Patents

Literature

45results about How to "Less susceptibility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

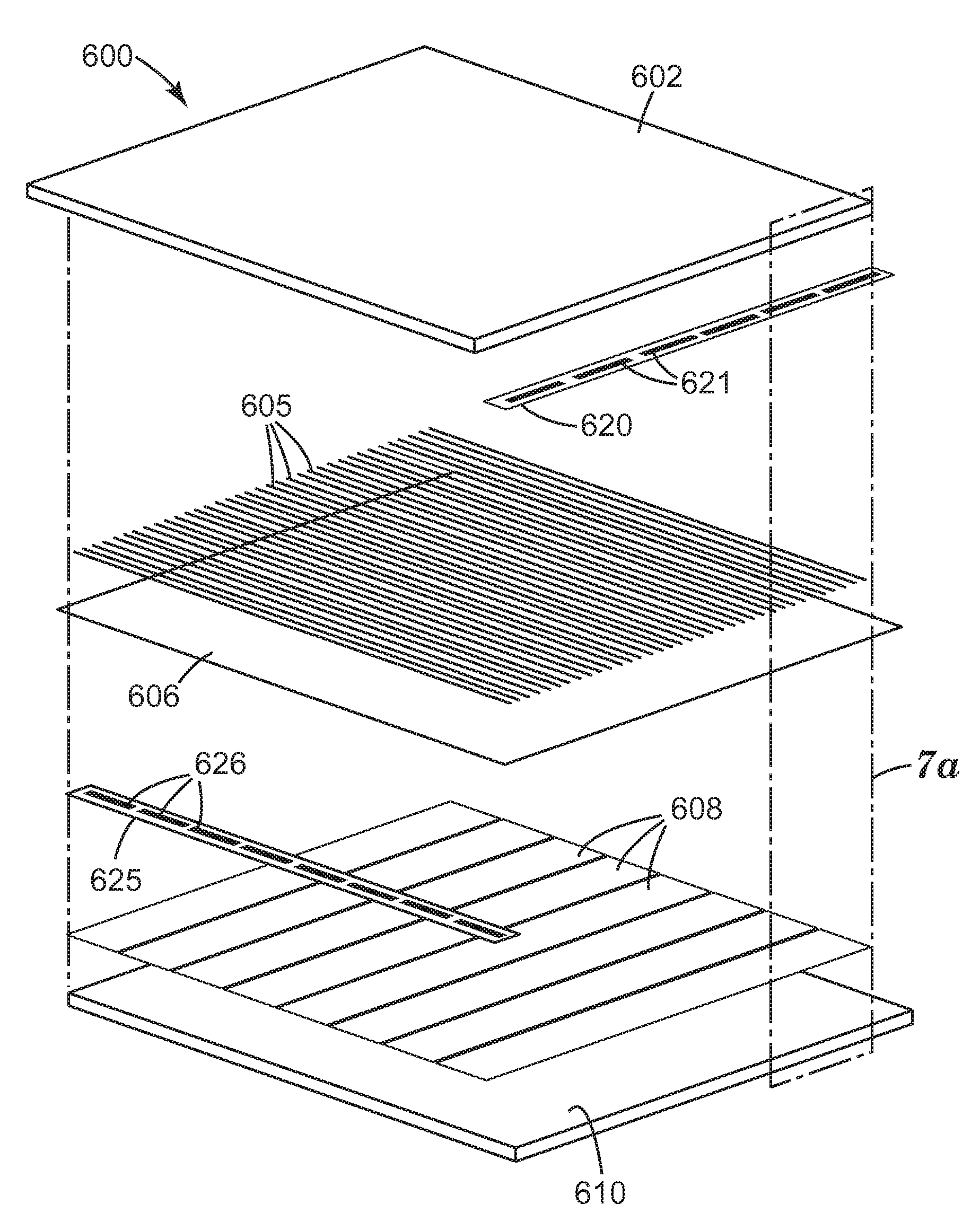

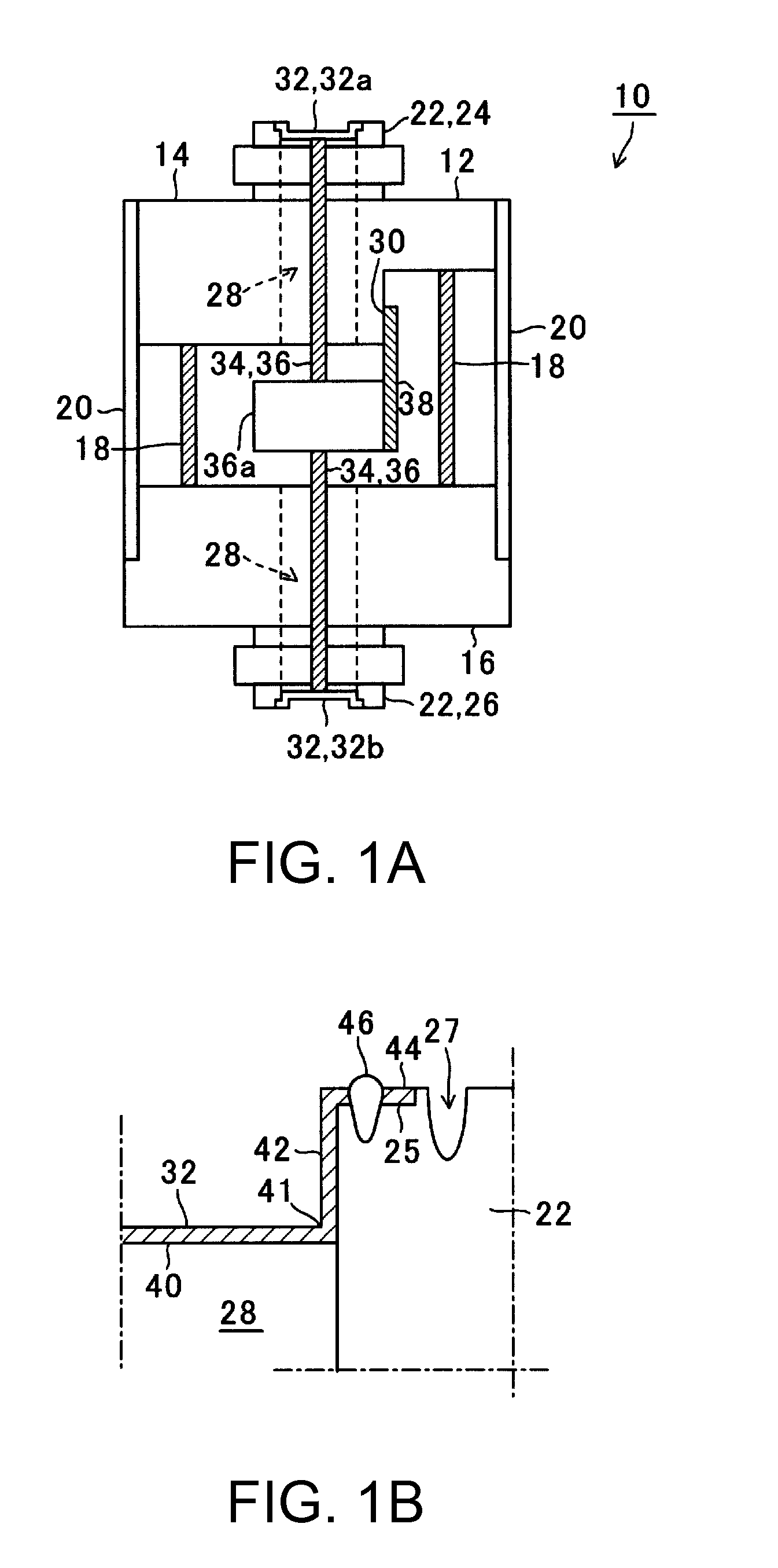

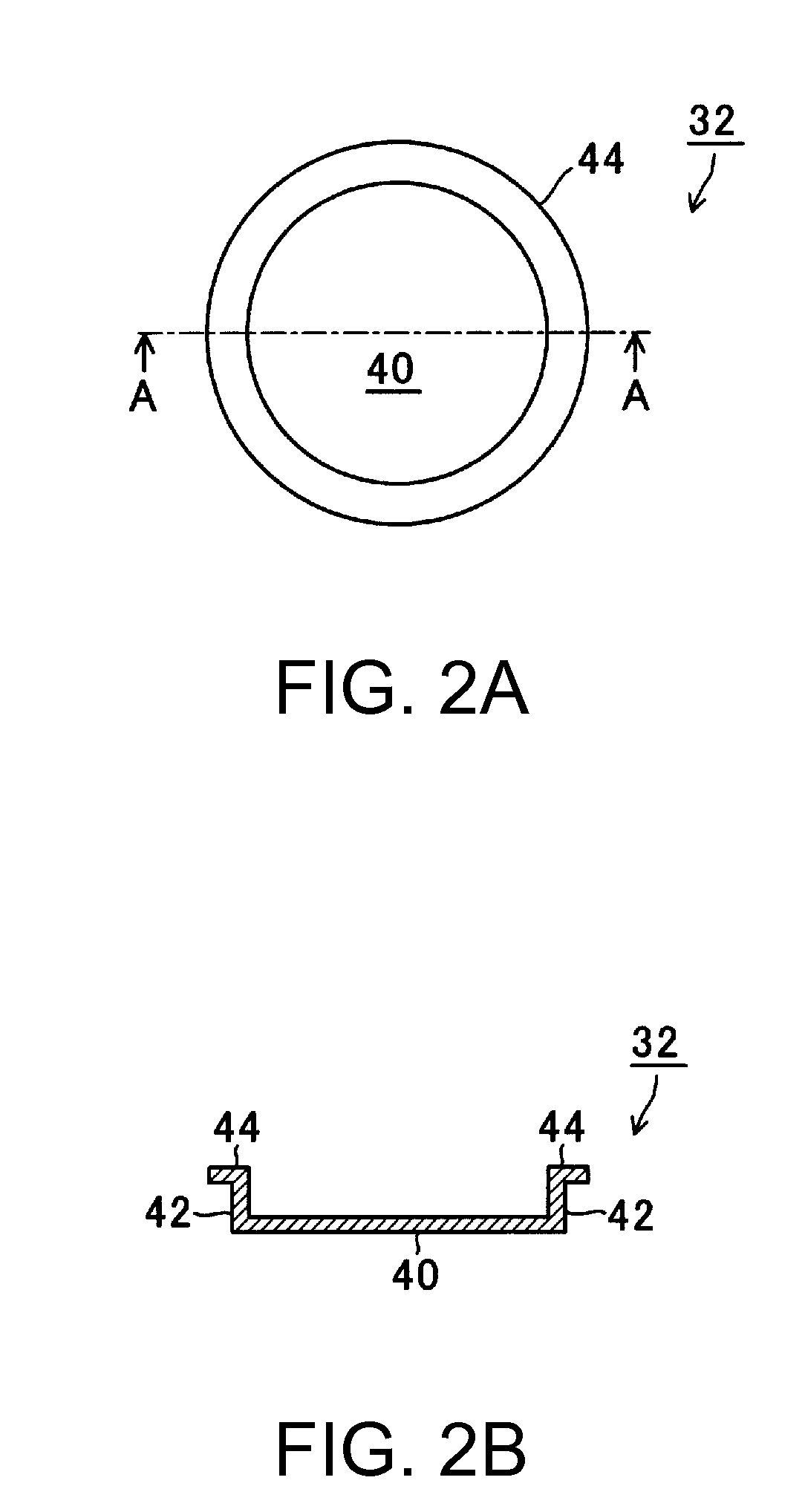

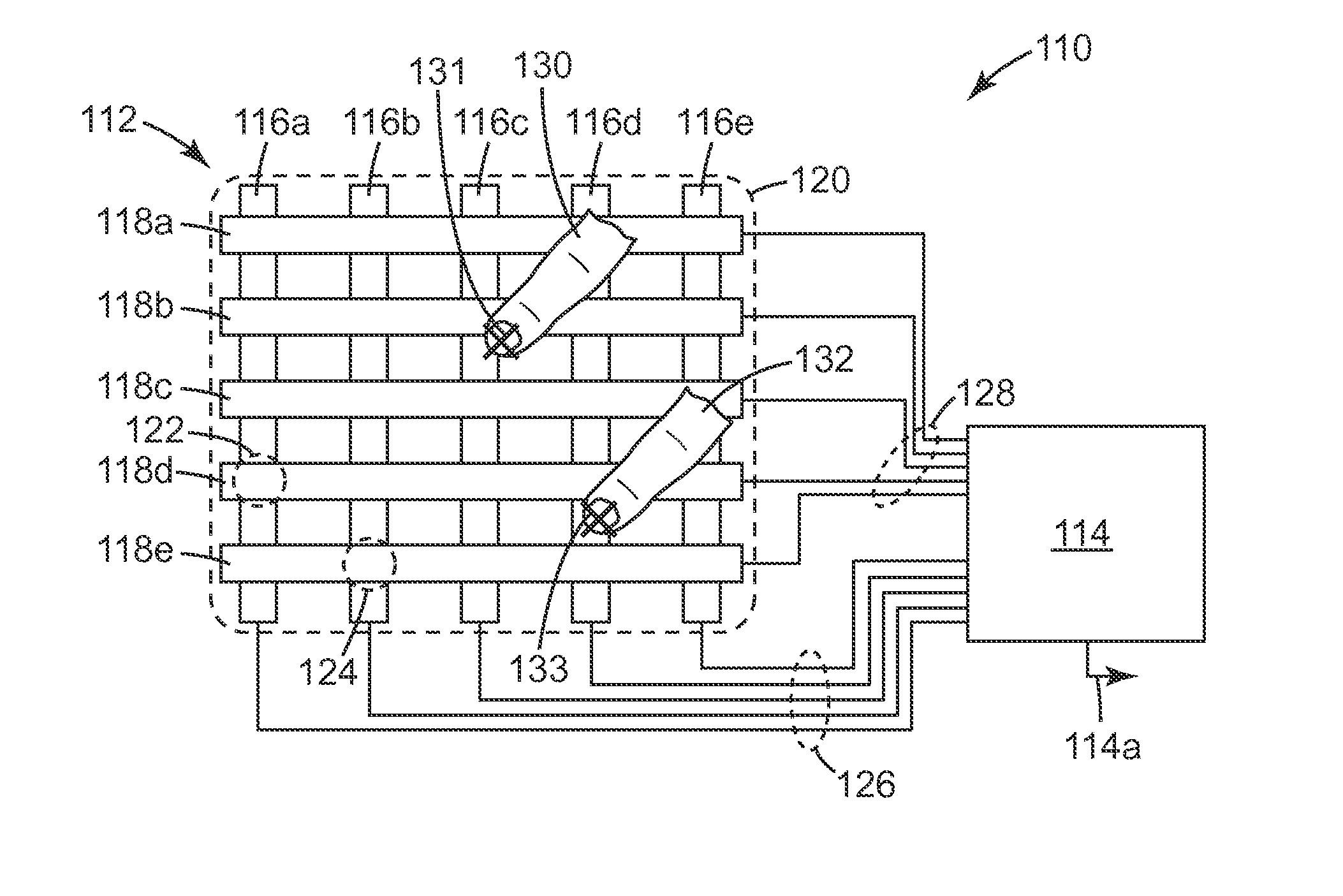

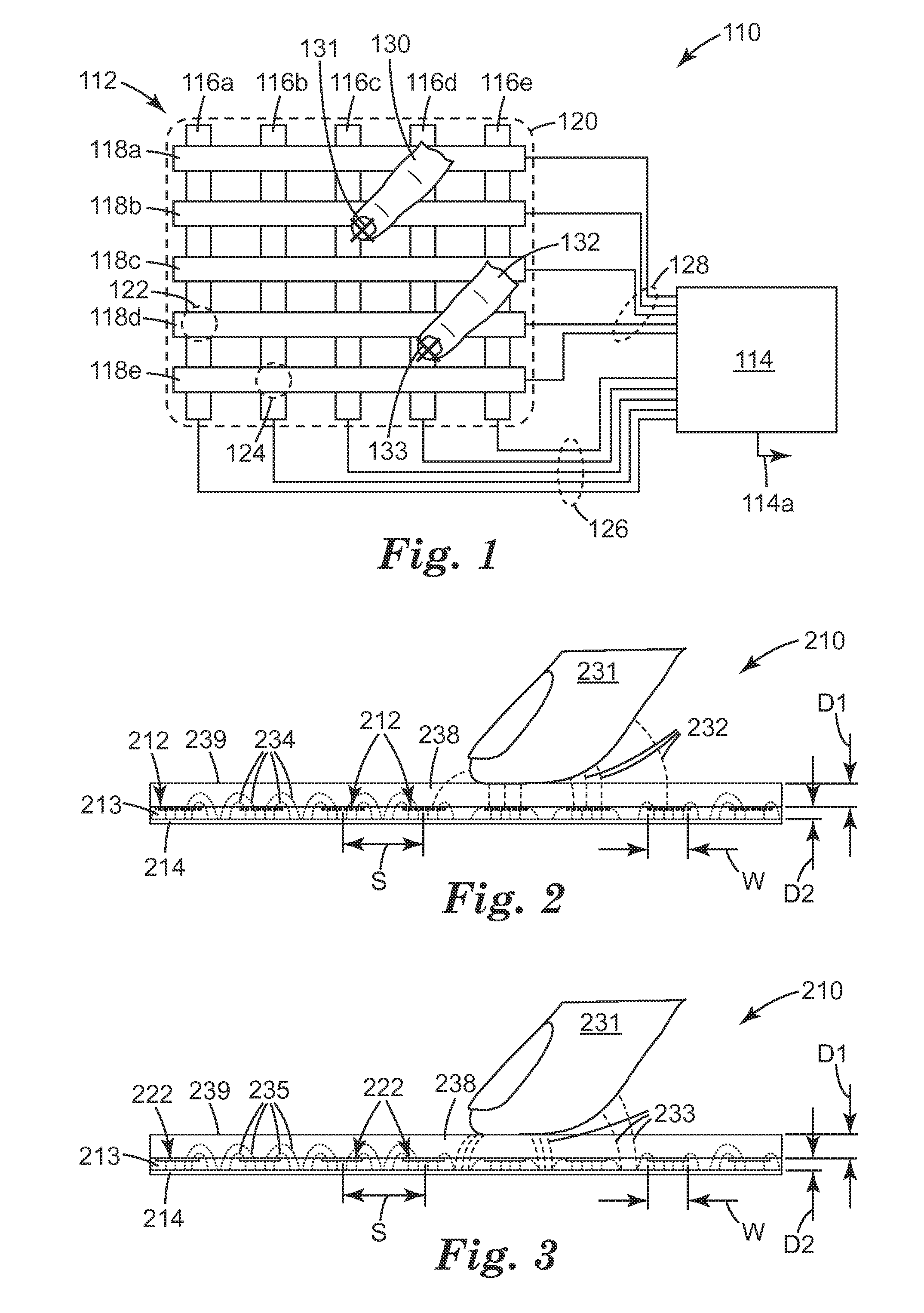

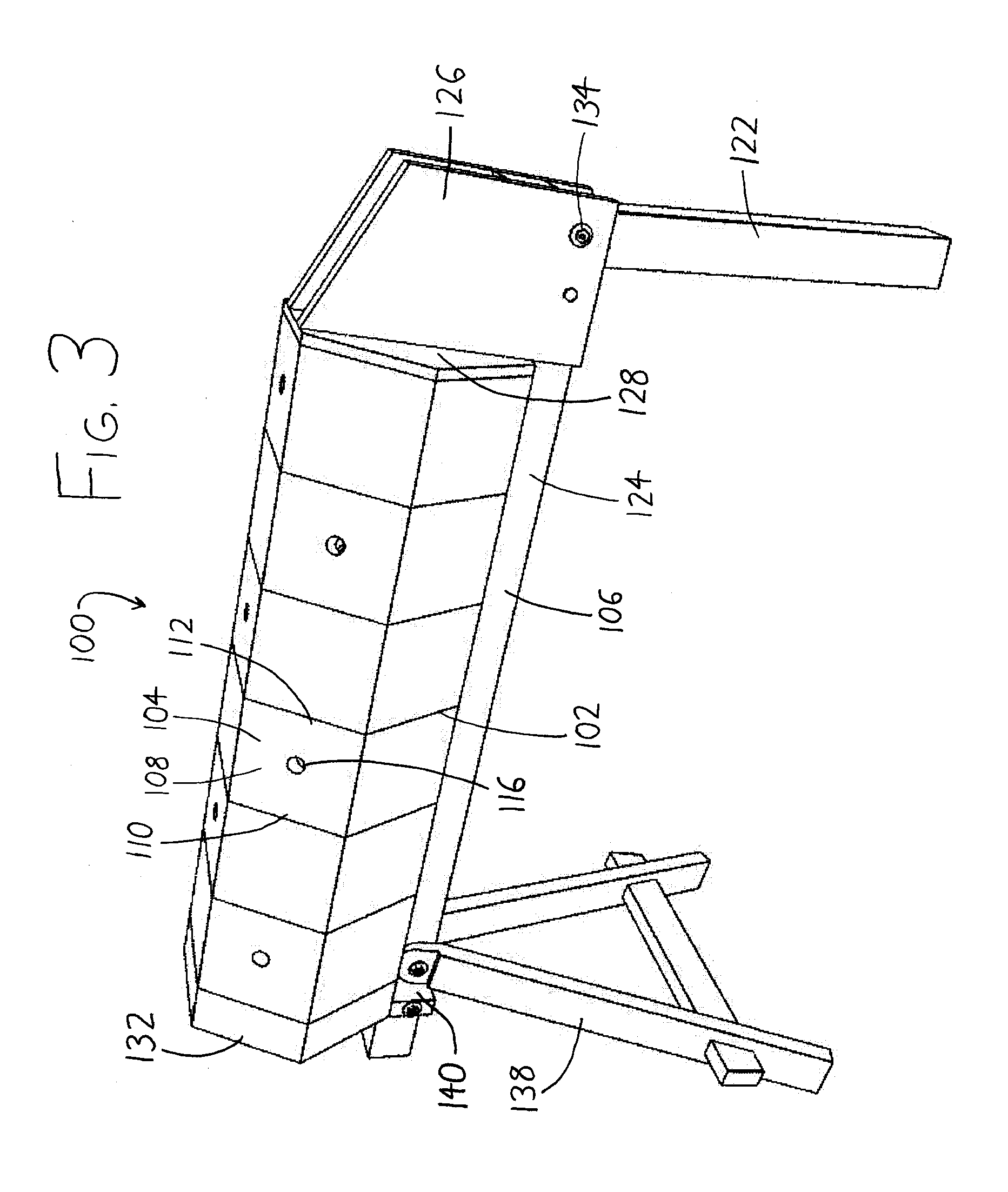

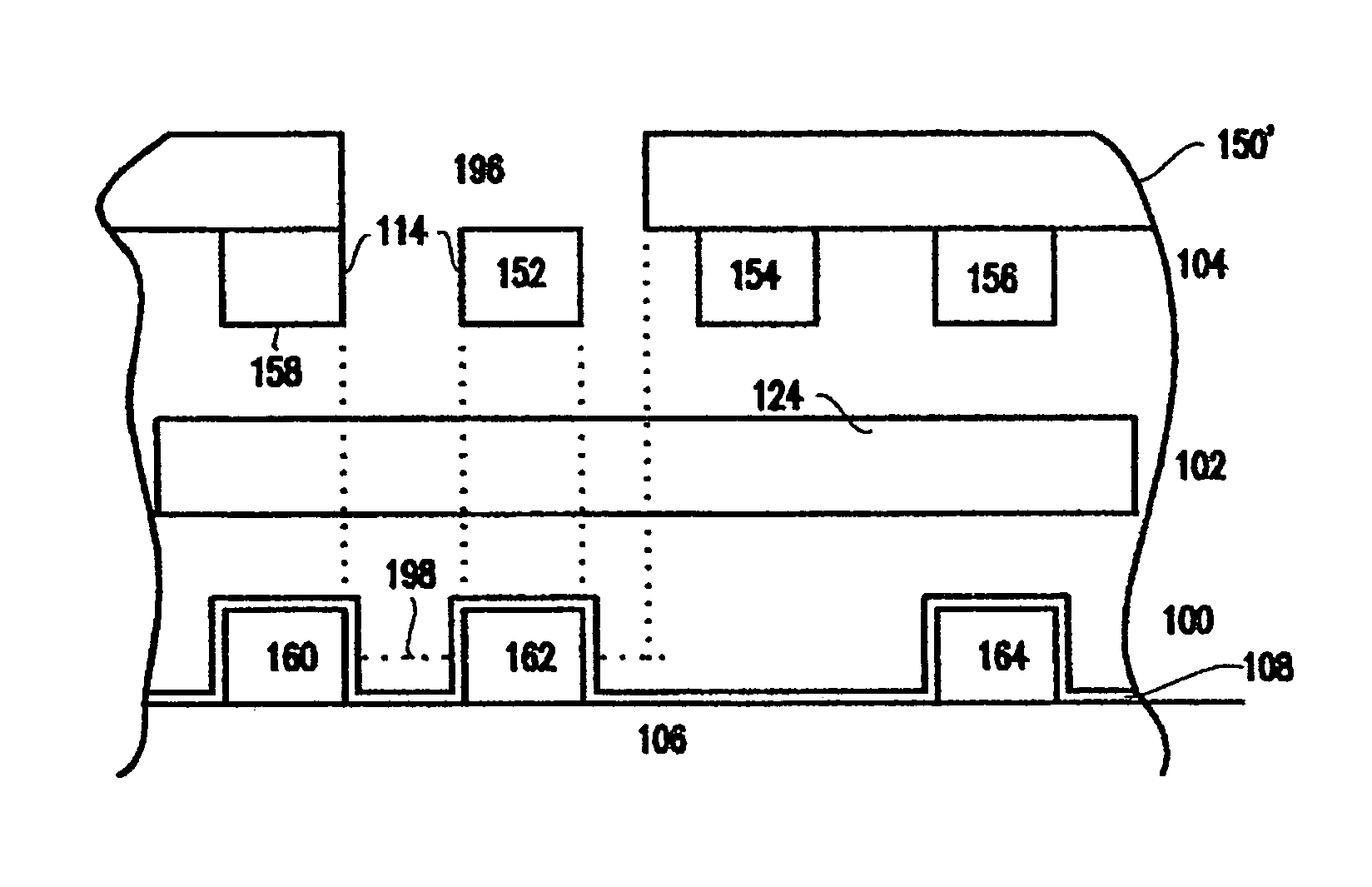

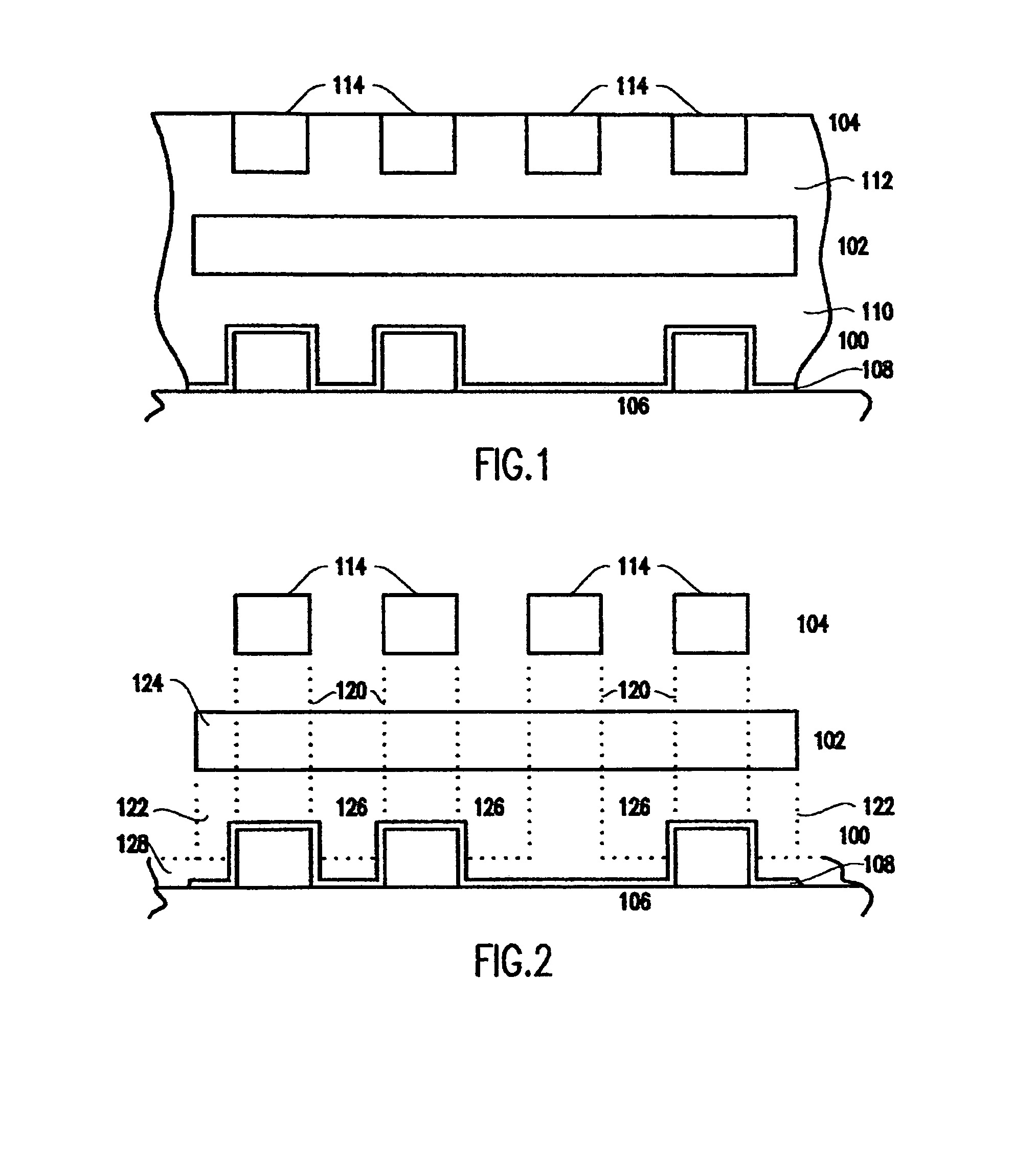

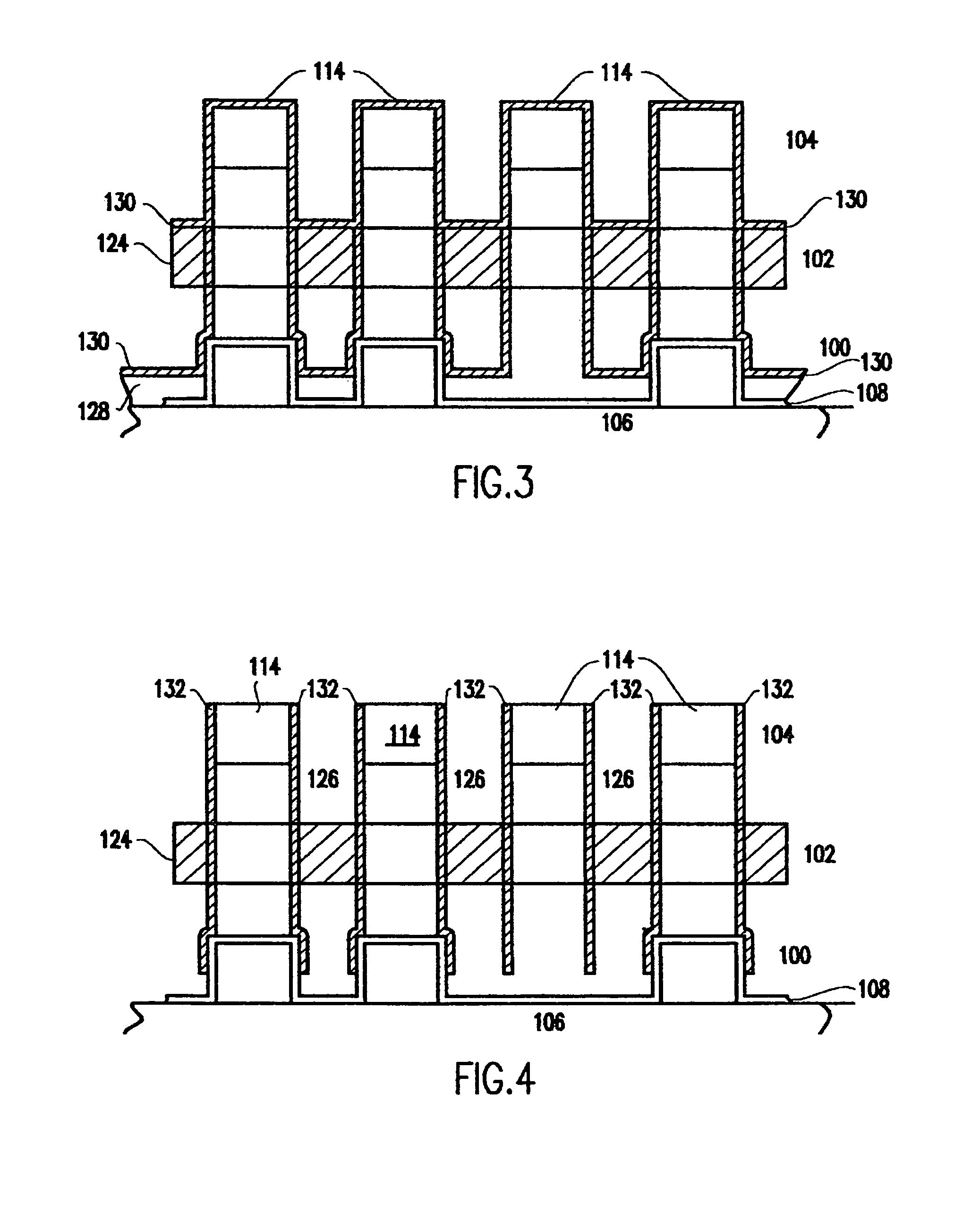

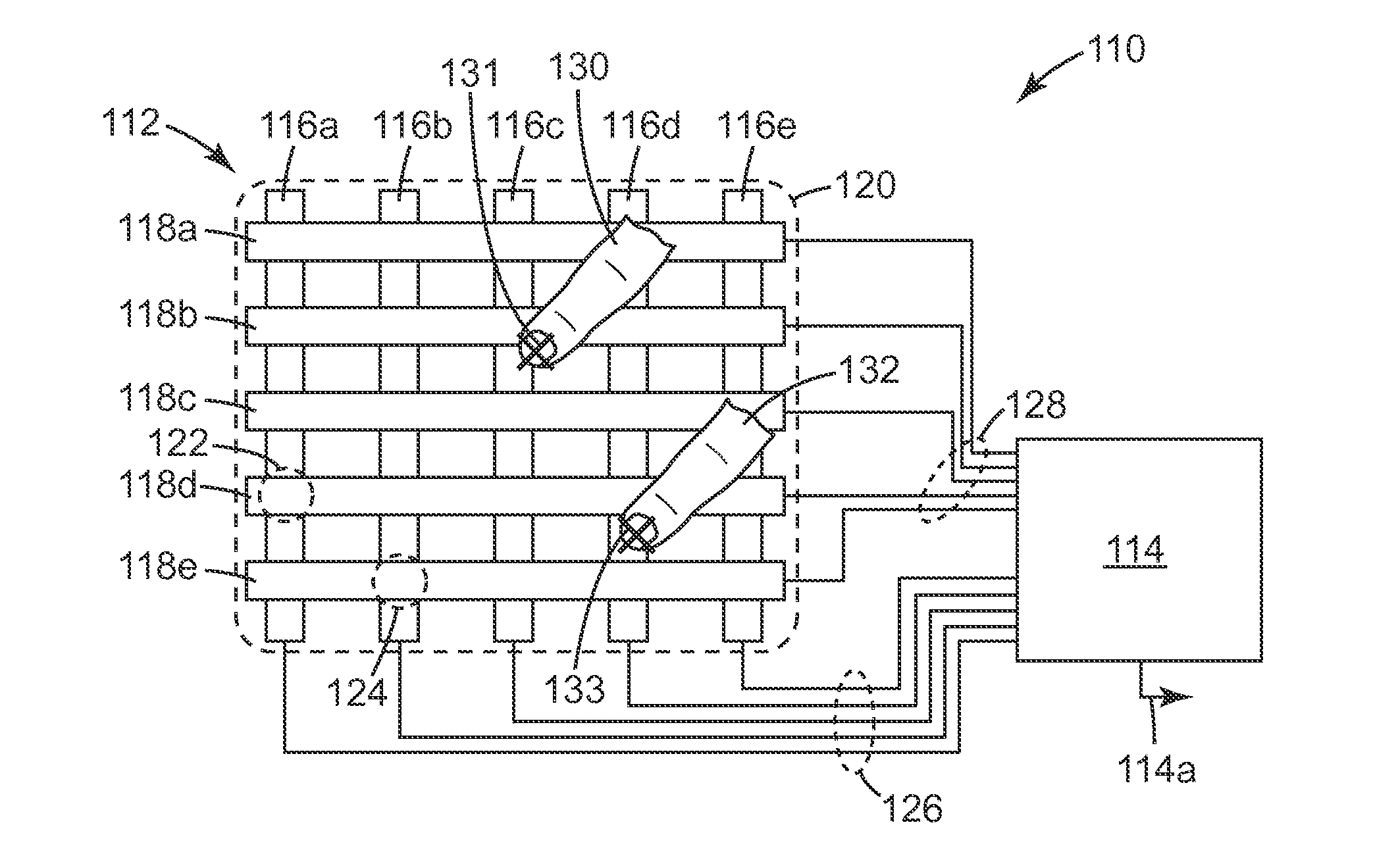

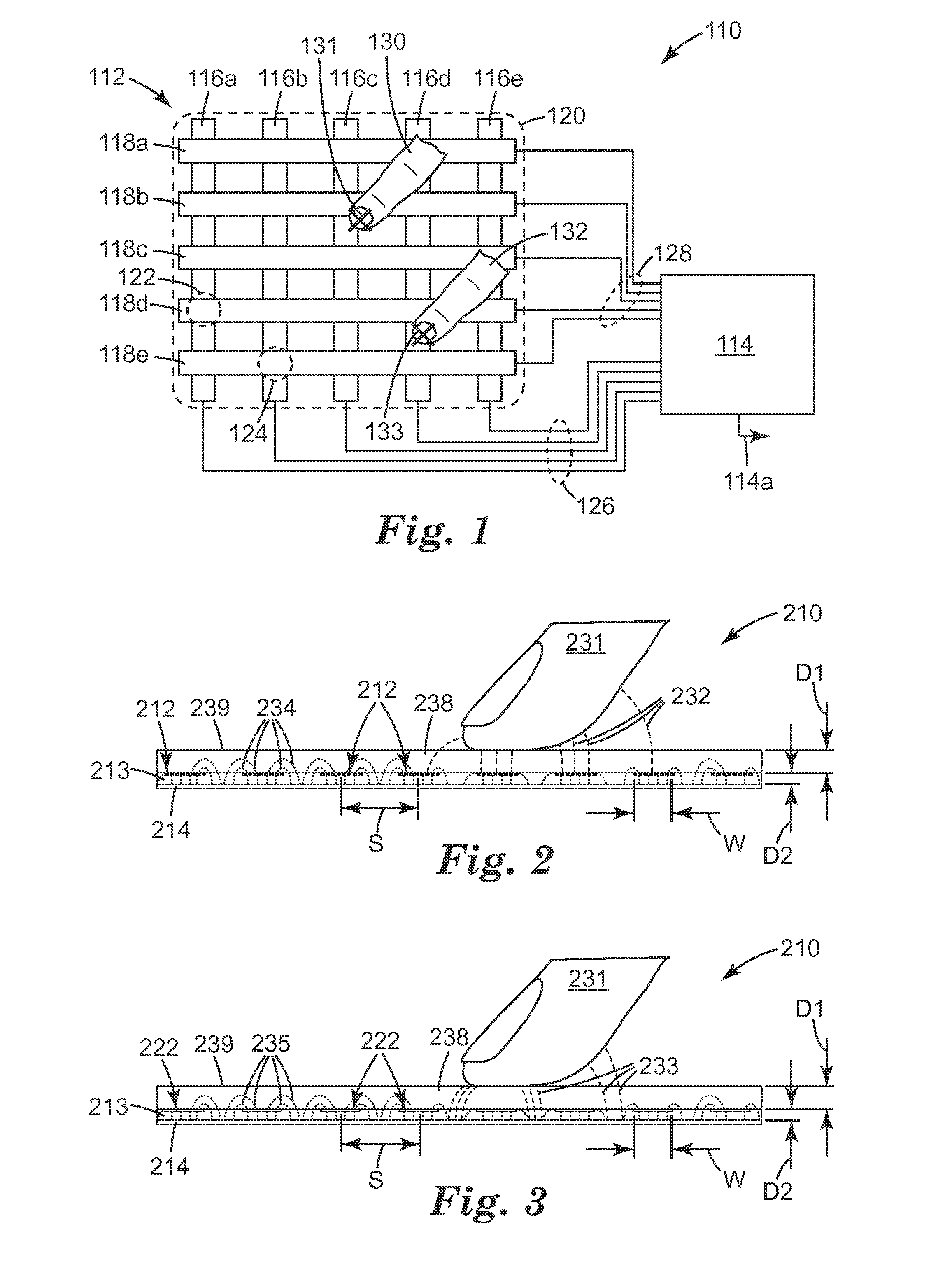

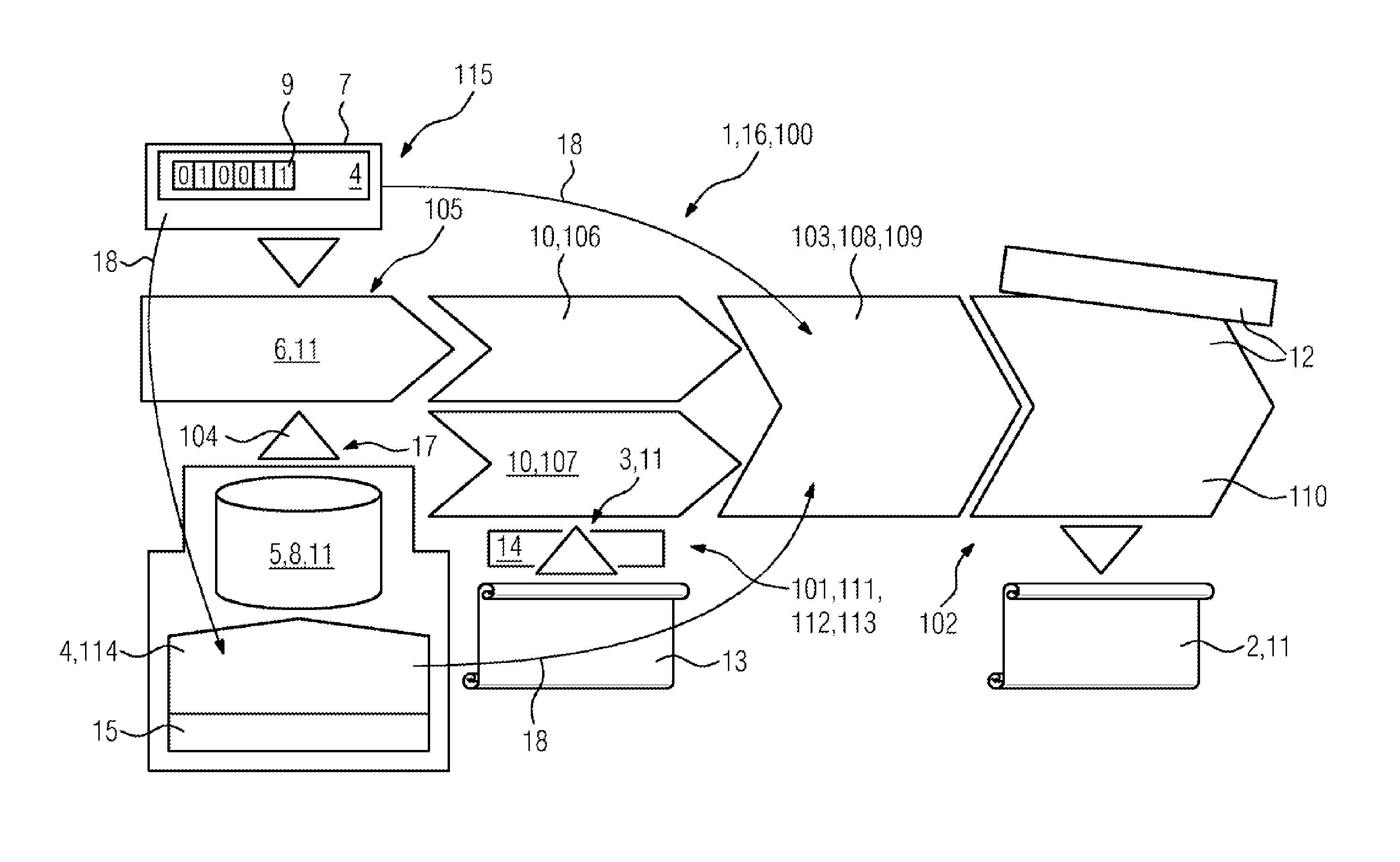

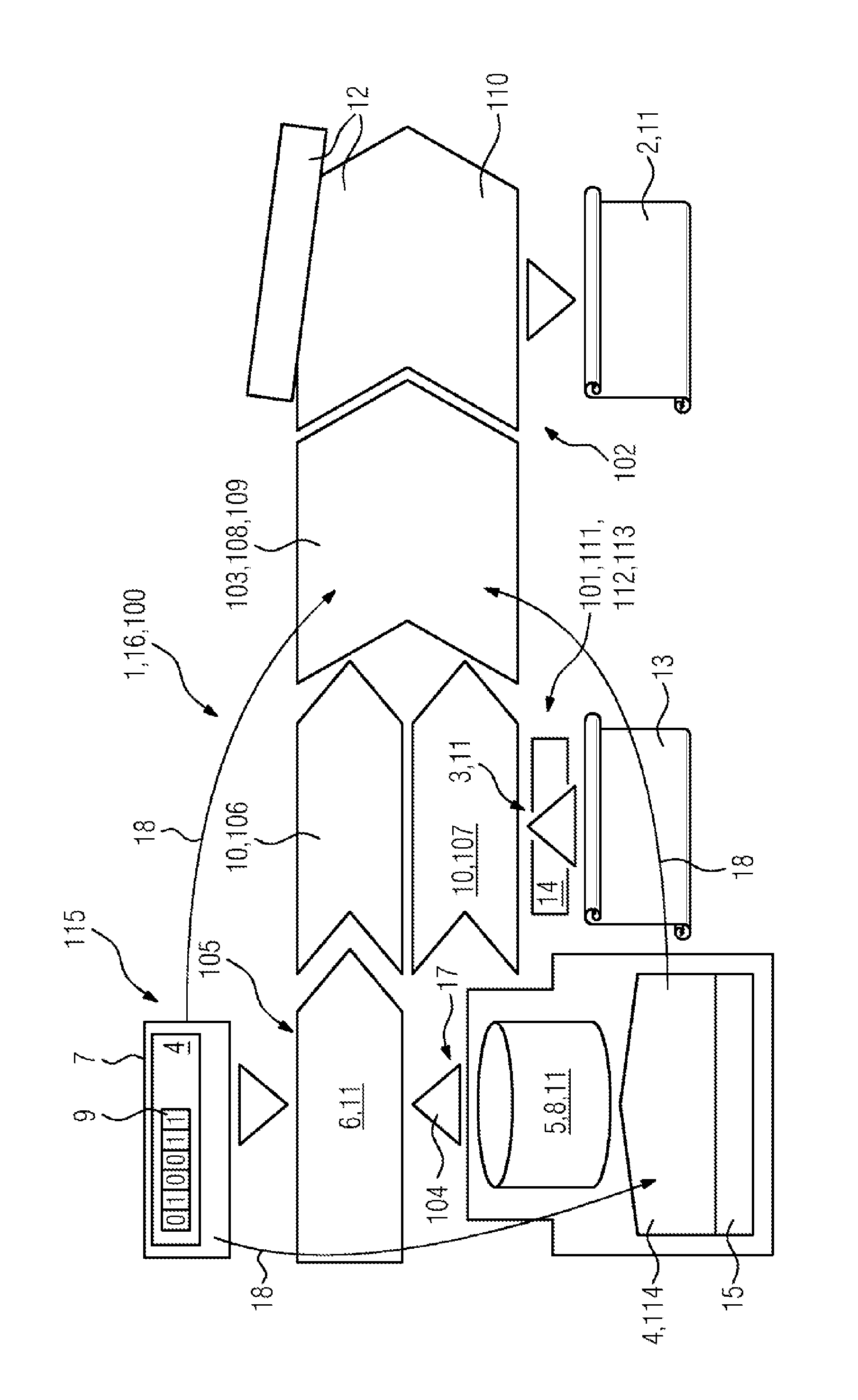

Touch sensitive devices with composite electrodes

ActiveUS20100026664A1Great mutual capacitance changeLess susceptibilityCathode-ray tube indicatorsAdhesivesCapacitanceCapacitive coupling

A matrix touch panel having upper and lower electrodes, the upper electrodes being composite electrodes made of a plurality of spaced micro-wires, and allowing, for example, an electric field from lower electrodes to pass between the micro-wires and thereby capacitively couple with a touching object, such as a finger.

Owner:3M INNOVATIVE PROPERTIES CO

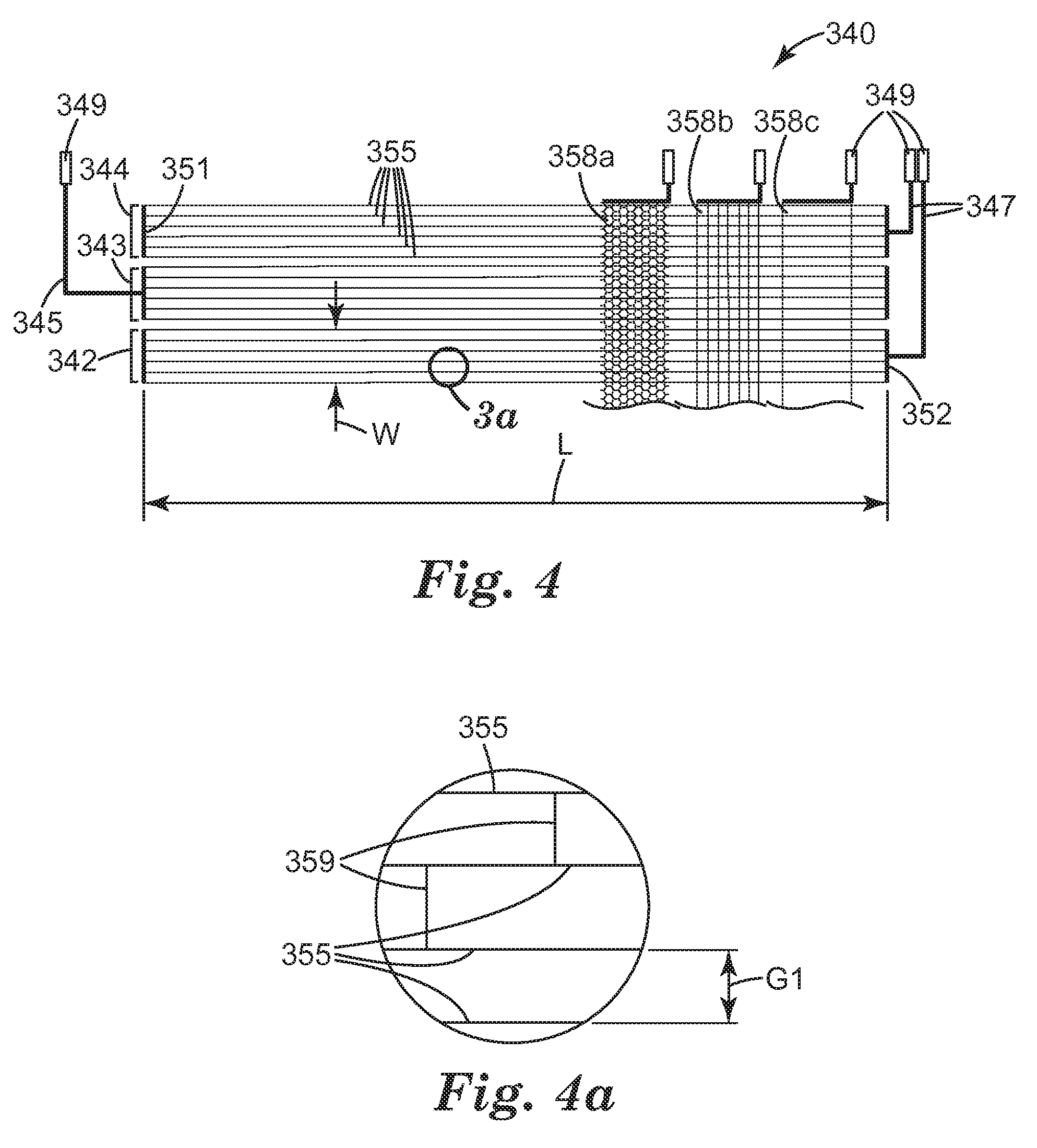

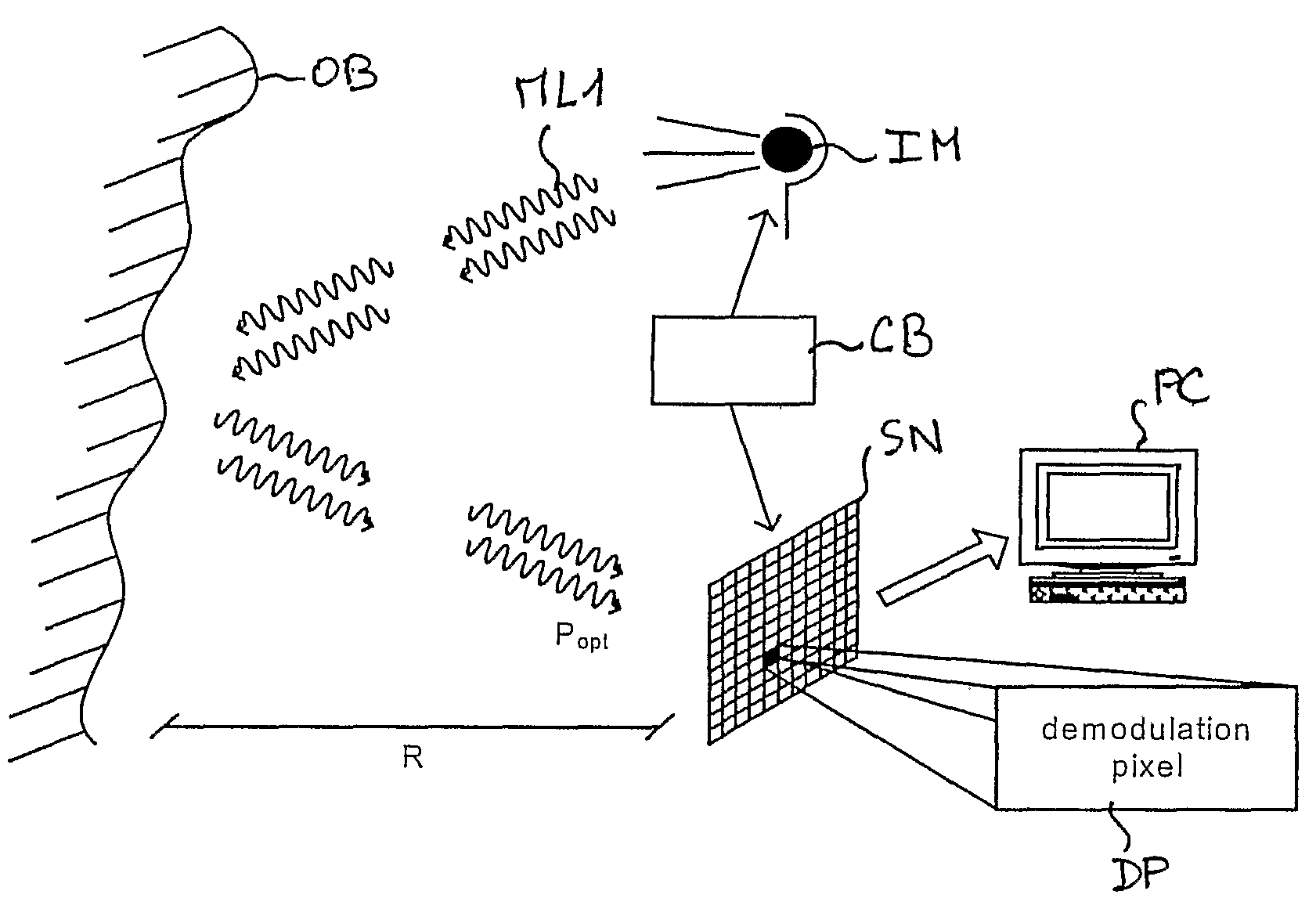

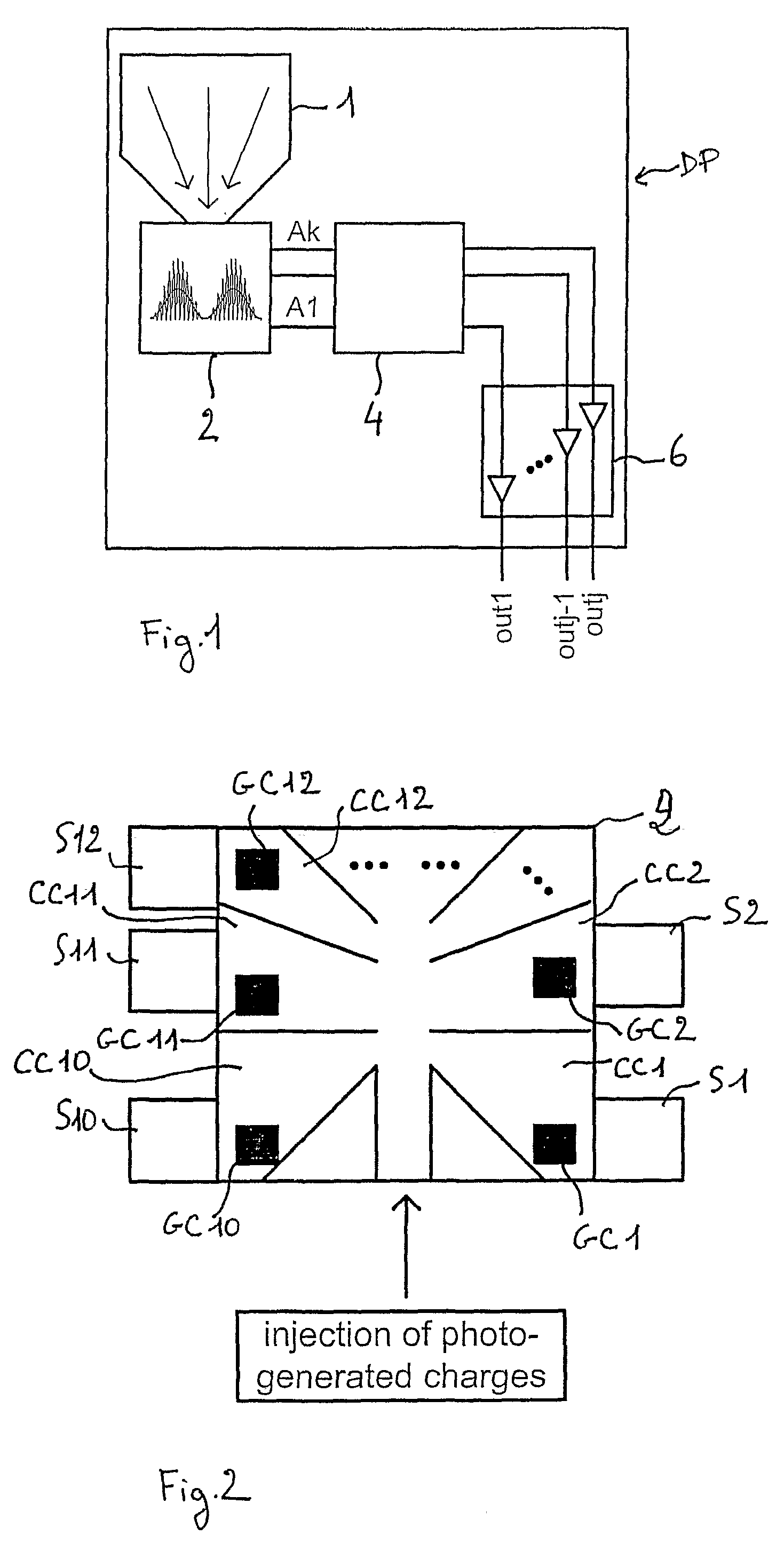

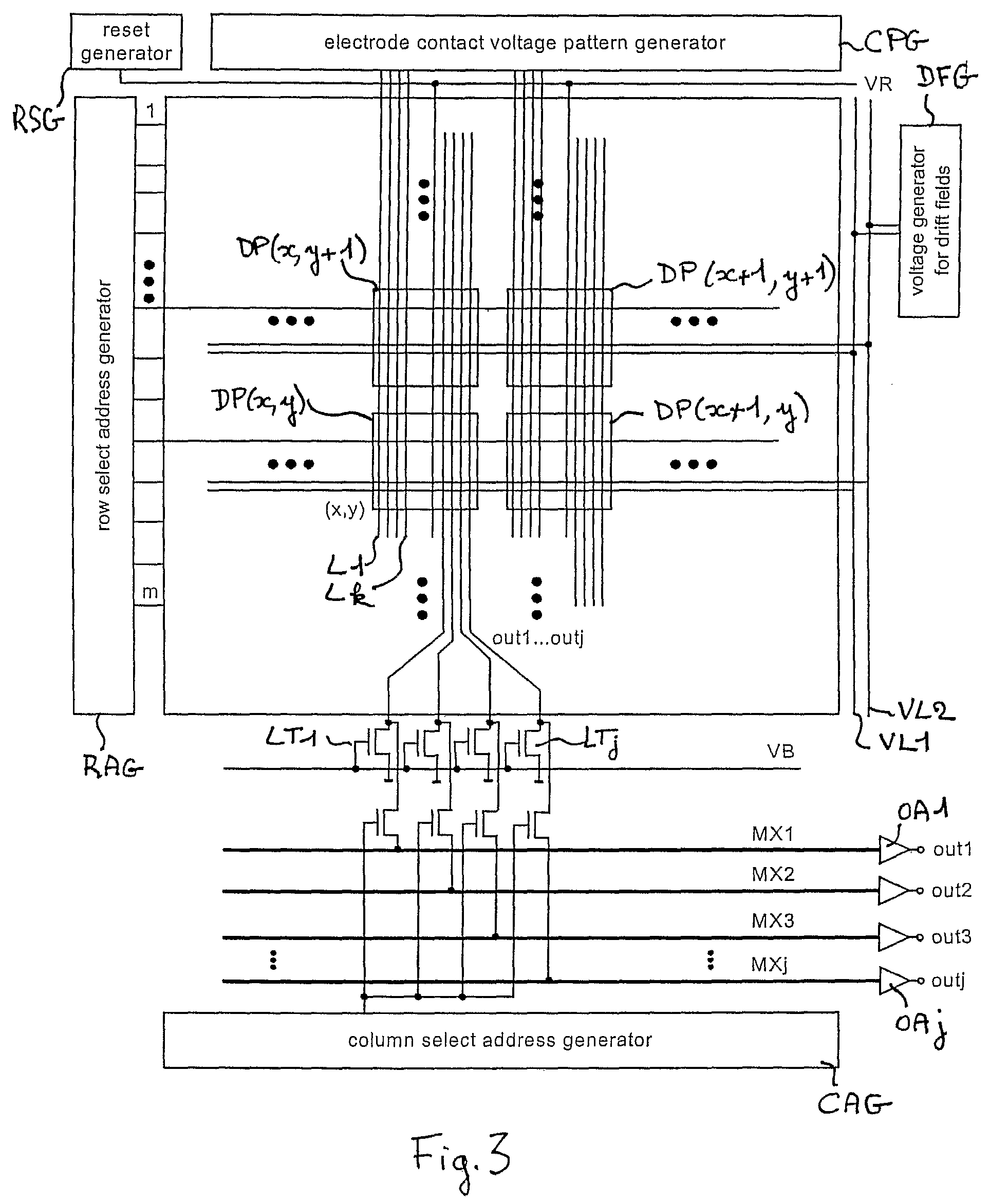

