Patents

Literature

68results about How to "Resistance to deterioration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

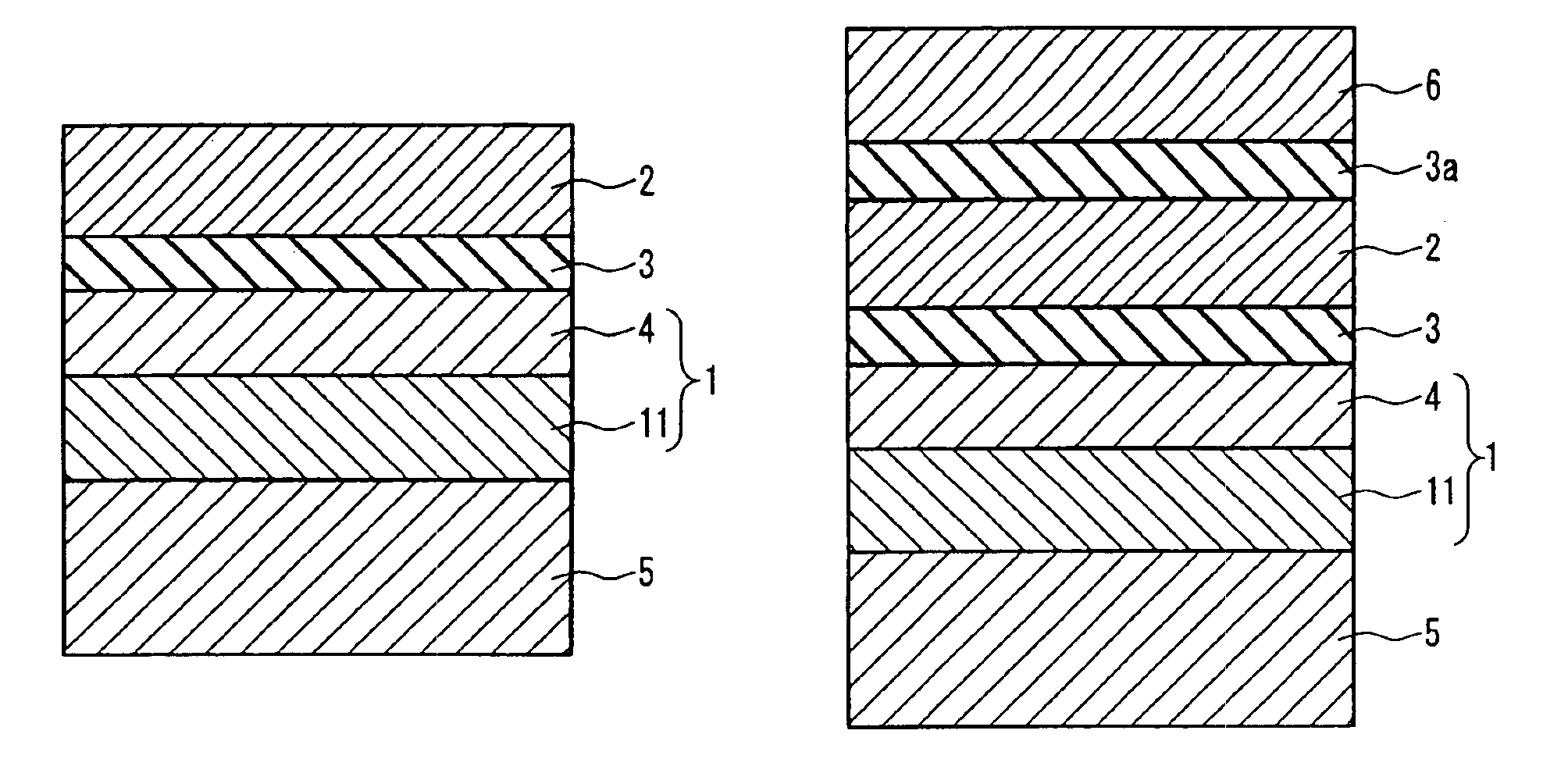

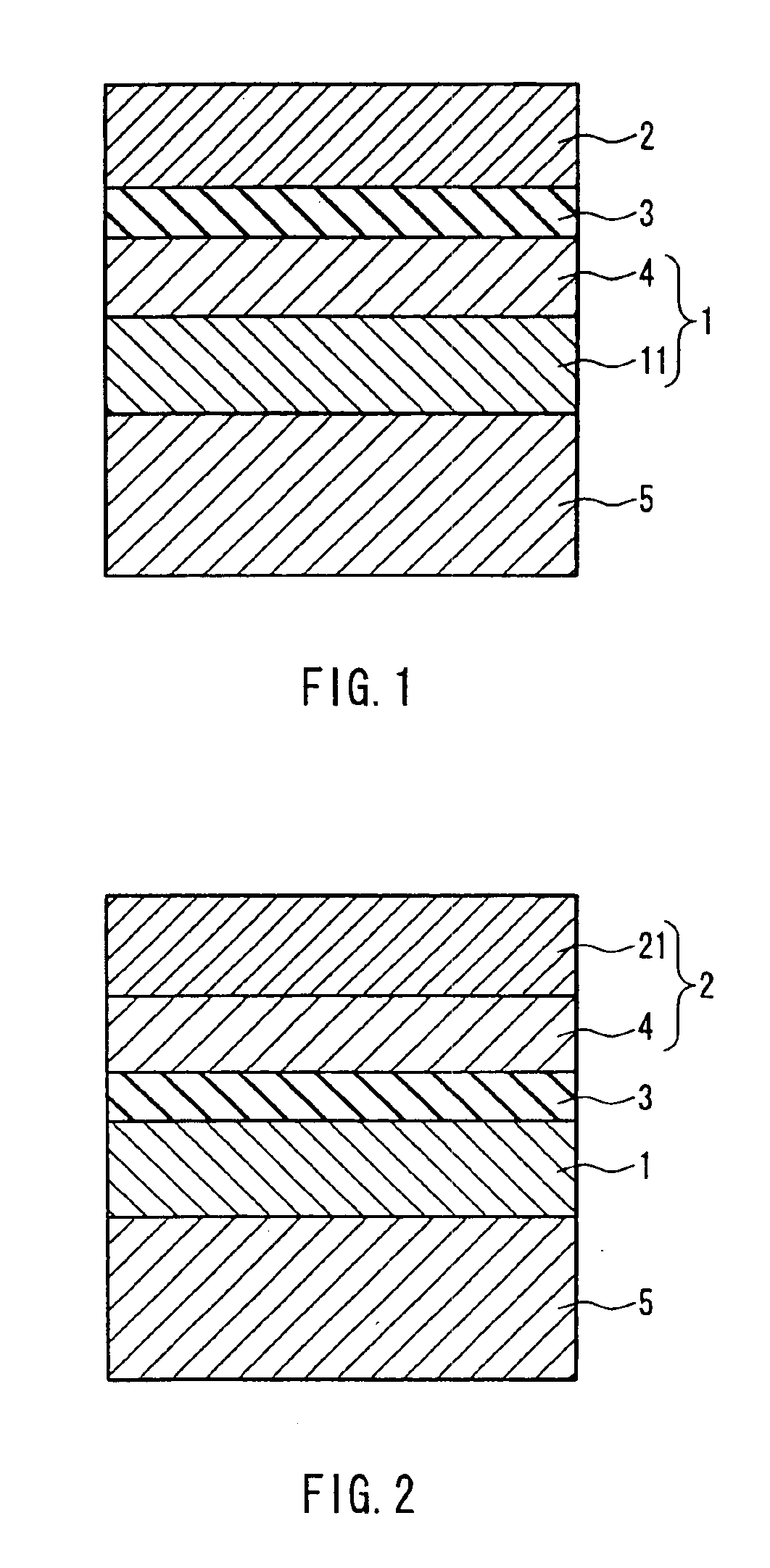

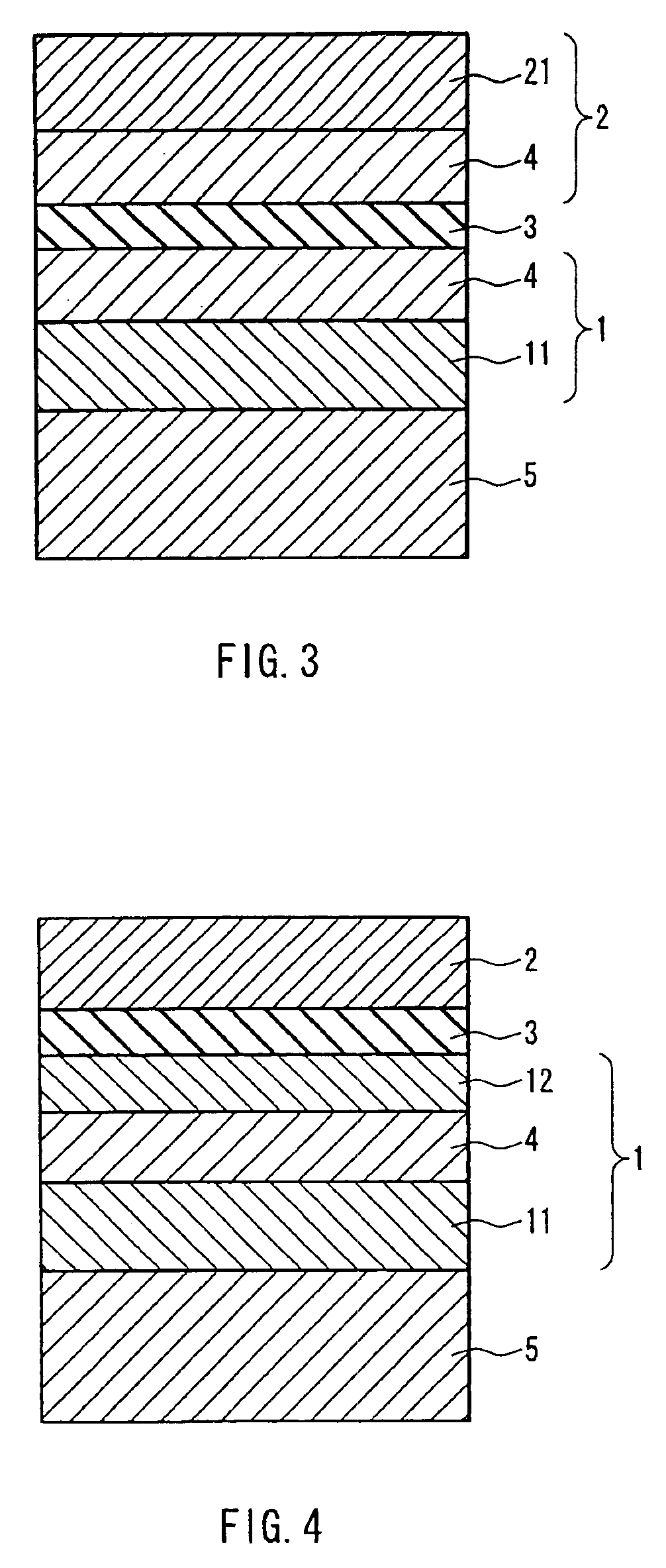

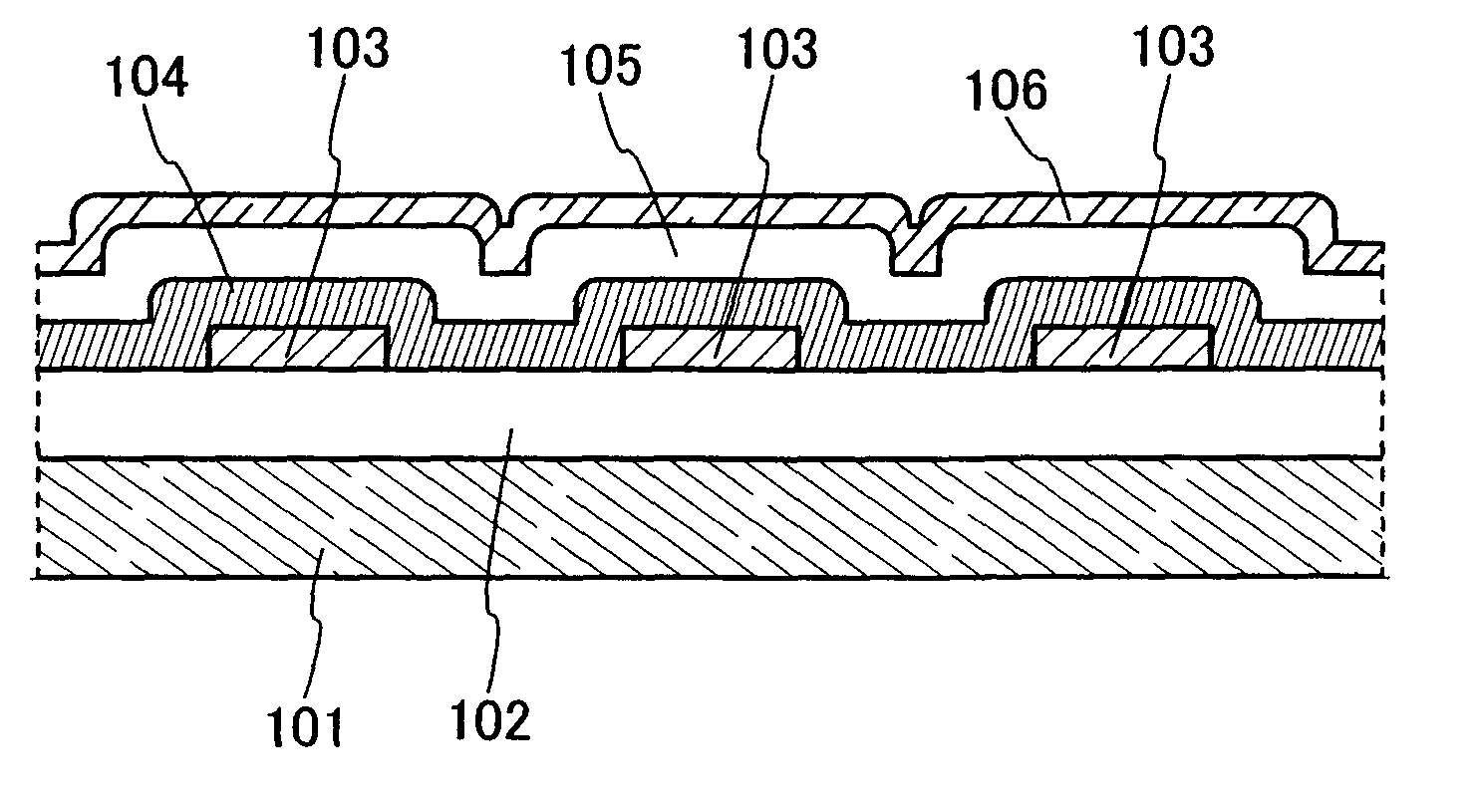

Magnetoresistive element, magnetic head, magnetic memory and magnetic recording apparatus using the same

InactiveUS6842317B2Good thermal stabilityImprove thermal stabilityNanomagnetismNanoinformaticsPhysicsMagnetic layer

A magnetoresistive element includes a multilayer film configuration including: a tunnel insulation layer; and a pair of magnetic layers that are laminated with the tunnel insulation layer interposed therebetween. A resistance value of the magnetoresistive element varies with a relative angle between magnetic orientations of both of the magnetic layers, and at least one of the magnetic layers includes a magnetic film having a thermal expansion coefficient not greater than a value obtained by adding 2×10−6 / K to a thermal expansion coefficient of the tunnel insulation layer. The thus configured magnetoresistive element can exert excellent thermal stability. The use of such a magnetoresistive element can realize a magnetic head, a magnetic memory element and a magnetic recording apparatus with excellent thermal stability.

Owner:PANASONIC CORP

Natural rubber, rubber composition and pneumatic tire

ActiveUS20050148723A1Improve processabilityImprove tensile propertiesSpecial tyresInflatable tyresNatural rubber latexAdverse effect

Natural rubber obtained by a deproteinizing treatment of a natural rubber latex and has a total nitrogen content adjusted in the range of 0.12 to 0.30% by weight and a rubber composition and a pneumatic tire using the natural rubber. The processability of natural rubber can be improved without adverse effects on the physical properties proper to natural rubber. The rubber composition exhibits an improved low hysteresis loss property and improved abrasion resistance and can be advantageously used for the tire case members and the tire tread of pneumatic tires.

