Patents

Literature

32results about How to "Large heat flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

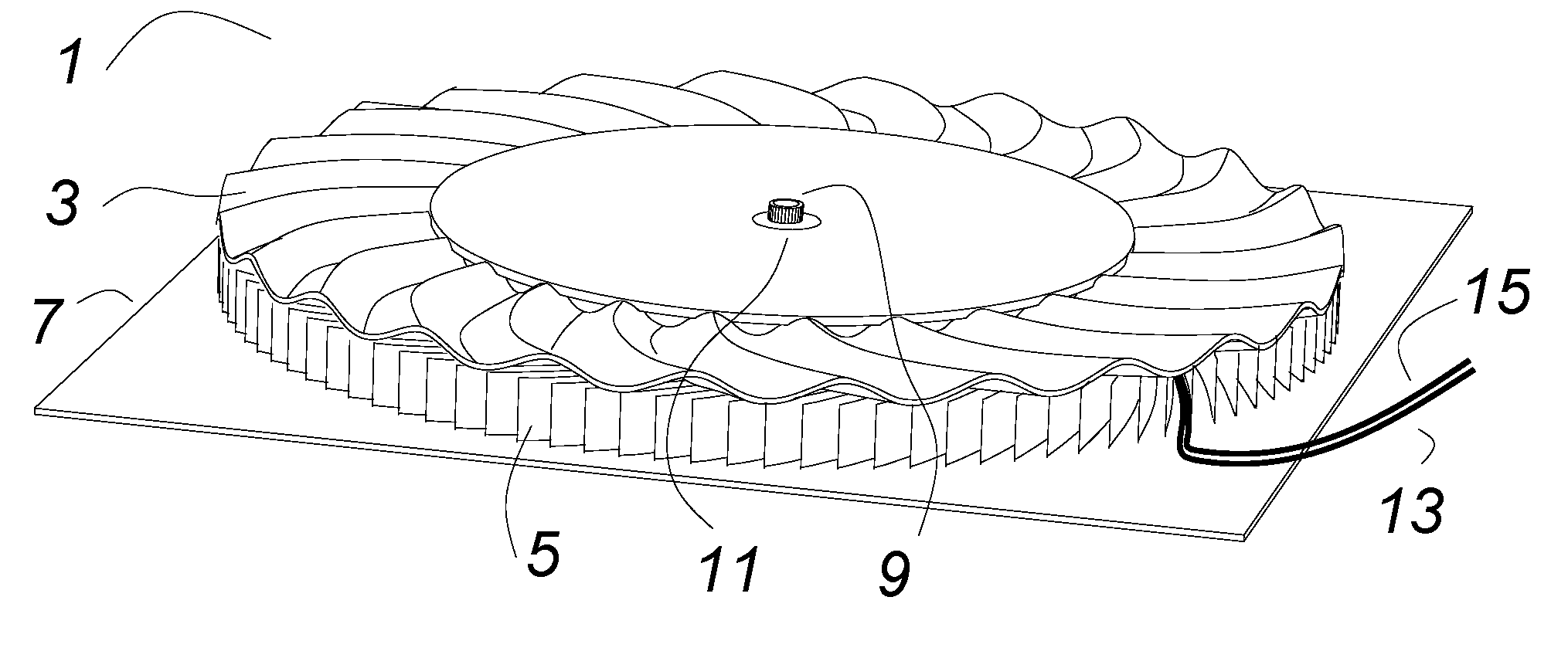

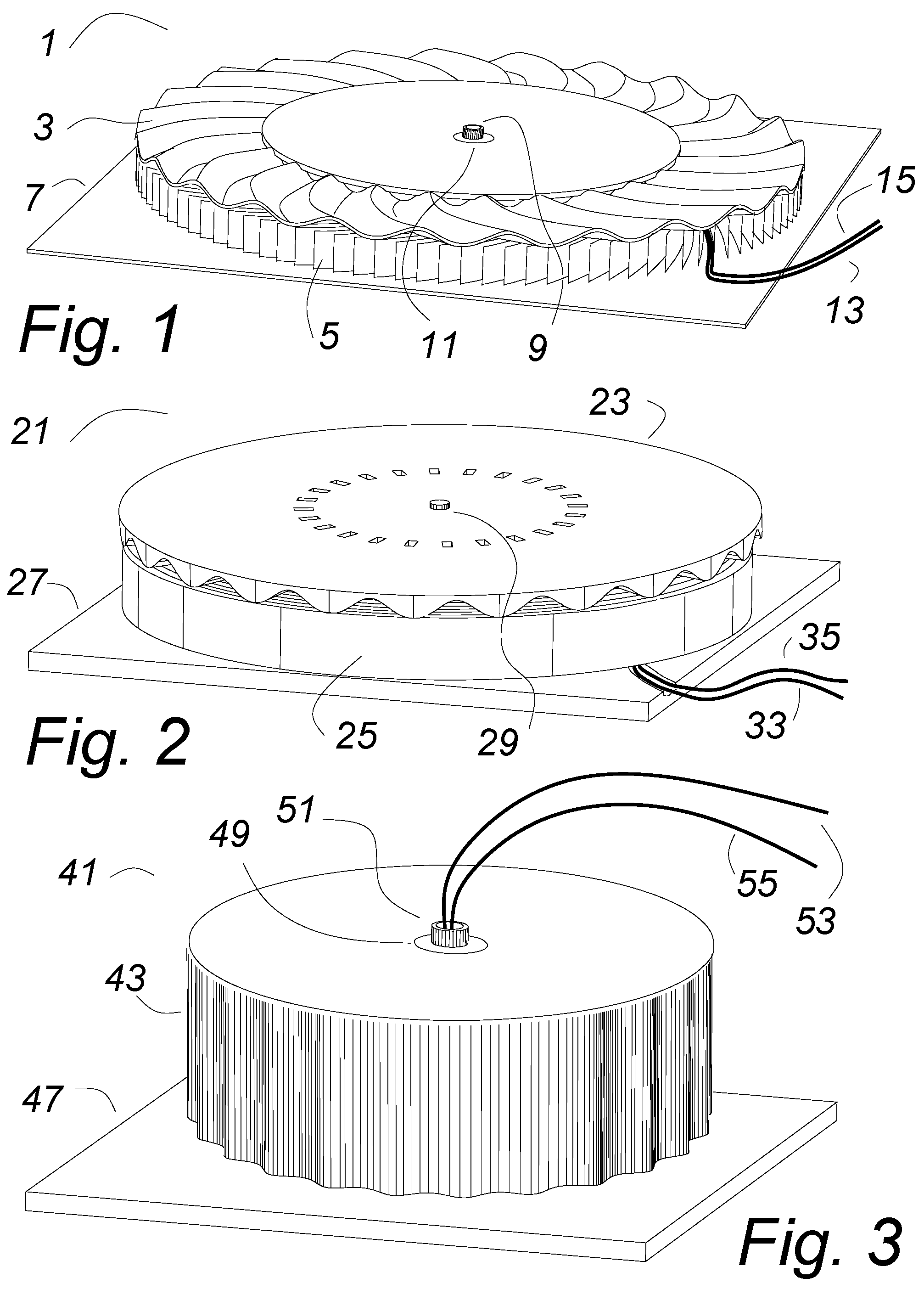

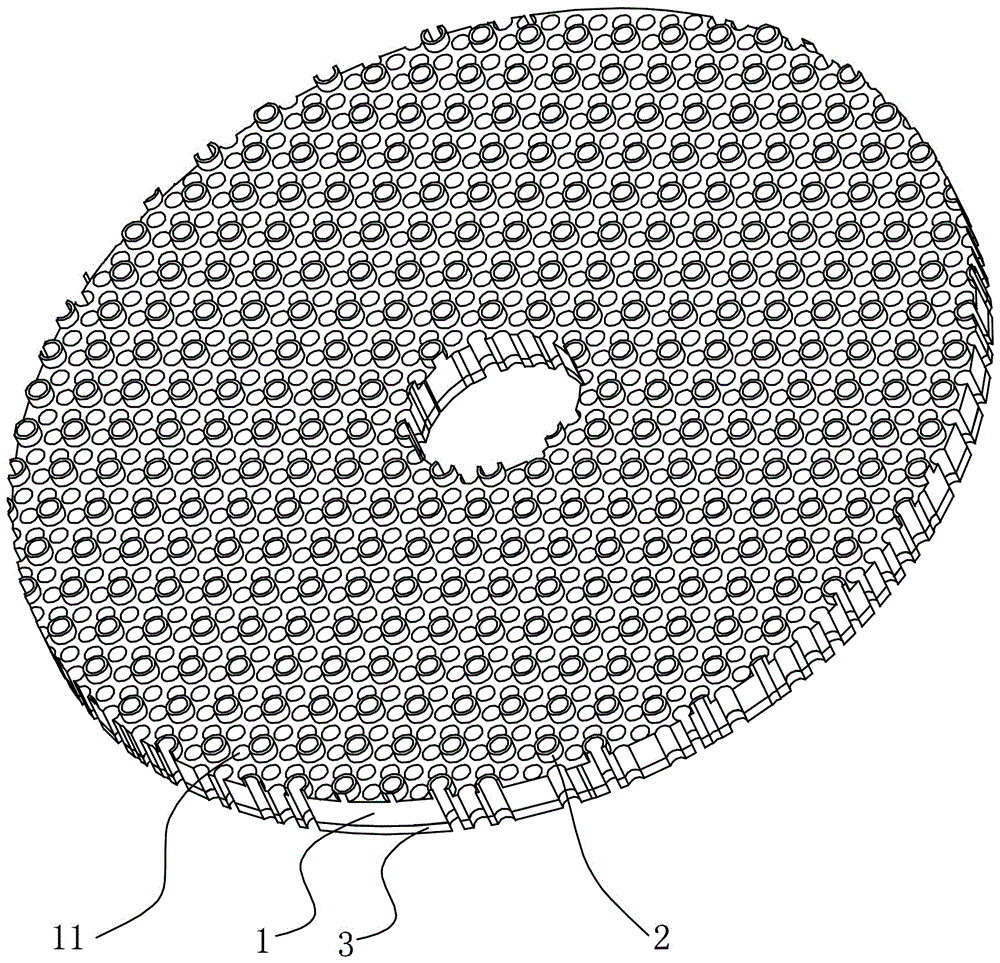

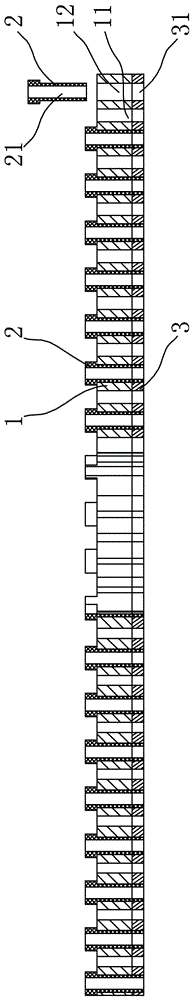

Wave-fans and wave-fans with heat sinks

InactiveUS7136285B1Increase local velocityLarge heat flowPropellersSemiconductor/solid-state device detailsHeat flowWave shape

A wave-fan comprises a wavy surface, generally sinusoidal in the direction of rotation, which rotates in close proximity to the fins of a heat sink. The wave-plane fan is suitable for use with a flat heat sink, and a wave-ring fan is suitable for use with a cylindrical heat sink. There are no airfoils as in a prior art fan. Instead, the ridges of the wave-fan agitate the air between the fins of the heat sink as each ridge passes, breaking down the boundary layer and effecting good heat flow into the air. In some embodiments of the wave-fan, the outer surfaces are smooth, so it is not a hazard to intruding fingers, so in many applications it may be used without a guard or enclosure. Incidental centrifugal force provides some airflow through the fan to transport the heated air away from the fan. Also, the configuration of the fan tends to keep contamination in the air out of the heat sink fins, so an inlet air filter may not be needed. Because the net airflow through the fan is low, less power is required and it is very quiet.

