Vegetable residue, crop straw and livestock and poultry excrement combined composting process

A technology for crop stalks and vegetable residues, which is applied in the field of resource utilization of organic waste, and can solve problems such as waste of straw resources, unreasonable disposal, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

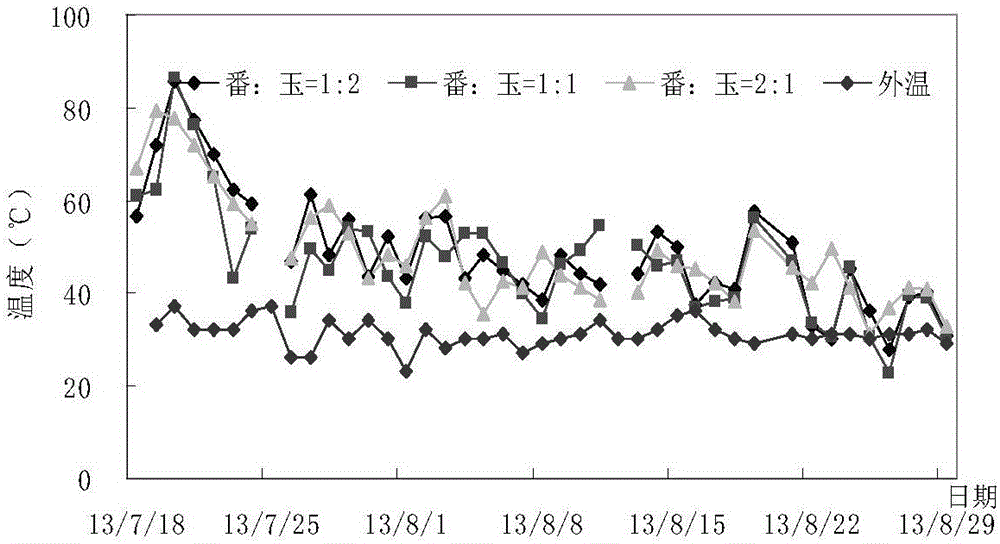

[0030] Embodiment 1 Tomato stalk, corn stalk and livestock and poultry manure combined composting process

[0031] The test uses tomato stalks, corn stalks and livestock and poultry manure for joint composting. From July to September 2013, it was carried out in the pilot composting pool of Gaocheng Experimental Demonstration Base. The basic properties of each material are listed in Table 1. The aerobic composting process was adopted, the tomato stalks were taken from the positioning test greenhouse, the corn stalks were green storage corn from the cattle farm, and the chicken manure was from fresh chicken manure from the chicken farm.

[0032] Table 1 Basic properties of compost materials

[0033]

[0034]The straw to be tested is crushed into 3-5cm by a pulverizer, the total weight of the material is 200kg, the initial moisture content is adjusted to 60-65%, and the height of the material pile is 1.2m. When the temperature of the pile body rises to 65°C-70°C, keep it for...

Embodiment 2

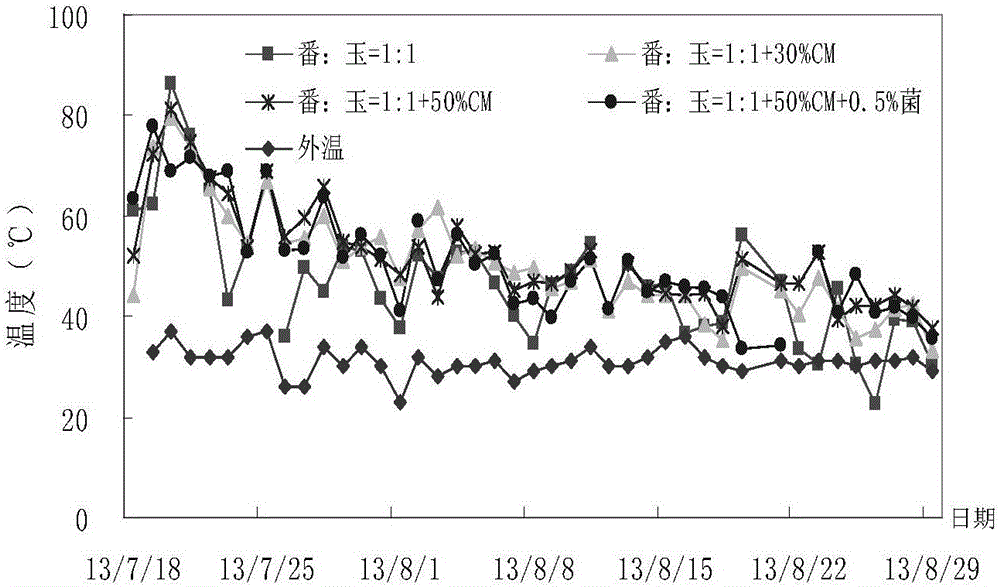

[0038] Example 2 Experiments on material moisture content, turning and ventilation control of combined composting of tomato stalks, corn stalks and livestock and poultry manure

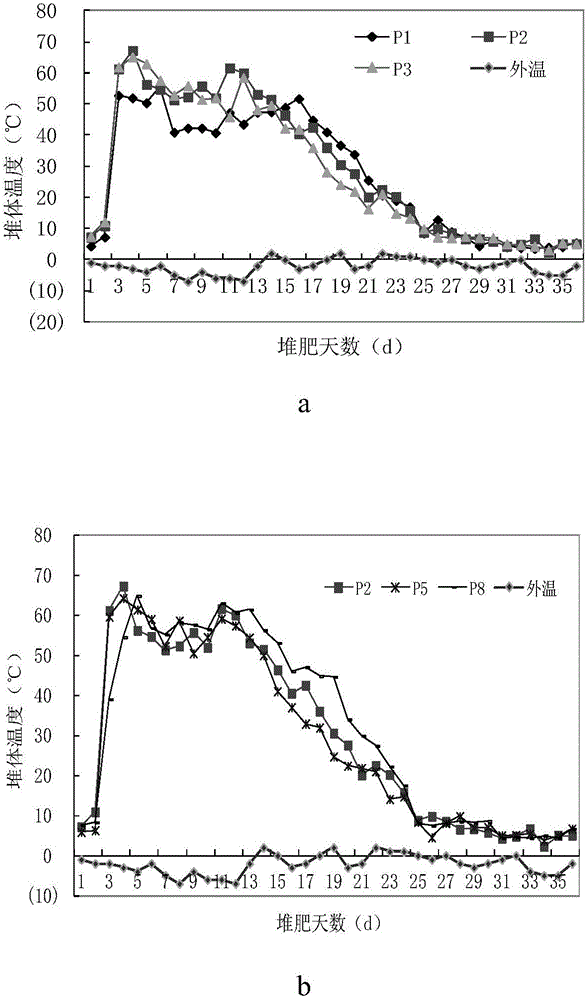

[0039] In the experiment, tomato stalks, corn stalks and livestock and poultry manure were used for joint composting. The ratio of dry weight of materials is tomato straw: corn straw = 2:1 + 30% chicken manure + 0.5% bacterial agent, and it is carried out in the pilot composting pond of Gaocheng Experimental Demonstration Base.

[0040] Experimental design: Treatment 1: P1, turning 2 times, initial moisture content 50%; Treatment 2: P2, turning 2 times, initial moisture content 60% (control); Treatment 3: P3, turning 2 times, initial moisture content 70%; treatment 4: P4, turning once, initial moisture content 50%; treatment 5: P5, turning once, initial moisture content 60%; treatment 6: P6, turning once, initial moisture content 70% %; Treatment 7: P7, no turning, forced ventilation, initial moistur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com