Owner:BRIDGESTONE CORP

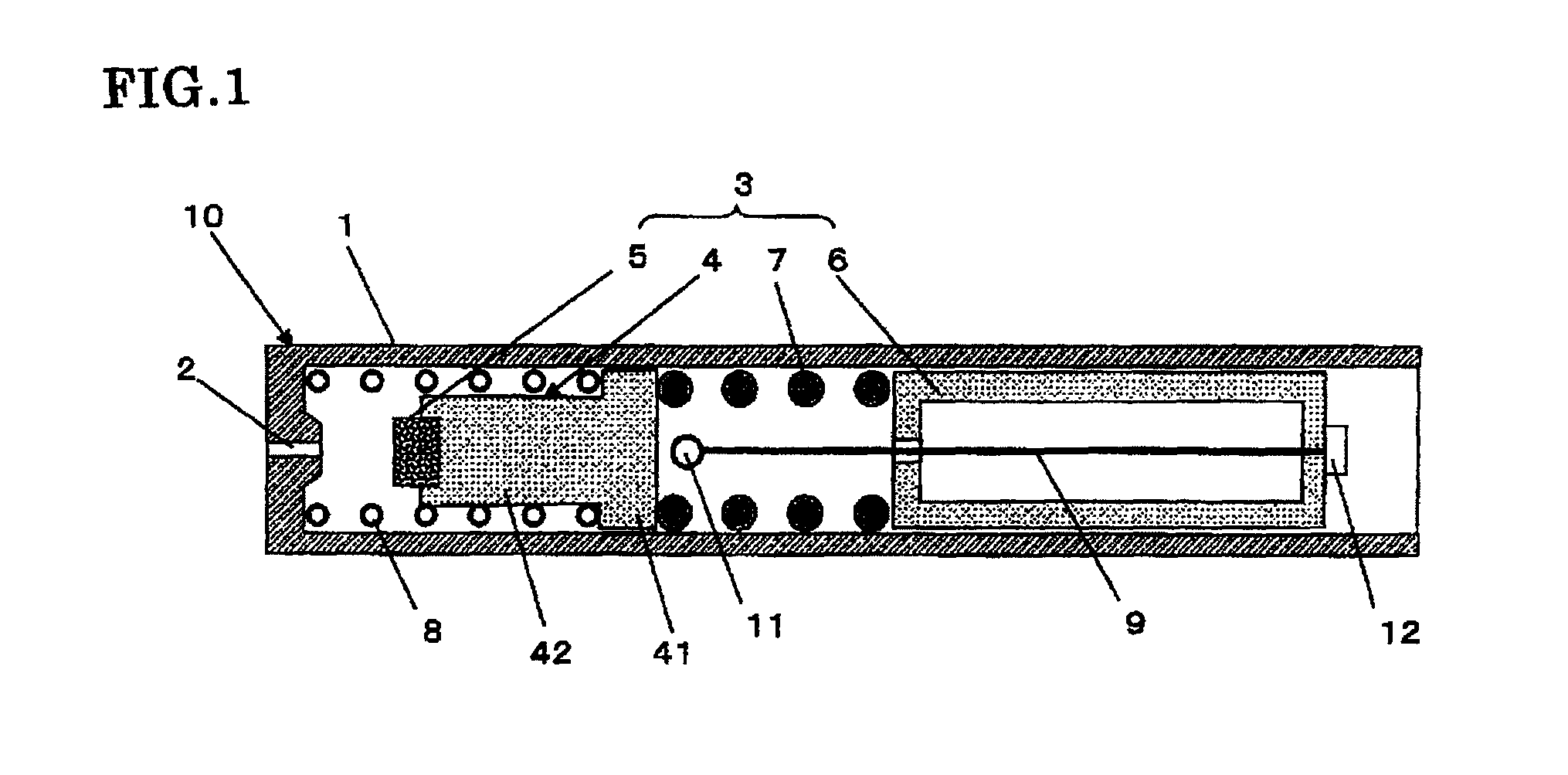

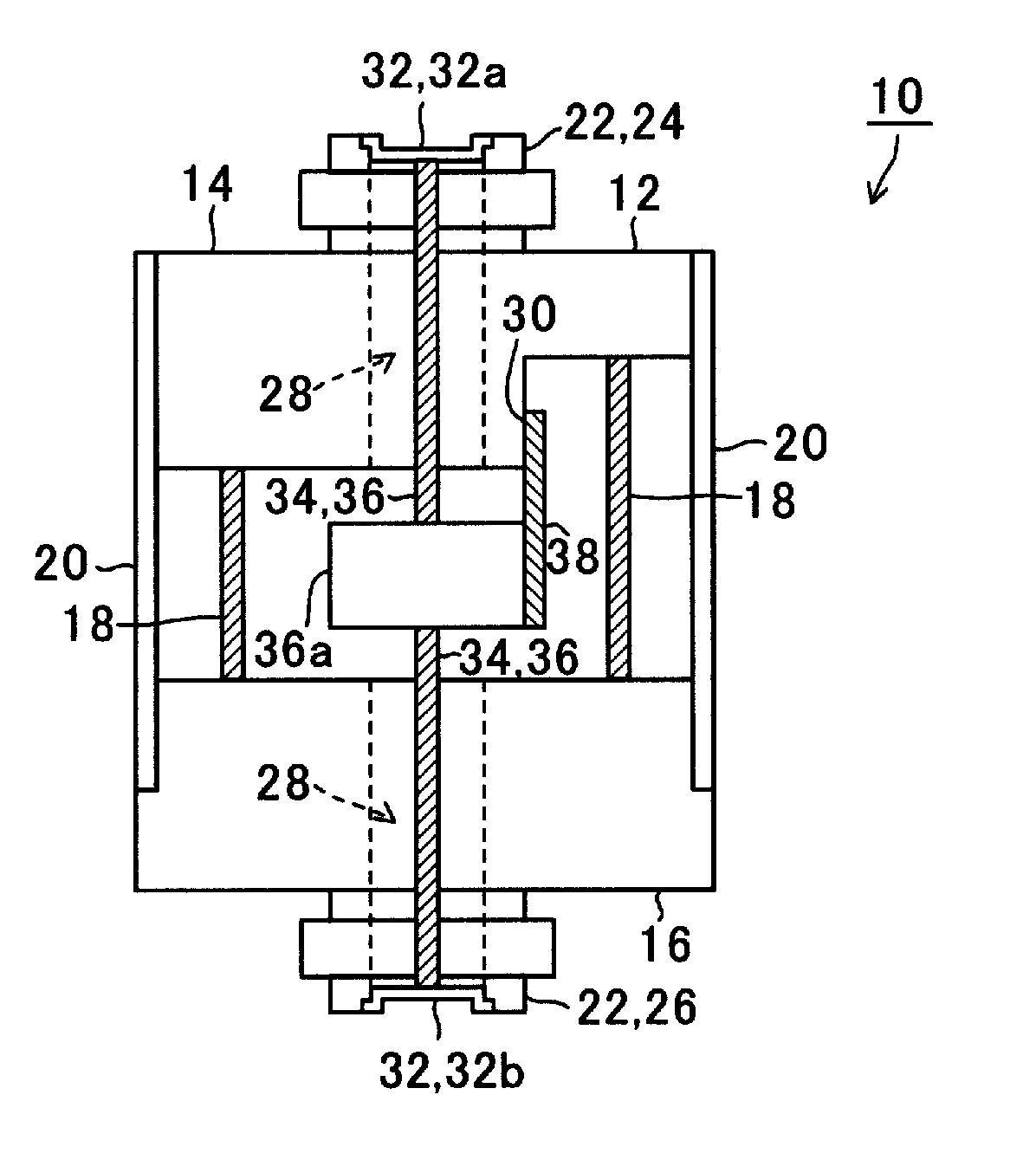

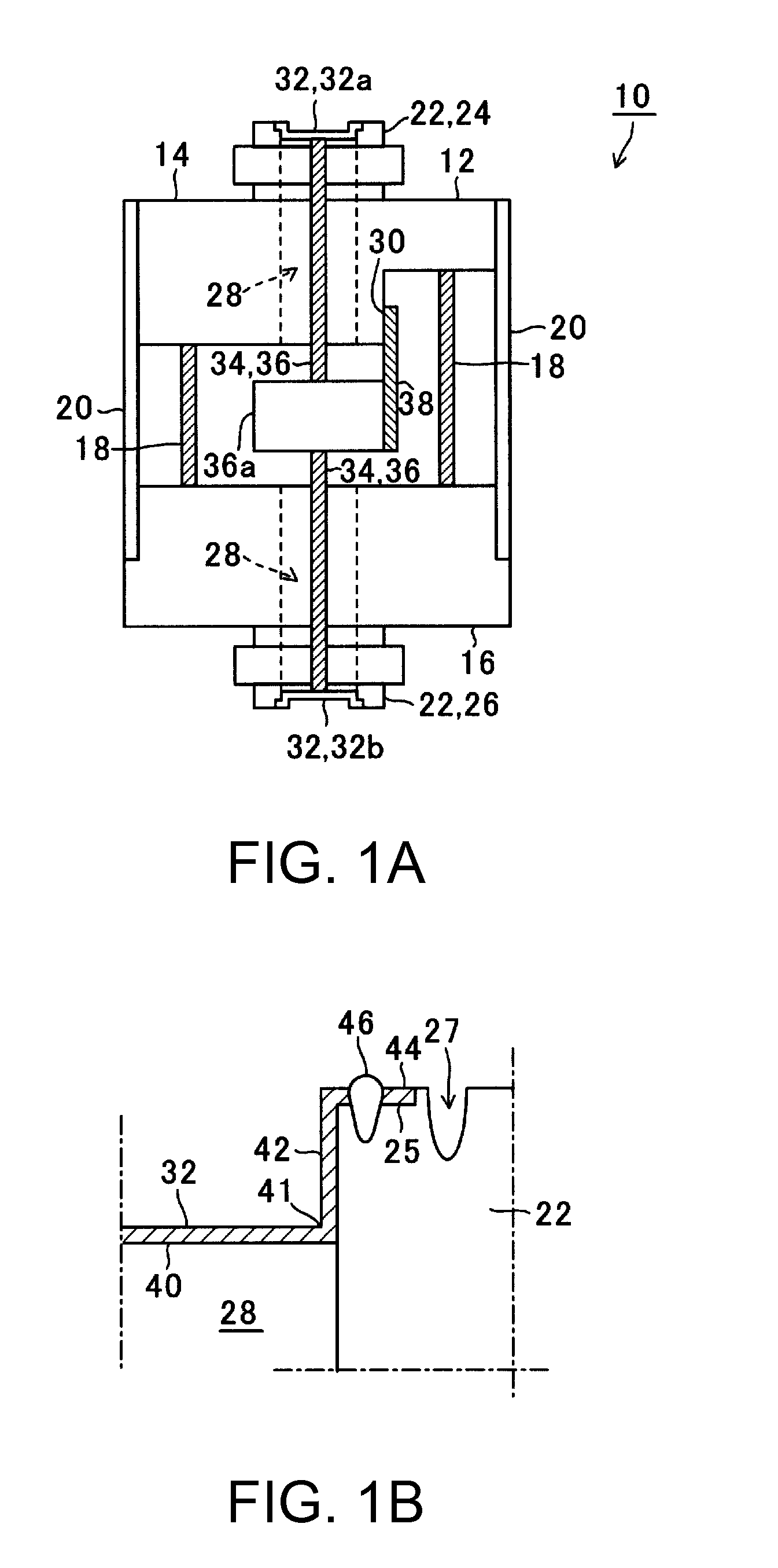

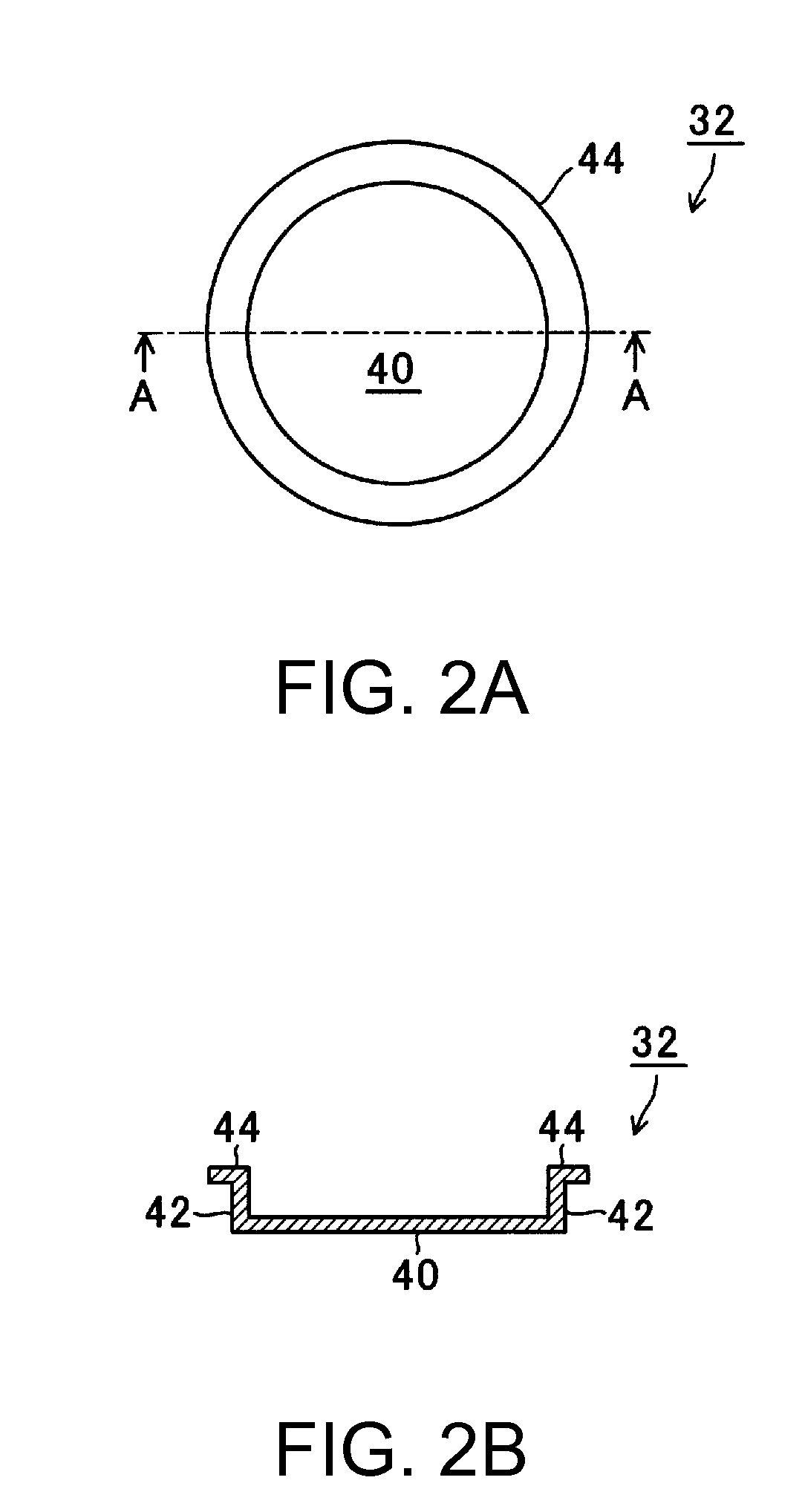

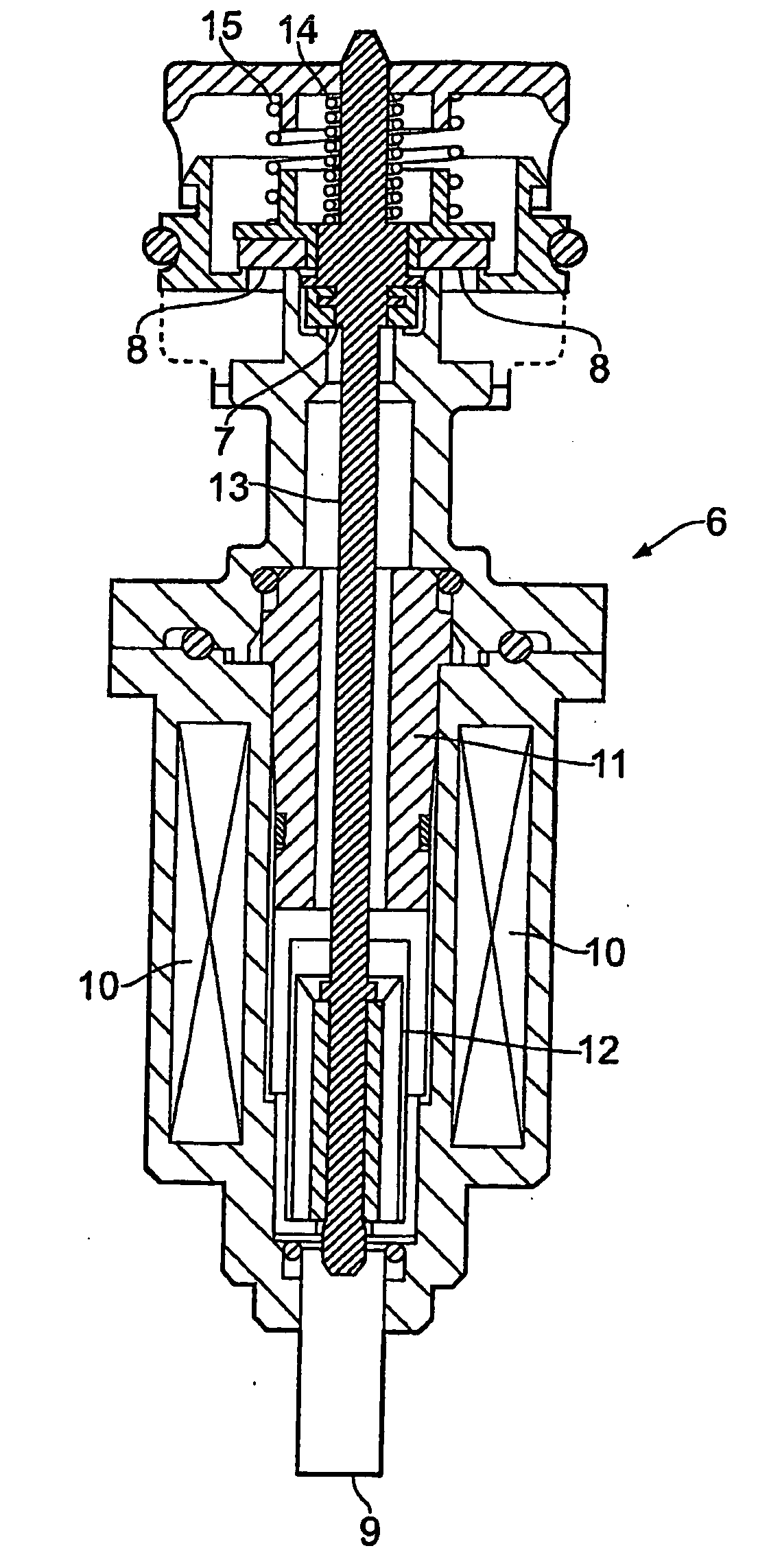

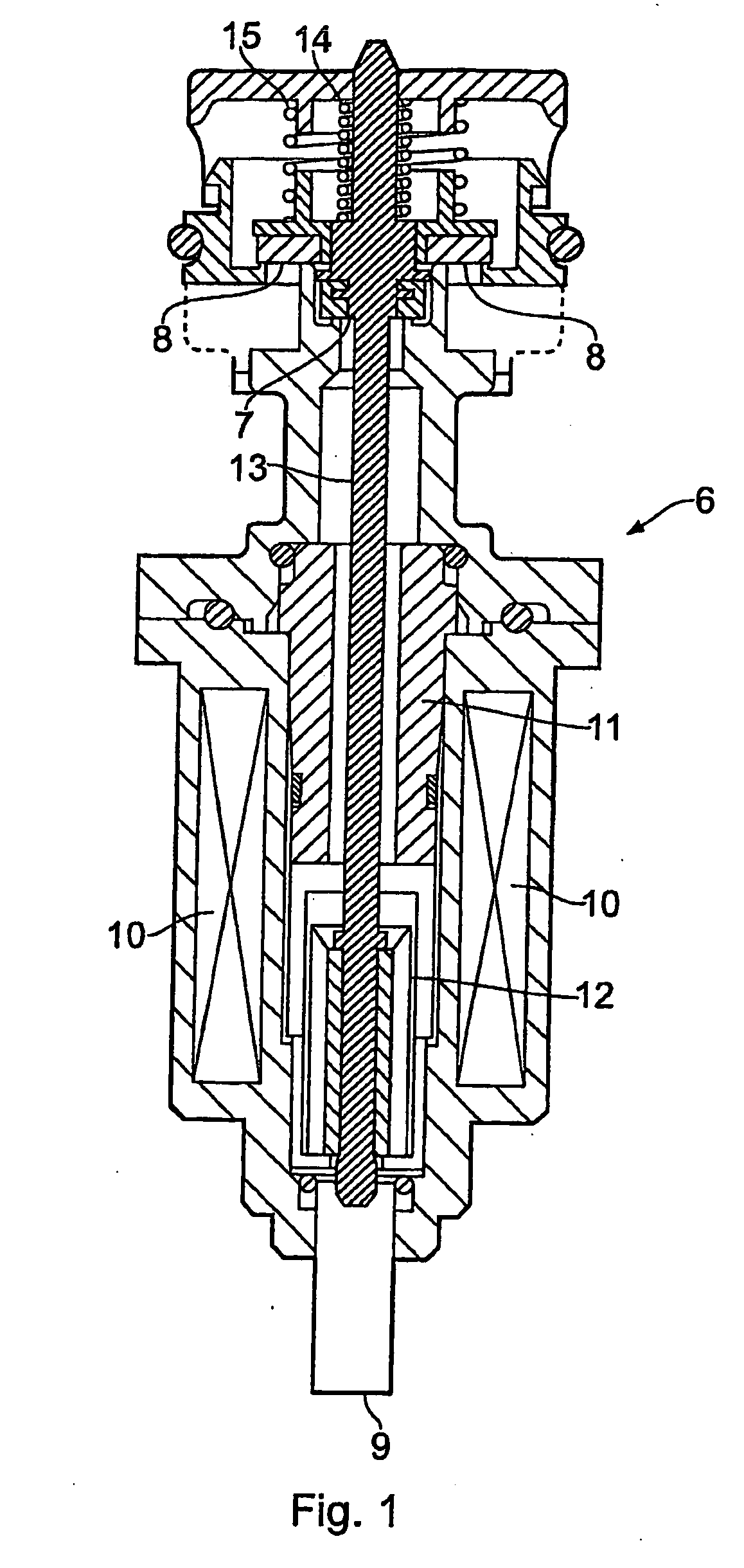

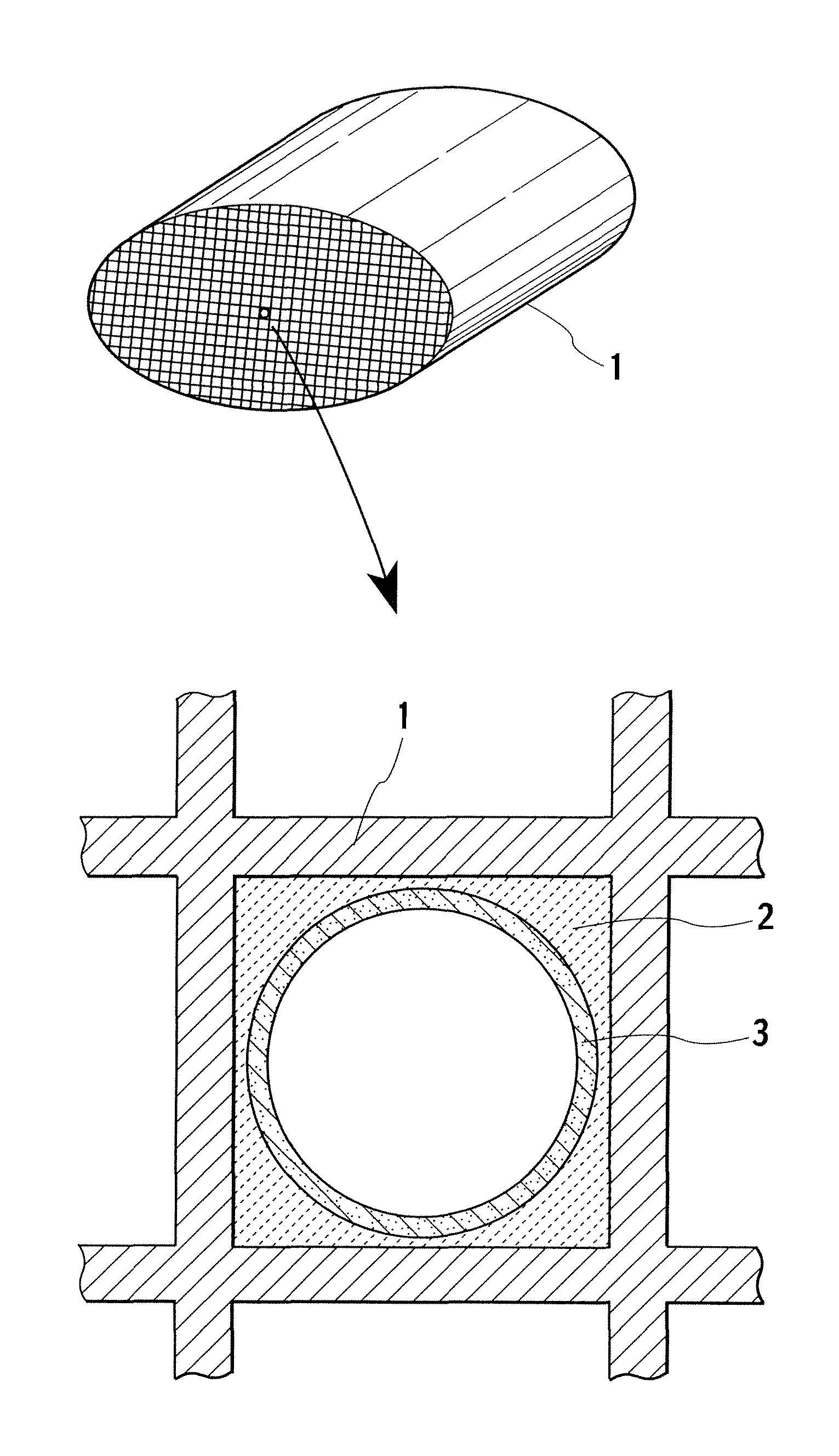

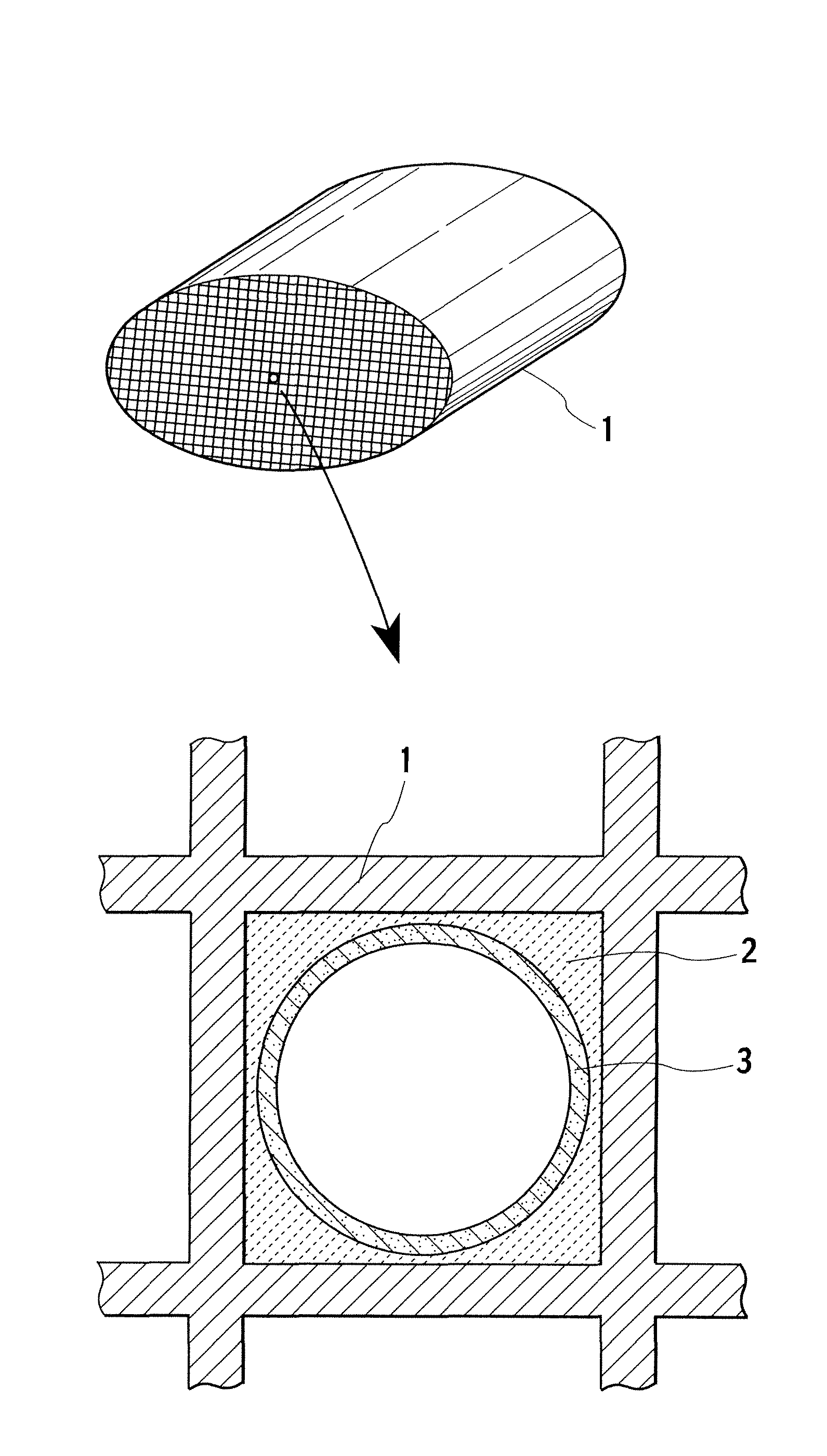

Compact valve

InactiveUS7815161B2Avoid it happening againResistance to deteriorationOperating means/releasing devices for valvesEqualizing valvesCoil springShape-memory alloy

A compact valve using a shape memory alloy comprises: a moving valve body that contacts an inner periphery of a guide pipe having an built-in orifice, is freely movable and has a sealing portion to seal the orifice; a biasing coil provided between the orifice and the moving valve body; and a wire formed of a shape memory alloy and held between a stationary electrode of the guide pipe and a moving electrode of the moving valve body. The orifice is sealed by moving the moving valve body due to transformation of the shape memory alloy by heating the wire. The moving valve body is enabled to be elastically deformable by providing a coil spring to reduce a stress, so that an overload to the moving valve body due to contraction of the wire is absorbed by elastic deformation of the moving valve body. Thereby, the overload to the shape memory alloy is reduced to prevent deterioration of repeatability of memorized shape, to increase durability and reliability of the valve.

Owner:MATSUSHITA ELECTRIC WORKS LTD

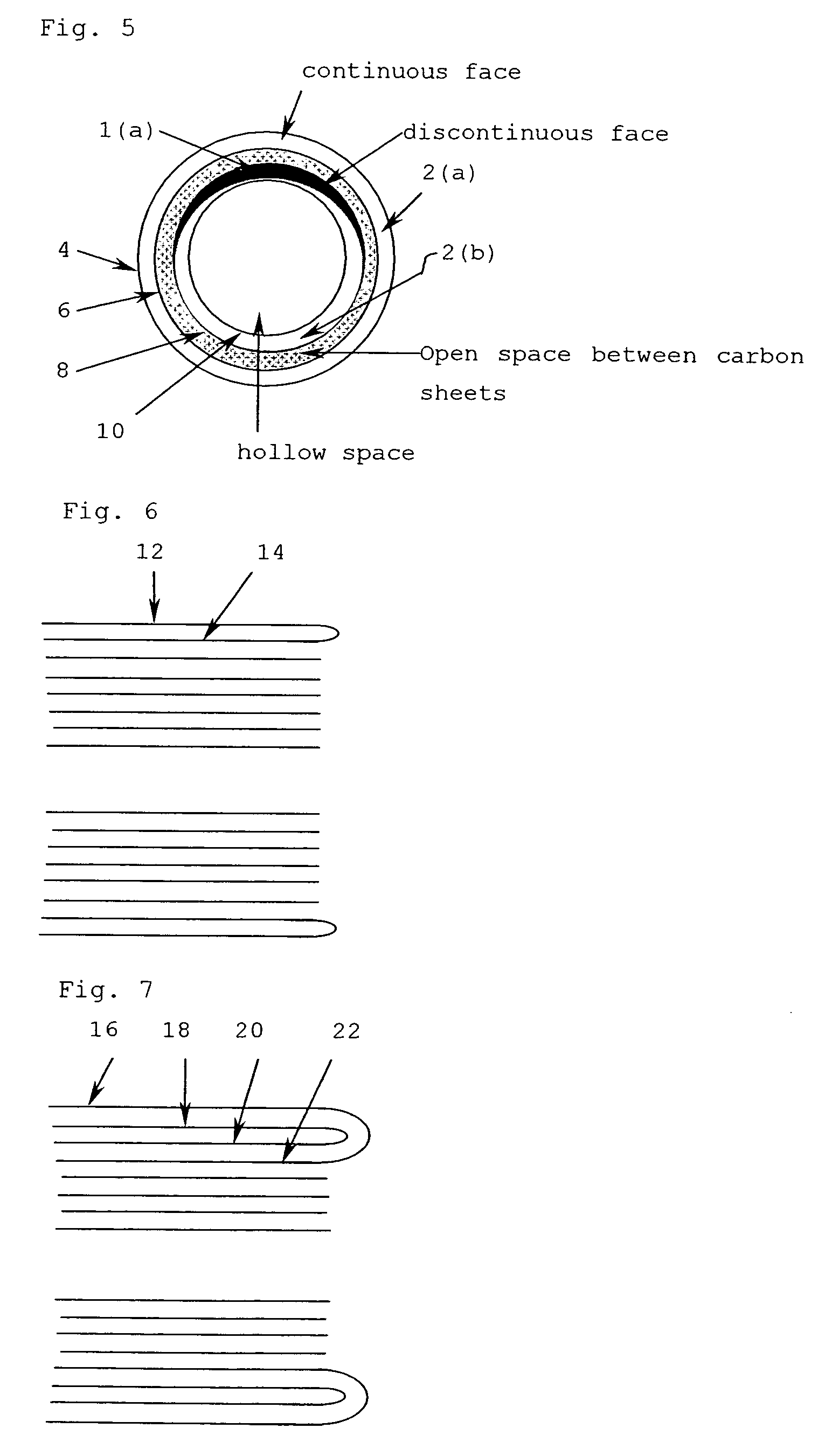

Graphite fine carbon fiber, and production method and use thereof

ActiveUS7150840B2Good dispersibilityImprove adhesionMaterial nanotechnologyLayered productsFiberCarbon fibers

A graphitized fine carbon fiber comprising a hollow space extending along its center axis, and a plurality of graphene sheets, wherein the fiber has an end surface comprising a portion of discontinuity in which ends of graphene sheets are not bonded to one another and at least one portion of continuity comprised of at least one group of graphene sheets in which one graphene sheet is bonded to another graphene sheet adjacent thereto.

Owner:SHOWA DENKO KK

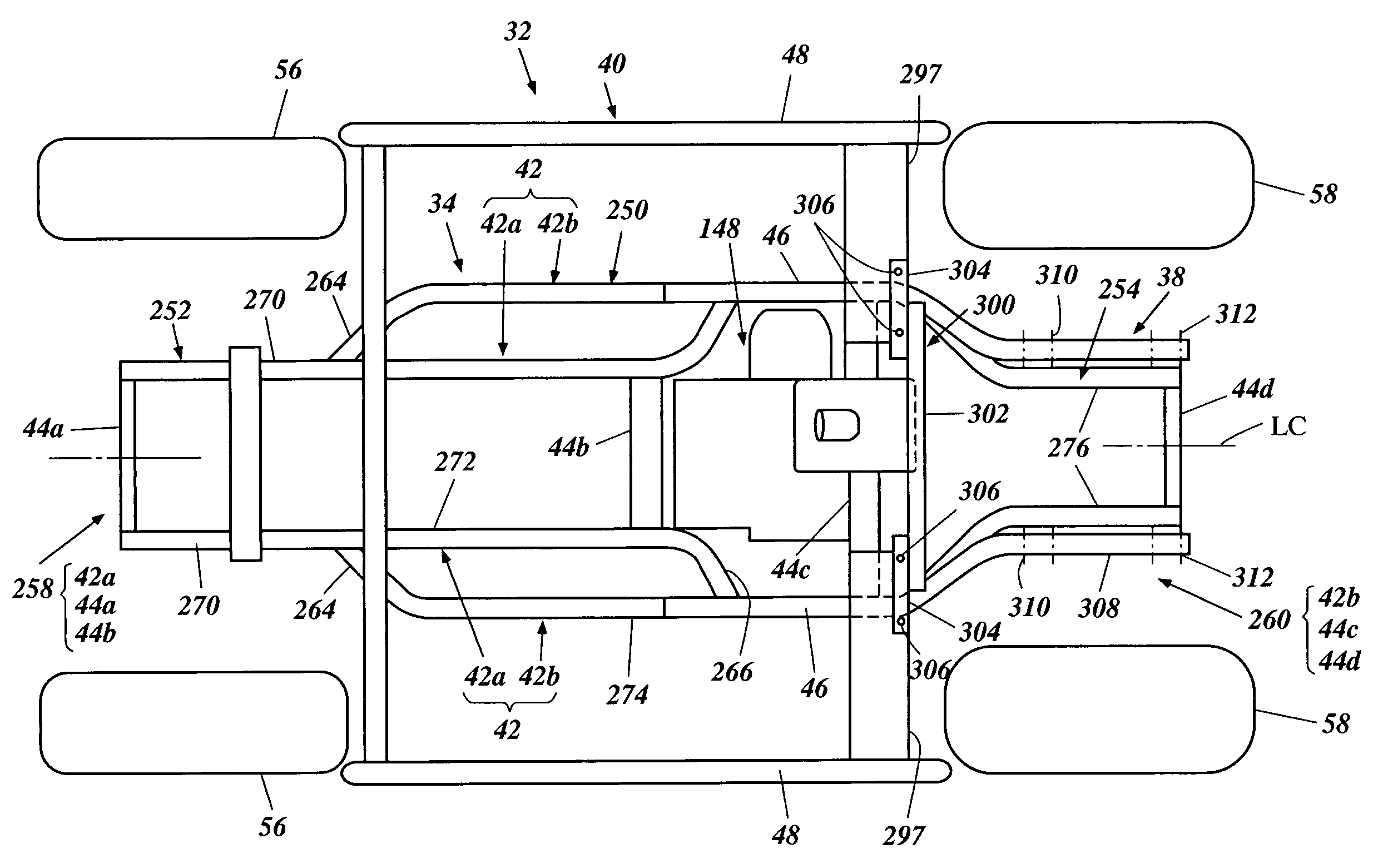

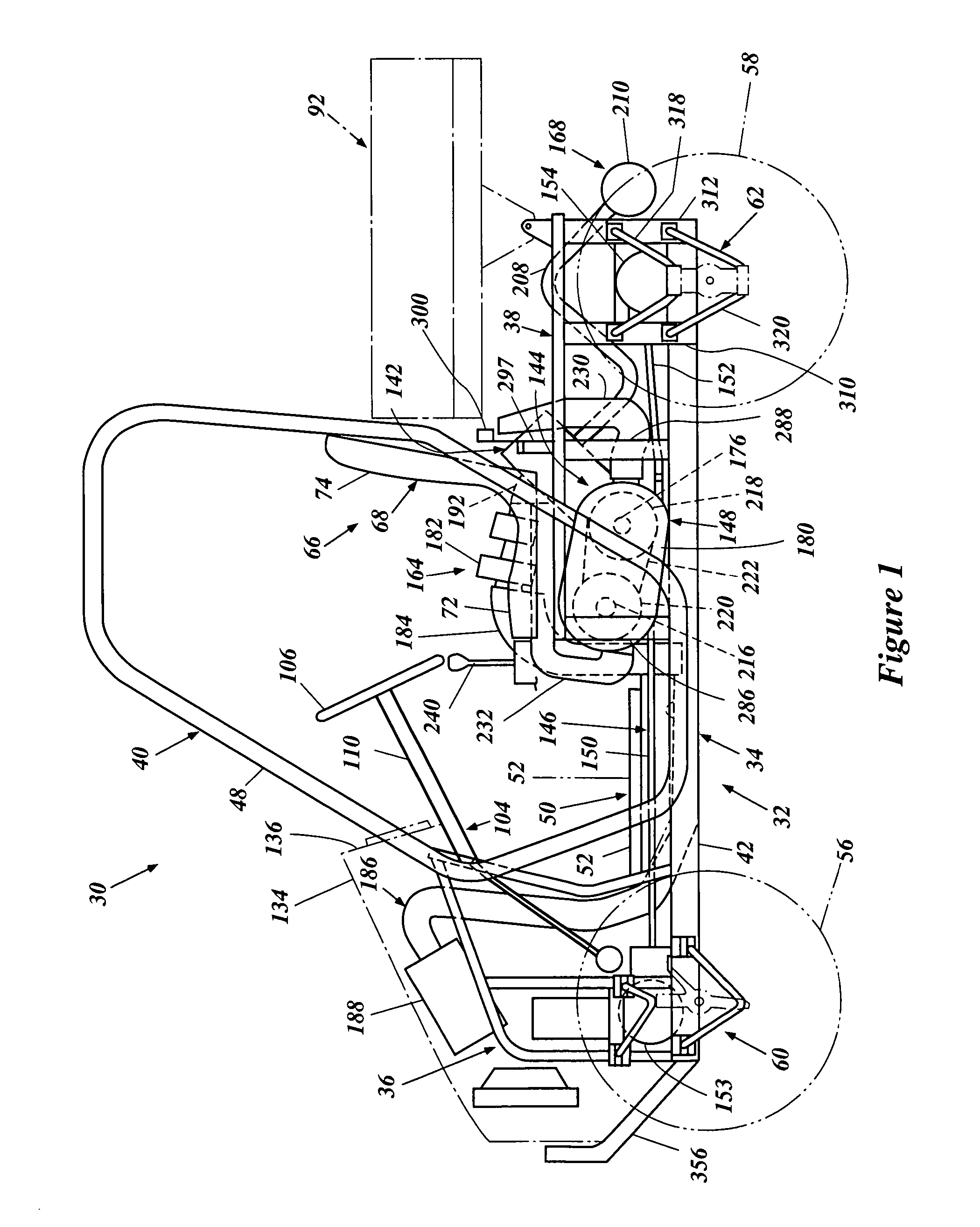

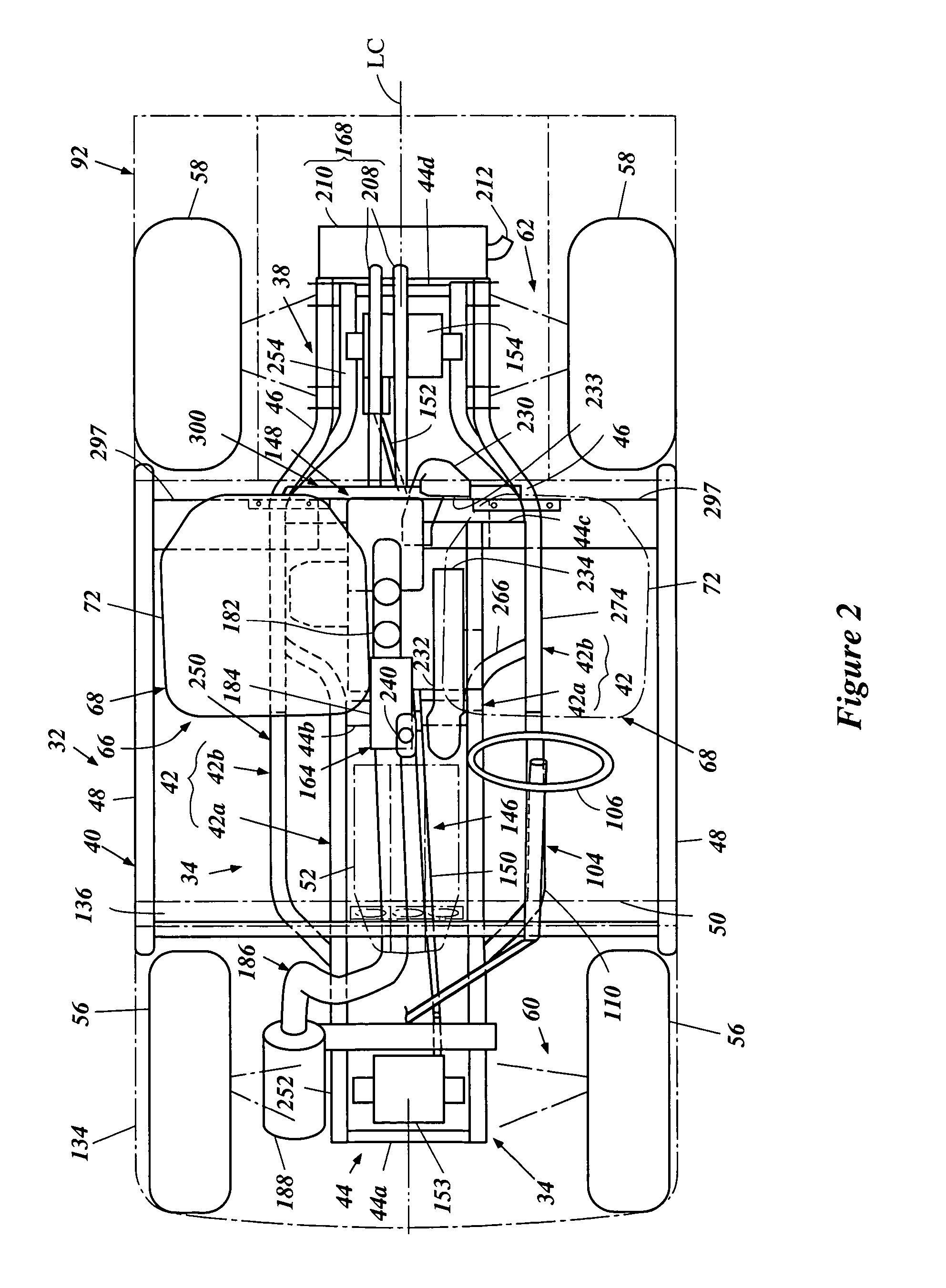

Frame arrangement for off-road vehicle

ActiveUS7650959B2High frame strengthEnhanced engine protectionVehicle body-frame connectionsElectric propulsion mountingVehicle frameMultiple frame

An off-road vehicle includes a frame and four wheels that support the frame. An engine powers the wheels. The engine is mounted on the frame. The frame includes multiple frame members that surround the engine. One of the frame members disposed behind the engine is detachably affixed to the rest of the frame members. The frame members are divided into first and second groups. The first and second groups are offset fore to aft relative to each other and overlap with each other in a rear section of the first group and in a front section of the second group. The rear section of the first group defines a bent portion coupled with the second group. The front section of the second group defines a bent portion coupled with the first group.

