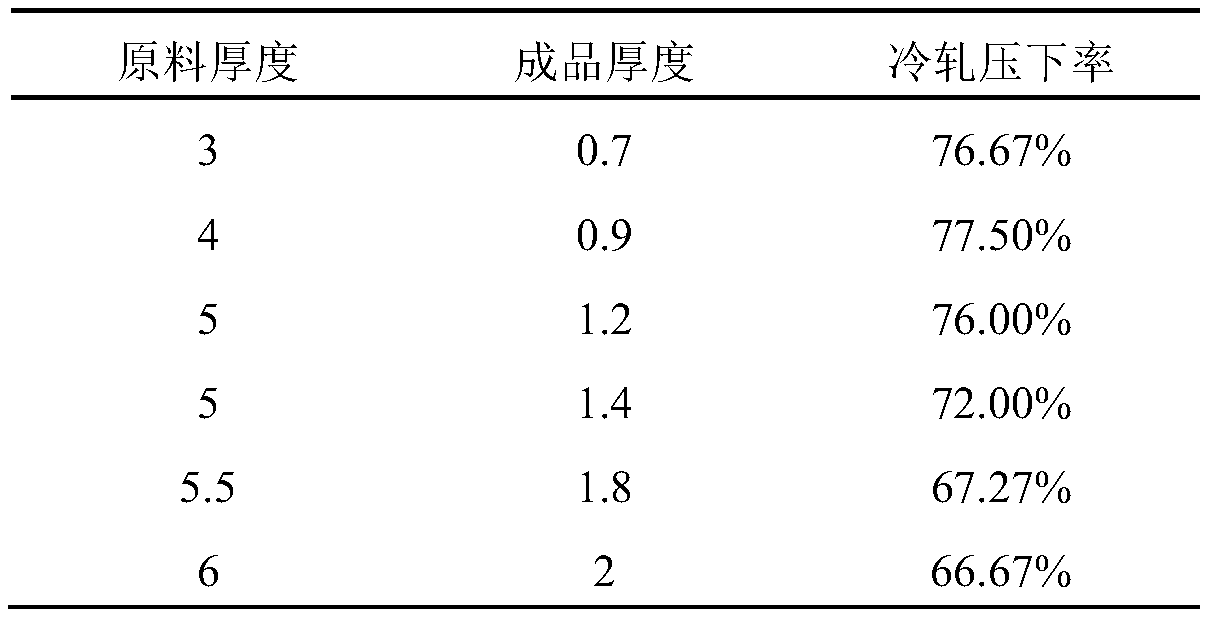

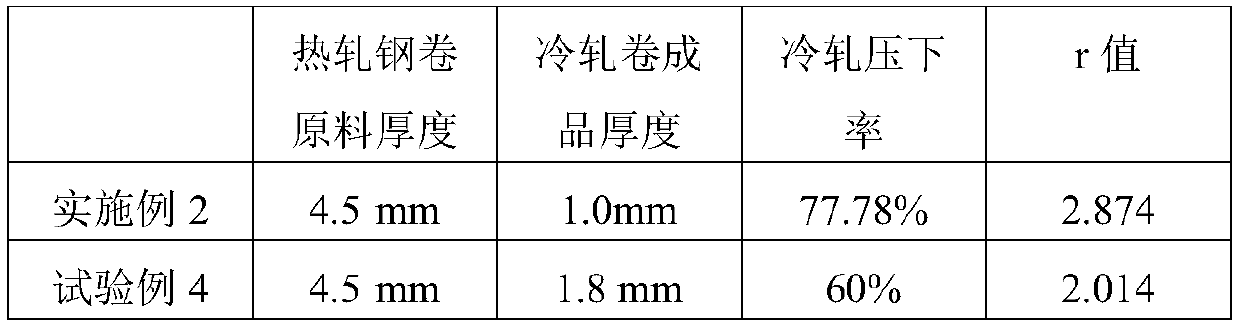

Method for improving the plastic strain ratio r value of cold-rolled deep-punching steel

InactiveCN110499408AIncrease the plastic strain ratio r valueImprove stampingReduction rateProduction line

The invention discloses a method for improving the plastic strain ratio r value of cold-rolled deep-punching steel. The method comprises the following steps of carrying out cold rolling by adopting acold rolling reduction rate of 66.67% - 77.78%, and then carrying out batch annealing and leveling to obtain the cold-rolled deep-punching steel. According to the method for improving the plastic strain ratio r value of the cold-rolled deep-punching steel, the method of optimizing the production process is adopted, so that the obtained cold-rolled deep-punching steel has a good plastic strain ratio r value, the stamping and drawability performance of a steel plate material is improved, the probability of breakage of the steel material in the stamping and drawability processes is reduced, and the production qualified rate is improved; and according to the method for improving the plastic strain ratio r value of the cold-rolled deep-punching steel, improvement is carried out on the basis ofan original steel production line, technological parameter control is optimized, and industrial production improvement is facilitated.

Owner:BAOTOU IRON & STEEL GRP

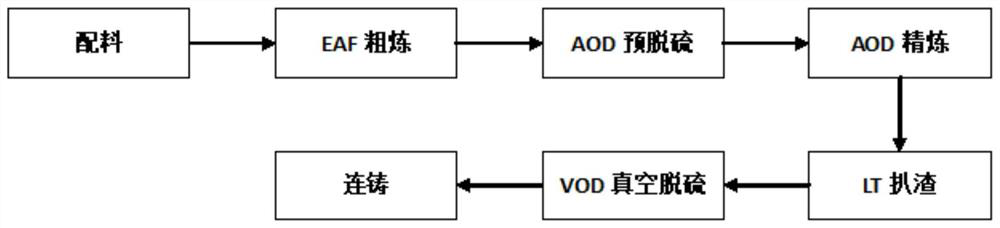

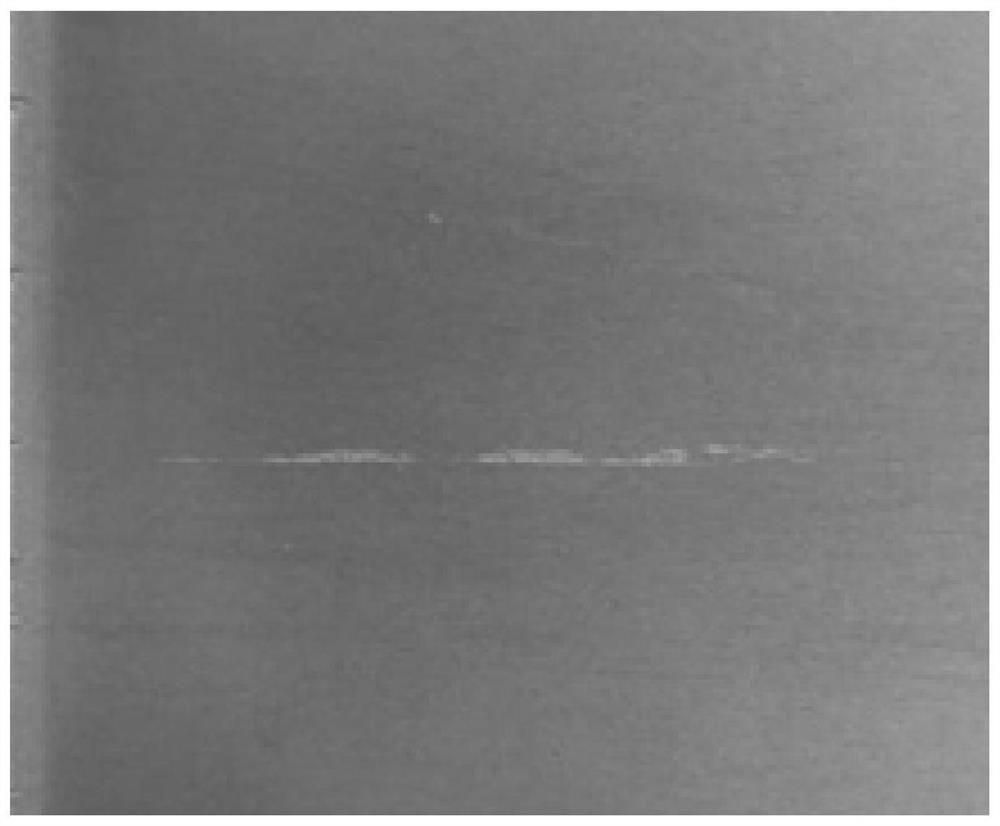

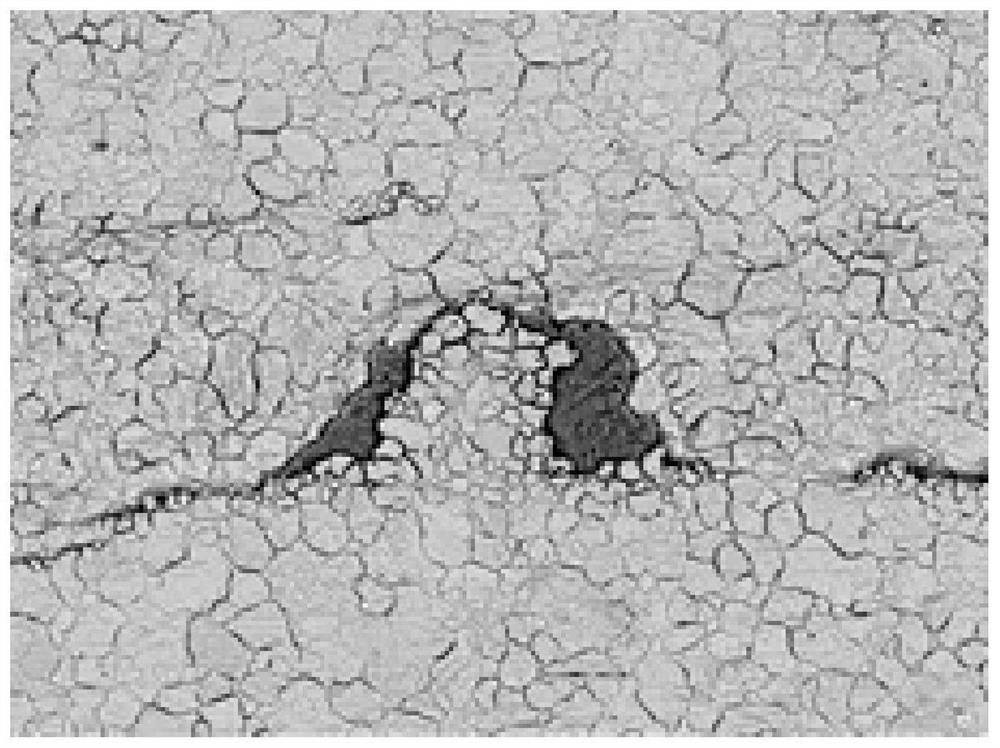

316L stainless steel and preparation method thereof

ActiveCN112342454AGuaranteed desulfurization effectImprove high temperature plasticity and calendering propertiesSmeltingSS - Stainless steel

The invention provides 316L stainless steel and a preparation method thereof. The preparation method comprises the steps that EAF coarse smelting is conducted on on a mixed material of 316L stainlesssteel; AOD pre-desulfurization is conducted on the mixed material subjected to EAF coarse smelting; AOD refining is conducted on the mixed material subjected to AOD pre-desulfurization; LT slagging-off treatment is conducted on the mixed material subjected to AOD refining; VOD vacuum desulfurization is conducted on the mixed material subjected to LT slagging-off treatment; and continuous casting is conducted on the mixed material subjected to VOD vacuum desulfurization to obtain the 316L stainless steel. The 316L stainless steel prepared through the method can effectively overcome the line scale defect of the edge portion of a cold (hot) rolled plate.

