Patents

Literature

170results about How to "Improve lateral pressure resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

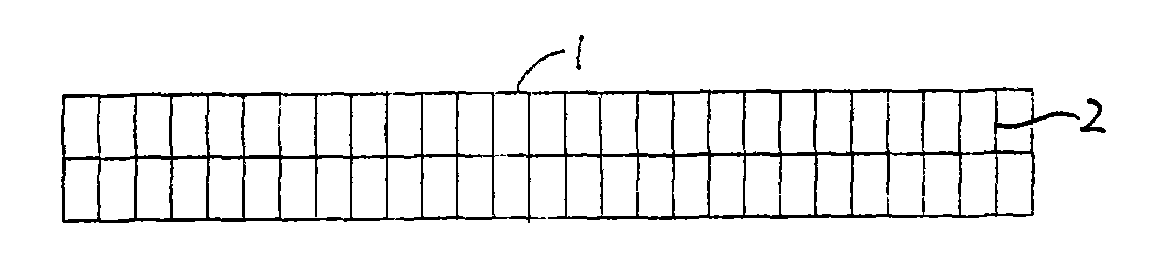

Drainage plate for silt consolidation, filter cloth and drainage plate core

The invention is the improvement on a longitudinal drainage plate for silt consolidation, filter cloth and a drainage plate core, which is characterized in that fibrous hot-pressed microporous filter cloth is planar filter cloth hot-rolled by a flat roller, the filter cloth is adhered to the surfaces of convex ribs of the drainage plate core through thermal thawing or a chemical way, the filter cloth adopts silk reeling and hot-press forming separation technology, and the drainage plate core is made of co-polypropylene, thereby overcoming the disadvantages of the prior art; and the aperture of the filter cloth can be adjusted according to treated silt, the drainage plate is difficult to block, the engineering on a soft foundation after the treatment cannot have the settlement after the construction and has smooth drainage and high drainage efficiency, and the plate core has long effective service life.

Owner:JIANGSU XINTAI GEOTECHNICAL TECH CO LTD

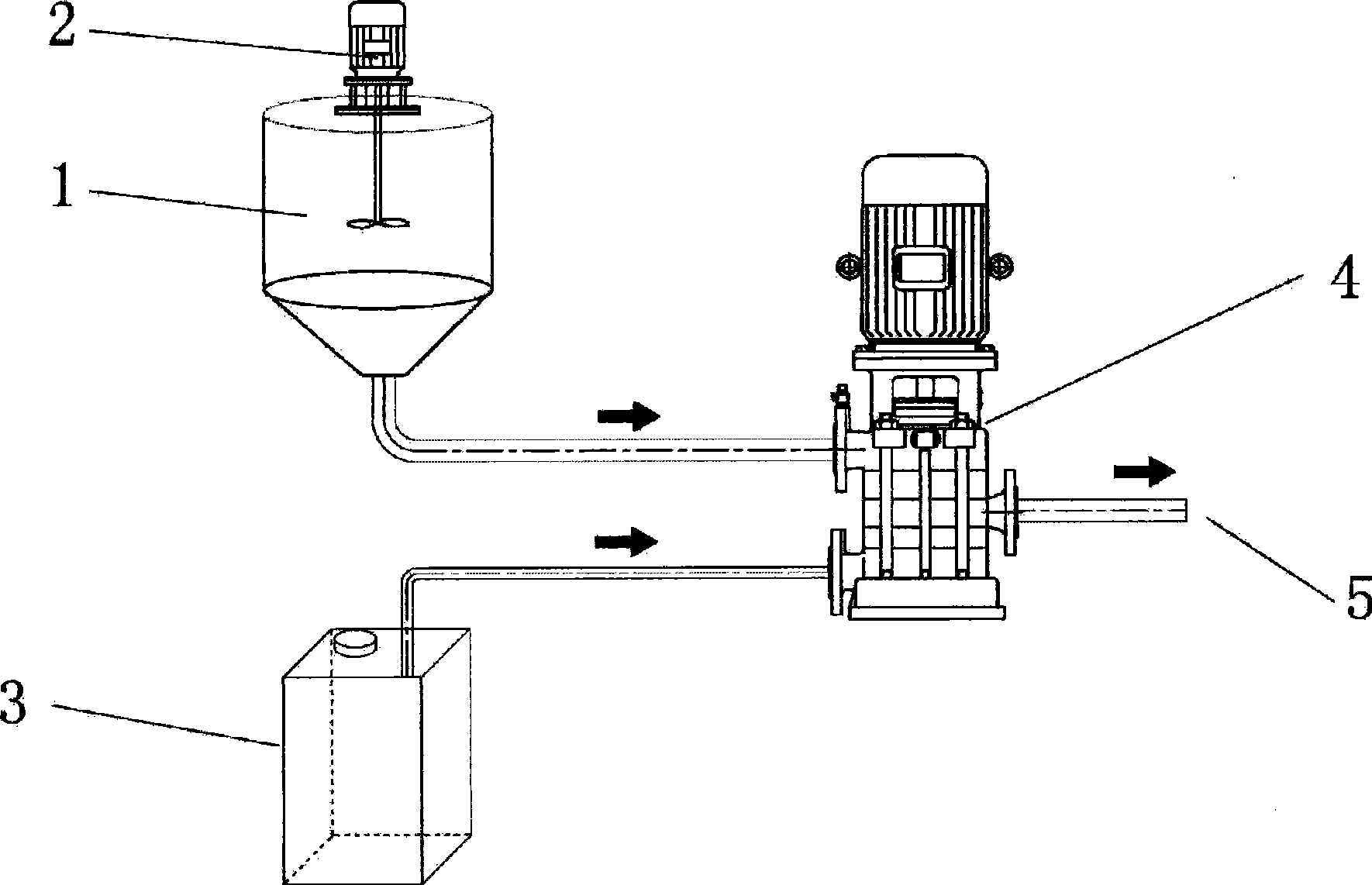

Sludge treatment method and sludge foaming lightweight concrete produced therefrom and use

InactiveCN101381191ASolve processing problemsNo pollutionSludge treatmentSolid waste managementFoaming agentFilling materials

The invention discloses a sludge treatment method, as well as sludge foamed lightweight concrete produced through the method and application thereof. In the method, sludge produced by sewage treatment first reacts with quicklime so as to form sludge hydrated lime; then the sludge hydrated lime is mixed with cement and water so as to form sludge concrete; foaming agent produces foam by utilizing a foaming system of a foaming machine; and the foam is mixed with the sludge concrete. The sludge treatment method can directly obtain the sludge foamed lightweight concrete. The sludge foamed lightweight concrete has a plurality of functions, which can be used as a filling material, a heat insulating material, a walling material, a sound insulation material, a mine tunnel filling material, an artificial landscape manufacturing material, a road recovery material, a pipe base filling material and the like. The sludge treatment method is low in cost and friendly to environment, can directly produce the sludge foamed lightweight concrete with a plurality of functions, and not only solves the sludge treatment problems in the sewage treatment industry, but also ensures the full utilization of the sludge.

Owner:BEIJING SIFANGRUGANG CONCRETE PROD

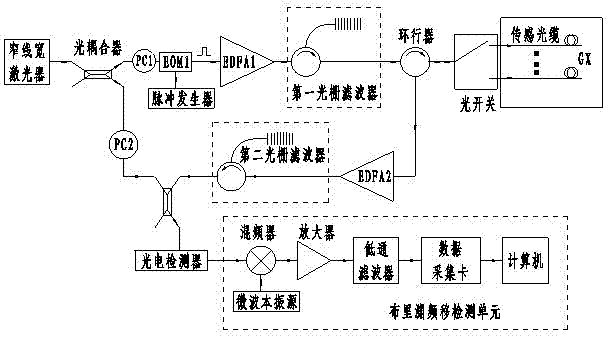

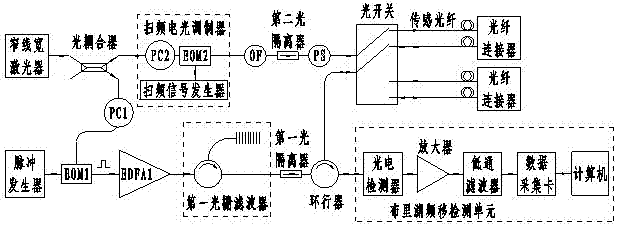

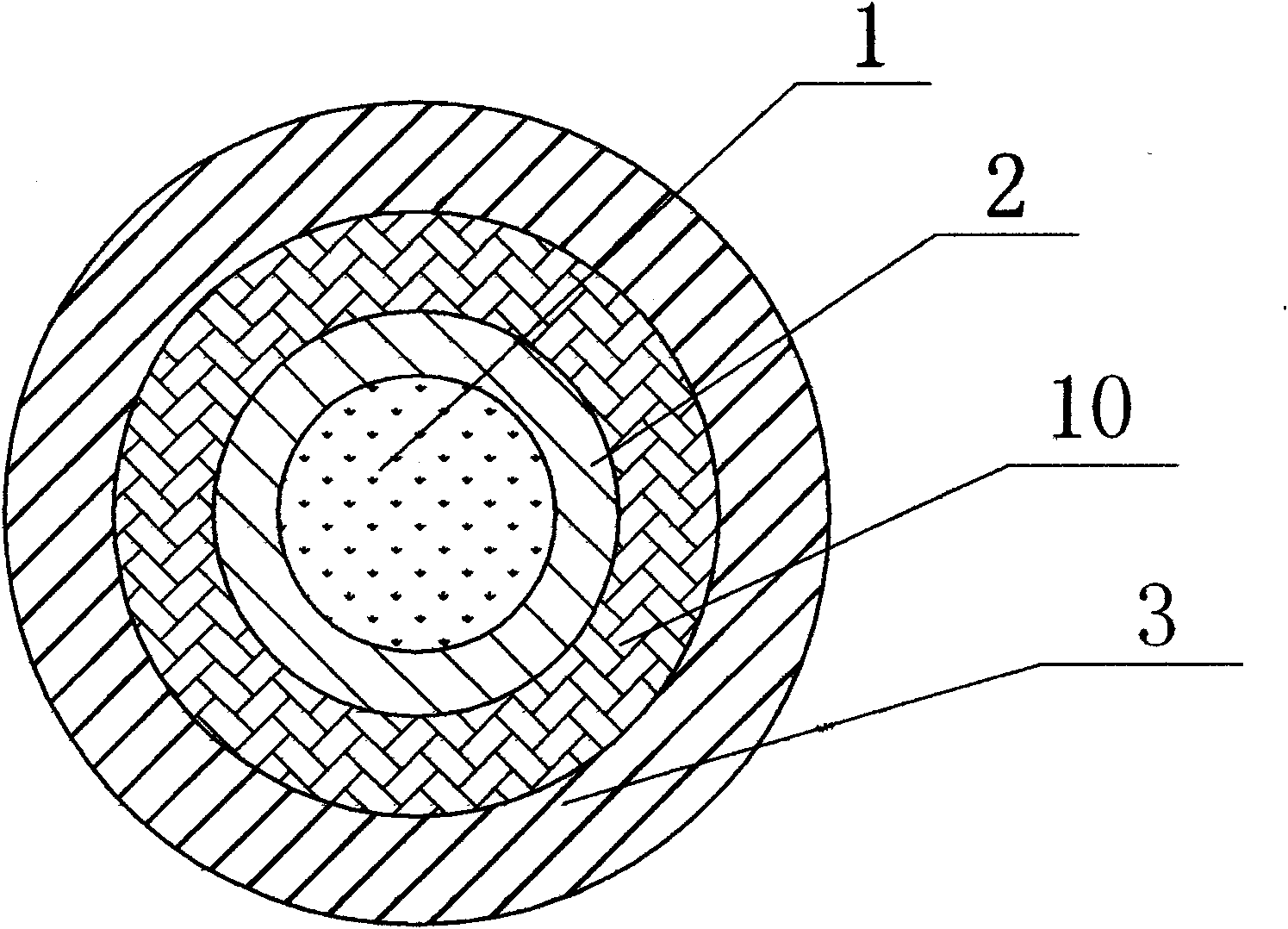

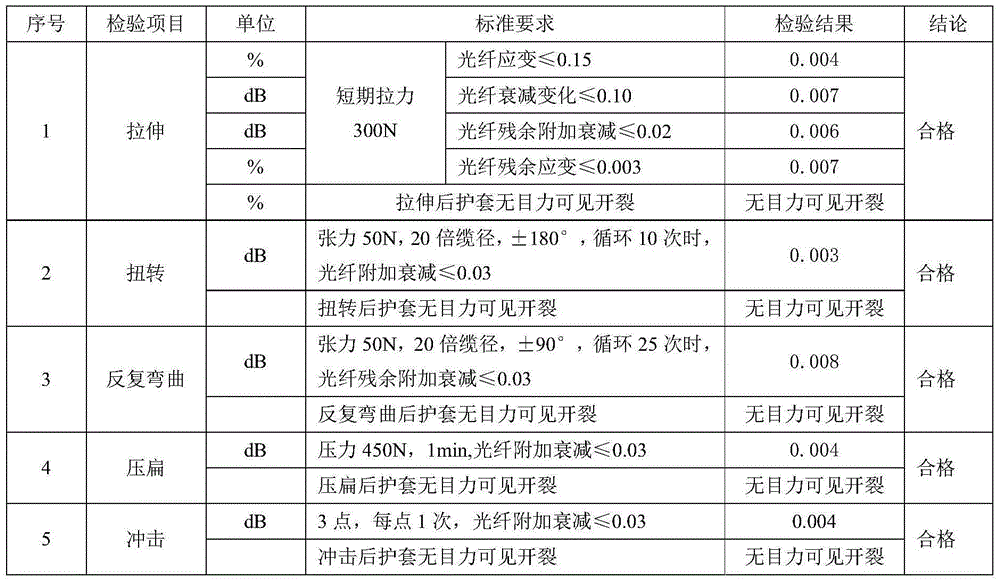

Seawater temperature profile BOTDA measuring method based on optical fiber Brillouin scattering principle

ActiveCN102353474AGood tensileGood resistance to lateral pressureThermometers using physical/chemical changesTemperature measurement of flowing materialsOptical couplerSeawater

A seawater temperature profile BOTDA measuring method based on an optical fiber Brillouin scattering principle is disclosed. In the invention, a sensitive optical cable is formed by combining a pressure sensing fiber which directly contacts with the seawater and a temperature sensing fiber which shields seawater pressure. A measuring part of a measuring system based on a BOTDA principle comprises: a narrow linewidth laser, an optical coupler, a pulse generator, a first light modulator, a light amplifier, a sweeping-frequency electrooptic modulator, a circulator, a grating filter, an optical isolator, a polarization scrambler, an optical filter, an optical switch and a Brillouin frequency shift detection unit. The sensitive optical cable used in the invention has a small volume, is convenient to be used and possesses good seawater corrosion resistance. The measuring system has high reliability and sensitivity, can provide continuous temperature field distribution of the seawater profile and is suitable for real-timely measuring the seawater temperature profile continuously.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

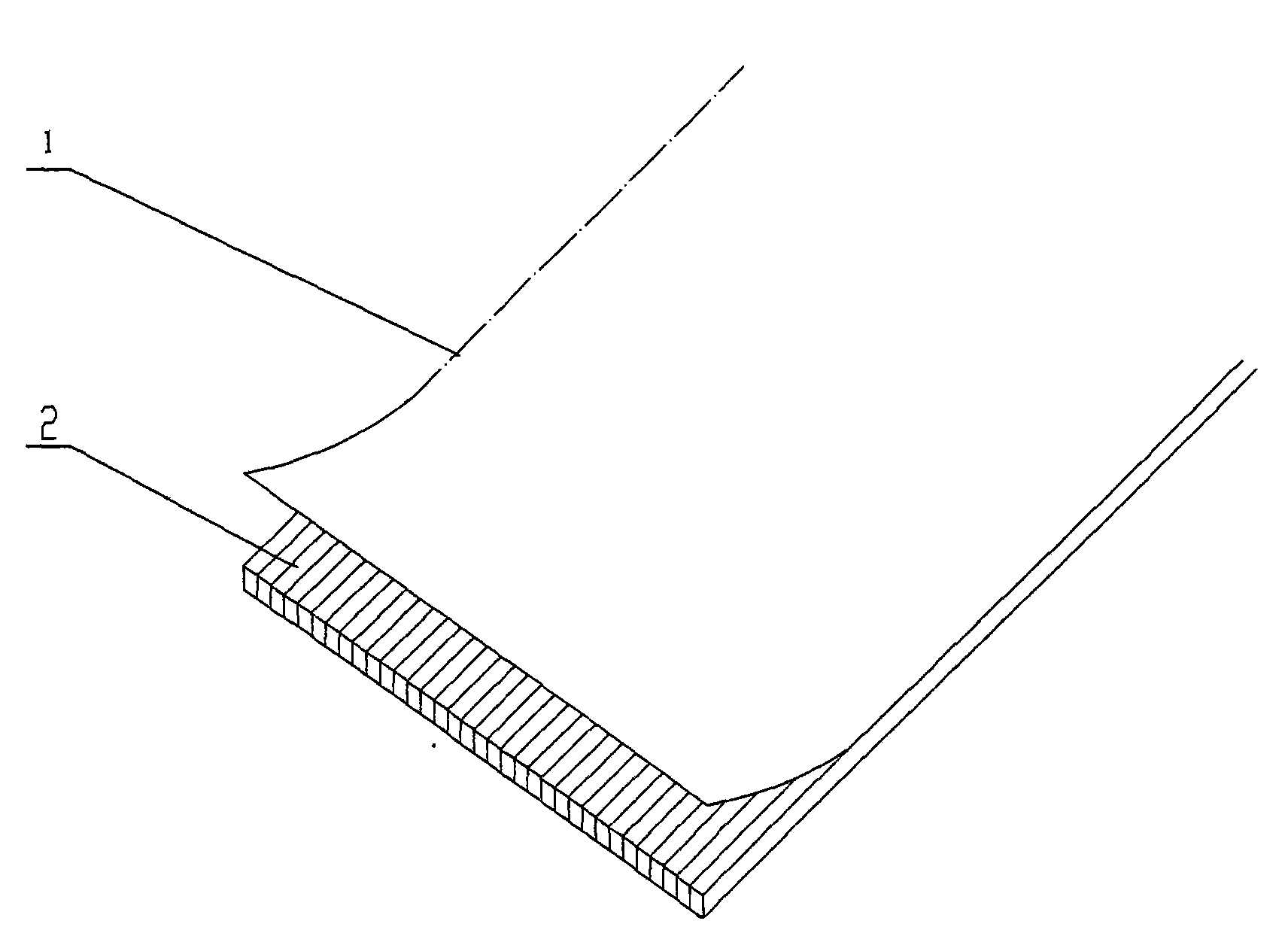

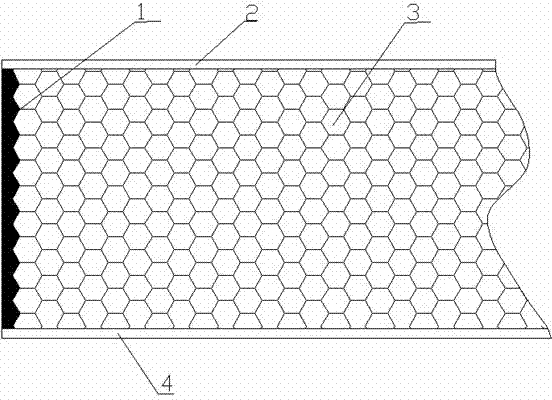

Edge sealing structure of honeycomb sandwich shelter wallboard, and edge sealing method thereof

InactiveCN103590532AImprove lateral pressure resistanceImprove rigiditySynthetic resin layered productsBuilding componentsHoneycombEngineering

The invention relates to an edge sealing structure of a honeycomb sandwich shelter wallboard, and an edge sealing method thereof. The edge sealing structure is low-density epoxy putty composed of an epoxy resin and a lightweight filler. The invention also relates to an edge sealing method of the honeycomb sandwich shelter wallboard by adopting the edge sealing structure. The edge sealing structure has a low cost, can substantially improve the side compression resistance and the whole rigidity of a honeycomb sandwich panel, and has frame reinforcing and waterproof sealing effects. The method is simple to operate, and is especially suitable for the rapid edge sealing treatment of a part with any shape in any positionof a honeycomb sandwich shelter wallboard after random perforation.