Owner:YAMAHA MOTOR CO LTD +1

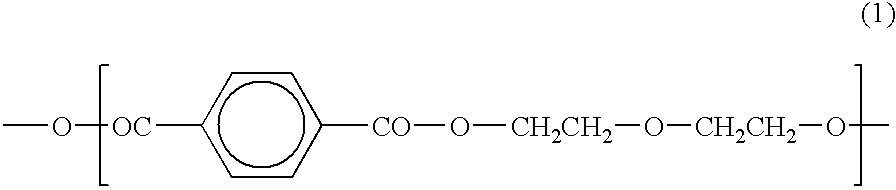

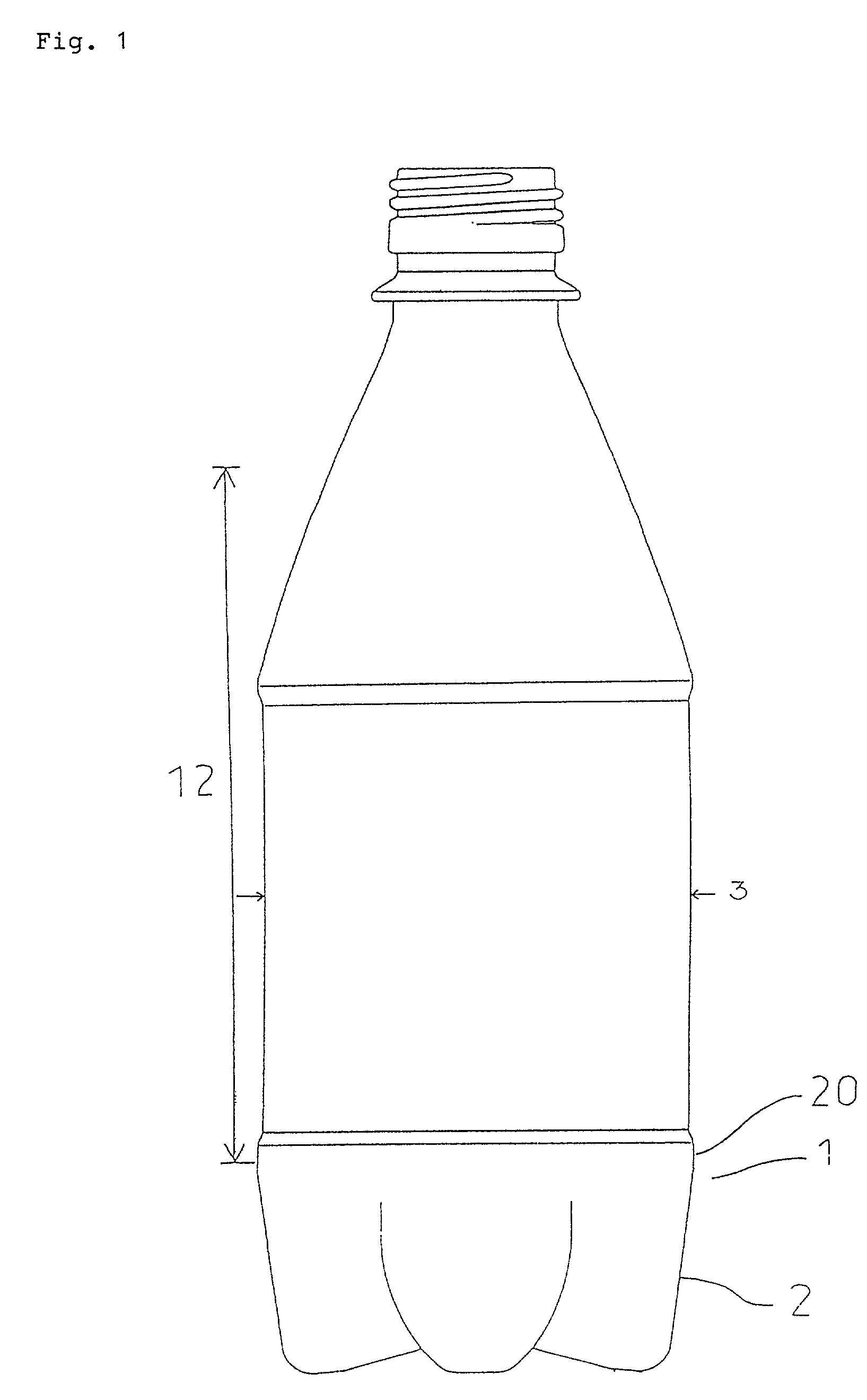

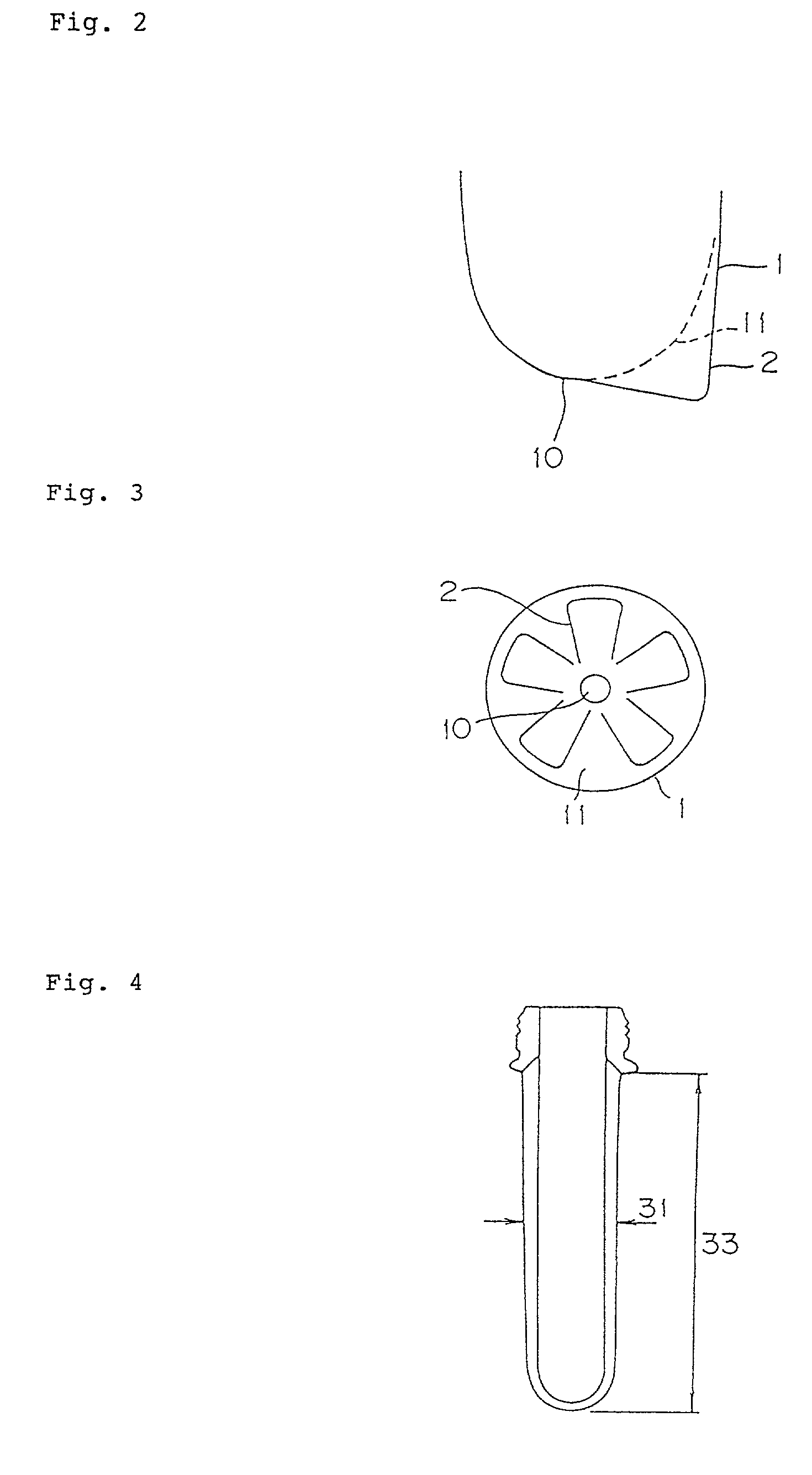

Polyester resin composition and a bottle therefrom

The present invention relates to a resin composition comprising polyethylene terephthalate and polyethylene naphthalate and a process for preparing the composition. The present invention relates also to a bottle produced from the composition and a process for the preparation of the bottle. The resin composition according to the present invention is prepared by melt-kneading (A) polyethylene terephthalate with (B) polyethylene naphthalate in a proportion of the ethylene naphthalate unit to a total of (A) and (B) of from 5 to 15 mole %, with a kneading extruder in a ratio of an extruder output rate to a screw rotation speed of 0.1 to 1.4 kg / hr.rpm. The present composition gives a bottle superior in transparency and in resistance to heat and pressure despite that it has a transesterification of 20% or lower.

Owner:NISHIHARA SHUN ICHI +3

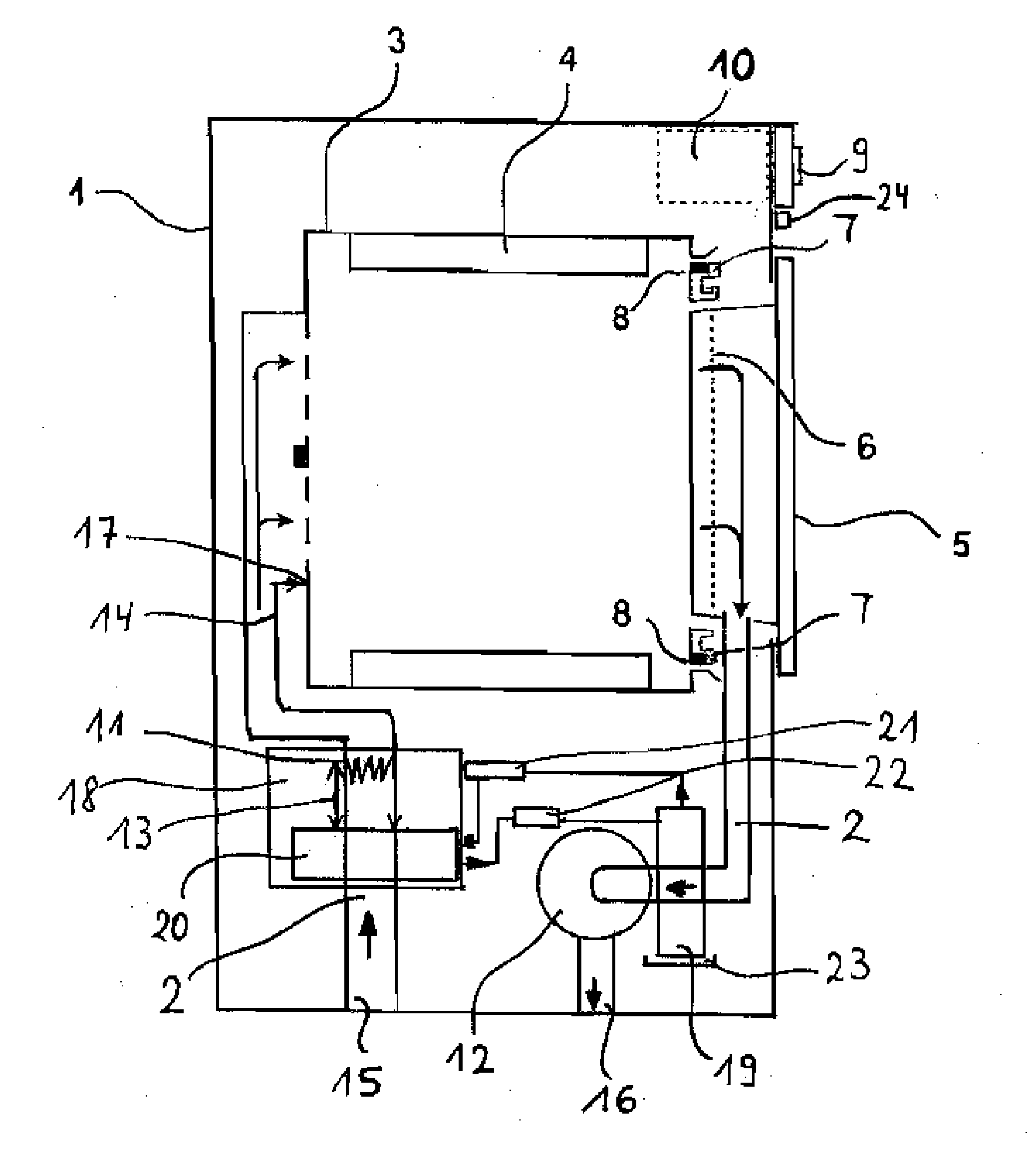

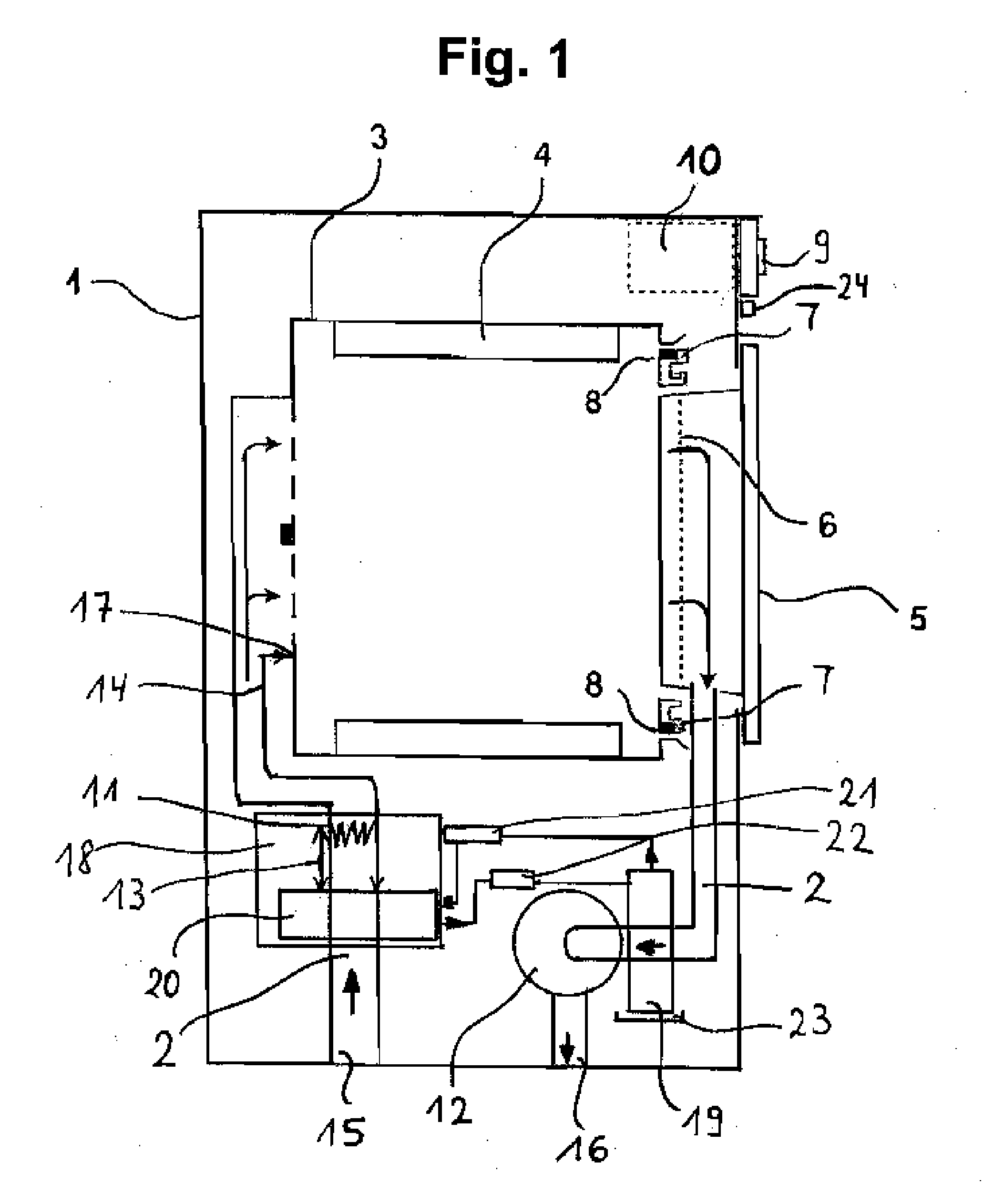

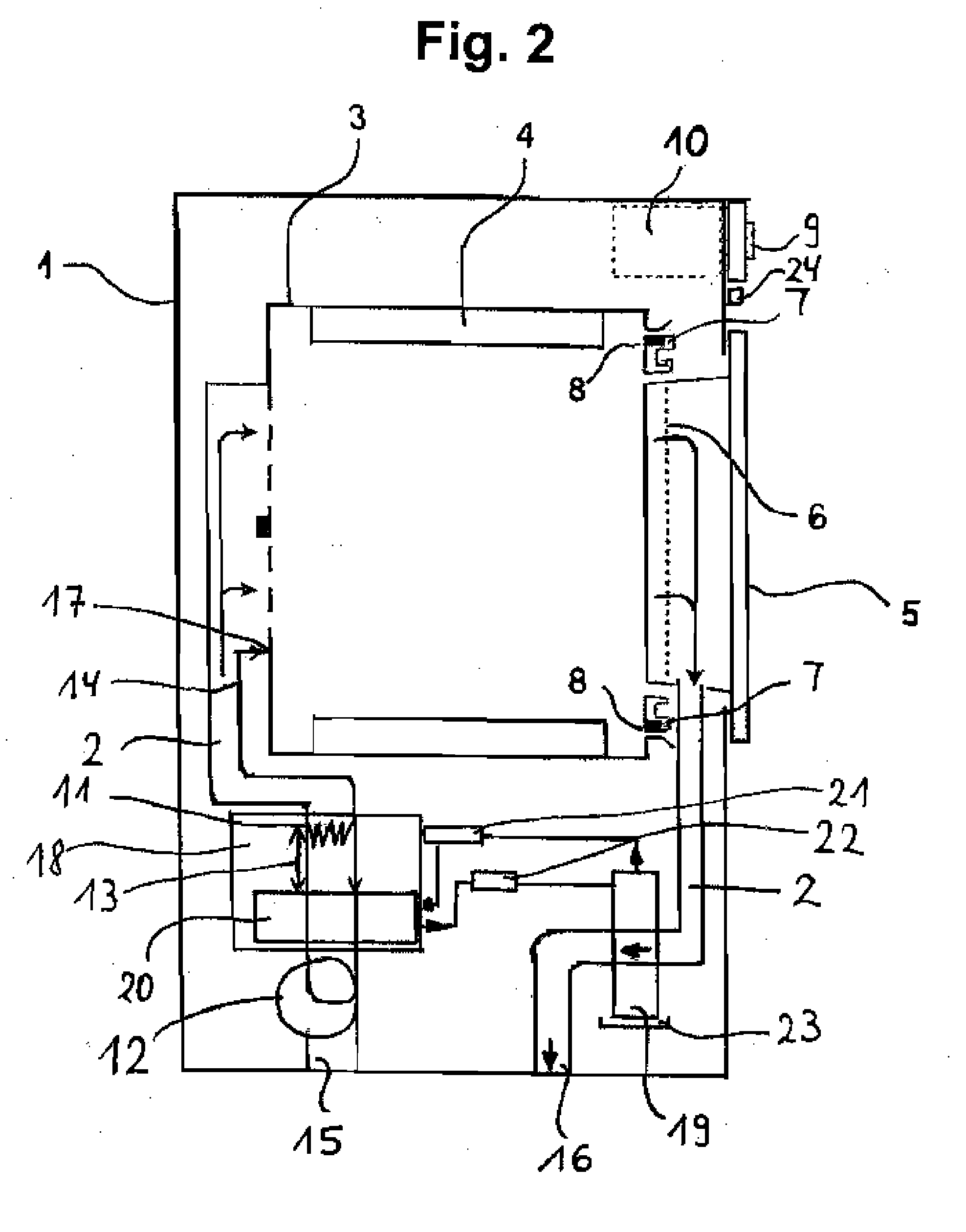

Dryer with a heat pump and an electrical heating element and also a method for its operation

InactiveUS20100132216A1Secure ability to regulateReduce the temperatureDrying solid materials with heatDrying chambers/containersElectricityProcess engineering

The invention relates to a dryer with a drying chamber for the items to be dried, a process air duct, a fan in the process air duct, a heat pump with a heat sink and a heat source thermally coupled to the process air duct, and also an electrical heating element. The electrical heating element is arranged in the direct vicinity of the heat source, with a first distance between the electrical heating element and the heat source being smaller than a second distance between the electrical heating element and an entry for the process air into the drying chamber. The invention also relates to a method for operating this dryer.

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

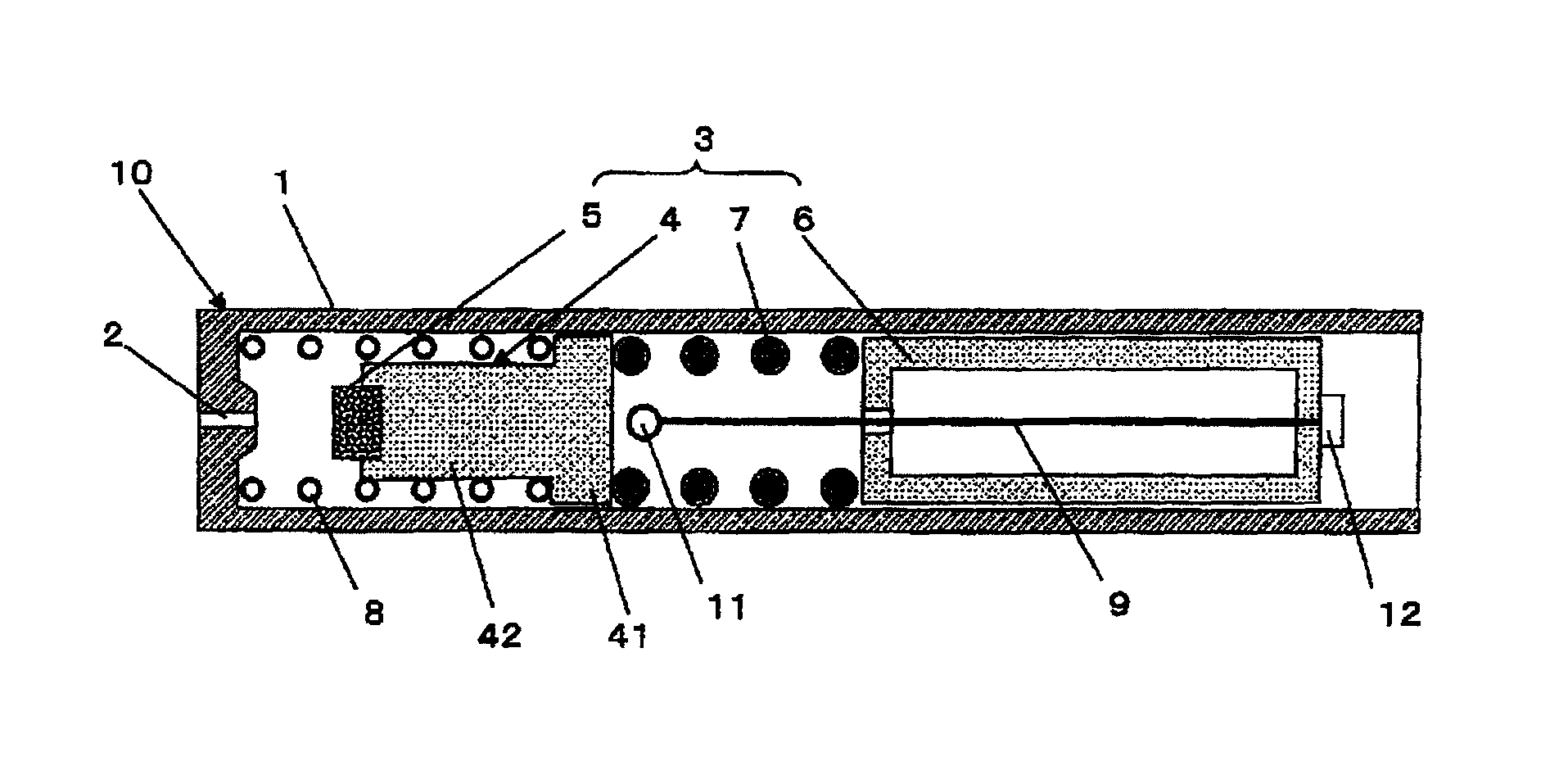

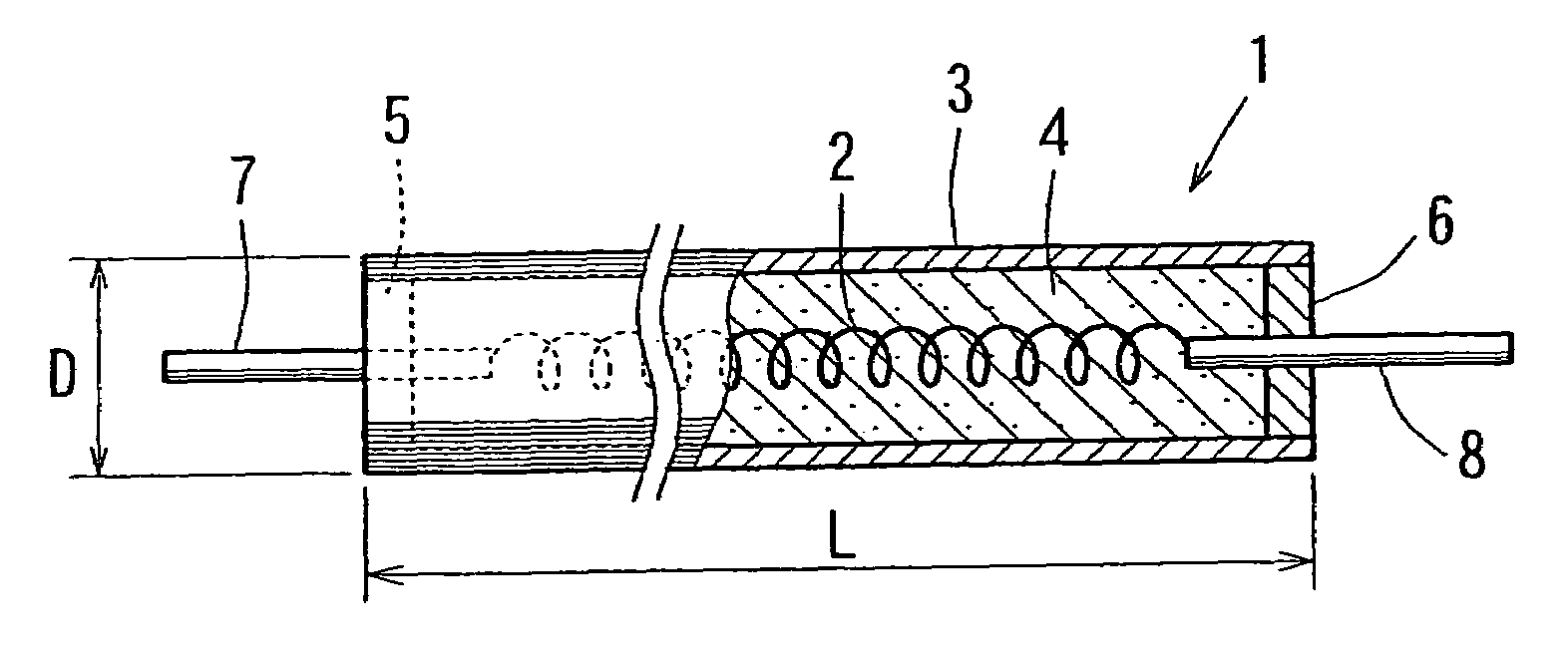

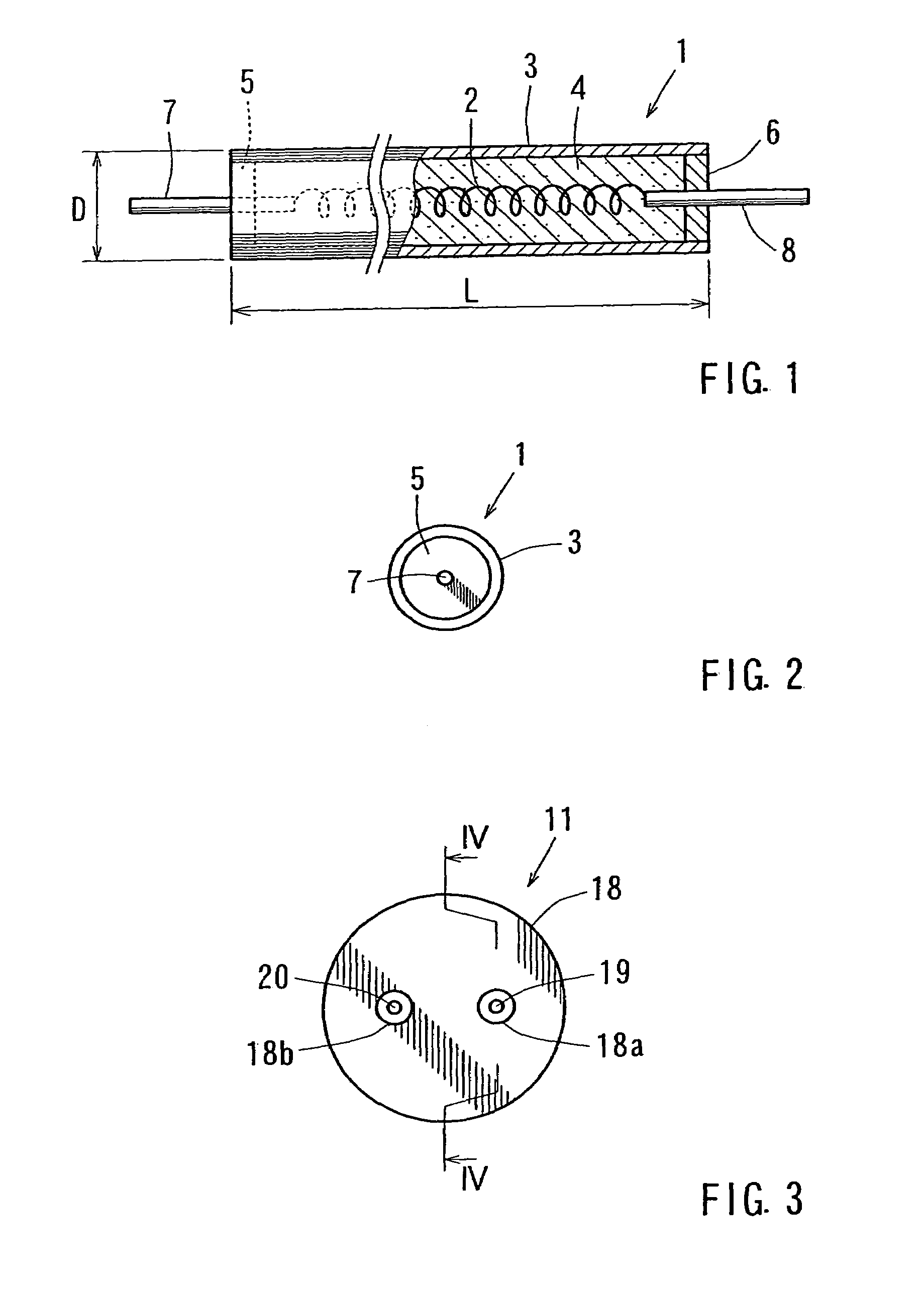

Heater

InactiveUS7019269B2Deterioration of the insulation resistance of the electrically insulating material is suppressedSuppress generationHeater elementsHeating element shapesEngineeringMetal

In a heater in which an electrically insulating material (4) including an oxide is filled between a heating element (2) made of metal including chromium and aluminum and a cover (3, 5, 6) for sealing the heating element (2), and in which a lead wire (7, 8) of the heating element (2) extends through a portion (5, 6) of an electrical insulator of the cover (3, 5, 6) in order to enable the heater to be used at temperatures higher than the prior art, an oxide film including aluminum oxide is formed on the surface of the heating element (2). The portion of the cover (3, 5, 6) excluding the portion (5, 6) serving as an electrical insulator is a metal pipe (3) that serves as a sheath and includes nickel and chromium, and an oxide film is formed on the surface of the metal pipe (3). Therefore, the heater can be used in dies for plastic forming or the like.

