Patents

Literature

601results about How to "Eliminate clogging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

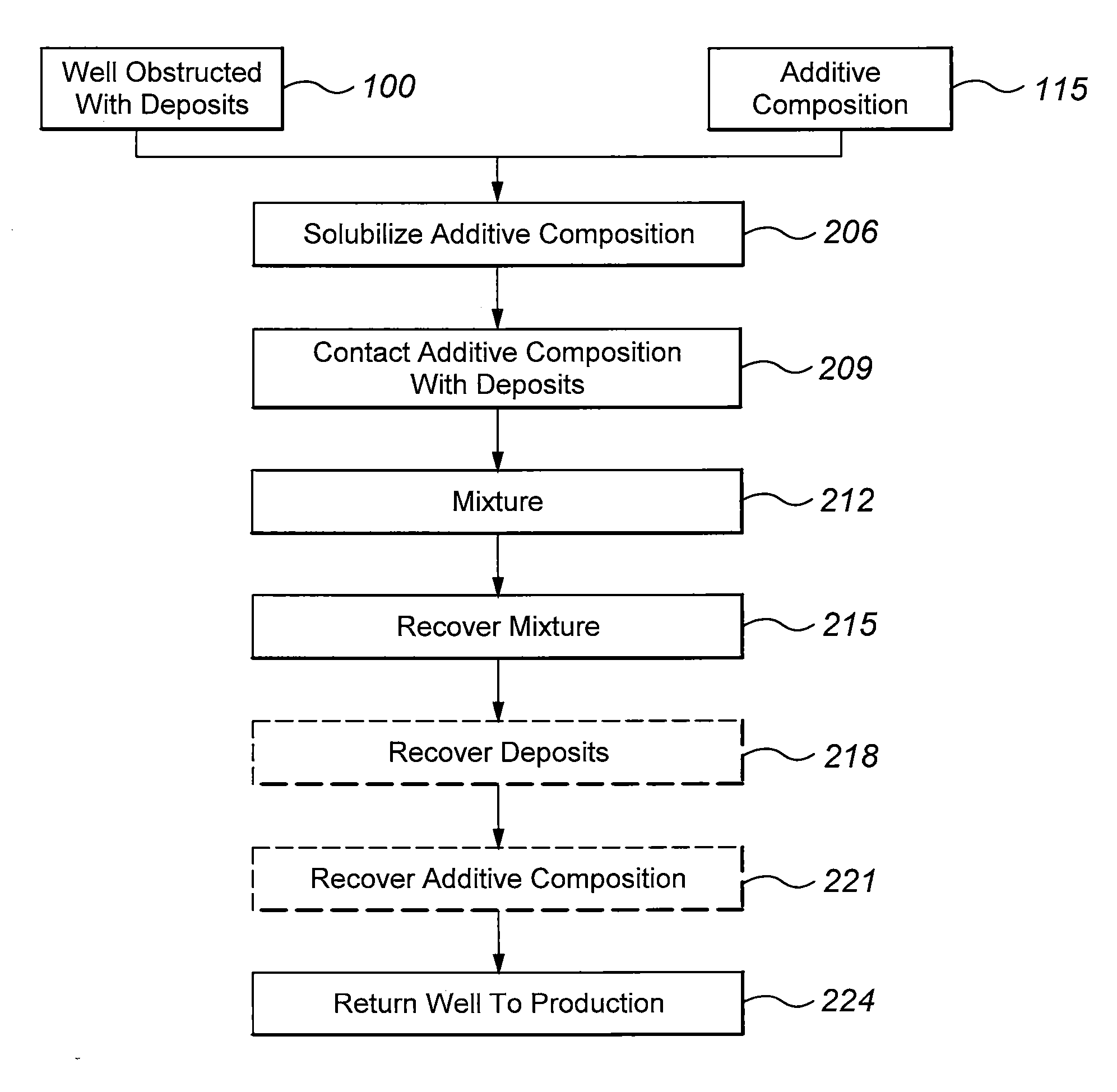

Composition comprising peroxygen and surfactant compounds and method of using the same

InactiveUS20090313772A1Reduce surface tensionReduce interfacial tensionHollow article cleaningFluid removalHydrocarbon

Owner:MICRO PURE SOLUTIONS

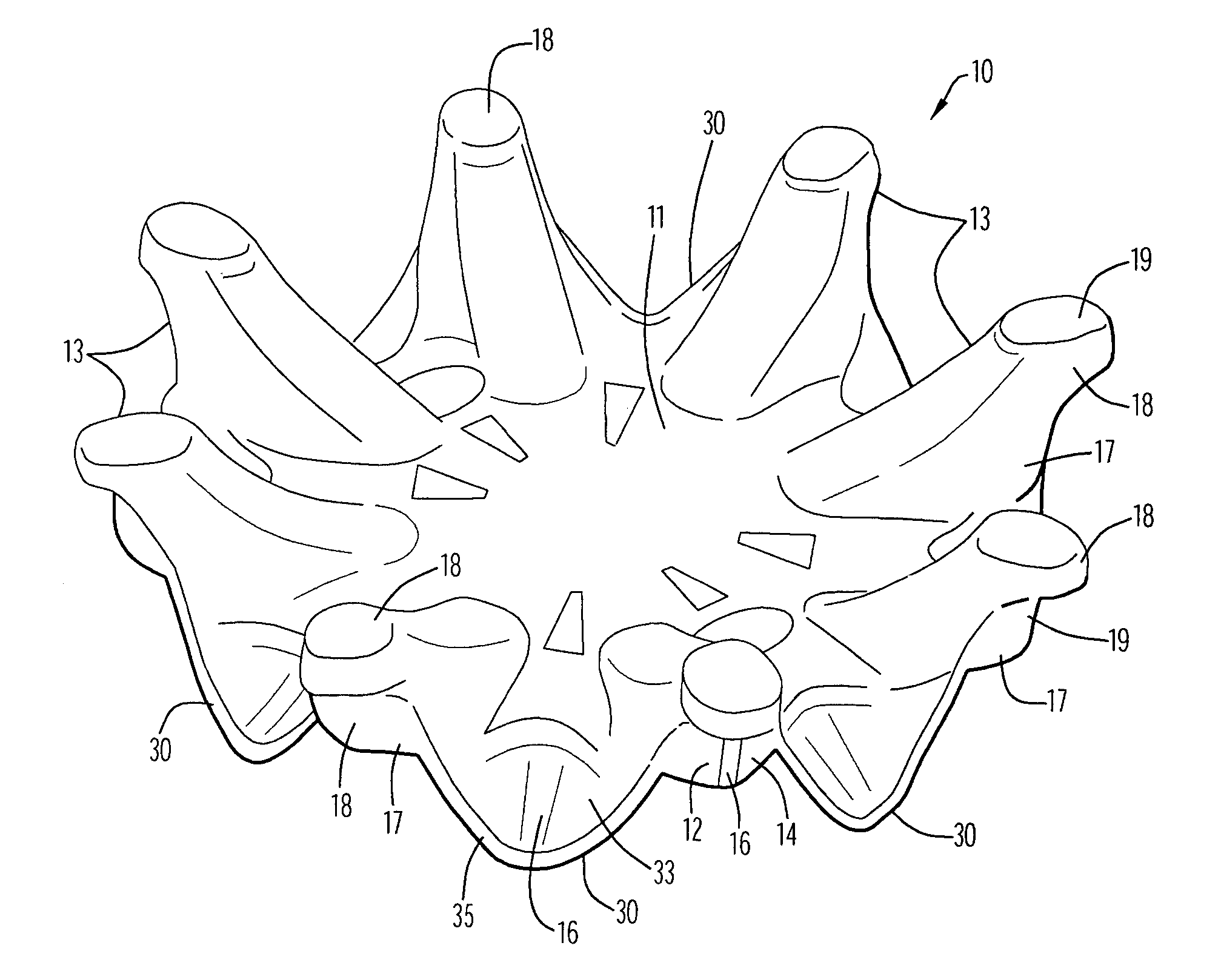

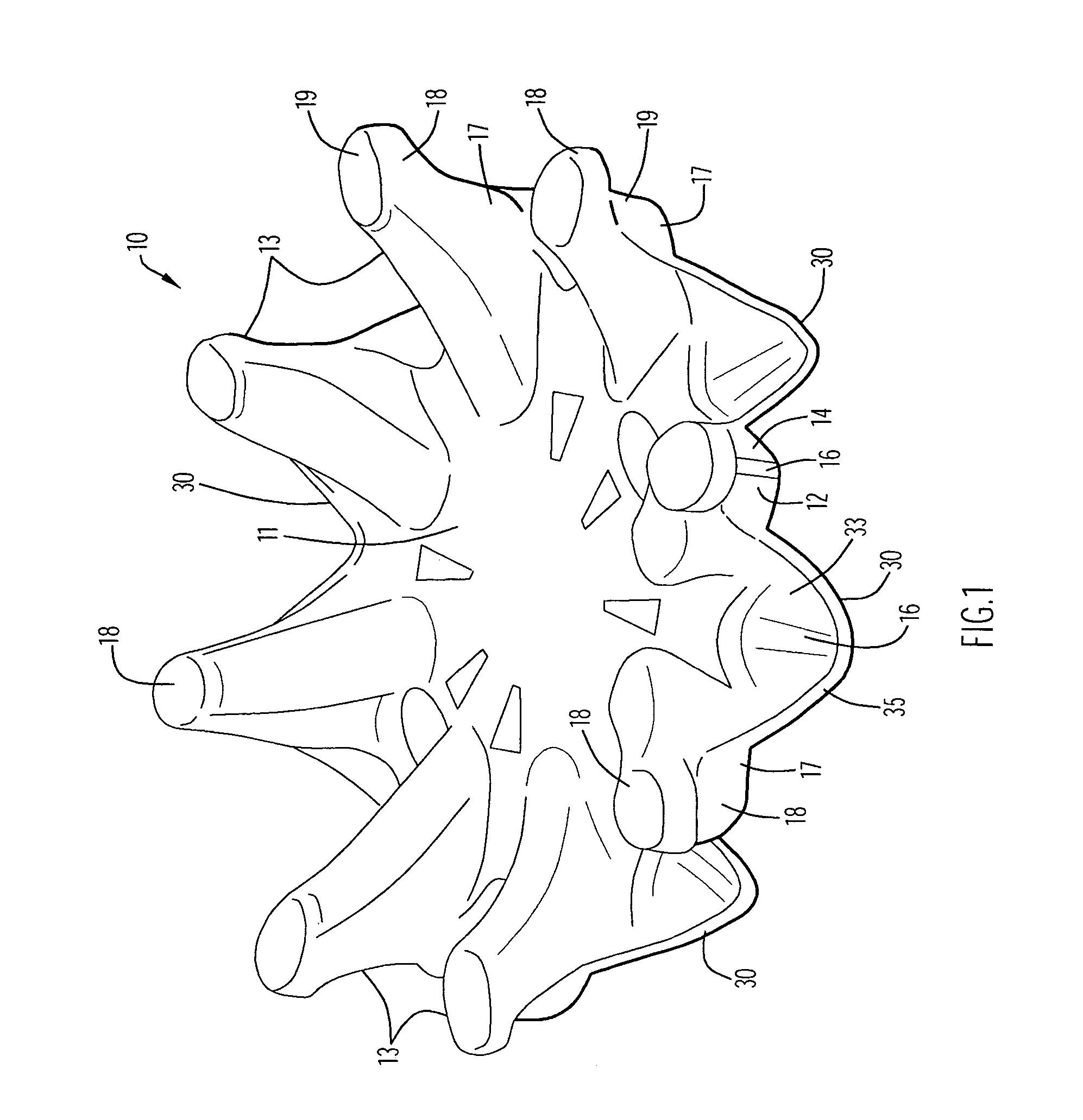

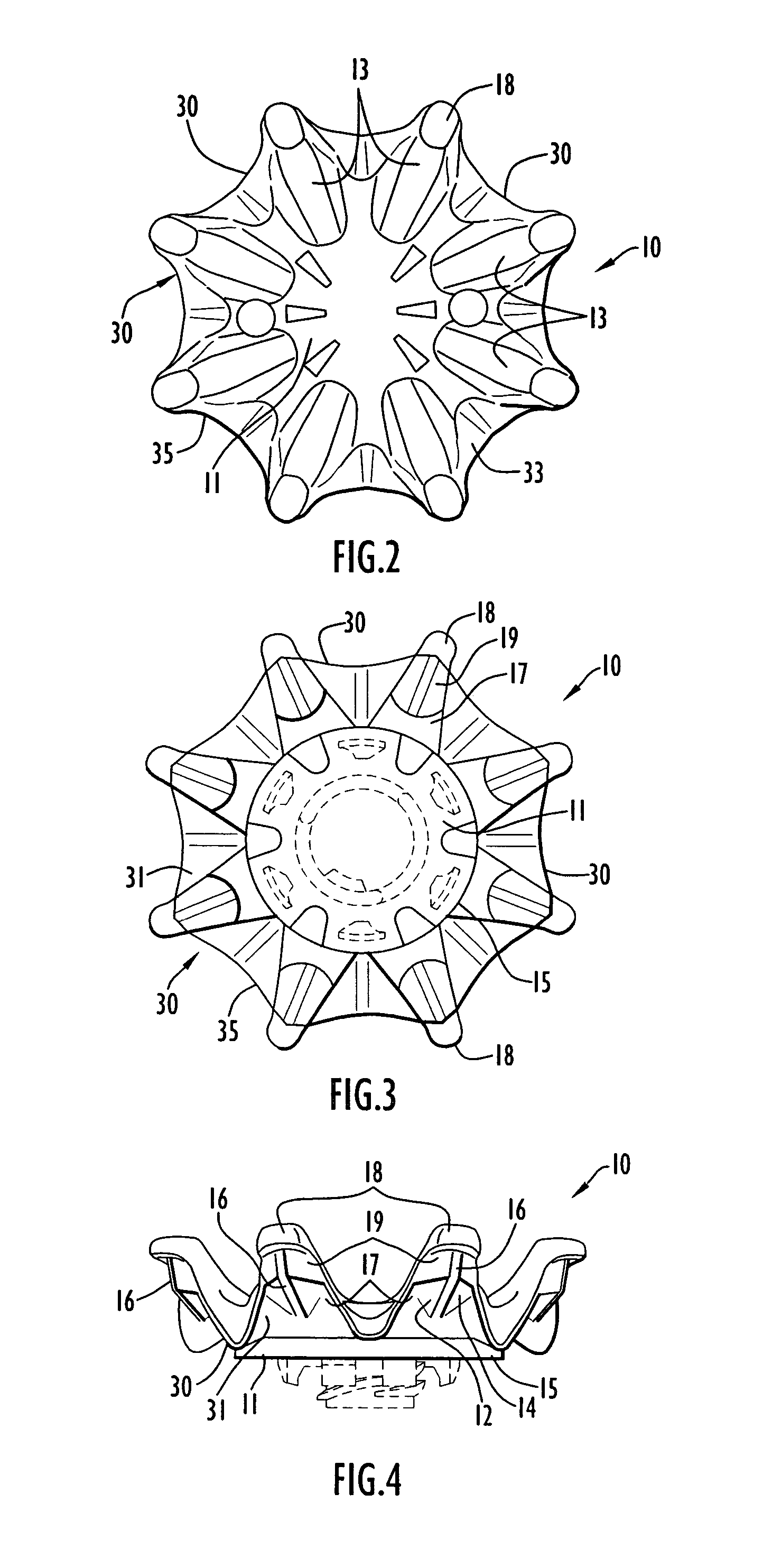

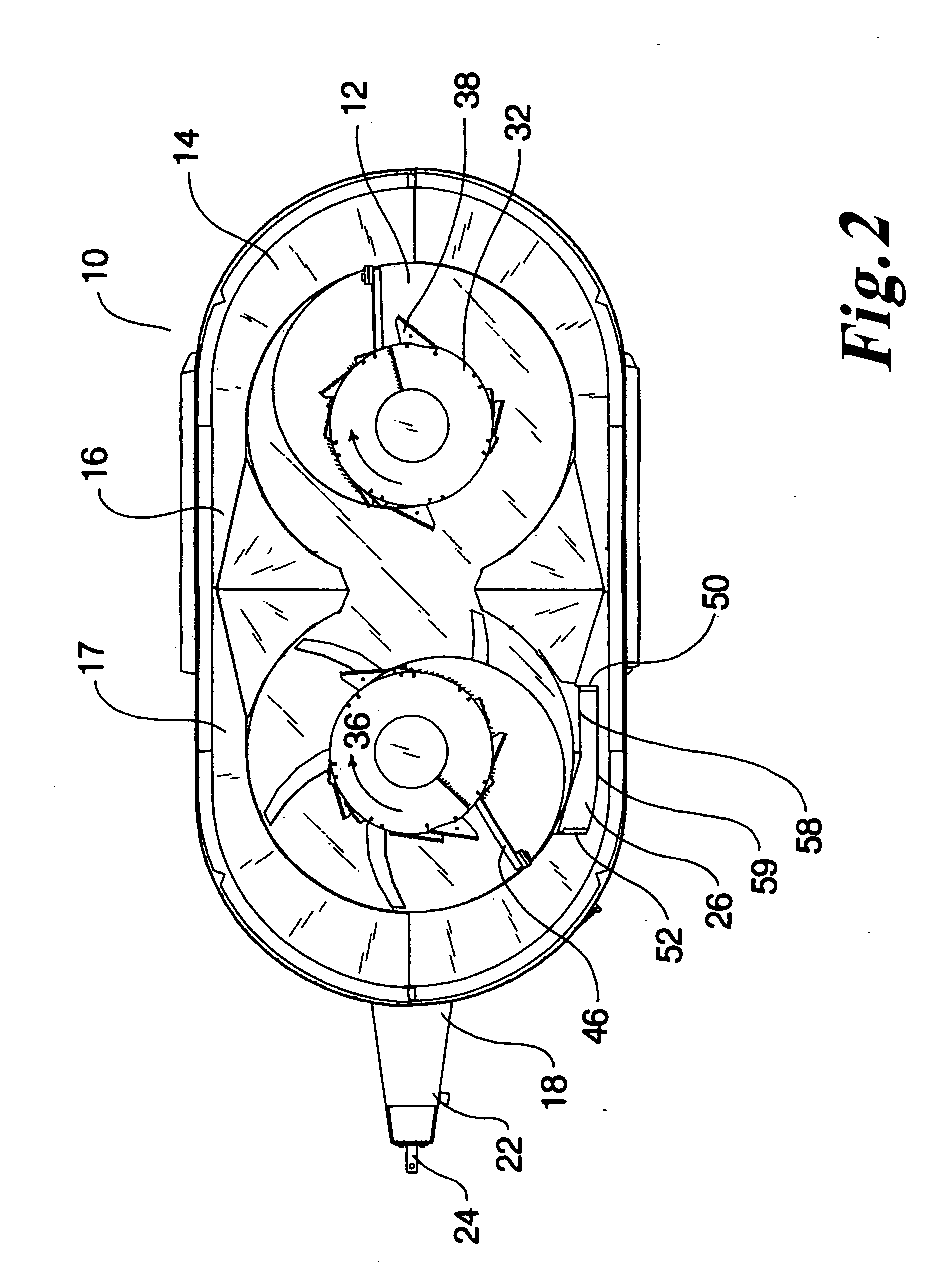

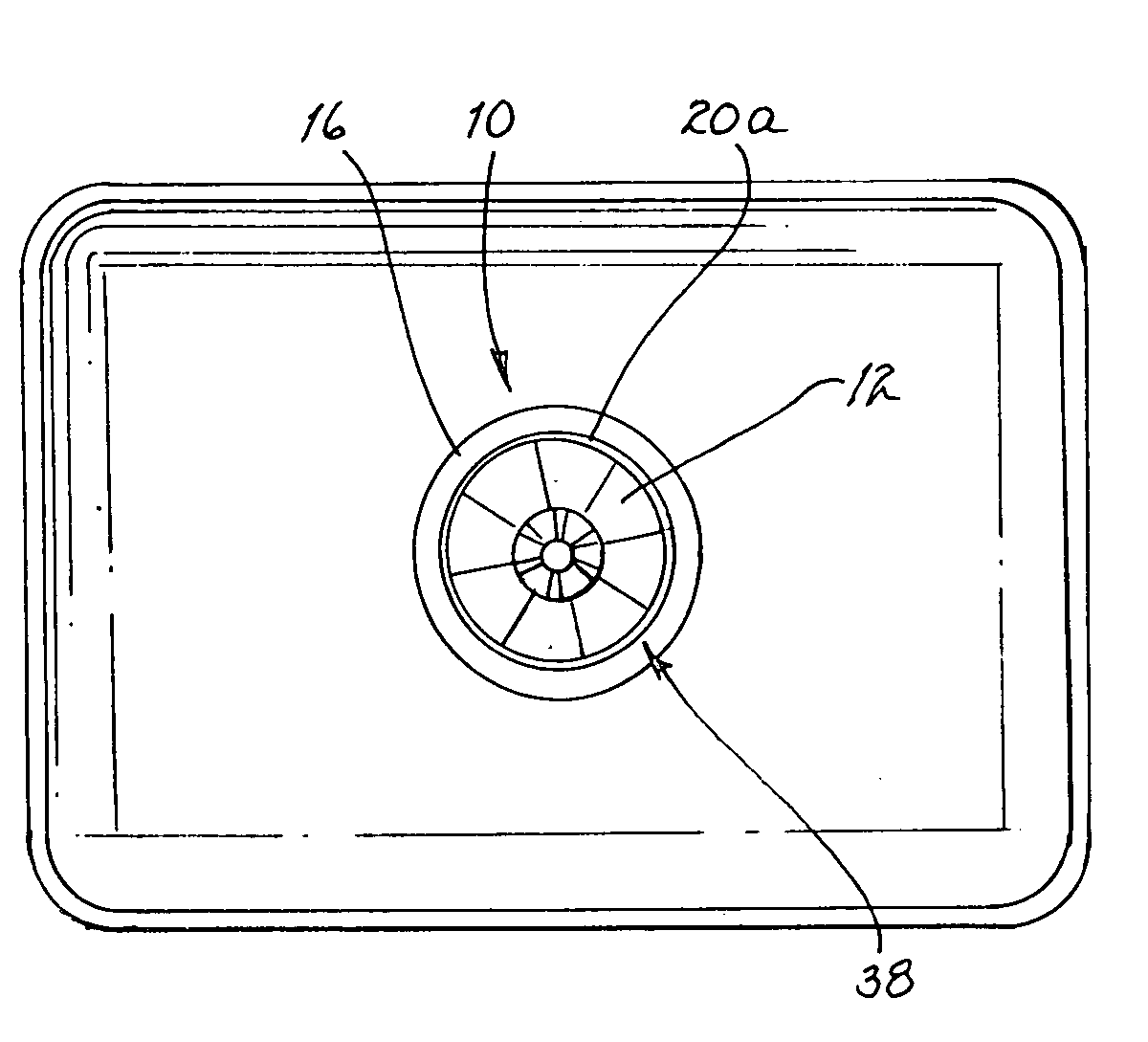

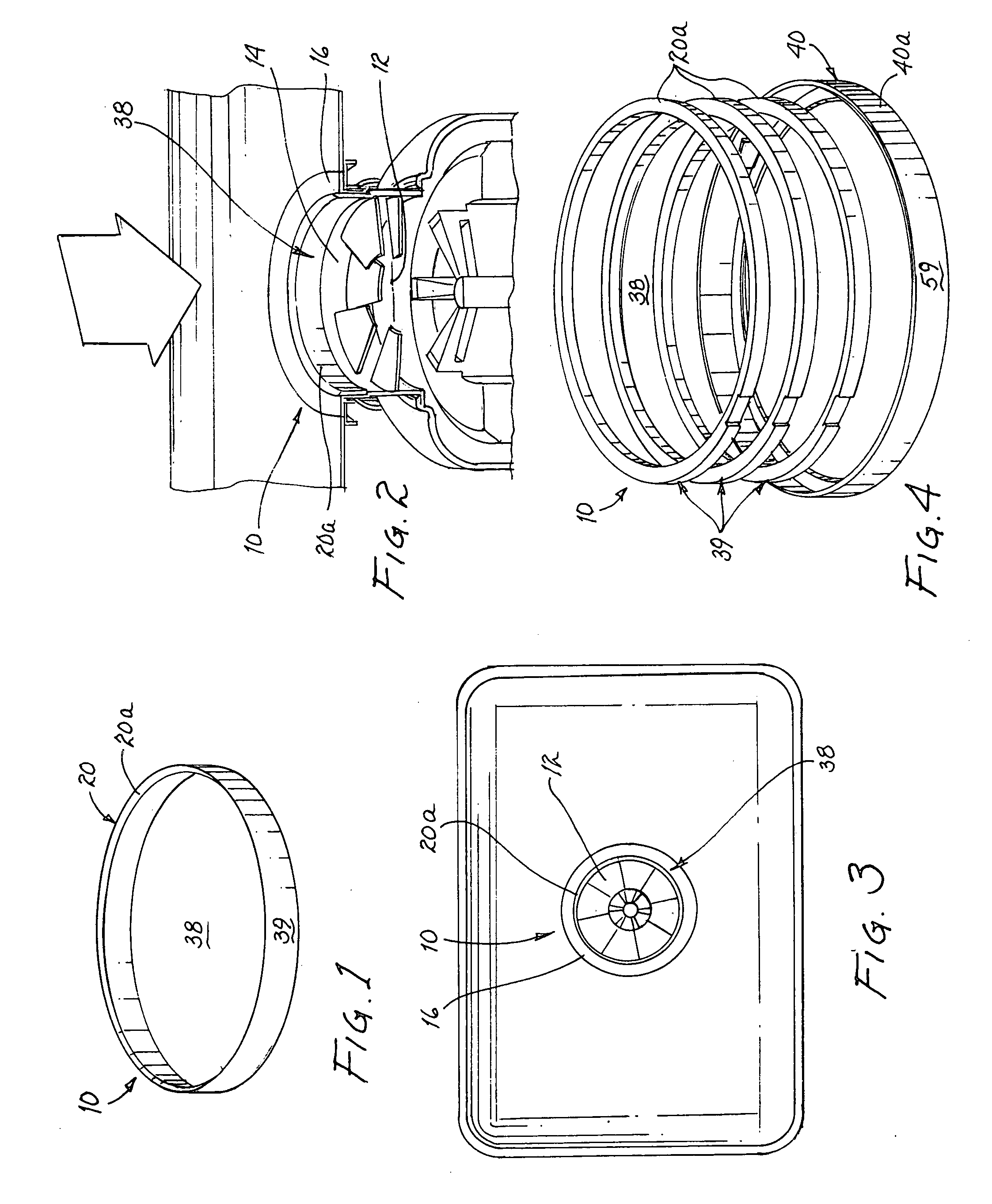

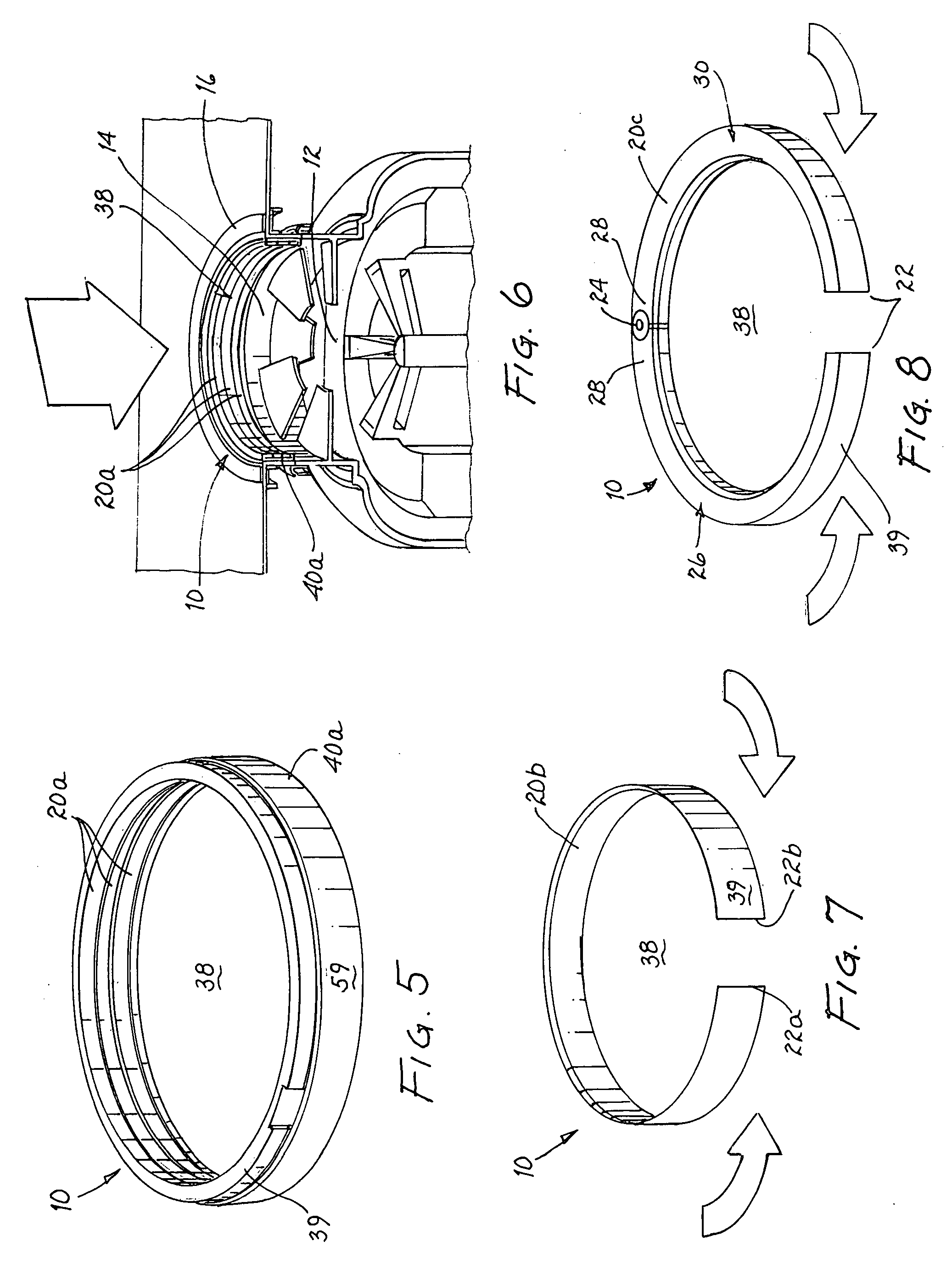

Shoe cleat

ActiveUS7040043B2Improve traction efficiencyReduce cloggingFasteningsWear resistanceUltimate tensile strength

An improved cleat for an athletic shoe provides for: enhanced strength and wear-resistance for the cleat traction element; and / or prevention of grass, mud and other debris from agglomerating and clogging the cleat. A resiliently flexible web is connected between adjacent traction elements to absorb the lateral and torsional forces tending to weaken the junctions between the cleat hub and the traction elements. The web is extended from the hub to prevent debris from entering the space between the shoe sole and the traction elements as well as between the traction elements themselves.

