Patents

Literature

47results about How to "Strong metallurgical bond" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for carrying out laser-cladding on high-hardness nickel-based alloy material in large area

ActiveCN102465294AImprove wear and corrosion resistanceDense tissueMetallic material coating processesLaser beam welding apparatusSurface engineeringHeat-affected zone

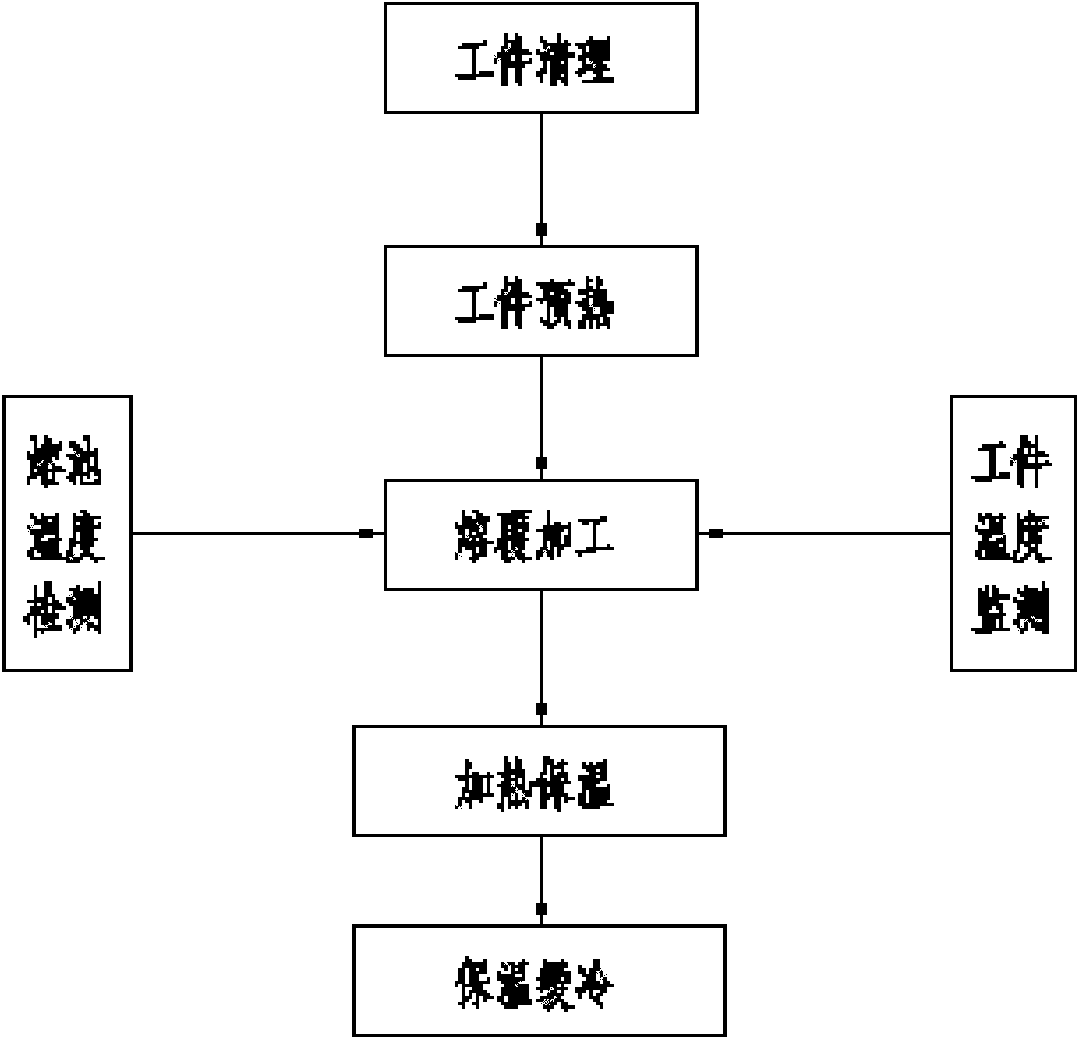

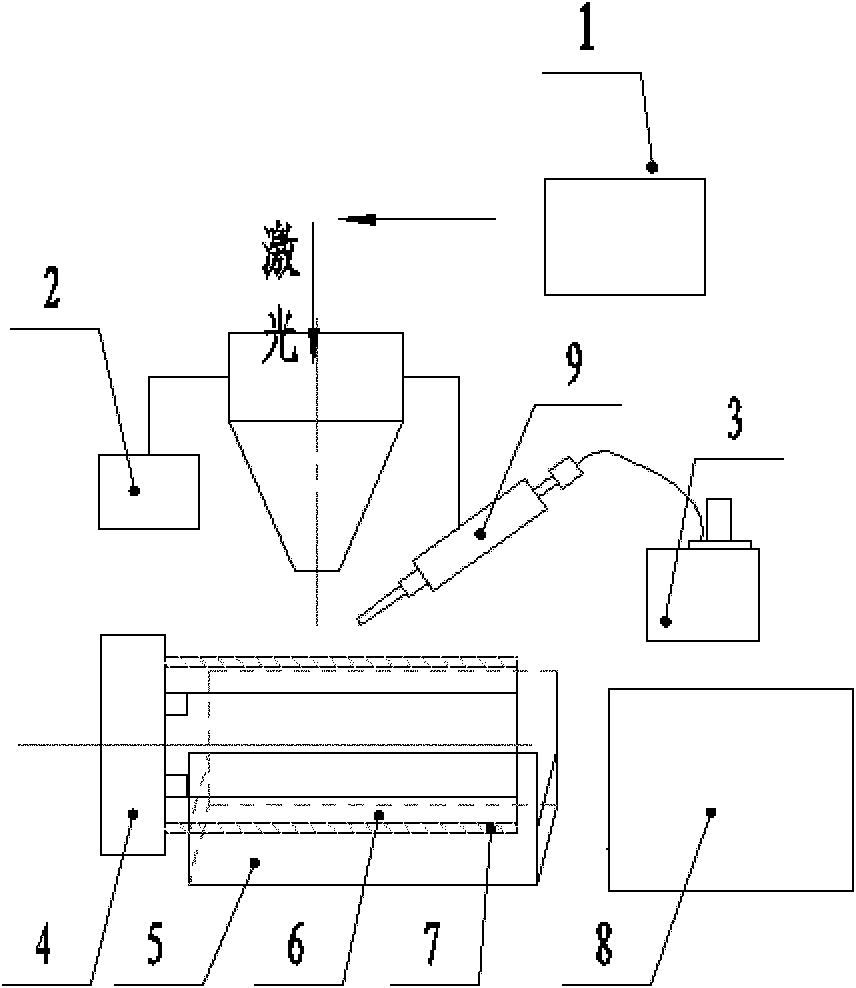

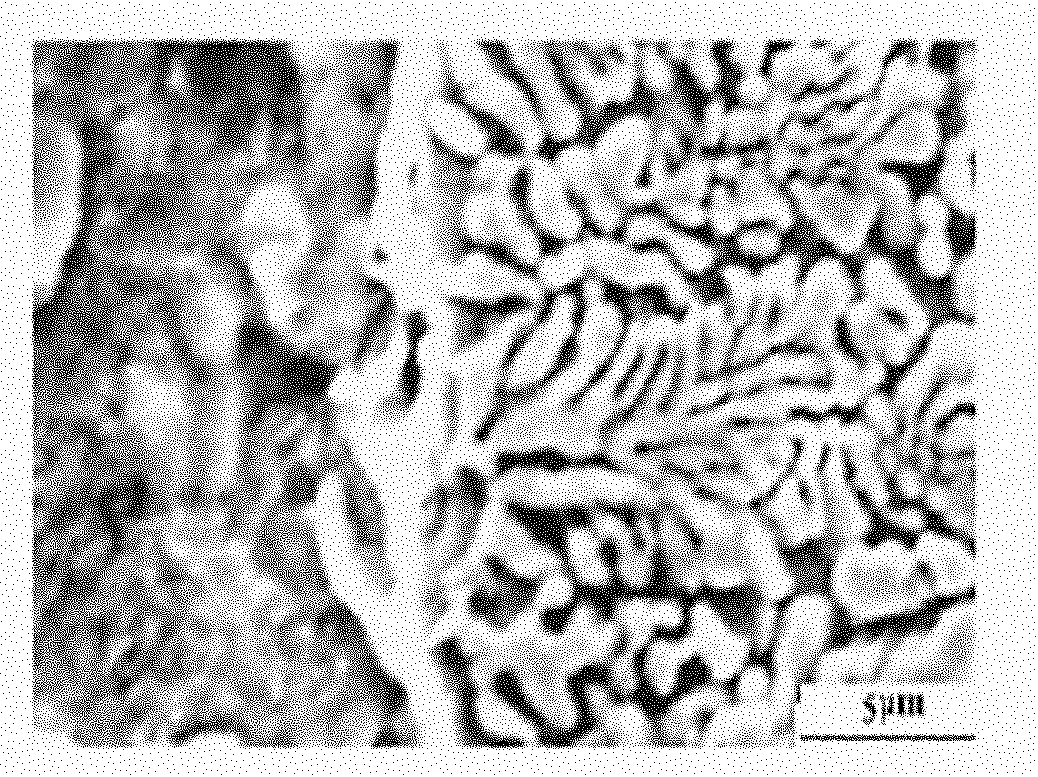

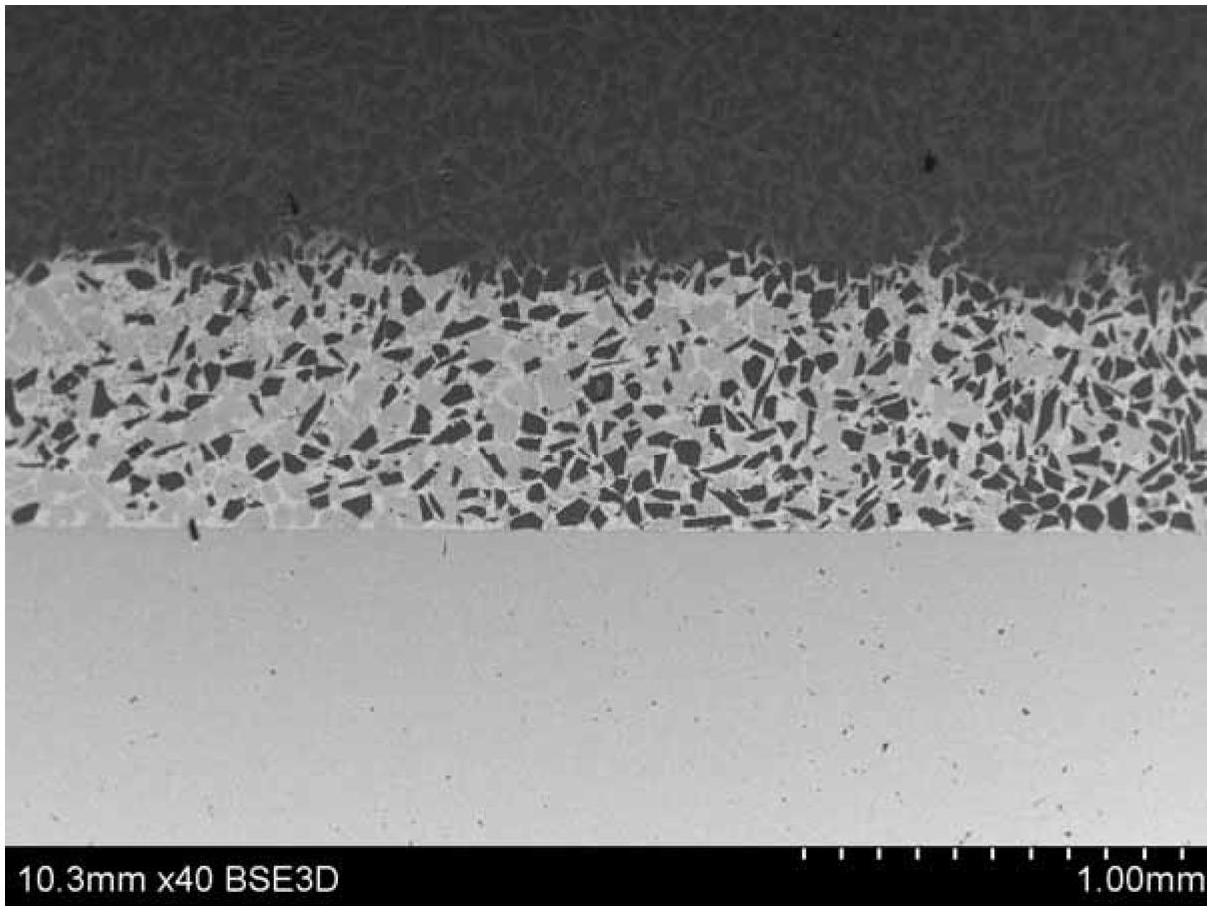

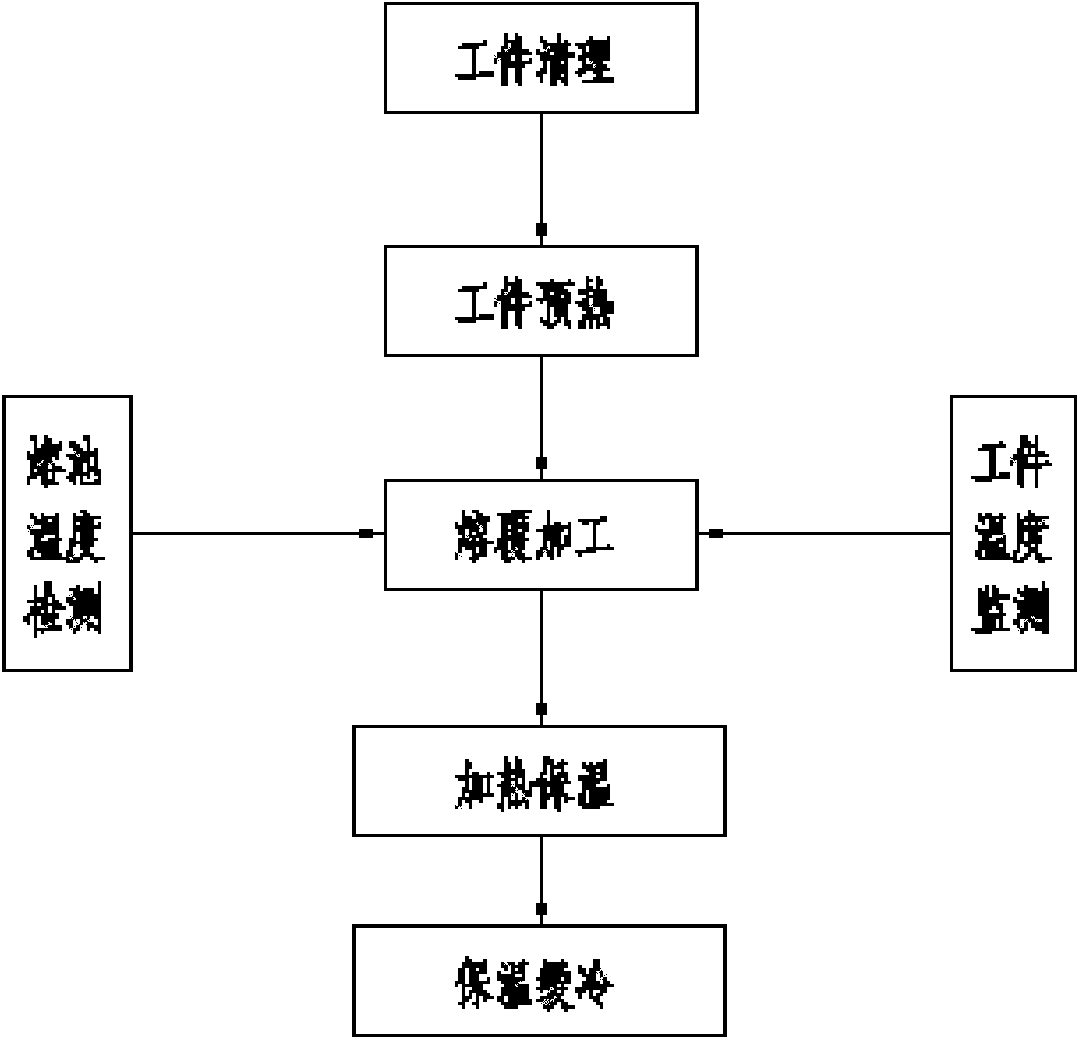

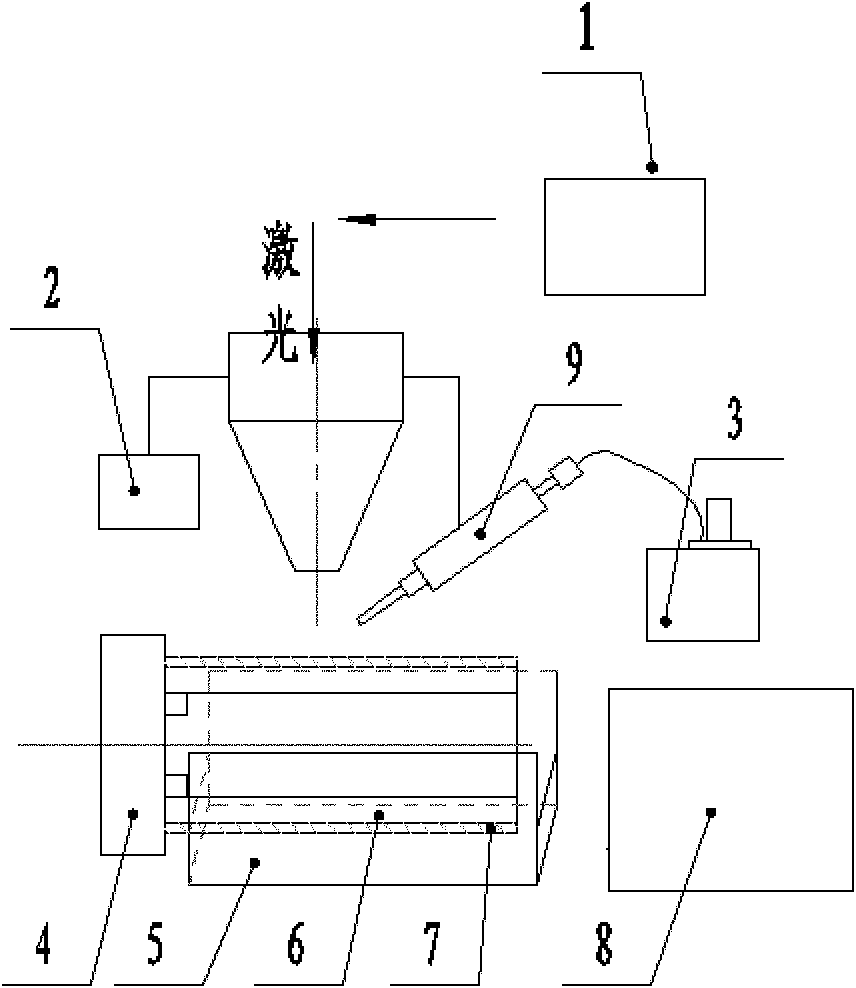

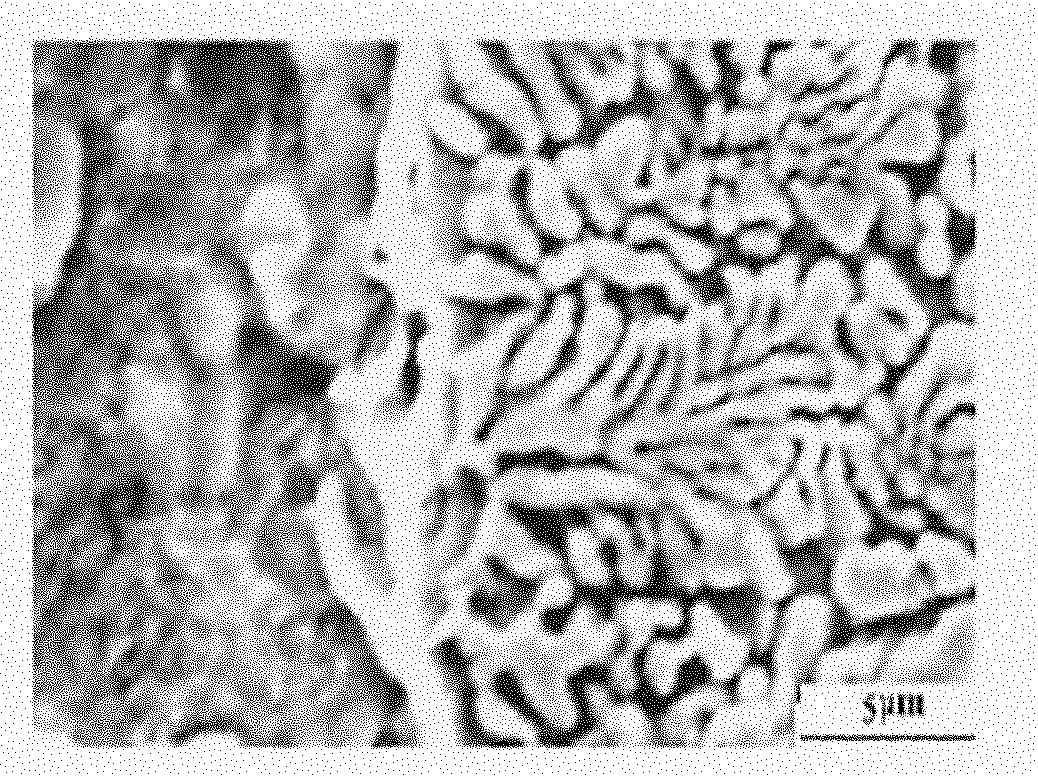

The invention belongs to the field of material surface engineering and more particularly relates to a method for carrying out cladding on a high-hardness wear-resistant anti-corrosion nickel-based alloy material on a metal substrate E in a large area by applying a laser cladding technology, solving the problem of cracks generated in the laser cladding process of the high-hardness wear-resistant nickel-based alloy, in particular the cladding defects, such as cracks with the thickness of more than 1mm, pores and the like during large-area cladding. According to the invention, the high-hardness nickel-based alloy powder material is cladded on the surface of the metal substrate in the large area to form a high-hardness wear-resistant anti-corrosion nickel-based alloy coating by applying the laser cladding technology and adopting a scientific and reasonable process method. According to the method disclosed by the invention, stability and consistency of laser cladding are foundationally ensured, defects, such as cracks, pores, impurities can be prevented from generating, heat affected regions of the substrate are reduced, dilution rate is reduced, the high-wear-resistance anticorrosion nickel-based alloy coating with firm metallurgical bonding and fine and compact grains is obtained and has the hardness reaching 58-63HRC, and the service life of the processed workpiece can be prolonged by more than 1-2 times.

Owner:NINGBO SIASUN ROBOT TECH CO LTD

Ultrasonic brazing method for high-volume-fraction silicon carbide particle enhanced aluminum-base composite and low-expansion alloy

ActiveCN102658411APromote wettingLow connection temperatureSoldering apparatusRoom temperatureMaterials science

The invention relates to an ultrasonic brazing method for an aluminum-base composite and low-expansion alloy, in particular to an ultrasonic brazing method for a high-volume-fraction silicon carbide particle enhanced aluminum-base composite and low-expansion alloy. The ultrasonic brazing method solves the problems that existing brazing methods for connection of the high-volume-fraction silicon carbide particle enhanced aluminum-base composite and the low-expansion alloy are complex in process and high in cost, connection temperature and joint residual stress. The method includes: firstly, cleaning to-be-brazed surfaces of the aluminum-base composite and the low-expansion alloy; secondly, coating a metal layer on the to-be-brazed surface of the low-expansion alloy; thirdly, lapping the to-be-brazed surfaces of the aluminum-base composite and the low-expansion alloy, wherein brazing materials are arranged on the lateral side of a lapping joint to form a to-be-brazed part; and fourthly, heating the to-be-brazed part, ultrasonically vibrating, heating, preserving heat, pressurizing at the joint while ultrasonically vibrating, and performing furnace cooling to the room temperature, so that ultrasonic brazing is completed. The ultrasonic brazing method is simple in process, low in cost, low in connection temperature and high in joint residual stress. The ultrasonic brazing method is used for the brazing field.