Owner:衡阳泰豪通信车辆有限公司

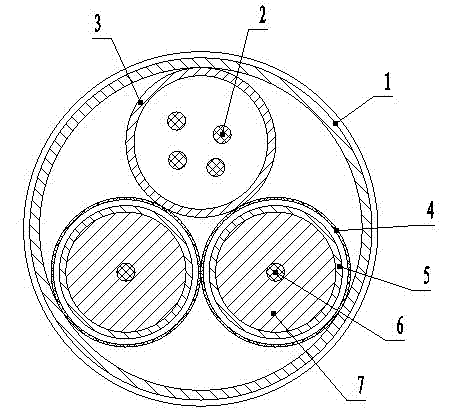

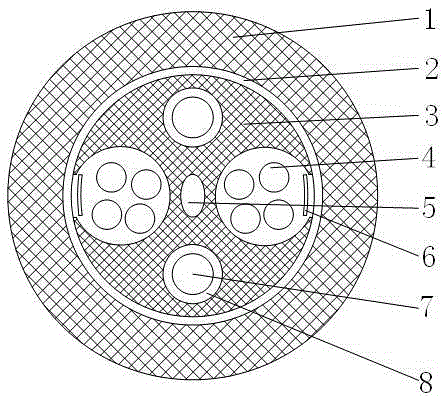

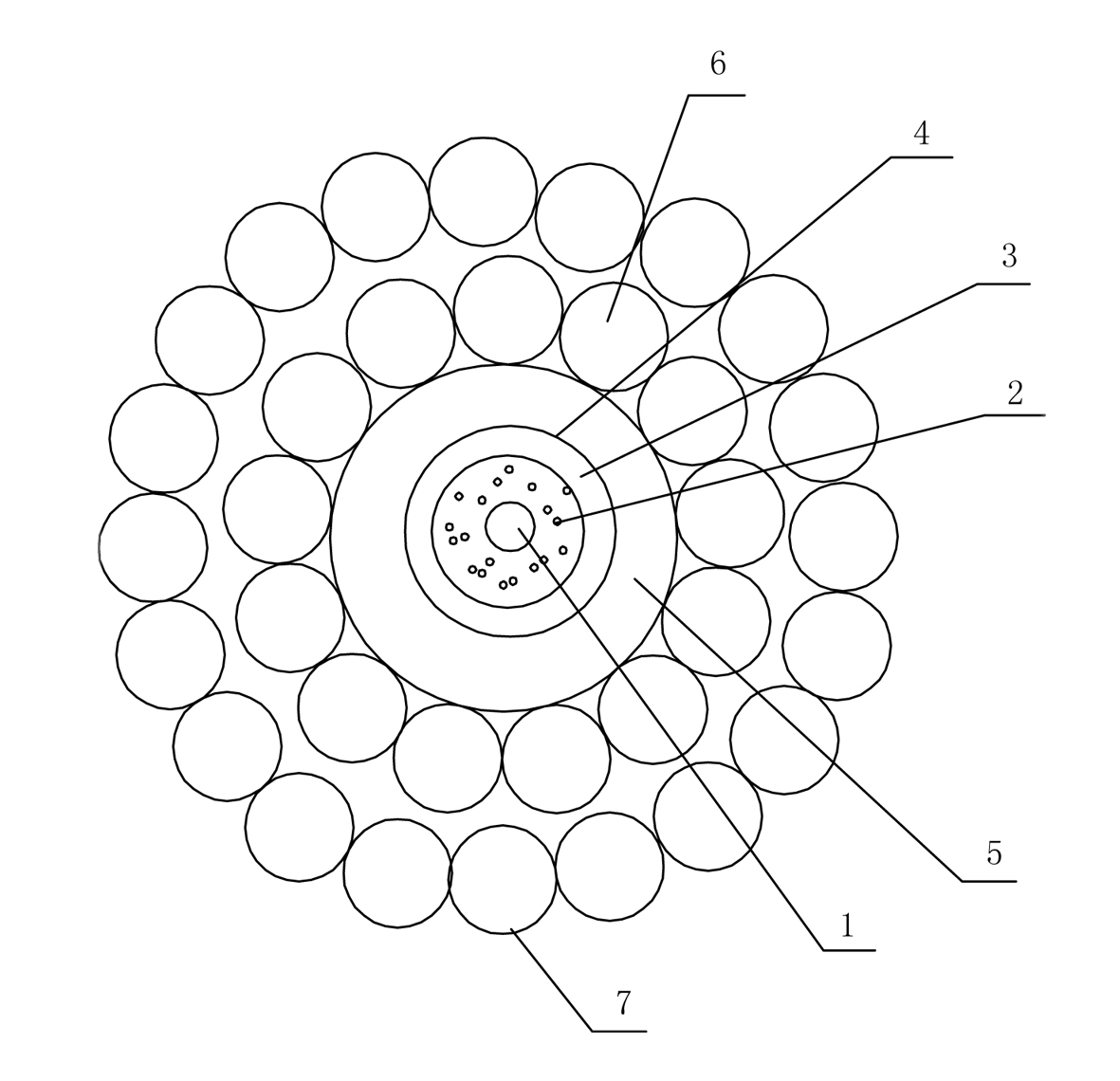

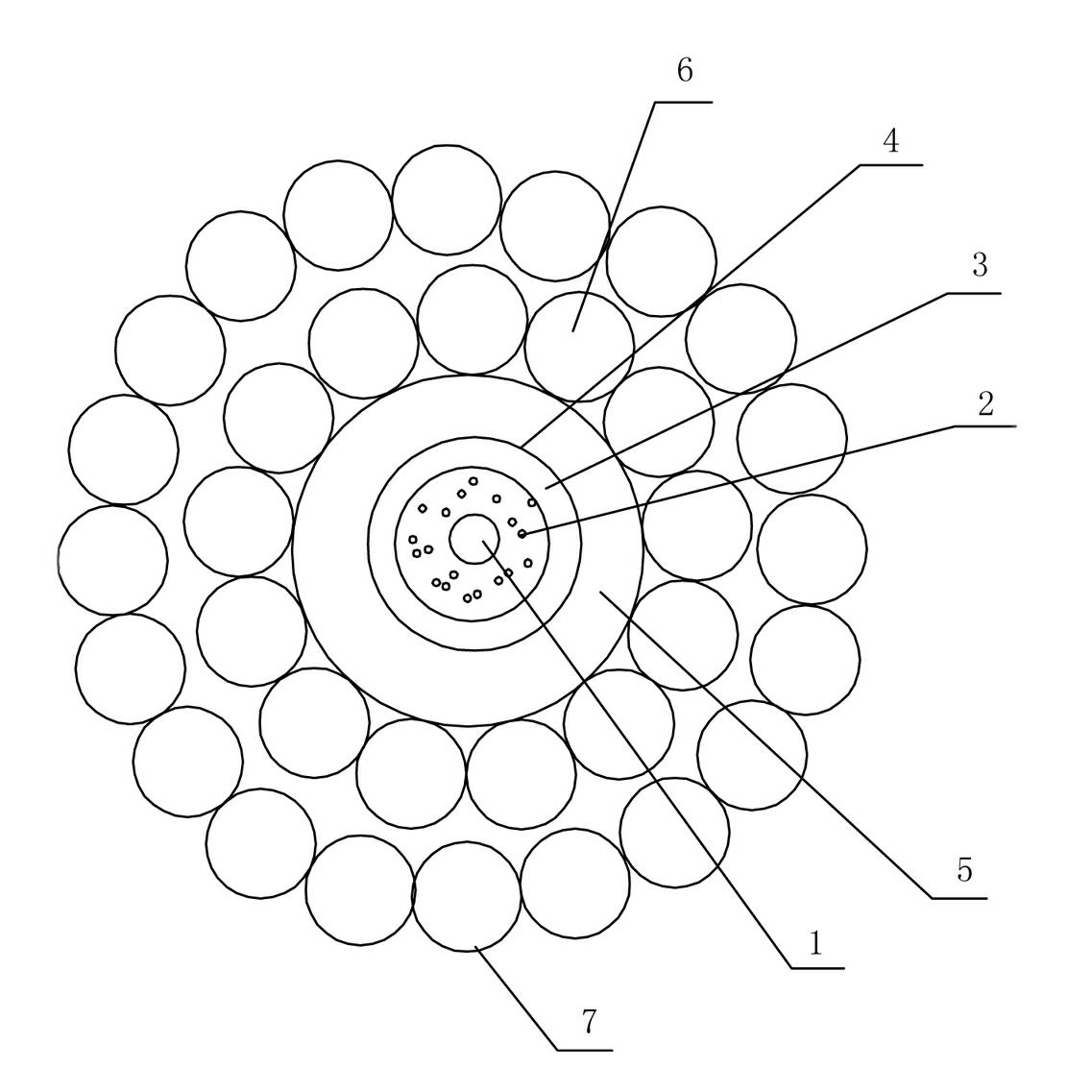

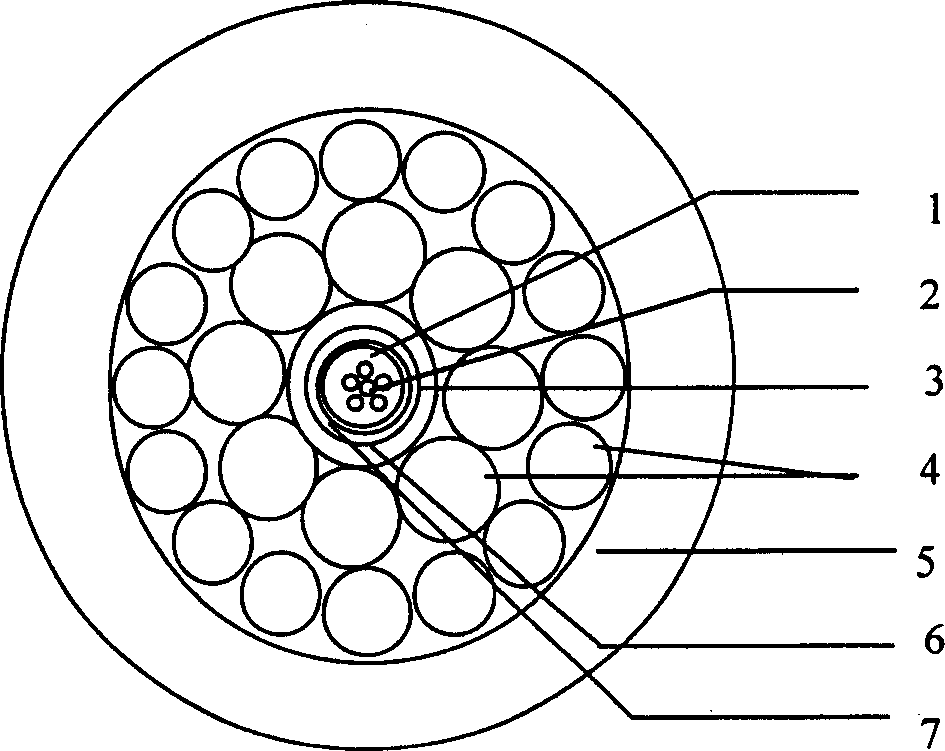

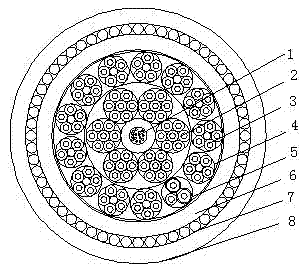

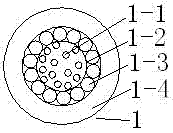

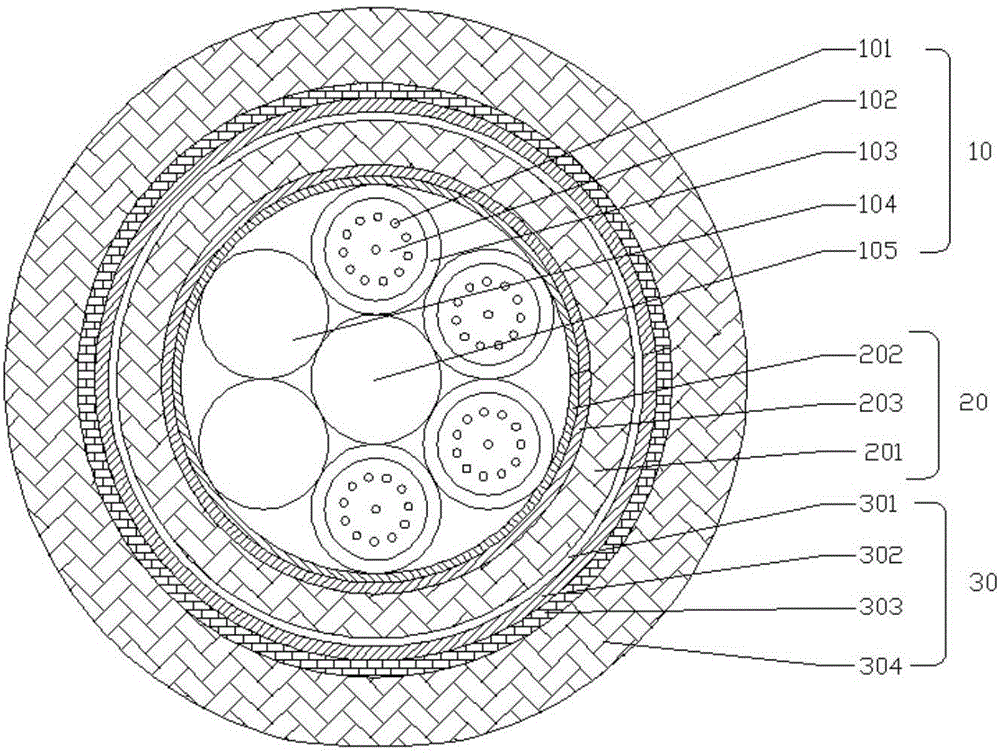

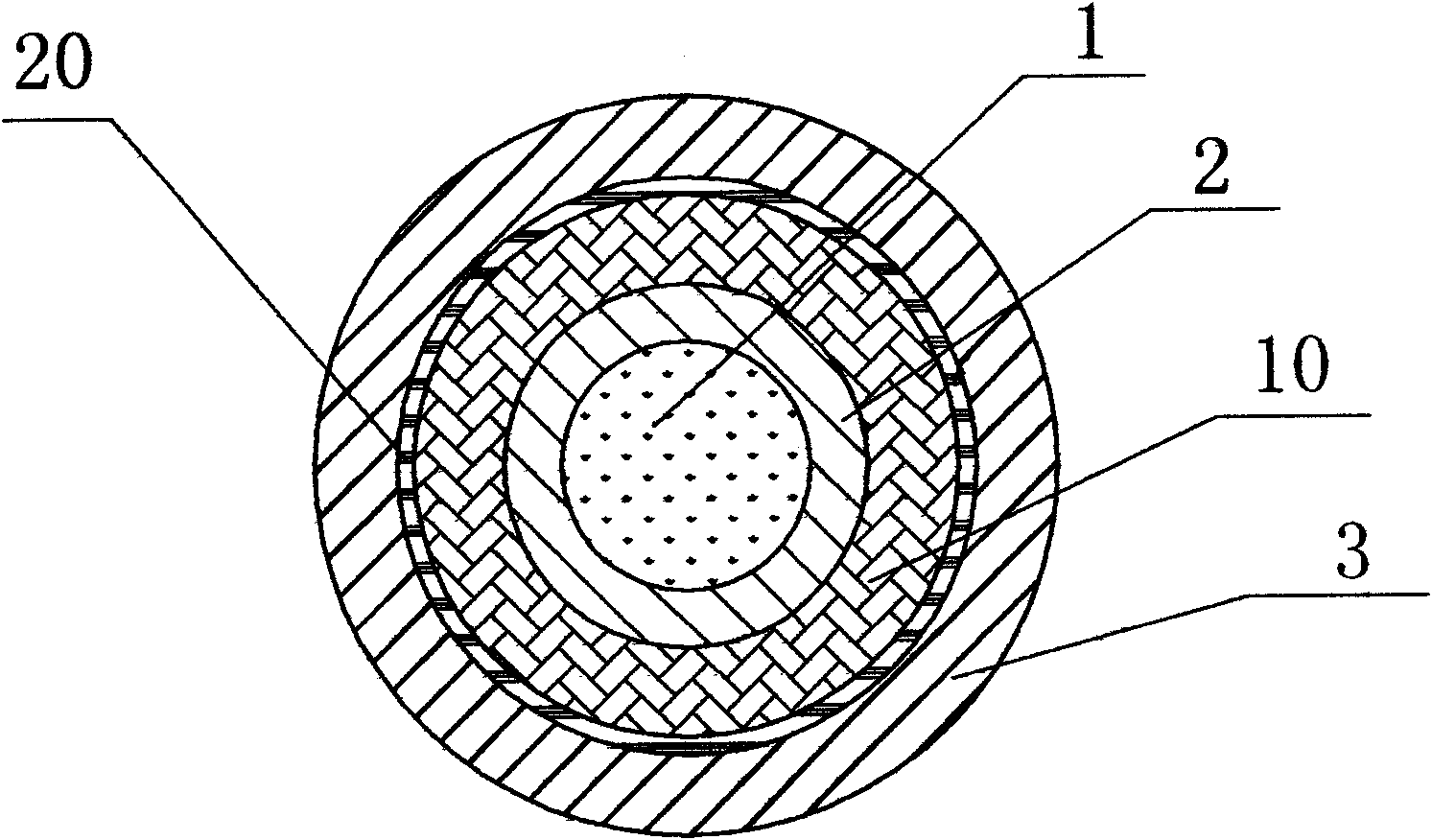

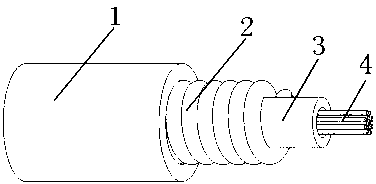

Skeleton type photoelectric composite cable and manufacturing method thereof

ActiveCN105427948AImprove mechanical propertiesImprove lateral pressure resistanceInsulated cablesFibre mechanical structuresElectricityWeather resistance

The invention relates to a skeleton type photoelectric composite cable and a manufacturing method thereof. The skeleton type photoelectric composite cable comprises a skeleton and an outer sheath wrapping the skeleton. The skeleton type photoelectric composite cable is characterized in that two sides of the skeleton are respectively provided with a skeleton groove whose radial section is a circle or a large semicircle, optical communication units are arranged in the skeleton grooves in a laying manner, and power supply conducting wires are arranged at the upper side and the lower side of the skeleton. According to the cable, optical units and electric units are integrated so that wiring space resources are greatly saved, the construction cost is reduced, the structural setting is reasonable, the size is small, the optical cable is flexible and light, the optical communication units in the optical cable are easily separated and continued, the mechanical performance, the weather resistance, and the flexibility performance are excellent, and the optical cable can be applied to indoor and outdoor applications. The manufacturing method is simple and reasonable, the quality and the process are easily controlled, the production efficiency is high, and the manufacturing cost is low.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

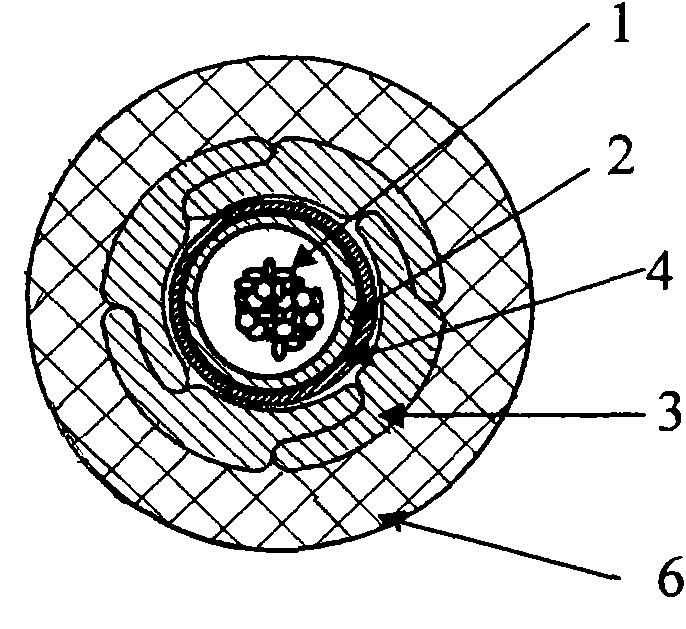

Intelligent photoelectric hybrid detecting optical cable and production method thereof

ActiveCN102074301AImprove bending performanceHigh strengthClimate change adaptationCommunication cablesCopper conductorAviation

The invention discloses an intelligent photoelectric hybrid detecting optical cable and a production method thereof, which relate to a novel intelligent detecting optical cable used in the fields of oil fields, coal mines, aviation, fire fighting and the like and a production method thereof. The intelligent photoelectric hybrid detecting optical cable comprises a miniature tightly-enveloped optical fiber unit, a net-like copper conductor conducting unit, a high temperature-resisting fluoroplastic insulating layer and a high-strength stainless steel wire armoring unit, wherein the net-like copper conductor unit is enveloped outside the miniature tightly-enveloped optical fiber unit; the high temperature-resisting fluoroplastic insulating layer is arranged outside the net-like copper conductor conducting unit to serve as a protective sleeve; the high-strength stainless steel wire armoring unit is arranged outside the high temperature-resisting fluoroplastic insulating layer; the miniature tightly-enveloped optical fiber unit consists of a high temperature optical fiber, a miniature stainless steel pipe and high temperature fiber paste; the optical fiber unit has a tightly-enveloped structure; the high temperature optical fiber is sleeved in the miniature stainless steel pipe; the high temperature fiber paste is filled around the high temperature optical fiber in the miniature stainless steel pipe; and the net-like copper conductor unit is formed by weaving a plurality of copper wires.