Owner:SOFTSPIKES

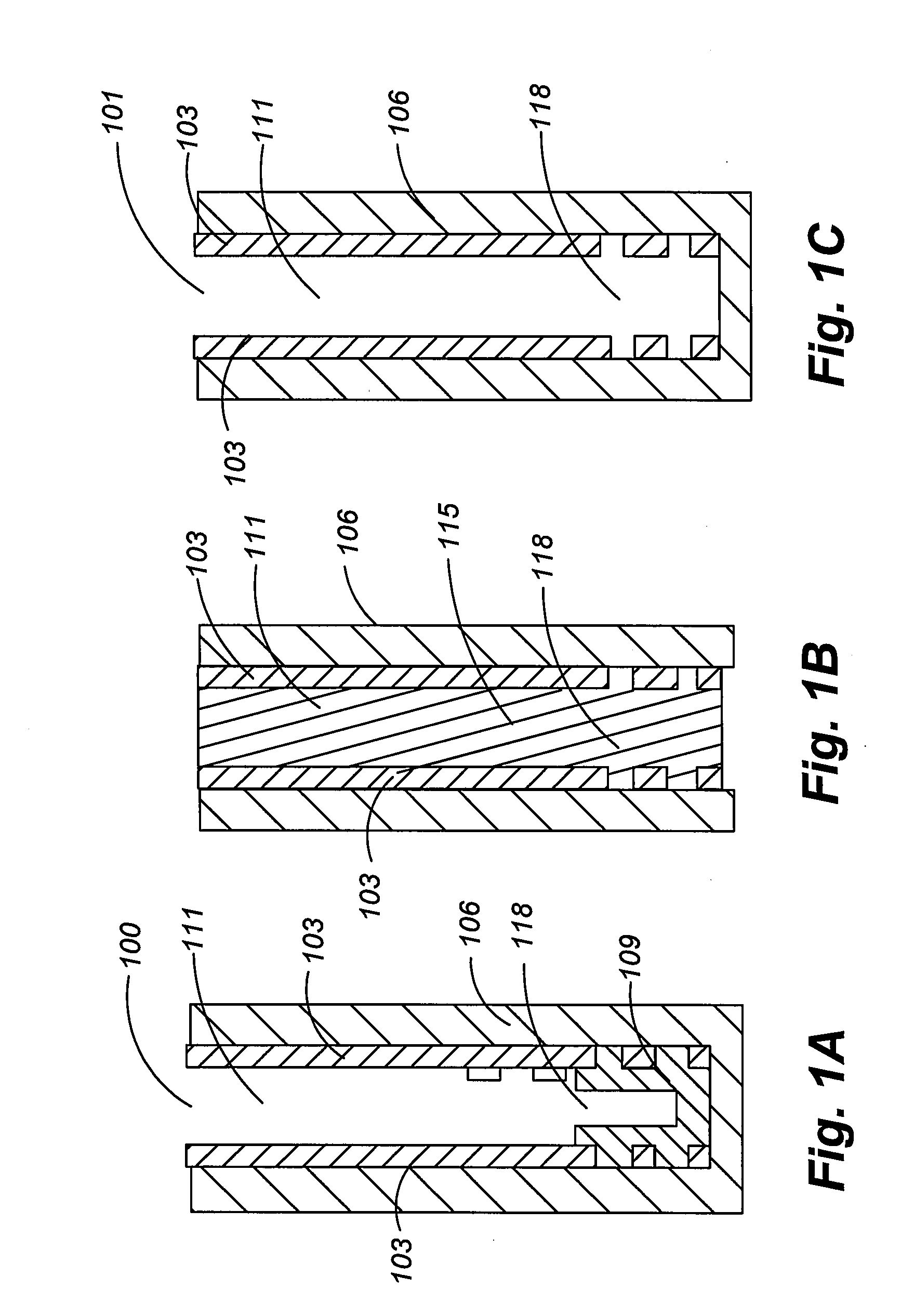

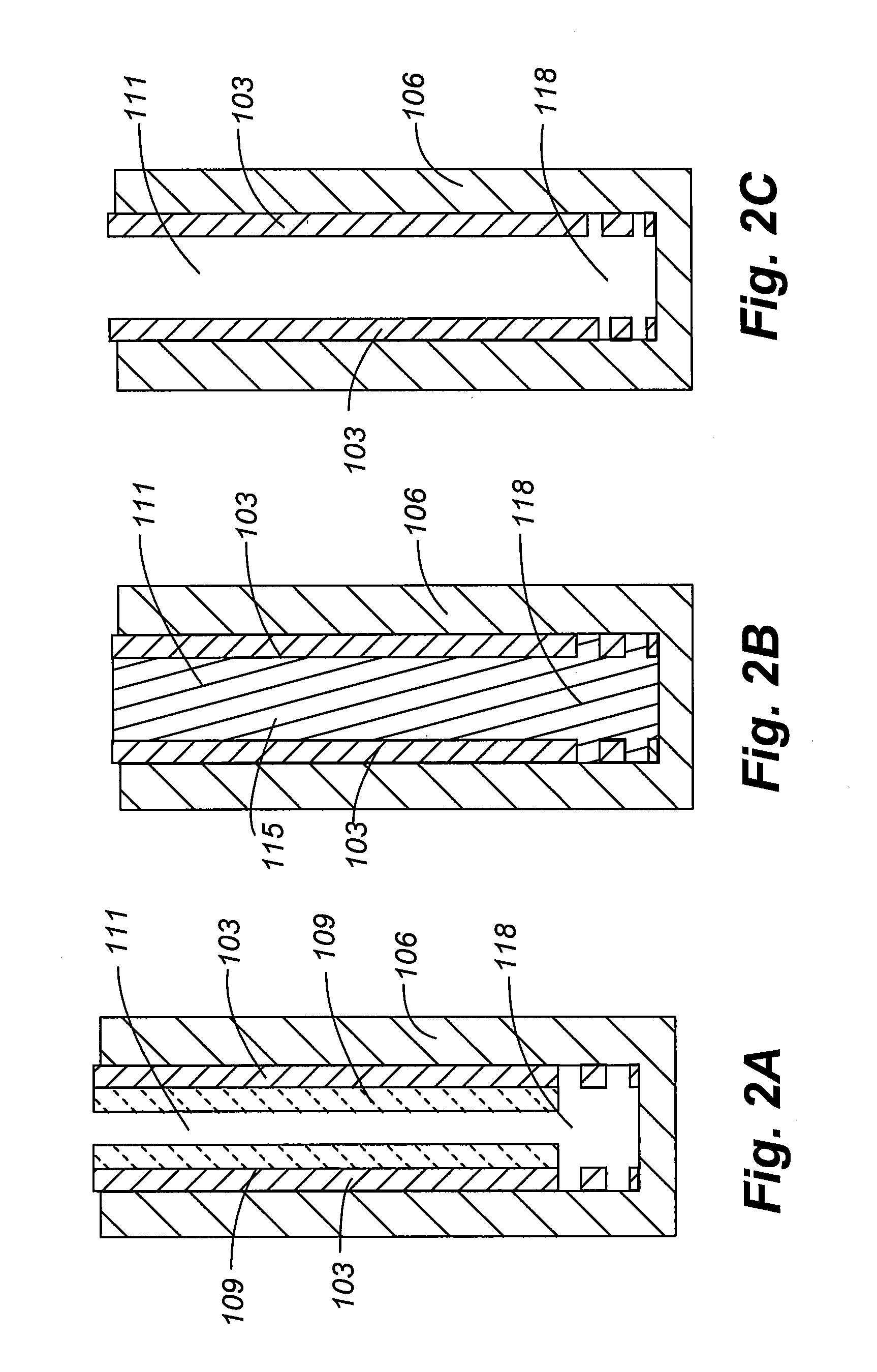

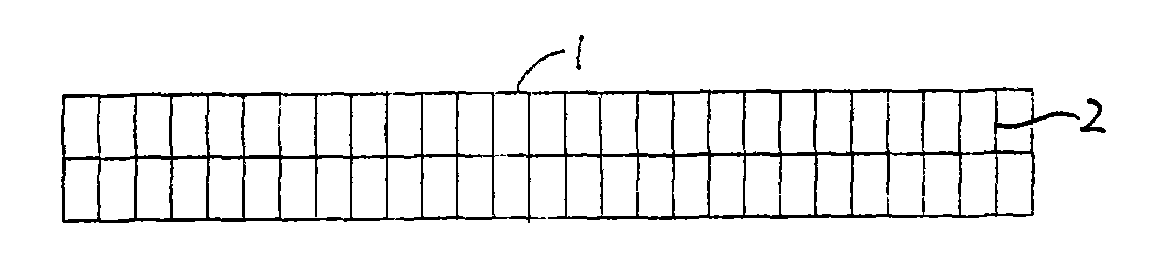

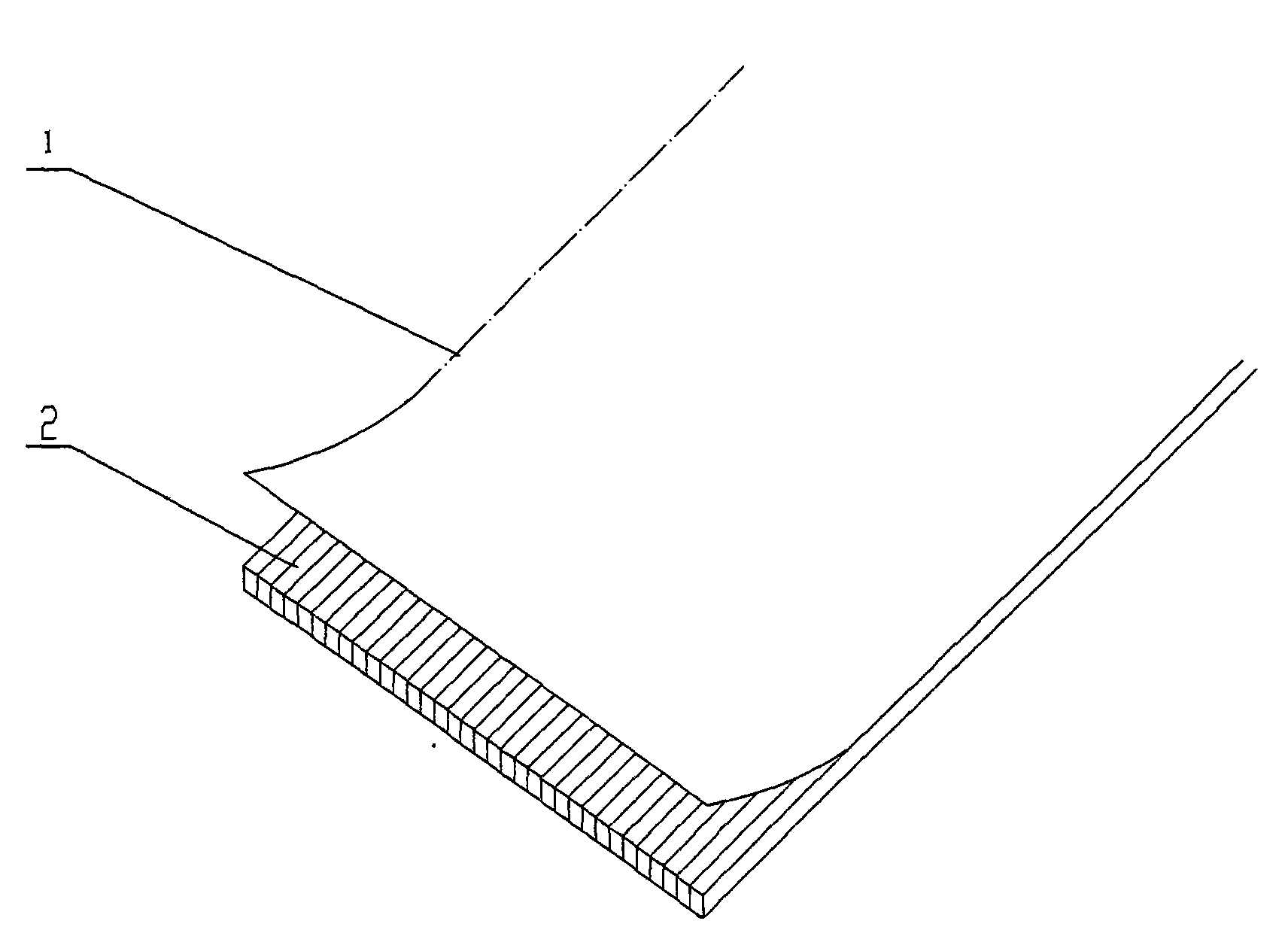

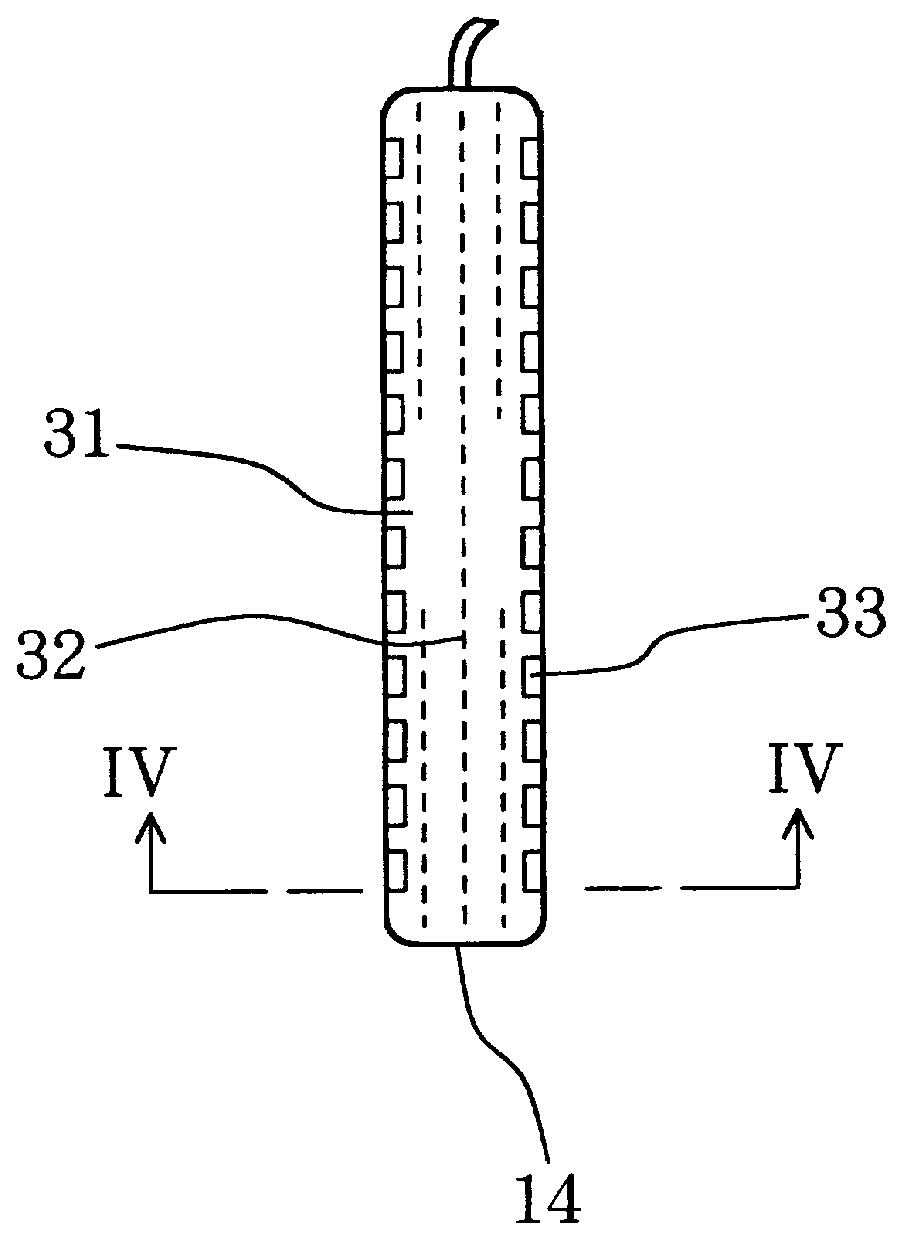

Drainage plate for silt consolidation, filter cloth and drainage plate core

The invention is the improvement on a longitudinal drainage plate for silt consolidation, filter cloth and a drainage plate core, which is characterized in that fibrous hot-pressed microporous filter cloth is planar filter cloth hot-rolled by a flat roller, the filter cloth is adhered to the surfaces of convex ribs of the drainage plate core through thermal thawing or a chemical way, the filter cloth adopts silk reeling and hot-press forming separation technology, and the drainage plate core is made of co-polypropylene, thereby overcoming the disadvantages of the prior art; and the aperture of the filter cloth can be adjusted according to treated silt, the drainage plate is difficult to block, the engineering on a soft foundation after the treatment cannot have the settlement after the construction and has smooth drainage and high drainage efficiency, and the plate core has long effective service life.

Owner:JIANGSU XINTAI GEOTECHNICAL TECH CO LTD

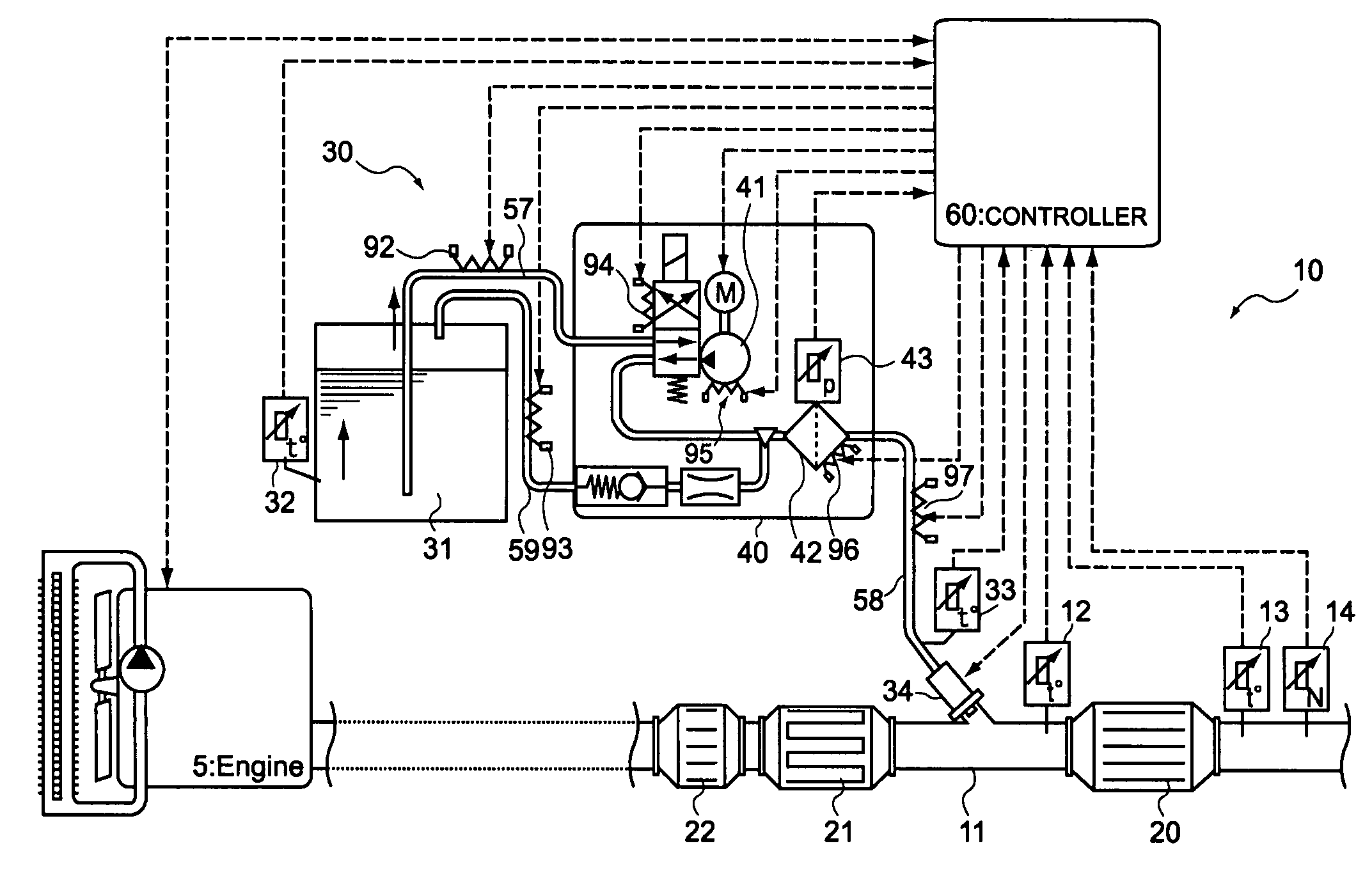

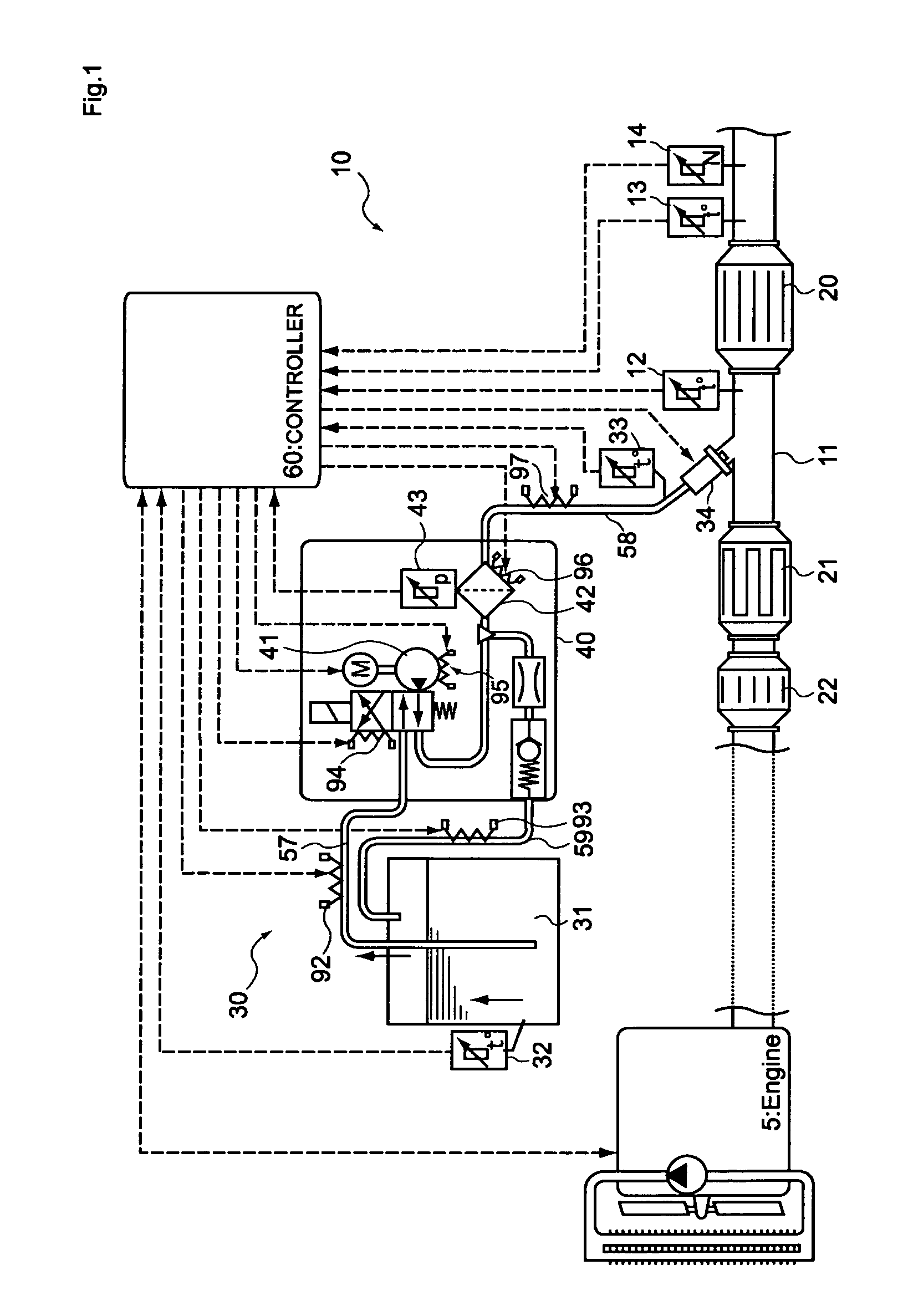

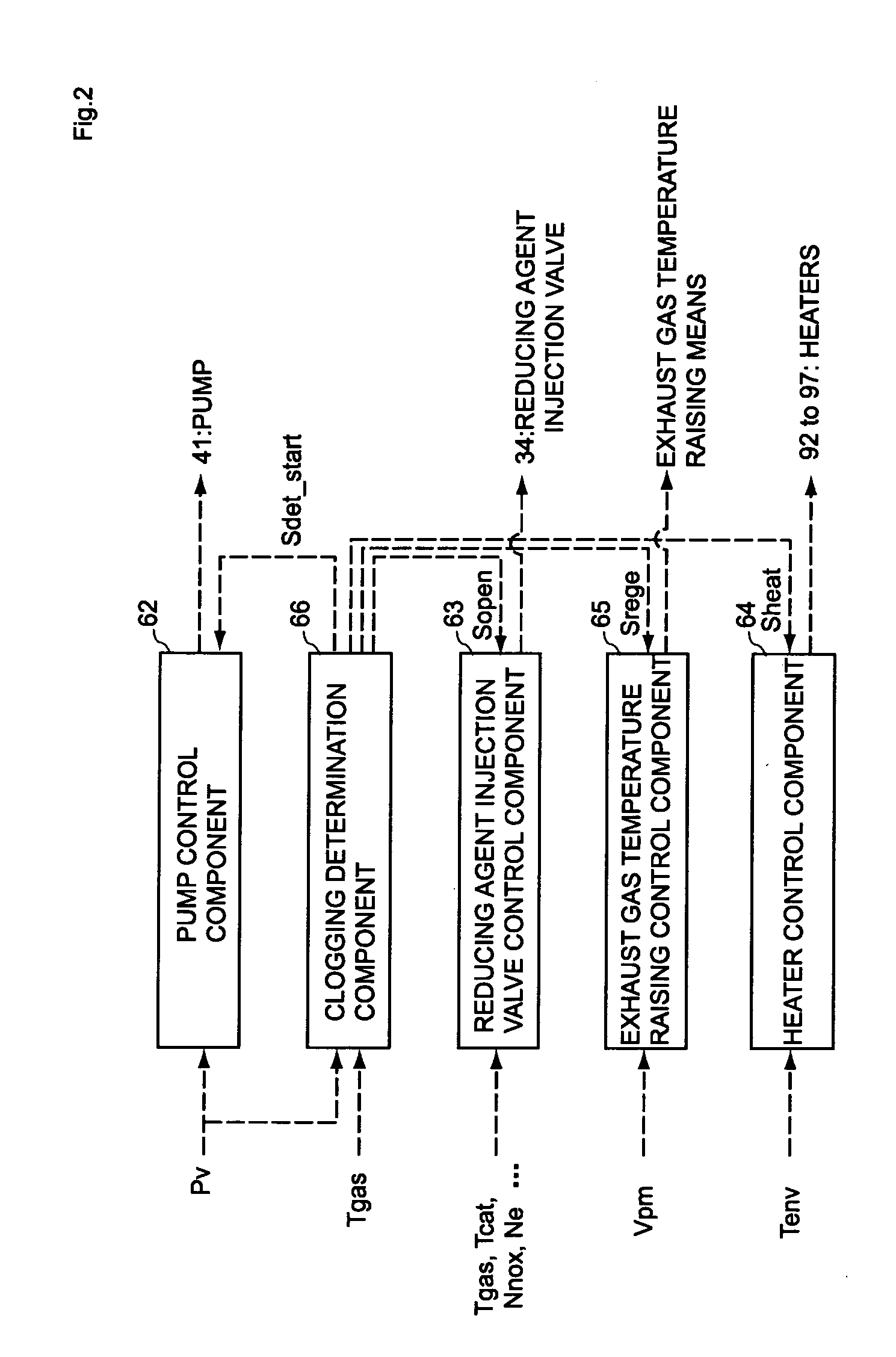

Reducing agent injection valve abnormality detection device and abnormality detection method

InactiveUS20110107742A1Eliminate cloggingEasy to replaceInternal combustion piston enginesExhaust apparatusBiomedical engineeringInjection device

A reducing agent injection valve abnormality detection device for detecting clogging of a reducing agent injection valve in a reducing agent injection device has a pressure detection component that detects the pressure inside a supply path based on a sensor value of a pressure sensor, a pump control component that fixes the output of a pump in a state where the pressure inside the supply path has become a value in a predetermined range, a reducing agent injection valve control component that opens the valve for a predetermined amount of time in a state where the output of the pump has been fixed, and a clogging determination component that determines the extent of clogging of the reducing agent injection valve by comparing, with plural threshold values, the pressure, or a pressure drop quantity, inside the supply path when the valve has been opened for the predetermined amount of time.

