Patents

Literature

1820 results about "Blasting machine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A blasting machine or shot exploder is a portable source of electric current to reliably fire a blasting cap to trigger a main explosive charge. It is mostly used in mining and demolition. The use of the term "machine" dates from early designs that used an electrical generator operated by winding a rotary handle or pushing down a T-handle. Modern blasting machines are battery-powered and operated by key switches and push-buttons, and do not resemble the older designs.

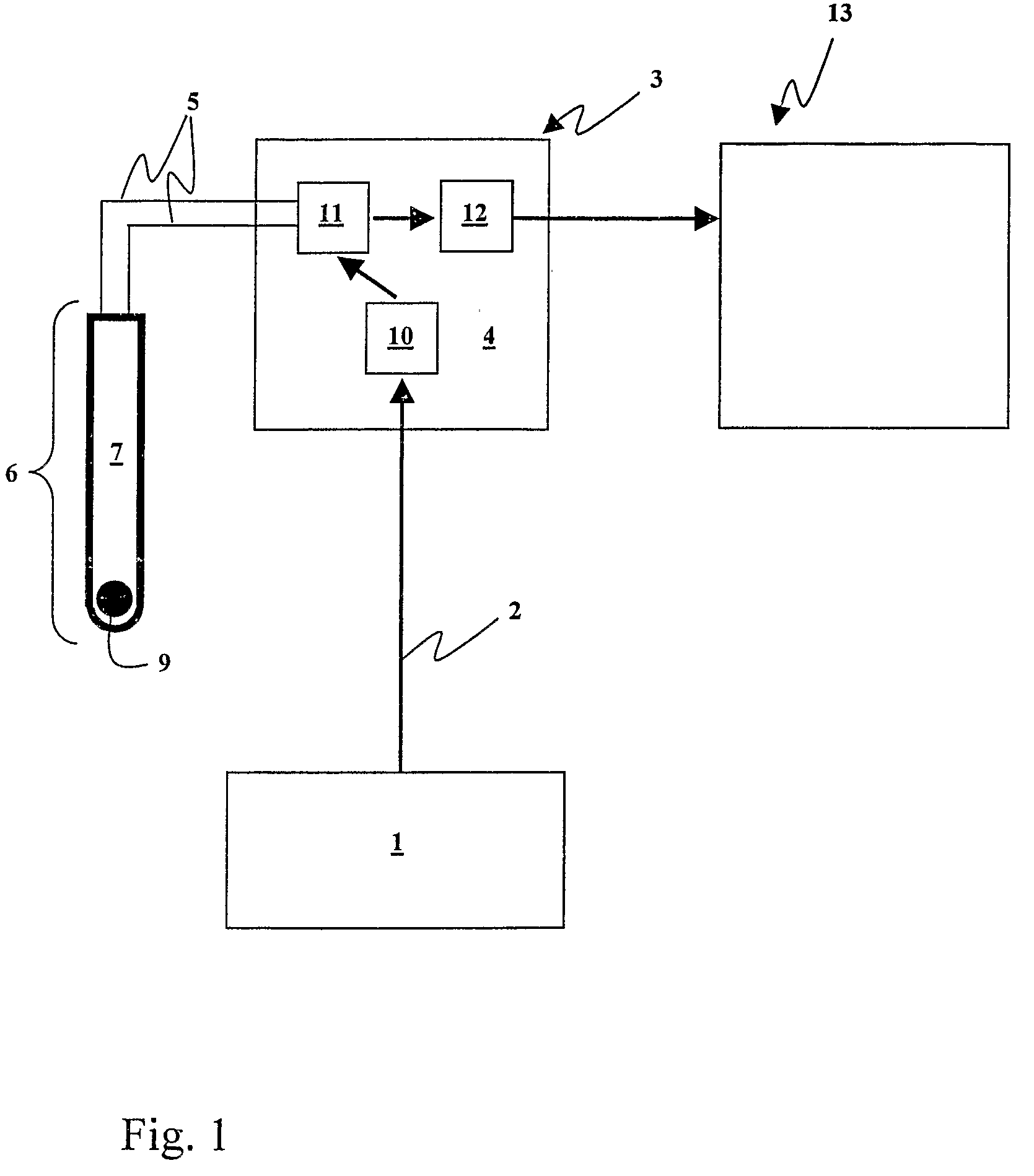

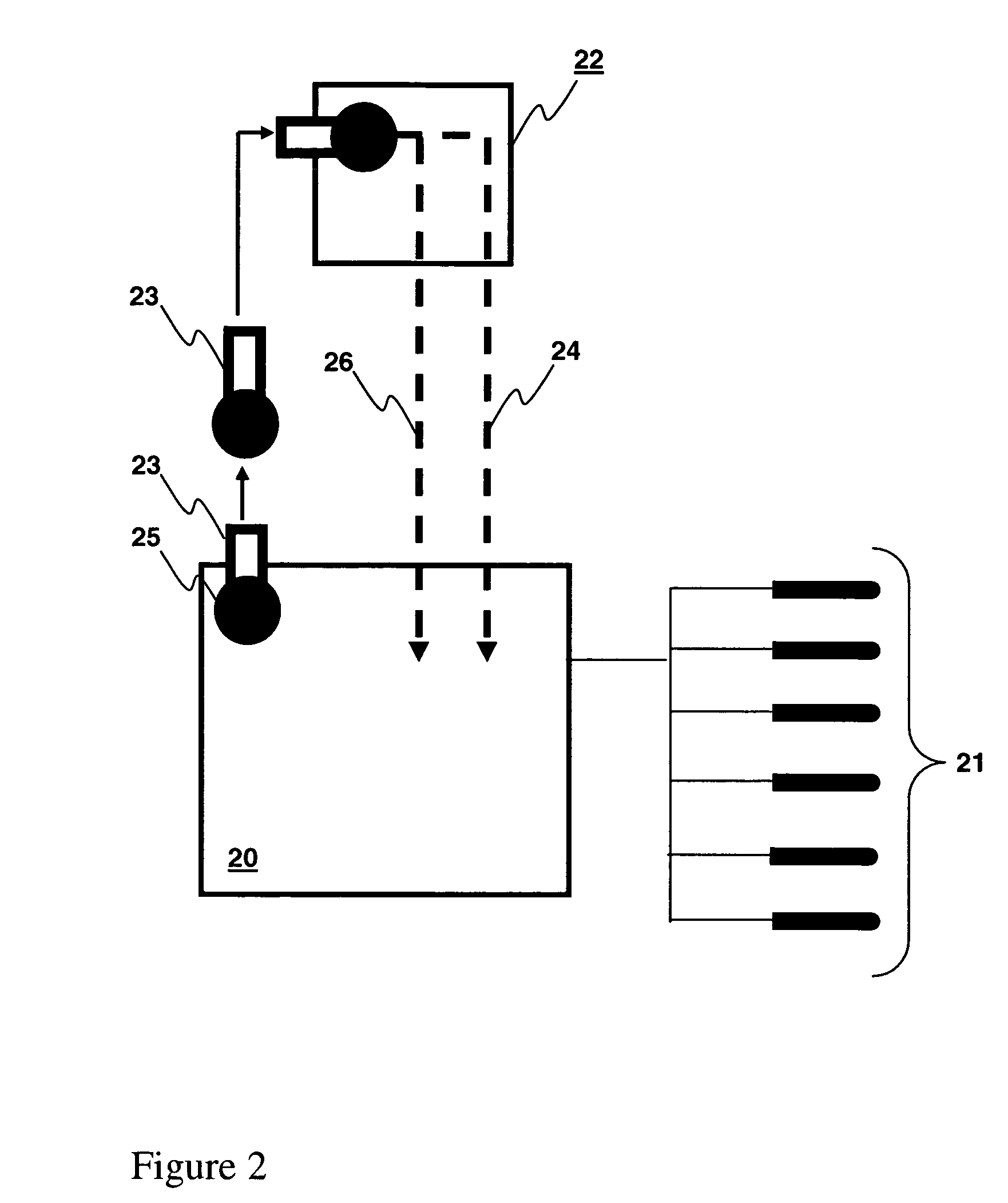

Wireless detonator assemblies, and corresponding networks

Wireless detonator assemblies (51-59) in use, form a cross-communicating network of wireless “detonator assemblies, such that communication of each wireless detonator assembly (57-59) with an associated blasting machine (50) can occur either directly, or via relay of signals (61-69) between other wireless detonator assemblies (51-56) in the network. Wireless detonator assemblies (51-59) can disseminate information (such as status information, identity information, firing codes, delay times and environmental conditions) among all of the wireless detonator assemblies in the network, while compensating for signal transmission relay delays at nodes in the network, thereby enabling the wireless detonator assemblies to detonate the explosive charges in accordance with the delay times. Various wireless detonator assemblies and corresponding blasting apparatus are disclosed and claimed. Methods of blasting using the wireless detonator assemblies and blasting apparatus are also disclosed and claimed.

Owner:ORICA EXPLOSIVES TECH PTY LTD

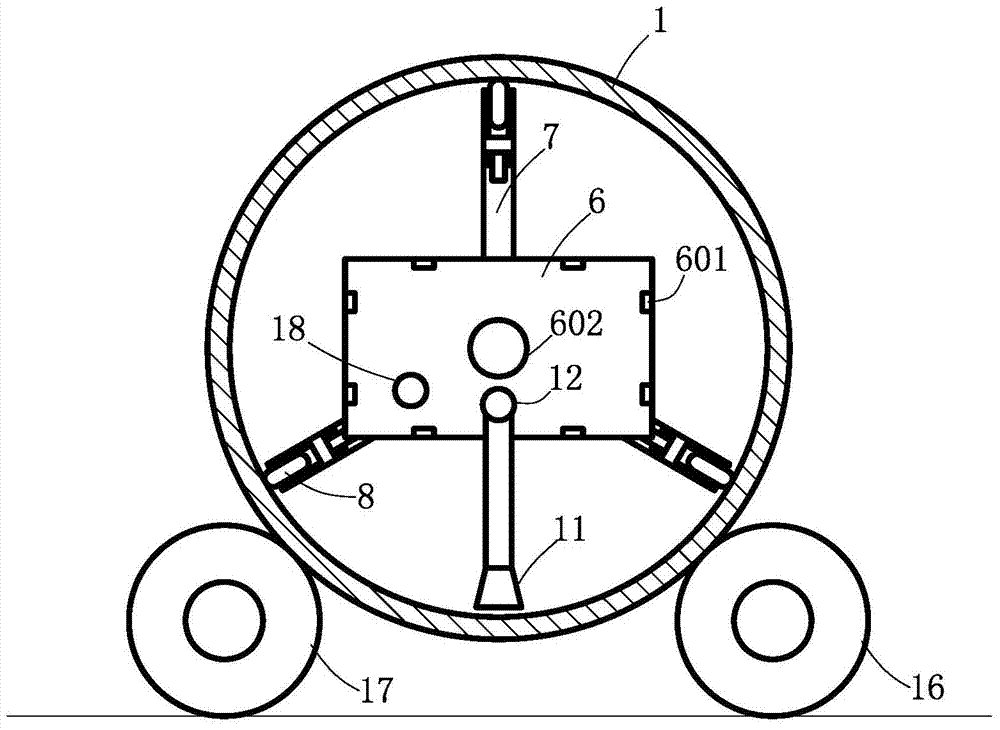

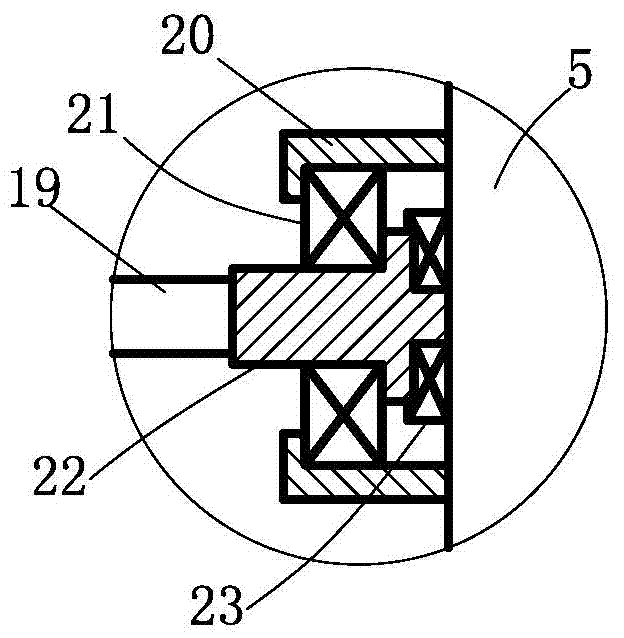

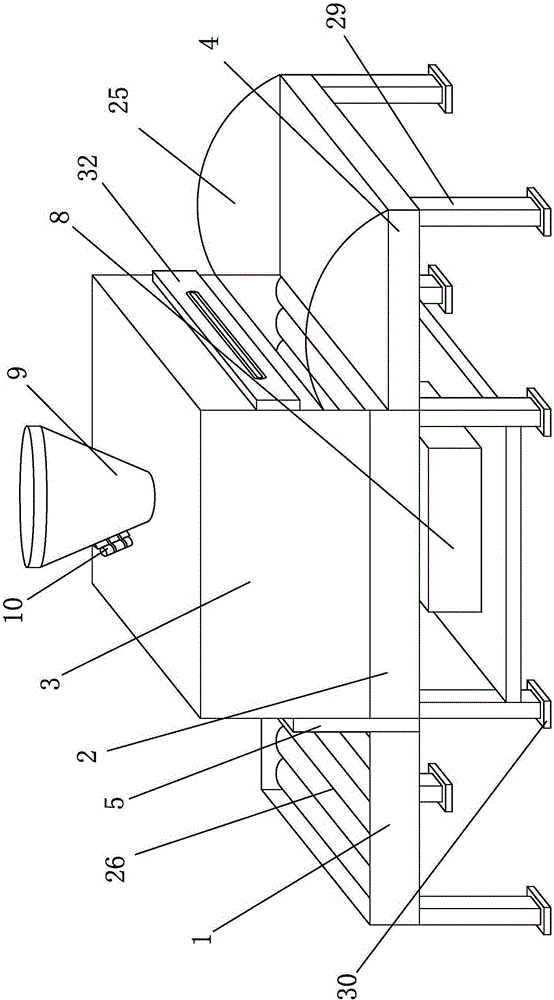

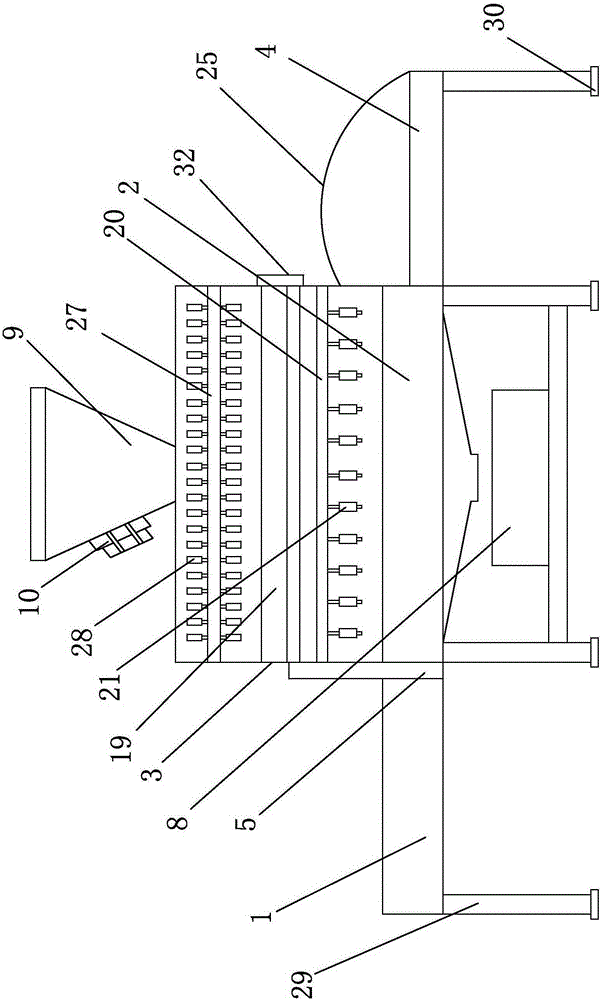

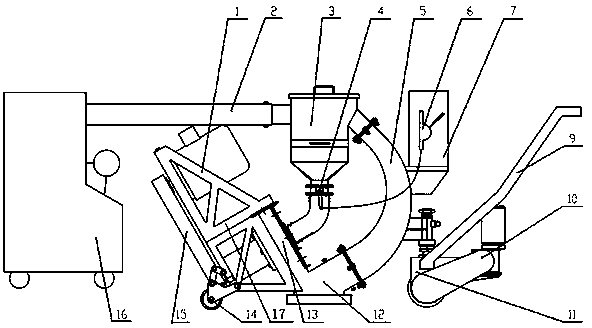

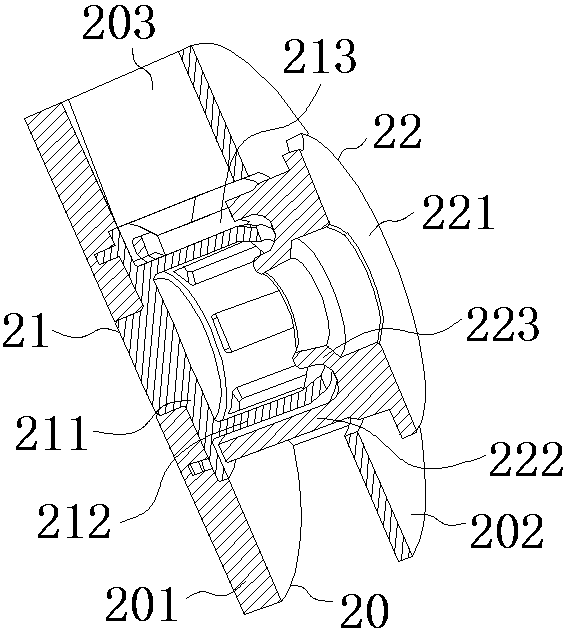

Pipeline inner wall rust removal device

ActiveCN104723223AAvoid pollutionReduce direct damageGrinding machinesAbrasive machine appurtenancesPneumatic motorPollution

The invention discloses a pipeline inner wall rust removal device, belonging to the technical field of polishing units. The device comprises a first end cover and a second end cover which are hermetically installed at two ends of the pipeline, a rust removal trolley is arranged in the pipeline, the dust removal trolley comprises a pneumatic motor with dual output shafts, a shell of the pneumatic motor is provided with a plurality of support shafts, the end part of each support shaft is provided with a roller wheel, a grinding disc is fixedly installed on the output shaft of the pneumatic motor, close to the first end cover, and is provided with a plurality of support rods in the radial direction, the end part of each support rod is provided with an abrasive disc, the output shaft of the pneumatic motor, close to the second end cover, is connected with a shot-blasting machine in a transmission manner; the end part of the grinding disc is connected with a traction rope, the traction rope extends out of the first end cover, one end of the shot-blasting machine, close to the second end cover, is connected with a shot feeding pipe, the pneumatic motor is connected with a gas inlet pipe, the shot feeding pipe and the gas inlet pipe extend out of the second end cover. The pipeline inner wall rust removal device can be used for solving the technical problems that the pipeline inner wall is serious in rust removal pollution and the rust removal effect is poor, and can be widely applied to pipeline cleaning.