Owner:ZHONGTIAN ELECTRIC POWER OPTICAL CABLES CO LTD

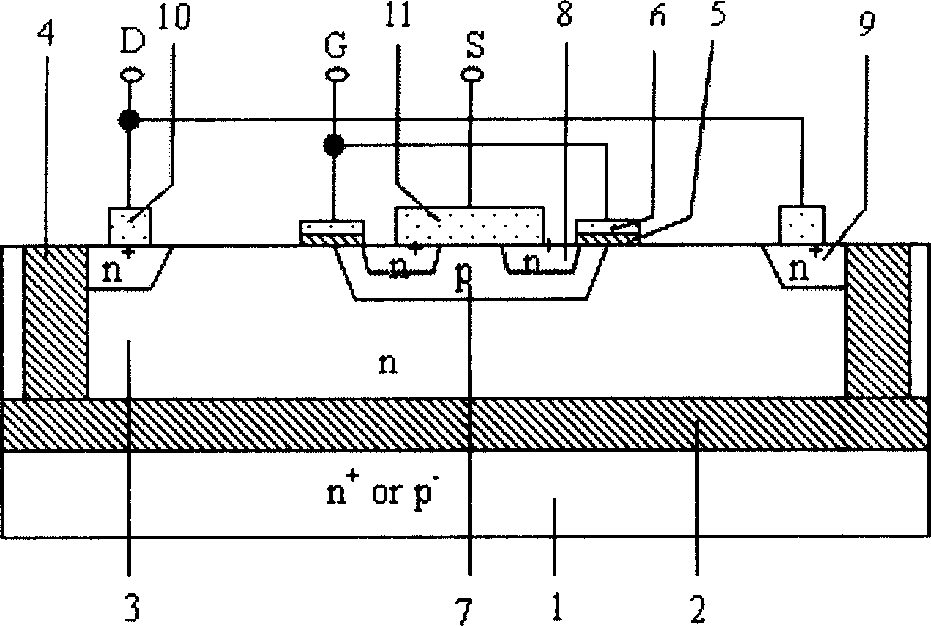

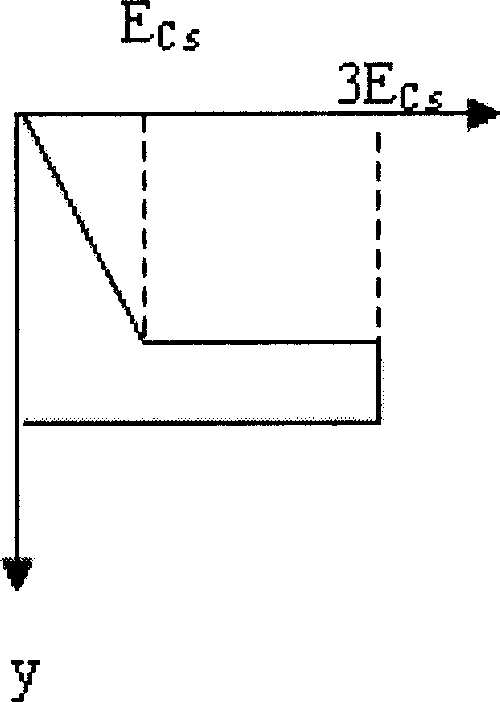

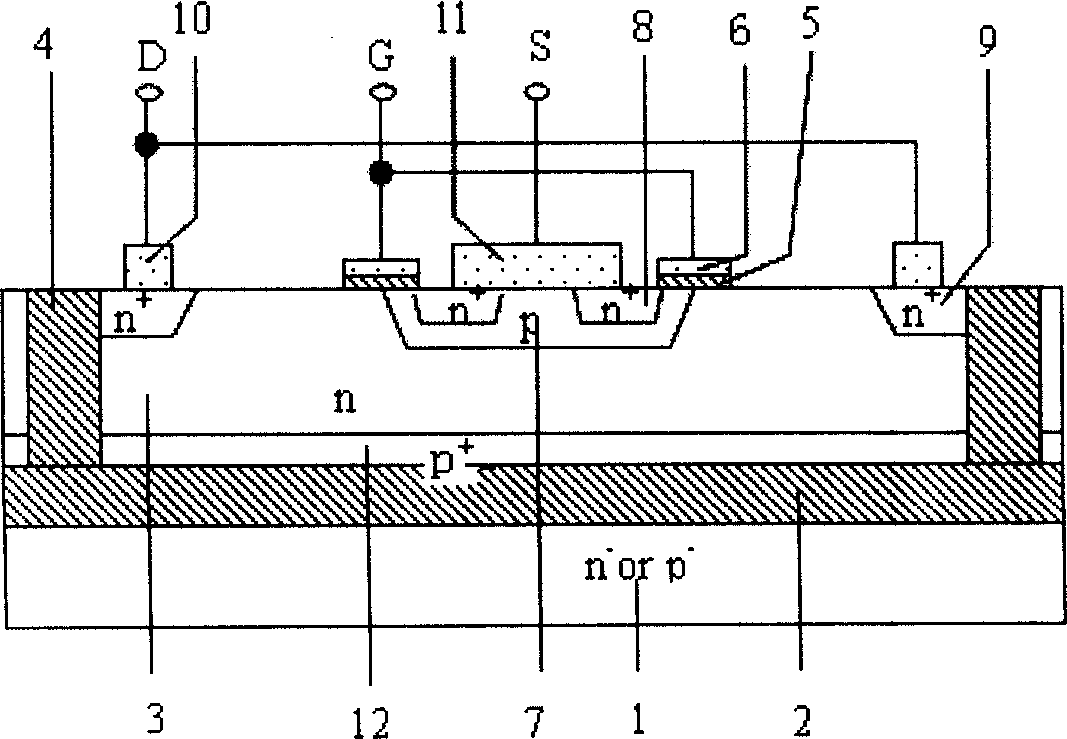

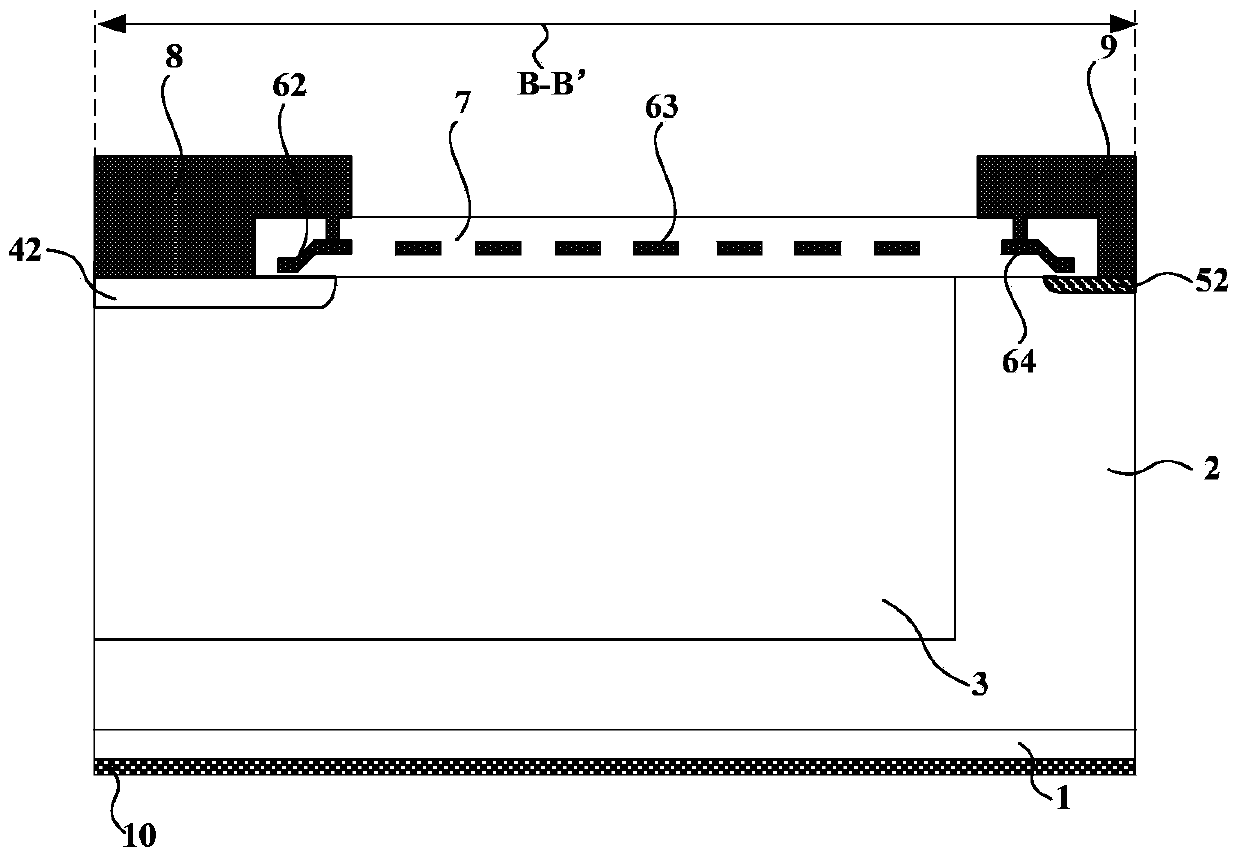

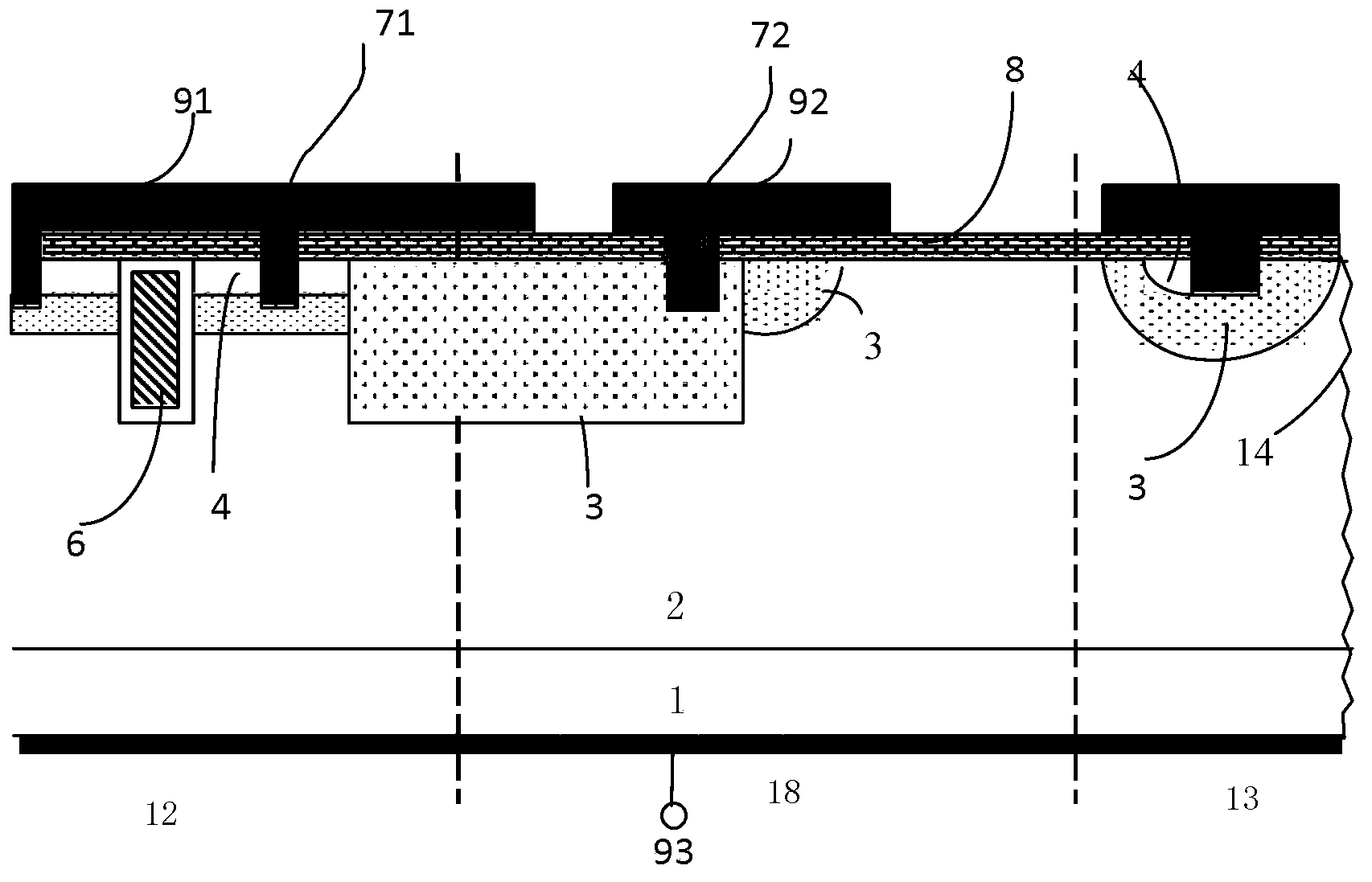

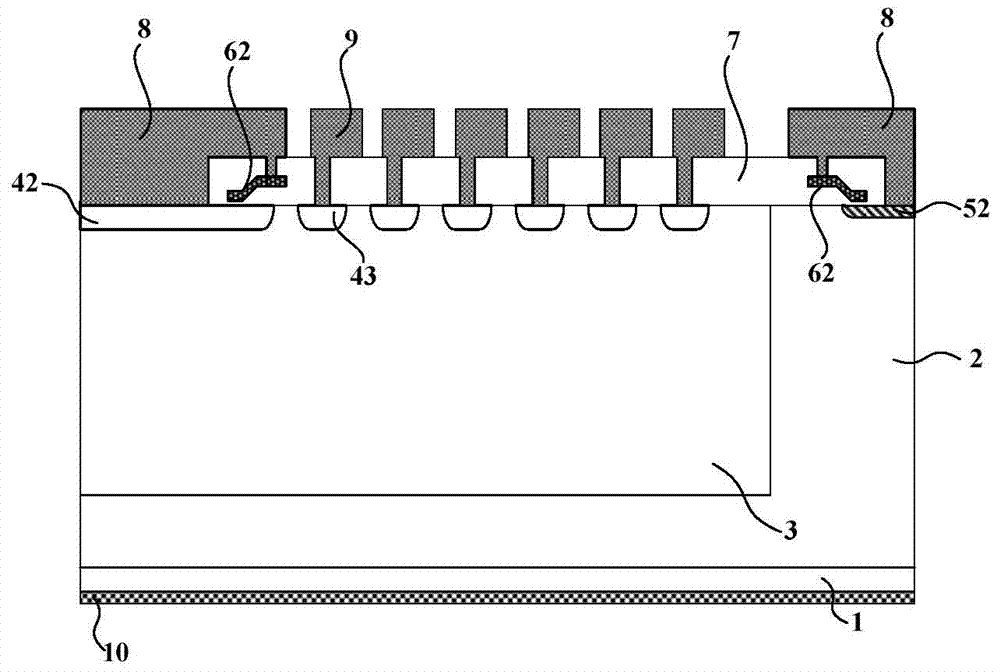

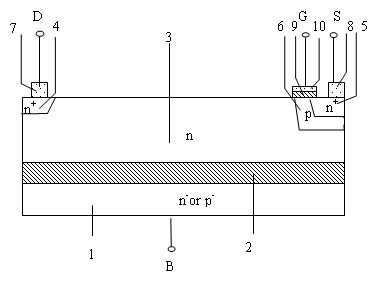

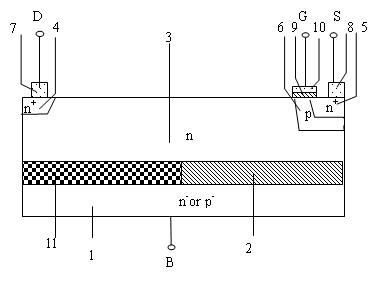

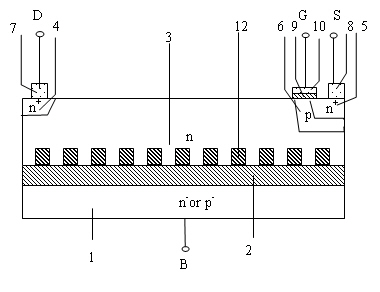

SOI structure with low k dielectric buried layer and its power device

InactiveCN1845332AImprove vertical pressure resistanceImprove lateral pressure resistanceTransistorThyristorCapacitanceLayer interface

The disclosed SOI power device with VLk SOI, Lk SOI, VLk PSOI and Lk PSOI four structures apples the low-k (dielectric coefficient) material to increase longitudinal electric field strength of the buried layer and modulate Si active electric field by the additional field on variable-k layer interface, while decrease the capacitor between drift region and substrate to improve on-off speed. This invention can be used to lots of new high pressure-resistant devices, such as lateral dual-diffusion FET, PN diode, etc.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

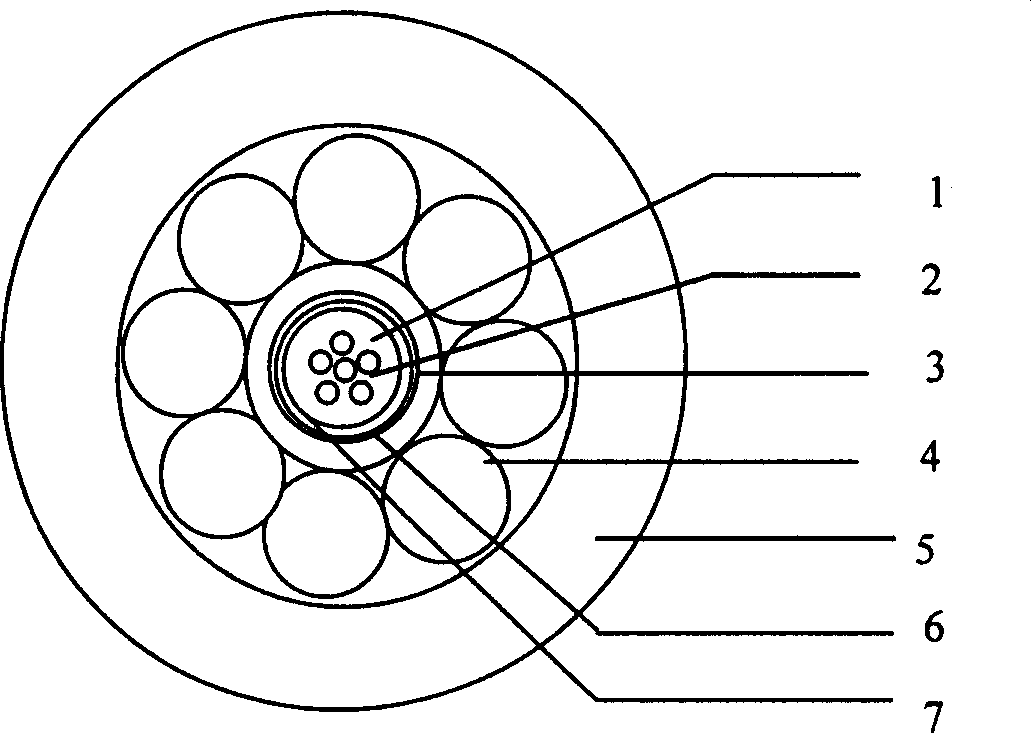

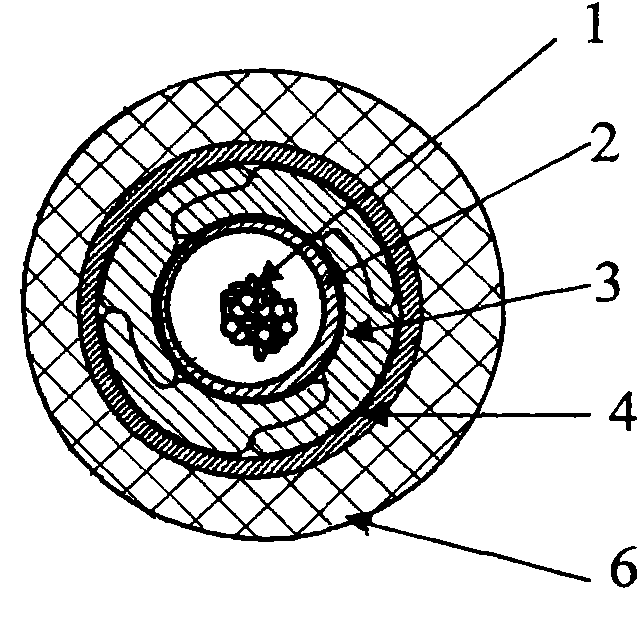

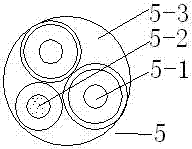

Buoyancy controllable optoelectrical composite cable

InactiveCN101866720AReasonable and flexible control of buoyancyGuaranteed tensile strength requirementsCommunication cablesFloating cablesCoaxial cableUnderwater

The invention relates to a buoyancy controllable optoelectrical composite cable comprising a cable core and a sheath, wherein the sheath is sleeved outside the cable core, the cable core comprises a reinforcing core, more than one optic bundle tube and a power lead, wherein the optic bundle tubes are twisted around the reinforcing core and comprise a loose tube, optical fibers arranged in the loose tube and filling fiber paste. The buoyancy controllable optoelectrical composite cable is characterized in that more than one buoyancy control unit twisting layer is additionally arranged in the sheath, a buoyancy control unit is a physical foamed plastic filling rope or a hollow plastic tube, the reinforcing core is formed by covering a plastic cushion layer by aramid fiber, the sheath mainly comprises a first water-blocking taping layer, two buoyancy control unit twisting layers, a second water-blocking taping layer, an aramid fiber reinforcing layer and an outer polyurethane sheath which are coated on the cable core sequentially, and a copper core signal wire and / or a coaxial cable signal wire are / is arranged in the cable core. The invention has the advantages of reasonably and flexibly controlling the buoyancy of an optoelectrical composite cable, satisfying special application requirements of operation positioned on a water surface or underwater and obviously improving the tension intensity.

Owner:天津立孚光电科技股份有限公司

Non-universal optical unit of submarine photoelectric composite cable and making method thereof

ActiveCN1862303AReasonable designCompact structureFibre mechanical structuresOcean bottomHigh intensity

The present invention relates to a submarine photoelectric composite cable non-universal type optical unit and its manufacture method. Its structure includes the following several portions: several optical fibres, plastic tube, stainless steel tube, water-proof material, high-strength armouring steel wire and external protective layer. Said invention also provides the concrete steps of its manufacture method.

Owner:ZHONGTIAN TECH SUBMARINE CABLE CO LTD

Side pressure resistant submarine optical fiber cable core

InactiveCN101943777AStable structureImprove tensile strengthFibre mechanical structuresOptical communicationCopper

The invention discloses a side pressure resistant submarine optical fiber cable core, which consists of an optical fiber, a protective tube, a side pressure resistant shell, a feed or detection copper tuber or copper strap, an internal armored steel wire, an insulating sheath and a filling wire. The side pressure resistant submarine optical fiber cable core is characterized in that a layer of tubular strong side pressure resistant shell stranded by a special-shaped wire is stranded outside the optical fiber unit. The side pressure resistant submarine optical fiber cable core has the advantages of remarkably improving the tensile stress and side pressure resistance of the cable core, ensuring that the submarine optical fiber is not damaged and facilitating safer and more reliable operation of optical communication along with very firm structure.

Owner:江苏通光海洋光电科技有限公司

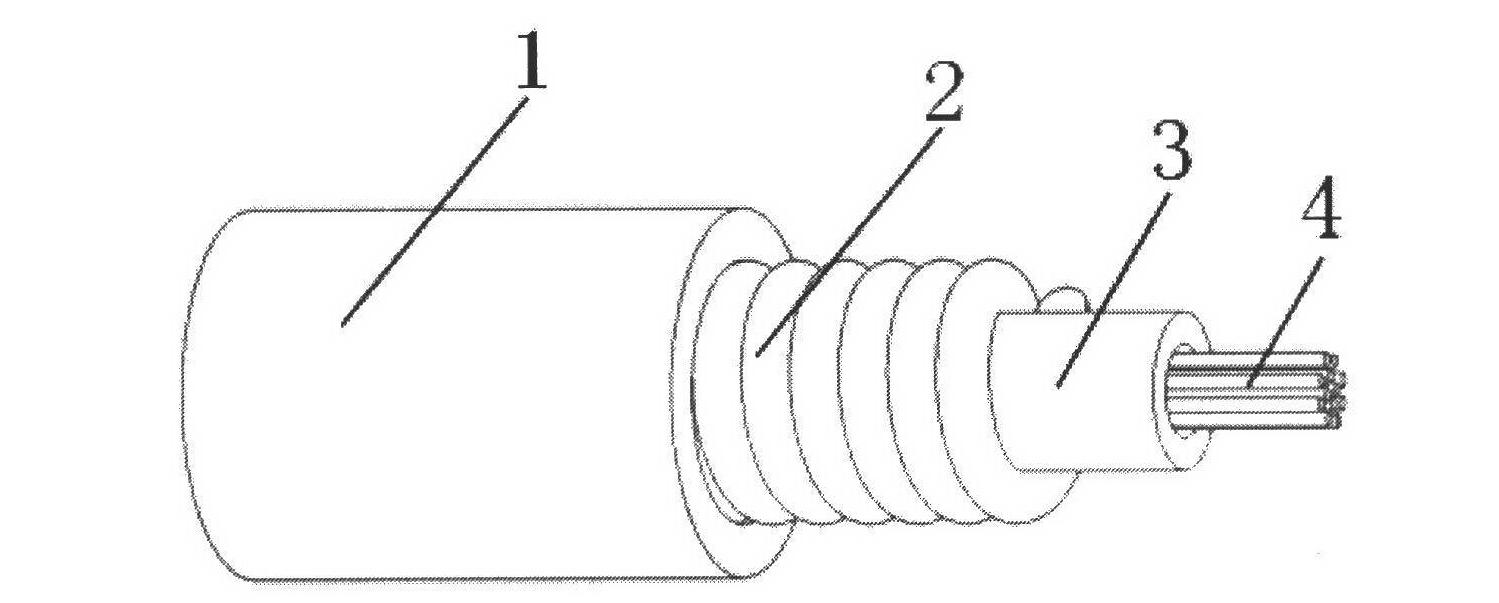

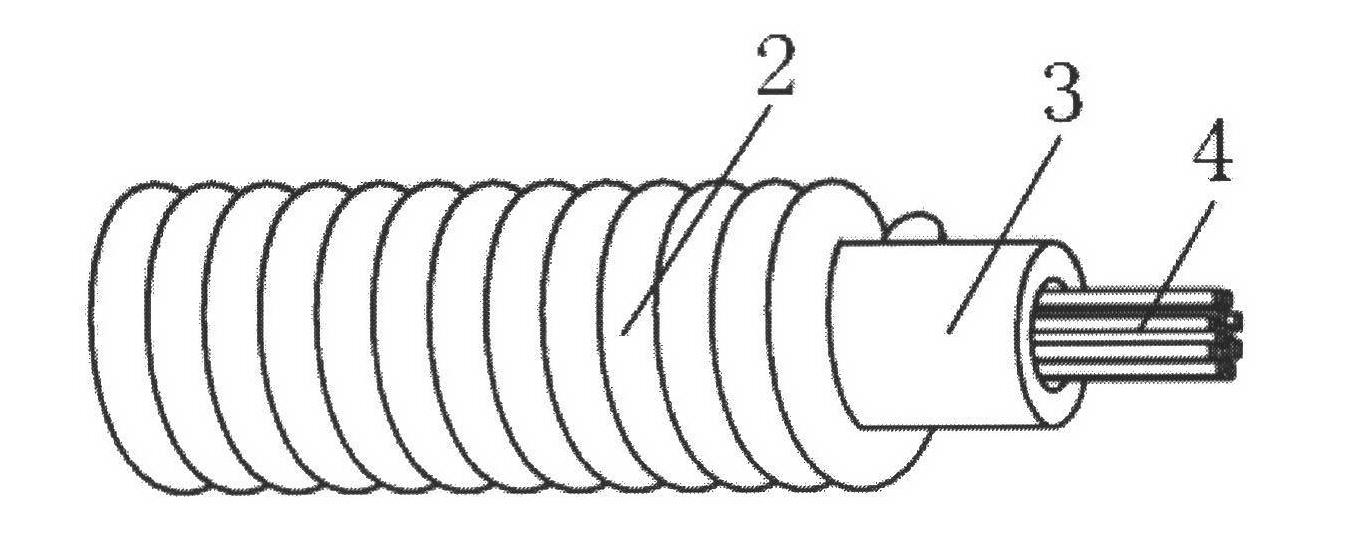

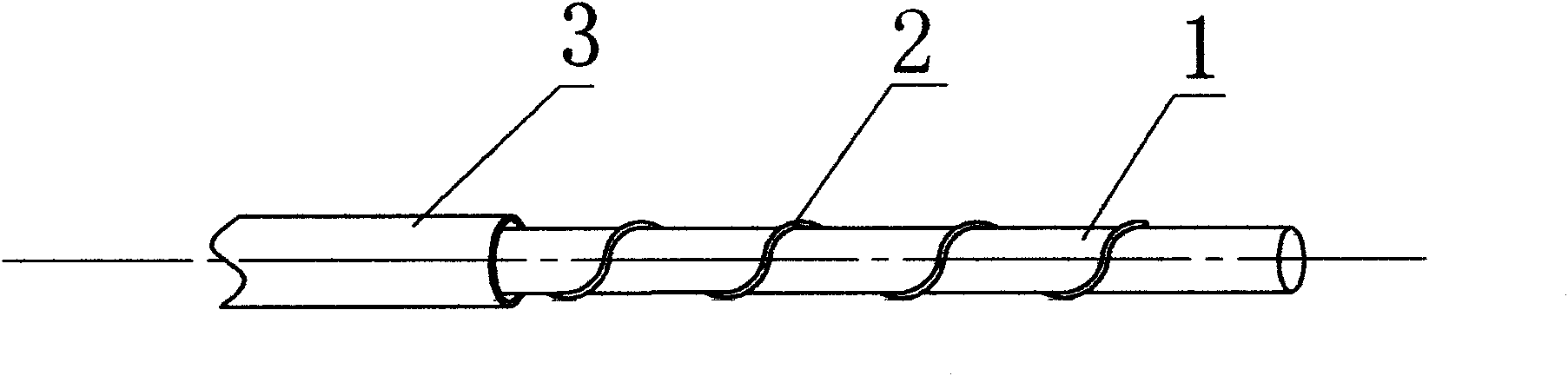

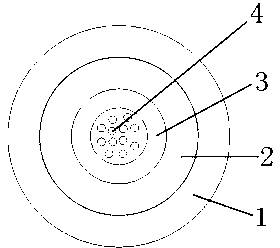

Spring cable

InactiveCN102590969AGood tensile strain resistanceImprove lateral pressure resistanceFibre mechanical structuresFiberTensile strain

The invention belongs to the technical field of cables, and particularly relates to a spring cable. The spring cable comprises a hollow central beam tube which is positioned in the center and a plurality of optical fibers which are positioned in the hollow part of the central beam tube. The spring cable is characterized in that the external of the central beam tube is provided with a spring armor layer which clings to the outer wall of the central beam tube; spring wires of adjacent layers in the spring armor layer are close to each other; and the spring armor layer is externally extruded with a jacket layer. The invention also discloses a device for forming the spring armor layer. Protected by the spring armor layer, the spring cable has excellent resistances to tensile strain, to side pressure and to bending and the spring cable is more flexible and has a wider application range; and the device is simple and reliable, the cost is low and the production method is simple and easy to learn.

