Patents

Literature

423results about How to "Won't peel off" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anode material for nickel-base lithium ion battery and preparation method of anode material

ActiveCN104409700AEasy to operateSuitable for industrial productionCell electrodesSecondary cellsOptoelectronicsOxygen

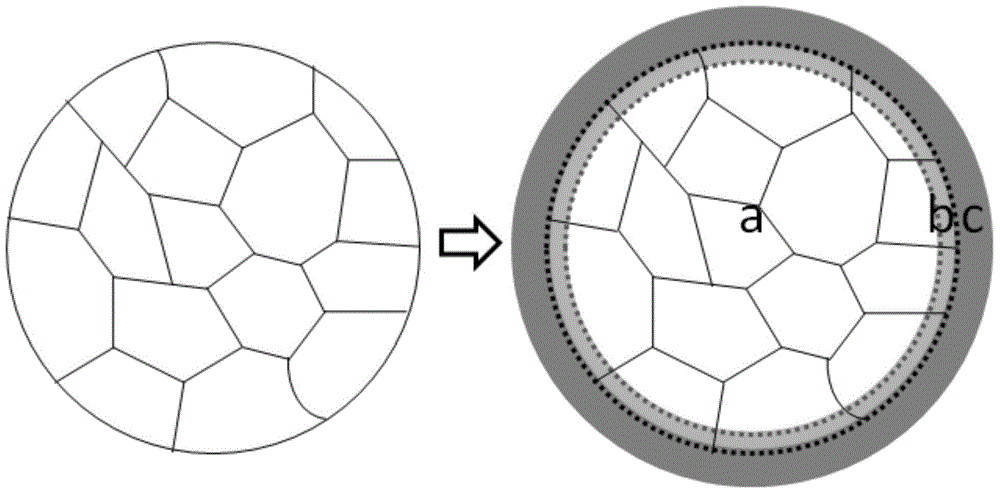

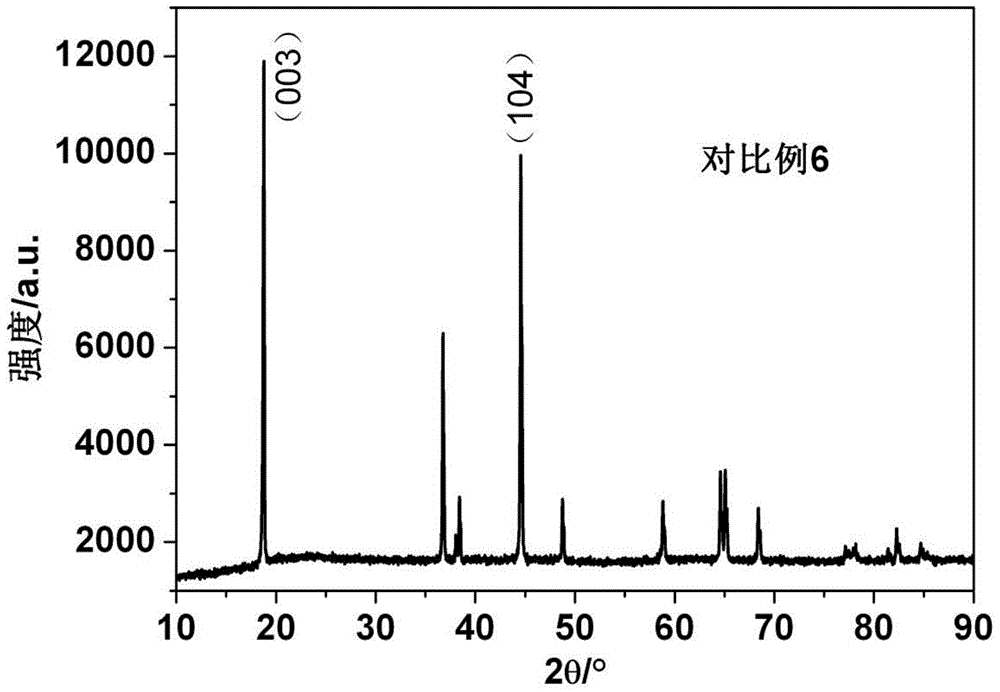

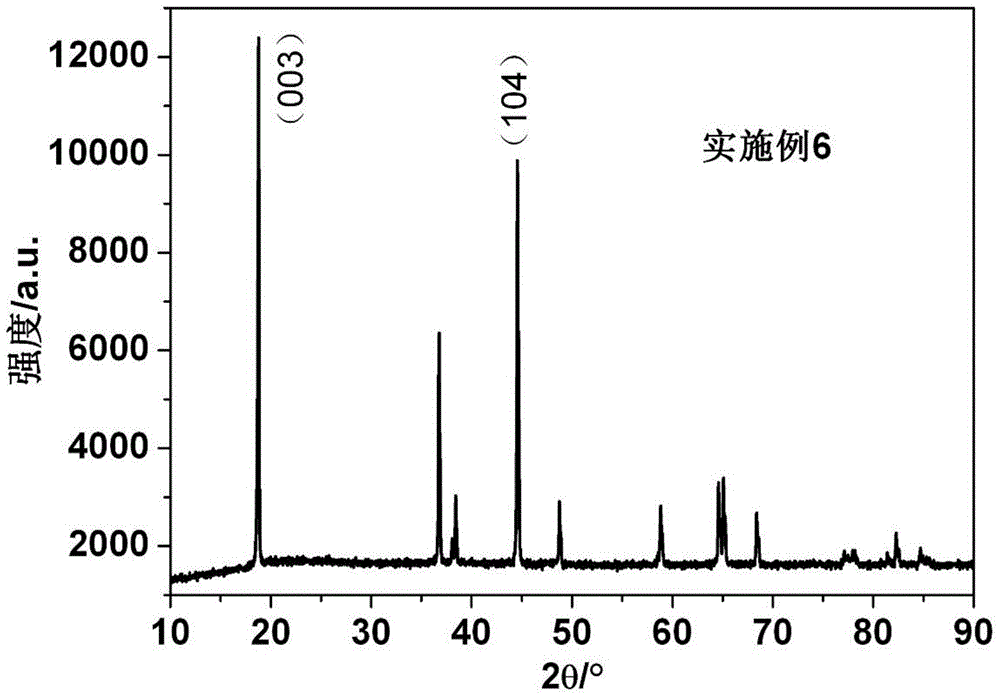

The invention provides an anode material for a nickel-base lithium ion battery and a preparation method of the anode material. The anode material comprises an inner core, a doping layer and a cladding layer, wherein the chemical formula of the inner core is LiaNixCoyMzO2; the doping layer is another inner core containing M'; at least M' and oxygen elements are contained in the cladding layer; the anode material is of a core-shell structure, and comprises the inner core, the doping layer and the cladding layer from inside to outside. The anode material for the nickel-base lithium ion battery provided by the invention is little in lithium-nickel mixing, and the cycling stability of the material is obviously improved.

Owner:BTR NEW MATERIAL GRP CO LTD

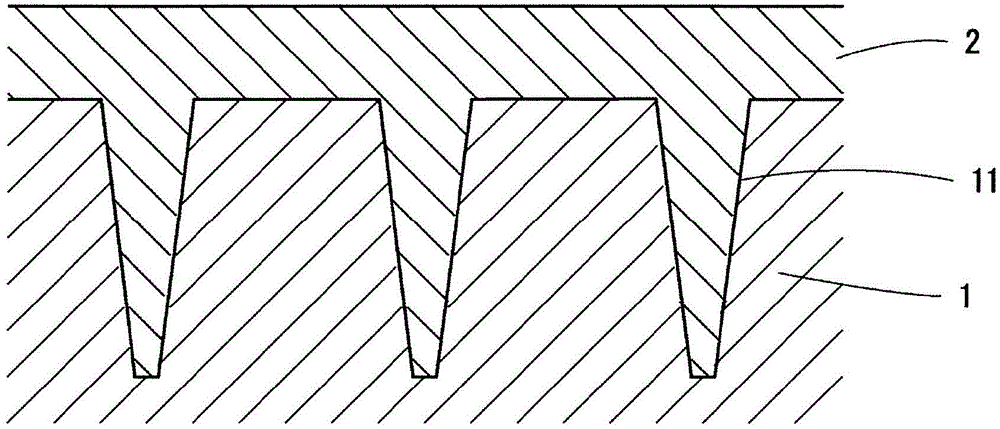

Method for manufacturing combination of aluminum alloy and thermoplastic resin

The invention provides a method for manufacturing a combination of an aluminum alloy and a thermoplastic resin, which at least comprises the following steps: providing an aluminum alloy sheet; performing pretreatment of removing a surface compact oxide layer on the aluminum alloy sheet; performing corrosion treatment at least comprising a plurality of two-layer micron-level holes on the surface of the aluminum alloy sheet; putting the aluminum alloy sheet in a die; and pouring the molten thermoplastic resin into the die to form the combination of the aluminum alloy and the thermoplastic resin. Because the thermoplastic resin and the aluminum alloy are not easy to strip, the combination has the advantages of both a metal shell and a thermoplastic resin structure in electronic machines and household electric appliances and has high production efficiency and the property of mass production, and the shape and the structure of the combination can be designed freely.

Owner:邓子平 +2

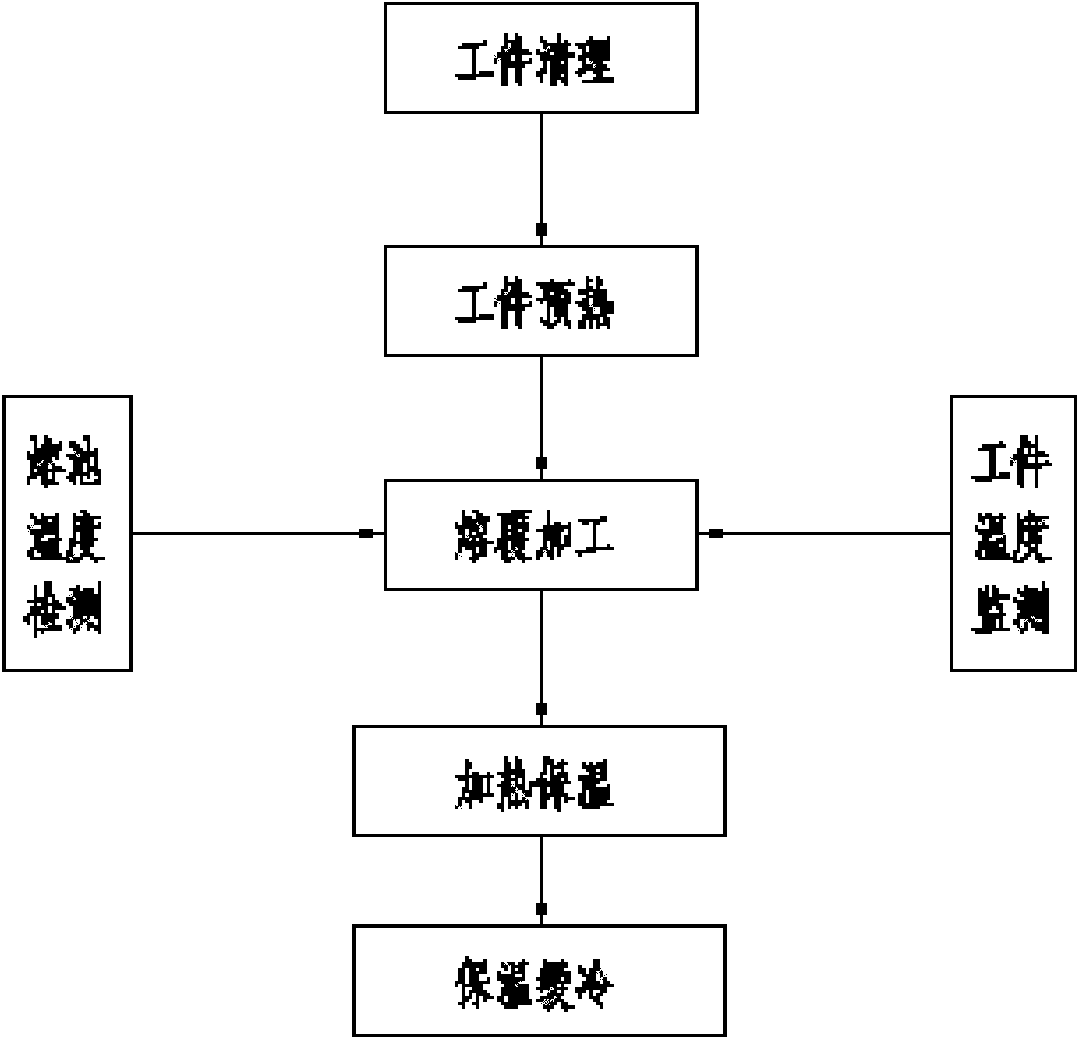

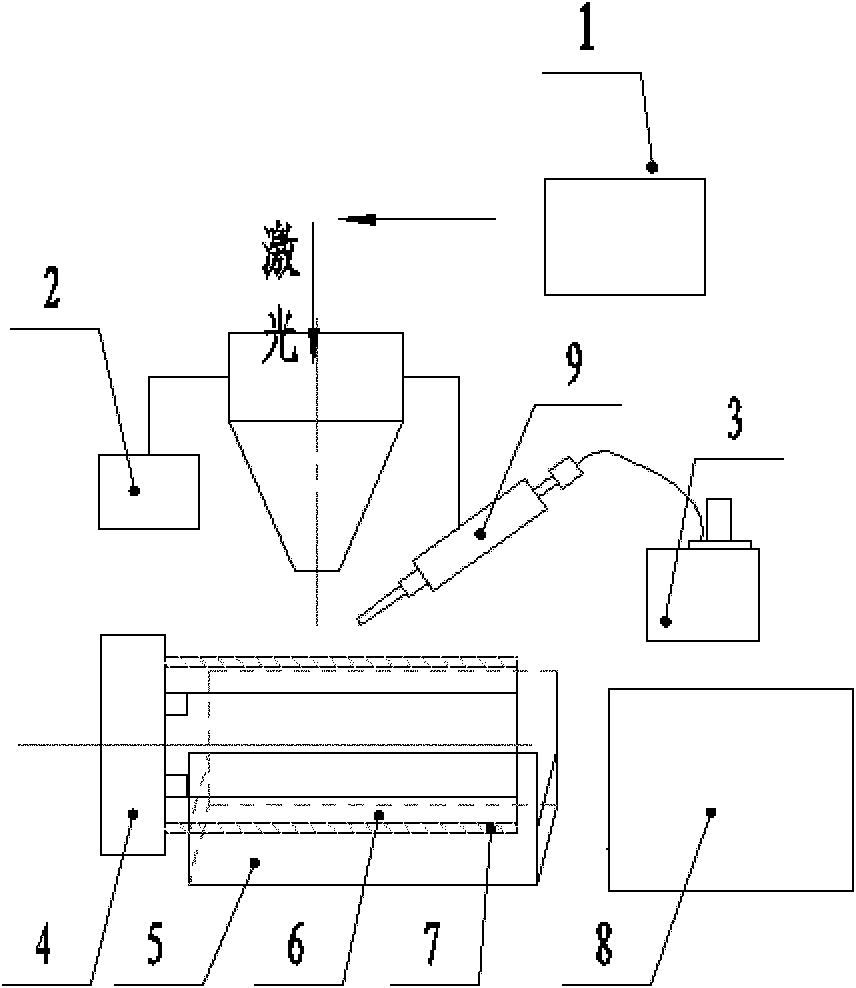

Method for carrying out laser-cladding on high-hardness nickel-based alloy material in large area

ActiveCN102465294AImprove wear and corrosion resistanceDense tissueMetallic material coating processesLaser beam welding apparatusSurface engineeringHeat-affected zone

The invention belongs to the field of material surface engineering and more particularly relates to a method for carrying out cladding on a high-hardness wear-resistant anti-corrosion nickel-based alloy material on a metal substrate E in a large area by applying a laser cladding technology, solving the problem of cracks generated in the laser cladding process of the high-hardness wear-resistant nickel-based alloy, in particular the cladding defects, such as cracks with the thickness of more than 1mm, pores and the like during large-area cladding. According to the invention, the high-hardness nickel-based alloy powder material is cladded on the surface of the metal substrate in the large area to form a high-hardness wear-resistant anti-corrosion nickel-based alloy coating by applying the laser cladding technology and adopting a scientific and reasonable process method. According to the method disclosed by the invention, stability and consistency of laser cladding are foundationally ensured, defects, such as cracks, pores, impurities can be prevented from generating, heat affected regions of the substrate are reduced, dilution rate is reduced, the high-wear-resistance anticorrosion nickel-based alloy coating with firm metallurgical bonding and fine and compact grains is obtained and has the hardness reaching 58-63HRC, and the service life of the processed workpiece can be prolonged by more than 1-2 times.

Owner:NINGBO SIASUN ROBOT TECH CO LTD

Diamond-like thick film, preparation method of diamond-like thick film and work-piece

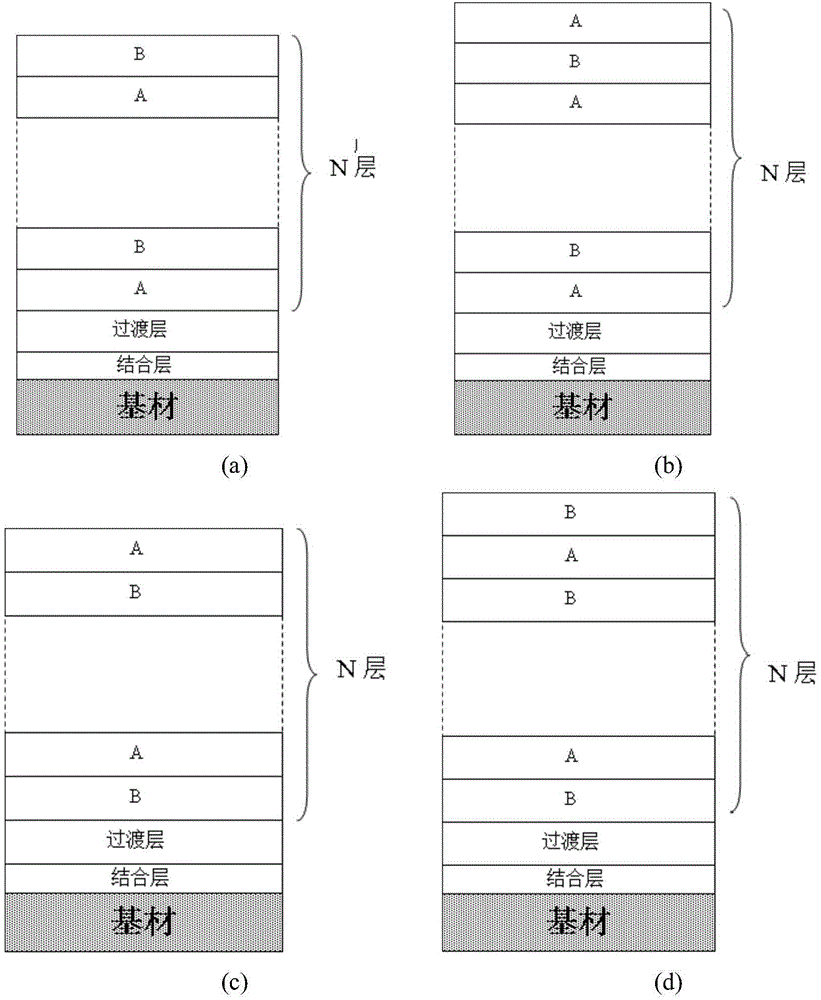

ActiveCN104630708AAvoid the problem of deterioration of mechanical propertiesReduce stressVacuum evaporation coatingSputtering coatingMechanical propertyTransition layer

The invention provides a diamond-like thick film. The diamond-like thick film comprises a binding layer, a transition layer and a diamond-like film layer, wherein the transition layer is compounded with the binding layer; the diamond-like film layer is compounded with the transition layer; and the diamond-like film layer is formed by overlapping diamond-like sub-films having different sp3 bond contents. According to the invention, the diamond-like film layer is formed by overlapping the diamond-like sub-films having different sp3 bond contents; additional hetero elements are not introduced; therefore, the difficulty that the mechanical property of the film layer is deteriorated due to doping of the hetero elements is effectively avoided; furthermore, by overlapping the diamond-like sub-films having different sp3 bond contents, the stress between the layers is greatly reduced; the binding force between the layers is higher; and thus, the layers cannot be separated.