Owner:BOSCH CORP

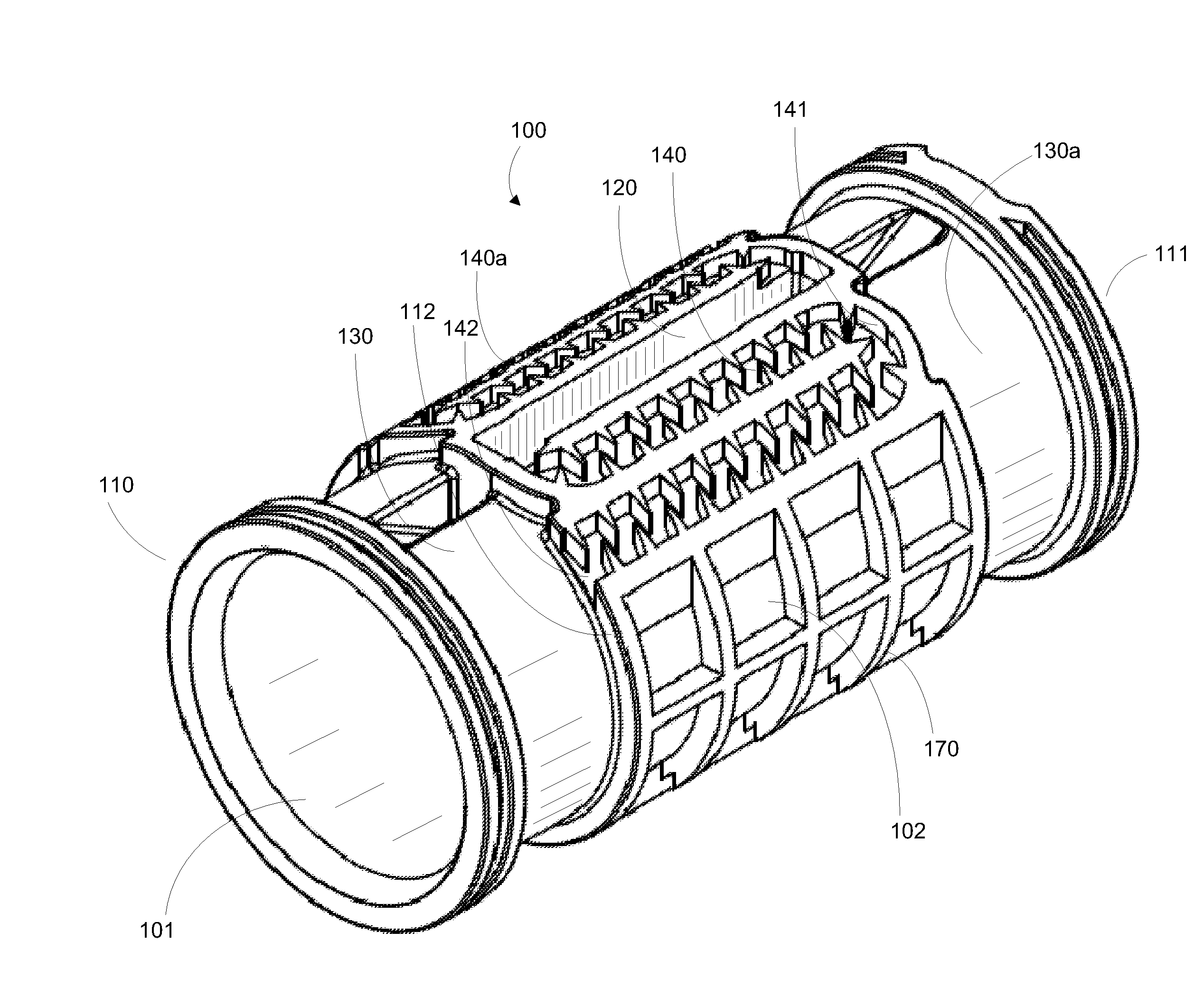

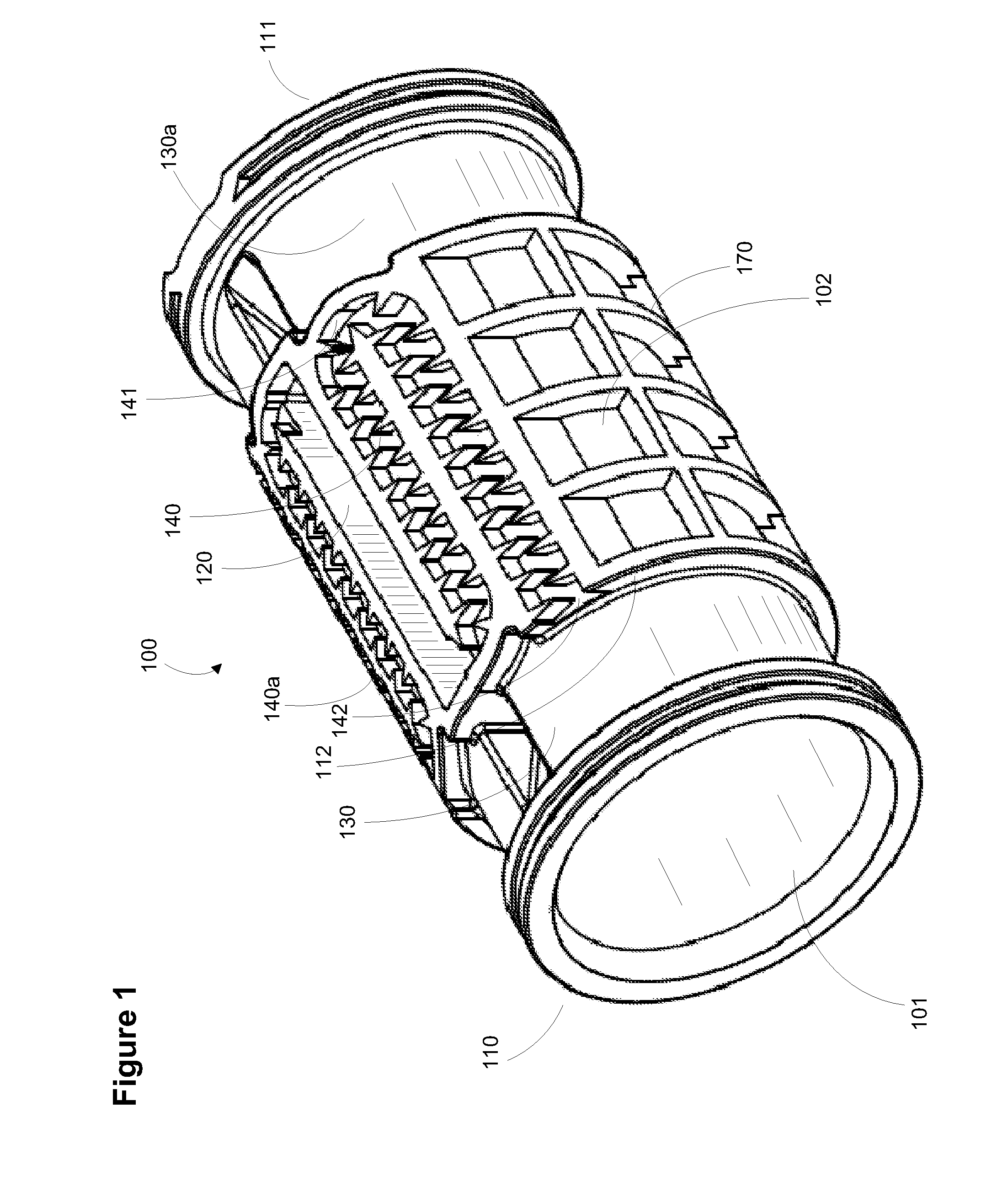

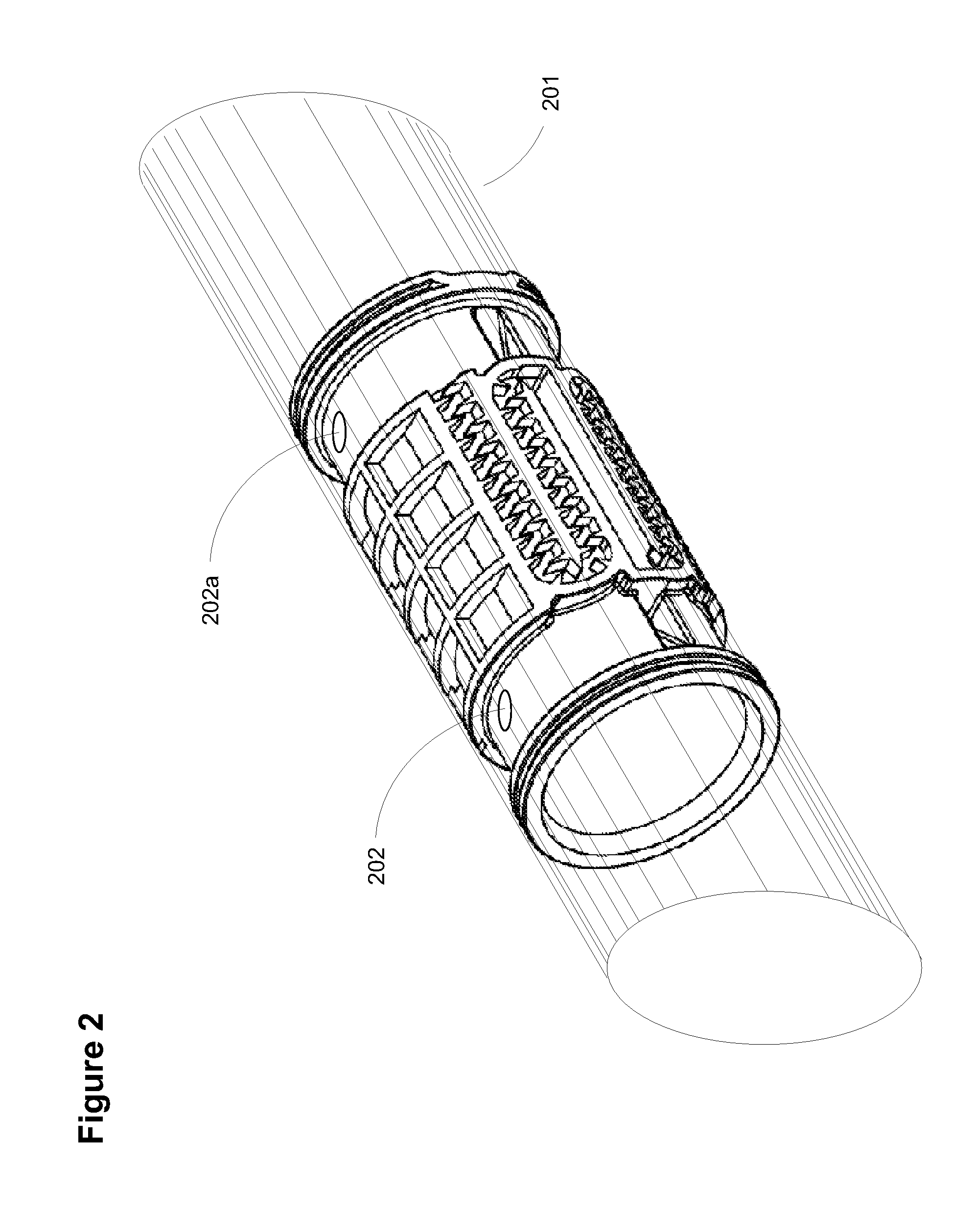

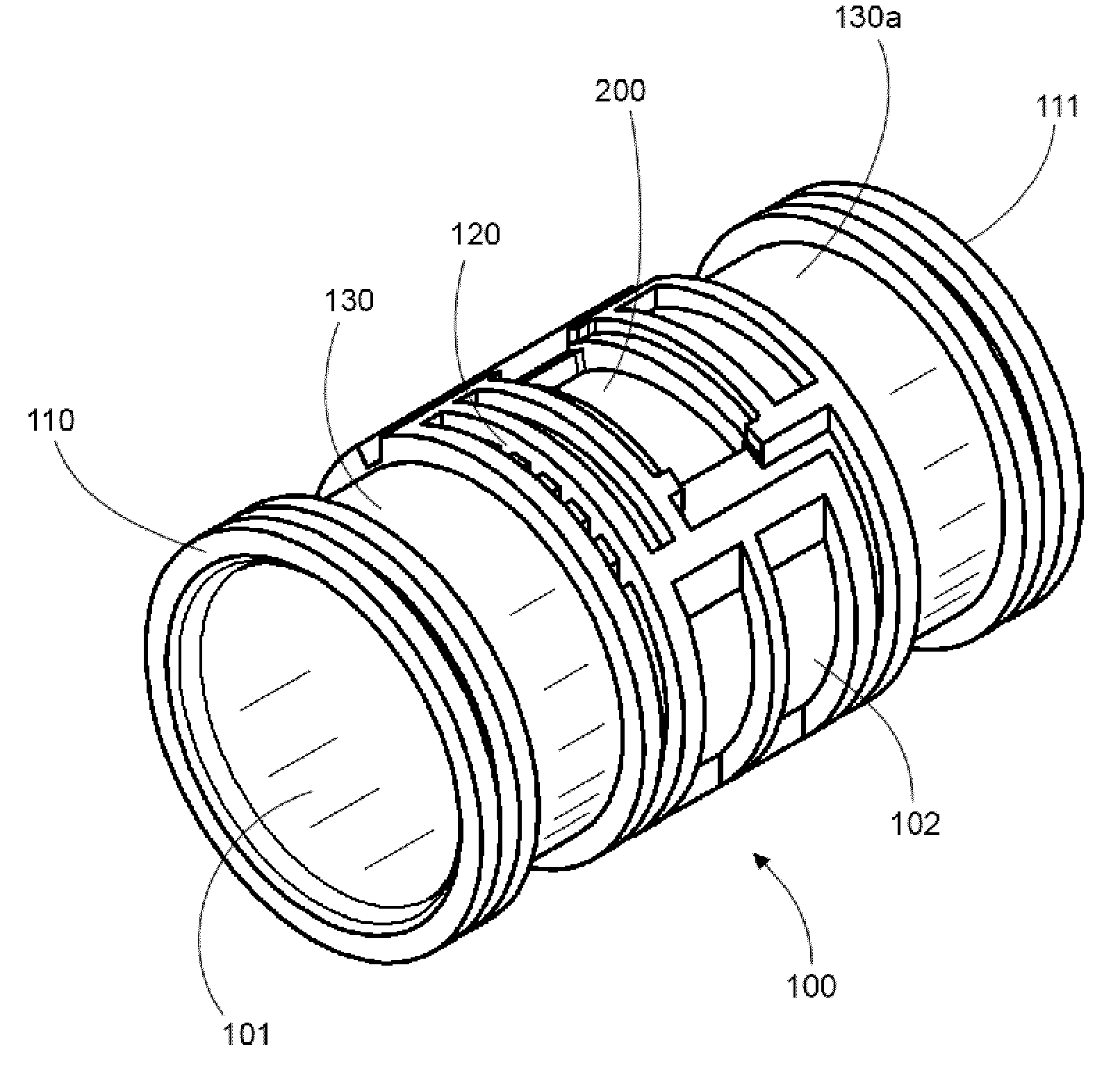

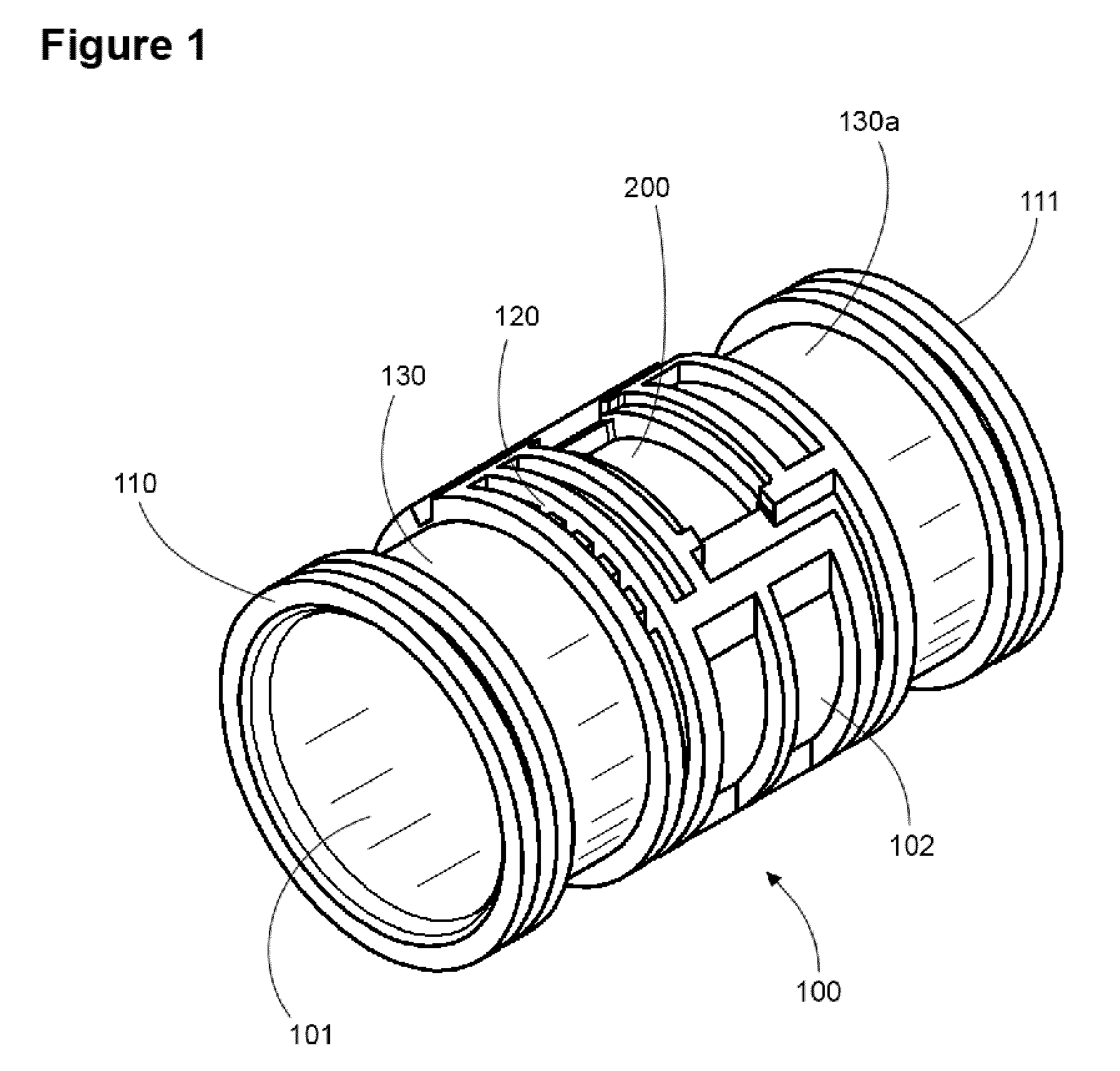

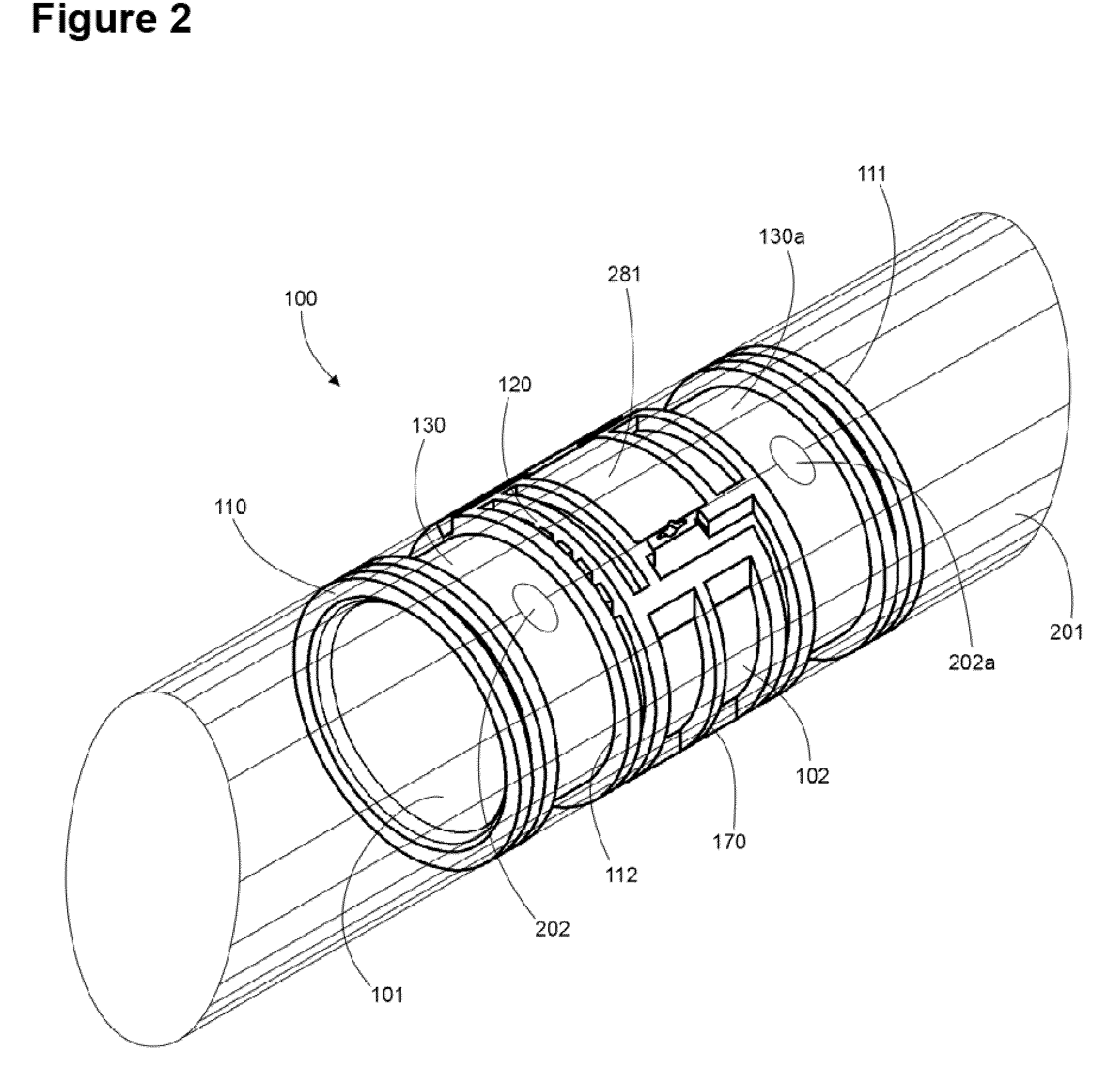

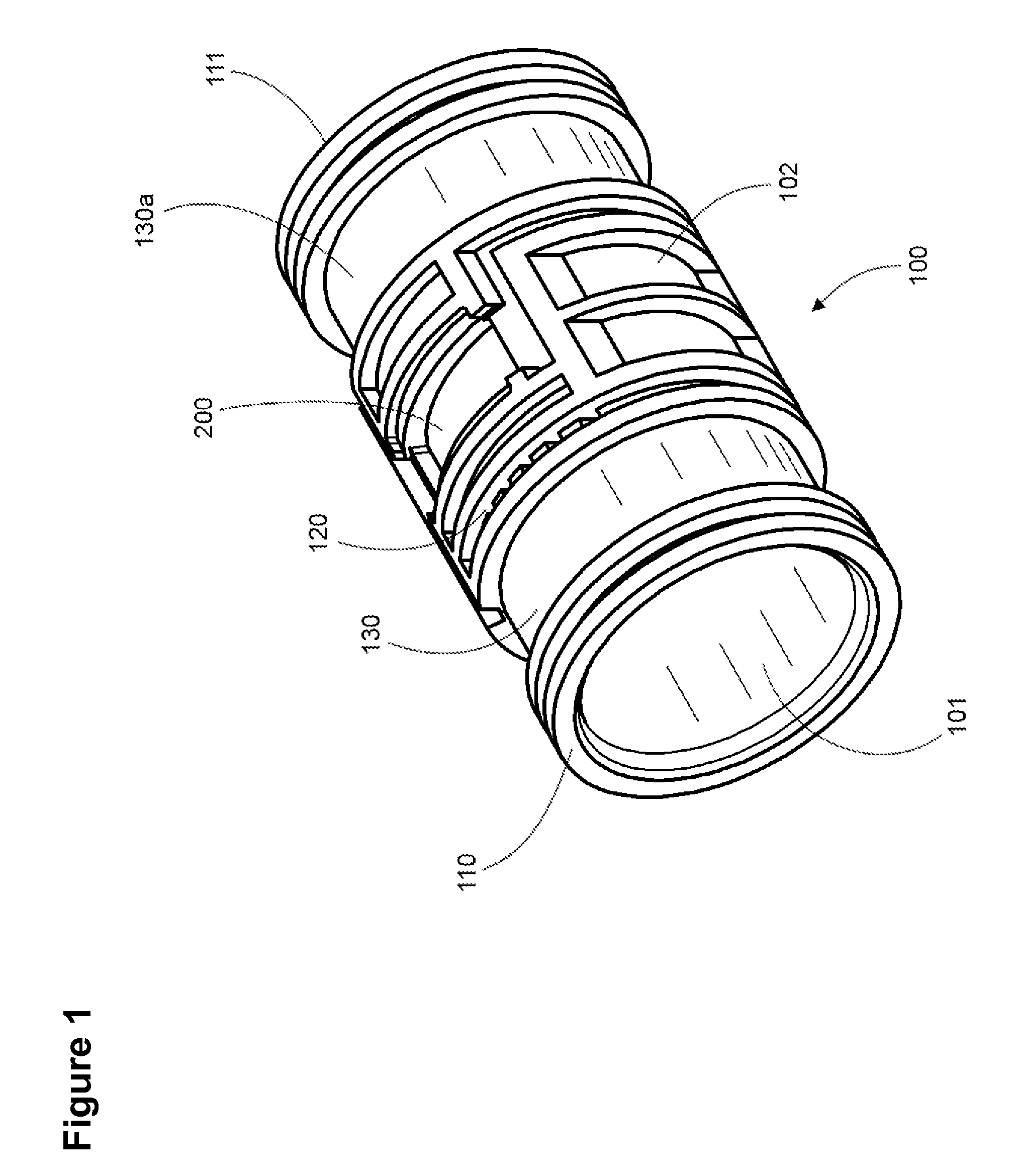

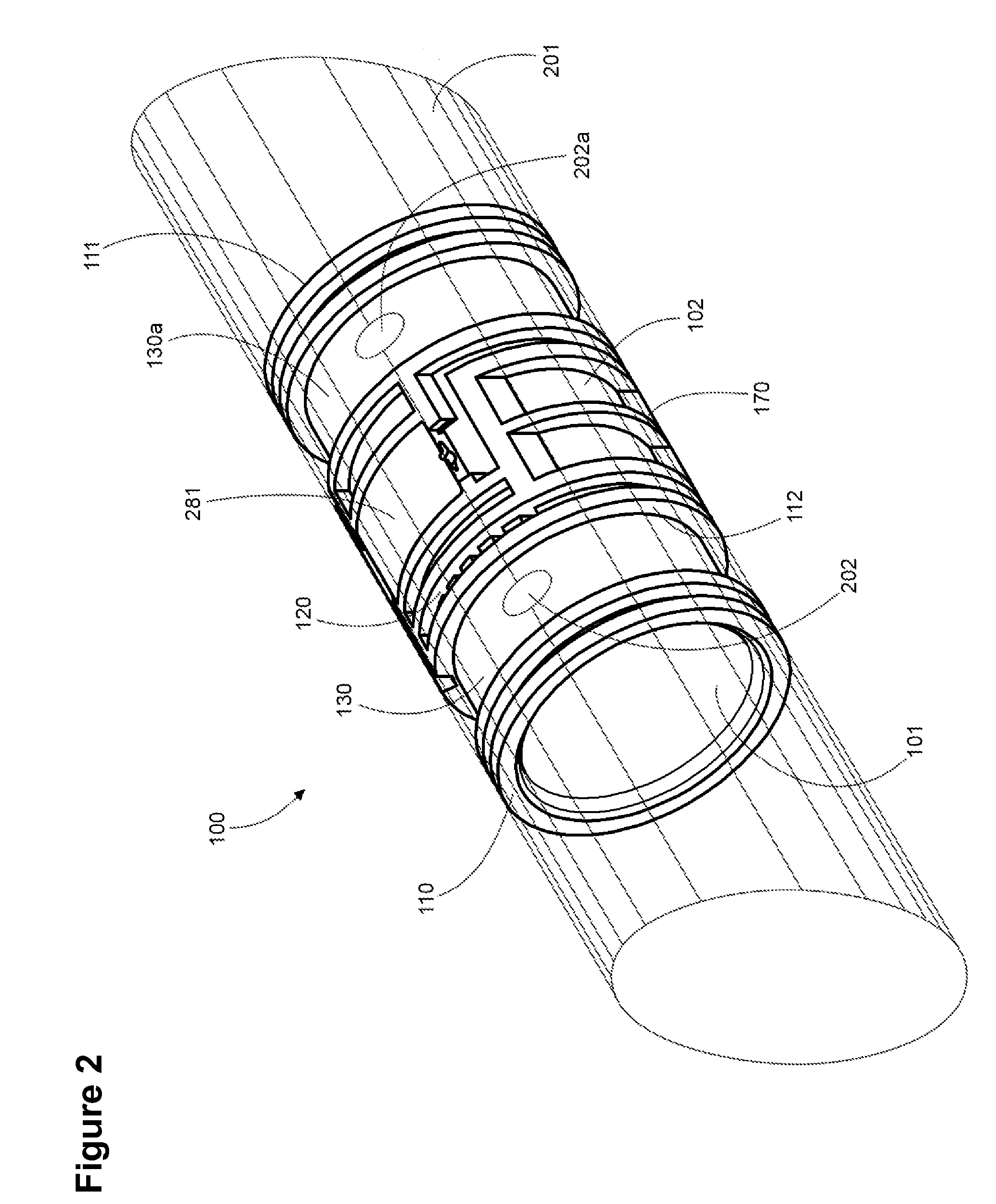

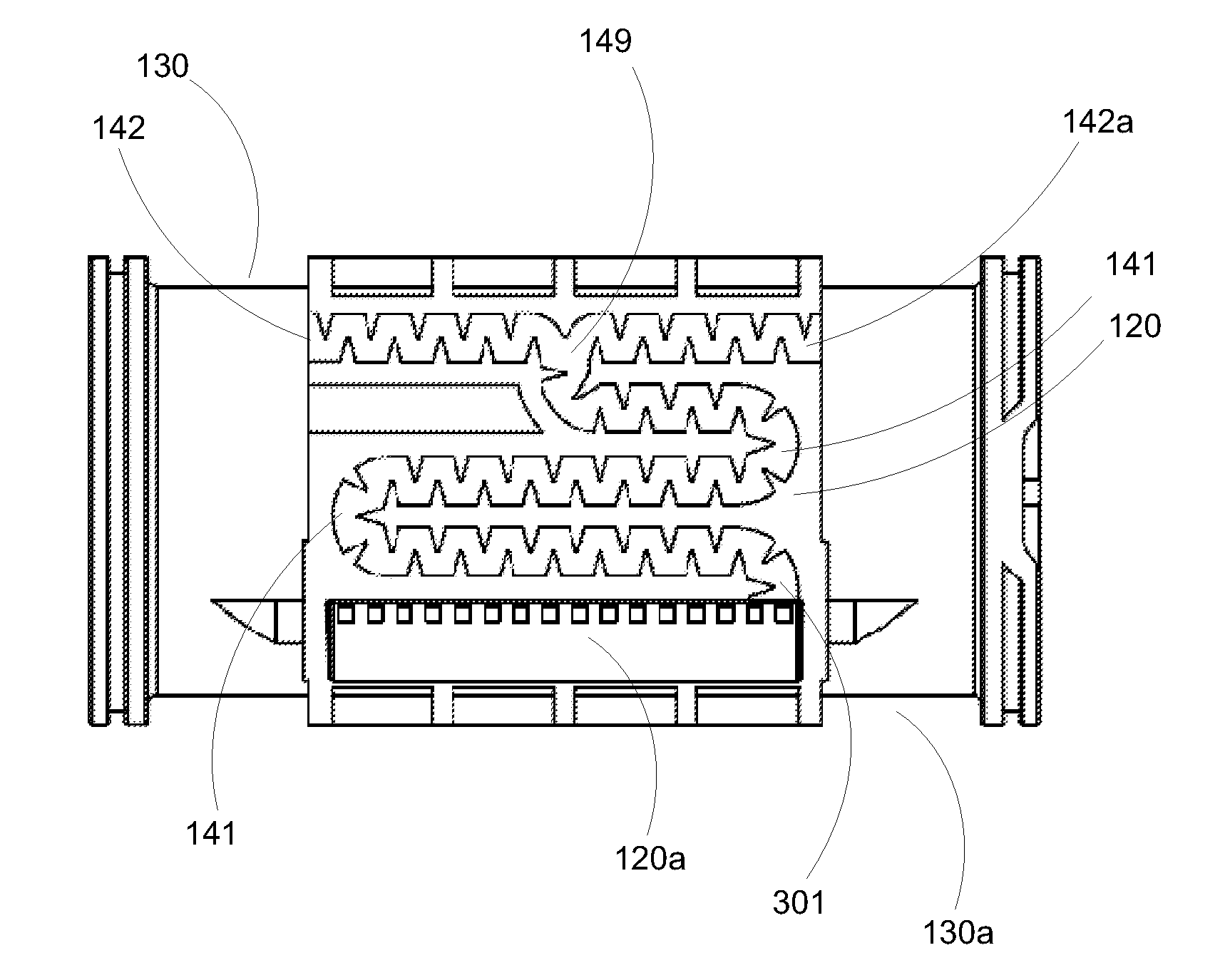

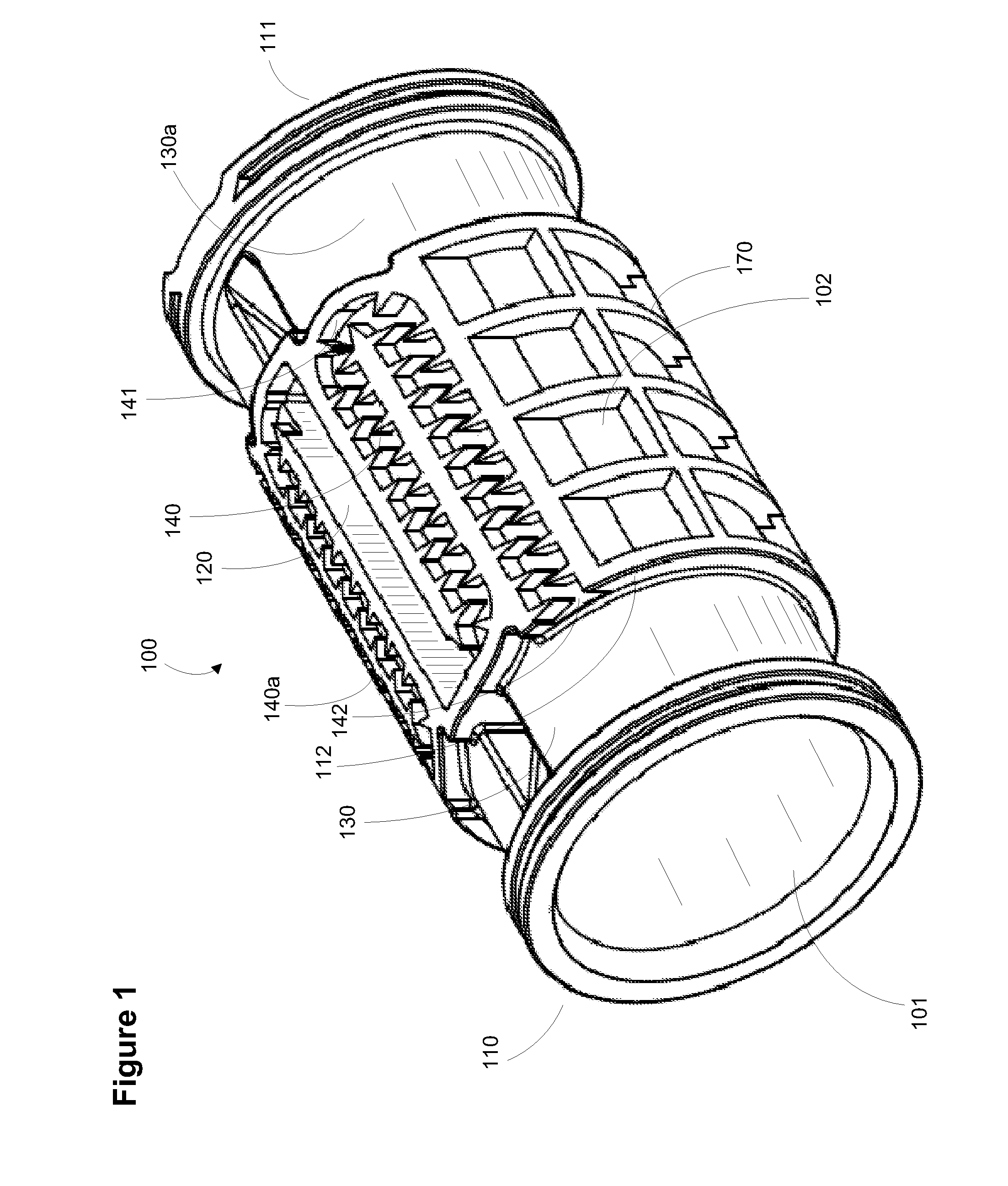

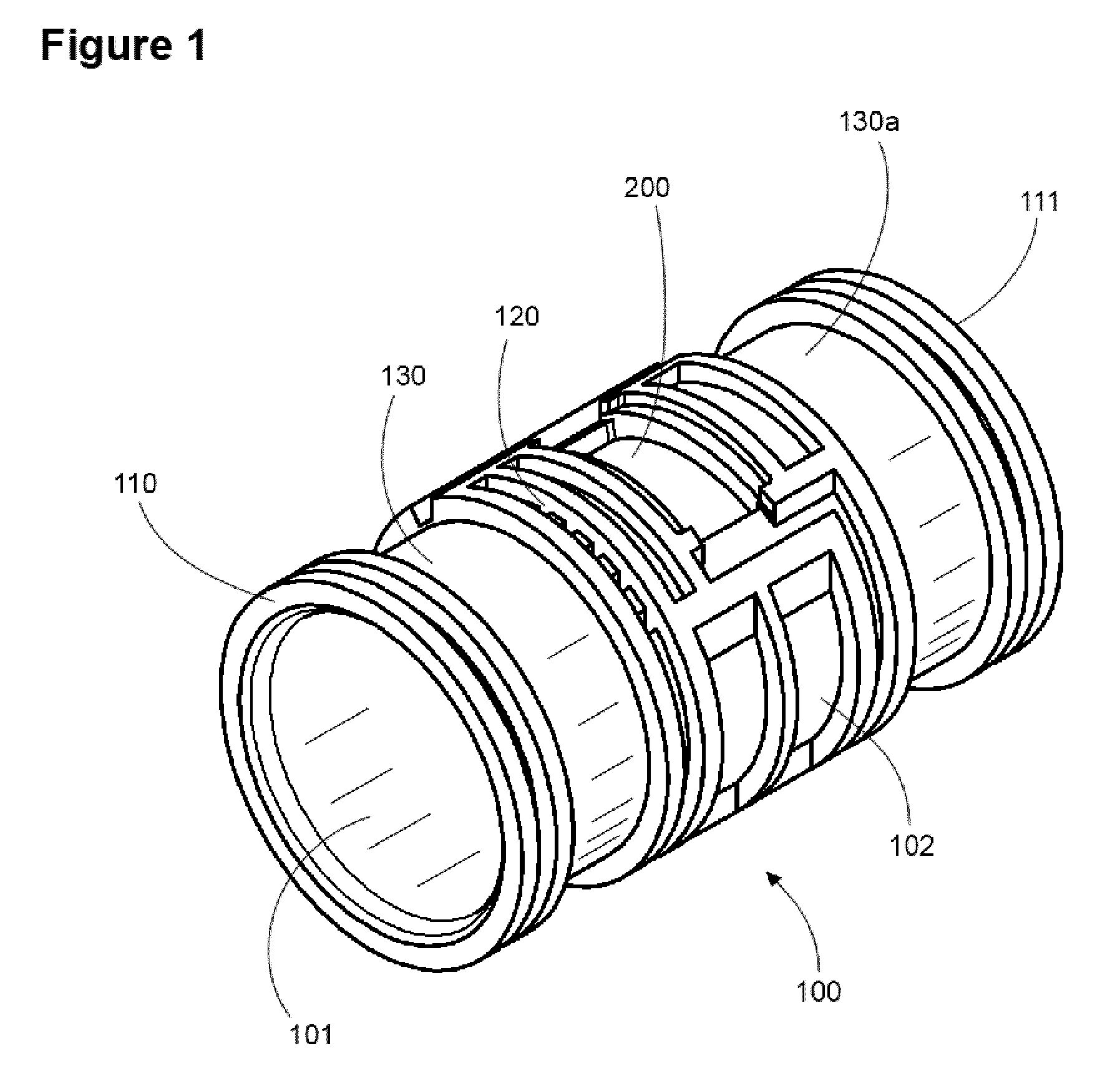

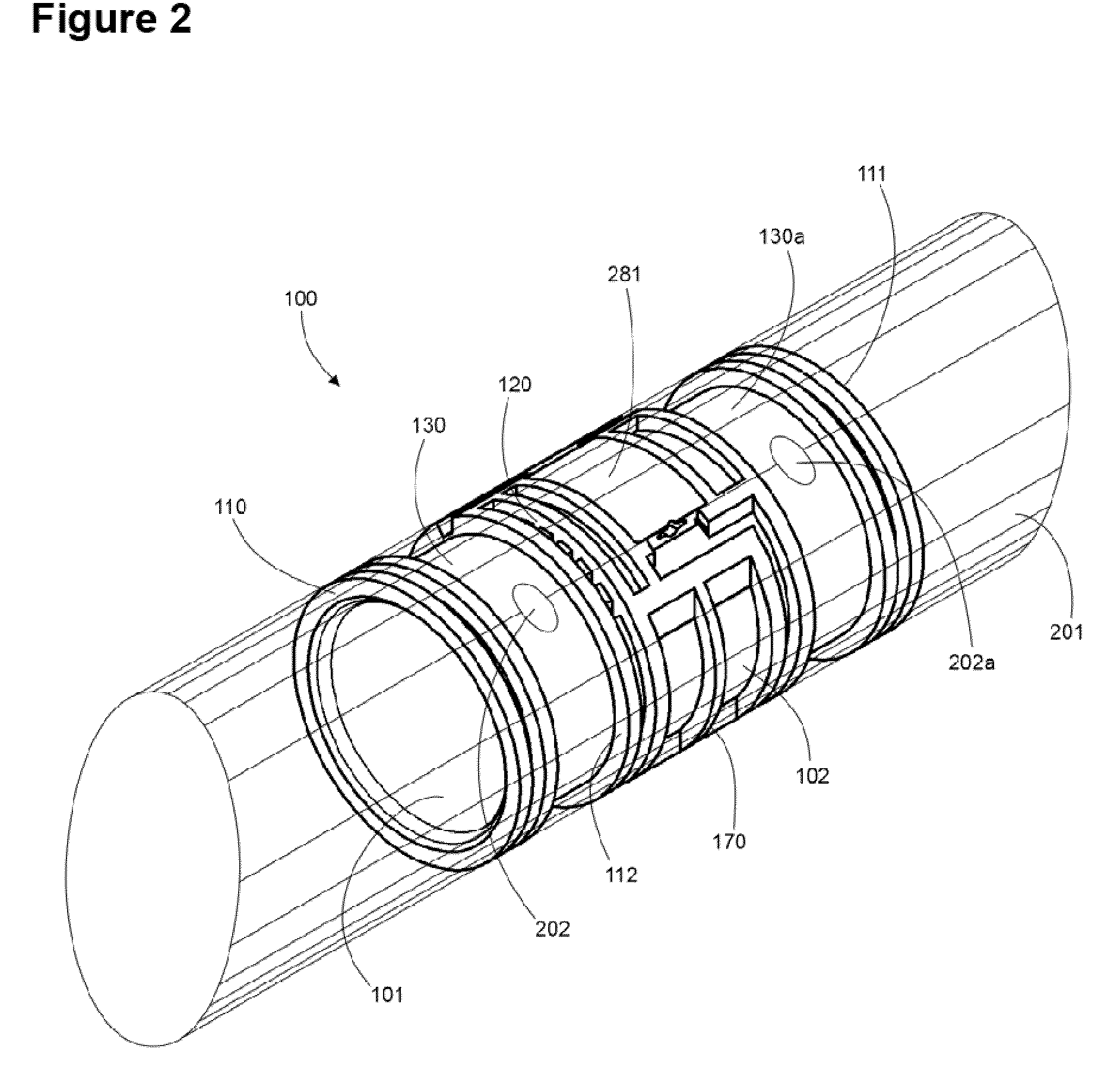

Non-clogging non-pressure compensated drip emitter

InactiveUS20100096478A1Eliminating potentialEliminate cloggingWatering devicesSpray nozzlesEngineeringSediment

A non-clogging non-pressure compensated drip emitter that utilizes one or more filters or one or more inwardly offset filters that have an inlet that projects inwardly toward a centerline of the hollow cylindrical emitter body and a labyrinth having only turbulent transfer zones after water enters the labyrinth, wherein the labyrinth couples the filter(s) or inwardly offset filter(s) to the pool. Prevents clogging by eliminating dead transfer zones where sediment can accumulate where no turbulence exists. Also prevents clogging when the filter is positioned downward as the inwardly offset filter rises above any sediment when the emitter is positioned in the field in this downward orientation. Also prevents clogging flat filter configurations that have filters offset radially, i.e., redundant filters per emitter.