Owner:HARBIN INST OF TECH

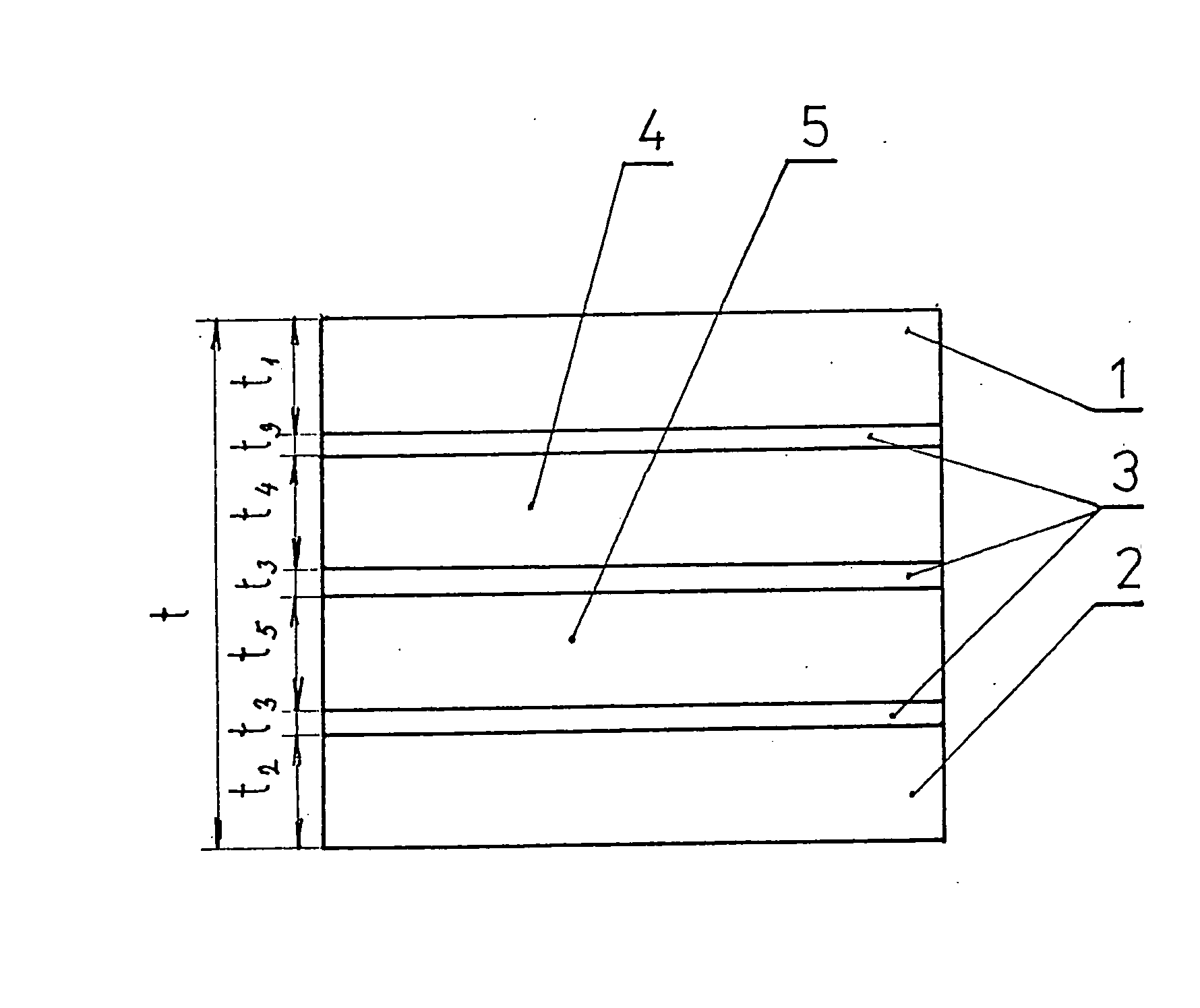

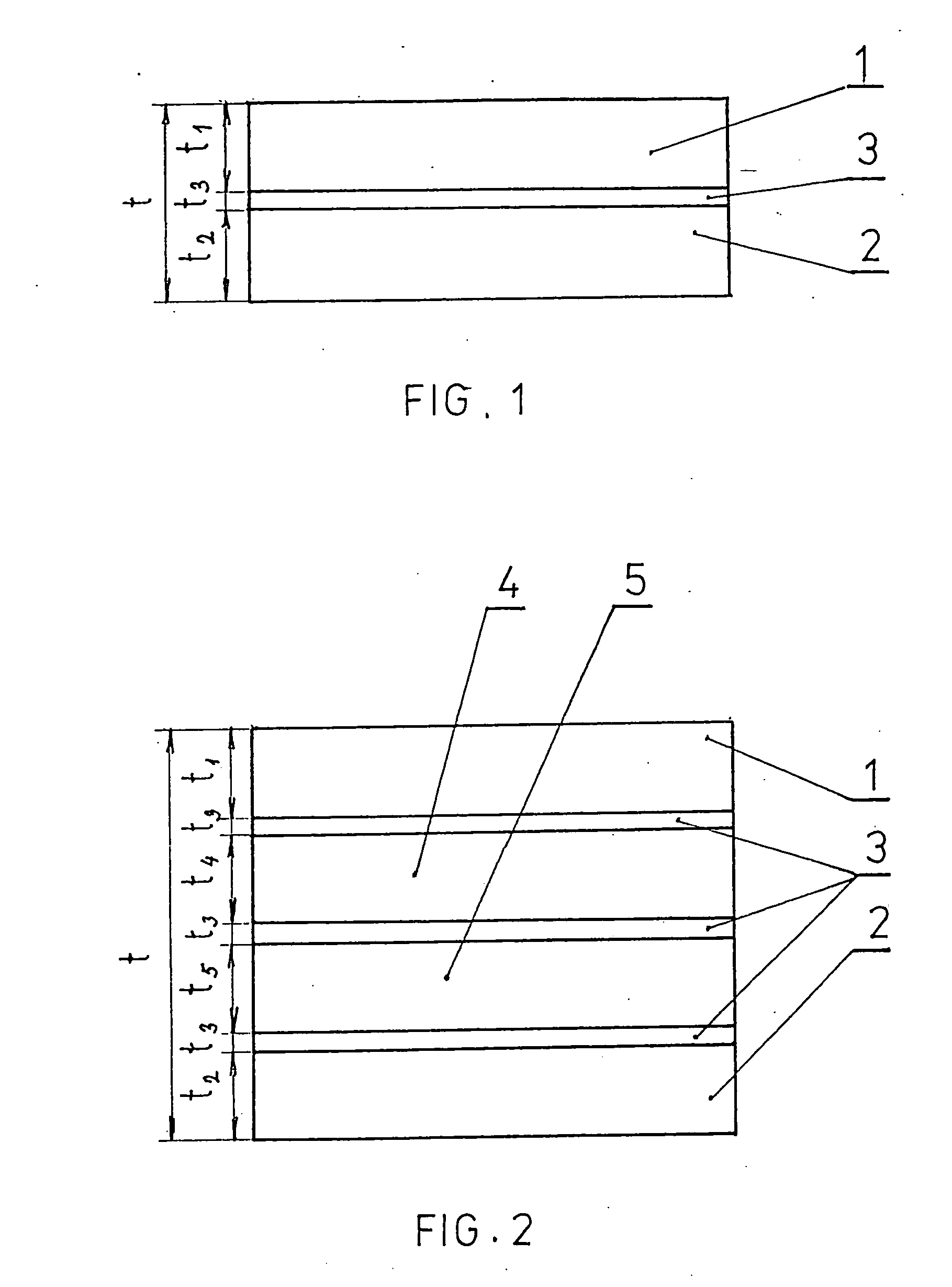

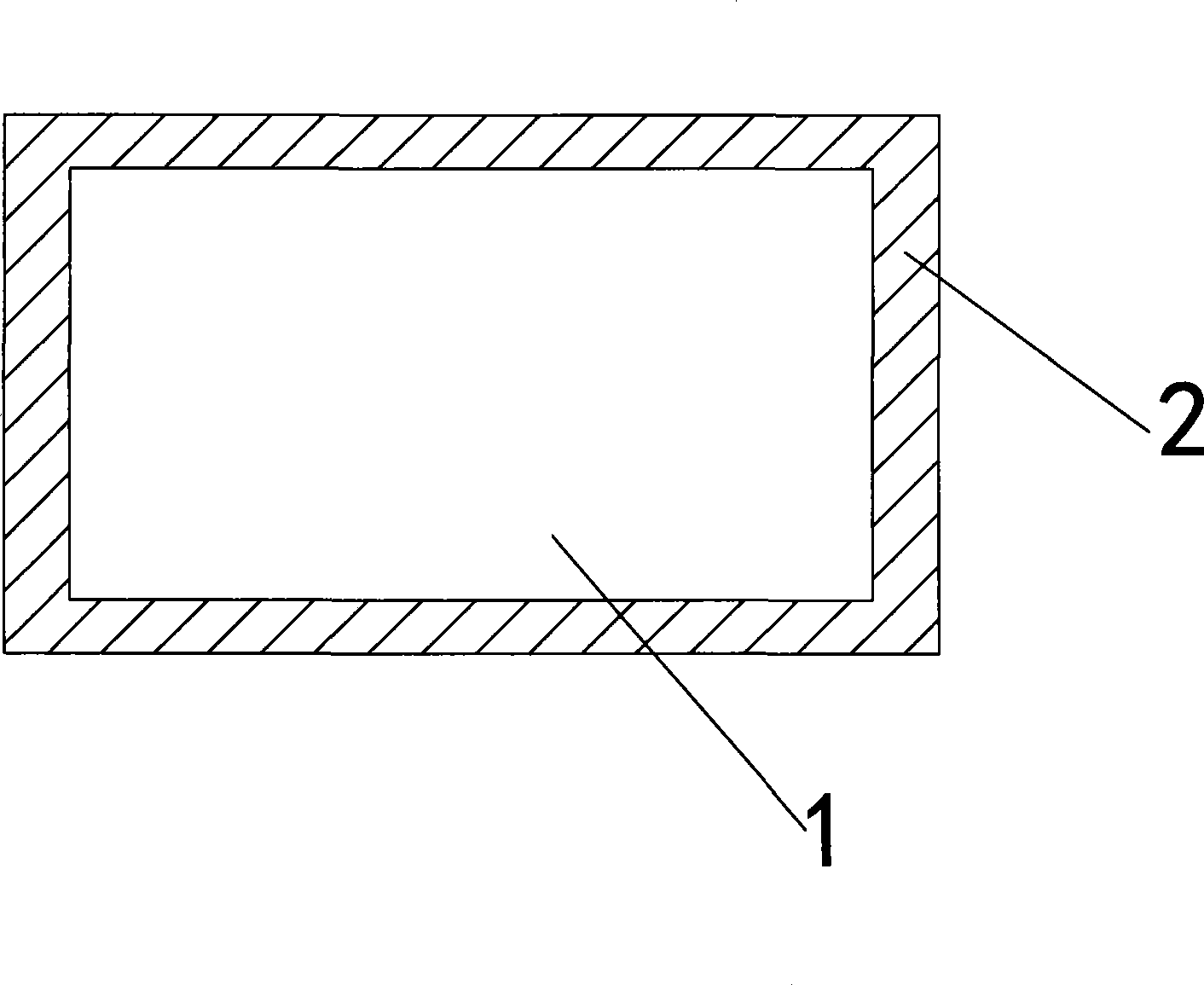

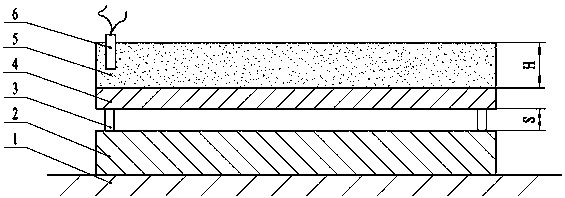

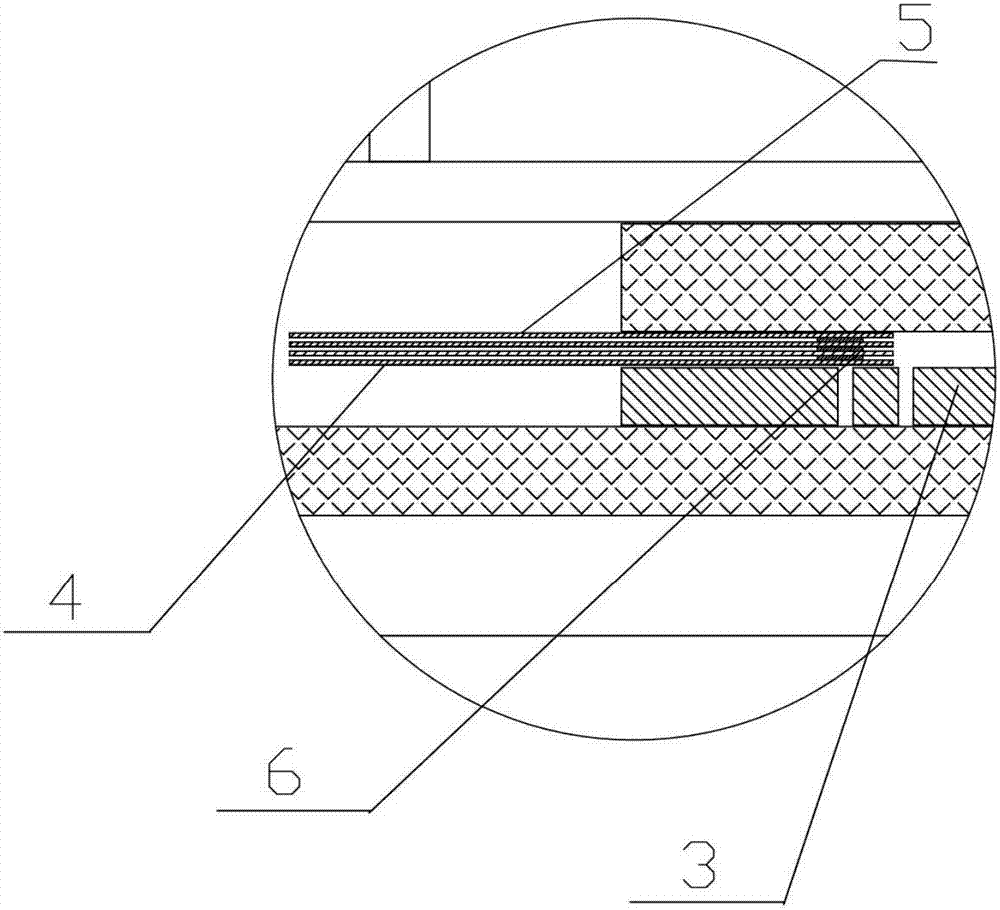

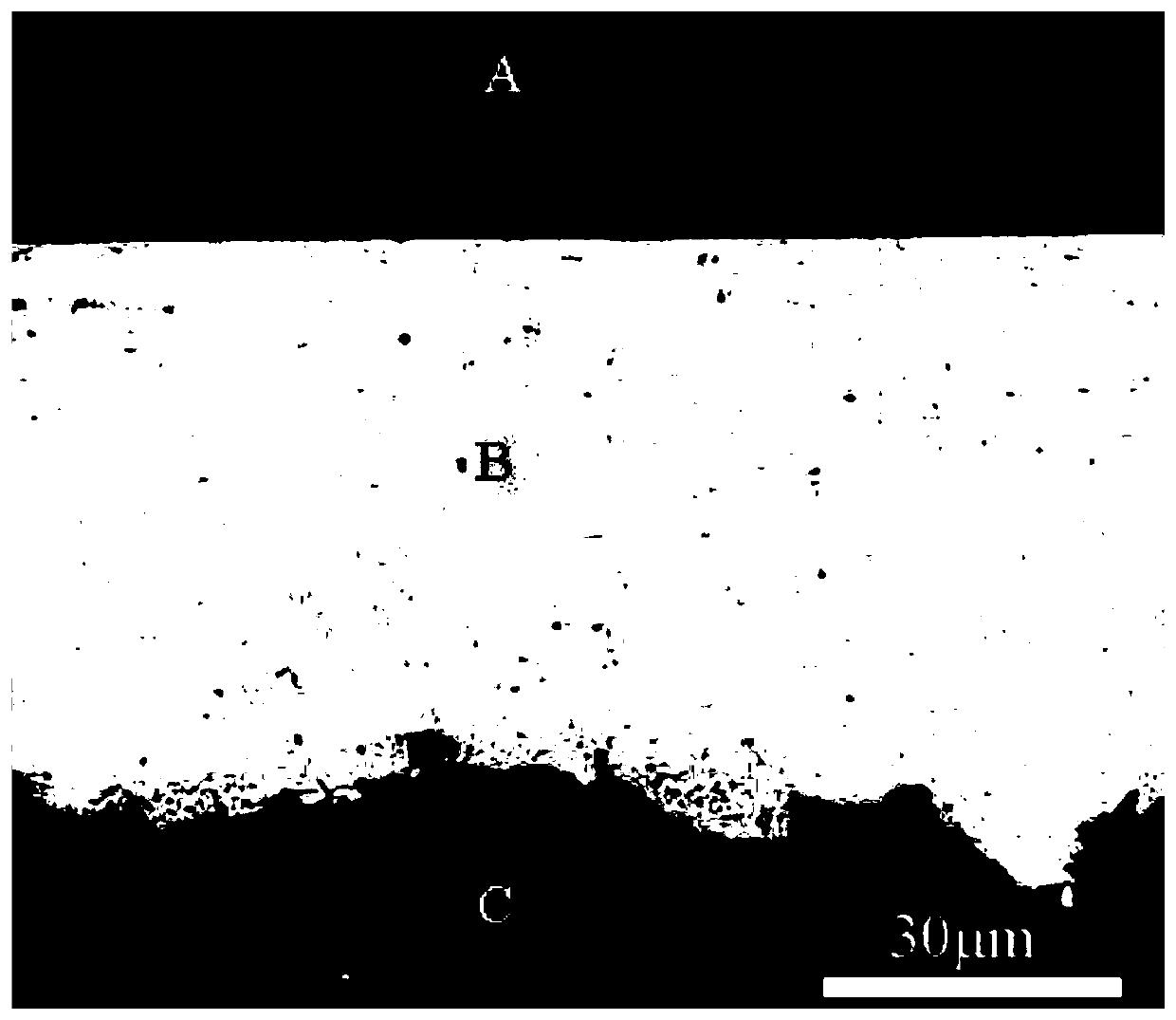

Multilayered steel armour

The multilayered steel armour consisting of the front-face ballistic-resistant armour layer (1) and the backing armour layer (2), which are fully metallurgically bonded by means of at least one joining metallic intermediate layer (3), for example, by casting, wide-area welding techniques, using technology of explosive cladding (high-velocity impact cladding), by roll welding or by a combination of the previous techniques. The joining metallic intermediate layer (3) between the front-face ballistic-resistant armour layer (1) and the backing armour layer (2) is made from the material featuring the face-centered cubic crystalline lattice (FCC lattice), in particular, from the nickel alloy containing maximally 98.0 wt % of nickel and / or from steel.