Owner:SHANGHAI HONGPU STEEL STRUCTURE ENG

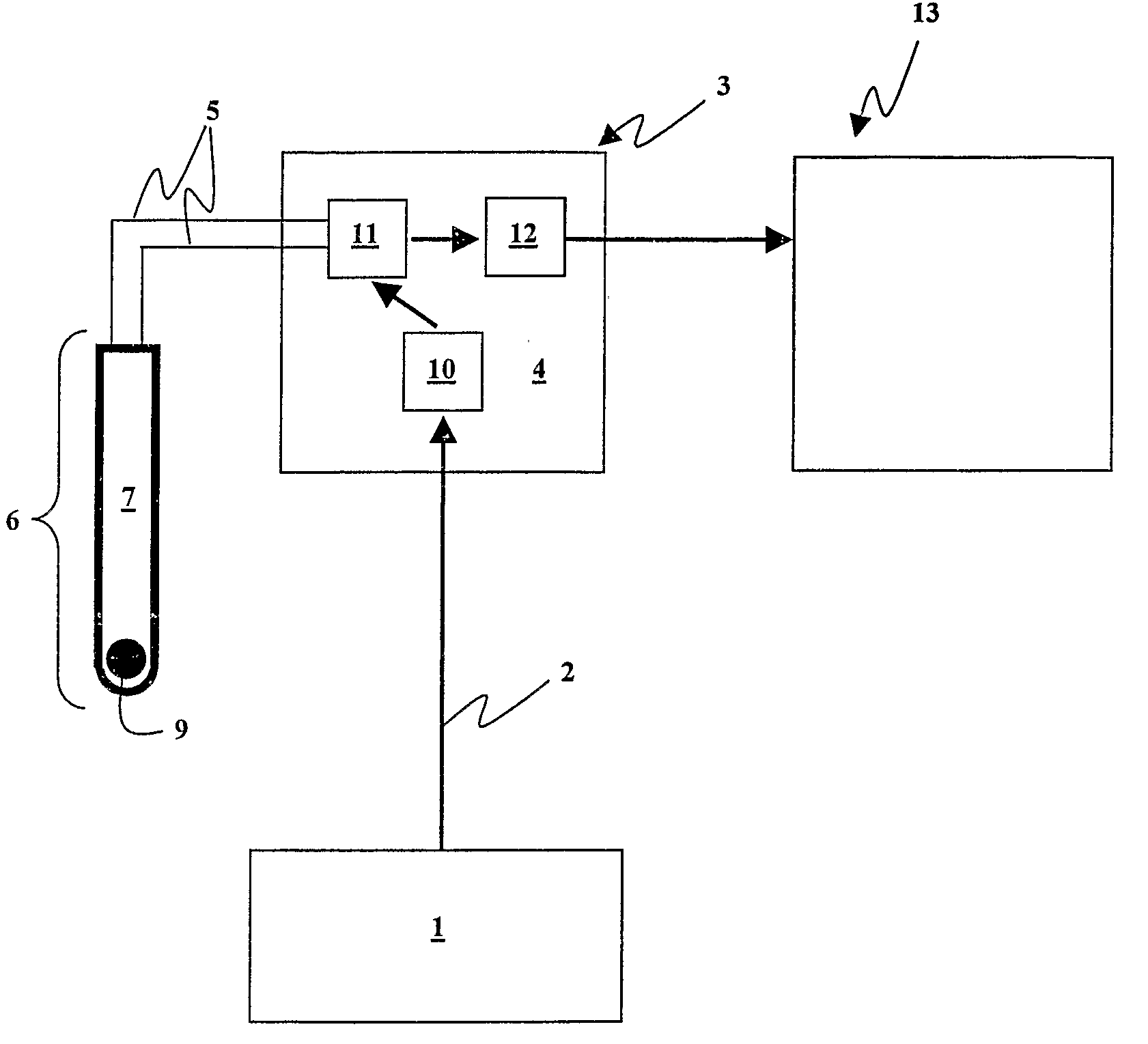

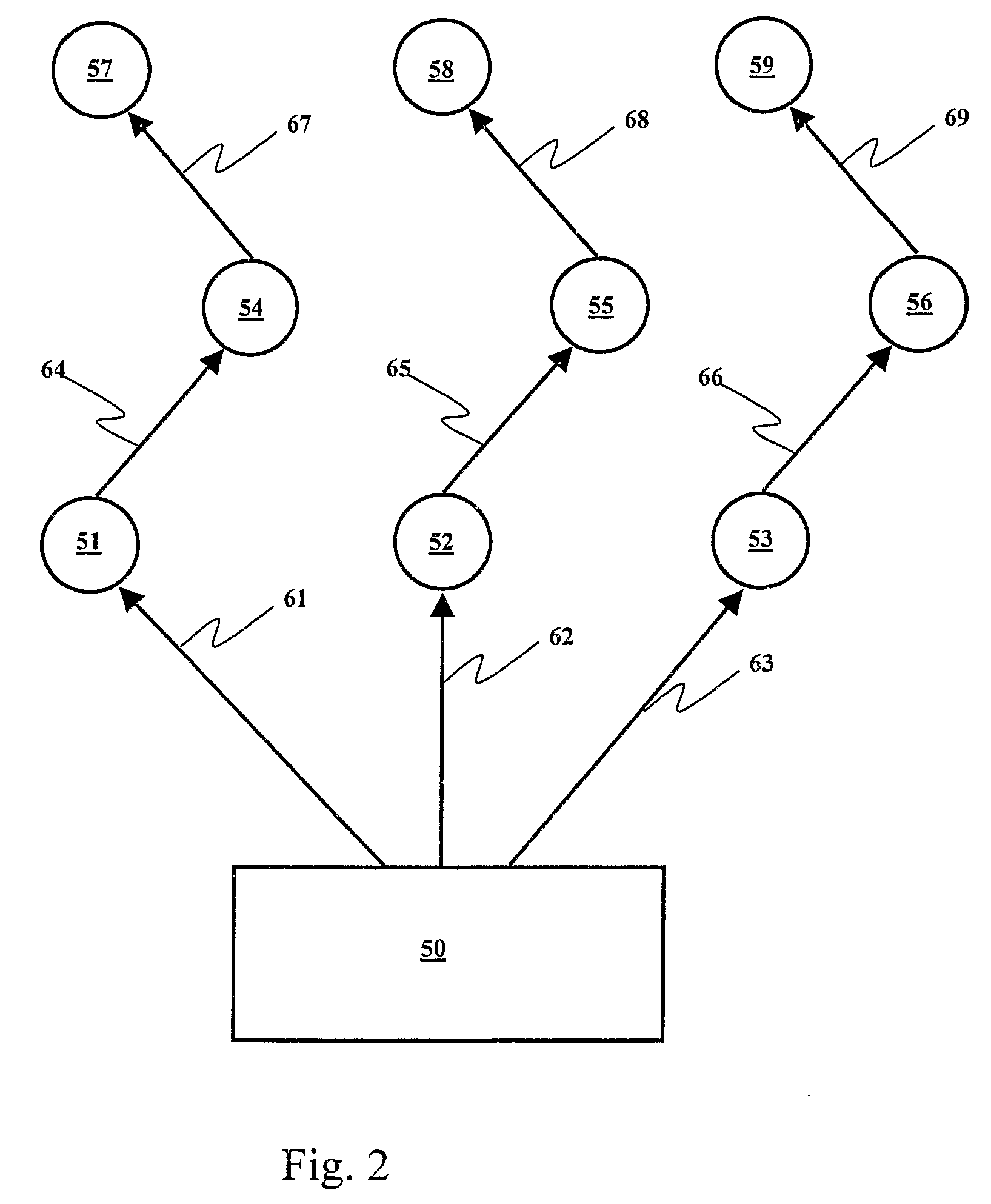

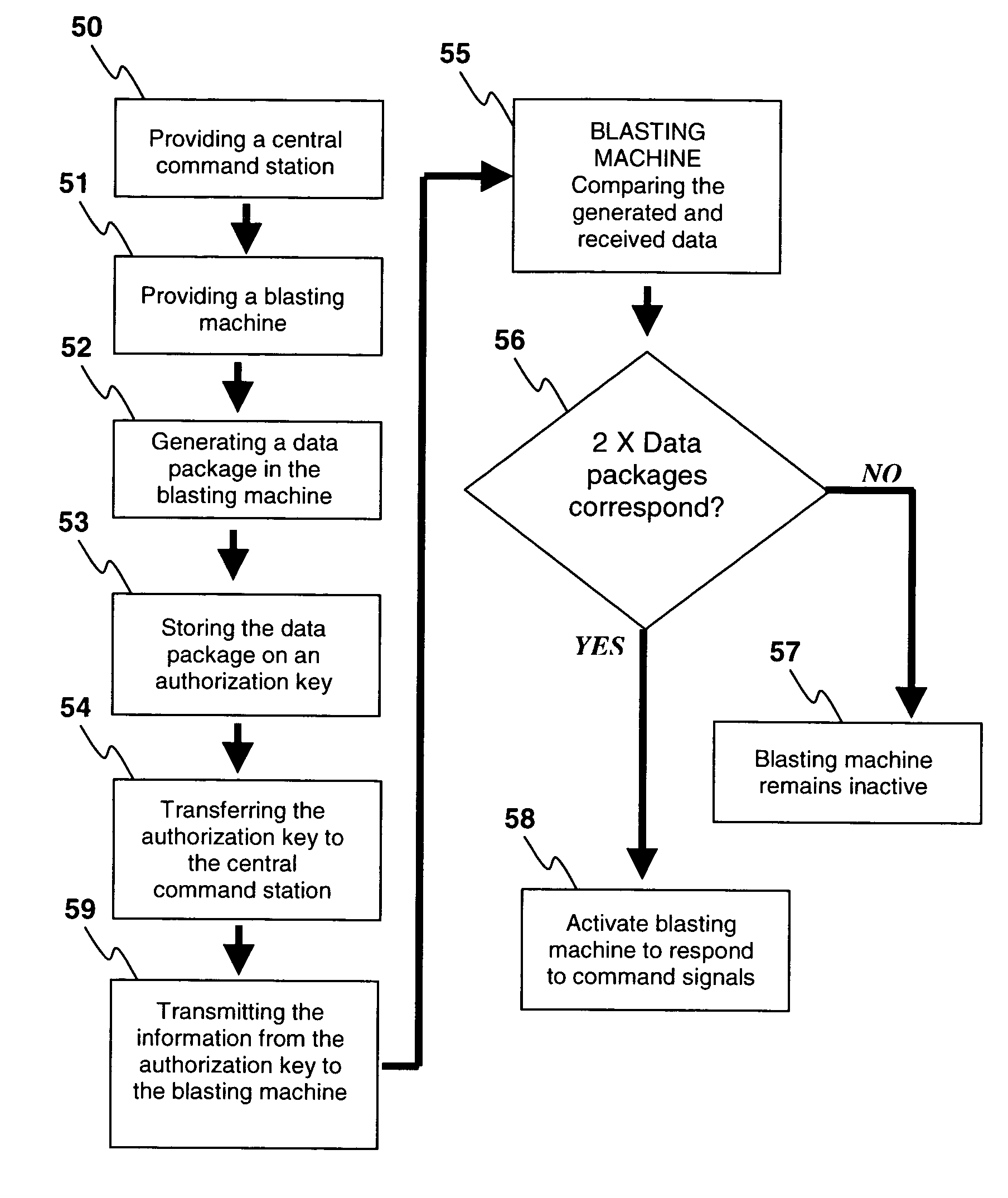

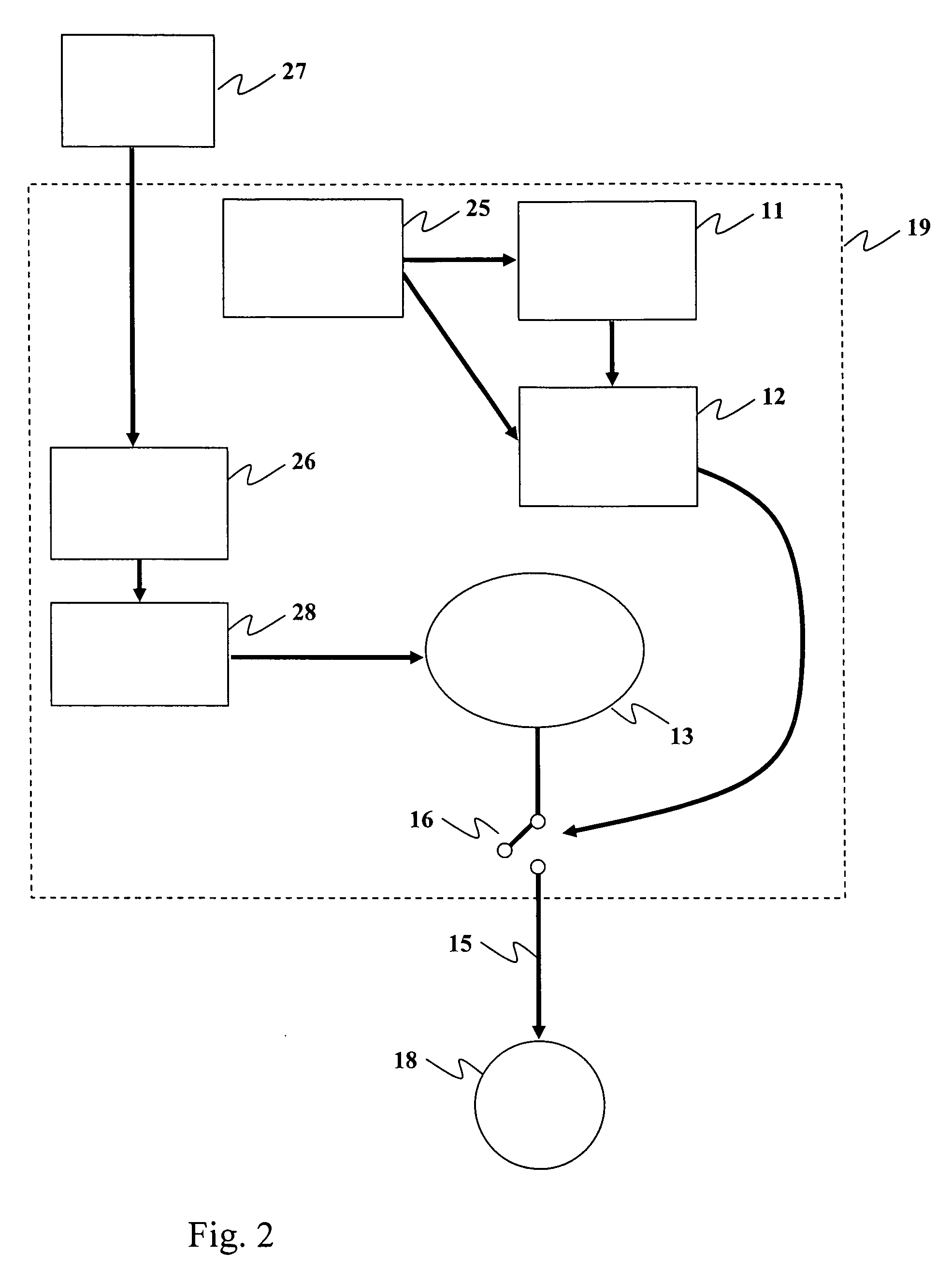

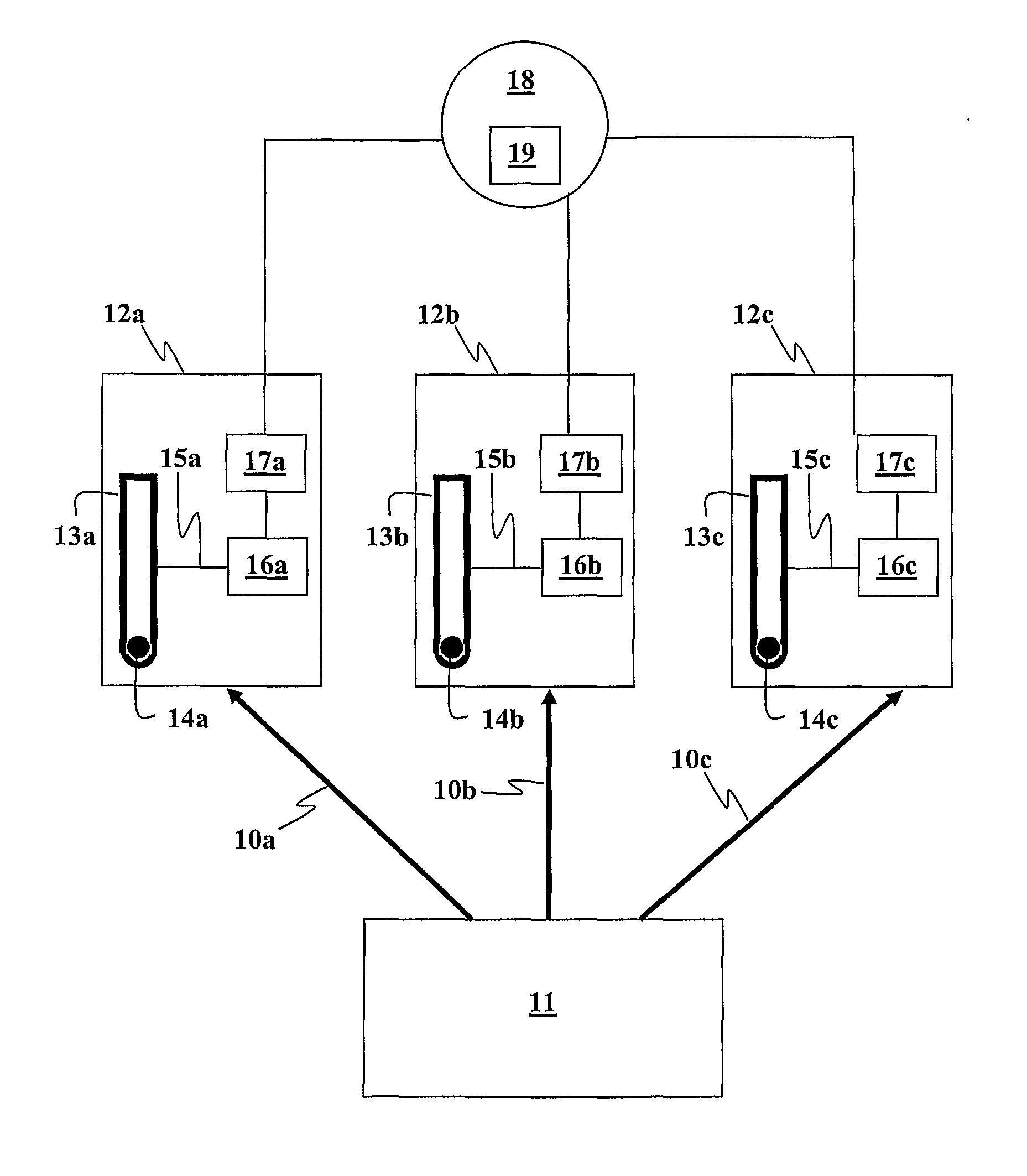

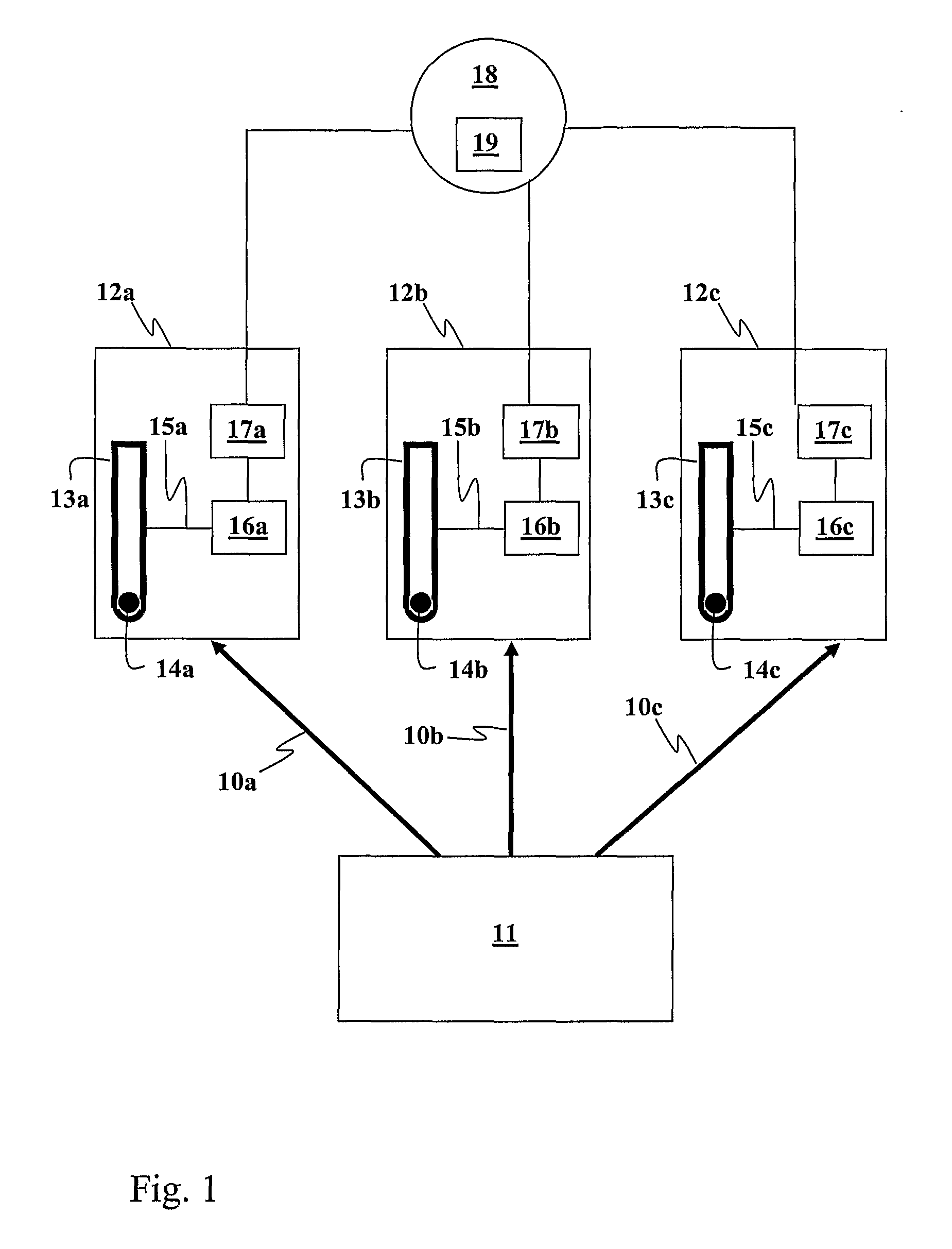

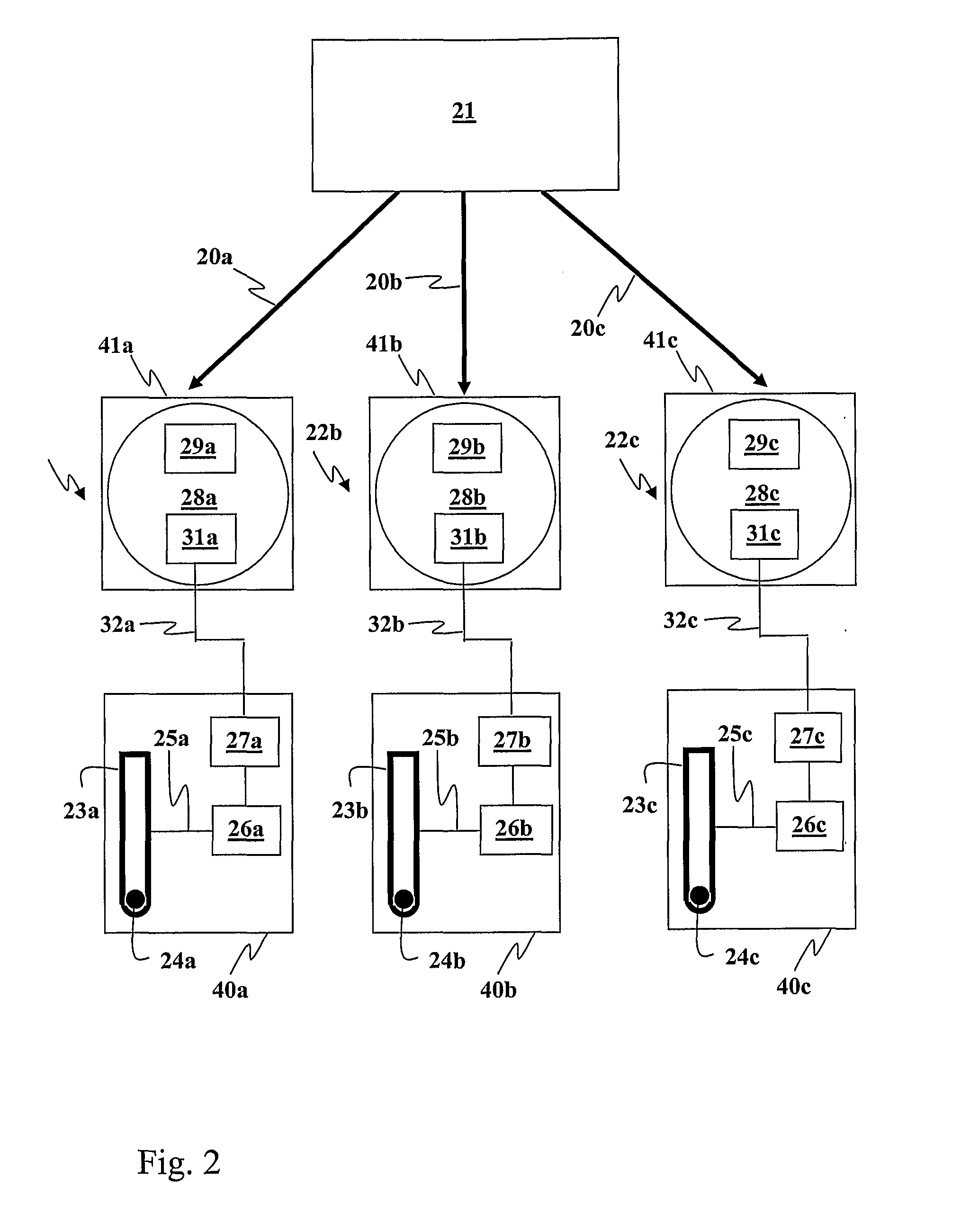

Access control for electronic blasting machines

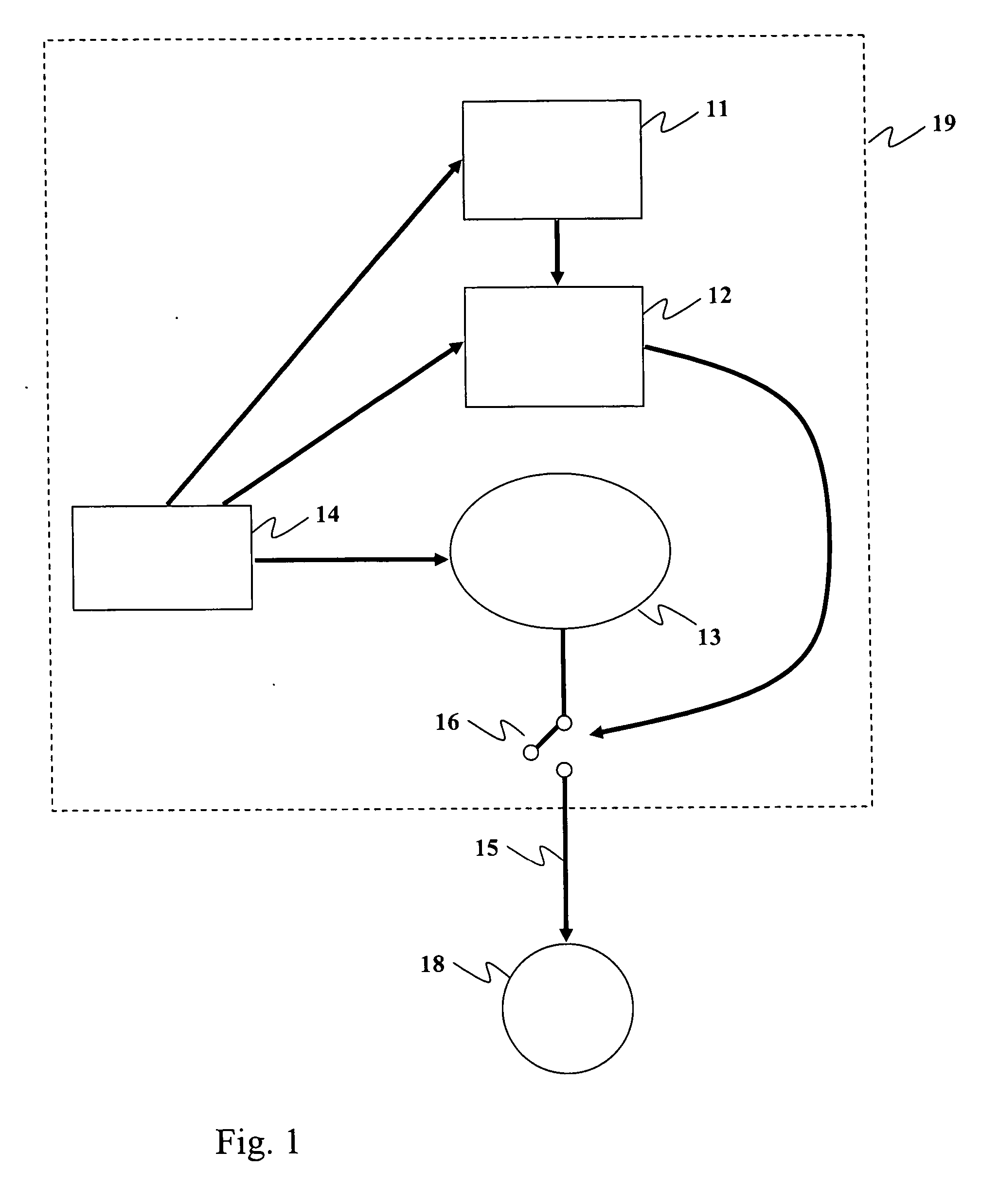

Blasting apparatuses and methods control actuation of a plurality of detonators, and involve the use of one or more authorization keys each associated with a blasting machine. The authorization key(s) are transferable from the blasting machine(s) to a central command station, each authorization key storing a data package comprising a randomly generated access code generated by its corresponding blasting machine. Transfer of the one or more authorization keys to a central command station allows the data packages (and associated randomly generated access codes) to be transmitted by the central command station for receipt by the blasting machine(s).