Owner:MAMO SHAY

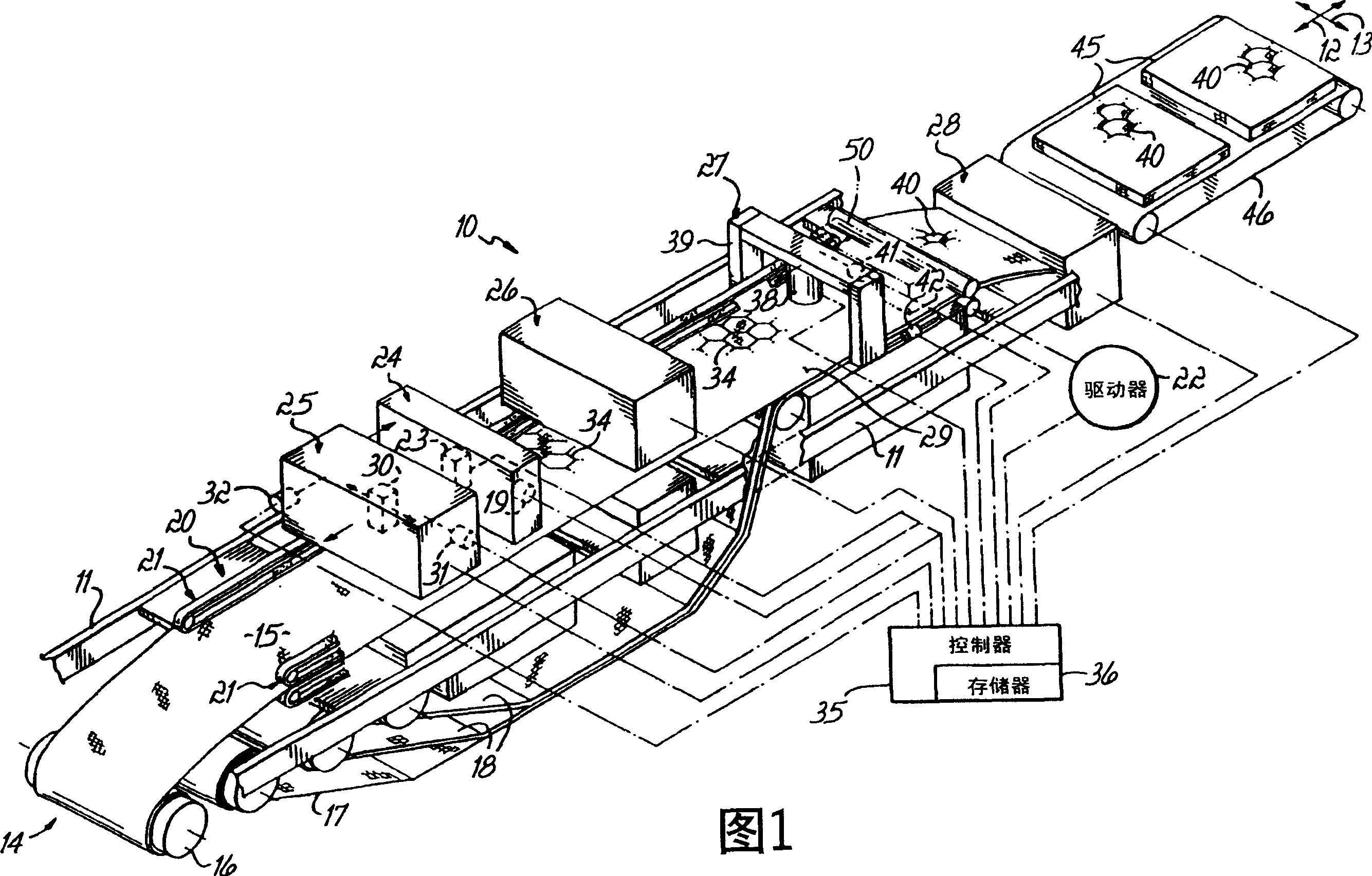

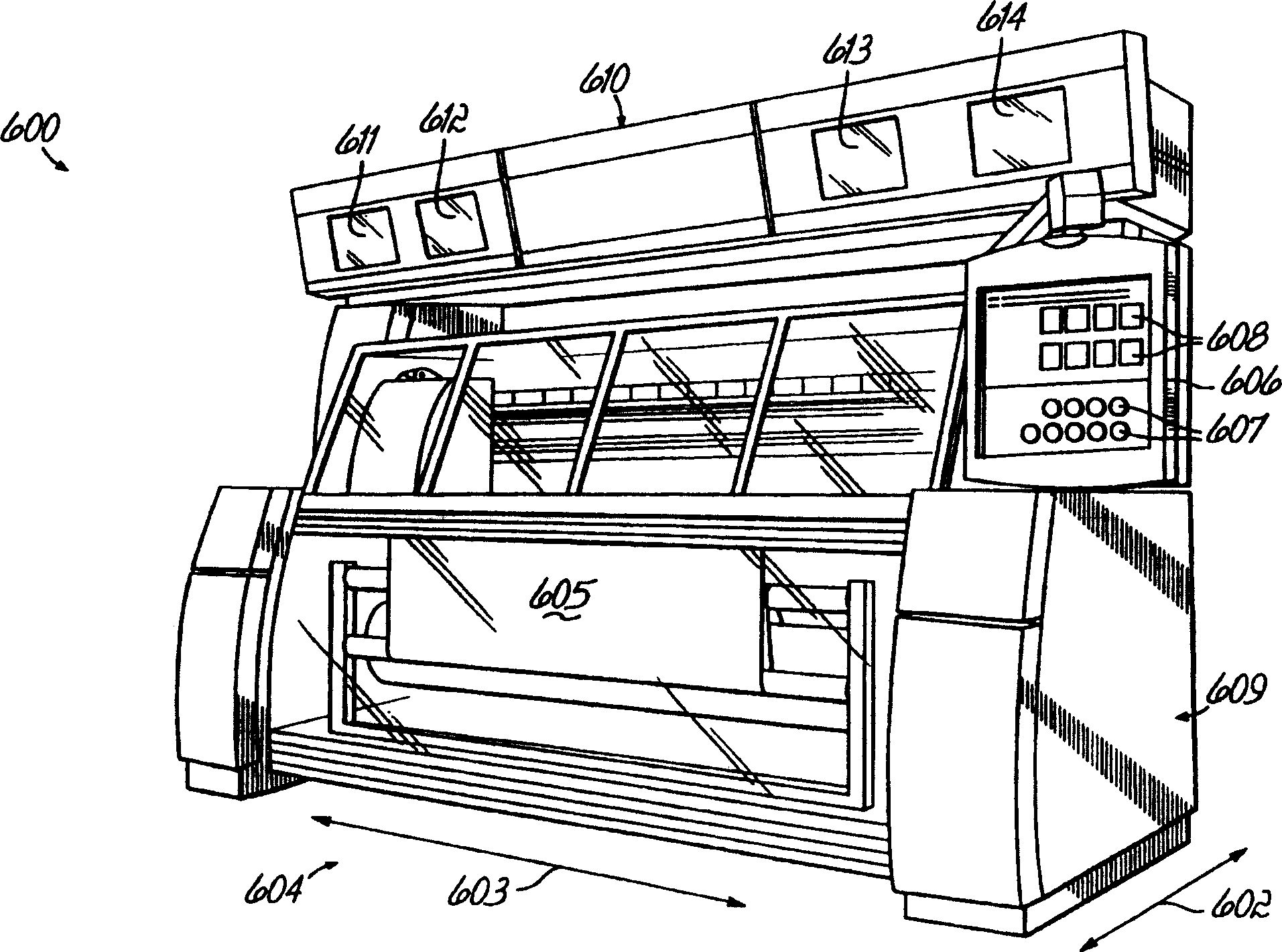

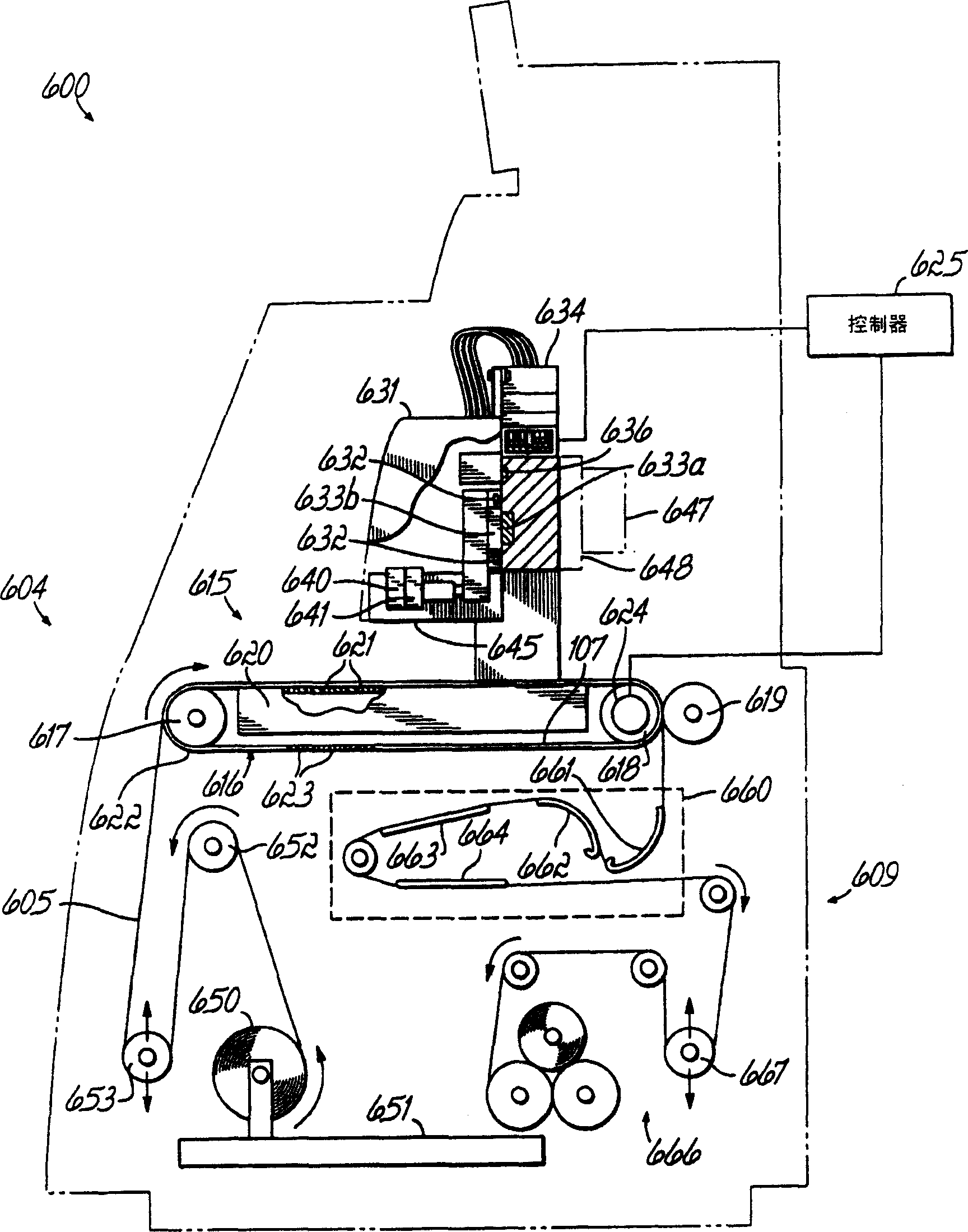

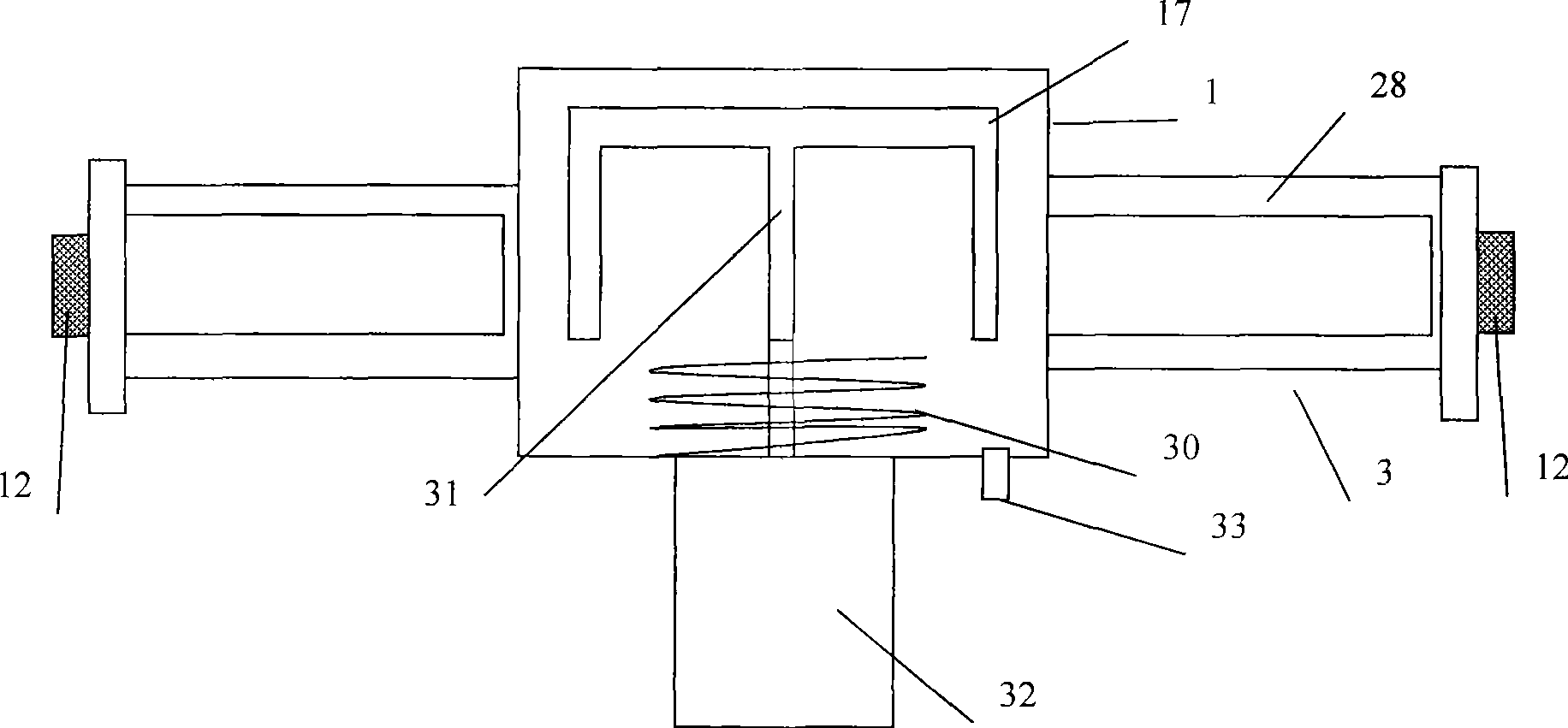

Method and apparatus for ink jet printing

InactiveCN1678458AEliminate cloggingImprove reliabilityDuplicating/marking methodsSpacing mechanismsPorous substratePolyester

Ink jet printing is provided on large area substrates such as wide width textile webs. The printheads are driven by linear servo motors (633) across a bridge (630) that extends across the substrate. The timing of the jetting of the ink is coordinated with the motion of the printheads (640, 641), so that the heads can be rapidly moved and the ink can be jetted while the printheads are accelerating or decelerating as they move on the bridge. Preferably, ultraviolet (UV) light curable ink is jetted and first partially cured with UV light (645, 646) and then subjected to heating to more completely reduce uncured monomers of the ink on the substrate. Preferably, the heat is applied by contacting the substrate with a heated plate (661, 662). Ink jet printing is provided using ultraviolet (UV) light curable or other curable composition or stable or other printable substance. In certain embodiments the UV ink has a dye-component therein. The ink is jetted onto a substrate, the composition is cured, then heated to set the dye. Sublimation dye-based UV ink printing onto polyester is preferred. A release layer of protective material (702, 704) such as a TEFLON film or sheet, covers a substrate support (705, 706). A porous substrate to be printed, such as a textile material (711), is supported on or above the support. Ink is jetted onto the substrate, with some of the ink passing through pores in the substrate and landing on the protective material. UV curable ink is preferably used and is exposed by UV light from a UV light curing head, which solidifies the ink on the substrate. The UV curing light has a long enough focal length to focus on the surface of the substrate and also, where it passes through pores in the substrate, on ink on the protective material, thereby solidifying the ink on the protective material. When the substrate is removed from the support, the solidified ink on the protective material may be wiped from the protective material.

Owner:L & P PROPERTY MANAGEMENT CO

Internally pressure compensated non-clogging drip emitter

Drip emitter having a pressure compensating element that does not contact the enclosing pipe. First known drip emitter formed from a two-shot injection mold process that includes a deformable element, membrane, compressible element or pressure compensating element that compensates pressure or flow of water against a stiff injection molded surface that is part of the drip emitter body. In addition, this is the first drip emitter (two-shot or otherwise) that includes a compensating surface that is not parallel to the membrane, i.e., at an angle to the plane of the pressure compensating element. May include fluid retainment valve, ventable / anti-siphon / non-drain or other, as part of second injection with second or third material. Allows for simple injection mold construction and eliminates need for ISO conditioning to properly seat the membrane before testing.

Owner:MAMO SHAY

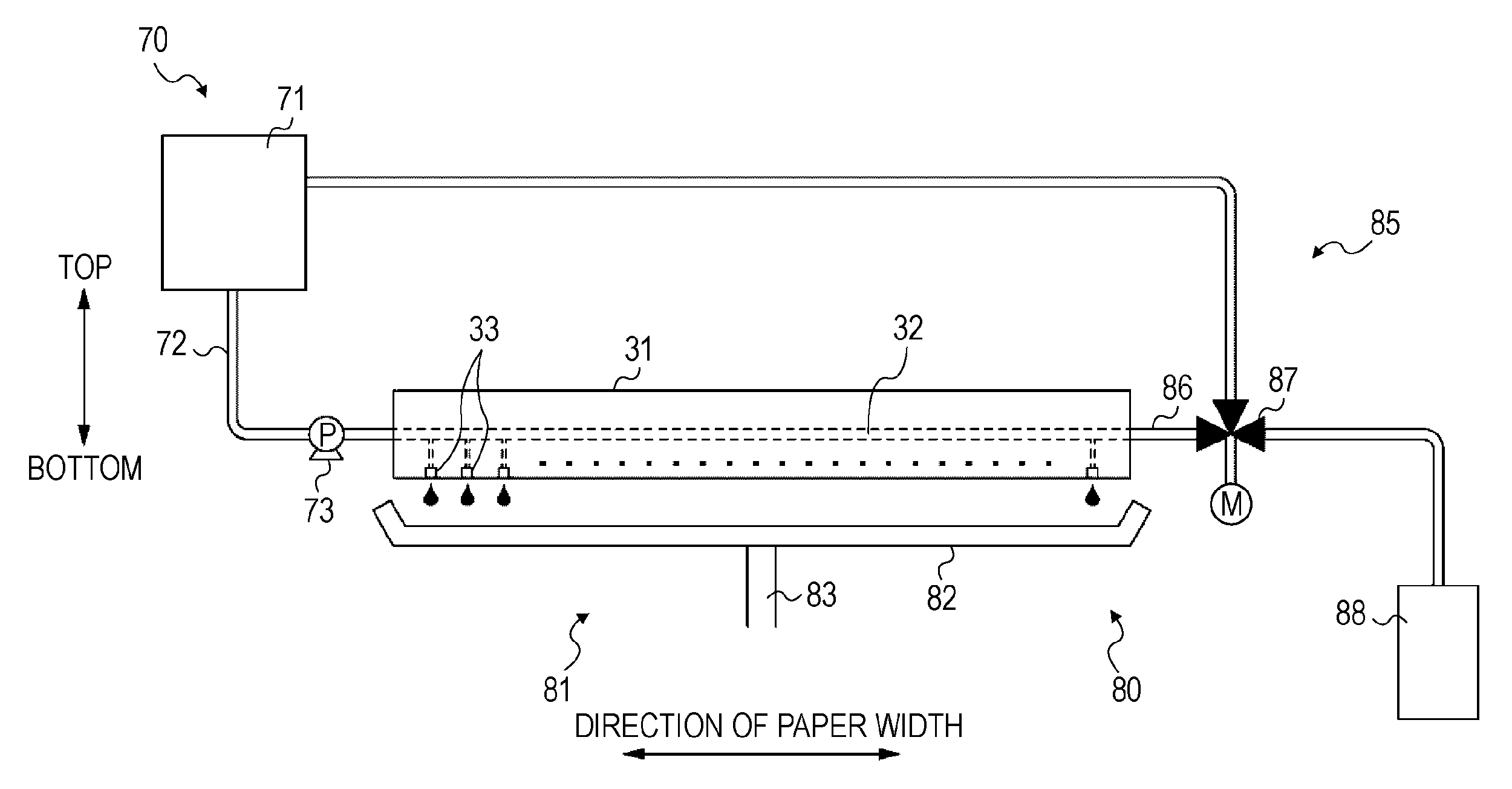

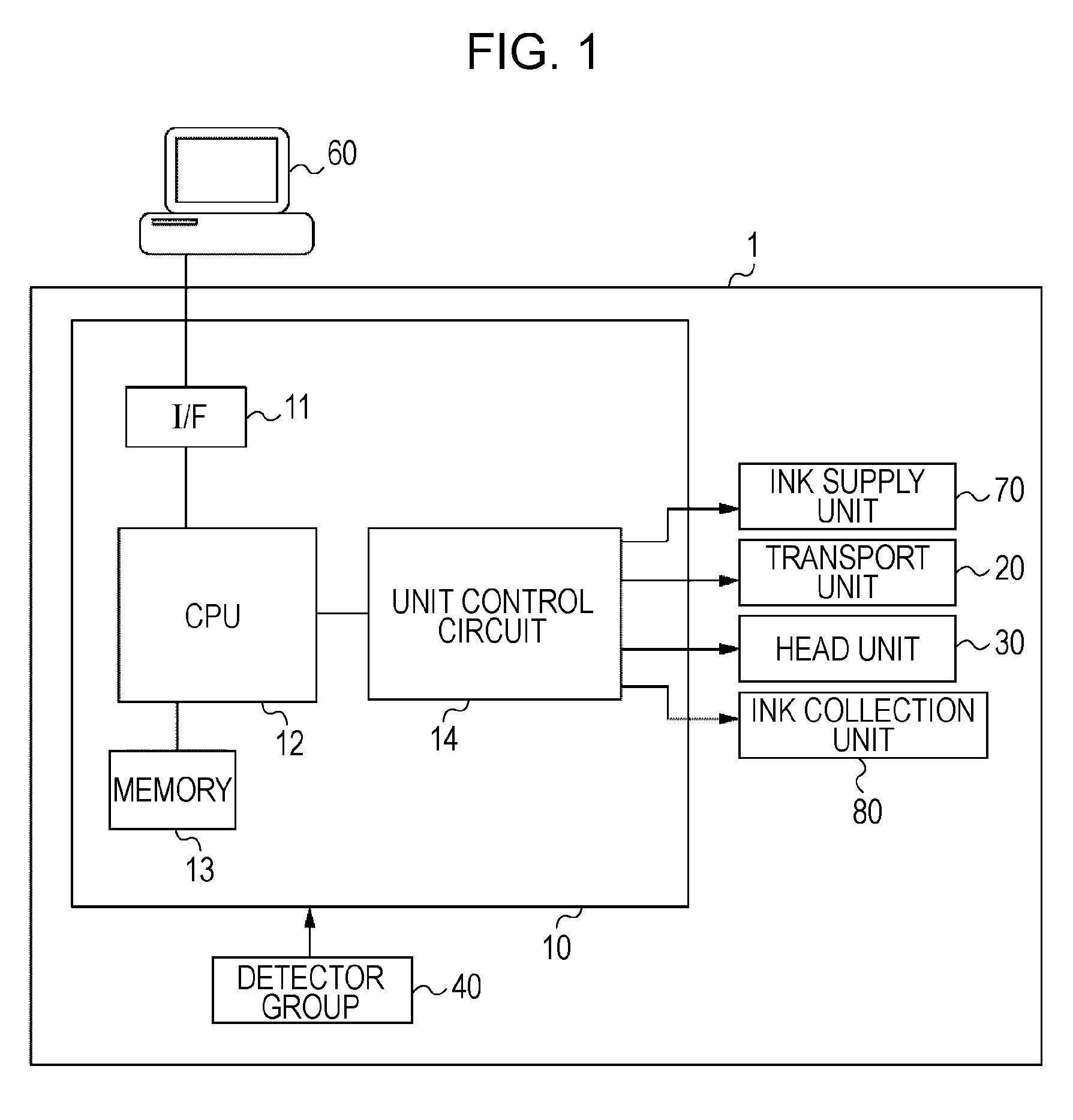

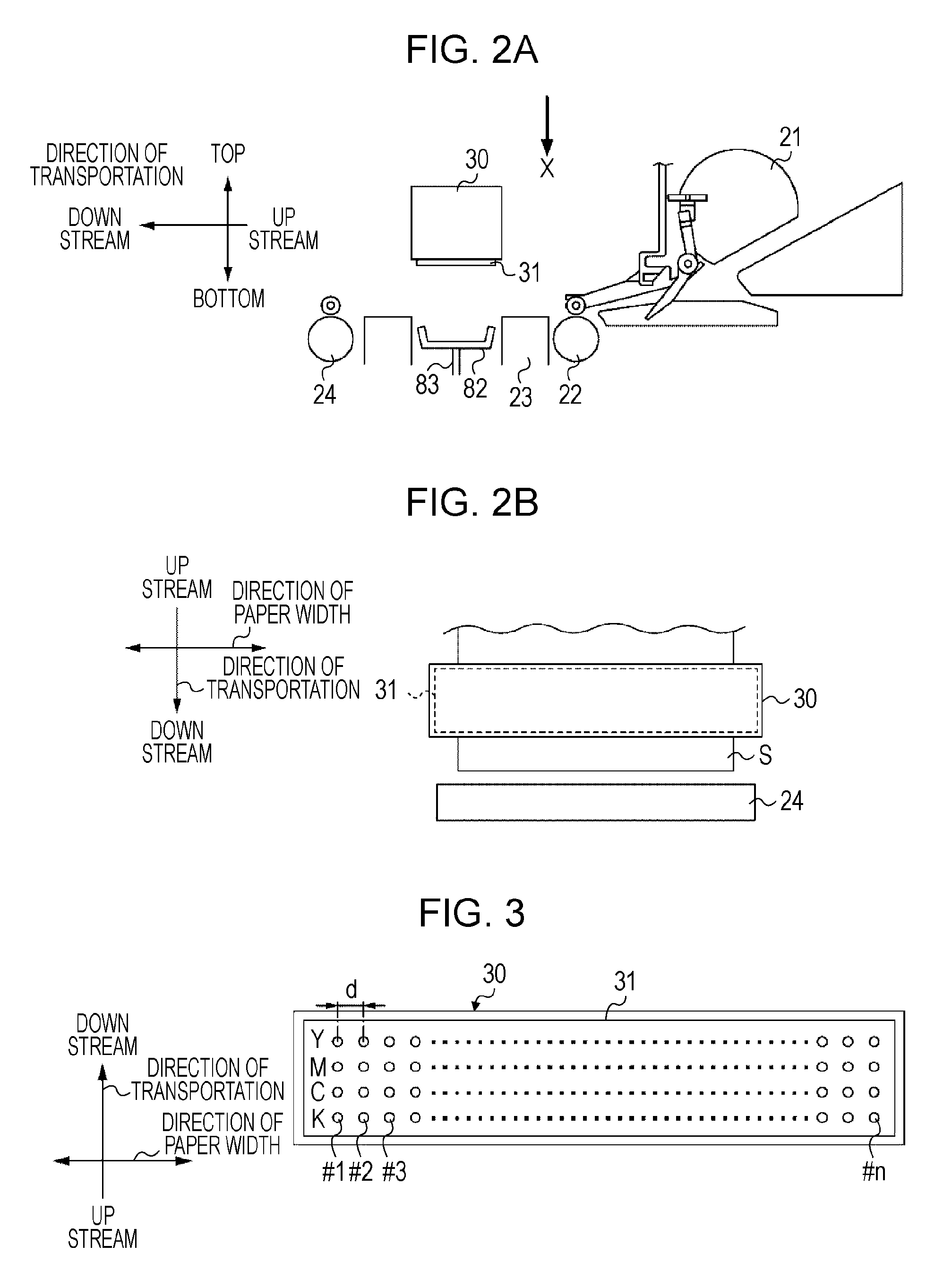

Fluid ejecting apparatus and method for controlling the same

A fluid ejecting apparatus including a head having a nozzle for ejecting fluid, a storing section that stores the fluid, a pressurizing section that applies pressure to the fluid so that the fluid flows from the storing section to the head, a discharge passage through which the fluid may be discharged from the head without passing through the nozzle, a valve provided in the discharge passage, a reservoir connected to the end of the discharge passage, and a circulating passage which connected to the end of the discharge passage which is connected to the storing section. The fluid ejecting apparatus has an ejection mode where the fluid is ejected from the nozzles, a discharge mode where the fluid is discharged to the reservoir, and a circulation mode where the fluid is discharged to the storing section through the circulating passage.

Owner:SEIKO EPSON CORP

Pressure compensated non-clogging drip emitter

A drip emitter that utilizes one or more filters and one or more labyrinths wherein the labyrinth couples the filter(s) to one or more water retainment valves that leads to at least one pool. Prevents clogging by eliminating air into the labyrinth via a water retainment valve that is situated after at least an initial portion of a labyrinth within the drip emitter. Includes non-drain, anti-siphon and ventable versions. Includes a method of two shot injection molding for embodiments of the drip emitter that include non-drain, anti-siphon and ventable variants.

Owner:MAMO SHAY

Non-clogging non-pressure compensated drip emitter

InactiveUS7988076B2Eliminating potentialEliminate cloggingWatering devicesSpray nozzlesEngineeringSediment

A non-clogging non-pressure compensated drip emitter that utilizes one or more filters or one or more inwardly offset filters that have an inlet that projects inwardly toward a centerline of the hollow cylindrical emitter body and a labyrinth having only turbulent transfer zones after water enters the labyrinth, wherein the labyrinth couples the filter(s) or inwardly offset filter(s) to the pool. Prevents clogging by eliminating dead transfer zones where sediment can accumulate where no turbulence exists. Also prevents clogging when the filter is positioned downward as the inwardly offset filter rises above any sediment when the emitter is positioned in the field in this downward orientation. Also prevents clogging flat filter configurations that have filters offset radially, i.e., redundant filters per emitter.

Owner:MAMO SHAY

Multifunctional preparation for controlling biological corrosion and blockage of oilfield production system

ActiveCN101875839AEliminate pollutionEliminate cloggingDrilling compositionDisinfectantSulfate-reducing bacteria

The invention relates to a multifunctional preparation for controlling biological corrosion and blockage of an oilfield production system. The contents of functional preparations in the treating water are as follows: 20 to 200 ppm of disinfectant: glutaraldehyde, acrolein, dodecyldimethylbenzyl ammonium chloride or dodecyldimethylbenzyl ammonium bromide, 10 to 100 ppm of inhibitor: sodium nitrateor sodium nitrite; and / or 10 to 20 ppm of sodium molybdate, sodium tungstate or lithium molybdate; 10 to 20 ppm of corrosion inhibitor: imidazoline quaternary ammonium; or / and 20 to 50 ppm of desulphurizing reagent: trihydroxymethyl nitromethane; or / and 10 to 20 ppm of penetrating agent: alkylpheol ethoxylates. The components undergo synergistic action so that the concentration of the single component is reduced obviously and reaches 25 to 90%, and the efficiency of killing the SRB (Sulfate Reducing Bacteria) reaches more than 90%.

