Explosive bolt resistant to space ultralow-temperature environment

An explosive bolt and ultra-low temperature technology, which is used in blasting cylinders, weapon accessories, offensive equipment, etc., can solve the problems of insufficient ultra-low temperature performance, and achieve the effect of avoiding sudden drop in impact toughness, excellent impact resistance, and ensuring structural integrity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

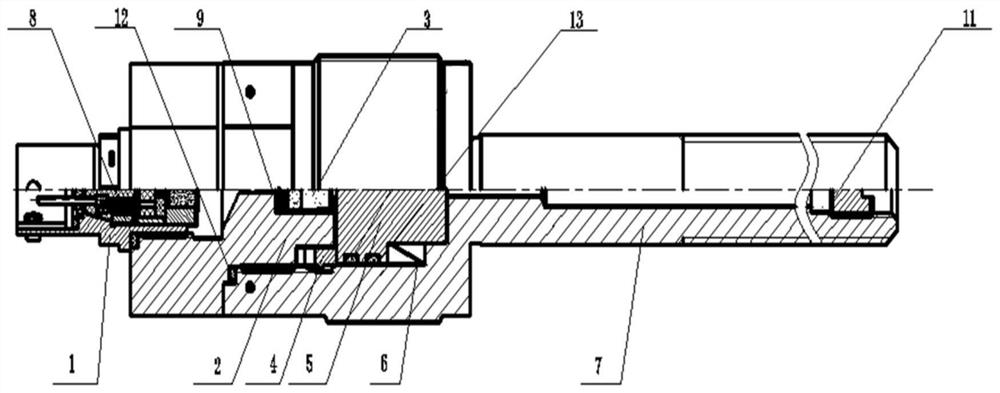

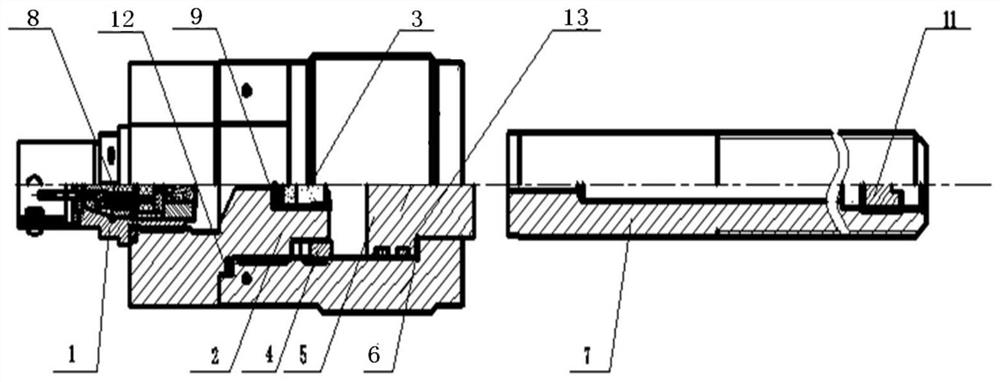

[0032] Aiming at the problem that the existing explosive bolt technology has the risk of structural damage during separation in the severe low temperature environment (below -120°C), the present invention proposes a non-polluting explosive bolt resistant to ultra-low temperature in space.

[0033] Such as figure 1 with 2 As shown, the space ultra-low temperature-resistant pollution-free explosive bolt can work below -120°C, including a membrane bridge belt igniter 1, a detonator seat 2, a detonator 3, a compression coil 4, a piston push rod 5, a sealing disc 6, Bolt body 7, O-ring Ⅰ 8, paper washer 9, piston push rod 5, plug 11, O-ring Ⅱ 12, O-ring Ⅲ 13;

[0034] Two O-rings III13 are installed in two annular grooves arranged axially along the piston push rod 5, O-ring II12 is installed on the stepped surface of the bolt body 7, O-ring I8 is installed on the stepped surface of the detonator seat 2, The first O-ring 8 is used for sealing between the igniter 1 and the detonato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com