Owner:ORICA EXPLOSIVES TECH PTY LTD

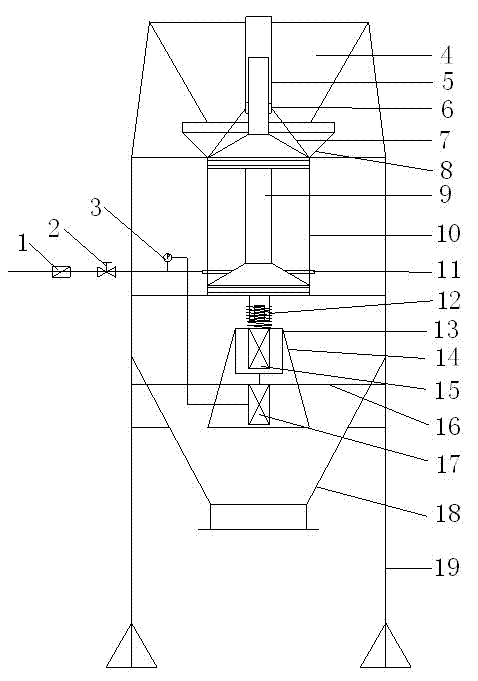

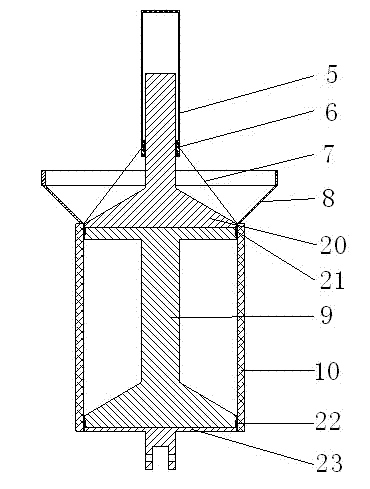

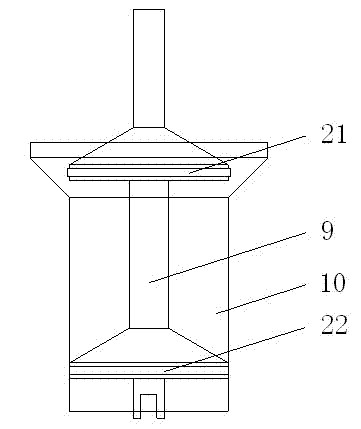

Steam blasting machine

ActiveCN103111231ASimple structureImprove work efficiencyPressurized chemical processMechanical engineeringPhysics

The invention discloses a steam blasting machine which comprises a sliding sealing disc, a movable upper limiting shaft, a lower sealing disc, an upper sealing ring, a lower sealing ring, a cylinder A for controlling the sliding sealing disc to move upwards and a cylinder B for controlling the sliding sealing disc to move downwards, wherein the sliding sealing disc is I-shaped; the lower part of the sliding sealing disc is in a conical disc structure having a high middle part and a low peripheral part; the lower end of the upper limiting shaft is matched with the upper end of the sliding sealing disc in a sealing manner through the upper sealing ring so as to form an integrated structure; the lower end of the sliding sealing disc is matched with the lower sealing disc in the sealing manner through the lower sealing ring so as to form another integrated structure; the sliding sealing disc is sealed in a sliding manner through the upper sealing ring and the lower sealing ring which slide up and down in a blasting bin; the cylinder A is connected with the bottom of the lower sealing disc; and the cylinder B is connected below the cylinder A. The steam blasting machine is simple in structure and high in working efficiency and can finish the supersonic steam blasting crush in milliseconds; materials are fed and blasted out more rapidly in the steam blasting process. In addition, the raw material accumulation and the material residues are avoided.

Owner:SICHUAN TUOPAI SHEDE WINE

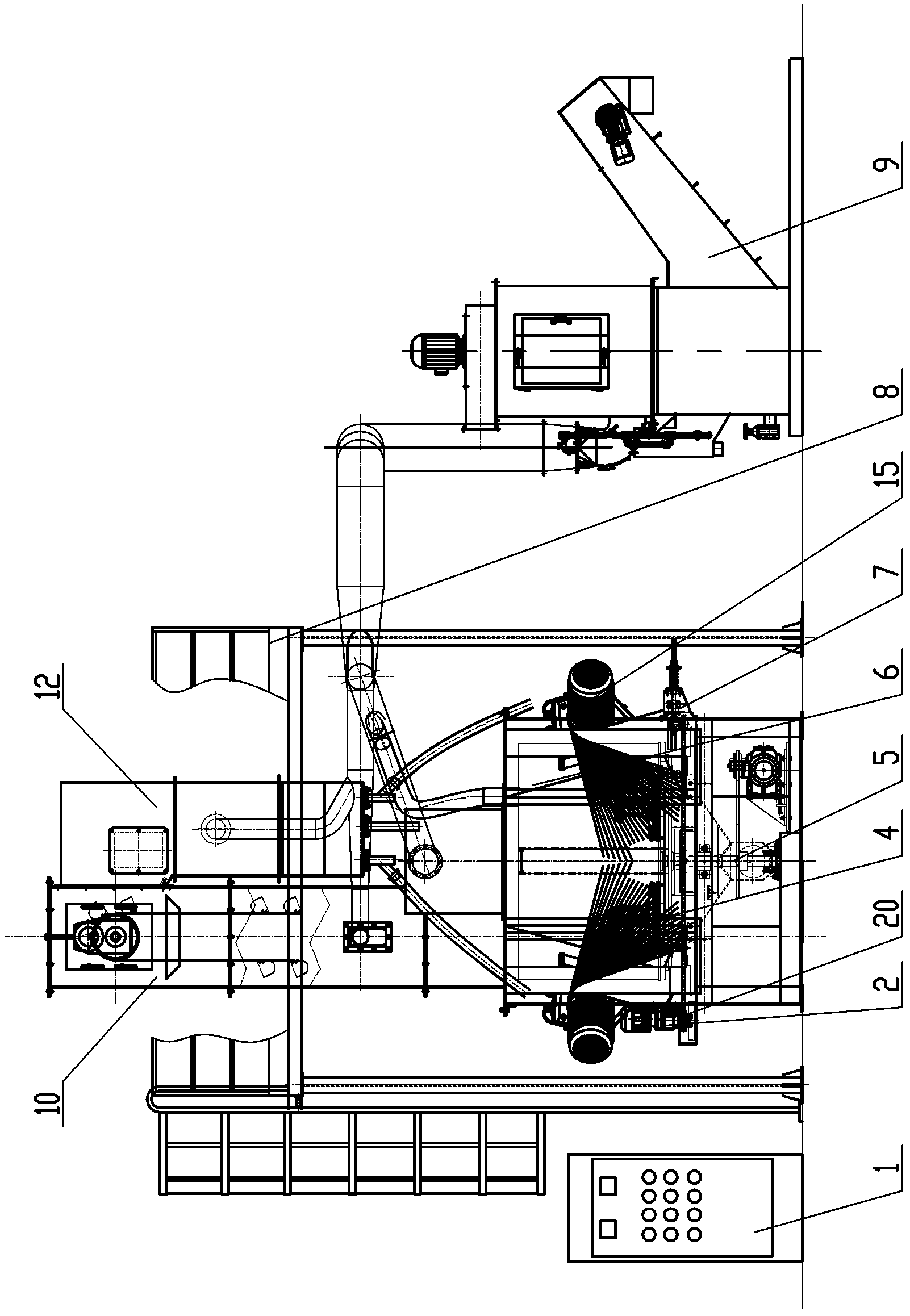

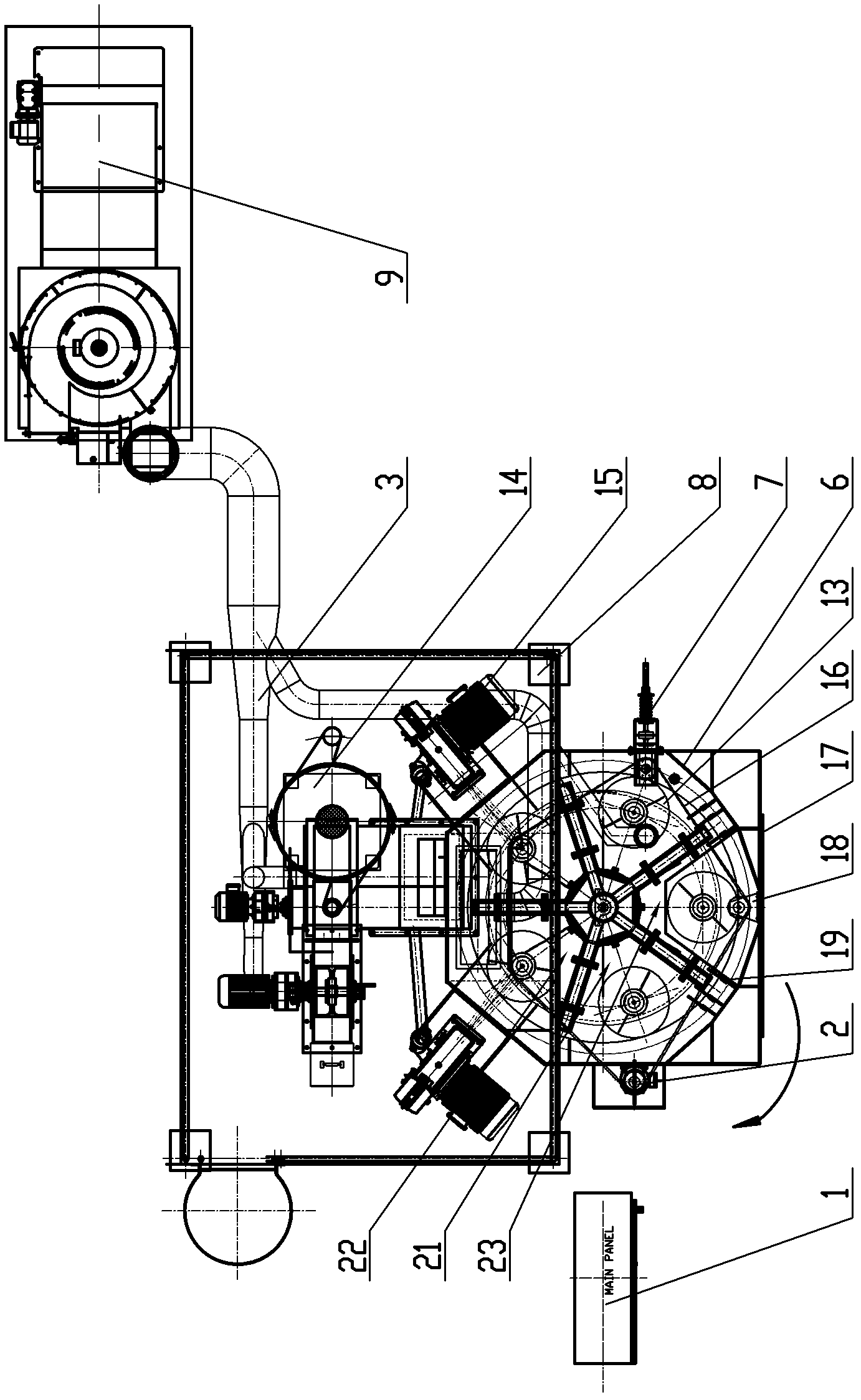

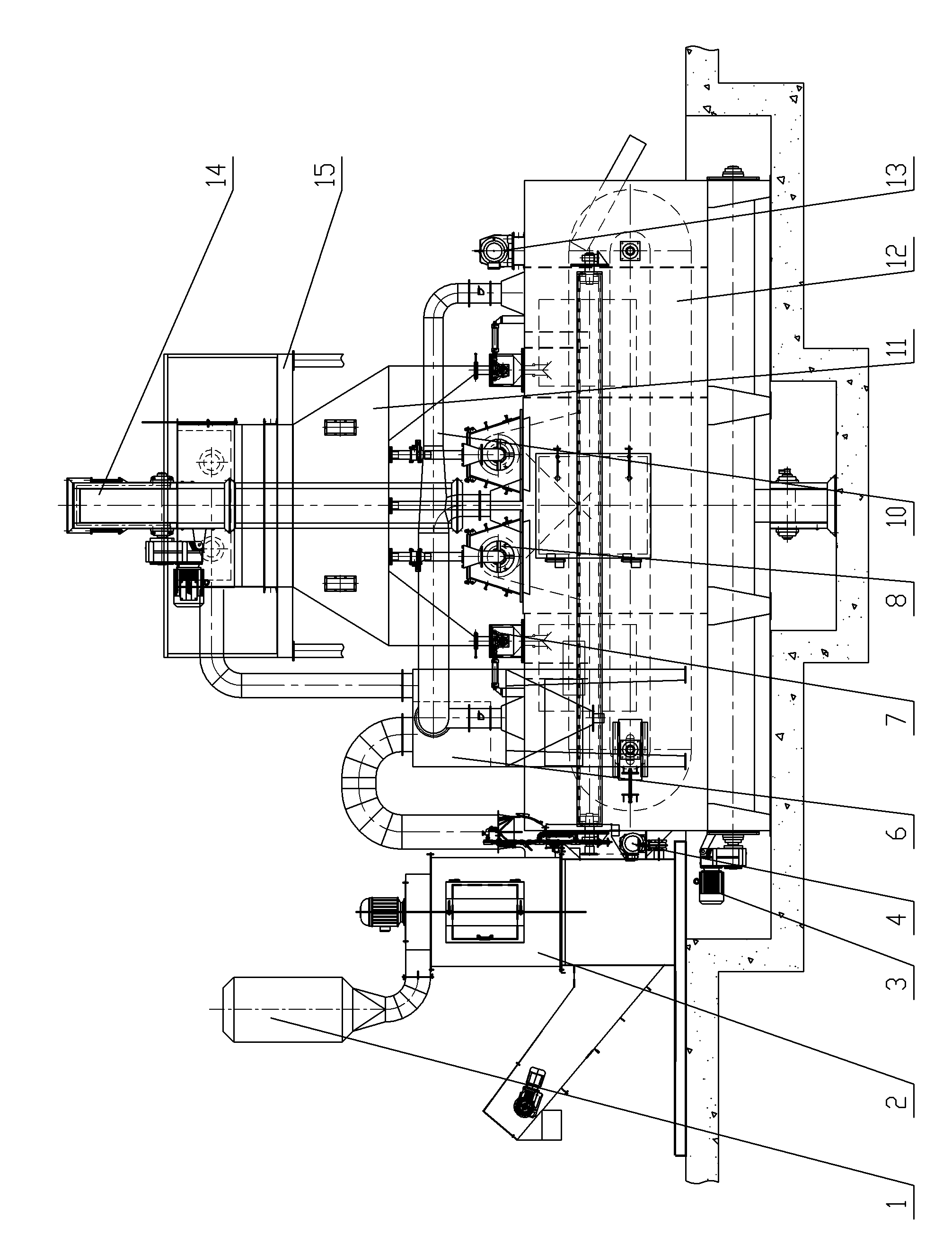

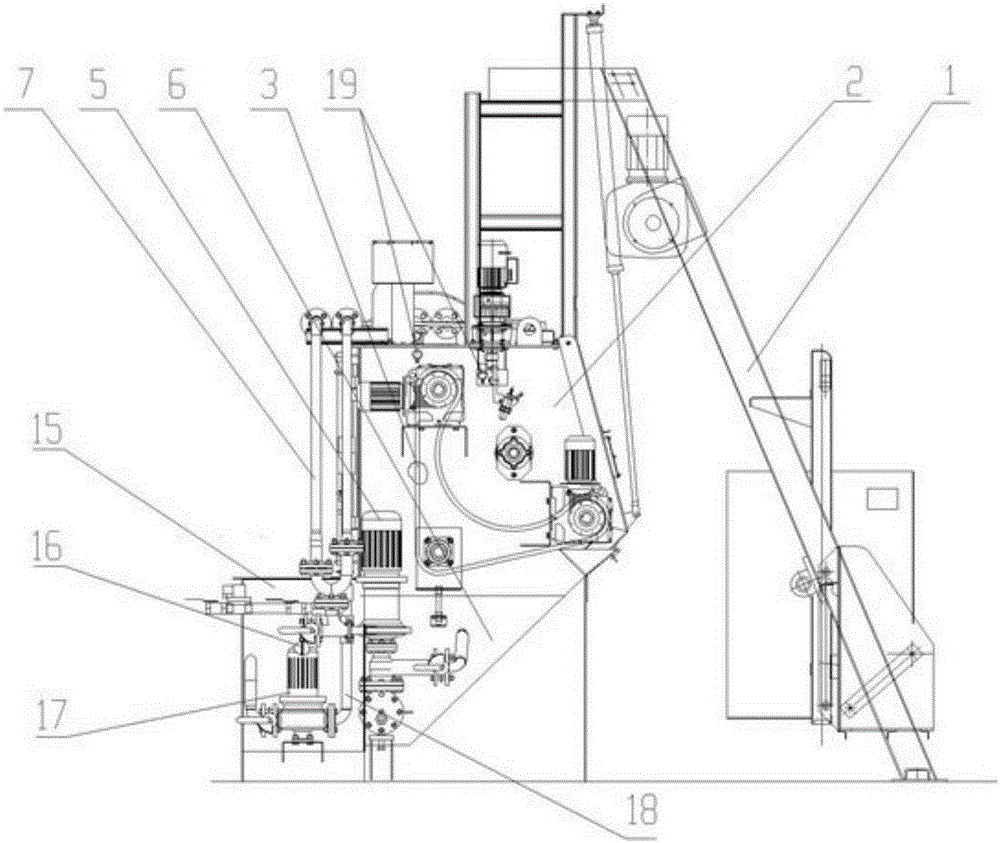

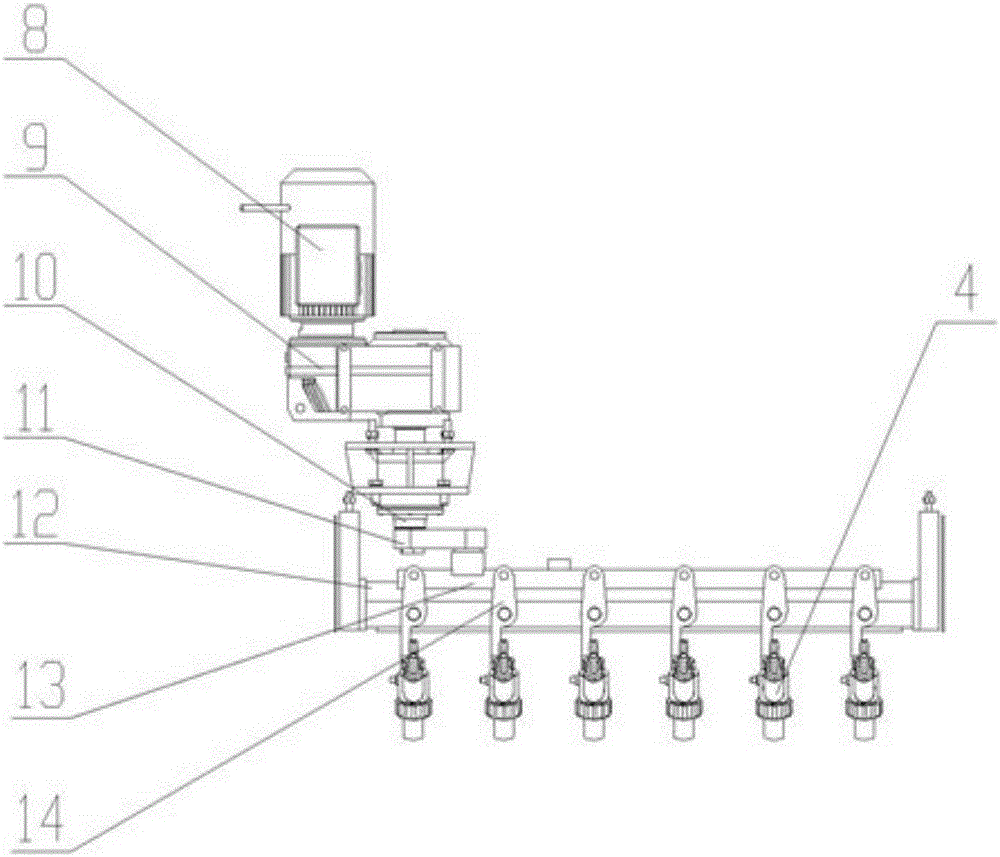

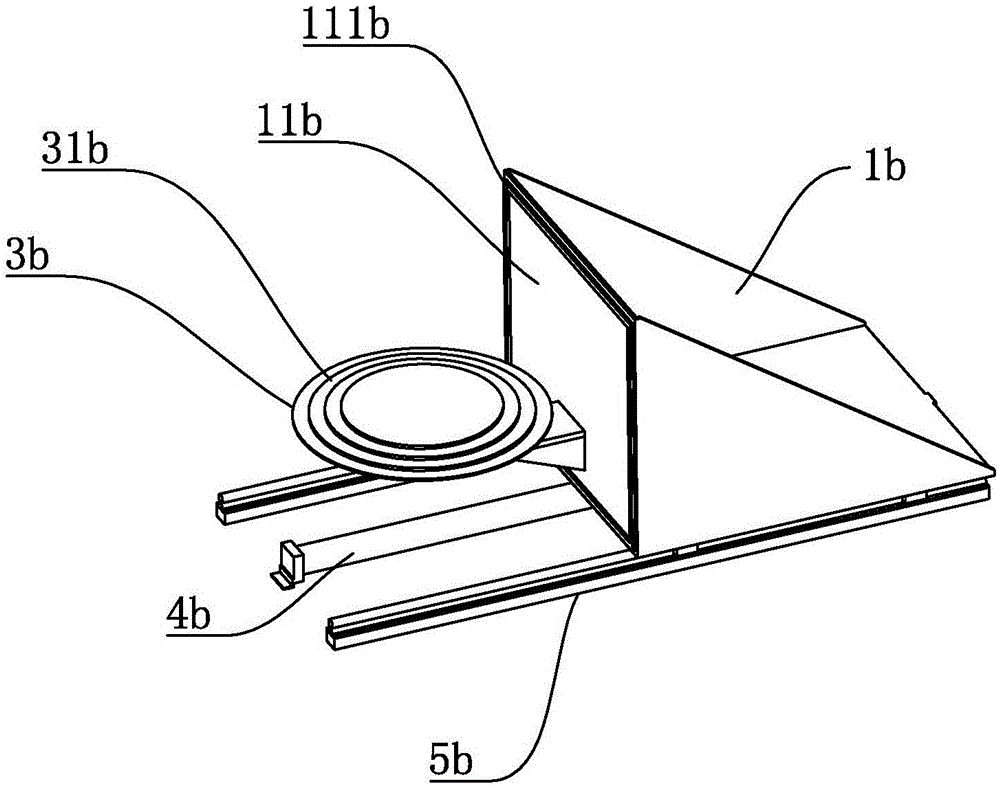

Reinforced shot blast machine for multi-position turntable

InactiveCN102248493APrevent flying outPrevent splashAbrasive blasting machinesEngineeringLoading unloading

The invention relates to a reinforced shot blast machine for a multi-position turntable. A main rotary worktable is mounted in a shot blast cleaning room, a shot blast machine is arranged out of the shot blast cleaning room, a steel shot selector is fixed above the shot blast cleaning room, a helical conveying device is fixed below the shot blast cleaning room, a hopper-type lifter is arranged behind the shot blast cleaning room, a feeding port and a discharging port of the hopper-type lifter are respectively connected with the helical conveying device and the steel shot selector, a discharging port of a steel shot separator is connected with the shot blast machine; the main rotary worktable is fixed with a partition wall assembly for partitioning the table-board of the main rotary worktable into five stations which are respectively two shot blast stations, two isolation stations and a loading-unloading station, and each station is rotatably equipped with a planetary worktable. The main rotary worktable is partitioned into the shot blast stations, the isolation stations and the loading-unloading station, the isolation stations are arranged between the loading-unloading station andthe shot blast stations with the effect of sealing; therefore, the shot can be prevented from flying out from the shot blast station, and the security is good.