Owner:国网山东东阿县供电公司

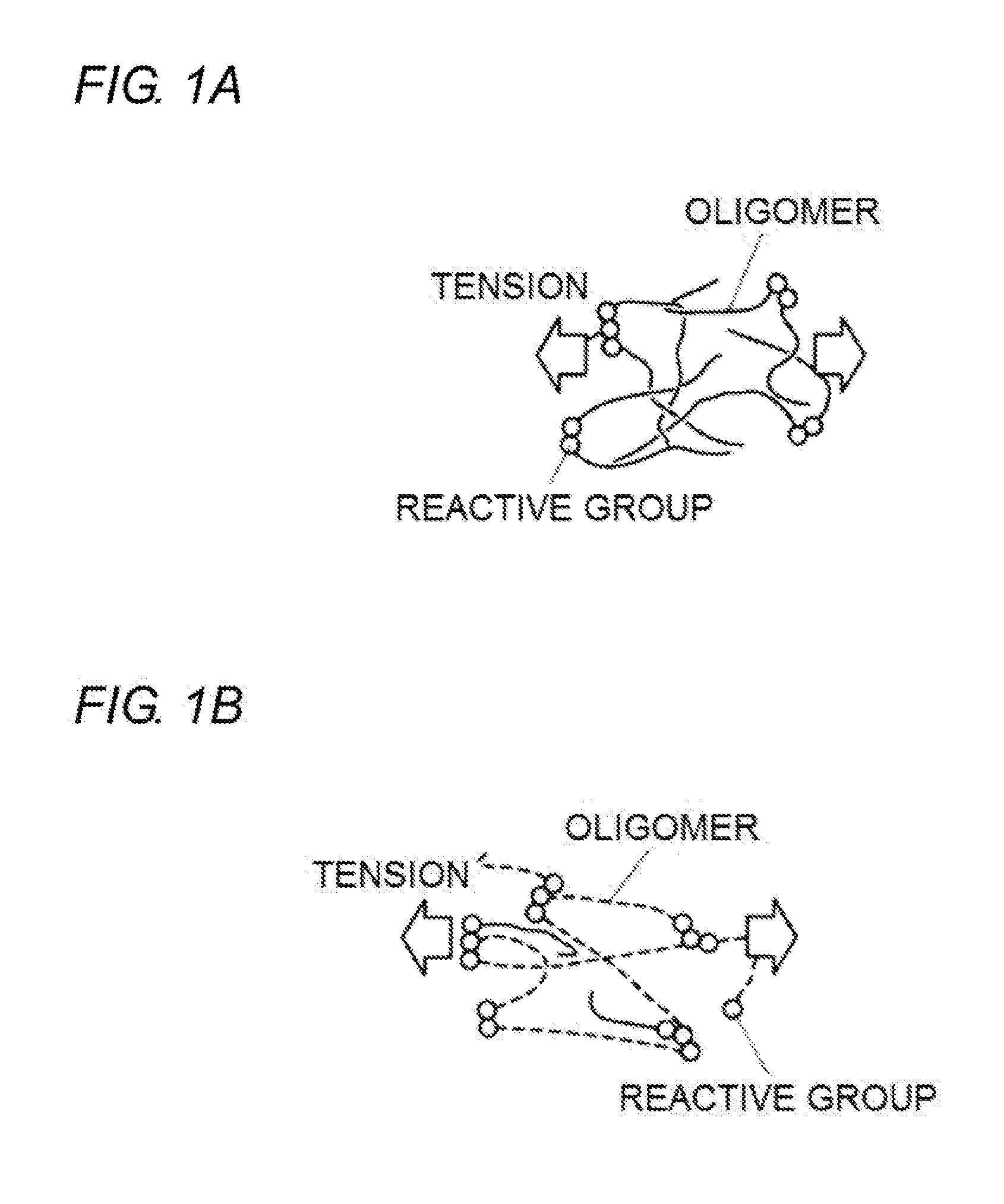

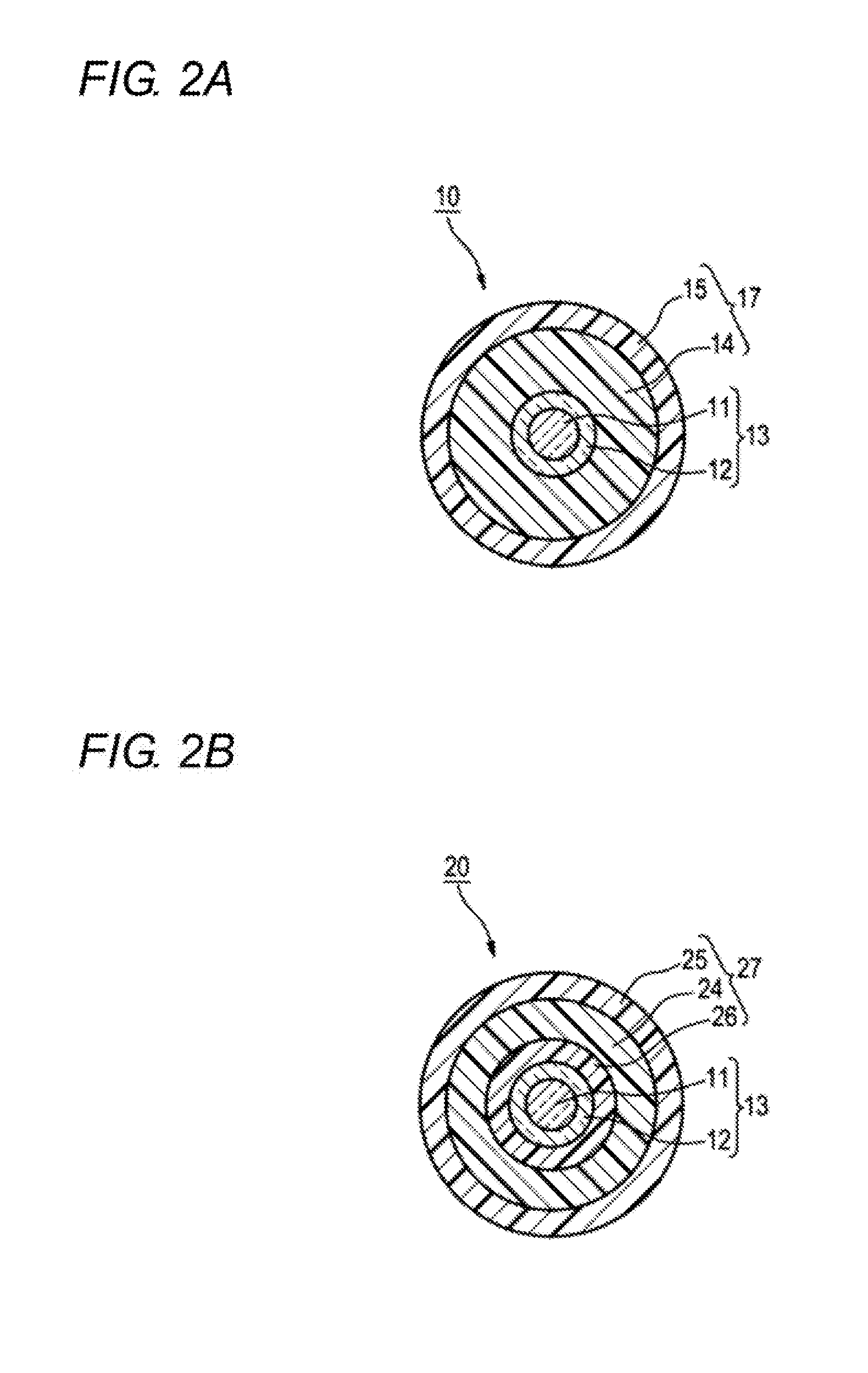

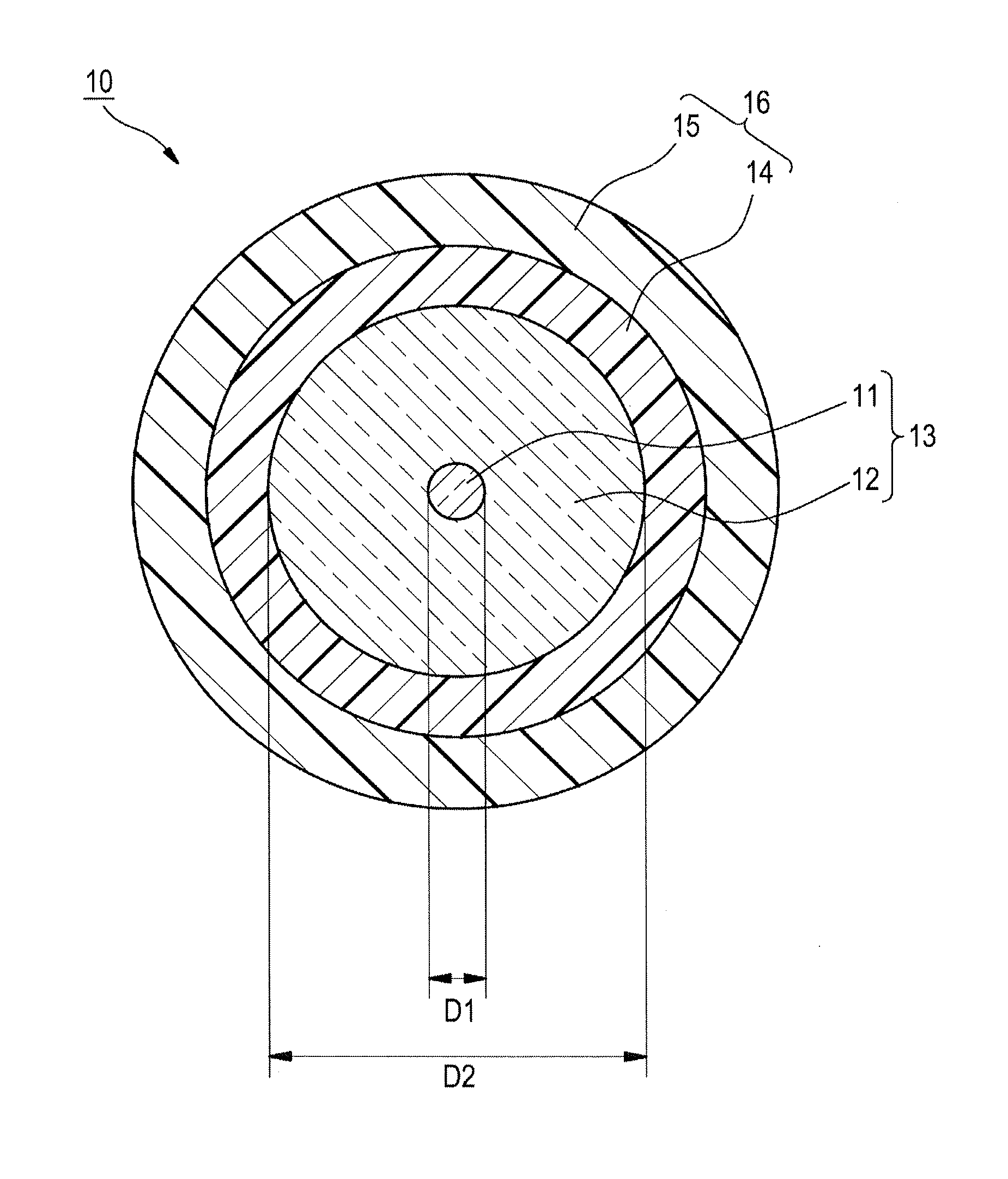

Optical fiber

ActiveUS20170003446A1Modulus is reducedResistance to deteriorationGlass optical fibreOptical fibre with graded refractive index core/claddingGlass fiberFiber

An optical fiber comprises a glass fiber which comprises a core and a cladding, a primary resin coating layer which covers the periphery of the glass fiber, and a secondary resin coating layer which covers the periphery of the primary resin coating layer. The glass fiber is a multimode fiber having a core diameter of 40-60 μm and a cladding diameter of 90-110 μm, and the primary resin coating layer is a layer formed by curing a curable resin composition which comprises oligomers, monomers, and a reaction initiator, the curable resin composition containing a one-end-capped oligomer in an amount of 30% by mass or larger based on all the oligomers.

Owner:SUMITOMO ELECTRIC IND LTD

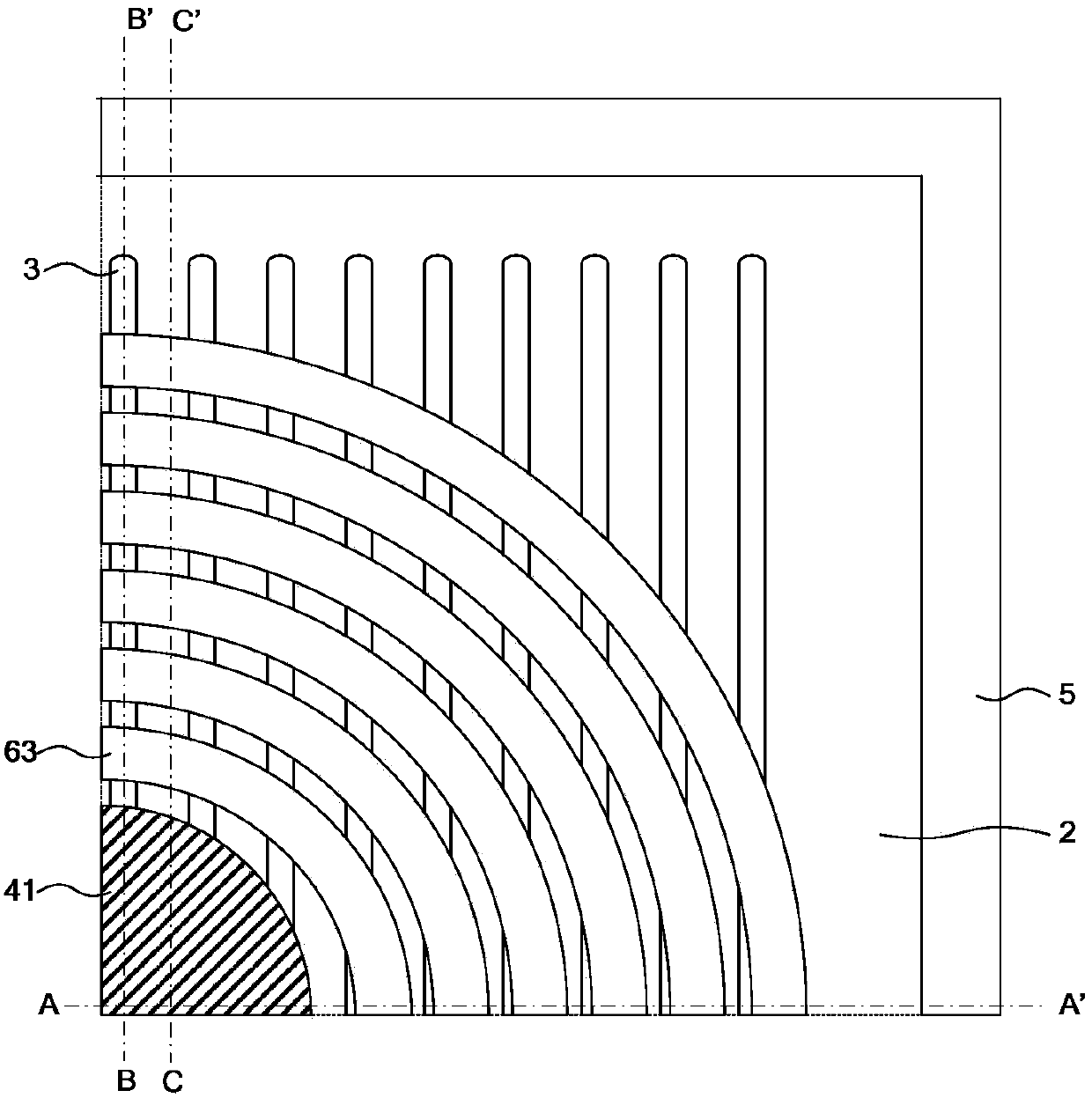

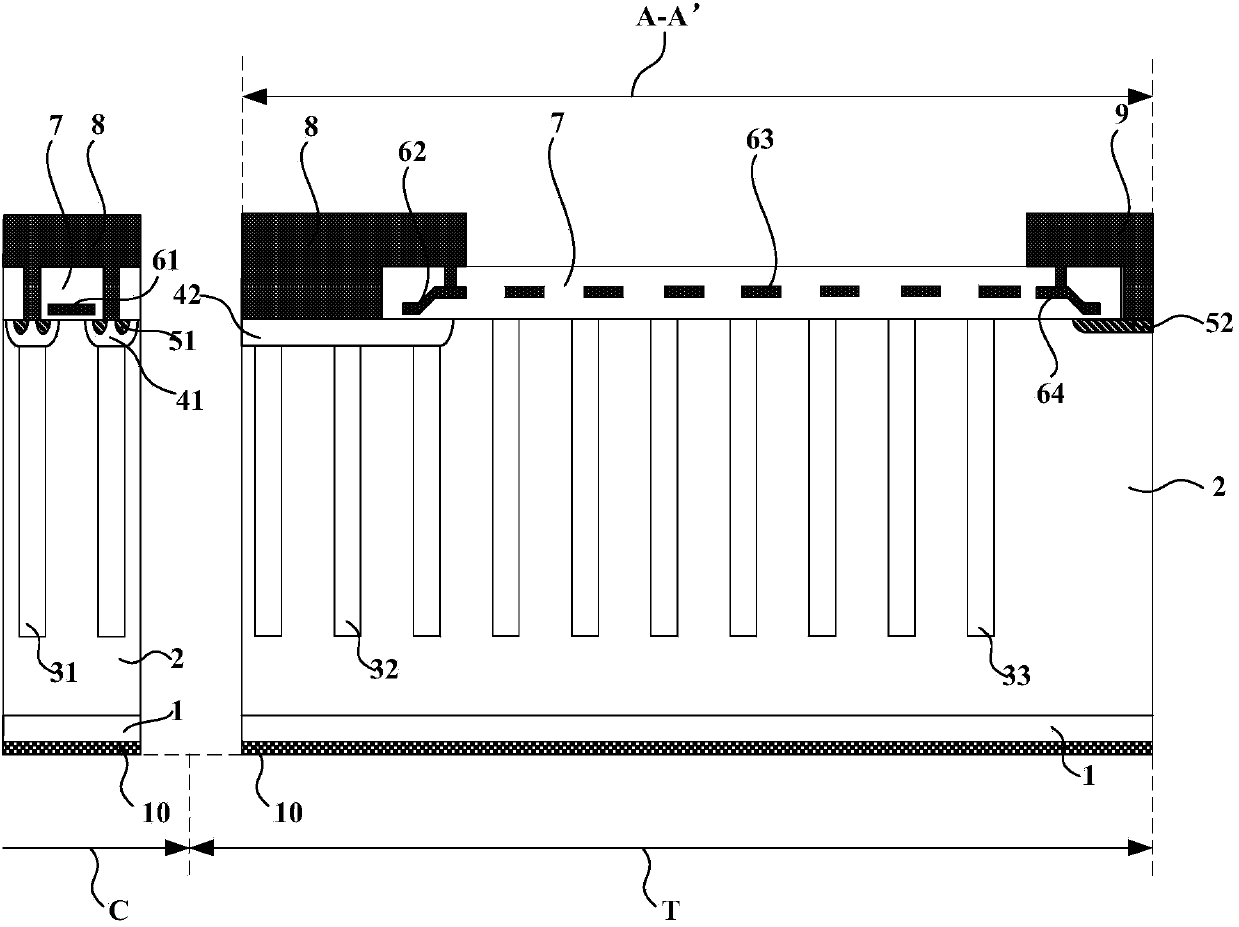

Semiconductor device with super junction structure

InactiveCN103779399AManufacturing process will not increaseImprove reliabilitySemiconductor devicesGate oxideDielectric layer

The invention provides a semiconductor device with a super junction structure. The semiconductor device comprises an N-type doped semiconductor substrate and an N-type doped epitaxial layer, wherein the N-type doped semiconductor substrate and the N-type doped epitaxial layer are sequentially arranged from bottom to top, and a first P-type filling well region, a second P-type filling well region and a third P-type filling well region are arranged inside the N-type doped epitaxial layer. A first P-type doping region is arranged on the upper side of the first P-type filling well region and provided with an N-type doping region, and a second P-type doping region is arranged on the upper side of the second P-type filling well region. A terminal pressure-withstanding structure T is arranged on the periphery of a primitive cell source electrode region C, wherein the terminal pressure-withstanding structure T comprises the second P-type filling well region, the second P-type doping region, the third P-type filling well region and the corresponding part of the N-type doped epitaxial layer, and the primitive cell source electrode region C comprises the first P-type filling well region, the first P-type doping region, the N-type doping region and the corresponding part of the N-type doped epitaxial layer. The parts, corresponding to polycrystalline silicon arranged in a part of dielectric layer above a gate oxide layer, of the terminal pressure-withstanding structure T and the primitive cell source electrode region C form a gate electrode structure and a polycrystalline silicon field plate structure respectively.

Owner:XIAN SEMIPOWER ELECTRONICS TECH

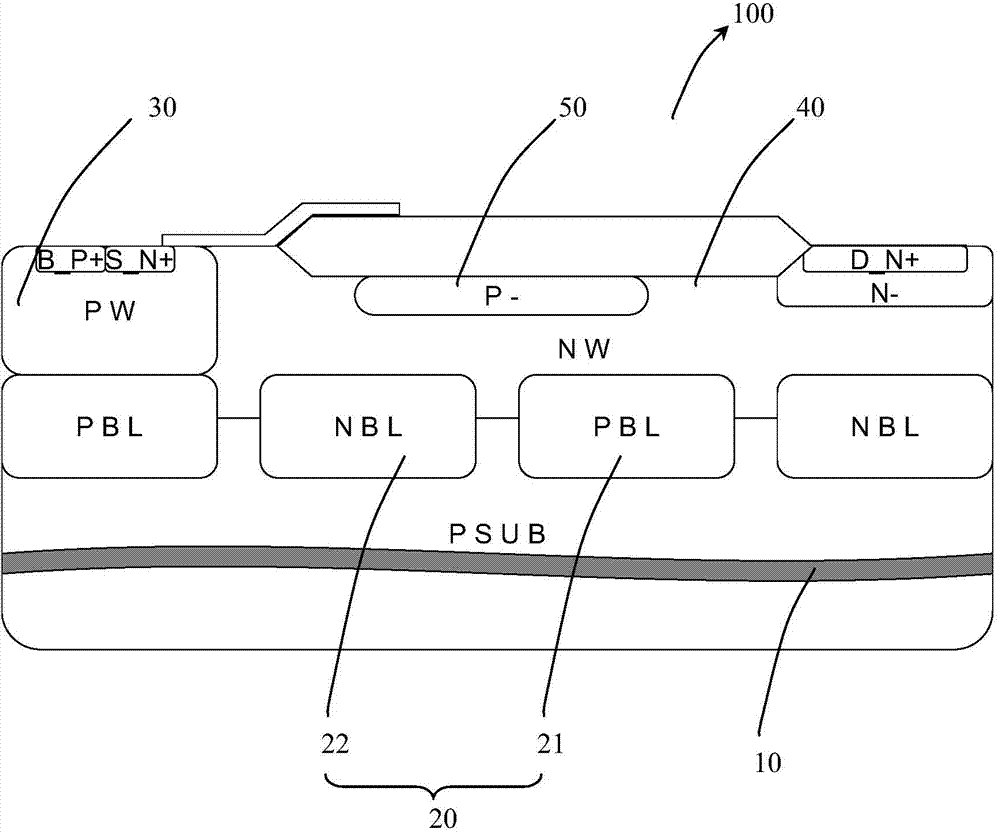

High-voltage LDMOS (laterally-diffused metal oxide semiconductor) device

ActiveCN104518023AIncrease the cross-sectional areaReduce push timeSemiconductor devicesOxide semiconductorOxide

A high-voltage lateral double-diffused metal oxide semiconductor (LDMOS) device comprises a P-type channel region, an N-type drift region, a voltage-resistance layer, and a P-type substrate located at the bottom, the voltage-resistance layer being provided between the P-type substrate and the N-type drift region. For the high-voltage LDMOS device, the trapping time in the process is shortened by adding a voltage-resistance layer, thereby increasing a sectional area of a current channel, improving the on resistance, and further enhancing lateral voltage resistance by enhancing longitudinal voltage resistance.