Owner:ZHANGJIAGANG POHANG STAINLESS STEEL

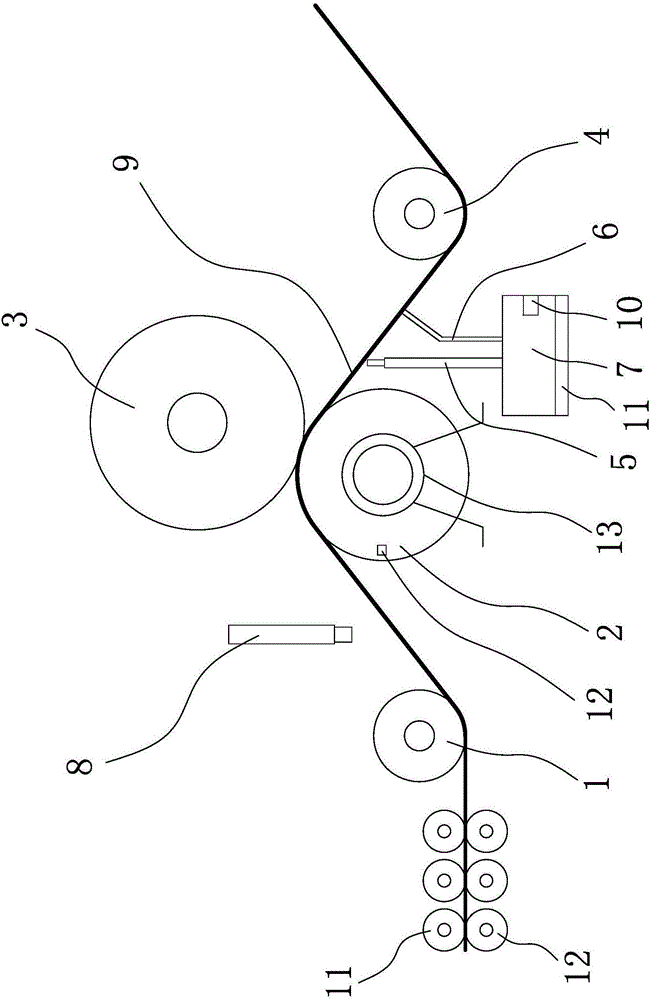

Calendering film coating machine for multifunctional fabric

ActiveCN106283445AGuaranteed coating effectIncrease temperatureTextile treatment containersLiquid/gas/vapor removalTextile technologySpray nozzle

The invention provides a calendering film coating machine for a multifunctional fabric, and belongs to the technical field of fabrics. The calendering film coating machine solves the problems of complicated post-arrangement procedures and poor coating adhering property in the existing fabric. The calendering film coating machine for the multifunctional fabric comprises a fabric feeding roll, a rigid hot roll, a soft roll and a fabric discharging roll in parallel, wherein the rigid hot roll is made of metal material, and an electric heater is arranged in the rigid hot roll; the soft roll is made of plastic or rubber, and the fabric feeding roll and the cloth discharging roll are respectively positioned at the two sides of the rigid hot roll; the soft roll is positioned just in front of the rigid hot roll, or is inclined to the oblique upper part of one side of the fabric discharging roll; at least one group of spray nozzles and scrapers is arranged between the rigid hot roll and the fabric discharging roll and is used for applying functional coating onto the bottom surface of the fabric; the spray nozzles are positioned at one side of the rigid hot roll, spraying openings of the spray nozzles face upwards, and the scrapers are positioned at one side of the fabric discharging roll. The calendering film coating machine has the advantage that while the fabric is calendared, the functional coating can be coated, so that the functional property of the fabric is improved.

Owner:海宁兄弟家具有限公司

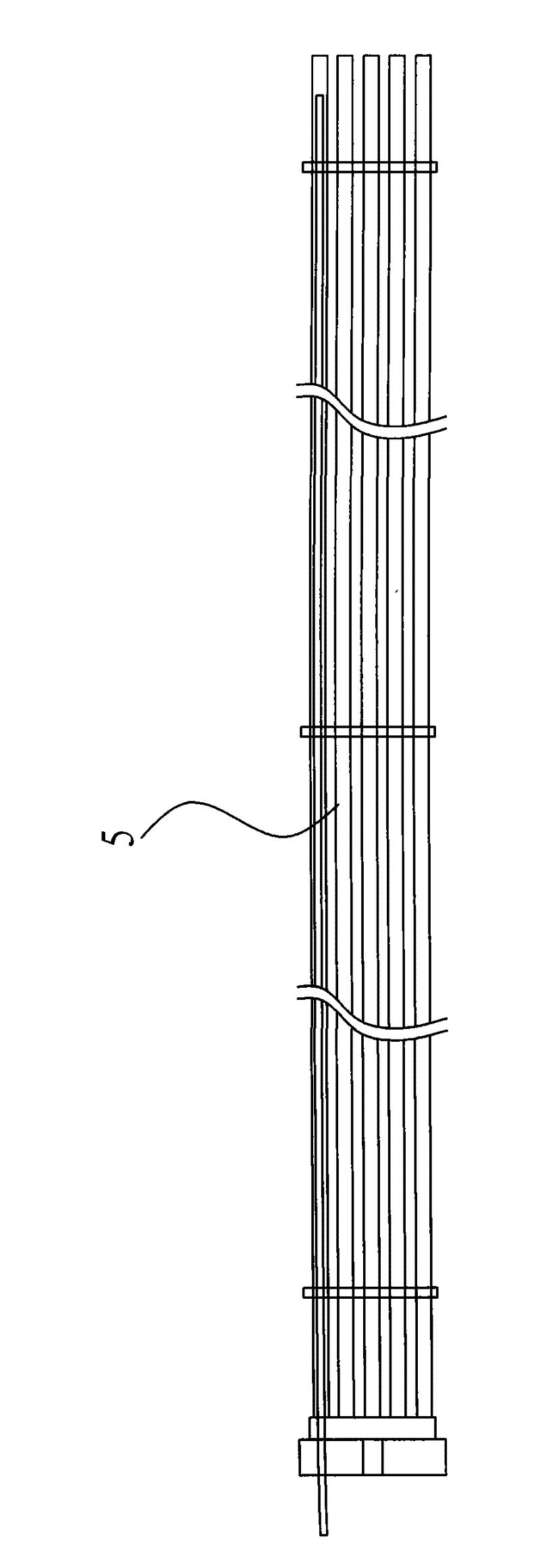

Method for producing polytetrafluoroethylene hollow fiber tube

InactiveCN106139918AUnique microporous structureUniform porositySemi-permeable membranesFiberHollow fibre membrane

Owner:QINGDAO YUANDONG FLON NEW MATERIALS

Stiff waist liner production process

InactiveCN103088640AIncrease thicknessImprove adhesion fastnessBleaching apparatusVegetal fibresCooking & bakingShrinkage rate

The invention discloses a waist liner production process which comprises the following steps of: weaving gray fabrics, singeing, performing pre-rolling hot water treatment, alkali rolling stacking, washing, oxygen bleaching treatment, stiff setting and finishing, powder point coating treatment, baking, polishing, final inspection coiling, and finished product boxing. The waist liner is good in handfeel, high in stiffness, stable in size, low in shrinkage rate, lasting in retaining effect, the stiffness is not reduced when the waist liner is arranged for a long time, and the waist liner is high in thickness, high in adhesion firmness, difficult to unglue, good in polishing effect, long in service life and environment-friendly.