Owner:无锡国达机械设备有限公司

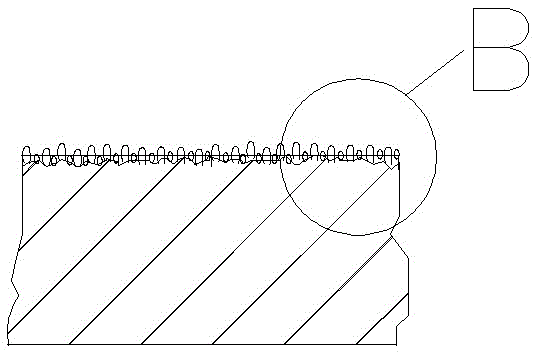

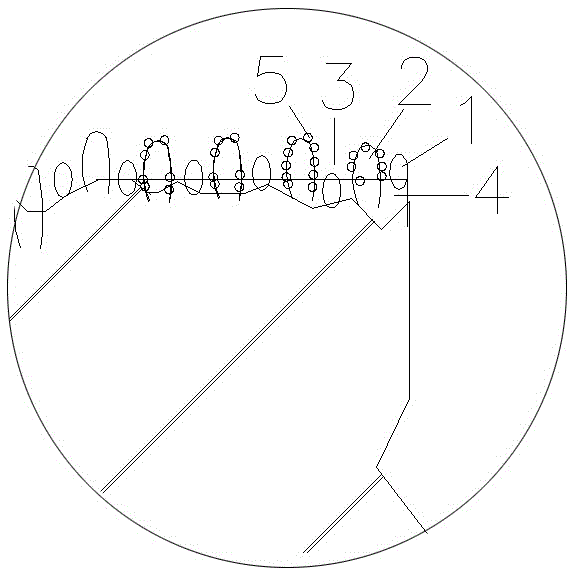

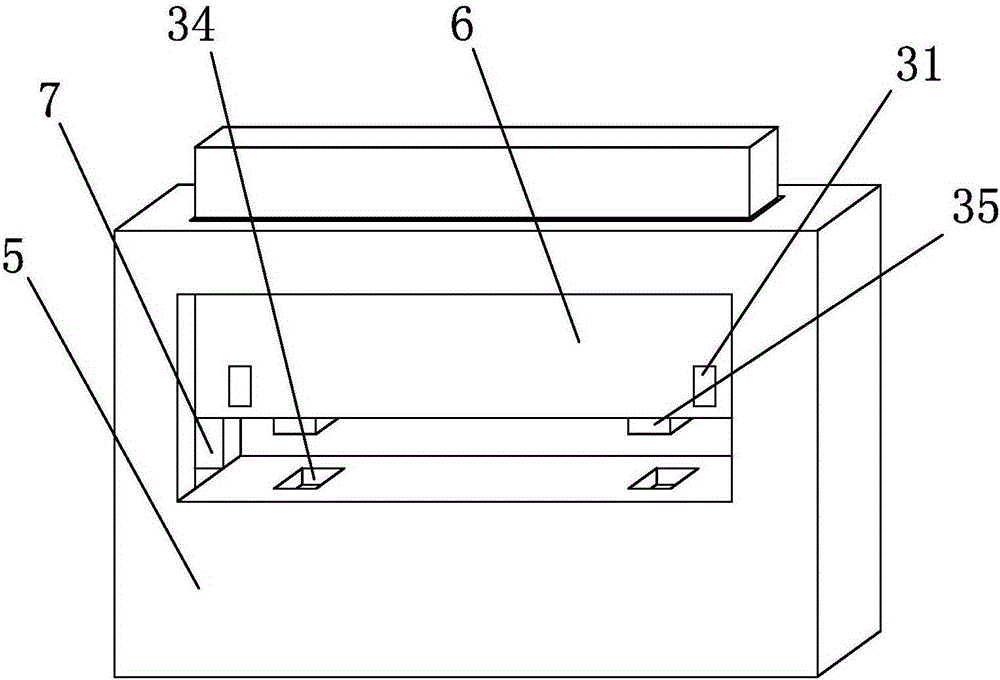

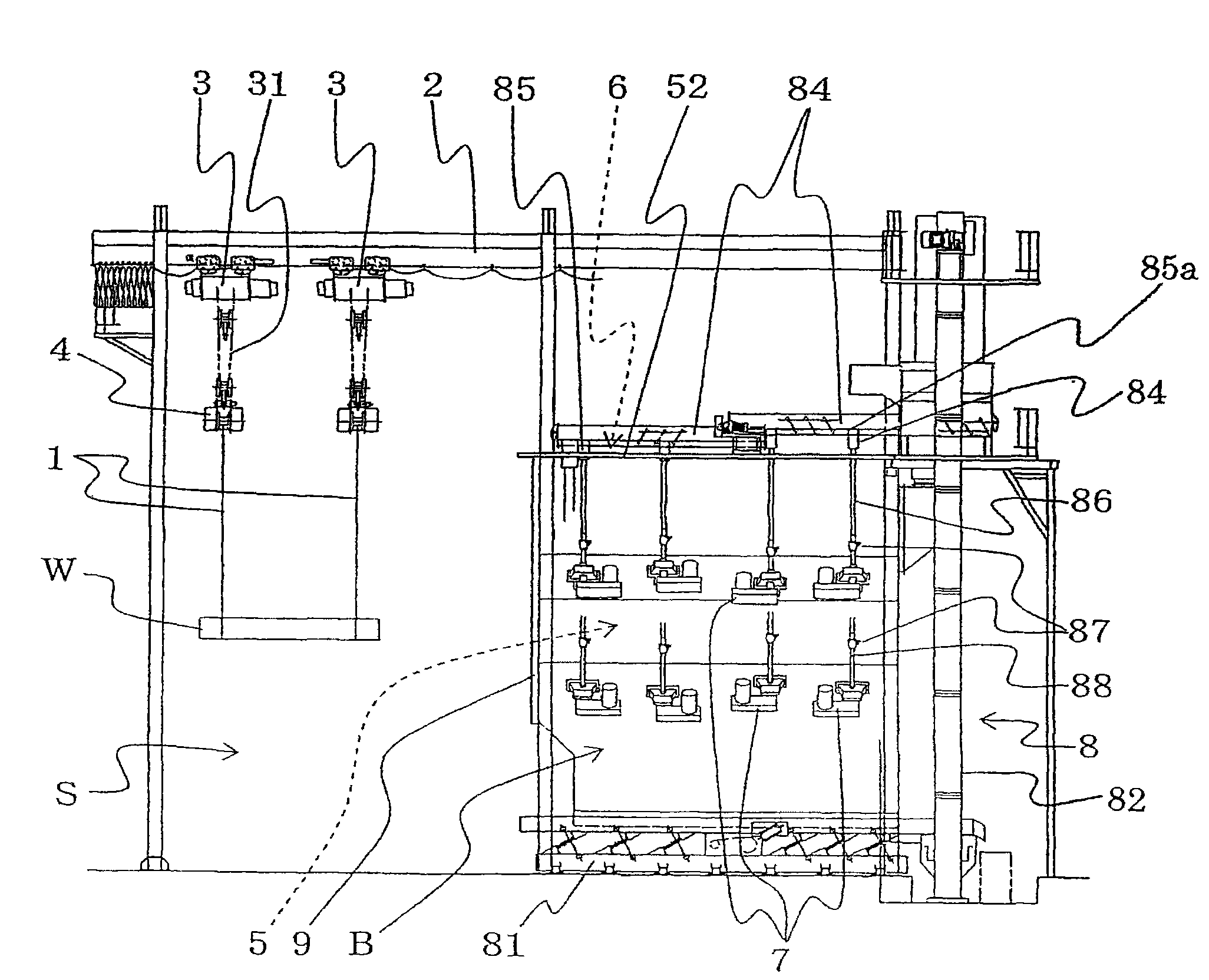

Abrasive-recovery mechanism in blasting machine

ActiveUS20090098810A1Eliminate cloggingSmall sizeAbrasive machine appurtenancesEngineeringMechanical engineering

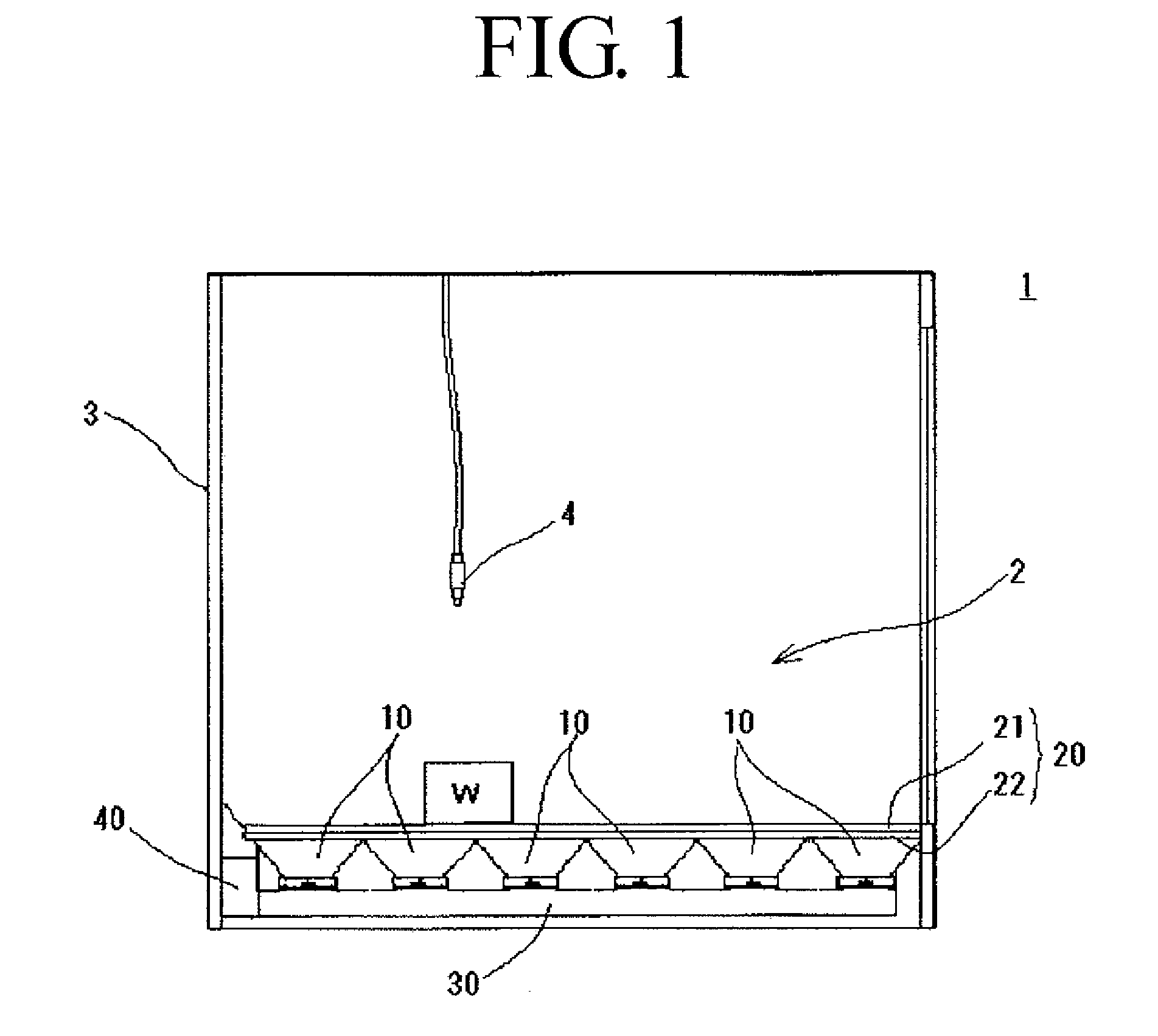

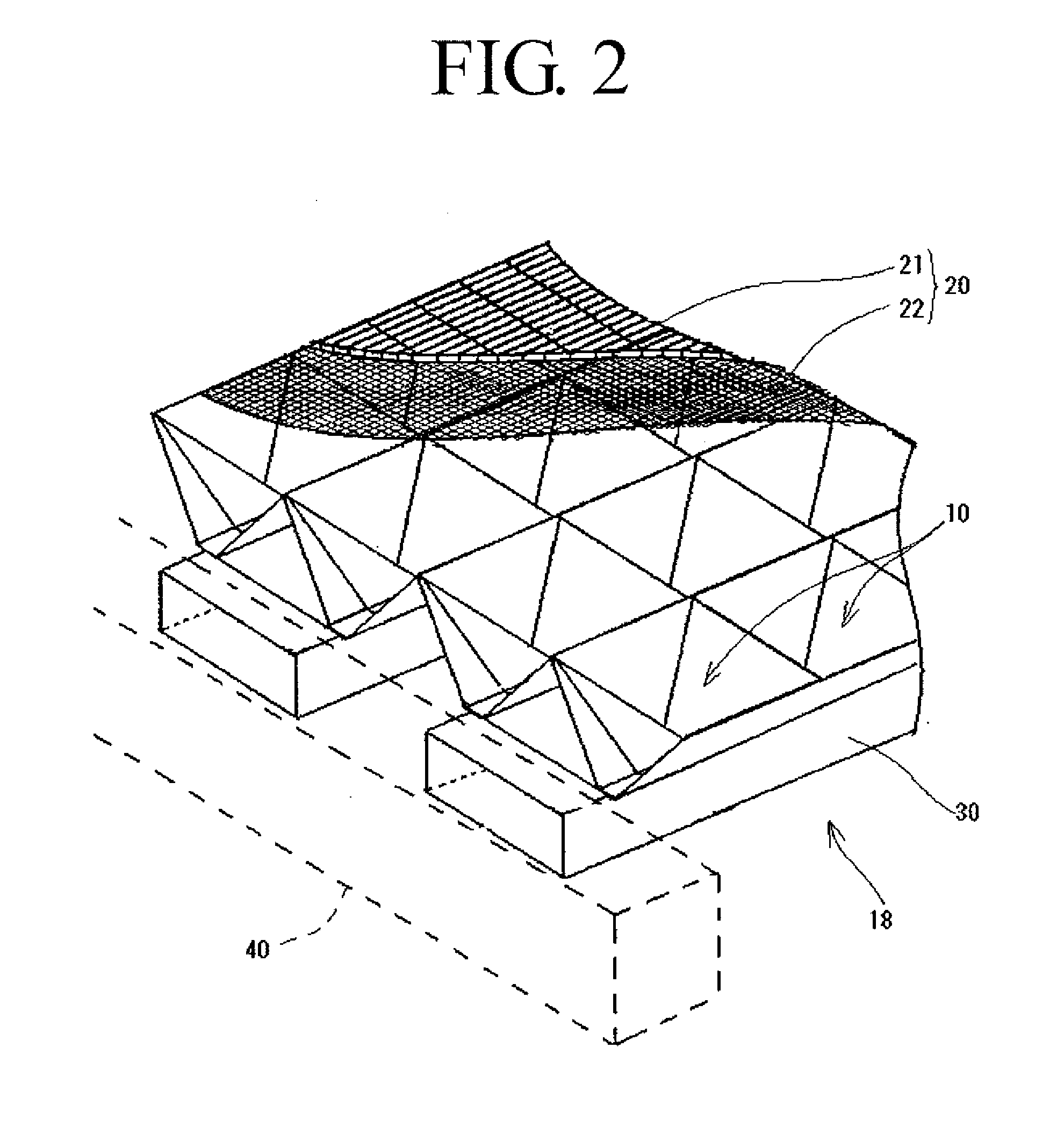

A bottom wall surface of a blasting chamber of a blasting machine provided with hoppers for recovering an abrasive is formed at a lowest possible position. A cabinet 3 of a blasting machine 1 is compartmentalized at a predetermined position into an upper space and a lower space by mesh members (21, 22) that allow the abrasive to pass therethrough to form a blasting chamber 2 having a bottom wall surface 20 defined by the mesh members (21, 22). Hoppers 10 substantially shaped like an inverted quadrangular pyramid are disposed below the mesh members (21, 22) such that top portions of the hoppers 10 are opened toward the mesh members (21, 22) and that the bottom end of each of the hoppers 10 is made to communicate with suction means, such as a dust collector, through a recovery pipe 30.

Owner:FUJI MFG CO LTD

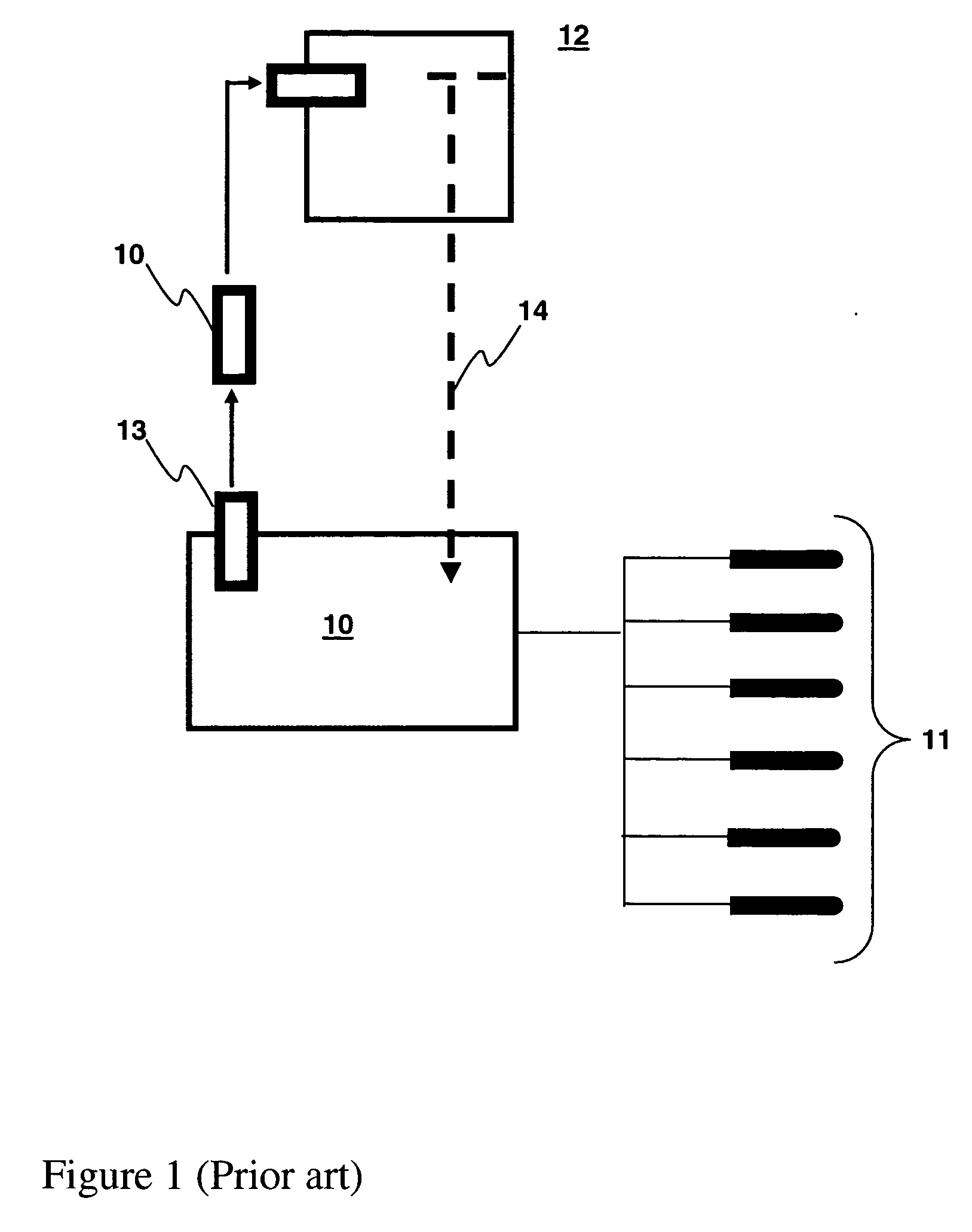

Wireless detonator assembly, and methods of blasting

ActiveUS20070044673A1Eliminate riskAvoid riskIncandescent ignitionBlasting cartridgesSpecific timeElectrical and Electronics engineering

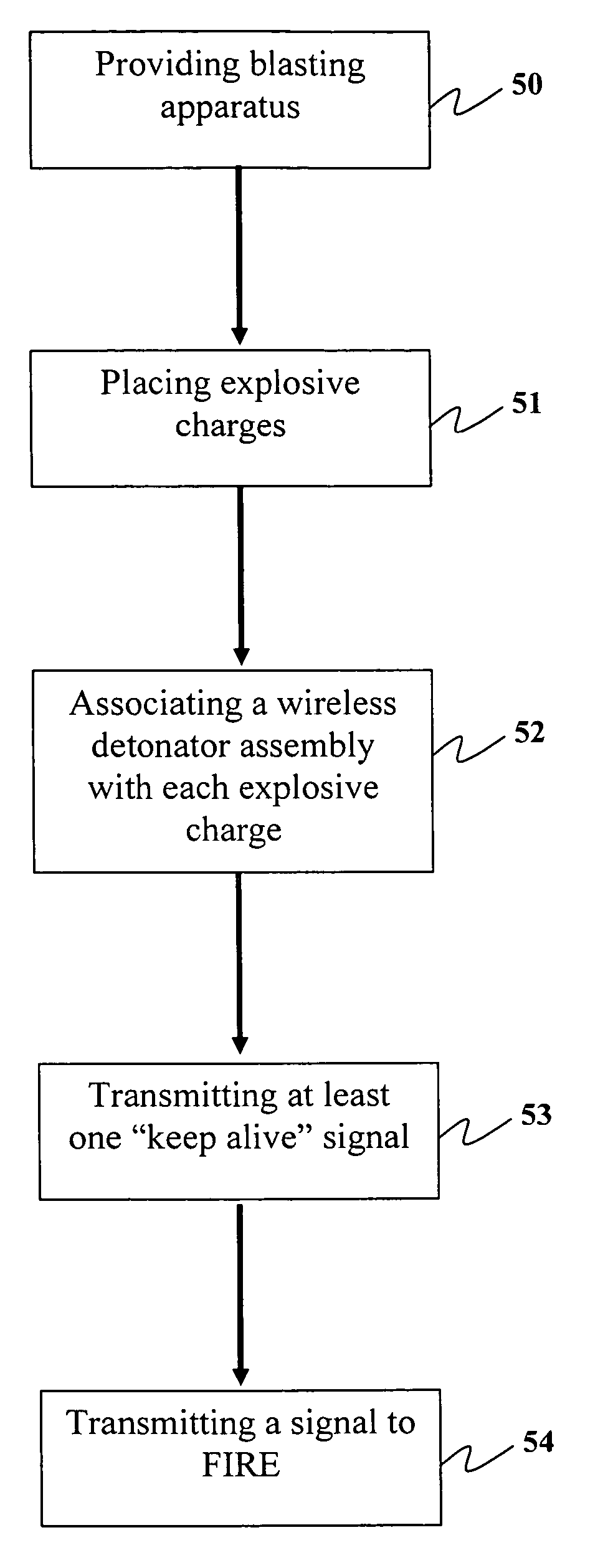

Wireless detonators, and corresponding wireless detonator systems present opportunities for blasting arrangements that avoid the need for physical wire connections between the blasting components. The present application discloses a wireless detonator assembly, a corresponding blasting apparatus, and a method of use thereof. The wireless detonator assembly comprises a charge storage device that is capable of storing charge for discharge into a firing circuit upon receipt of an appropriate wireless command signal to FIRE, from an associated blasting machine. In preferred embodiments, the charge storage device remains or becomes charged, at least for a specific time period, if the wireless detonator assembly receives a suitable “keep alive” command signal from an associated blasting machine—otherwise the charge storage device discharges with little or no effect upon the firing circuit, such that the wireless detonator assembly retain or adopts a safe mode.

Owner:ORICA EXPLOSIVES TECH PTY LTD

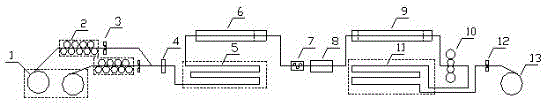

Continuous annealing acid pickling system and method for hot rolling stainless steel composite steel belt

InactiveCN105002348AImprove continuityGood pickling effectFurnace typesHeat treatment furnacesProcessing costSteel belt

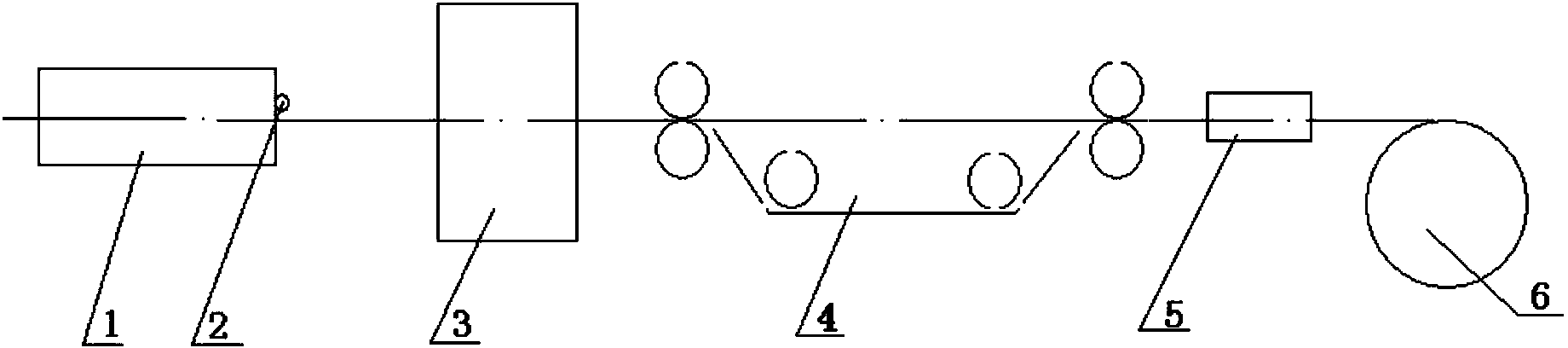

The invention discloses a continuous annealing acid pickling system for a hot rolling stainless steel composite steel belt. The system comprises two uncoilers, a straightener, two crop end shears, an MIG argon arc automatic welder, a front loop, a continuous annealing furnace, a straightener, four shot blasting machines, six shallow slot turbulent flow acid pickling grooves, a temper mill, a rear loop, a slitting shear and a recoiler. The invention also discloses an acid pickling method which utilizes the system. After the technology is adopted, the production efficiency is high; the product performance and the surface quality are stable; a product can meet the requirements of customers; the processing cost is low; and the market competitiveness is strong.