Owner:SANYO NETABUINDS

Diaphragm for pressure sensor and pressure sensor

InactiveUS20090308168A1Less occurrenceLess susceptibilityFluid pressure measurement using piezo-electric devicesFluid pressure measurement using elastically-deformable gaugesEngineeringDiaphragm seal

A diaphragm for a pressure sensor includes: a central section serving as a diaphragm body, the central section including: an external surface deformed upon receipt of an external pressure; and an internal surface transmitting a force to a pressure sensitive element inside a housing of the pressure sensor; a peripheral section that is an exterior of the central section and welded to an outer circumference of a pressure input orifice that is provided to the housing; and a step wall provided between the central section and the peripheral section. The central section and the peripheral section are integrally and concentrically provided. The diaphragm seals the pressure input orifice.

Owner:SEIKO EPSON CORP

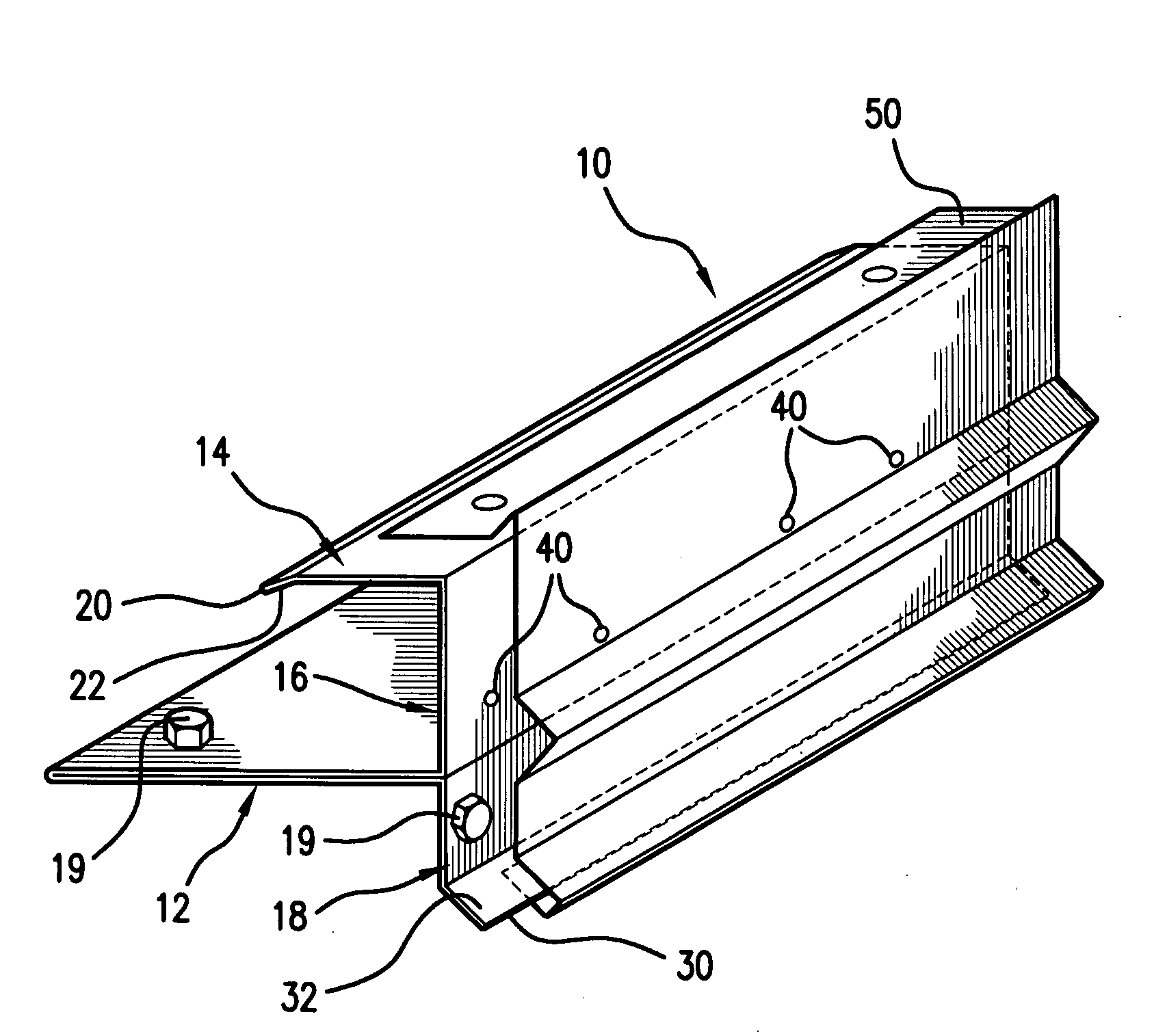

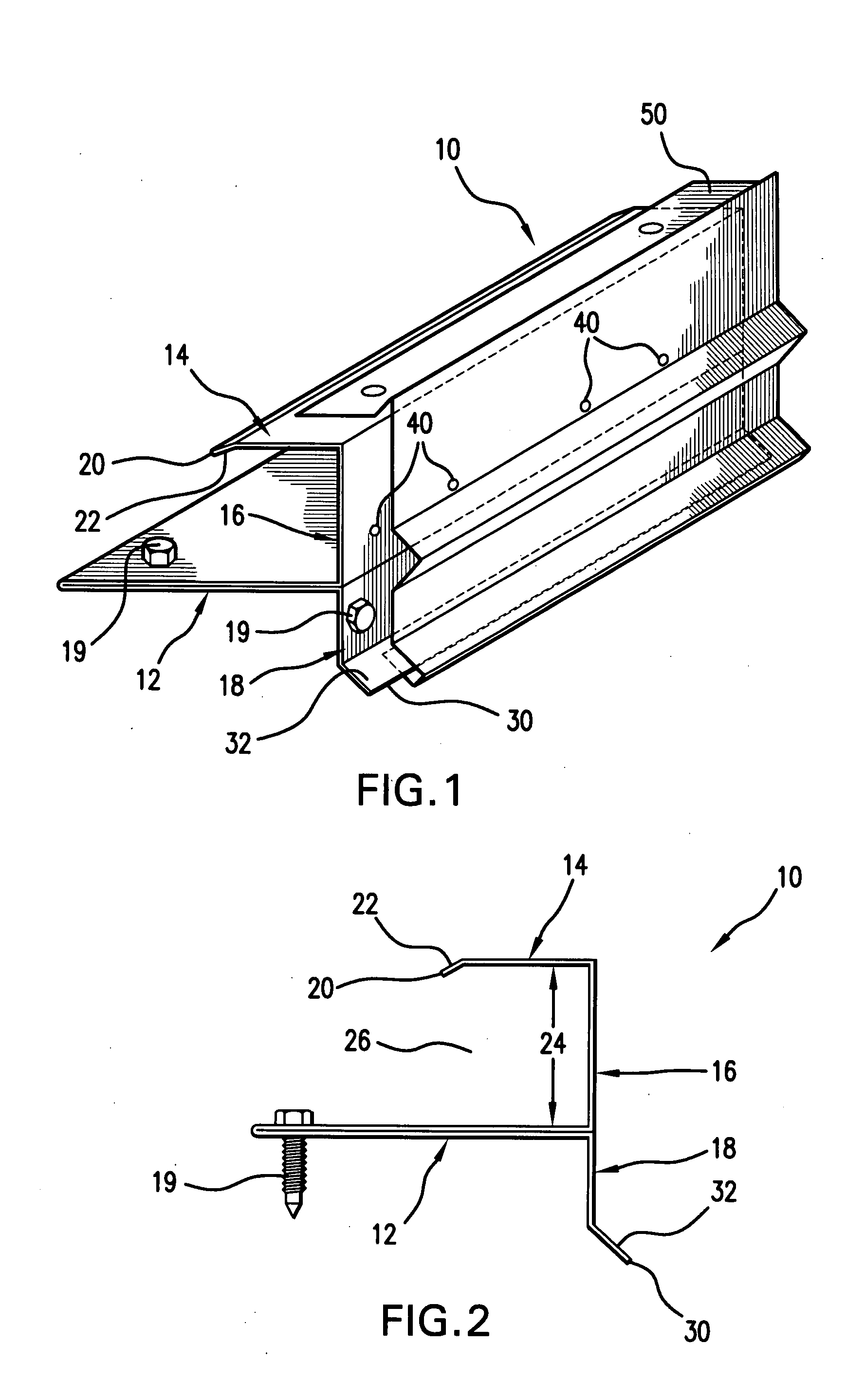

Edge closure for roof systems

An edge closure for installation on a roof structure is fabricated as an integral unit from a non-corrosive, durable material. The edge closure includes an anchoring flange for attachment to the roof structure, an upper flange with an upper longitudinal edge zone, and intermediate panel spanning between the anchoring flange and the upper flange, and a fascia portion integral with the anchoring flange and extending downwardly to a lower longitudinal edge zone. The anchoring flange and upper flange are spaced apart for receiving a thickness of insulative lightweight concrete therebetween. The upper and lower longitudinal edge zones are angled to provide added rigidity and strength to the edge closure.

Owner:GEMBALA HENRY

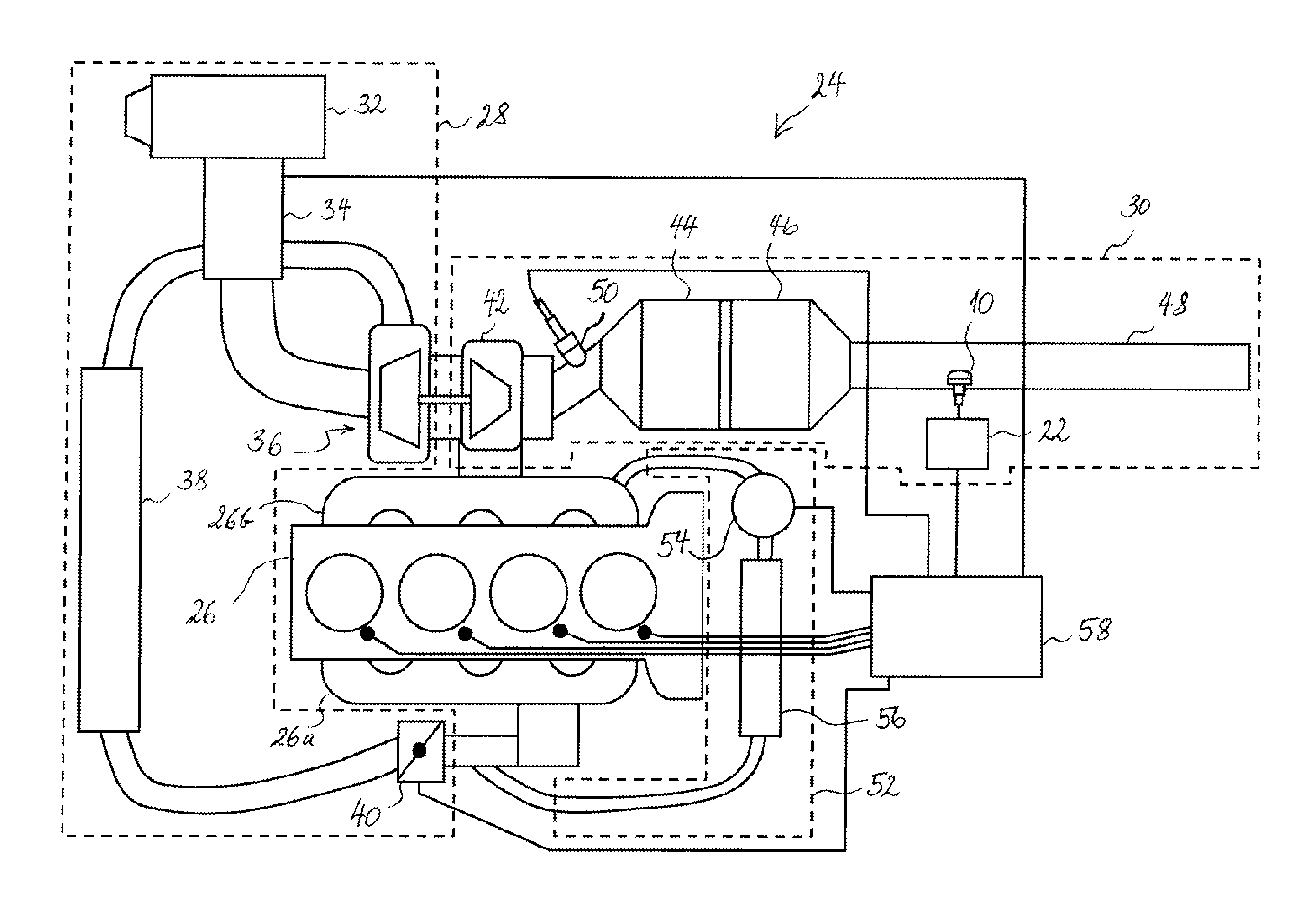

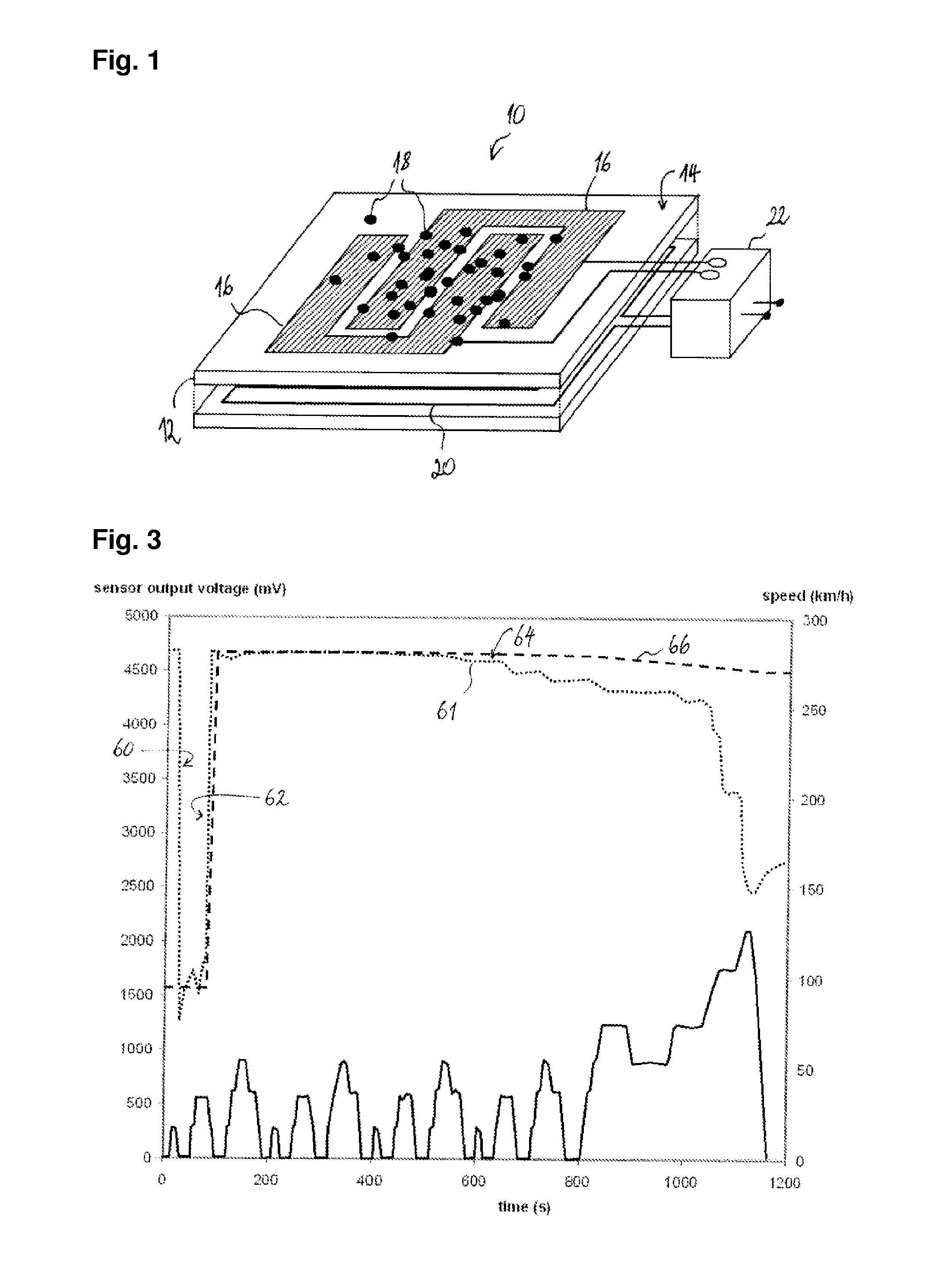

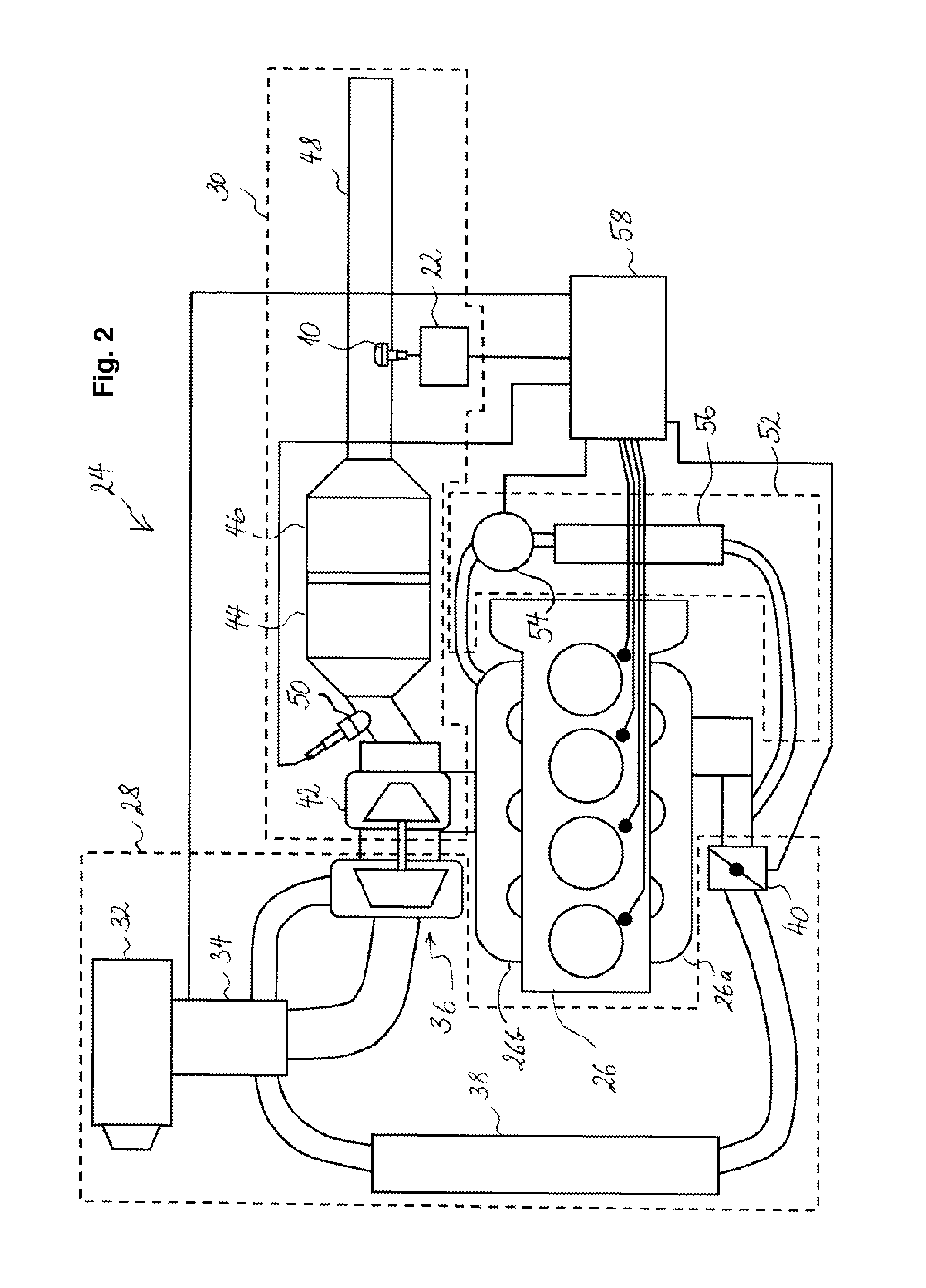

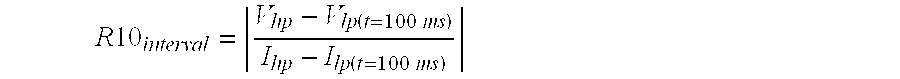

Soot sensor functional capability monitoring

InactiveUS20130318948A1Quick checkResistance to deteriorationVehicle testingInternal-combustion engine testingEngineeringSoot

A method of monitoring functional capability of a soot sensor that is responsive to deposition of soot from an exhaust gas stream on a sensor surface comprises acquiring a measurement signal of the soot sensor and running a plausibility check, in which it is ascertained whether the measurement signal agrees with an expected finding. According to the invention it is detected whether conditions are present, on which liquid, e.g. water, from the exhaust gas stream condensates on the sensor surface. Additionally or alternatively, such conditions are produced. The plausibility check then includes ascertaining whether the measurement signal reflects the condensation of liquid. The detection of presence of conditions for condensation comprises a measurement or an estimation of temperature on the sensor surface.

