Amorphous composite coating and preparation method thereof

A technology of composite coating and iron-based amorphous alloy, which is applied in the direction of coating, metal material coating process, fusion spraying, etc., can solve the problem of low graphene density, difficulty in uniform dispersion of metal powder, and high requirements for graphene coating. problems, to achieve the effect of increased corrosion potential and reduced wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

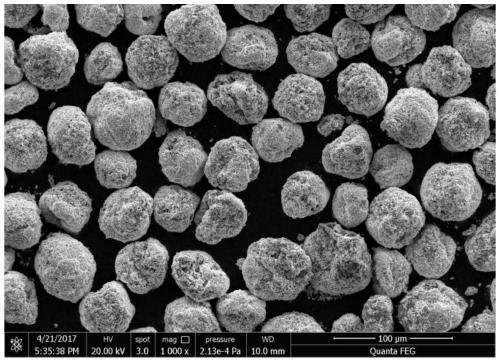

[0040] (1) Weigh single-layer graphene oxide powder with a thickness of 0.1-10 μm and a sheet diameter of 5-100 μm and metal nickel powder with a particle size of 0.5-50 μm, and mix them at a mass ratio of 1:49 to form a composite powder, Added to the mixed solution composed of binder, dispersant and deionized water accounting for 38%, 1.3% and 180% of the total mass of the composite powder respectively, after ultrasonic oscillation for 0.5h and mechanical stirring for 0.5h, the mixed slurry.

[0041] (2) carry out spray granulation to above-mentioned mixed slurry in spray drying tower, its inlet temperature is 150 ℃, and outlet temperature is 100 ℃, and pressure is 0.5MPa, and the rotating speed of atomizing disc in spray drying tower is 15000r / min, Under the action of surface tension, the mixed slurry shrinks into a composite feeding ball with a particle size of 20-40 μm.

[0042] (3) Thermally reduce the above composite feeding balls in a vacuum heat treatment furnace, the...

Embodiment 2

[0045] (1) Weigh multilayer graphene oxide powder with a thickness of 0.1-10 μm and a sheet diameter of 5-100 μm and nickel alloy powder with a particle size of 0.5-50 μm, and mix them at a mass ratio of 1:9 to form a composite powder, Add it to the mixed solution consisting of binder, dispersant and deionized water accounting for 30%, 0.5% and 100% of the total mass of the composite powder, and after ultrasonic oscillation for 0.2h and mechanical stirring for 3h, the mixed slurry is obtained material.

[0046] (2) The above-mentioned mixed slurry is sprayed and granulated in the spray drying tower. The inlet temperature is 300°C, the outlet temperature is 140°C, and the pressure is 1MPa. The rotating speed of the atomizing disc in the spray drying tower is 30000r / min. Under the action of surface tension, the mixed slurry shrinks into a composite feeding ball with a particle size of 40-70 μm.

[0047] (3) Thermally reduce the above composite feeding balls in a vacuum heat tre...

Embodiment 3

[0049] (1) Weigh single-layer graphene oxide powder with a thickness of 0.1-10 μm and a sheet diameter of 5-100 μm and nickel alloy powder with a particle size of 0.5-50 μm, and mix them at a mass ratio of 1:99 to form a composite powder, Add it to the mixed solution composed of binder, dispersant and deionized water accounting for 70%, 3% and 300% of the total mass of the composite powder, and after ultrasonic oscillation for 0.3h and mechanical stirring for 1h, the mixed slurry was prepared material.

[0050] (2) The above-mentioned mixed slurry is sprayed and granulated in the spray drying tower, the inlet temperature is 200°C, the outlet temperature is 120°C, the pressure is 0.8MPa, and the rotating speed of the atomizing disc in the spray drying tower is 20000r / min, Under the action of surface tension, the mixed slurry shrinks into a composite feeding ball with a particle size of 40-70 μm.

[0051] (3) Thermally reduce the above compound feeding balls in a vacuum heat tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com