Processing method of carbon steel and 304 stainless steel single-sided composite board

A 304 stainless steel, processing method technology, applied in the field of carbon steel and 304 stainless steel single-sided composite plate processing, can solve the problems of low production efficiency, noise and smoke pollution, high cost, etc., achieve good mechanical strength and processing performance, and reduce project cost , the effect of good social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

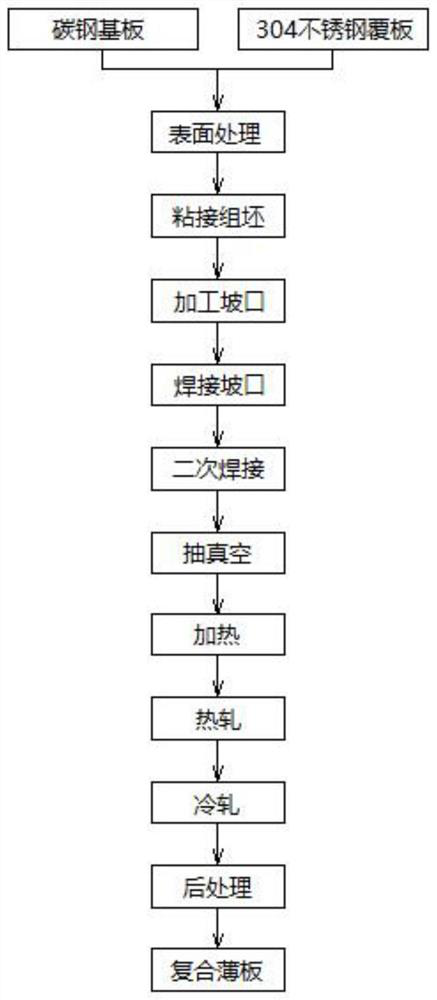

[0037] see figure 1 , a base plate is made of carbon steel plate, and a cladding plate is made of 304 stainless steel plate. The specific processing steps are as follows:

[0038] S1. Surface treatment: Surface treatment is carried out on the surface to be bonded of the substrate and the surface to be bonded of the superstrate, that is, one side of the substrate and one side of the superstrate respectively, and the surface to be bonded of the substrate and the surface to be bonded of the superstrate are cleaned sticky sand and scale.

[0039]Specifically, the substrate is sent into the shot blasting machine, and the shot blasting device of the shot blasting machine throws projectiles (steel balls) at high speed, impacts one side of the substrate respectively, and removes the sticky sand and scale on the surface until the surface is clean and free of Rust spots; send the cladding plate into the shot blasting machine, and the shot blaster of the shot blasting machine throws pro...

Embodiment 2

[0054] see figure 1 , a base plate is made of carbon steel plate, and a cladding plate is made of 304 stainless steel plate. The specific processing steps are as follows:

[0055] S1. Surface treatment: Surface treatment is carried out on the surface to be bonded of the substrate and the surface to be bonded of the superstrate, that is, one side of the substrate and one side of the superstrate respectively, and the surface to be bonded of the substrate and the surface to be bonded of the superstrate are cleaned sticky sand and scale.

[0056] Specifically, the substrate is sent into the shot blasting machine, and the shot blasting device of the shot blasting machine throws projectiles (steel balls) at high speed, impacts one side of the substrate respectively, and removes the sticky sand and scale on the surface until the surface is clean and free of Rust spots; send the cladding plate into the shot blasting machine, and the shot blaster of the shot blasting machine throws pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com