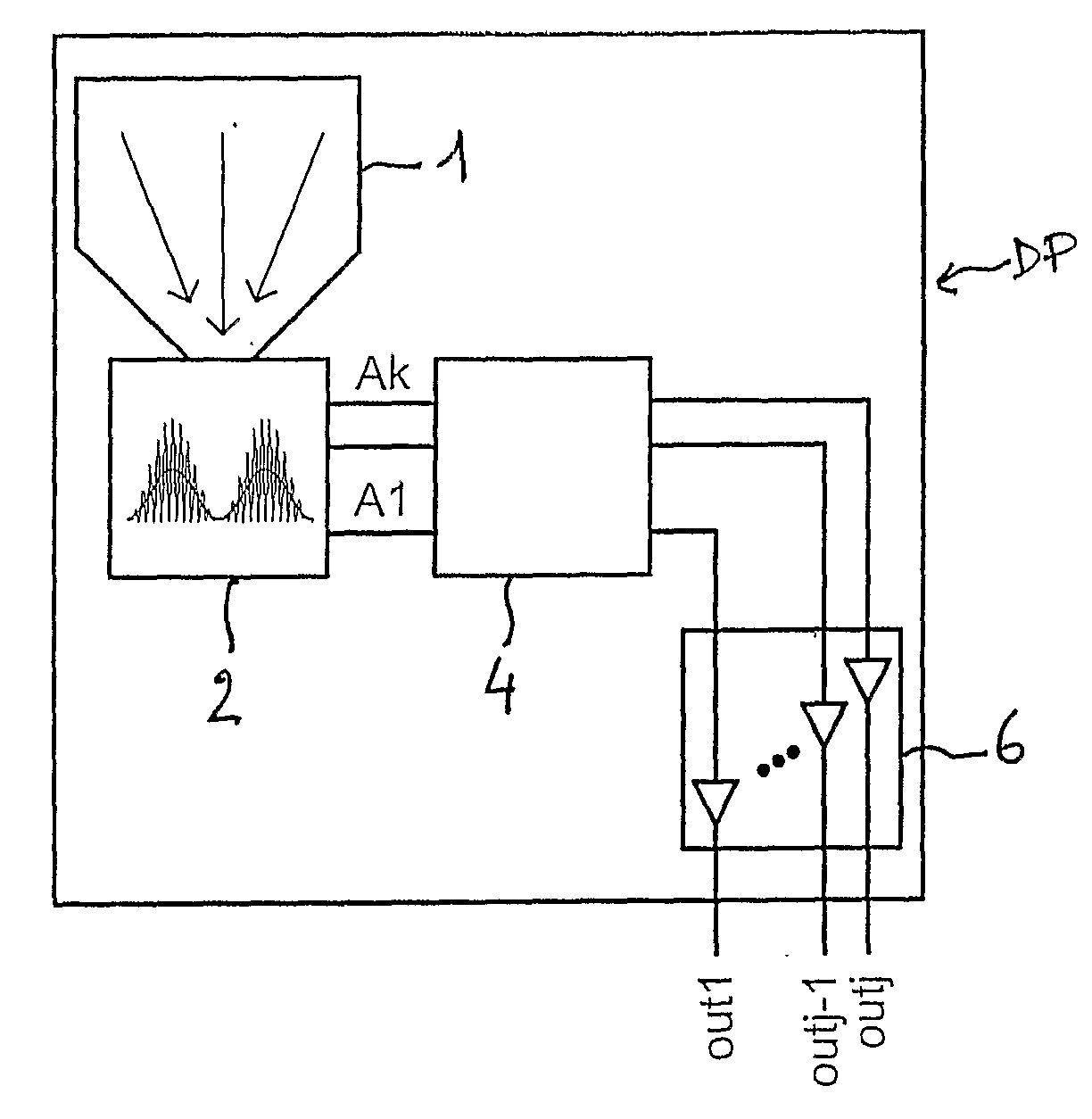

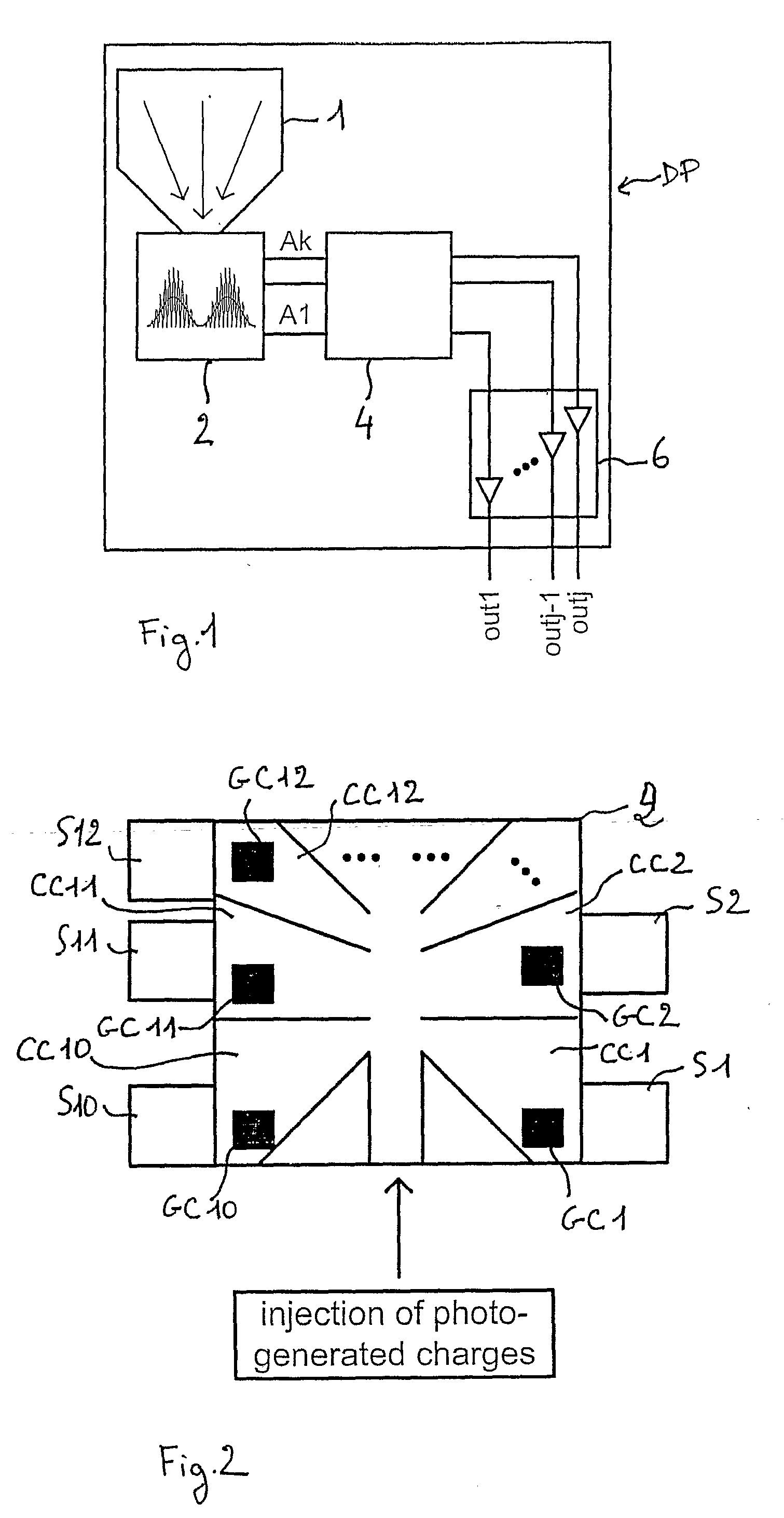

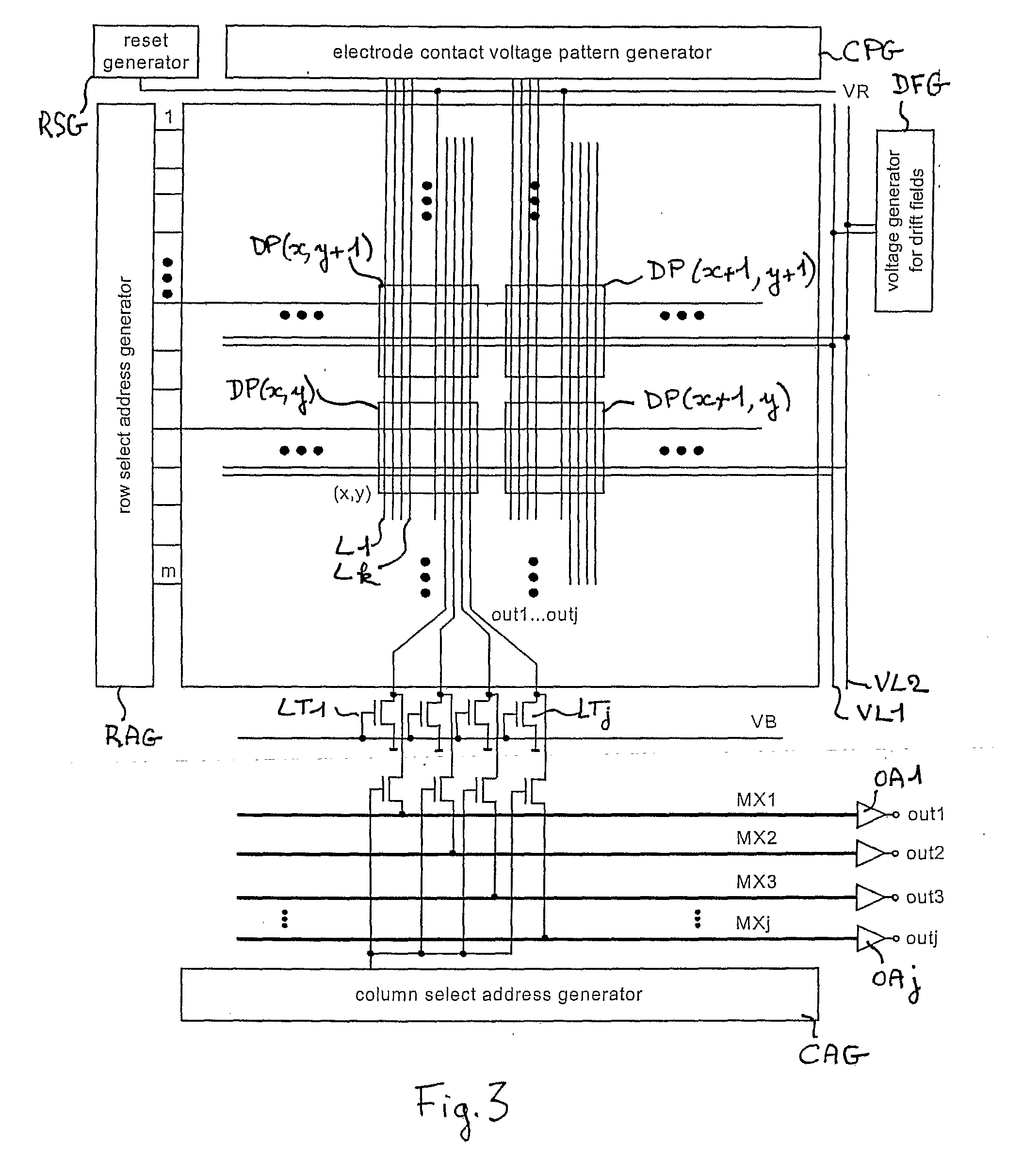

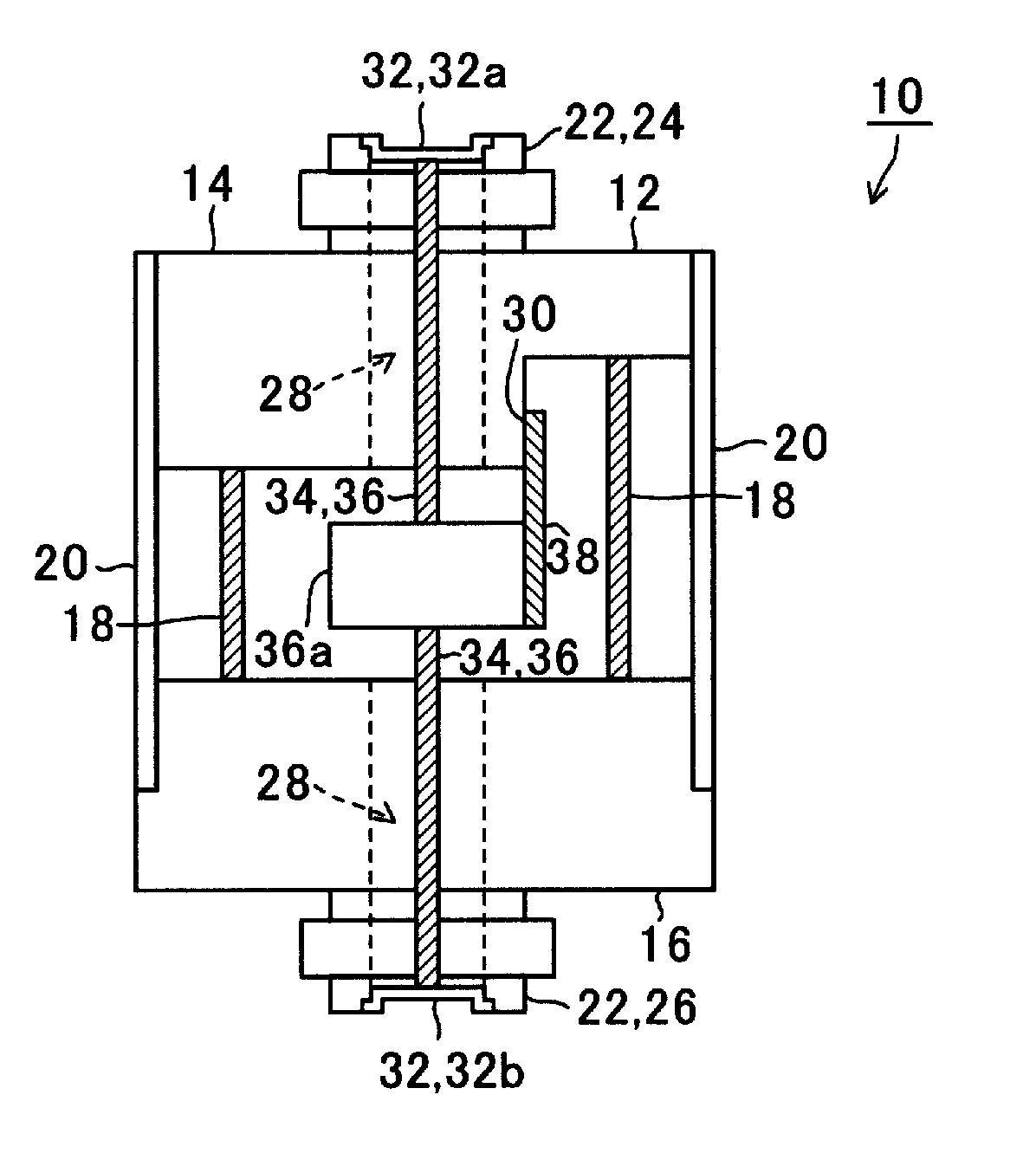

Device and method for the demodulation electromagnetic wave fields having separated detection and demodulation regions

ActiveUS7884310B2Increase speedFast shippingTelevision system detailsSolid-state devicesCharge currentWave field

A new pixel in semiconductor technology comprises a photo-sensitive detection region (1) for converting an electromagnetic wave field into an electric signal of flowing charges, a separated demodulation region (2) with at least two output nodes (D10, D20) and means (IG10, DG10, IG20, DG20) for sampling the charge-current signal at least two different time intervals within a modulation period. A contact node (K2) links the detection region (1) to the demodulation region (2). A drift field accomplishes the transfer of the electric signal of flowing charges from the detection region to the contact node. The electric signal of flowing charges is then transferred from the contact node (K2) during each of the two time intervals to the two output nodes allocated to the respective time interval. The separation of the demodulation and the detection regions provides a pixel capable of demodulating electromagnetic wave field at high speed and with high sensitivity.