Owner:HERBERT EDWARD

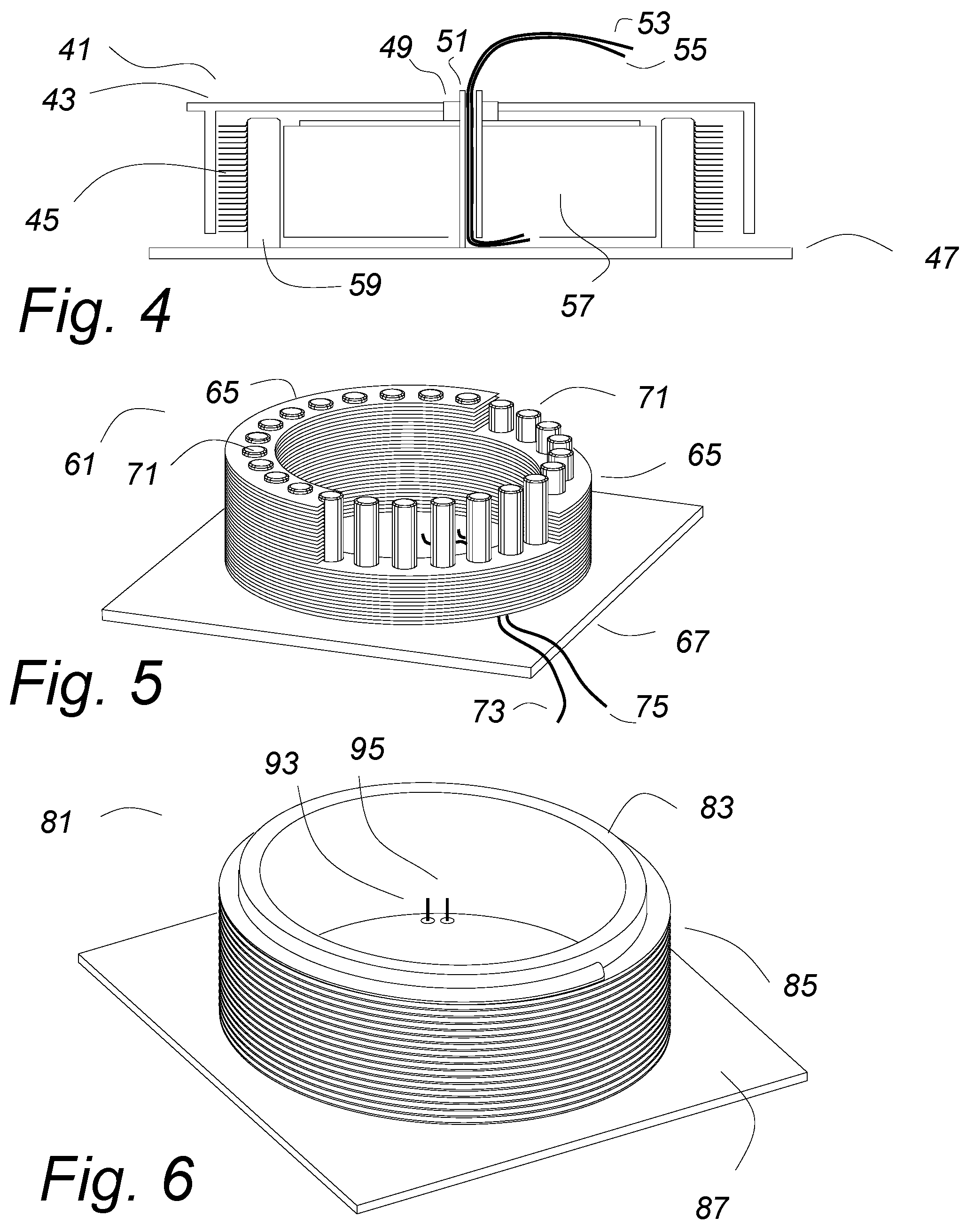

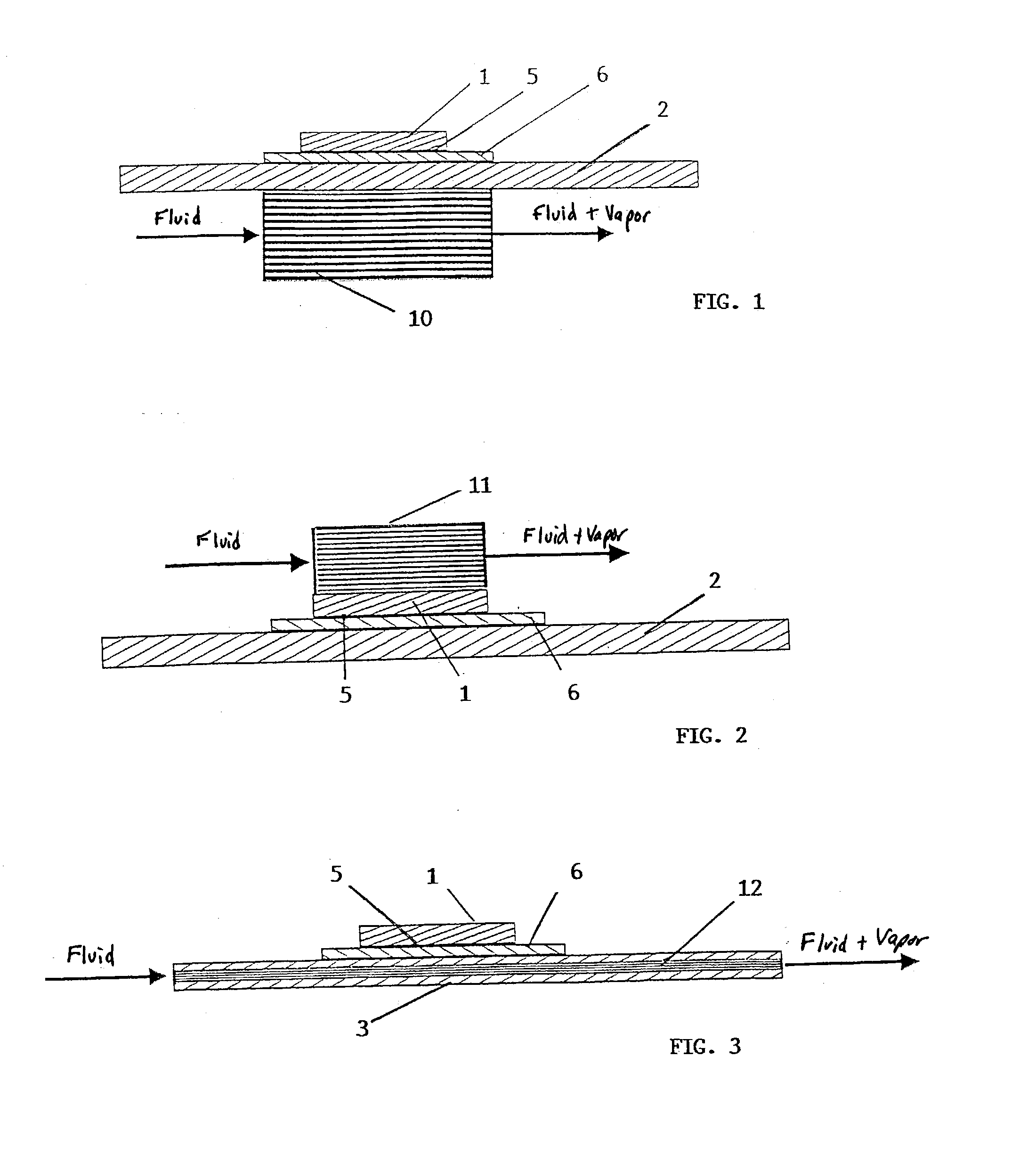

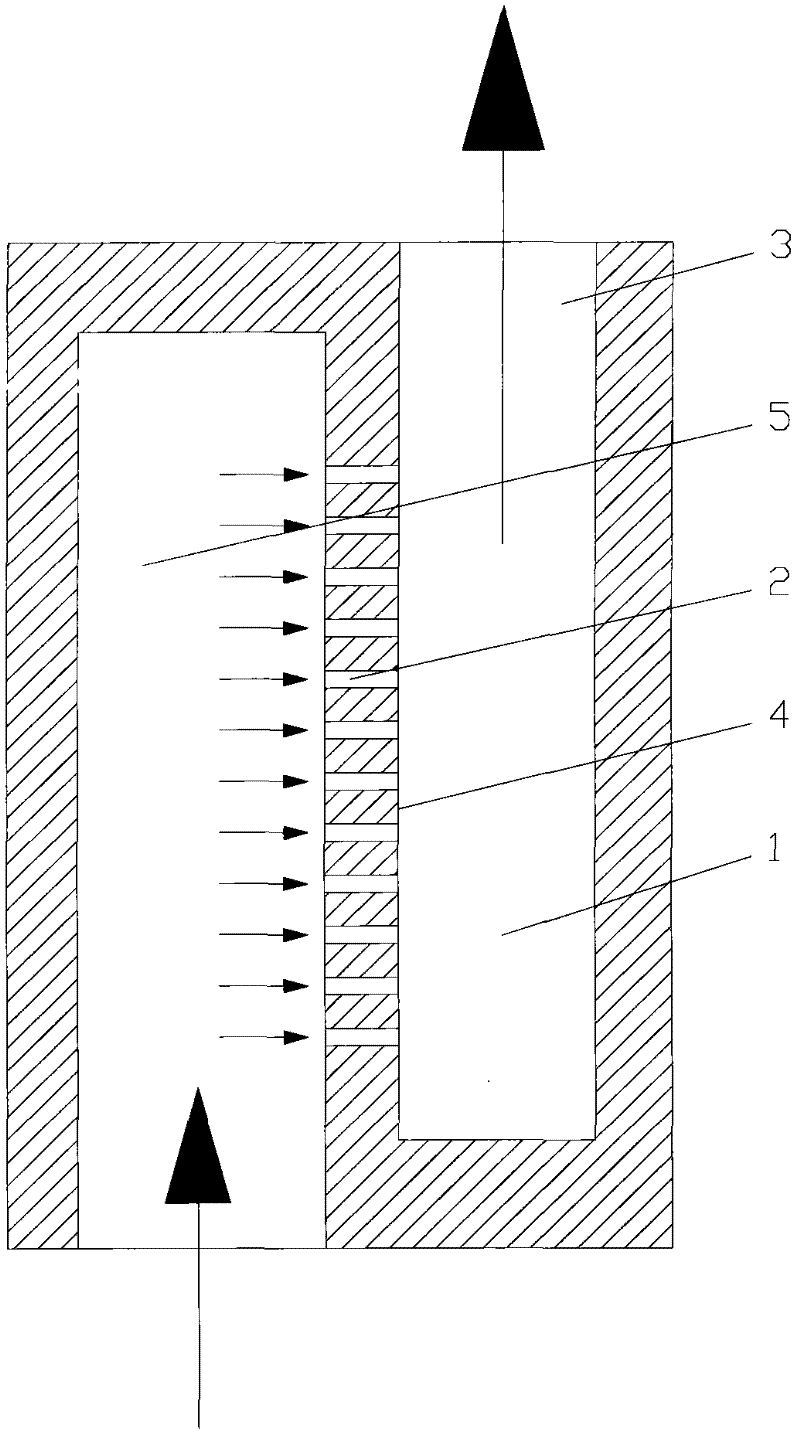

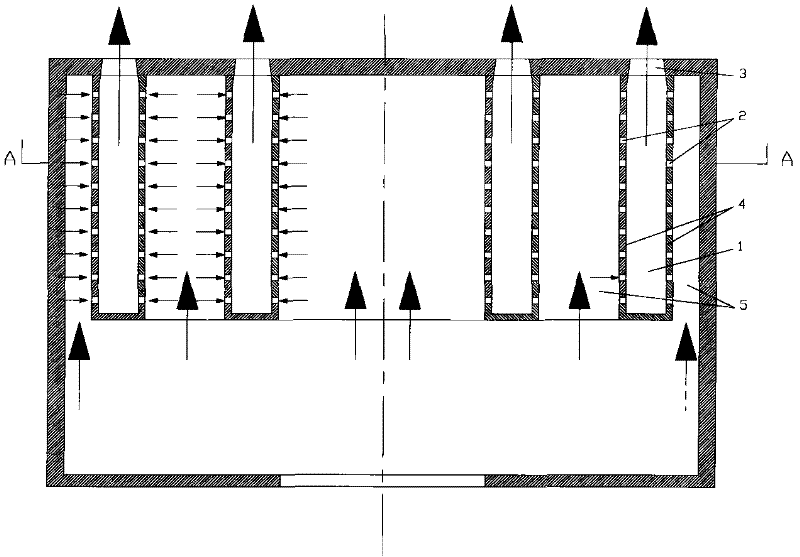

Cooling device for cooling components of the power electronics, said device comprising a micro heat exchanger

InactiveUS20030178178A1Large heat transfer surfaceLarge heat flowDomestic cooling apparatusSemiconductor/solid-state device detailsNuclear engineeringCooling power

The present invention relates to a cooling device, in particular for cooling of components of power electronics, using a coolant which flows through a micro heat exchanger (10) having a good heat contact with the component (1), and wherein the coolant is selected in such a way that it evaporates in the micro heat exchanger (10) at the desired component temperature.