Owner:DELPHI INT OPERATIONS LUXEMBOURG S A R L

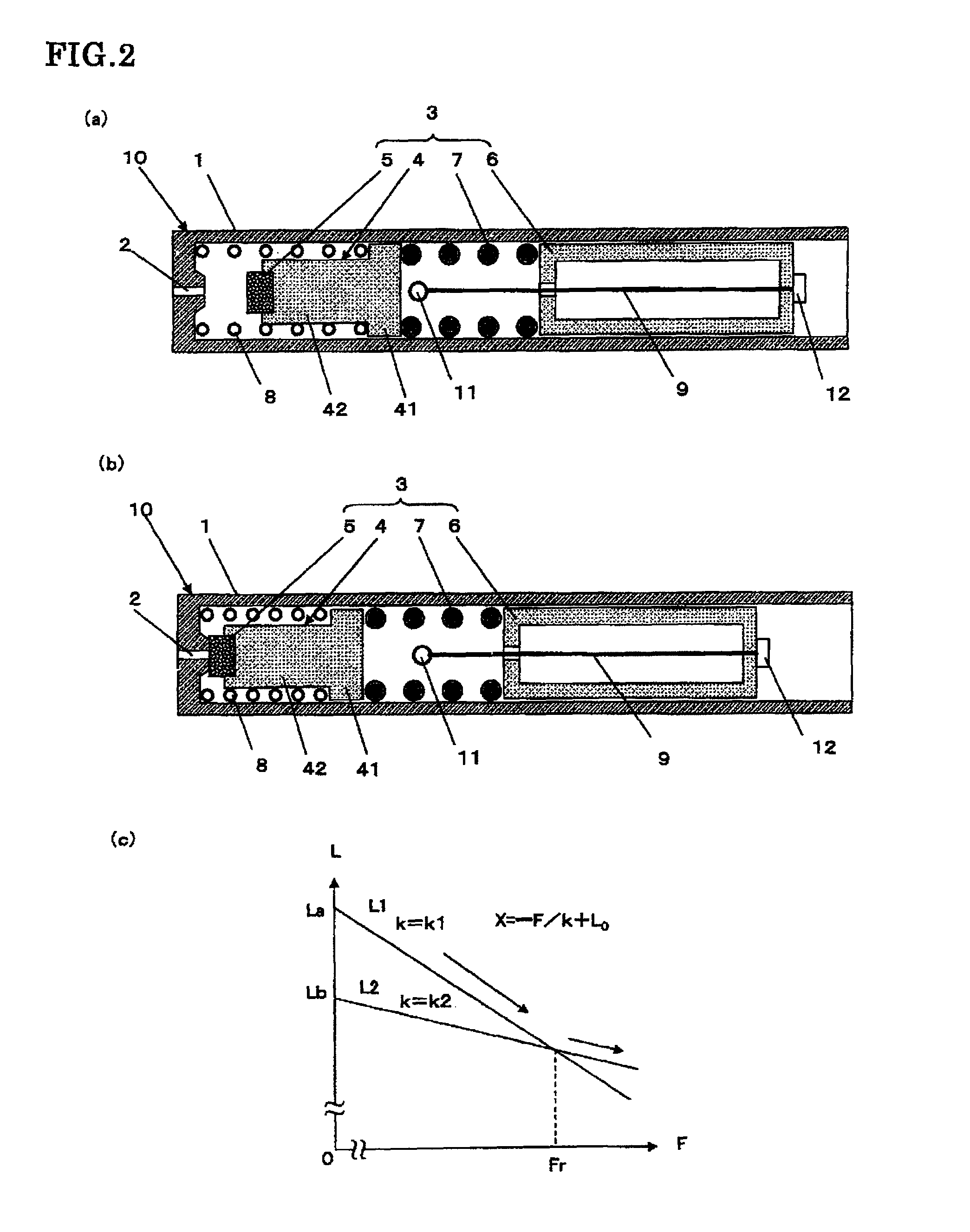

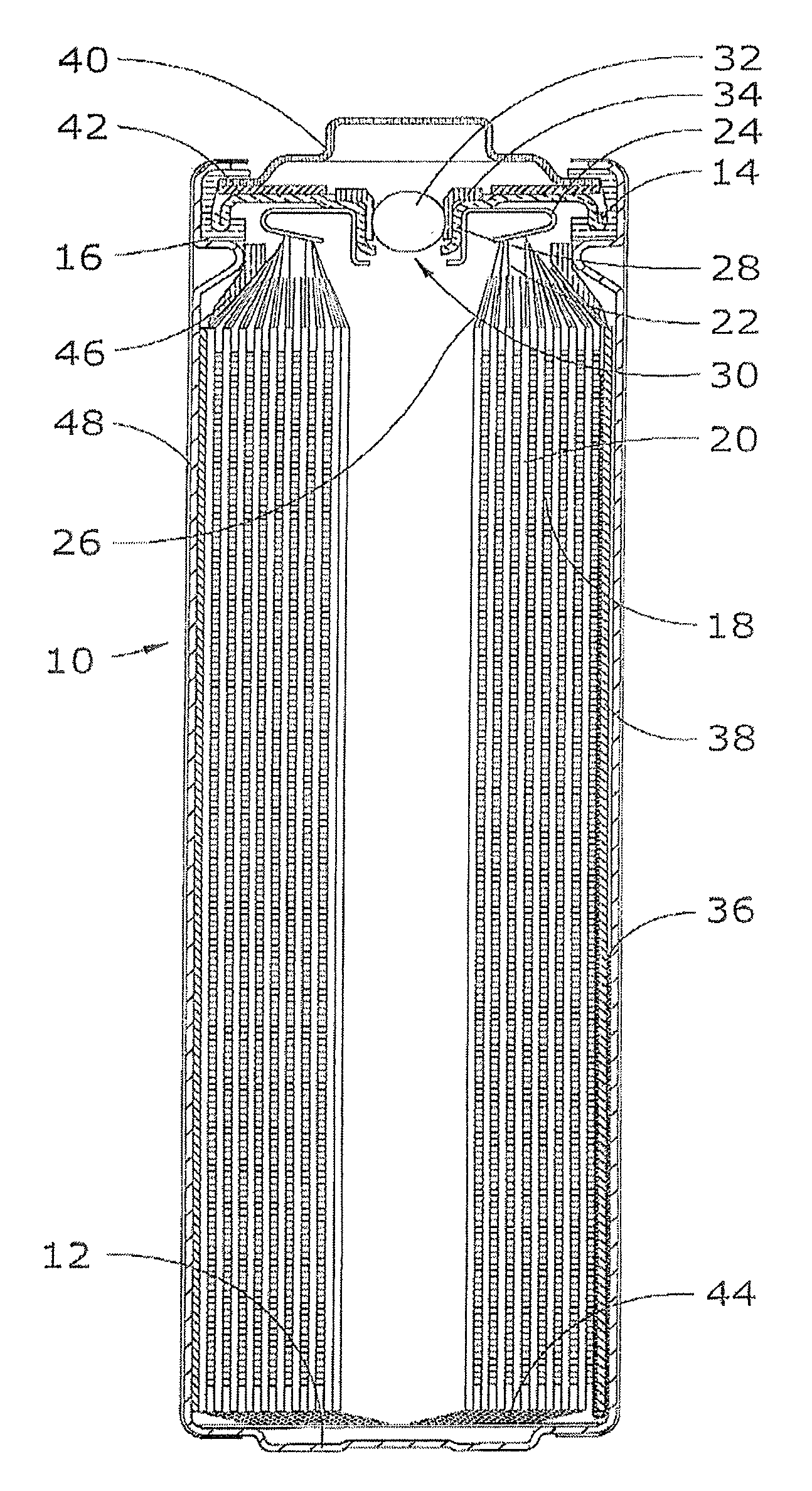

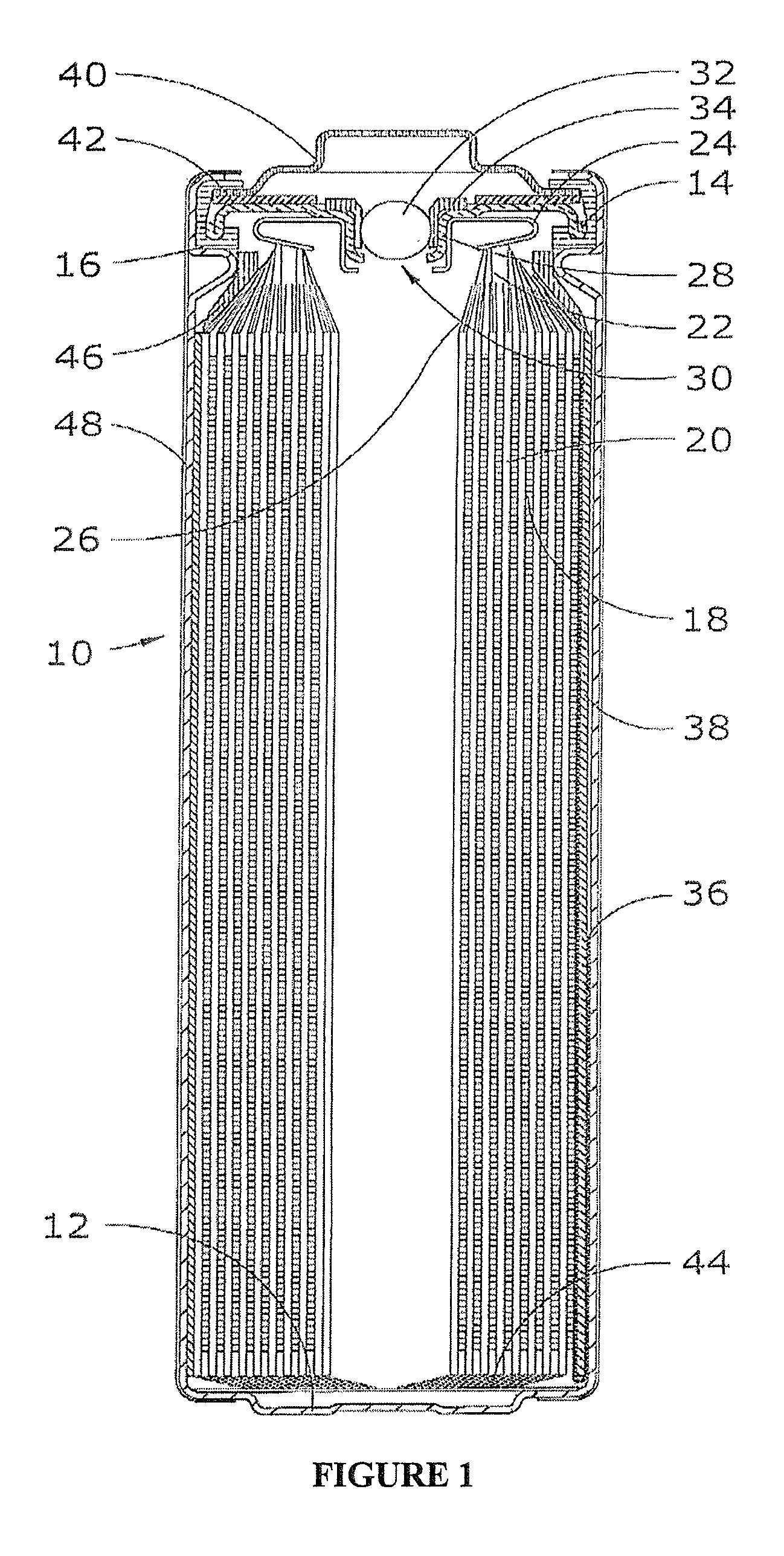

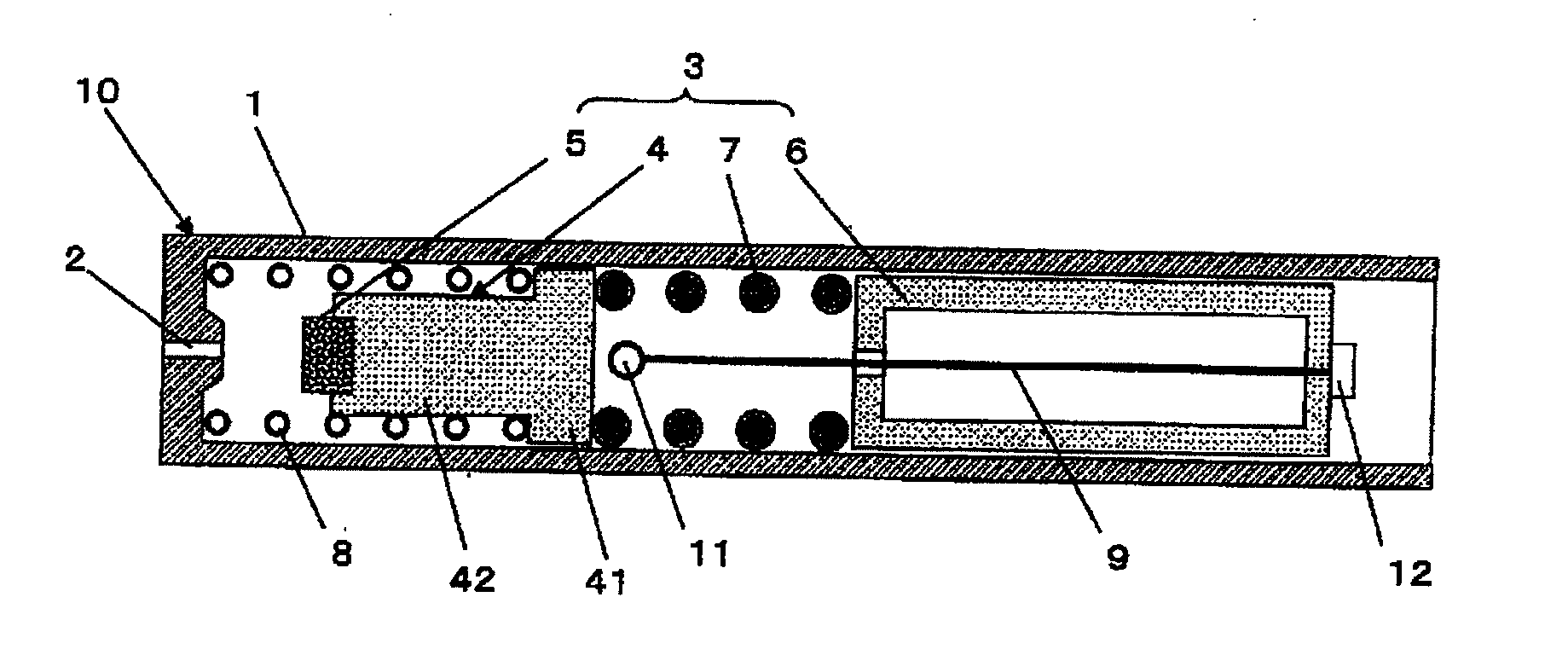

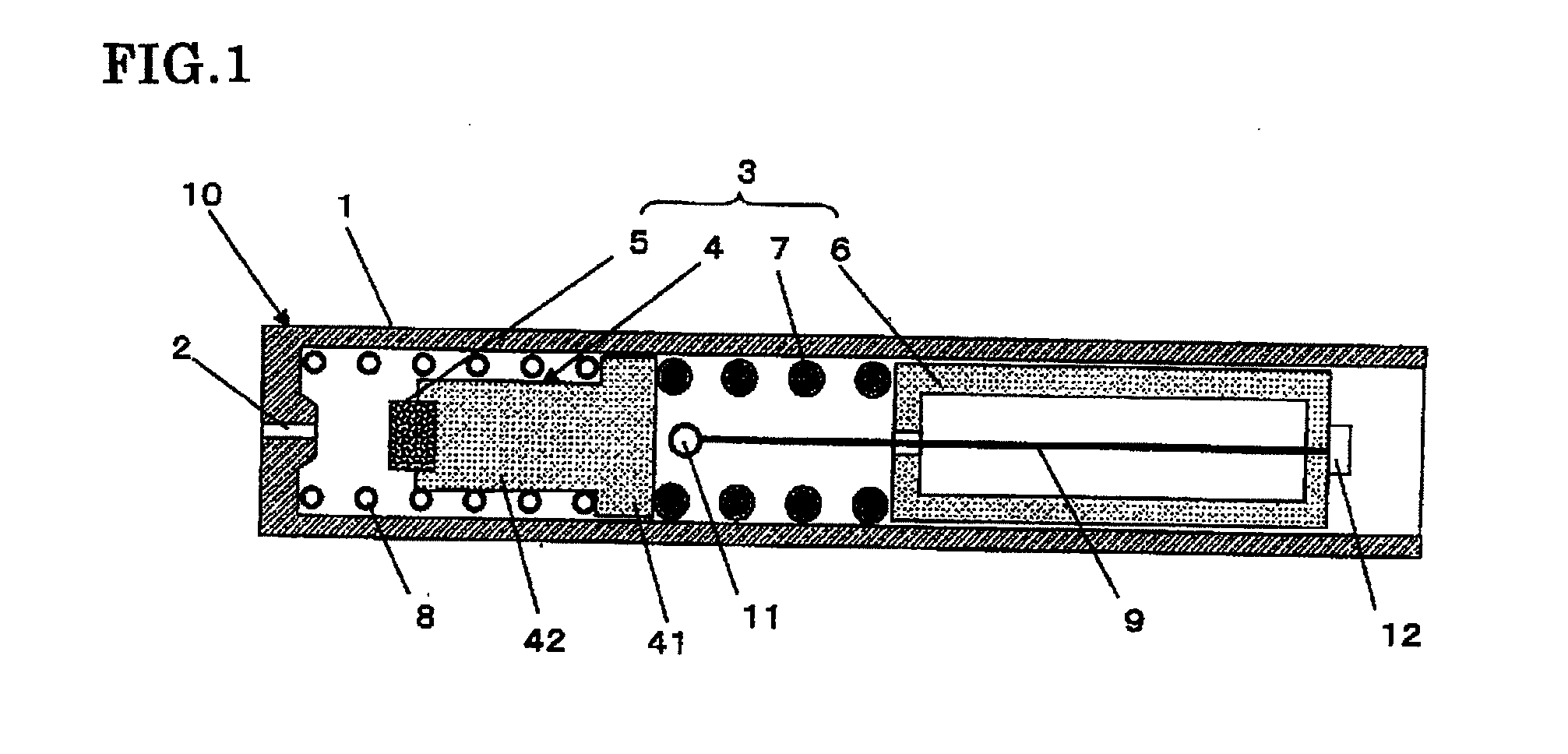

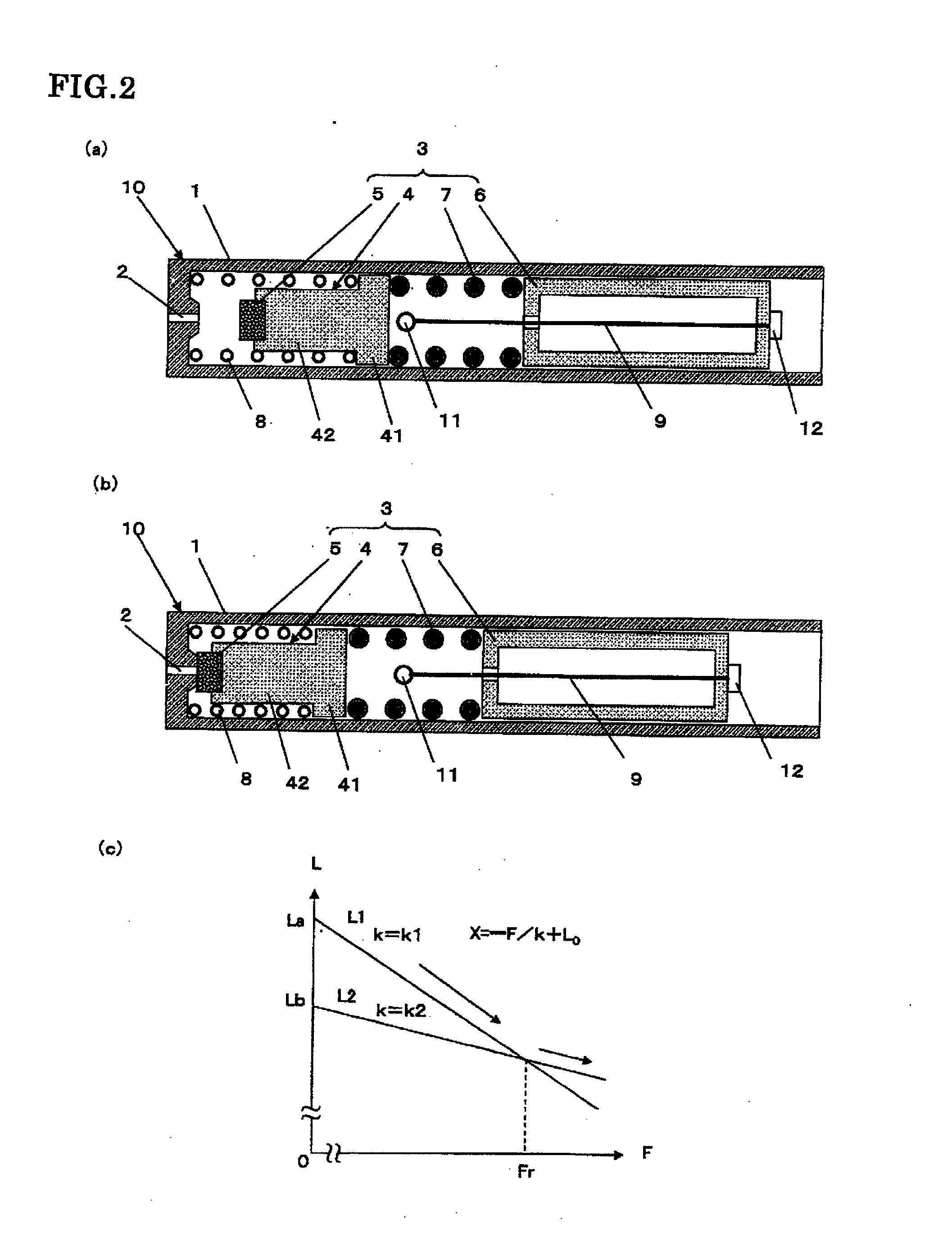

Lithium-Iron Disulfide Cell Design

ActiveUS20100310910A1MiniaturizationEasy to controlCell seperators/membranes/diaphragms/spacersFinal product manufactureCell designOptoelectronics

A lithium-iron disulfide electrochemical cell design is disclosed, relying on judicious selection of the electrolyte, a thicker lithium anode and a cathode with specific characteristics selected to cooperate with the electrolyte. The resulting cell has a reduced interfacial surface area between the anode and the cathode but, surprisingly, maintains excellent high drain rate capacity.

Owner:ENERGIZER BRANDS

Water draining system for a fuel filter

InactiveUS20090173639A1Less spaceReduce the possibilityWater/sewage treatmentMachines/enginesFuel filterEngineering

A water draining system for a fuel filter having a water collecting reservoir is disclosed. The water draining system has a housing adapted for attachment to the reservoir, the housing having a water sensor arranged to protrude into the reservoir and having a valve with an inlet for draining water collected in the reservoir. The valve is selectively moveable between an open and a closed configuration. The water draining system also has a controller connected to the sensor such that when the water level in the reservoir reaches a predetermined level, the sensor sends a signal to the controller and movement of the valve between the open and closed configuration is directly or indirectly dependent upon subsequent signals generated by the controller.

Owner:PARKER HANNIFIN MFG (UK) LTD

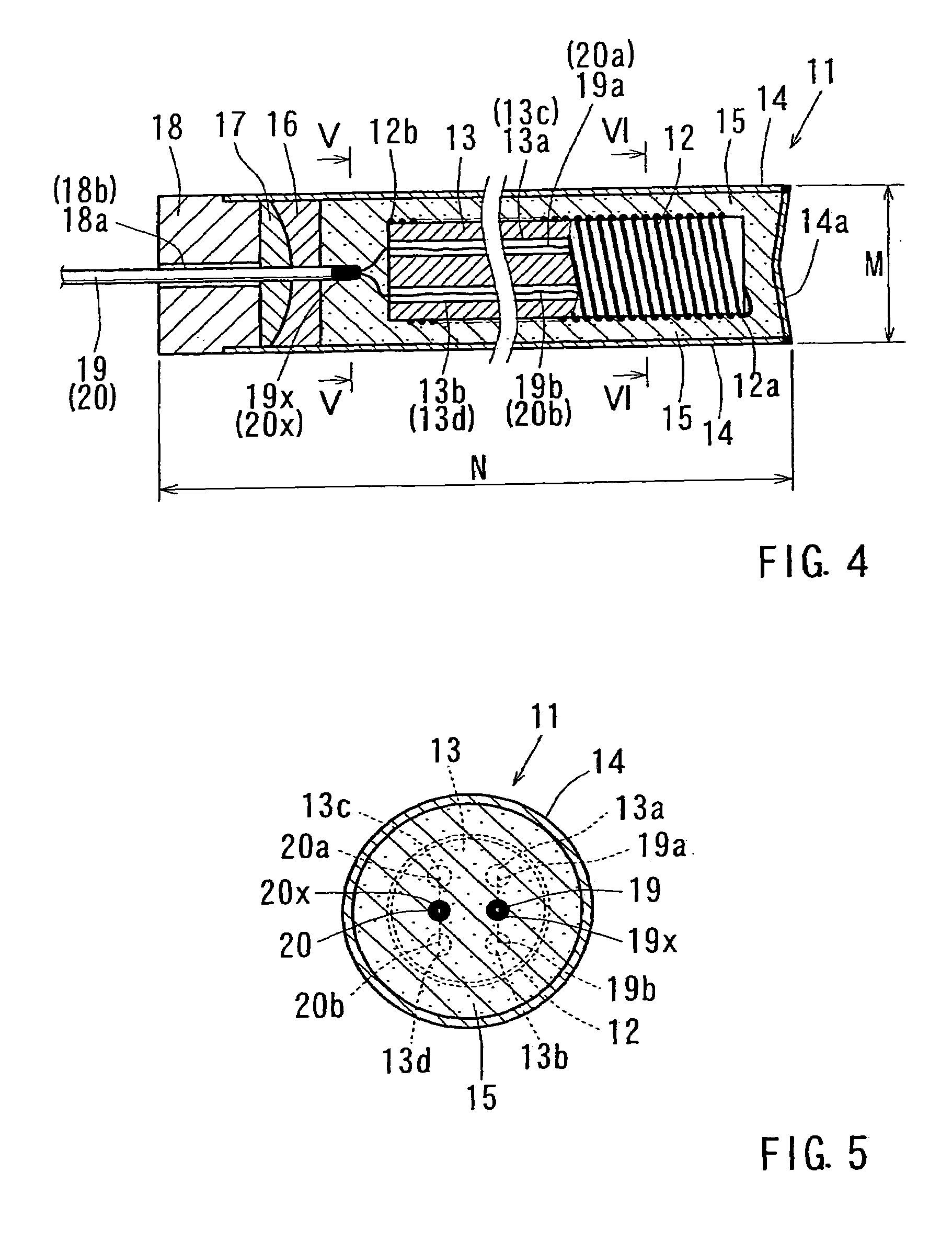

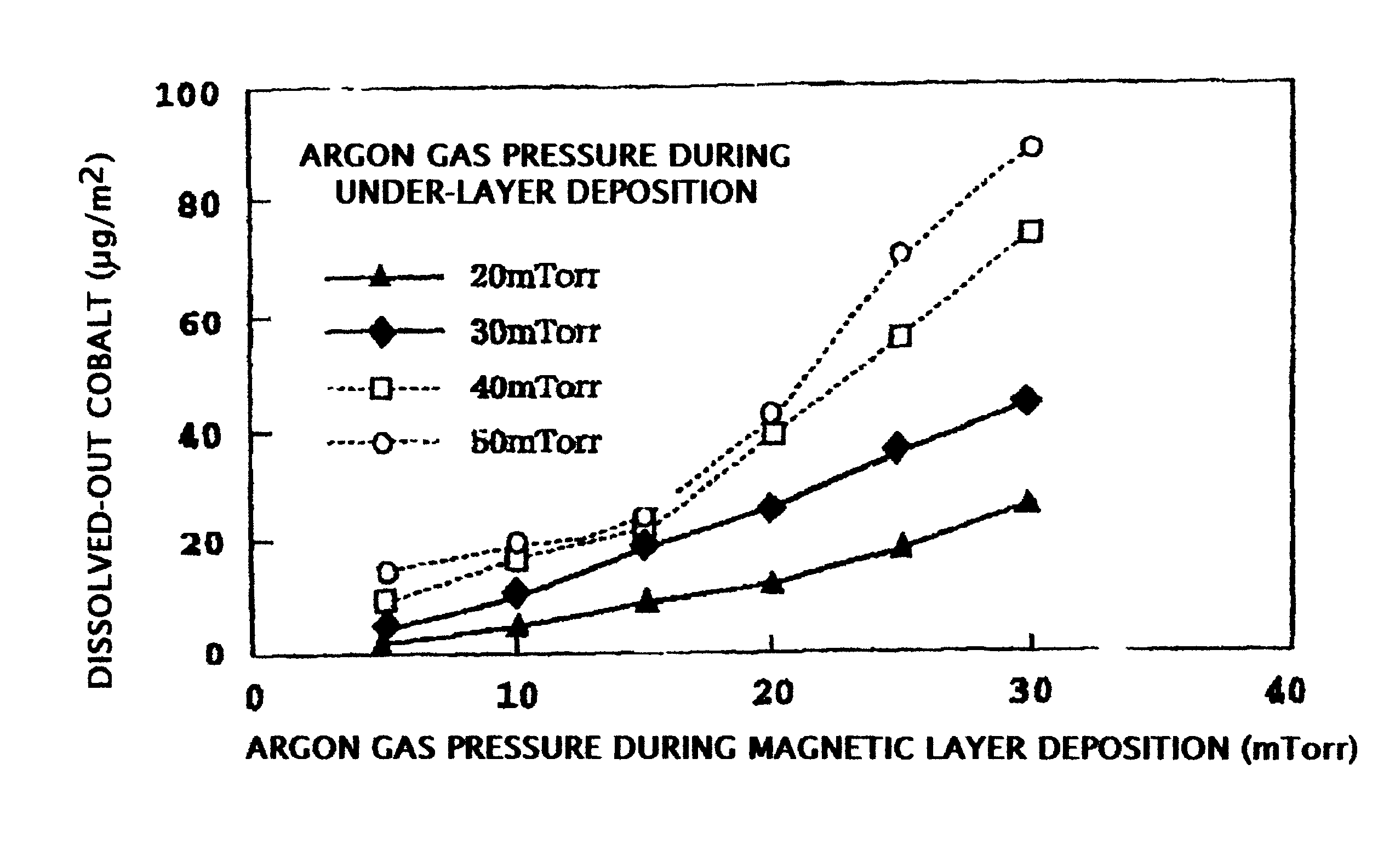

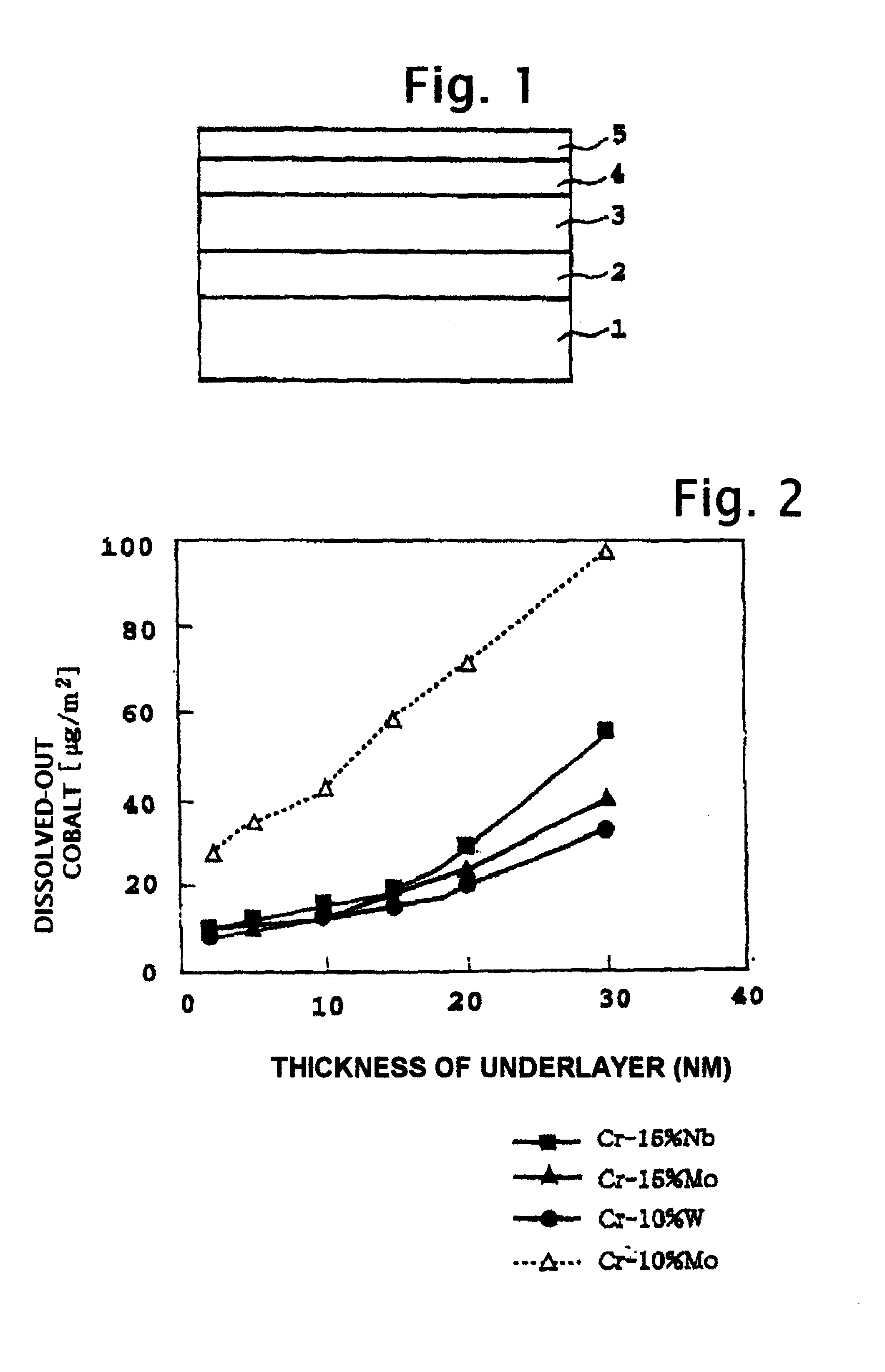

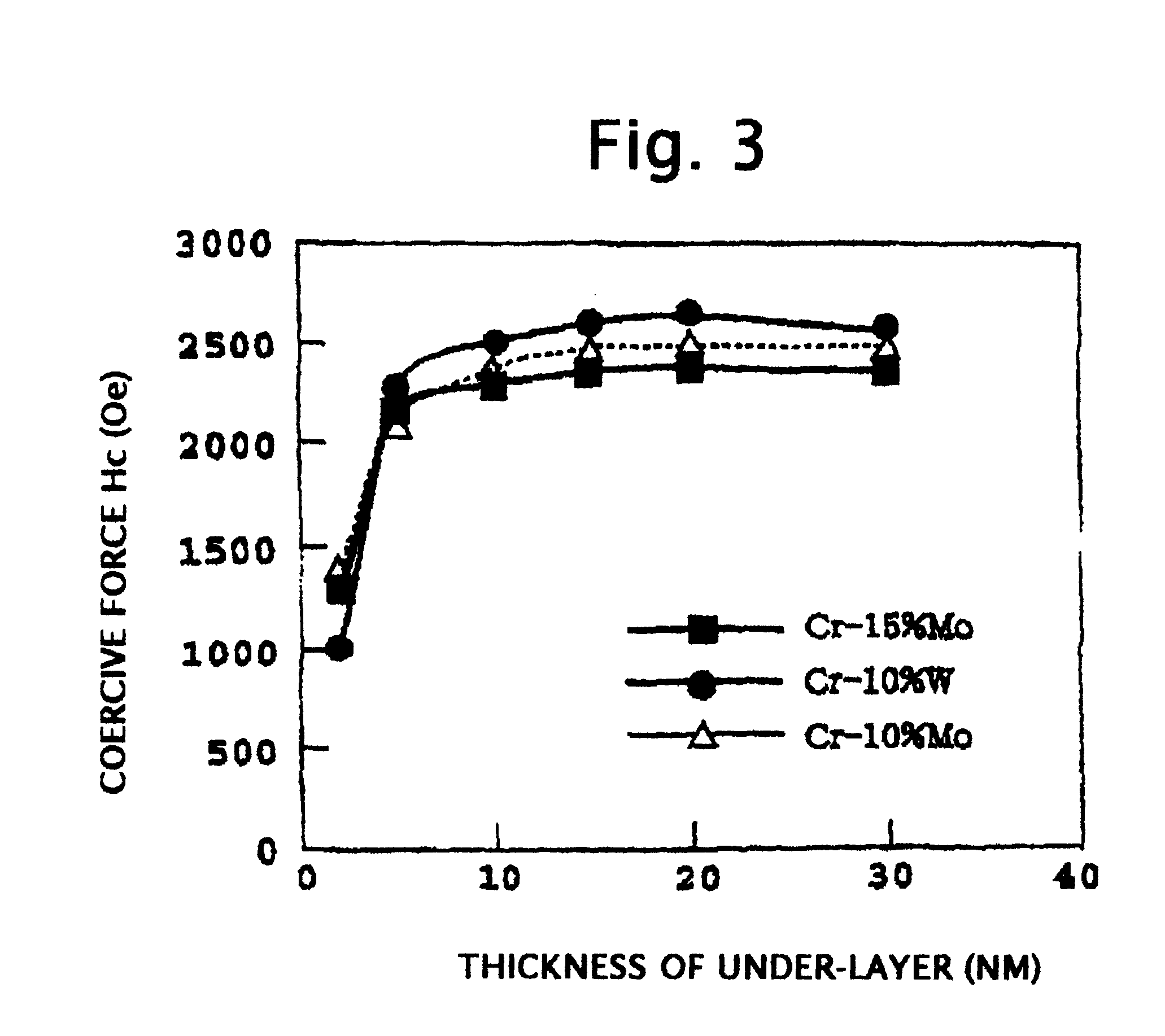

Magnetic recording medium and manufacturing method for the same

InactiveUS6589669B2Excellent magnetic property and electromagnetic transformation characteristicIncreased durabilityBase layers for recording layersVacuum evaporation coatingAtmospheric pressureNon magnetic

A magnetic recording medium according to the invention includes a plastic substrate, a non-magnetic under-layer on the substrate, a magnetic layer including cobalt on the under-layer, a protective film on the magnetic layer, and a liquid lubricant layer on the protective film. The under-layer is composed of a chromium alloy having a body centered cubic lattice structure, and containing at least one element selected from the group consisting of Zr, Nb, Mo, Ru and Pd in a total amount of at least 15 at %, or containing at least one element selected from the group consisting of Hf, Ta, W, Re, Pt and Au in a total amount of at least 10 at %. The amount of cobalt dissolved out of the magnetic layer is limited by performing sputtering deposition of at least the magnetic layer at low pressures of argon.