Owner:AMS SENSORS SINGAPORE PTE LTD

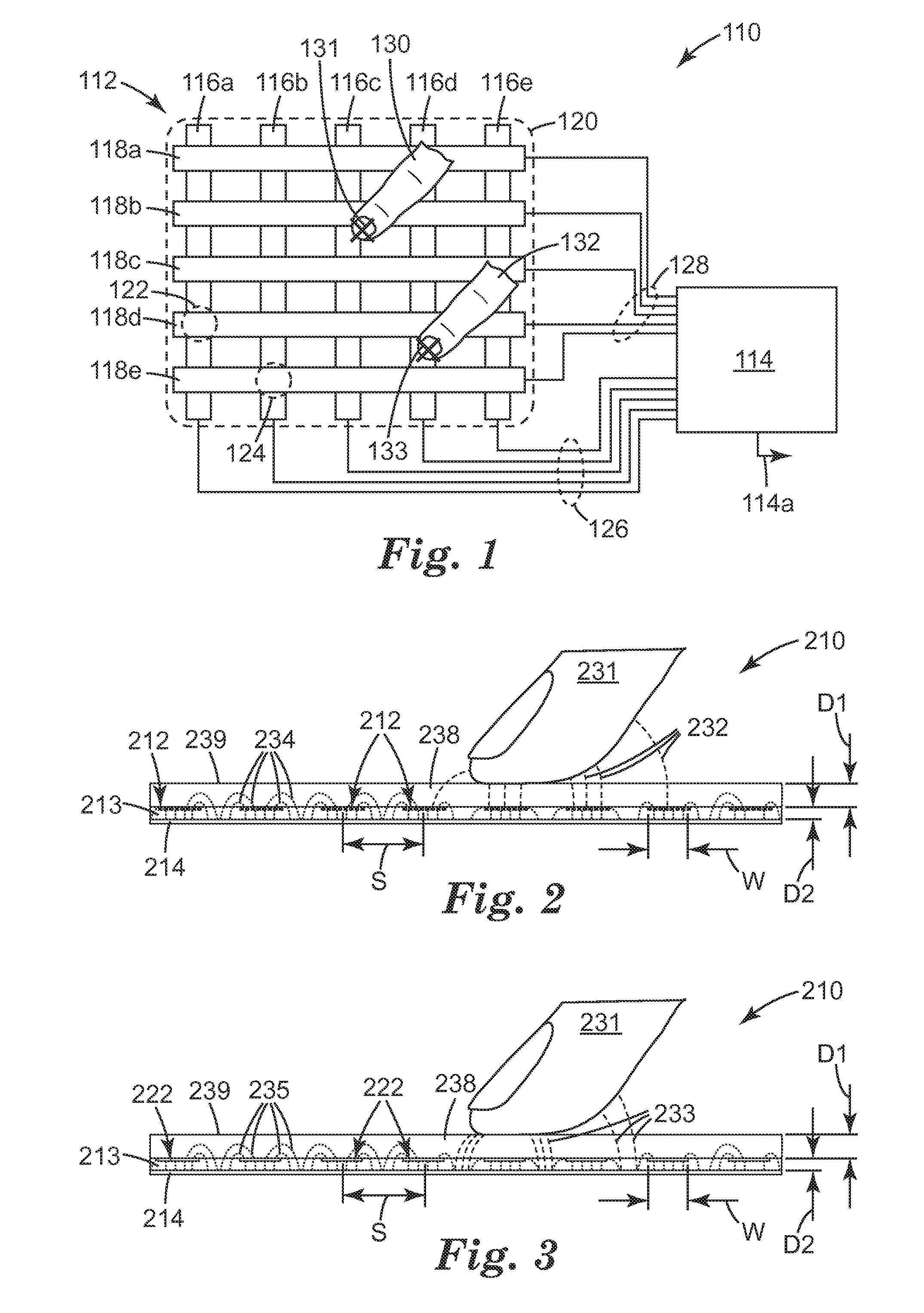

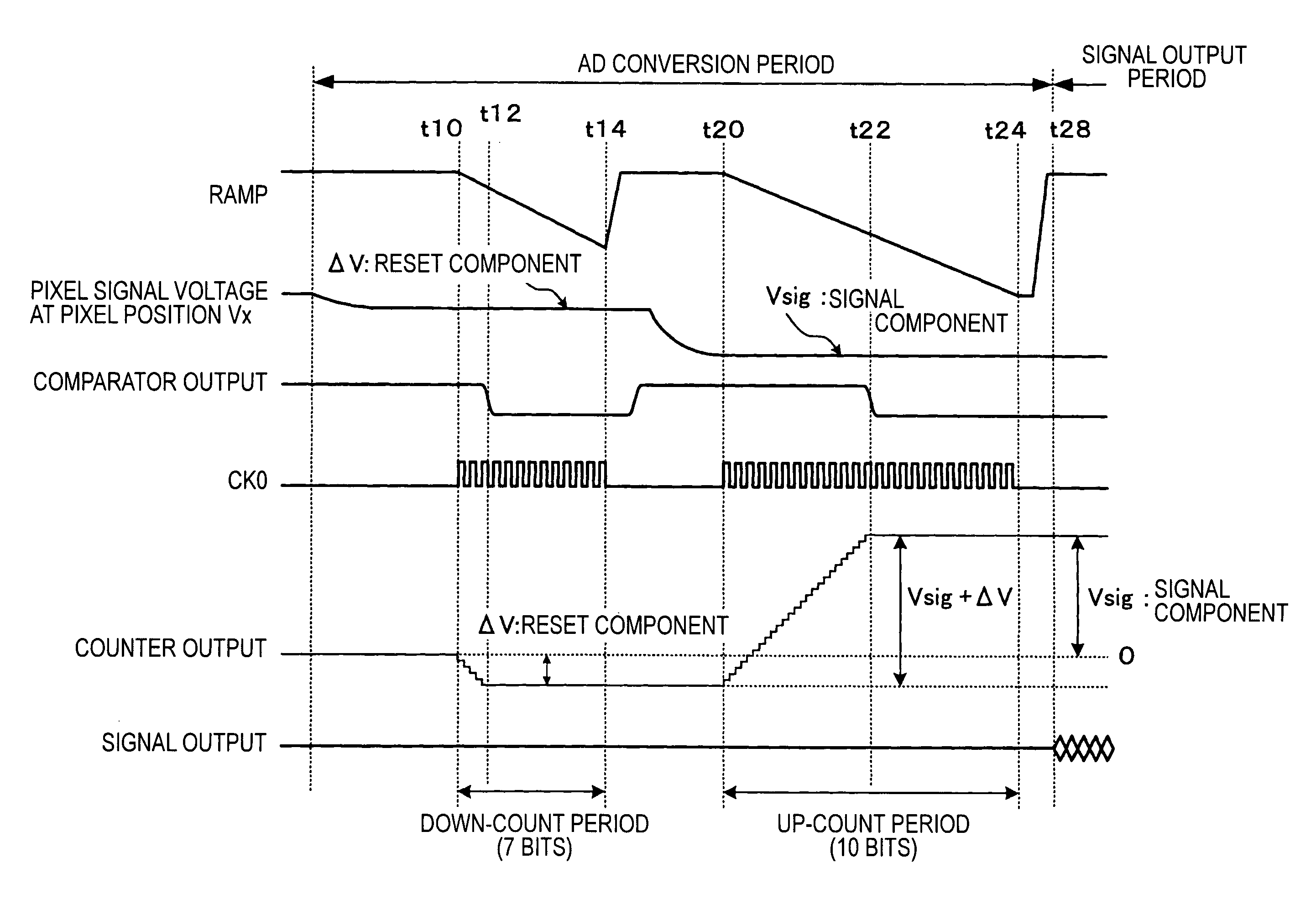

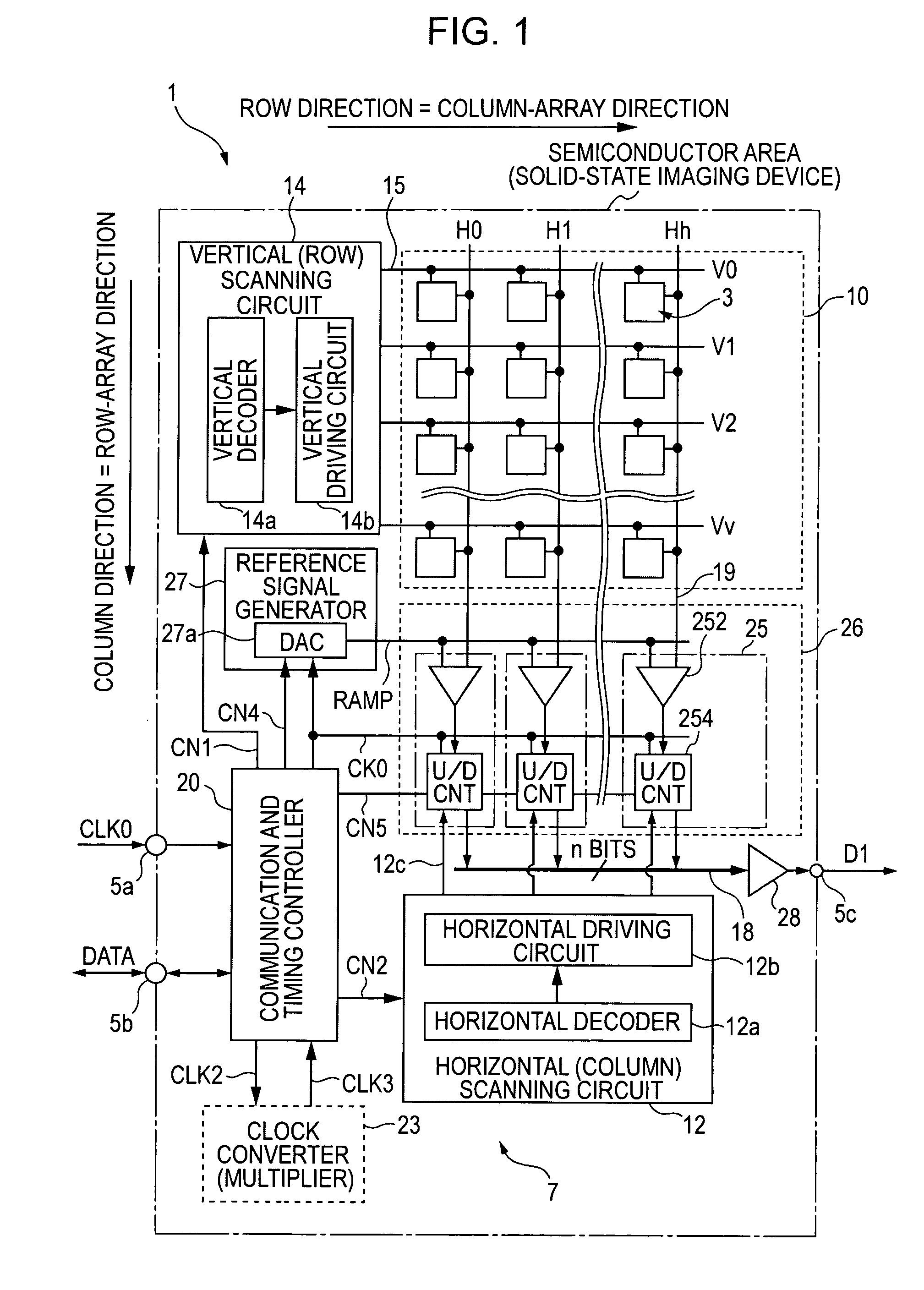

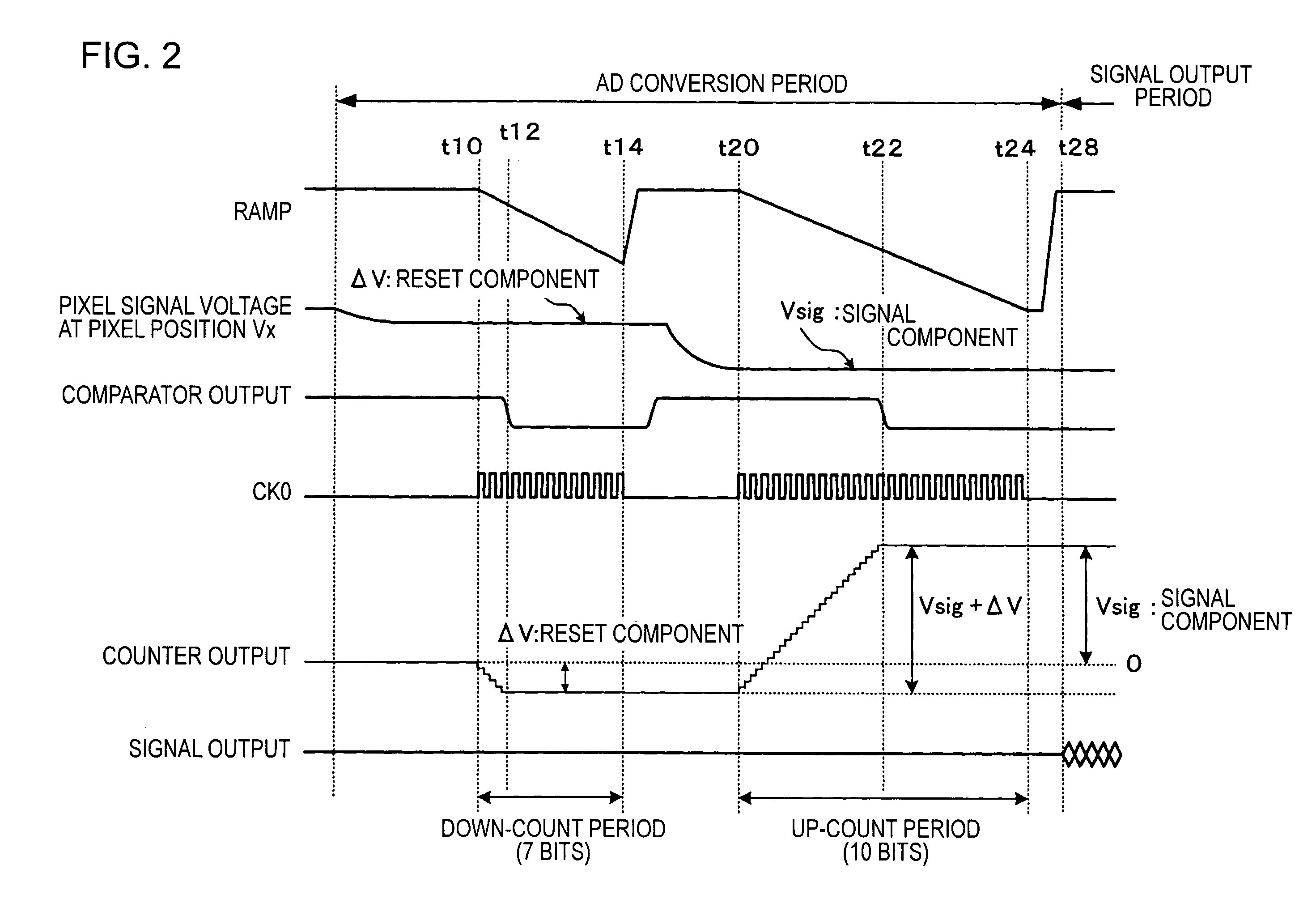

Analog-to-digital conversion method, analog-to-digital converter, semiconductor device for detecting distribution of physical quantity, and electronic apparatus

ActiveUS20060097902A1Increase currentImprove noiseTelevision system detailsElectric signal transmission systemsDigital dataA d converter

In an analog-to-digital conversion method for converting a difference signal component representing a difference between a reference component and a signal component in an analog signal to be processed into digital data, in a first process, a signal corresponding to one of the reference component and the signal component is compared with a reference signal for conversion into the digital data. Concurrently with the comparison, counting is performed in one of a down-count mode and an up-count mode, and a count value at a time of completion of the comparison is held. In a second process, a signal corresponding to the other one of the reference component and the signal component is compared with the reference signal. Concurrently with the comparison, counting is performed in the other one of the down-count mode and the up-count mode, and a count value at a time of completion of the comparison is held.

Owner:SONY CORP

Device and Method for the Demodulation Electromagnetic Wave Fields

ActiveUS20080239466A1Less susceptibleLess susceptibilityTelevision system detailsSolid-state devicesCharge currentWave field

A new pixel in semiconductor technology comprises a photo-sensitive detection region (1) for converting an electromagnetic wave field into an electric signal of flowing charges, a separated demodulation region (2) with at least two output nodes (D10, D20) and means (IG10, DG10, IG20, DG20) for sampling the charge-current signal at at least two different time intervals within a modulation period. A contact node (K2) links the detection region (1) to the demodulation region (2). A drift field accomplishes the transfer of the electric signal of flowing charges from the detection region to the contact node. The electric signal of flowing charges is then transferred from the contact node (K2) during each of the two time intervals to the two output nodes allocated to the respective time interval. The separation of the demodulation and the detection regions provides a pixel capable of demodulating electromagnetic wave field at high speed and with high sensitivity.

Owner:AMS SENSORS SINGAPORE PTE LTD

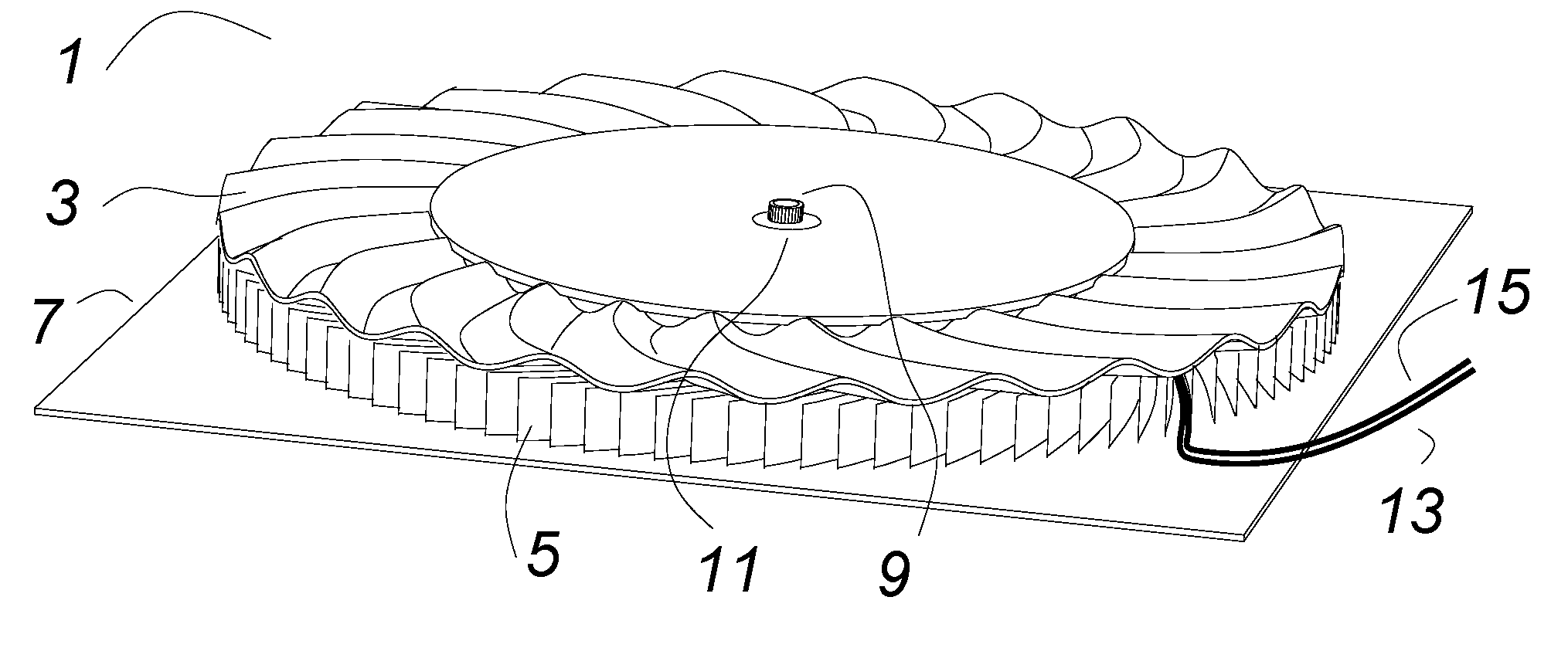

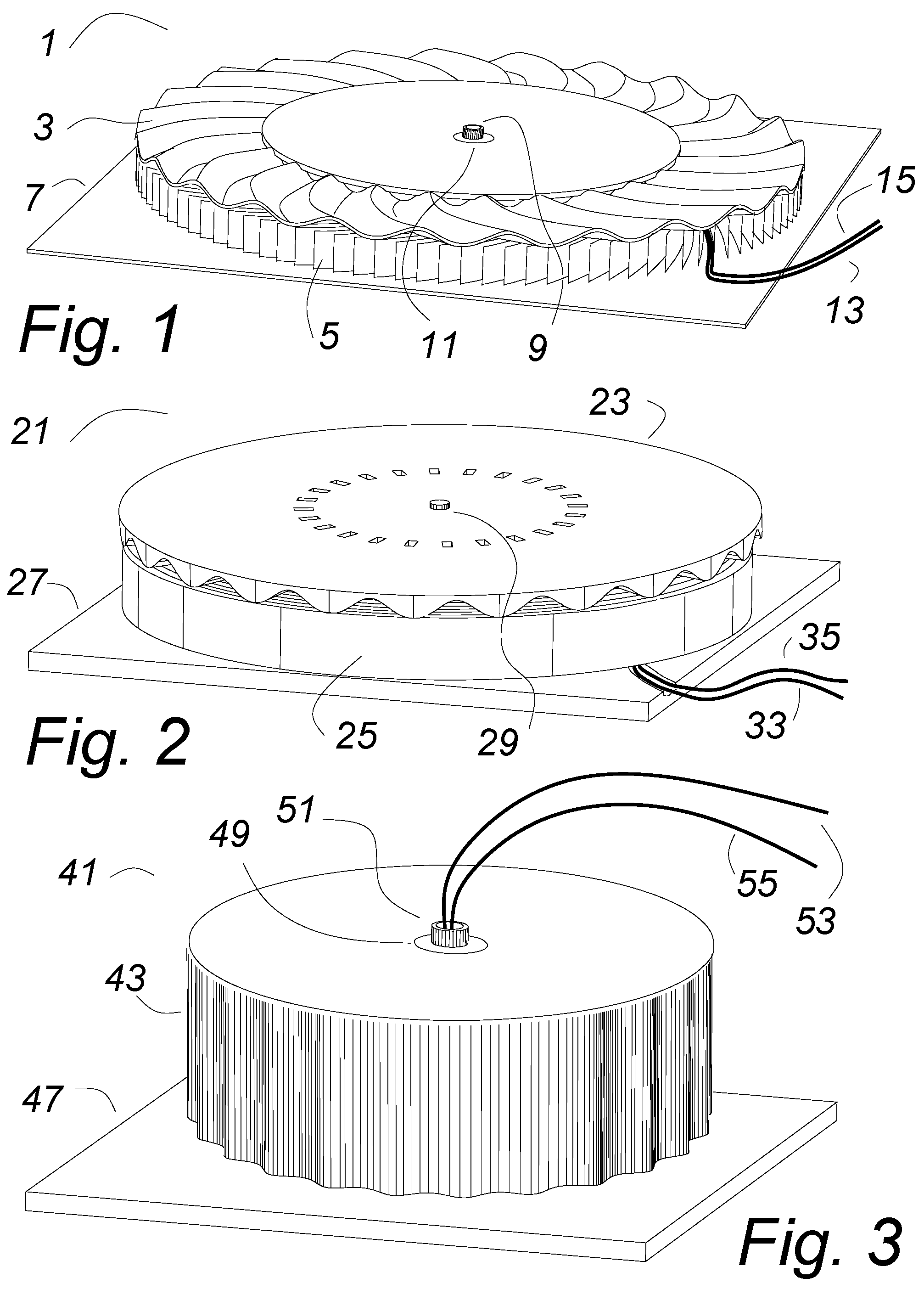

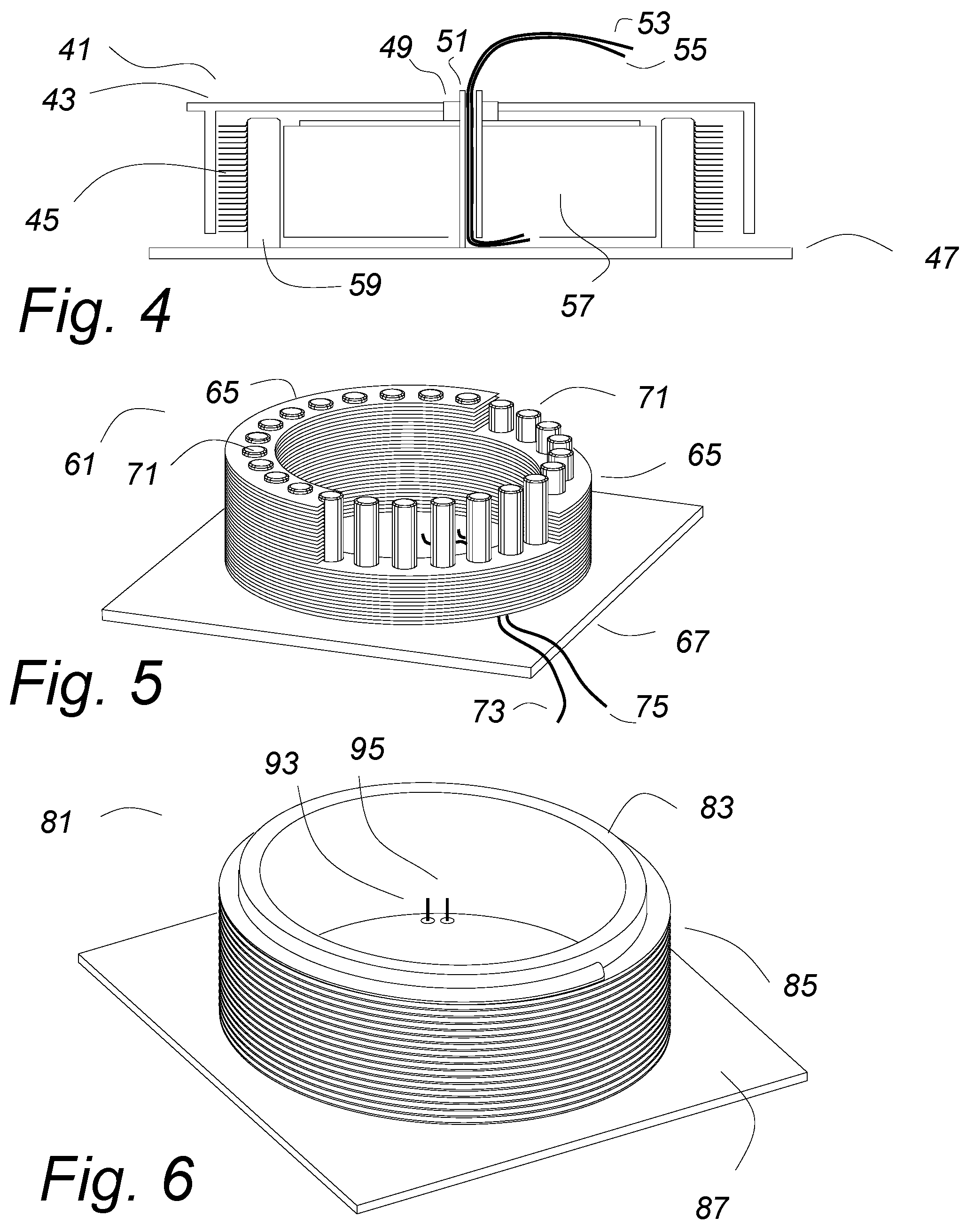

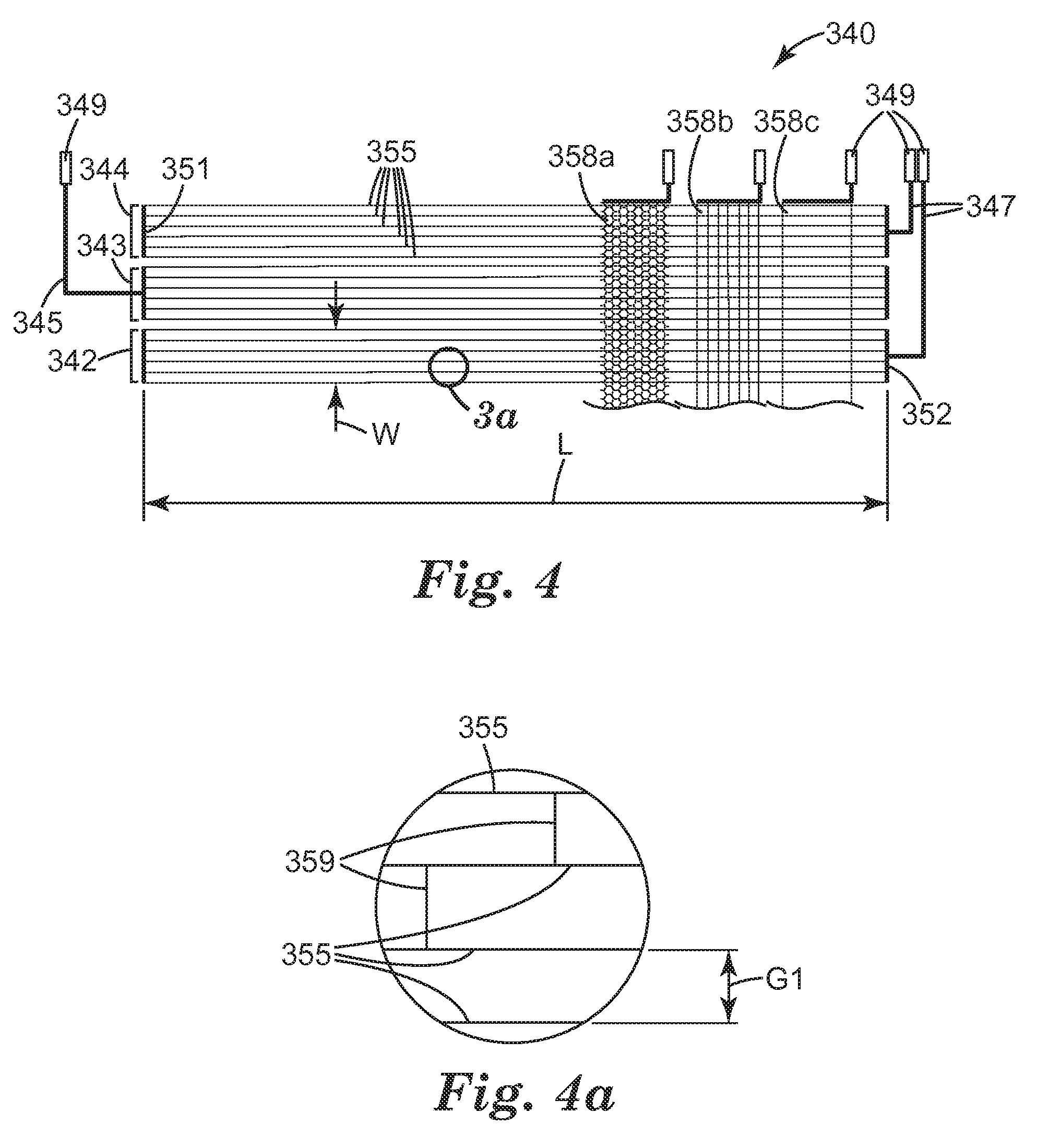

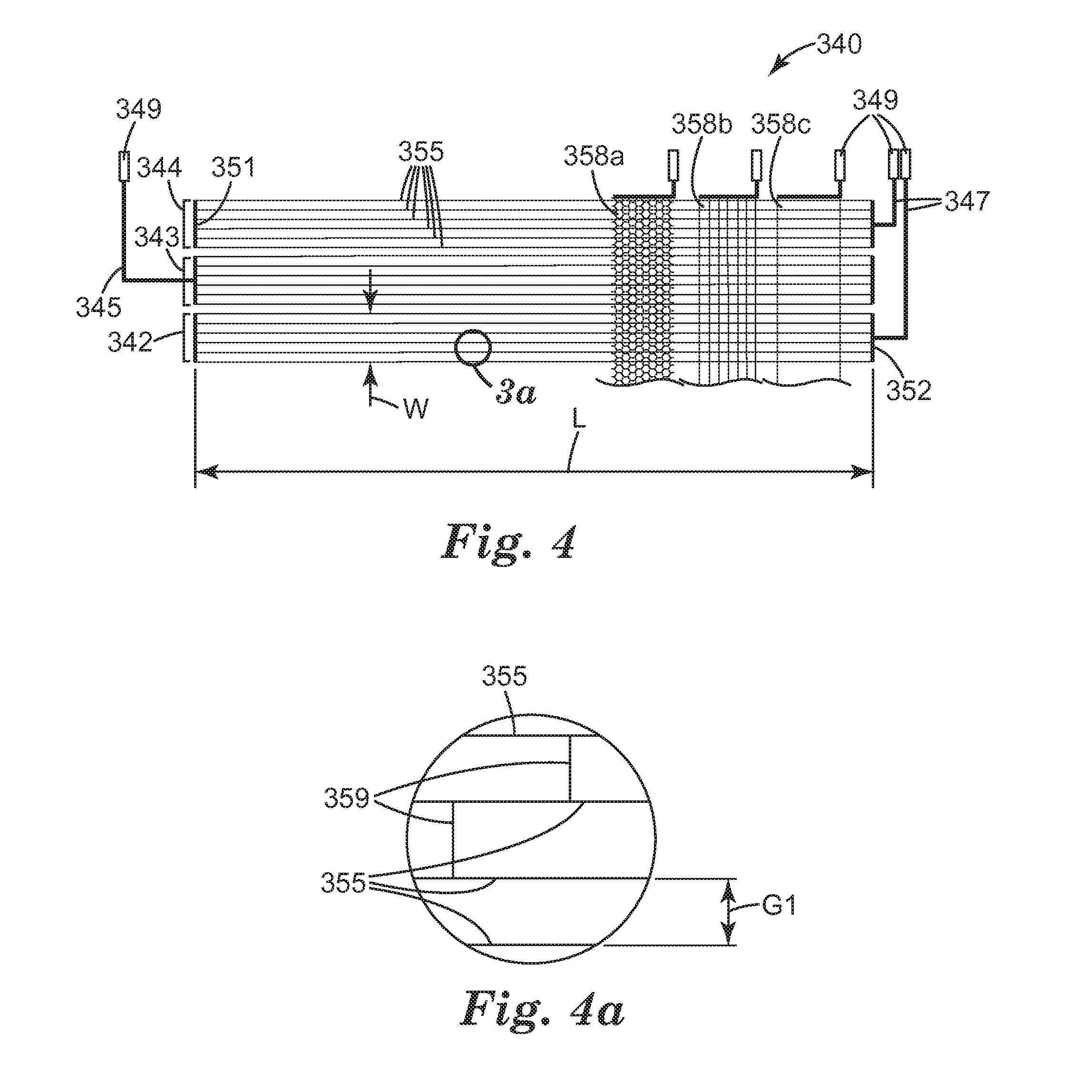

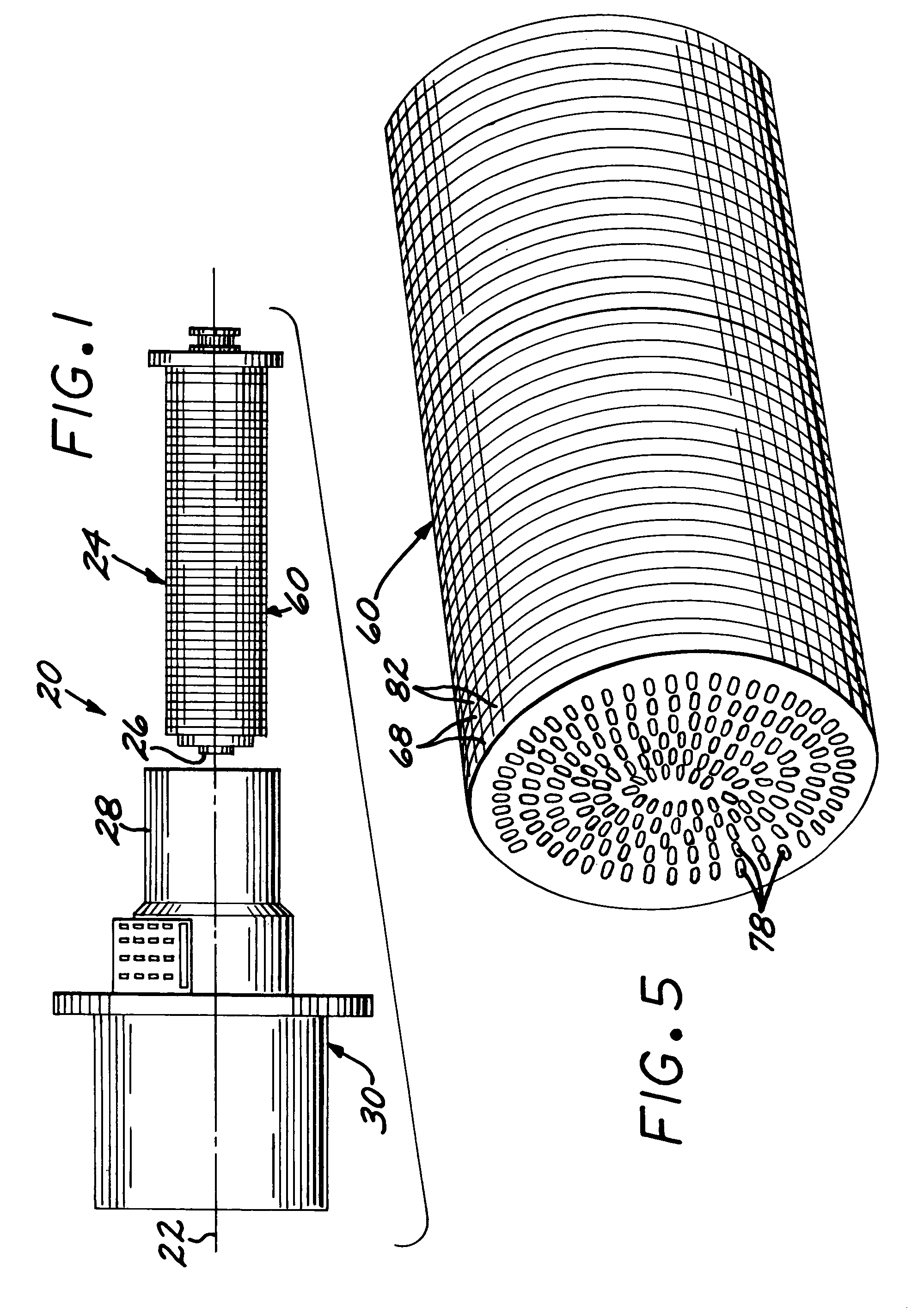

Wave-fans and wave-fans with heat sinks

InactiveUS7136285B1Increase local velocityLarge heat flowPropellersSemiconductor/solid-state device detailsHeat flowWave shape

A wave-fan comprises a wavy surface, generally sinusoidal in the direction of rotation, which rotates in close proximity to the fins of a heat sink. The wave-plane fan is suitable for use with a flat heat sink, and a wave-ring fan is suitable for use with a cylindrical heat sink. There are no airfoils as in a prior art fan. Instead, the ridges of the wave-fan agitate the air between the fins of the heat sink as each ridge passes, breaking down the boundary layer and effecting good heat flow into the air. In some embodiments of the wave-fan, the outer surfaces are smooth, so it is not a hazard to intruding fingers, so in many applications it may be used without a guard or enclosure. Incidental centrifugal force provides some airflow through the fan to transport the heated air away from the fan. Also, the configuration of the fan tends to keep contamination in the air out of the heat sink fins, so an inlet air filter may not be needed. Because the net airflow through the fan is low, less power is required and it is very quiet.

