Composite insulator

A technology of composite insulators and mandrels, used in insulators, electrical components, circuits, etc., can solve the problems of destroying the sealing effect, prone to gaps, and sealing failures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to further illustrate the present invention, the following preferred embodiments are described in detail in conjunction with the accompanying drawings as follows:

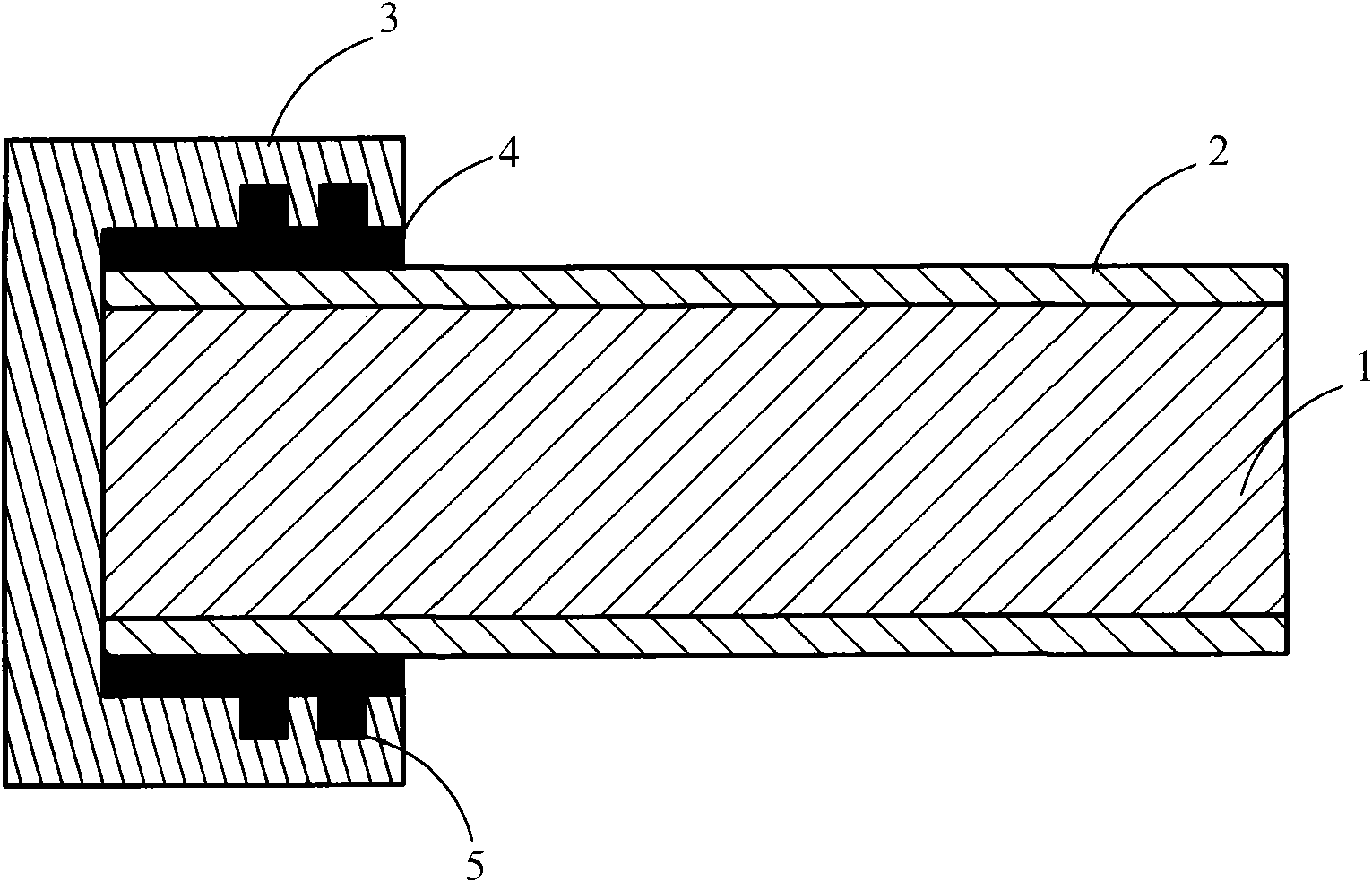