Owner:余永生

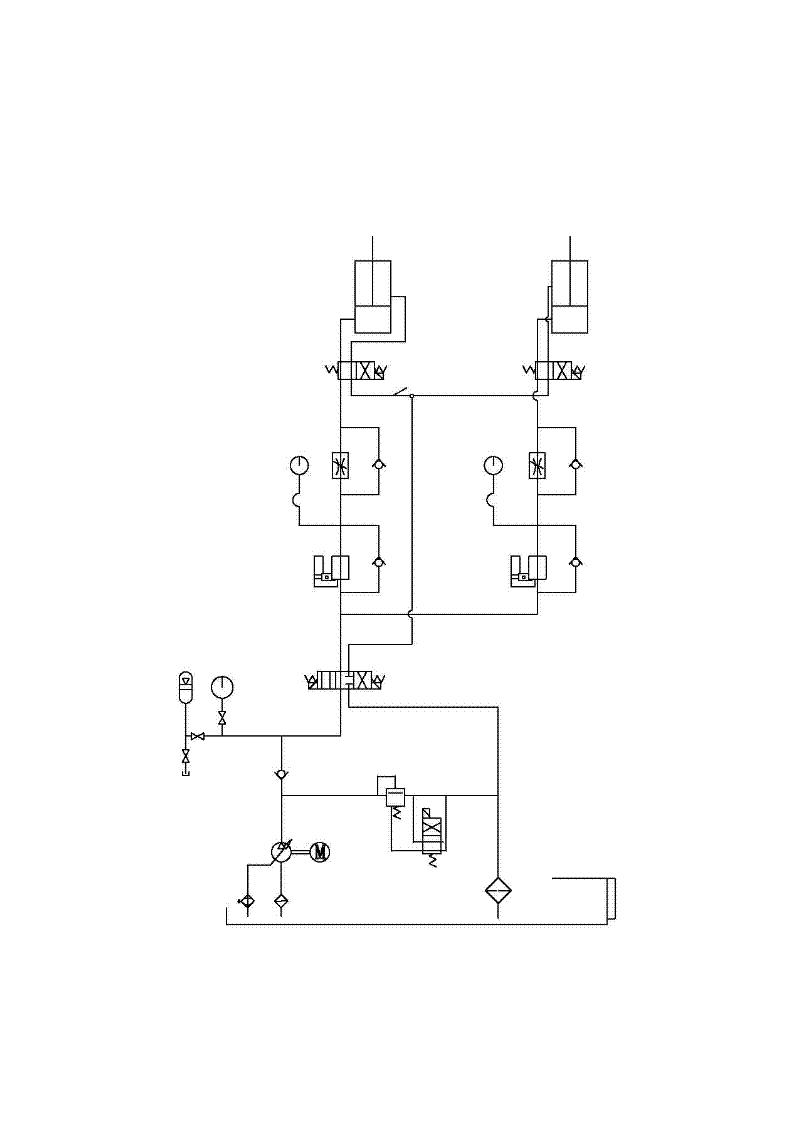

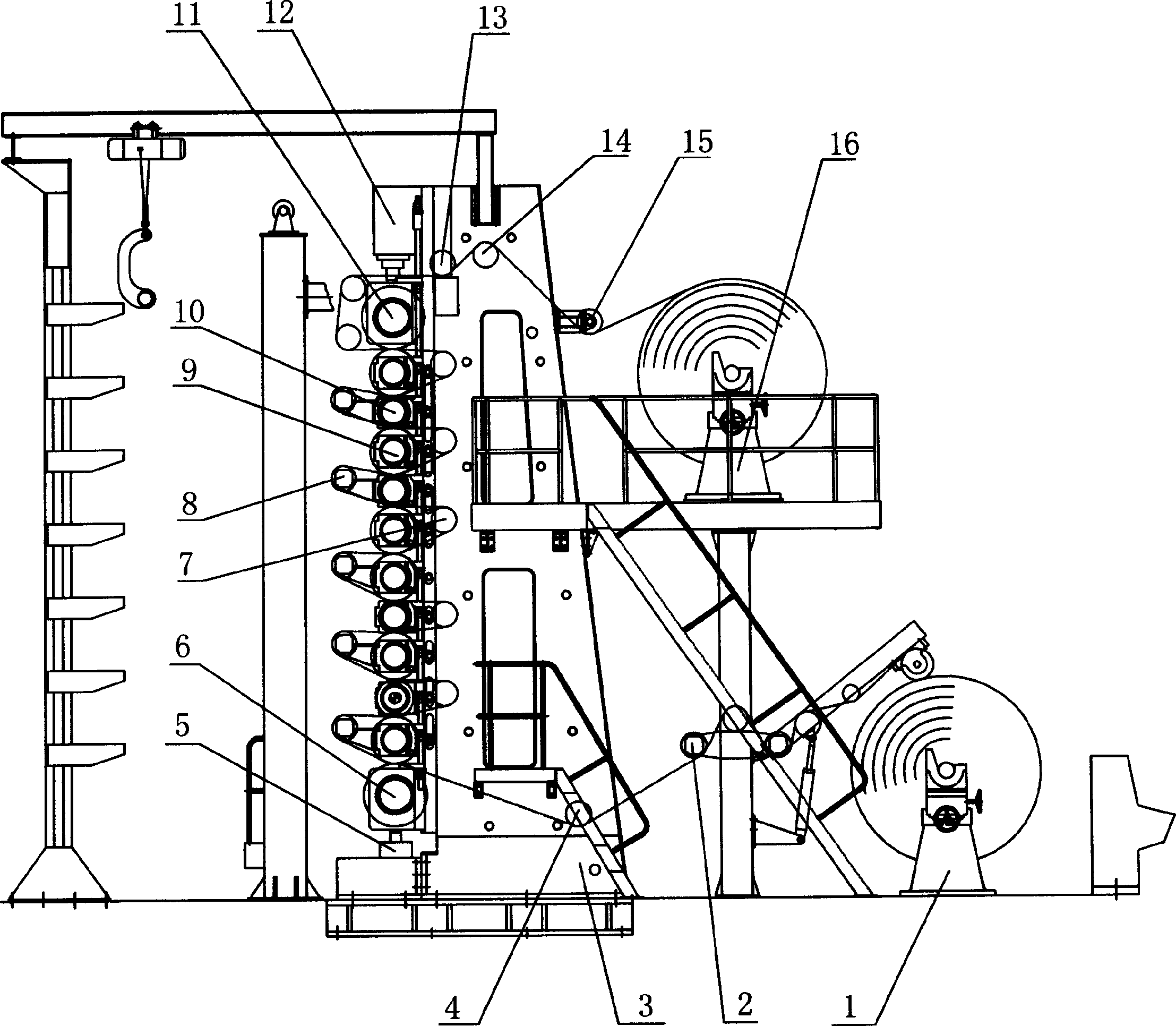

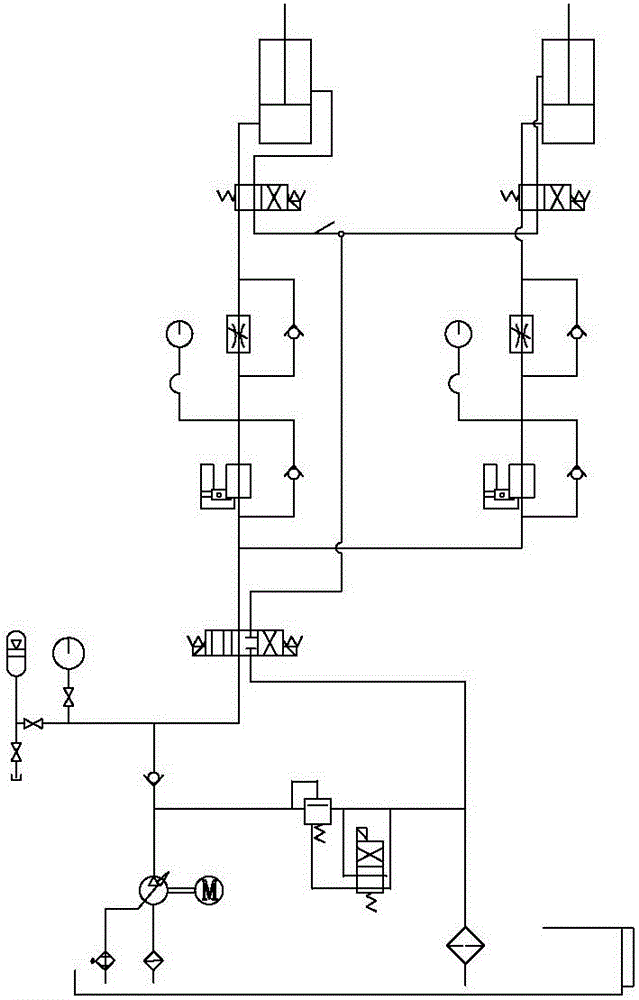

All hydraulic subarea controllable middle-high super plating press

InactiveCN1558024AShow superiorityMedium and High GuaranteeCalendersPulp and paper industryHydraulic control

The hydraulic sectional controllable super calender for paper making includes frame, planishing roller connected to the frame, top roller and bottom roller, hydraulic controller connected to frame. It features the controllable top roller and bottom roller with planishing roller weight compensating units set between the roller end and the frame, and the fast hydraulic separator set below the bottom roller. The calender can raise greatly the transverse smoothness of paper, planish great-width paper, make the top and bottom roller separate timely to avoid dry friction and damage when the paper breaks.