Owner:CSMC TECH FAB2 CO LTD

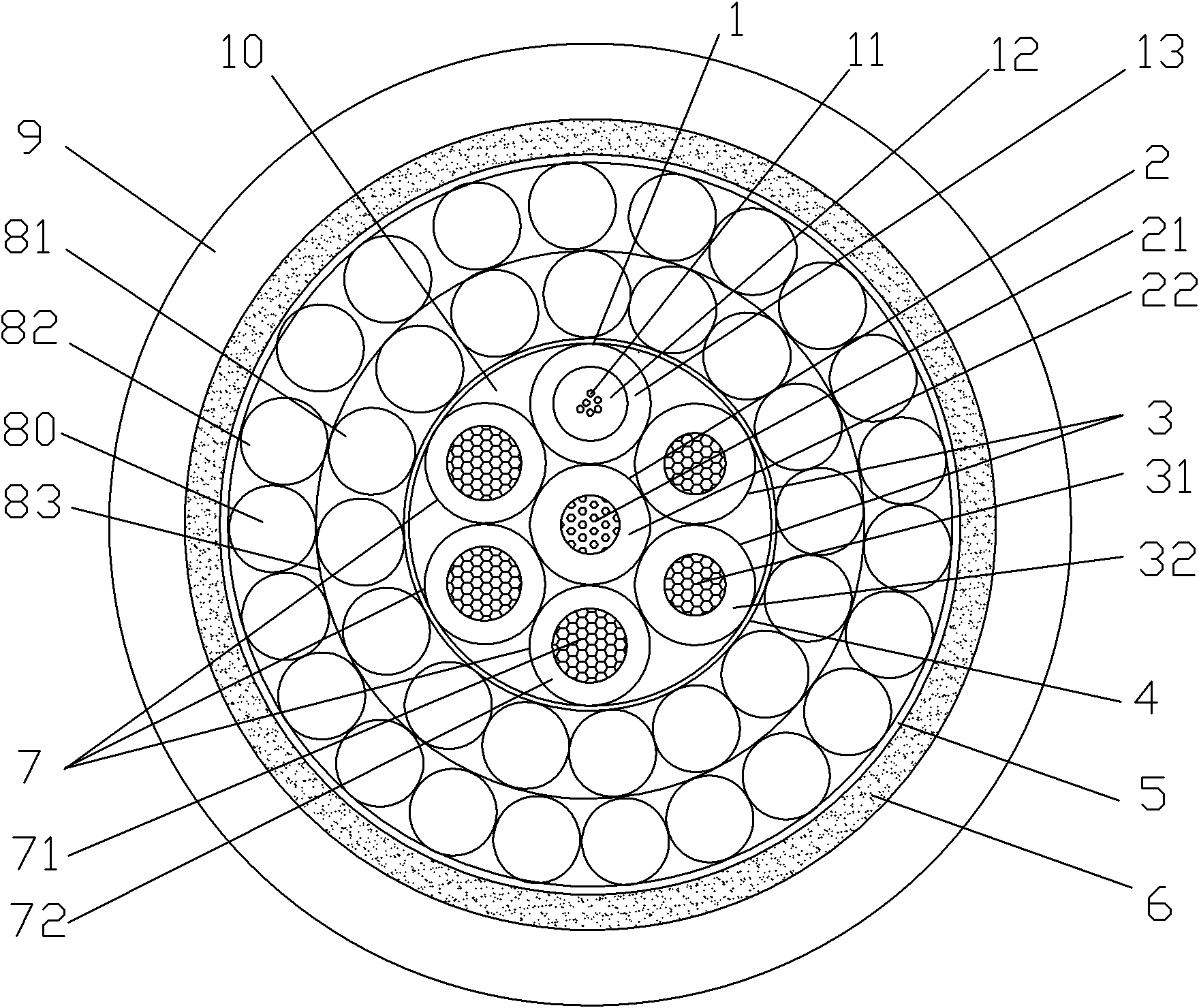

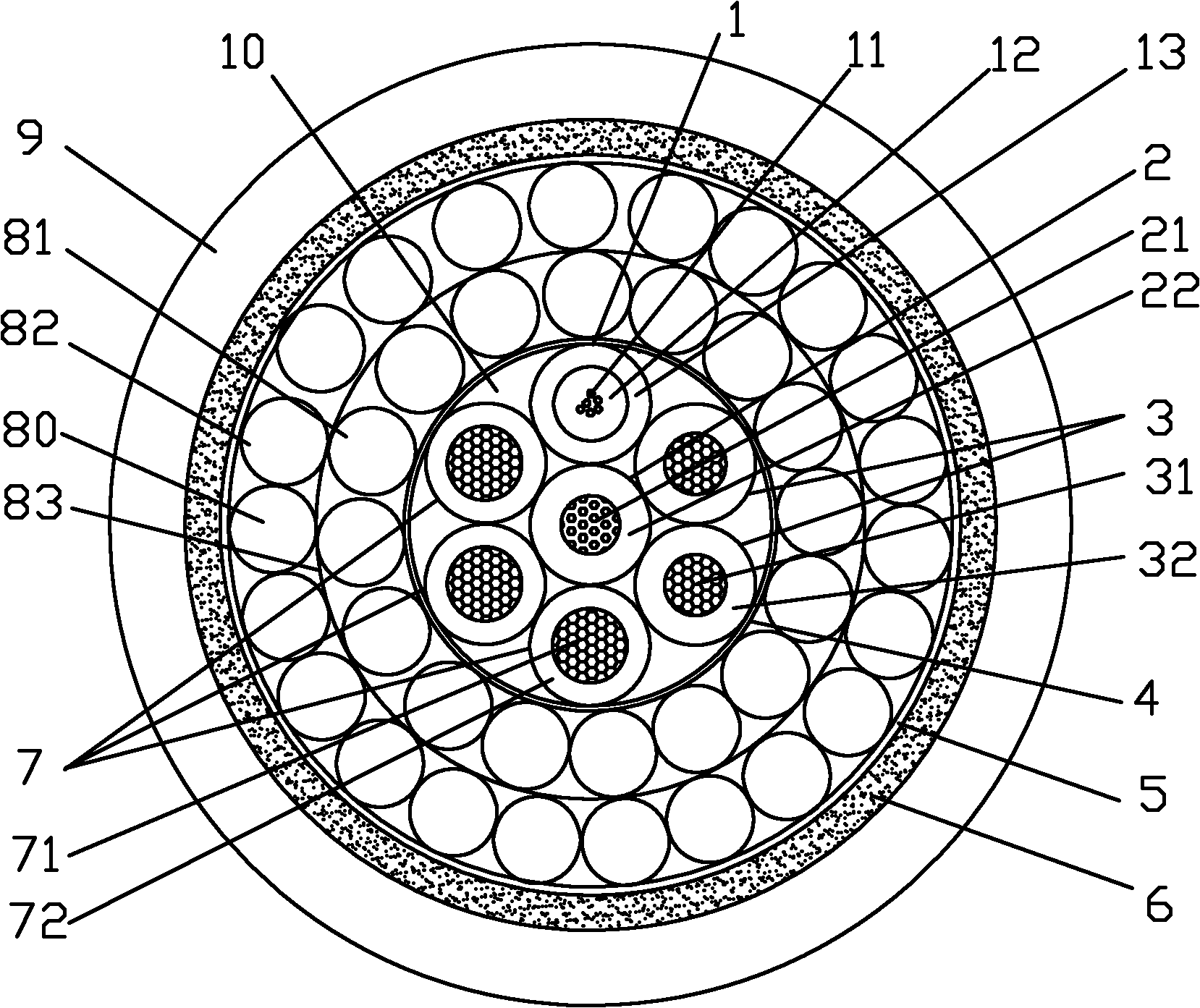

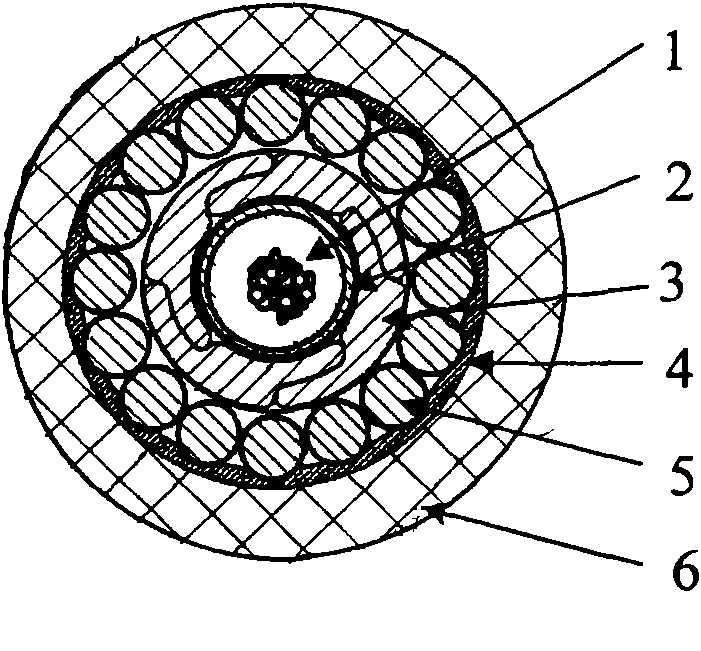

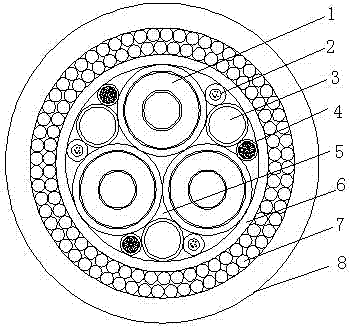

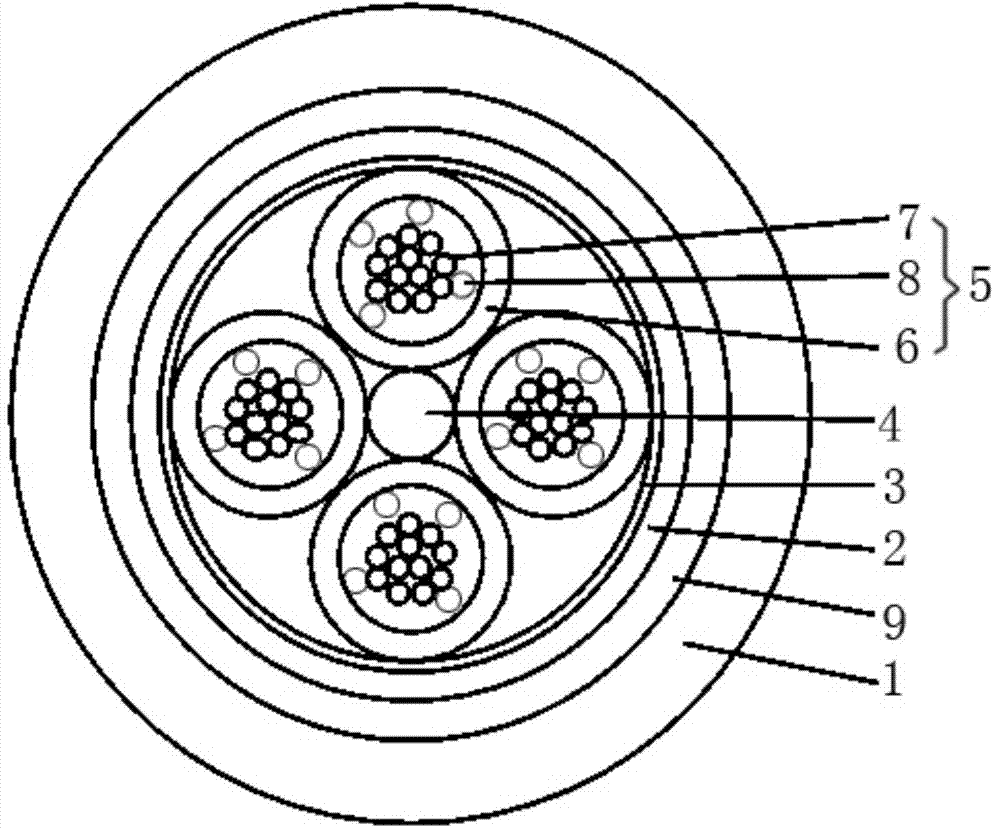

Array digital analogy integrated signal cable for offshore oil platform underwater pre-warning system

ActiveCN103680724AImprove lateral pressure resistanceHigh tensile strengthCoaxial cables/analogue cablesBraided wire conductorsCoaxial cableMarine engineering

The invention provides an array digital analogy integrated signal cable for an offshore oil platform underwater pre-warning system, and relates to the technical field of offshore oil platforms or underwater security and protection facility array signal cables. The array digital analogy integrated signal cable is an integrated cable with strong current analog and digital signals and weak current analog and digital signals in a mixed mode. The array digital analogy integrated signal cable comprises a center reinforcing unit, a seven-core cable unit, a five-core cable unit, a main woven shielding layer, a coaxial-cable unit, an inner protection layer, an armor layer and an outer protection layer. The center reinforcing unit or the coaxial-cable unit is internally provided with optical fibers for transmitting optical signals. The seven-core cable unit is arranged outside the center reinforcing unit, the five-core cable unit and the coaxial-cable unit are arranged outside the seven-core cable unit, the main woven shielding layer is arranged outside the five-core cable unit and the coaxial-cable unit, the inner protection layer is arranged outside the main woven shielding layer, the armor layer is arranged outside the inner protection layer, and the outer protection layer is arranged outside the armor layer.

Owner:ZHONGTIAN TECH SUBMARINE CABLE CO LTD

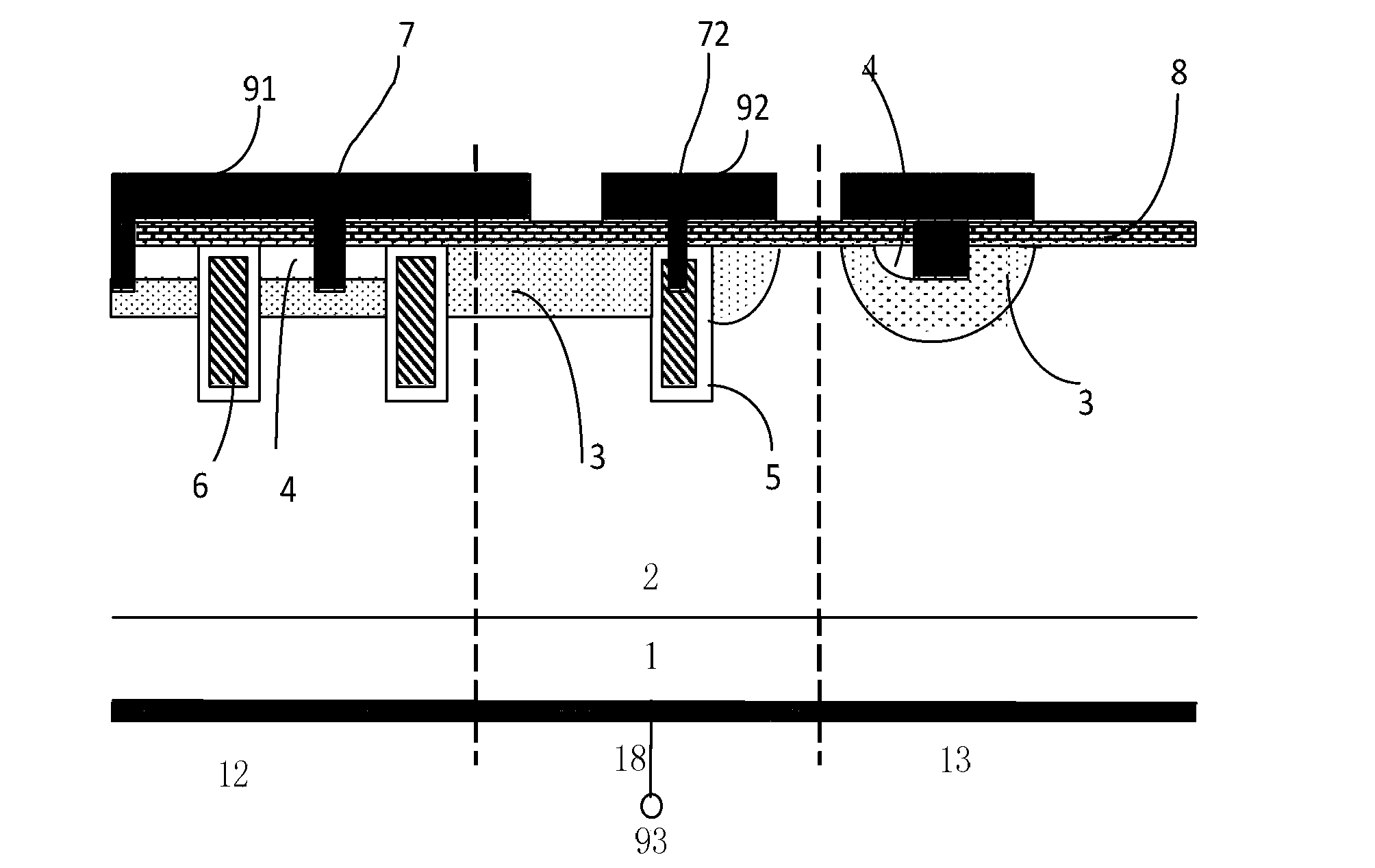

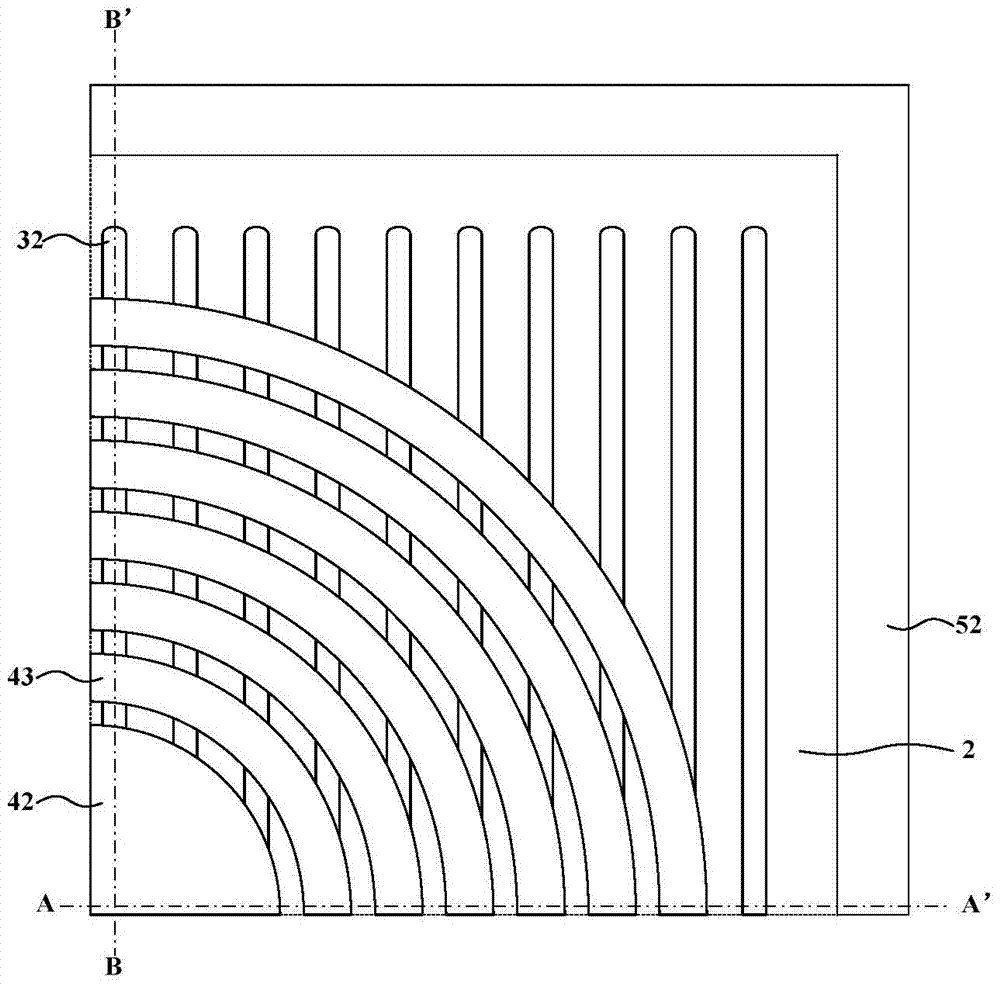

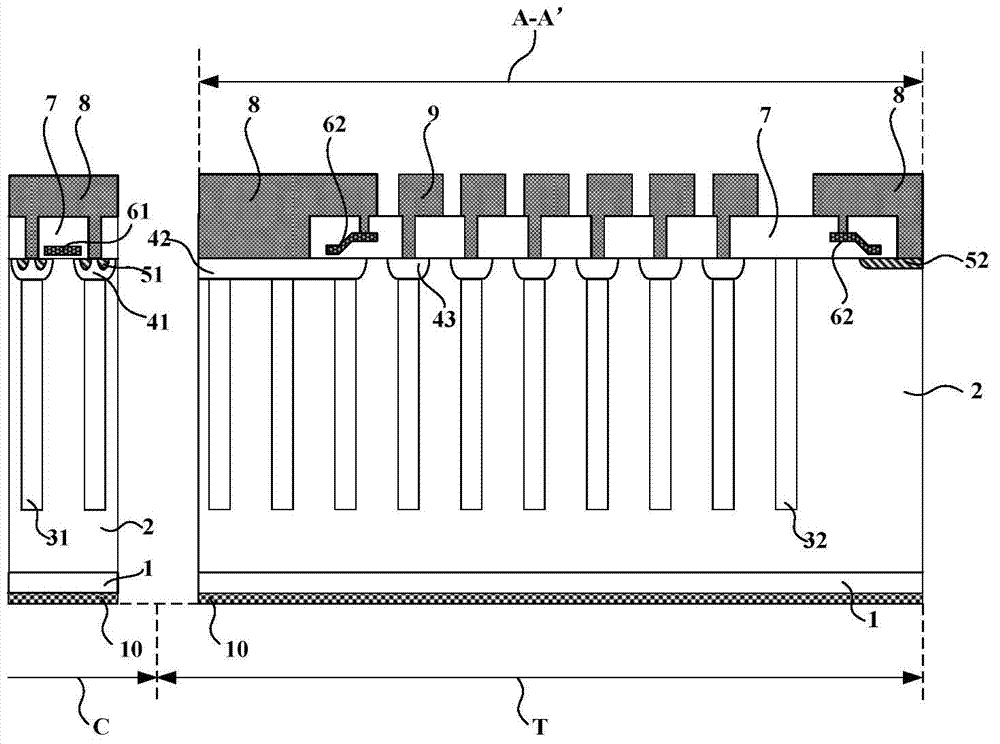

Groove MOSFET with terminal voltage-withstanding structure and manufacturing method of groove MOSFET

ActiveCN103824883AReduce leakageImprove pressure resistanceSemiconductor/solid-state device manufacturingSemiconductor devicesIsolation effectTrench mosfet

The invention brings forward a groove MOSFET with a terminal voltage-withstanding structure and a manufacturing method of the groove MOSFET. Grooves are formed in a cellular area and a terminal area of the groove MOSFET respectively. The grooves of the terminal area are at least two enclosed annular grooves which surround the cellular area. At least one annular groove, which is close to the cellular area, is an isolation ring which is connected with a zero potential. At least one annular groove, which is close to a scribing channel, is a cutoff ring which is connected with the scribing channel. According to the groove MOSFET with the terminal voltage-withstanding structure, the isolation ring is connected with the zero potential so that electric leakage can be effectively inhibited; and the cutoff ring is connected with the scribing channel so that carriers are not accumulated along the cutoff ring, and thus isolation effect and voltage-withstanding effect of the terminal voltage-withstanding structure are enhanced. According to the manufacturing method, voltage-withstanding and electric leakage problems of the groove MOSFET prepared by the three-layer photo-etching technology are solved, transverse electric leakage of the groove MOSFET is reduced, voltage withstanding of devices is enhanced, technology process is simplified and manufacturing cost is lowered without increasing technology complexity.