Owner:FUJI ELECTRIC CO LTD

Method of producing fuel hose material and fuel hose material produced by the same

InactiveUS20070202287A1Improve dispersion uniformityResistance to deteriorationSynthetic resin layered productsThin material handlingPlasticizerCarbon nanotube

A method of producing a fuel hose material which is obtained at low costs and has excellent properties such as antistatic property, resistance to thermal aging and resistance to sour gasoline, and a material produced by the method. The method includes the steps of: dispersing a carbon nanotube in a polar plasticizer comprising at least one of a sulfonamide plasticizer and an ester plasticizer; and blending the resulting compound into a polyamide resin having a relative viscosity (ηr) of 2.5 to 3.5, in which the carbon nanotube is present in a proportion of not less than 7 wt %.

Owner:SUMITOMO RIKO CO LTD

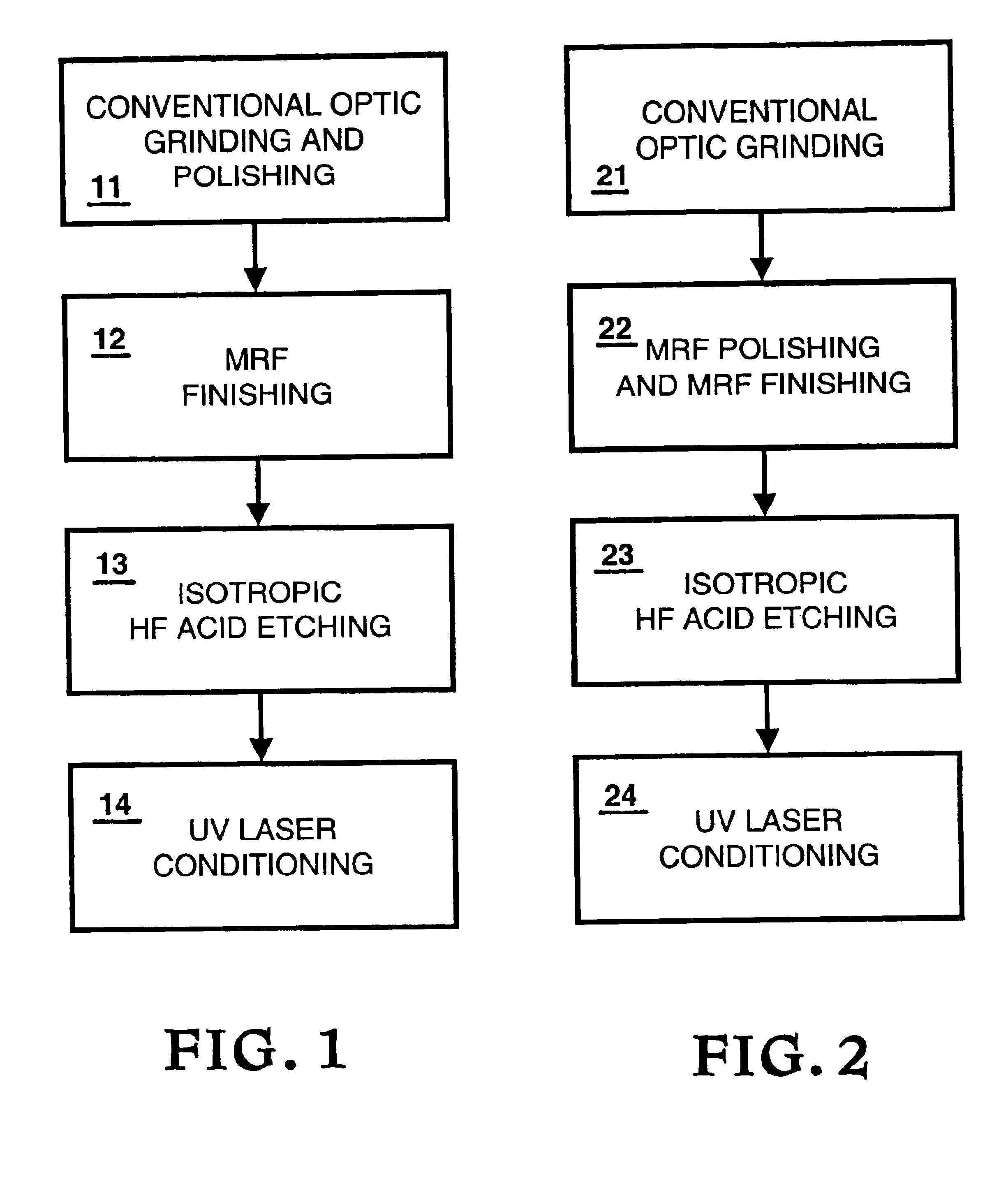

Combined advanced finishing and UV laser conditioning process for producing damage resistant optics

InactiveUS6920765B2Reduce harmFewer catastrophic defectsGlass making apparatusOptical surface grinding machinesUv laserHigh power lasers

A method for reducing the density of sites on the surface of fused silica optics that are prone to the initiation of laser-induced damage, resulting in optics which have far fewer catastrophic defects, and are better capable of resisting optical deterioration upon exposure to a high-power laser beam.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

Natural rubber, rubber composition and pneumatic tire

InactiveUS7427646B2Improve tensile propertiesLow viscositySpecial tyresInflatable tyresHysteresisPolymer science

Owner:BRIDGESTONE CORP

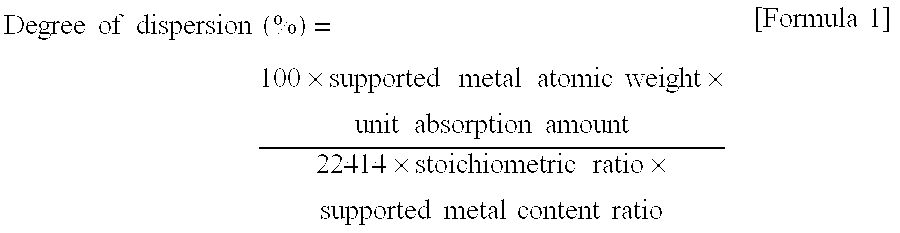

Exhaust gas purifying catalyst and method for manufacturing the same

ActiveUS8273681B2Resistance to deteriorationReduce usageInternal combustion piston enginesOther chemical processesCeriumPotassium

Owner:NISSAN MOTOR CO LTD

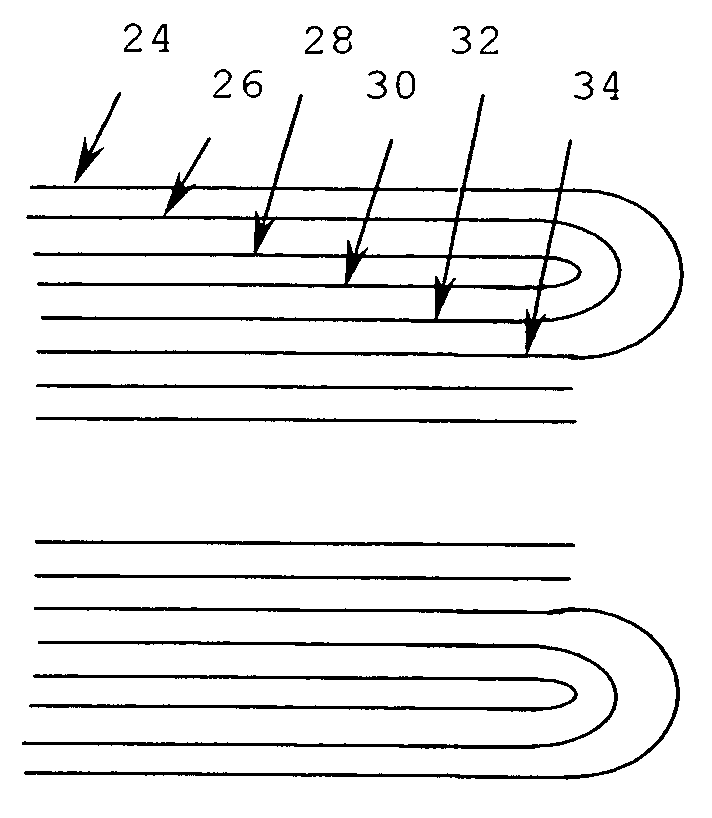

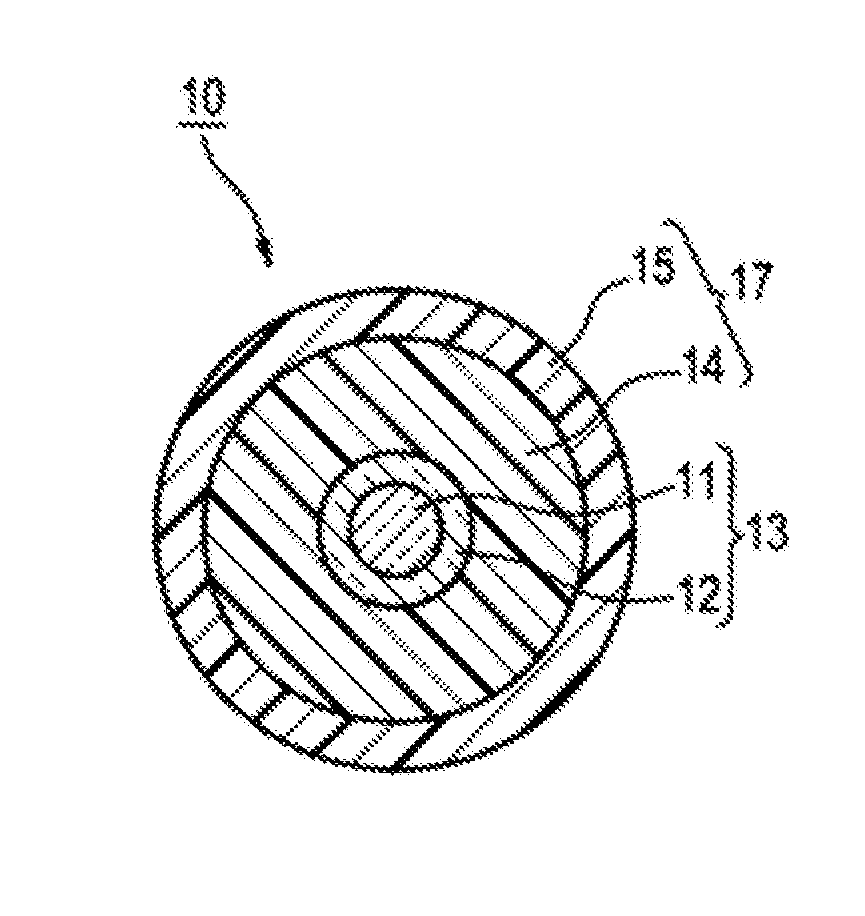

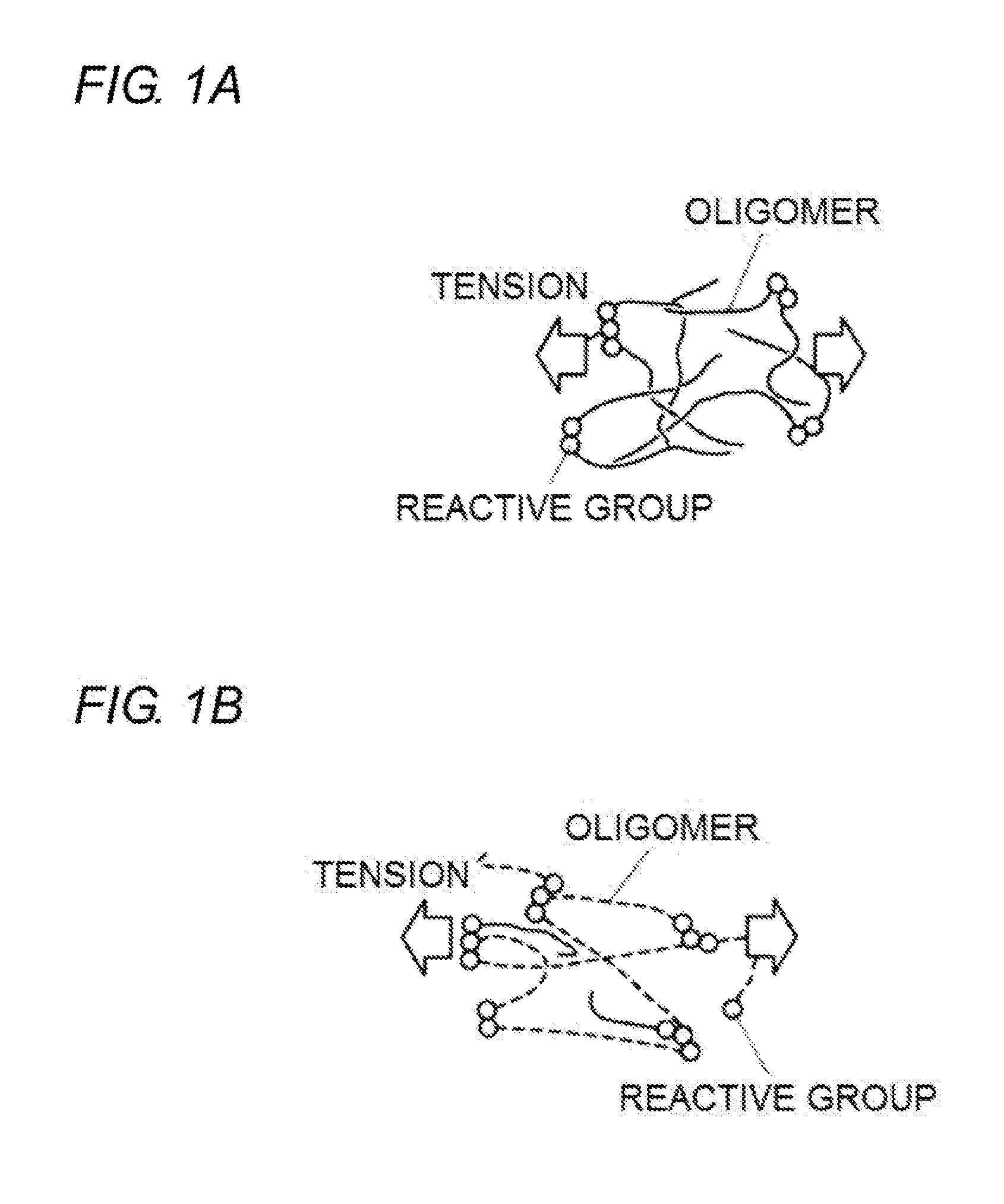

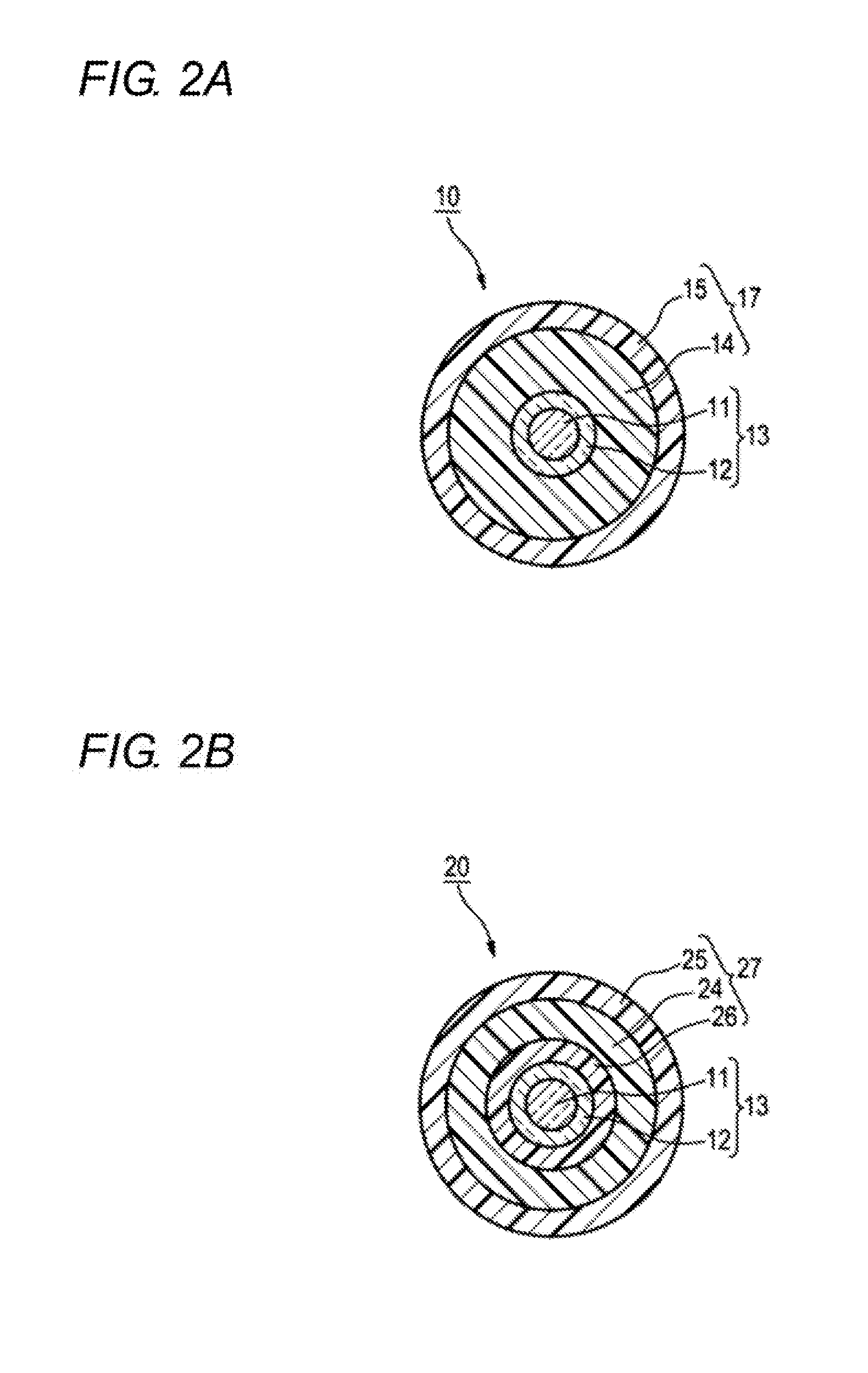

Optical fiber

ActiveUS20170003446A1Modulus is reducedResistance to deteriorationGlass optical fibreOptical fibre with graded refractive index core/claddingGlass fiberFiber

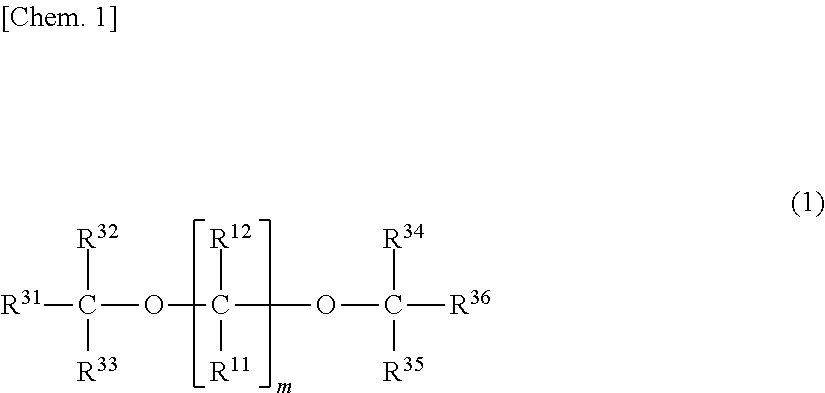

An optical fiber comprises a glass fiber which comprises a core and a cladding, a primary resin coating layer which covers the periphery of the glass fiber, and a secondary resin coating layer which covers the periphery of the primary resin coating layer. The glass fiber is a multimode fiber having a core diameter of 40-60 μm and a cladding diameter of 90-110 μm, and the primary resin coating layer is a layer formed by curing a curable resin composition which comprises oligomers, monomers, and a reaction initiator, the curable resin composition containing a one-end-capped oligomer in an amount of 30% by mass or larger based on all the oligomers.

Owner:SUMITOMO ELECTRIC IND LTD

Compact valve

InactiveUS20100139785A1Easily realizedLarge stroke of displacementOperating means/releasing devices for valvesEqualizing valvesCoil springShape-memory alloy

A compact valve using a shape memory alloy comprises: a moving valve body that contacts an inner periphery of a guide pipe having an built-in orifice, is freely movable and has a sealing portion to seal the orifice; a biasing coil provided between the orifice and the moving valve body; and a wire formed of a shape memory alloy and held between a stationary electrode of the guide pipe and a moving electrode of the moving valve body. The orifice is sealed by moving the moving valve body due to transformation of the shape memory alloy by heating the wire. The moving valve body is enabled to be elastically deformable by providing a coil spring to reduce a stress, so that an overload to the moving valve body due to contraction of the wire is absorbed by elastic deformation of the moving valve body. Thereby, the overload to the shape memory alloy is reduced to prevent deterioration of repeatability of memorized shape, to increase durability and reliability of the valve.

Owner:MATSUSHITA ELECTRIC WORKS LTD

Resin composition for pavement, and asphalt composition for pavement and process for producing the same

InactiveUS20130184389A1Excellent in wettability and adhesionExcellent durabilityIn situ pavingsFilm/foil adhesivesWinter seasonVinyl acetate

The present invention relates to a resin composition for pavement which comprises at least an ethylene-vinyl acetate copolymer having a vinyl acetate content of 25 to 45% by weight, a melting temperature of 40 to 100° C. and a melt flow rate of not less than 400 g / 10 min, a petroleum-based process oil having an aromatic ring-derived carbon content (CA) of 20 to 40%, and a teleblock polymer. The resin composition for pavement according to the present invention can be melted for a short period of time, and is excellent in wettability and adhesion to an aggregate, and can provide a paved surface having an excellent durability which is free from problems such as deformation in the summer season and occurrence of cracks in the winter season.

