High-temperature and high-pressure composite material slagging ball valve assembly

A high-temperature and high-pressure ball valve technology, which is applied in the field of high-pressure slag discharge ball valves and high-temperature combined materials, can solve problems such as economic loss and reduce the service life of the two valves, and achieve the effects of increasing service life, improving service life and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

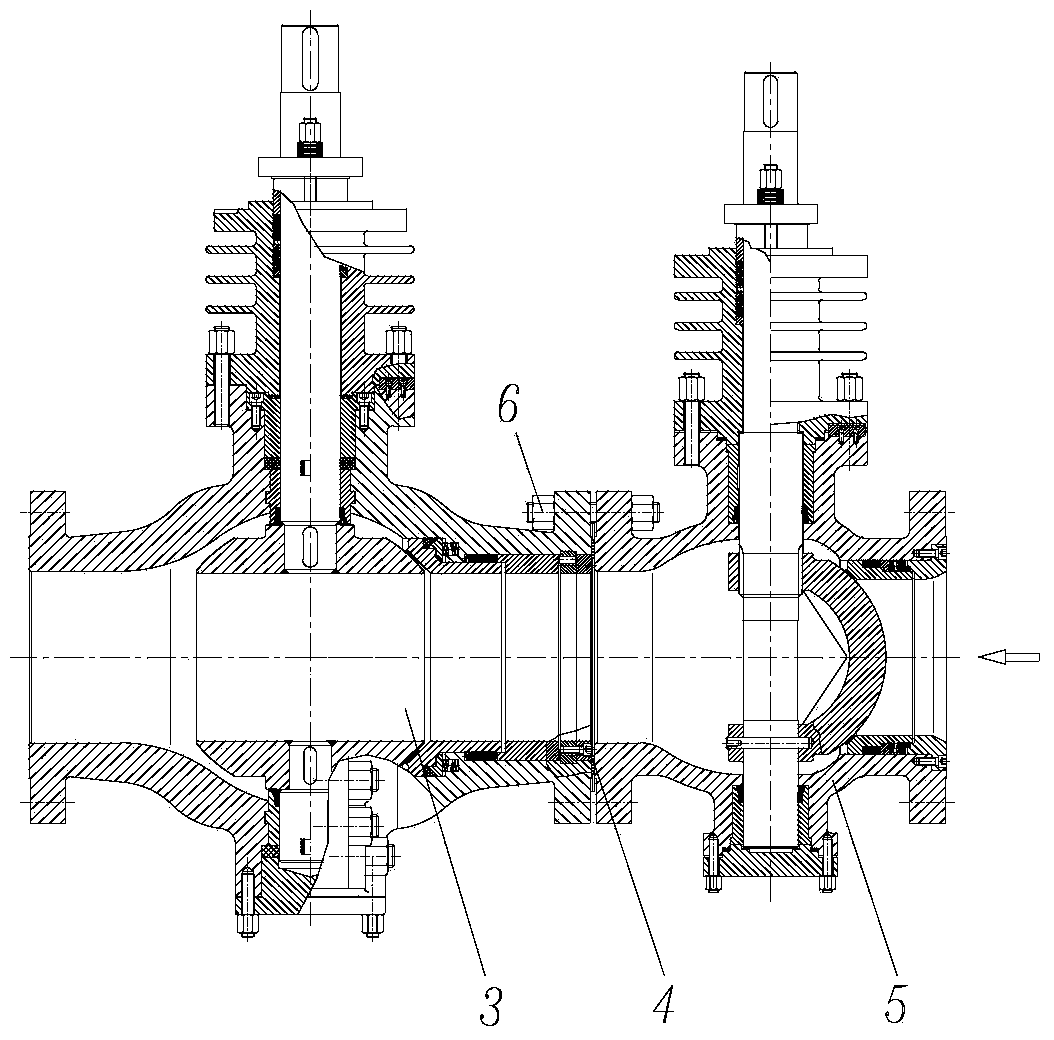

[0028] see image 3 , the composite material high temperature and high pressure slag discharge ball valve of the present invention includes a high temperature wear-resistant O-type ball valve 3, a flange sealing gasket 4, a high-temperature wear-resistant V-type ball valve 5, and a stud nut 6. The high-temperature wear-resistant O-type ball valve 3 The stud bolt nut 6 is connected with the high temperature and wear-resistant V-shaped ball valve 5 to form an integrated control valve, forming a combined material high-temperature and high-pressure slag discharge ball valve. A flange sealing gasket 4 is provided to ensure the sealing of the combined valve. The high-temperature wear-resistant O-type ball valve 3 has a single valve seat structure, the valve seat is arranged on the medium inlet side, and the outlet side valve cavity is designed as an arc transition structure, so that the medium flows in the valve cavity without dead angle. The high temperature wear-resistant V-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com