Owner:BYD SEMICON CO LTD

Flame retardant optical cable

InactiveCN106019514AEasy to bendImprove stress resistanceFibre mechanical structuresCable transmissionPolyolefin

The invention provides a flame retardant optical cable which comprises a cable core and also comprises a first water blocking belt layer, a metal composite belt layer, a flame retardant inner protective layer, a second water blocking belt layer, a ceramic flame retardant composite belt layer, a steel plastic composite layer and a flame retardant outer protective layer which are orderly arranged outside the cable core. In order to prevent the cracking of a low smoke halogen free flame retardant polyolefin outer sheath, when the flame retardant optical cable is laid, the laying speed should be slowed down appropriately. The optical cable has excellent bending and compression performance and excellent flame retardant and fire resistant performance. The ceramic flame retardant composite belt arranged in the outer sheath is soft in a normal state, the bending performance of the optical cable is not affected, after the optical cable is laid, a hard ceramic shell can be formed to protect the optical cable. The smoothness of a line in a fire is ensured, the system failure of optical cable transmission is prevented, and the safety of life and property is protected to the maximum.

Owner:TONGDING INTERCONNECTION INFORMATION CO LTD

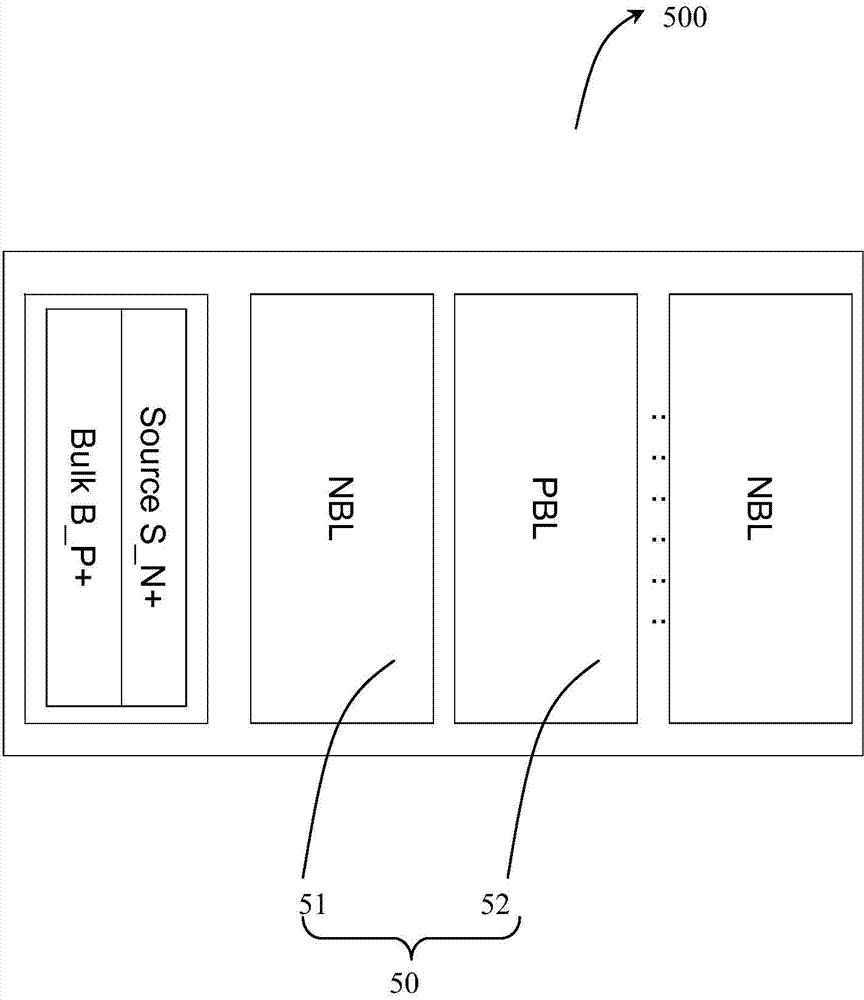

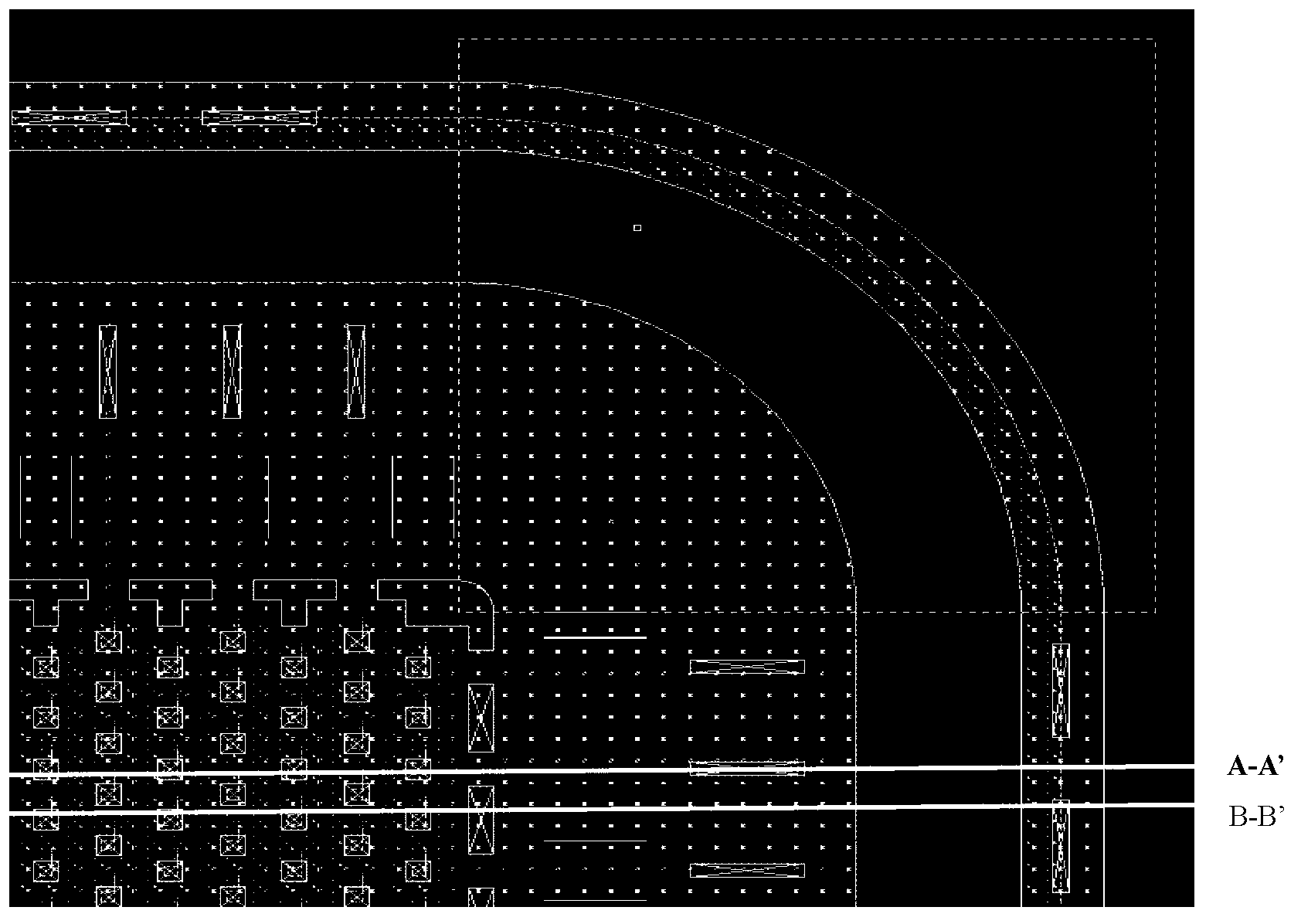

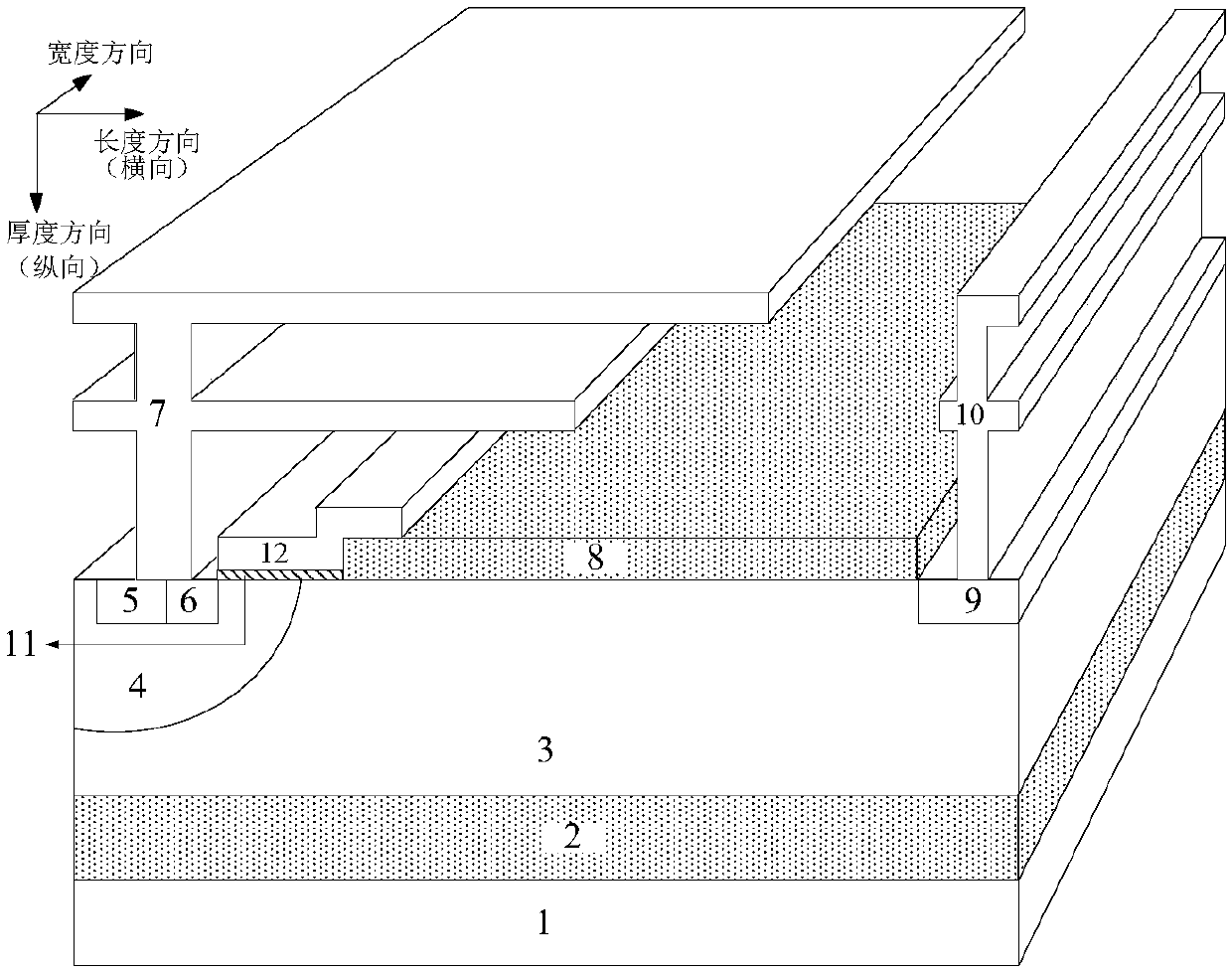

Longitudinal super junction metal oxide field effect transistor

ActiveCN103700697ATo achieve uniform distributionLarge PN junction contact area ratioSemiconductor devicesTerminal voltageField-effect transistor

The invention discloses a longitudinal super junction metal oxide field effect transistor, which comprises an N type doped semiconductor substrate and an N type doped epitaxial layer formed in sequence from bottom to top, wherein a first P type filling trap area and second P type filling trap areas with the same structures are formed inside the N type doped epitaxial layer from inside to outside; the upper side of the first P type filling trap area is provided with a first P type doped area; a second P type doped area and a P type doped unipotential ring are arranged on the upper side of each second P type filling trap area from inside to outside, and a terminal voltage-resistant structural area T is formed by the three parts; the second P type doped areas are arranged corresponding to the second P type filling trap areas; the P type doped unipotential rings are larger than the second P type filling trap areas in widths, and are correspondingly arranged in parallel over the second P type filling trap areas respectively along the length direction of the transistor; an N type doped area is arranged in each P type doped area, and constructs a primitive cell source electrode area C with the first P type filling trap area. By adopting the transistor, the surface potential distribution is optimized.

Owner:XIAN SEMIPOWER ELECTRONICS TECH

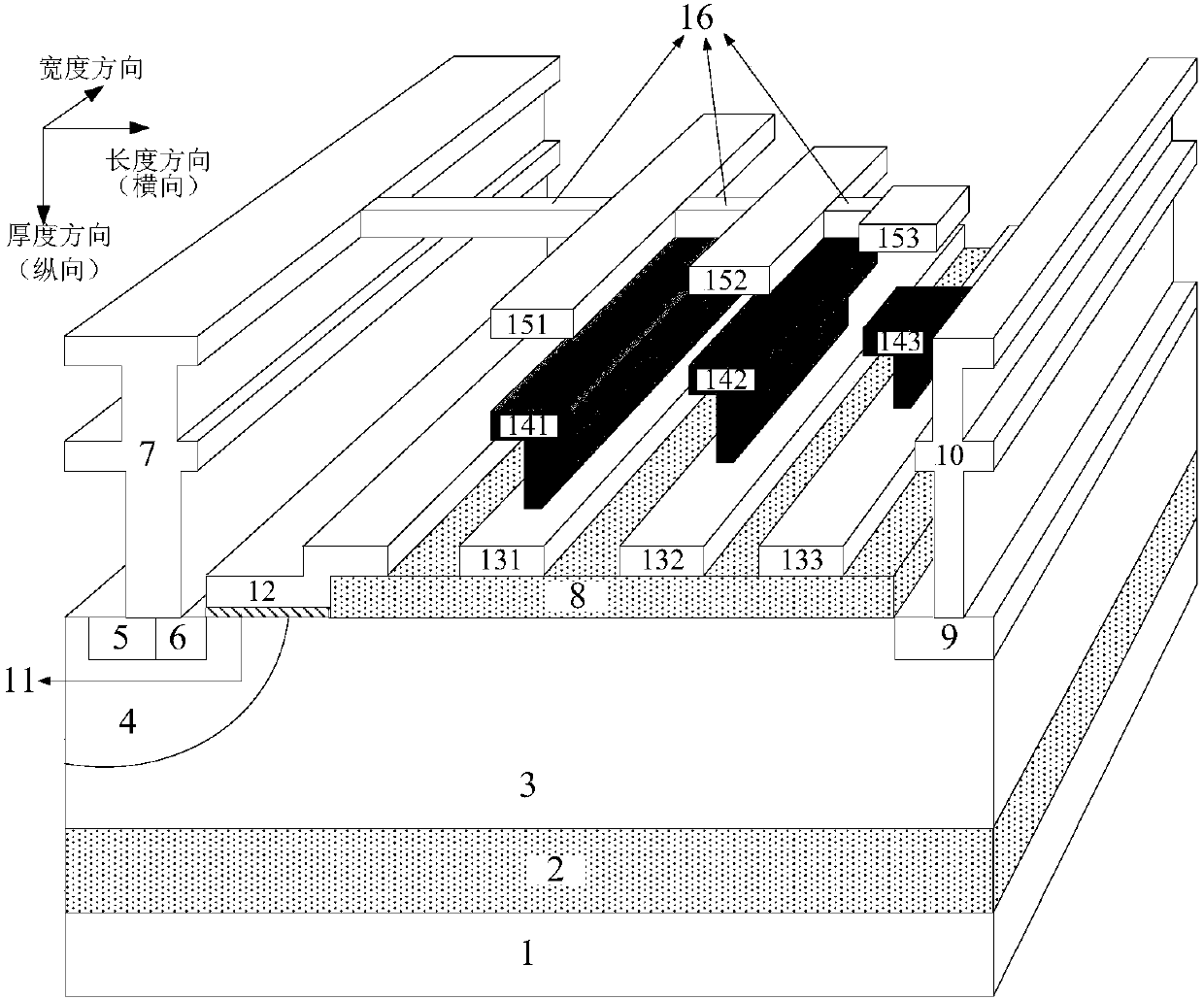

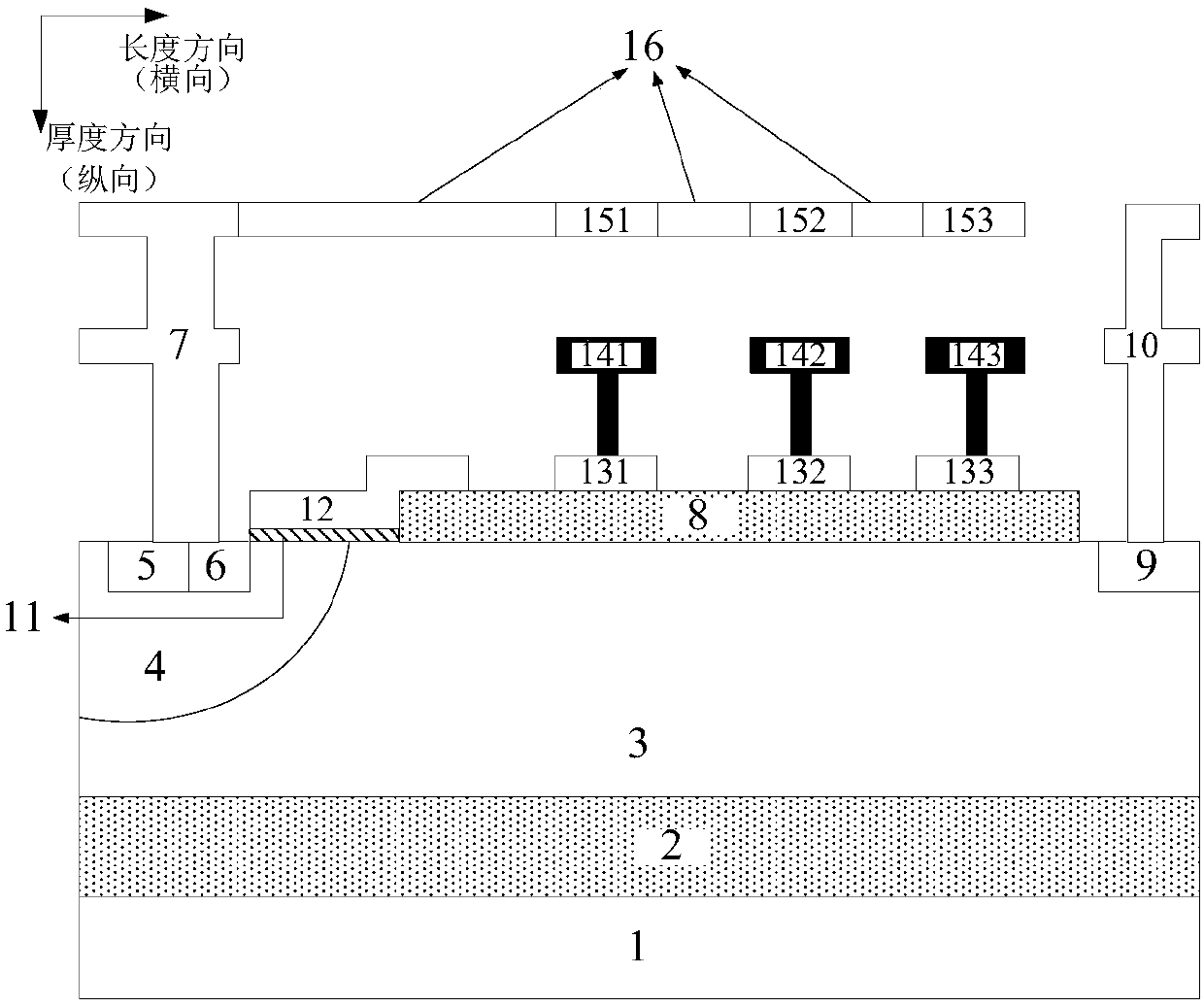

Lateral double-diffused metal oxide semiconductor field effect transistor with adjustable field plates

ActiveCN107680997AImprove lateral pressure resistanceUniform distribution of transverse electric fieldSemiconductor devicesCapacitanceField-effect transistor

The invention provides a lateral double-diffused metal oxide semiconductor field effect transistor with adjustable field plates. The lateral double-diffused metal oxide semiconductor field effect transistor comprises a field oxide layer and a drift region located at the lower part of the field oxide layer, wherein the surface of the field oxide layer is provided with a plurality of adjustable field plates; two adjacent adjustable field plates are spaced at a set distance; and each adjustable field plate is connected with a regulating capacitor. Inductive charge quantity and inductive potentialon each adjustable field plate can be adjusted through adjusting the sizes of the adjustable field plates and positive and negative electrodes of the regulating capacitor, so that uniform surface transverse electric field distribution is obtained in the drift region. According to the lateral double-diffused metal oxide semiconductor field effect transistor, the surface transverse electric field distribution of the drift region can be improved and the lateral double-diffused metal oxide semiconductor field effect transistor has very high lateral voltage endurance capability and very low on-resistance.

Owner:UNIV OF JINAN

Pressure-sensitive optical cable with armor layer

InactiveCN101852904AImprove environmental adaptabilityNo reduction in bendabilityForce measurement by measuring optical property variationFibre mechanical structuresYarnTime domain

The invention discloses a pressure-sensitive optical cable with armor layer, which takes a signal optical fiber and fiber yarns spirally wound on the signal optical fiber and which is peripherally provided with an armor layer and an outer protective layer in sequence. As pressure is applied to the pressure-sensitive optical cable, the fiber yarns spirally wound on the signal optical fiber lead the signal optical fiber to bending deformation in order to change the bending loss of the signal optical fiber. As a result, pressure signals are converted into optical signals which are then transmitted via the signal optical fiber to achieve the purpose of remote measurement. The armor layer made of fine fiber material has the characteristics of excellent bending flexibility, facilitating manufacture, storage, transportation and use of the pressure-sensitive optical cable, similarity to common optical cables, being capable of remarkably reducing manufacturing and use costs, and having no impact on pressure detection. The pressure-sensitive optical cable has simple structure, reasonable design, convenient processing and manufacturing, diversified using ways, high sensitivity and good using effect, and distributive pressure measurement can be realized by means of optical time domain reflectometer or other measurement instruments.