Owner:HERBERT EDWARD

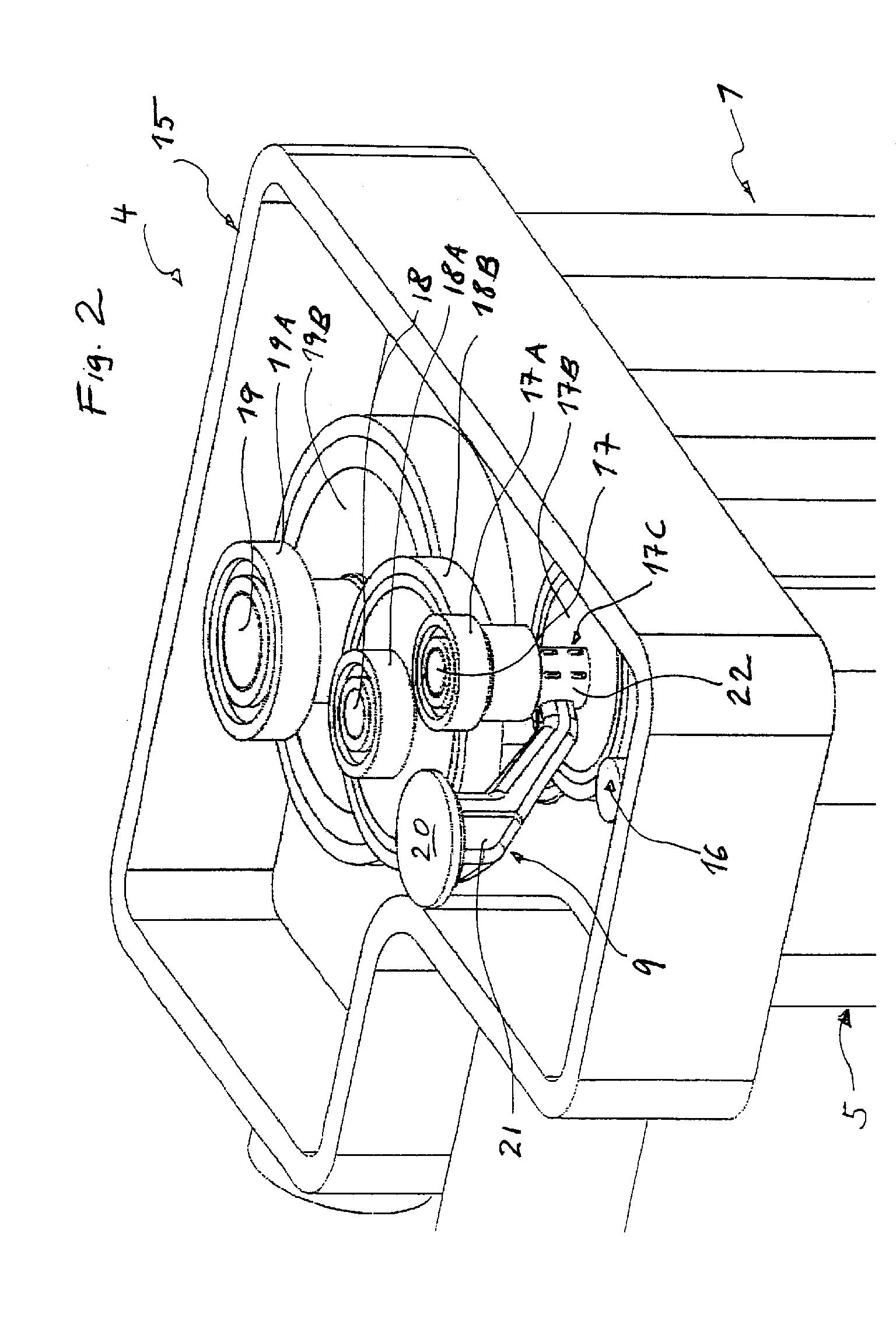

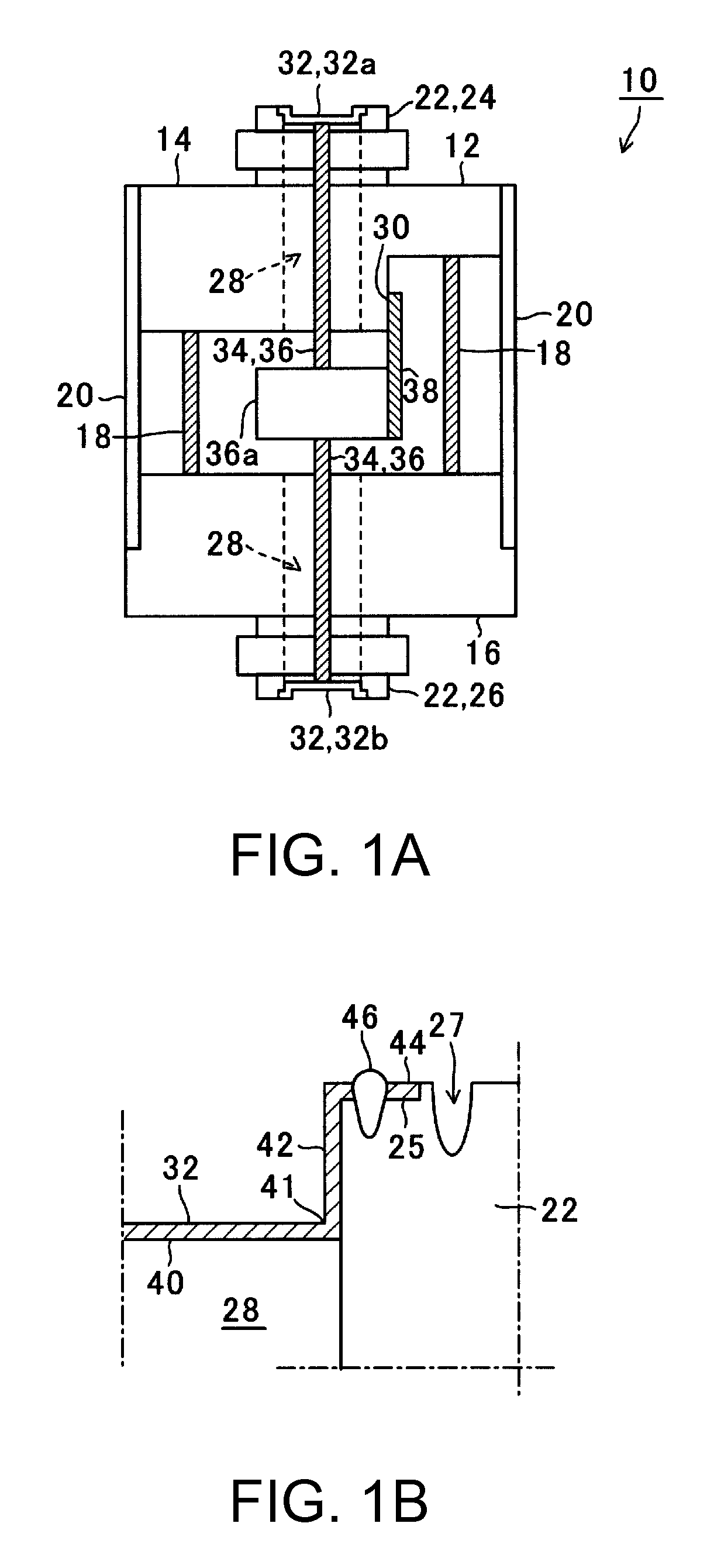

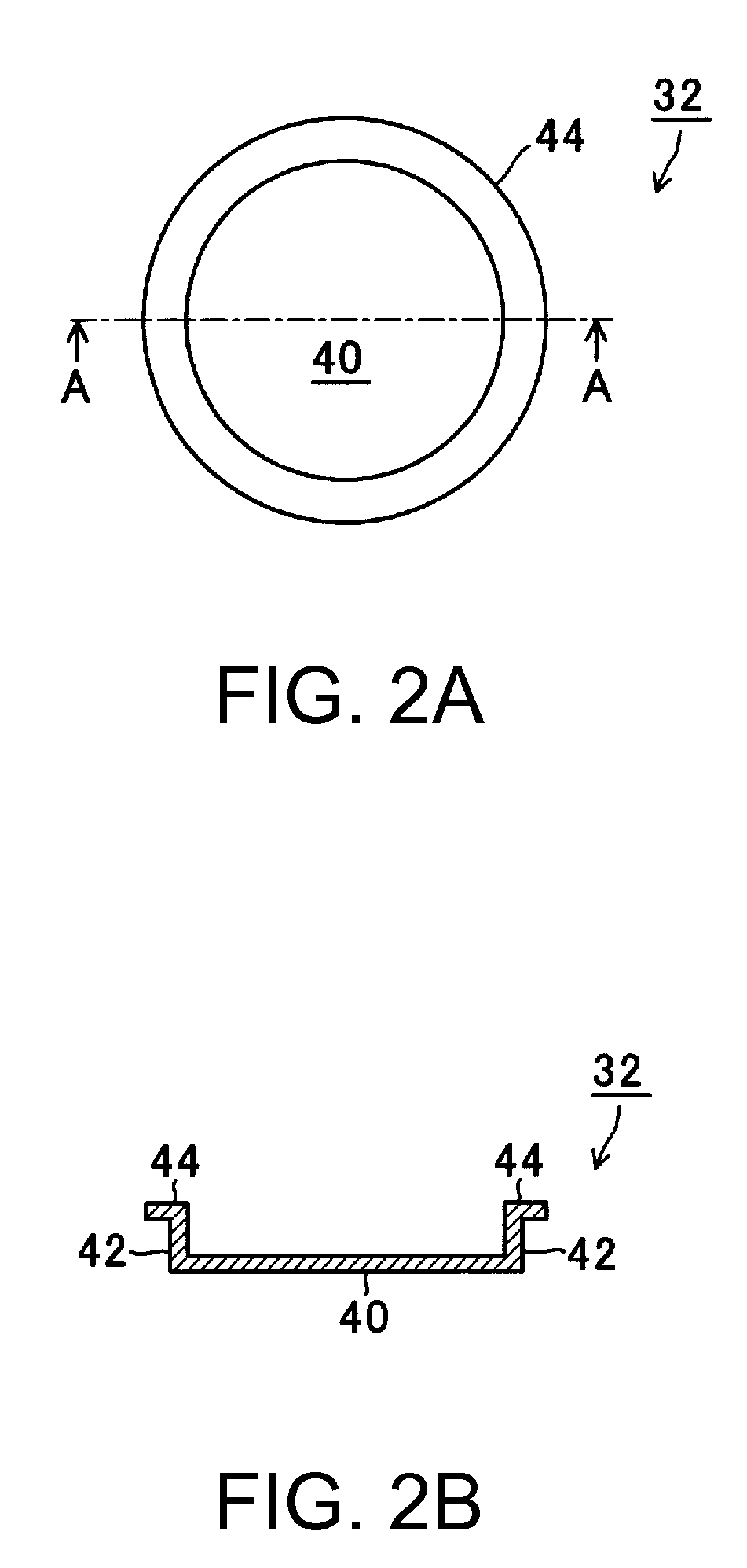

Diaphragm for pressure sensor and pressure sensor

InactiveUS20090308168A1Less occurrenceLess susceptibilityFluid pressure measurement using piezo-electric devicesFluid pressure measurement using elastically-deformable gaugesEngineeringDiaphragm seal

A diaphragm for a pressure sensor includes: a central section serving as a diaphragm body, the central section including: an external surface deformed upon receipt of an external pressure; and an internal surface transmitting a force to a pressure sensitive element inside a housing of the pressure sensor; a peripheral section that is an exterior of the central section and welded to an outer circumference of a pressure input orifice that is provided to the housing; and a step wall provided between the central section and the peripheral section. The central section and the peripheral section are integrally and concentrically provided. The diaphragm seals the pressure input orifice.

Owner:SEIKO EPSON CORP

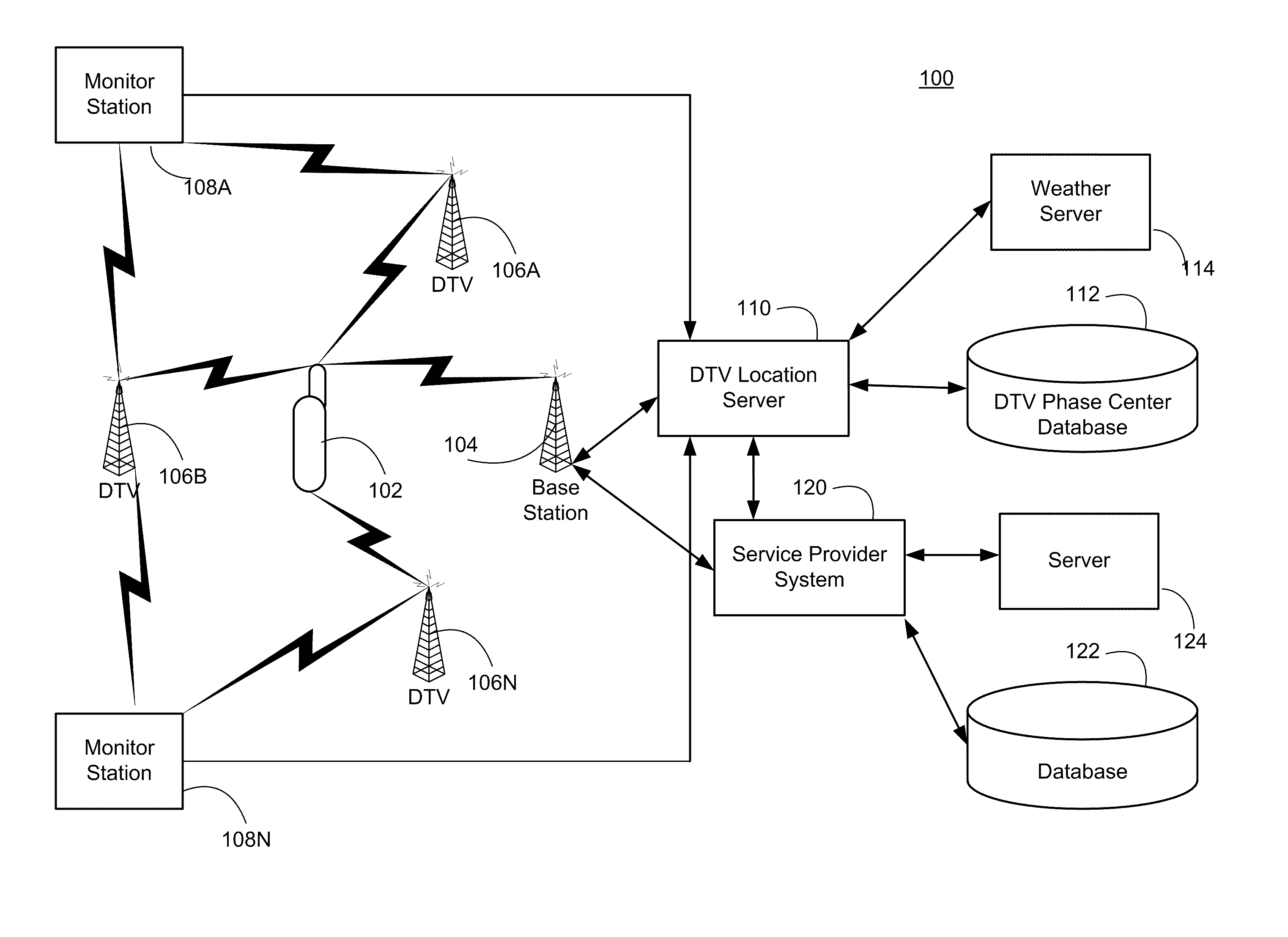

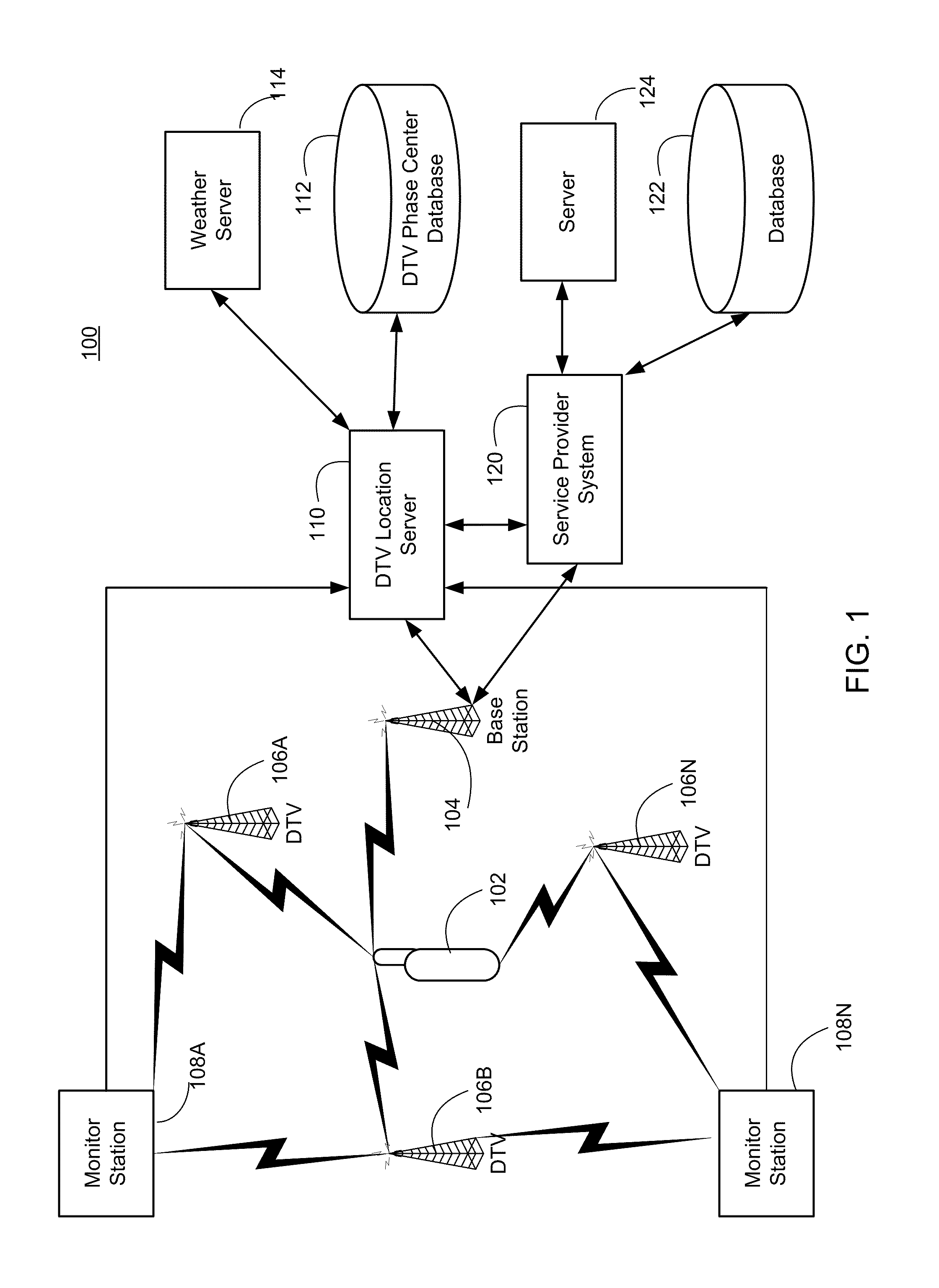

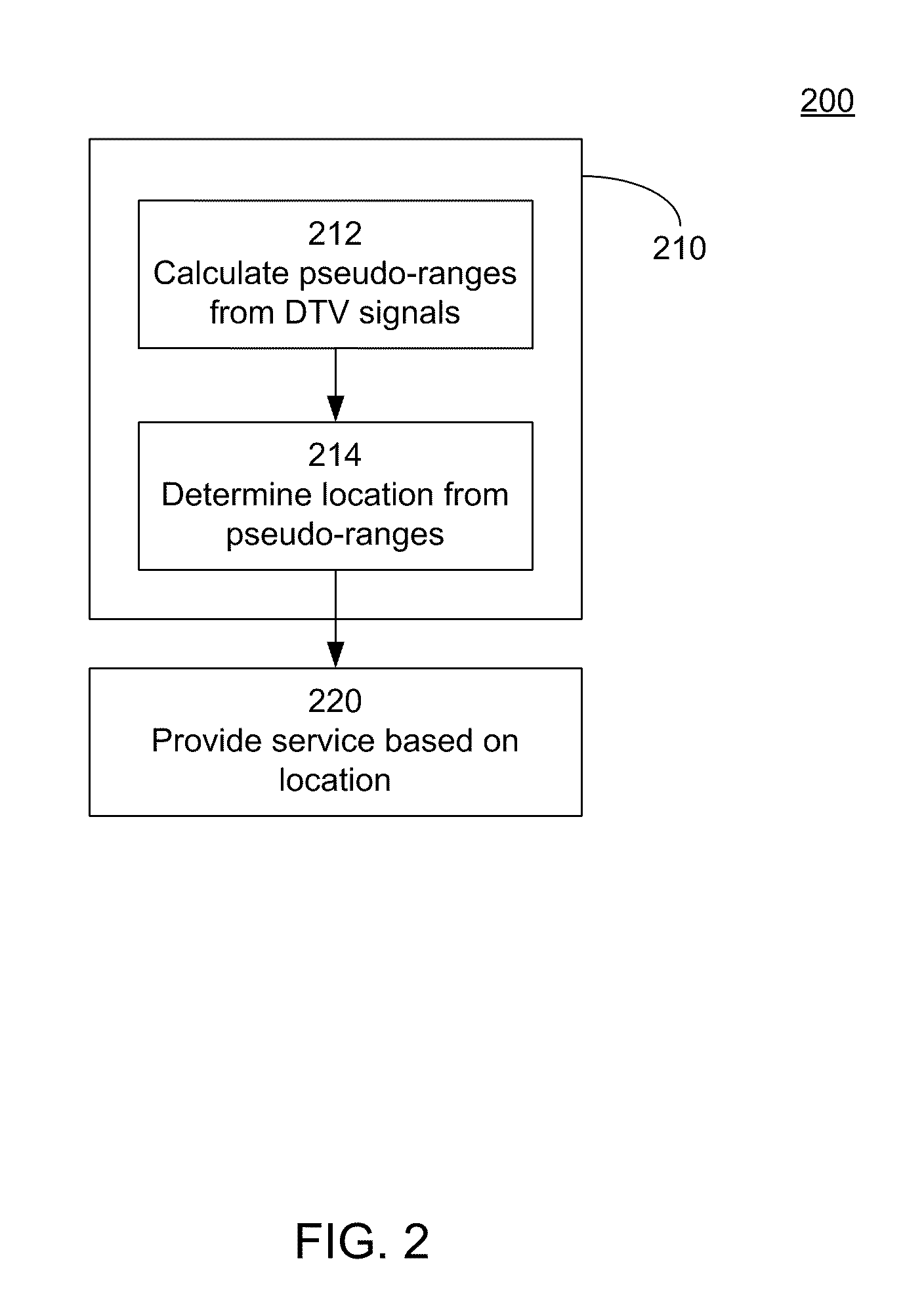

Navigation services based on position location using broadcast digital television signals

InactiveUS8041505B2Simple and inexpensive implementationStrong and large bandwidth signalPulse modulation television signal transmissionIndoor gamesDigital television transitionEngineering

A service depends on the location of a device. The device location is determined using DTV signals. More specifically, the device location is determined based on pseudo-ranges between the device and a plurality of digital television (DTV) transmitters and the pseudo-ranges are determined based on broadcast DTV signals received by the device from the DTV transmitters. Examples of DTV signals include the American Television Standards Committee (ATSC) signals, the European Telecommunications Standards Institute Digital Video Broadcasting-Terrestrial (DVB-T) signals and the Japanese Integrated Service Digital Broadcasting-Terrestrial (ISDB-T) signals.

Owner:TRUE POSITION INC

Touch sensitive devices with composite electrodes

ActiveUS8279187B2Great mutual capacitance changeLess susceptibilityTransmission systemsCathode-ray tube indicatorsCapacitanceComposite electrode

Owner:3M INNOVATIVE PROPERTIES CO

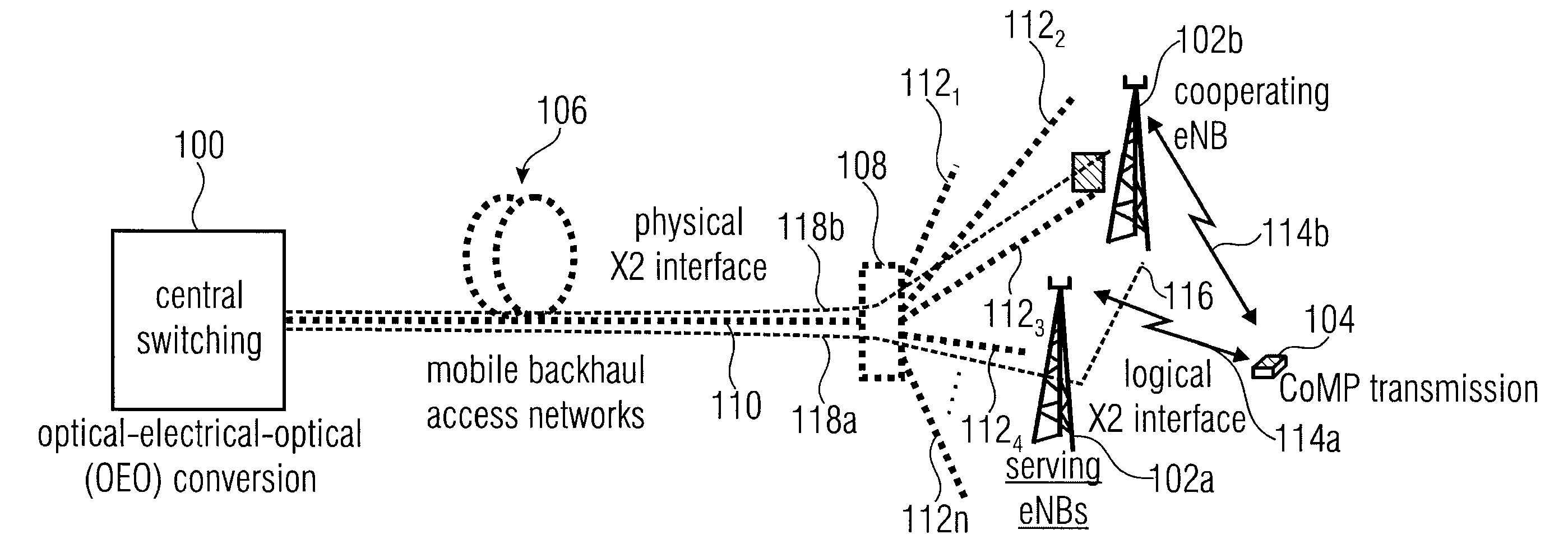

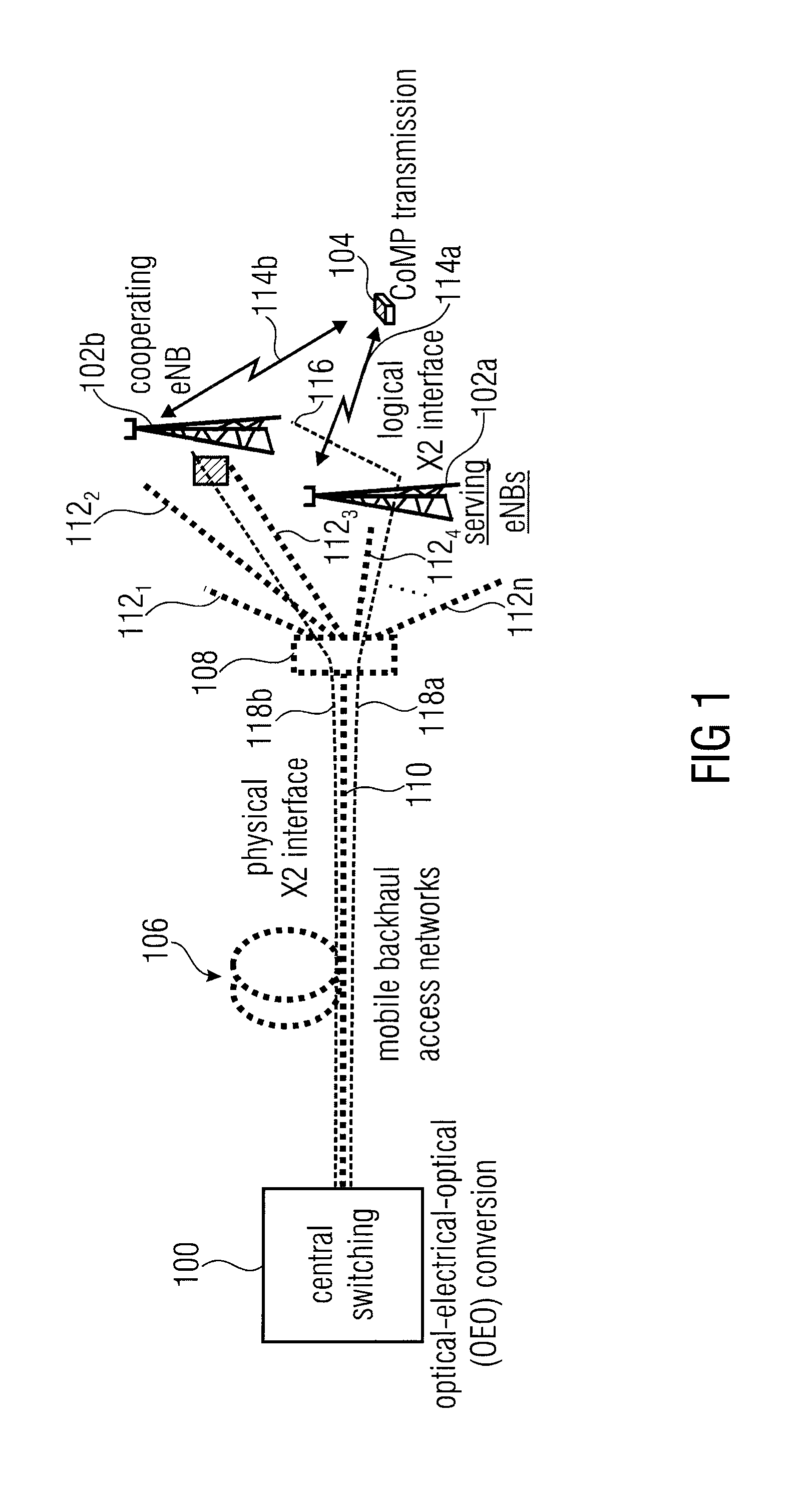

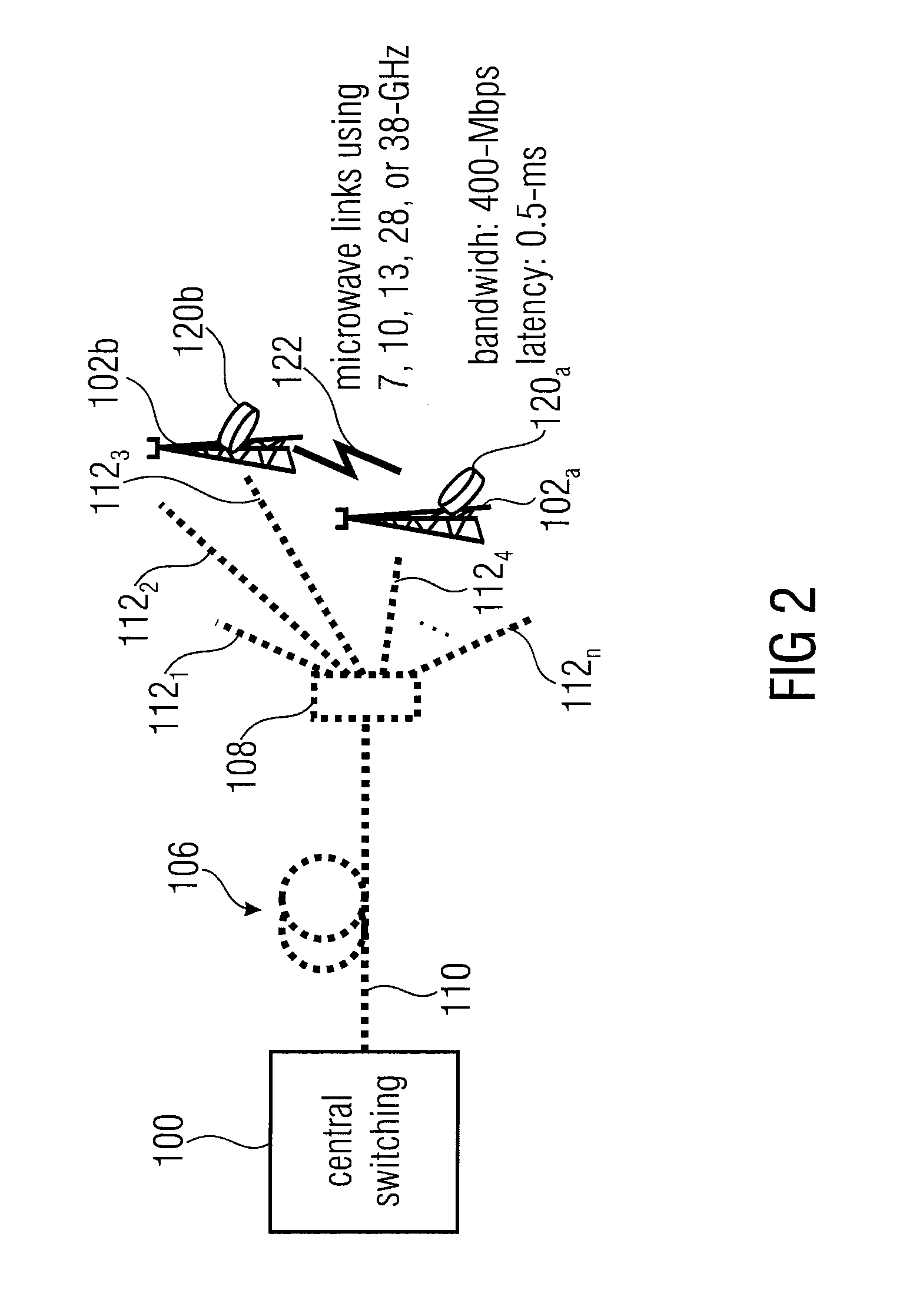

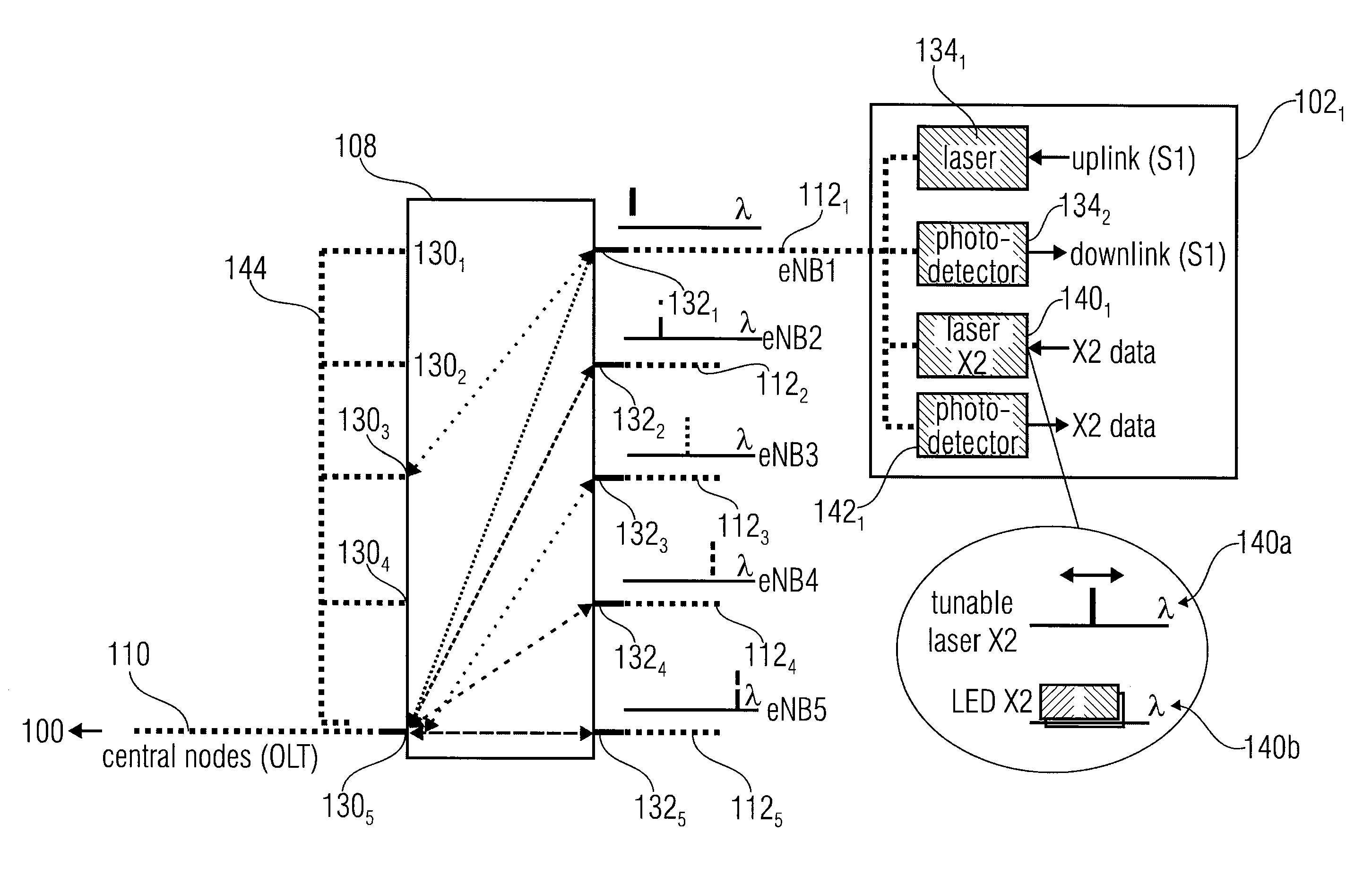

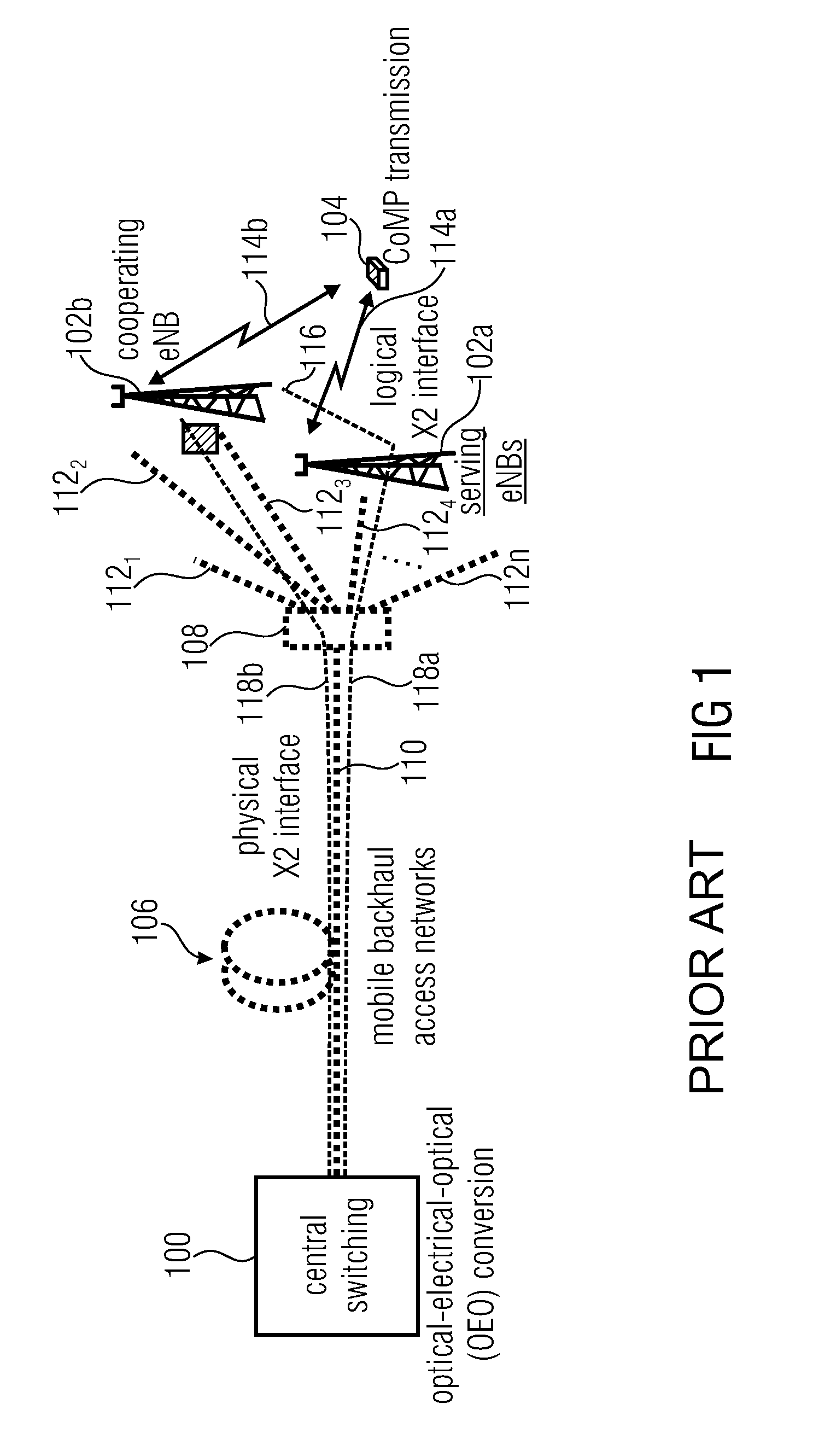

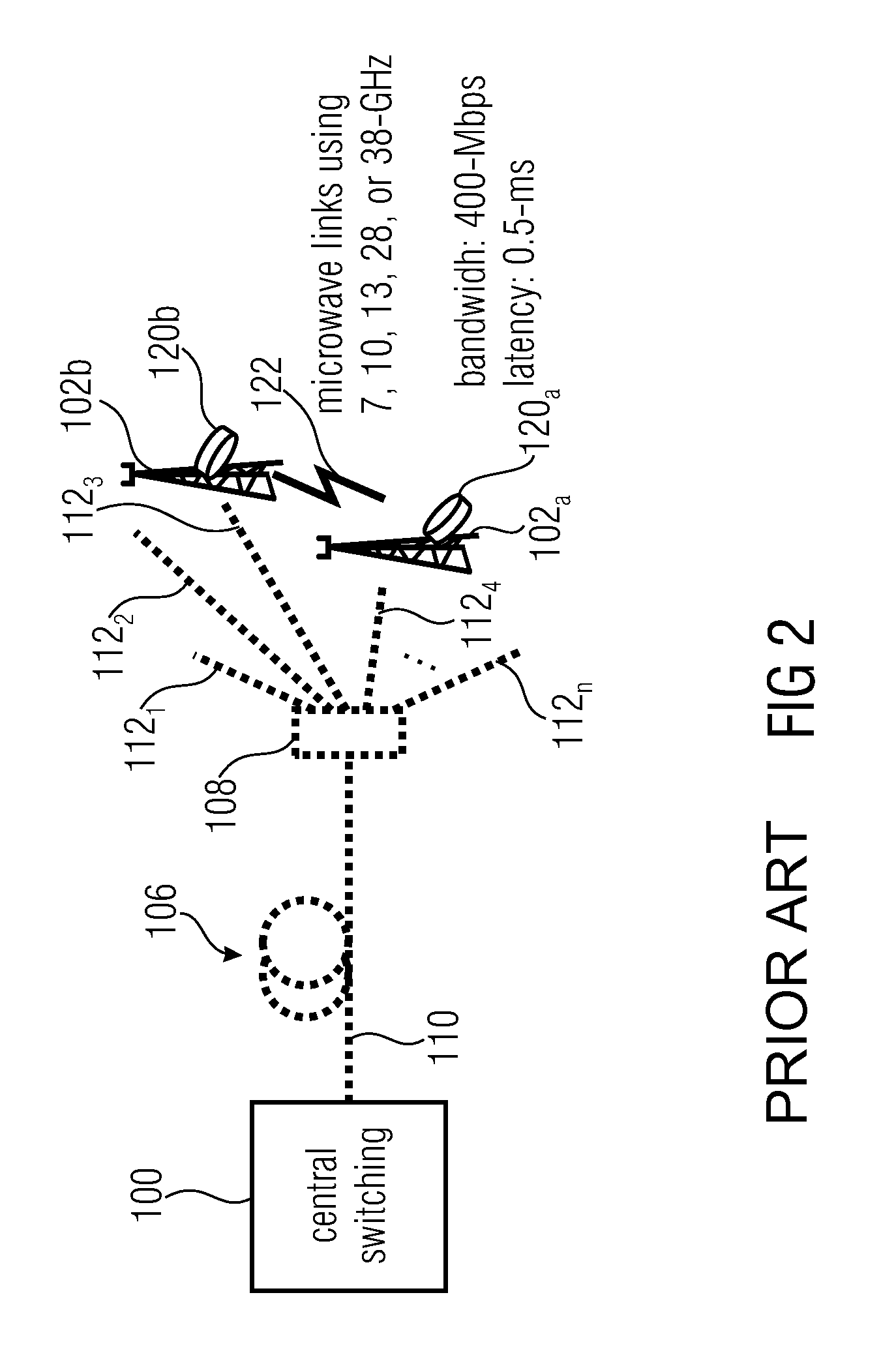

Communication system and method for directly transmitting signals between nodes of a communication system

InactiveUS20120177373A1Improve user throughputLarge capacityWavelength-division multiplex systemsMultimode transmissionCommunications systemMultiplexer

A communication system has a plurality of nodes adapted to provide for a communication with one or more devices, a central node, a passive optical network having a multiplexer / demultiplexer device adapted to demultiplex a first optical signal from the central node to the plurality of nodes, and to multiplex second optical signals from one or more of the nodes, each node having allocated a wavelength for generating its optical signal, wherein for directly transmitting signals from one node to at least one of the other nodes, the one node is adapted to generate an optical signal at the wavelength allocated to the at least one of the other nodes, the optical signal including the signal to be transmitted, and wherein the multiplexer / demultiplexer device of the passive optical network is adapted to combine the optical signal from the one node with the first optical signal.