Owner:SVOS

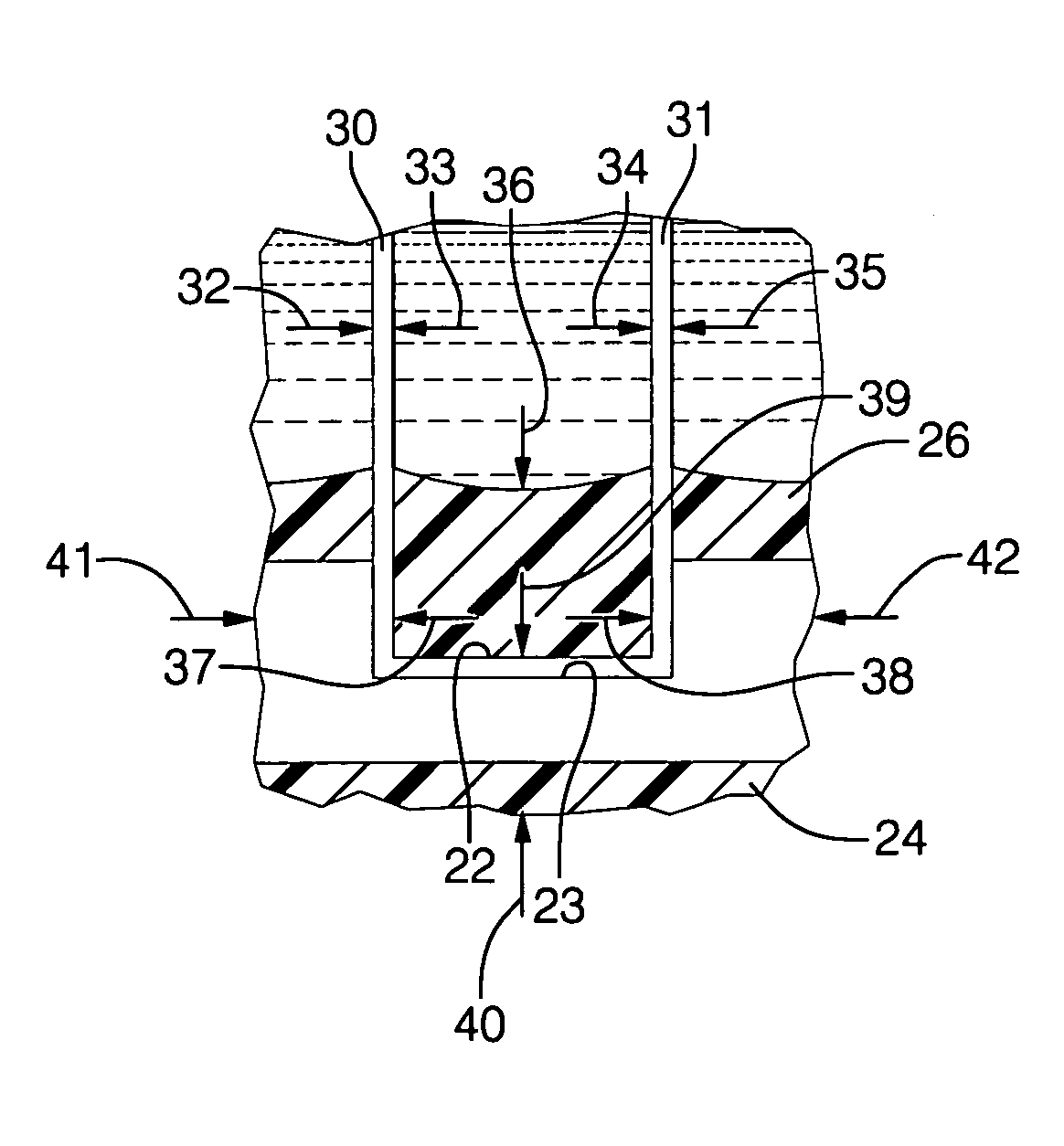

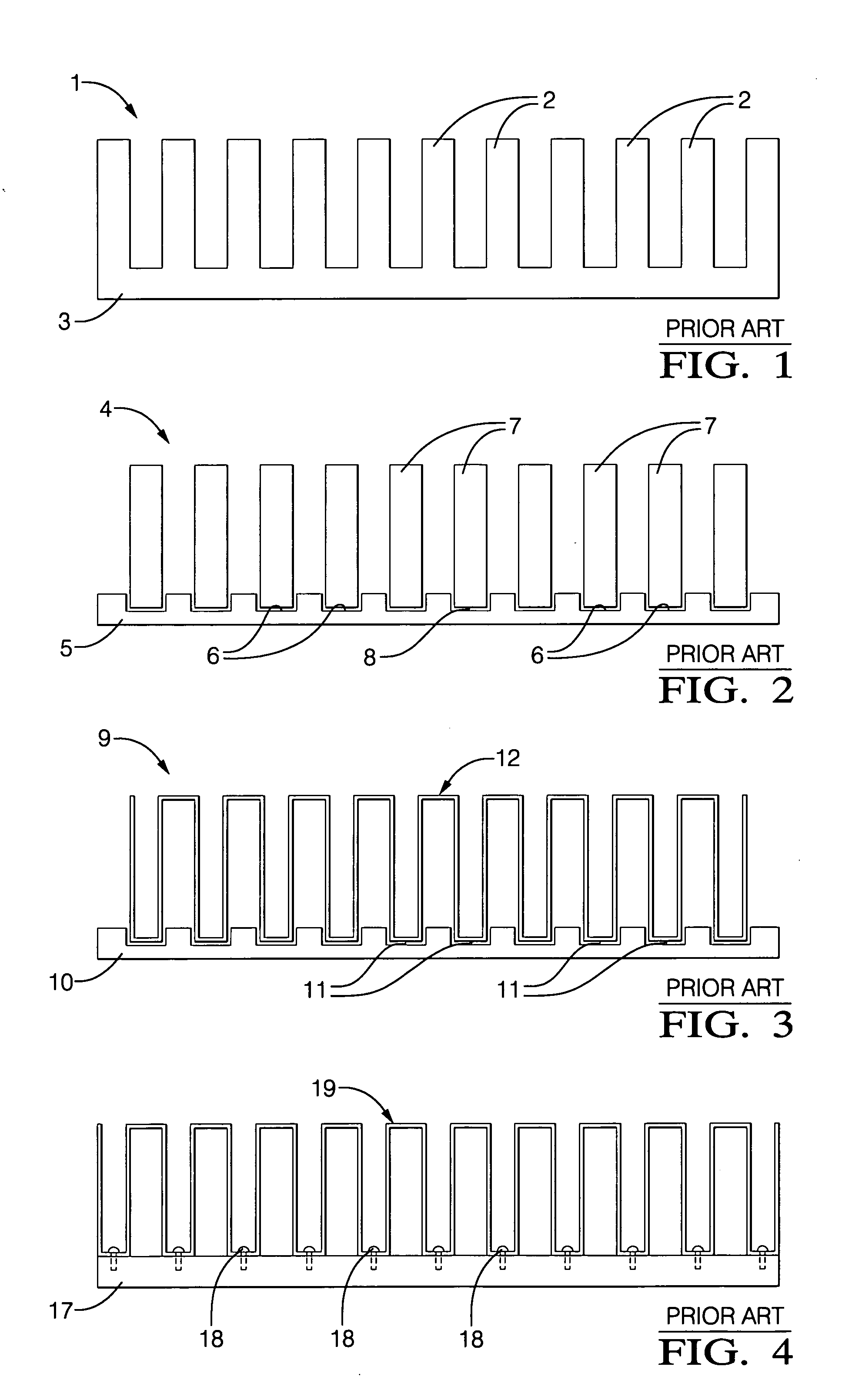

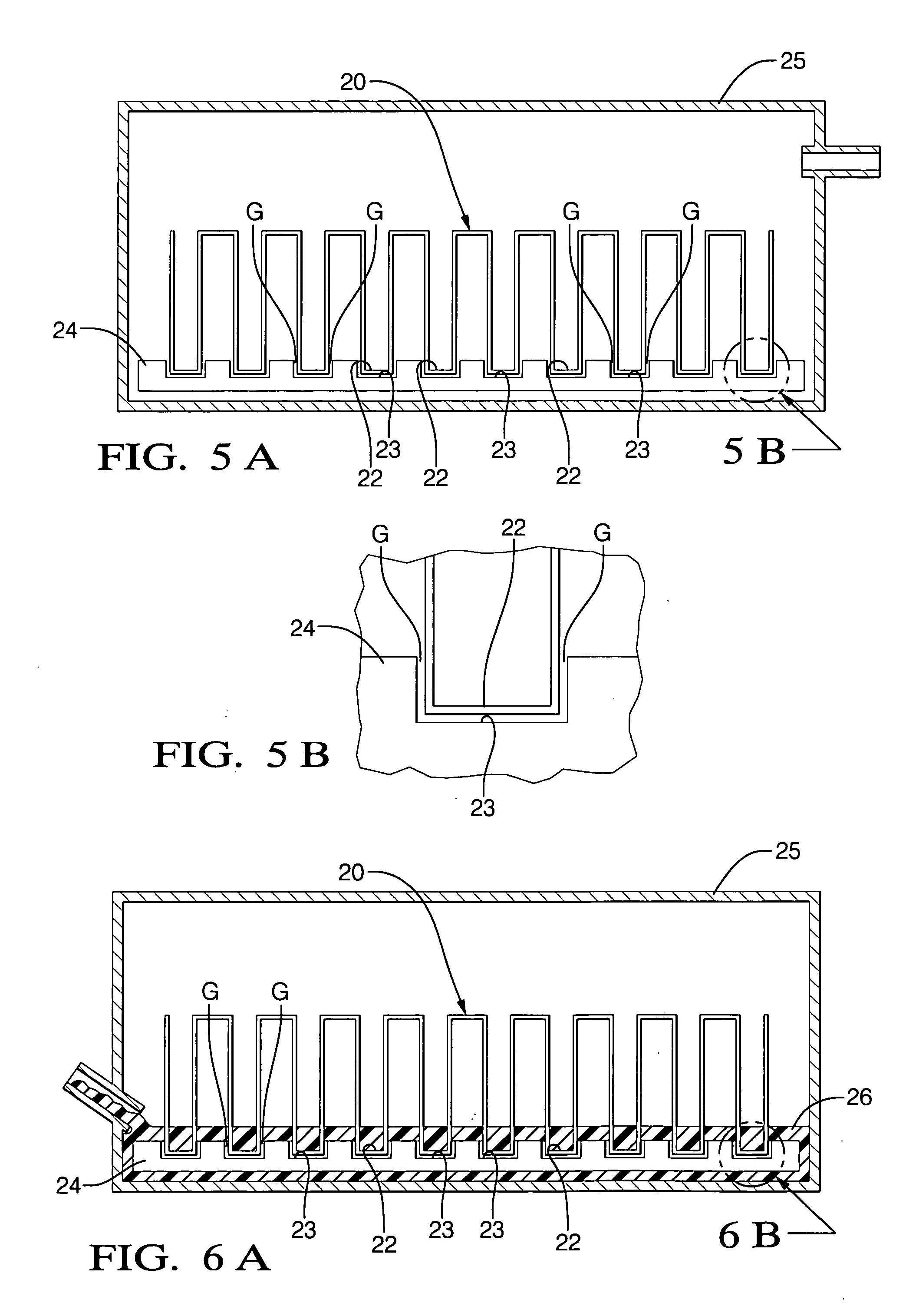

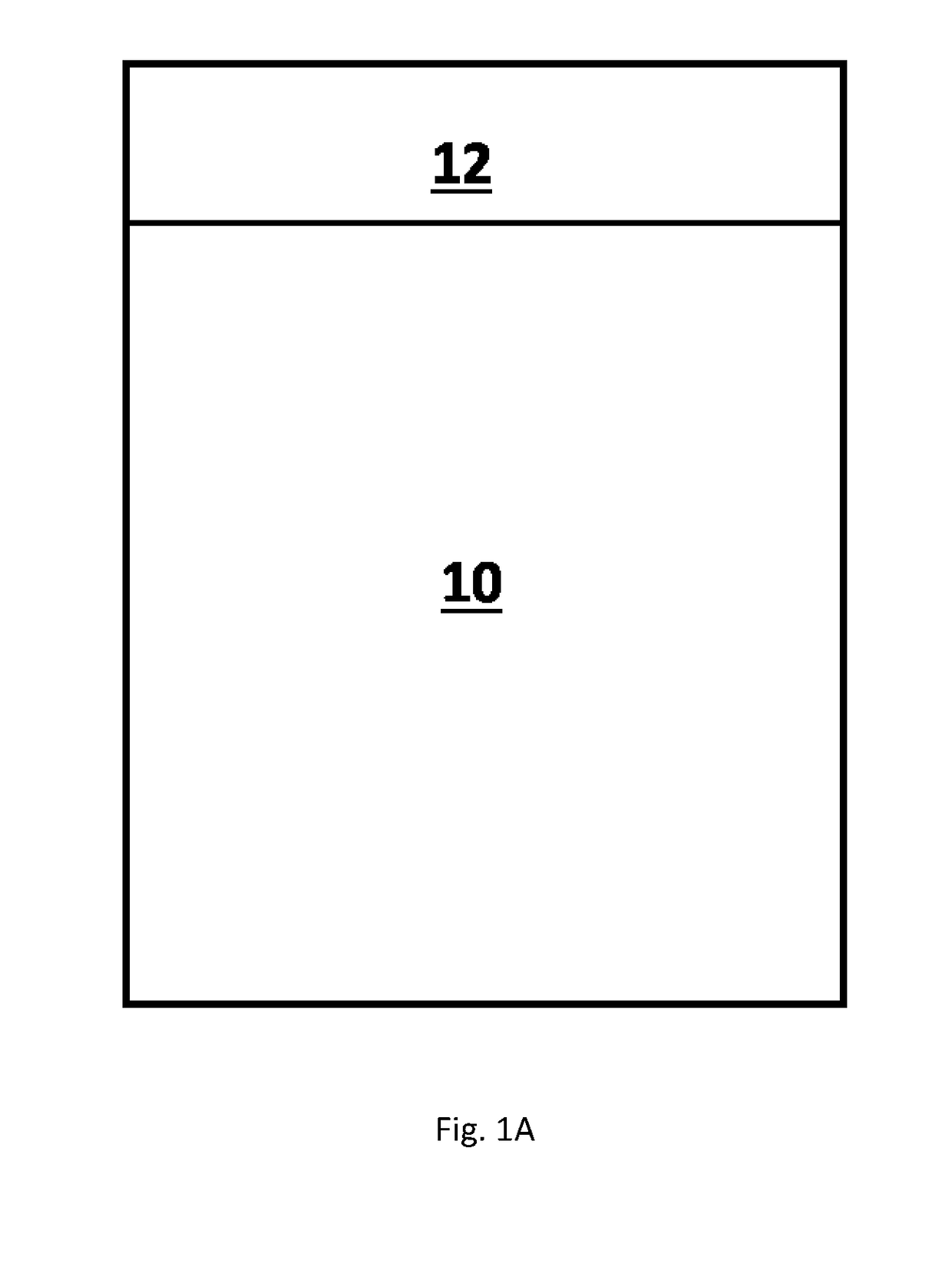

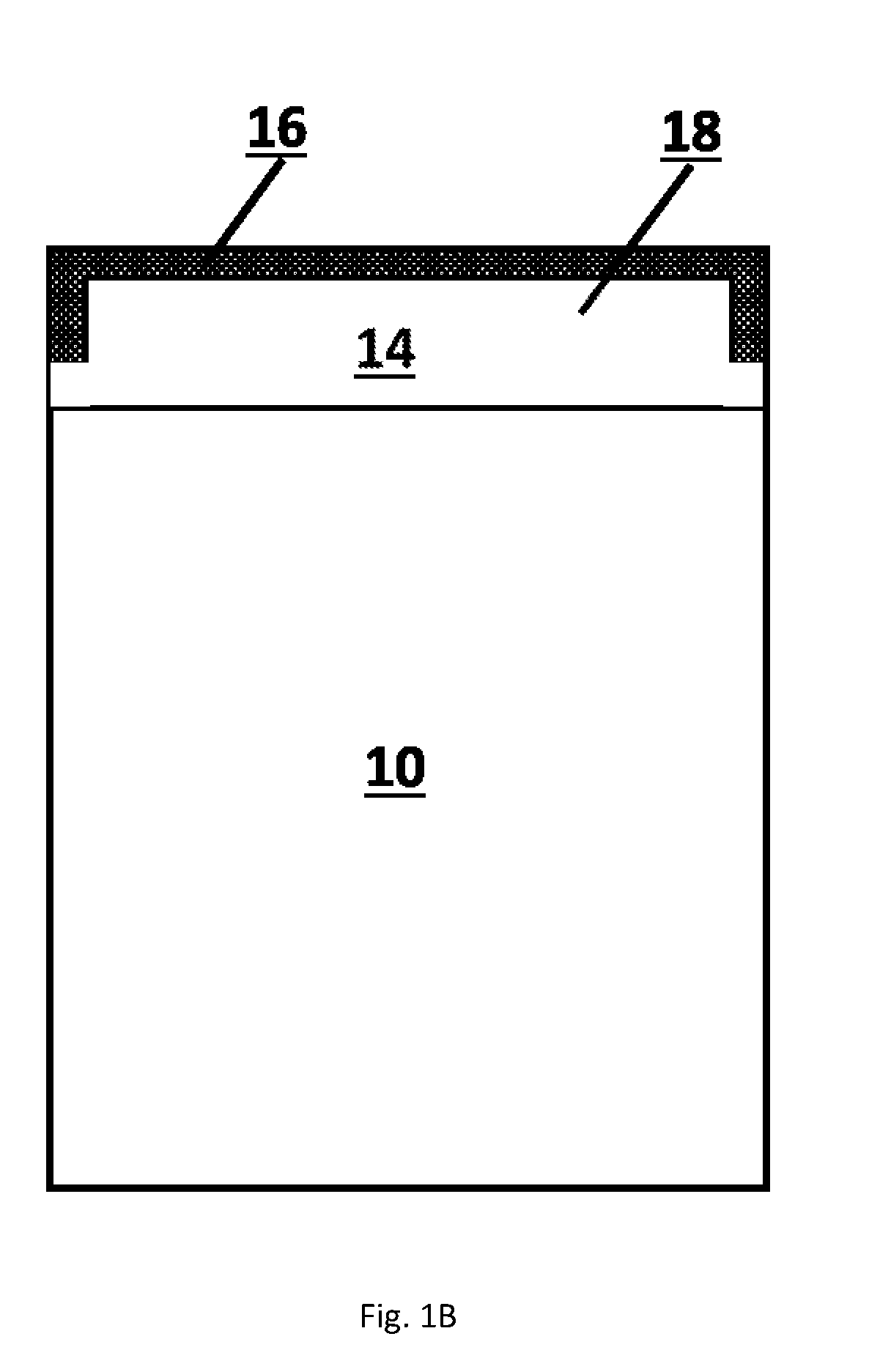

Method of making high performance heat sinks

InactiveUS20050156013A1Different functionsDifferent shapesSemiconductor/solid-state device detailsSolid-state devicesEngineeringHeat spreader

A method of heat sink manufacture in which the crests of a conductive fin are nested down into close fitting grooves in a flat, conductive base plate, with small interface gaps G. A compressive material is set inside the fin crests and the grooves, viscous enough to not intrude into the gaps G, to a level sufficient to substantially fill the grooves. The work piece thus created is subjected to a cold hydrostatic oil bath, crushing the outer surfaces of the fin crests into the internal surfaces of the grooves where the compressed seal covers, while the rest of the fin is supported against net deformation by the surrounding oil.

Owner:COOLIT SYSTEMS INC

Gradient alloy material and method for laser strengthening of copper plate of crystallizer of continuous casting machine

InactiveCN103805813AImprove toughnessStrong metallurgical bondMetallic material coating processesWear resistantHigh-temperature corrosion

The invention provides a gradient alloy material and method for laser strengthening of a copper plate of a crystallizer of a continuous casting machine. The method comprises the following steps: enabling transition of a nickel-based alloy material and a substrate on the working surface of a narrow chromium zirconium copper plate of the crystallizer by a laser cladding technology; and then cladding a special cobalt-based alloy material on the nickel-based alloy transition layer to form a new gradient alloy layer on the working surface of the narrow chromium zirconium copper plate of the crystallizer, wherein the gradient alloy layer is resistant to high temperature corrosion and wear resistant and is of an ultrafine and high-toughness metallographic structure. The cobalt-based alloy material is the novel cobalt-based alloy material prepared from the cobalt-based alloy by adding Hf, B and Si elements on the basis of satellite, and then properly lowering down the melting point of the alloy. Compared with the prior art, the gradient alloy material and method have the beneficial effects that the resistance to high-temperature corrosion and the wear resistance of the working surface of the narrow plate of the crystallizer are improved, the laser repair and reproduction of a crystallizer out of work are realized, and the use performance of the crystallizer can also be recovered and improved; in addition, the problem due to the repair of a chromium zirconium copper crystallizer out of work can be effectively solved; the quality of a casting blank is improved; the casting cost of steel per ton can be decreased.

Owner:鞍山煜宸科技有限公司

Process method for repairing gas turbine vanes by micro-arc deposition coating

The invention relates to the maintenance field of gas turbines, in particular to a process method for repairing gas turbine vanes by a micro-arc deposition coating. The invention relates to a process method that adopts the micro-arc deposition coating to repair the local damage area of a geometrical component or a surface coating caused during the service process of air compressor vanes of a heavy gas turbine, turbine rotor vanes and guider vanes / nozzles. The method can carry out micro-arc deposition coating restoration on the gas turbine vanes. The micro-arc deposition coating process is defined into a metallurgical process as follows: an electrode rod is used as an anode; a workpiece is used as a cathode; the high-frequency direct-current pulse micro-arc discharge is carried out between the electrode rod and a workpiece surface; and the material of the electrode rod is self-consumed and transferred to the contact area of the workpiece surface; and the environment during the transferring and depositing process of material is inert gas or vacuum or insulating oil. The process method can solve the problems that in the prior art, the restoration process is complex, the deformation occurs easily, the cost is high, and the restoration can not be done reliably and timely.

Owner:无锡中科金研激光燃气轮机部件有限公司

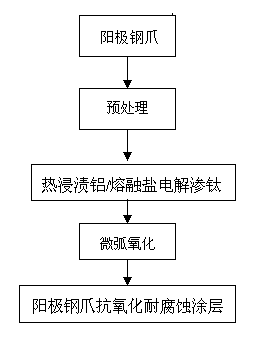

Preparation method for coating on electrolytic aluminum prebaked anode steel claw

InactiveCN103526212AImprove mechanical propertiesReduce consumption costMicro arc oxidationPlasma electrolytic oxidation

The invention relates to a preparation method for a coating on an electrolytic aluminum prebaked anode steel claw, which belongs to the technical field of metallurgical materials. The method comprises the following steps: removing dirt on the surface of the electrolytic aluminum prebaked anode steel claw through polishing, cleaning and drying the electrolytic aluminum prebaked anode steel claw and successively removing oil by using an oil removal agent and removing rust by using acid; subjecting the pretreated electrolytic aluminum prebaked anode steel claw to hot dip aluminum plating or fused salt electrolysis titanizing; and finally, carrying out micro-arc oxidation on the electrolytic aluminum prebaked anode steel claw treated by any method in a NaSiO3 solution, NaOH solution, NaH2PO4 solution or Na2SiO3 solution by using constant-current electrolysis so as to prepare the oxidation-resistant corrosion-resistant electrolytic aluminum prebaked anode steel claw treated by using a hot dip aluminum plating or fused salt electrolysis titanizing method and a micro-arc oxidation method. The preparation method provided by the invention overcomes the problems of high-temperature oxidation consumption of the anode steel claw and corrosion of electrolyte cryolite.