Owner:XIAN JINHE OPTICAL TECH

Composite jumper cable for offshore oil platform

ActiveCN103680754AFully consider water resistanceReasonable structureRubber insulatorsCommunication cablesElectric power transmissionCommunication unit

The invention discloses a composite jumper cable for an offshore oil platform, and relates to the technical field of cable connection between offshore oil platforms, between an offshore oil platform and an oil tanker, between oil tankers, and between an offshore fixed facility and a movable facility, and transmission of power energy resources, control signals, communication signals, oil, gas, water and the like. The composite jumper cable comprises three power transmission split-phase protecting bush insulating cable core units, an optical fiber communication unit, pipeline units, a control cable unit, a filling unit, a buffering and isolating protection unit, high-tensile steel wire reinforcing units and an outer protection layer unit. The three same power transmission split-phase protecting bush insulating cable core units are twisted, the pipeline units are embedded into three large gaps respectively, the optical fiber communication unit and the control cable unit are embedded into parts among the pipeline units respectively, the solid filling unit is arranged in an integral cabling unit, the buffering and isolating protection unit wraps the cabling unit, two layers of the high-tensile steel wire reinforcing units wrap the buffering and isolating protection unit, and the outer protection layer unit wraps the high-tensile steel wire reinforcing units in a squeezing mode.

Owner:ZHONGTIAN TECH SUBMARINE CABLE CO LTD

Silicon on insulator (SOI) pressure resistant structure with interface lateral variation doping

InactiveCN102194832AIncrease the doping concentrationImprove vertical pressure resistanceSolid-state devicesSemiconductor devicesSemiconductorSilicon on insulator

The invention discloses a silicon on insulator (SOI) pressure resistant structure with interface lateral variation doping, and relates to a semiconductor power device comprising a substrate layer, a medium buried layer, an active semiconductor layer and an interface lateral variation doping layer, wherein, the medium buried layer is arranged between the substrate layer and the active semiconductor layer; and the interface lateral variation doping layer is arranged between the medium buried layer and the active semiconductor layer, in the invention, by adopting the condition that the interface lateral variation doping layer is arranged in the active semiconductor layer on the interface of the medium buried layer, when the structure is used in the semiconductor device, and the dosage concentration of the silicon at the top of the lateral variation doping layer terminal interface is higher, thus effectively improving the longitudinal pressure resistance and the lateral pressure resistance of the device, thus the structure can effectively improve the pressure resistance of the whole device, and remit the problem that a 'hot spot' area is generated because the dosage concentration of a source end of a lateral variation doping structure of the whole active semiconductor layer is too low, which can be realized in a thick active semiconductor layer.

Owner:CHONGQING UNIV

Production technology of air-blowing optical fiber cable double-layer co-extrusion casing pipe

InactiveCN105108996AImprove lateral pressure resistanceHigh impact strengthCoatingsCo extrusionOptical fiber cable

The invention discloses a production technology of an air-blowing optical fiber cable double-layer co-extrusion casing pipe. The technology comprises the following steps that (1), PBT is dried at a temperature ranging from 80 DEG C to 90 DEG C, and PC is dried at a temperature ranging from 90 DEG C to 100 DEG C; (2), the dried PC and the dried PBT in the step (1) are put into a first extruder and a second extruder respectively to be molten and plastified, the first extruder extrudes the PC, the temperature of the PC ranges from 268 DEG C to 280 DEG C, the second extruder extrudes PBT, and the temperature of the PBT ranges from 250 DEG C to 265 DEG C; (3), the molten and plastified PC and PBT in the step (2) are jointed in a machine head bush die and then are compositely molded, and meanwhile, an optical fiber which penetrates into a machine head and is filled with ointment is wrapped; (4), the casing pipe with the optical fiber which is molded in the step (3) and wrapped and filled with the ointment is cooled in circulating water at a temperature ranging from 20 DEG C to 40 DEG C, and 4N force is used for carrying out traction while cooling is carried out; and (5), the casing pipe in the step (4) is reeled with the speed ranging from 150 to 220m / min.

Owner:JIANGSU HENGTONG PHOTOELECTRIC

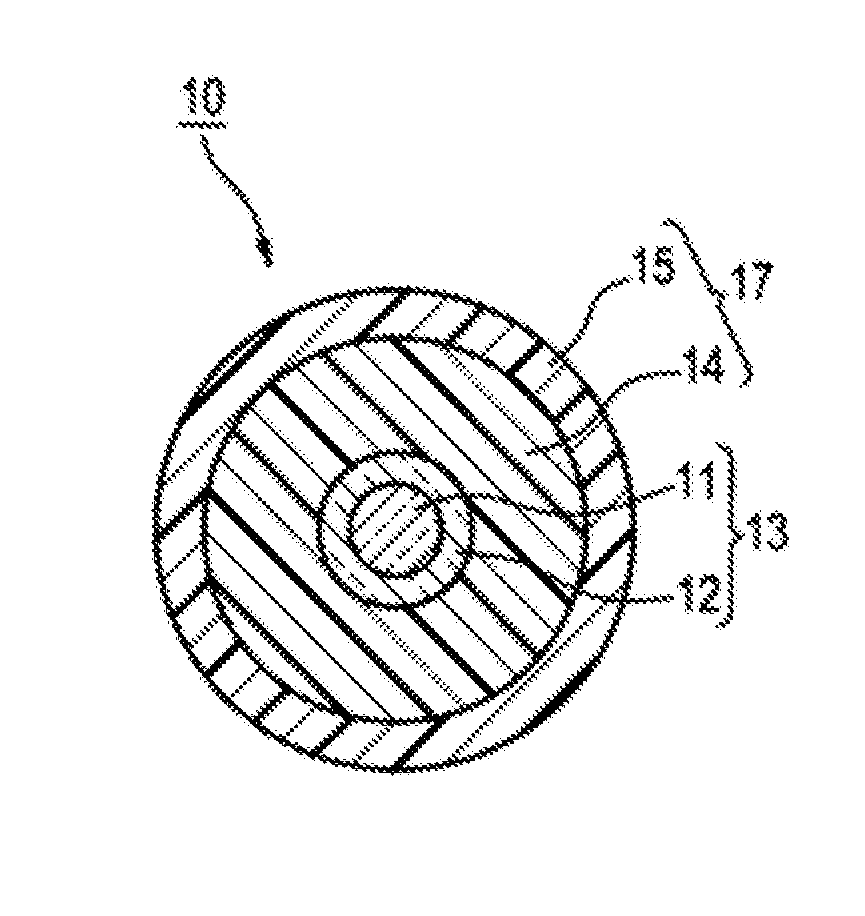

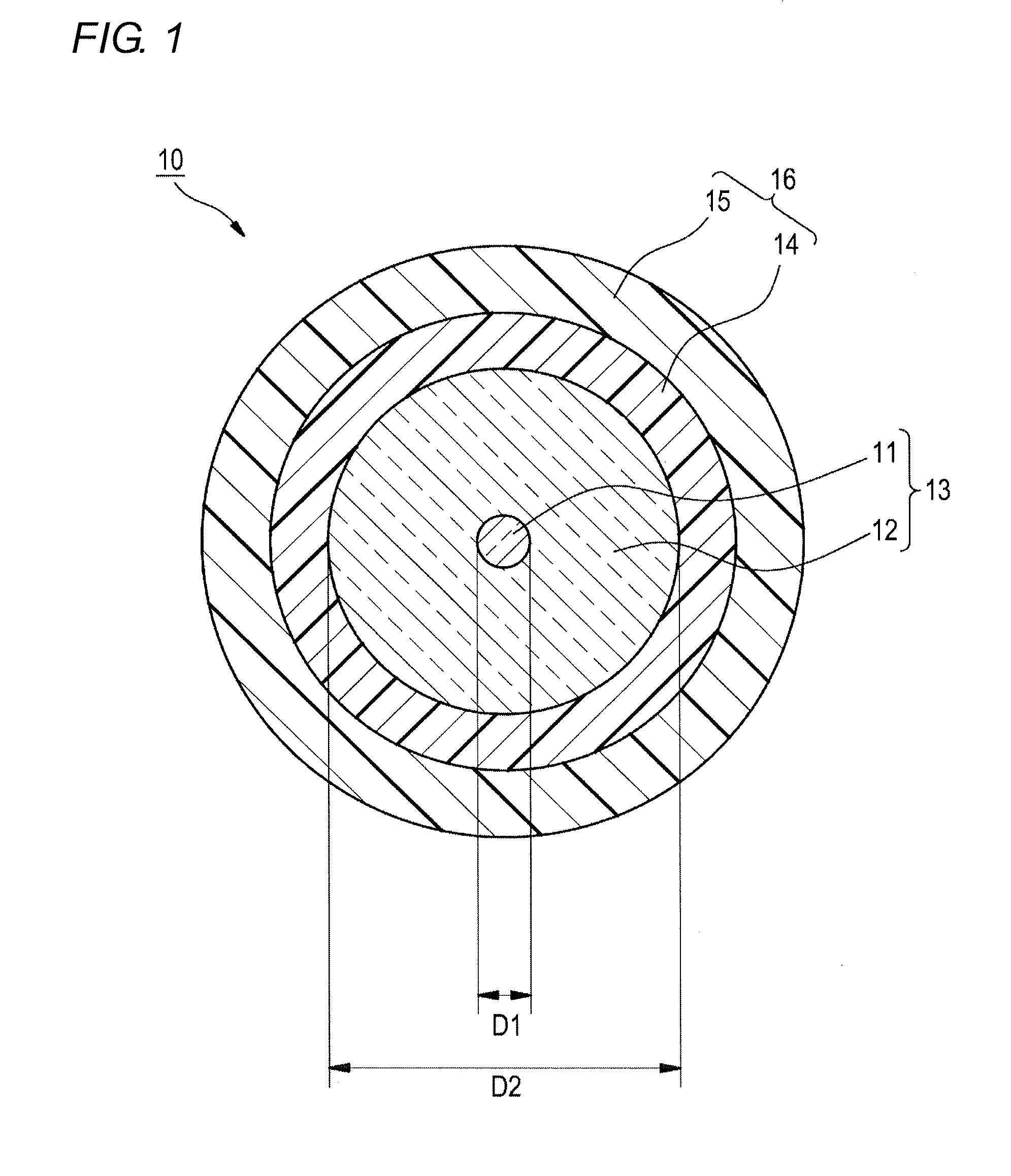

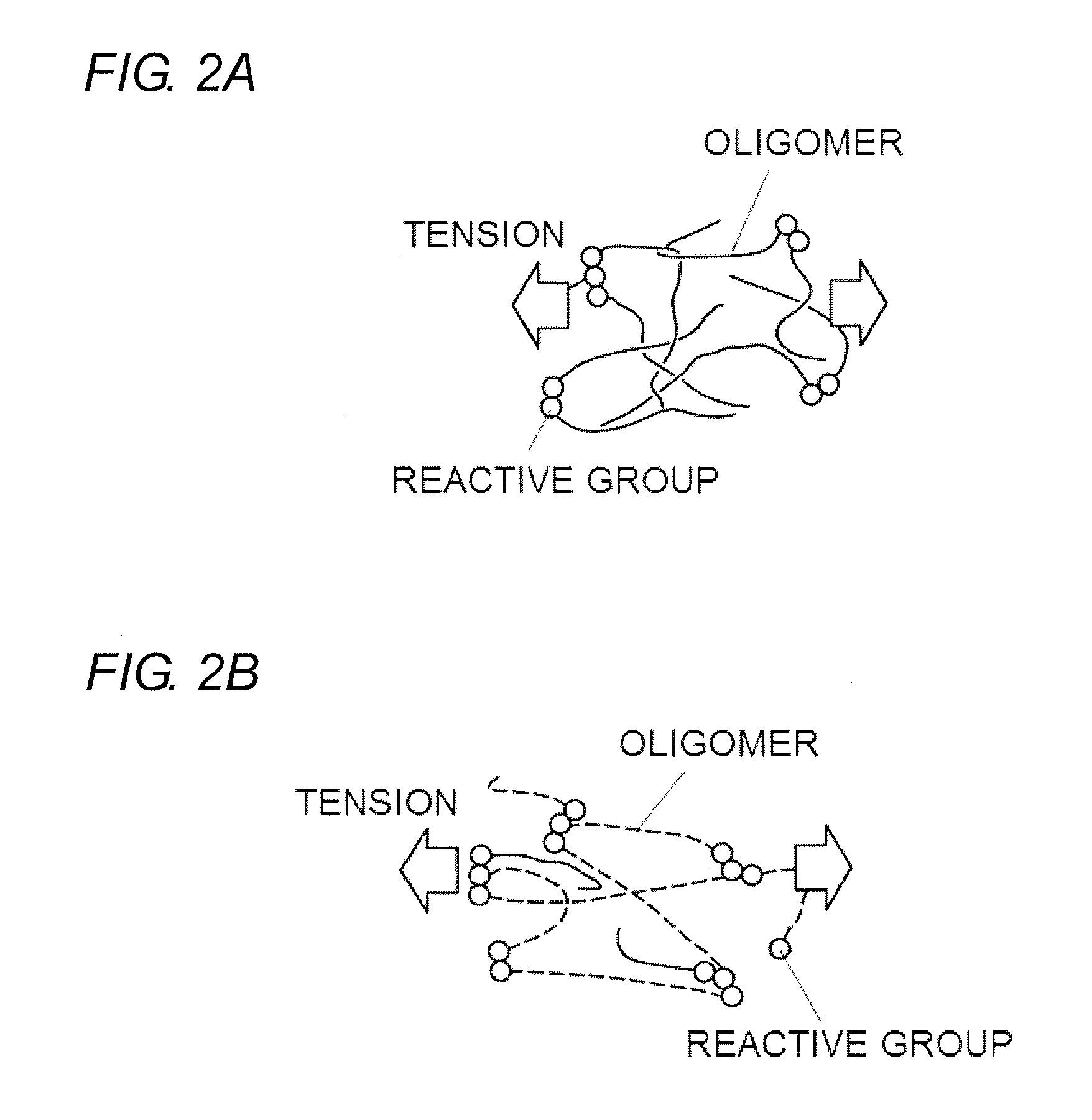

Optical fiber and process for producing the same

ActiveUS20160047977A1Improve lateral pressure resistanceInhibit the generation of voidsGlass optical fibreOptical fibre with multilayer core/claddingGlass fiberOligomer

A process for producing an optical fiber including a glass fiber, a primary resin coating layer which covers the periphery of the glass fiber, and a secondary resin coating layer which covers the periphery of the primary resin coating layer, wherein the primary resin coating layer is formed by curing a curable resin composition which includes one or more oligomers, one or more monomers, and a reaction initiator, the curable resin composition containing a one-end-capped oligomer in an amount of 30% by mass or larger based on all the oligomers. The optical fiber produced by this production process does not deteriorate in low-temperature transmission loss, because the primary resin coating layer is inhibited from generating voids even when having a low Young's modulus.

Owner:SUMITOMO ELECTRIC IND LTD

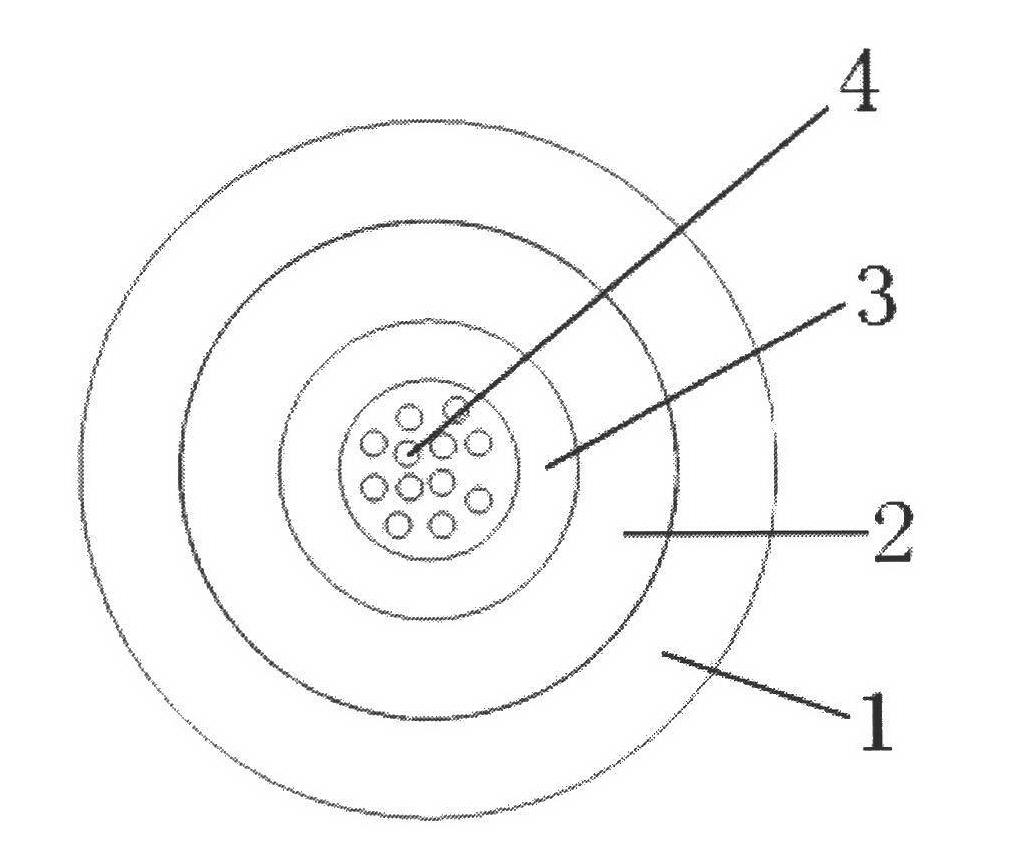

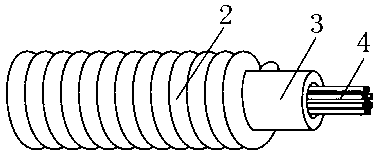

Spring cable

InactiveCN103217763AGood tensile strain resistanceImprove lateral pressure resistanceFibre mechanical structuresPolytetramethylene terephthalateHigh density

The invention belongs to the technical field of cables and particularly relates to a spring cable. The spring cable comprises a central bundle pipe which is located at the center and is hollow, and a plurality of light-guide fibers which are located in a hollow part inside the bundle pipe; a spring armor layer is arranged outside the bundle pipe; the spring armor layer is tightly stuck on the outer wall of the bundle pipe; spring wires of adjacent layers in the spring armor layer are tightly close to each other; a protecting bush layer is extruded outside the spring armor layer; and the bundle pipe is made of polybutylene terephthalate or polypropylene; the light-guide fibers are single-mode optical fibers or multi-mode optical fibers; the protecting bush layer is made of low-density polyethylene or middle-density polyethylene or high-density polyethylene or rubber; and the spring wires of the spring armor layer are stainless steel wires or zinc-plated steel wires or phosphorized steel wires. The spring cable is characterized in that the spring armor layer is formed by a spring armor layer forming device. The device disclosed by the invention is simple and reliable, and is low in cost; and a production method is simple and easy to learn.

Owner:STATE GRID CORP OF CHINA +1

Super-strength large core number multi-purpose optical fiber cable

The invention provides a super-strength large core number multi-purpose optical fiber cable which is light in weight, small in external diameter, more in inner core, and capable of meeting different laying environments. A brand novel optical fiber cable is provided for FTTx establishment in our country. The sequentially arranged cross section structure of the super-strength large core number multi-purpose optical fiber cable comprises an outer sheath, a metal hose and a water-blocking tape from outside to inside. An inner cavity of the water-blocking tape is a cabling cable core. The outer side of the cabling cable core is covered with the water-blocking tape. The center of the cabling cable core is provided with a centre reinforcer. The outer ring surface of the centre reinforcer is evenly provided with three or more optical cable units. Each optical cable unit comprises a micro beam tube arranged outside, fiber optical bundles arranged in the center and water-blocking yarns arranged between the inner wall of the micro beam tube and the outer walls of the fiber optical bundles.

Owner:JIANGSU HENGTONG PHOTOELECTRIC

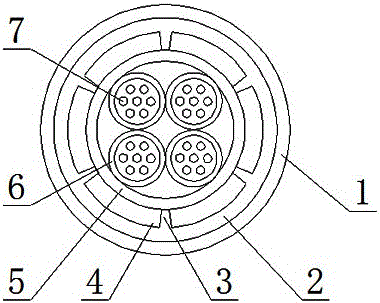

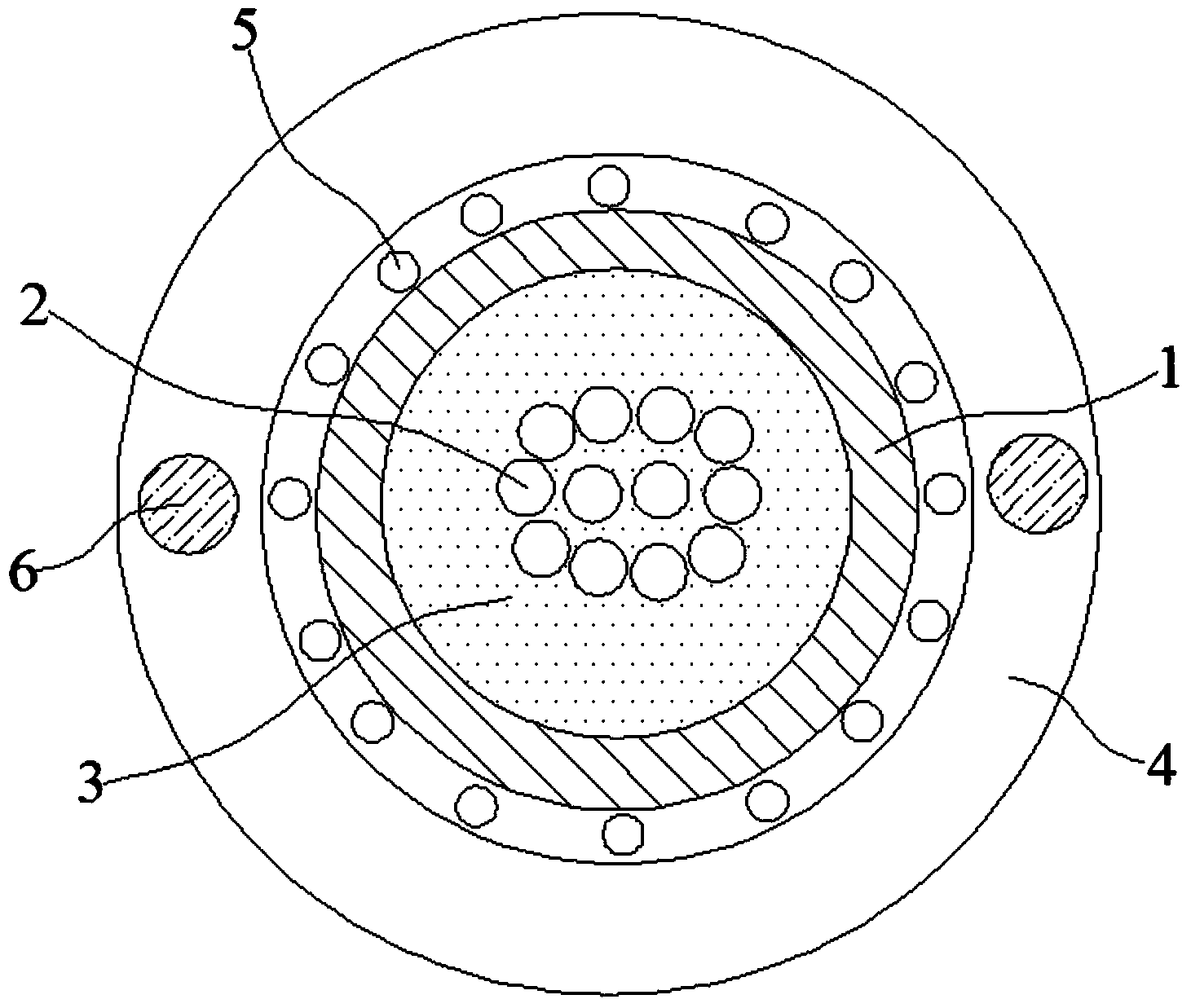

Optical cable with high side pressure resisting capacity

InactiveCN106154451AReduce wearReduce torqueFibre mechanical structuresEngineeringOptical fiber cable

The invention discloses an optical cable with strong lateral pressure resistance, which comprises an outer sheath (1), a support sleeve (2) arranged in the outer sheath (1), and an inner sheath arranged in the support sleeve (2). Sleeve (5), several optical fiber sleeves (6) arranged in the inner sheath (5) and several optical fibers (7) arranged in the optical fiber sleeve (6), the inner side of the support sleeve (2) is set There are several protrusions (3), and the inner sheath (5) is supported by the protrusions (3). The beneficial effects of the present invention are: the present invention supports the inner sheath by providing protrusions, and when the outer sheath and the supporting sleeve are twisted, the protrusions can be deflected to reduce the internal transmission of the optical cable to the inner sheath. Torque, and can reduce the wear of the inner sheath, thereby improving the torsion resistance and lateral pressure resistance of the optical cable, and prolonging the service life of the optical cable.