Owner:CHONGQING UNIV

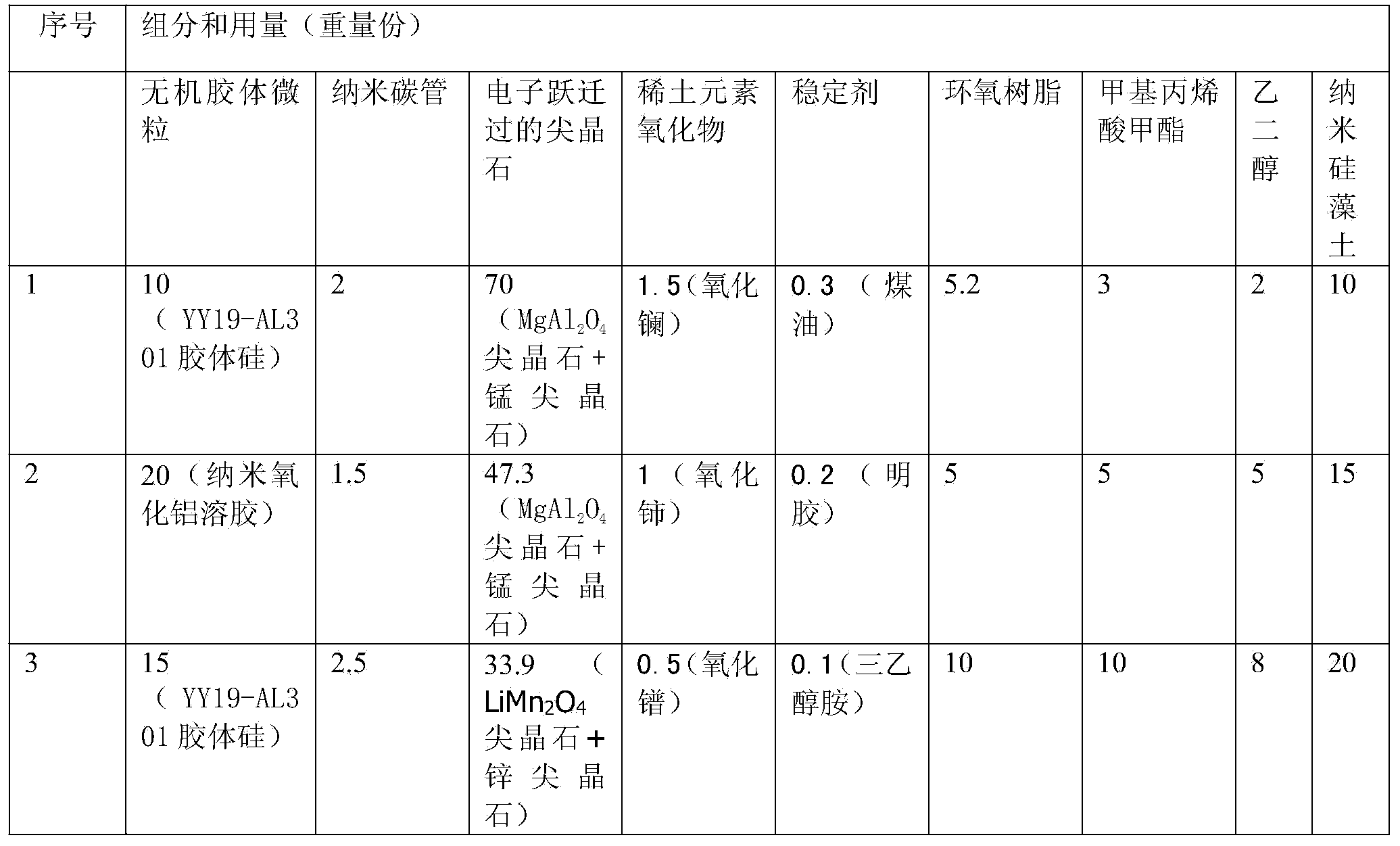

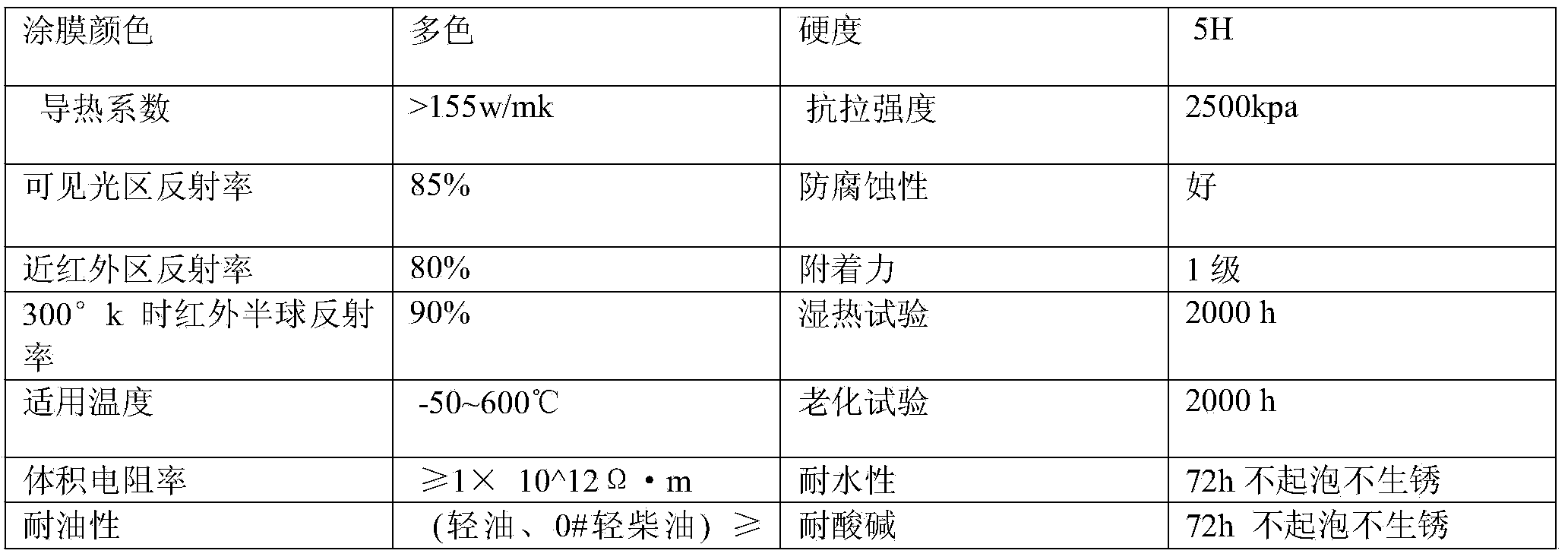

Coating for cooling surface of light-emitting diode (LED) radiator

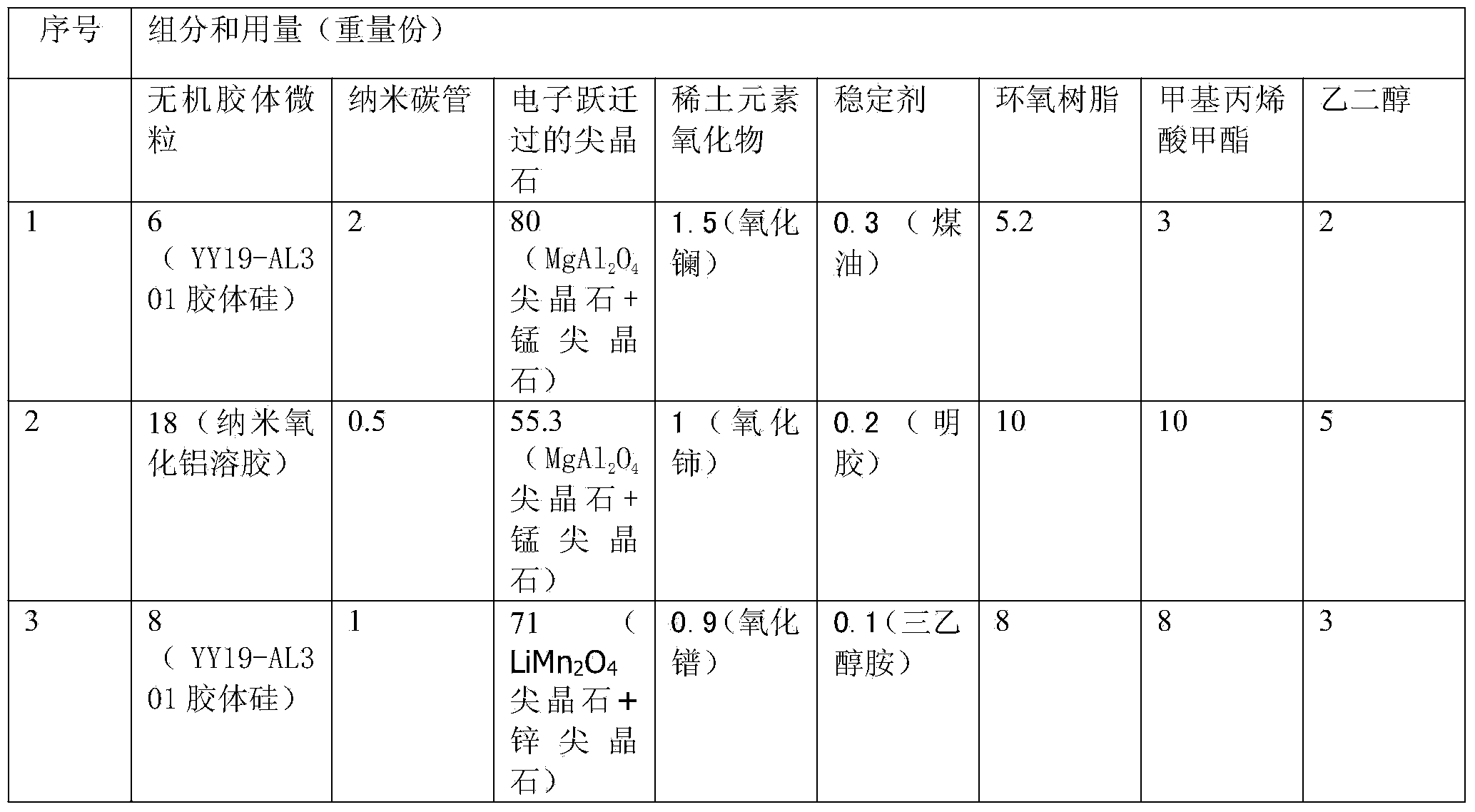

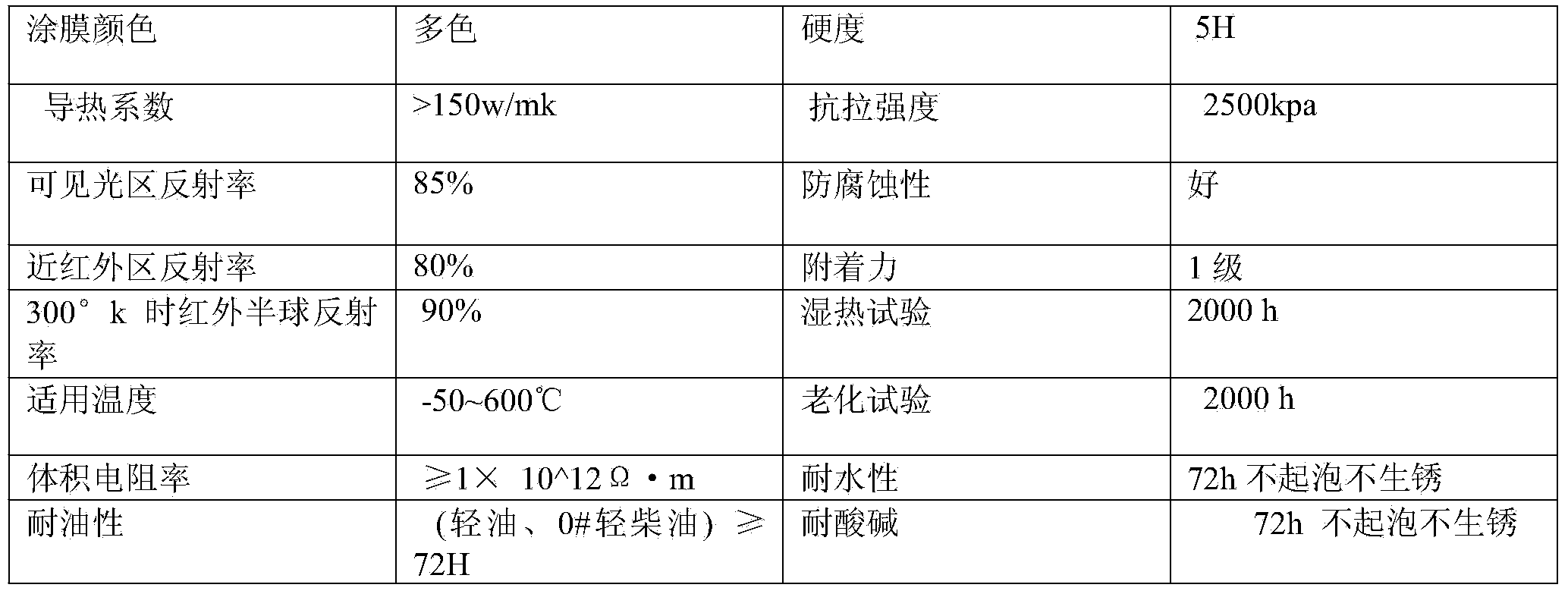

ActiveCN103965671AGood self-cleaningEasy constructionReflecting/signal paintsRare-earth elementCorrosion

The invention discloses a coating for cooling the surface of a light-emitting diode (LED) radiator. The coating is characterized by being prepared from the following components in parts by weight: 6-20 parts of inorganic colloidal particle, 0.5-2 parts of carbon nano-tube, 15-80 parts of electron transition spinel, 0.05-2 parts of rare-earth element oxide, 0.1-0.3 parts of stabilizer, 3-10 parts of epoxy resin, 3-10 parts of methyl methacrylate and 2-5 parts of ethylene glycol. The coating has obvious heat dissipating and cooling effects, is not affected by surrounding medium when taking the cooling effect, can be used in a vacuum environment, also has the advantages of good self-cleaning property, corrosion resistance, waterproofness, fire retardancy, insulativity, and acid and alkali resistance, and convenient construction when taking a radiation cooling effect.