Owner:SHANDONG TAISHAN STEEL GROUP

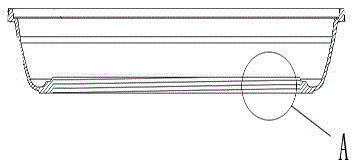

Cookware with high wear resistance and manufacturing method of cookware

InactiveCN105476490AIncrease hardnessImprove scratch resistanceCooking-vessel materialsMolten spray coatingHigh pressureAdhesion strength

The invention relates to the field of metal cookware manufacturing, in particular to cookware with high wear resistance and aims to overcome the defects in the prior art. The cookware is high in non-stick layer adhesion strength, high in abrasion resistance and high in wear resistance. According to the technical scheme, a manufacturing method of the cookware includes the steps of firstly, forming a cookware body through die-casting; secondly, using a numerically controlled lathe to perform metal processing; thirdly, finishing and polishing; fourthly, removing oil on the surface of the cookware body; fifthly, cleaning the cookware body with purified water, 3% alcohol solution and oil dissolving agent, and drying; sixthly, guaranteeing that the base material of the cookware body is clean before spraying, sand blasting the surface of the cookware body after preheating, and using the high-pressure gas of a sand blasting machine to further roughen the surface of the cookware body; seventhly, spraying the cookware body for the first time, cleaning the cookware body, then loading the cookware body onto a spraying machine, and spraying metalizing materials which include TiO2 and Al2O3 to the cookware body.

Owner:ZHEJIANG CHUNZHOU ALUMINUM IND

Sand blasting machine with adjustable sand blasting angle

The invention discloses a sand blasting machine with an adjustable sand blasting angle. The sand blasting machine comprises a base and a sand blasting chamber arranged on the base. A linear guide railis transversely erected on the top end of the interior of the sand blasting chamber, and the lower end of the linear guide rail is connected with a sand storage cylinder in a left-right sliding manner. A spray gun is vertically and downwards guided out from the lower end of the sand storage cylinder, and an infrared distance measuring device is installed at one end of the spray gun. The lower endof the interior of the sand blasting chamber is provided with a net-shaped material table, and two lifting rods are vertically arranged at the two ends of the net-shaped material table. Two rotatingmotors are symmetrically arranged at the upper ends of the two lifting rods, and a rotating shaft rod is transversely and inwards guided out from each rotating motor. An elastic clamping claw is connected with one end of each rotating shaft rod. A worktable is arranged on one side of the base, and a control platen is installed on the worktable. By means of the above manner, the sand blasting anglecan be adjusted, and the sand blasting machine is suitable for surface sand blasting treatment of irregular parts and complex parts.

Owner:WUXI RISHENG MACHINERY FACTORY

Pickling process and device utilizing residual heat of hot rolled silicon steel strip

The invention discloses pickling process and device utilizing residual heat of a hot rolled silicon steel strip. According to the pickling process, a 120-500 DEG C steel strip which is taken out from a cooling section of a normalizing furnace enters a shot blasting machine to carry out shot blasting and then directly enters the bottom of a pickling tank to carry out pickling, and the steel strip after pickling enters a reeling machine to carry out reeling to obtain a steel strip to be rolled, wherein an oxide scale of the steel strip to be rolled is removed. With the adoption of the pickling process and device, as the residual heat of the silicon steel strip after normalizing is utilized to carry out pickling, the reaction speed of the oxide scale and acid at high temperature is increased, the effect is better, the concentration and the temperature of the acid can be lowered, the warming is not needed, and the energy is saved; in addition, as the high-temperature steel strip is arranged at the bottom of the pickling tank after entering the pickling tank, the heated acid liquor is difficult to volatilize, and the environment pollution is avoided. Compared with the existing descaling process, according to the pickling process, the adopted equipment is less, a flame heating device can not be needed, the energy, the equipment cost and the production cost are saved, and the pickling process is economic and feasible.

Owner:武汉钢铁有限公司

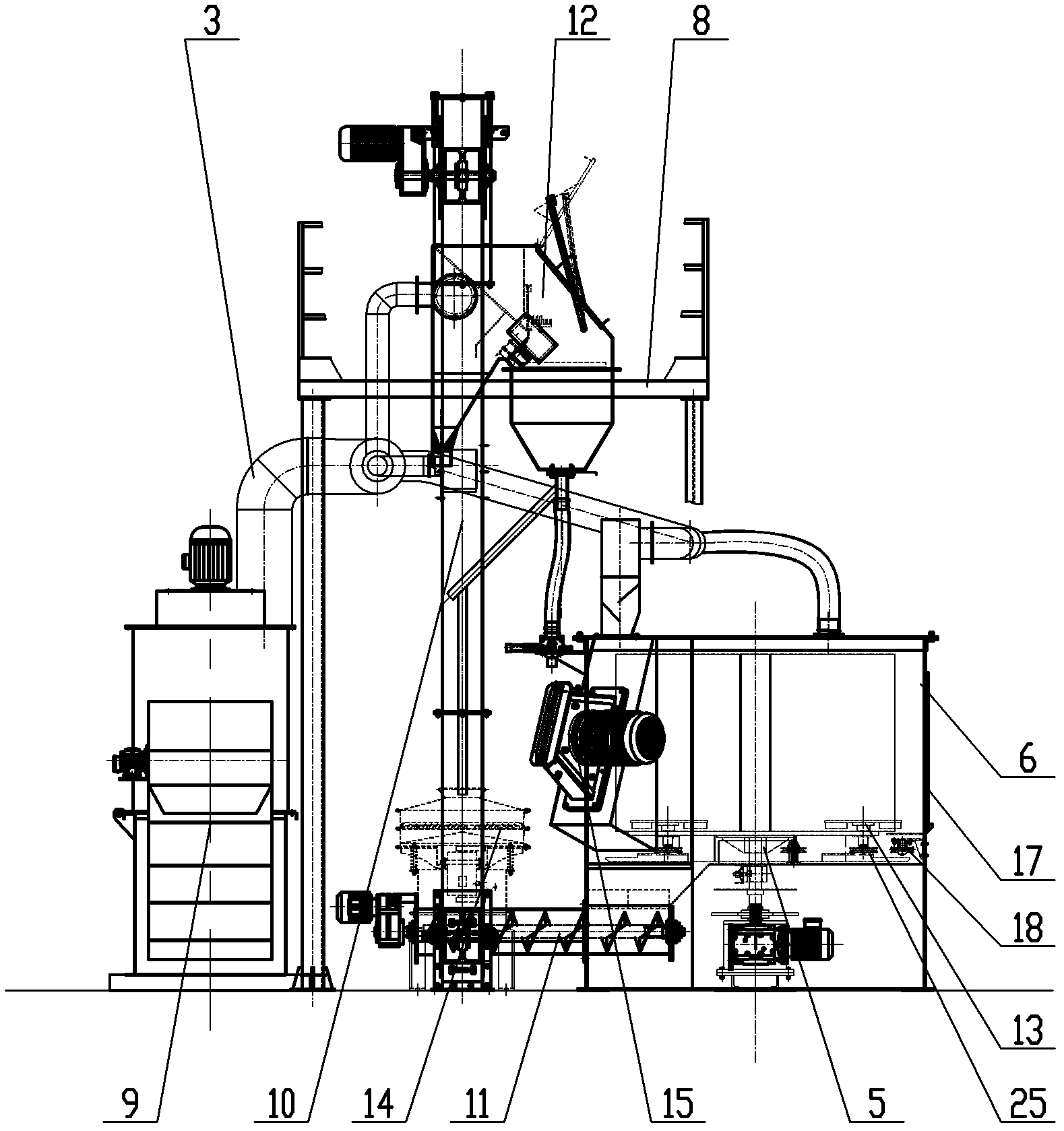

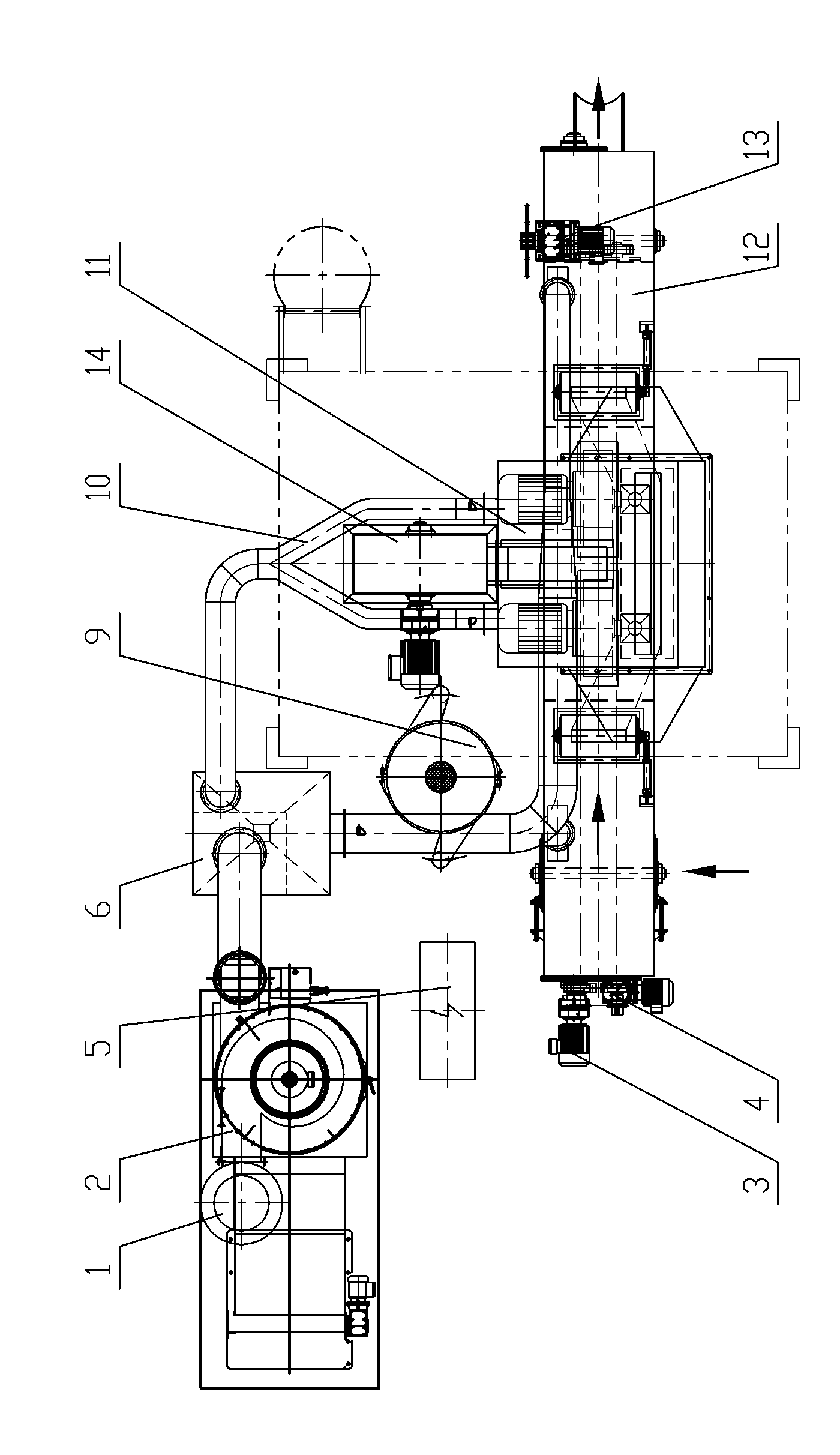

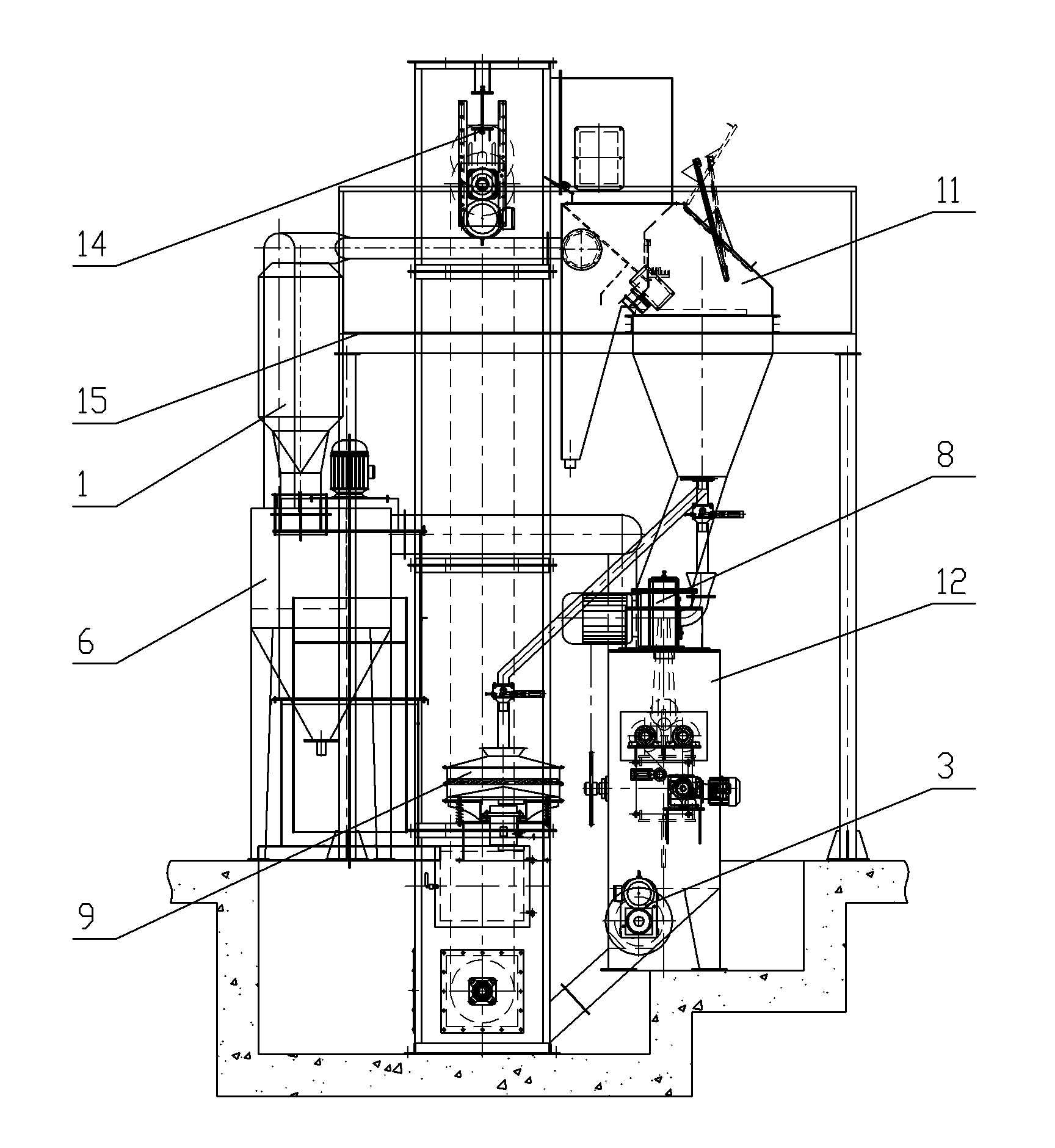

Energy-efficient spring reinforced shot blast machine

InactiveCN102189496APrevent splashing and hurting peopleReduce power consumptionAbrasive blasting machinesEnvironmental resistanceWaste material

The invention relates to an energy-efficient spring reinforced shot blast machine. The technical schemes of the invention comprise that: the shot blasting machine comprises shot blast cleaning chambers and shot blast devices; a steel shot separator is arranged fixedly above the blast cleaning chambers; the steel shot separator comprises an upper tank body, a separation tank body and a shot storage tank body, wherein the upper tank body, the separation tank body and the shot storage tank body are connected respectively in a top-to-bottom order; the separation tank body is separated into three parts of a material feeding chamber, a winnowing chamber and a miscellaneous material loading chamber; an upper portion of the material feeding chamber is communicated with the upper tank body and an lower portion of the material feeding chamber is communicated with the winnowing chamber through a feed opening; the winnowing chamber is provided with an air inlet opening and a catching plate mechanism which is utilized for adjustment of feed opening size and is arranged in the winnowing chamber, wherein the bottom of the winnowing chamber is communicated with the shot storage tank body and a side portion of the winnowing chamber is communicated with the miscellaneous material loading chamber; the miscellaneous material loading chamber is provided with an air door adjusting mechanism at a location where the miscellaneous material loading chamber and the winnowing chamber are communicated, wherein the miscellaneous material loading chamber is provided with an air outlet opening at the upper portion, and a waste material outlet opening at the bottom; and the shot storage tank body is provided with shot outlet openings communicated with the shot blast devices. The steel shot separator utilized in the reinforced shot blast machine utilizes a winnowing way and has the advantages of requiring no mechanical power and reducing power consumption. The whole energy-efficient reinforced shot blast machine has the advantages of low energy consumption, reliable service behaviour, energy conservation and environmental protection.

Owner:无锡国达机械设备有限公司

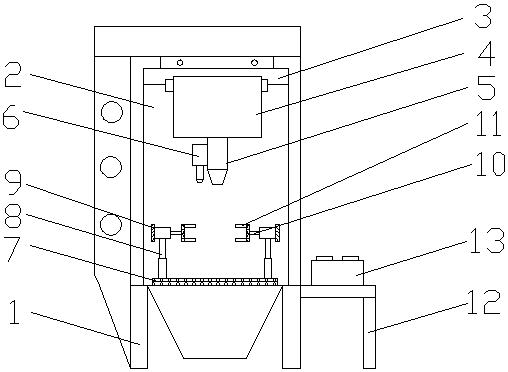

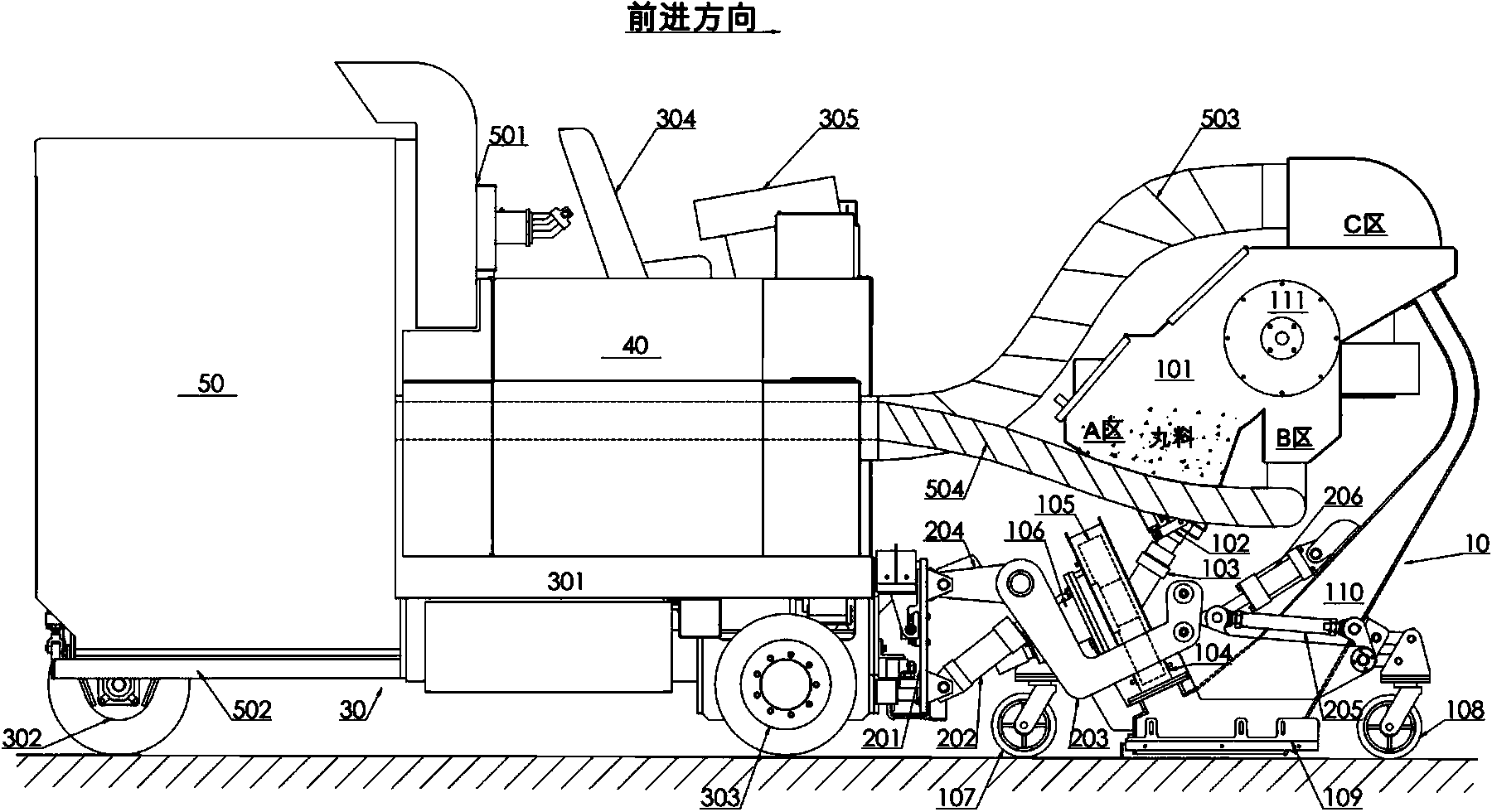

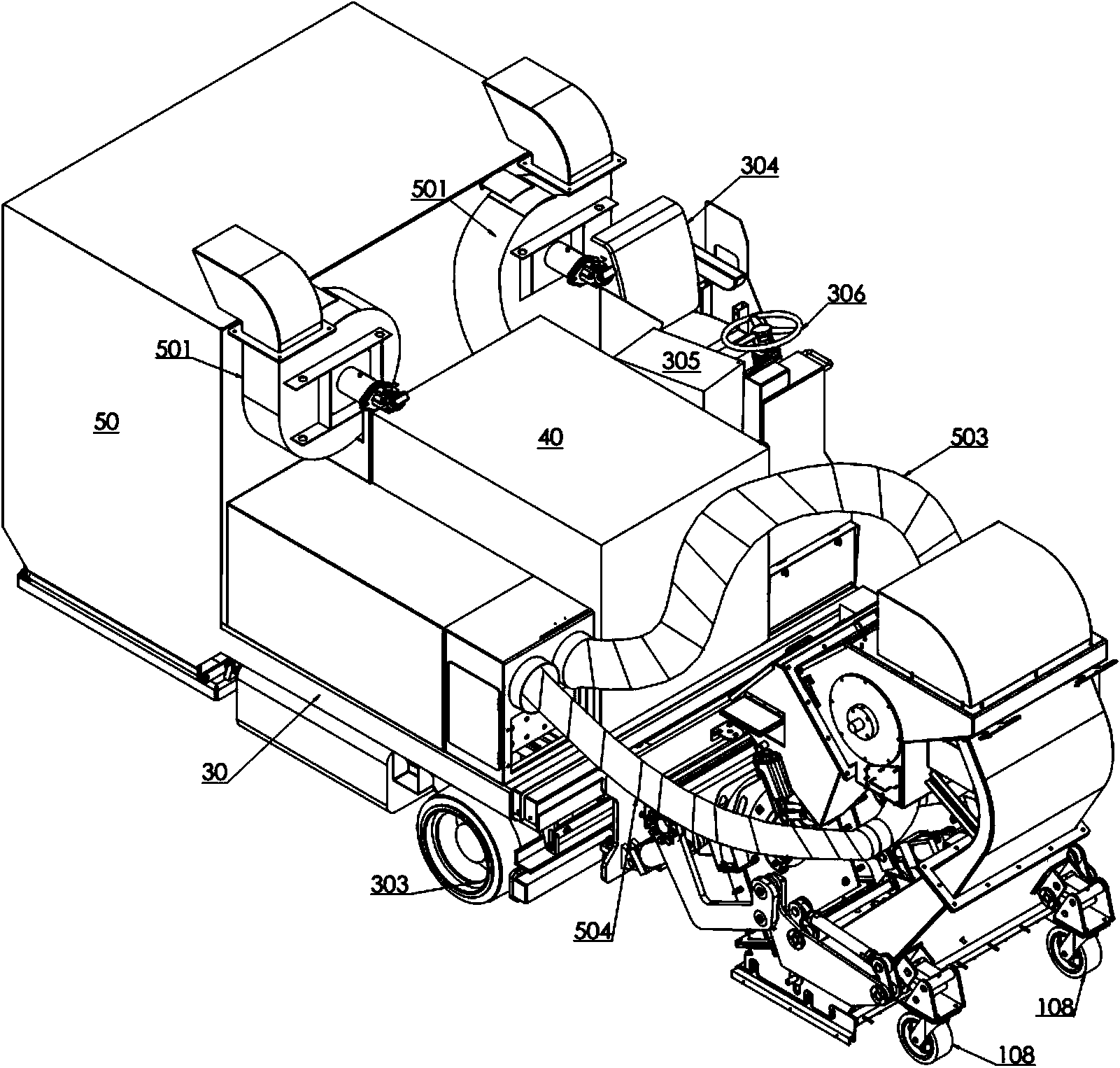

Driving-type shot blasting machine

ActiveCN103522198AReduce the level of conversionReduce lossAbrasive machine appurtenancesAbrasive blasting machinesEngineeringDust particles

A driving-type shot blasting machine consists of a shot blasting unit, a lifting lateral-shifting frame, a machine frame unit, a power unit and a dedusting unit; the shot blasting unit is arranged at the front part of the shot blasting machine, and connected with the machine frame unit via the lifting lateral-shifting unit; the power unit and the dedusting unit are both installed on the machine frame unit; the lifting lateral-shifting unit controls the position of the shot blasting unit; the power unit provides power for the shot blasting machine; and the dedusting unit is arranged at the back of the machine frame unit for adsorbing and removing dust particles. Compared with the prior art, the driving-type shot blasting machine has the advantages of reduced energy consumption, improved service life, high work efficiency and the like.