Owner:KUNMING UNIV OF SCI & TECH

Conductive bus and manufacturing method thereof

InactiveCN101478092AImprove conductivityLow priceContact member manufacturingCoupling contact membersAluminum canCopper

The invention relates to a conducting bar and a manufacturing method thereof. The conducting bar comprises an aluminum core and a copper layer covering the aluminum core. The copper layer is closed around the aluminum core. The cross section of the conducting bar is rectangular; the area of the cross section of the copper layer accounts for 13 to 21 percent of the area of the cross section of the conducting bar. The conducting bar with copper covering aluminum can reach various parameter standards of the conducting bar. The invention further provides a new conducting material. By comparing the conducting bar with a fine copper conducting bar with equal cross section area, the price is low; the weight is light; and the conducting bar provided by the invention can be installed and transported conveniently, and is favorable for the environmental protection.

Owner:崔纪康 +1

Iron-based alloy material for laser repair of rotor main shaft and manufacturing method thereof

InactiveCN101758219AStrong metallurgical bondGuaranteed uptimeElectric arc furnaceChemical composition

The invention relates to an iron-based alloy material for laser repair of a rotor main shaft. The iron-based alloy material comprises the following chemical components in percentage by weight: 0.30-0.35% of C, 18-20% of Cr, 0.35-0.50% of Mn, 1.50-1.70% of Mo, 0.80-1.0% of Si, 0.02% of Ti, 0.06% of V, and the balance of Fe. The method has the manufacturing steps of: firstly, manufacturing the iron-based alloy into powder, wherein the particle size of the iron-based alloy respectively selects two ranges: (1) 50-150 micrometers and (2) 100-325 micrometers; then, smelting by an electric arc furnace or a vacuum electric arc furnace, and manufacturing alloy powder on a horizontal atomizing process producing device protected by full Ar gas or full N2 gas, wherein the powder is in a uniform solid particle shape, and the content of satellite-shaped particles does not exceed 3-5%. The invention provides the iron-based alloy material for laser repair of the rotor main shaft, which has the advantages of quick repair operation, good quality, no damage to the rotor and the shaft diameter, safe and reliable running after the repair, long service life, and the like.

Owner:四川新吉隆环保科技有限公司

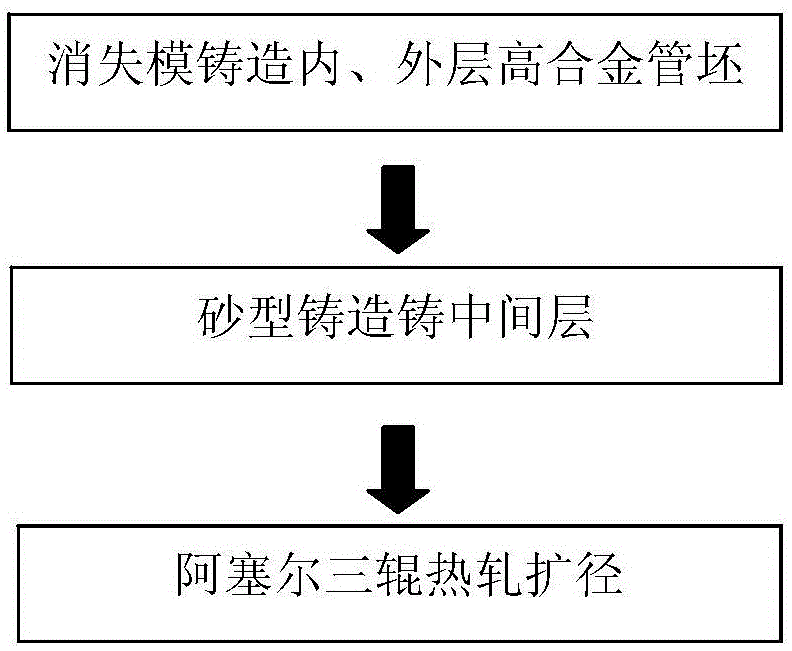

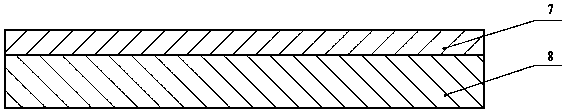

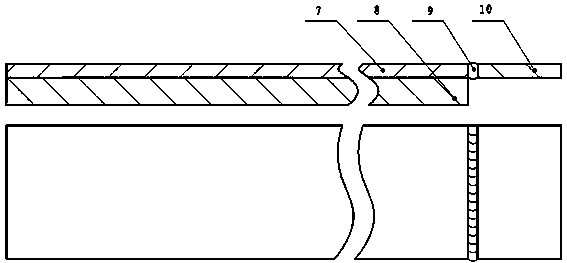

Preparation method for bimetal metallurgy composite pipe of three-layer structure

The invention discloses a preparation method for a bimetal metallurgy composite pipe of a three-layer structure. The method includes the steps that firstly, a thin-walled high alloy anti-corrosion pipe blank on the inner layer and a thin-walled high alloy anti-corrosion pipe blank on the outer layer are prepared through pouring according to a lost foam casting method; then, an interlayer carbon steel pipe blank is prepared through pouring and EPS modeling with the high alloy pipe blanks on the inner layer and the outer layer as mold cores, and a stainless steel / carbon steel / stainless steel bimetal composite pipe blank of a three-layer structure is obtained; and the bimetal composite pipe of the three-layer structure is manufactured by conducting three-roller hot rolling expanding deformation on the obtained bimetal pipe blank of the three-layer structure. The high-accuracy metal surfaces on the inner layer and the outer layer are obtained according to the lost foam casting method, and the metal thickness of the inner layer and the outer layer can be controlled. The resistance to three-roller hot rolling expanding deformation is small. The three layers of metal are combined through high-strength metallurgy. The surfaces on the inner layer and the outer layer are high in accuracy, good in ovality and high in wall thickness accuracy.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Manufacturing method for copper-stainless steel double-metal compound contact piece substrate material

InactiveCN107553060AHigh strengthIncrease elasticityWelding/soldering/cutting articlesMetal layered productsCopperUltimate tensile strength

The invention discloses a manufacturing method for a copper-stainless steel double-metal compound contact piece substrate material. The manufacturing method comprises the following steps of bonding acopper plate blank and a stainless steel plate blank together in an explosive welding manner, and then performing rolling to obtain the copper-stainless steel double-metal compound contact piece substrate material. According to the manufacturing method, for the copper-stainless steel double-metal compound contact piece substrate material, relative to a copper contact piece prepared from a single material, by adding a stainless steel layer, the strength and the elastic modulus are improved; and meanwhile, through reasonable selection of a thickness ratio of copper and stainless steel, the contact piece substrate material is ensured to be capable of still keeping higher electric conductivity on the basis of having certain elastic modulus.

Owner:LUOYANG SHUANGRUI METAL COMPOSITE MATERIAL

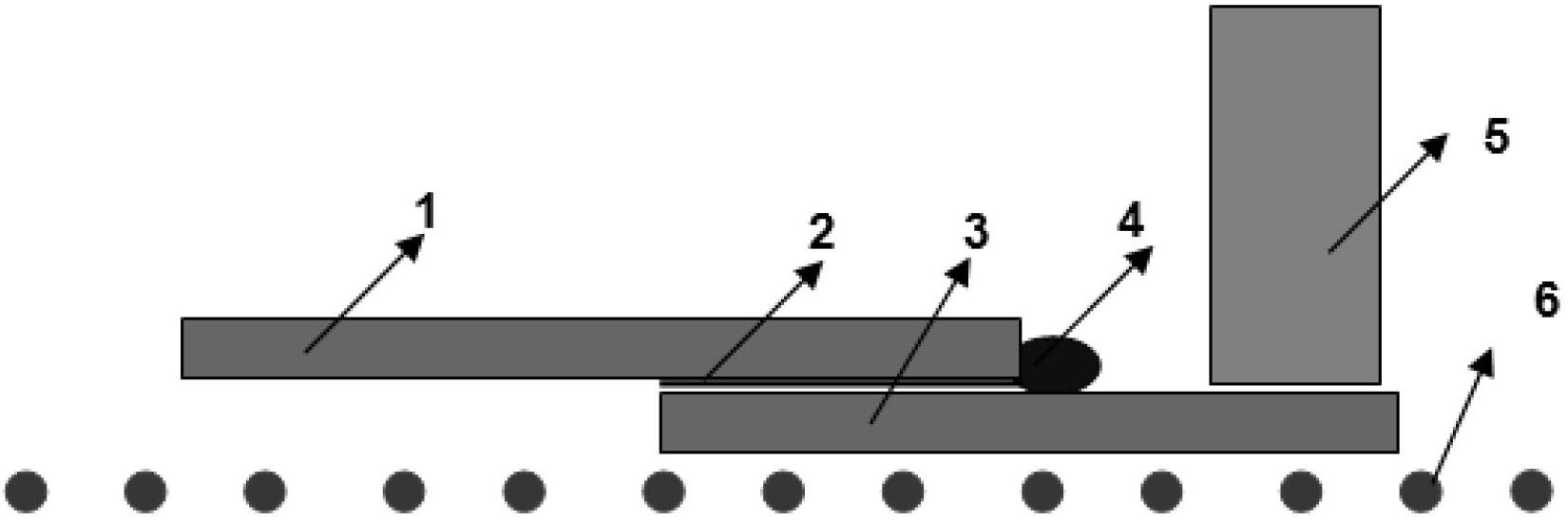

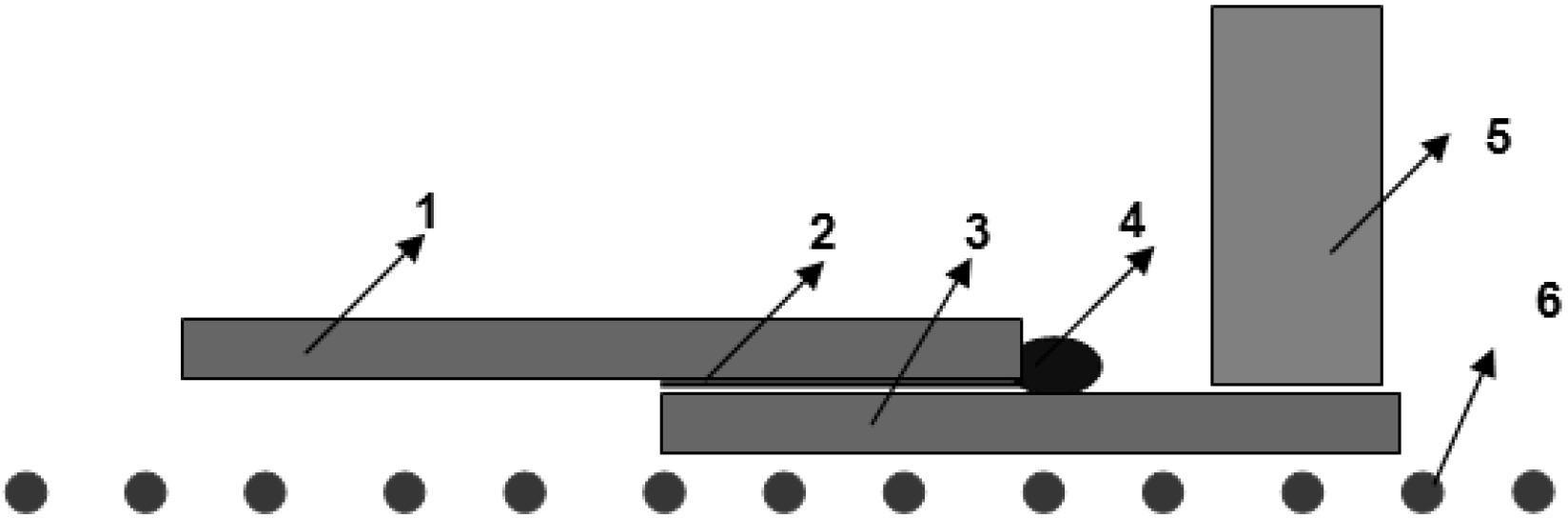

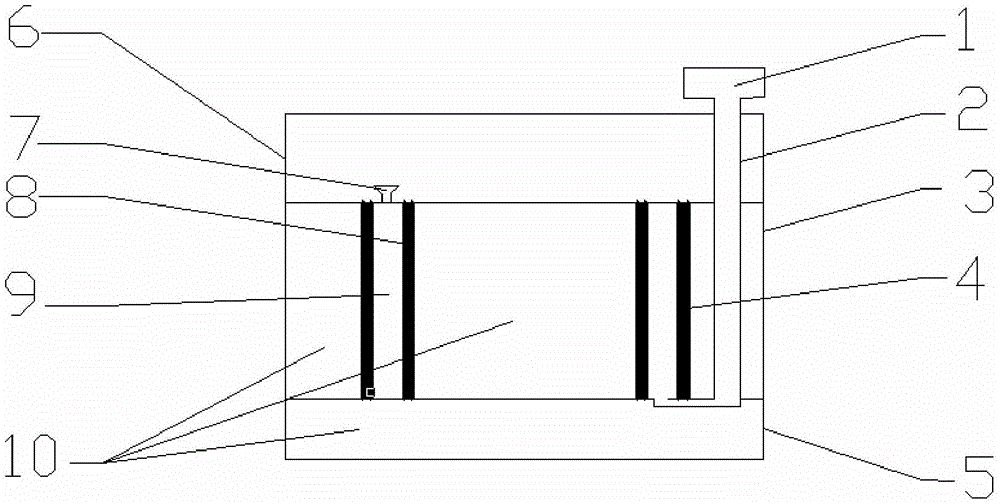

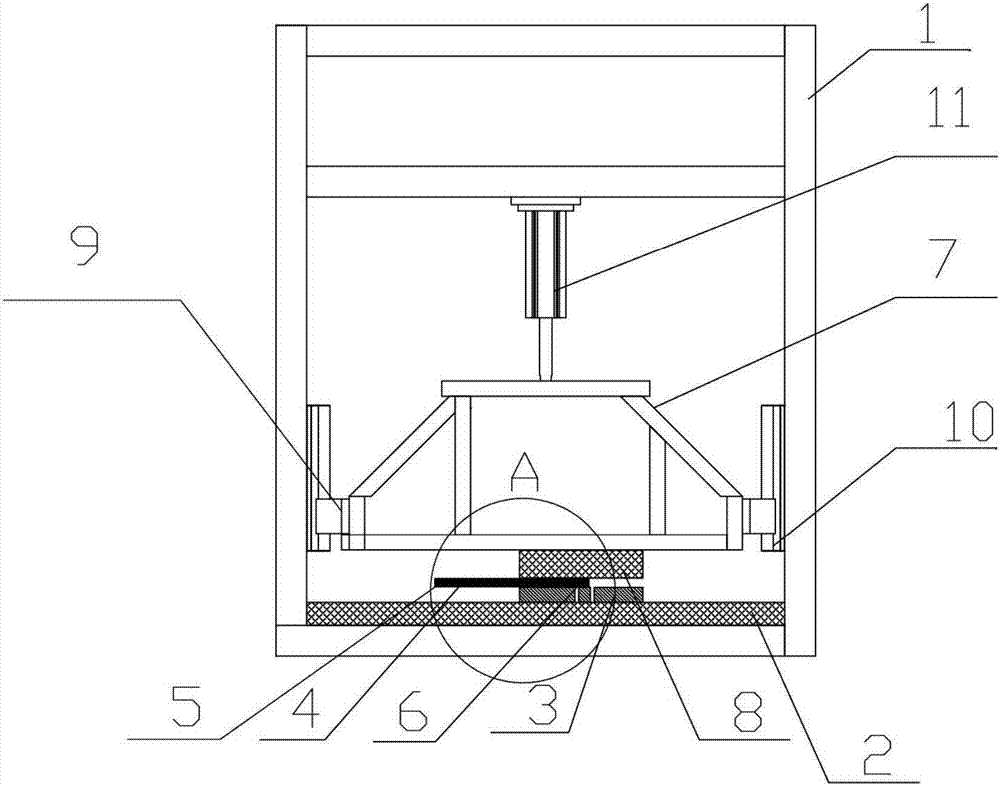

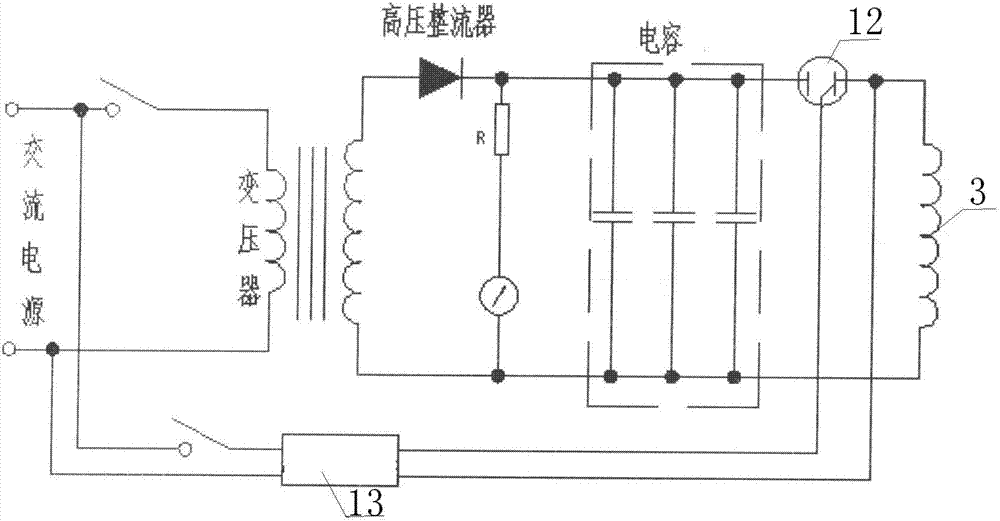

Electromagnetic pulse welding method of multilayer battery aluminum plate lugs and copper pole lugs