Owner:NINGBO AISHI ELECTRIC EQUIP

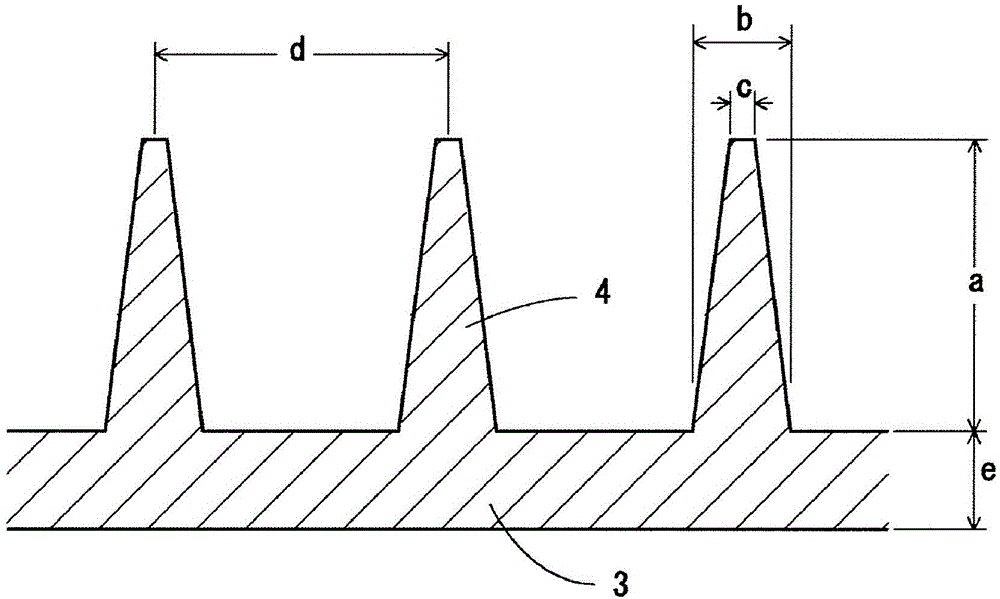

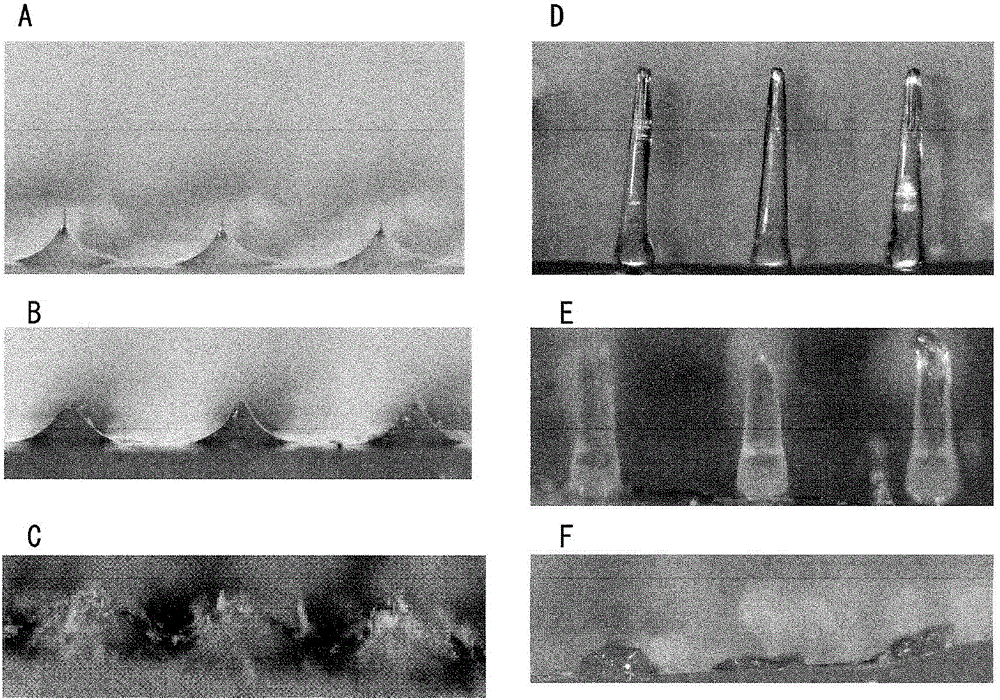

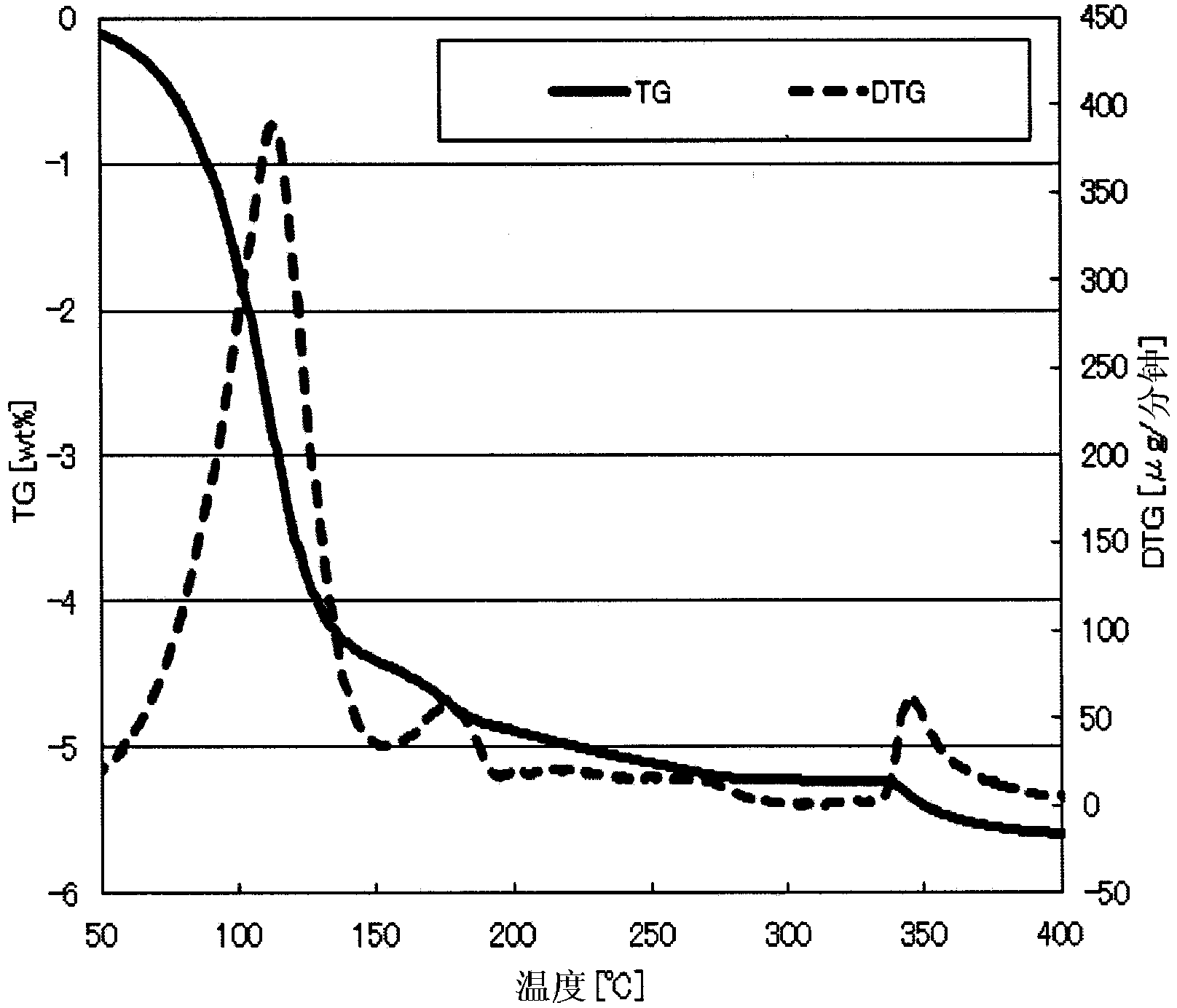

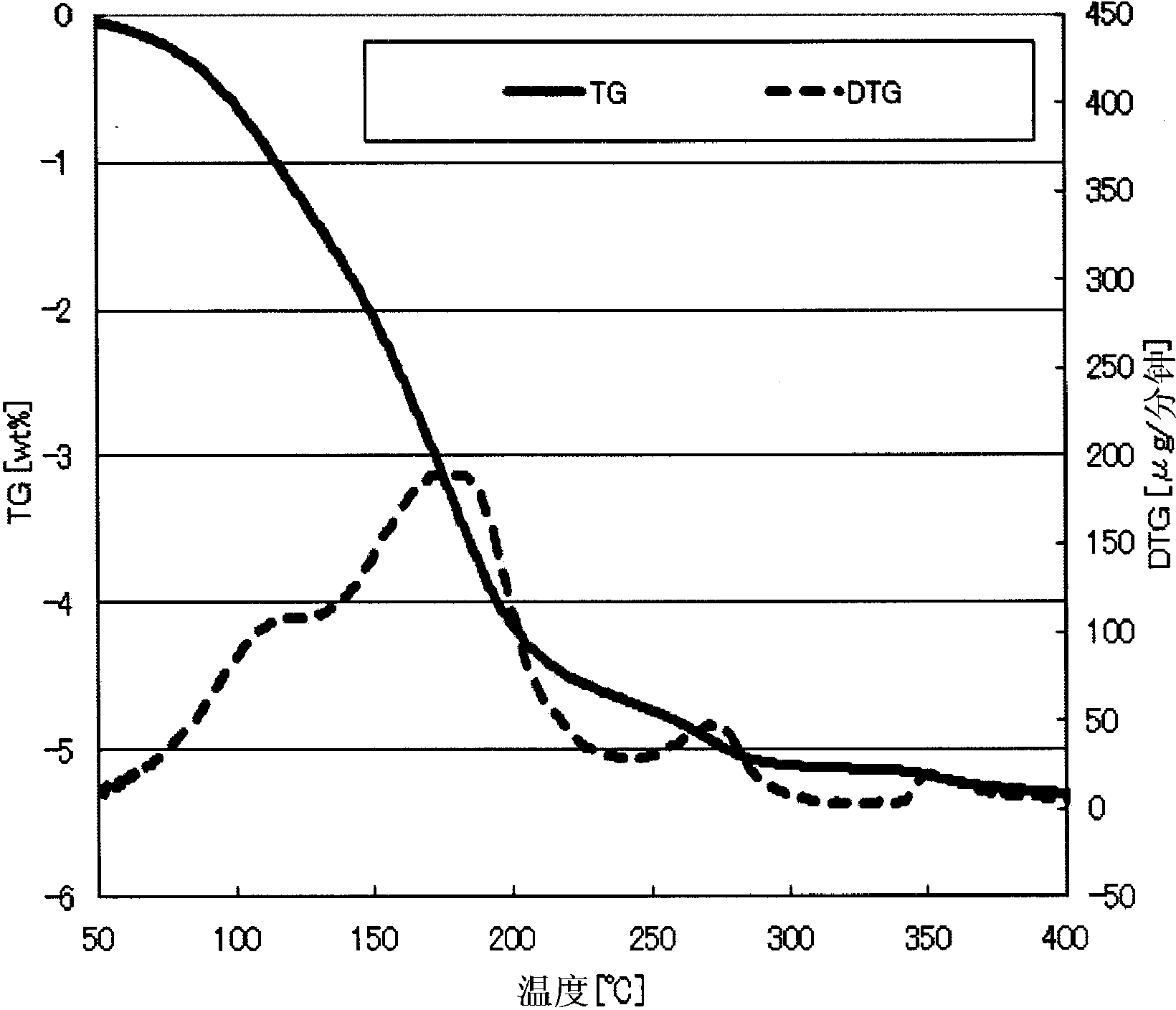

Microneedle of short-time dissolution type

ActiveCN104066475AShorten absorption timeReduce the burden onMicroneedlesSurgeryDissolutionSynthetic Polymeric Macromolecules

Provided is a microneedle material which dissolves in a short time and can be rapidly absorbed. Thus, the time required for microneedle application is shortened. As the microneedle material, use is made of a mixture of one or more water-soluble polymers and one or a plurality of saccharides selected from monosaccharides and disaccharides. Suitable for use as the water-soluble polymer(s) is a synthetic polymer, a protein, a polysaccharide, or a mixture of these. Suitable for use as the saccharides is any of glucose, fructose, sucrose, and lactose or a mixture of these.

Owner:COSMED PHARMA

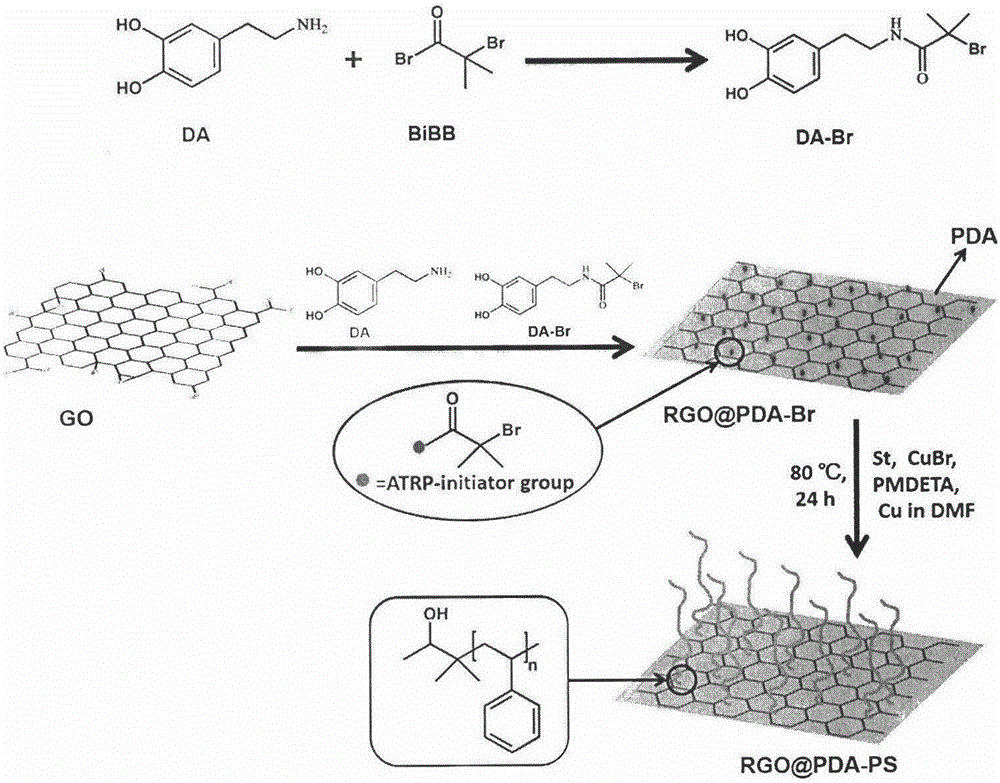

Novel method for modifying graphene with polymer

The invention discloses a novel method for modifying graphene with polymer. By introducing polydopamine and combining covalent modification with non-covalent modification, the method increases the stability of the modified product structure under the premise of ensuring the integrity of the graphene structure. Firstly, by utilizing the strong adhesion of dopamine, the dopamine is self-polymerized to form a film on the surface of a graphene sheet, moreover, 2-Bromo-2-methylpropionyl bromide (BiBB) as common initiator for atom transfer radical polymerization (ATRP) is grafted on the dopamine by amidation, at the same time, graphene oxide (GO) is partially reduced by the dopamine (DA), and thereby graphene macroinitiator RGO@PDA-Br is obtained. Polymeric monomer is then added, so that the ATRP of the polymeric monomer is initiated on the surface of the graphene, and thereby a polymer-modified graphene material is obtained. By controlling conditions such as monomer concentration and reaction time, the novel method can obtain modified graphene materials with different densities and chain lengths of polymer grafted on the surfaces, meeting the characteristics of controllable / living ATRP. In addition, the feasibility and universality of the novel method for modifying graphene with polymer put forward by the invention are applicable to various monomers suitable for ATRP.

Owner:JIANGNAN UNIV

Ultraviolet curing adhesive

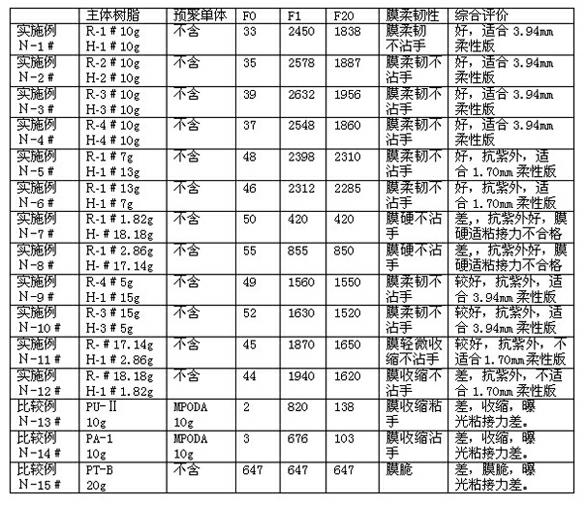

ActiveCN102079961ASolve the problem of unexposed initial tackHigh softening pointPolyureas/polyurethane adhesivesPhotosensitive materials for photomechanical apparatusAcrylic resinAdhesive

The invention discloses an ultraviolet curing adhesive comprising a resin main body, a dissolvent, an ultraviolet light initiator and an addition agent, wherein the resin main body is composed of a resin R and a resin H; the R resin is an active polyurethane acrylic resin with a main chain containing a polyether structure and a branch chain containing a vinyl optical active group as well as with a lower molecular weight; and the H resin is an inert polyurethane acrylic resin with a main chain containing a polydiene and aryloxide structure and with a relatively higher molecular weight. The adhesive contains no monomer or prepolymer, has high softening point, can be precoated on a base material, has super strong cohesive force on a high-oilness contact surface and has characteristics of high-temperature resistance, small internal stress and good flexibility.

Owner:LUCKY HUAGUANG GRAPHICS

Production processing method of colored crystal glass

ActiveCN102582300AStrong sense of hierarchyFull of abstractionOther printing apparatusPrinting inkEngineering

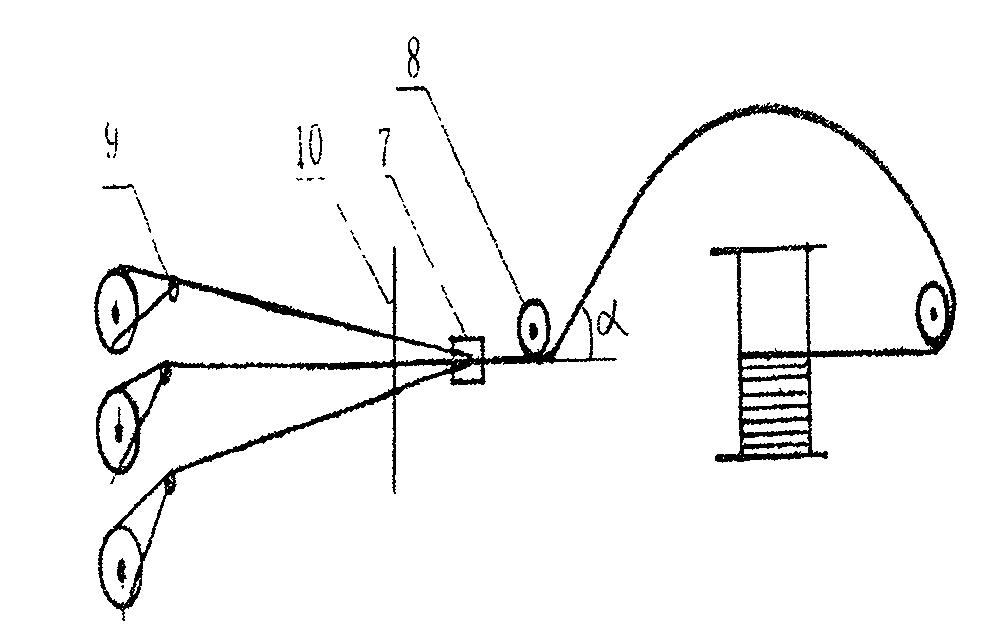

The invention discloses a production processing method of colored crystal glass, wherein the colored crystal glass is prepared by the steps of cutting, edge processing, high temperature colored crystal printing and low temperature colored crystal printing, a double-layer screen printing manner is utilized in the high temperature colored crystal printing procedure, the mesh number of a second screen layer is more than that of a first screen layer, an included angle alpha of a radial line of the first screen layer and a radial line of the second screen layer is more than 0 degree and less than 900 degrees, a high temperature printing ink layer is fully merged in a glass substrate after the colored crystal glass is dried twice and tempered twice, so that the patterns have strong stereoscopic impression and stereovision, and sufficient abstract feeling, and look noble, elegant and upscale; besides, the printing ink is firmly combined with the glass substrate, so that the printing ink cannot be stripped by a cleaning cloth or other acidic and alkaline substances if being used as a refrigerator door panel. The back surface of the glass is processed by low temperature printing ink printing, thereby the procedures are fewer, the processing technique is simple, and the cost is low.

Owner:焦作飞鸿安全玻璃有限公司

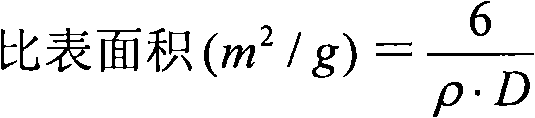

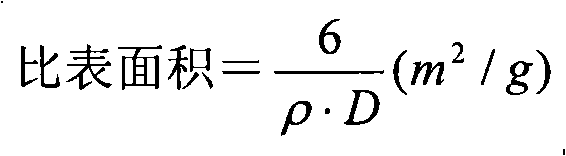

Grinding roller manufacturing/remanufacturing abrasion-resistant material and preparation method thereof

InactiveCN106238709AWide adjustment of hardnessWidth adjustment toughnessFurnace typesWelding/cutting media/materialsCouplingBoron containing

The invention discloses a grinding roller manufacturing / remanufacturing abrasion-resistant material and a preparation method thereof. A grinding roller is formed by a core roller body, a substrate abrasion-resistant layer, a transition layer and a roller face abrasion-resistant shape layer in a coupling mode. A core material is provided with the highly-abrasion-resistant modified boron-containing high-chromium cast iron substrate abrasion-resistant layer through casting and compounding. The substrate abrasion-resistant layer comprises, by mass, 1.75%-3.0% of C, 12.0%-18.0% of Cr, 0.2%-2.0% of B, 0.4%-0.8% of Mn, 0.4%-1.2% of Si, 0.30%-0.80% of Ni, 0.02%-0.04% of Mg, 0.03%-0.05% of Ce, 0.05%-0.10% of Ti, 0.006%-0.015% of N, 0-0.04% of S, 0-0.04% of P, and the balance Fe. Then surfacing of materials of the roller face abrasion-resistant shape layer is conducted on the surface of the transition layer. The roller face abrasion-resistant shape layer is formed by flux-cored wires through surfacing. The flux-cored wires comprises, by mass, 2.3%-3.5% of C, 14.0%-26.0% of Cr, 1.5%-2.0% of Ni, 0.8%-2.0% of Nb, 1.3%-2.0% of Mo, 1.2%-2.3% of Si, 1.0%-1.7% of Ti, 0.3%-1.0% of V, 0.2%-1.5% of B, 0-<0.007% of S, 0-0. 015% of P, and the balance Fe.