Owner:HUSQVARNA AB

Casting process of abrasion-resistant low-porosity shot blasting machine vane

The invention discloses a casting process of an abrasion-resistant low-porosity shot blasting machine vane. Firstly, drying treatment is carried out on molding sand used for manufacturing a casting mold, casting burdened materials are selected, loaded into an electric furnace and melted into raw molten iron, pretreating agents are added into the raw molten iron, then the raw molten iron is discharged from the furnace and sequentially subjected to spheroidizing, two times of inoculation and casting molding, the shot blasting machine vane finished product is obtained after annealing, quenching, tempering, shot blasting cleaning and machining, and the shot blasting machine vane finished product is checked and put in storage. The casting process of the abrasion-resistant low-porosity shot blasting machine vane can largely improve the abrasion resistance and toughness of the shot blasting machine vane, reduces air holes in the shot blasting machine vane, prolongs the service life of the shot blasting machine vane, is easy to operate, is low in cost and produces a little smoke dust in the casting process.

Owner:江苏飞腾铸造机械有限公司

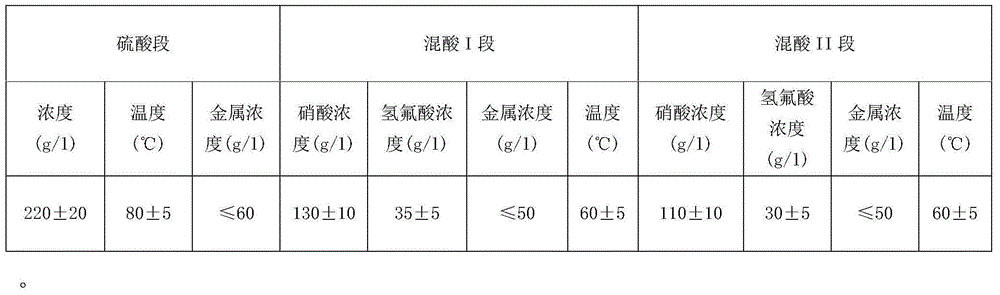

Steel annealing and pickling method for hot-rolled 430 ferrite stainless steel band

ActiveCN103882218AImprove the surface quality levelHigh yieldElectrolysis componentsFurnace typesStrip steelFerric

The invention discloses a steel annealing and pickling method for a hot-rolled 430 ferrite stainless steel band. The method comprises the following steps: carrying out scale breading on a steel band by using a descaling mill after annealing by a bell-type furnace, and then carrying out descaling on the steel band by using a shot blasting machine; processing the steel band by a sulfuric acid electrolytic pickling tank after descaling by the shot blasting machine; grinding and rinsing after electrolytic pickling by a sulfuric acid; processing by a sulfuric acid pickling tank after grinding and rinsing; processing by a mixing pickling bath after pickling by the sulfuric acid, wherein the metal ion concentration is 10-30g / l, and the metal ion concentration is 5-15g / l after processing by the mixing pickling bath. The annealing temperature, the steel band speed, the ductility, the projection quantity and the rotating speed of the shot blasting machine, the grinding and rinsing rotation speed, the current size and the picking process are effectively adjusted, so that scale on the surface of the steel band is removed, and the surface quality grade of the steel band after pickling is improved, a good surface NO.1 is obtained, and the yield is improved.

Owner:WISDRI ENG & RES INC LTD

Glass sand-blasting machine used for glass surface processing

InactiveCN105171616AScientific sandblastingOperational securityBlast gunsAbrasive feedersSand blastingEngineering

The invention discloses a glass sand-blasting machine used for glass surface processing. The glass sand-blasting machine comprises a feed table, a sand-blasting table, a sand-blasting chamber and a discharge table. A partition plate is arranged between the feed table and the sand-blasting table. An automatic induction door is formed on the partition plate. A feed hopper is arranged above the sand-blasting chamber. A vibrator is arranged on the outer wall of the feed hopper. A toothed plate is arranged on the inner wall of the feed hopper. A first stirring device is arranged in the feed hopper. A sand-blasting device, a filter sieve plate and a second stirring device are arranged in the sand-blasting chamber. The glass sand-blasting machine is simple in structure and high in practicability, and glass can be more conveniently moved through material conveying rollers; due to the design of the first stirring device and the second stirring device, diamond sand can be prevented from being coagulated in the conveying process, blocking a spray gun and influencing the work efficiency; due to the design of a transparent protection cover on the discharge table, the noise pollution can be reduced, flying of dust can be prevented, use is more convenient and easier, the energy consumption is lowered, and the comprehensive utilization efficiency is improved.

Owner:SHENGZHOU HUANDING GLASS TECH CO LTD

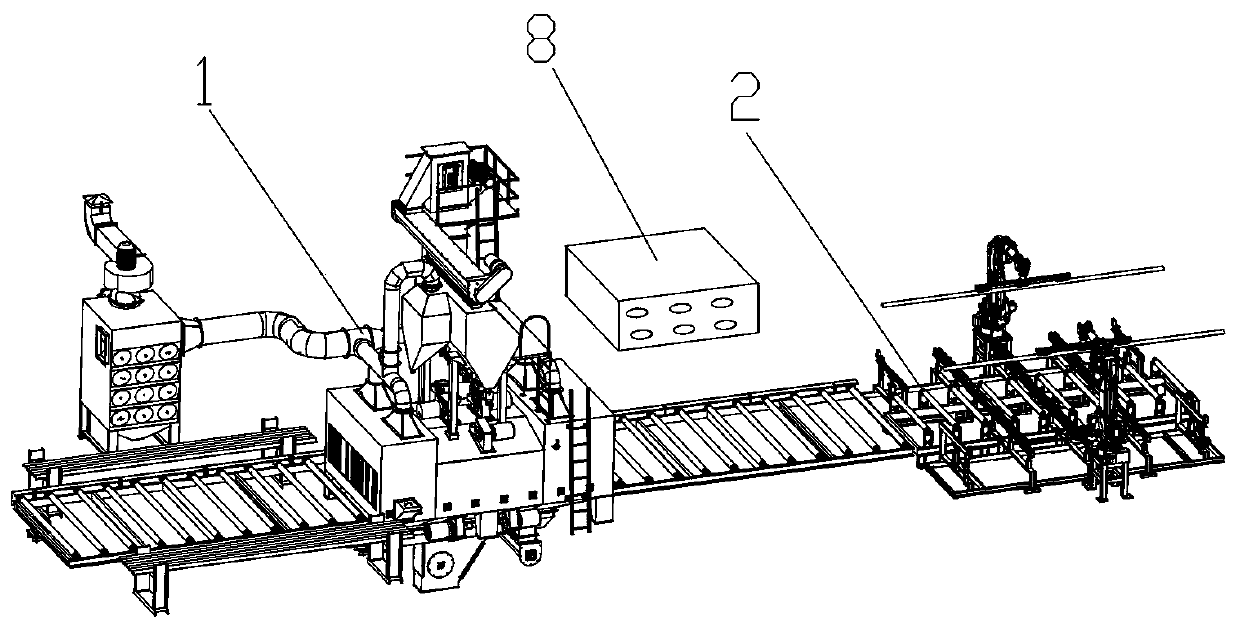

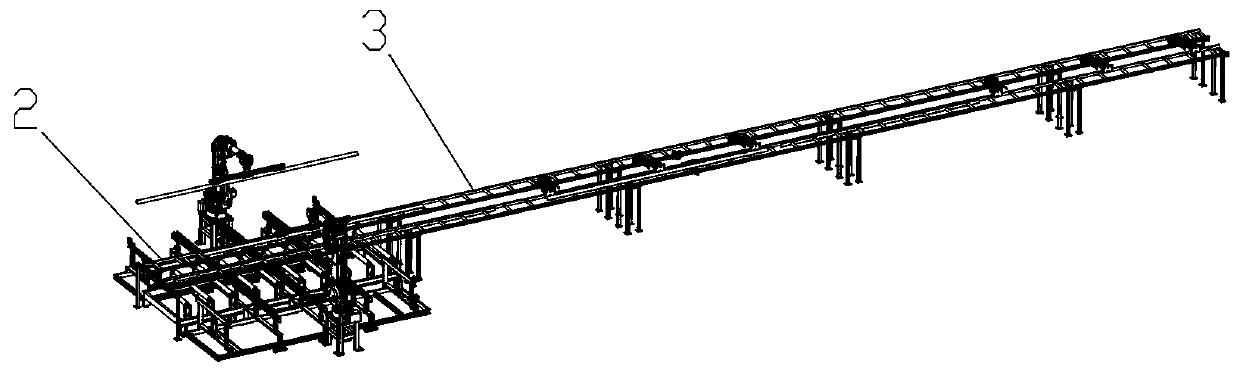

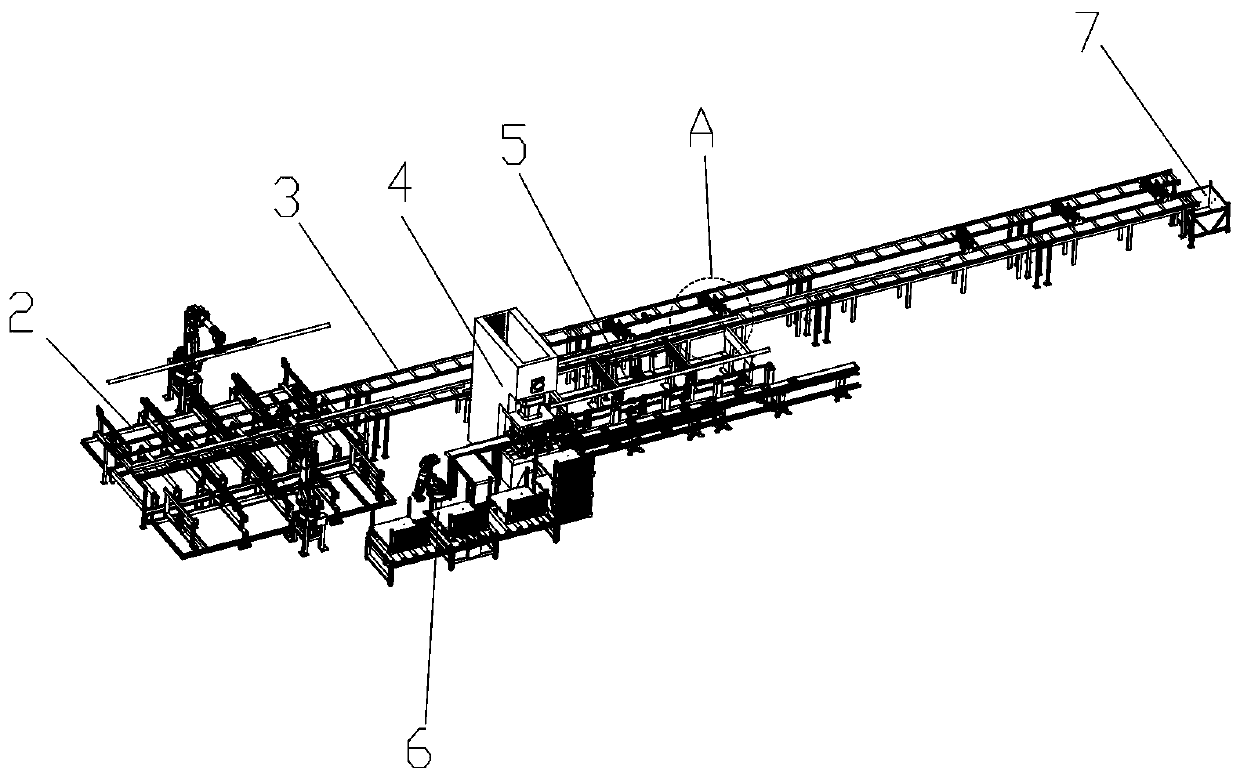

Full-automatic angle steel processing device and method

PendingCN110814774AImprove processing efficiencyPerforating toolsMetal-working feeding devicesPunchingMachined surface

The invention discloses a full-automatic angle steel processing device. The full-automatic angle steel processing device comprises a shot blasting machine, a shunting platform used for shunting anglesteel of different types, two processing conveyer belts, more than one punching integrated die arranged on the side edge of each processing conveyer belt, more than one punching conveying mechanism used for conveying the angle steel on the processing conveyer belts into the corresponding punching integrated dies, more than one stacking mechanism used for placing the processed angle steel, a wastecollection system for collecting waste, and an equipment controller for communicating and controlling the various components. According to the full-automatic angle steel processing device and method,by arranging the shunting platform, different types of angle steel are shunted and conveyed to the different punching integrated dies, various types of angle steel can be processed, the angle steel processing surface treatment, transportation, fixed-length cutting, finished product stacking and waste and tailing collection are integrated, and the processing efficiency of the angle steel is improved.