Owner:PETROCHINA CO LTD

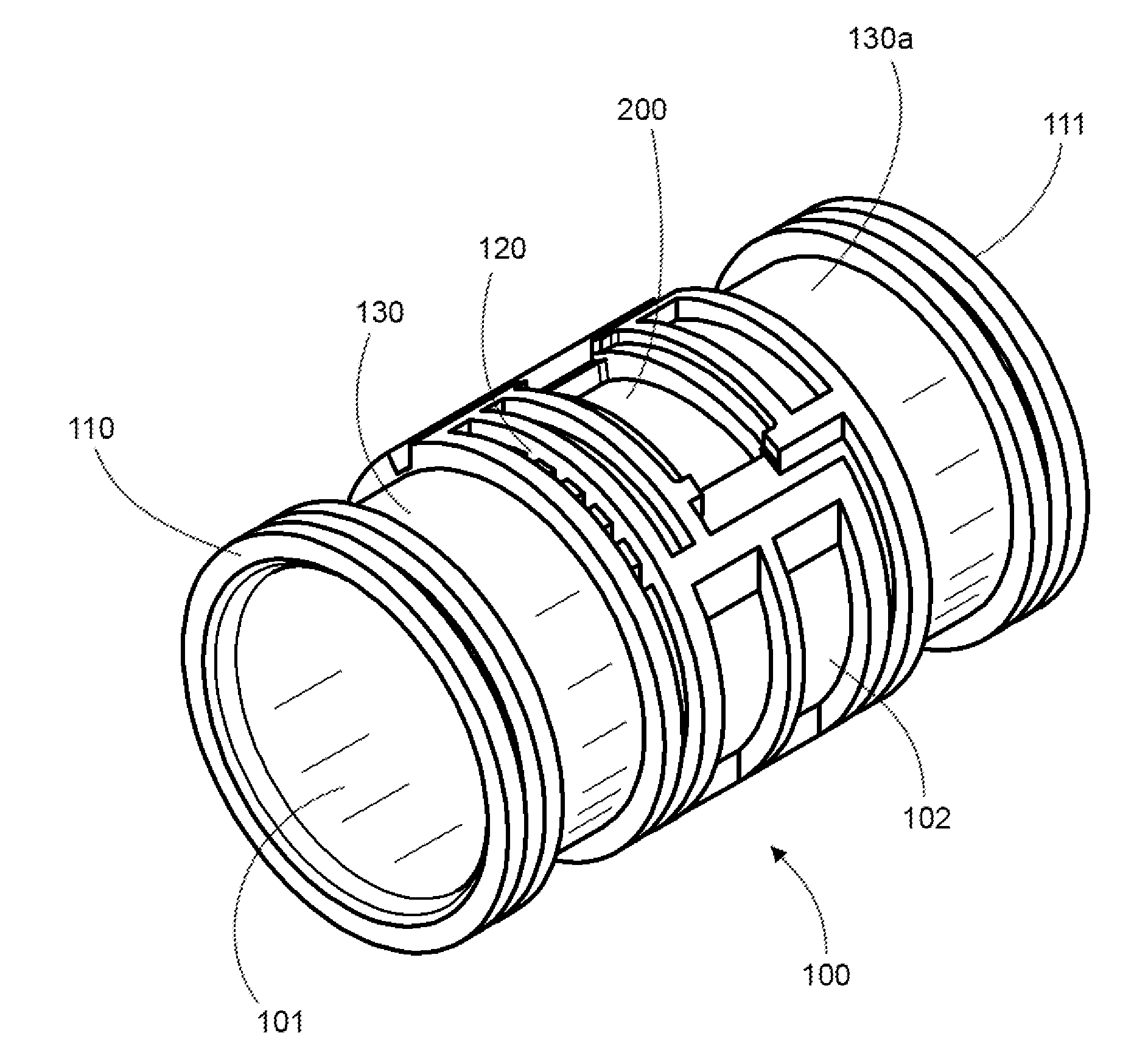

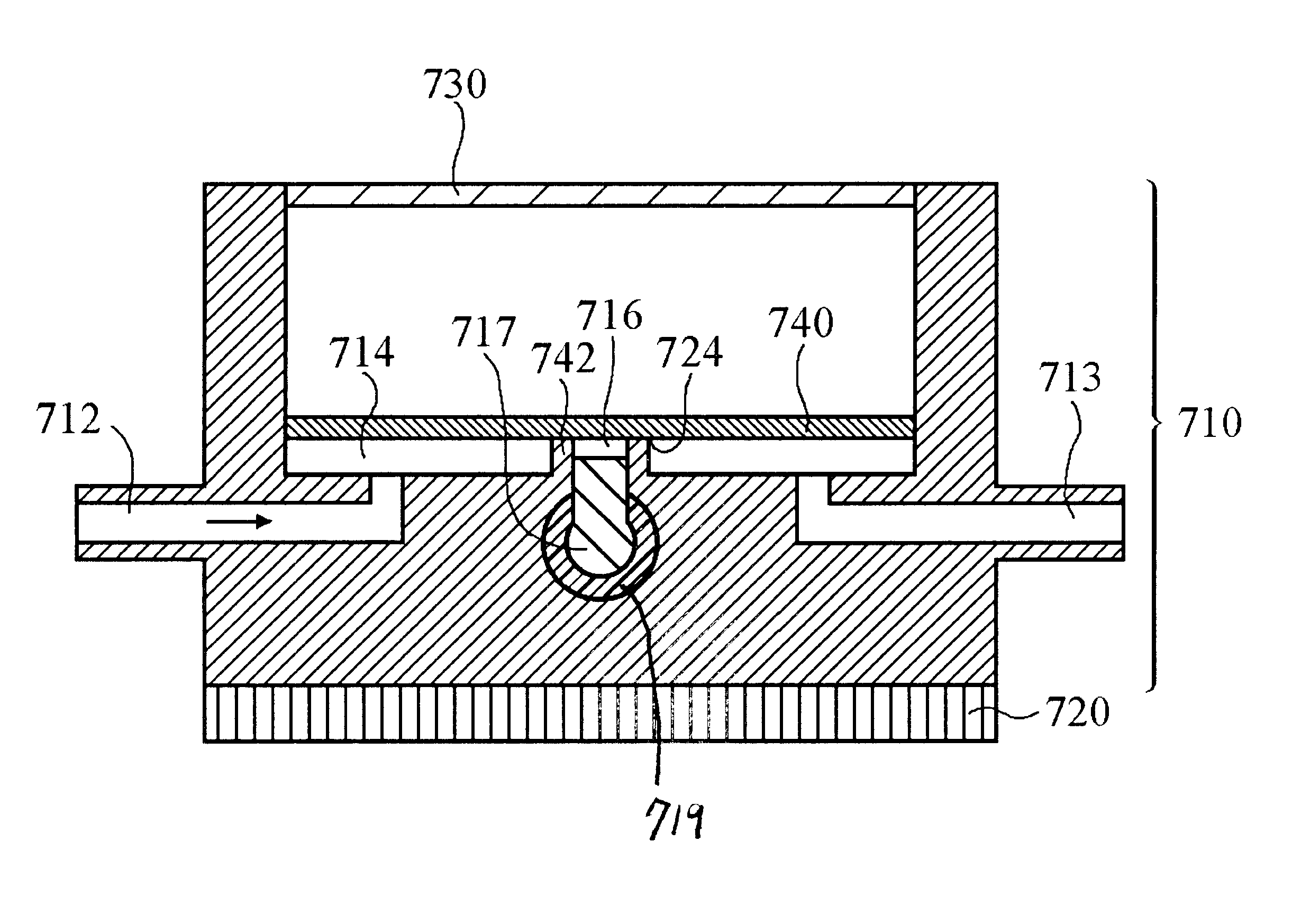

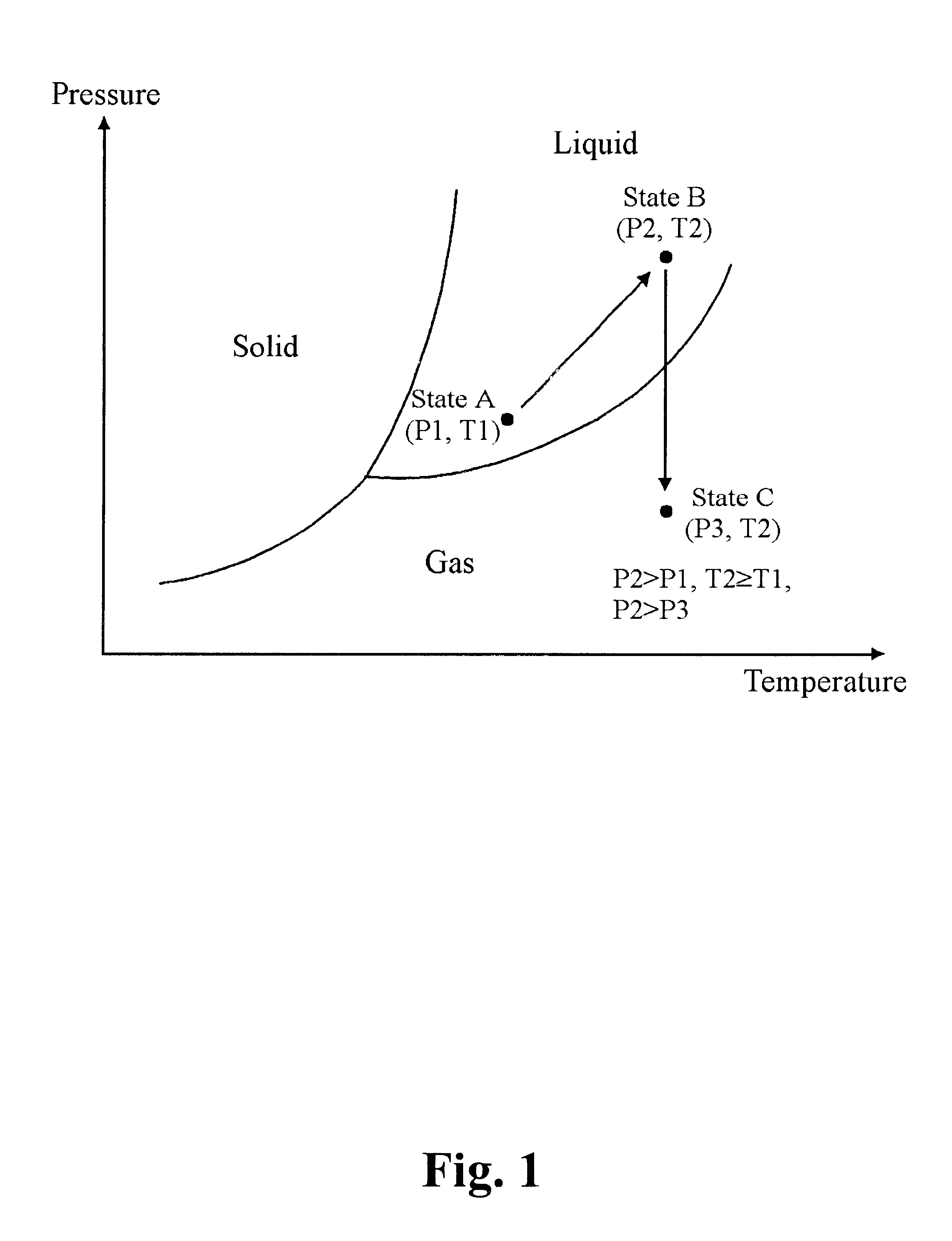

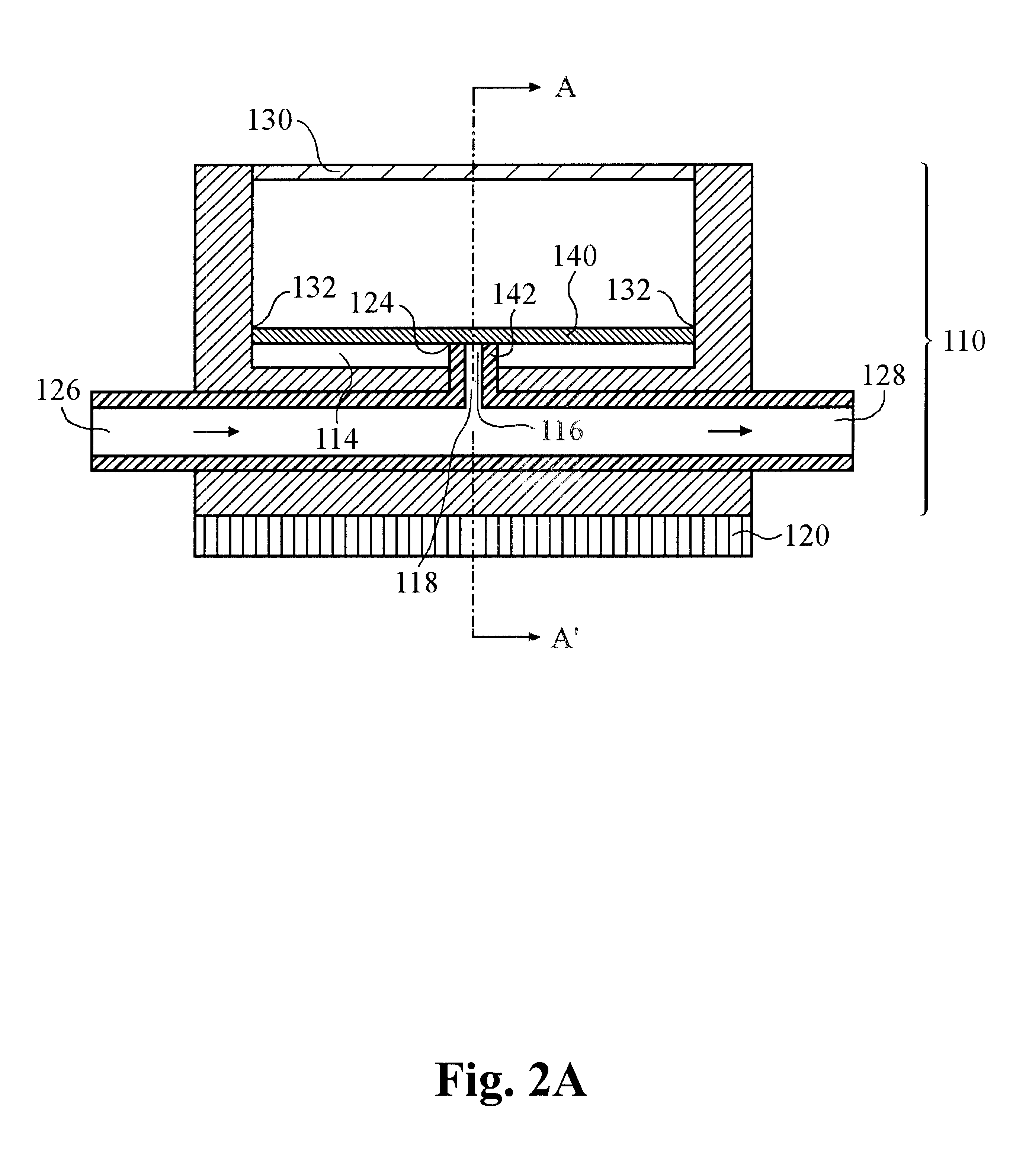

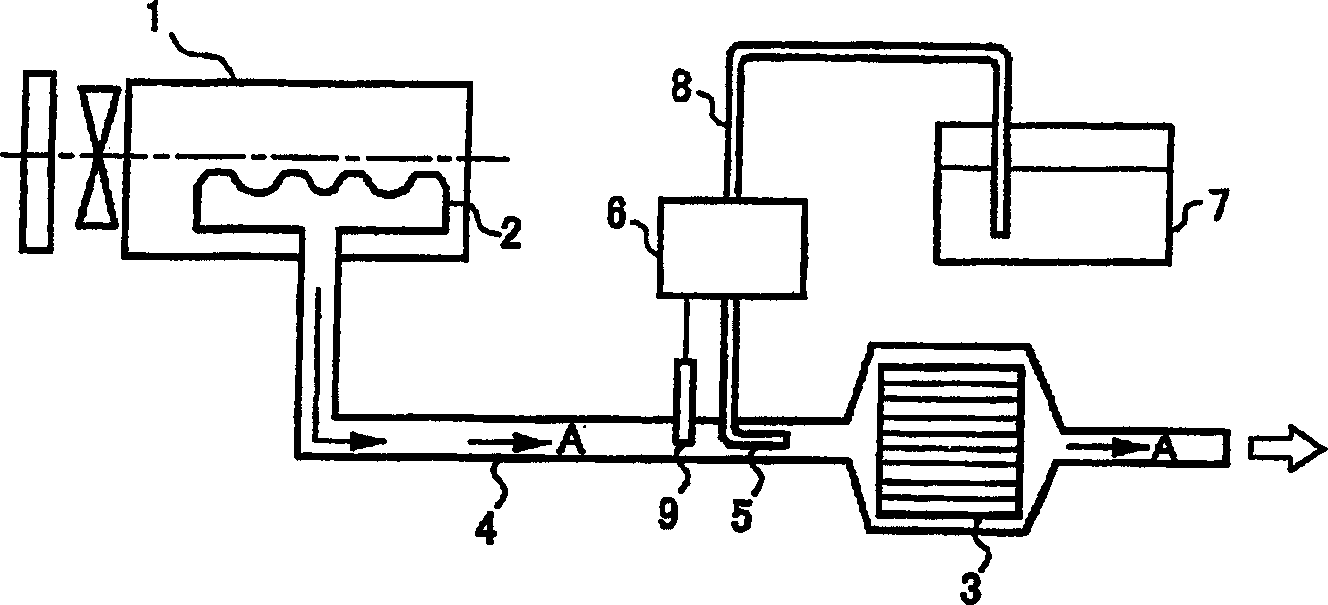

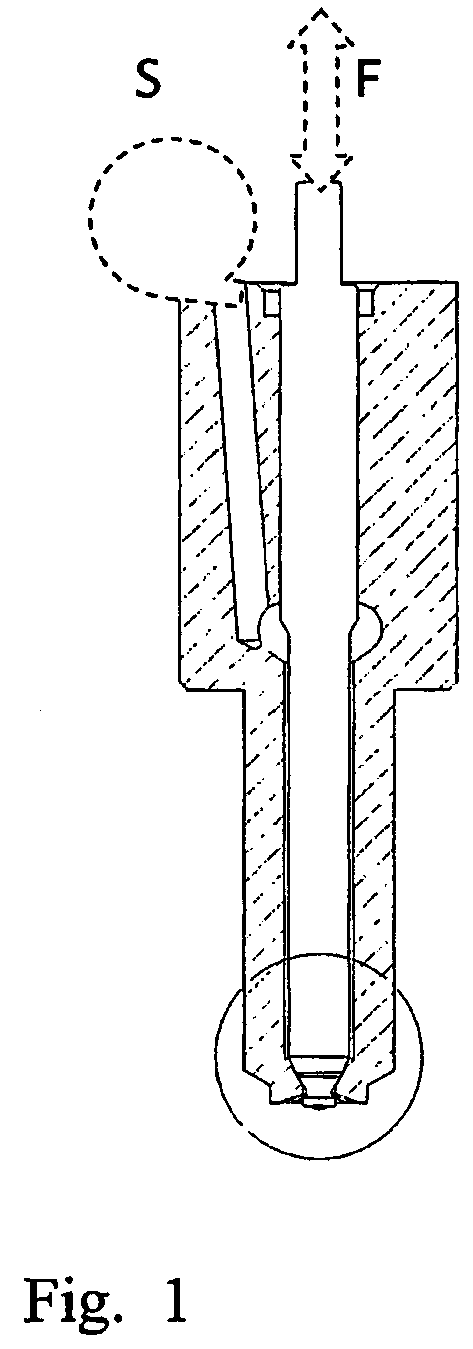

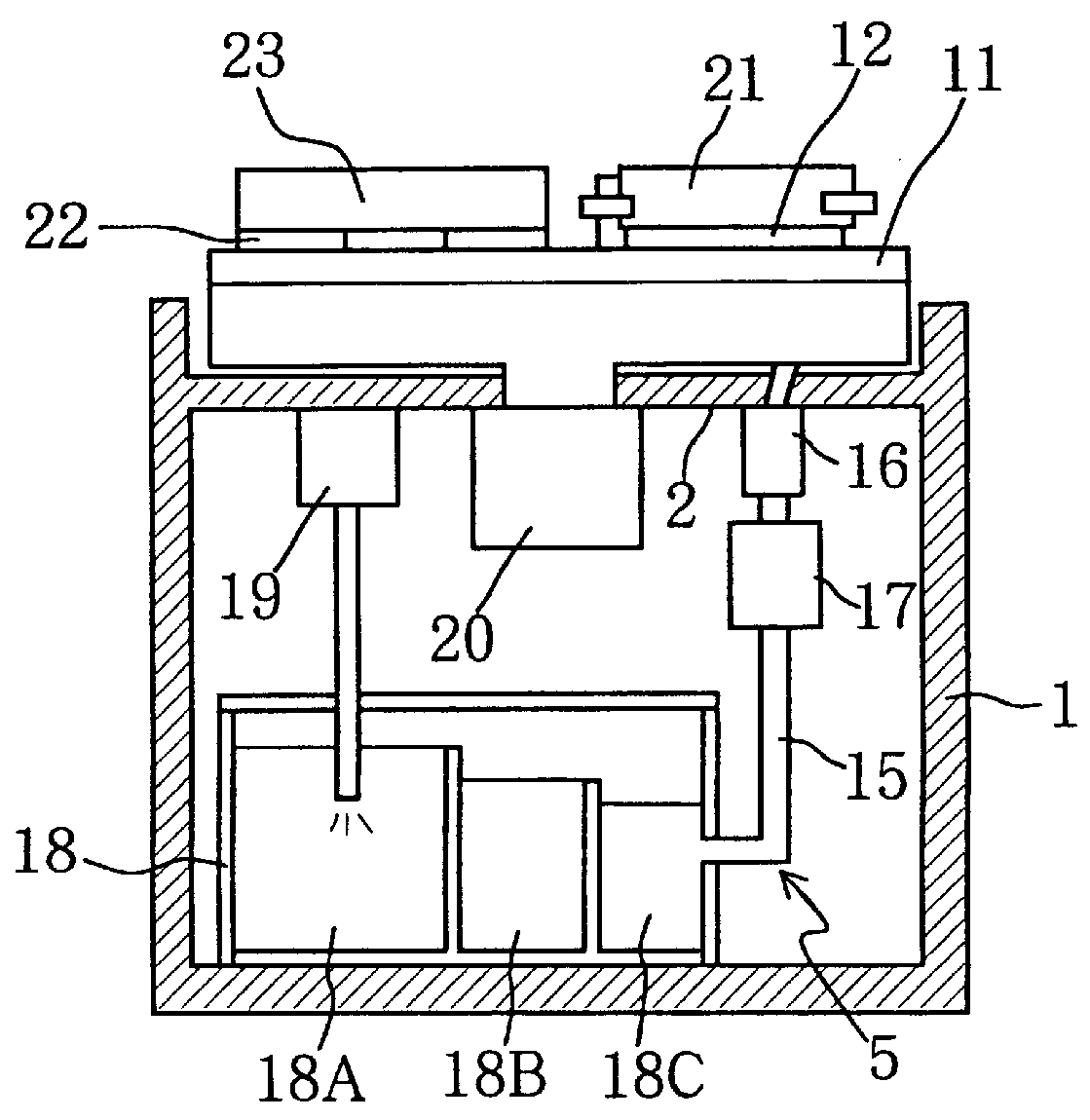

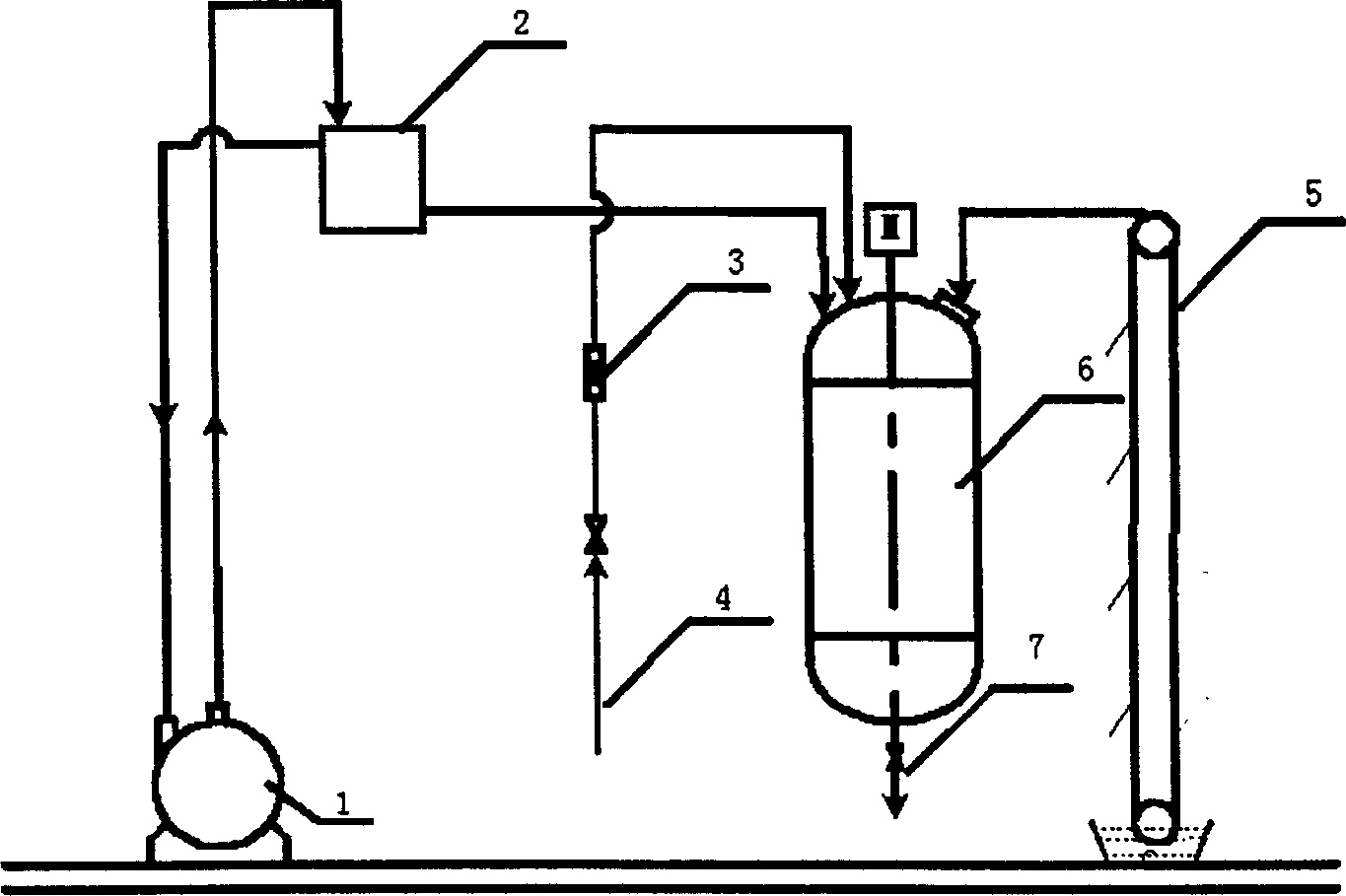

Method of vaporizing liquid sources and apparatus therefor

InactiveUS6380081B1Reduce the possibilityEliminate cloggingSemiconductor/solid-state device manufacturingChemical vapor deposition coatingSource materialLiquid state

A method and apparatus for vaporizing liquid source materials, where such vaporized source materials are supplied to a deposition tool such as Chemical Vapor Deposition (CVD) apparatus, and more particularly in such areas as Metalorganic Chemical Vapor Deposition (MOCVD) and Atomic Layer Deposition (ALD) applications, is disclosed. The method disclosed herein involves with increasing the temperature and the pressure of given liquid source materials to a high level of temperature and pressure states while maintaining the source materials in a liquid state, and then exposing the liquid source material instantaneously to a low pressure while maintaining the temperature of the liquid source material at the high temperature. Such sudden exposure to a low pressure makes the liquid source material vaporized, so that such vaporized source material can be supplied to such deposition tools as Metalorganic Chemical Vapor Deposition (MOCVD) and Atomic Layer Deposition (ALD) apparatus. The structure and the operation of the apparatus that vaporizes liquid source materials in accordance with the present invention are also disclosed.

Owner:ASM KOREA LTD

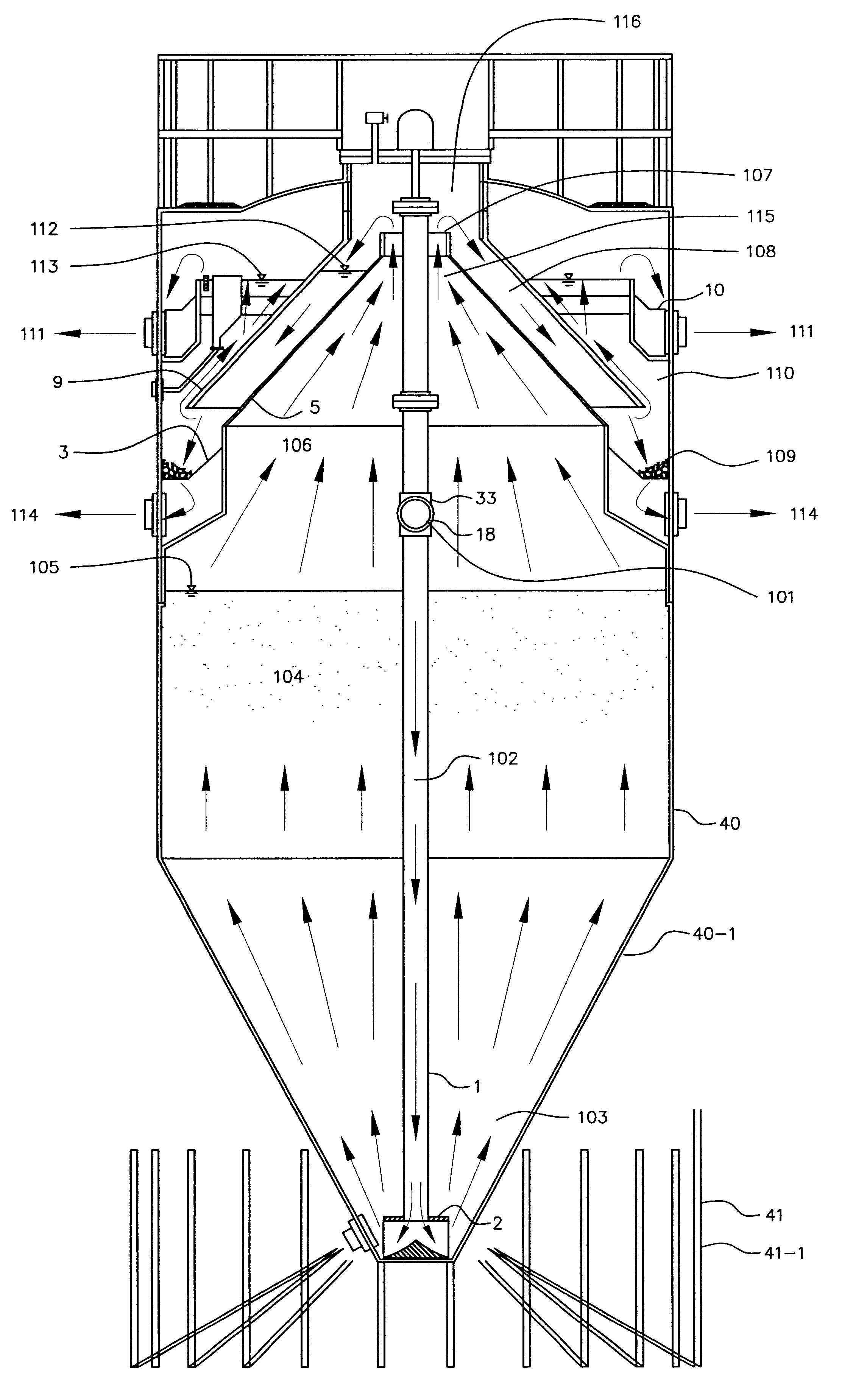

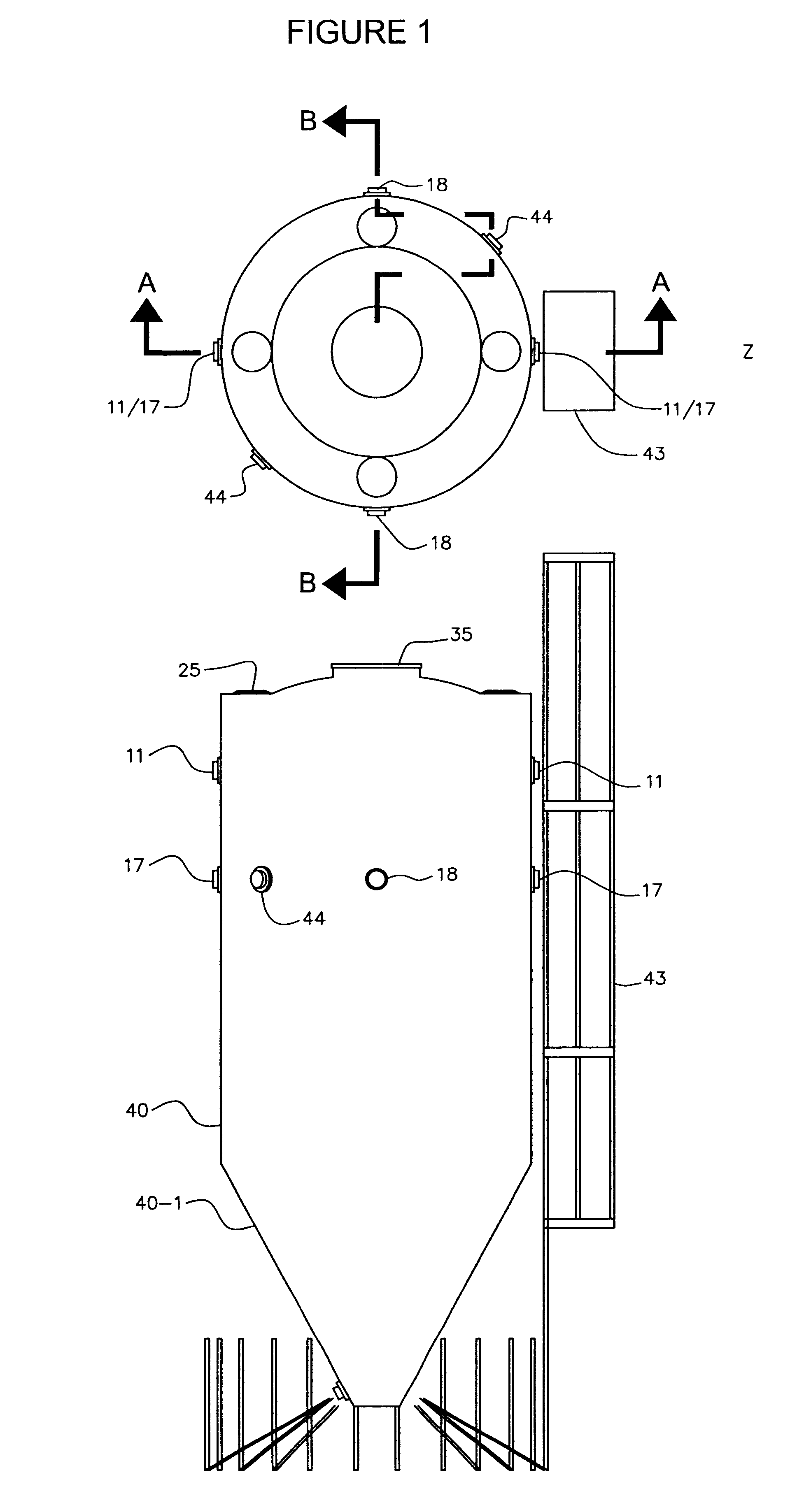

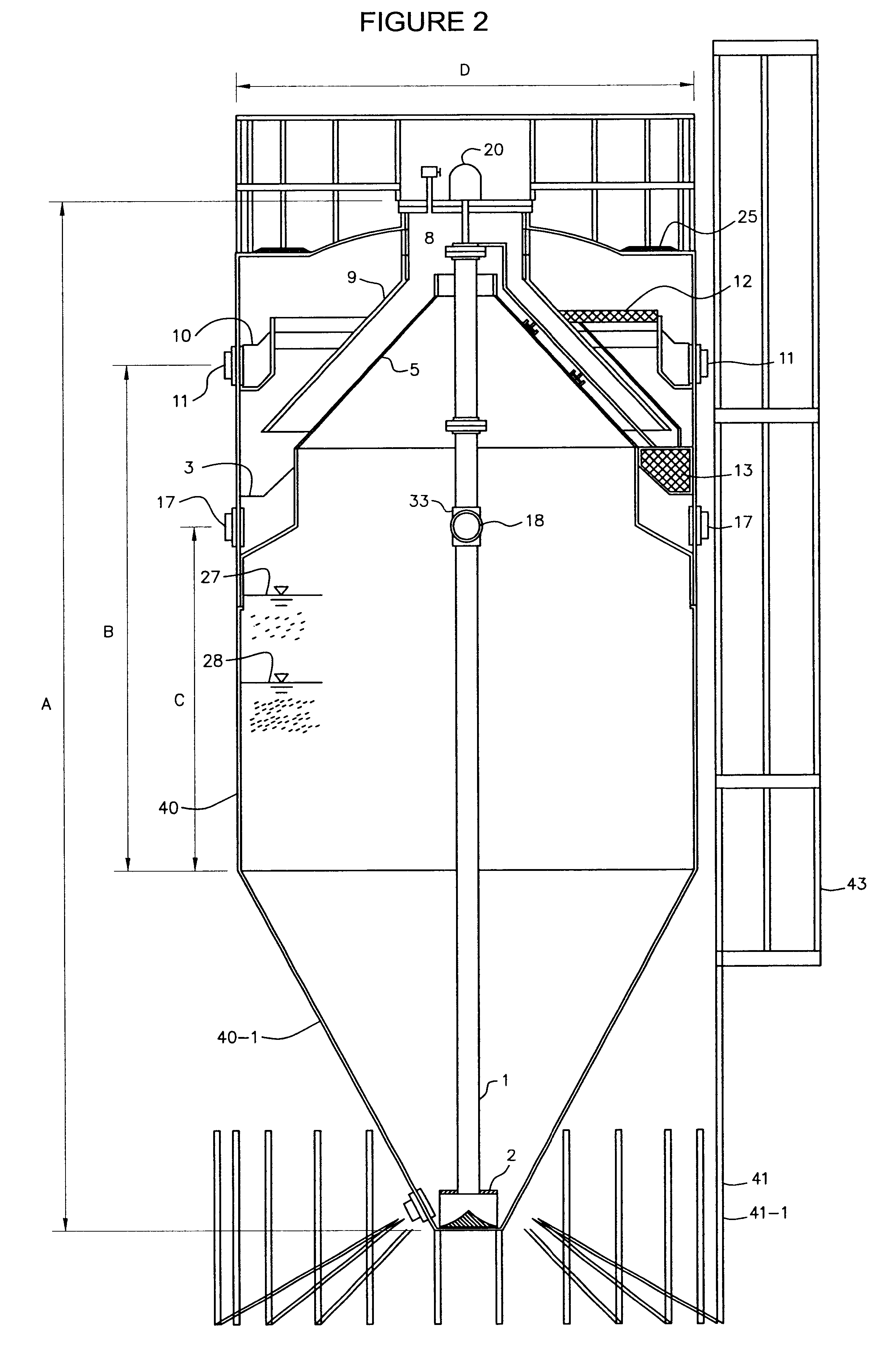

Biological fluidized bed apparatus

InactiveUS6531058B1High load rateImprove water qualityLiquid degasificationMultistage water/sewage treatmentFluidized bedBlanket

A pre-fabricated, self-contained biological fluidized bed apparatus for the treatment of wastewater, which offers easy and uniform expansion for various types of commercially available media, by means of a conical bottom and a single, non-clogging flow distribution pipe. Besides the biological treatment accomplished within the fluidized bed, this reactor provides mechanical solids / gas / liquid separation and upflow sludge blanket clarification to improve effluent quality. Additional unique features of this apparatus are a rotating surface skimmer and an excess sludge collection and thickening device powered by an externally mounted drive. With this reactor configuration, anaerobic and anoxic biological treatment and subsequent clarification are achieved in a single enclosed tank.

Owner:INT WASTE MANAGEMENT SYST

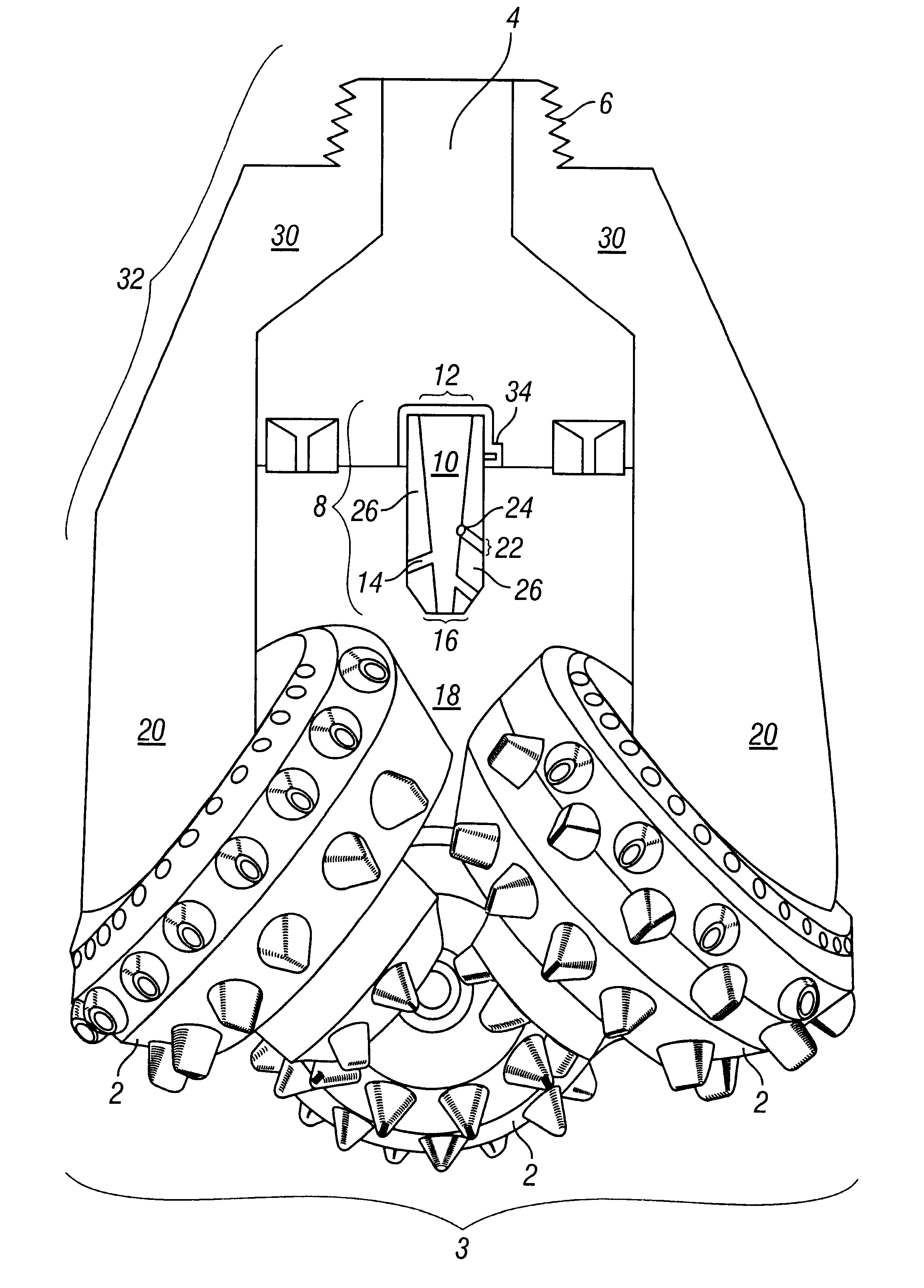

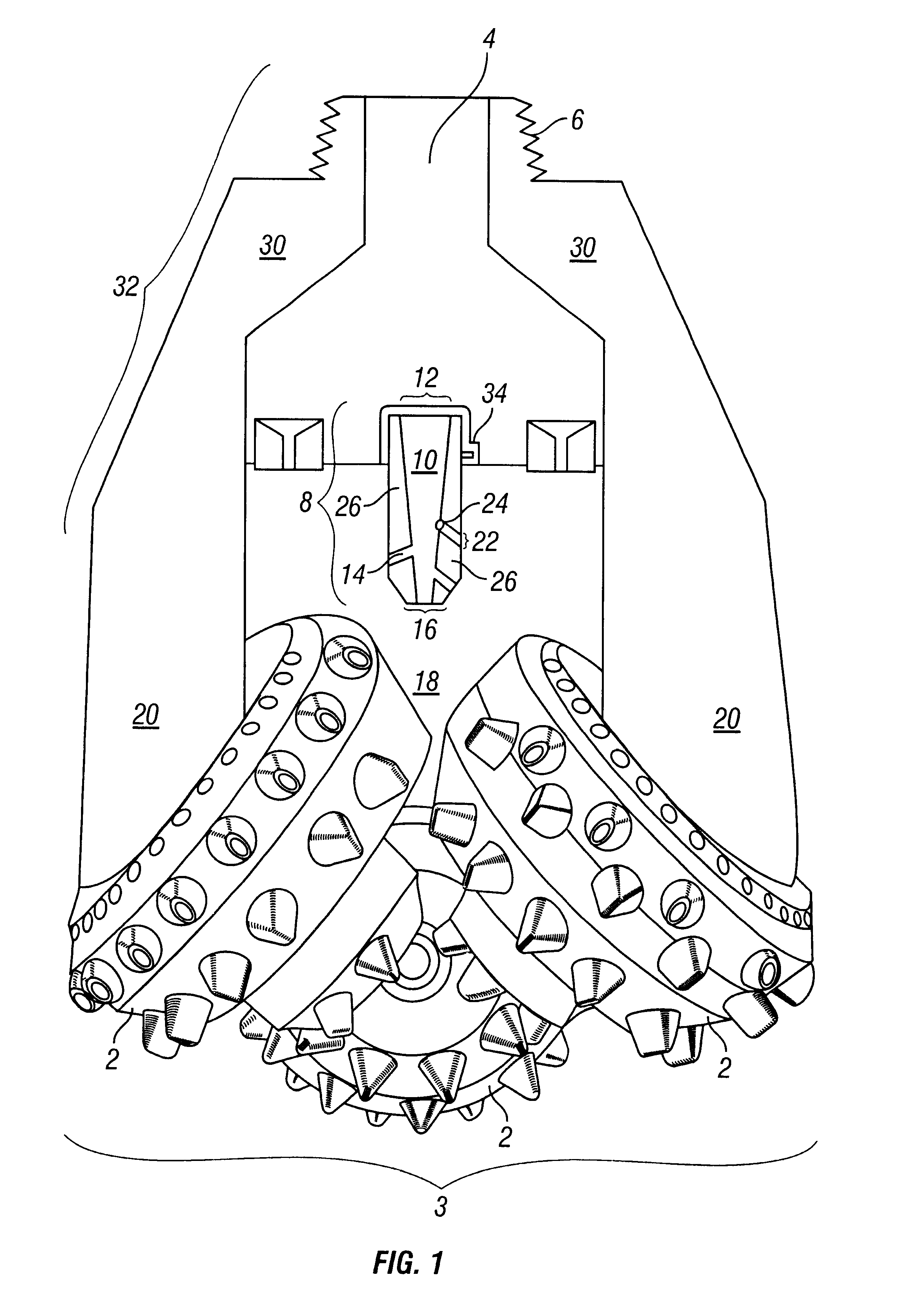

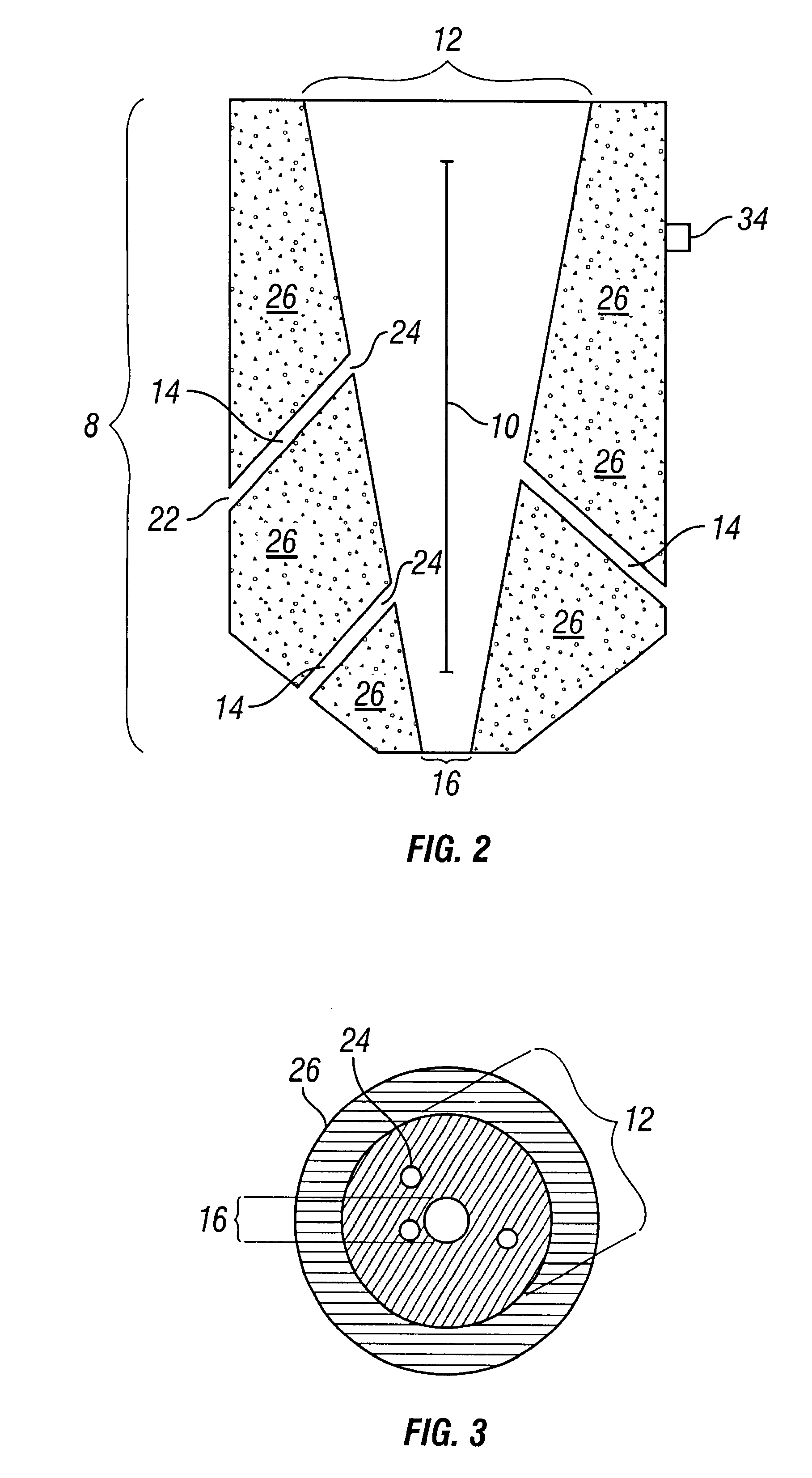

Three-cone rock bit with multi-ported non-plugging center jet nozzle and method

A three-cone rock bit employing a non-plugging center jet nozzle with a plurality of staggered inlet orifices leading to side passageways to reduce bit balling. The nozzle defines a tapered cavity through which drilling mud flows and exits in streams. Streams are directed from the nozzle through a main exit aperture of sufficient size to avoid plugging and from side passageways boring through a sidewall of the nozzle. Jetting streams promote washing of voids within the bit and of cutting surfaces. The nozzle uses staggered inlet orifices leading to side passageways, in conjunction with a tapering shape of a central passageway to facilitate maintenance of drilling mud velocity within the central passageway and thus of stream velocity to targeted regions of the drill bit.