Owner:镇江富华轧辊有限公司

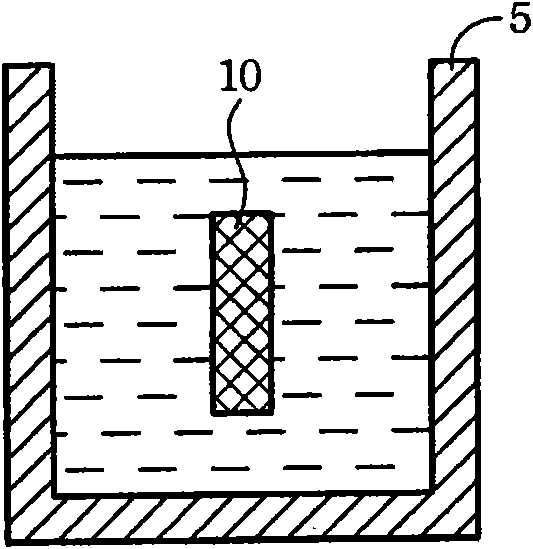

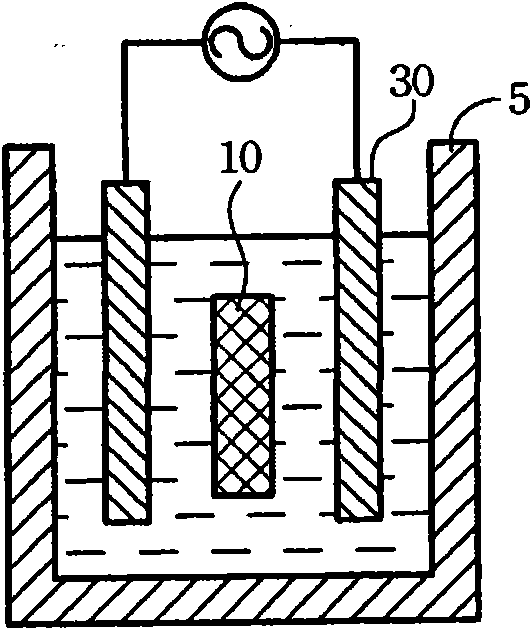

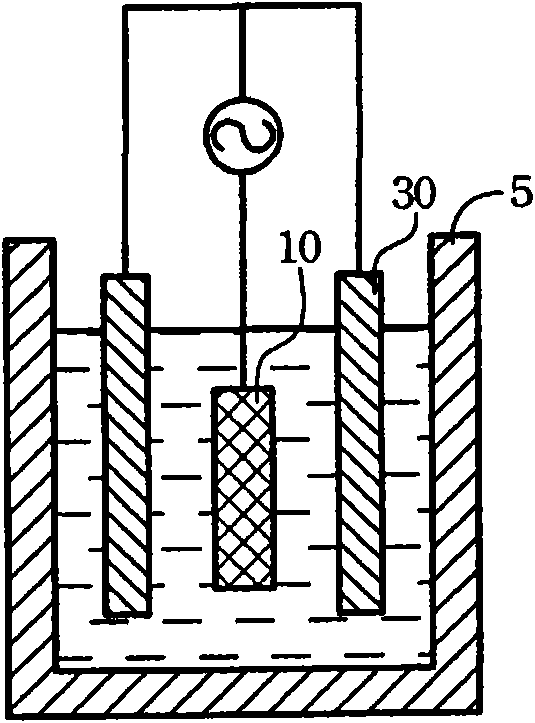

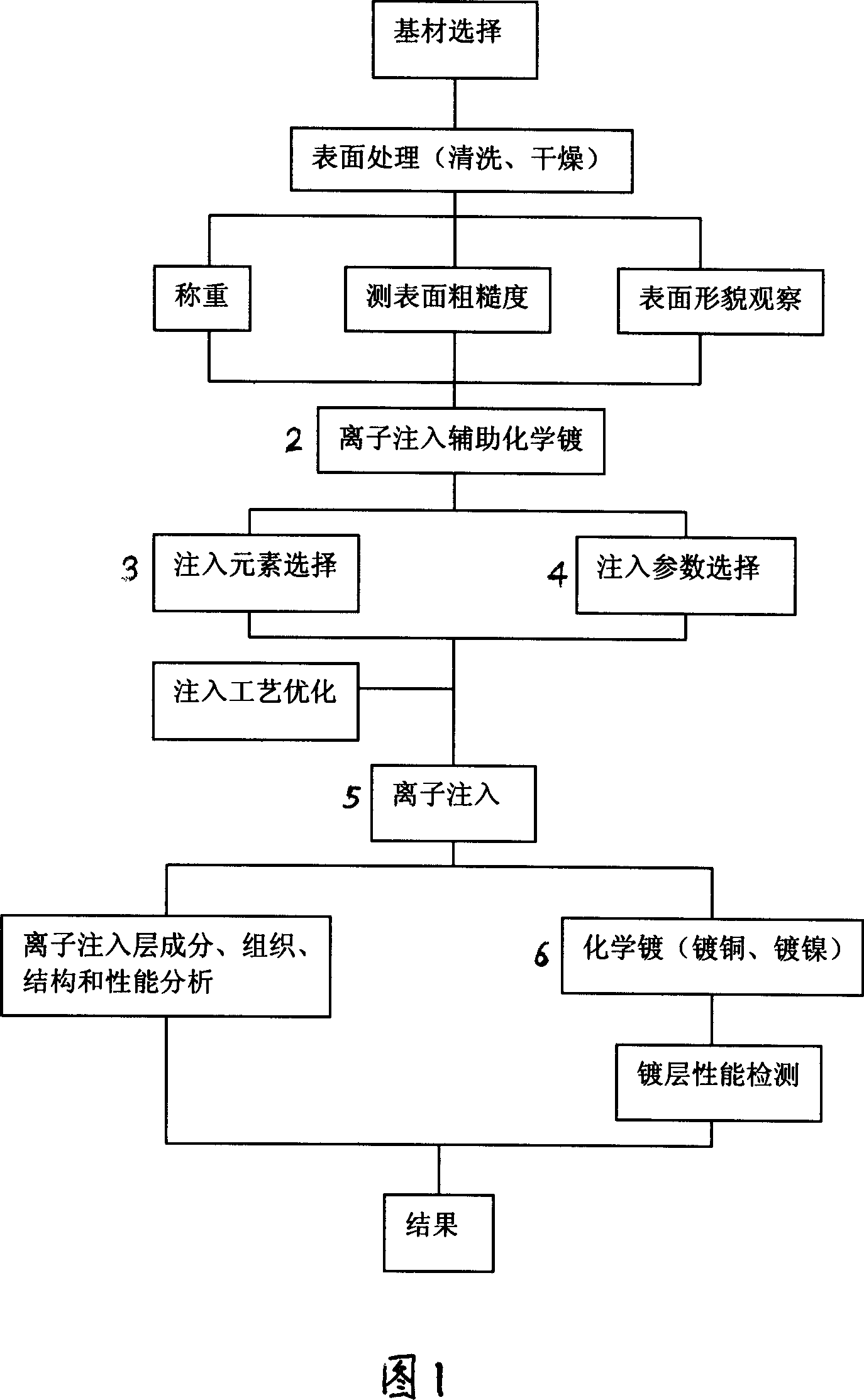

Ion implantation of cupper, nickel as pretreatment technique for electroless copper on surface of ceramics

This invention discloses a method for ion implantation of Cu, Ni or Fe as pretreatment process for chemical deposition on ceramic surface. The method comprises: cleaning ceramic surface, placing cleaned in an ion implantation apparatus, vacuumizing, cleaning the workpiece by gas sputtering, performing ion implantation by using Cu, Ni or Fe at an amount of 0.2*10e17-4.2*10e17 ions / cm2 and an energy of 6-30 keV, and placing the implanted ceramic in chemical deposition solution for chemical plating of Cu, Ni or Fe. This invention combines ion implantation and chemical deposition, and utilizes ion implantation to form a layer of metal identical to that to be deposited. Therefore, the formed deposition layer has such advantages as high uniformity, low porosity, good appearance, and high adhesiveness with the matrix. The method has such advantages as simple process, no secondary pollution, no need for implantation of noble metals, and high deposition efficiency.

Owner:CHINA UNIV OF MINING & TECH

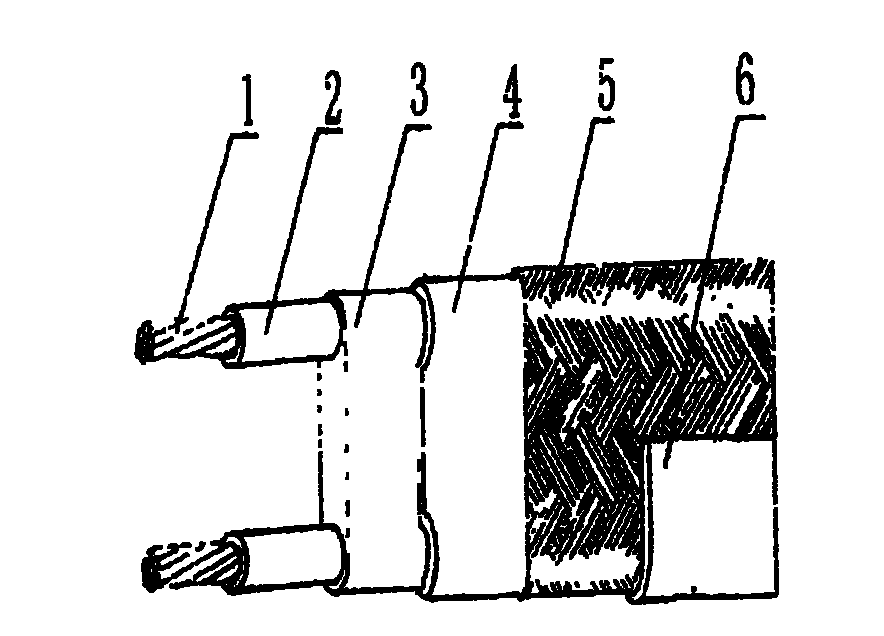

Self-temperature limiting heat tracing belt with dual-layer resin conductor and manufacturing method thereof

InactiveCN101977452AImprove interface contact resistanceExtend your lifeOhmic-resistance electrodesHeating element shapesUltrasound attenuationInsulation layer

The invention relates to a self-temperature limiting heat tracing belt with a dual-layer resin conductor and a manufacturing method thereof. The self-temperature limiting heat tracing belt is characterized by comprising a metal conductive electrode, a resin conductor layer, a heating element and an insulation layer. A shielding layer or a sheath can also be arranged outside the insulation layer. In the invention, the formulas of the resin conductor layer and the heating element are improved, and through the implementation of the technical scheme of the invention, and the problems existing in the aspects that the power attenuation of the traditional heat tracing belt is serious, the starting current of the traditional heat tracing belt becomes big, the heat tracing belt is burnt out frequently, the performance is not stable and the like can be well solved. The invention greatly improves the performance of the heat tracing belt, has the advantages of small starting current and high heat tracing belt temperature and is suitable for the industrial application.

Owner:王崇

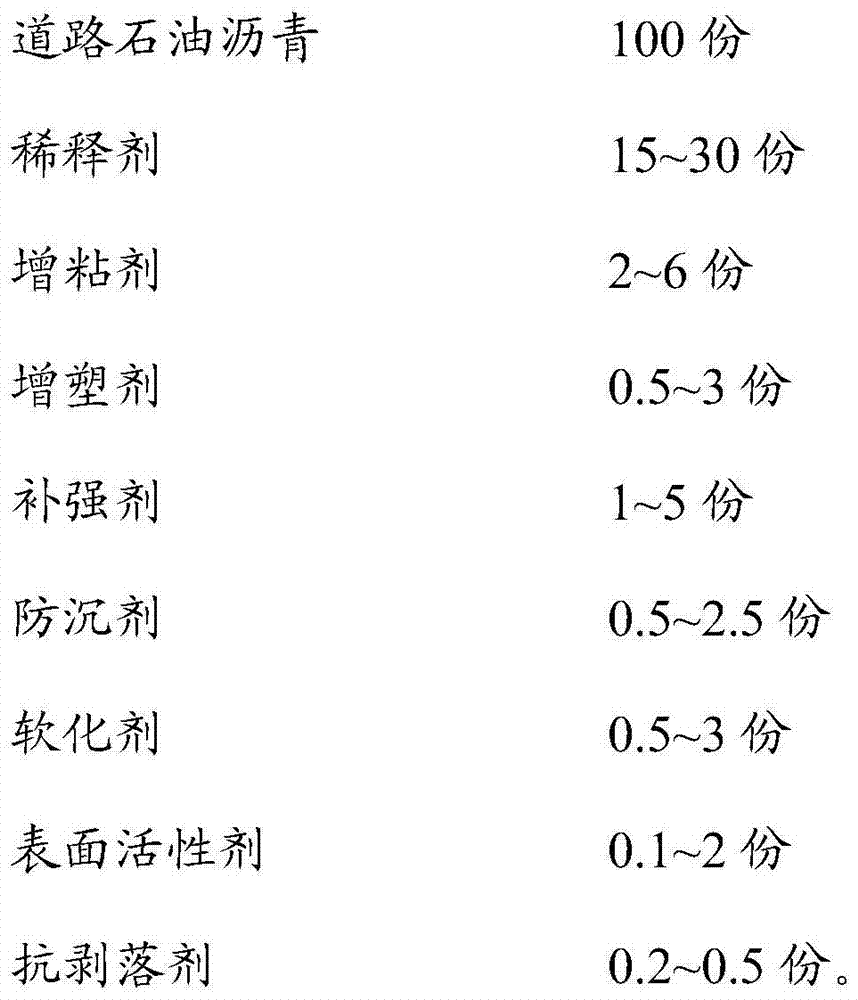

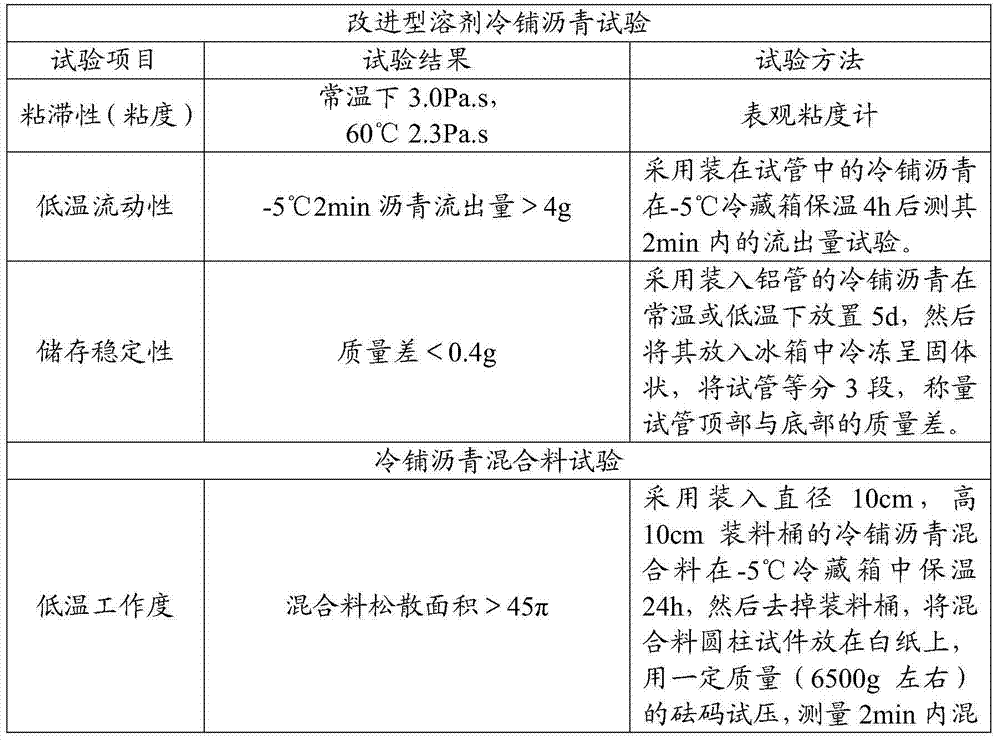

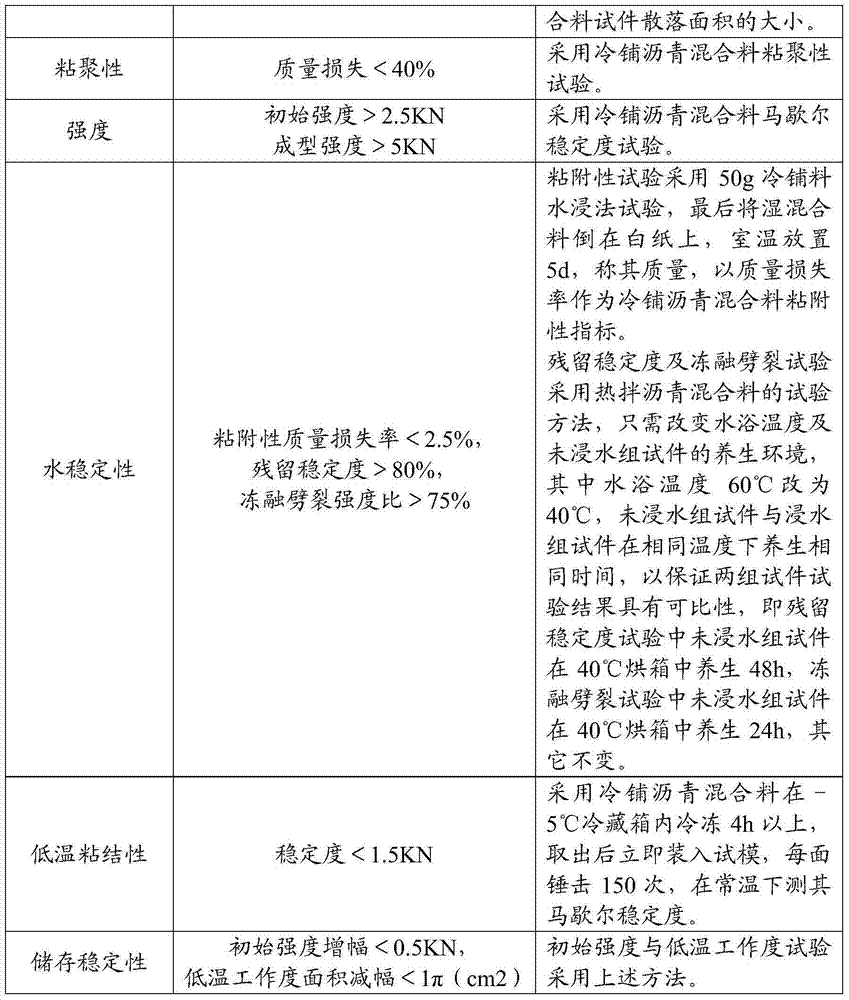

Improved solvent cold laid asphalt as well as preparation process and using method thereof

InactiveCN103923475AImprove adhesionImprove liquidityIn situ pavingsBuilding insulationsLiquid stateEngineering

The invention discloses an improved solvent cold laid asphalt as well as a preparation process and using method thereof. The improved solvent cold laid asphalt is at a liquid state under normal temperature or low temperature; cold oil and cold materials can be directly blended for construction on the spot without heating, and the construction can be carried out at high / low temperature seasons and rain / snow weather, and a large number of machinery and labor are not required in the construction process, the construction is simple and convenient and the repair effect is good; traffic can be immediately opened after repair without affecting the travel of people; the improved solvent cold laid asphalt is usually used for daily maintenance, such as pot slot repair and emergency repair; meanwhile, the improved solvent cold laid asphalt has the advantages of no deterioration, no layering and the like after being stored for a long time.

Owner:CHANGAN UNIV

Paint with strong adhesion for cooling surface for LED (light emitting diode) radiator

ActiveCN103965672AImprove self-cleaningImprove anti-corrosion performanceReflecting/signal paintsRare-earth elementEpoxy

The invention discloses paint with strong adhesion for cooling the surface for an LED (light emitting diode) radiator. The paint is characterized by being prepared from the following components in parts by weight: 10-25 parts of inorganic colloidal particles, 1-3 parts of carbon nano-tube, 25-90 parts of electron transited spinel, 0.05-1.5 parts of rare earth oxide, 0.1-0.5 part of a stabilizing agent, 3-15 parts of epoxy resin, 2-10 parts of methyl methacrylate, 10-25 parts of nano- diatomite and 2-10 parts of ethylene glycol. The paint has remarkable heat dissipating and cooling effects, is not influenced by peripheral media, can be used in a vacuum environment, plays a role in radiating and cooling, and has the advantages of good self-cleaning performance, corrosion resistance, water resistance, flame retardance, insulating performance and acid-alkali resistance, and is convenient to construct.