InactiveCN107081513AReduce labor intensityIncrease productivityHigh frequency current welding apparatusWelding/soldering/cutting articlesCapacitanceElectrical battery

The invention discloses an electromagnetic pulse welding method of multilayer battery aluminum plate lugs and copper pole lugs. The aluminum plate lugs and the copper pole lugs are fixed on a welding device; the welding device comprises a rack; a cushion plate is arranged on the rack; an electromagnetic coil is arranged on the cushion plate; welding areas of the multilayer aluminum plate lugs are placed on the electromagnetic coil; the copper pole lugs are placed on the upper portion of the aluminum plate lug at the uppermost layer; interval pieces are arranged between the welding areas of the aluminum plate lugs as well as the welding areas of the aluminum plate lugs and the copper pole lugs; the aluminum plate lugs and the copper pole lugs are fixed through a pressing plate; the electromagnetic coil is connected with a capacitance switch of a capacitance power supply device; the capacitance switch is controlled by a pulse generator to be switched on and switched off; and the pulse generator is started to charge a capacitor of the capacitance power supply device, when the charging voltage reaches the set value, the capacitance switch is turned on, and the capacitor quickly discharges, so that welding of the battery aluminum plate lugs and the copper pole lugs is achieved. The welding efficiency is improved, the welding quality is improved, energy consumption is reduced, auxiliary materials are not consumed, and energy saving and environmental friendliness are achieved.

Owner:INST OF OPTICAL MASCH CHONGQING CITY +1

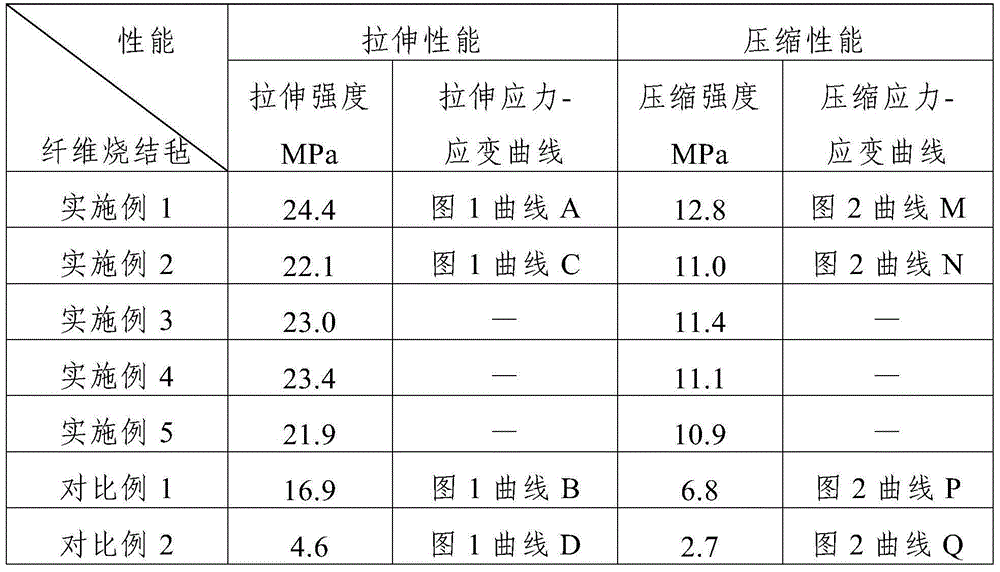

Preparation method for stainless steel fiber sintered felt

The invention provides a preparation method for stainless steel fiber sintered felt. The preparation method comprises the following steps that firstly, stainless steel fiber felt is put in a vacuum sintering furnace, the stainless steel fiber felt is heated up to 300 DEG C-600 DEG C under vacuum conditions, and then the temperature is kept for 30 min-120 min, low temperature sintering treatment is conducted, low temperature sintered felt is obtained after natural cooling; and secondly, the low temperature sintered felt is compressed to be 60%-95% in porosity by adopting a hydraulic press, then the compressed low temperature sintered felt is put in the vacuum sintering furnace, the compressed low temperature sintered felt is heated up to 900 DEG C-1000 DEG C under vacuum conditions, then the temperature is kept for 1 min-30 min, high temperature sintering treatment is conducted, and the stainless steel fiber sintered felt is obtained after natural cooling. According to the preparation method for the stainless steel fiber sintered felt, not only is firm metallurgical bonding among fibers achieved, but also coarsening of crystal grains inside the fibers is avoided, so that the mechanical property of the stainless steel fiber sintered felt is improved.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

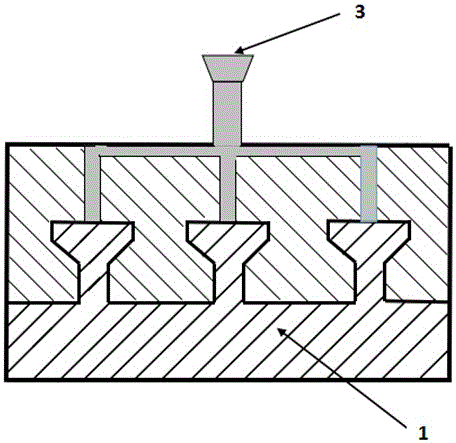

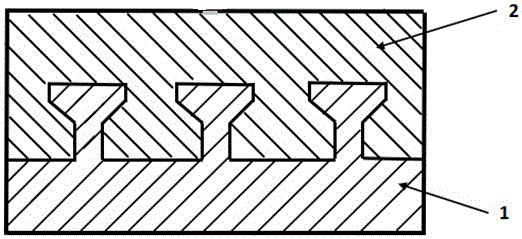

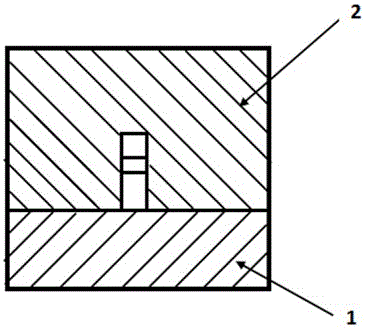

Bimetallic wear-resisting lining plate and preparation method thereof

InactiveCN106350738AIncrease composite areaThe interface is tightly combinedGrain treatmentsQuenching agentsManganeseAlloy

The invention discloses a bimetallic wear-resisting lining plate and a preparation method thereof and belongs to the technical field of metal material casting. The bimetallic wear-resisting lining plate comprises a matrix layer and a wear-resisting layer, wherein the wear-resisting layer is provided with more than two T-type projections inlaid into the matrix layer, the height ratio of every T-type projection to the wear-resisting layer is 1:1.2-1:2, the height ratio of the wear-resisting layer to the matrix layer is 1:1-1:3, the width ratio of every T-type projection to the lining plate is 1:8-1:15, the wear-resisting layer and the T-type projections are made of medium-carbon low-alloy silicon-manganese steel, the matrix layer is made of low-alloy carbon steel, and the bimetallic wear-resisting lining plate is prepared through compounding, smelting, casting, annealing and isothermal quenching. The bimetallic wear-resisting lining plate and the preparation method thereof have the advantages that through adoption of reasonable structural design and a layered casting technology, combination of a composite layer at an interface is closer, and the composite layer is less prone to separation; produced through the thermal treatment technology of simple isothermal quenching, the bimetallic wear-resisting lining plate is highly resistant to wear, high in tenacity, simple in preparation technology and convenient to produce, and production cost can be reduced effectively.

Owner:KUNMING UNIV OF SCI & TECH

Sealing process of turbine rotor blade cover plate top hole of gas turbine

InactiveCN109261965AImprove conductivityImprove thermal conductivityIncreasing energy efficiencyEngineeringAlloy

The invention discloses a sealing process of a turbine rotor blade cover plate top hole of a gas turbine. The process comprises the steps that (1), top hole pre-processing is conducted; (2), a red copper bar cooperates with the top hole is prepared to be used as a lining; (3), the red copper bar is installed at the bottom of the top hole, sealing alloy powder is delivered into the top hole througha coaxial gas carrying powder delivering device to perform laser cladding process, and the path is single-passage and multi-layer; (4), the red copper bar is separated from the cover plate, and castmodification processing is conducted on the cover plate of which the top hole is sealed; (5), nondestructive examination is conducted on the cover plate on which cast modification is conducted. According to the sealing process, a traditional vacuum brazing process is abandoned, a laser cladding technology is adopted to seal the turbine rotor blade cover plate top hole of the gas turbine, metallurgical bonding is formed between the sealing alloy powder and the top hole inner wall, the bonding strength is high, the bonding does not easily fall in the using process, vacuum does not need to be ensured, the sealing cost is low, and the cladding quality is improved by multi-layer clading.

Owner:成都青石激光科技有限公司

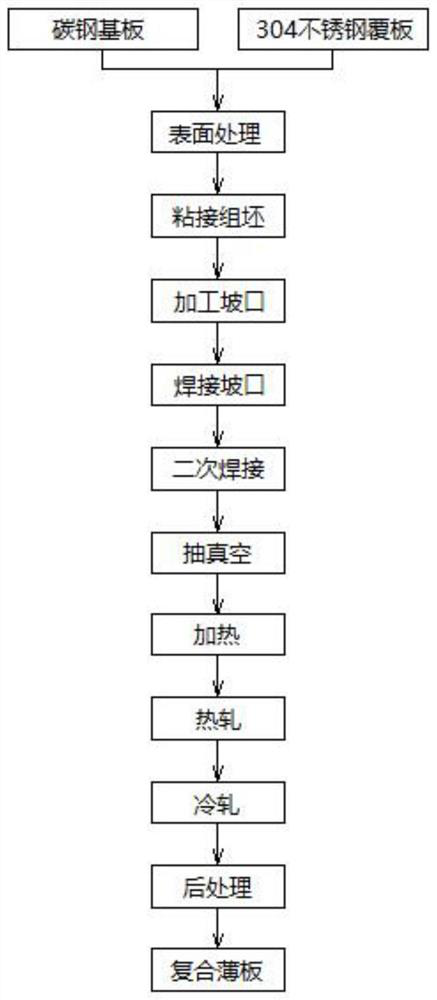

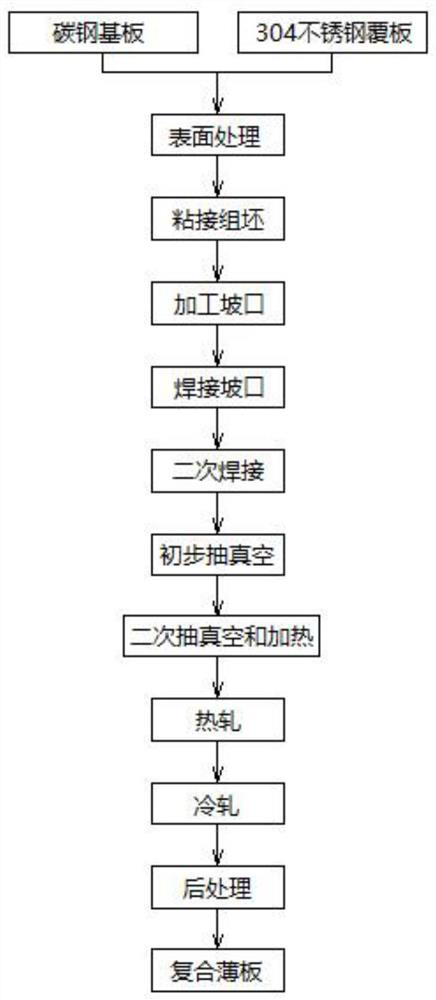

Processing method of carbon steel and 304 stainless steel single-sided composite board

ActiveCN112643292ARealize the combinationMetal bonding is achieved by evenly coating the joint surfaceAdhesiveComposite slab

The invention discloses a processing method of a carbon steel and 304 stainless steel single-sided composite board. The processing method of the carbon steel and 304 stainless steel single-sided composite board comprises the following steps of (1) conducting surface treatment; (2) assembling; (3) processing grooves; (4) applying pressure in a segmented mode, welding the grooves, and then welding and sealing all the grooves; (5) vacuumizing; (6) heating; (7) conducting hot rolling; (8) conducting cold rolling; and (9) carrying out post-treatment to obtain the composite sheet. According to the processing method of the carbon steel and 304 stainless steel single-sided composite board provided by the invention, an adhesive is adopted for bonding in the assembling process, so that primary connection is achieved; the grooves are processed in the welding process, and the pressure is applied in the segmented mode, welding and secondary welding are conducted on the grooves, so that local upheaval or upwarping of a combined blank plate is avoided, and firm metallurgical bonding can be formed between a base plate and a covering plate; and the carbon steel and stainless steel single-sided composite sheet processed by each processing step has corrosion resistance and good mechanical strength and processability.

Owner:ANHUI BAOHENG ADVANCED MATERIAL TECH CO LTD

Polycrystalline Diamond Compact Cutters Having Protective Barrier Coatings

ActiveUS20180371845A1Improve antioxidant capacityGood adhesionConstructionsVacuum evaporation coatingPolycrystalline diamondOxidation resistant

The present disclosure relates to a polycrystalline diamond compact (PDC) cutter with protective barrier coating. The PDC cutter consists of an unleached or leached polycrystalline diamond (PCD) table, a cemented carbide body substrate, and a coating disposed on the cutter. The coating covers at least partially the exterior surfaces of the PCD table of the PDC cutter, and it may also extend over partially or entirely the exterior surfaces of the cemented carbide body. The coating is either a single layer or multilayer. The coating has a thickness of 0.4 μm-100 μm. The coating may have a strong metallurgical bonding with PDC cutter. The coating comprises an oxidation-resistant layer that protects the PDC cutter from thermal and mechanical degeneration during brazing and cutting applications. Methods for preparing such the coating comprise physical vapor deposition, chemical vapor deposition, thermoreactive deposition and diffusion, electrical plating, electroless plating, or their combinations.

Owner:JIANG WENHUI

Machining method of three-layer clad steel plate

ActiveCN112548499ARealize the combinationMetal bonding is achieved by evenly coating the joint surfaceAdhesiveSS - Stainless steel

The invention discloses a machining method of a three-layer clad steel plate. The machining method comprises the following steps: (1) surface treatment; (2) assembling; (3) groove machining; (4) segmental pressure application, groove welding and complete welding and sealing; (5) primary vacuumizing treatment; (6) secondary vacuumizing treatment and heating; (7) hot rolling; (8) cold rolling; (9) post-treatment to obtain a composite sheet. According to the machining method, an adhesive is adopted for bonding in the assembling process, so that primary connection is achieved; the grooves are machined in the welding process, pressure is applied in a segmented mode, and welding and secondary welding are conducted on the grooves, so that a combined blank plate is prevented from locally protruding or tilting; a two-time vacuumizing treatment mode and a heating mode are adopted during vacuumizing, so that firm metallurgical bonding can be formed between a base plate and a covering plate; and the carbon steel and stainless steel double-sided composite sheet machined by the machining steps has corrosion resistance, high mechanical strength and machinability.