Owner:ROBERT BOSCH GMBH

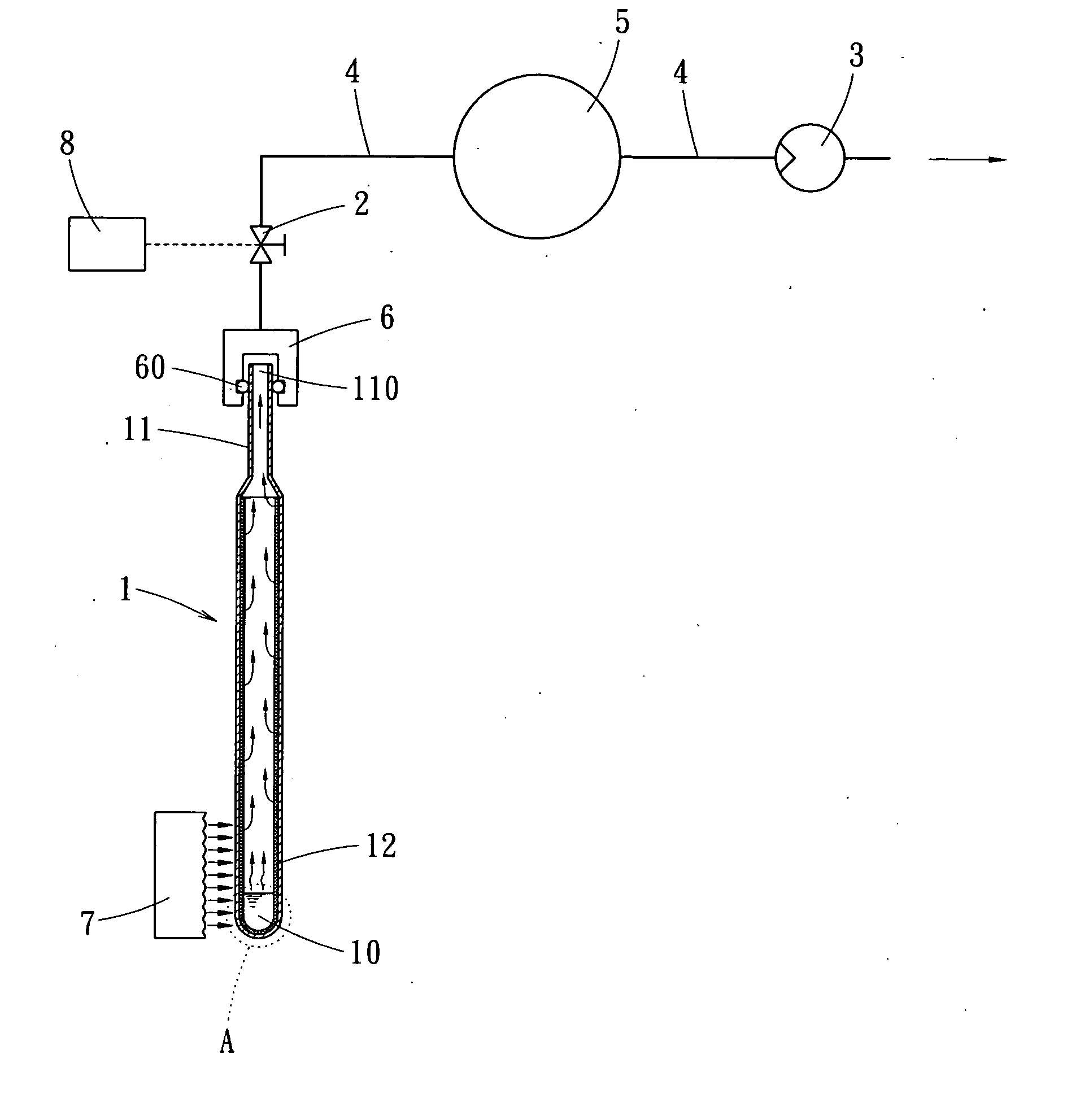

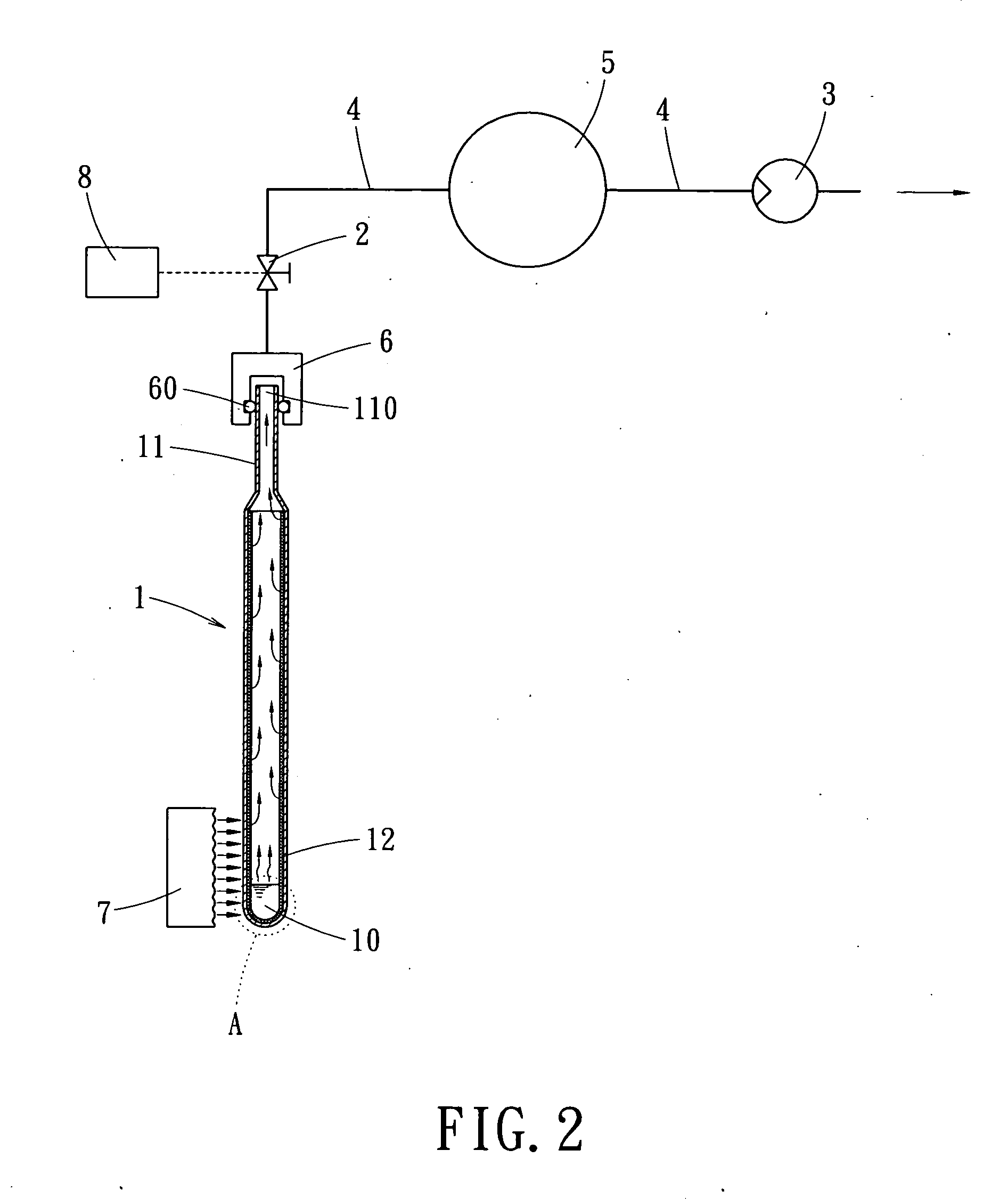

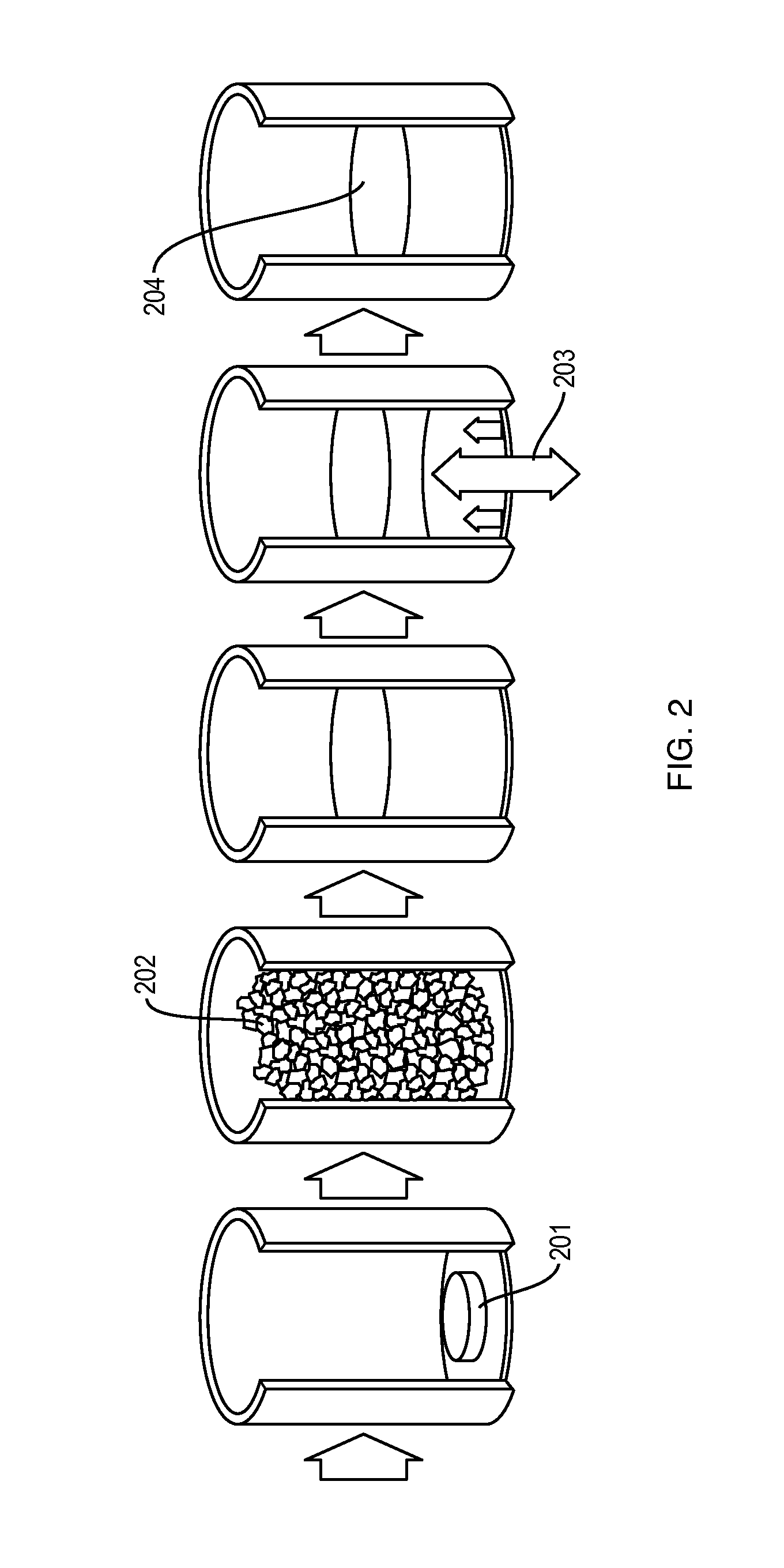

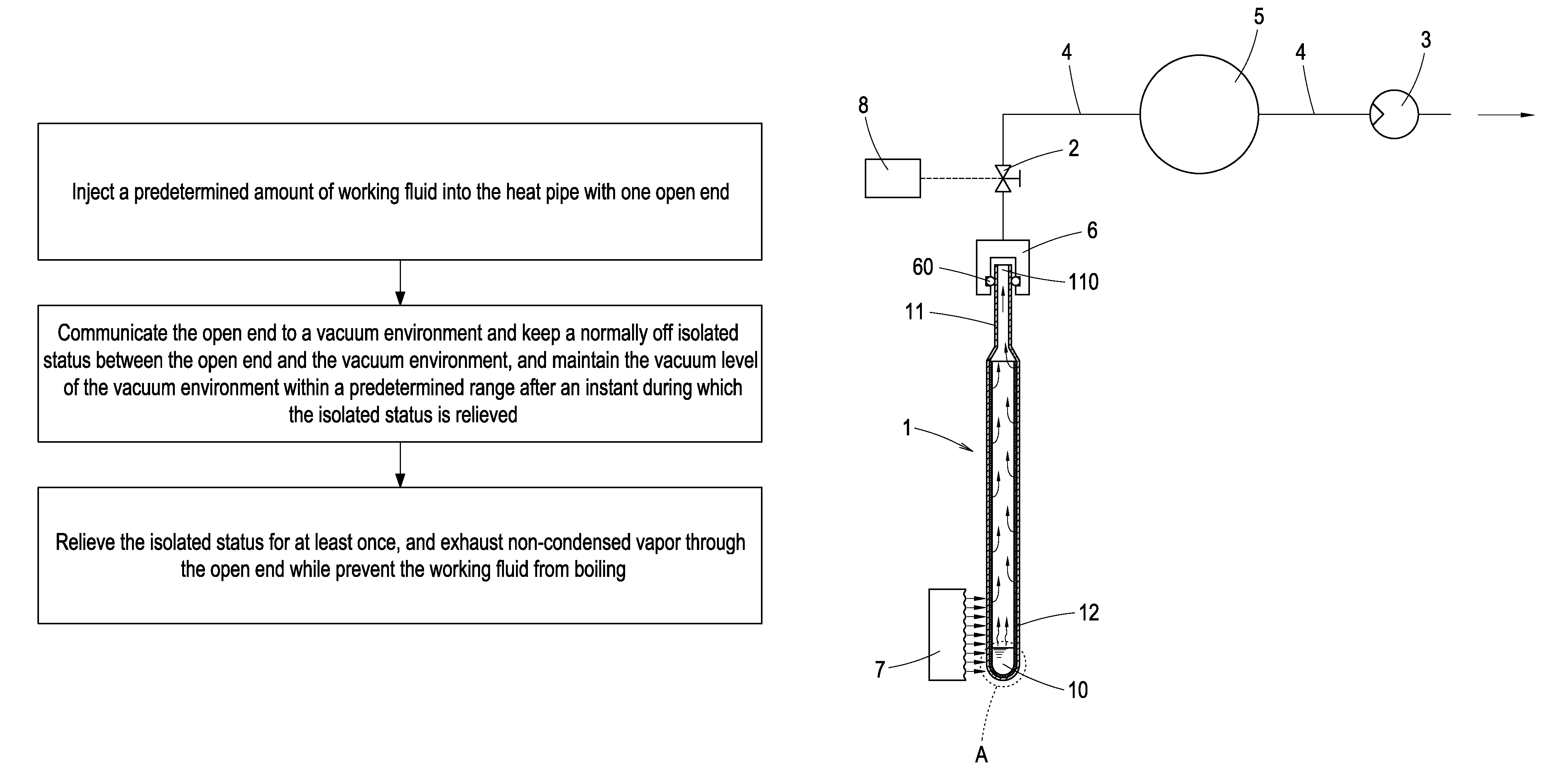

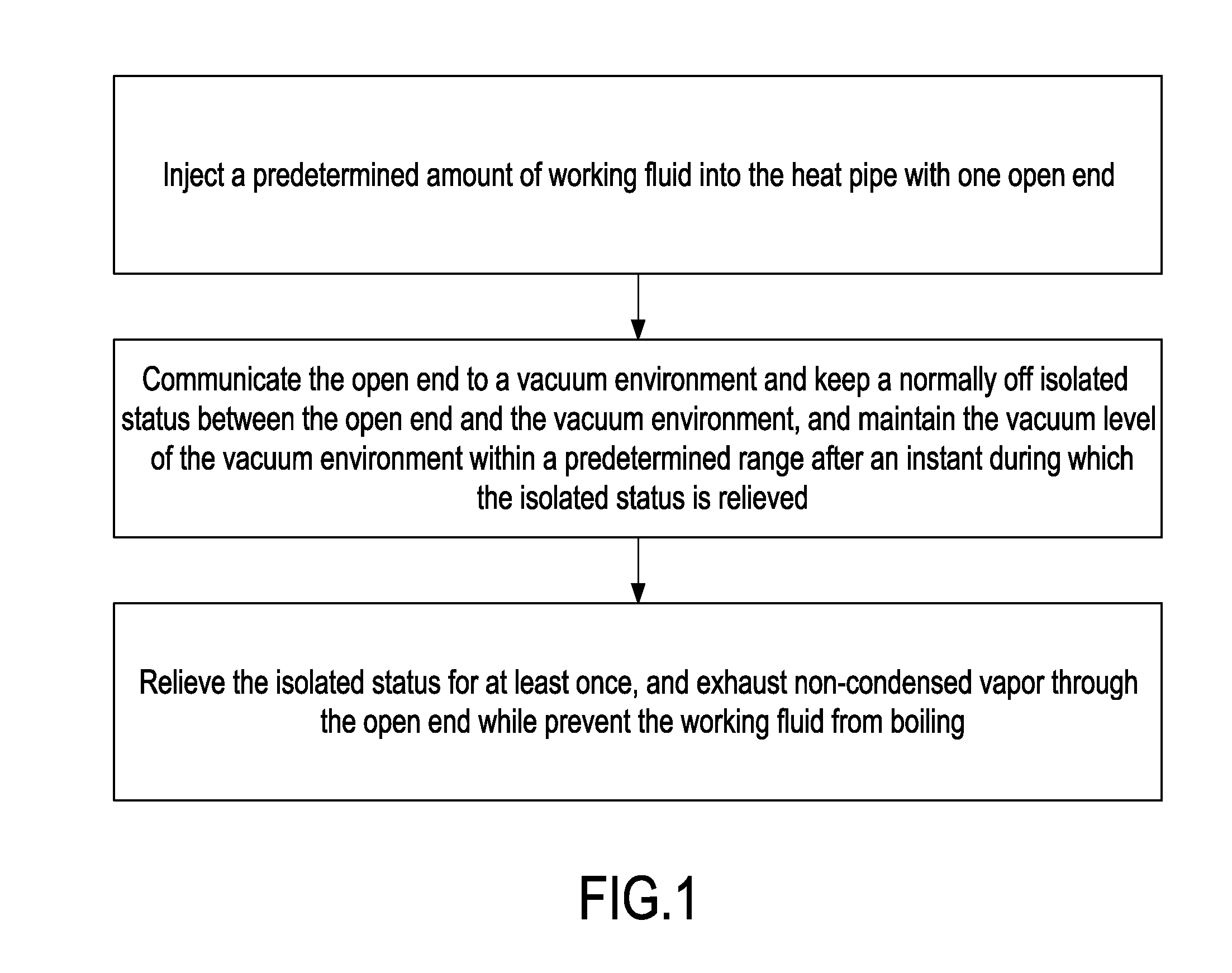

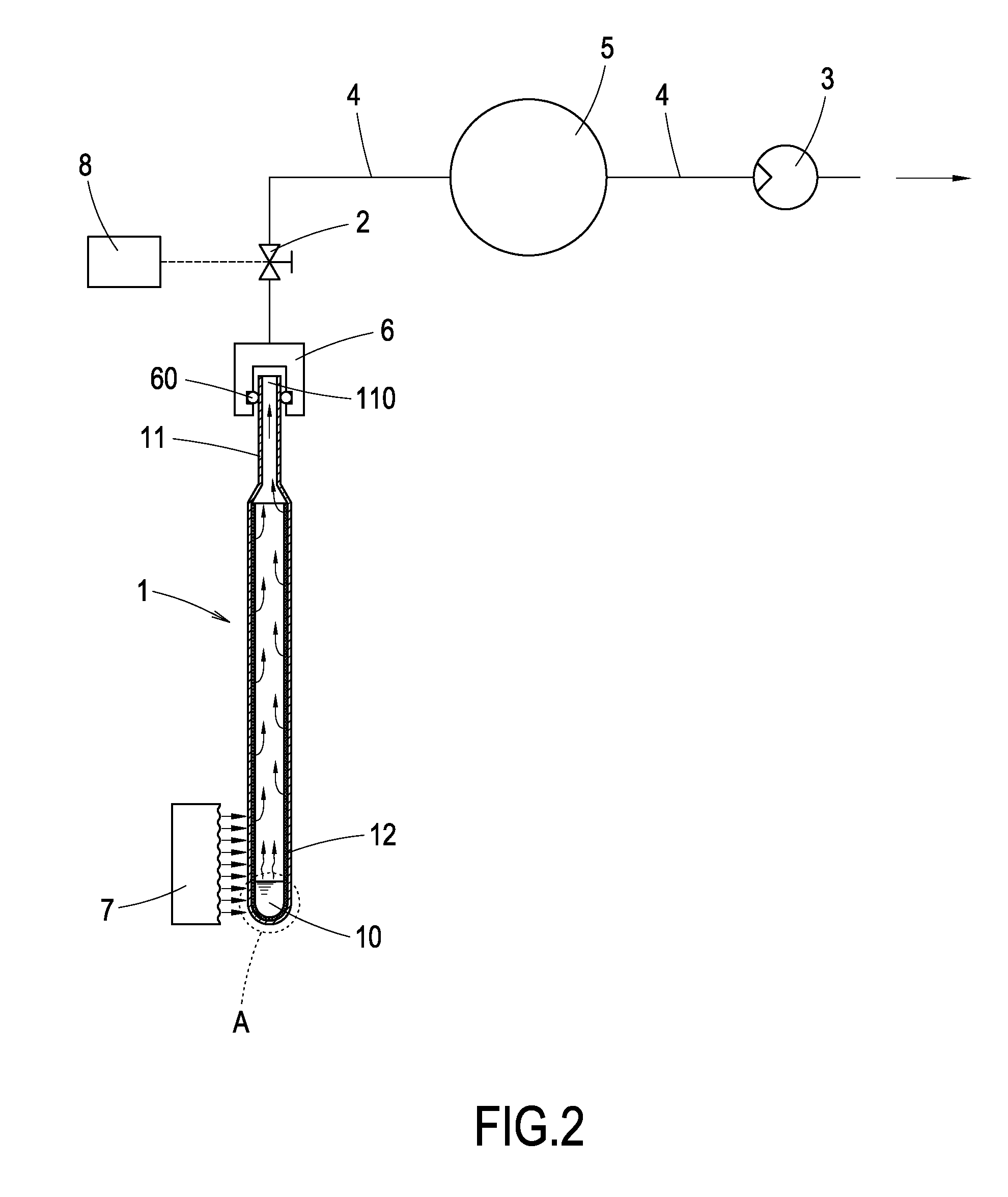