Owner:NINGBO AISHI ELECTRIC EQUIP

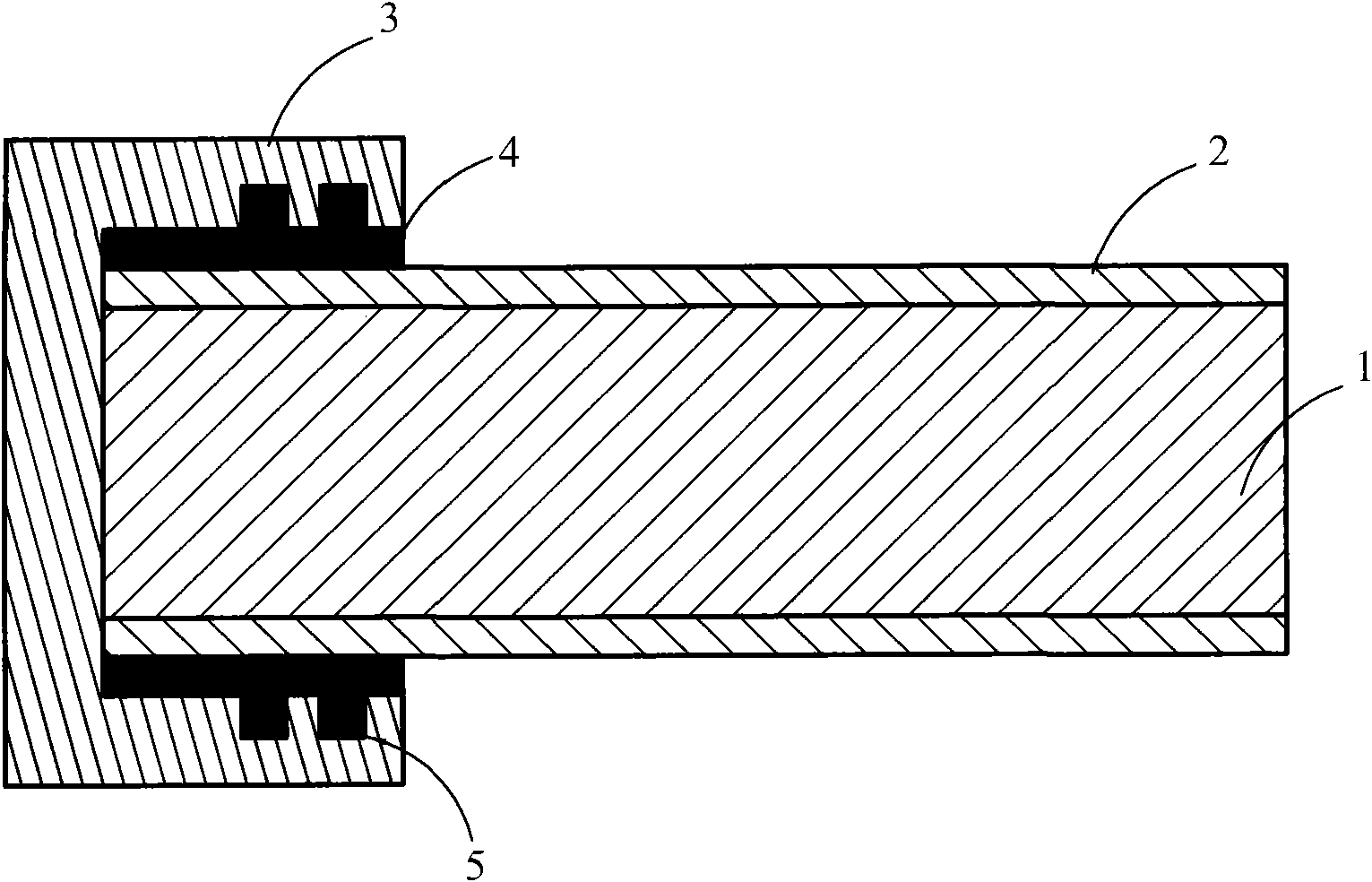

Composite insulator

The invention discloses a composite insulator. The composite insulator comprises a core rod, a sheath and a connecting piece, wherein the sheath is coated on the outer side of the core rod; the connecting piece is connected with the core rod and the sheath; the sheath is made of high-temperature vulcanized silicon rubber; the connecting piece comprises a body and a bump which is arranged by surrounding the outer wall of the body; the body comprises at least one wedged groove which is circularly arranged on the outer wall of the body; and the sheath is coated on the outer walls of the bump andthe wedged groove. In the composite insulator, room-temperature vulcanized silicon rubber is not used as a sealant, and the high-temperature vulcanized silicon rubber is adopted. Since the high-temperature vulcanized silicon rubber is aging-resistant, the sealing effect of the composite insulator is difficult to damage by erosion of an external environment when the composite insulator is exposed outdoors and even in certain severe environments. Meanwhile, the sheath cannot be stripped off from encapsulated rubber on a hardware tool and the core rod by an external force factor produced during transportation, mounting and maintenance by using the buckling effect of the bump and the wedged groove on the sheath, so that the sealing failure cannot be caused.

Owner:JIANGSU SHENMA ELECTRIC CO LTD

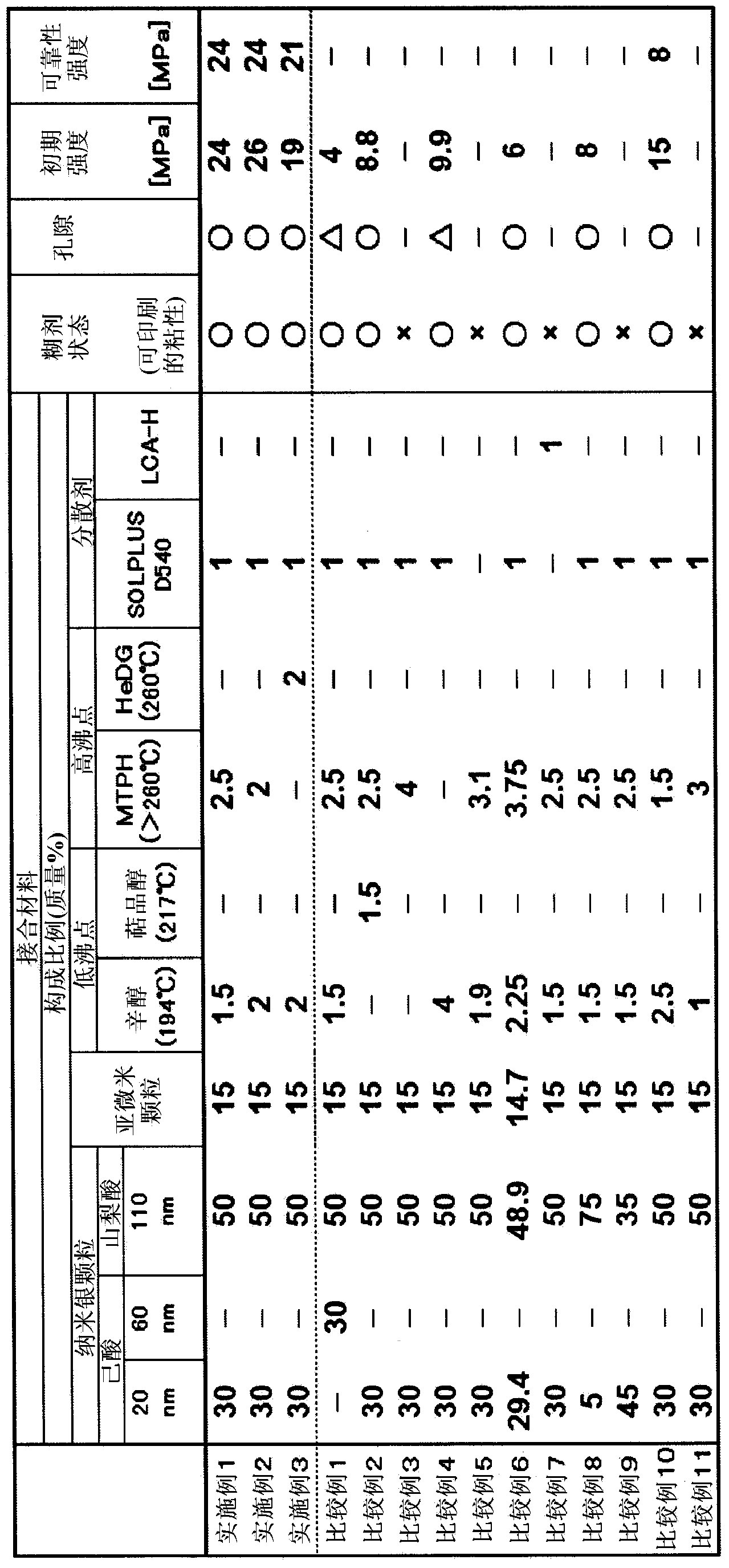

Bonding material and bonding method in which said bonding material is used

InactiveCN104066534AImprove reliabilityIncrease contentTransportation and packagingWelding/cutting media/materialsIn planeCarbon number

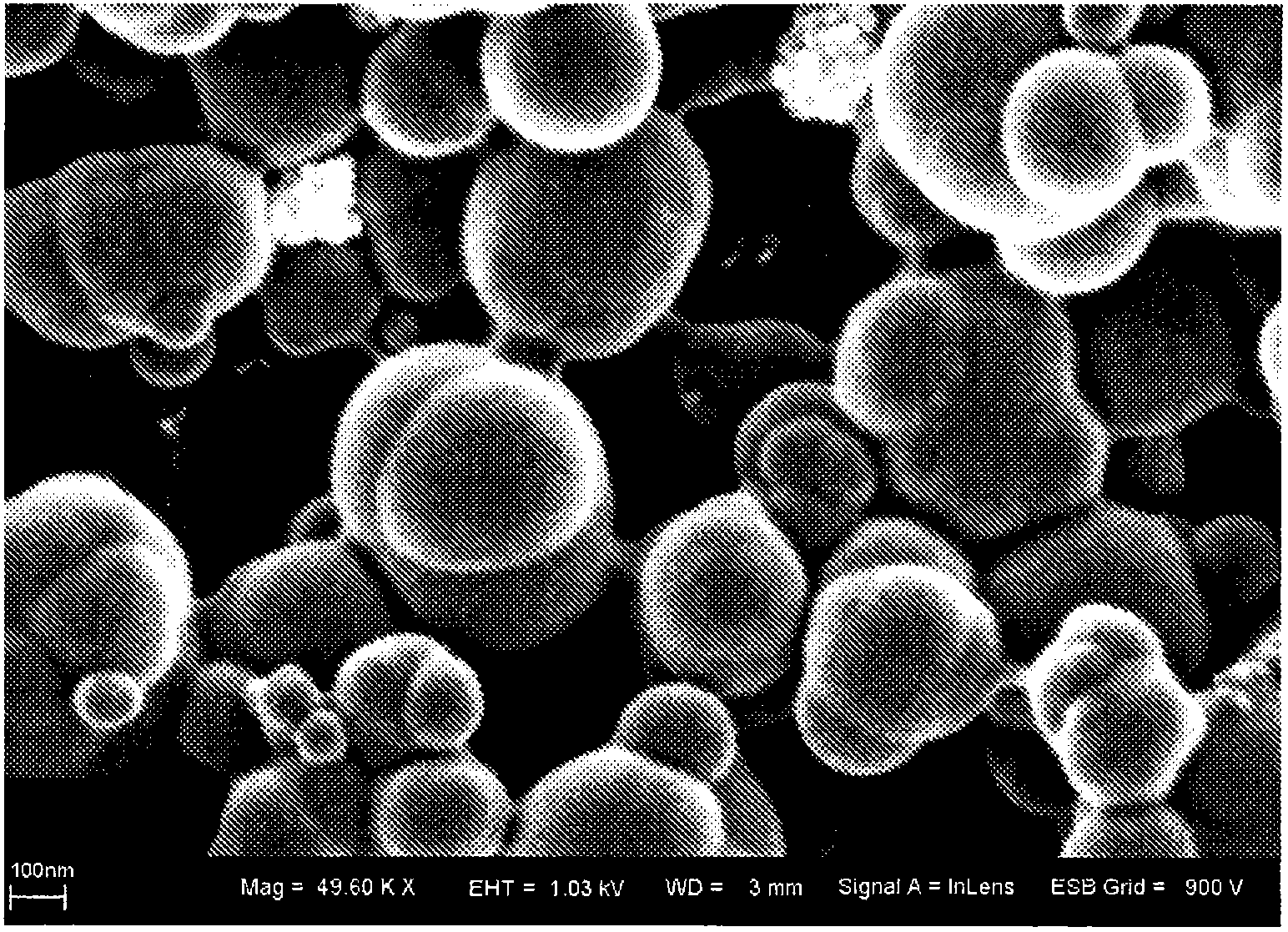

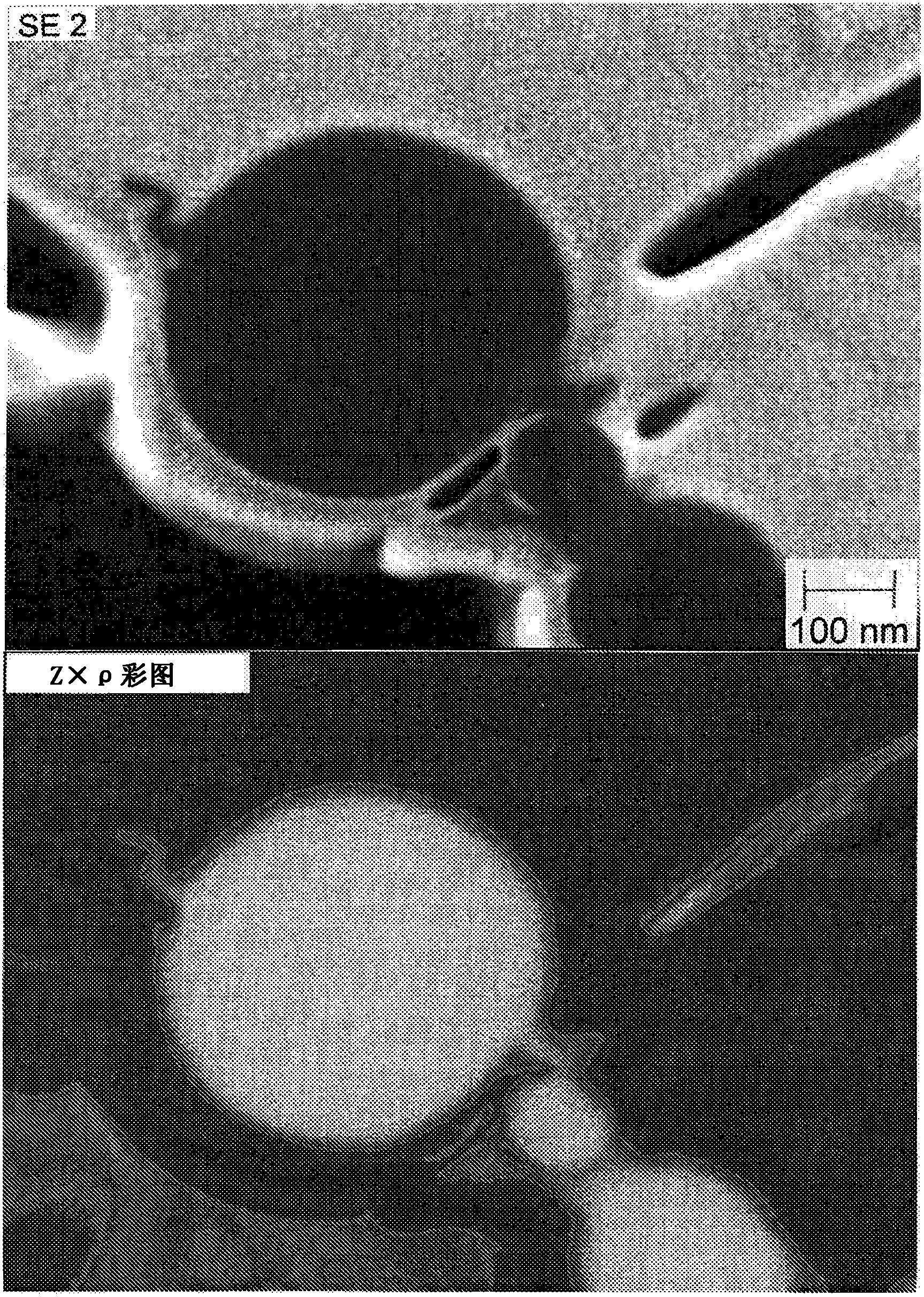

The purpose of the present invention is to enable highly-reliable bonding of bonding surfaces to be carried out such that the occurrence of uneven drying at the center and ends of the bonding surfaces, which occurs in-plane on a bonding layer in a desolvation process of a preliminary drying step, is reduced, thereby ensuring that the bonding surfaces do not detach even if repeatedly exposed to heat shock after bonding. This bonding material, which solves the aforementioned problem, is characterized by being covered by organic matter with a carbon number of six or less, comprising main silver particles, and covered by organic matter with a carbon number of six or less, comprising nano silver particles having an average primary particle size of 10 to 30 nm, and sub silver particles. The bonding material is further characterized by containing nano silver particles with an average primary diameter of 100 to 200 nm, two types of solvents with different boiling points, and a dispersant.

Owner:DOWA ELECTRONICS MATERIALS CO LTD

Aluminum-silicon-zinc-rare earth-magnesium-ferrum-containing hot dip coating alloy and method for preparing same

ActiveCN101736217AUniform compositionImprove toughnessHot-dipping/immersion processesRare-earth elementDip-coating

The invention relates to hot dip coating alloy specially used for surface coatings of titanium alloy parts. The hot dip coating alloy consists of aluminum, silicon, zinc, rare earth elements, magnesium, ferrum and reinforcing agent of particles of nano oxides, and based on the total weight of the alloy, the alloy comprises 8 to 24 percent of silicon, 1.2 to 3.1 percent of zinc, 0.02 to 0.5 percent of rare earth elements, 0.5 to 3.2 percent of magnesium, 0.05 to 1 percent of ferrum, 1 to 2 percent of reinforcing agent of particles of nano oxides, and the balance of aluminum and inevitable impurities, wherein the reinforcing agent of the particles of the nano oxides may be one or two of TiO2 and CeO2. The hot dip coating alloy produced by the method can form a coating with good corrosion resistance and wearing resistance and good metallurgical bonding property with a matrix on the surface of the titanium alloy.

Owner:JIANGSU LINLONG NEW MATERIALS

Environmental protecting multifunctional coating and its preparing method

InactiveCN101544855AImprove brittlenessImprove heat resistanceElectrically-conductive paintsMaterials scienceMetal

The invention relates to an environmental protecting multifunctional coating and its preparing method, which employs organic-inorganic composite raw charge with the weight percentage: organosilicon resin 10-15%, silicasol 20-25%, silver oxide 40-45%, cupric oxide 1-3%, bengala 1-5%, nickel oxide 1-3%, filling agent 20-25%, dispersants 0.05-0.10%, thickening agents 0.05-0.10%, wedding agent 0.05-0.10% and foam killer 0.05-0.10%, and obtains products after proportioning, commingle, milling, mixing round and natural drying. This invention is widely used at the surface of metal, inorganic metal(such as glass, ceramic) materials to have the function of heat resisting and electric conduction with easy preparing pressure, easy-controlled, dispensing with calcining technology, energy-saving. environmental-protecting, high temperature of heat resisting, low cost of manufacture and good product performance.