Owner:ANHUI BAOHENG ADVANCED MATERIAL TECH CO LTD

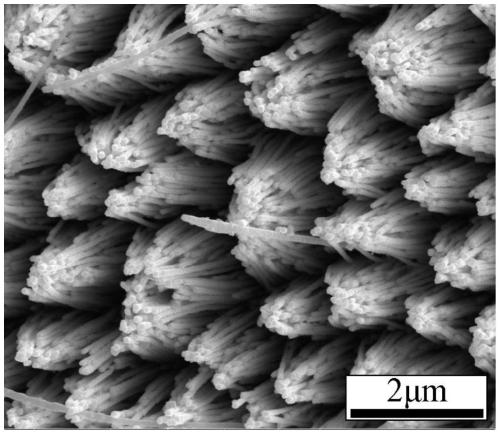

Method for preparing silver nanowire array by using capillary wetting effect

ActiveCN110093602AEasy to operateImprove wettabilityNanotechnologyMetallic material coating processesBound propertyPhase change

The invention provides a method for preparing silver nanowire arrays by using capillary wetting effect, and relates to a method for preparing the silver nanowire arrays. The method aims to solve the technical problems that an existing silver nanowire array is complex in preparation process and poor in binding property with a target matrix. The method comprises the following steps of 1, mixing Ag powder with CuO powder; 2, heating the mixed powder; and 3, carrying out hydrothermal reaction. The method for preparing the silver nanowire arrays on an inert metal surface or a ceramic surface by using the capillary wetting effect is simple and effective in operation; and meanwhile, a method for removing a phase-changed AAO template through corrosion is provided, and the application prospect is good.

Owner:HARBIN INST OF TECH

Manufacturing and processing method of rectangular section dissimilar metals composite wires

InactiveCN101007385AHigh strengthImprove thermal conductivityOther manufacturing equipments/toolsExplosivesDetonatorManufacturing cost reduction

The invention discloses a preparation method of rectangular cross section heterologous metal composite wire. It assemblies the metal core rob which surface is treated in coated metal tube and installs it on the positioning device of bottom, blocks the top of coated metal pipes and metal core rob with top positioning device, the gap between inner wall of coated metal pipe and metal core rob is 0.5mm - 2.5mm; puts the coated metal pipe and metal core rob in cylindrical annular tube, setting explosives and electric detonator between the coated metal pipe and cylindrical annular tube uniformly; detonates electric detonator and realizes the explosive recombination of two metal of coated metal pipe and metal core rob in a moment; heat treats the combination rob which is connected and combined by explosion, plastically rotating forges and draws at temperature of 350 DEG C-950DEG C, then prepares the needed round cross section heterologous metal composite wire; rolls the round cross section heterologous metal composite wire into rectangular cross section heterologous metal composite wire. The invention is a method of simple production processes, high production yield and productivity, reducing the manufacturing cost significantly.

Owner:CENT SOUTH UNIV

Copper-cladding aluminum wire, aluminum rod for copper-cladding aluminum wire and processing method thereof

InactiveCN102420023ASuperior performanceStrong metallurgical bondSingle bars/rods/wires/strips conductorsMetal/alloy conductorsCopper-clad aluminium wireAluminum can

The invention discloses an aluminum rod for a copper-cladding aluminum wire, which comprises the following ingredients by weight percent: 95.3 to 94.9 percent of aluminum pig, 3 to 3.3 percent of magnesium and 1.7 to 1.8 percent of chromium. The invention also provides a processing method of the aluminum rod for the copper-cladding aluminum wire, which comprises the following steps that: 95.3 to 94.9 percent of aluminum pig and 1.7 to 1.8 percent of chromium are added, 3 to 3.3 percent of magnesium is added after the aluminum pig and the chromium are molten, water is discharged after multi-time foreign matter removal processing and after the heat is preserved for a period of time, and then the wire drawing processing and the wire take-up processing are carried out; and the above wire is annealed to standby use after being polished. The aluminum rod has excellent performance, firm metallurgical bonding between the aluminum rod and a copper layer can be realized, and the overall performance of the copper-cladding aluminum can be improved. The invention also provides a copper-cladding aluminum utilizing the aluminum rod.

Owner:安徽瑞隆电工有限公司

Process method for repairing gas turbine vanes by micro-arc deposition coating

The invention relates to the maintenance field of gas turbines, in particular to a process method for repairing gas turbine vanes by a micro-arc deposition coating. The invention relates to a process method that adopts the micro-arc deposition coating to repair the local damage area of a geometrical component or a surface coating caused during the service process of air compressor vanes of a heavy gas turbine, turbine rotor vanes and guider vanes / nozzles. The method can carry out micro-arc deposition coating restoration on the gas turbine vanes. The micro-arc deposition coating process is defined into a metallurgical process as follows: an electrode rod is used as an anode; a workpiece is used as a cathode; the high-frequency direct-current pulse micro-arc discharge is carried out betweenthe electrode rod and a workpiece surface; and the material of the electrode rod is self-consumed and transferred to the contact area of the workpiece surface; and the environment during the transferring and depositing process of material is inert gas or vacuum or insulating oil. The process method can solve the problems that in the prior art, the restoration process is complex, the deformation occurs easily, the cost is high, and the restoration can not be done reliably and timely.

Owner:无锡中科金研激光燃气轮机部件有限公司

Method for manufacturing inner covered stainless steel compound steel pipe

InactiveCN101670383BOvercoming the problems that reduce the corrosion resistance of stainless steelOvercome the problem of anti-corrosion performanceFurnace typesHeat treatment process controlSolution treatmentInterference fit

Owner:大连合生科技开发有限公司

Combined roller sleeve, manufacturing method thereof and roller

ActiveCN109174971AStrong metallurgical bondExtended service lifeRollsMetal rolling arrangementsSlagThermite

The invention discloses a combined roller sleeve, a manufacturing method thereof and a roller comprising the combined roller sleeve. The combined roller sleeve comprises an outer operation layer, a combined transition layer and an inner seamless pipe. The inner seamless pipe is a prefabricated low-carbon seamless steel pipe. The outer operation layer is a cast-in-place abrasion-resistant alloy steel layer. The combined transition layer is jointly formed by molten iron generated by reaction of thermite and a slag former and cast-in-place alloy liquid as well as molten iron on the surface layerof the inner seamless pipe. The outer operation layer, the combined transition layer and the inner seamless layer are metallurgically bonded. By coating the mixed coating of the thermite and the slagformer to the outer surface of the inner seamless pipe, the mixed coating has a chemical reaction with the high-temperature alloy liquid in the cast-in-place process of the outer operation layer, molten iron is generated, heat is released to melt the surface layer of the seamless steel pipe, the generated molten iron and the molten iron molten on the surface layer of the seamless steel pipe jointly form the combined transition layer, and therefore, firm combination of the outer operation layer and the inner seamless pipe can be achieved.

