Method for carrying out laser-cladding on high-hardness nickel-based alloy material in large area

A technology of laser cladding and nickel-based alloys, which is applied in metal material coating technology, laser welding equipment, metal processing equipment, etc., can solve problems such as cracks, cracks, and pores, and achieve performance enhancement and reduction in corrosion resistance. Dilution rate, effect of life improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

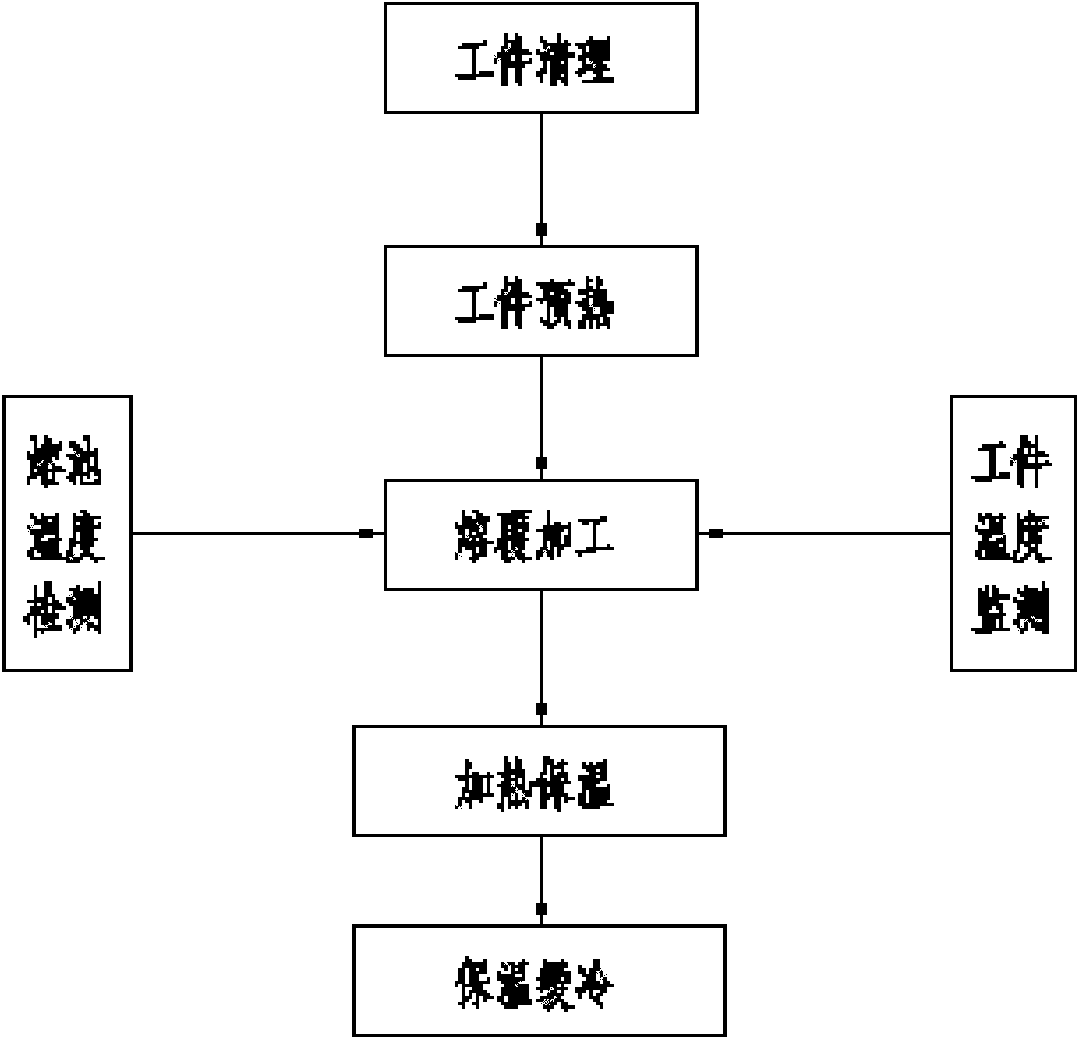

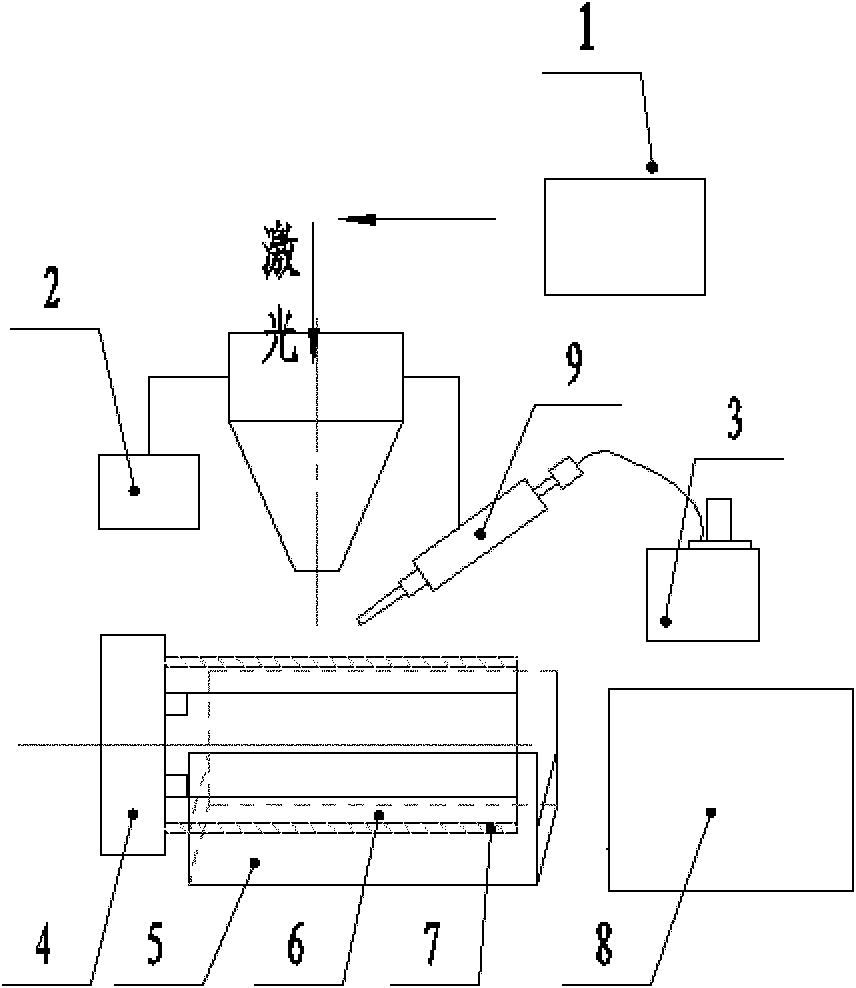

[0055] In order to solve the wear and corrosion problem of a nuclear power plant pump shaft sleeve (material 1Cr18Ni9Ti, size ¢240×200mm, wall thickness 25mm), it was decided to use the present invention to coat the outer peripheral surface of the shaft sleeve with a high hardness, wear-resistant and corrosion-resistant nickel-based alloy coating. Processing, as follows:

[0056] 1) The laser processing technology is: laser power 2.5KW, scanning speed 180mm / min, spot diameter 3.0mm, overlap rate 40%, cladding thickness 2.0mm, cladding powder material is Ni60A.