Owner:NTT DOCOMO INC

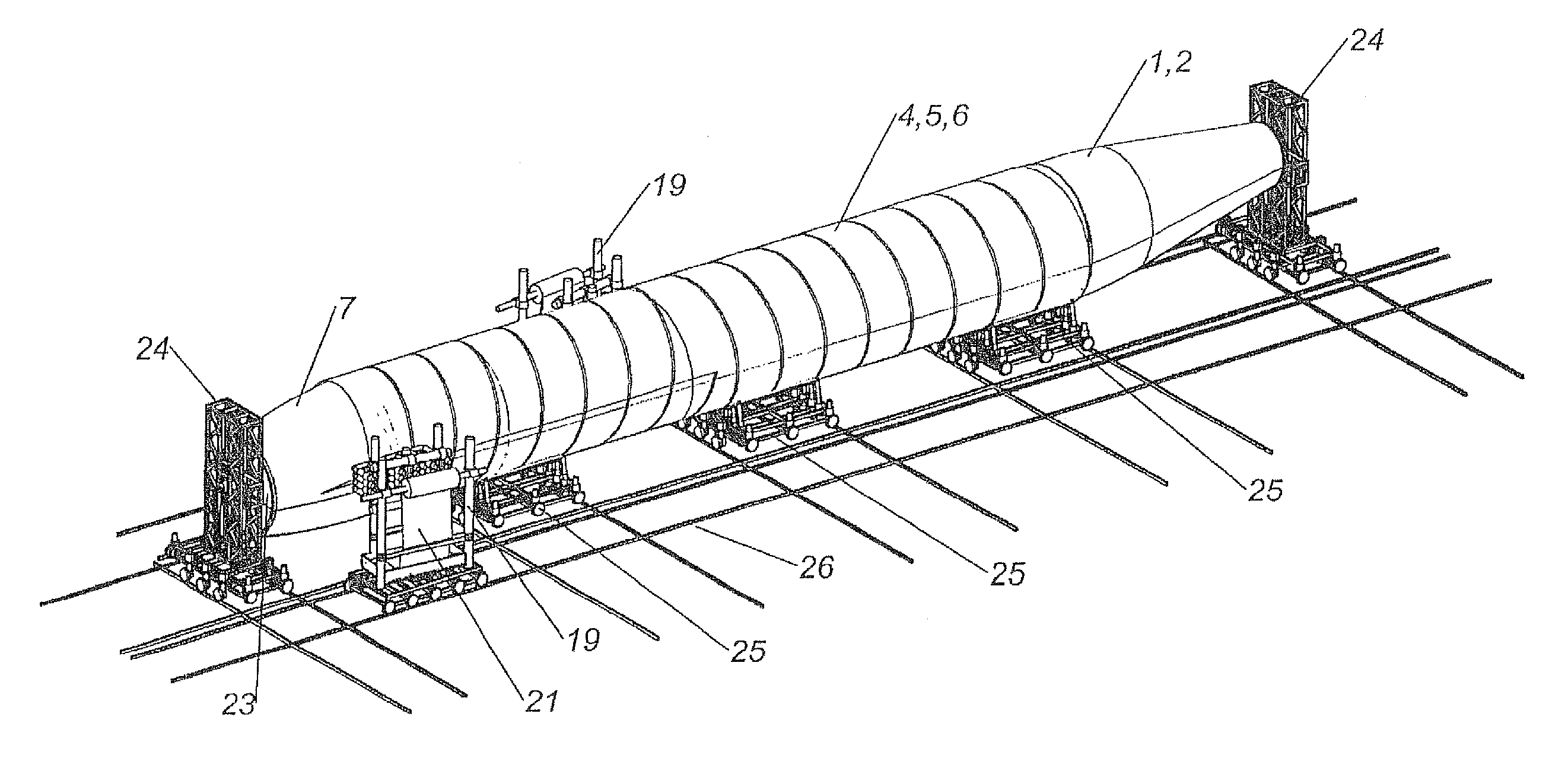

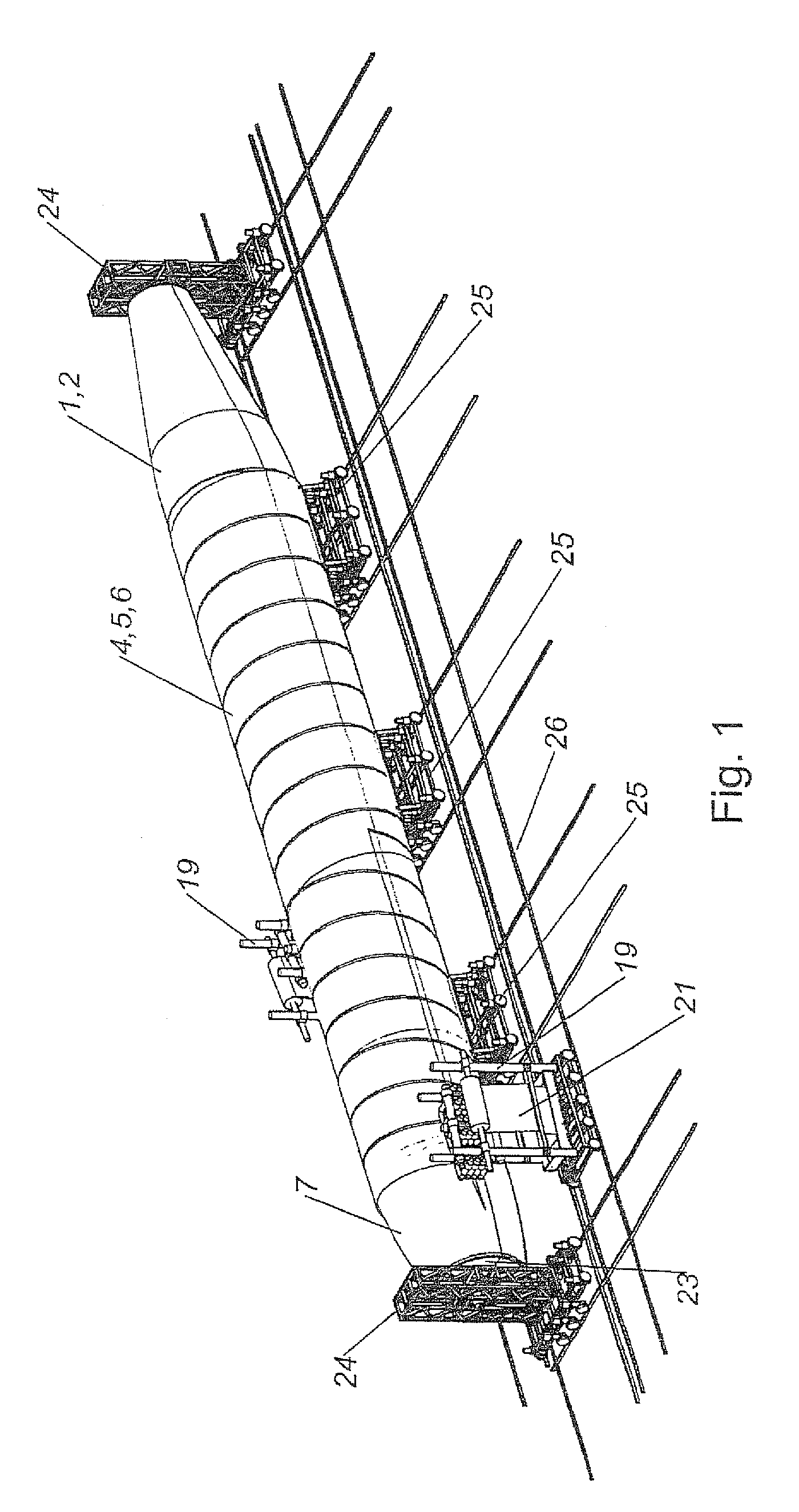

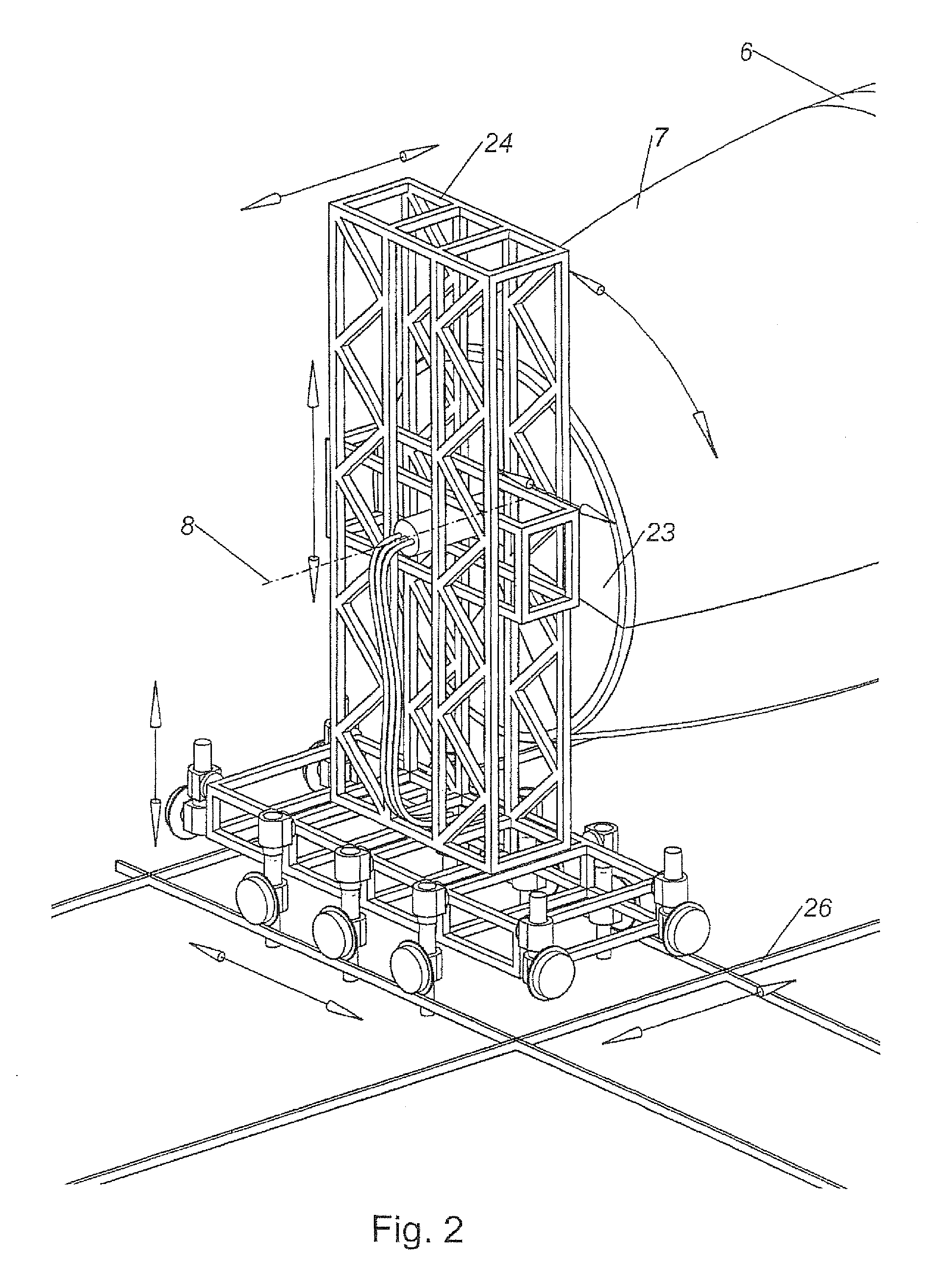

Method for producing a hollow body

InactiveUS20110052845A1Reduce weightHigh mechanical load capacityEnvelopes/bags making machineryLiquid surface applicatorsFiberCarrying capacity

In a method for producing a hollow body—implemented as a sandwich construction—in particular an aircraft fuselage, an inner layer is formed from a specifiable number of plies of a specifiable at least resin-wetted fiber material, for simple, rapid, and cost-effective formation of a large-volume cavity, which has a low weight and a high mechanical carrying capacity in relation to its size. At least a first ply of the inner layer has a helical configuration and is configured without interruption essentially over an entire length of the hollow body.

Owner:DERMOND FORSTNER & SREBOTH OG

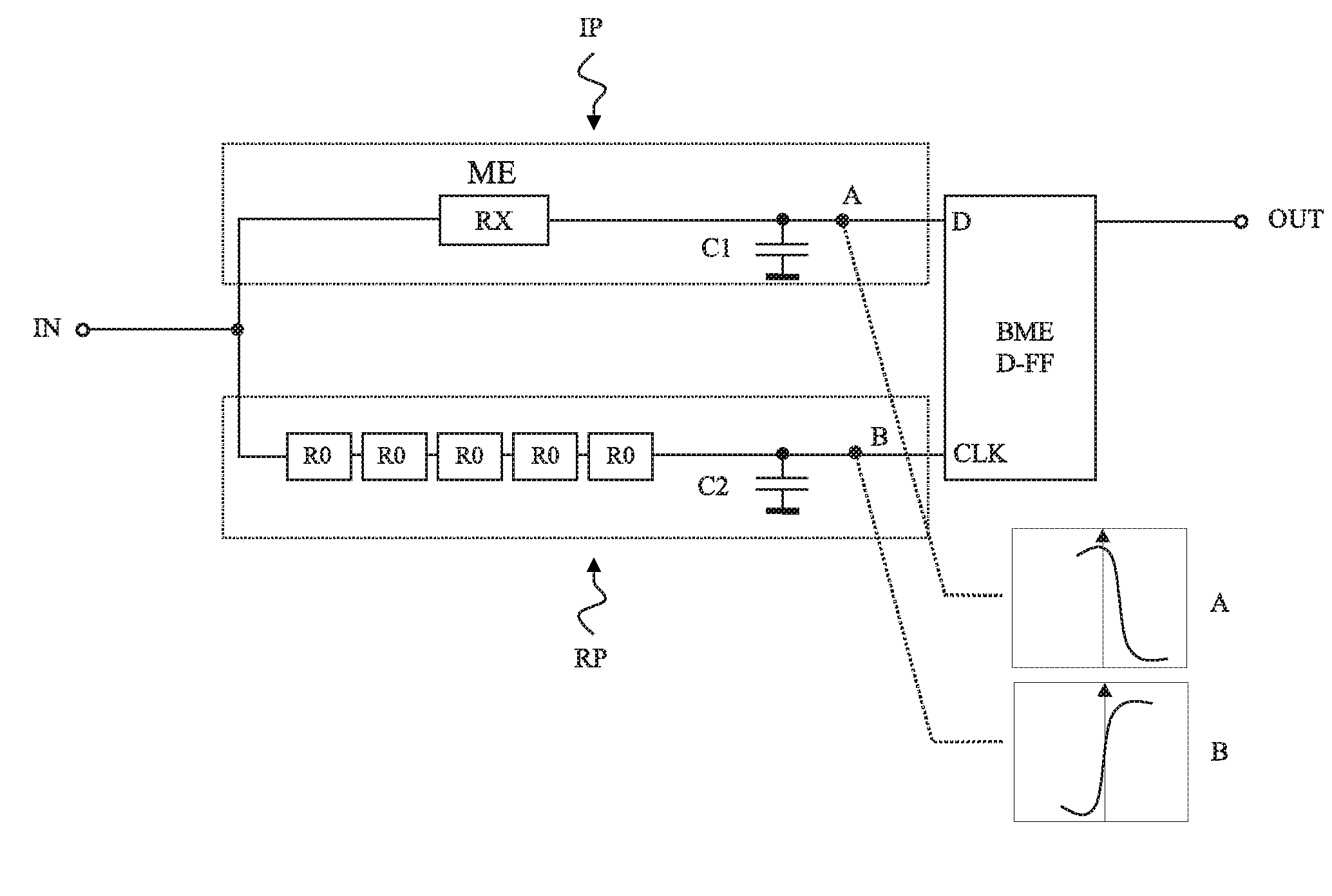

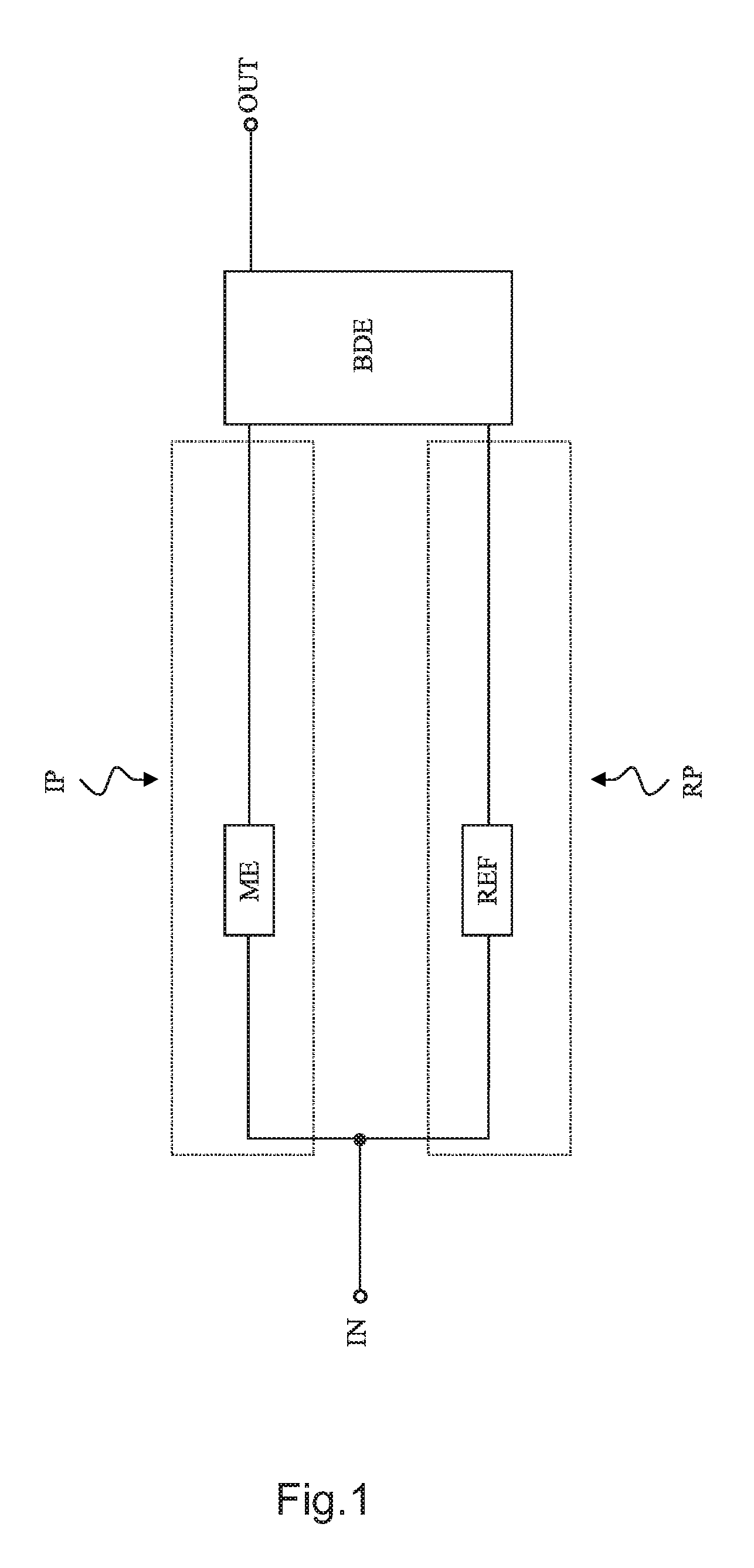

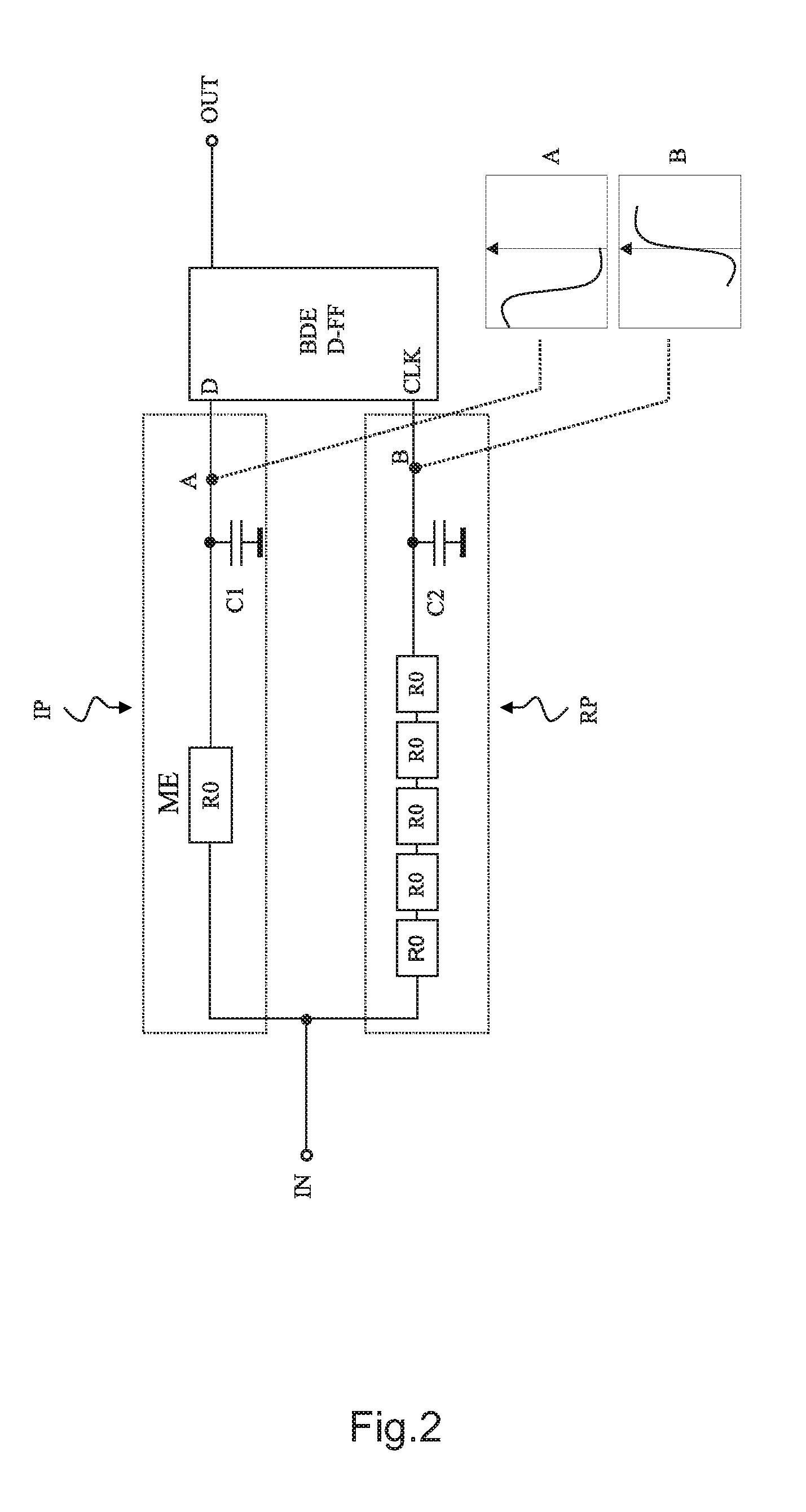

Read enhancement for memory

ActiveUS20100020624A1Reduce power consumptionImprove reliabilityDigital storageSpecial data processing applicationsComputer scienceDigital signal

An electronic circuitry is provided for reading out a memory element (ME). The electronic circuitry comprises a first electronic path (IP) being coupled to the memory element (ME), a second electronic path (RP) having predetermined electrical properties, and a basic detection element (BDE) being coupled to the first and second electronic paths (IP, RP) such that the information contained in the memory element (ME) can be determined by the basic detection element (BDE) based on the relation of a digital signal being propagated over the first path (IP) to a digital signal being propagated over the second path (RP).