Owner:HUNAN 3T NEW MATERIAL

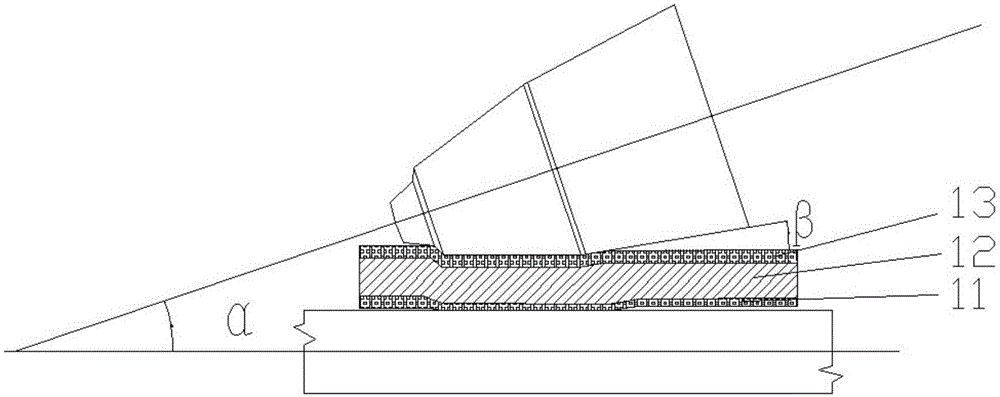

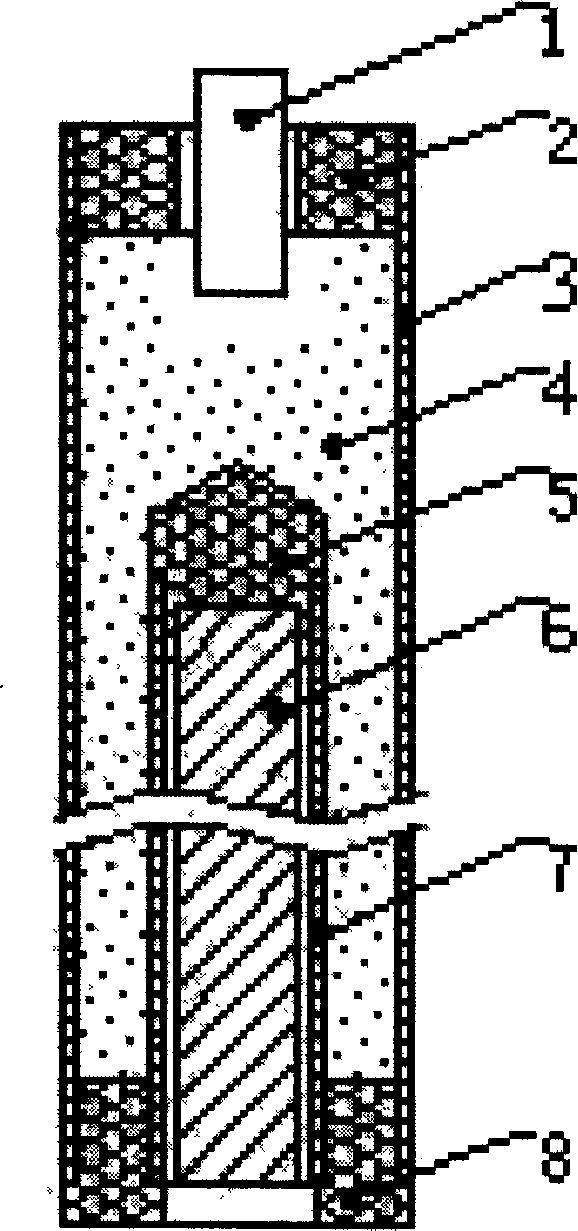

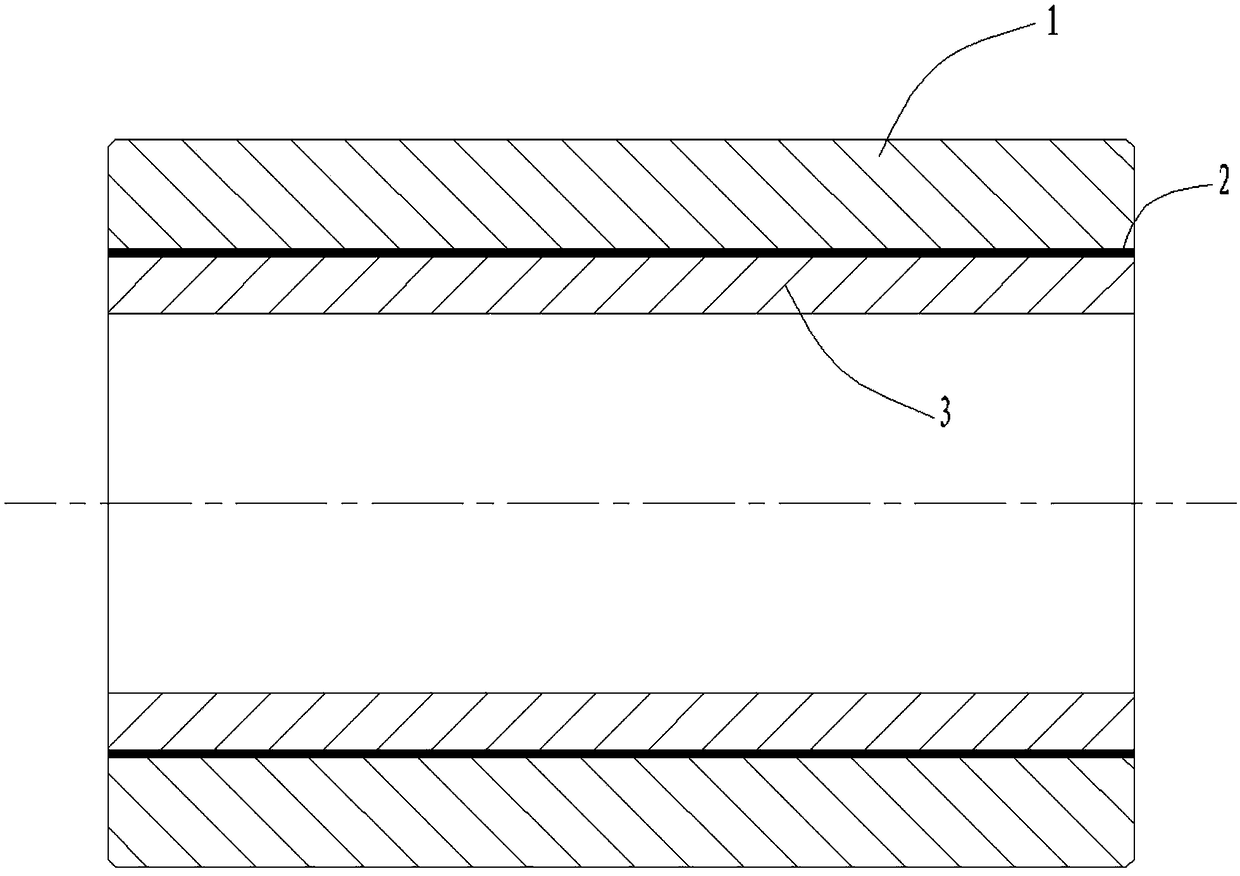

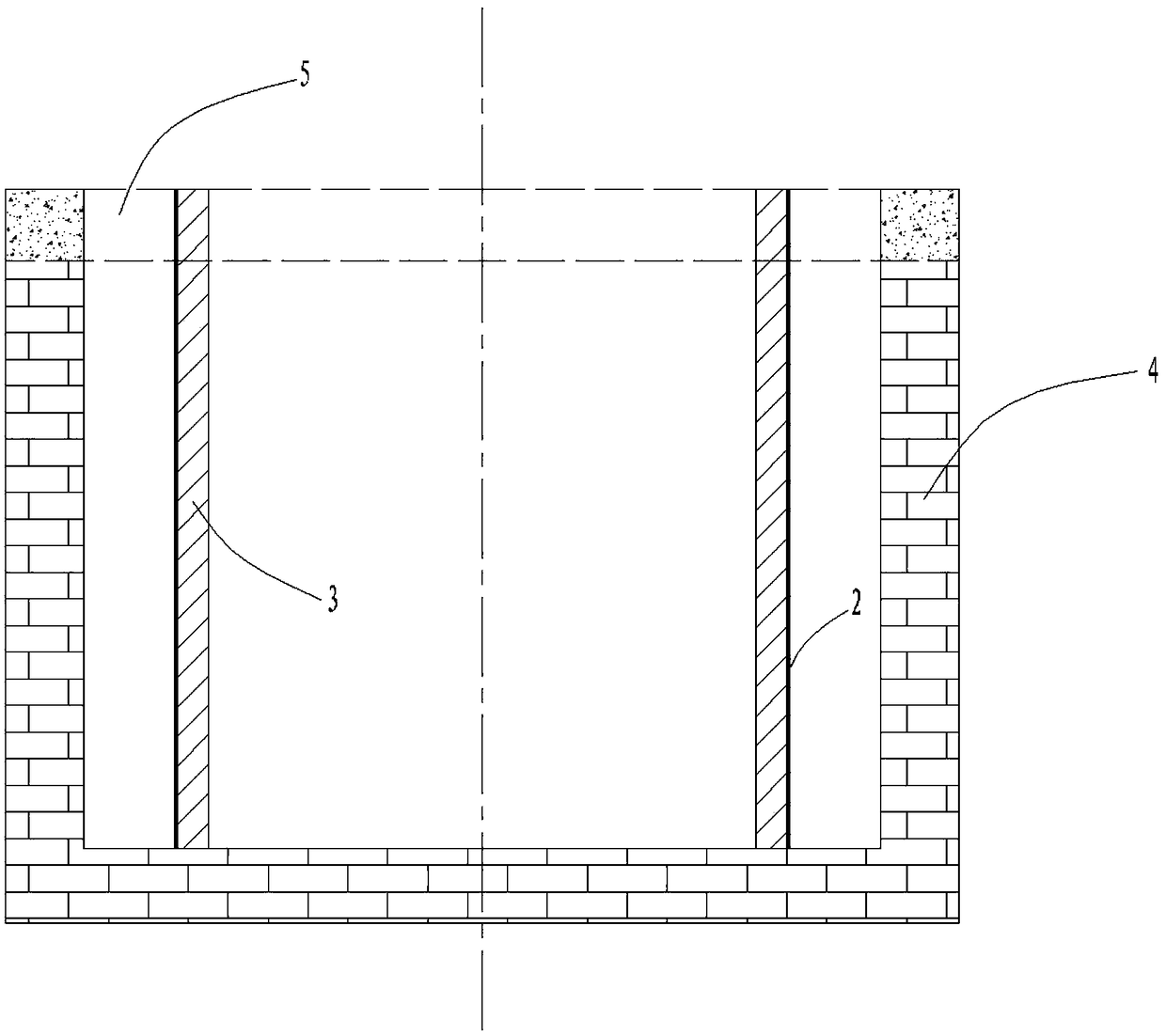

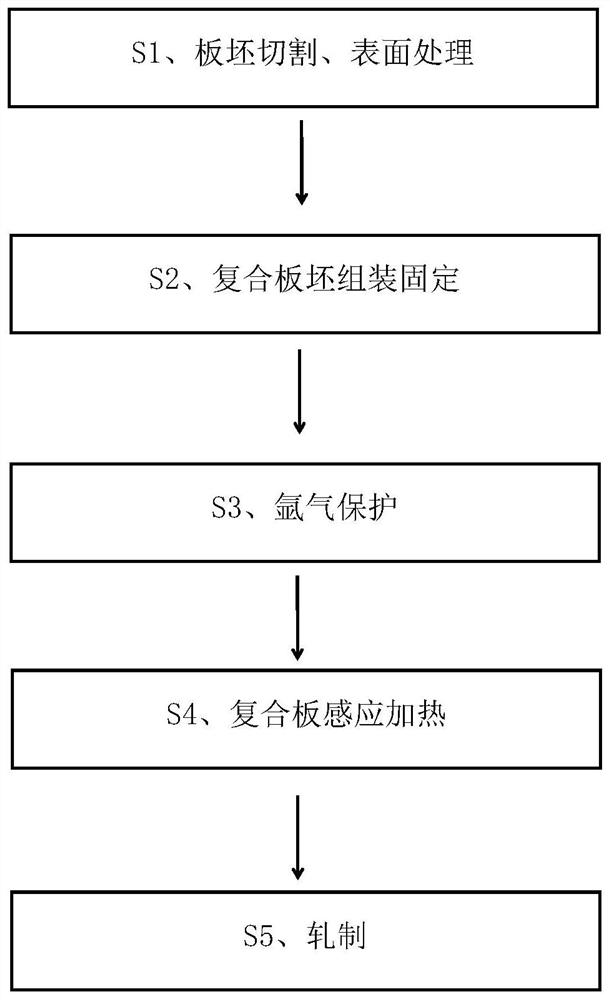

Method for preparing titanium-steel composite plate by adding pure iron interlayer through electromagnetic induction heating rolling

InactiveCN112828039AAvoid the defects of long heating time and low production efficiencyAvoid generatingWork treatment devicesMetal rolling arrangementsTitaniumComposite plate

The invention provides a method for preparing a titanium-steel composite plate by adding a pure iron interlayer through electromagnetic induction heating rolling. The method comprises the following steps: S1, cutting a plate blank and carrying out surface treatment; S2, assembling and fixing the composite plate blank; S3, carrying out argon protection; S4, carrying out induction heating of the composite plate; and S5, carrying out rolling. The characteristics that pure iron interlayer metal is good in mobility and easy to combine with pure titanium and carbon steel are utilized, electromagnetic induction heating is adopted to replace traditional resistance wire heating furnace heating to achieve rapid heating of the composite plate blank in the protective gas atmosphere, the production process is simplified, the titanium-steel composite plate has a certain temperature difference through electromagnetic induction heating, the warping degree of the rolled composite plate blank is reduced, and the titanium-steel composite plate with high bonding strength and good deformation coordination can be efficiently prepared.

Owner:YANSHAN UNIV

Environment-friendly water pipe with natural bacteriostasis function

InactiveCN105090626AFlat surfaceReduce air leakage rateRigid pipesComposite plateUltimate tensile strength

The invention provides an environment-friendly drinking water pipe with a natural bacteriostasis function. The drinking water pipe is made of materials of copper and aluminum metallurgical composite single-side copper; a copper and aluminum metallurgical composite plate belt uses aluminum as base materials; a metal aluminum base composite material of a single-side metallurgical composite copper belt is required to reach the metallurgical compounding between copper and aluminum; the copper belt needs to be pure copper or copper alloy with the copper content being higher than 60 percent. The copper layer surface of the copper and aluminum metallurgical composite materials is used as the inner surface of an air pipe. The copper and aluminum metallurgical compounding drinking water pipe belongs to a new generation of natural bacteriostasis (sterilization) environment-friendly drinking water pipe replacing the drinking water pipe made of pure copper, stainless steel or other materials. The drinking water pipe is made of copper and aluminum metallurgical compounding composite materials, and the bonding intensity is higher than or equal to 100MPa. The surface of the prepared copper and aluminum composite plate is smooth and flat. In the production process, phenomena of cracking, falling and the like cannot occur during the processing of bending, hole drilling, hole punching, thread tapping, antique processing, lacquering and the like, and the product quality and the finished product rate of the drinking water pipe are ensured.

Owner:洛阳市伟创复合材料科技有限公司 +1

Method for carrying out laser-cladding on high-hardness nickel-based alloy material in large area

ActiveCN102465294BImprove wear and corrosion resistanceDense tissueMetallic material coating processesLaser beam welding apparatusSurface engineeringHeat-affected zone

Owner:NINGBO SIASUN ROBOT TECH CO LTD

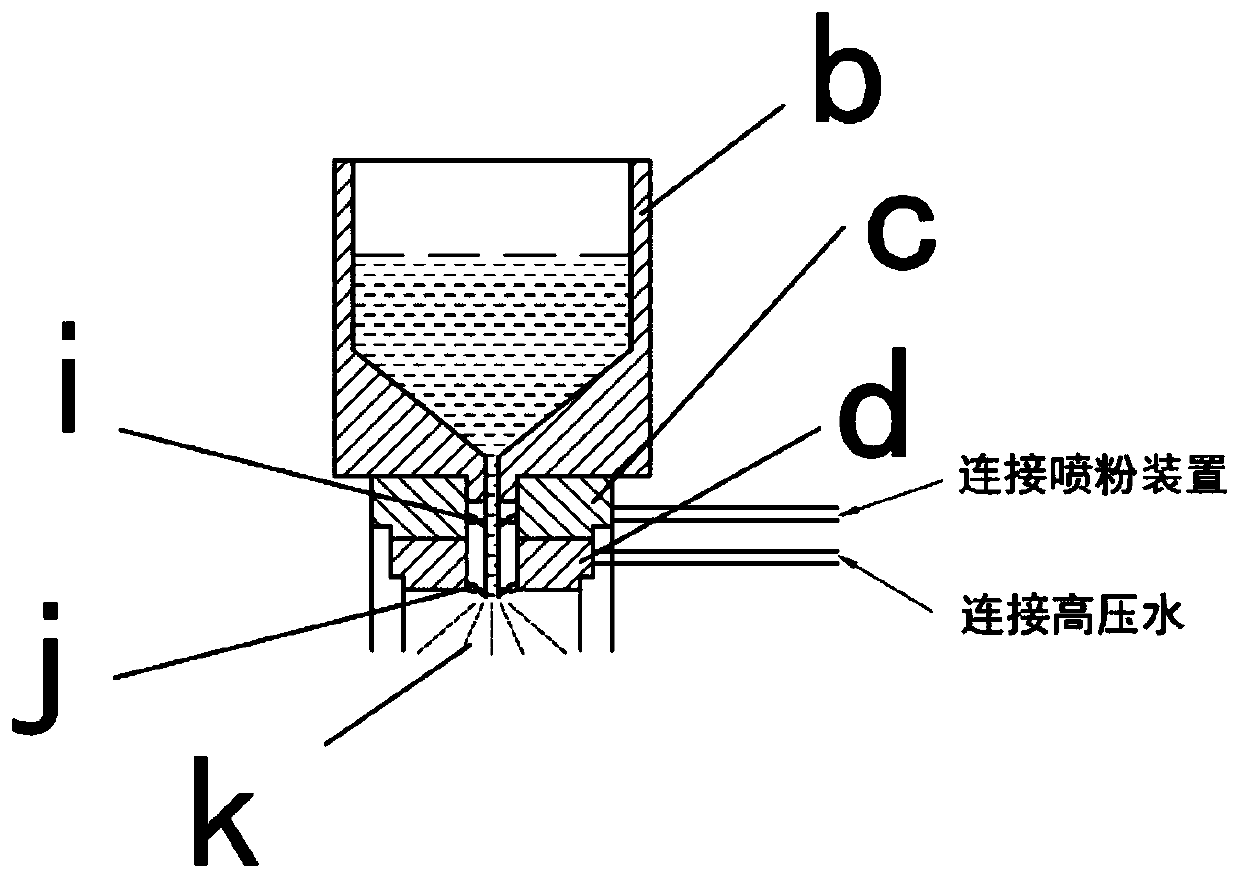

Integrated device for powder preparation and powder mixing, and application thereof

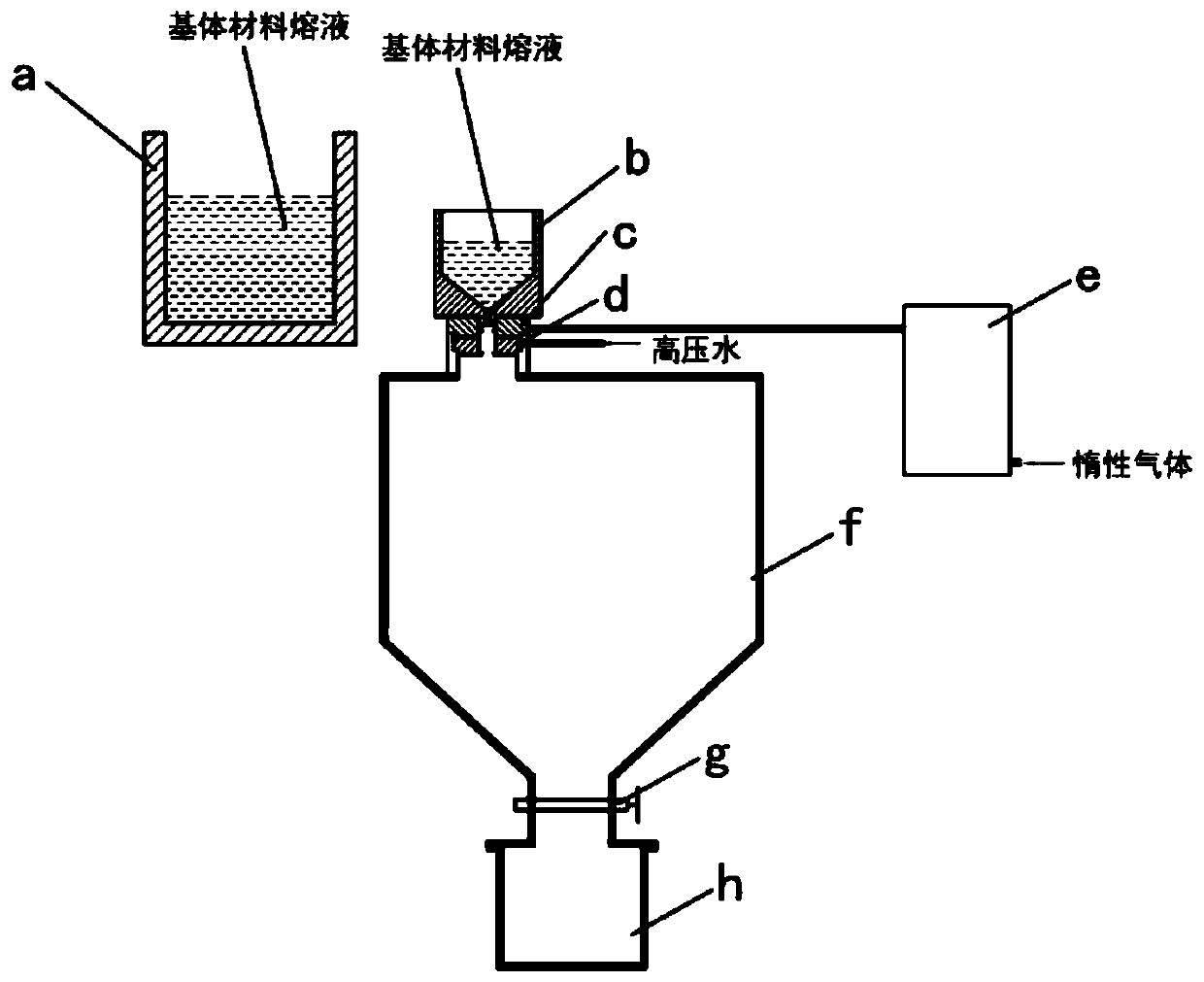