Owner:DICKEY WINTON B

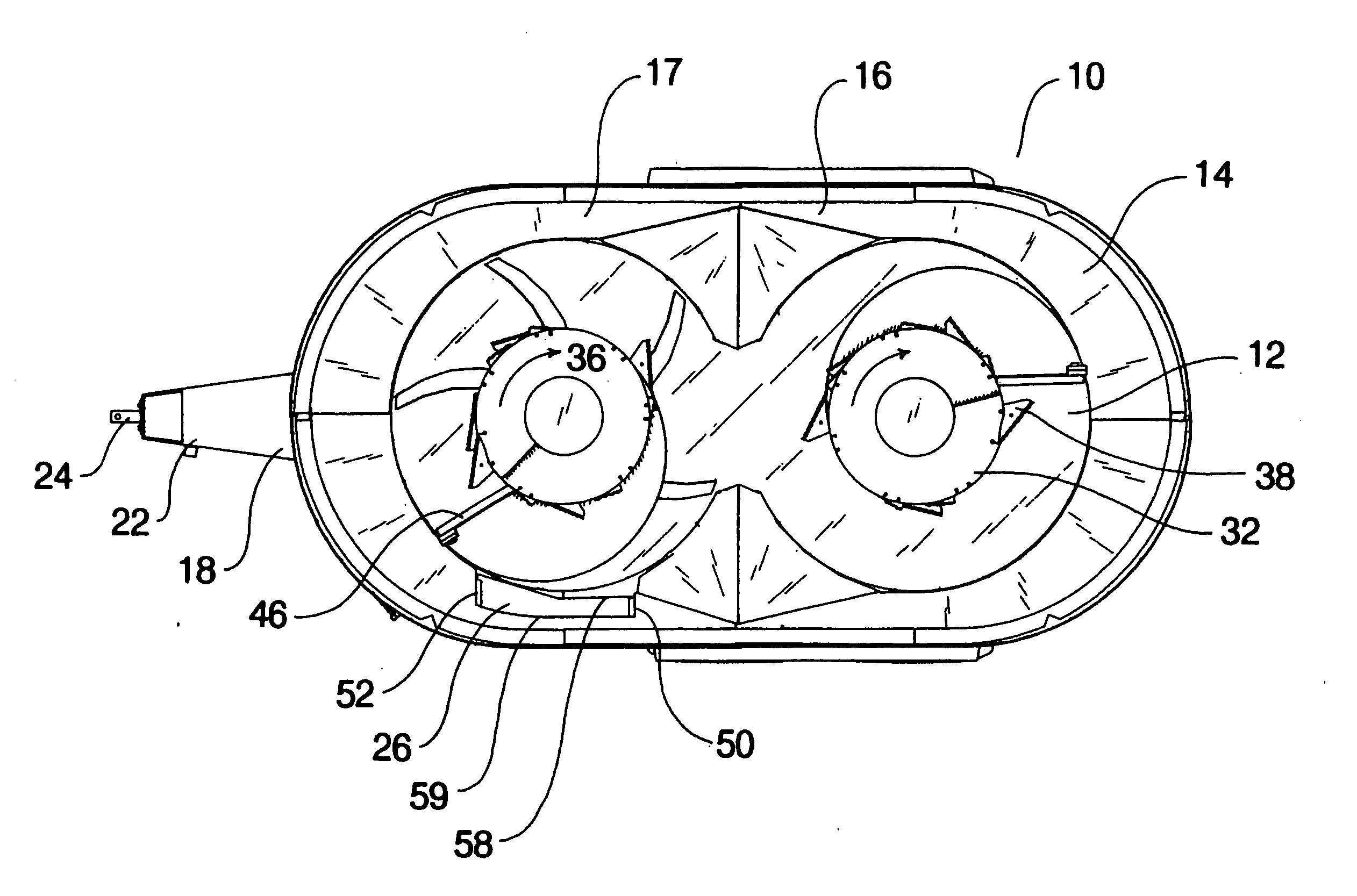

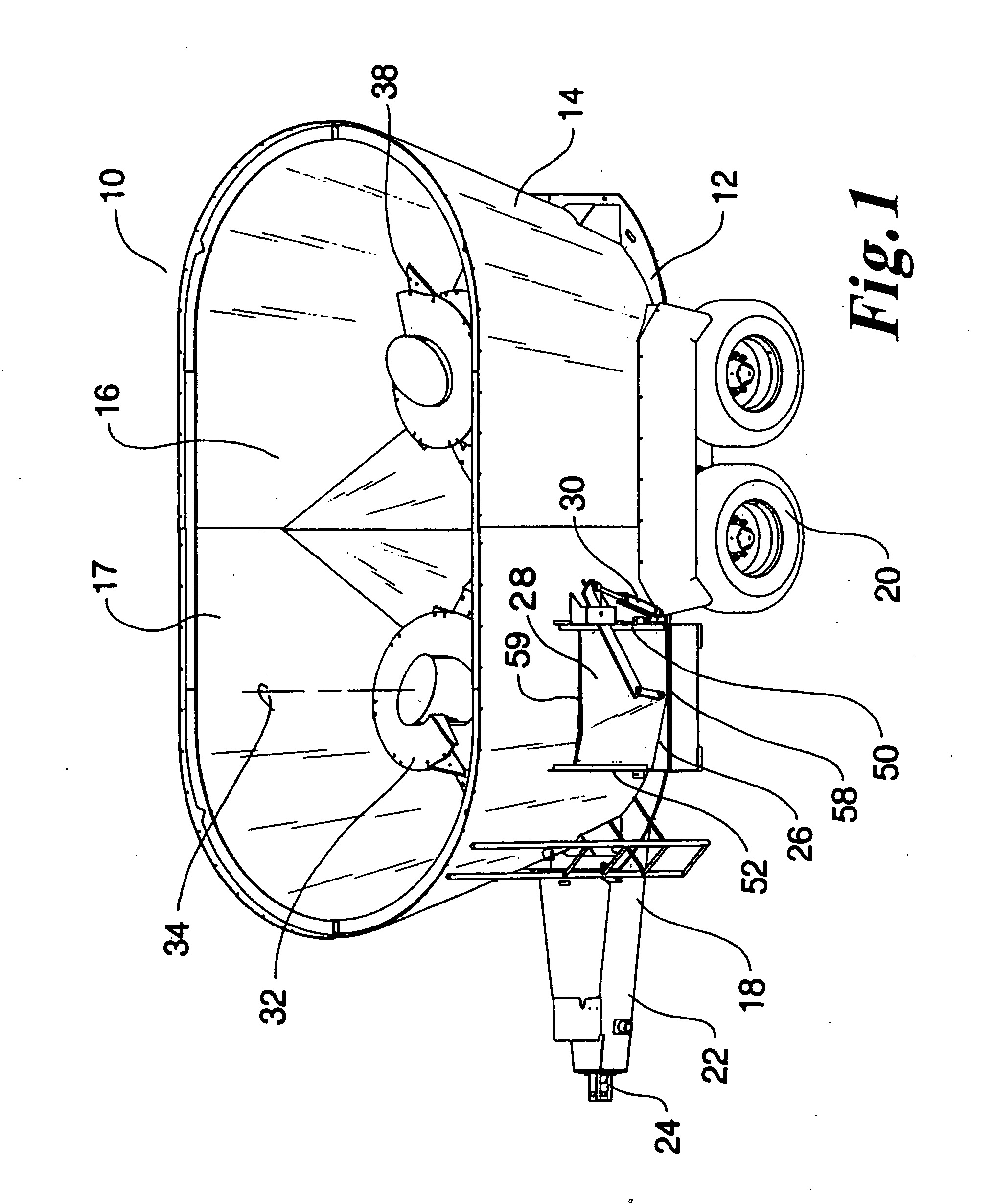

Swept kickers for vertical mixer augers

ActiveUS20070274151A1Enhanced interactionSpeed up the flowOther chemical processesTransportation and packagingEngineeringMechanical engineering

A vertical feed mixer apparatus has a container for the reception of feed. The container includes a floor, a wall extending away from the floor such that the wall is disposed above the floor. The wall has a top opening disposed remotely from the floor to define an enclosure for feed received through the top opening. The container has a discharge opening in the wall adjacent to the floor. There is at least one auger disposed within the enclosure. The auger includes an auger core with an axis of rotation extending substantially vertically through the floor. The auger has a helical flighting secured to and disposed around the auger core. The auger has at least one swept kicker secured to the auger core or flighting, disposed adjacent to the floor, and configured to discharge the feed through the discharge opening.

Owner:KUHN NORTH AMERICA

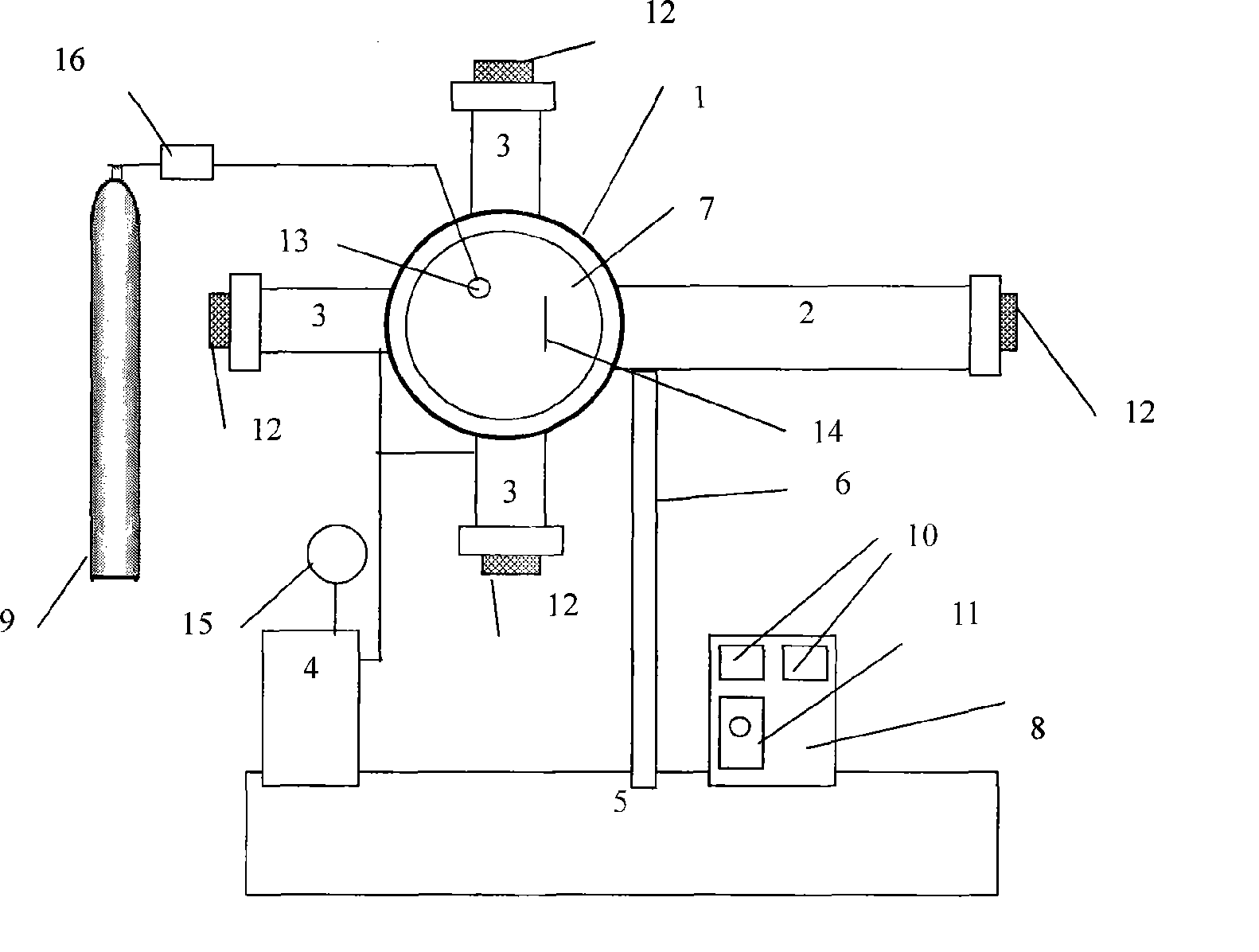

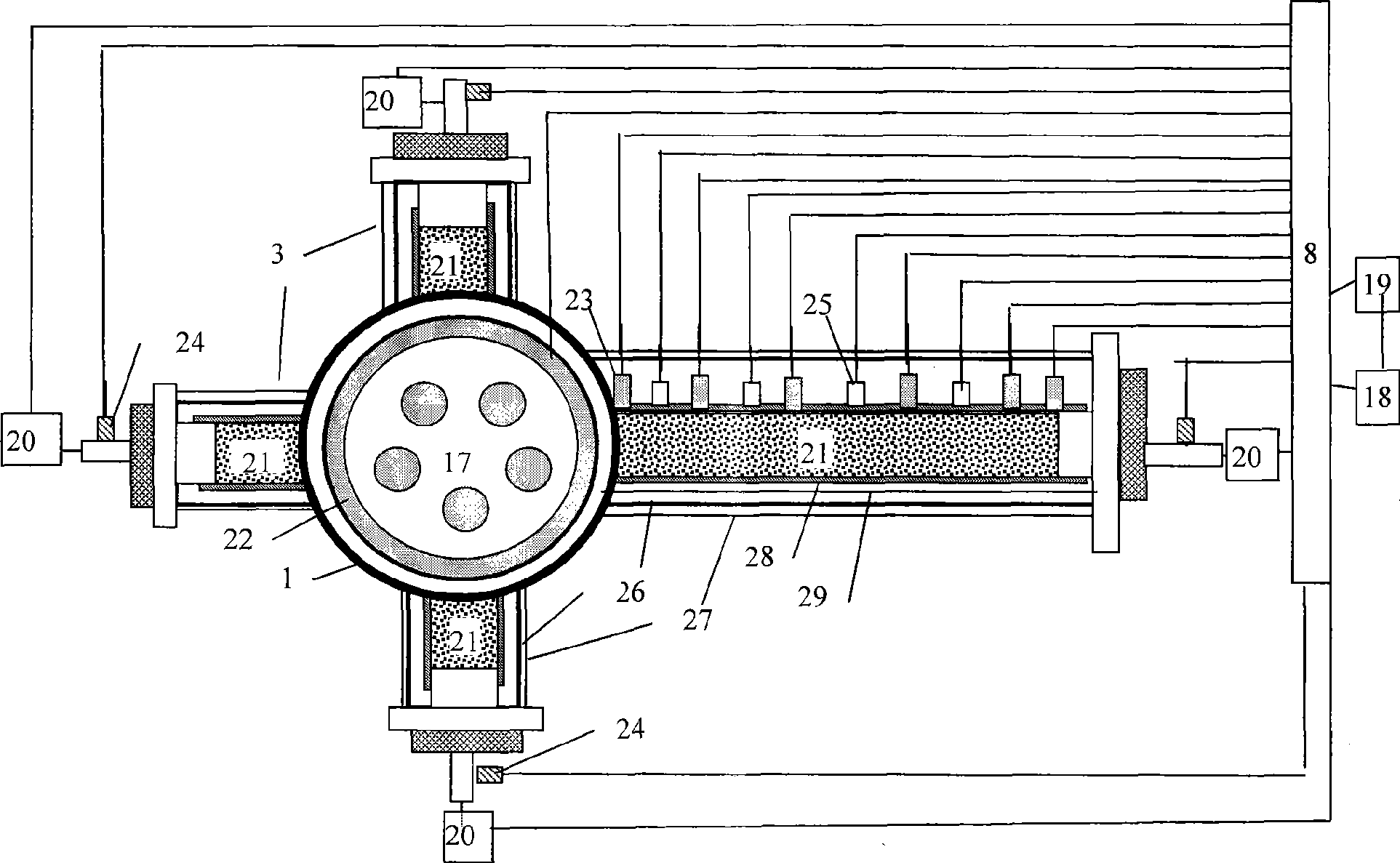

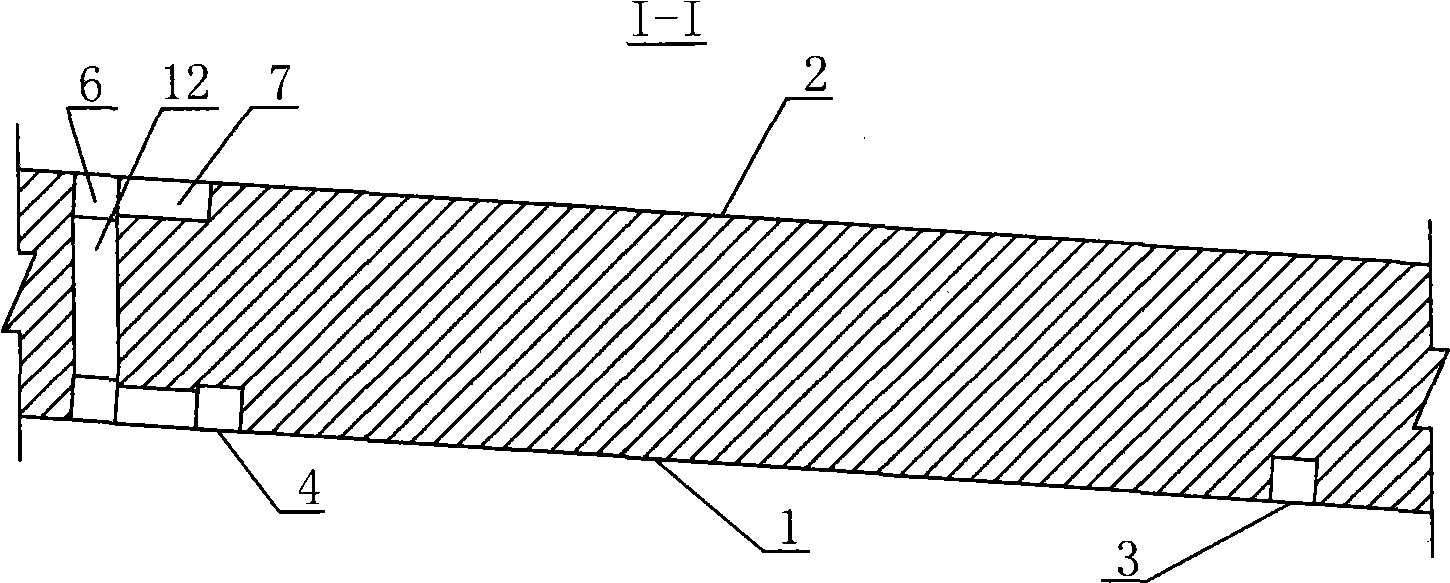

High-temperature high-pressure multifunctional horizontal well damage appraisement instrument

InactiveCN101482009AAddressing the effects of damageReduce dosageSurveyPermeability/surface area analysisWorking fluidMeasurement point

The invention relates to a high temperature and high pressure multi-functional horizontal well damage assessment instrument which mainly comprises a working fluid cycle kettle body, a long core gripper, three short core grippers, a confining pressure pump, a collection control box, and a bracket; the long core gripper and the short core grippers are connected together by the cycle kettle body and supported by the bracket with the angle of 90 degrees respectively and the axial lines on the same plane; the top part of the cycle kettle body has a pressurizing hole; the bottom part of the cycle kettle body has a fluid discharge port; the cycle kettle body has a magnetic rotor; the plunger of each gripper is hollow and is connected with a flowmeter; a rubber sleeve has an electrode, a pressure measurement point and an electrode measurement point, and the like; and the internal part of the collection control box has a temperature controller, a cycle motor controller and a data acquisition card. The invention has high automatic degree, can simulate the damage on the top part, side part and bottom part of the horizontal well body caused by the working fluid in the drilling process of the horizontal well under the temperature and pressure conditions, monitor the filtration loss process of the working fluid and the changing situations of the resistivity and pressure of the long core at different sections along with the time, and evaluate the damage degree and depth on different parts of the long core caused by the working fluid.

Owner:SOUTHWEST PETROLEUM UNIV

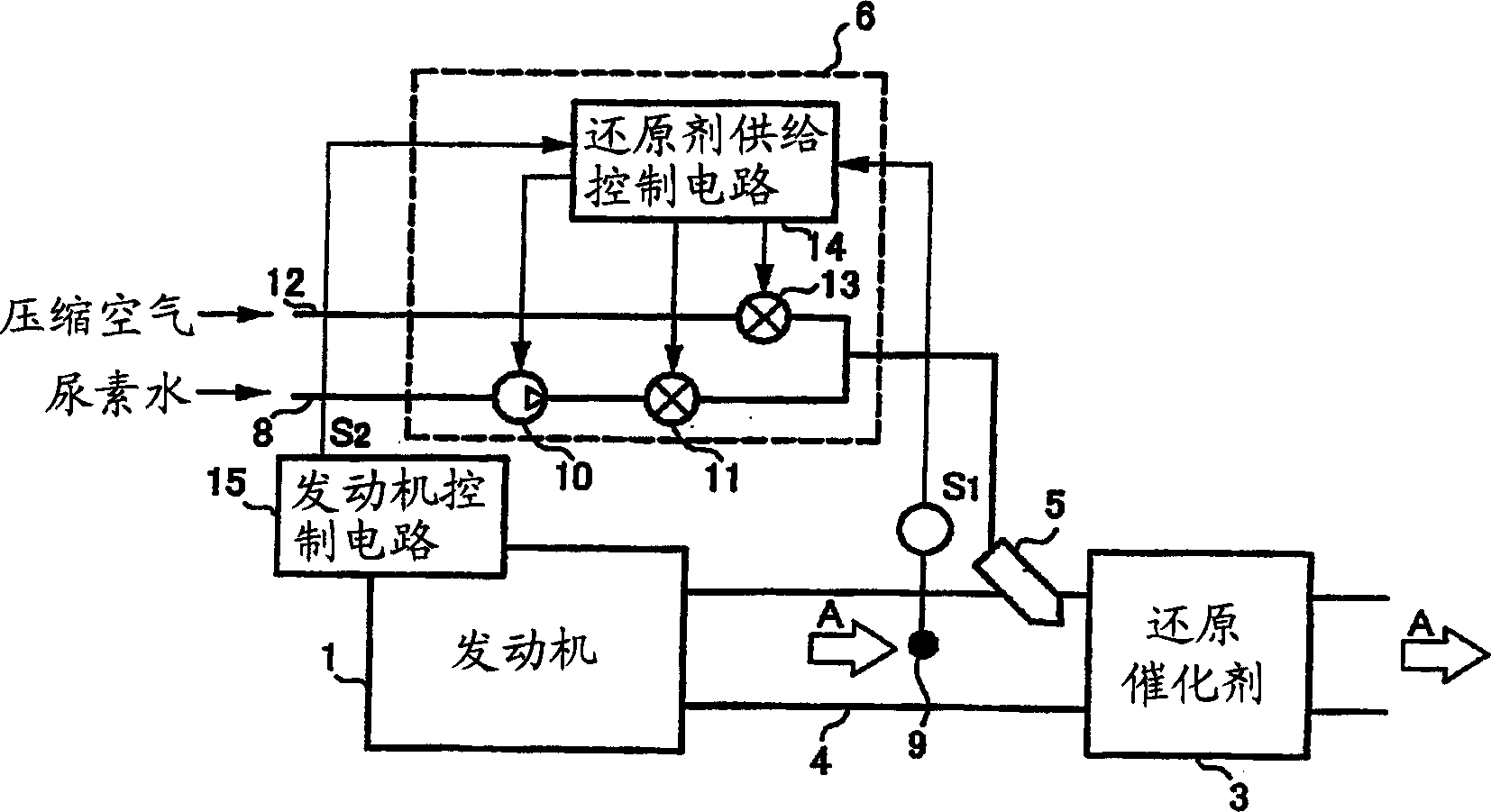

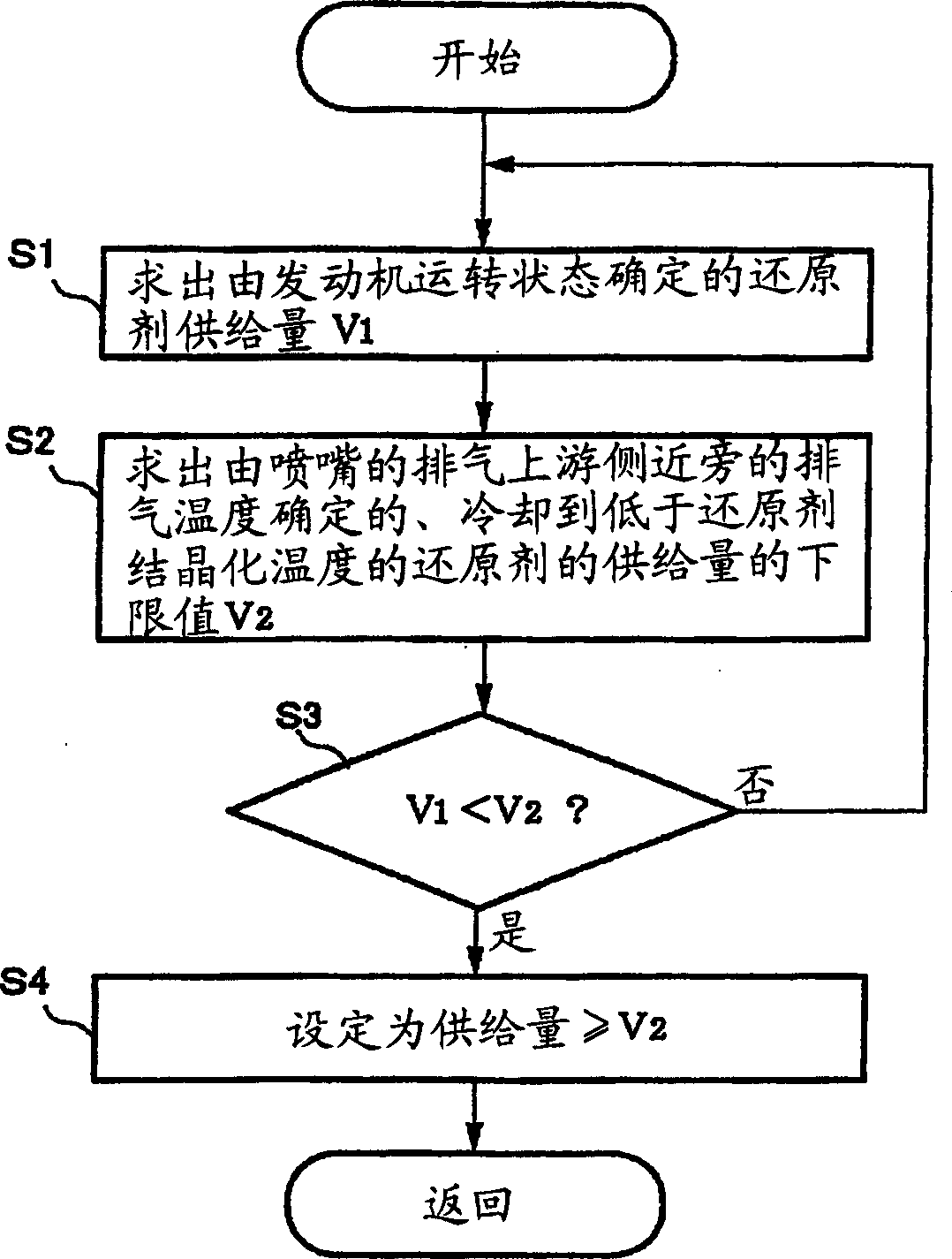

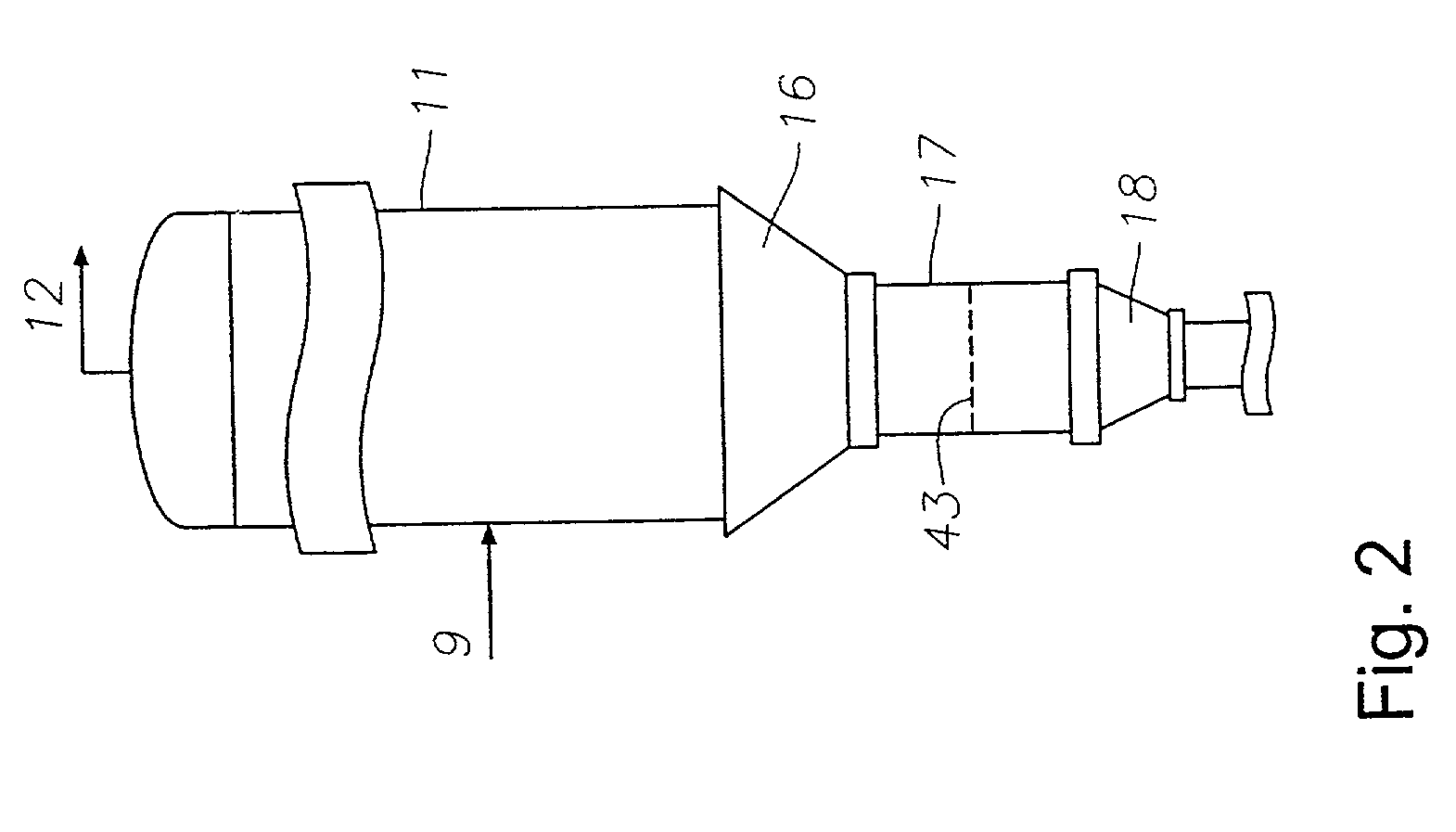

Exhaust gas cleaner for engine

ActiveCN1863987AAvoid cloggingImprove purification efficiencyInternal combustion piston enginesExhaust apparatusLower limitEnvironmental engineering

An exhaust gas cleaner of an engine in which cleaning efficiency of Nox is enhanced by preventing clogging of an injection nozzle for supplying a reducing agent to the upstream side of exhaust gas of a reducing catalyst. Using a detection signal S1 of the exhaust gas temperature from an exhaust gas temperature sensor (9), a reducing agent supply unit (6) sets a supply quantity larger than a lower limit of the supply quantity for cooling the inside of an injection nozzle (5) at a temperature below the crystallizing point of urine water and supplies the set supply quantity of urine water to the injection nozzle (5) at the detected exhaust gas temperature. Consequently, the inside of the injection nozzle (5) is cooled at a temperature below the crystallizing point of urine water. Since urine water is not crystallizing in the injection nozzle (5), the injection nozzle (5) can be prevented from clogging and the cleaning efficiency of Nox can be enhanced.