Owner:NXP BV

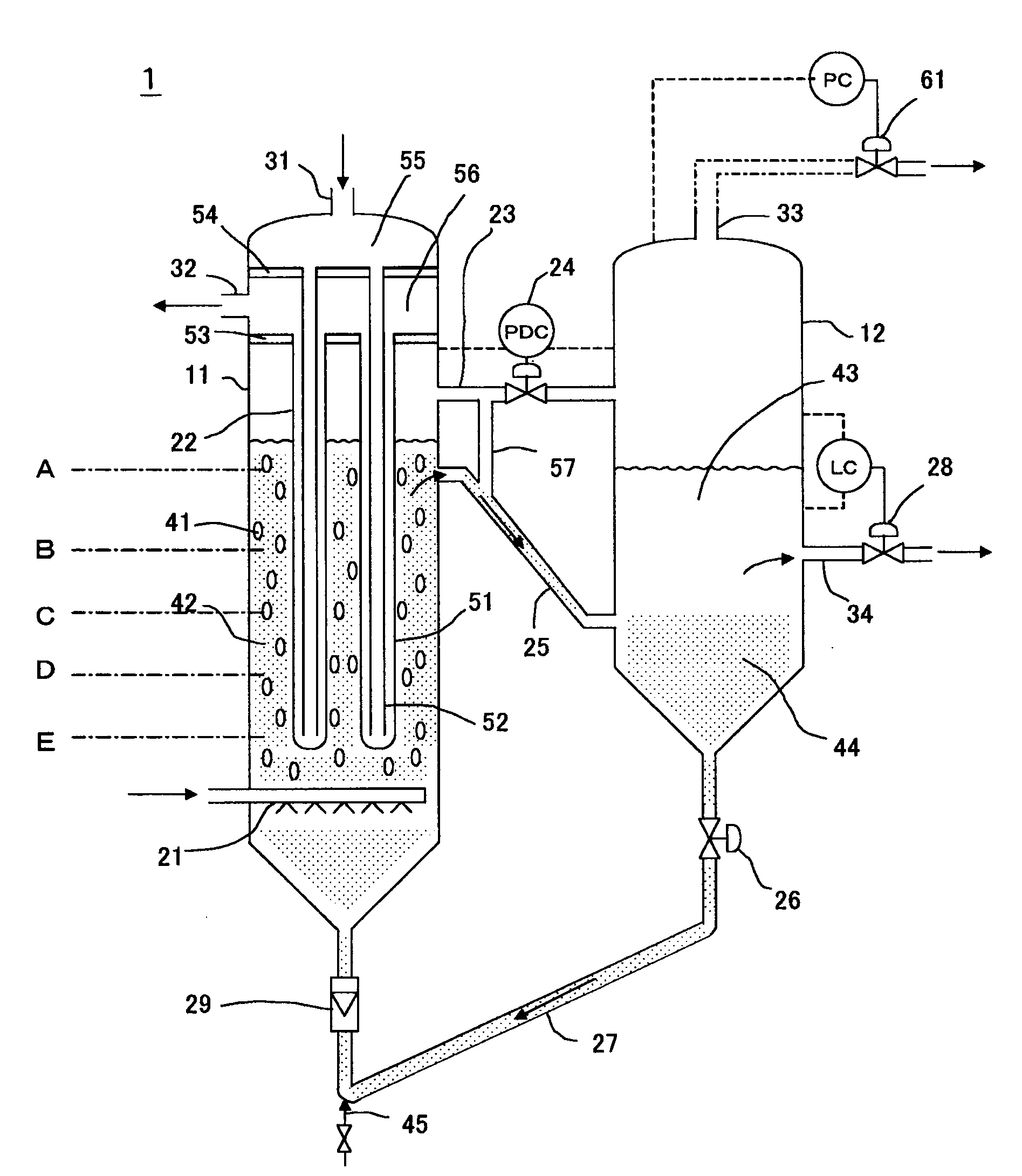

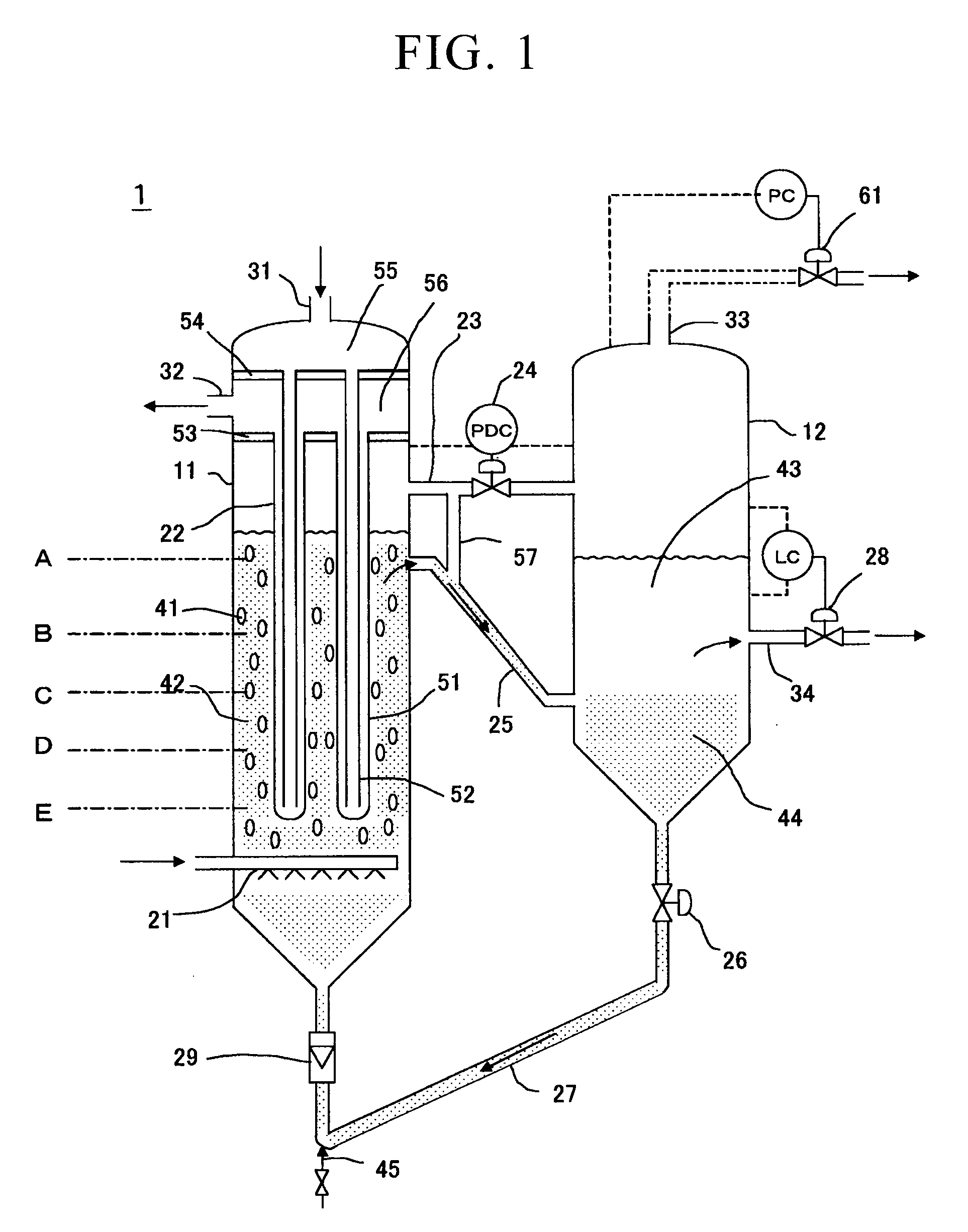

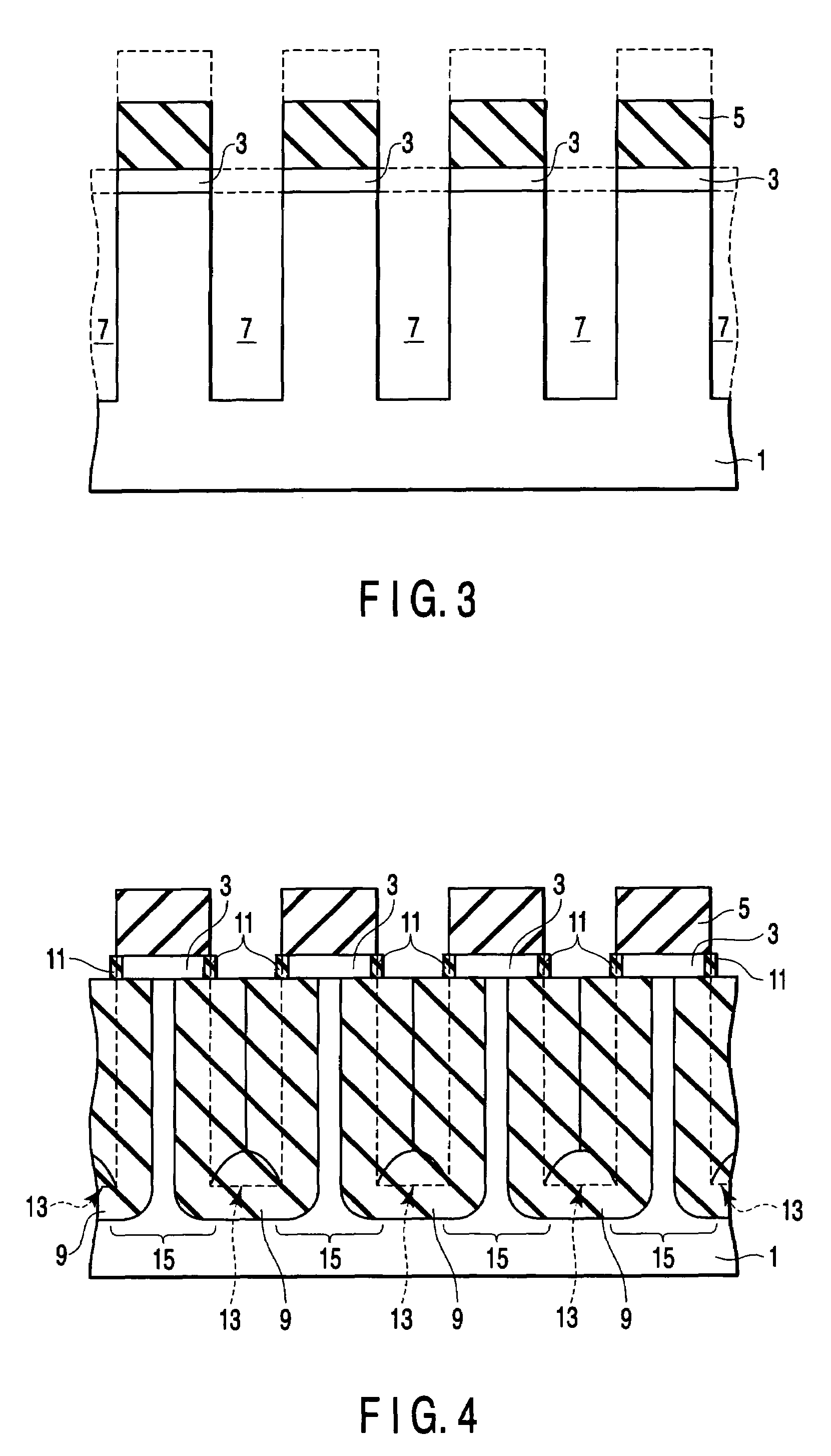

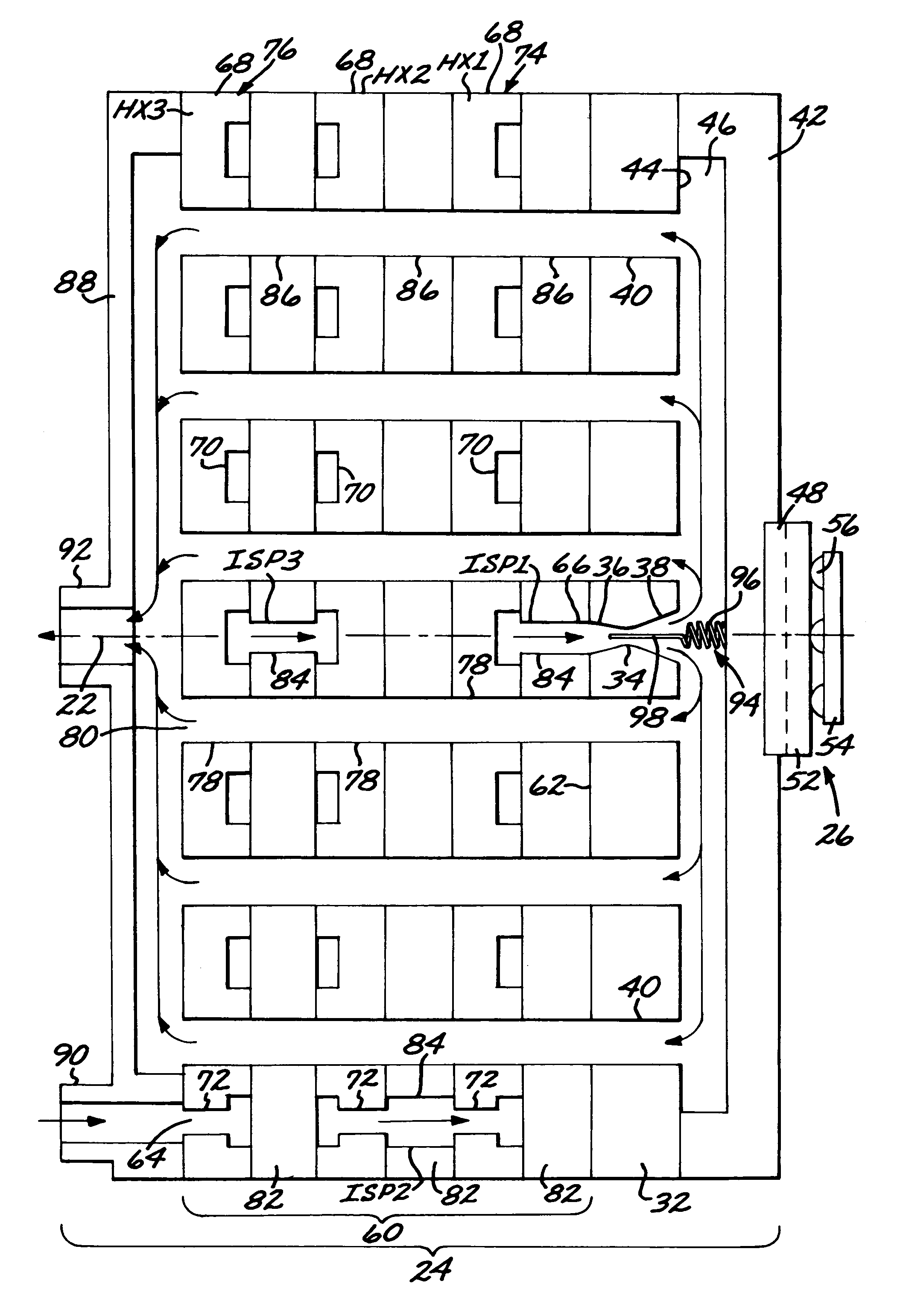

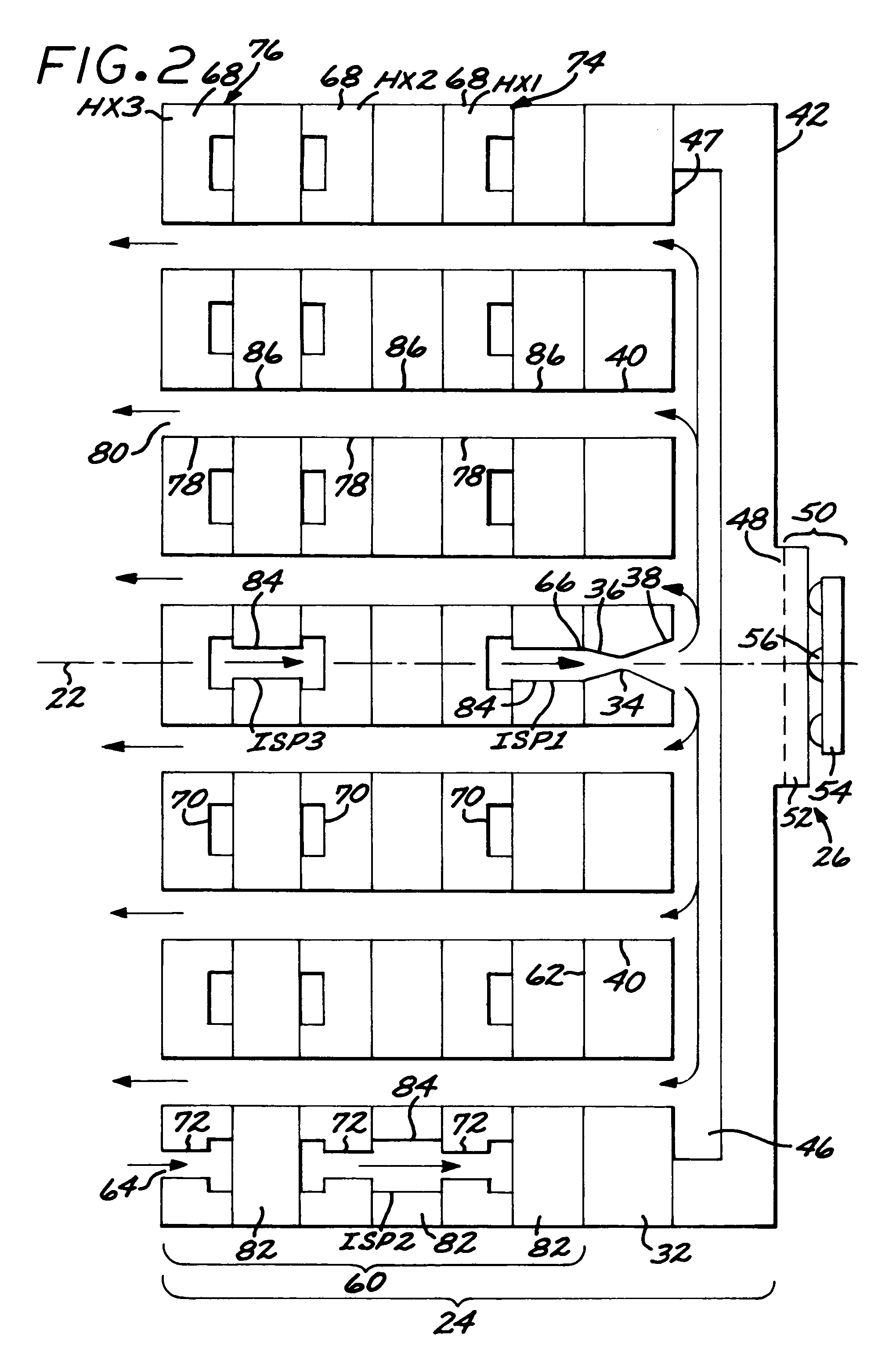

Bubble column-type fischer-tropsch synthesis slurry bed reaction system

InactiveUS20090220389A1Easy to monitorEasy to exportLiquid hydrocarbon mixture productionTreatment with hydrotreatment processesLiquid productSyngas

A bubble column-type slurry bed reaction system is provided in which an operating system, which synthesizes liquid hydrocarbons by the Fischer-Tropsch (FT) synthesis reaction and separates and derives a catalyst and liquid hydrocarbon products from a slurry composed of gas, liquid and solid phases, can be simplified, and deterioration of catalyst particles caused by attrition and so forth can be reduced. In this FT synthesis reaction system, a bubble column-type slurry bed Fischer-Tropsch synthesis reaction process, in which synthesis gas supplied continuously from the bottom of a reactor and suspended catalyst particles are contacted to form liquid hydrocarbons, gaseous hydrocarbons and water, a process in which a slurry of suspended liquid products formed in the Fischer-Tropsch synthesis reaction process and catalyst particles moves from the reactor to the lower portion of a separation vessel through a downwardly inclined transfer pipe to separate the catalyst particles and gaseous products, a process in which the liquid products formed in the Fischer-Tropsch synthesis reaction process is sent to the separation vessel through a horizontal connecting pipe installed above the downwardly inclined transfer pipe and derived from its apex, a process in which liquid products are derived from the separation vessel, and a process in which aslurry in which catalyst particles are concentrated is derived from the bottom of the separation vessel and circulated to the bottom of the reactor, are driven by the driving force of synthesis gas introduced from the bottom of the reactor and which rises through the slurry bed reactor without using an external drive power source for circulation, and the formed liquid hydrocarbon products, gaseous hydrocarbon products and water are separated and derived without using an external drive power source for separation.

Owner:INPEX CORP +4

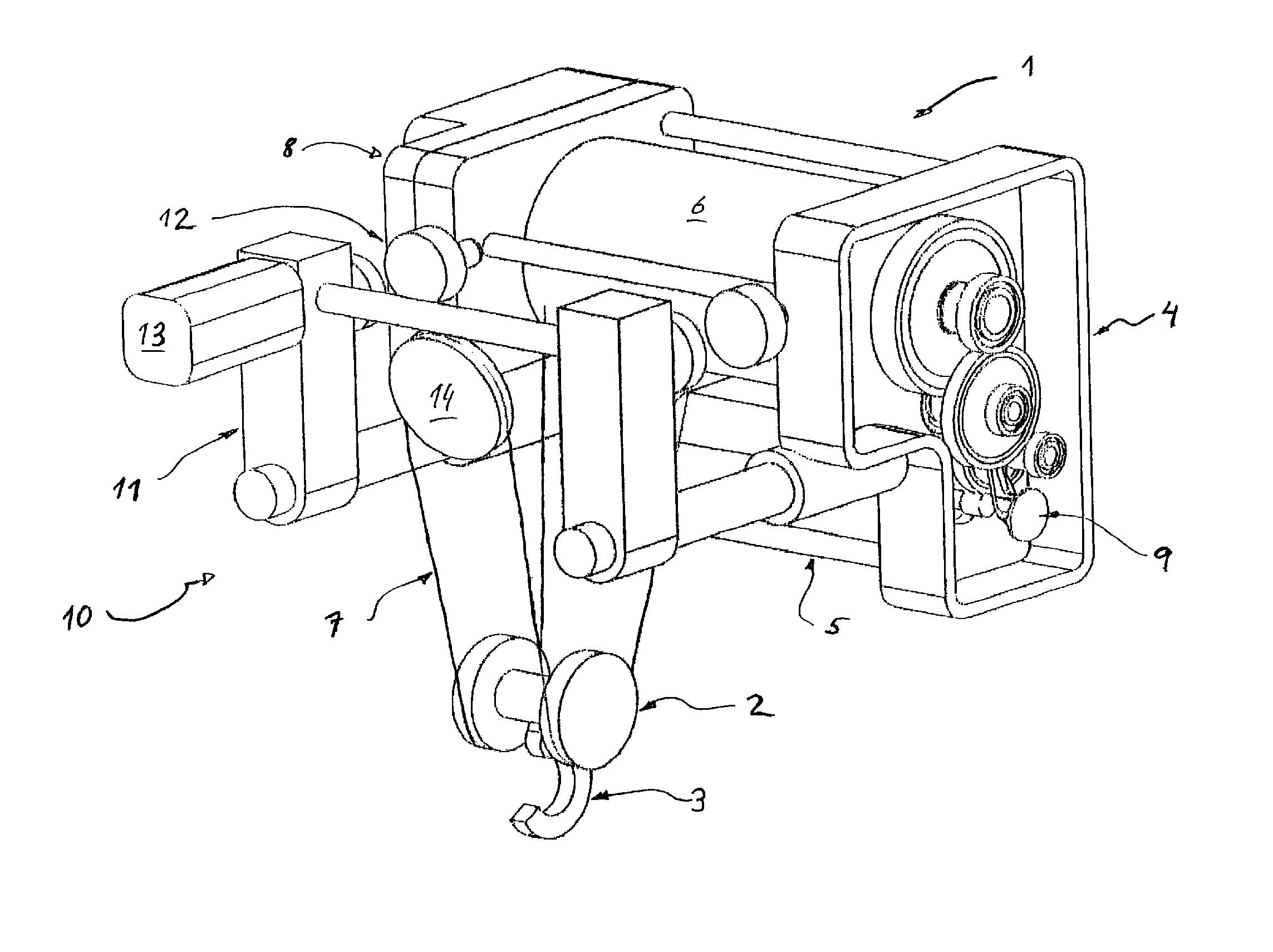

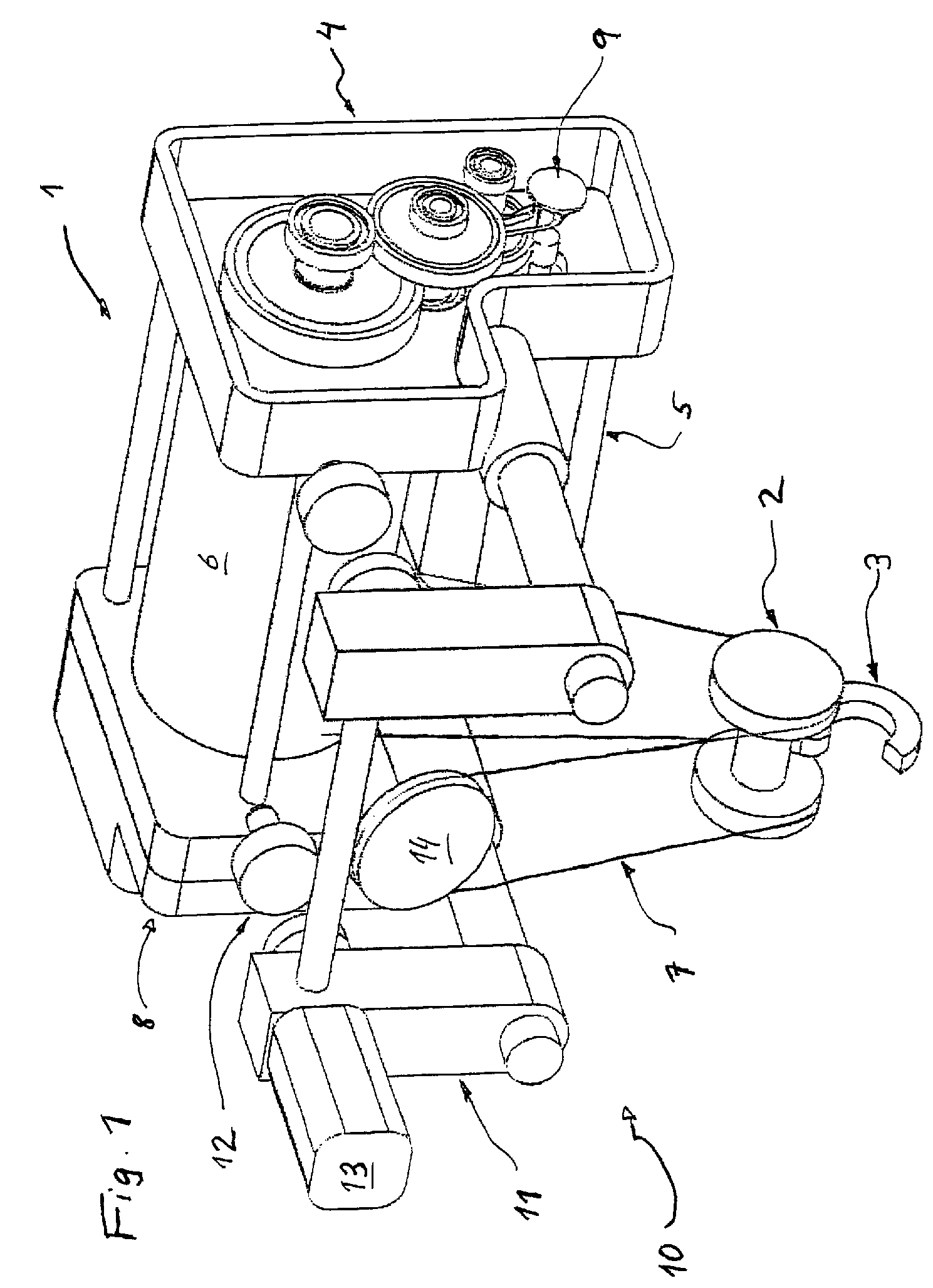

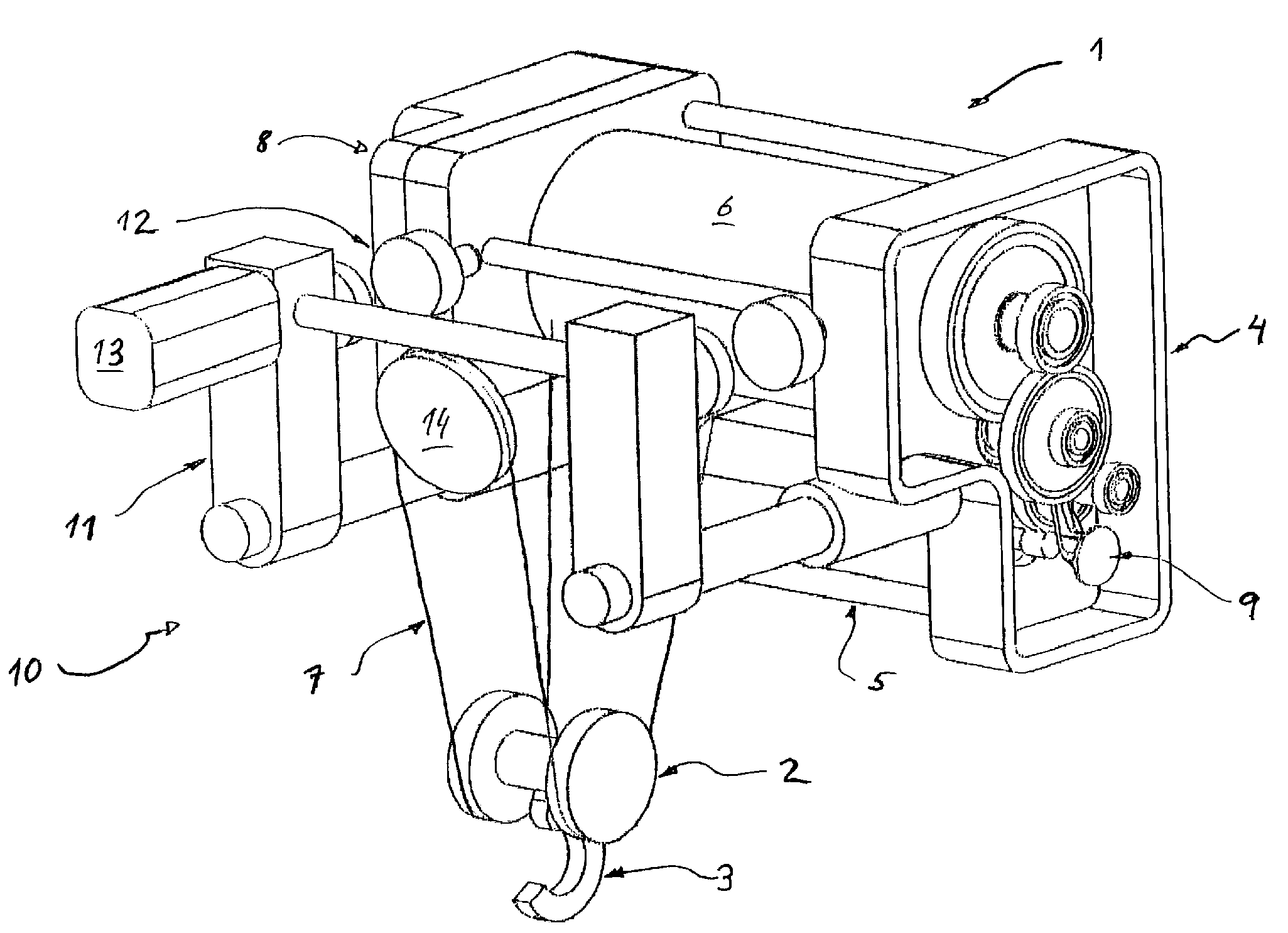

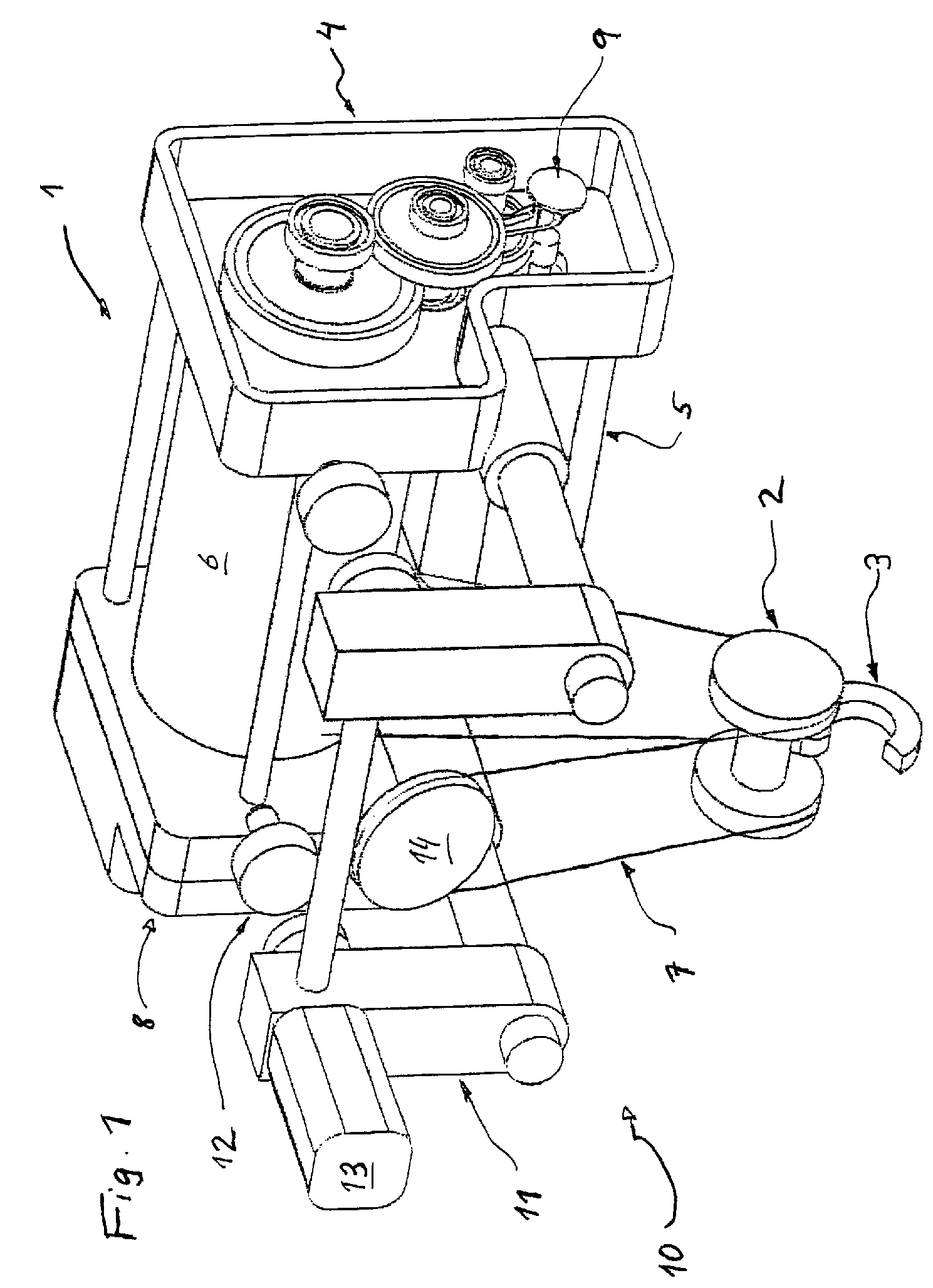

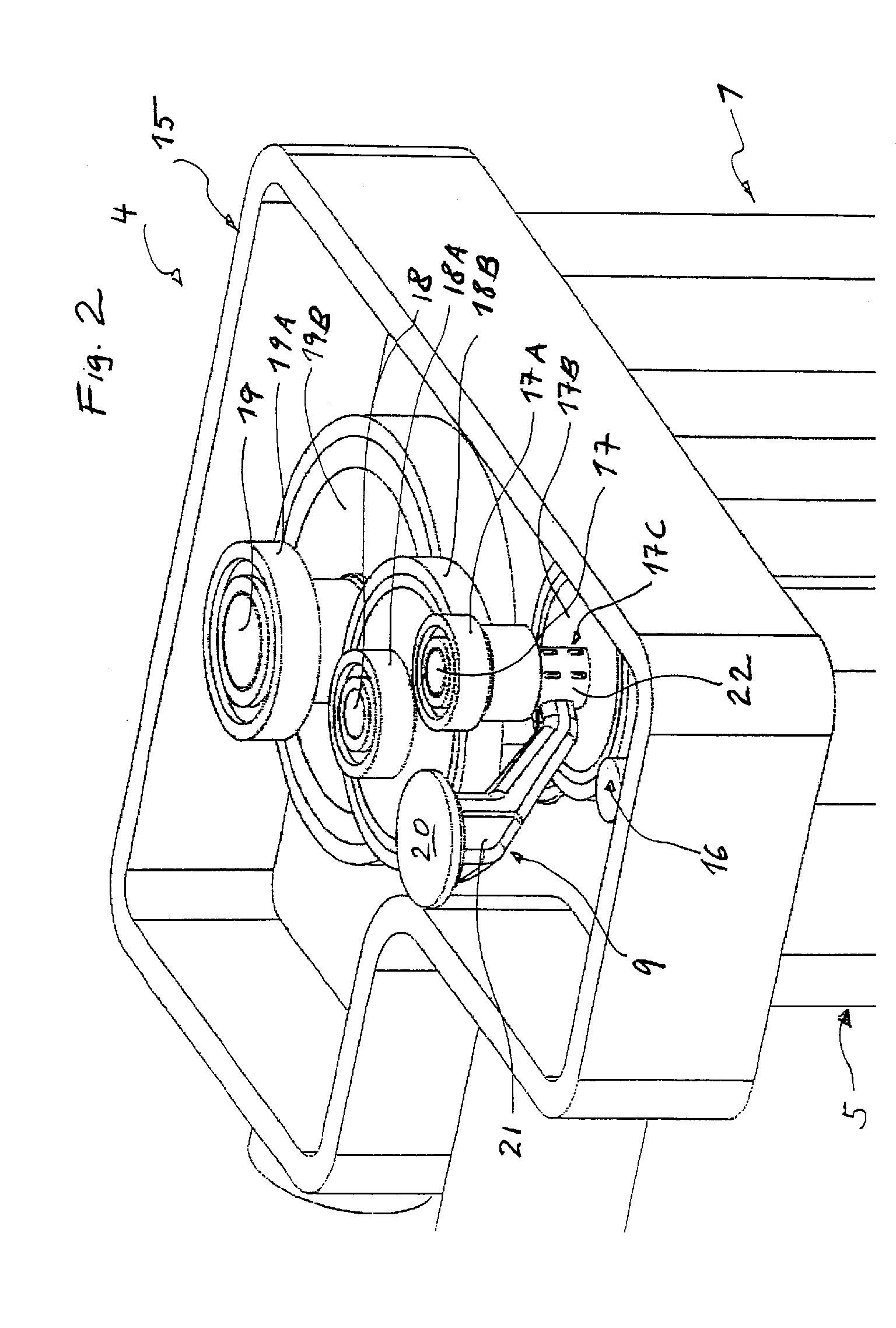

Hoisting device with load measuring mechanism and method for determining the load of hoisting devices

InactiveUS20050279976A1Accurate measurementThe result is accurate and reliableWork measurementTorque measurementEngineering

Owner:TEREX MHPS

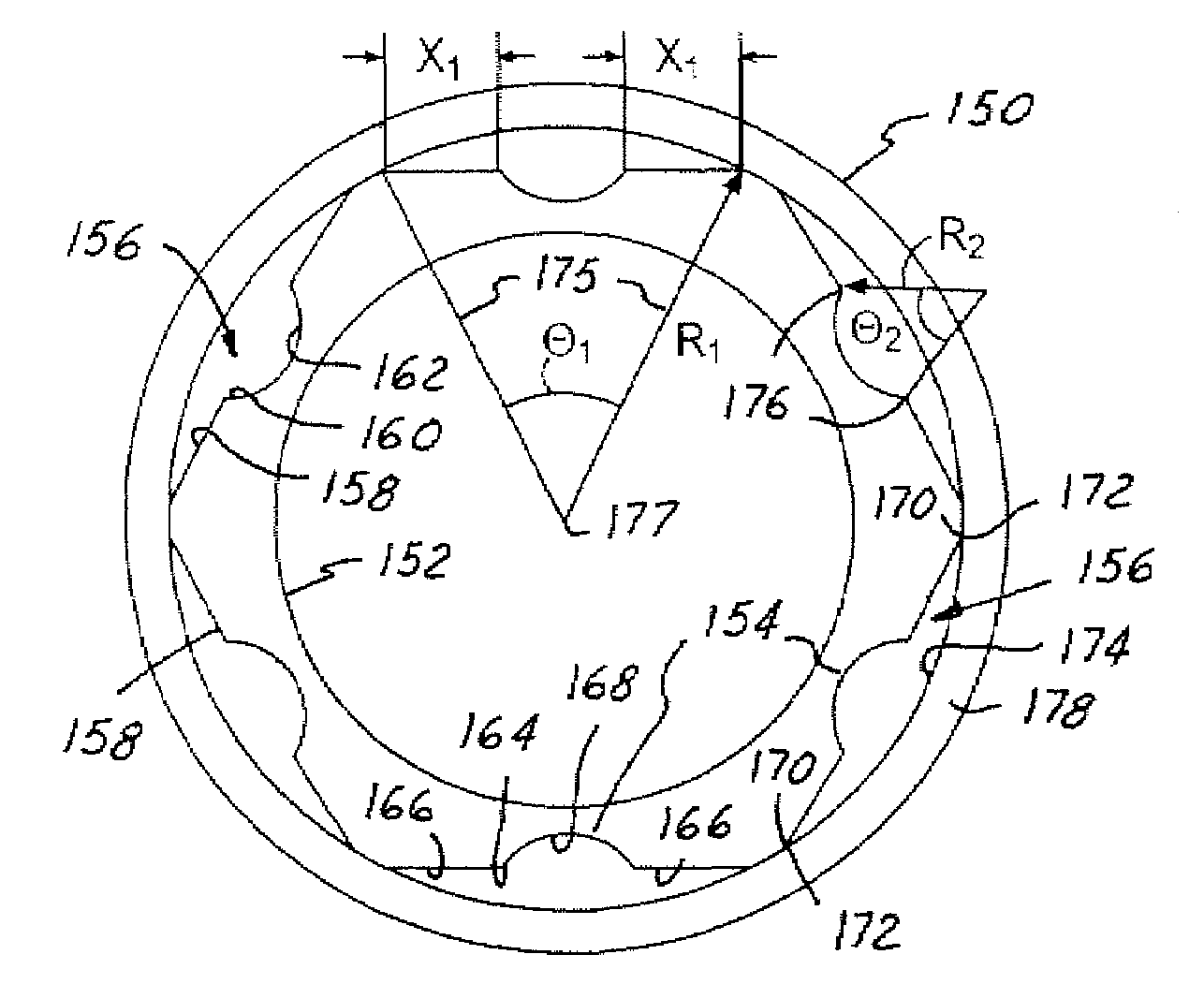

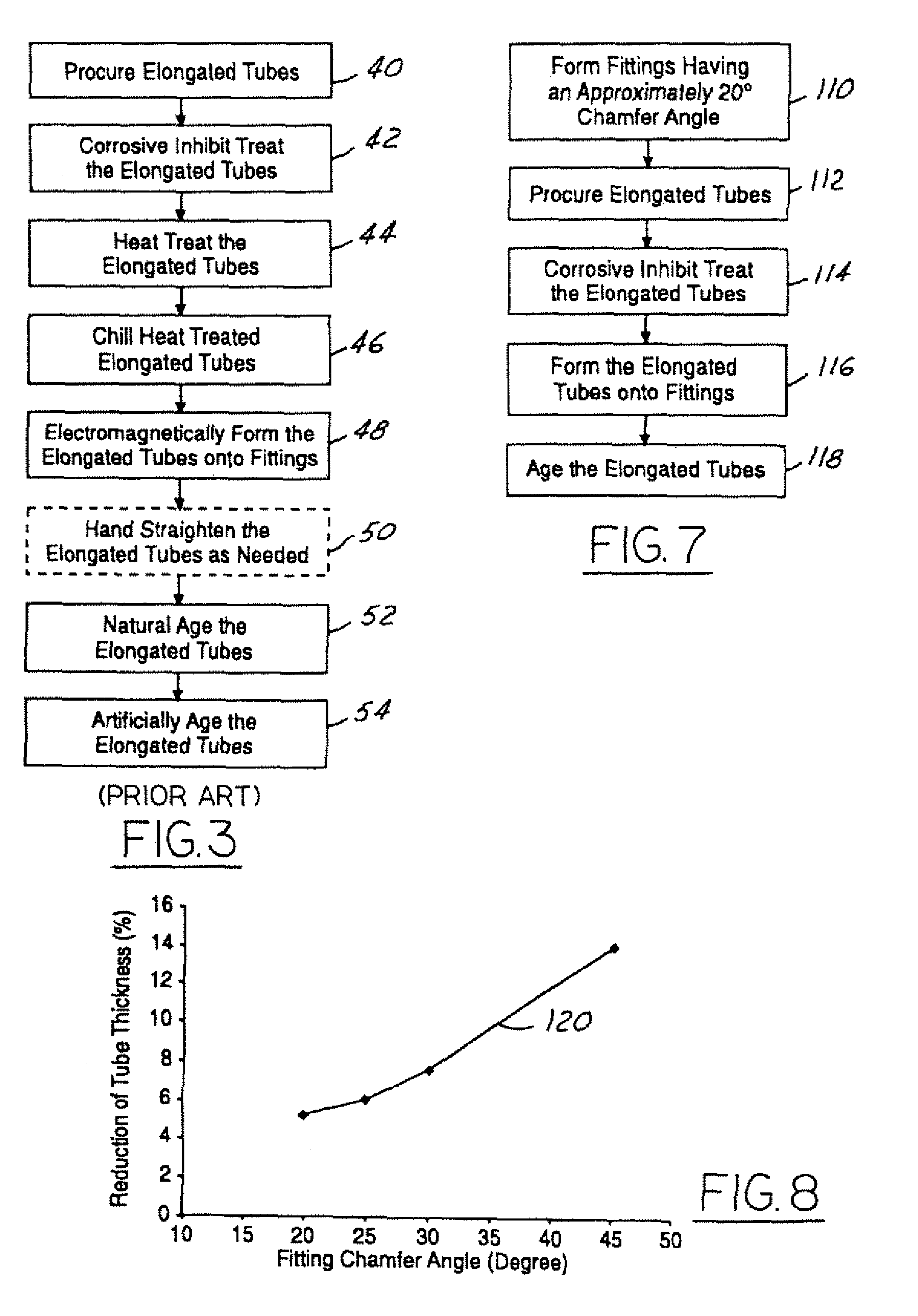

Low chamfer angled torque tube end fitting with elongated overflow groove

InactiveUS7363945B2Improve fatigue lifeIncrease load strengthGearboxesJoints with sealing surfacesCouplingTorque tube

A method of forming a torque-transmitting coupling (193) includes forming at least one fitting (192) having a tube conforming area (200). The forming area (200) includes a material overflow groove (194) and multiple flat surfaces (202). The forming area (200) has an associated tube arc length that is approximately equal in length to a formed area length of the flat surfaces (202) with the elongated overflow groove (194). An elongated tube (190) is procured. The elongated tube (190) is formed onto the tube conforming area (200) to form the torque-transmitting coupling (193).