Owner:成都迪谱光电科技有限公司

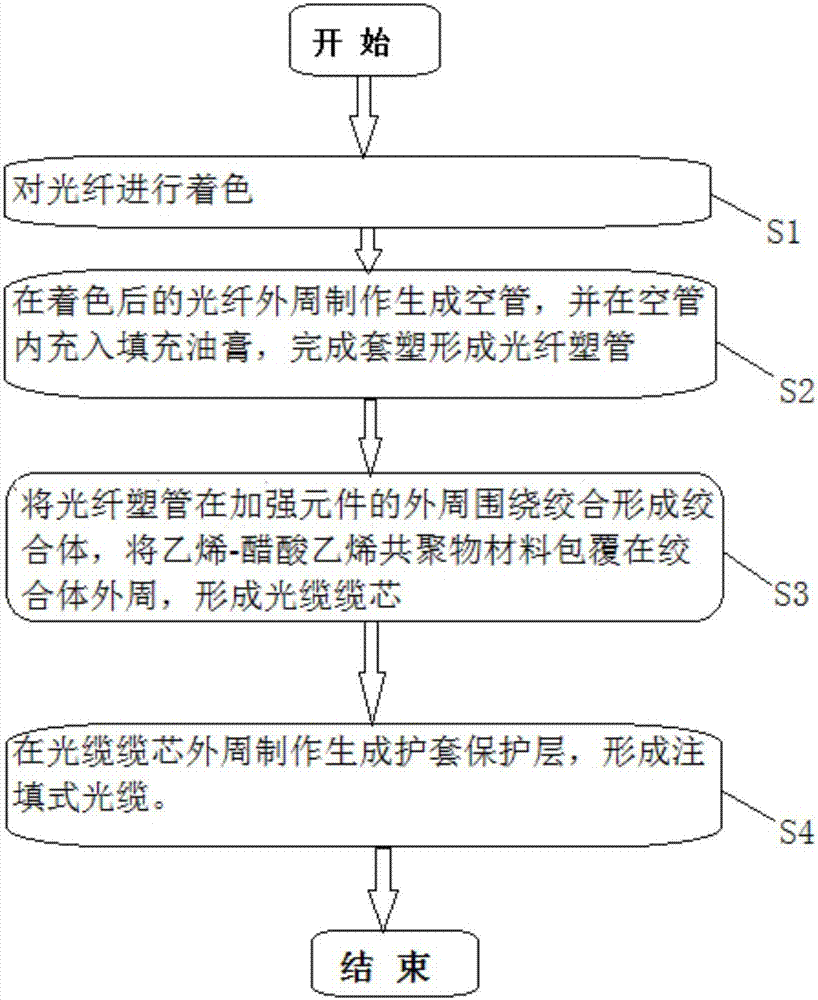

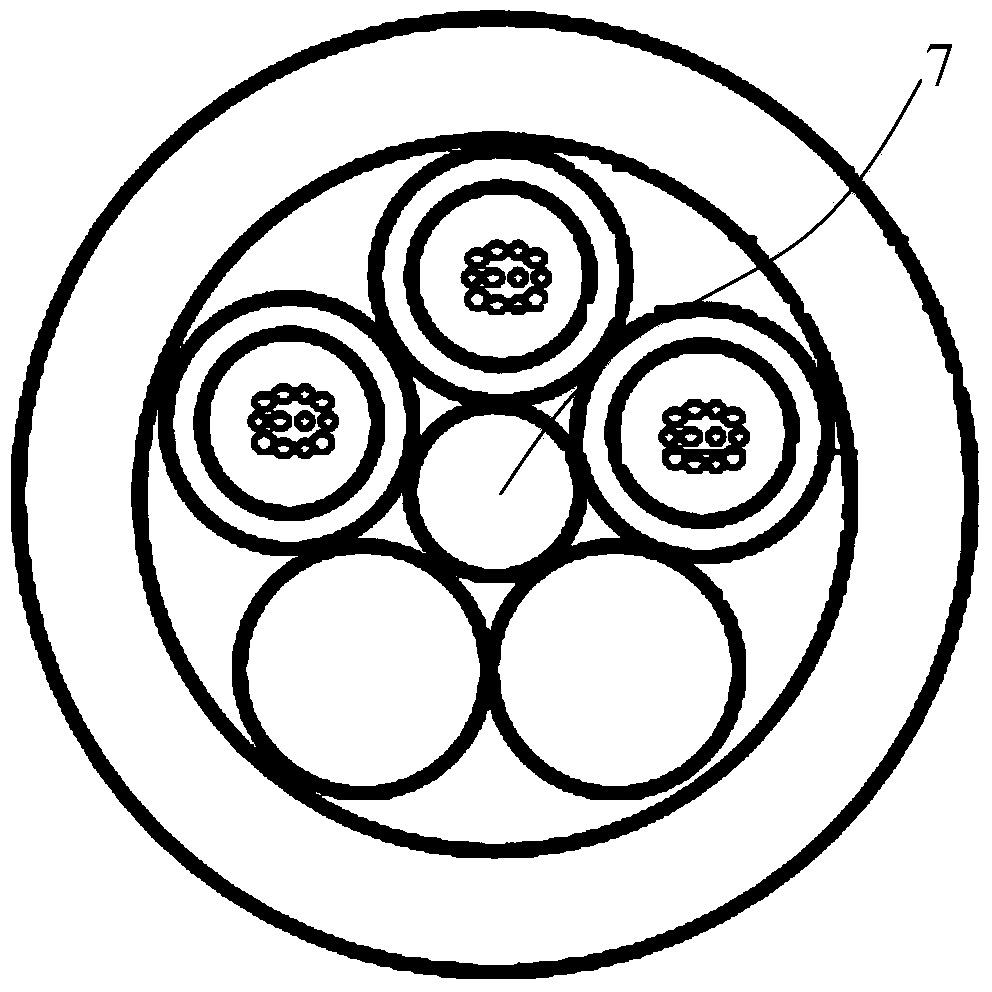

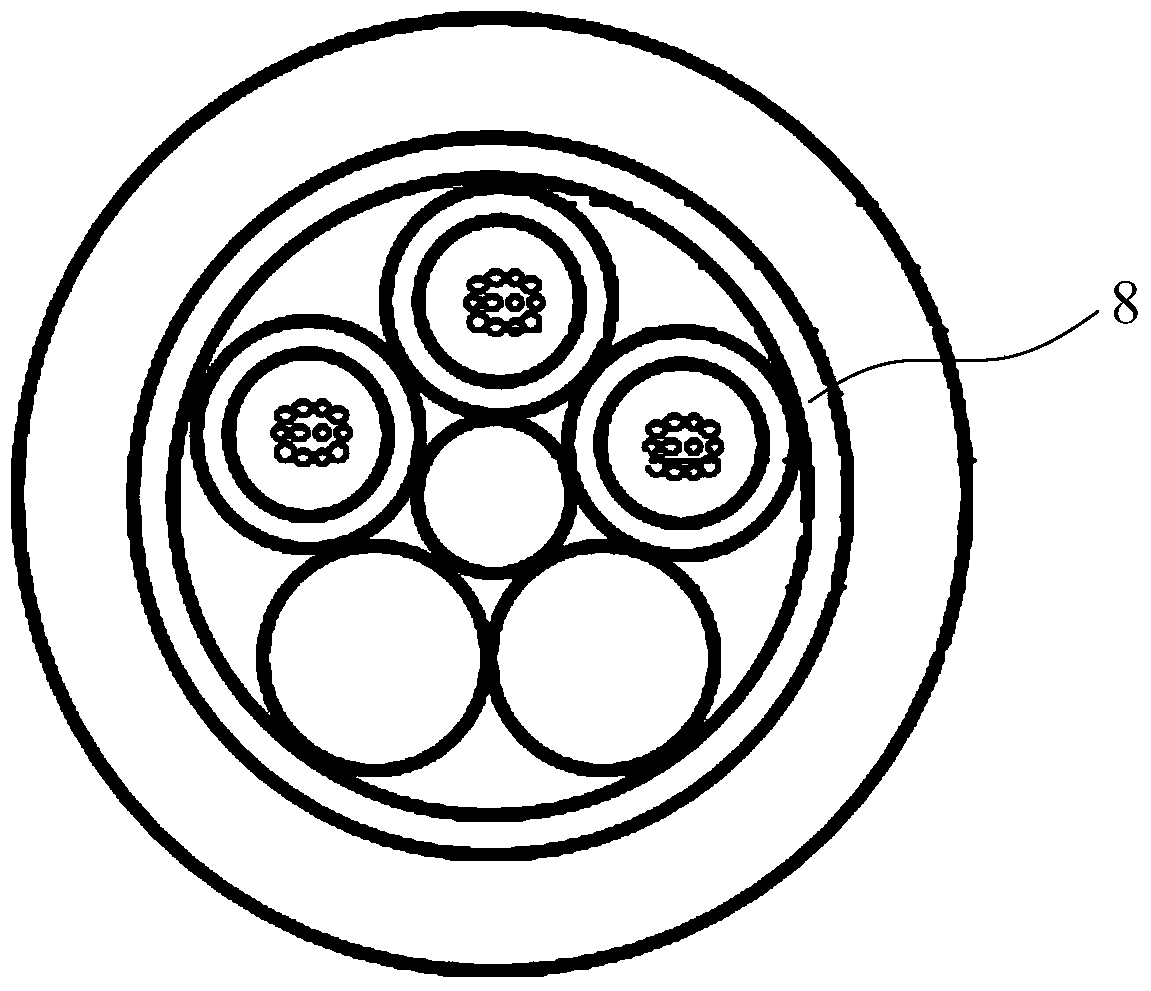

Method for manufacturing filling type cable

The invention relates to a method for manufacturing a filling type cable. The method comprises: coloring is carried out on a fiber; a blank pipe is manufactured at the periphery of the colored fiber, the blank pipe is filled with filling ointment, and then plastic sleeving is completed to form a fiber plastic pipe; the fiber plastic pipe encircles the periphery of a reinforced element in a twisting manner to form a twisting body, an ethylene-vinyl acetate copolymer material coats the periphery of the twisting body to form a cable core; and a sheath protection layer is manufactured at the periphery of the cable core to form a filling type cable. According to the manufacturing method, the process is simple; the generated cable core number is large; the structure is stable; and the anti-side pressure and anti-impact capabilities are high.

Owner:TONGDING INTERCONNECTION INFORMATION CO LTD

Central-tube-type high-strength all-dielectric introductive optical fiber cable

InactiveCN103513379AHas natural shieldingHigh strengthFibre mechanical structuresDielectricMetallic materials

The invention discloses a central-tube-type high-strength all-dielectric introductive optical fiber cable. The central-tube-type high-strength all-dielectric introductive optical fiber cable comprises a loose sleeve in the center and a plurality of glass optical fibers inside he loose sleeve, wherein thixotropic water-proof fiber paste is filled between the loose sleeve and the glass optical fibers; a PE (polyethylene) sheath layer coats the outer surface of the loose sleeve; a plurality of water-proof aramid fibers are uniformly distributed between the loose sleeve and the PE sheath layer circumferentially; at least 2 enhanced glass fiber plastic rods are positioned on the two sides of the loose sleeve and are embedded into the PE sheath layer. The central-tube-type high-strength all-dielectric introductive optical fiber cable does not use the conventional metal material, so that the central-tube-type high-strength all-dielectric introductive optical fiber cable has a natural shielding effect on lightning or strong electricity and has an obvious lightning-proof effect, and potential safety hazards existing in the construction of an access network are eliminated.

Owner:JIANGSU HENGTONG PHOTOELECTRIC

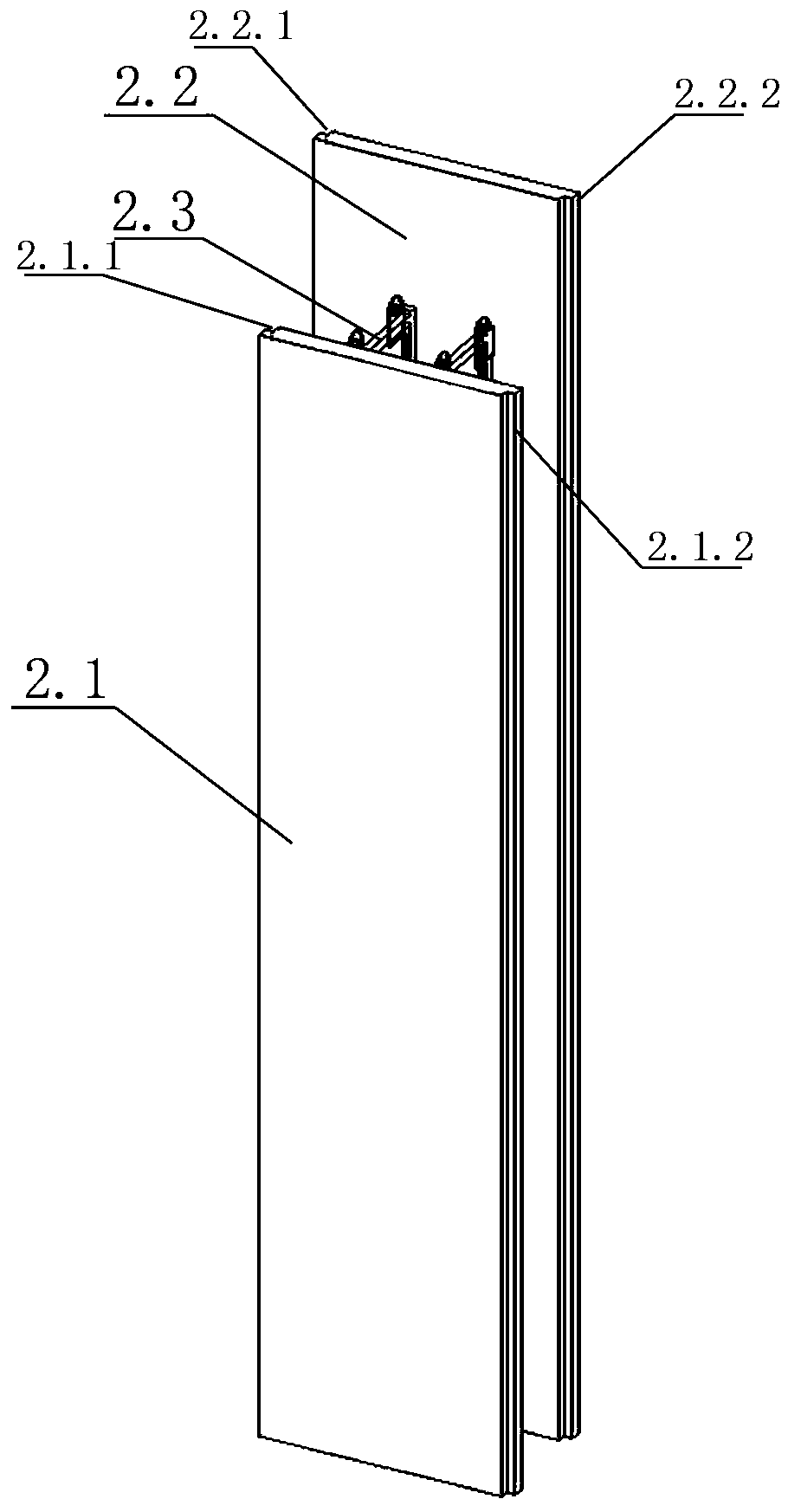

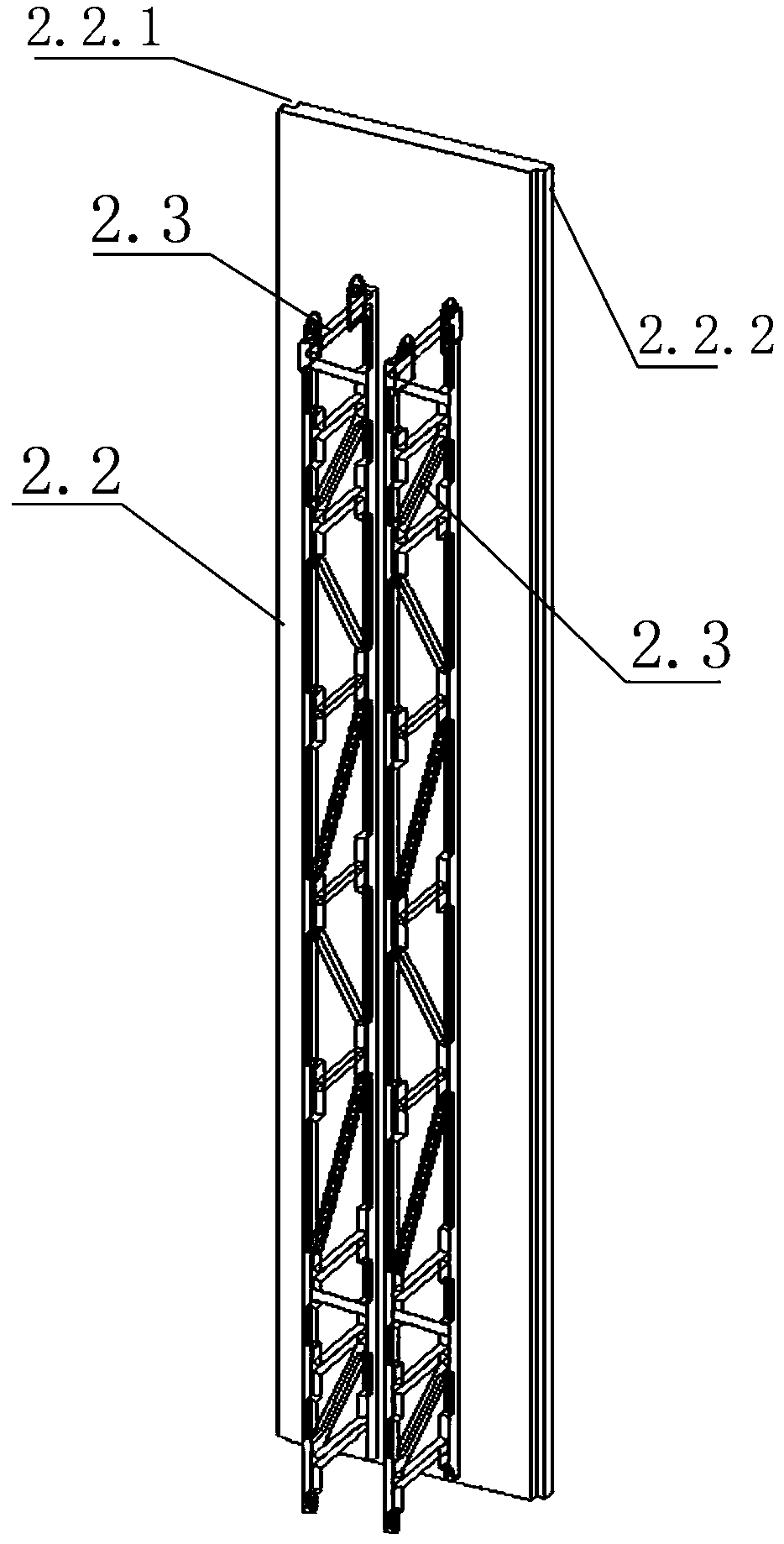

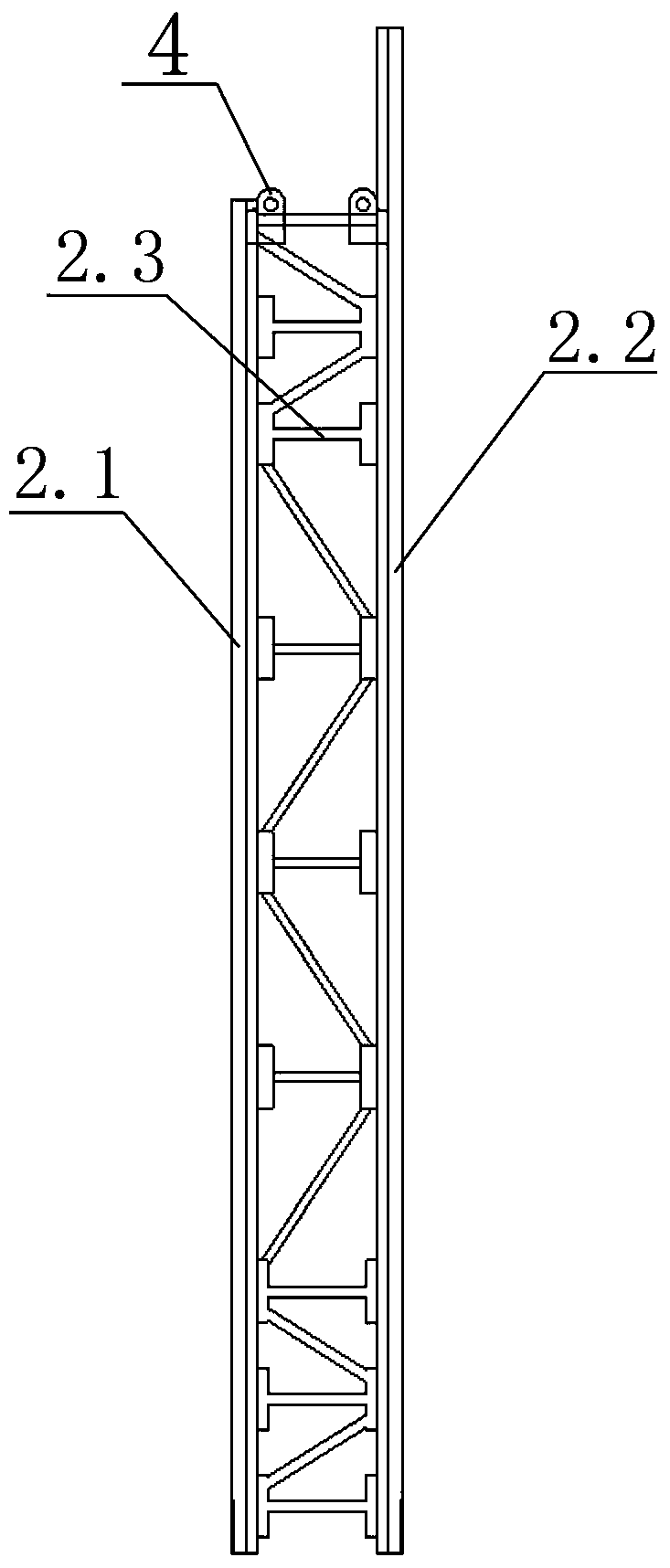

Profile steel truss double-skin wall structure and construction method thereof

The invention discloses a profile steel truss double-skin wall structure and a construction method thereof. The profile steel truss double-skin wall structure comprises a main body structure, a double-skin wall structure unit and a cast-in-place concrete layer, the double-skin wall structure unit is transversely connected in a spliced manner; the cast-in-place concrete layer is cast in the double-skin wall structure unit; the double-skin wall structure unit comprises a first precast concrete slab and a second precast concrete slab; a group of profile steel trusses are transversely arranged between the first precast concrete slab and the second precast concrete slab at an interval in parallel; each profile steel truss is arranged vertically in the length direction, a chord member on one side of each profile steel truss is cast in the first precast concrete slab, the chord member on the other side of each profile steel truss is cast in the second precast concrete slab. Scaffold and formwork support procedures in traditional cast-in-situ technology are simplified, labor force is saved, potential safety risks caused by high-formwork support are avoided, and the technical problems thatexisting steel bar truss double-skin walls have small thickness and height not exceeding 4 m and existing double-skin wall structures have low overall rigidity and concrete lateral pressure resistanceare solved.

Owner:CHINA CONSTR FIRST DIV GROUP CONSTR & DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com