[0057] 2) The heat treatment method is as follows: the workpiece preheating temperature is 300°C, the heating time is 2 hours, the heating and holding temperature is 300°C±20°C during the cladding process, and immediately after the processing is completed, it is placed in a resistance furnace with a furnace temperature of 200°C±20°C for 5 hours Keep warm and slowly cool to room temperature with the furnace.

[0058] I...

Embodiment 2

[0068] The difference from Example 1 is:

[0069] The material of a punch is H13 steel. In order to improve the high temperature wear resistance and cold and heat fatigue performance of the punch, the surface of the punch is strengthened by laser cladding using the present invention:

[0070] 1) Laser power 6.0KW, scanning speed 800mm / min, spot diameter 5.0mm, overlap rate 30%, cladding thickness 1.0mm, cladding powder material is Ni60A;

[0071] 2) The preheating temperature of the workpiece is 200°C, and the heating time is 1 hour; during the cladding process, the heating and heat preservation is 300°C±20°C; immediately after the processing, the workpiece is placed in a furnace temperature of 200°C±20°C for 3 hours of heat preservation and slow cooling with the furnace to room temperature.

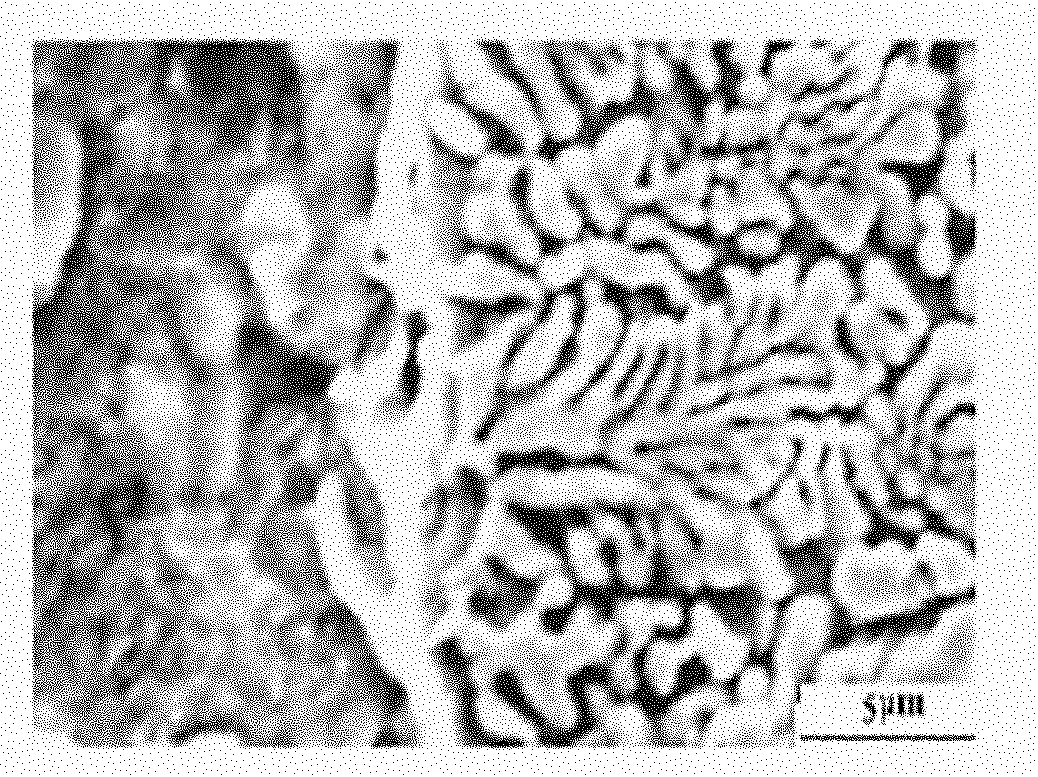

[0072] Such as Figure 4 As shown, the coating structure is a typical rapid solidification structure with fine and dense grains, and the cladding layer forms a good metallurgical bond ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com