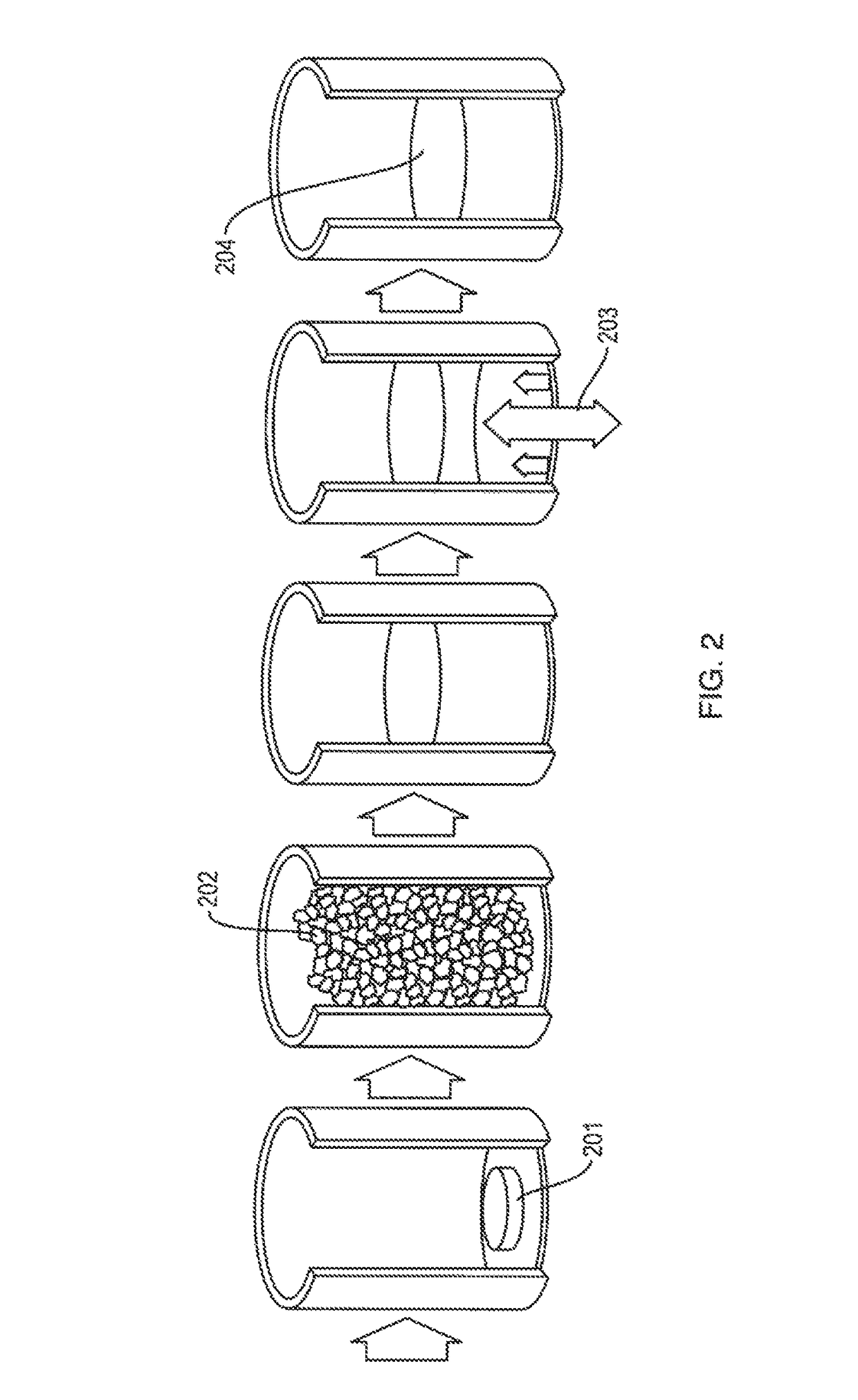

Method and apparatus for removing vapor within heat pipe

InactiveUS20050022414A1Stable quantityQuality improvementIndirect heat exchangersDrying machines with progressive movementsWorking fluidEngineering

A method and an apparatus for removing vapor within a heat pipe. A