Owner:山东恒星股份有限公司

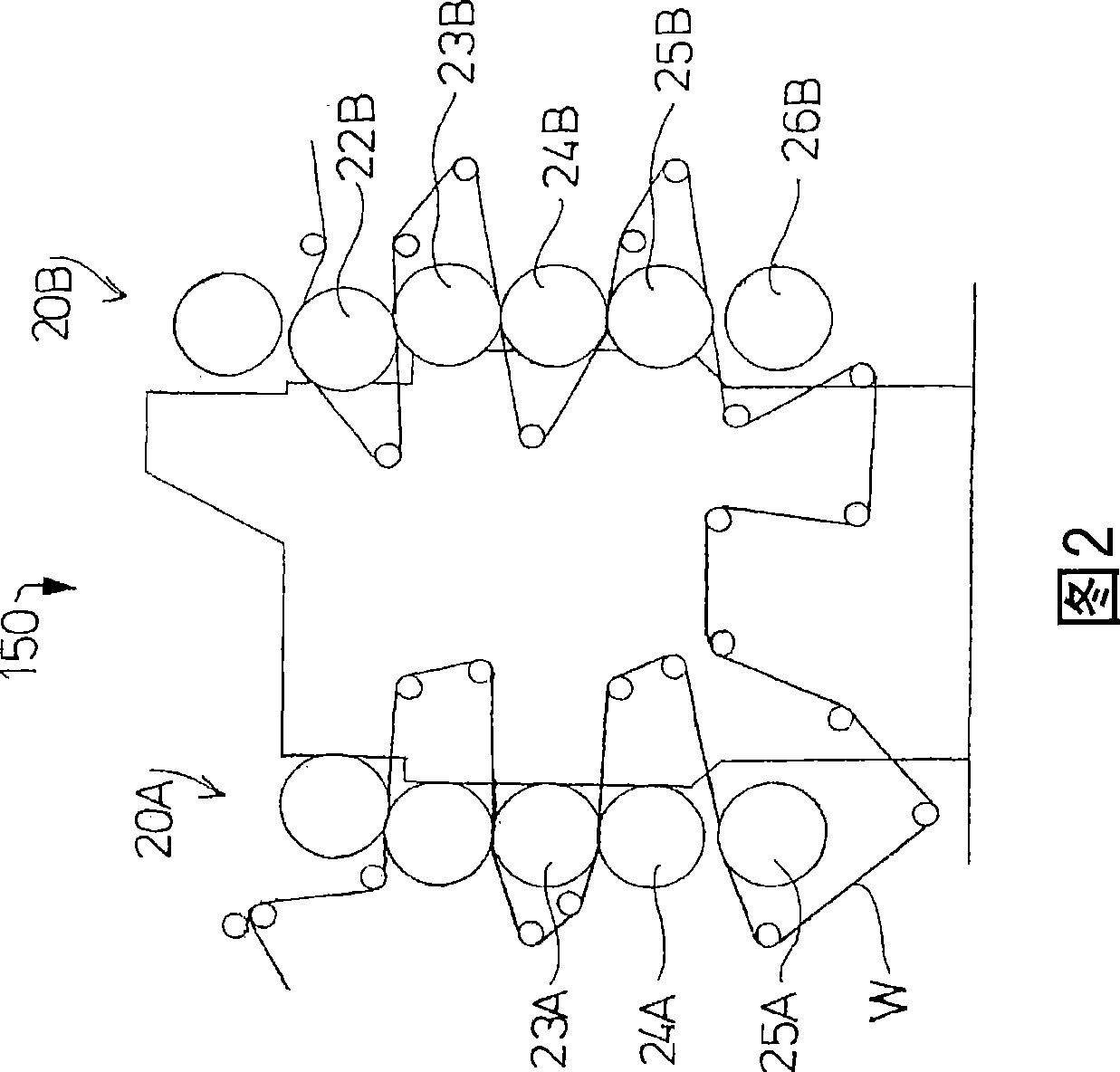

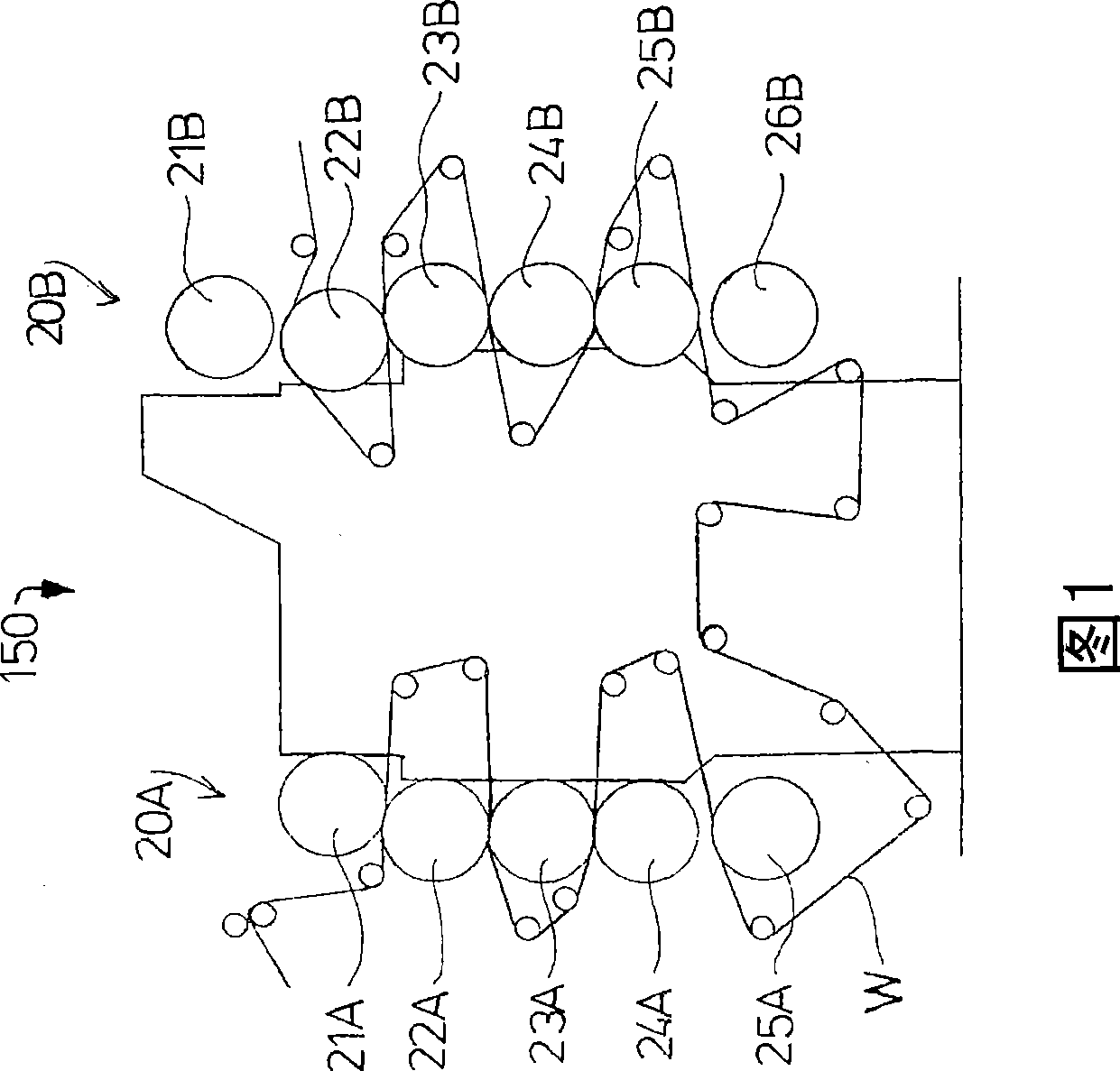

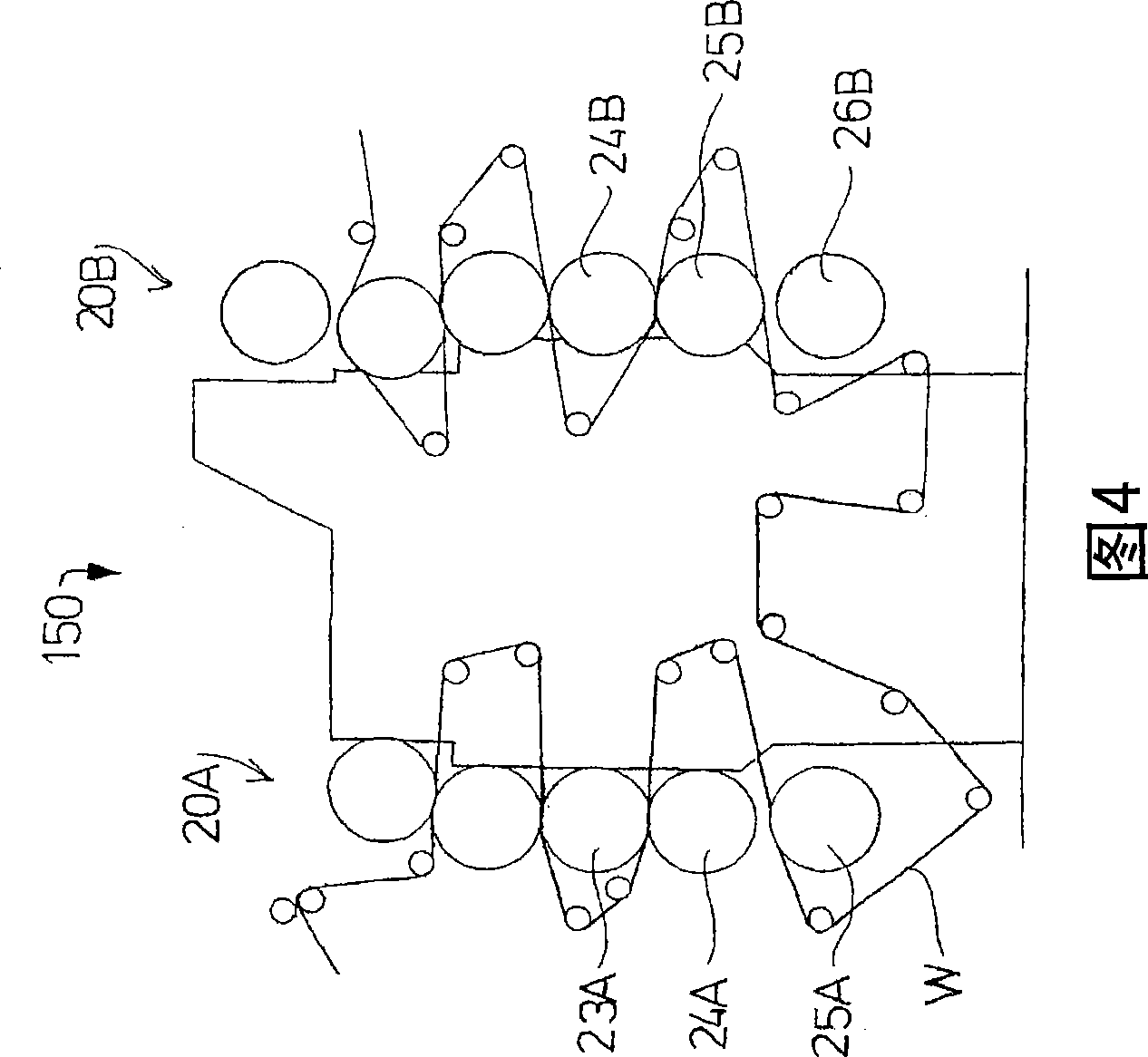

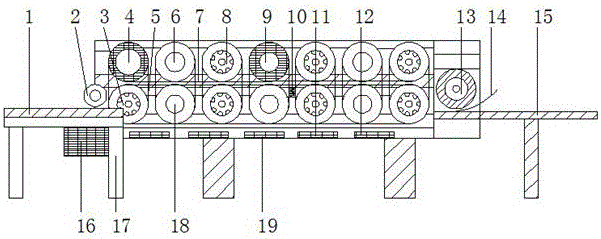

Method in a multiroll calender, a multiroll calender and a method for loading a calender roll of a multiroll calender and a multiroll calender

The invention relates to a method for a multi-roll calender and the multi-roll calender for calendering a fiber web. In the method, the fiber web, in particular a paper web or a paper board web, is calendered by the multi-roll calender comprising two sets of rolls; the two sets of rolls are provided with at least two calendering rolls; in the method, a calendered work area is maximized, namely, a loading system of the rolls and a loading system of the calender are designed into a running area for providing wide linear load kN / m x calendered area number. The multi-roll calender comprises the two sets of rolls comprising at least two calendering rolls, and is characterized in that a possible calendered work area obtaining the maximum width, namely, a loading system of a calendering device and the loading system of the calender can achieve the running area wide kN / m x calendered area number. Therefore, the calendering method and the calender suitable for quite diversified levels of various different papers can be obtained.

Owner:METSO PAPER INC

Novel plating press

InactiveCN101463543BNo seal failureImprove flexibilityTextile shapingPulp and paper industryCopper tubing

The invention provides a novel press-polishing machine which can effectively avoid invalidation of sealing equipment, comprising a frame and hard roller which can rotate and is arranged on the frame; wherein, the hard roller comprises a roller body, two shaft heads, a supporting tube and a heating device, the roller body is of a prismatical hollow structure, the two shaft heads are respectively fixedly arranged at the two ends of a roller body along the axial direction, at least one sealing equipment is arranged between the shaft heads and the roller body, at least two fixed trays are arranged in the roller body along axial direction at intervals, the supporting tube penetrates through the radial central part of the fixed trays, the heating device is arranged in the supporting tube, an input end of the heating device is electrically connected with an external power source by a revolving connector, the sealing equipment comprises an internal tray, a ring-shaped copper tube and an external tray along the axial direction of the roller body, the lateral wall of the ring-shaped copper tube is respectively connected with the adjacent external side of an internal tray and internal side of the external tray and are combined into a whole, the other side of the internal tray and the other side of the external tray are respectively connected with the shaft head and the roller body and are combined into a whole.

Owner:张贻景

Heat-resistant nylon 66 as-spun filament and indirect spinning method thereof, and application of as-spun filament in producing high-elasticity weft

InactiveCN106350890AReduce manufacturing costSimple methodFilament manufactureArtificial filament heat treatmentHeat resistanceNylon 66

The invention provides a heat-resistant nylon 66 as-spun filament which comprises nylon 66 and a heat-resistant agent in a ratio of (100-1000):1; and the heat-resistant agent comprises copper acetate and potassium iodide in a ratio of 1:(3-20). The invention also provides an indirect spinning method of the heat-resistant nylon 66 as-spun filament and application of the heat-resistant nylon 66 as-spun filament in producing high-elasticity weft. The production cost of the heat-resistant nylon 66 as-spun filament is greatly lowered; and the copper acetate has favorable heat stability in the polymerization or spinning process, and can not be lost or decomposed, so that the heat resistance is greatly enhanced. Thus, after the spun weft is subjected to 240-DEG C heat treatment for 3 minutes, the high power is 312cN, and the elongation percentage is 245%; and after gum dipping, the high power is greater than 295cN, and the elongation percentage is greater than 228%, thereby completely satisfying the requirements of the radial tire builder fabric for the elastic weft.

Owner:山东合信科技股份有限公司

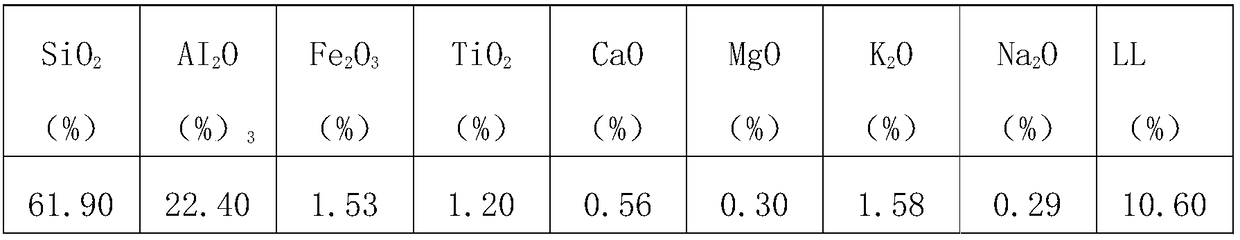

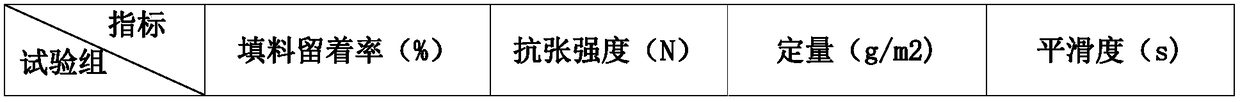

Production process of myopia prevention paper

ActiveCN108914680AReduce deforestationPrevent myopiaWater-repelling agents additionPaper/cardboardPapermakingChemistry

The invention belongs to the technical field of papermaking and particularly discloses a production process of myopia prevention paper. The production process comprises the following steps: (1) preparing raw materials; (2) preparing pulp by treating straws and reeds to obtain first pulp and treating wood and cluster bamboo to obtain second pulp; (3) mixing and pulping; (4) preparing mixed liquid;(5) adding filler by mixing and stirring silica micropowder, talcum powder and Dongsheng soil to obtain a mixed filler, adding the mixed liquid into the mixed filler, stirring to obtain a mixed material, adding the mixed material into the pulping liquid, stirring, heating the liquid in the stirring process, and stopping heating when the temperature of the liquid is heated to 78-84 DEG C to obtainpapermaking pulp; (6) drying; (7) calendering; and (8) coiling. The paper produced by the technical scheme has a myopia prevention effect; meanwhile, the produced paper has good properties of strength, smoothness, printing adaptability and the like.