The invention discloses an integrated device for powder preparation and powder mixing, and an application thereof. The integrated device for powder preparation and powder mixing comprises a medium-frequency smelting furnace, a heat-insulation furnace, an upper spray disc, a lower spray disc, a collection bucket and a powder spray device. The medium-frequency smelting furnace is a fixed-point casting furnace, and a casting center corresponds to the center of the heat-insulation furnace; and the lower spray disc and the upper spray disc are placed in an upper-end connector of the collection bucket, the lower spray disc is connected with a high-pressure water pipeline, the upper spray disc is connected with the powder spray device, the heat-insulation furnace is installed at the top of the upper spray disc, a discharge spout is formed in the bottom of the heat-insulation furnace, and the center of the discharge spout corresponds to the centers of the spray discs. The lower end of the collection bucket is connected with a filter-pressing bucket, and a butterfly valve is arranged between the collection bucket and the filter-pressing bucket. According to the integrated device for powderpreparation and powder mixing, and the application thereof, the two actions of preparation and mixing for metal powder are realized on one piece of equipment, and the integrated device for powder preparation and powder mixing is simple and convenient to operate, high in production efficiency, and low in labor intensity; and moreover, the distribution uniformity and the bonding strength of dispersion-strengthening-phase particles or high-melting-point-phase particles in a matrix material are improved and increased, and the integrated device for powder preparation and powder mixing is simple inprocess path, short in processing flow, and suitable for large-batch production.

Owner:ZHEJIANG FUDA ALLOY MATERIALS TECH CO LTD

Polycrystalline diamond compact cutters having protective barrier coatings

ActiveUS10704334B2Improve antioxidant capacityGood adhesionConstructionsVacuum evaporation coatingMetallurgyPolycrystalline diamond

The present disclosure relates to a polycrystalline diamond compact (PDC) cutter with protective barrier coating. The PDC cutter consists of an unleached or leached polycrystalline diamond (PCD) table, a cemented carbide body substrate, and a coating disposed on the cutter. The coating covers at least partially the exterior surfaces of the PCD table of the PDC cutter, and it may also extend over partially or entirely the exterior surfaces of the cemented carbide body. The coating is either a single layer or multilayer. The coating has a thickness of 0.4 μm-100 μm. The coating may have a strong metallurgical bonding with PDC cutter. The coating comprises an oxidation-resistant layer that protects the PDC cutter from thermal and mechanical degeneration during brazing and cutting applications. Methods for preparing such the coating comprise physical vapor deposition, chemical vapor deposition, thermoreactive deposition and diffusion, electrical plating, electroless plating, or their combinations.

Owner:JIANG WENHUI

Environmental friendly heating and ventilating air pipe with natural antibacterial function

The invention discloses an environmental friendly heating and ventilating air pipe with the natural antibacterial function. The heating and ventilating air conditioner air pipe is made of copper and aluminum metallurgy composite single-face or double-face composite copper, and aluminum serves as the base material of a copper and aluminum metallurgy composite board belt. According to the metallic aluminum matrix composite material of the single-face or double-face composite copper belt, metallurgy composition between copper and aluminum is required, the copper belt is made of pure copper or copper alloy, and the copper content of the copper belt must be more than 60 percent. According to the heating and ventilating air conditioner air pipe, the copper layer face of the copper and aluminum metallurgy composite material serves as the inner surface of the air pipe. The heating and ventilating air conditioner air pipe made of the copper and aluminum metallurgy composite material is a new generation natural antibacterial environmental friendly air pipe for replacing a galvanized sheet air pipe, a stainless steel air pipe and air pipes made of other materials. The heating and ventilating air conditioner air pipe is made of the copper and aluminum metallurgy composite material, the bonding strength of the heating and ventilating air conditioner air pipe is equal to or larger than 100 Mpa. The surface of a manufactured copper and aluminum composite plate is clean and smooth. Cracking, disengaging and other phenomena cannot occur in the producing process of bending, drilling, punching, tapping, old making, painting and the like, and the yield and quality of heating and ventilating air conditioner air pipelines are guaranteed.

Owner:洛阳市伟创复合材料科技有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com