Environment-friendly water pipe with natural bacteriostasis function

An environmentally friendly and functional technology, applied to pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve the problems of high construction costs and expensive copper pipes, and achieve low air leakage rate, light weight and smooth surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

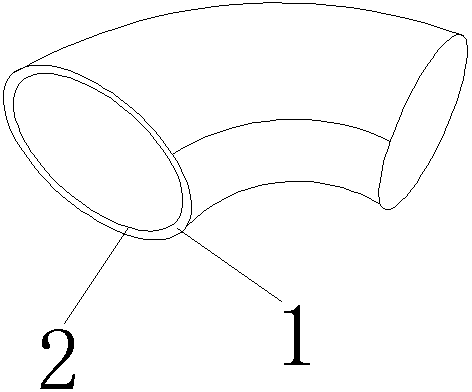

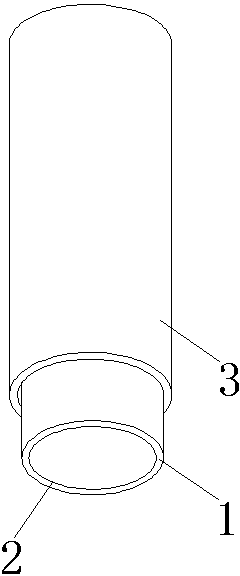

[0024] The environment-friendly drinking water pipe with natural antibacterial function described in this embodiment is copper-aluminum metallurgy combined with a single-sided copper composite structure on the inner surface. The drinking water pipe includes an aluminum substrate 1 and a copper foil 2, and the aluminum substrate 1 is pure The aluminum or aluminum alloy strip has a thickness of 0.15mm-10mm, and a copper foil 2 is metallurgically bonded to one side of the aluminum substrate 1, and the thickness of the copper foil is 0.15mm-2.5mm. During production, according to the design requirements, copper-aluminum metallurgical composite plate strips of different specifications can be produced by shearing, sawing, laser cutting, and wire cutting, and then made by bending, welding, riveting, buckling and other mechanical processing processes. 2 round pipes on the inner surface of the copper foil. The outer surface of the drinking water pipe is covered with a plastic pipe and f...

Embodiment 2

[0026] The environment-friendly drinking water pipe with natural antibacterial function described in this embodiment is a single-sided copper clad structure on the inner surface of copper-aluminum metallurgy. The drinking water pipe includes an aluminum substrate 1 and a copper foil 2, and the aluminum substrate 1 is The pure aluminum or aluminum alloy plate has a thickness of 0.15mm-10mm, and copper foil 2 is metallurgically bonded on both sides of the aluminum substrate 1, and the thickness of the copper foil is 0.3mm-1.5mm. During production, according to the design requirements, copper-aluminum metallurgical composite plates of different specifications can be produced by shearing, sawing, laser cutting, and wire cutting, and then made of copper-aluminum metallurgical composite plates through bending, welding, riveting, buckling and other mechanical processing processes. Foil 2 circular ducts on the inner surface. The outer surface of the drinking water pipe is covered with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com