Owner:TODA IND

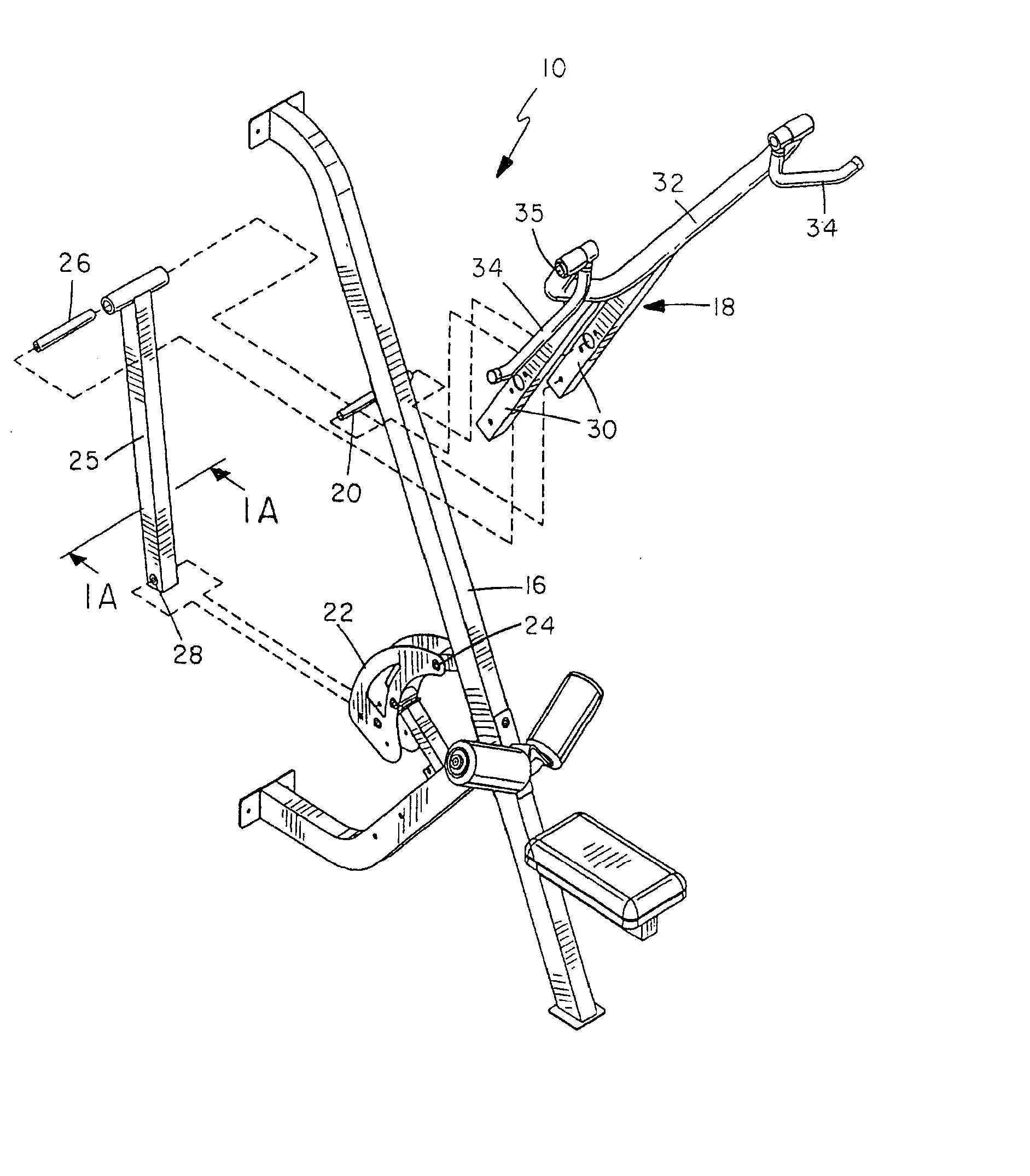

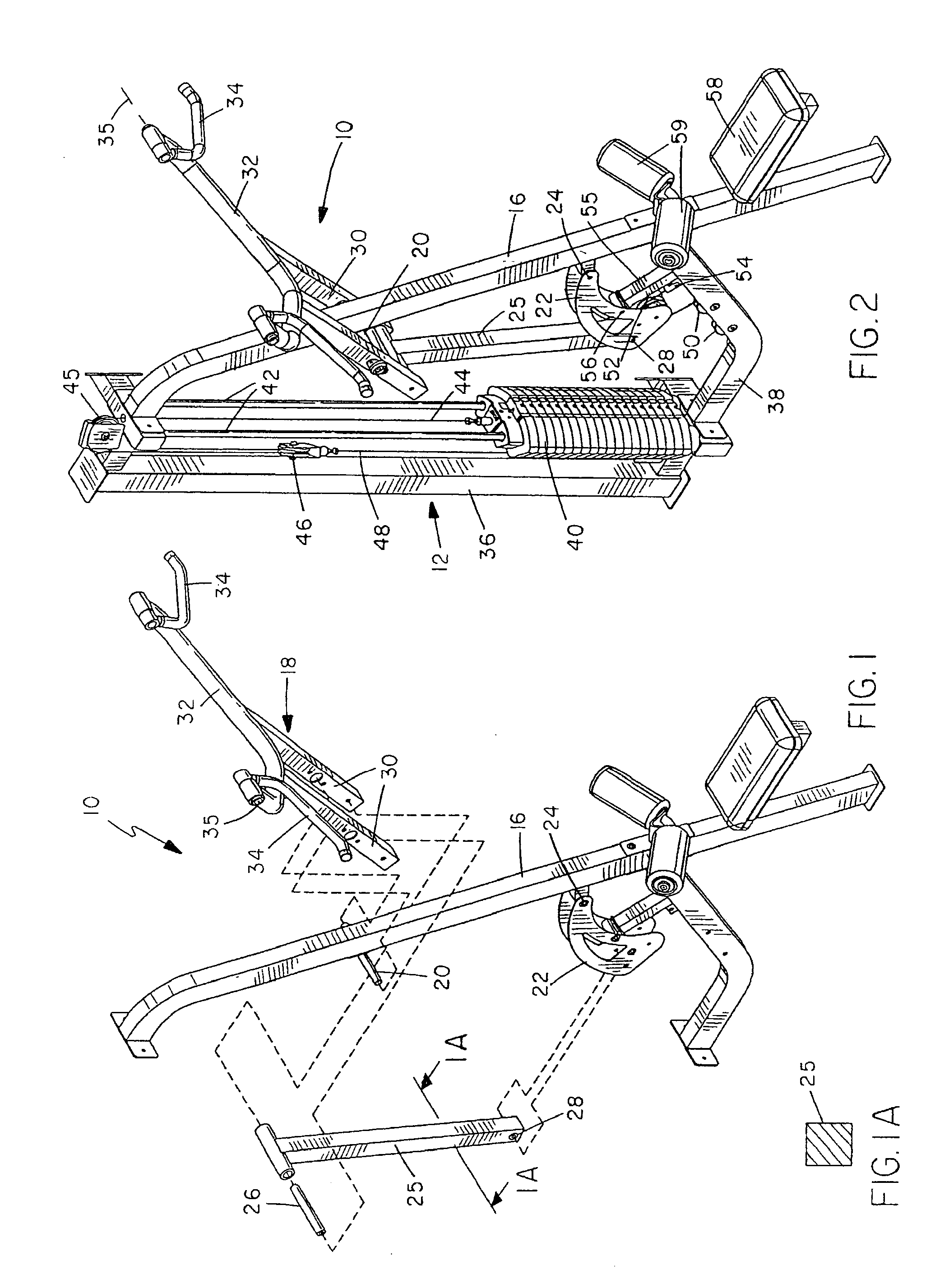

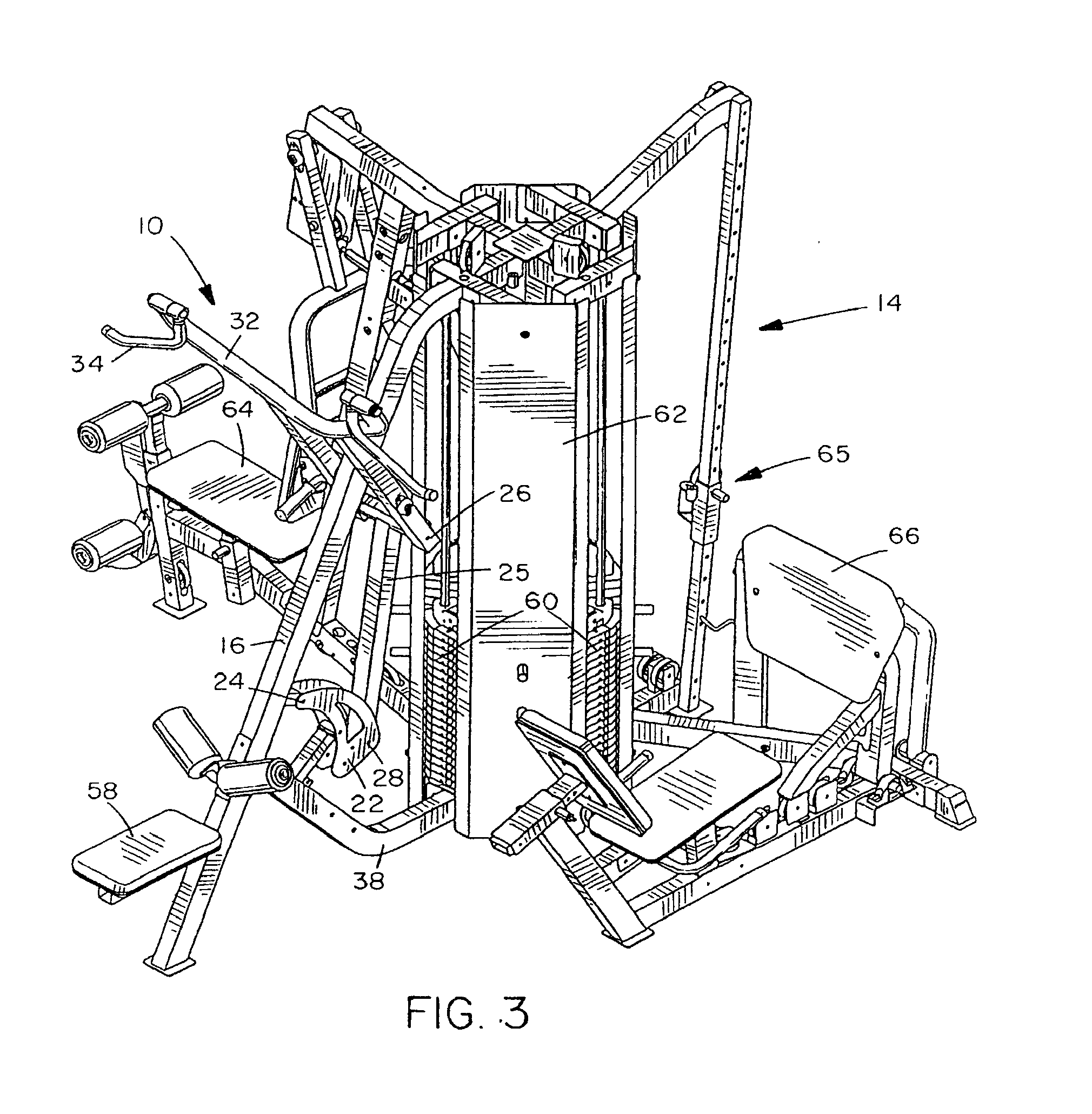

Exercise arm apparatus with pivotal linkage system

An exercise arm apparatus has a stationary frame, a first pivoting arm pivoted to the frame at a location intermediate its ends for rotation about a first pivot axis, a second pivoting arm pivotally connected to the frame for rotation about a second pivot axis spaced from the first pivot axis, and a connecting link pivotally connected to the first arm and second arm. The first arm is an exercise arm with handles at one end for gripping by a user, and the connecting link is of sufficient weight to form a counter-weight to counter-balance the first exercise arm into a rest position corresponding to a start position for an exercise movement. In one example the connecting link is a solid, elongate bar of heavy metal or equivalent material.

Owner:HOIST FITNESS SYST

Chocolate for food to be exposed to light

InactiveUS20060159830A1Avoid quality lossResistance to deteriorationCocoaEdible oils/fats with aqeous phaseLight exposureFood flavor

There is provided chocolate for a food to be exposed to light which comprises a hard butter of refined fats having a Y-value of 20 or less as measured with a Lovibond calorimeter, whose non-fat components being substantially being free from cacao components. The chocolate may contain at least one component selected from tocopherol, a tea extracts and rutin. Also provided is a chocolate product using the chocolate such as ganache. The chocolate is capable of preventing quality deterioration such as unpleasant flavor and smell even when the chocolate is placed under light exposure conditions.

Owner:FUJI OIL CO LTD

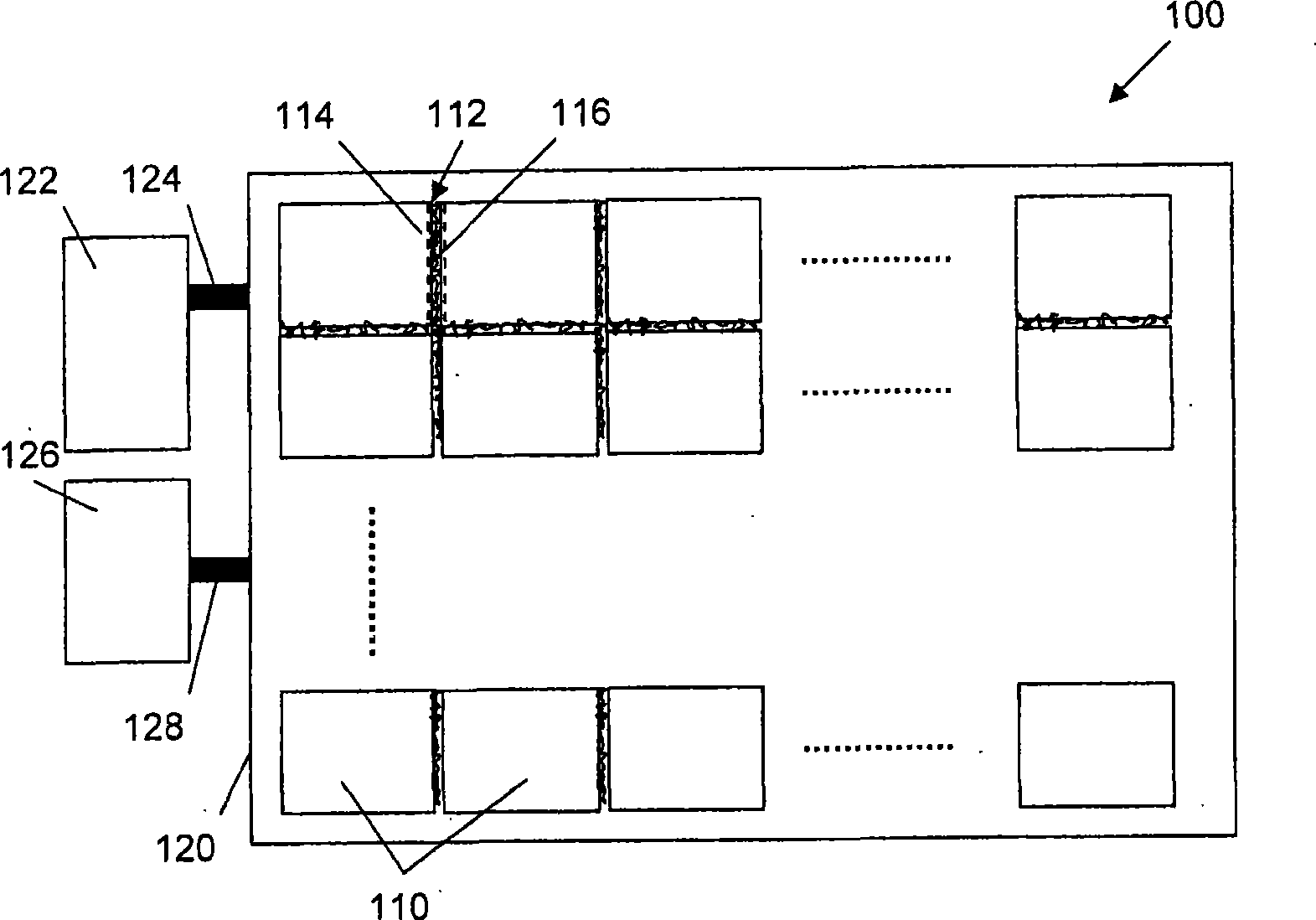

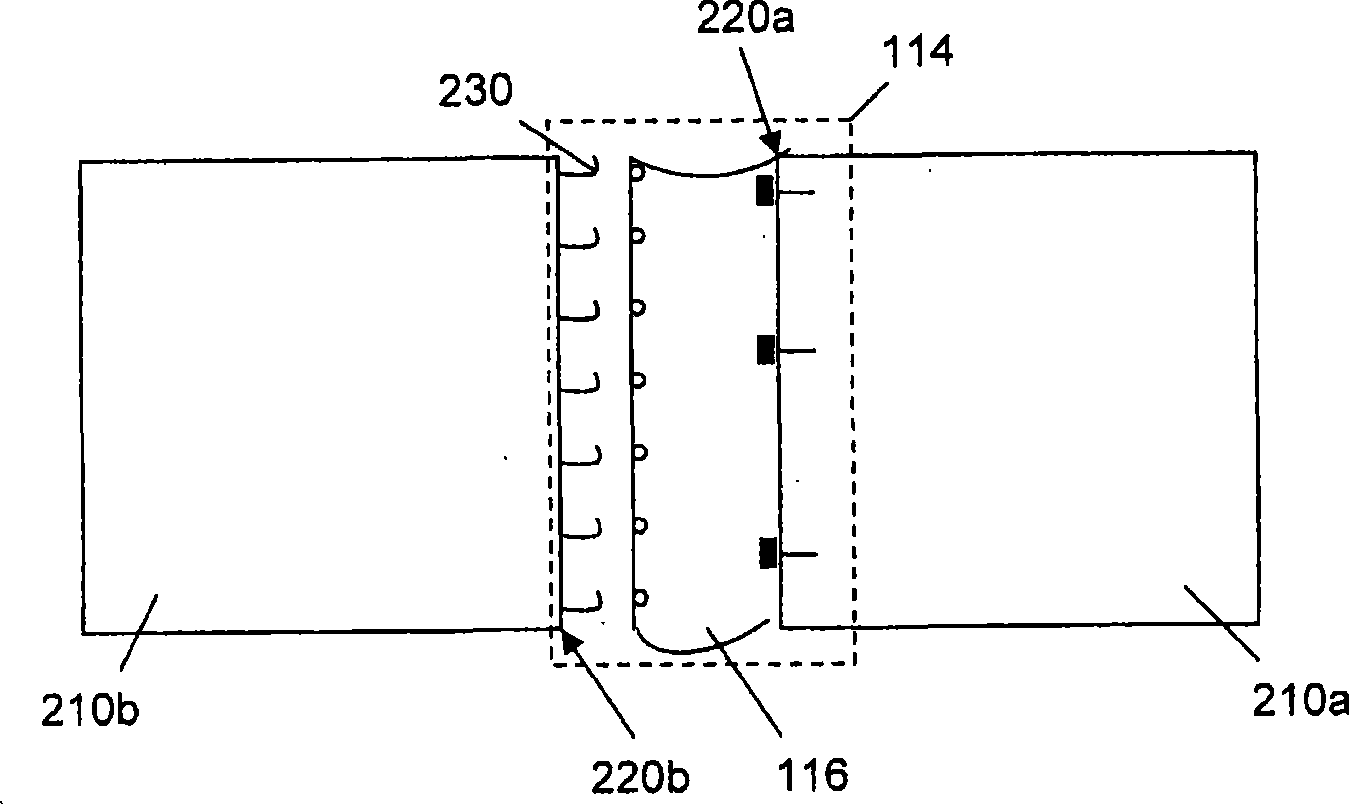

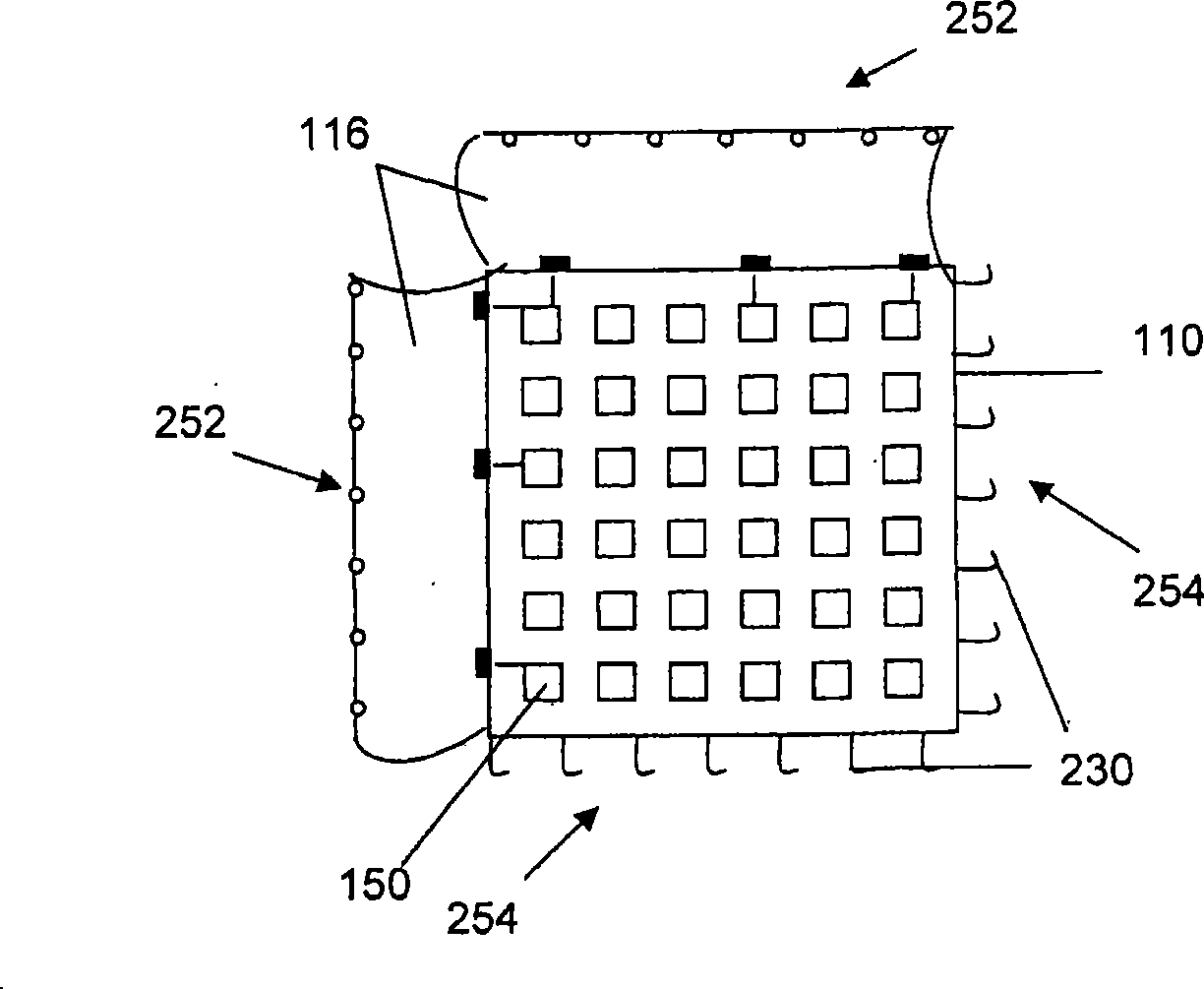

Seam hider for tiled displays

ActiveCN101393702AQuality improvementImprove uniformityNon-linear opticsIdentification meansMechanical engineeringStray light

A tiled display (100) for lighting or imaging is described. The tiled display (100) includes a plurality of display tiles (110) arranged side by side. The tiled display (100) furthermore includes a seam hiding arrangement (114) formed of at least one light absorbing cloth or textile (114) in a seam (112) between two neighbouring display tiles (110). A corresponding method for assembling or adjusting a tiled display is described. The seam hiding arrangement may be used for blocking environmental light or stray light in the seams and optionally also for aligning or controlling the position of the display tiles.