Owner:JINGDEZHEN CERAMIC INSTITUTE

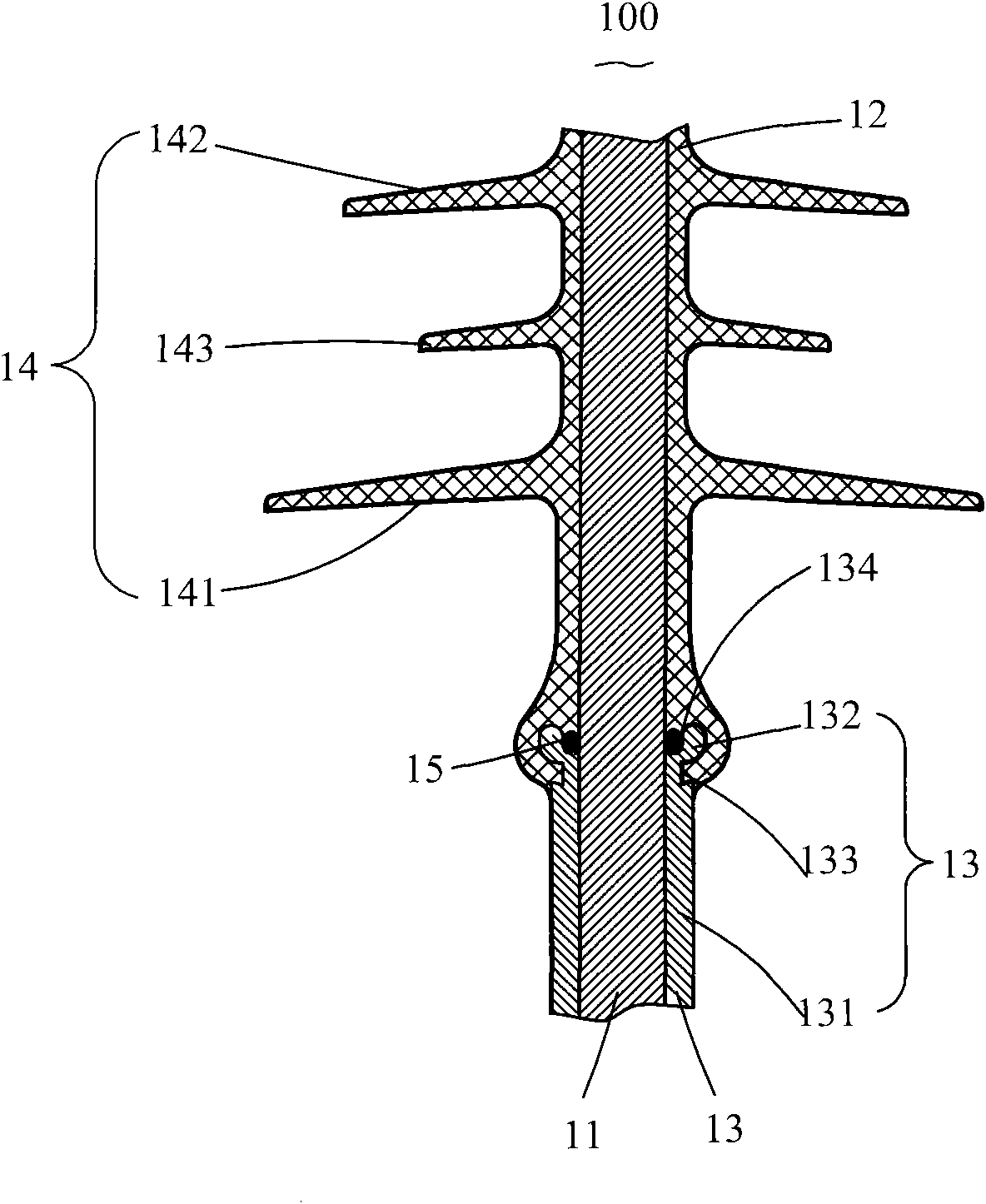

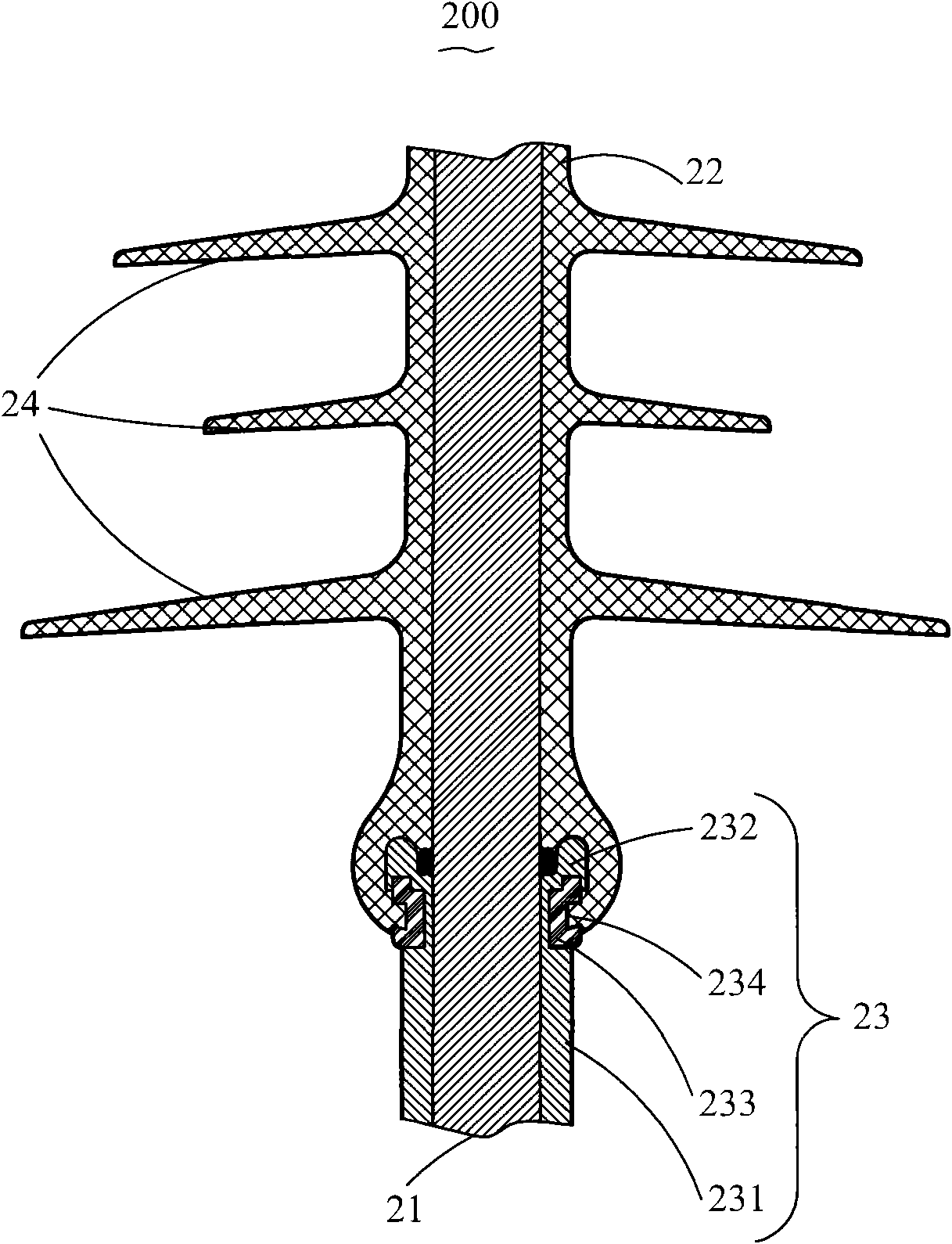

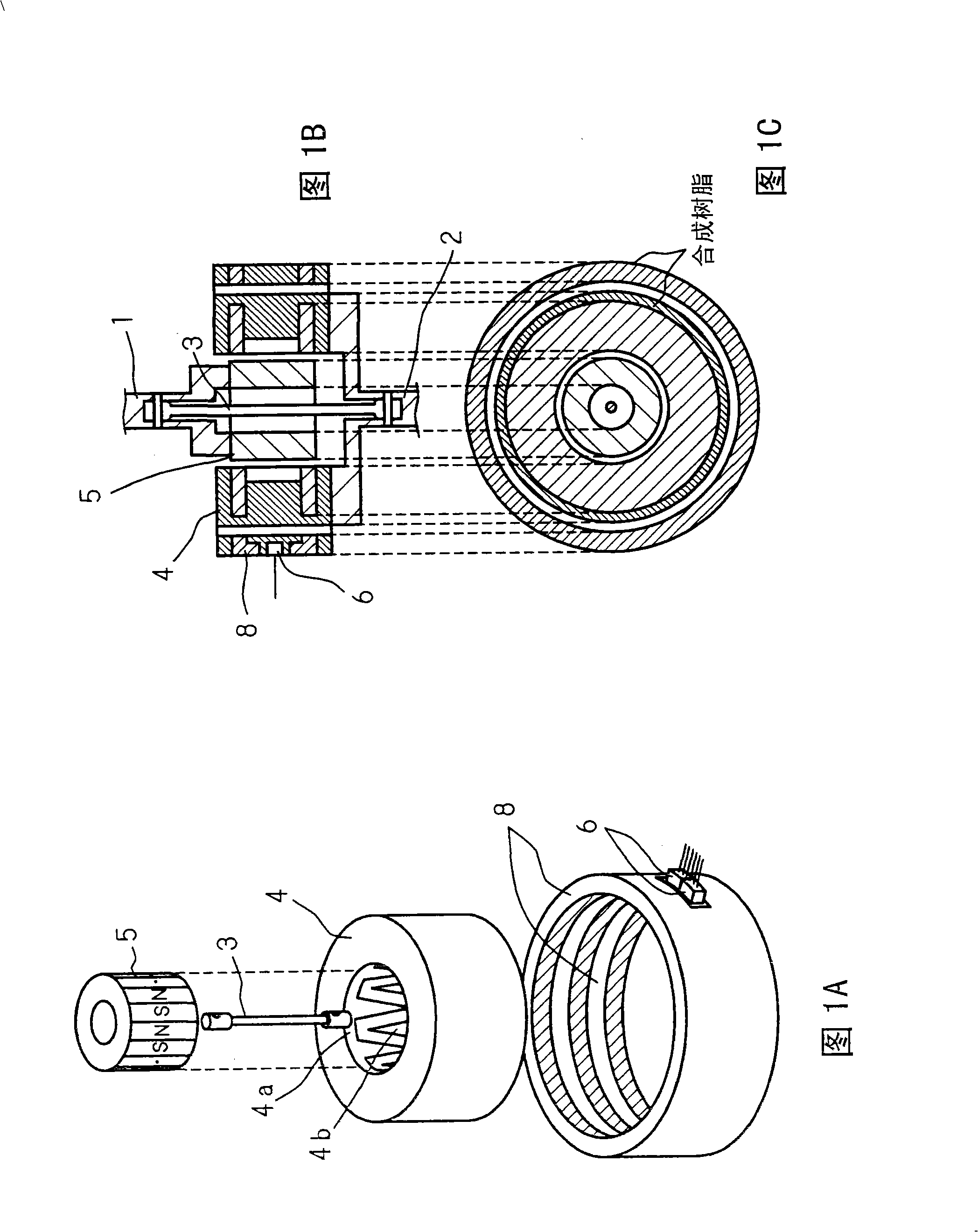

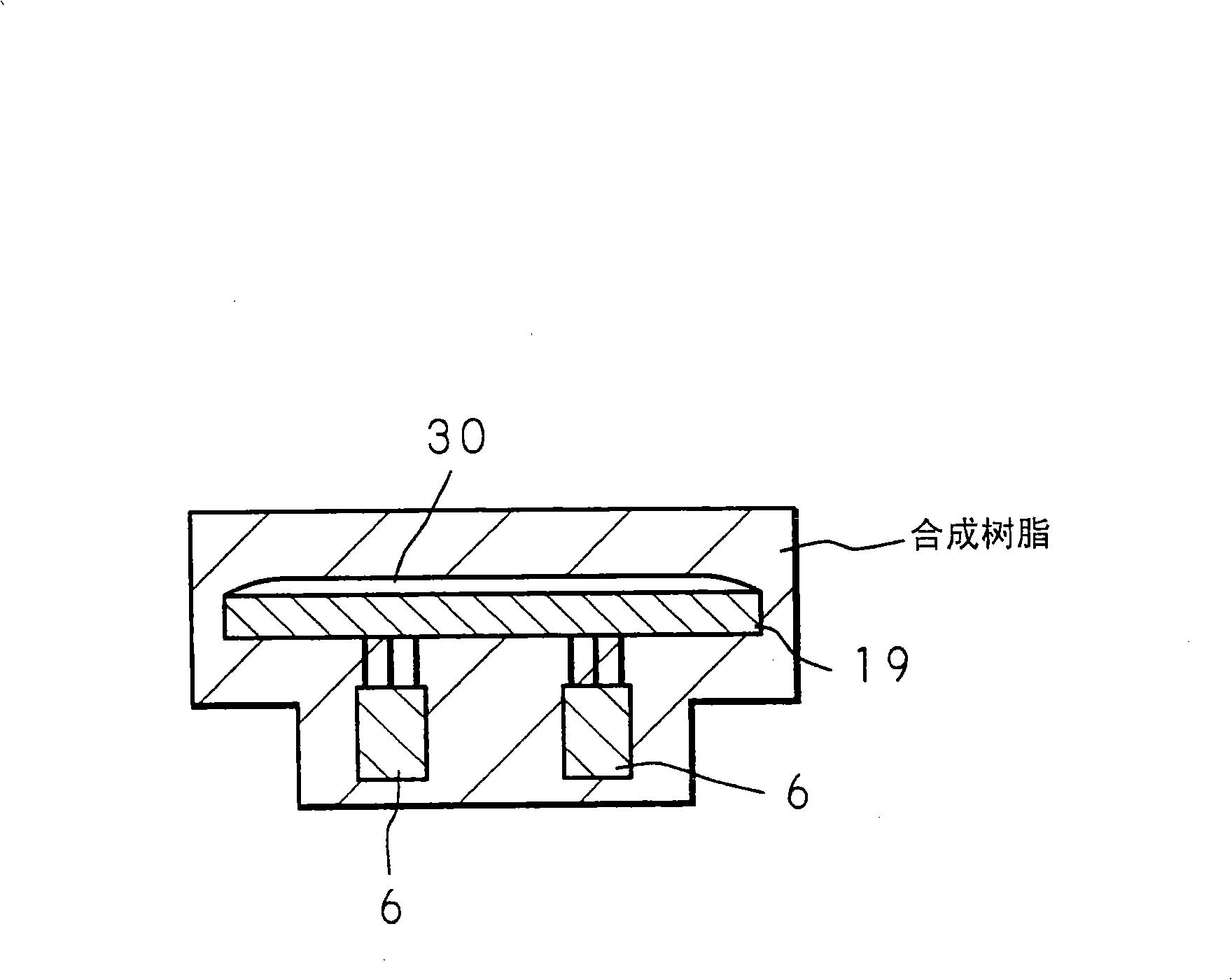

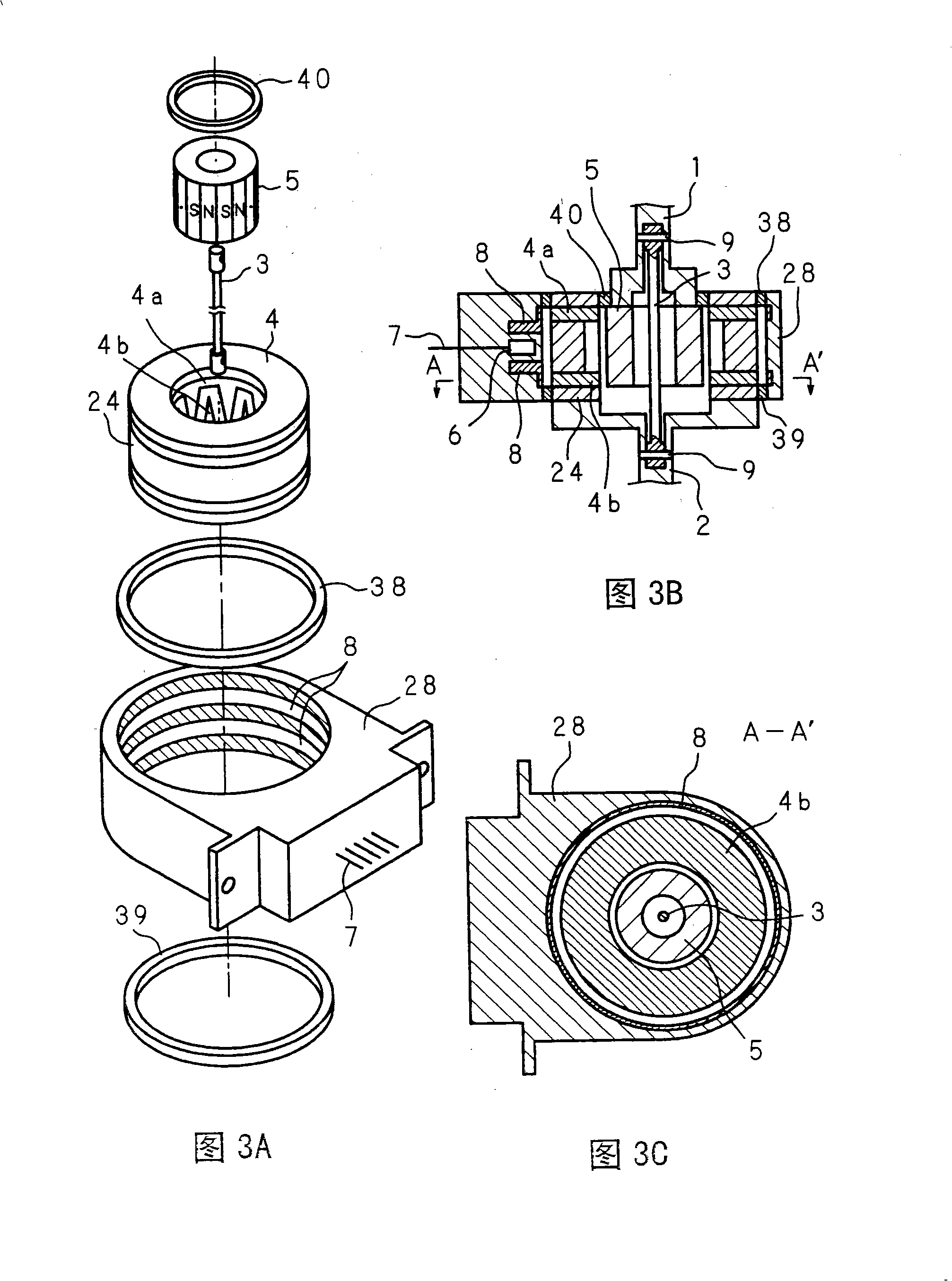

Torque detecting apparatus and electric power steering apparatus

InactiveCN101334324AWon't peel offEnsure tightnessWork measurementElectrical steeringElectric power steeringNon magnetic

The invention provides torque detecting apparatus and electric power steering apparatus. The torque detecting apparatus comprises a first shaft and a second shaft connected coaxially to each other through a connecting shaft, a permanent magnet fixed to the first shaft, a plurality of soft magnetic members having a collar provided therein, fitted by pressing with the second shaft and disposed in a magnetic field of the permanent magnet to form a magnetic circuit, and a detector for detecting magnetic flux generated from the soft magnetic members, wherein the soft magnetic members are integrally molded with a mold body made of synthetic resin, and when a torque is applied to the first shaft or the second shaft, the torque is detected based on an output of the detector. The collar is made of a non-magnetic material.

