Integrated device for powder preparation and powder mixing, and application thereof

A system and powder mixing technology, which is applied in the field of powder preparation and powder mixing integrated device, can solve the problems of high manufacturing cost, poor distribution uniformity of dispersion strengthening phase, environmental pollution, etc., to improve distribution uniformity and bonding strength, improve Production efficiency and labor intensity, the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0027] like Figure 1 to Figure 2 As shown, in the embodiment of the present invention, embodiment one:

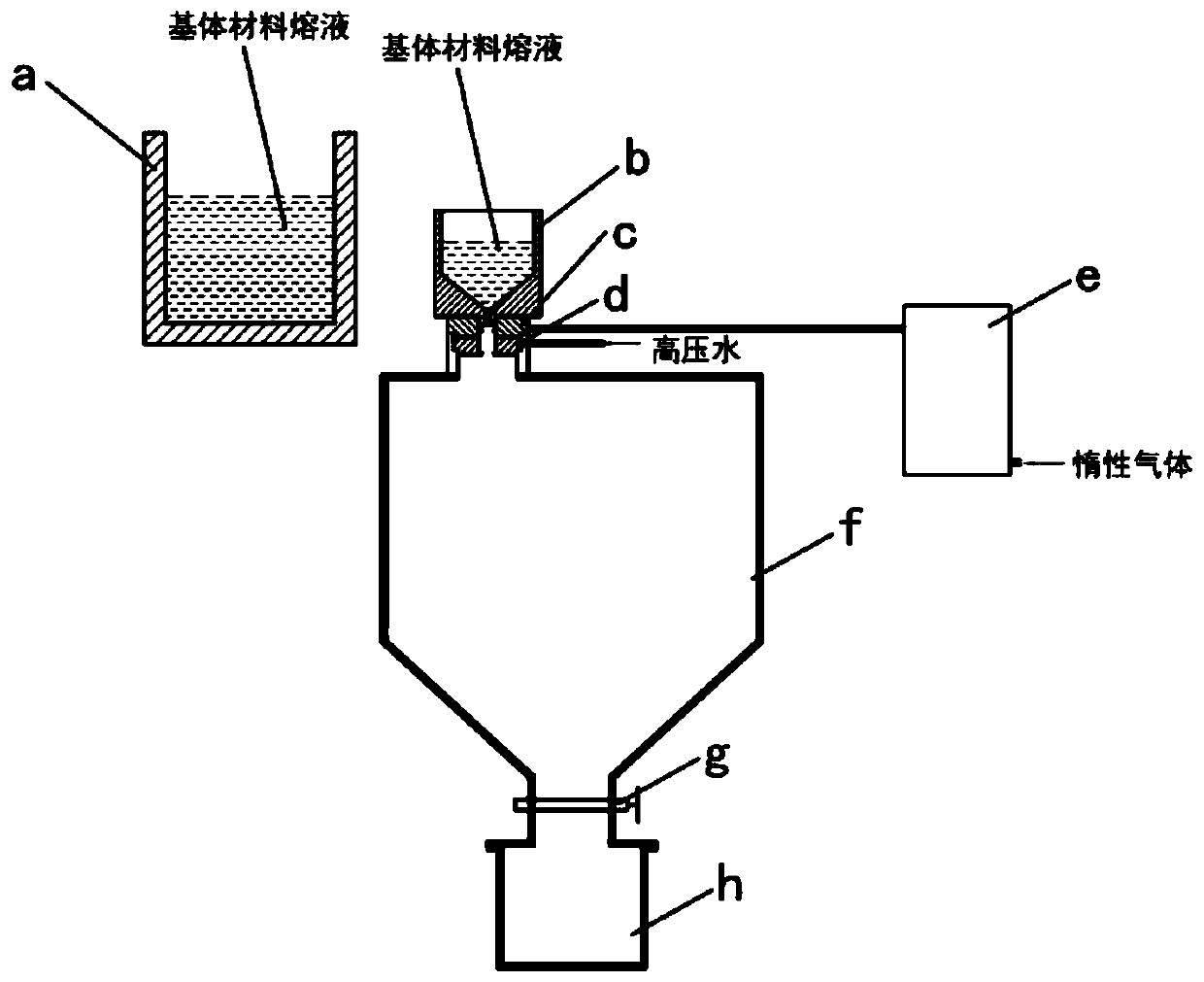

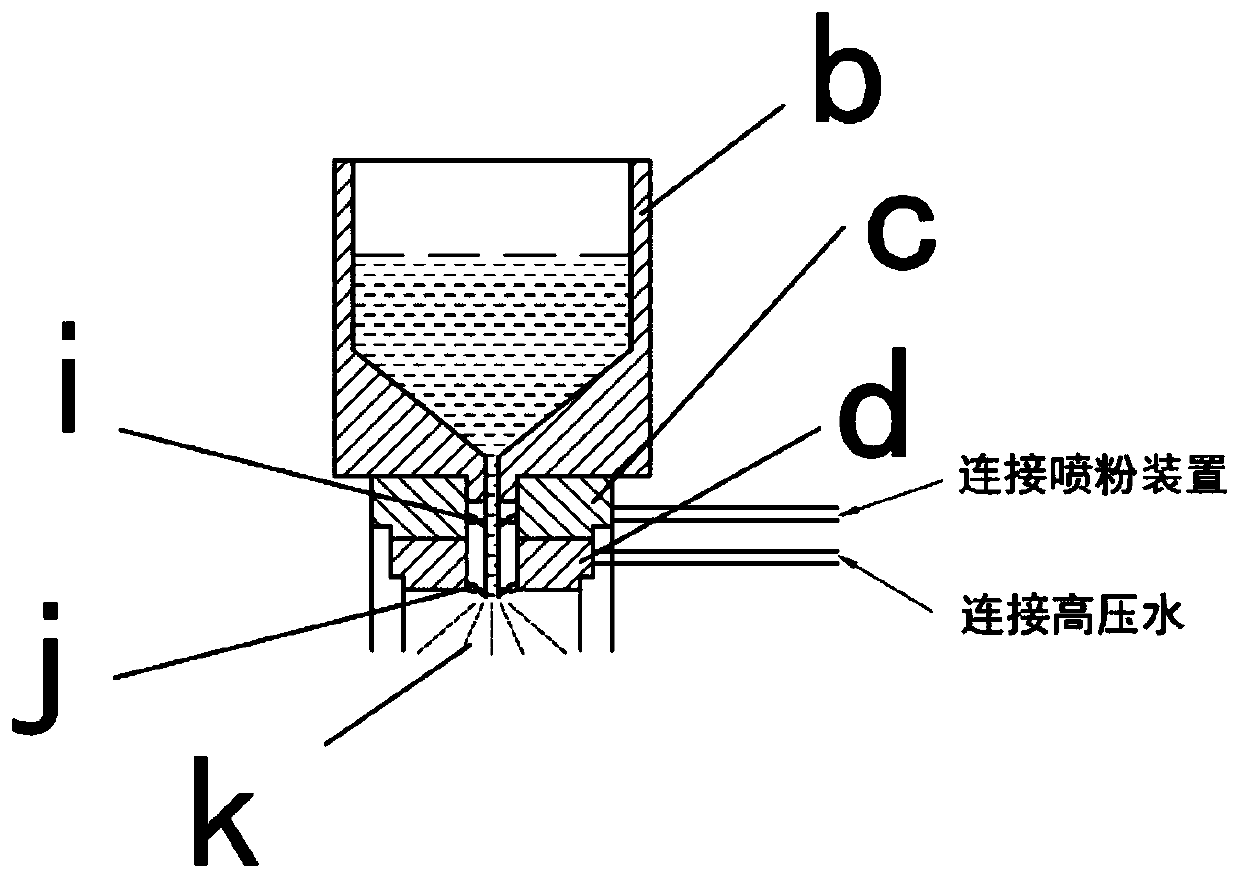

[0028] The metal powder preparation-powder mixing integrated equipment based on high-pressure water atomization equipment described in this embodiment one, such as figure 1 and figure 2 As shown, it includes an intermediate frequency melting furnace (melting crucible a), holding furnace (holding crucible b), upper spray plate c, lower spray plate d, collection bucket f, and powder spraying device e. Among them, the intermediate frequency melting furnace (melting crucible a) is a fixed-point casting furnace, and the casting center corresponds to the center of the holding furnace (holding crucible b). The spray plate seat at the upper end of the collection b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com