Owner:THE BOEING CO

Hoisting device with load measuring mechanism and method for determining the load of hoisting devices

Owner:TEREX MHPS

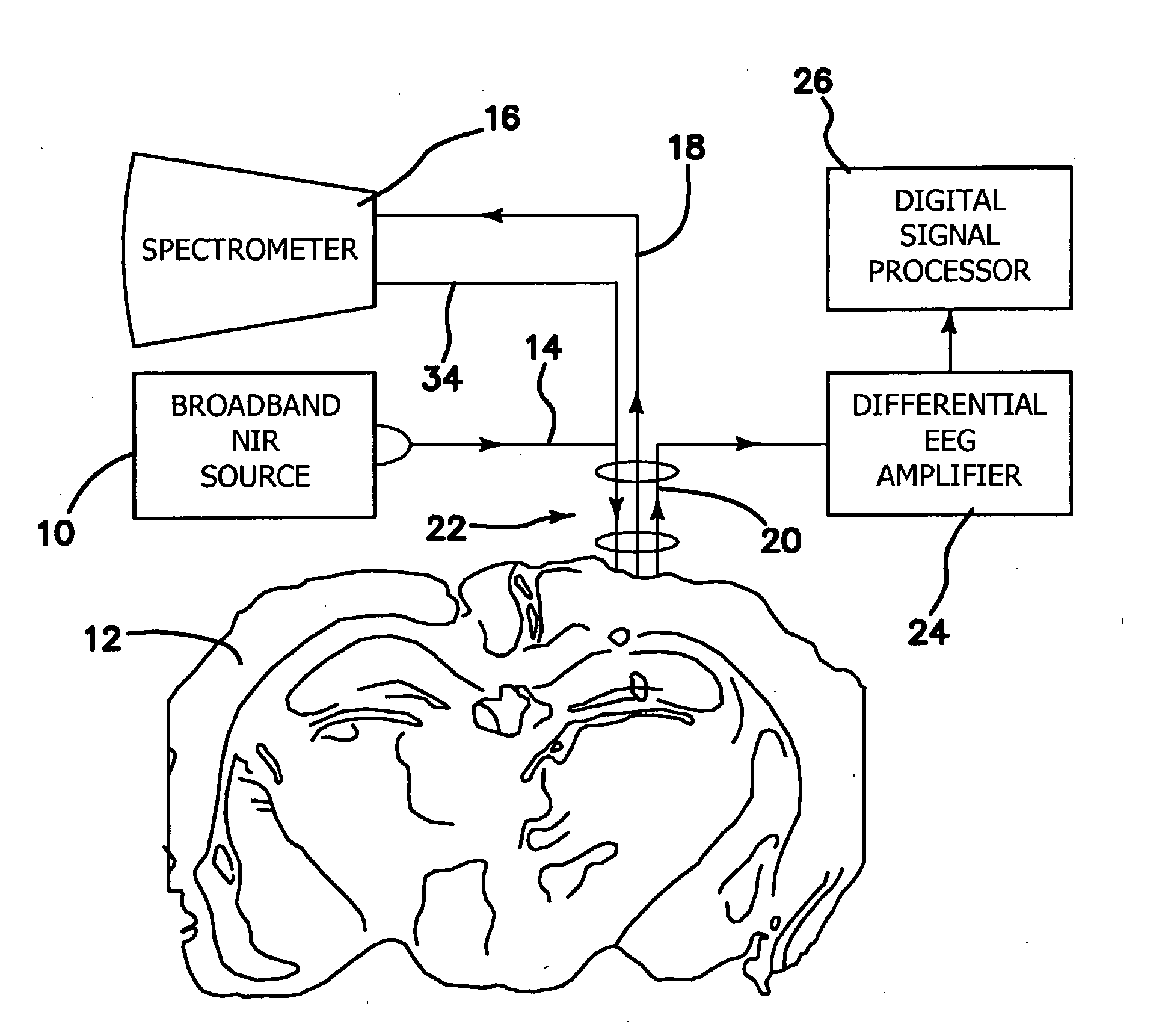

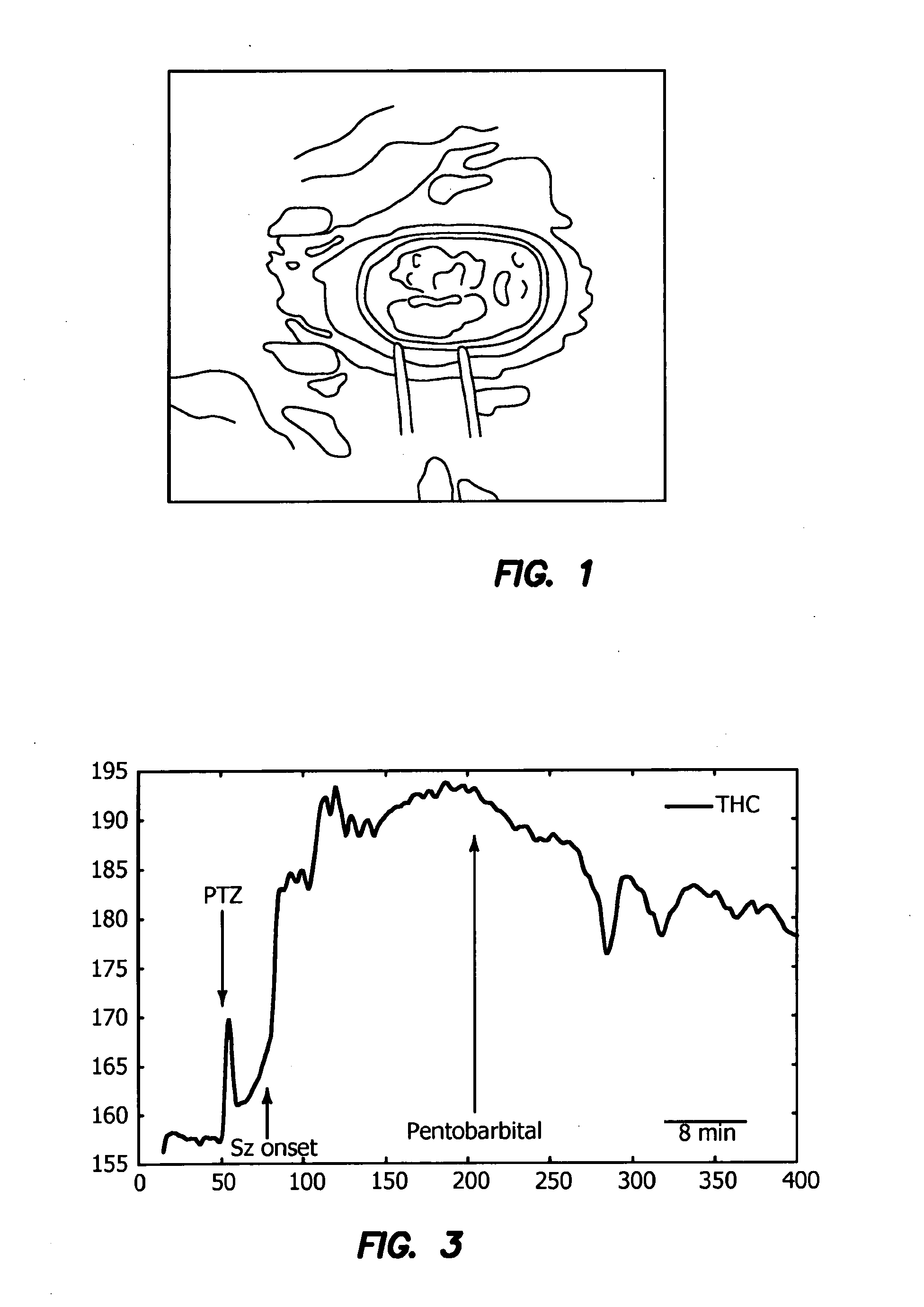

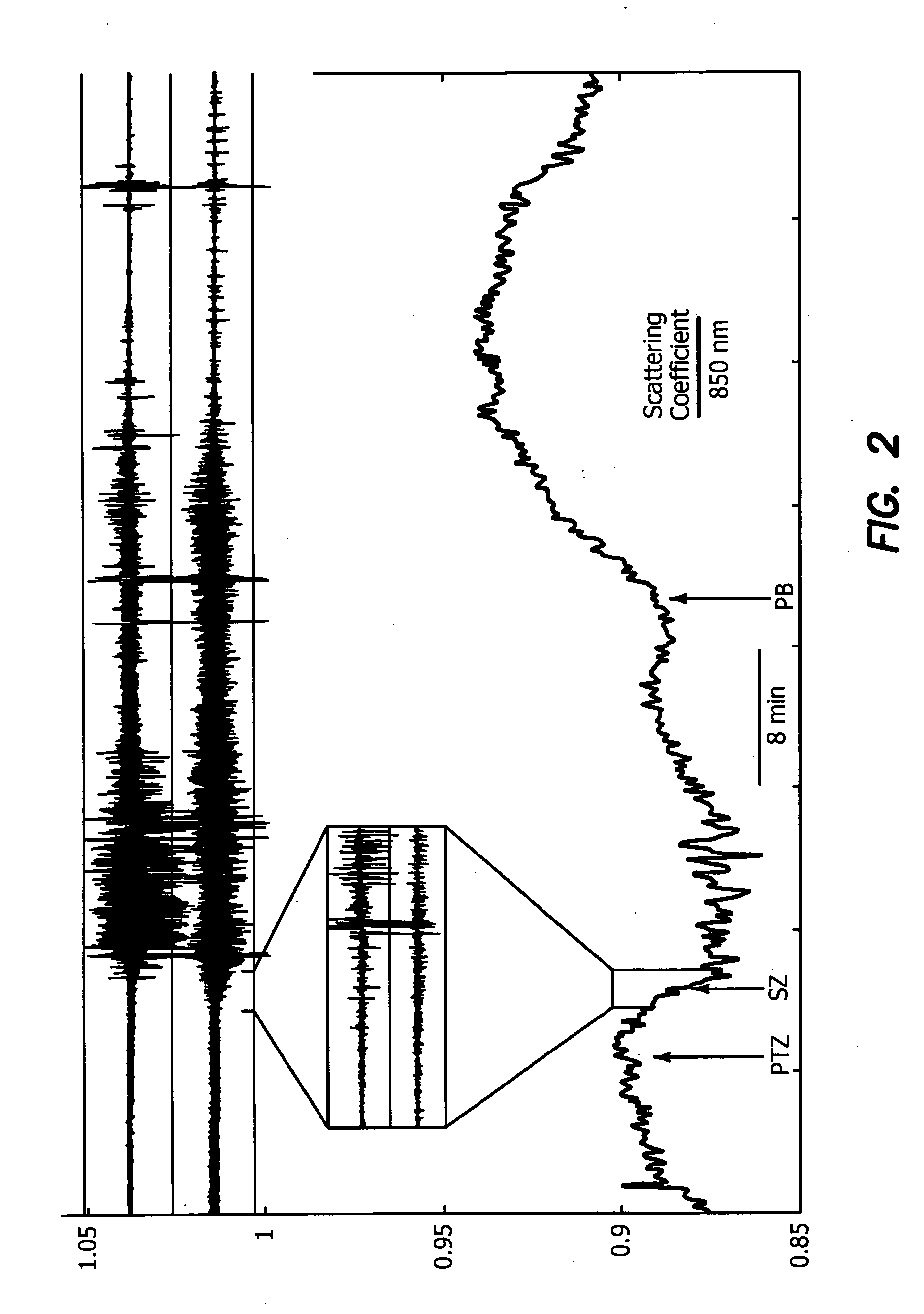

Optical detection of seizure, a pre-seizure state, and cerebral edema and optical fiber detection of the same

InactiveUS20090312646A1Degree of reductionReliable detectionDiagnostics using lightSensorsCerebral edemaSignal processing

A method for using optical parameters to monitor for a physiological event and / or a state prior to the physiological event includes the steps of: illuminating neural tissue with diagnostic light of a predetermined frequency at a predetermined location; detecting magnitude of optical scattering by neural tissue of the diagnostic light as a function of time; and determining a signature signal of the optical scattering of the diagnostic light before the physiological event in the neural tissue becomes clinically manifested. An apparatus includes a source of diagnostic light of a predetermined frequency for illuminating neural tissue at a predetermined location, a detector of optical scattering and / or optical absorption by neural tissue of the diagnostic light as a function of time, and a signal processor for determining a signature signal of the optical scattering and / or optical absorption of the diagnostic light before the physiological event becomes clinically manifested.

Owner:RGT UNIV OF CALIFORNIA

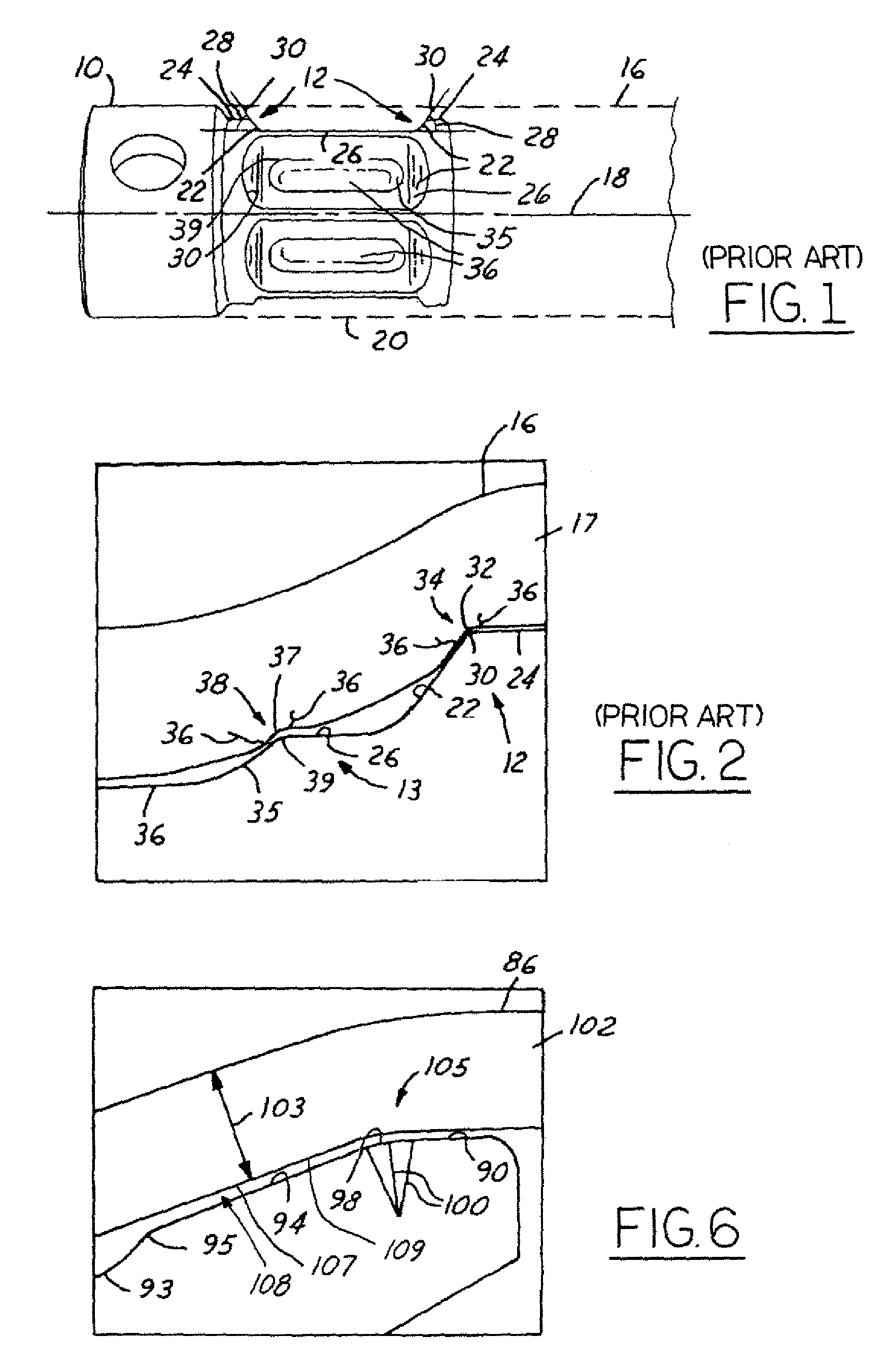

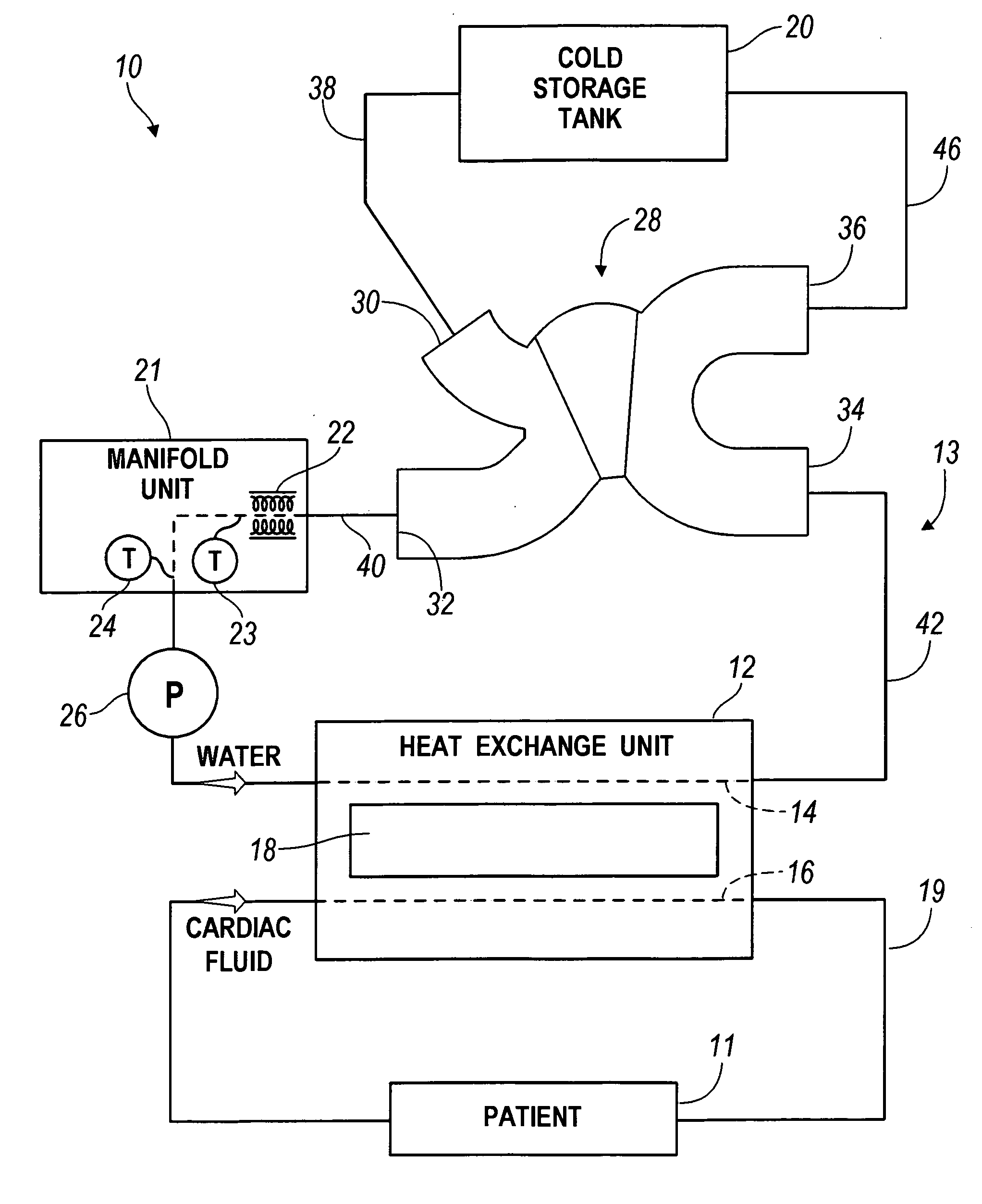

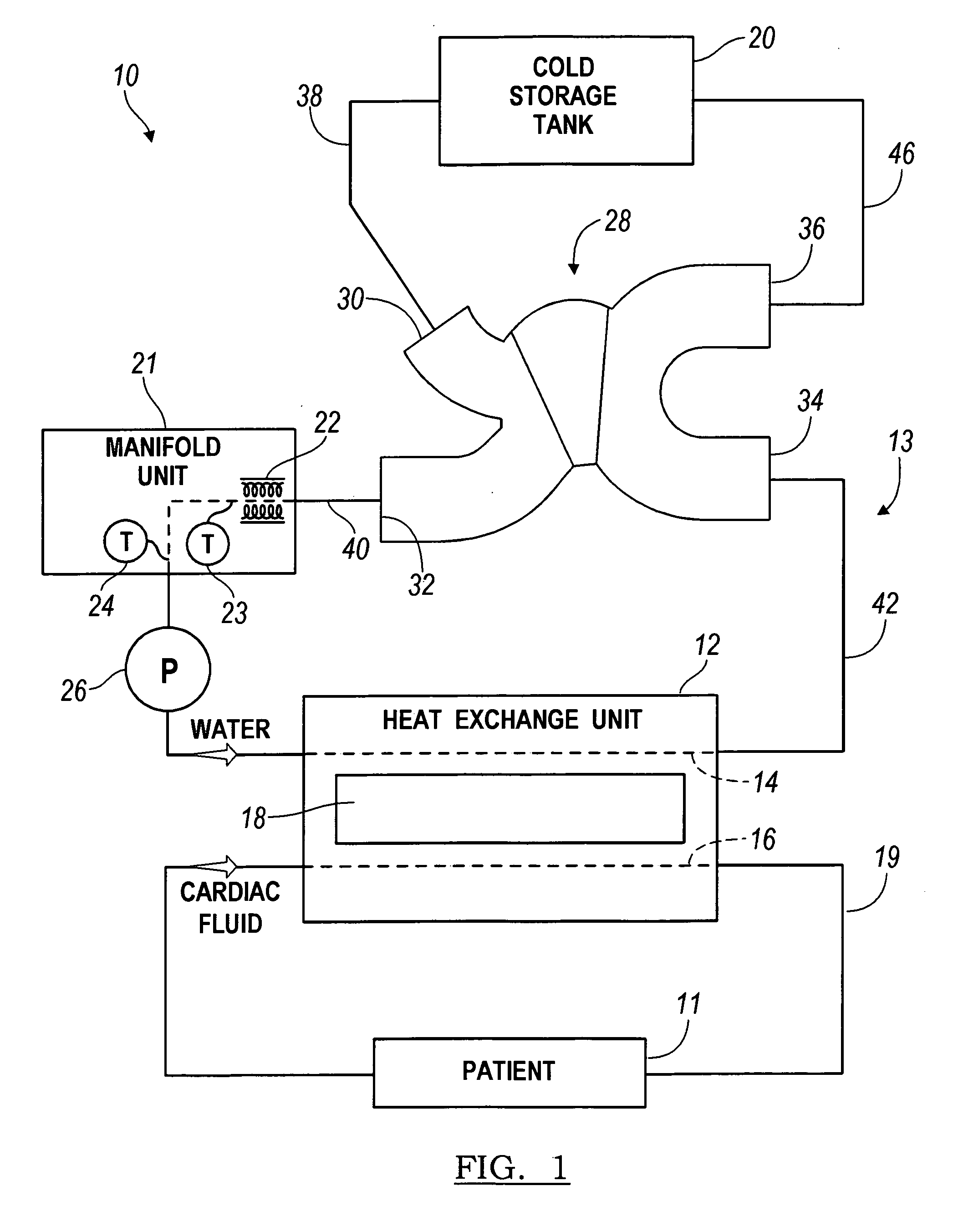

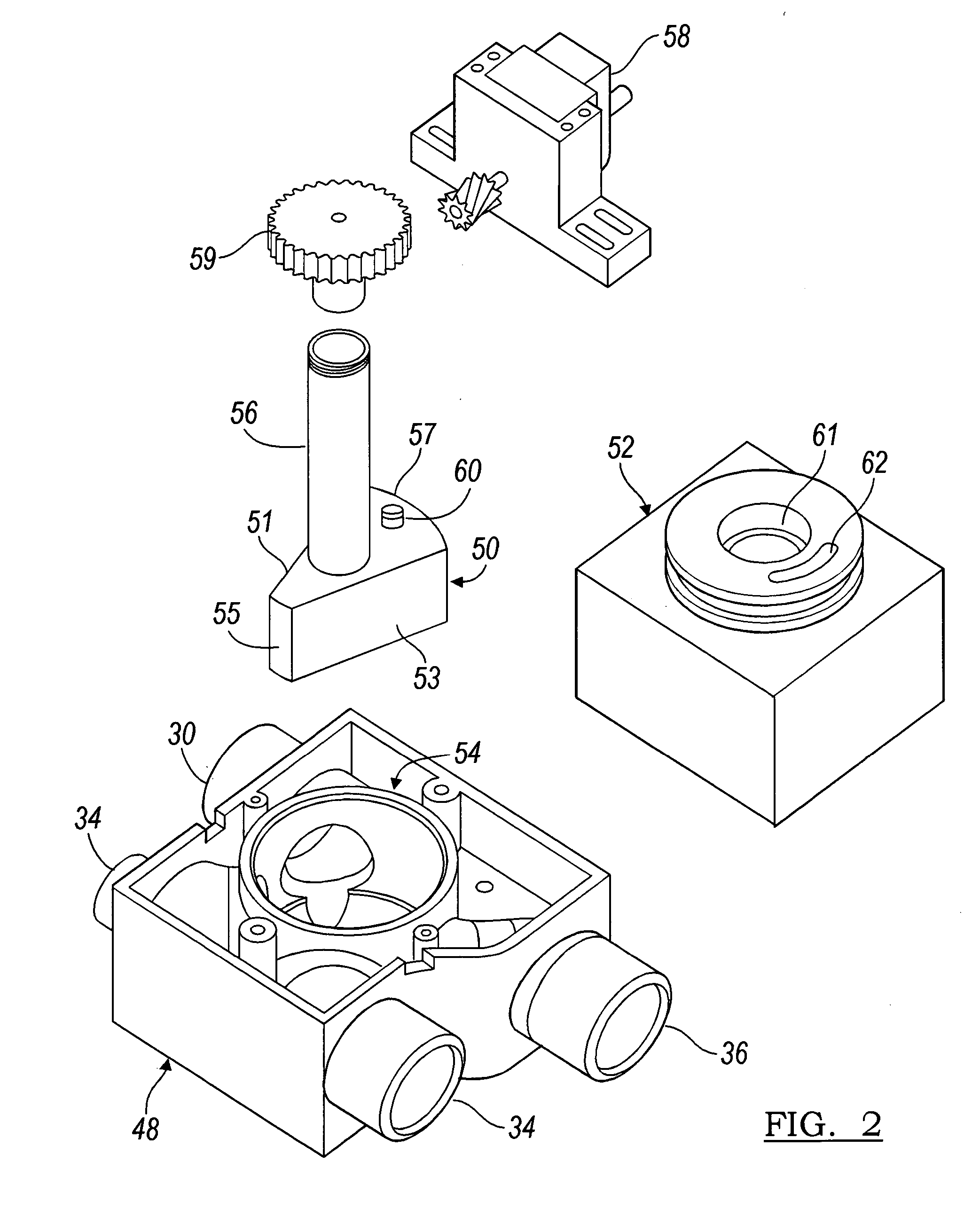

Heater cooler valve

InactiveUS20070197951A1Quiet operationEasy temperature controlMedical devicesIntravenous devicesRotary valveEngineering

A rotary valve unit is provided for blending fluid sources to regulate a temperature of fluid flowing to a heat exchange device in an extracorporeal blood perfusion circuit. A valve body includes a valve chamber having a first inlet port, a second inlet port, a first outlet port, and a second outlet port. A wedged-shaped rotary valve is disposed within the valve chamber and is rotatable within the valve chamber for controlling a blending of the cold fluid entering the fluid chamber from the first inlet port and the return fluid entering the fluid chamber from the second inlet port to regulate the desired temperature of fluid provided to the heat exchanger. The wedge-shaped rotary valve is positionable to provide either only cold fluid to the first outlet port, only return fluid to the first outlet port, or blending of the cold fluid and return fluid to the first outlet port.

Owner:TERUMO CARDIOVASCULAR SYST CORP

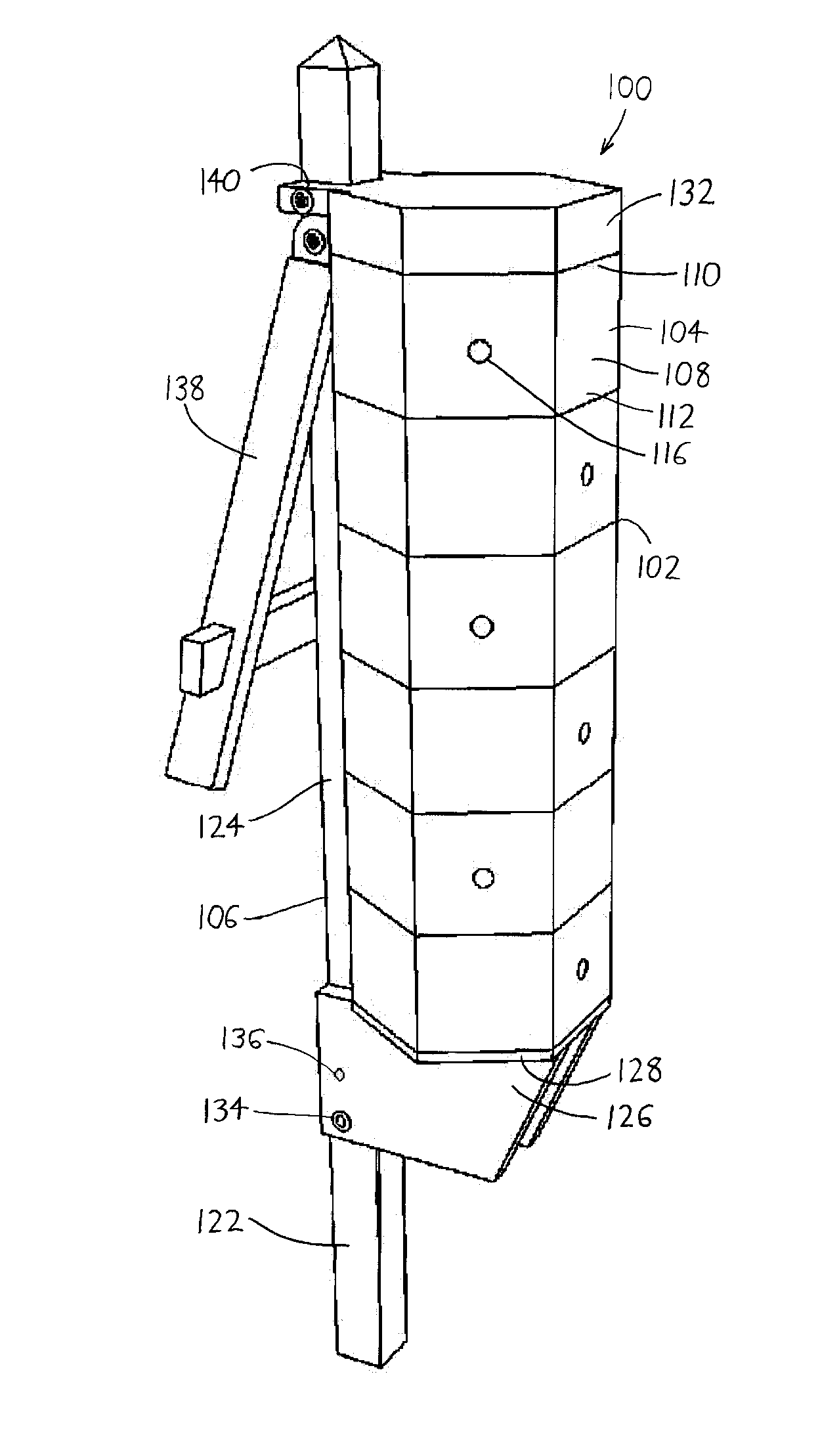

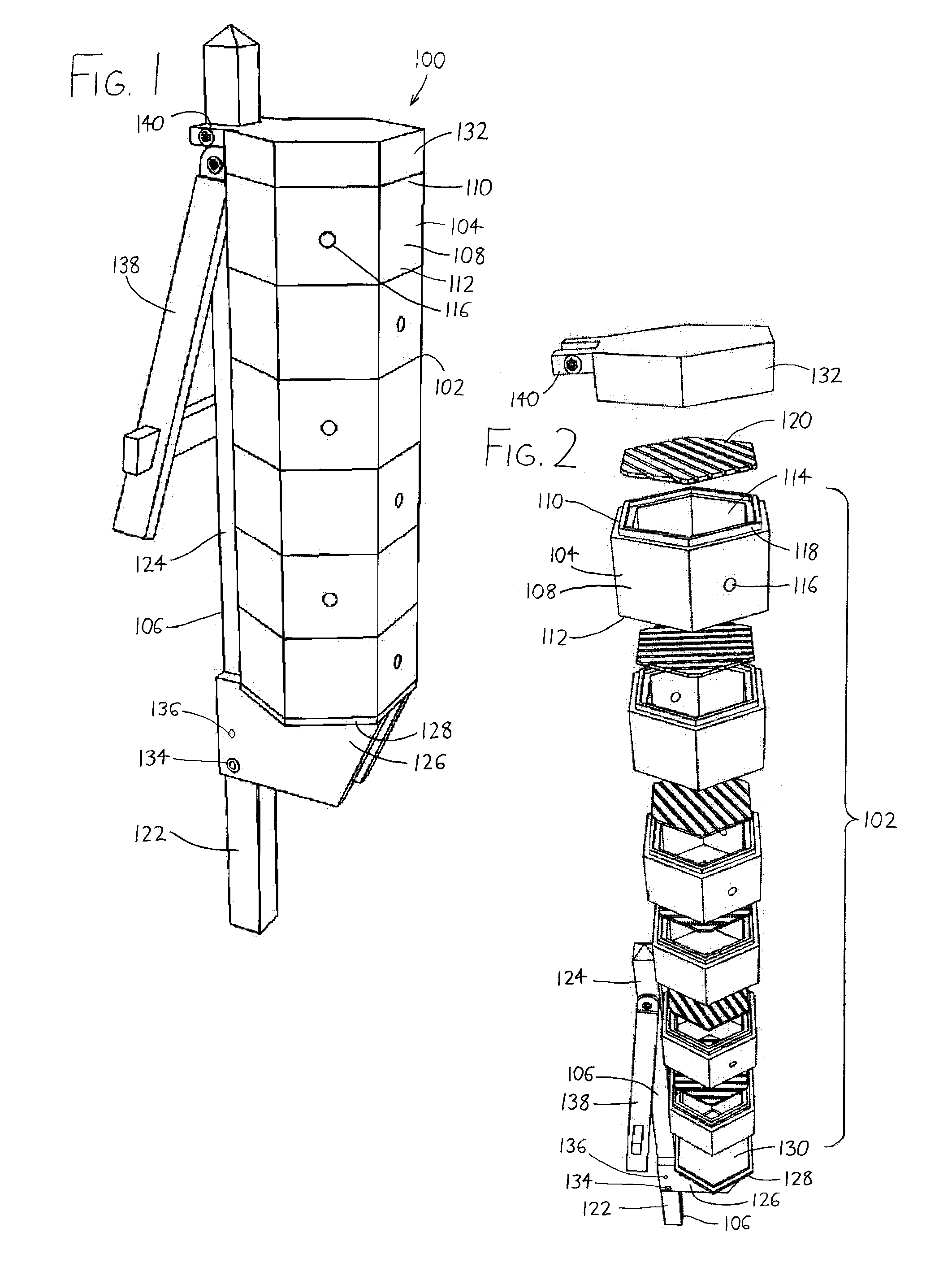

Beehive

InactiveUS20110312244A1Assist with ventilationReduce mites and other intrudersBeehivesBeehiveEngineering

Owner:VINCENT RICHARD SCOTT

Freestanding multiplayer IC wiring structure

InactiveUS7211496B1More stressImprove the immunitySemiconductor/solid-state device detailsSolid-state devicesDielectricTransistor circuits

A dielectric wiring structure and method of manufacture therefor. The wiring structure includes air dielectric formed in a hemisphere. The wiring structure also includes, in embodiments, a method of simultaneously forming a MEMS structure with a transistor circuit using substantially the same steps. The MEMS structure of this embodiment includes freestanding electrodes which are not fixed to the substrate.

Owner:GLOBALFOUNDRIES INC

Touch sensitive devices with composite electrodes

ActiveUS20120313893A1Great mutual capacitance changeLess susceptibilityTransmission systemsCathode-ray tube indicatorsCapacitanceComposite electrode

A matrix touch panel having upper and lower electrodes, the upper electrodes being composite electrodes made of a plurality of spaced micro-wires, and allowing, for example, an electric field from lower electrodes to pass between the micro-wires and thereby capacitively couple with a touching object, such as a finger.

Owner:3M INNOVATIVE PROPERTIES CO

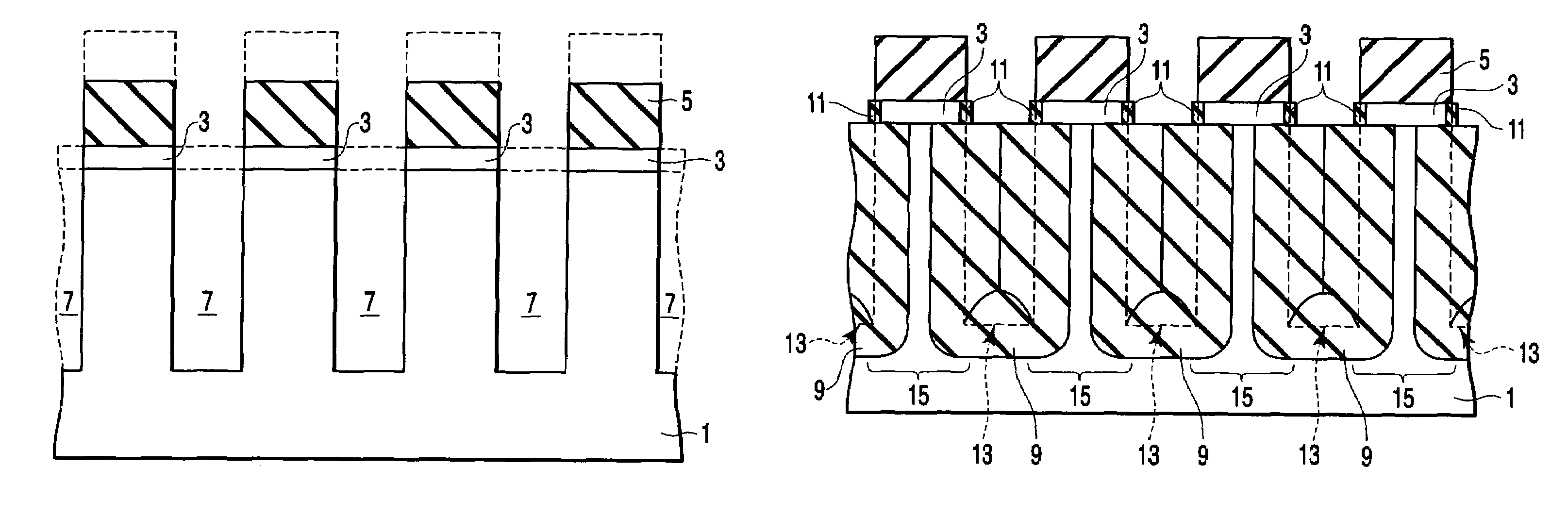

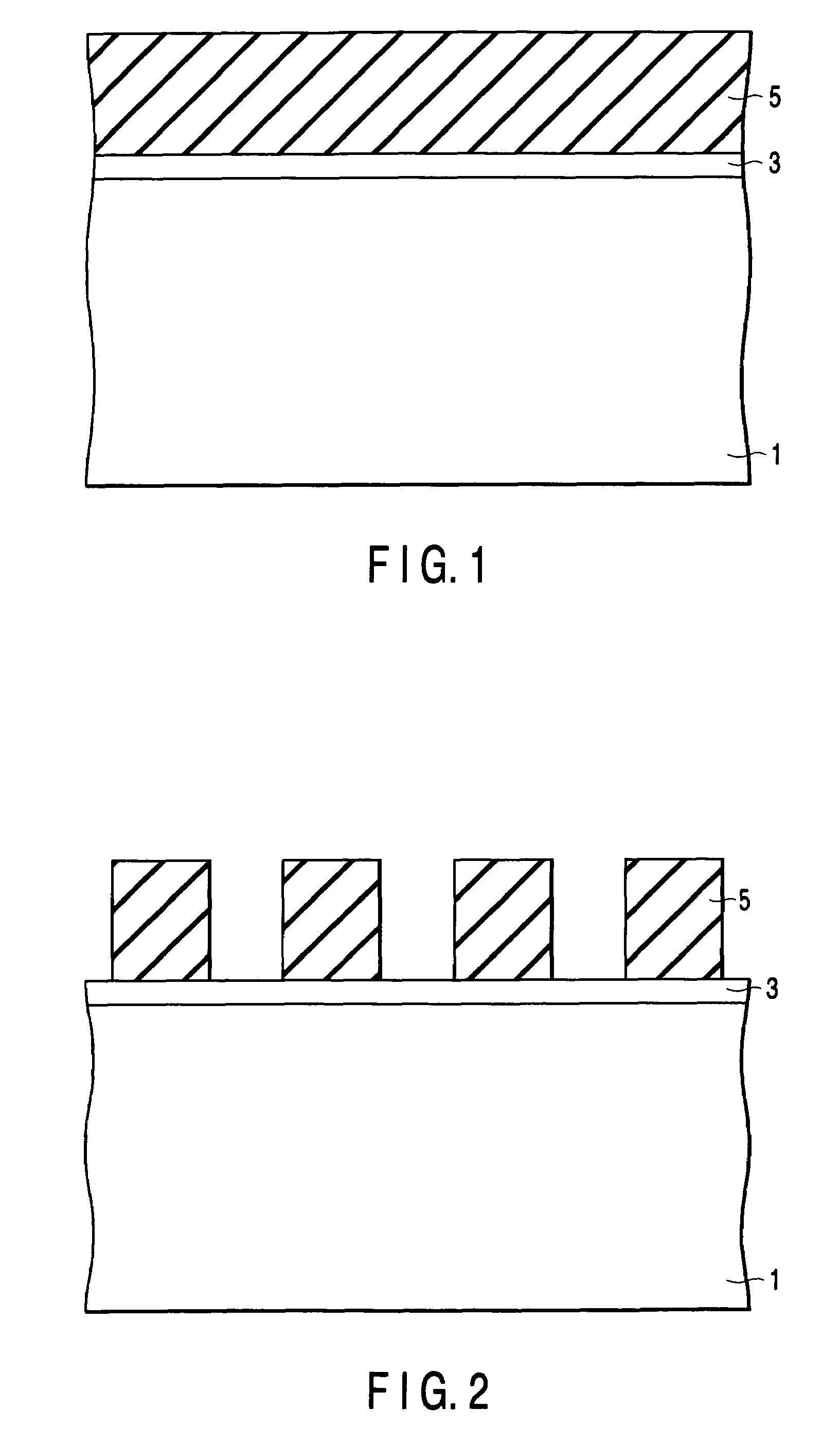

Semiconductor device manufacturing method

InactiveUS7687368B2Less susceptibilitySemiconductor/solid-state device manufacturingSemiconductor devicesElectrical conductorSemiconductor package

A semiconductor device manufacturing method is disclosed. The method is to form a second semiconductor layer which has less susceptibility to adopting insulative characteristics than a first semiconductor layer on the first semiconductor layer. Then, grooves which expose portions of the second and first semiconductor layers are formed to extend from the upper surface of the second semiconductor layer into the first semiconductor layer. Next, portions of the first and second semiconductor layers which are exposed to the grooves are changed into an insulator form to fill the grooves with the insulator-form portions of the first semiconductor layer.