Owner:JTEKT CORP +1

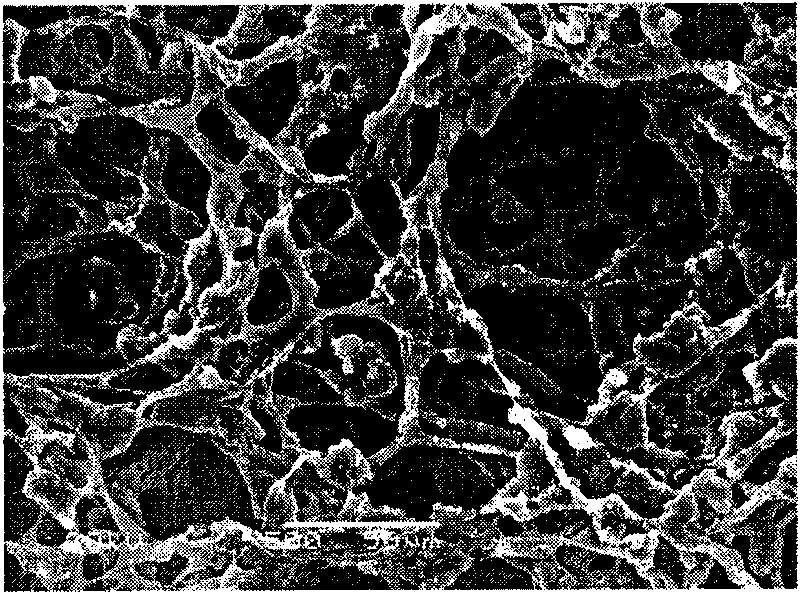

Medical degradable polyester asymmetric membrane and preparation method thereof

The invention discloses a medical degradable polyester asymmetric membrane and a preparation method thereof. The asymmetric membrane uses degradable polyester as a membrane material, one surface of the asymmetric membrane is a compact layer, the other surface of the asymmetric membrane is a porous layer, the compact layer and the porous layer are molded integrally once, the aperture of micropores in the compact layer is 0.5 to 5 mu m, the aperture in the porous layer is 50 to 600 mu m, and the pores are intercommunicated. The preparation method for the asymmetric membrane mainly comprises the following steps: dissolving polymers such as PLA and the like into solvents such as methylene dichloride and the like to prepare solution, adding a powdery pore-forming agent into the polymer solution, stirring, fully mixing and defoaming the solution and then pouring the solution into a die, then soaking the die into neutral or acid distilled water at the temperature of between 4 and 100 DEG C to perform membrane forming, removing the die in water and taking the formed membrane out, flushing the formed membrane by running water or / and soaking the formed membrane into running water to remove residual inorganic salt, and drying the formed membrane to obtain the medical degradable polyester asymmetric membrane. The asymmetric membrane provided by the invention has the characteristics of biodegradability and adjustable performance such as degrading rate, thickness, aperture, pore communication, tensile strength and the like.

Owner:CHENGDU MAIDIMEI SCI & TECH

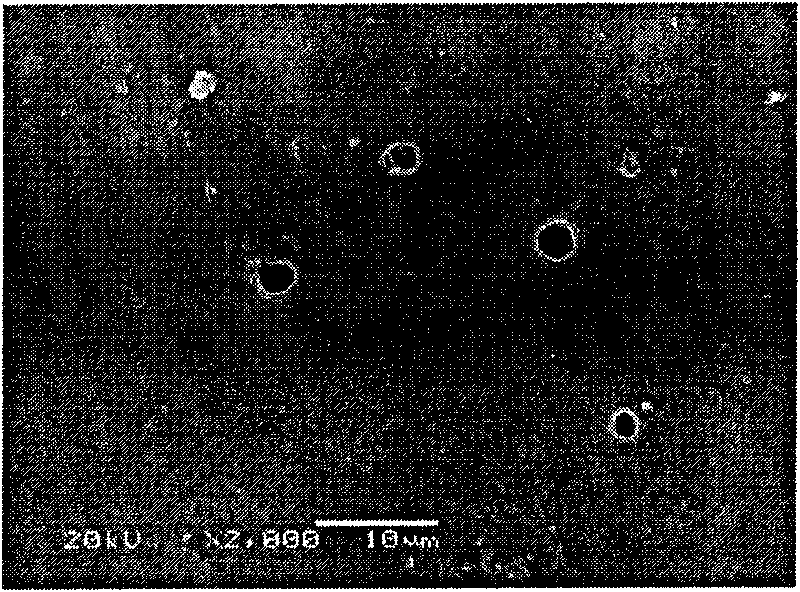

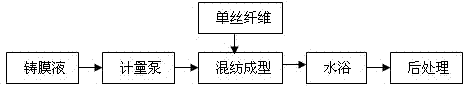

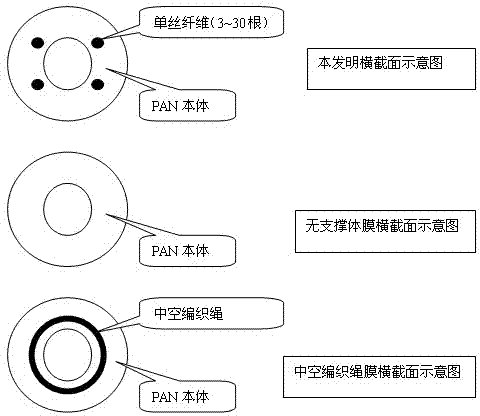

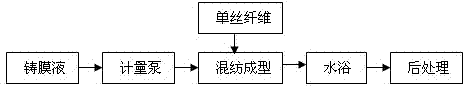

Polyacrylonitrile membrane with supporting materials and preparation method thereof

InactiveCN102389721AIncrease the number ofHigh strengthSemi-permeable membranesHollow fibrePolyester

The invention discloses a polyacrylonitrile membrane with supporting materials and a preparation method thereof. The preparation method is characterized by comprising the following steps: taking calcium nitrate or lithium nitrate as an oxidant, polyethylene glycol or polyvinylpyrrolidone as a pore-forming agent and one or two of N,N-dimethylacetamide and N,N-dimethylformamide to prepare a polyacrylonitrile hollow fibrous membrane by a dry-wet method, ensuring monofilaments to enter into a spinneret via other inlets and carrying out blending to prepare the polyacrylonitrile hollow fibrous composite membrane with the supporting materials, wherein the monofilament fibrous materials are polyester, spandex, nylon 6, nylon 66 or polyurethane and have diameter of 0.01-2mm. The membrane and the preparation method have the following beneficial effects: the defect that the hollow fibrous membranes without supports have insufficient physical tensile strength and are easy to suffer from filament break is overcome; the physical tensile strength of the membrane disclosed by the invention is improved by more than several times compared with that of the hollow fibrous membranes without supports; support and membrane stripping can be avoided; the water flux and manufacturing cost of the membrane disclosed by the invention are equivalent to the water flux and manufacturing cost of the hollow fibers without supports; and the membrane can replace the existing hollow fiber products and has great economic and social benefits.

Owner:ZHEJIANG CREATION ENVIRONMENT TECH

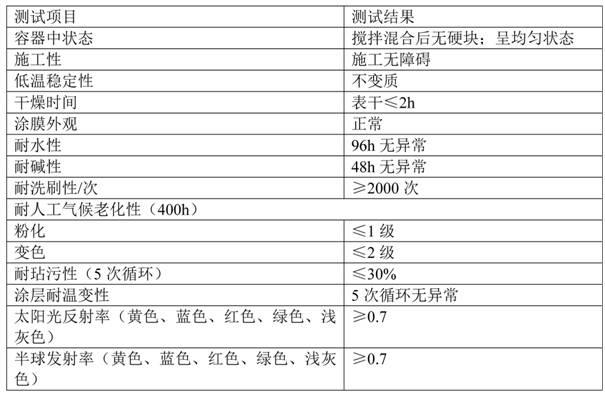

Colorful heat insulating and waterproof building paint

InactiveCN102675993AGood heat insulationReduce cooling energy consumptionNatural rubber coatingsGlass fiberSpray coating

The invention discloses colorful heat insulating and waterproof building paint, which comprises the components in parts by weight as follows: 20-30 parts of styrene-acrylic emulsion, 20-30 parts of natural rubber resin, 3-10 parts of paint dispersant, 10-15 parts of ethylene glycol, 0.5-1 parts of defoamer, 10-20 parts of pigment, 30-50 parts of low heat conductive coefficient filler, 4-8 parts of white carbon black and 10-15 parts of water. The colorful heat insulating and waterproof building paint is abundant in color, and can well meet the requirement of colorful outer wall paint of buildings with excellent heat insulating and waterproof effects which are same as those of white paint. The paint contains neither heavy metals nor formaldehyde and is relatively beneficial to health of human bodies. The paint is applicable for concrete pavements, asphalt pavements, plastic pavements, pavements of glass fiber reinforced plastics, and metal pavements, and is convenient to construct in ways of spray coating, brush coating and rolling coating.

Owner:开平市日固力涂料有限公司

Aqueous composite coating for plastic

InactiveCN105385250AHigh hardnessImprove adhesionPolyurea/polyurethane coatingsPolyolefinAcrylic resin

The invention discloses aqueous composite coating for plastic. The aqueous composite coating is prepared from the following raw materials in parts by weight: 20 to 40 parts of aqueous chlorinated polyolefin resin, 20 to 40 parts of aqueous acrylic resin, 15 to 30 parts of aqueous polyurethane dispersoid, 2 to 5 parts of silane coupling agent, 20 to 40 parts of nano calcium carbonate, 5 to 10 parts of ultrafine talcum powder, 10 to 20 parts of nano silicon dioxide, 5 to 15 parts of aluminum silicate, 1 to 6 parts of barium sulfate, 1 to 3 parts of titanium dioxide, 1 to 4 parts of zinc phosphate, 1 to 4 parts of adhering force accelerant, 0.5 to 2.5 parts of dimethylethanolamine, 1 to 2 parts of flatting agent, 1 to 2 parts of antibacterial agent, 1 to 2 parts of de-foaming agent, 1 to 2 parts of mildew preventive and 1 to 2 parts of wetting agent. The aqueous composite coating has great hardness and strong adhering force.

Owner:ANHUI JINDUN PAINT

Method for cleaning surface of anodize parts

ActiveCN101152652AEasy to cleanAchieve removalDrying solid materials without heatNon-surface-active detergent solventsAnodic oxidationMegasonic cleaning

The invention provides a cleaning method for surface of anode oxidized component. The core of the method is as follows that organic solution is firstly used for cleaning of the surface the component; then alkaline solution and acid solution is used for cleaning of the surface of the component in turn but not in sequence; at last, ultrasonic wave is adopted to clean the component. Removing of settlings on the surface of the component can be realized. The method is an effective and simple method without destructiveness for cleaning of the anode oxidized surface and mainly comprises that organic solution, alkaline solution, diluted acid solution and ultrasonic cleaning is used for removing of anode oxidation and treatment of contamination on the surface. The method cannot lead to flaking of anode oxidation and newly anode oxidation treatment of the component even if micro-damage is produced.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Molded product with decoration surface layer and manufacturing method thereof

ActiveCN1799828ASolve interface sticking problemsWon't peel offAdhesive processesDecorative surface effectsSurface layerShell molding

The invention provides a molding product whose surface has decoration label, which comprises a decoration label layer, a molding layer and micro-capsule adhesive agent between said two layers. The producing method comprises following steps: (1) coating or printing micro-capsule adhesive agent on the decoration label layer; (2) putting it into mould to be molded into final product. The invention has the advantages that it can effectively solve the problem in molding process that the decoration label can not adhere incompatible plastic material to make the plastic material which can be used in molding diversified; the solidification agent capsule in the micro-capsule adhesive agent can react solidification intercross reaction with the material of active groups at the instant of breaking or the adhesive agent capsule with active group or hidden active group in carrier resin can react solidification intercross reaction in high-temperature high-pressure molding. Therefore, it can avoid melting the adhesive agent and the detachment of decoration layer when it is used in high temperature.

Owner:SICHUAN YIBIN WULIANGYE GROUP

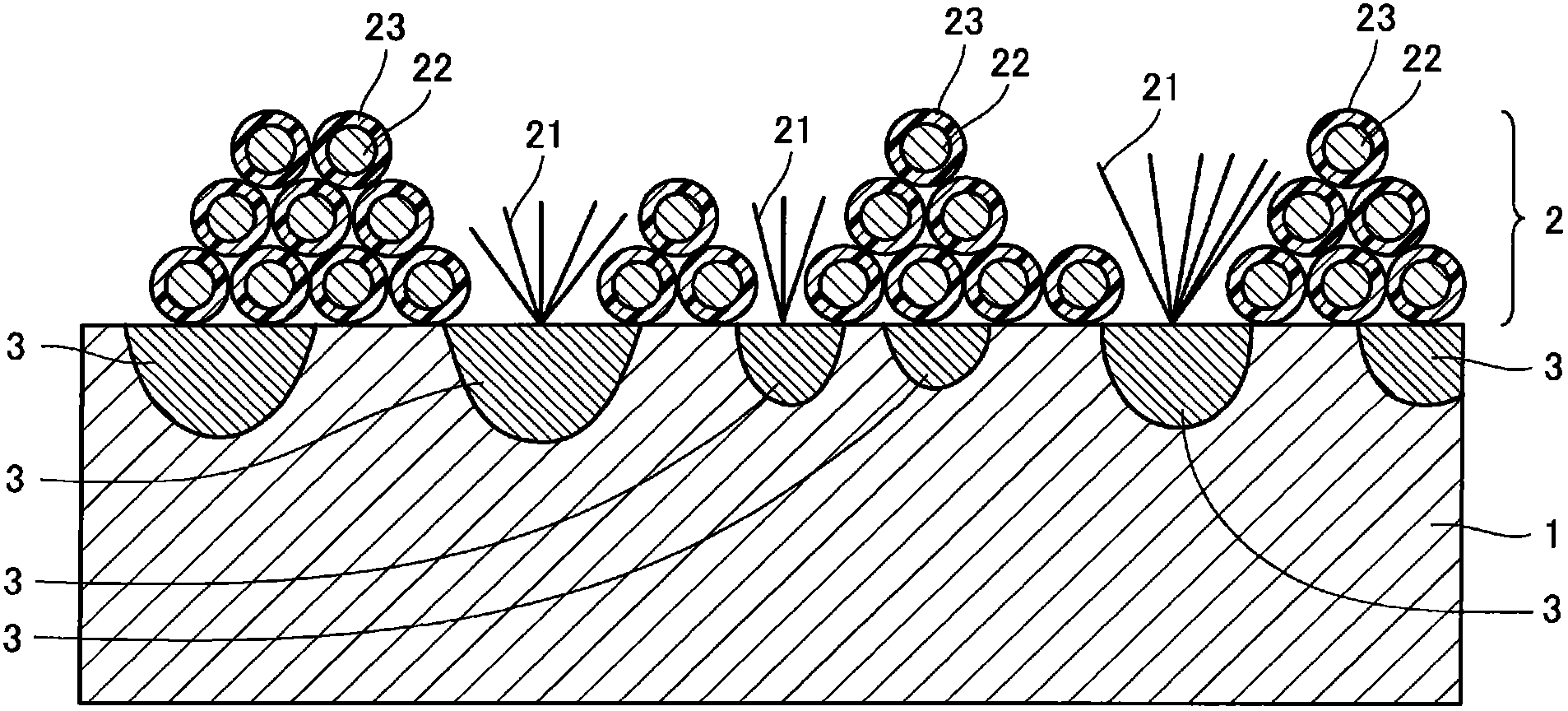

Carbon-coated aluminum member and method for producing the same

ActiveCN102037158AExcellent adhesionWon't peel offHybrid capacitor electrodesElectrode carriers/collectorsCarbideOrganic matter

Disclosed is a carbon-coated aluminum member wherein adhesion between a carbon-containing layer and an aluminum material as well as adhesion between carbon-containing particles contained in the carbon-containing layer are improved. Also disclosed is a method for producing such a carbon-coated aluminum member. Specifically disclosed is a carbon-coated aluminum member comprising an aluminum foil (1), a carbon-containing layer (2) formed on the surface of the aluminum foil (1), and an intervening layer (3) which contains aluminum carbide and is formed on at least a part of the surface of the aluminum foil (1) between the carbon-containing layer (2) and the aluminum foil (1). The carbon-containing layer (2) contains a plurality of carbon-containing particles (22), and an organic matter layer (23) is formed on the surface of each carbon-containing particle (22). Also specifically disclosed is a method for producing a carbon-coated aluminum member, wherein a resin layer is formed on the surface of each carbon-containing particle (22), then the resin-coated carbon-containing particles are adhered to the surface of an aluminum foil (1), and then the aluminum foil (1) and the resin-coated carbon-containing particles are placed and heated in a space containing a hydrocarbon-containing material.