Owner:VOLVO LASTVAGNAR AB

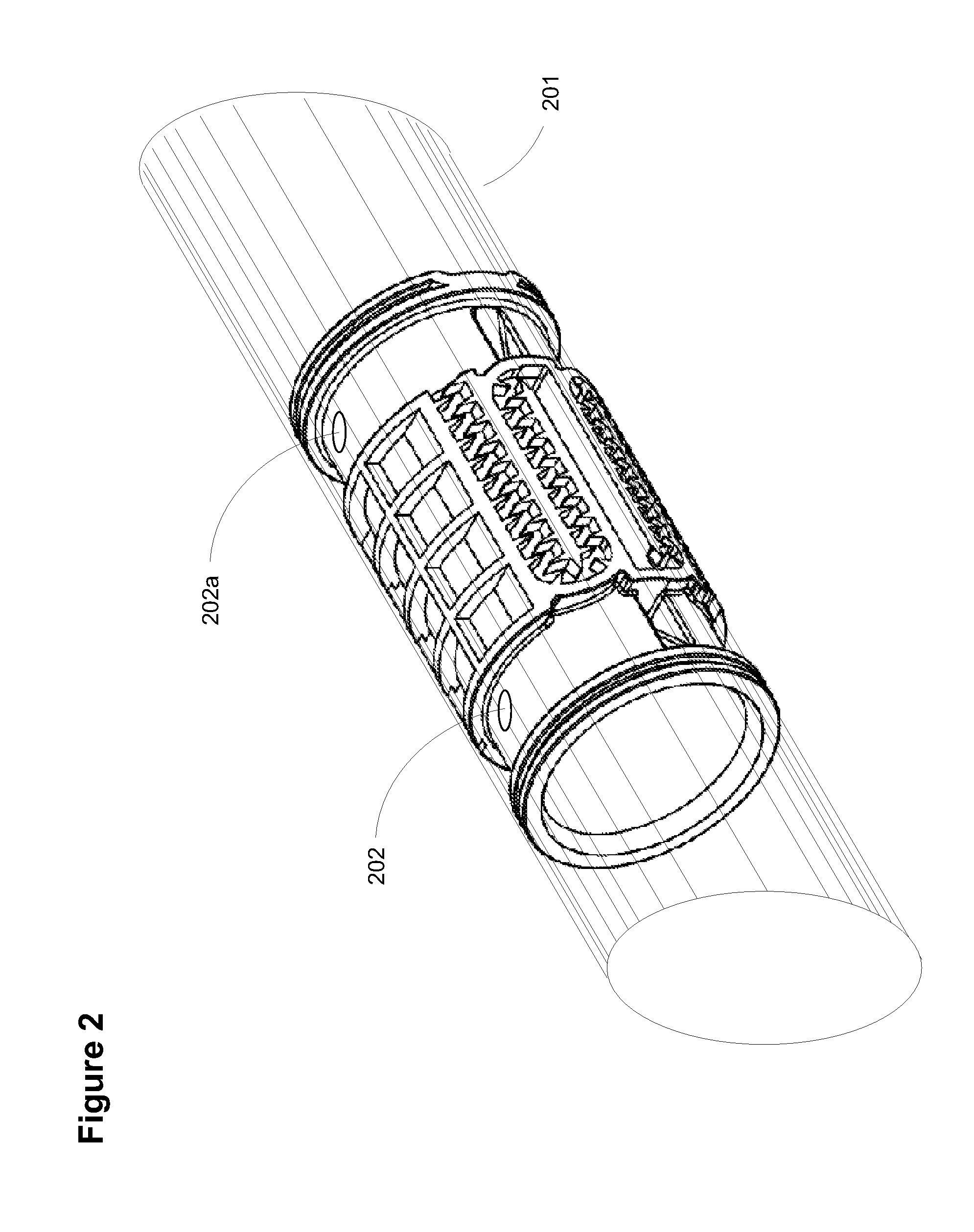

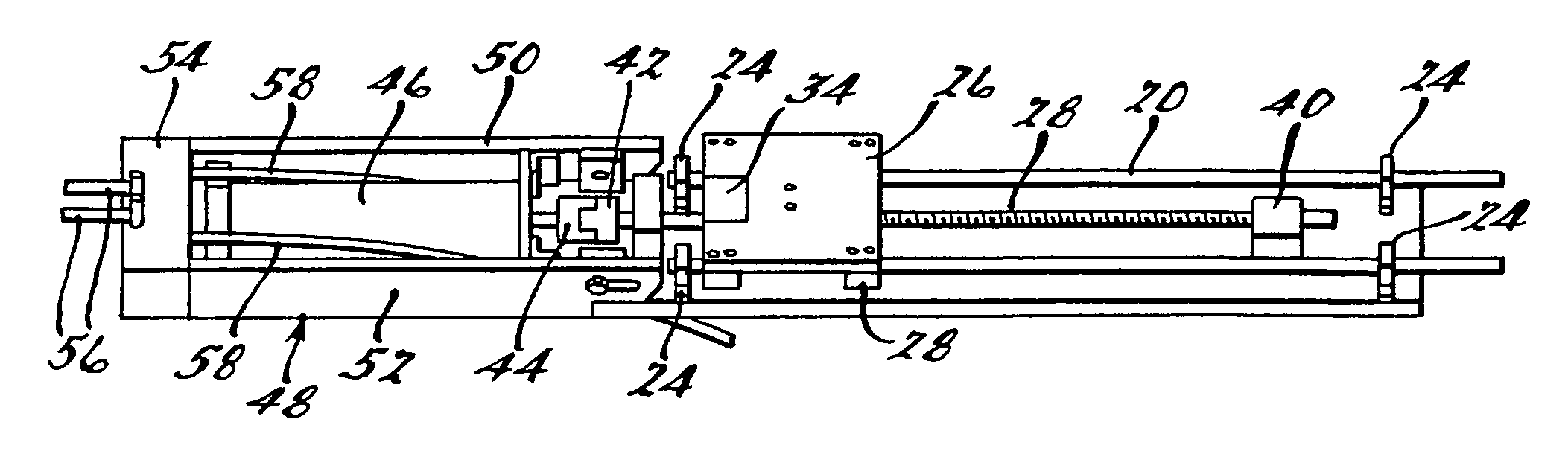

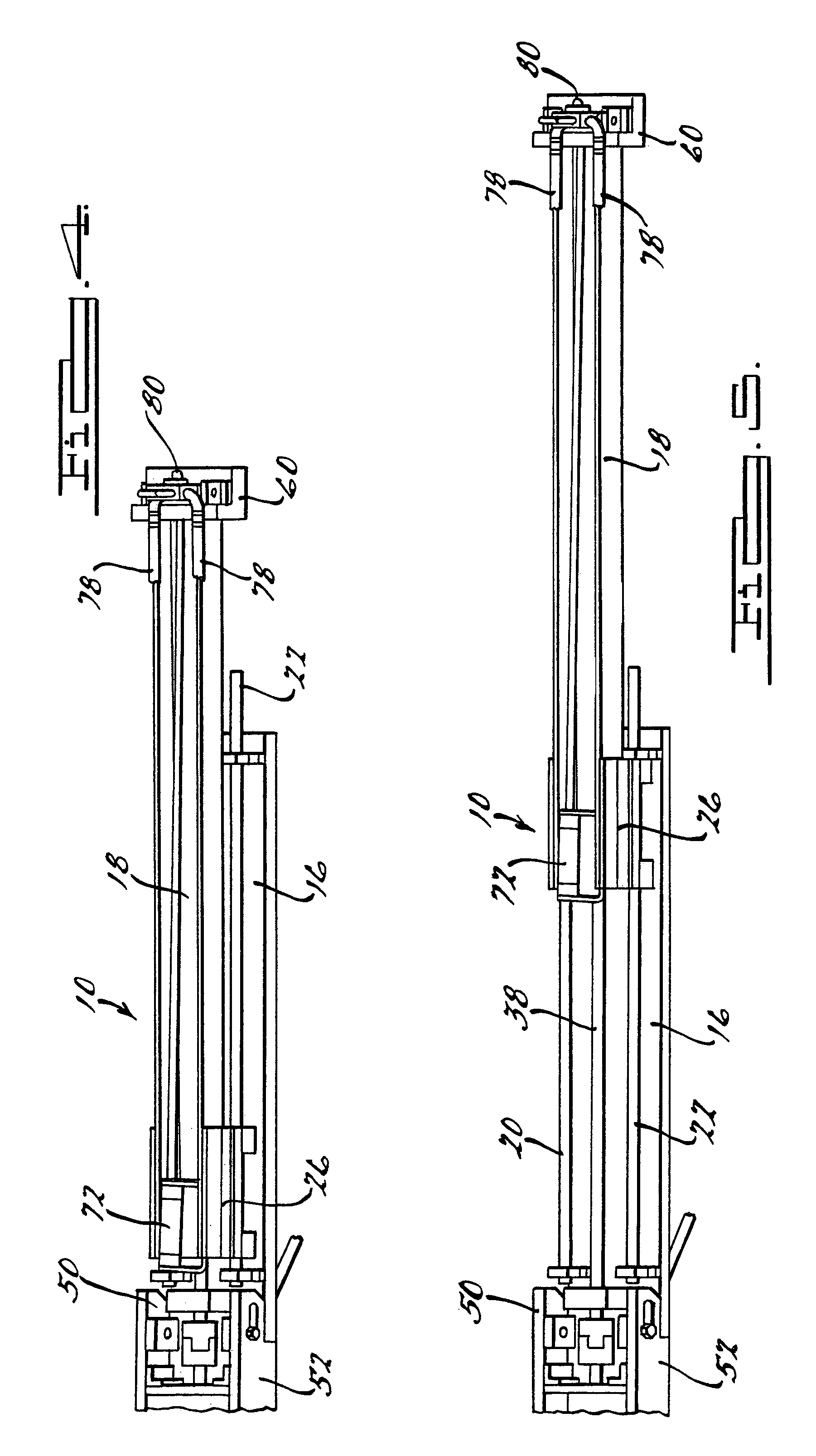

Sprayed in place pipe lining apparatus and method thereof

InactiveUS6986813B2Simple methodShorten speedLiquid surface applicatorsMovable spraying apparatusSpray coatingMotor module

Owner:THE HANSON GROUP

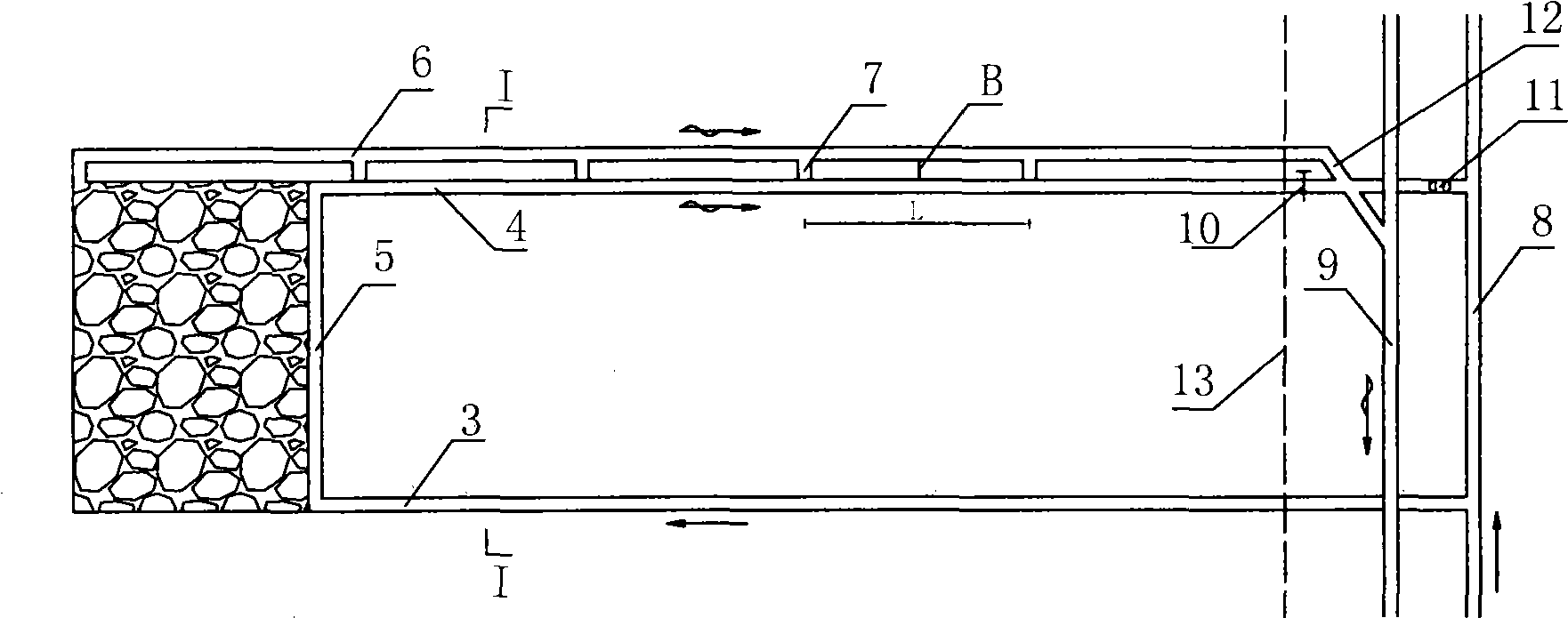

U+I type ventilating system for top-coal caving face

InactiveCN101498225AEfficient dischargeEliminate buildupUnderground miningSurface miningSpelunkingCoal dust

The invention provides a U+I type ventilation system for a work surface of top coal caving, which is an improvement of the arrangement of the U type, the U+L type and the E type or B type laneways and the ventilation systems in the prior art. An air intake way and an air return way of the work surface of top coal caving are arranged along a bottom board of a coal bed, and a regulation air door is arranged on the part of the air return way close to a big air return lane to control the reasonable ventilating parameter of the U+I type ventilating system. The invention is mainly characterized in that air exhausting lanes of top boards are arranged in parallel along the air return way with the parallel outward-staggered distance of 0 m to 5 m from the air return way to form the U+I type ventilating system of a one-intake and two-return mode. The invention fundamentally solves the problem of the accumulation of gas and coal dust on the upper section, the upper spatial angle and the gob area of the work surface of top coal caving, in particular the problem of the accumulation of the gas and the coal dust of the upper space of the upper gob area, provides a safe and high-effect ventilating system, and creates an excellent mechanical environment for realizing the exploitation of the top coal caving of small coal pillars and increasing the recovery rate of coal.

Owner:TAIYUAN UNIV OF TECH

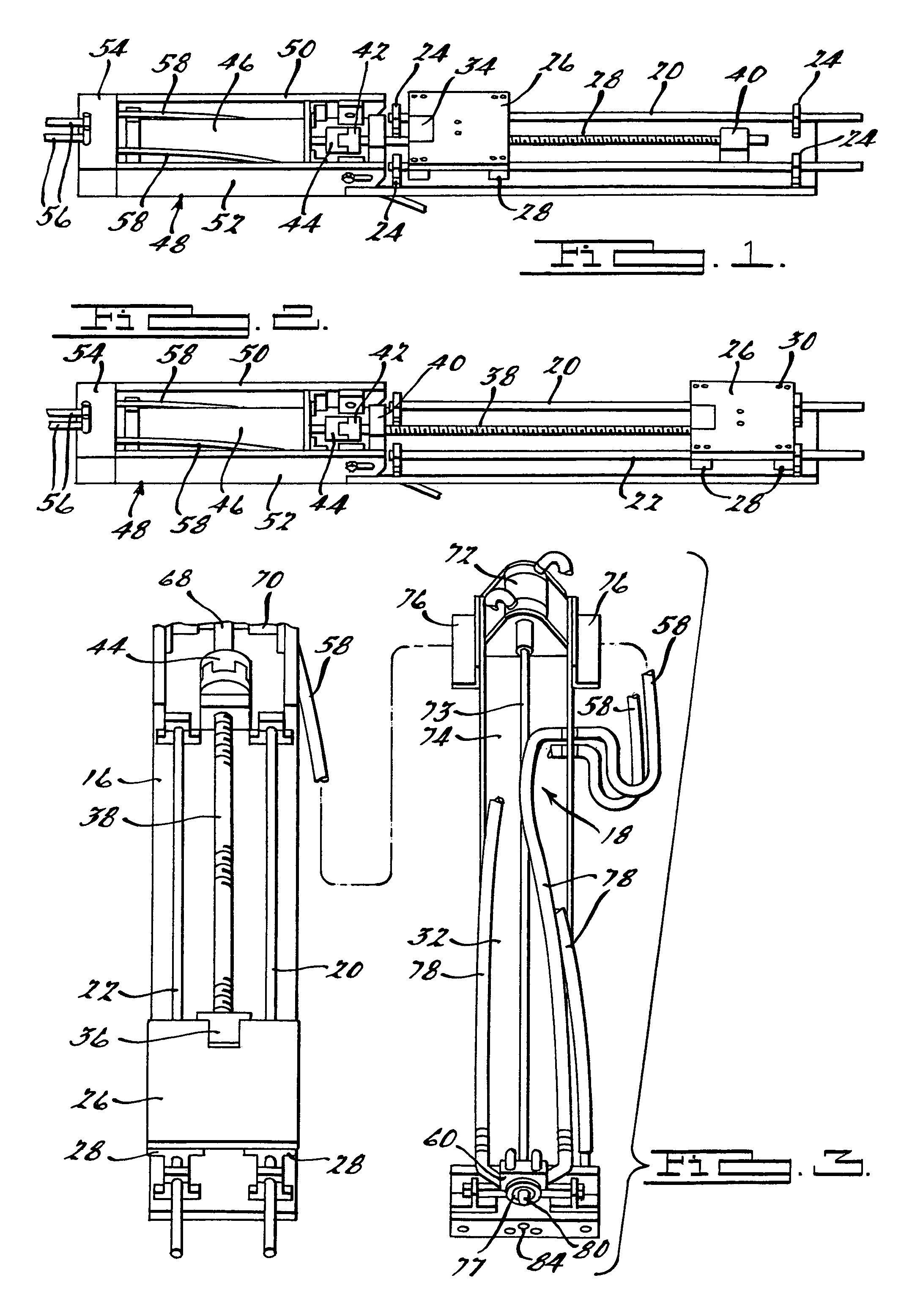

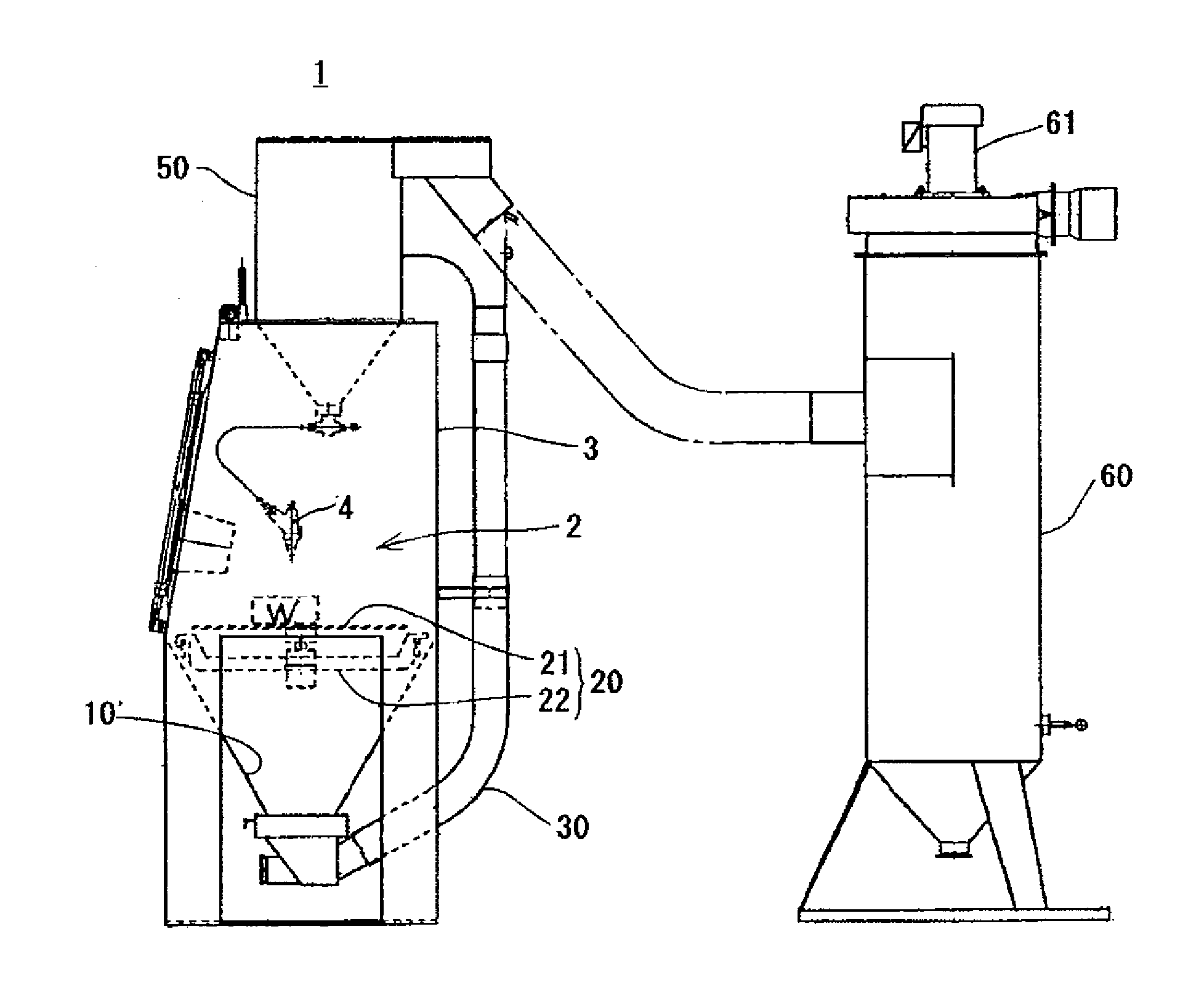

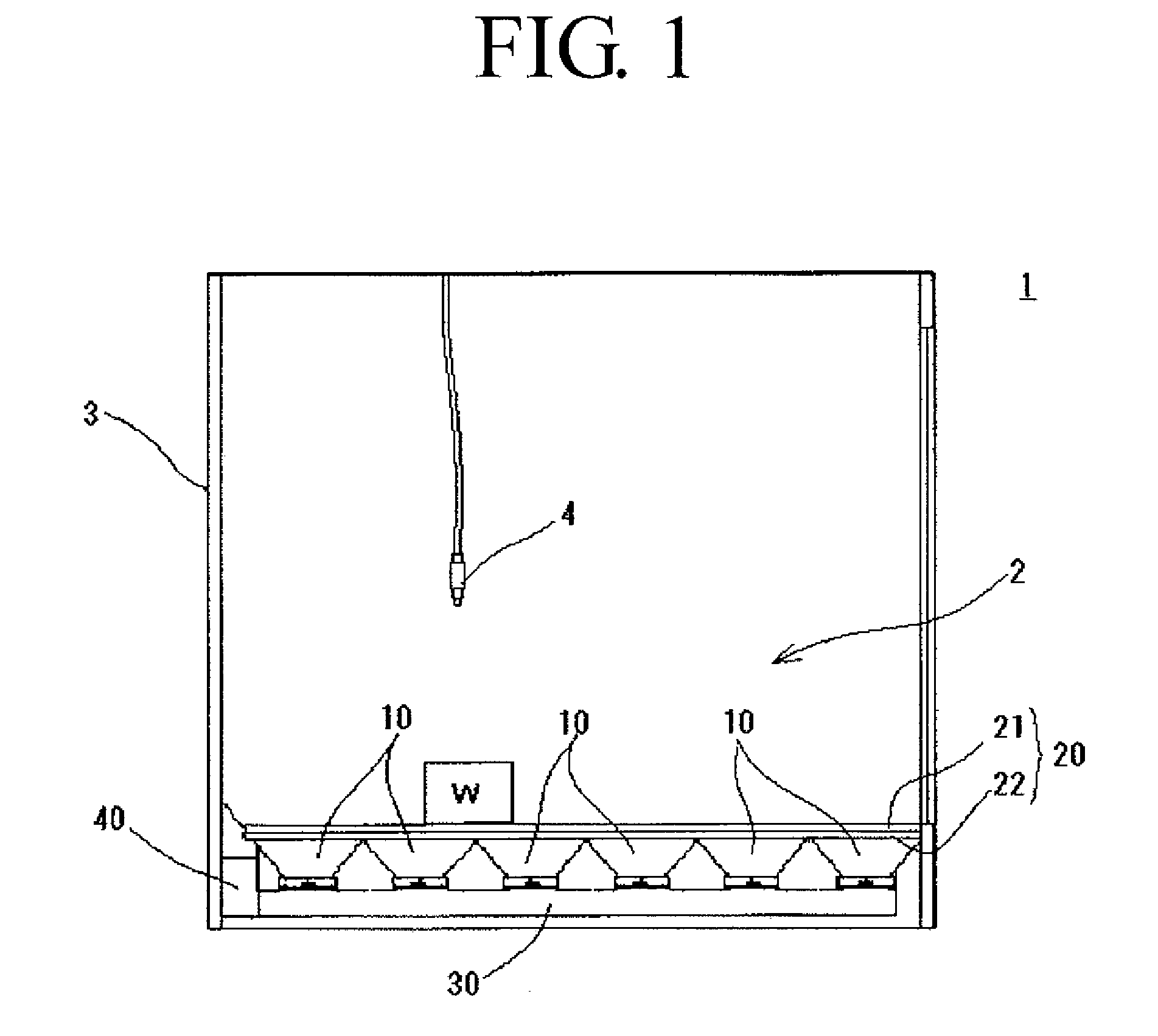

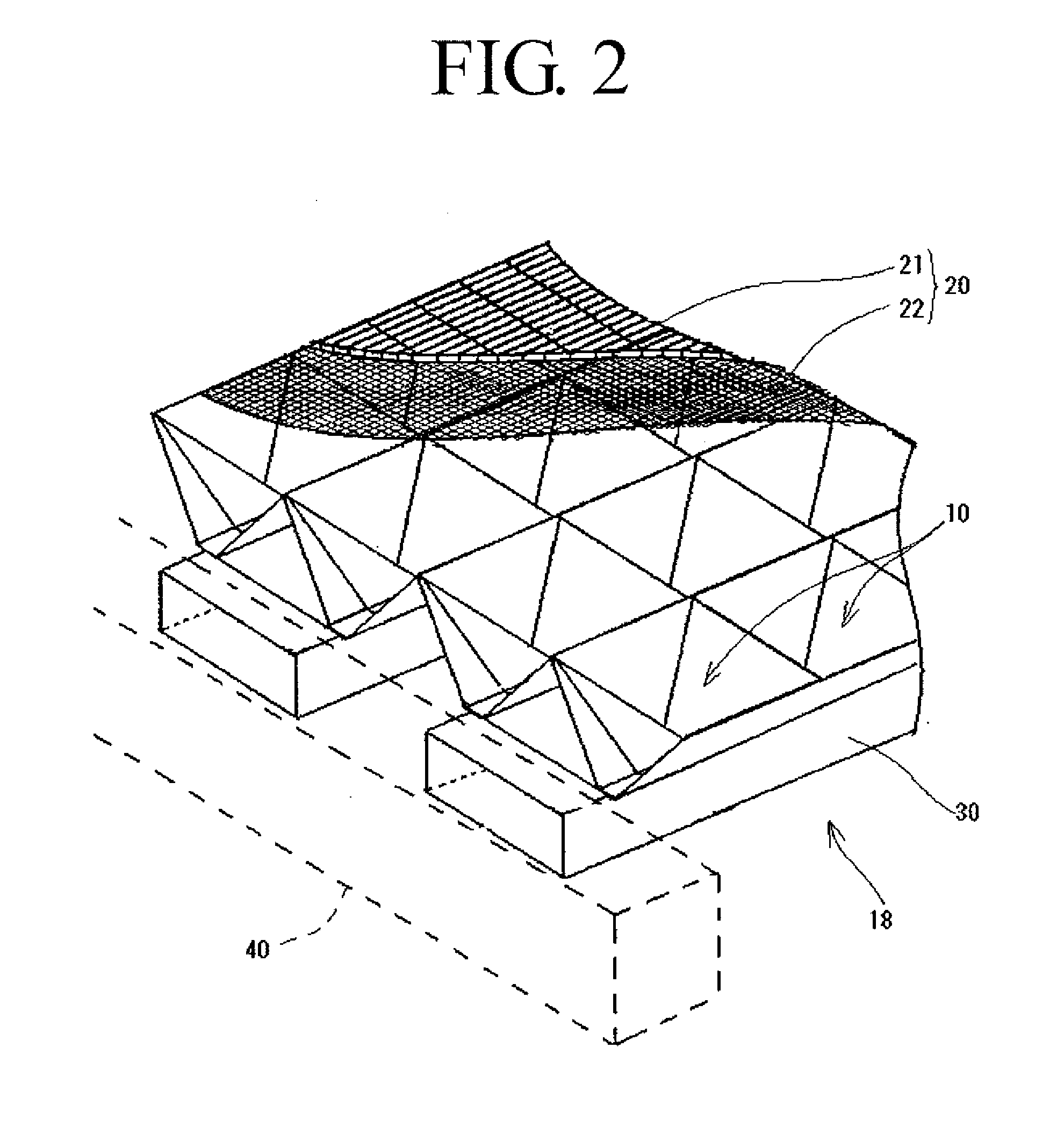

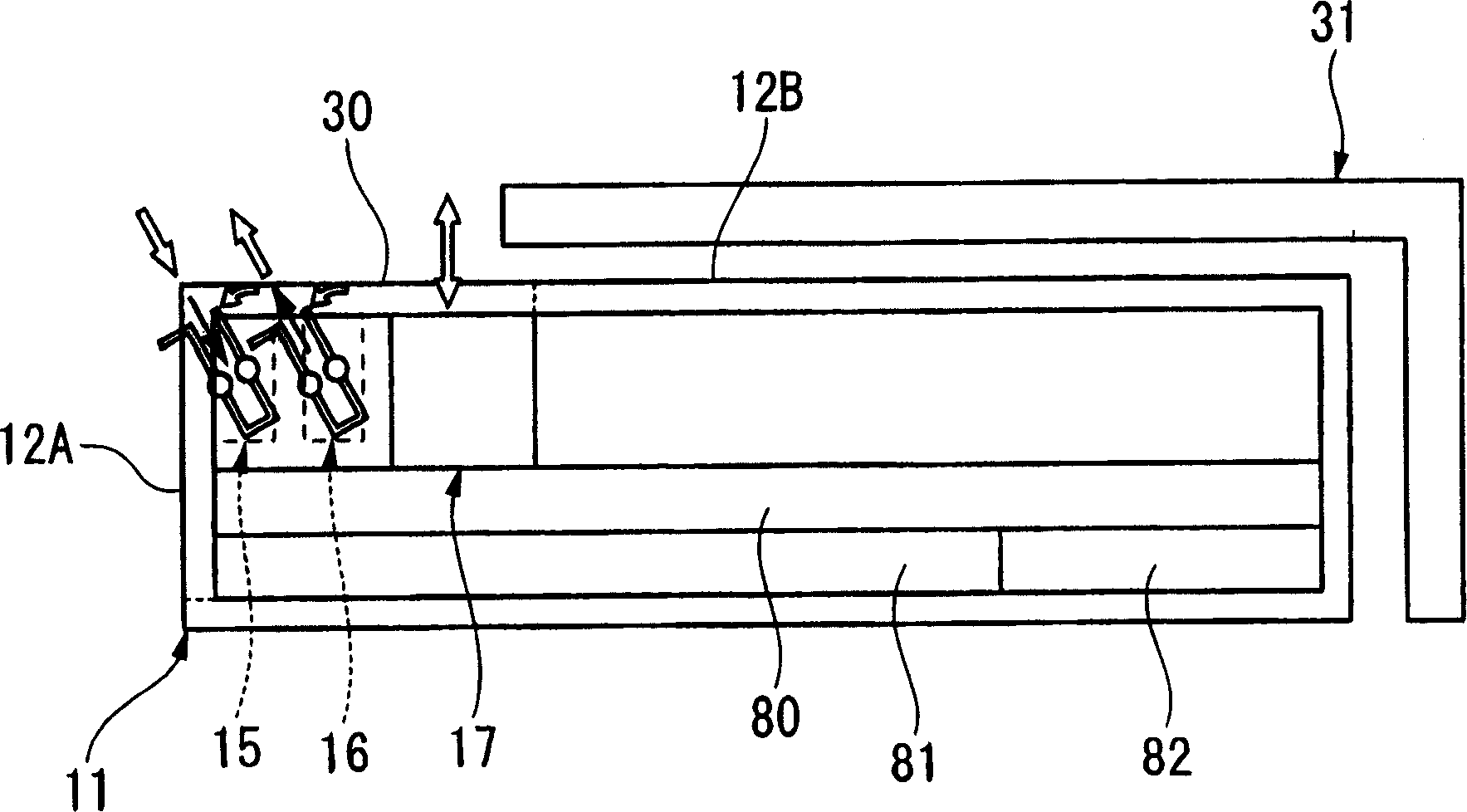

Abrasive-recovery mechanism in blasting machine

ActiveUS20090098810A1Eliminate cloggingSmall sizeAbrasive machine appurtenancesEngineeringMechanical engineering

A bottom wall surface of a blasting chamber of a blasting machine provided with hoppers for recovering an abrasive is formed at a lowest possible position. A cabinet 3 of a blasting machine 1 is compartmentalized at a predetermined position into an upper space and a lower space by mesh members (21, 22) that allow the abrasive to pass therethrough to form a blasting chamber 2 having a bottom wall surface 20 defined by the mesh members (21, 22). Hoppers 10 substantially shaped like an inverted quadrangular pyramid are disposed below the mesh members (21, 22) such that top portions of the hoppers 10 are opened toward the mesh members (21, 22) and that the bottom end of each of the hoppers 10 is made to communicate with suction means, such as a dust collector, through a recovery pipe 30.

Owner:FUJI MFG CO LTD

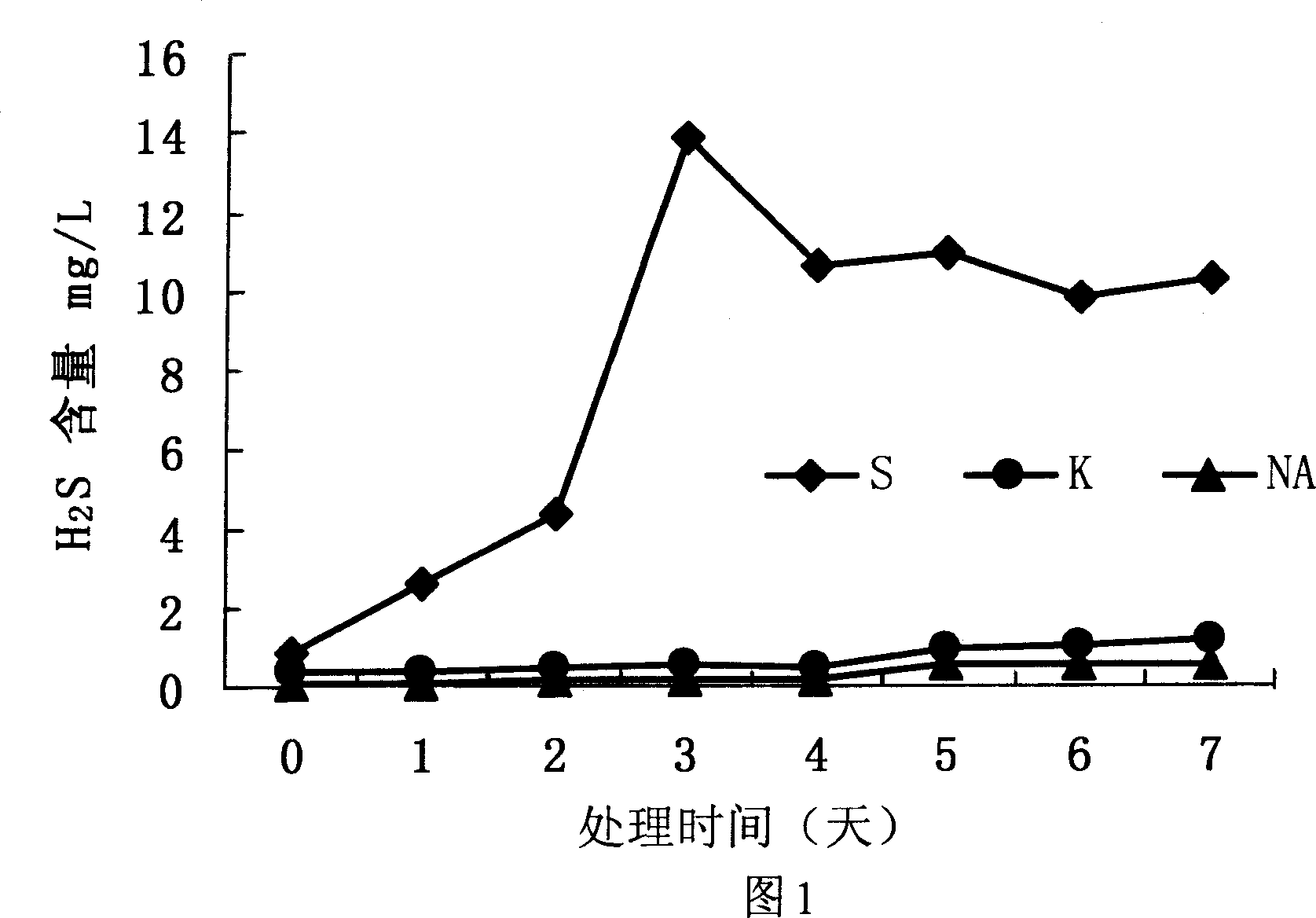

Microorganism for controlling harm of oil field sulfate reductive bacterium and application thereof

InactiveCN1920004AReduce corrosion costsEliminate pollutionBacteriaBiological water/sewage treatmentMetaboliteDenitrifying bacteria

The invention relates the microorganism agent used to control oil field sulfate-reducing bacteria and its application. The invention can used to control oil field secondary depletion sulfate-reducing bacteria and microorganism. The water outlet system of secondary depletion technology comprises sulfate-reducing bacteria, H2S and sulphide, which can cause corrosion and pollution of sulphide. Microorganism agent comprises denitrifying bacteria culture, nutrescin and synergic nutrescin. 0.01-1wt% denitrifying bacteria culture, 5-100g / L culture and 10-200ppm synergic nutrescin. Microorganism agent can avoid SRB growing, SRB producing H2S, and removing sulphide. At the same time, metabolite can improve recovery efficiency.