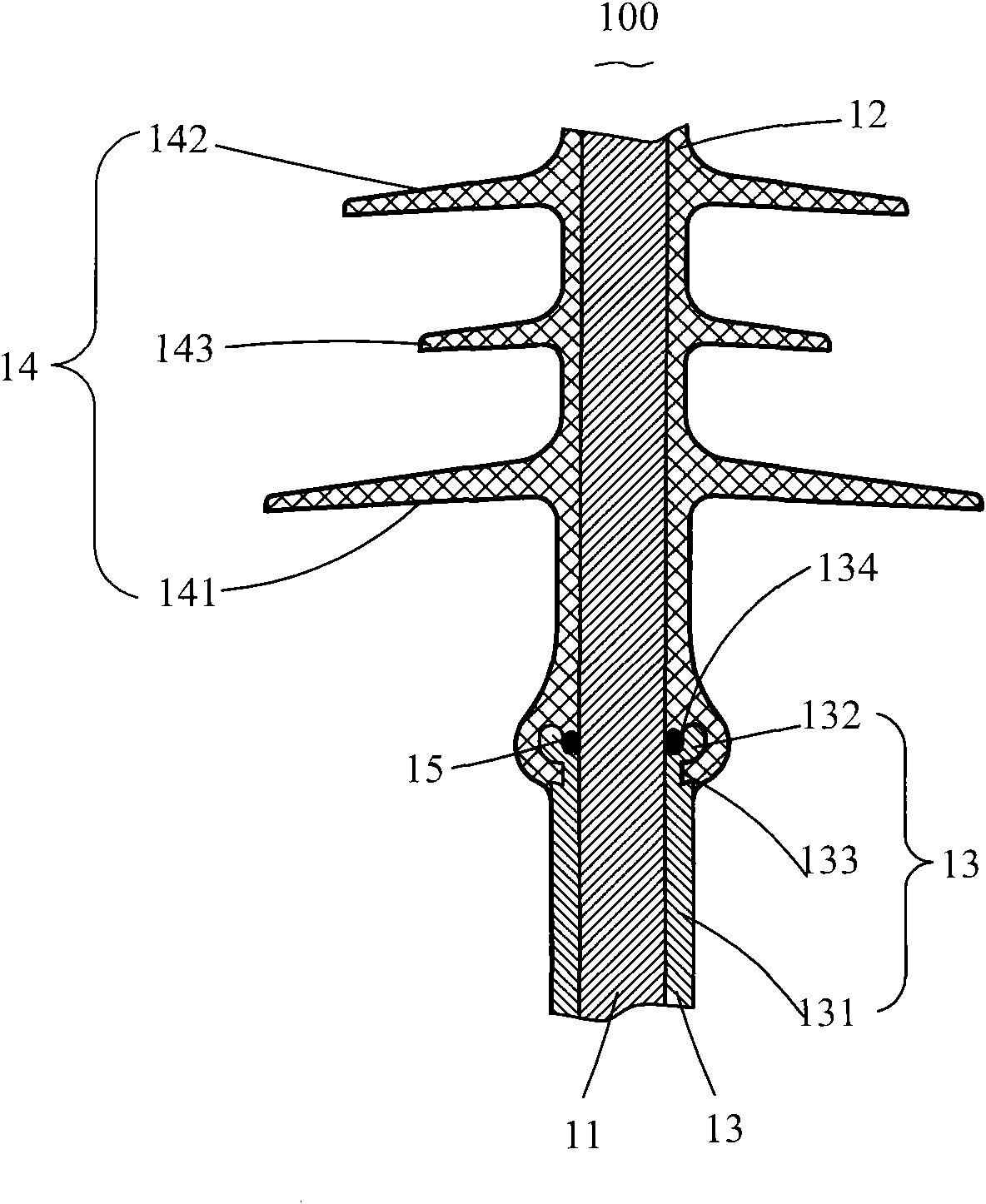

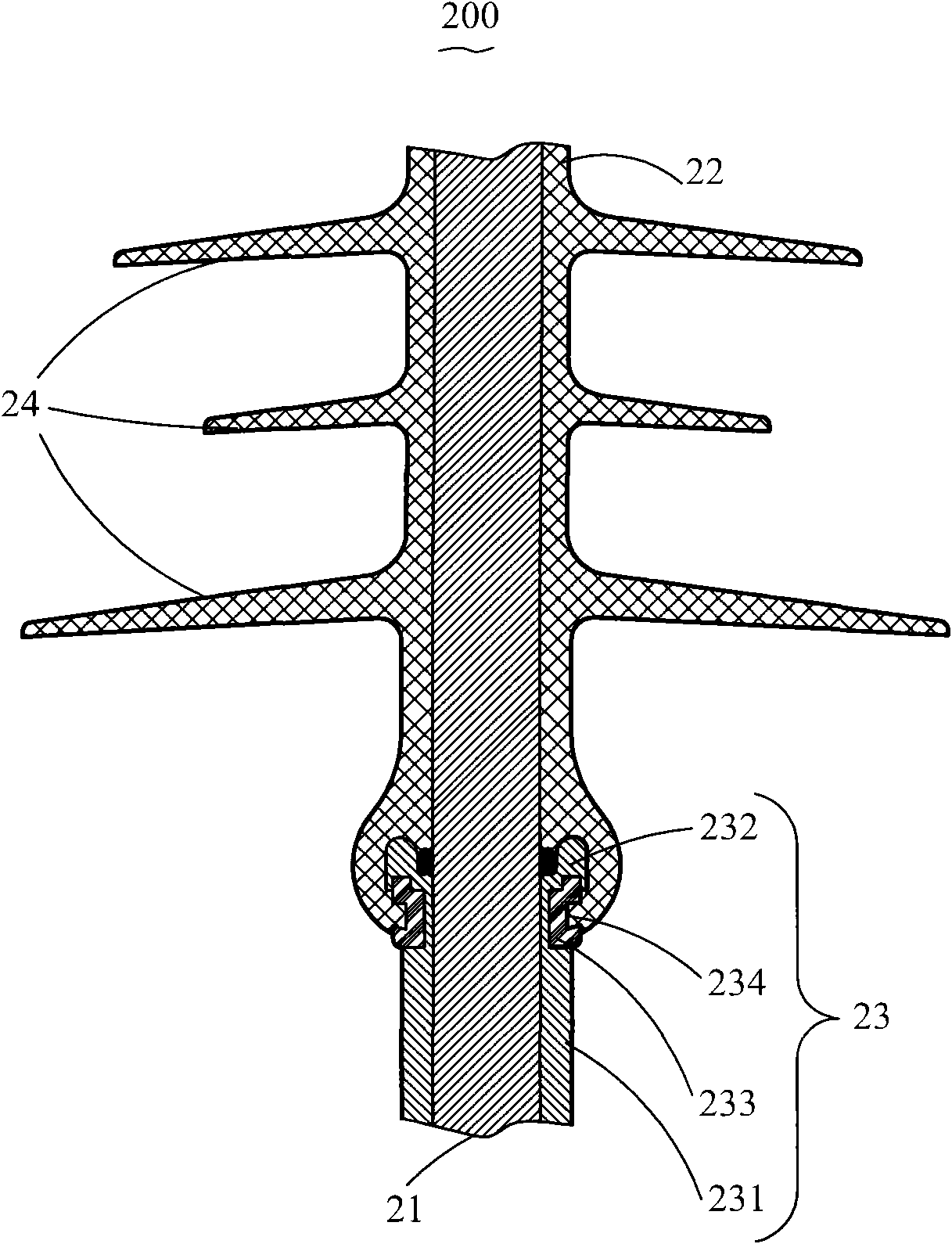

[0015] see figure 2 , is a schematic structural diagram of the composite insulator 100 of the first embodiment provided by the present invention. It should be further explained that, in the first embodiment, the composite insulator 100 is a line insulator. The composite insulator 100 includes a mandrel 11, a sheath 12 covering the outer side of the mandrel 11, a metal fitting 13 connected to the mandrel 11 and the sheath 12, and at least one set on the outer wall of the sheath 12 umbrella skirt14.

[0016] The mandrel 11 is a solid epoxy glass fiber reinforced plastic rod, which is formed by pultrusion of glass fiber soaked with epoxy resin glue. During the molding process of epoxy FRP rods, epoxy resin glue and glass fibers undergo a series of physical and chemical changes to form an epoxy resi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com