Owner:TOYO ALUMINIUM KK

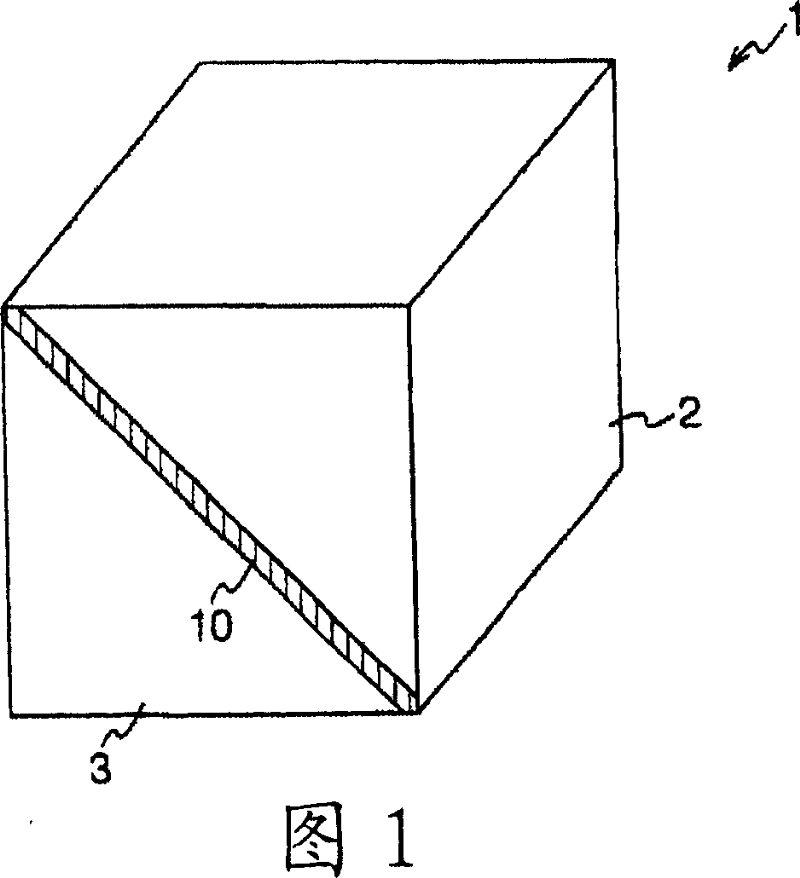

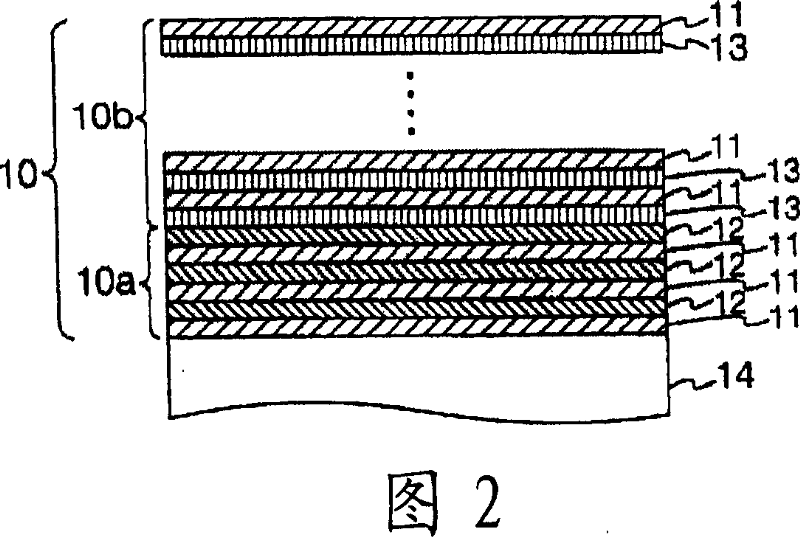

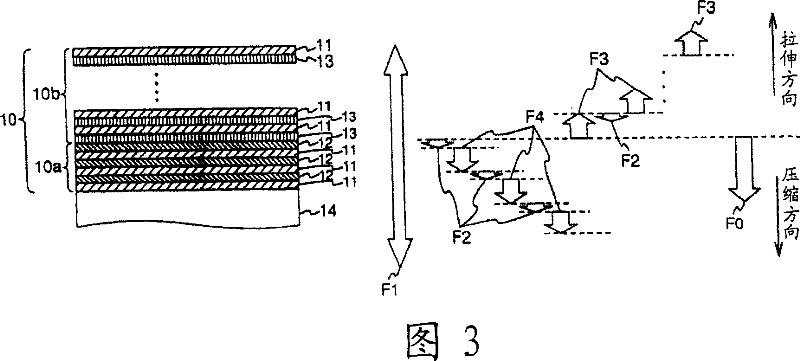

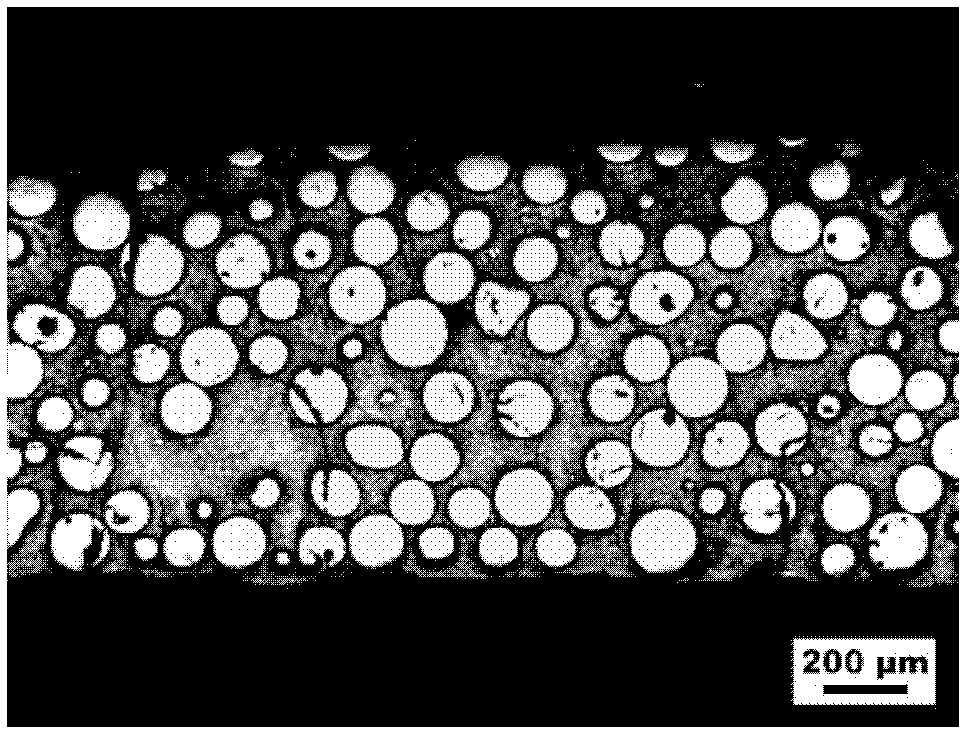

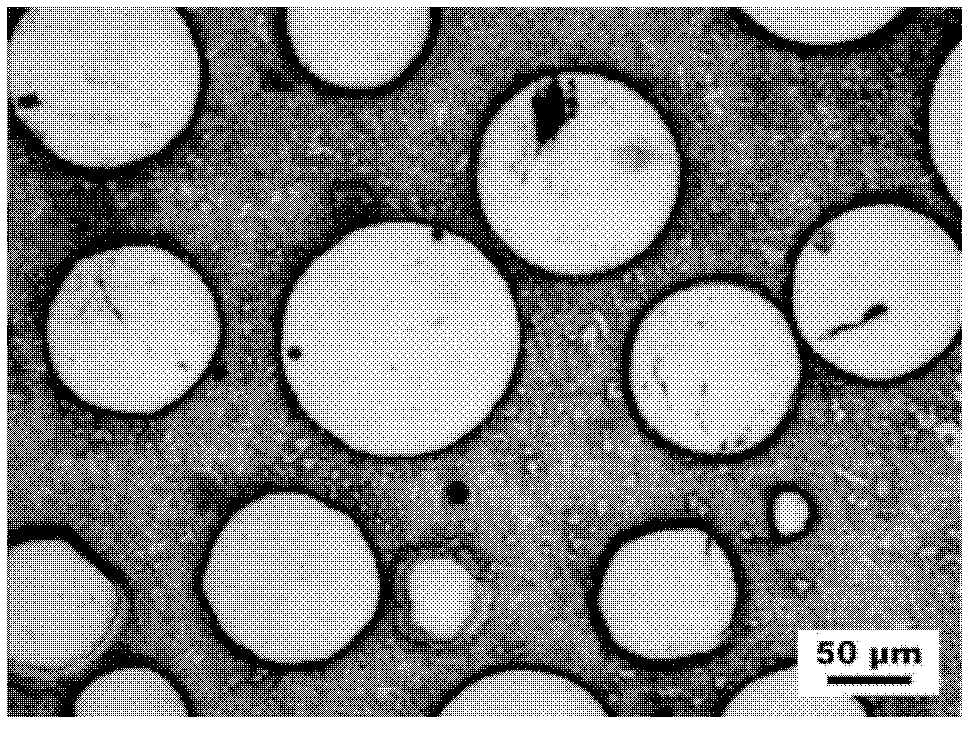

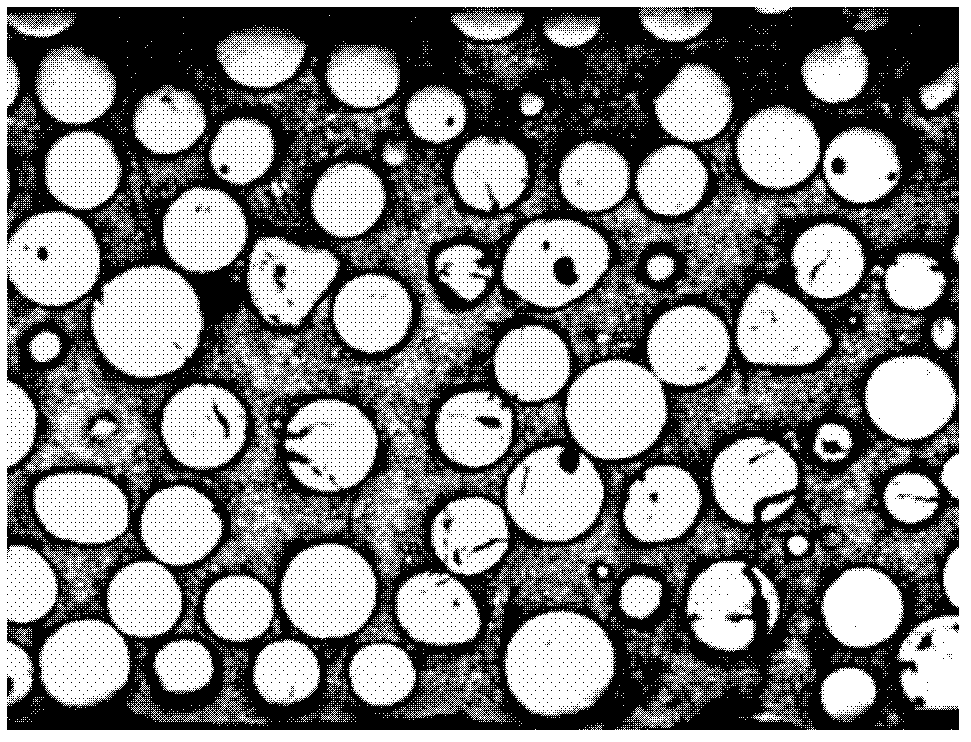

Polarized light splitting device and method for manufacturing the same

To provide a polarized beam splitter free from peeling of a polarized light splitting film or cracks on an interface with a prism.The polarized light beam splitter 1 comprises two right triangular prisms bonded to each other at inclined surfaces thereof via a polarized light splitting film 10, wherein the polarized light splitting film 10 comprises a first polarized light splitting film layer 10a formed by alternately laminating SiO2coatings 12 having compressive stress and lanthanum titanate films 11, and a second polarized light splitting film layer 10b formed by alternately laminating MgF2films 13 having tensile stress and lanthanum titanate films 11.

Owner:TOYO TSUSHINKI

Method for preparing high-content WC (Wolfram Carbide) enhanced alloy powder coating

ActiveCN103290403AImprove corrosion resistanceImprove high temperature performanceMetallic material coating processesSurface engineeringAfter treatment

The invention belongs to the field of material surface engineering and in particular relates to a method for preparing a high-content WC (Wolfram Carbide) enhanced alloy powder coating by employing a laser cladding technology. The composite powder is clad on the surface of a workpiece by employing laser cladding, wherein the composite powder is prepared from WC powder and bonding-phase alloy powder according to a weight ratio, the content of WC powder in the composite powder is 50-70wt%, and the content of bonding-phase alloy powder is 30-50wt%. The WC enhanced alloy powder composite functional coating is prepared by employing the process method, the wear resistance and high-temperature performance of the workpiece are greatly improved after treatment, the service life is prolonged by over 8 times, and the economic benefits are obvious.

Owner:无锡新松机器人自动化有限公司

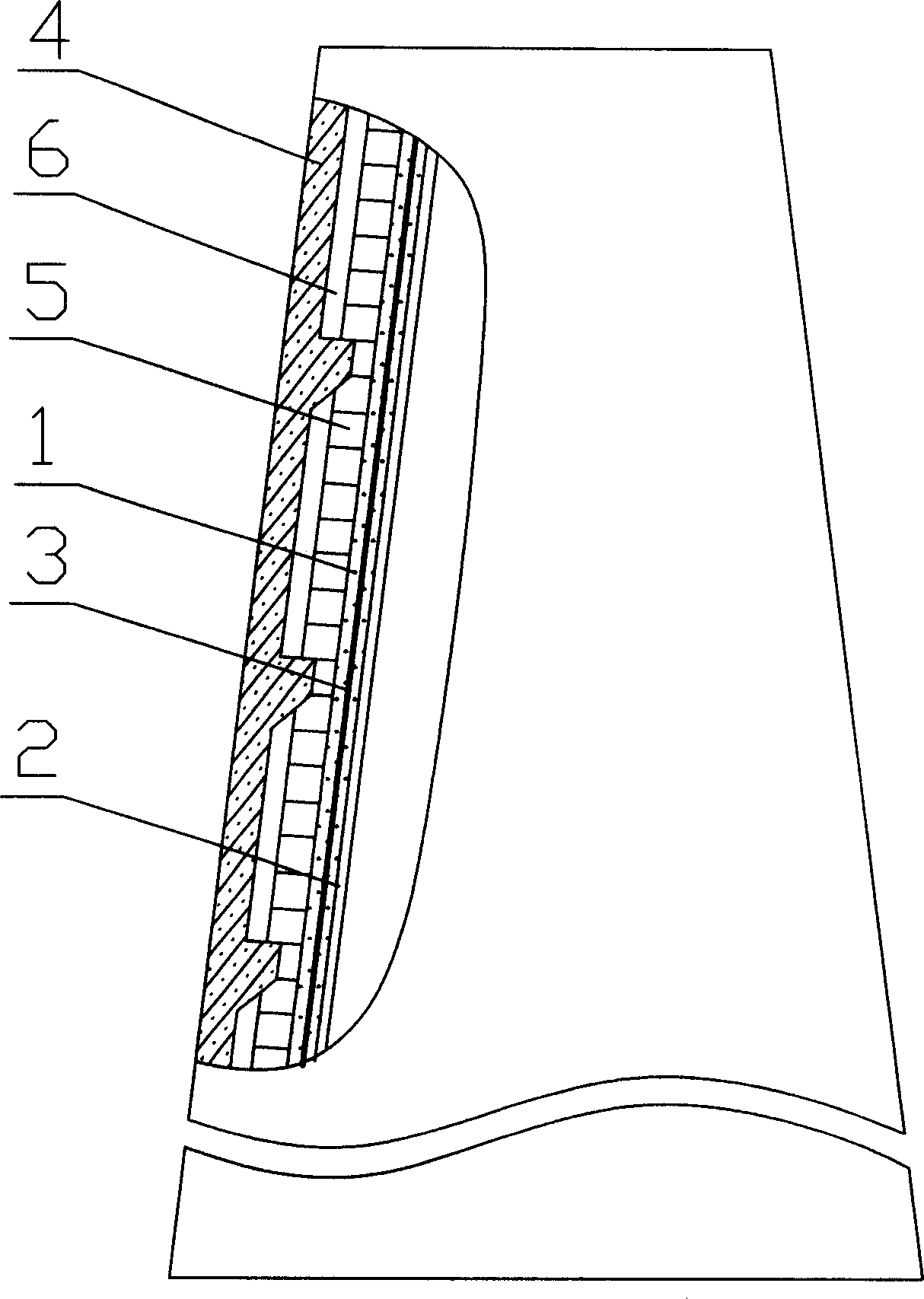

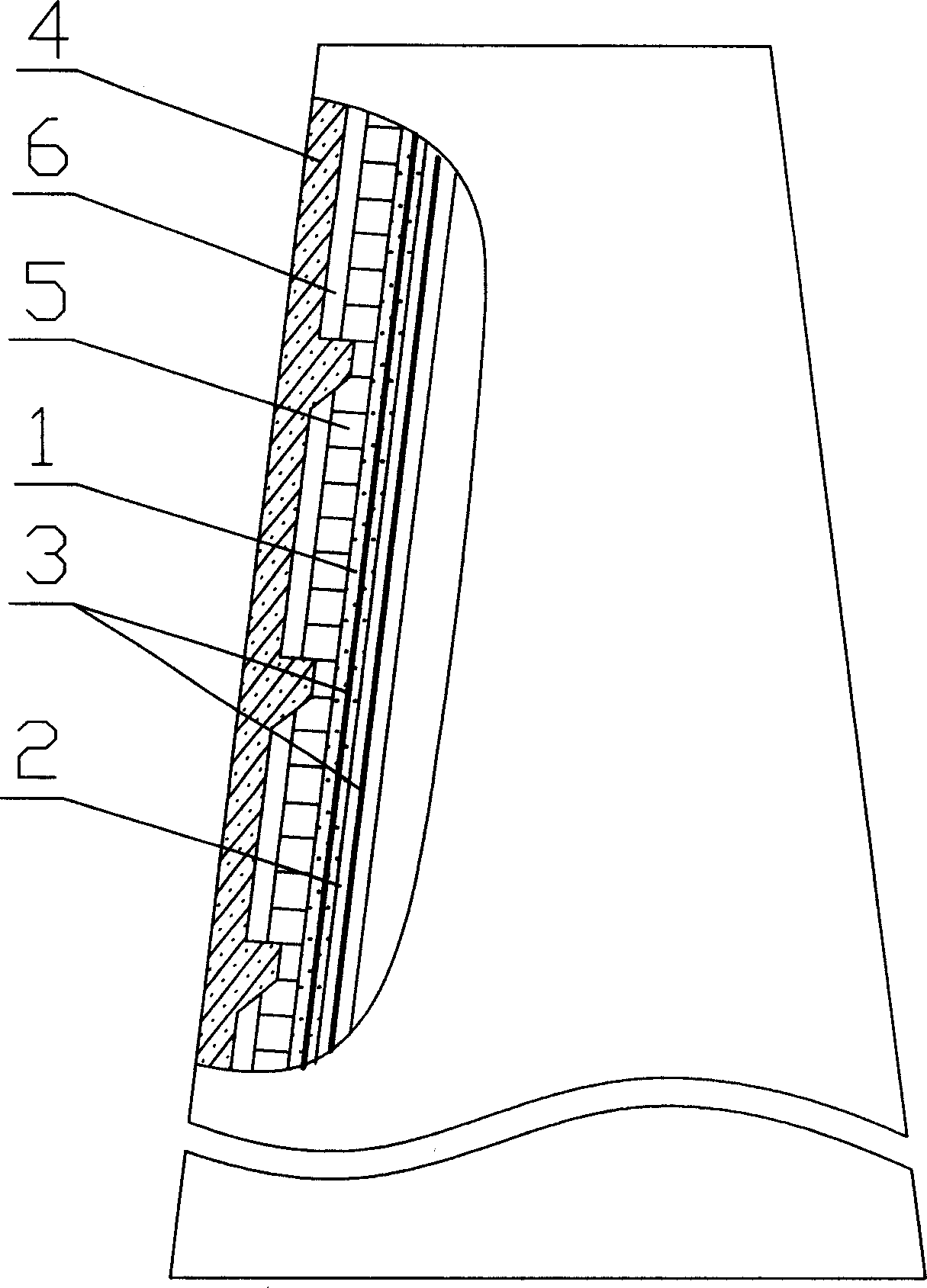

Boiler chimney body and method for forming its inner wall protection structure

InactiveCN1827985AImprove bindingReasonable collocationTowersBuilding insulationsEpoxyFiberglass mesh

The invention relates to a boiler chimney and the method for forming inner-wall protective element. The inventive boiler comprises an outer frame and a liner. Wherein, said liner has a inner-wall protective, which is formed by a polymer silicate solidify layer, a epoxy paint solidify layer while said two layers can be resistant to acid and high temperature, and a strength layer; the polymer silicate solidify layer is fixed on the inner surface of liner; the epoxy paint solidify layer is fixed on the polymer silicate solidify layer; the strength layer is glass fiber grid cloth, which is extended and embedded into the polymer silicate solidify layer, or individually embedded into the polymer silicate solidify layer and the epoxy paint solidify layer to form the inner-wall protective element. Said invention has lower cost, the high temperature resistance, antisepsis property and the anti-leakage property.

Owner:陈海渊

Aluminum-silicon-zinc-rare earth-copper-containing hot dip coating alloy and method for preparing same

ActiveCN101736222AUniform compositionImprove toughnessHot-dipping/immersion processesRare-earth elementDip-coating

The invention relates to hot dip coating alloy specially used for surface coatings of titanium alloy parts. The hot dip coating alloy consists of aluminum, silicon, zinc, rare earth elements, copper and reinforcing agent of particles of nano oxides, and based on the total weight of the alloy, the alloy comprises 8 to 24 percent of silicon, 1.2 to 3.1 percent of zinc, 0.02 to 0.5 percent of rare earth elements, 0.05 to 0.5 percent of copper, 1 to 2 percent of reinforcing agent of particles of nano oxides, and the balance of aluminum and inevitable impurities, wherein the reinforcing agent of the particles of the nano oxides may be one or two of TiO2 and CeO2. The hot dip coating alloy produced by the method can form a coating with good corrosion resistance and wearing resistance and good metallurgical bonding property with a matrix on the surface of the titanium alloy.

Owner:JIANGSU LINLONG NEW MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com