Owner:重庆市开州区三中印务有限公司

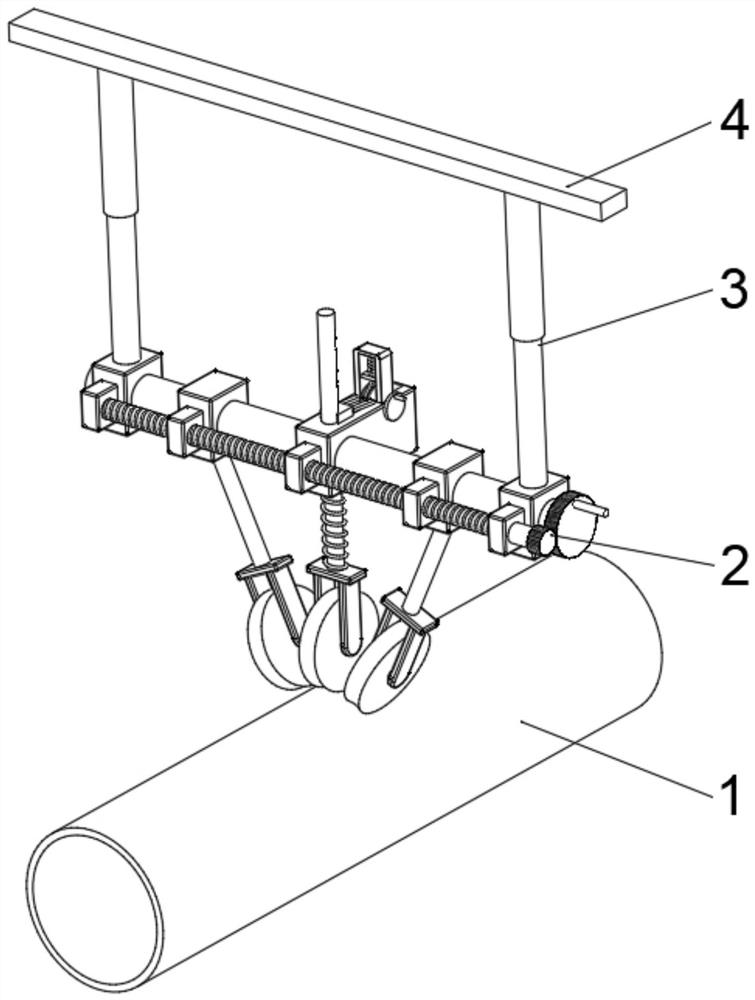

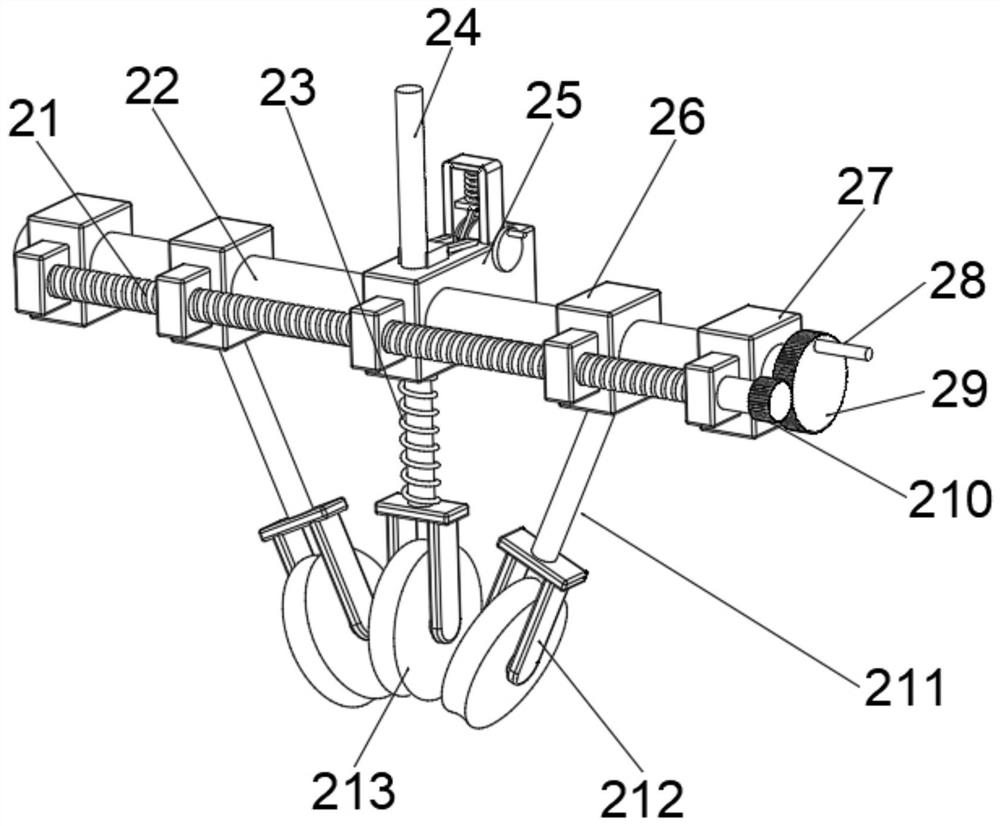

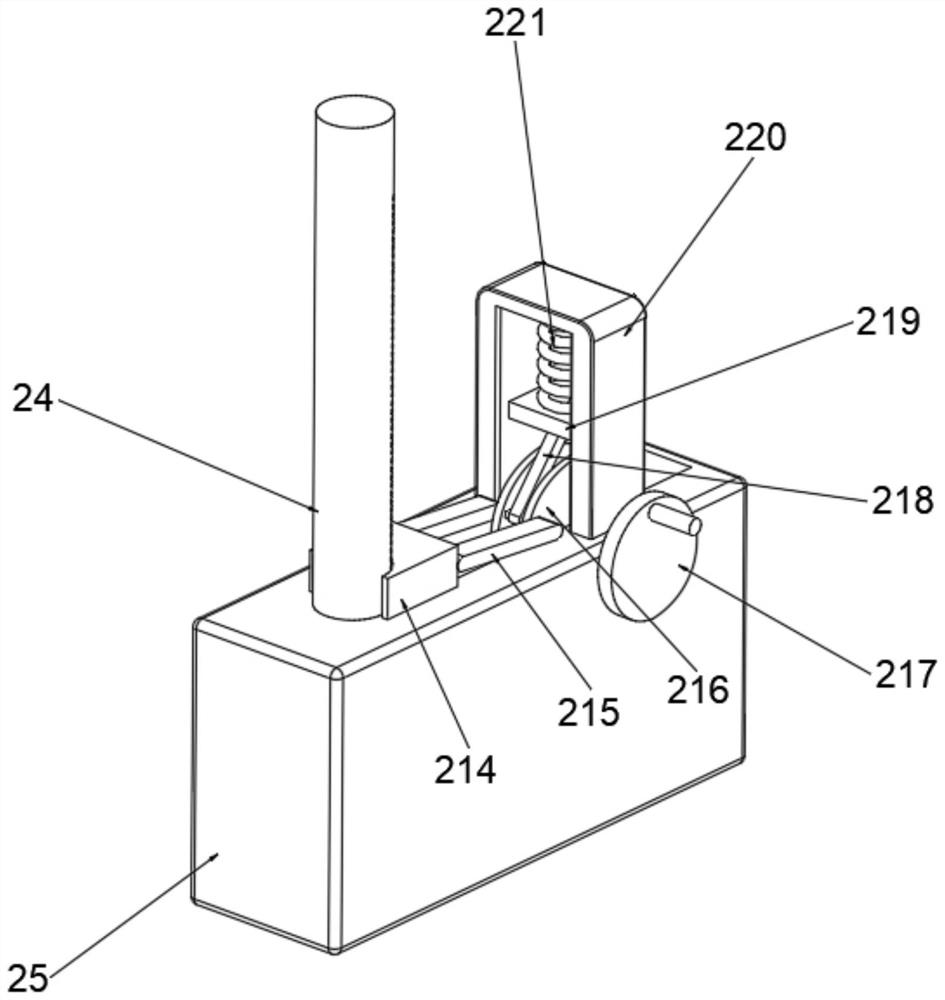

Three-piece type roller for calendering of weld

ActiveCN113102944AReduce the difficulty of cleaningGuaranteed flatnessStructural engineeringMechanical engineering

The invention discloses a three-piece roller for calendering of a weld, and relates to processing equipment. The three-piece roller specifically comprises a mounting rack, hydraulic rods and a mounting plate, two ends of the bottom surface of the mounting plate are respectively and fixedly connected with the top ends of the vertically-mounted hydraulic rods, the bottom ends of the hydraulic rods are respectively and fixedly connected with two ends of the mounting rack, and a pipeline needing to be calendered is arranged at the bottom of the mounting rack. According to the roller, the weld calendering technology adopting the three-piece type roller is adopted, and redundant solder at the weld is extruded out and protrudes on the outer wall of the pipeline so that the influence on the sealing performance of the weld of the pipeline can be effectively avoided when the solder is cleaned, and the smoothness of the surface of the pipeline is guaranteed.