Owner:KK TOSHIBA

Bubble column-type Fischer-Tropsch synthesis slurry bed reaction system

InactiveUS8057744B2Easy to operateReduce deteriorationLiquid hydrocarbon mixture productionTreatment with hydrotreatment processesLiquid productBubble column

According to an exemplary embodiment, a bubble column-type slurry bed Fischer-Tropsch synthesis reaction process can be provided, in which synthesis gas supplied continuously from the bottom of a reactor contacts suspended catalyst particles to form liquid hydrocarbons, gaseous hydrocarbons and water. Additionally, a slurry of suspended liquid products and catalyst particles can move from the reactor to the lower portion of a separation vessel to separate the catalyst particles and gaseous products. Further, a process can be provided in which the liquid products formed are sent to the separation vessel a process in which liquid products can be derived. Additionally, a process can be provided in which a slurry in which catalyst particles are concentrated is derived from the bottom of the separation vessel and circulated to the bottom of the reactor, are driven by the driving force of synthesis gas without using an external drive power source.

Owner:INPEX CORP +4

Automated project design of a control technology for a technical system

InactiveUS20140358817A1Spend lessNot easy to make mistakesProgramme controlComputer controlDesign documentationDocumentation

A method for producing a system-specific project design document for control technology to be project-designed for a technical system as well as a device designed for the implementation of the method is provided. A reference project design document for the technical system is produced. Through a comparison of a project-specific project design document for the technical system the reference project design document, performed using a comparison marking, wherein the project-specific project design document is created using standard project design objects, the system-specific project document is created.

Owner:SIEMENS AG

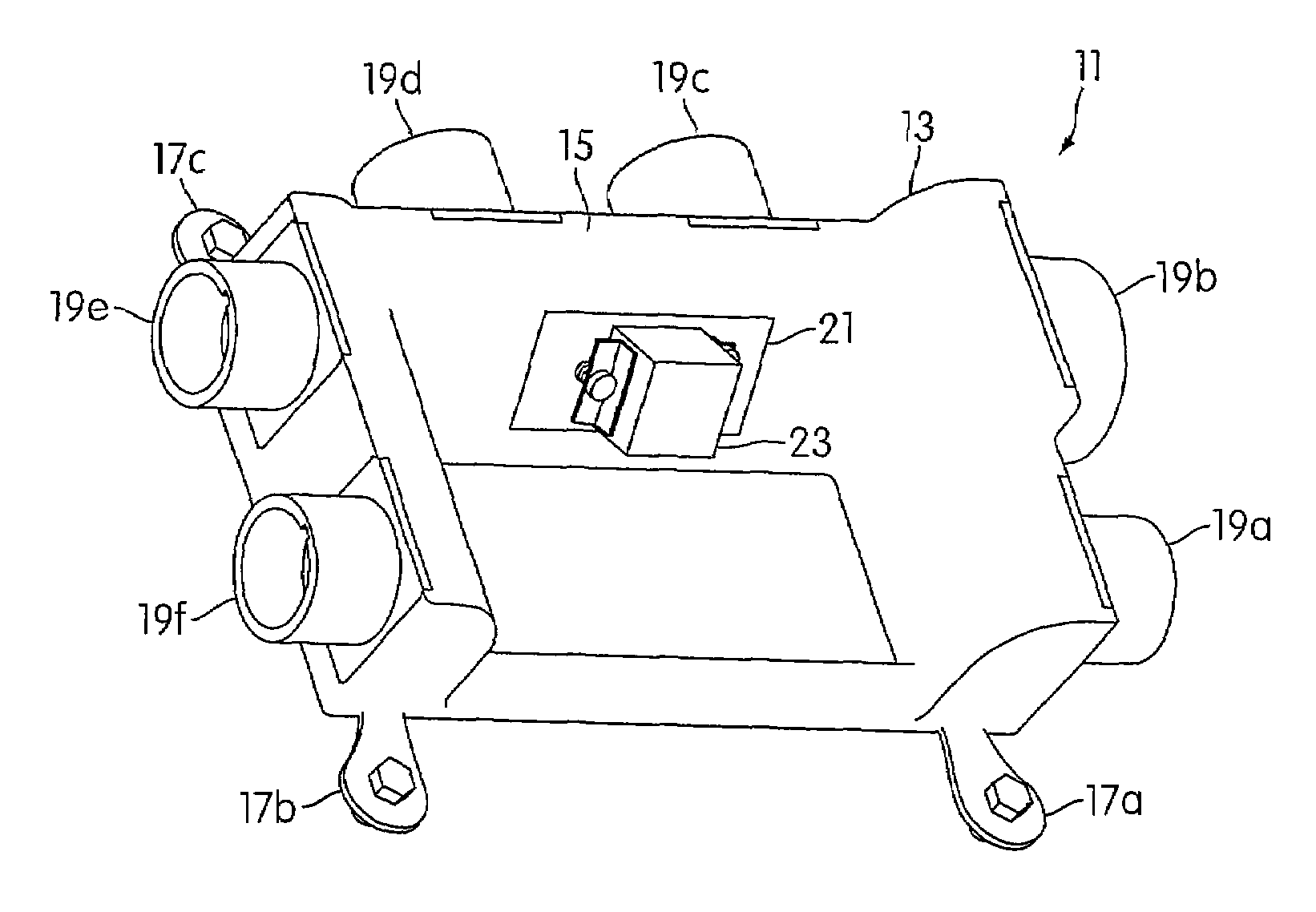

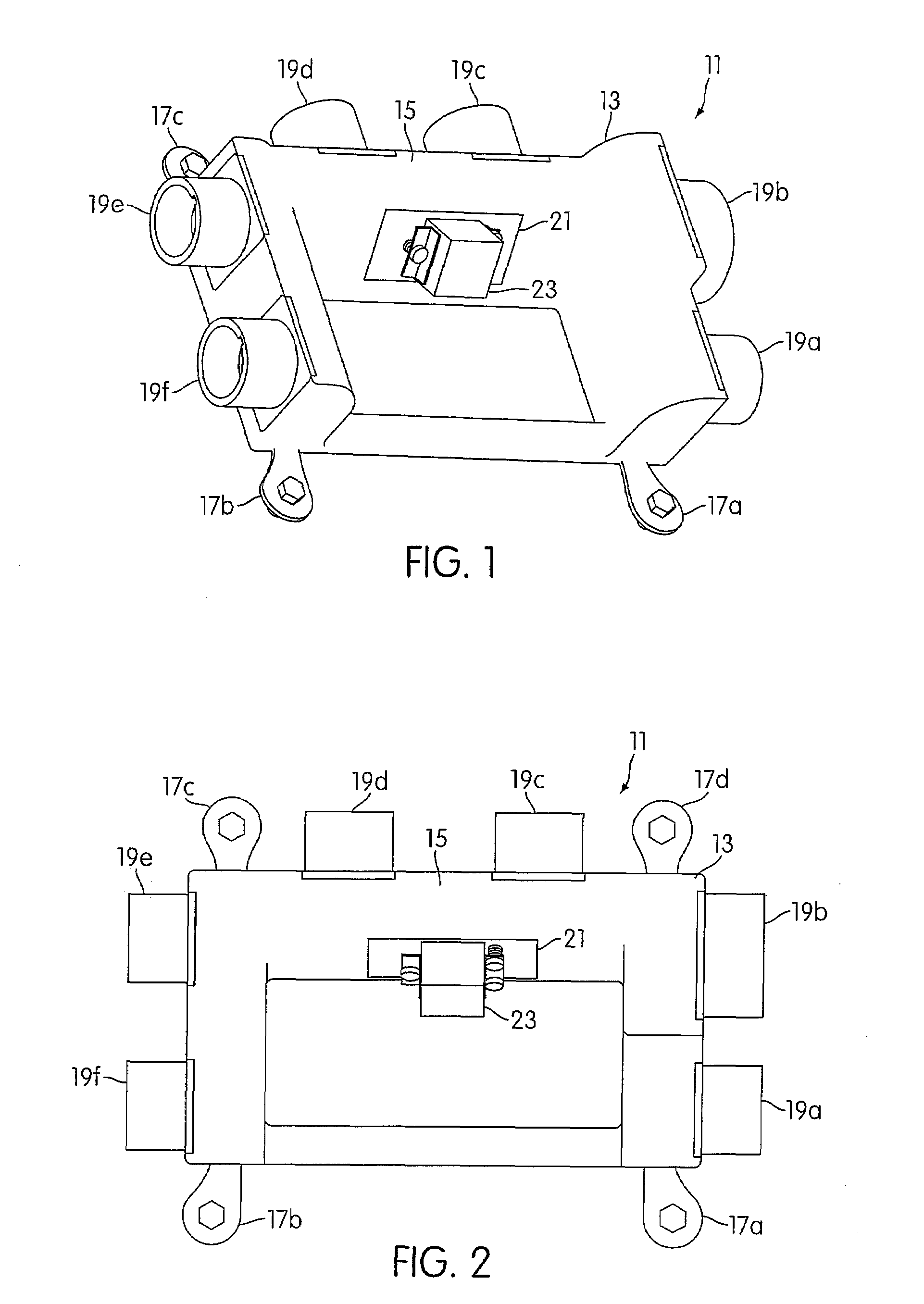

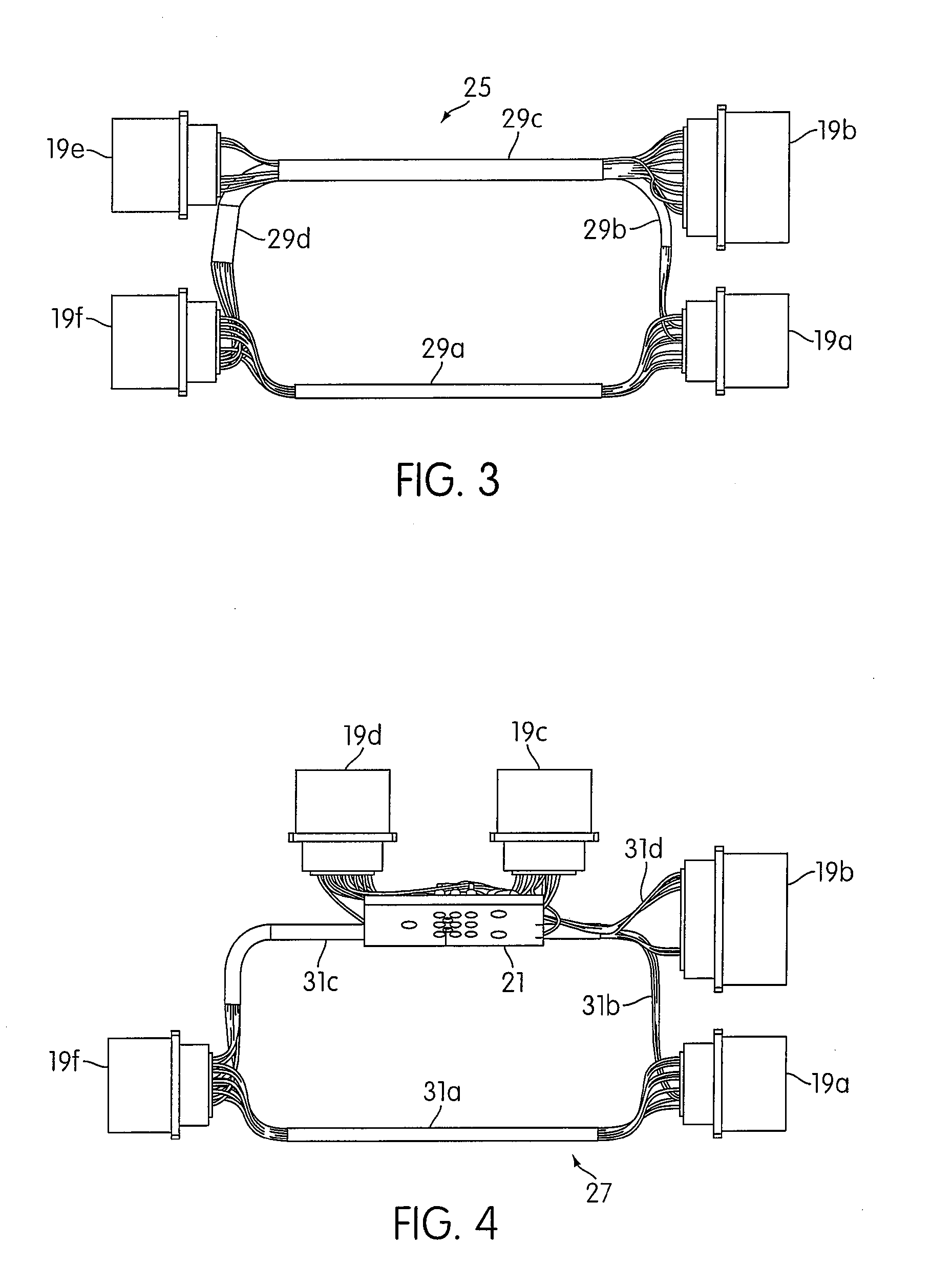

Molded electronic assembly

ActiveUS7462780B2Few partsSmall volumeInsulated cablesCouplings bases/casesPlastic materialsConductive coating

A molded electronic assembly of the present invention includes a wiring harness with connectors connected thereto, and a molded body formed to encapsulate the wiring harness and provide access to the connectors. The molded may comprise a plastic material such as polyurethane or other moldable material. A conductive coating may be placed on the outer surface of the molded body to provide electrical shielding. Additionally, the wiring harness may be shielded with a wrapping of metallic tape or the like. The molded electronic assembly of the present invention may include a grounding fixture or grommet that provides mechanical properties of a structural fixture and allows for ground wires to be terminated.

Owner:BELL HELICOPTER TEXTRON INC

Catalyst supported on alumina for use in polymerization of olefins and method of preparing them

InactiveUS20140038809A1High mechanical resistanceExcellent catalytic activityOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationOlefin polymerizationAlkene

The present invention relates to a supported catalyst for the polymerization of olefins. More specifically, the present invention provides a catalyst comprising a spherical alumina support modified by the addition of a magnesium compound containing a magnesium alkoxide and the product of the reaction of it with a titanium halide. The present invention also relates to the method for preparing said supported catalyst.

Owner:GASOLINEEO BRASILEIRO PATROBRAS

Stacked-plate gas-expansion cooler assembly, fabrication method, and use

InactiveUS7178345B2Heat dissipation fastLess susceptibilitySolidificationLiquefactionIn planeEngineering

Owner:RAYTHEON CO

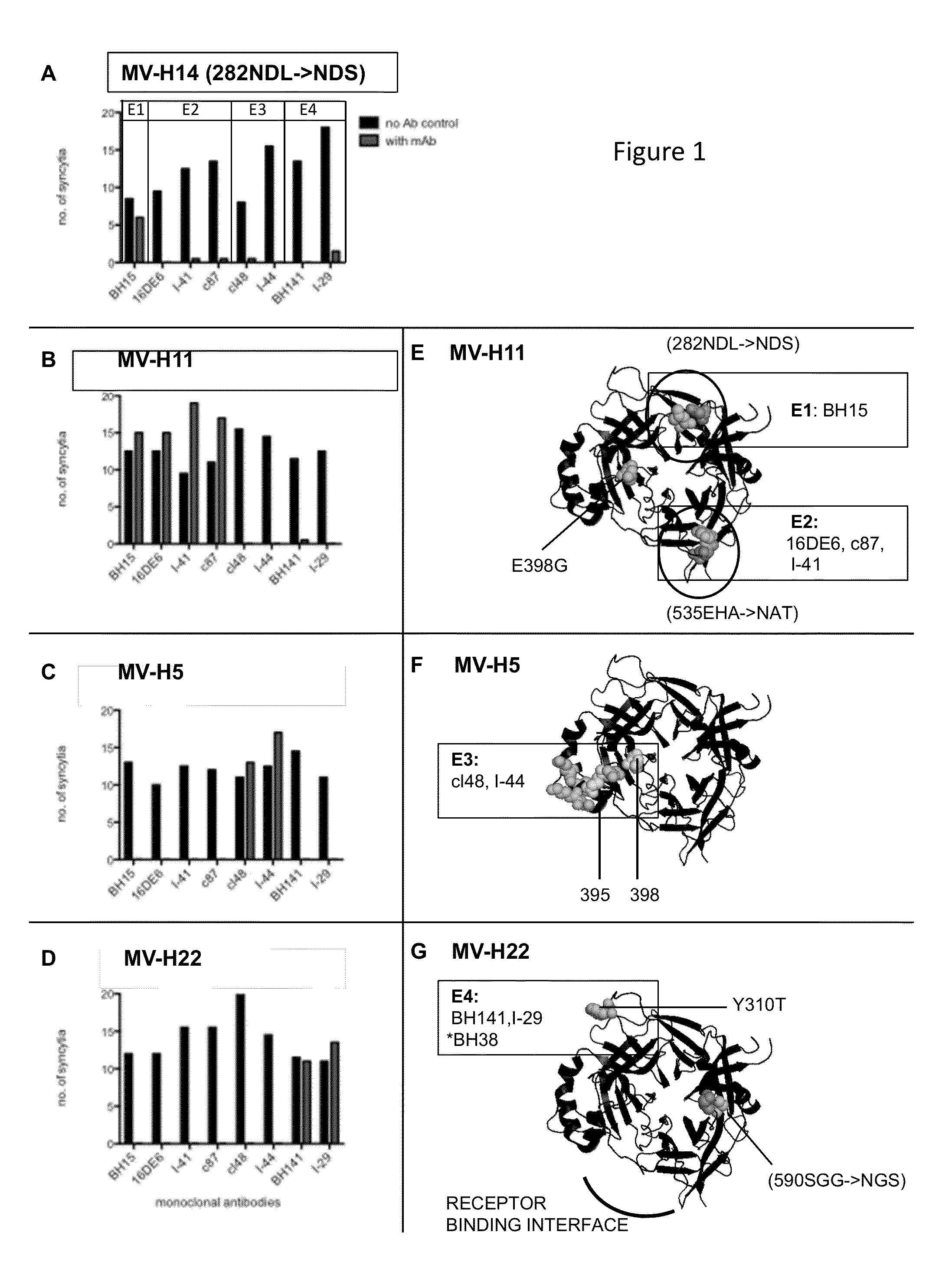

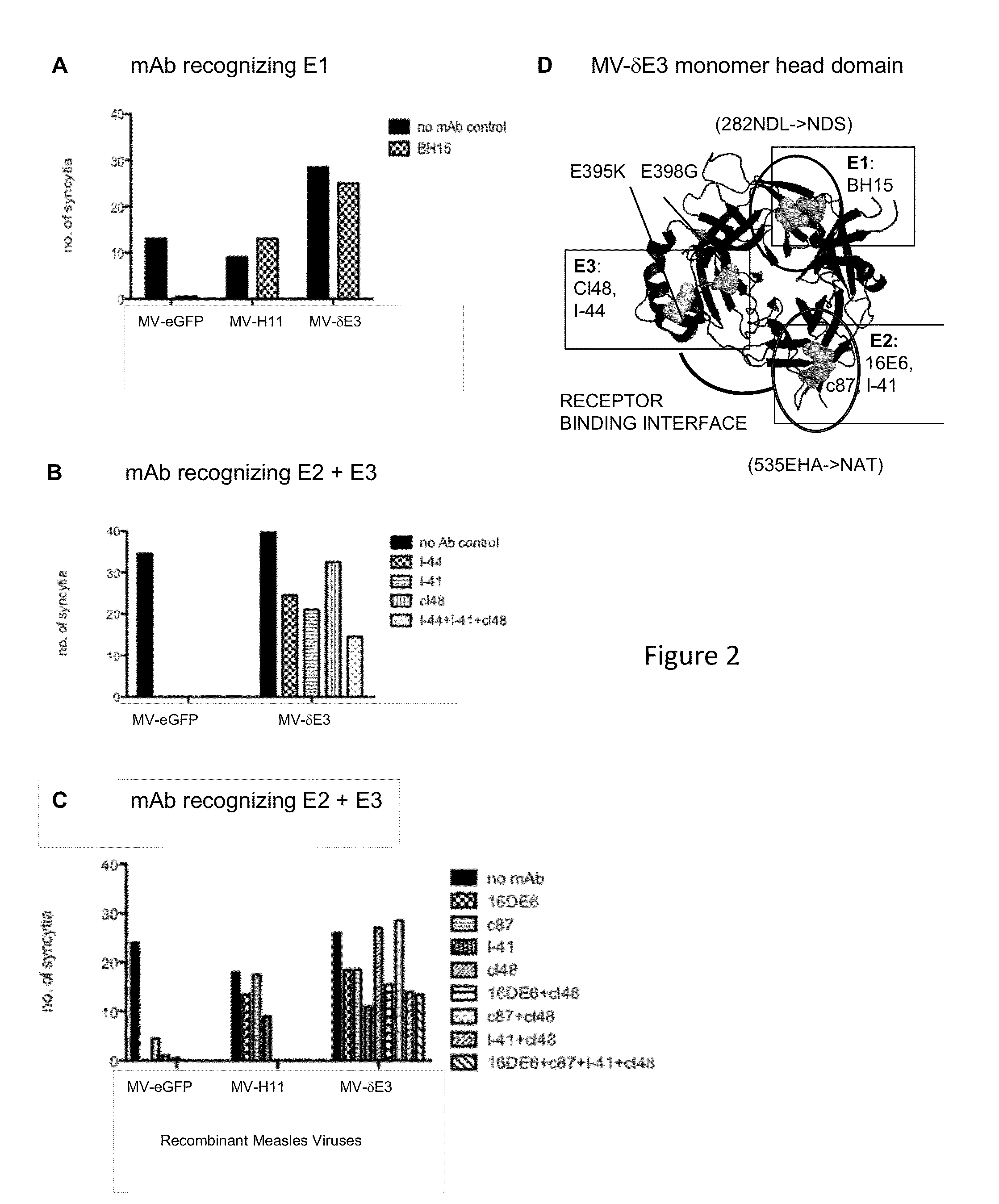

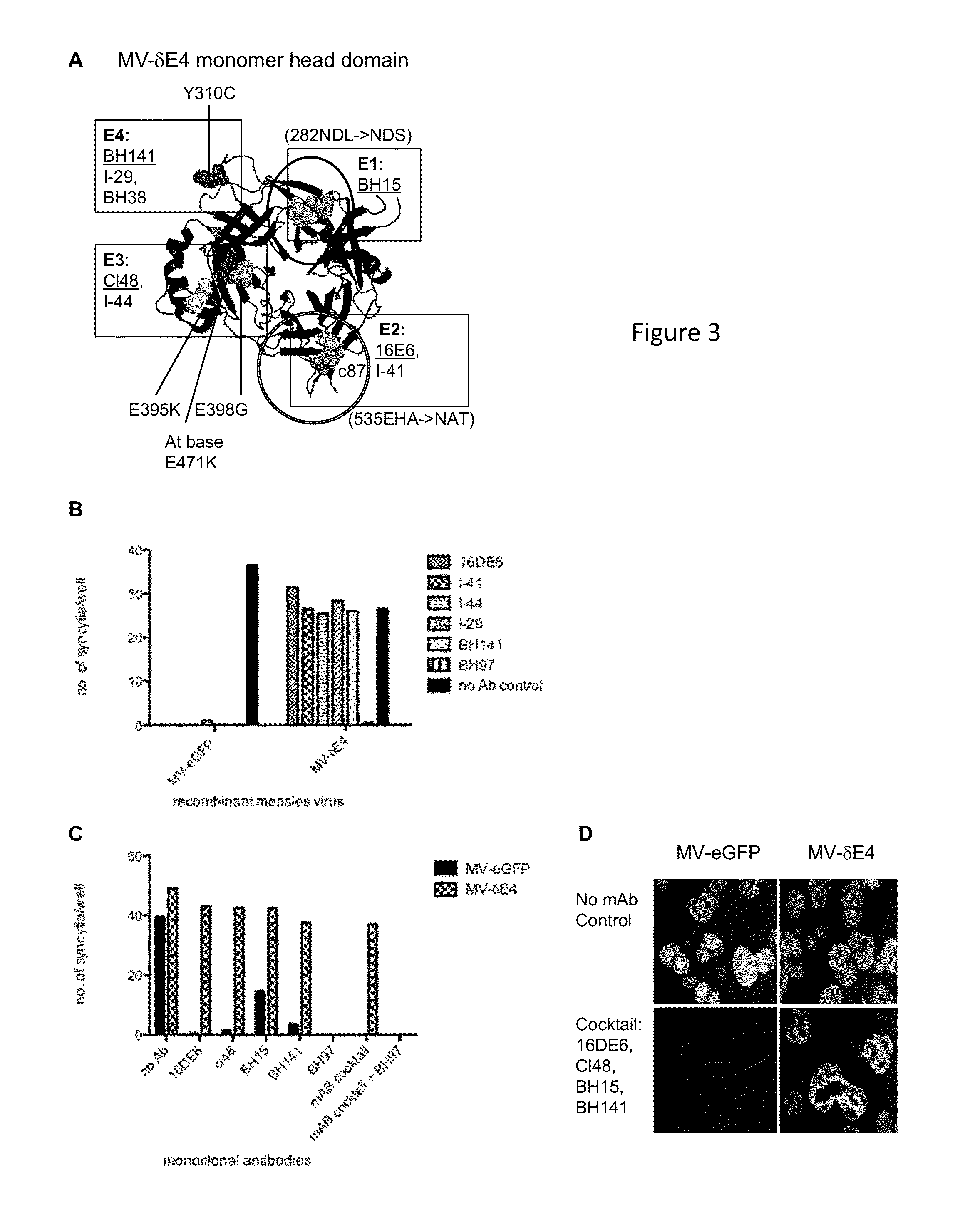

Measles viruses with reduced susceptibility to neutralization

InactiveUS20140024100A1Reduce sensitivityLess susceptibilitySsRNA viruses negative-senseSugar derivativesPre-existingMeasles virus vaccine

This document provides methods and materials for making and using measles viruses having a reduced susceptibility to antibody neutralization (e.g., antibody neutralization by monoclonal anti-measles virus antibodies and / or serum from measles virus vaccinees). For example, H polypeptides having a reduced ability of being recognized by anti-measles virus antibodies that were generated against a wild-type measles virus or a pre-existing measles virus vaccine such as MV-Edm as compared to a wild-type measles virus H polypeptide or the H polypeptide of MV-Edm are provided.

Owner:BIOLOGICAL MIMETICS +1

Diaphragm for pressure sensor and pressure sensor

InactiveUS8312775B2Less occurrenceLess susceptibilityFluid pressure measurement using piezo-electric devicesFluid pressure measurement using elastically-deformable gaugesEngineeringDiaphragm seal

A diaphragm for a pressure sensor includes: a central section serving as a diaphragm body, the central section including: an external surface deformed upon receipt of an external pressure; and an internal surface transmitting a force to a pressure sensitive element inside a housing of the pressure sensor; a peripheral section that is an exterior of the central section and welded to an outer circumference of a pressure input orifice that is provided to the housing; and a step wall provided between the central section and the peripheral section. The central section and the peripheral section are integrally and concentrically provided. The diaphragm seals the pressure input orifice.

Owner:SEIKO EPSON CORP

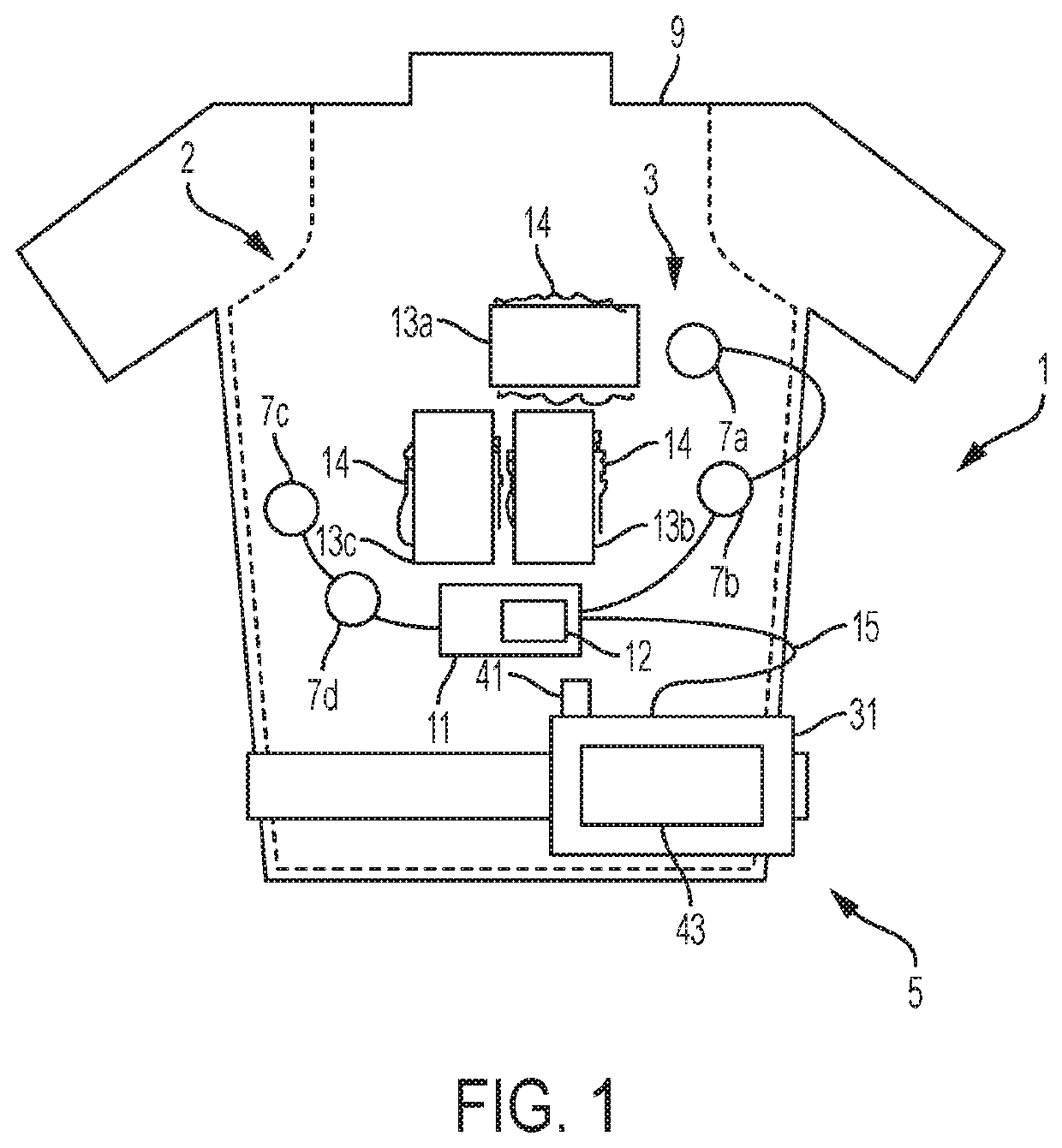

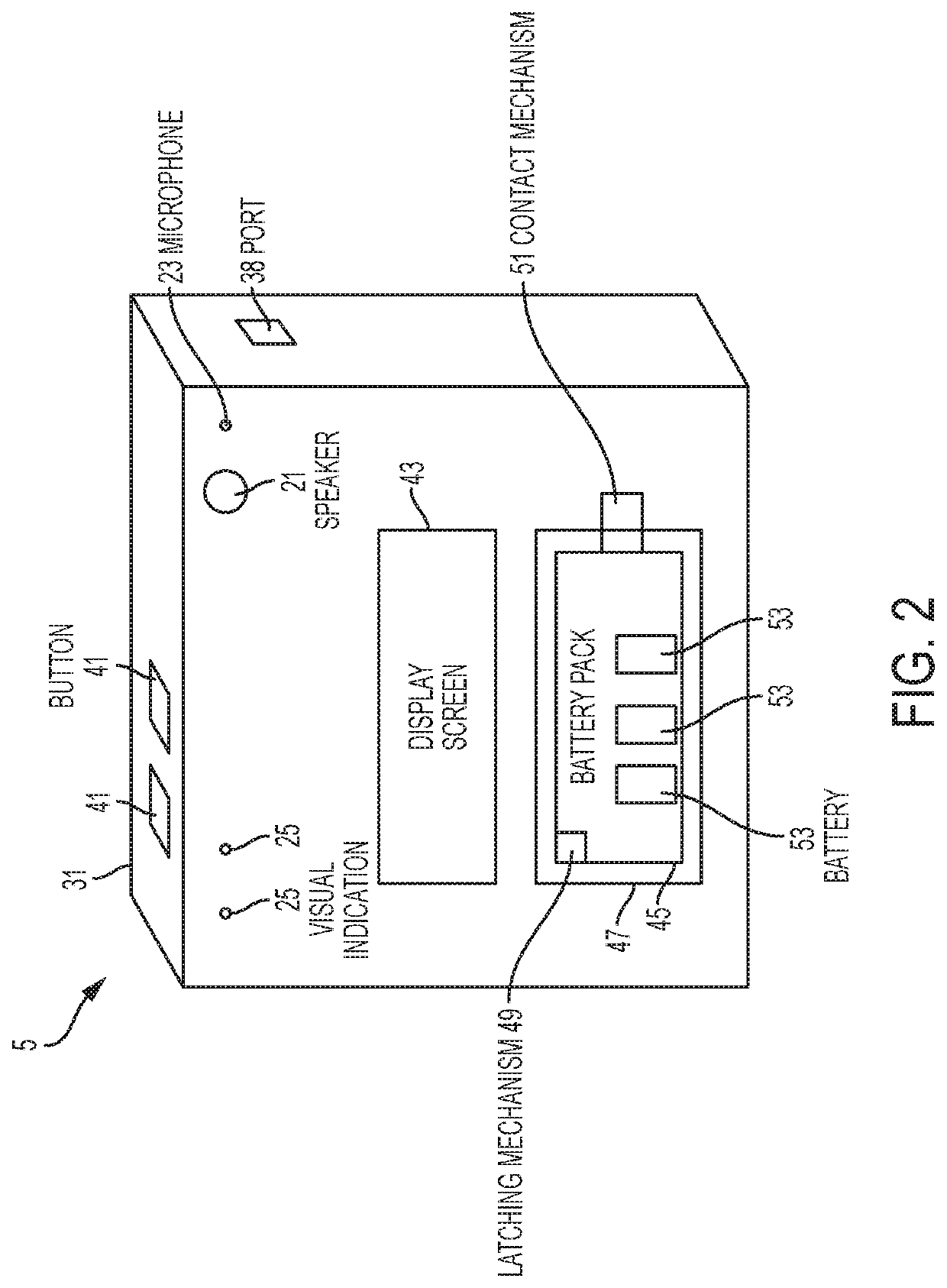

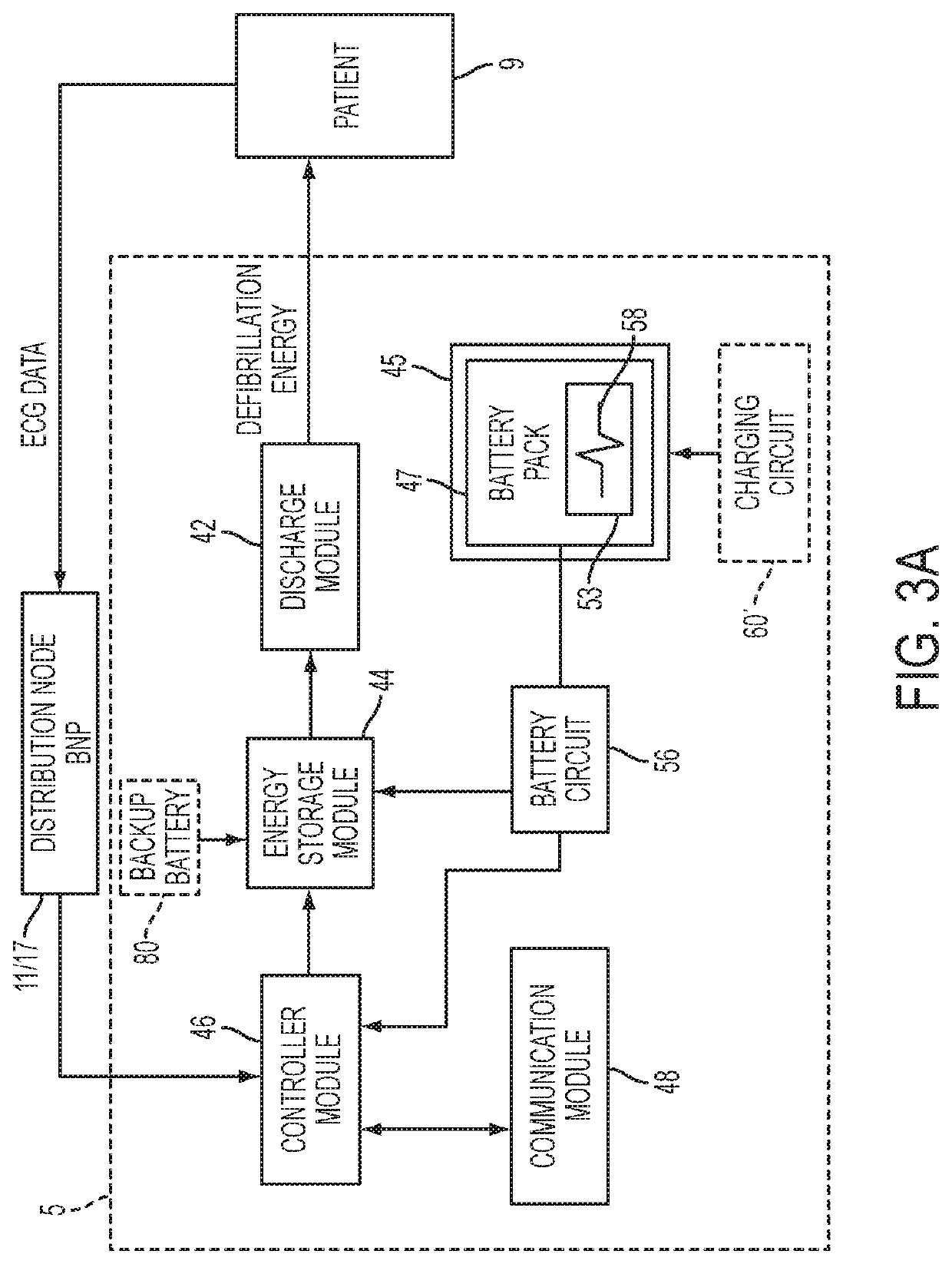

Systems and methods for monitoring battery life status

ActiveUS10578677B2Improve reliabilityLess susceptibilityHeart defibrillatorsElectrical testingHemt circuitsEmergency medicine

An external medical device includes a battery that can support a plurality of charge-discharge cycles prior to a predetermined battery life threshold. The device also includes a battery circuit that is operative for monitoring a condition of the battery, determining a battery life status of the battery based on the monitored condition and the predetermined battery life threshold, and, responsive to the determined battery life status, causing the device to enter into a low power operating mode. The low power operating mode can include modifying device functions that are performed, or modifying the manner in which a capacitor of the device is charged, or changing the battery that charges the capacitor, or isolating the capacitor from charge drainage, or causing the device to operate from charge stored on the capacitor.

Owner:ZOLL MEDICAL CORPORATION

Communication system and method for directly transmitting signals between nodes of a communication system

InactiveUS8837943B2Large capacityImprove user throughputWavelength-division multiplex systemsMultimode transmissionCommunications systemMultiplexer

A communication system has a plurality of nodes adapted to provide for a communication with one or more devices, a central node, a passive optical network having a multiplexer / demultiplexer device adapted to demultiplex a first optical signal from the central node to the plurality of nodes, and to multiplex second optical signals from one or more of the nodes, each node having allocated a wavelength for generating its optical signal, wherein for directly transmitting signals from one node to at least one of the other nodes, the one node is adapted to generate an optical signal at the wavelength allocated to the at least one of the other nodes, the optical signal including the signal to be transmitted, and wherein the multiplexer / demultiplexer device of the passive optical network is adapted to combine the optical signal from the one node with the first optical signal.

Owner:NTT DOCOMO INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com