Manufacturing method for copper-stainless steel double-metal compound contact piece substrate material

A matrix material, composite contact technology, applied in the direction of manufacturing tools, metal layered products, metal processing equipment, etc., can solve the problems of large system resistance, small elastic modulus, large contact resistance, etc., to achieve good overall performance, improve Strength, elastic modulus, and small contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

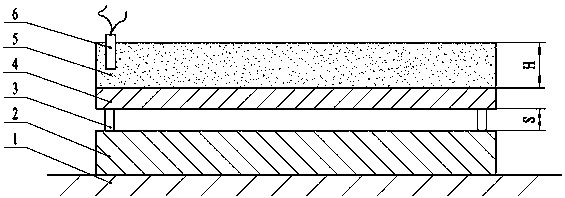

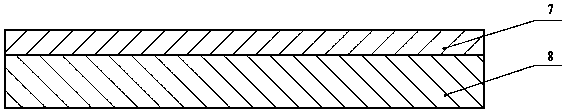

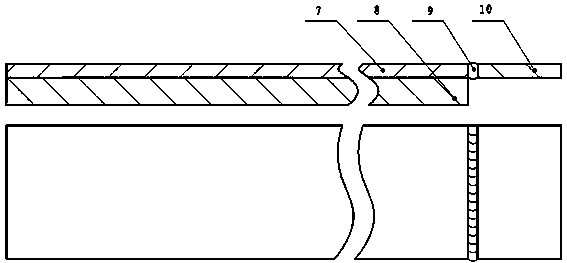

[0022] As shown in the figure, the specific implementation method is as follows:

[0023] The material of the copper plate embryo is TU1, and the material of the stainless steel plate embryo is S30408.

[0024] A method for manufacturing a base material of a copper-stainless steel bimetallic composite contact, comprising the steps of:

[0025] Step 1, get the copper slab blank that plate thickness is 4mm and the stainless steel slab blank that plate thickness is 2mm standby, the thickness ratio of copper slab blank and stainless steel slab blank is 2;

[0026] Step two, combined with figure 1 Instructions, take the copper plate blank 2 in step 1 and place it on a flat sandy foundation 1, place copper support objects 3 evenly on the upper surface of the copper plate blank 2 at intervals of 80mm, and the height of the copper support objects is bimetallic The spacing S, S is controlled within the range of 4~5mm; the sum of the contact area between the copper support and the cop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com