Owner:BARCO NV

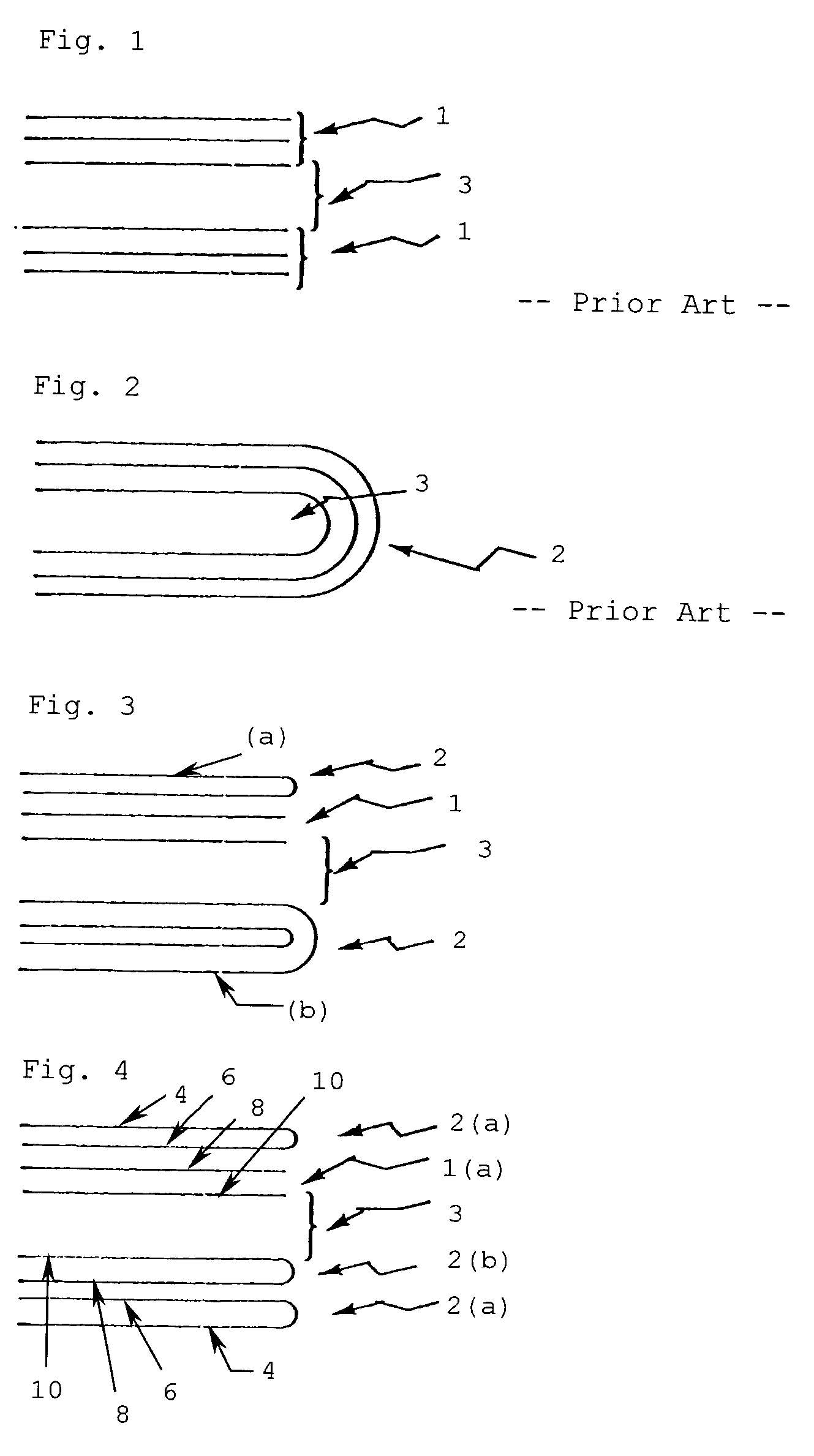

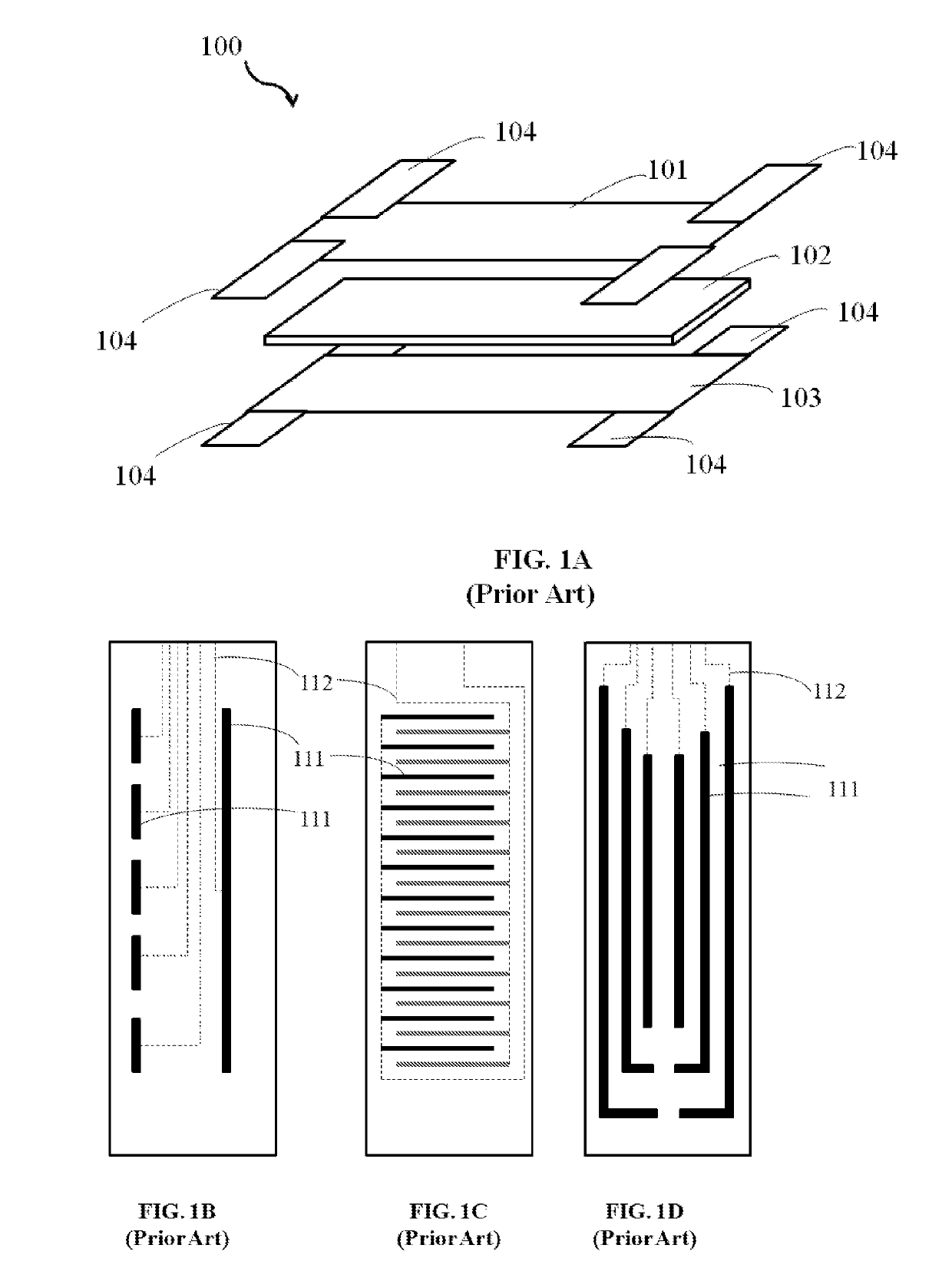

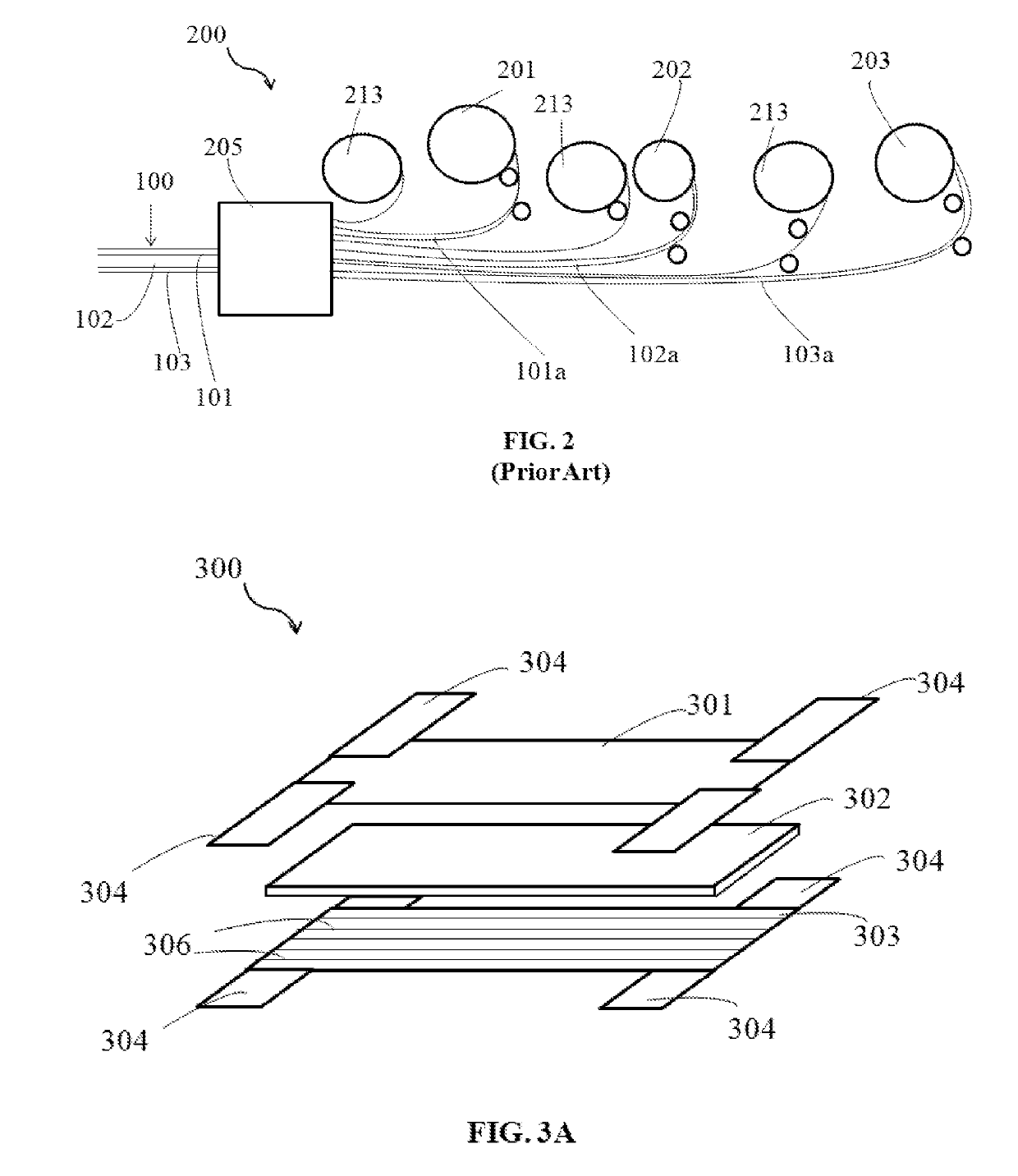

Method of manufacturing a diaper with moisture sensors

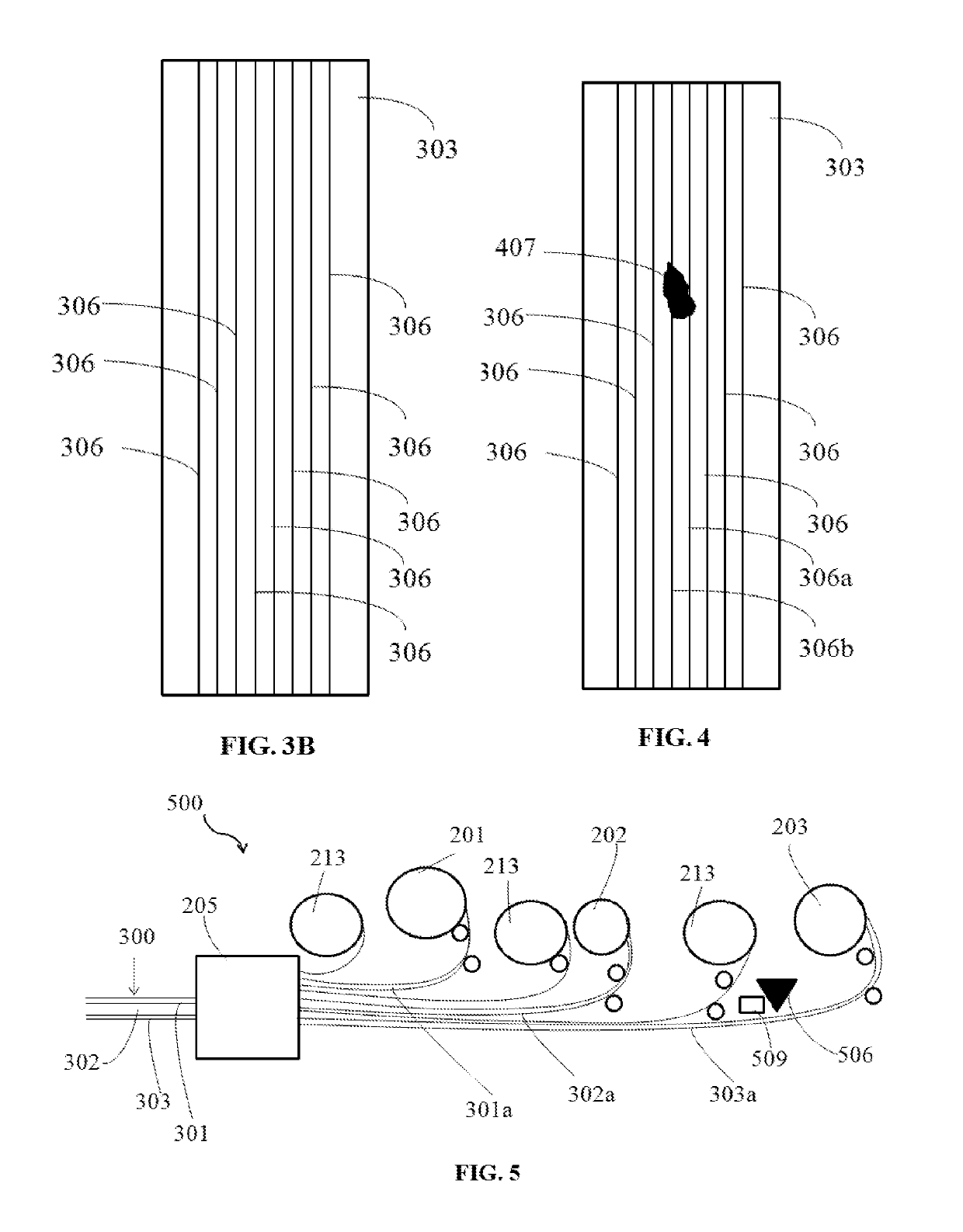

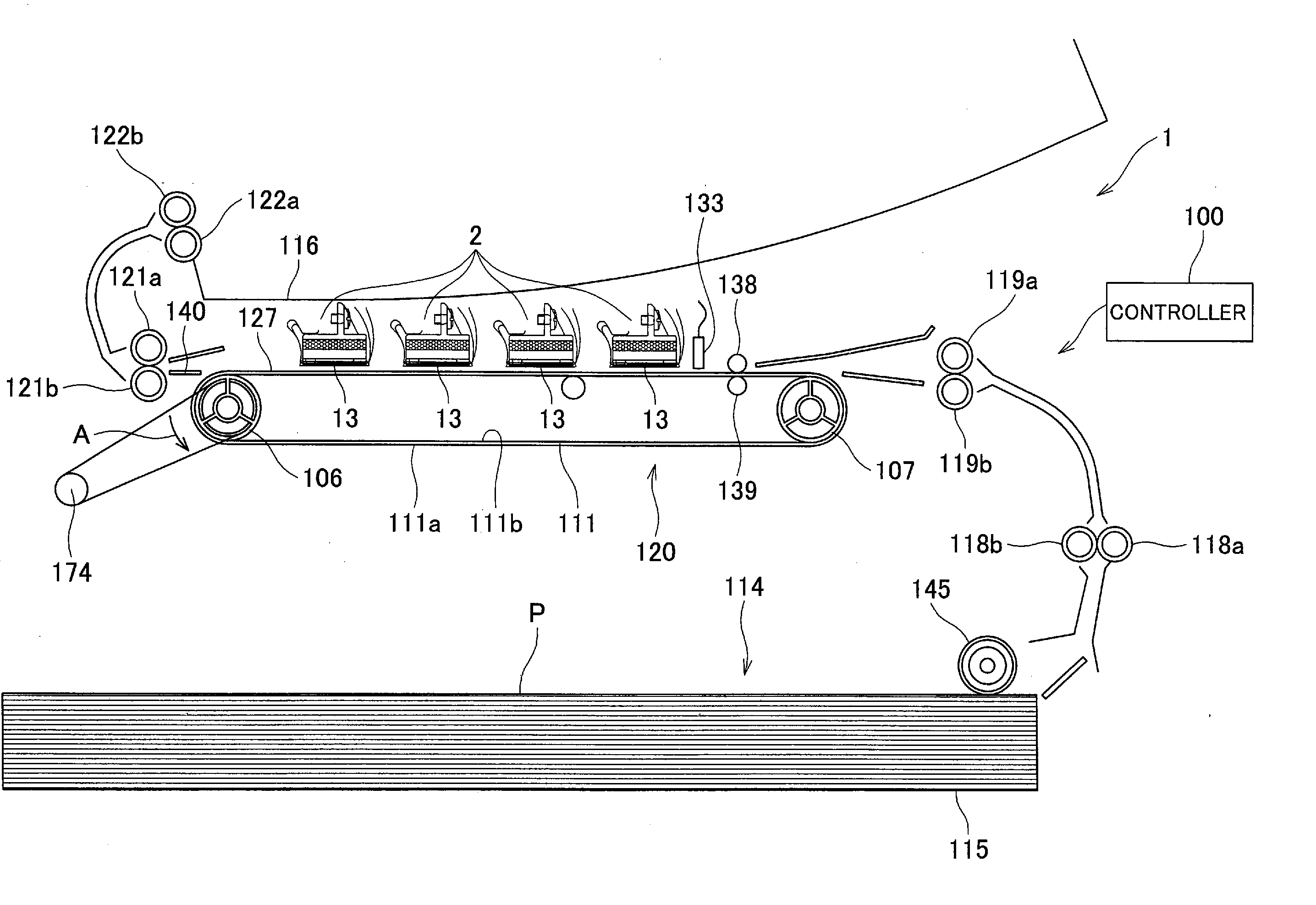

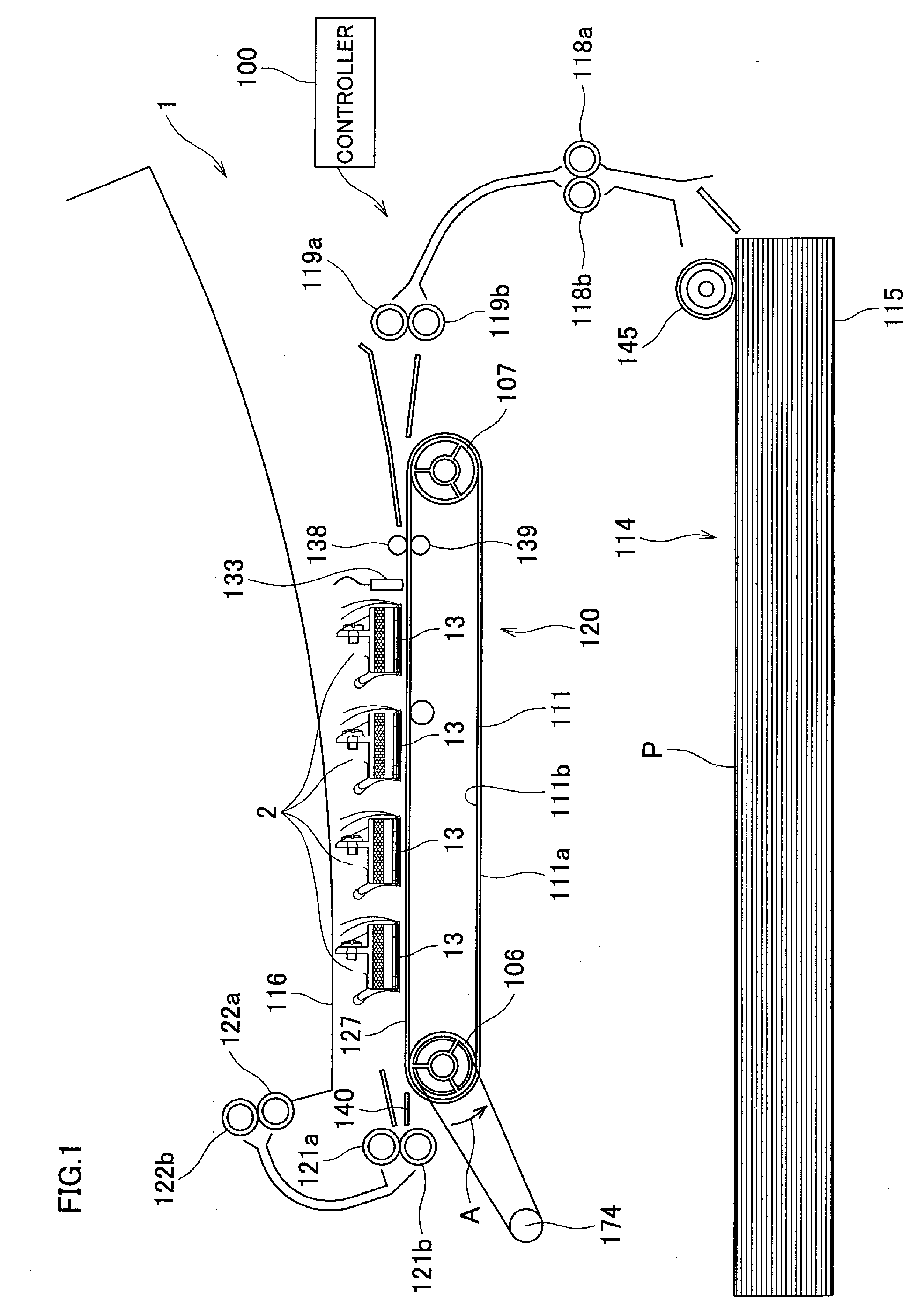

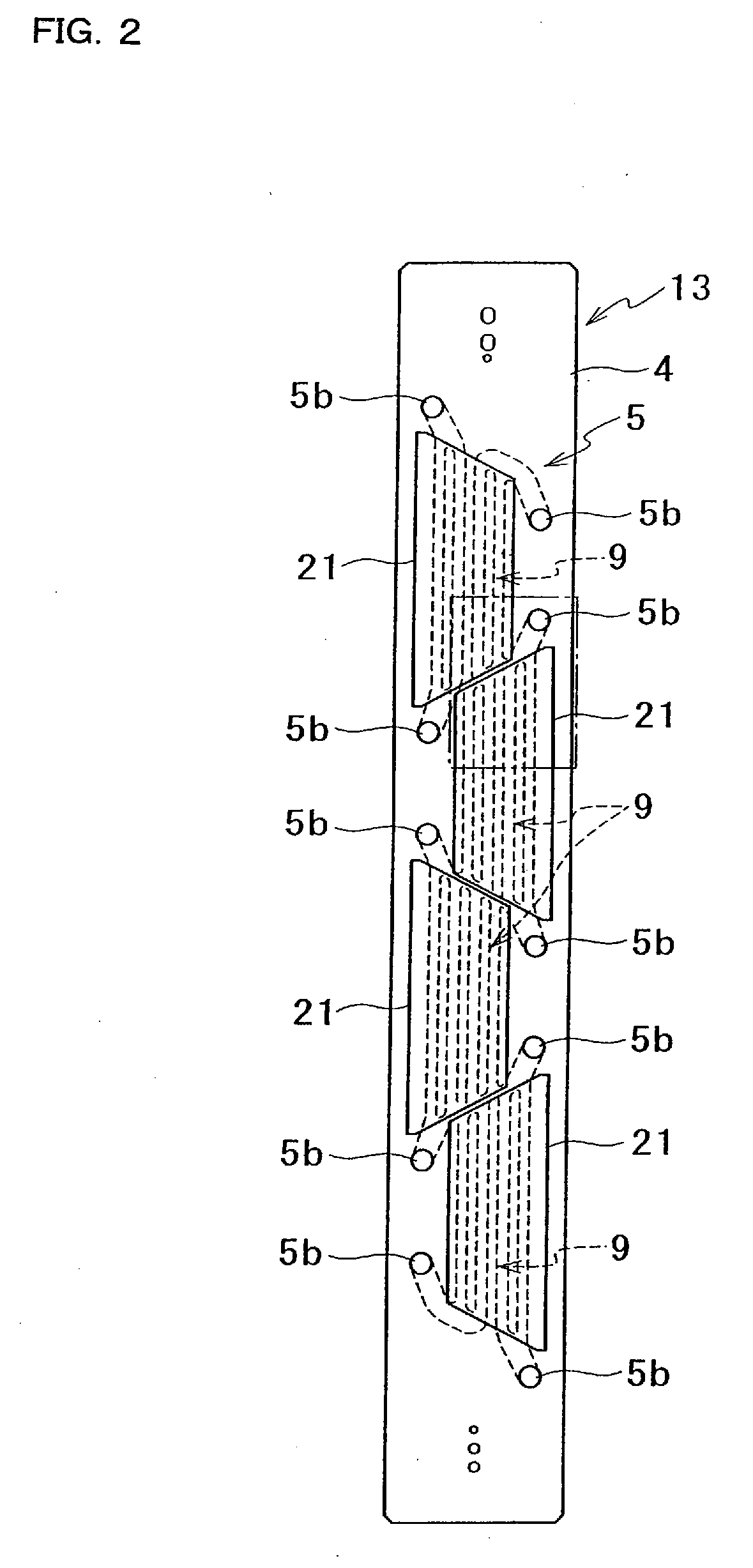

ActiveUS20190240079A1Increase volumeResistanceAbsorbent padsPrinted circuit manufactureSaturated LevelAssembly line

The present invention discloses a method of manufacturing a diaper that has multiple moisture sensing elements on interior side of its bottom impermeable layer or on any surface of the top permeable layer. The moisture sending elements are made by spraying conductive ink on a moving sheet of either the bottom impermeable layer or the top permeable layer, before other layers of the diaper are attached. Spraying of conductive ink on the moving sheet causes parallel lines of conductive inks to be formed on the layer. The parallel lines of conductive ink run through the entire length of either of the layers and are designed to get connected with a detecting device. When a user urinates inside the diaper, the moisture causes a closed circuit between at least two of the parallel lines of conductive inks. These formations of closed circuits, between parallel lines of conductive inks, are detected by the detecting device. Also, with increasing volume of moisture, the resistance of the closed circuits also tends to decrease. This rate of decrease of resistance is also detected by the detecting device and is used to calculate a volume of moisture present in the diaper. The detecting device then generates a suitable alarm to give an idea about the saturation level of the diaper. The process of manufacturing sensing elements by spraying conductive inks on moving sheet of layer reduces the processing and modification overhead of specially designed conductive ink printers and also does not impact the manufacturing time of a diaper manufacturing assembly line.

Owner:TULI RAJA SINGH

Polypropylene resin composition and use thereof

ActiveUS20150274948A1Good shaping effectAvoid serious impactVehicle seatsOther chemical processesPolymer scienceAlpha-olefin

[Solution]A polypropylene resin composition includes 100 parts by weight of basic components including a polypropylene resin (A) including a propylene polymer, the propylene polymer having a MFR of 10 to 300 g / 10 min and containing 98 mol % or more of structural units derived from propylene, an ethylene.α-olefin copolymer (B) having an ethylene content of 65 to 90 mol %, and optionally an inorganic filler (E); 0.2 to 1 part by weight of a fatty acid amide (C); and 0.2 to 1 part by weight of a surfactant (D).[Effect]The polypropylene resin compositions of the invention have excellent shaping properties such as injection molding properties and can give shaped articles which exhibit excellent properties such as rigidity and impact resistance and which are effectively prevented from deteriorations in surface properties due to friction with soft substances such as rubbers (namely, have excellent kicking scuff resistance), thus finding suitable applications in automobile interior and exterior parts.

Owner:PRIME POLYMER CO LTD +1

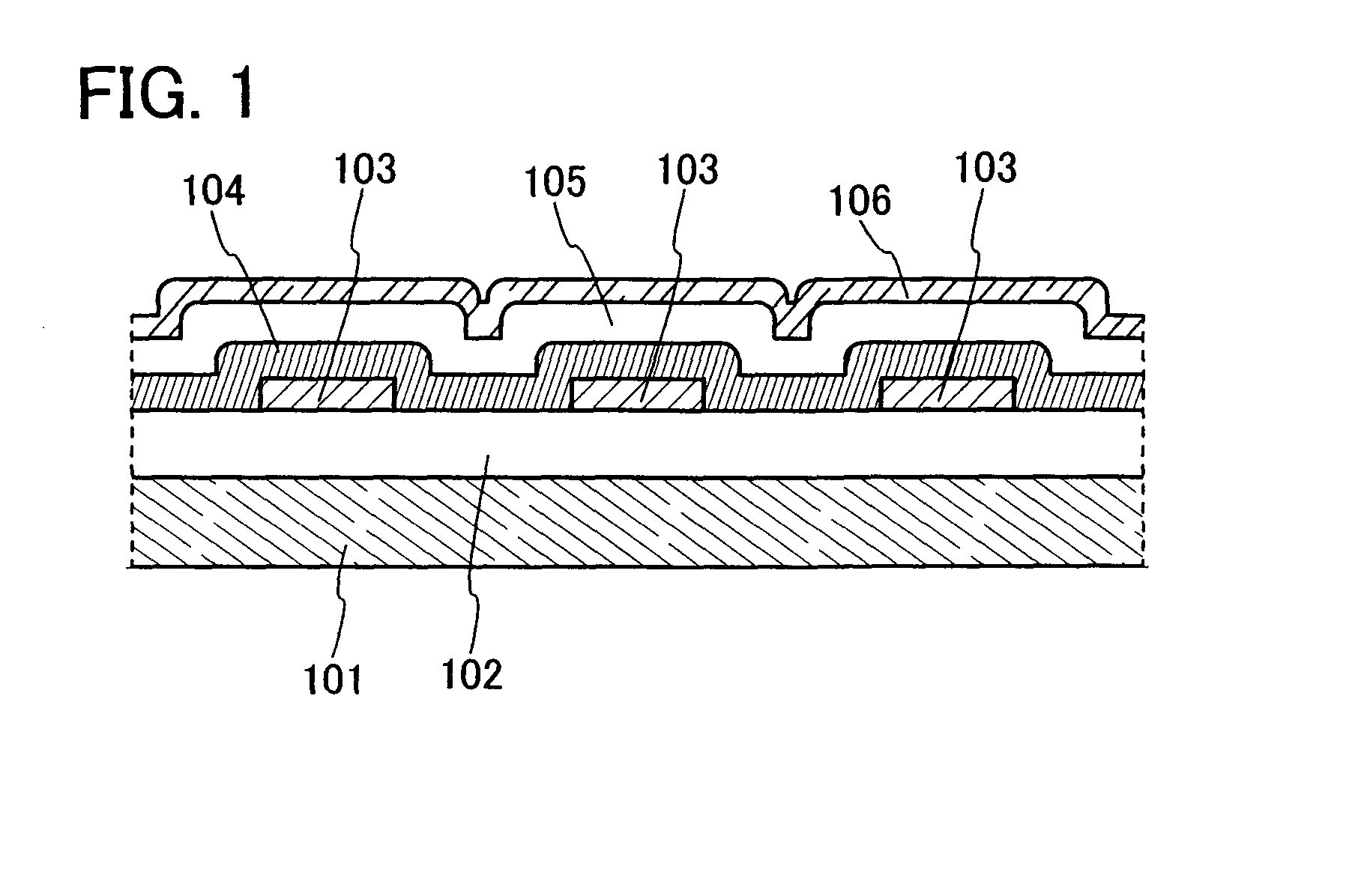

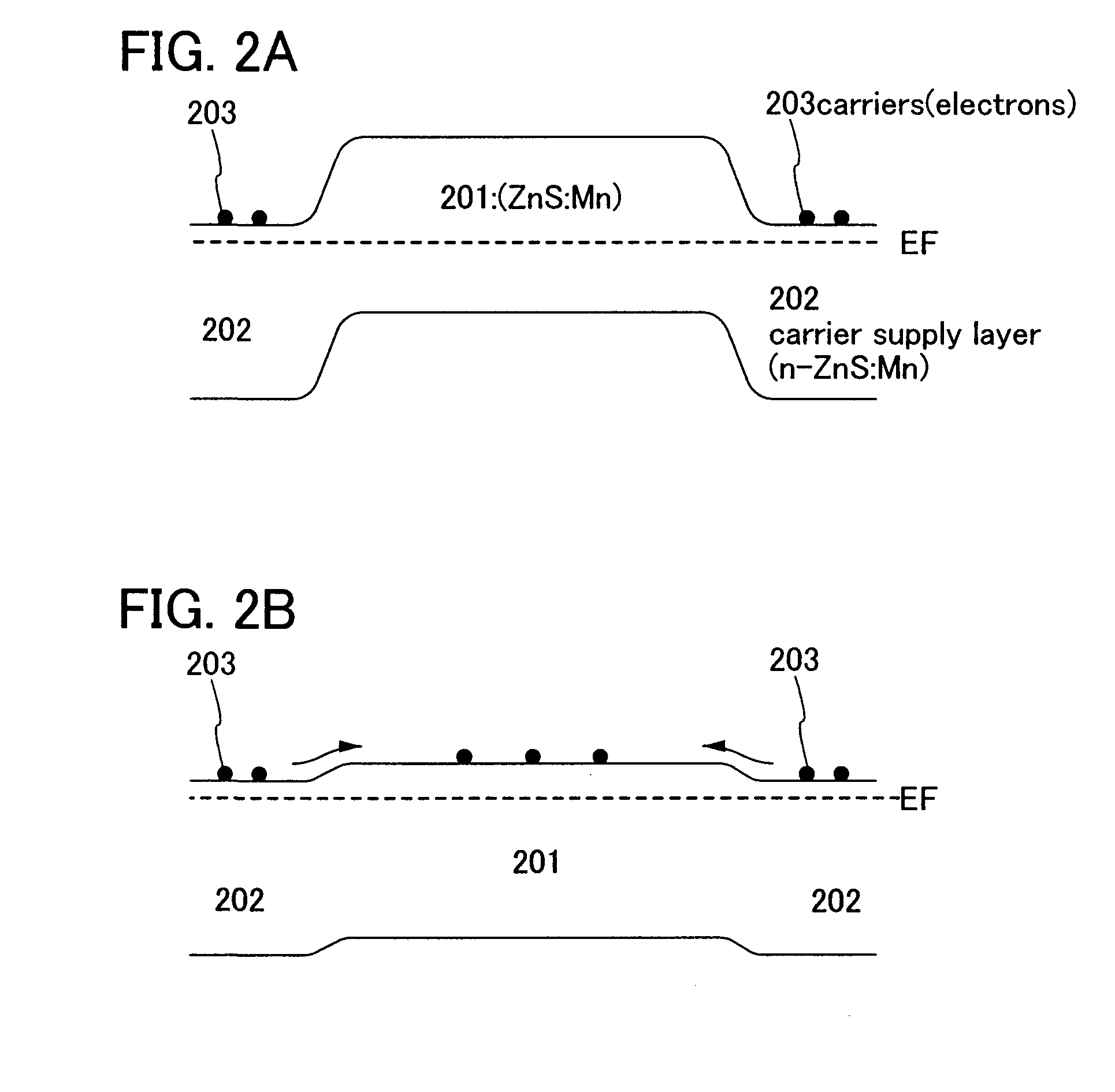

Light emitting device

ActiveUS20070194334A1Solve low luminous efficiencyReduce the driving voltageElectroluminescent light sourcesSolid-state devicesLow voltageInorganic compound

An object is to provide a light emitting element using an inorganic compound as a light emitting material, which has ever-higher luminous efficiency and can be driven with low voltage. The chance of excitation of light emitting centers (atoms) in a light emitting layer is increased to enhance luminous efficiency by providing a carrier supply layer in order to increase the number of carries in the light emitting layer of a light emitting element using an inorganic compound, and drive voltage of the light emitting element or a light emitting device is reduced.

Owner:SEMICON ENERGY LAB CO LTD

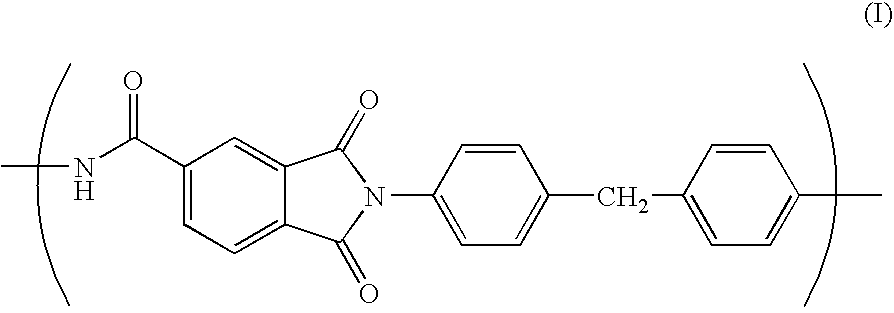

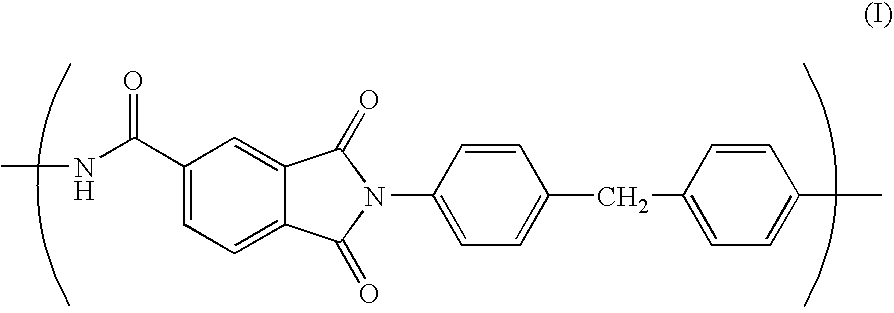

Porous film, process for producing the same, and lithium-ion secondary cell made with the same

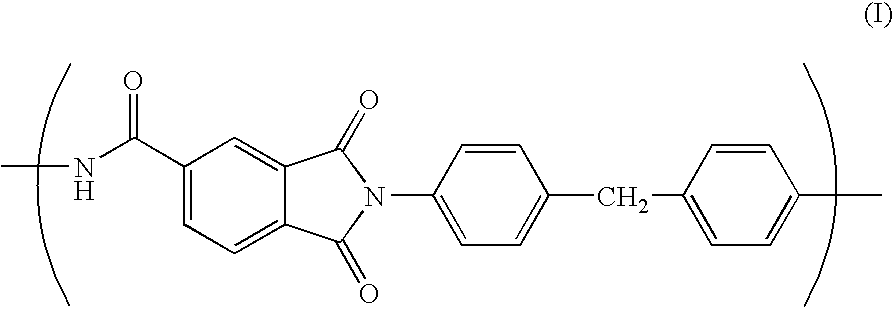

InactiveUS20070134484A1Improve balanceDeterioration of characteristicLayered productsSecondary cellsStructural formulaGlass transition

The present invention provides an inexpensive separator satisfactory in shutdown properties and meltdown properties and having excellent insulating properties. A porous film having a thickness of 5 to 100 μm, characterized by including a porous layer of a polyamide-imide resin which has a glass transition temperature of 70° C. or higher and an inherent viscosity of 0.5 dl / g or higher and containing a unit represented by the following structural formula (I), the amount of the unit being 20 mol % or more based on all repeating structural units. Also provided is the porous film which is characterized in that the porous polyamide-imide resin layer has an amide bond / imide bond ratio of from 10 / 90 to 45 / 55. Further more provided is a lithium-ion secondary cell which contains a positive electrode and a negative electrode which are capable of occluding / releasing lithium ions and either of the porous films disposed as a separator between the electrodes.

Owner:TOYOBO CO LTD

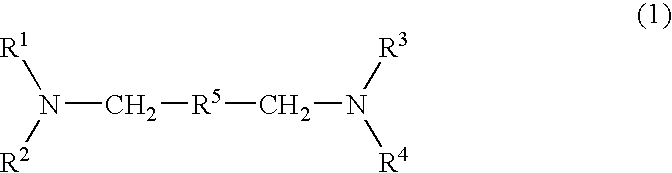

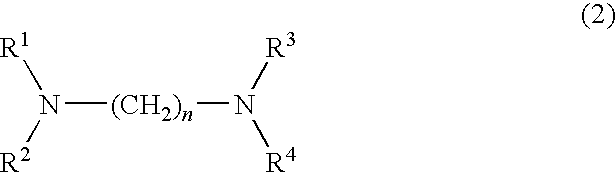

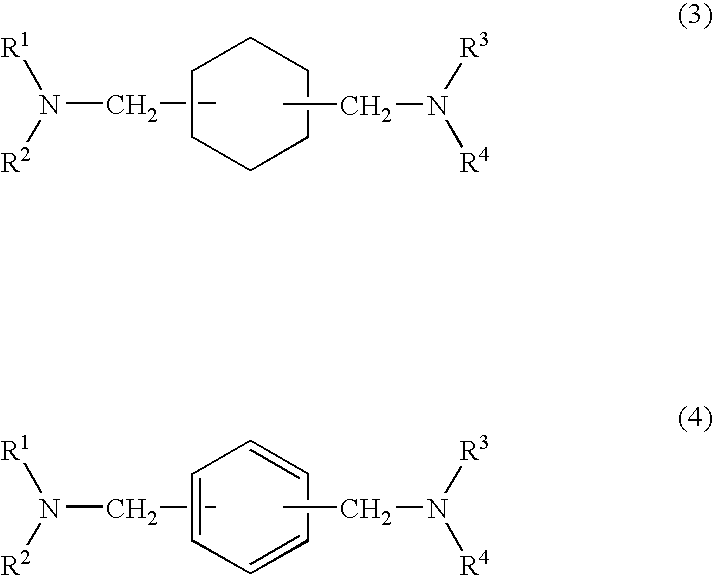

Water-soluble metal-processing agent, coolant, method for preparation of the coolant, method for prevention of microbial deterioration of water-soluble metal-processing agent, and metal processing

ActiveUS20100093868A1Improve the immunityInhibition of decayBiocideOrganic chemistryMicrobial corrosionWater soluble

Disclosed are a water-soluble metal-processing agent and a coolant both of which have excellent microbial deterioration resistance and are less likely to go rotten, a method for preparing the agent or the coolant, and a metal processing method. The water-soluble metal-processing agent or the coolant comprises an N,N,N′,N′-tetraalkyldiamine compound. The metal processing method is characterized by processing a metal of interest by using the water-soluble metal-processing agent or the coolant.

Owner:YUSHIRO CHEM IND CO LTD

Method Of Manufacturing Ink-Jet Head

ActiveUS20070144000A1Avoid it happening againInsulation deteriorationPiezoelectric/electrostrictive device manufacture/assemblyInking apparatusPiezoelectric actuatorsEngineering

There is provided a method of manufacturing an ink-jet head comprising a passage unit, a piezoelectric actuator, and a wire member. The passage unit has a surface on which a pressure chamber is provided in a form of a recess. The piezoelectric actuator includes a piezoelectric body that closes the recess, an electrode that is formed on the piezoelectric body, and a conductive land that is formed on the electrode. The wire member includes a wiring provided thereon with a terminal electrically connected to the land. The method comprises the steps of forming on the electrode a land made of a resin paste, bonding the passage unit and the piezoelectric actuator to each other by pressing the land except a part thereof in a state where the electrode is opposed to the pressure chamber, and electrically connecting the land to the terminal by bringing the part of the land not pressed in the step of bonding into contact with the wire member.

Owner:BROTHER KOGYO KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com