Novel plating press

A calender, a new type of technology, applied in textiles and papermaking, fabric surface trimming, etc., can solve problems such as high temperature, sealing failure, heat transfer oil leakage, etc., achieve good calendering effect, avoid bursting, and reliable sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

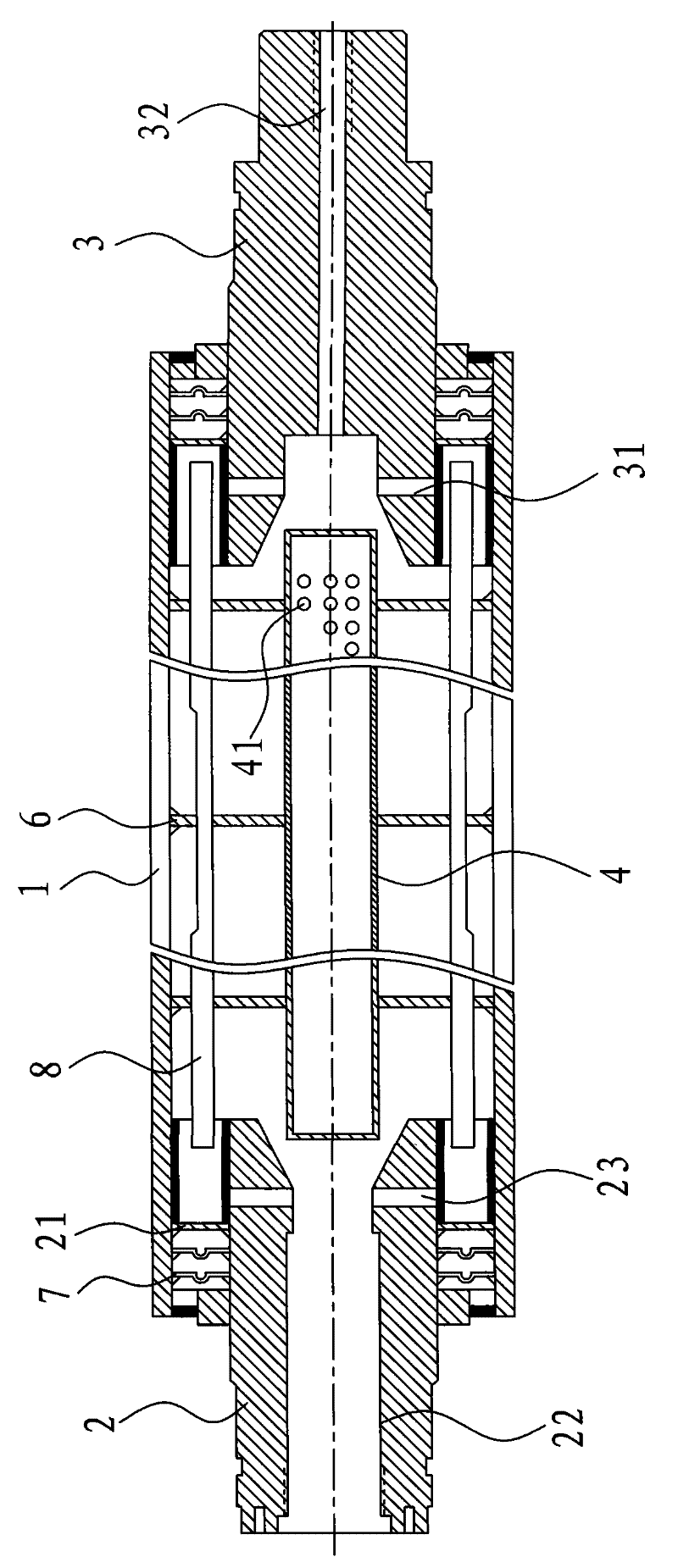

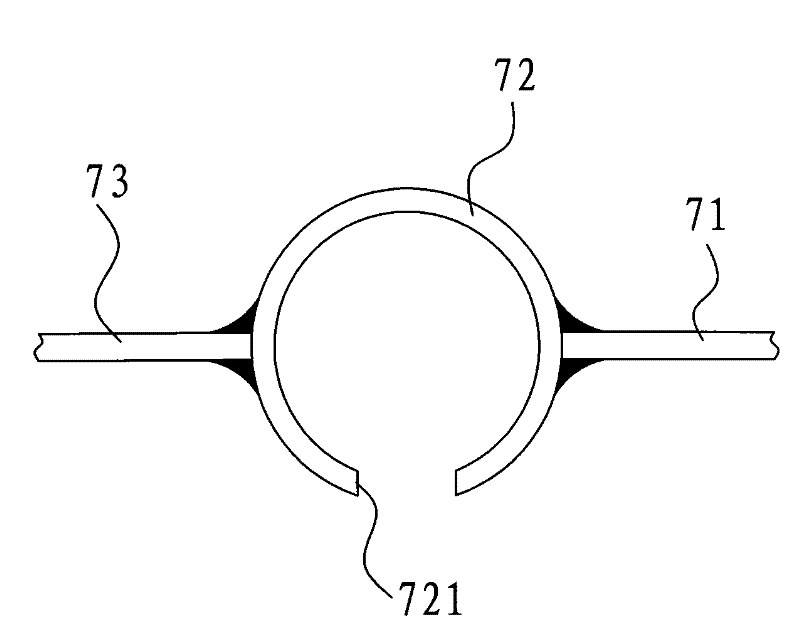

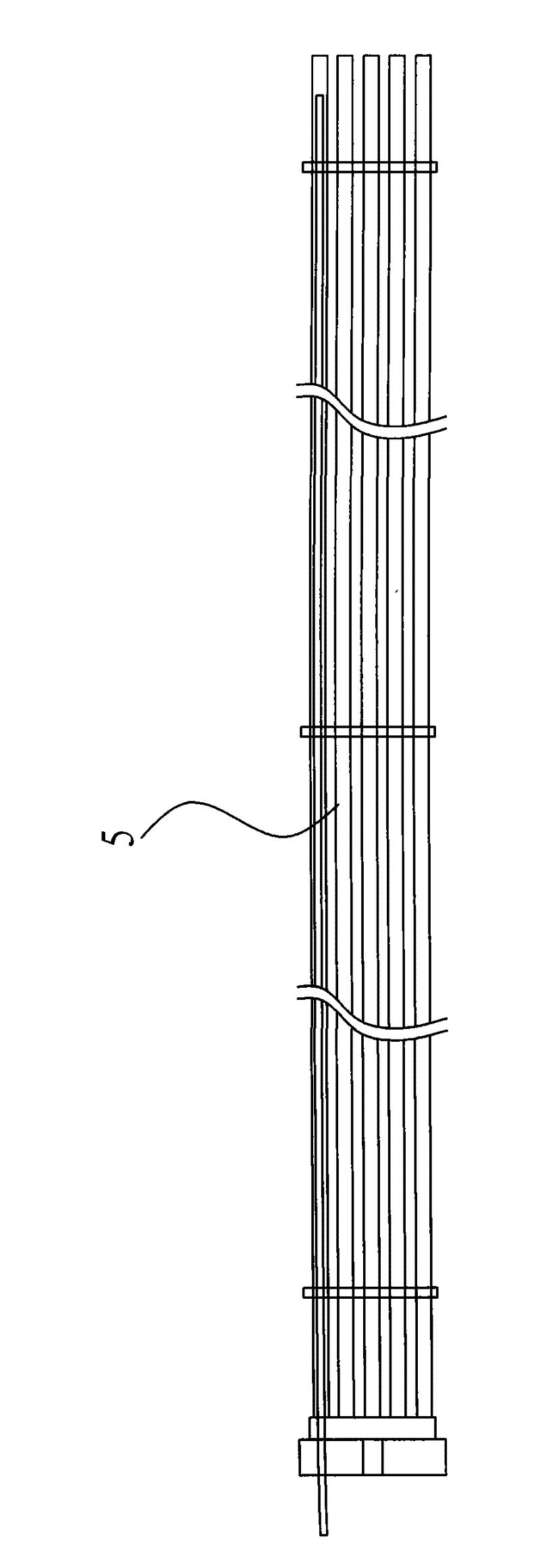

[0015] reference Figure 1 to Figure 5 , The embodiment discloses a new type of calender, which is based on the existing calender to improve and optimize the structure of the hard roller, in view of the calender frame, soft roller, driving device, temperature control device, etc. The structure and the relative positional relationship are well-known technologies, so the embodiment focuses on the hard roller and its structure. Specifically, this new type of calender includes a frame and a hard roller rotatably arranged on the frame. The hard roller includes a roller body 1, a shaft head 2, a shaft head 3, a support tube 4, a heating device 5, and three One fixed plate 6, four sealing devices 7 and four oil mixing pipes 8, among which:

[0016] reference figure 1 , The roller body 1 has a cylindrical hollow structure, and the outer side wall of the roller body 1 has a high surface finish, which is suitable for high-temperature light pressing treatment on the surface of the fiber or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com