Owner:NINGBO HONGTENG ELECTROMECHANICAL

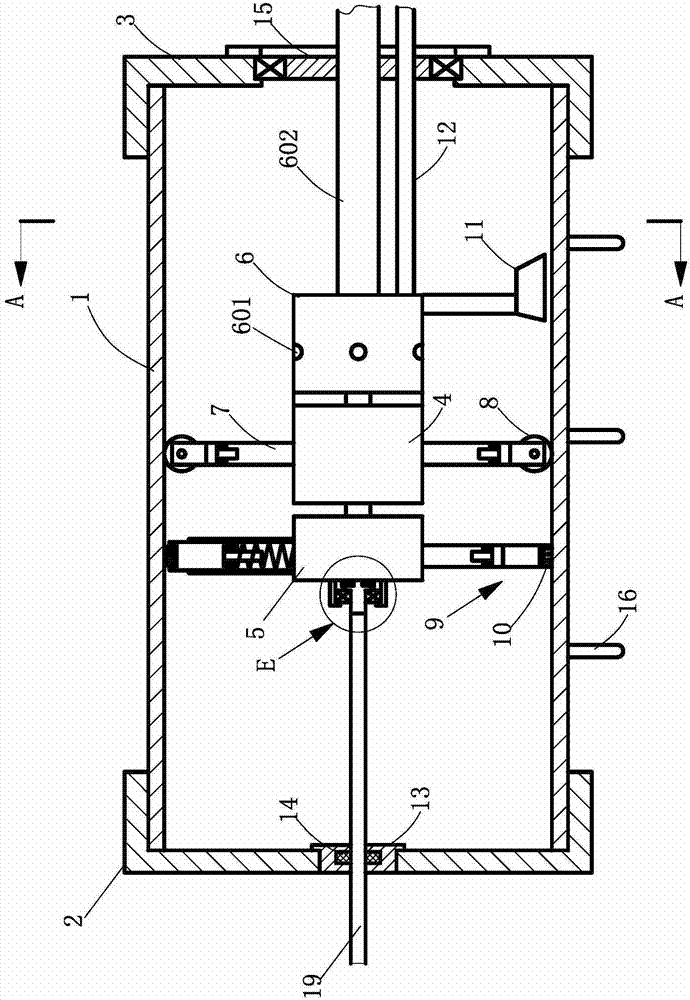

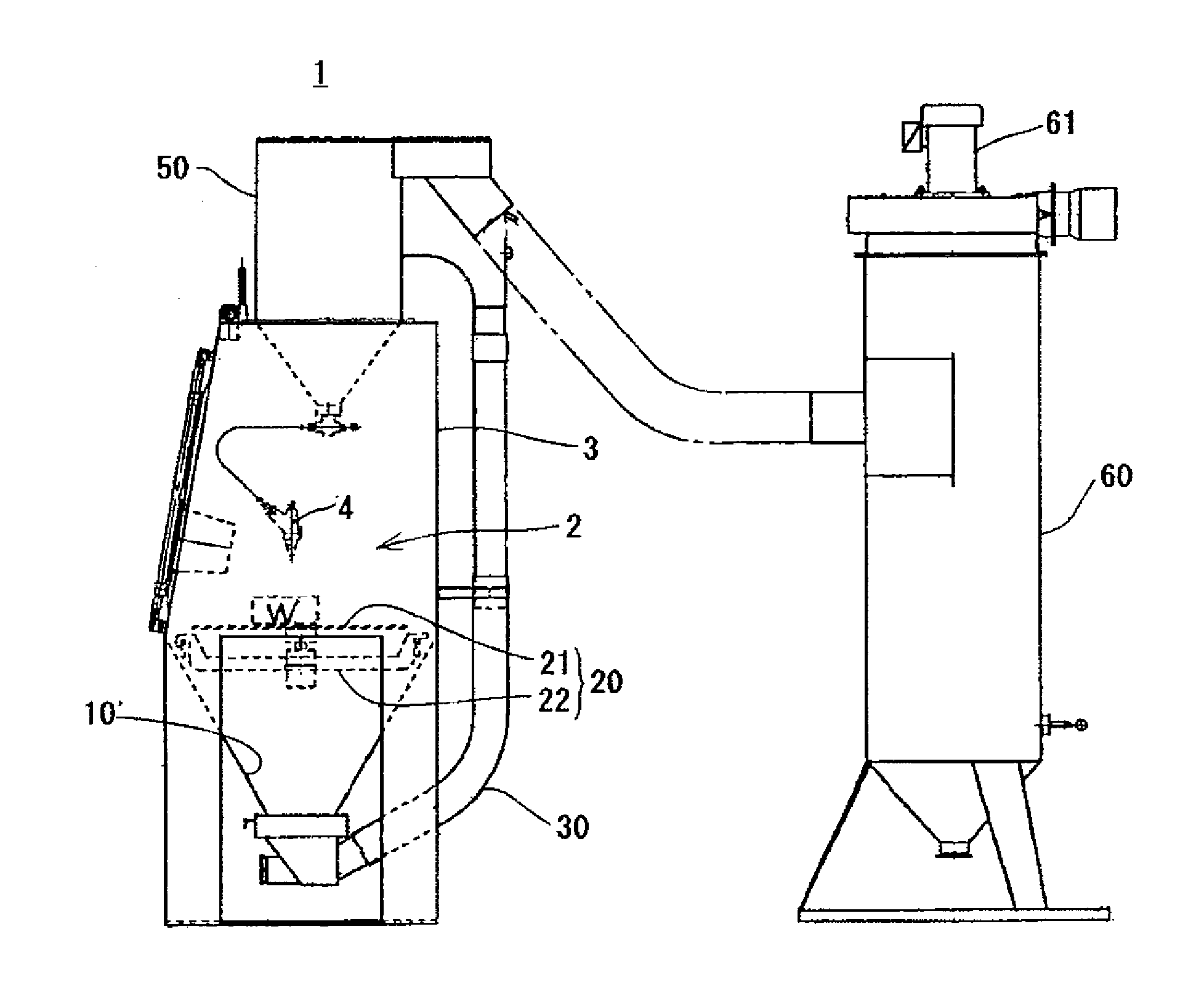

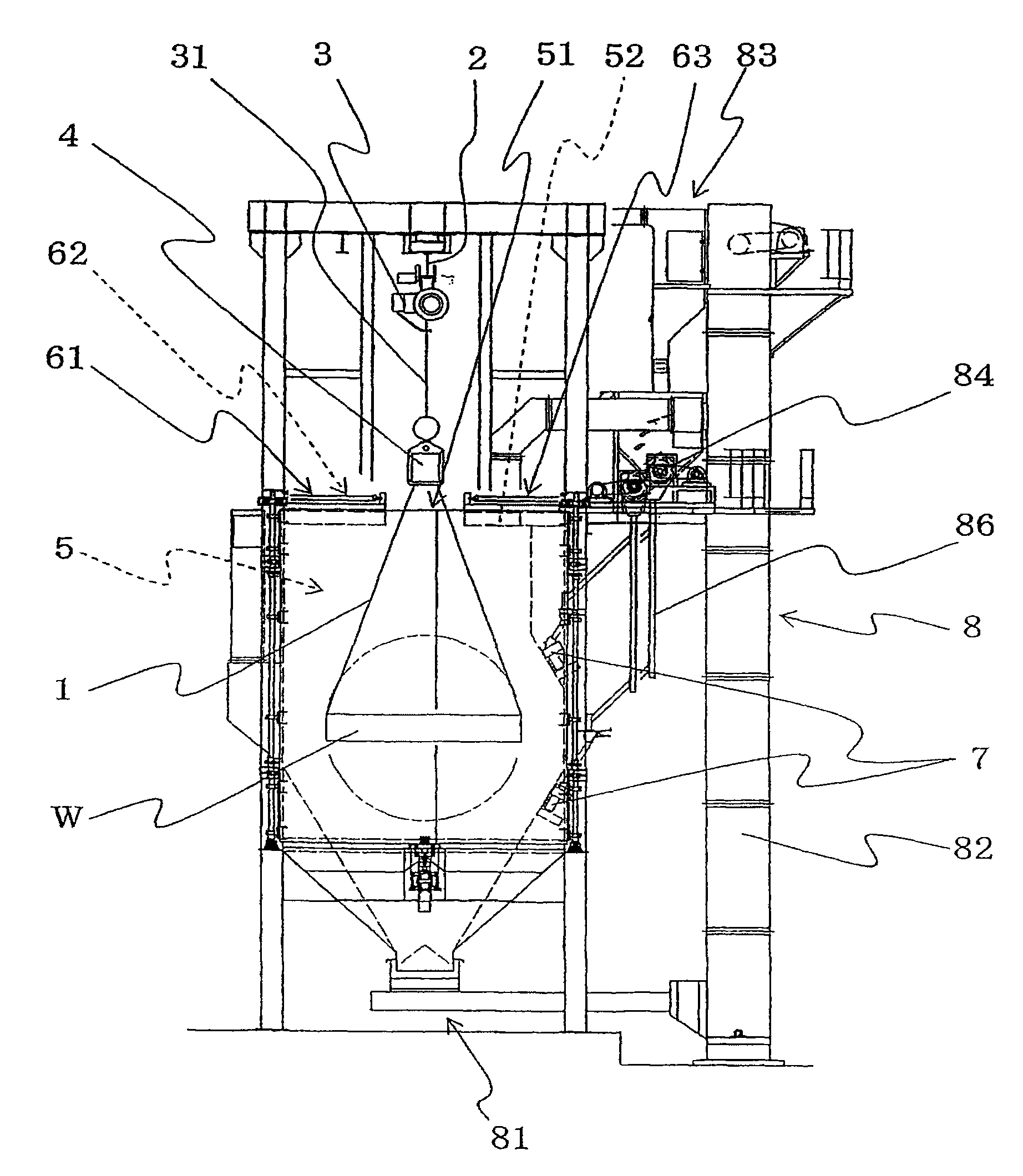

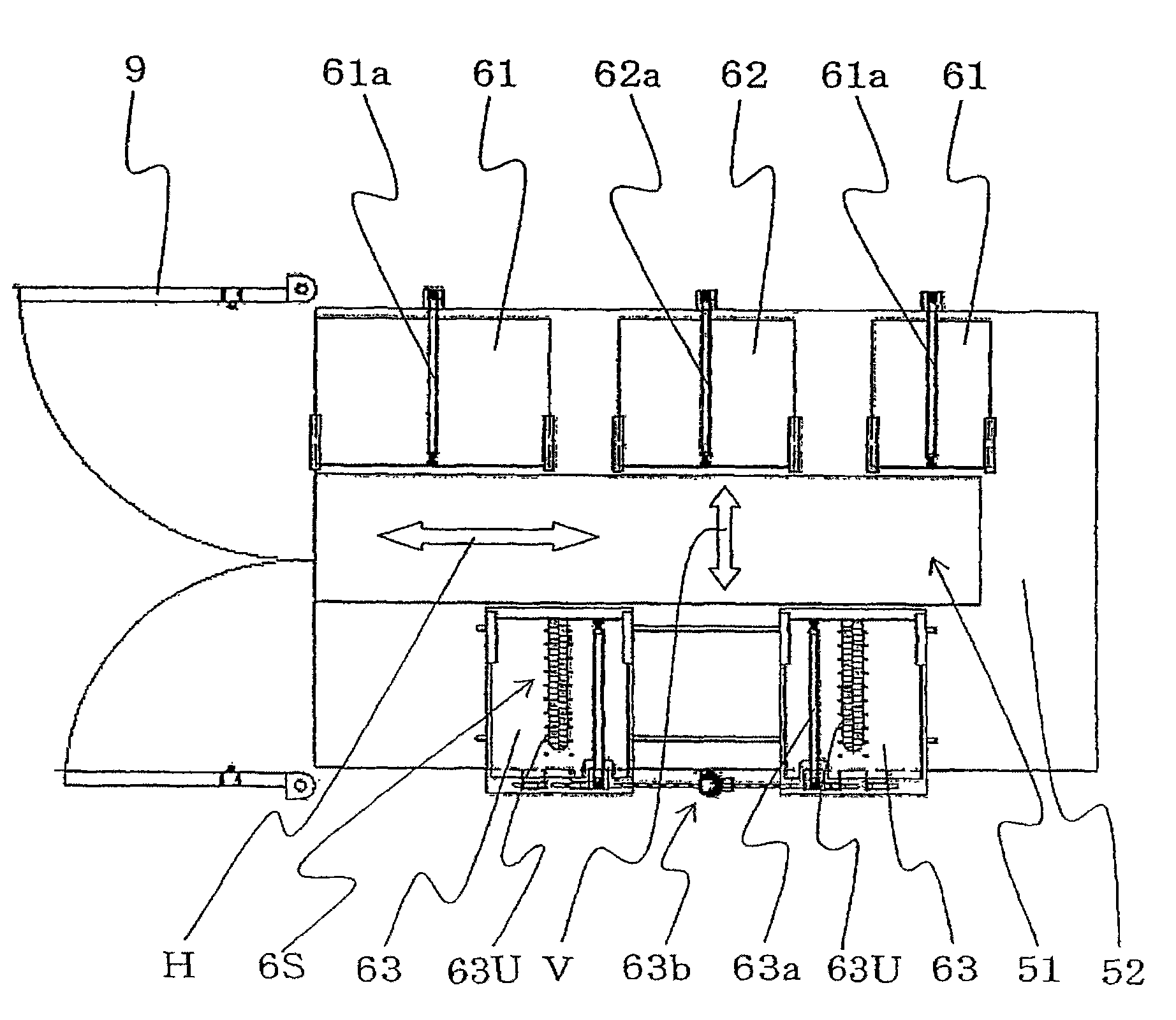

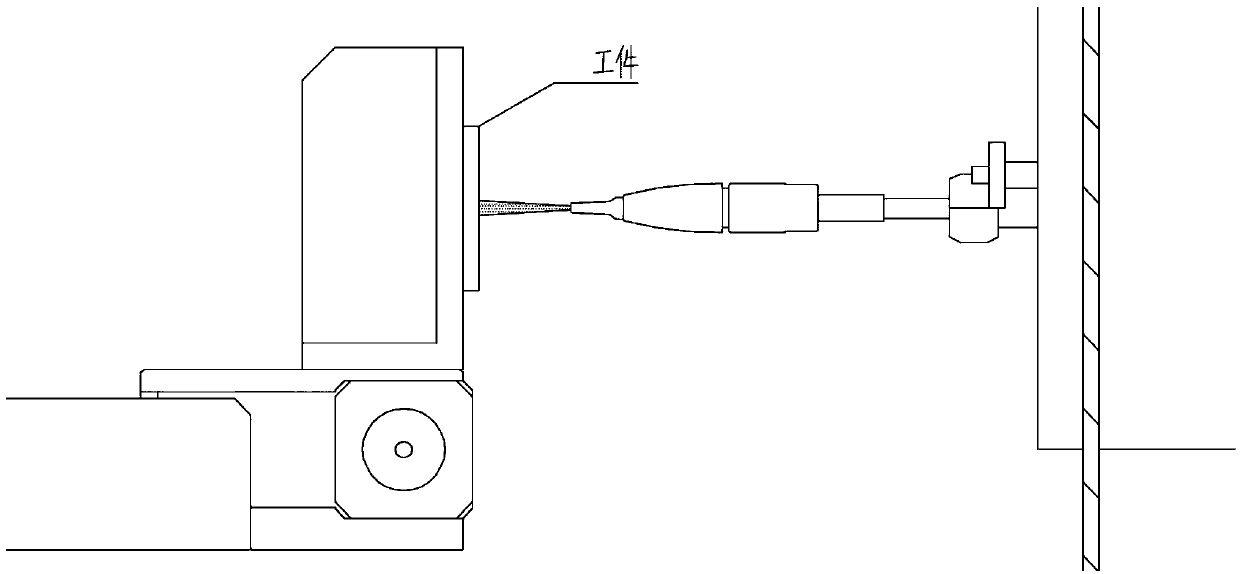

Shot-blasting machine

ActiveCN101687308ASmall volumeAvoid flyingAbrasive machine appurtenancesAbrasive blasting machinesEngineeringMechanical engineering

A shot-blasting machine for shot blasting a workpiece is disclosed. The shot-blasting machine comprises a rail 2 mounted on an upper part of the shot-blasting machine and extending in a horizontal direction, one or two hoists movable along the rail, and two inverting mechanisms 4. Each inverting mechanism 4 includes chain slings 1 for supporting one workpiece W at one end or the other end such that the workpiece W is suspended therefrom and includes a feeder for feeding the chain sling 1. An enclosure B in the shot-blasting machine has an entrance at one side and defines a projecting chamber 5therein. The upper surface of the enclosure B is provided with an elongated opening 51. The volume of the projecting chamber 5 is to allow the workpiece W supported by the chain slings 1 to be movedalong the direction that the rail 2 extends by running the hoist 3, while the workpiece W can be rotated about a rotating axis that is parallel to the direction that the rail 2 extends. The upper surface of the enclosure B is provided with a sealing mechanism 6 for preventing the shots from dispersing from the opening 51 by closing the opening 51 in which the chain slings 1 are inserted.

Owner:SINTOKOGIO LTD

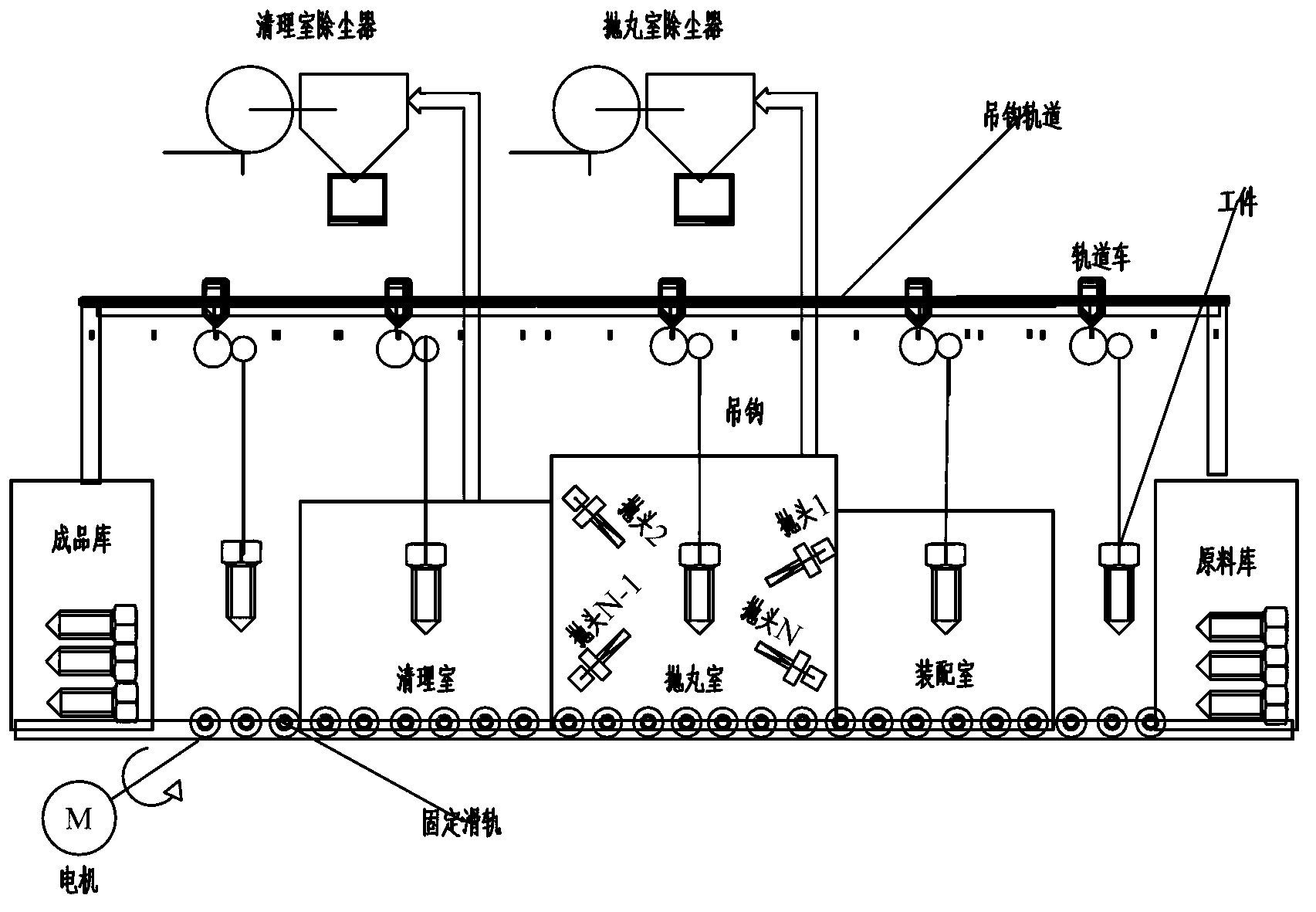

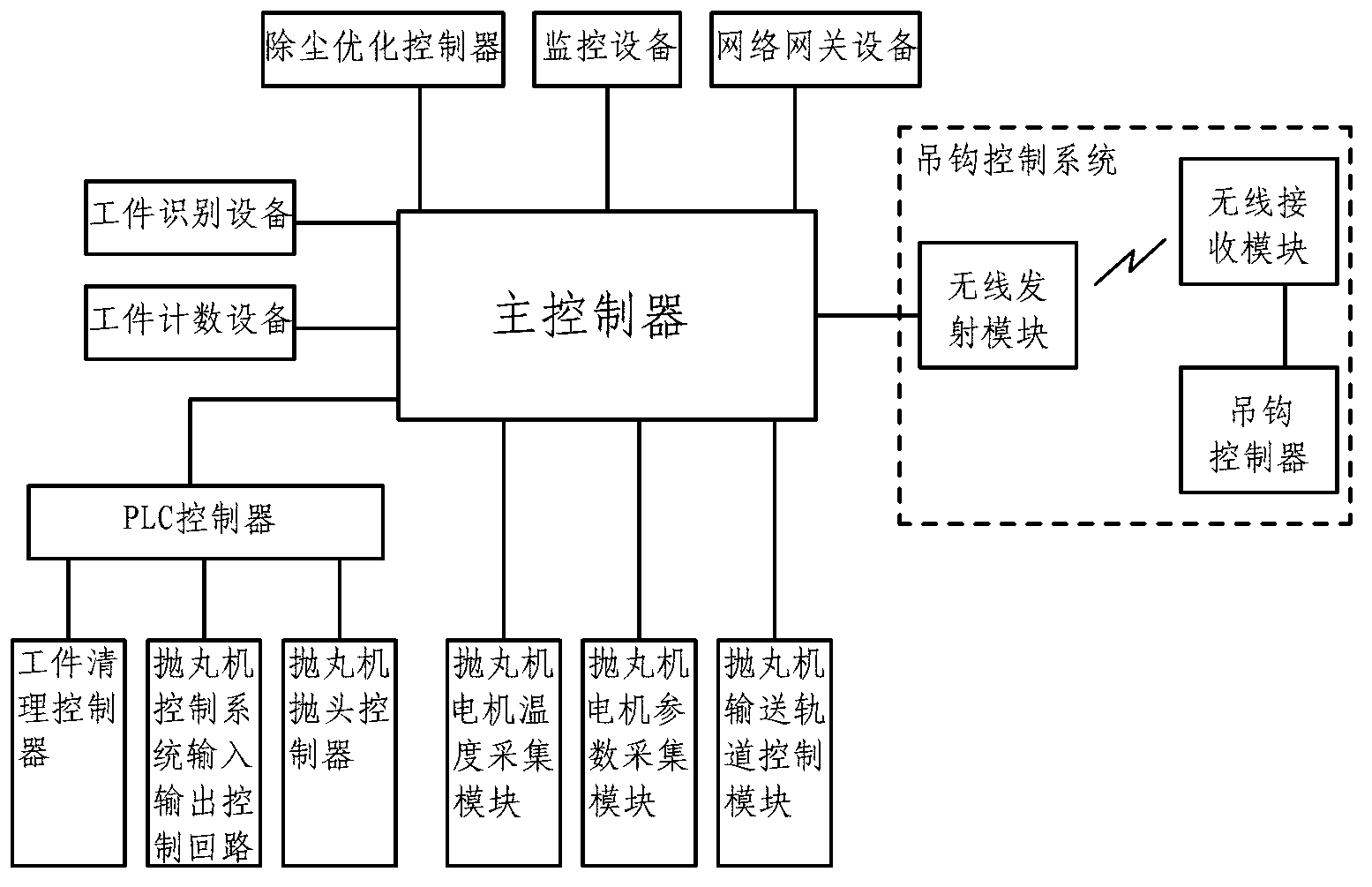

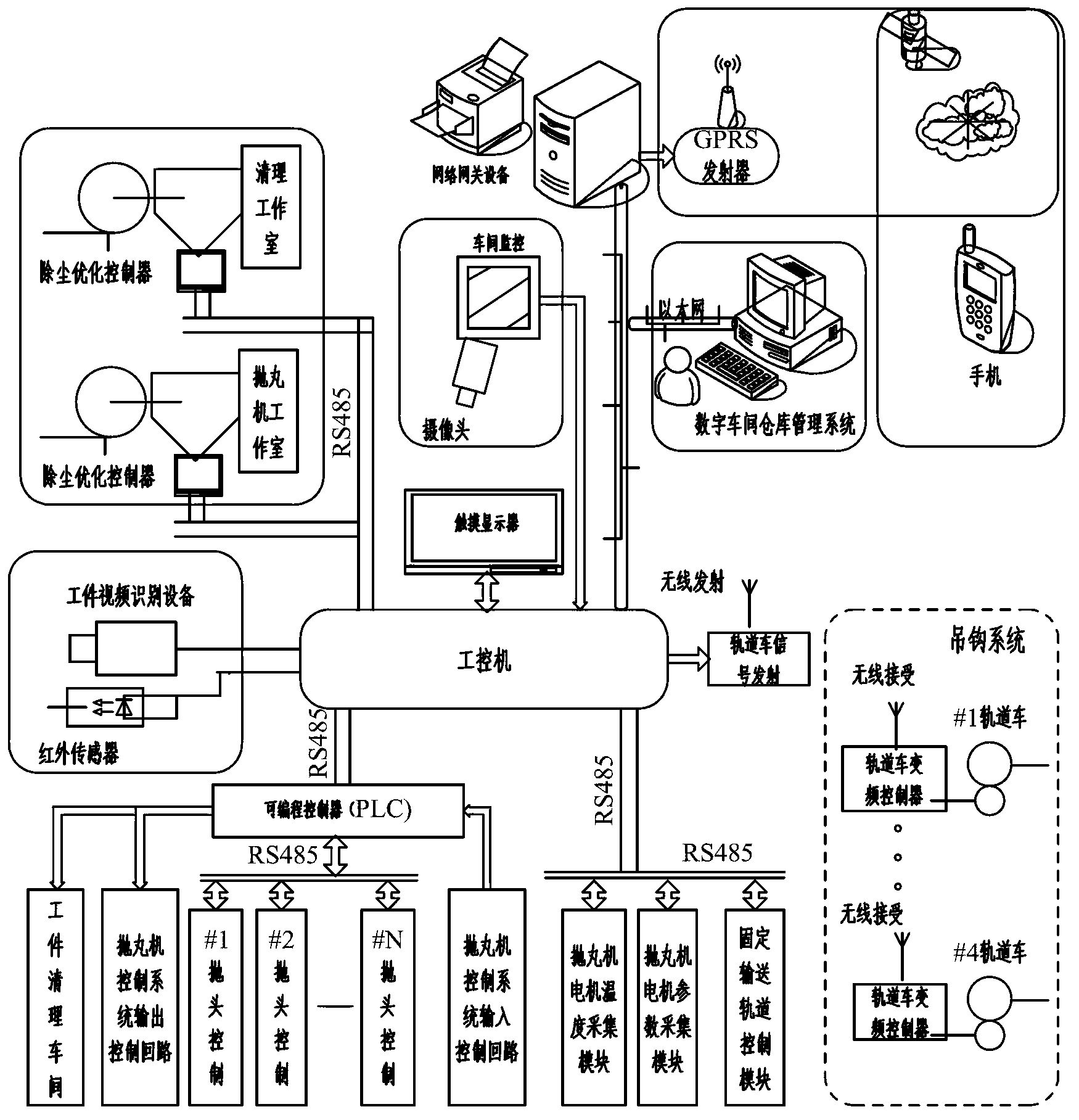

Production process intelligent control system for shot blast machine for construction machine

ActiveCN103309305AReach the automatic production modeProcess coordinationEnergy industryTotal factory controlProgrammable logic controllerElectric machinery

The invention discloses a production process intelligent control system for a shot blast machine for a construction machine. The production process intelligent control system comprises a main controller for controlling shot blast, a lifting hook control system, workpieice identification equipment, workpiece counting equipment, a PLC (programmable logic controller), a shot blast machine control system input / output control loop, a shot head controller of a shot blast machine, a motor parameter data acquisition module of the shot blast machine, a workpiece conveying track control module, a workpiece cleaning controller and a dust removal optimization controller, wherein the lifting hook control system, the workpiece identification equipment, the workpiece counting equipment, the PLC, the motor parameter data acquisition module of the shot blast machine, the workpiece conveying track control module and the dust removal optimization controller are respectively connected with the main controller; the shot blast machine control system input / output control loop, the shot head controller of the shot blast machine and the workpiece cleaning controller are respectively connected with the PLC; and the production process intelligent control system not only can control the shot blast machine in an intelligentized and digitalized manner, but also can be networked to enable all working procedures to be coordinated and consistent, so that the production efficiency is greatly improved, and the production cost is reduced.

Owner:山东开泰工业科技有限公司

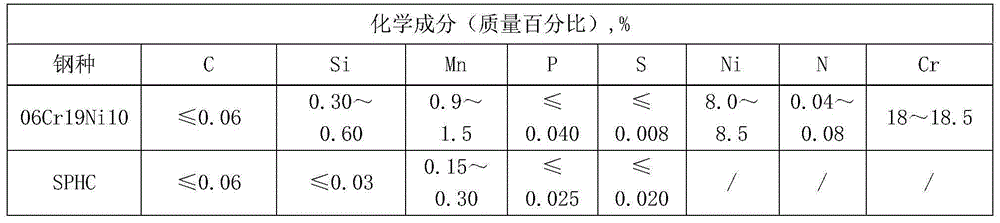

Production method for continuous pickling of hot rolled superaustenitic stainless strip steel

ActiveCN103820799AIncrease pickling speedIncrease productionGrinding machinesHydrofluoric acidStrip steel

The invention discloses a production method for continuous pickling of hot rolled superaustenitic stainless strip steel. The production method comprises the following steps: strip steel shot blasting and descaling after annealing; electrolytic pickling pretreatment with sulfuric acid; grinding and scrubbing; treatment in a sulfuric acid pickling bath; treatment in a mixed acid pickling bath; treatment in another mixed acid pickling bath, wherein the concentration of nitric acid in the bath is 150-250g / l, the concentration of hydrofluoric acid in the bath is 50-70g / l, the concentration of metal ions in the bath is 5-20g / l, the acid liquor temperature is 50-65 DEG C and the pickling speed is 22-28m / min. The production method has the beneficial effects that by adjusting the casting amount and rotating speed of a shot blasting machine, the pickling process, the acid liquor concentration, the acid liquor temperature and the acid liquor components, the strip steel pickling speed can be effectively increased, the yield can be increased and a good NO.1 surface can be obtained.