Owner:溧阳市嘉雄不锈钢设备有限公司

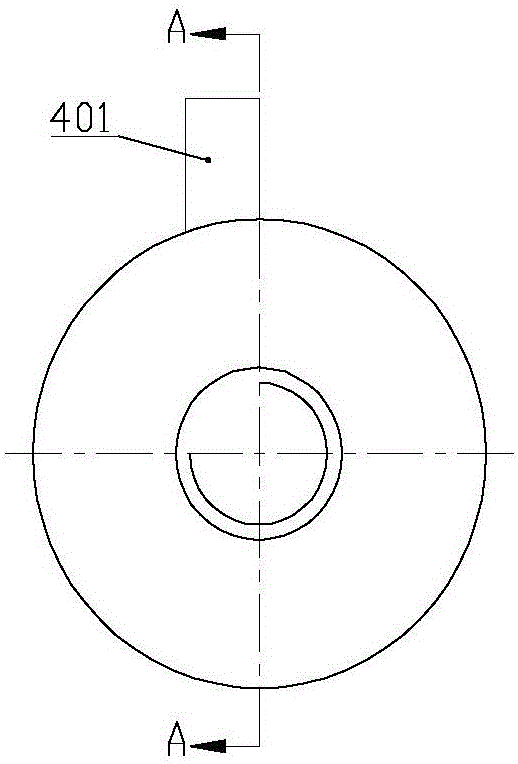

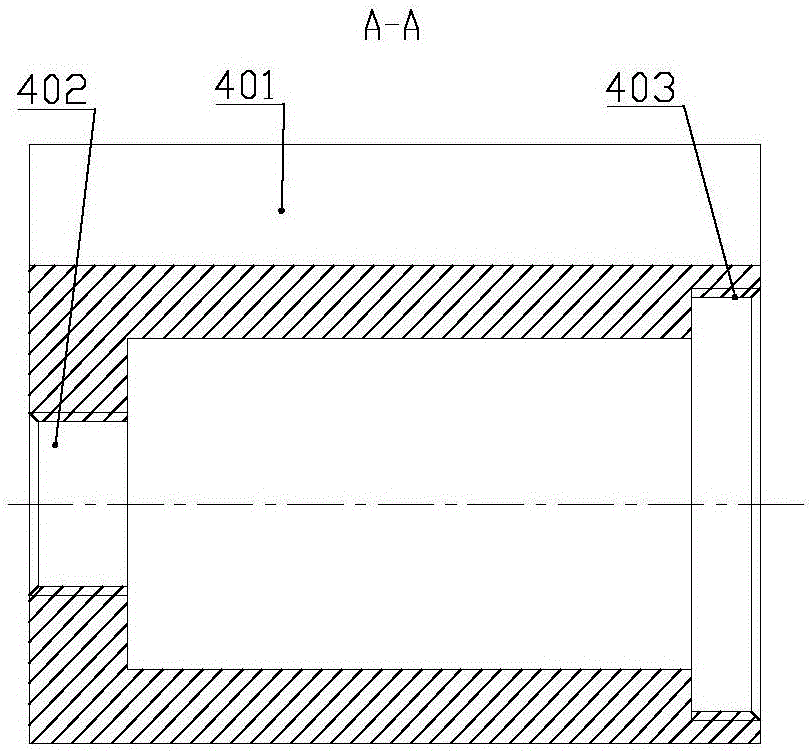

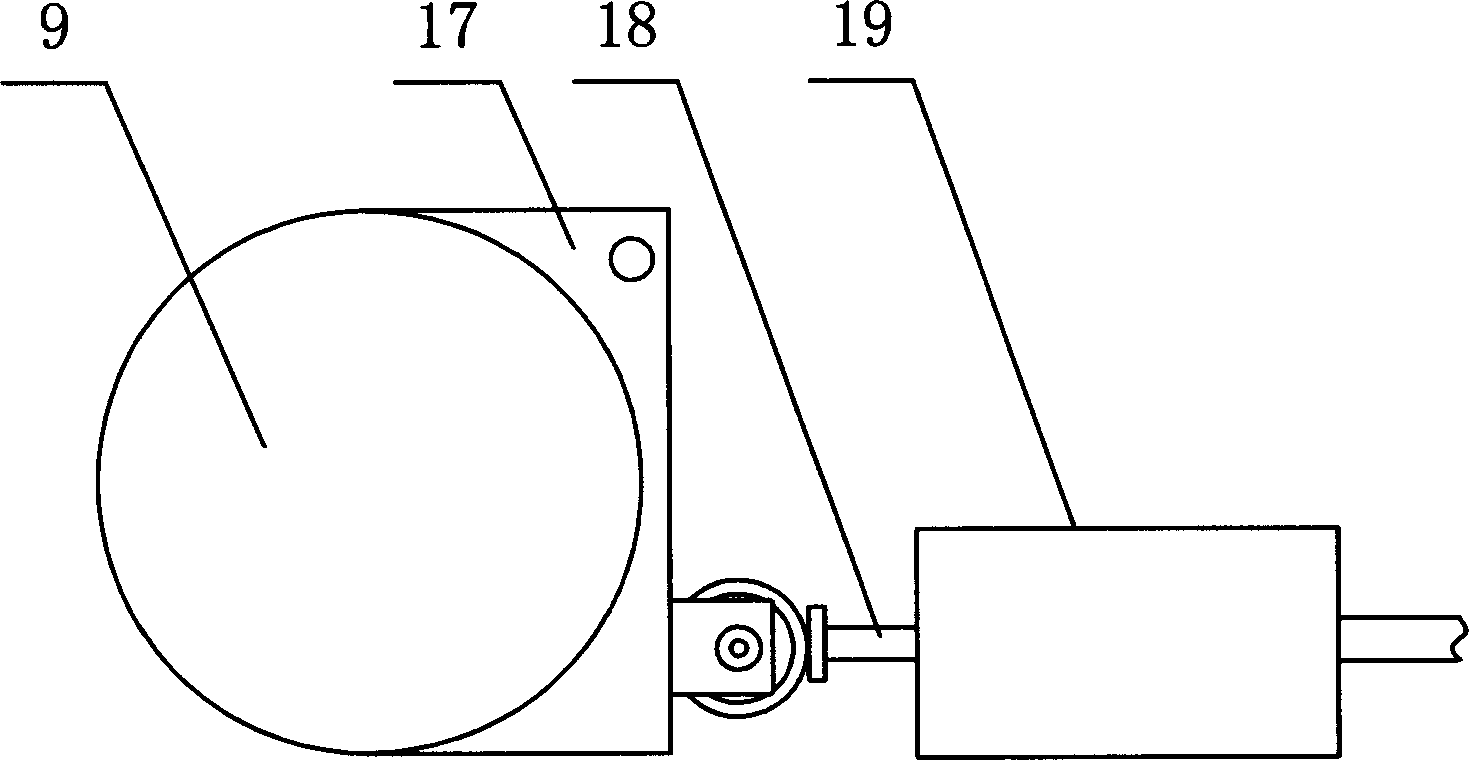

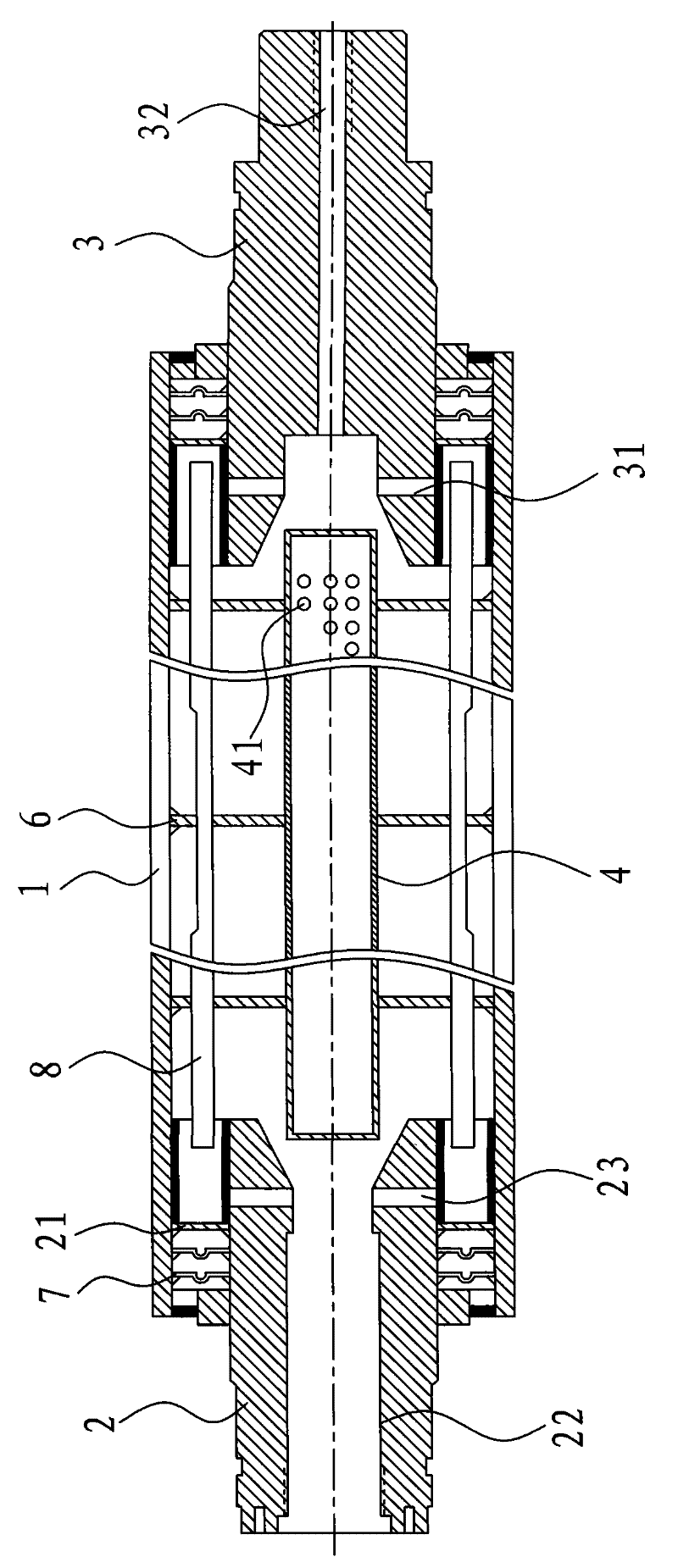

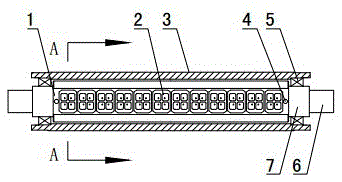

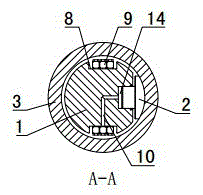

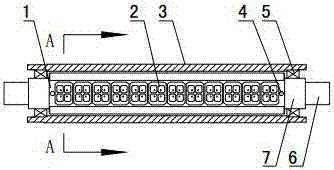

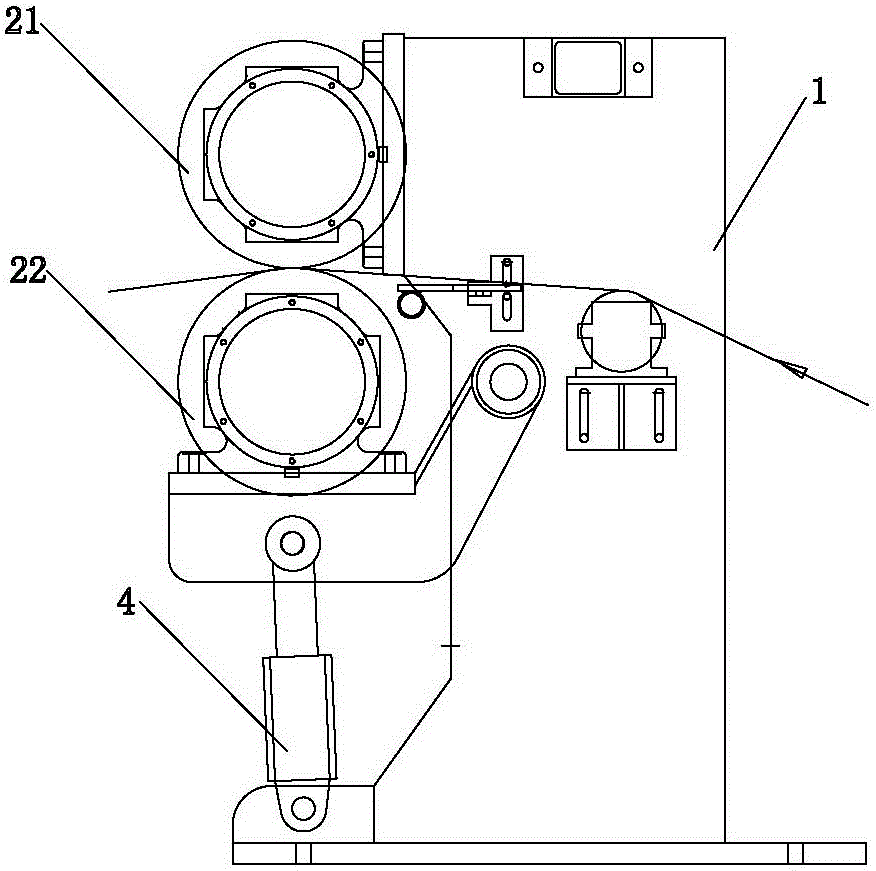

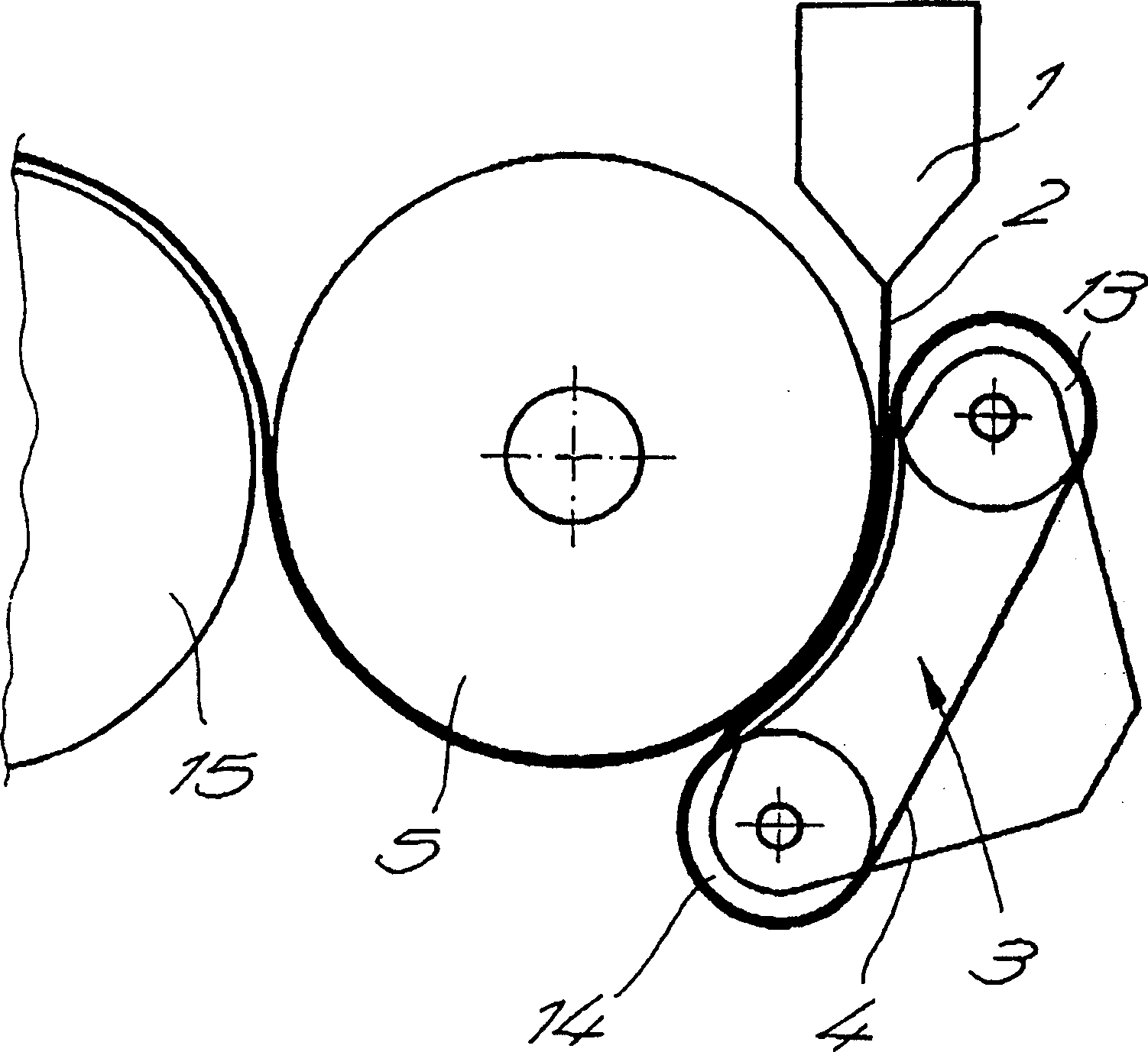

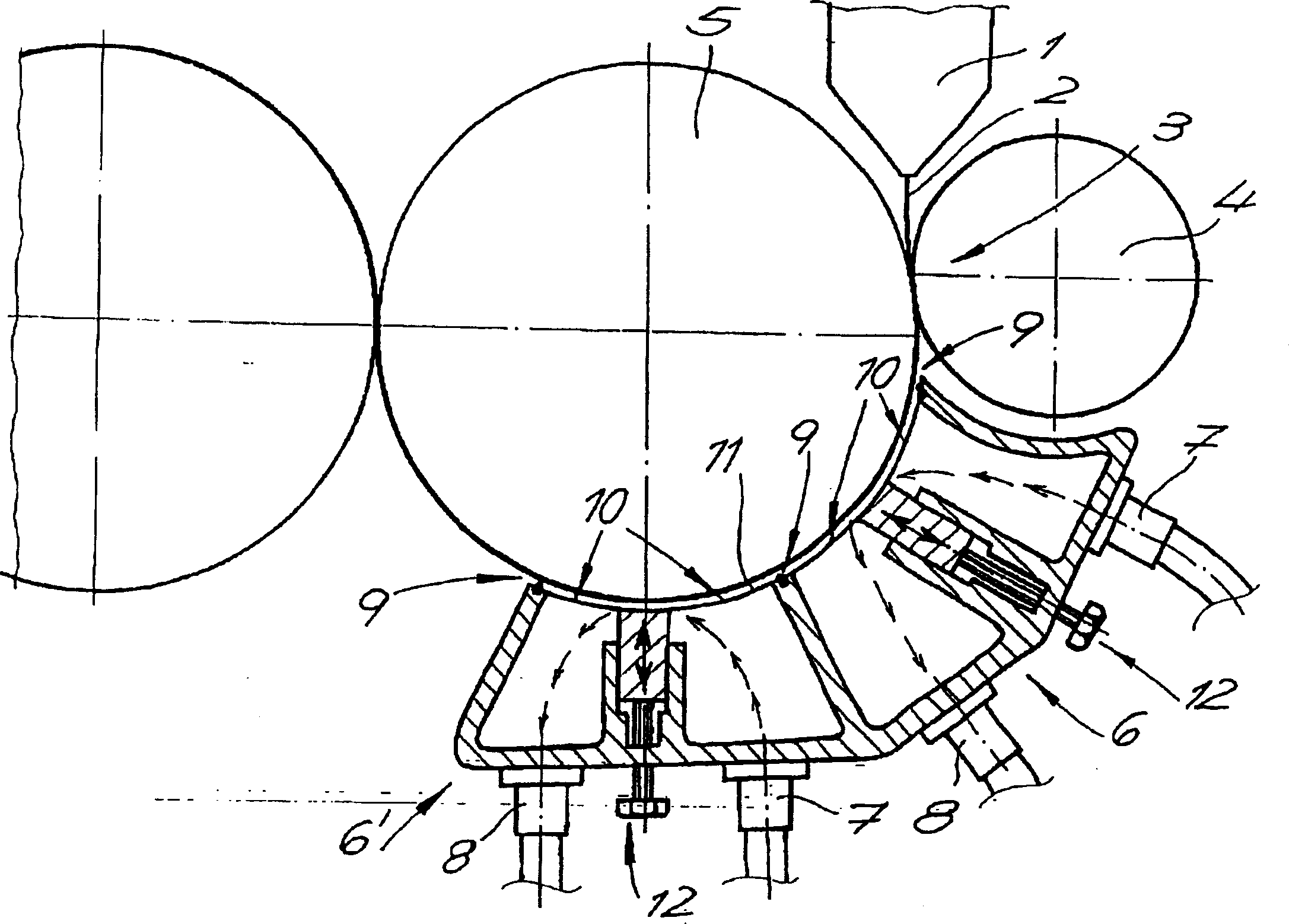

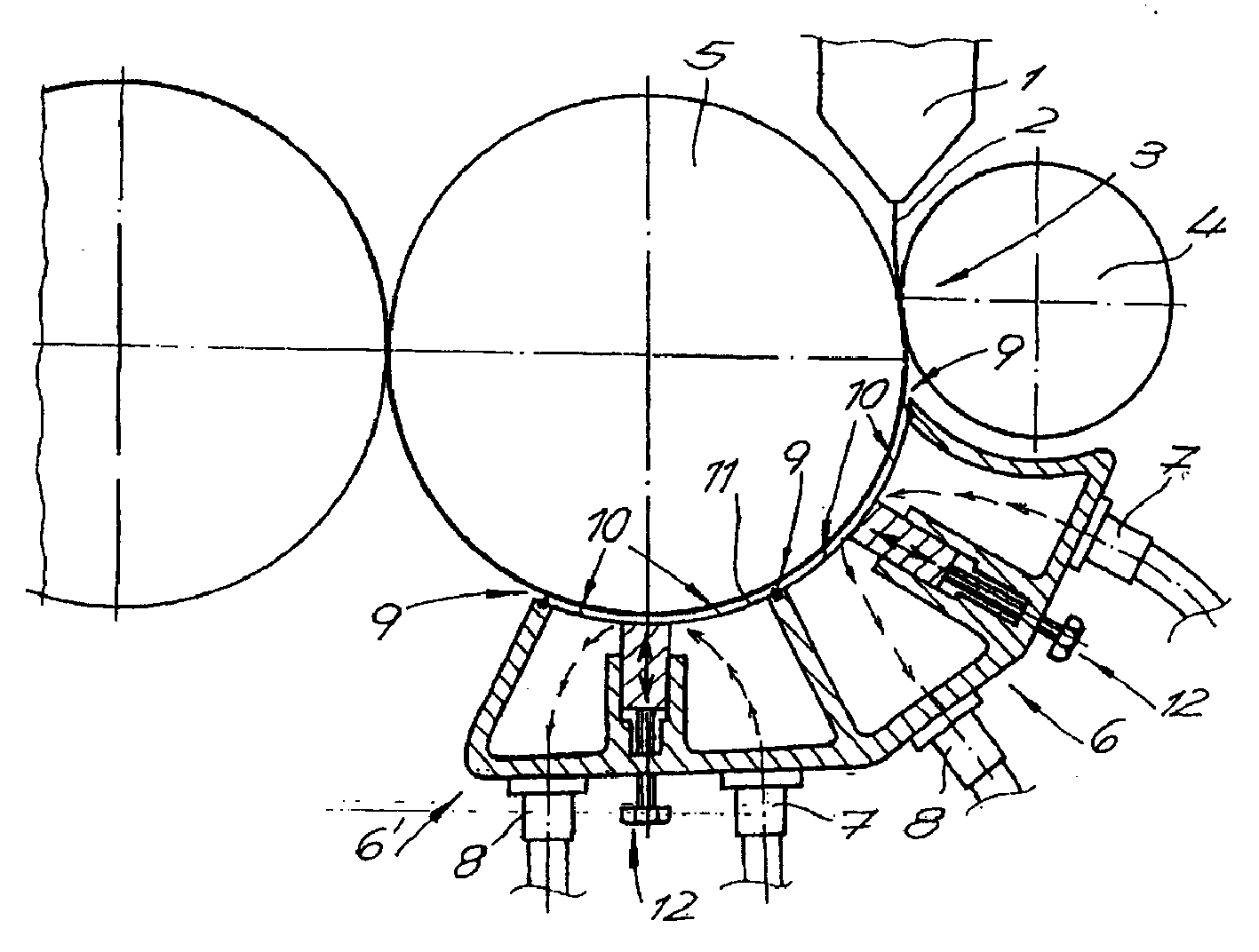

Controllable crown roll

ActiveCN105648828AReduce processing difficultyReduce difficultyCalendersPulp and paper industryMachining

The invention provides a controllable crown roll and belongs to the technical field of papermaking equipment. The controllable crown roll is characterized in that a containing groove (8) is formed in the side face of a mandrel (1), an oil inlet hole (10) communicated with a static-pressure bearing piston (2) and a transition hole (13) communicated with the end face of the mandrel (1) are formed in the containing groove (8), and an oil pipe (12) communicated with the transition hole (13) and the oil inlet hole (10) is arranged in the containing groove (8). The containing groove is formed in the side face of the mandrel of the controllable crown roll, the oil pipe is installed in the containing groove, hydraulic oil is conveyed to the static-pressure bearing piston through the oil inlet hole and the transition hole in the containing groove, an axial through hole does not need to be machined in the middle of the mandrel during machining, and machining difficulty is greatly reduced. Besides, installation is convenient, the sealing requirement is low, maintenance is hardly needed, people only need to replace the damaged oil pipe or a sealing element, and maintenance difficulty is greatly reduced.