Owner:SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI

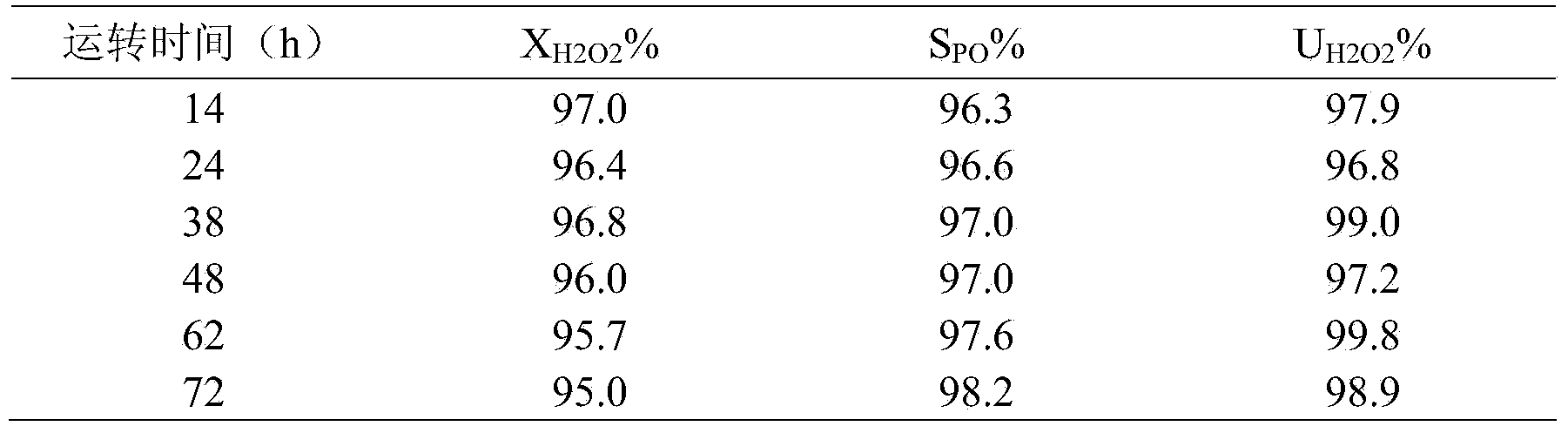

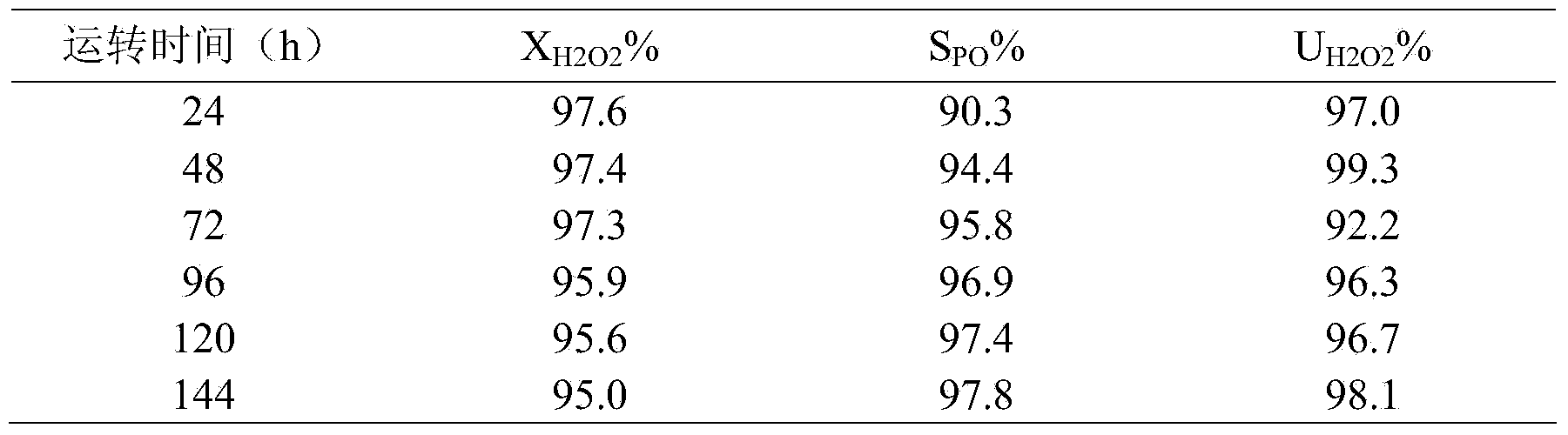

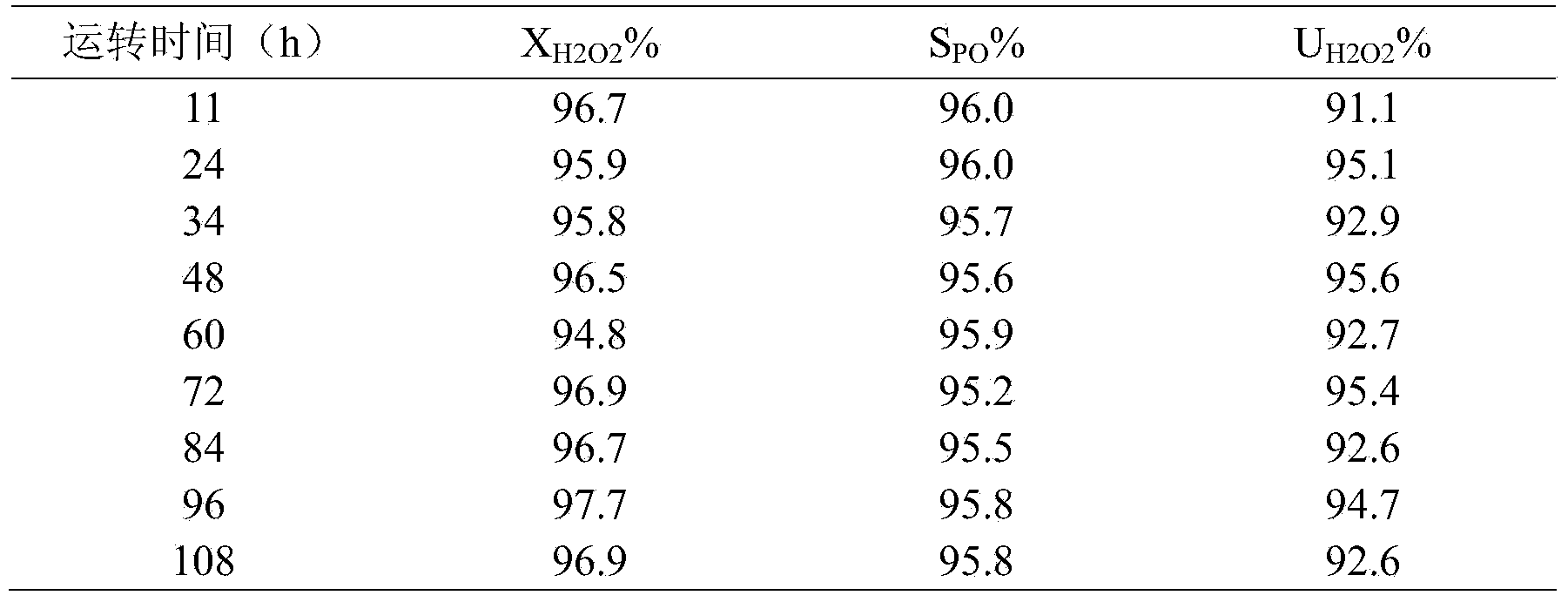

Propylene epoxidation catalyst, as well as preparation method and application thereof

ActiveCN103464197AHigh activityImprove stabilityOrganic chemistryMolecular sieve catalystsMolecular sievePolymer science

The invention provides a preparation method of a propylene epoxidation catalyst. The propylene epoxidation catalyst with high activity and high stability is prepared by the following steps: adding a pore-forming agent, a binding agent and a lubricating agent into raw materials comprising a titanium silicon molecular sieve and an inorganic oxide; mixing, kneading and forming to obtain a forming body; drying and roasting the forming body; treating the roasted forming body by adding an alkaline solution; and filtering, drying and roasting to obtain the high-activity and stable propylene epoxidation catalyst. The propylene epoxidation catalyst prepared by the preparation method has excellent mechanical strength and excellent diffusibility and can be directly applied to a fixed bed reactor. Experiments prove that the catalyst prepared by the preparation method has excellent catalytic activity, excellent product selectivity and long catalytic life when being applied to propylene epoxidation reaction.

Owner:DALIAN UNIV OF TECH

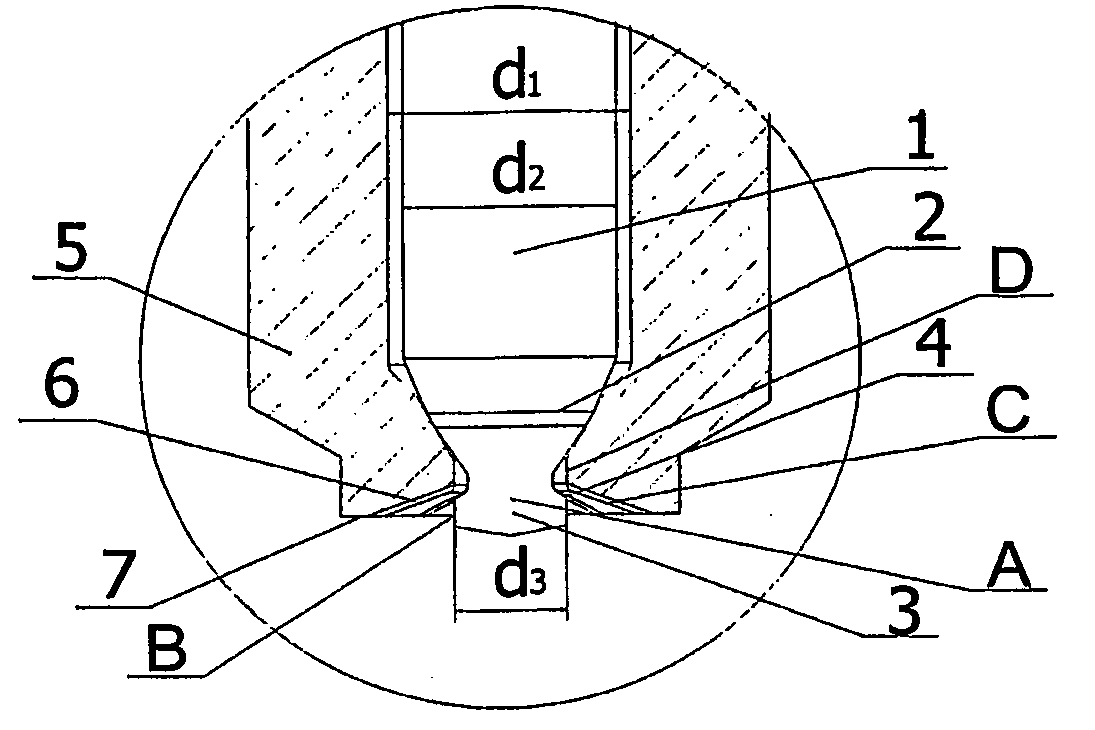

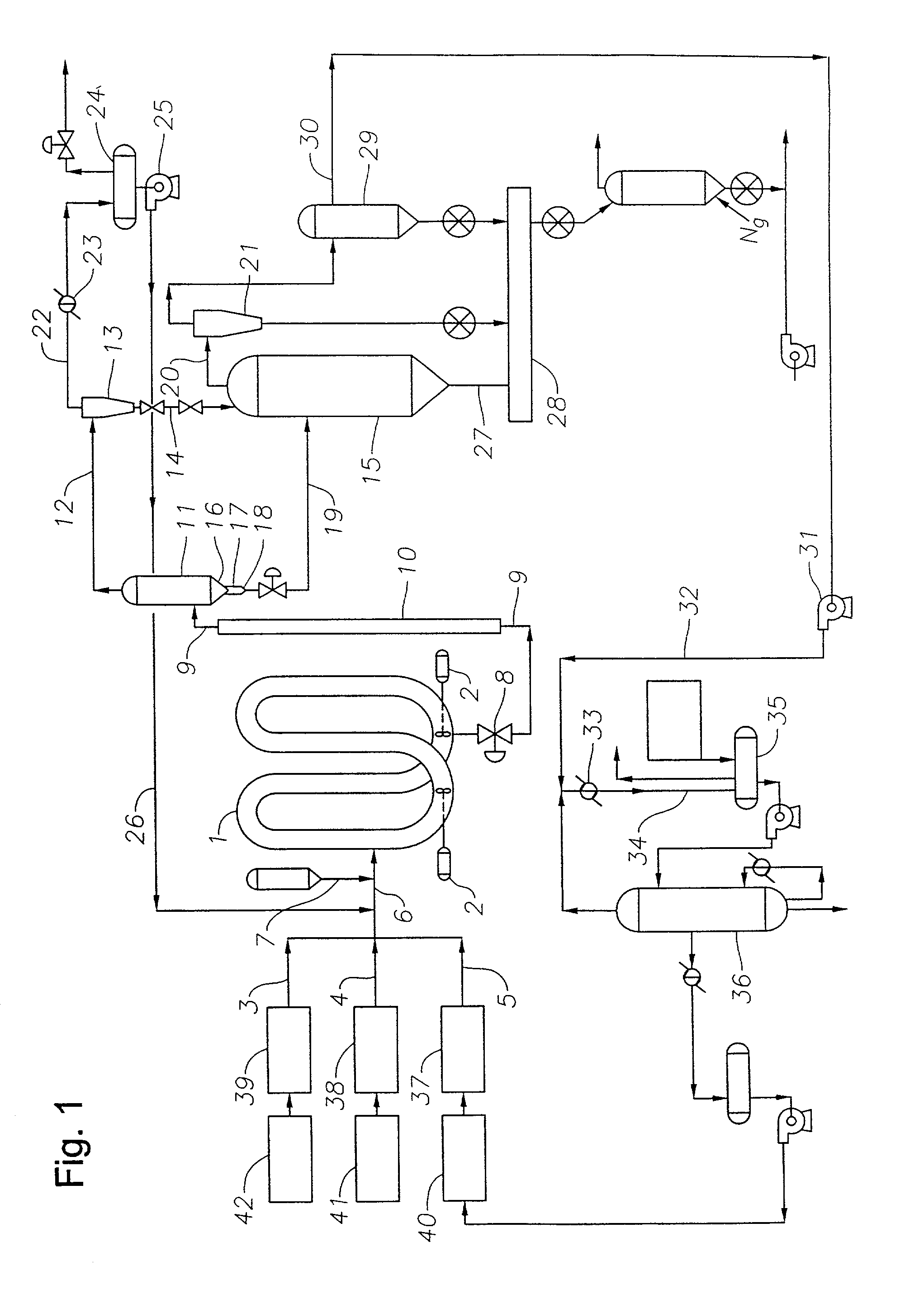

Mixed-Mode Fuel Injector with a Variable Orifice

InactiveUS20080245902A1Reduce total pressure lossPromote atomizationFuel injection apparatusMachines/enginesGasolineEngineering

The invention disclosed a mixed-mode fuel injector with micro-variable-circular-orifice (MVCO), which is a fuel injection device for internal combustion engines, either diesel or gasoline engines. The fuel injector is a high-accuracy couple of components comprising a needle valve (1) and a nozzle body (5). Said needle valve is movable back and forth and received in said nozzle body to provide an opening position for fuel injection and a biased closing position. Said nozzle body has multiple-micro-channels (6) on the inner conical surface (C) close to the tip of the nozzle body. The injector has a MVCO (4) comprising a micro-variable-circular aperture and multiple-micro-channels, and has means of generating variable mixed-mode sprays of conical and multi-jet shapes, with a major homogeneous conical spray at low to medium injection loads.

Owner:HOU DEYANG +1

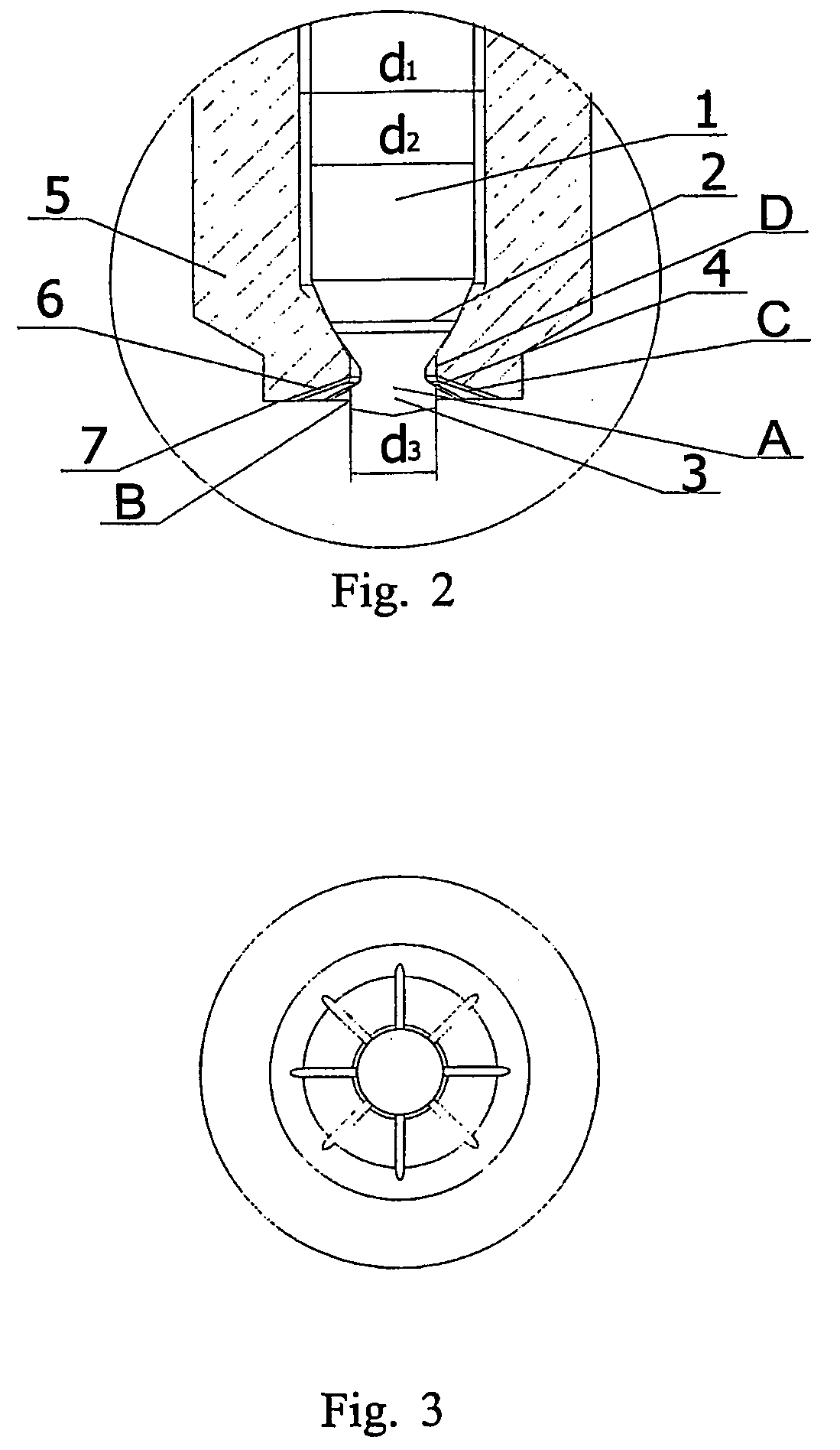

Continuous slurry polymerization volatile removal

InactiveUS7034090B2Increasing ethylene concentrationReduce energy consumptionChemical/physical/physico-chemical stationary reactorsFlash distillationLiquid mediumSlurry reactor

A process / apparatus is disclosed for continuously separating a liquid medium comprising diluent and unreacted monomers from a polymerization effluent comprising diluent, unreacted monomers and polymer solids, comprising a continuous discharge of the polymerization effluent from a slurry reactor through a discharge valve and transfer conduit into a first intermediate pressure flash tank with a conical bottom defined by substantially straight sides inclined at an angle to that of horizontal equal to or greater than the angle of slide of the slurry / polymer solids and an exit seal chamber of such diameter (d) and length (l) as to maintain a desired volume of concentrated polymer solids / slurry in the exit seal chamber such as to form a pressure seal while continuously discharging a plug flow of concentrated polymer solids / slurry bottom product of said first flash tank from the exit seal chamber through a seal chamber exit reducer with inclined sides defined by substantially straight sides inclined at an angle to that of horizontal equal to or greater than the angle of slide of the polymer solids which remain after removal of about 50 to 100% of the inert diluent therefrom to a second flash tank at a lower pressure.

Owner:EXXONMOBIL CHEM PAT INC

Device for deodorizing a sink drain and method therefor

InactiveUS20050135979A1Eliminate cloggingSolid sorbent liquid separationDomestic plumbingBiomedical engineeringNew device

A device for deodorizing a sink drain that allows the sink drain to remain substantially entirely open. Preferably, the device would deodorize sink drains. Further preferably, the device would treat sink drain clogs. Further preferably, the device would both deodorize the sink drain and treat sink drain clogs. Still further preferably, the device would have a wear indicator to signal the user when a new device is needed.

Owner:JOURNEY IPD

Internally pressure compensated non-clogging drip emitter

Drip emitter having a pressure compensating element that does not contact the enclosing pipe. First known drip emitter formed from a two-shot injection mold process that includes a deformable element, membrane, compressible element or pressure compensating element that compensates pressure or flow of water against a stiff injection molded surface that is part of the drip emitter body. In addition, this is the first drip emitter (two-shot or otherwise) that includes a compensating surface that is not parallel to the membrane, i.e., at an angle to the plane of the pressure compensating element. May include fluid retainment valve, ventable / anti-siphon / non-drain or other, as part of second injection with second or third material. Allows for simple injection mold construction and eliminates need for ISO conditioning to properly seat the membrane before testing.

Owner:MAMO SHAY

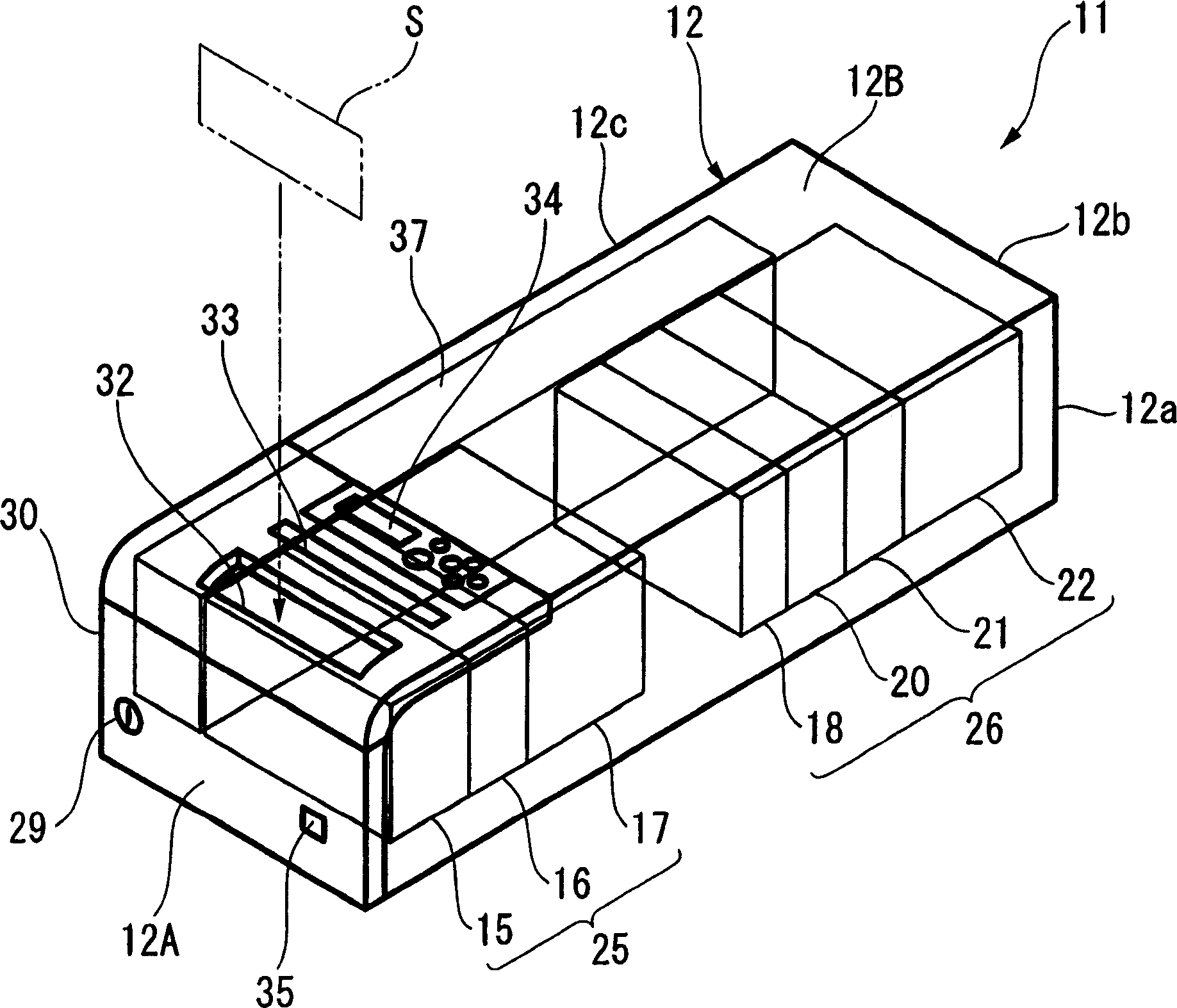

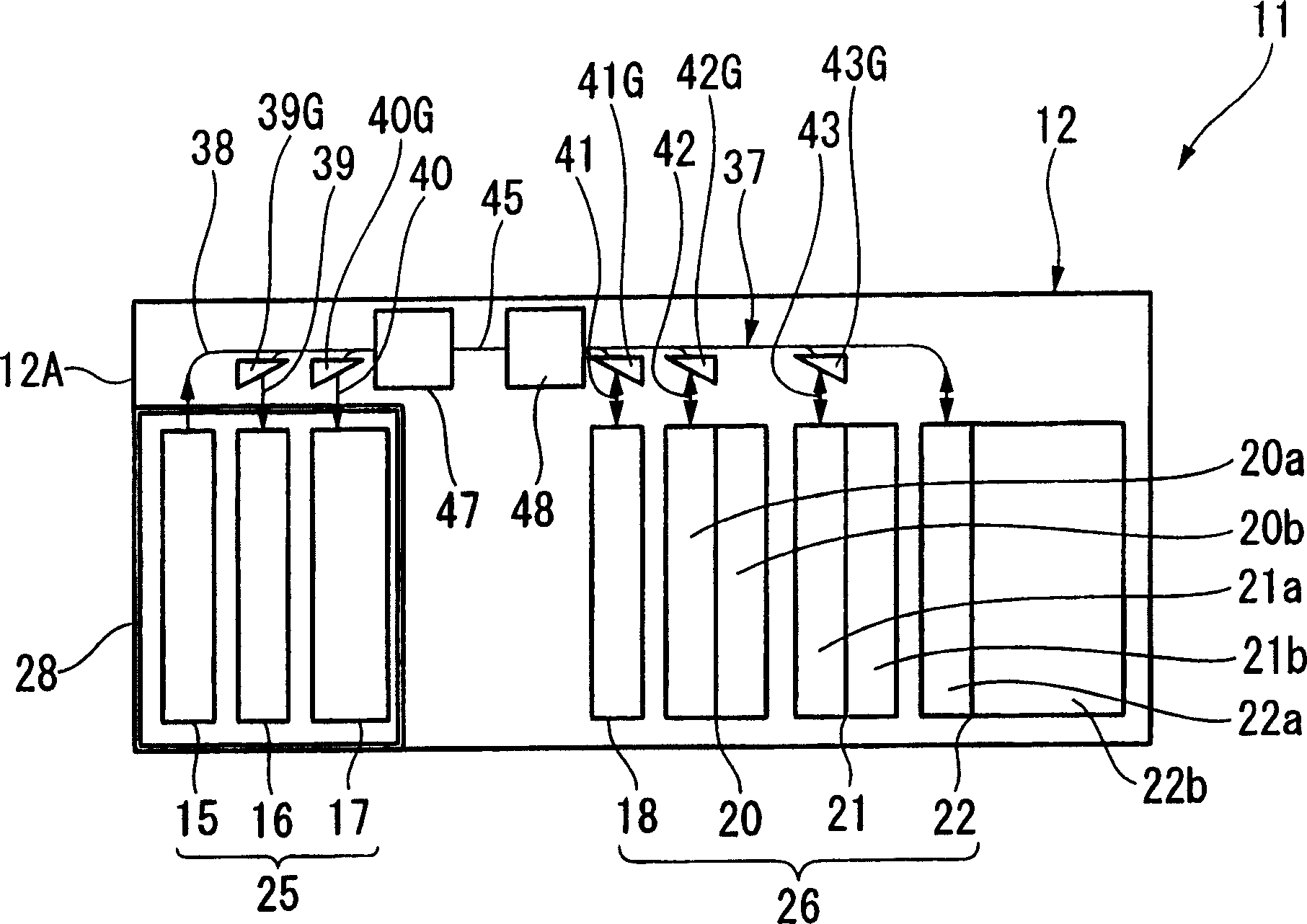

Paper money input and output device

InactiveCN1892708AAvoid cloggingEliminate cloggingCoin/currency accepting devicesOutput deviceEngineering

In the banknote depositing and dispensing machine of the present invention, the following parts are arranged side by side in this direction so that the thickness direction of the received banknotes is in the same direction. Putting in banknotes; the payment unit (16), sending banknotes out of the machine; multiple return storages (20-22), storing banknotes and outputting the stored banknotes to the payment unit (16); recycling storage (17), which can store Banknotes from the deposit section (15) or return storage (20-22); the payment rejection banknote storage (18) accommodates the payment rejection banknotes exported from the return storage (20-22), and only in Part (15), payment department (16), recovery storehouse (17), payment reject banknote storehouse (18) and return storehouse (20~22) are arranged side by side in the direction vertical to one side in the direction of the parallel direction, have connection these parts Conveyor (37).

Owner:LAUREL PRECISION MACHINES

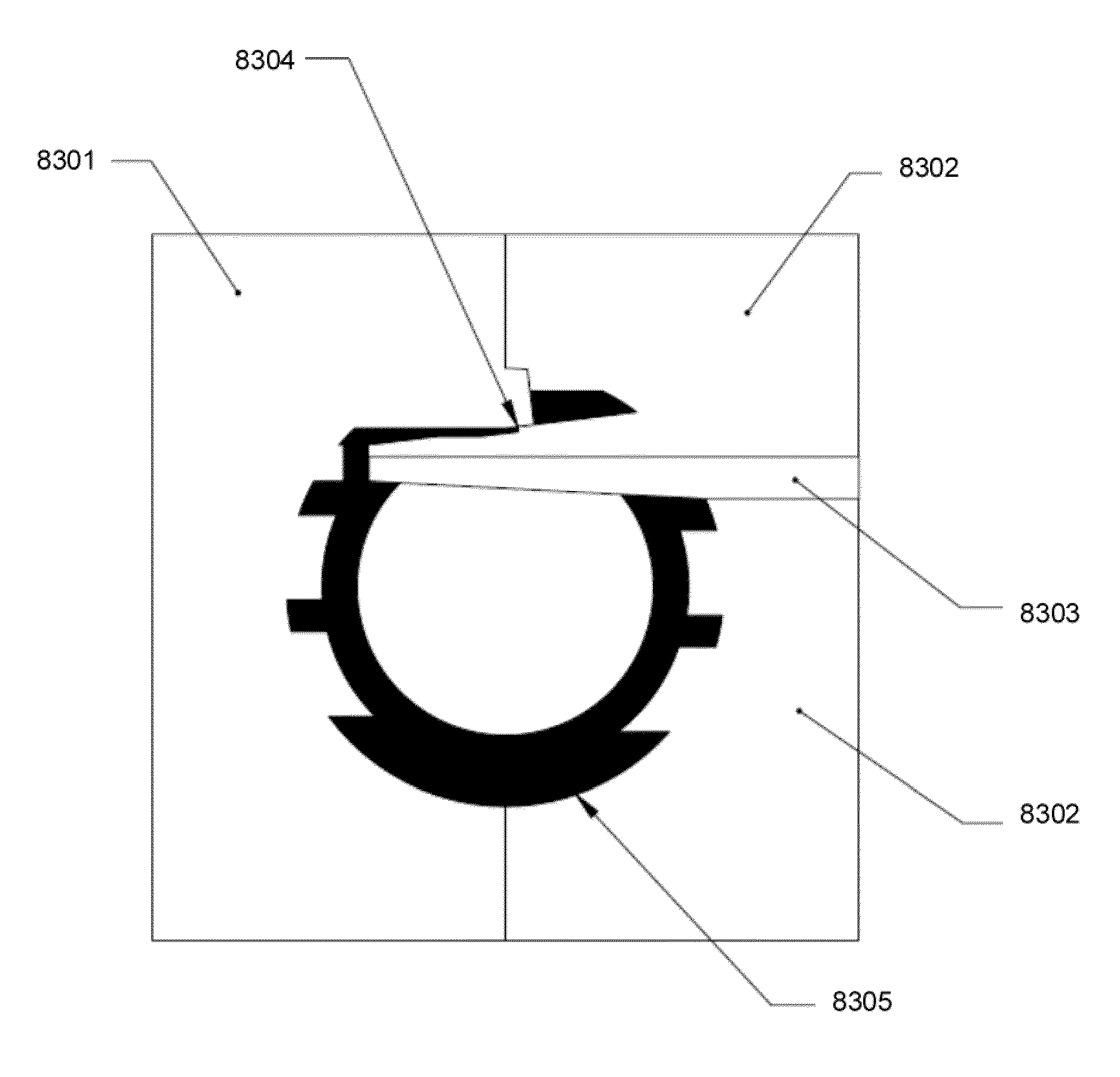

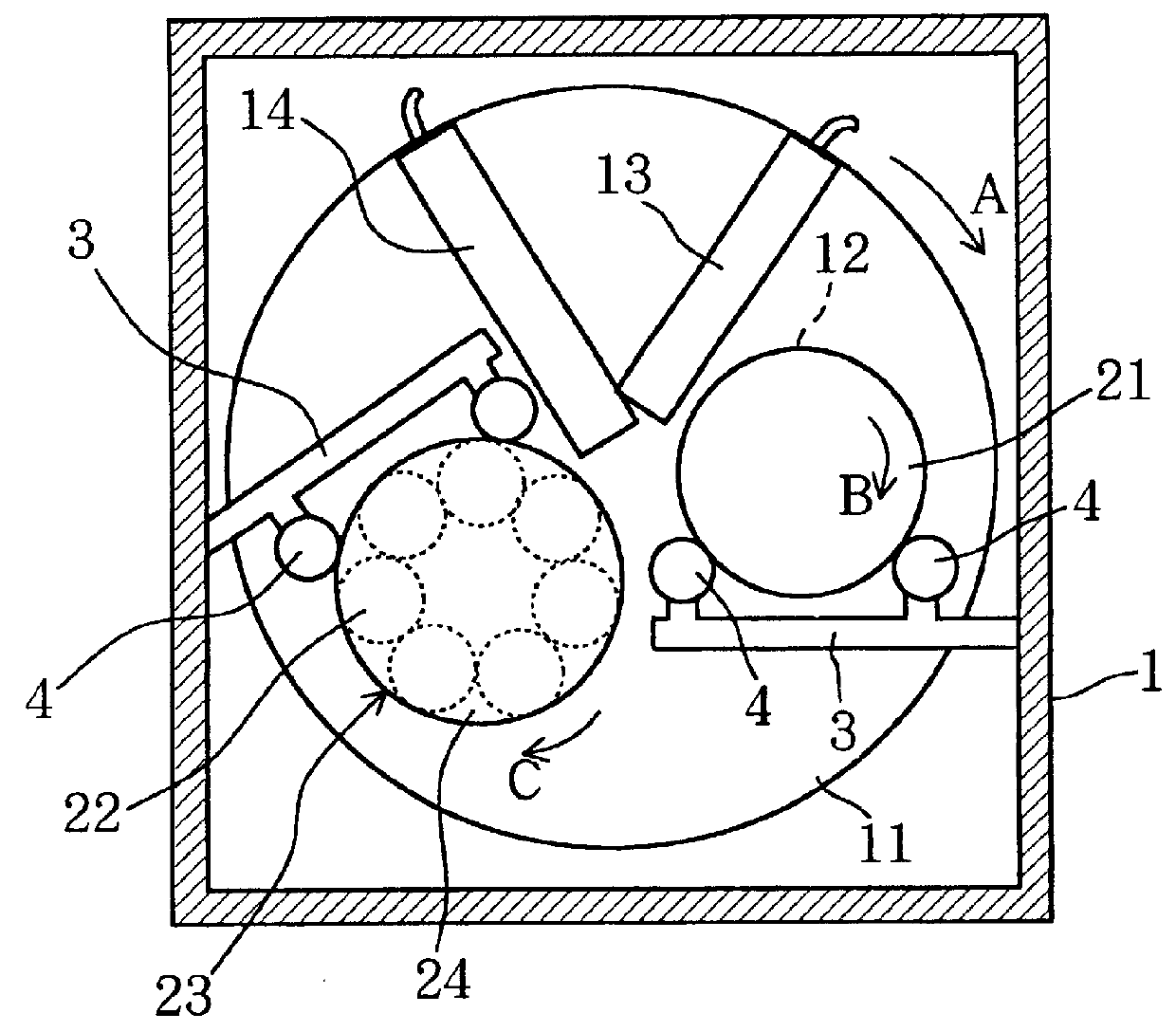

Surface polishing apparatus including a dresser

InactiveUS6039635AEliminate cloggingConstant amount of polishingEdge grinding machinesPolishing machinesSlurryEngineering

A surface polishing apparatus which presses a work piece 12 into contact with the processing surface of a disk-shaped polishing tool 11 which is rotated and driven, to polish the surface of the work piece 12 as supplying abrasive slurry to the processing surface. The surface polishing apparatus includes an abrasive slurry-supply mechanism 13 which supplies abrasive slurry to the processing surface. The slurry supply mechanism is provided on the backward side of the work piece with respect to the rotation direction of the polishing tool. A dresser 23, which sets the processing surface, is provided on the forward side of the work piece an abrasive slurry-suction mechanism, which sucks and recycles abrasive slurry from the processing surface, is provided on the forward side of the dresser and on the backward side of abrasive slurry-supply mechanism 13.

Owner:NEC CORP

Acid liquid fertilizer for drip irrigation and its prepn

The present invention relates to one kind of acid liquid fertilizer for drip irrigation and including nitrogen fertilizer, phosphate fertilizer, potash fertilizer, rooting promoter, dissolution promoter, trace elements and sulfuric acid. It is prepared through the steps of: dissolving phosphate fertilizer, potash fertilizer, trace elements and dissolution promoter in water through stirring, dissolving nitrogen fertilizer, adding sulfuric acid and adding rooting promoter. Its preparation process is scientific, low in power consumption and low in cost and uses simple apparatus. Its dissolution promoter can raise the dissolution degree of routine phosphate fertilizer and its rooting promoter can promote the growth of plant root system and the plant absorption capacity to nutrients. Its acidity can prevent jamming of drip holes.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Micro-suspension self-selection water shutoff and profile control agent and application method thereof

ActiveCN102516960AEliminate cloggingThe space occupied by the blockage is formed to eliminate the mechanical blockage of the water flowDrilling compositionSealing/packingHigh water contentSodium hydroxide

A micro-suspension self-selection water shutoff and profile control agent. A layer self-selection water shutoff and profile control agent applied to oil deposit with middle and high water content can carry out self-selection water shutoff and profile control in a layer of complex oil deposit with middle and high water content, a lateral well and a secondary big pore channel. The water shutoff and profile control agent comprises 5-50% of asphalt, 1-5% of olefin, 0.5-1.0% of octadearyl dimethyl ammonium chloride, 0.1-0.15% of carboxymethyl cellulose sodium, 5-15% of stable control agent sodium hydroxide aqueous solution and the balance of water. The preparation method comprises step of processing the raw materials into stable micro fluid suspension with a particle size of 1 mum-1mm through machinery crushing and grinding by a colloid mill. The invention has the following beneficial effects: the water shutoff and profile control agent can be applied to layer self-selection water shutoff and profile control of oil deposit with high water content; a main agent asphalt can be dissolved in light oil completely but not in water; plastic colloid can be precipitated; and blocking of different strength can be realized through reasonable selection and assembly of softening points of the main agent.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com