Owner:WISDRI ENG & RES INC LTD

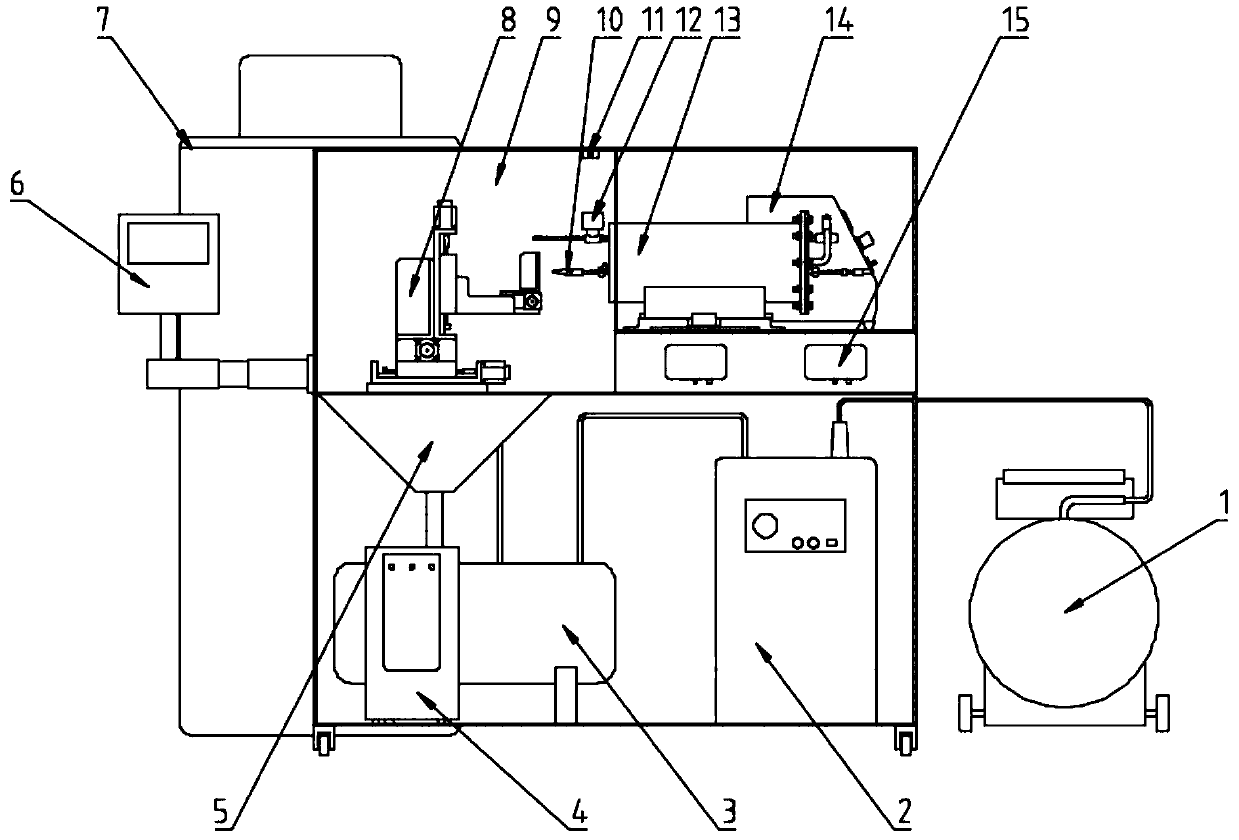

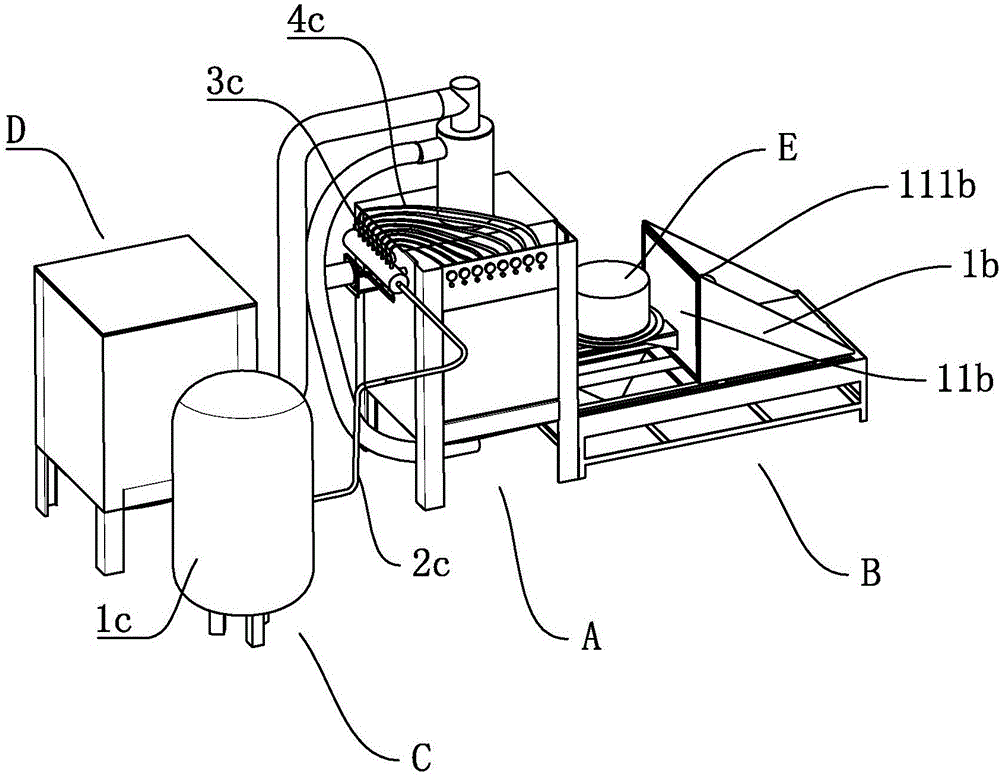

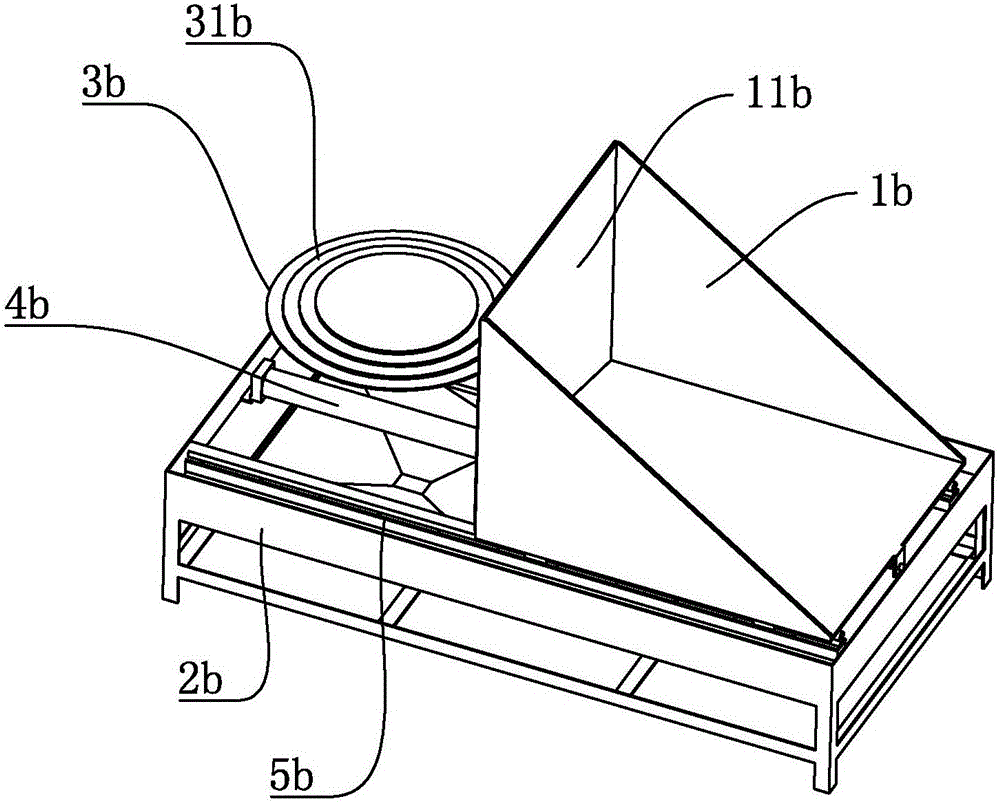

Low-temperature micro-abrasive-material air jet flow processing machine tool

ActiveCN109676538ASolve the problem of pollution caused by difficult recyclingSolve the problem of clogged jet nozzle 10Abrasive feedersAbrasive machine appurtenancesAir compressorMoisture

The invention discloses a low-temperature micro-abrasive-material air jet flow processing machine tool. The low-temperature micro-abrasive-material air jet flow processing machine tool is characterized in that the machine tool comprises a micro-abrasive-material air jet flow generating part, a cooling part, a processing part, an abrasive material recycling part and a controller part; the micro-abrasive-material air jet flow generating part mainly comprises an air compressor (1), an air drier (2), a gas storage tank (3) and a sand-blasting machine (14); an air outlet of the air compressor (1) is connected with an air inlet of the air drier (2); an air outlet of the air drier (2) is connected with a gas inlet end of the gas storage tank (3); and a gas outlet end of the gas storage tank (3) is connected with the sand-blasting machine (14). The low-temperature micro-abrasive-material air jet flow processing machine tool is simple in structure and suitable for processing plastic materials such as a high polymer material; the processing efficiency is high; and the problems that when low-temperature processing is conducted, moisture in air is liquefied and iced to block a jet flow nozzle(10), and abrasive materials cannot be recycled easily to cause pollution are solved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Method for lowering surface roughness of cold-rolled nickel stainless steel bright plate

ActiveCN103831627AReduce roughnessOther manufacturing equipments/toolsMetal rolling arrangementsSurface roughnessAcid concentration

The invention relates to a method for lowering surface roughness of a cold-rolled nickel stainless steel bright plate. A novel process is designed, and surface roughness of finished belt steel products is lowered by selecting a steel shot of a belt steel shot blasting machine, using acid concentration, pickling time, deformation rate during rolling and rollers and controlling parameters like smooth elongation rate. Any equipment does not need to be added, and surface roughness of the nickel stainless steel bright plate can be effectively lowered to be blew 0.05 micrometer only by improving the process.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Compound enrofloxacin pellets and preparation method thereof

InactiveCN102526054ASimple processReduce energy consumptionAntibacterial agentsGranular deliveryFluidized bed dryingCarboxymethyl starch

The invention relates to compound enrofloxacin pellets and a preparation method of the compound enrofloxacin pellets, wherein the enrofloxacin pellets comprise coatings and medicine-carrying pill cores; the coatings wrap the medicine-carrying pill cores; the medicine-carrying pill cores are prepared by the following steps that: amoxicillin and enrofloxacin are mixed with starch, microcrystalline cellulose, carboxymethyl starch and the like uniformly; an appropriate amount of pelleting adhesive is added in the mixture to prepare the soft material, the soft material is added into an extrusion pelleter to be extruded out, the extruded material is placed in a shot blasting machine to prepare the medicine-carrying pill cores. Then, the pill cores are placed into a fluidized bed to be dried andthen sieved; finally the sieved pill cores are placed into the fluidized bed, coating liquid is injected for coating, fluidized drying is then carried out after the coating, and then the finished product is obtained. According to the invention, both the amoxicillin and enrofloxacin are used, so that double effects are achieved, the medicine administration frequency and dose are reduced, and the pellets are easy to take only by stirring, and feed intake of animals is not influenced. In addition, the preparation method of the compound enrofloxacin pellets has simple process steps and low energyconsumption, is safe to produce and easy to implement, and the prepared pellets have uniform granularity.

Owner:GUANGDONG WENS DAHUANONG BIOTECH

High manganese steel shot blasting machine blade shot peening strengthening technological parameter determination method

InactiveCN107229783AAccurate calculationGood practical effect in engineeringGeometric CADDesign optimisation/simulationSurface layerElement model

The invention discloses a high manganese steel shot blasting machine blade shot peening strengthening technological parameter determination method based on ABAQUS finite element analysis. The method comprises establishing finite element models of shots and a high manganese steel shot blasting machine blade based on the material attribute of the shots and the high manganese steel shot blasting machine blade; setting different shot peening strengthening technological parameters by means of orthogonal tests to carry out finite element analysis; obtaining the residual pressure on the surface of the blade after shot peening strengthening, obtaining an optimal regression equation by means of a regression analysis method, and determining the shot blasting machine blade shot peening strengthening technological parameter by means of the optimal regression equation. According to the invention, the value of the residual stress on the surface layer of the high manganese steel shot blasting machine blade which is subjected to shot peening strengthening in different shot peening technological parameters is predicted by means of finite element analysis and the regression equation, and therefore the optimal shot peening technological parameter of the high manganese steel shot blasting machine blade is determined in order to prolong the service life of the shot blasting machine blade, and an appropriate shot peening strengthening technological parameter can be customized in dependence on the demand of the maximum residual stress on the high manganese steel workpiece surface layer.

Owner:UNIV OF JINAN

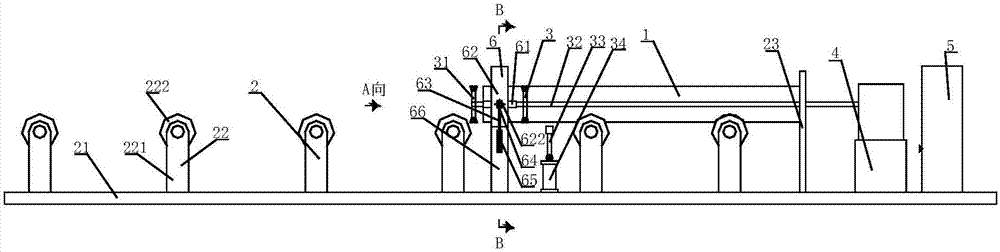

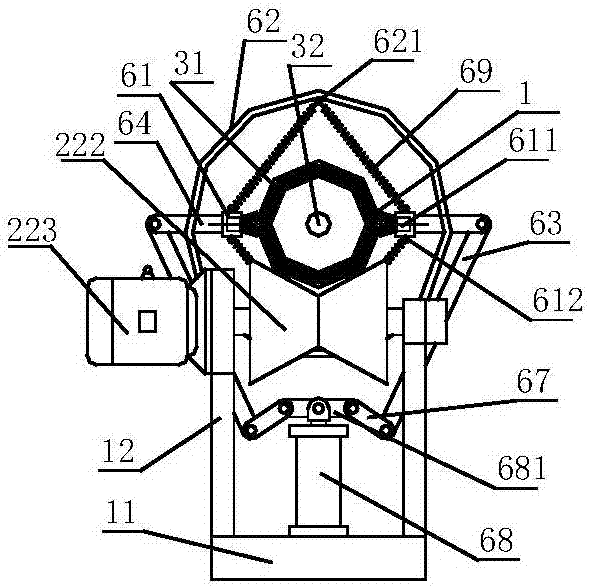

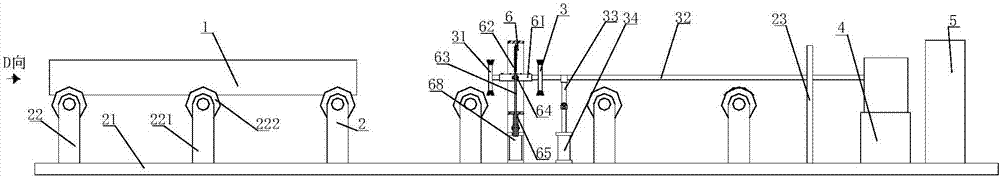

Movable intelligent shot blasting machine for plane

ActiveCN103522199AEnable mobile processingSimple structureAbrasive machine appurtenancesRoads maintainenceDrive shaftControl engineering

The invention provides a movable intelligent shot blasting machine for a plane. The movable intelligent shot blasting machine comprising a shot blasting machine, an intelligent control system and a driving and execution system, wherein the shot blasting machine comprises an electromotor, a transmission device and a blast wheel which are all mounted on a frame, a transmission shaft of the electromotor is connected with a rotating shaft of the blast wheel through the transmission device, the blast wheel is connected with a high-pressure rebounding chamber provided with an opening parallel to a working plane, the intelligent control system comprises a state detection apparatus and an intelligent analysis module, and the driving and execution system comprises a walking driving unit and a state adjusting device. According to the invention, a shot blasting process is applied to a large steel plate plane, the shot blasting machine carries out processing on surfaces in an enclosed range while walking on a carrying apparatus, steel shots are recovered and reused through equipment, and a deduster is arranged so as to realize dust-free and pollution-free construction, thereby improving efficiency and protecting the environment. Compared with conventional processing equipment, the movable intelligent shot blasting machine has the characteristics of a simple structure, low cost, convenience in maintenance, good work efficiency, etc.

Owner:中船重工重庆长平机械有限责任公司

Calibration of detonators

A plurality of detonator assemblies in signal communication with a blasting machine, each detonator assembly consisting of a detonator, a storage compartment for storing programmed delay time and / or oscillation count and a countdown oscillator. A transmitter for transmitting a blast rehearsal stop start and stop signal, said signals being separated by said programmed delay time individually selected for each detonator signal. The oscillator counting the total oscillation count corresponding to said delay time. When a detonator assembly receives a FIRE command, the individual countdown oscillators countdowns the total oscillation count associated with its detonator assembly.

Owner:ORICA EXPLOSIVES TECH PTY LTD

Wet type sand-blasting machine

ActiveCN106272090AImprove blast cleaning resultsImprove injection efficiencyBlast gunsAbrasive machine appurtenancesSand blastingEnergy conservation

The invention discloses a wet type sand-blasting machine. The wet type sand-blasting machine comprises a feeding device and a sand-blasting machine body, wherein a cleaning chamber is arranged in the sand-blasting machine body; a carrier for a workpiece to be cleaned and a plurality of sand-blasting spray guns for cleaning the workpiece to be cleaned are arranged in the cleaning chamber; a grinding fluid pump conveys grinding fluid in a grinding fluid storage tank to the sand-blasting spray guns through a grinding fluid conveying pipe; and the plurality of sand-blasting spray guns are arranged on a spray gun oscillating mechanism. The wet type sand-blasting machine also comprises a water cleaning device, wherein the water cleaning device comprises a sedimentation water tank; the sedimentation water tank and the grinding fluid storage tank are separated by one, two or more filter screens, so that the grinding fluid can be filtered to obtain clean washing water and the clean washing water is stored in the sedimentation water tank; and a washer pump conveys the washing water to a washing spray gun through a washing water conveying pipe to wash the workpiece and the cleaning chamber. The wet type sand-blasting machine has the characteristics that the production cost is low; the surface of the workpiece is processed perfectly; the dust-removing effect is good; and energy conservation and emission reduction are realized.

Owner:永红保定铸造机械有限公司

Sand blasting machine

ActiveCN106078533AAdjustable angleAccurate in and outBlast gunsAbrasive feedersSand blastingSpray nozzle

The invention discloses a sand blasting machine, which comprises a sand blasting chamber. The sand blasting chamber comprises a feeding hole for feeding and discharging workpieces, and spray nozzles arranged in the sand blasting chamber; the spray nozzles are fixed on a spray nozzle drive mechanism; a feeding mechanism capable of driving the workpieces to feed and discharge is matched on the feeding hole; the spray nozzle drive mechanism comprises at least one swinging mechanism arranged in the sand blasting chamber; each swinging mechanism is provided with one spray nozzle and is driven by a first drive part to swing to the left and right; the feeding mechanism comprises a placement platform used for placing workpieces and a second drive part; and the placement platform comprises at least one positioning table used for placing the workpieces, and a sealing plate arranged behind the positioning table and matched with the feeding hole of the sand blasting chamber. A plurality of swinging mechanisms are arranged in the sand blasting chamber, and a plurality of spray nozzles can swing to blast sand on the workpieces when being used for blasting sand, so that a uniform and efficient sand blasting effect is realized; and in addition, the workpieces can be quickly fed and discharged in the sand blasting chamber through the feeding mechanism, so that the sand blasting efficiency of the workpieces is further improved.

Owner:宁波精益微型轴有限公司

Pipeline rust removing machine removing rust on inner wall and outer wall at same time and using method

InactiveCN107322443AImprove working environmentReduce manual labor intensityRevolution surface grinding machinesGrinding work supportsDistal portionWorking environment

The invention discloses a pipeline derusting machine for simultaneously derusting inner and outer walls and a use method thereof, which mainly includes a raceway device, an inner derusting part and an outer derusting part, and a plurality of conveying rollers are fixedly arranged on the front side of a positioning baffle , the outer derusting part is fixedly arranged on the middle part of the base set longitudinally, and the brush shaft support cylinder of the inner derusting part is fixedly arranged on the rear side thereof, and the piston rod end of the brush shaft support cylinder is fixedly installed with a brush shaft support, and the inner derusting part The brush shaft of the rust part is vertically arranged, and its rear end is fixedly installed on the upper front side of the air source device through the positioning baffle, and at least one disc-shaped wire brush is fixedly installed on the front end, and the front end of the brush shaft is in the shape of Set through the outer rust-like shape. When the conveying roller is moving back and forth, it drives the pipe body to rotate spirally and moves back and forth at the same time to remove rust on the inner and outer walls of the pipe, realizing the function of simultaneous rust removal on the inner and outer walls of the pipe, reducing the labor intensity, improving work efficiency, and improving the operating efficiency of operators. working environment.

Owner:CHINA THIRD METALLURGICAL GRP

Separated initiation control system and initiation control method

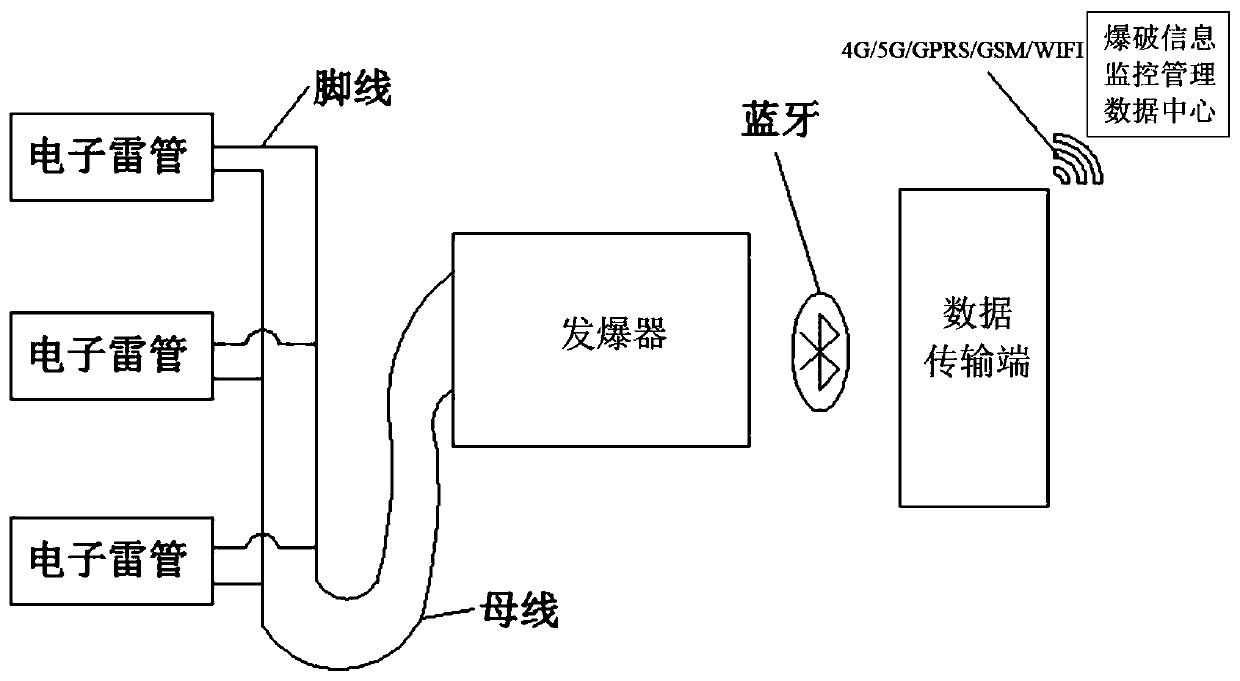

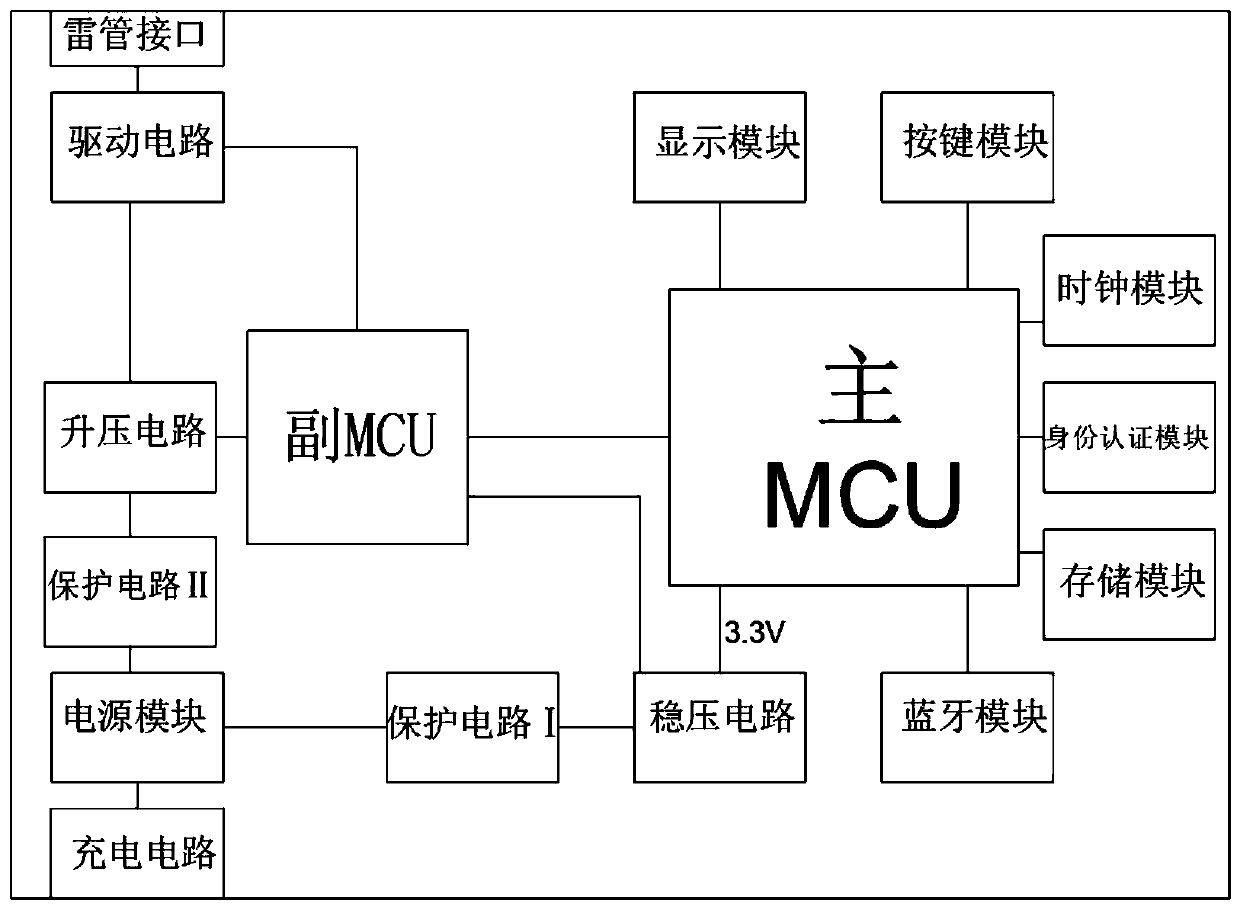

The invention discloses a separated initiation control system, and relates to the technical field of detonator engineering blasting. The separated initiation control system comprises a blasting information monitoring and management data center, a data transmission end, a blasting machine and a detonator with fixed delay time, the data transmission end is APP software applied to a hand-held terminal, the blasting machine comprises a main control module, and further comprises a voltage rising circuit, a voltage stabilizing circuit, a driving circuit, a display module, a key module, a storage module, a power supply module, a clock module, an identity authentication module and a Bluetooth module which are correspondingly connected with the main control module. The invention further discloses aseparated initiation control method. The separated initiation control method comprises the following steps of acquisition of an authorization document, transmission of the authorization document, single-shot detection of the detonator, detection of detonator networking, verification of the authorization document, three-way chain authentication, initiation of the detonator and uploading of an initiation log. According to the separated initiation control system and the initiation control method, operation is simple and fast, the application range is wide, the safety performance is high, and thecoal allowable standard is conformed.

Owner:BEIJING QAML OF SCI & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com