Owner:ZIBO TAIDING MASCH TECH CO LTD

Supercalender

The invention discloses a supercalender, comprising a feeding platform, a first heating roller, a first supporting roller, a second calendaring rubber roller, a cooling roller, a feeding platform control device, and a third fan. The feeding platform control device is connected with the feeding platform by a circuit. The right end of the feeding platform is rotatably connected with a feeding roller. The first heating roller is rotatably connected with a first calendaring rubber roller, and the right end is fixedly connected with a scraper mechanism. The first supporting roller and a second supporting roller are connected through a rotation band, and the right end is fixedly provided with a calendaring steel belt. The right end of the second calendaring rubber roller is symmetrically provided with second heating rollers. A supporting device is fixedly connected under the feeding platform. The supercalender is provided with a plurality of rotation motors, automation degree is high, and the internal of the supercalender is provided with the heating rollers, so paper can receive heat of electrical heating. Thus, the paper finally has good glossiness, flatness, and tightness. The whole machine is simple in structure, convenient in use, and relatively high in creativity.

Owner:HENAN ZHONGYA PAPERMAKING EQUIP

Water-based buffing oil for paper and preparation method thereof

InactiveCN101725082AGood calendering effectSmall smellSpecial visual effect coatingsWaxTemperature resistance

The invention relates to water-based buffing oil for paper and a preparation method thereof. In the invention, thermoplastic acrylic emulsion as the main film forming emulsion, thermoplastic acrylic resin as dispersion resin and isobutanol as an initiator are dispersed at high speed at normal temperature, then other additives are gradually added, ployethylene wax is hydrolyzed by de-ionized water to generate a release agent with high temperature resistant effect, and then the release agent is added to the formula. The water-based buffing oil for paper obtained in the invention has little toxicity and odor, small environment pollution, high luster, especially good high temperature resistance and demolding property, and good stability in storage and use, and can be widely used for glazing and buffing finishing of the surfaces of various paper products.

Owner:YUYAO SHUNCAI COATING

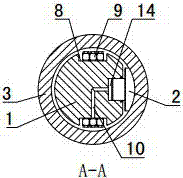

a mirror roller

InactiveCN102788082BSimple processHigh surface hardnessShaft and bearingsTextile shapingHigh surfaceMachining

The invention discloses a mirror roller and its production technology. The mirror roller comprises an outer roller, an inner cylinder, and two shaft sleeves. The production technology of the mirror roller comprises the following steps: preparing materials comprising an No.45 steel seamless steel tube adopted by the outer roller, Q235 adopted by the inner cylinder, and No.45 steel adopted by the shaft sleeves; carrying out rough machining on the excircle of the outer roller, and carrying out boring hole processing on the outer roller; sending the outer roller, the inner cylinder and the shaft sleeves to an electric furnace, heating them to 250DEG C, welding the inner cylinder and the shaft sleeves together, and welding the outer roller and the shaft sleeves together; quenching and tempering the integral body; carrying out semi-fine machining on the outer surfaces of the outer roller and shaft heads; carrying out hole reaming processing on center holes on the shaft sleeves; carrying out high frequency quenching on the cylindrical surface of the outer roller; grinding and polishing the excircle of the outer roller and the shaft heads after cooling; and electroplating hard chromium on the cylindrical surface of the outer roller. By adopting the above mode, the technology disclosed in the invention has the advantages of simplicity and low production cost, and the processed mirror roller has the advantages of high surface hardness, uniform temperature, good calendering effect, compact structure and durable service.

Owner:常州欧亚重工机械有限公司

A controllable middle and high roller

ActiveCN105648828BReduce processing difficultyReduce difficultyCalendersPulp and paper industryMachining

The invention provides a controllable crown roll and belongs to the technical field of papermaking equipment. The controllable crown roll is characterized in that a containing groove (8) is formed in the side face of a mandrel (1), an oil inlet hole (10) communicated with a static-pressure bearing piston (2) and a transition hole (13) communicated with the end face of the mandrel (1) are formed in the containing groove (8), and an oil pipe (12) communicated with the transition hole (13) and the oil inlet hole (10) is arranged in the containing groove (8). The containing groove is formed in the side face of the mandrel of the controllable crown roll, the oil pipe is installed in the containing groove, hydraulic oil is conveyed to the static-pressure bearing piston through the oil inlet hole and the transition hole in the containing groove, an axial through hole does not need to be machined in the middle of the mandrel during machining, and machining difficulty is greatly reduced. Besides, installation is convenient, the sealing requirement is low, maintenance is hardly needed, people only need to replace the damaged oil pipe or a sealing element, and maintenance difficulty is greatly reduced.

Owner:ZIBO TAIDING MASCH TECH CO LTD

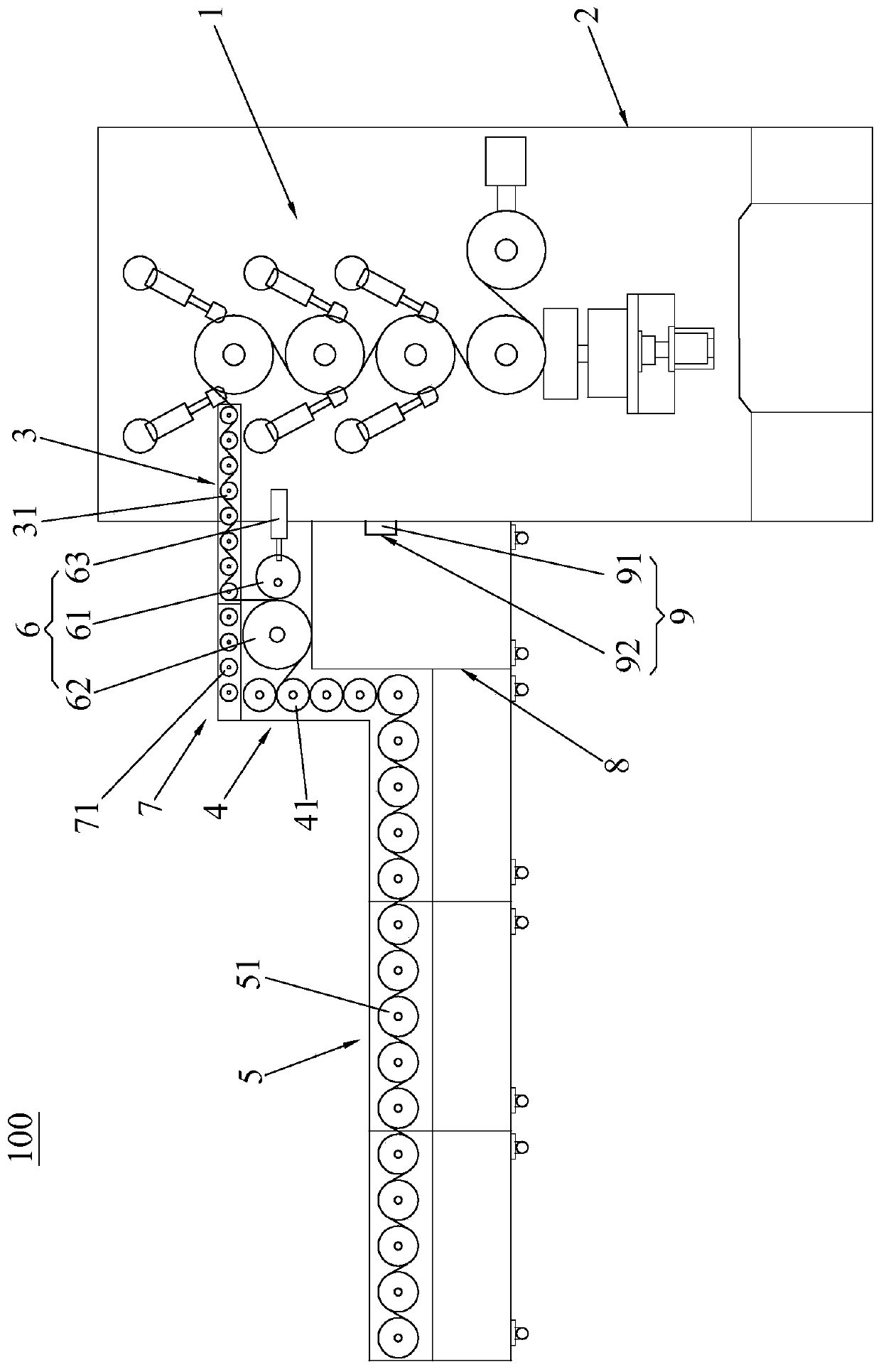

Calendering production equipment

The invention discloses calendering production equipment. The calendaring production equipment comprises a calendaring main machine, a rack, a first stripping roller set, a cooling guide roller set, an auxiliary mechanism and a calendering mechanism, the calendaring main machine is arranged on the rack, one end of the first stripping roller set is located on one side of the upper end of the calendaring main machine, the calendering mechanism is arranged on the lower side of the other end of the first stripping roller set, the upper end of the cooling guide roller set is located on one side ofthe calendering mechanism, the auxiliary mechanism is arranged at the lower end of the cooling guide roller set; and the calendering mechanism comprises a first steel roller and a second steel roller.The calendering production equipment can calender thermoplastic materials, and the calendering effect is good.

Owner:YIWU SHUNDA PLASTIC CO LTD

A calender with improved structure

The present invention relates to the technical field of calenders, in particular to a calender with improved structure, which includes a frame and a calender roller, the calender roller is connected to the frame, and the calender roller includes a top roller and a calender roller. Bottom roll, the calender also includes a gap adjustment system for adjusting the gap between the top roll and the bottom roll and a double power device, the double power device drives and connects the calender roll, the The roll gap adjustment system includes a PLC control system and a hydraulic station, the hydraulic station is connected with the calender roll, and the PLC control system is electrically connected with the hydraulic station. The invention can make the joint of the paper web pass through the nip of the calender roller automatically, reduces the manual link of manual operation, reduces the labor intensity, has a high degree of automation, high production efficiency, and effectively improves the calendering effect of the paper web. The quality of the rolled paper web is good, and the smoothness of the paper web is much higher than the standard of high-grade products stipulated by the national GB / T16797-2008.

Owner:GUANGDONG QIAOSHENG ANTI COUNTERFEITING MATERIALS CO LTD

Process for preparing SBS aqueous emulsion

The SBS water emulsion is prepared with SBSM 20-60 wt%, non-ionic emulsifier 0.2-0.5 wt%, ionic emulsifier 0.5-1.0 wt%, electrolyte 0.2-0.4 wt% and defoaming agent 0.1-0.3 except water. The preparation process includes dissolving polarized SBS (SBSM) in organic solvent; adding water solution of emulsifier, defoaming agent and electrolyte slowly under stirring of 3000-5000 rpm to obtain O / W type emulsion; stirring in raised rotation speed of 8000-10000 rpm to crush the particles to under 1 micron; heating and decompressing to eliminate solvent via pumping to obtain stable SBS water emulsion. The SBS water emulsion has small particle size, high stability, solidified matter content of 1-4 %, good compatibility with stuffing and has high stuffing capacity.

Owner:BALING PETRO CHEM CO LTD SINOPEC +1

Device for polishing and cooling plastic tapes from gas nozzles

Owner:REIFENHAUSER GMBH & CO MASCHFAB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com