predetermined amount of working fluid is injected into the heat pipe. The opening of the heat pipe is communicated with a vacuum environment. By controlling the working fluid to be evaporating instead of being boiling, the vapor is exhausted. The apparatus includes a valve, a vacuum apparatus and a vacuum conduit serially connected between the vacuum apparatus and the valve. The valve has one end distal to the vacuum apparatus connected to the heat pipe. The valve is normally off and intermittently switched on and off.

Owner:HSU HUL CHUN

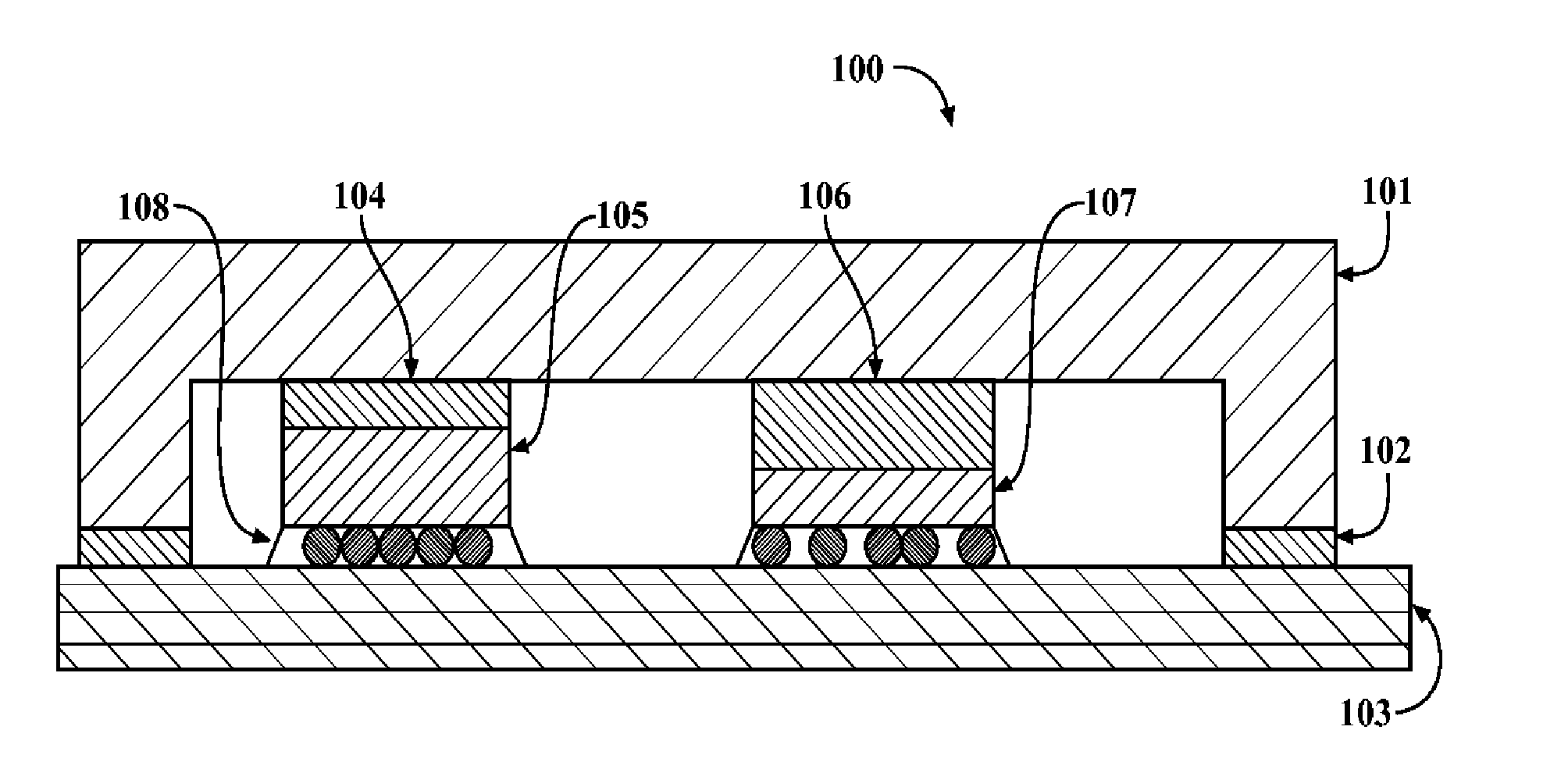

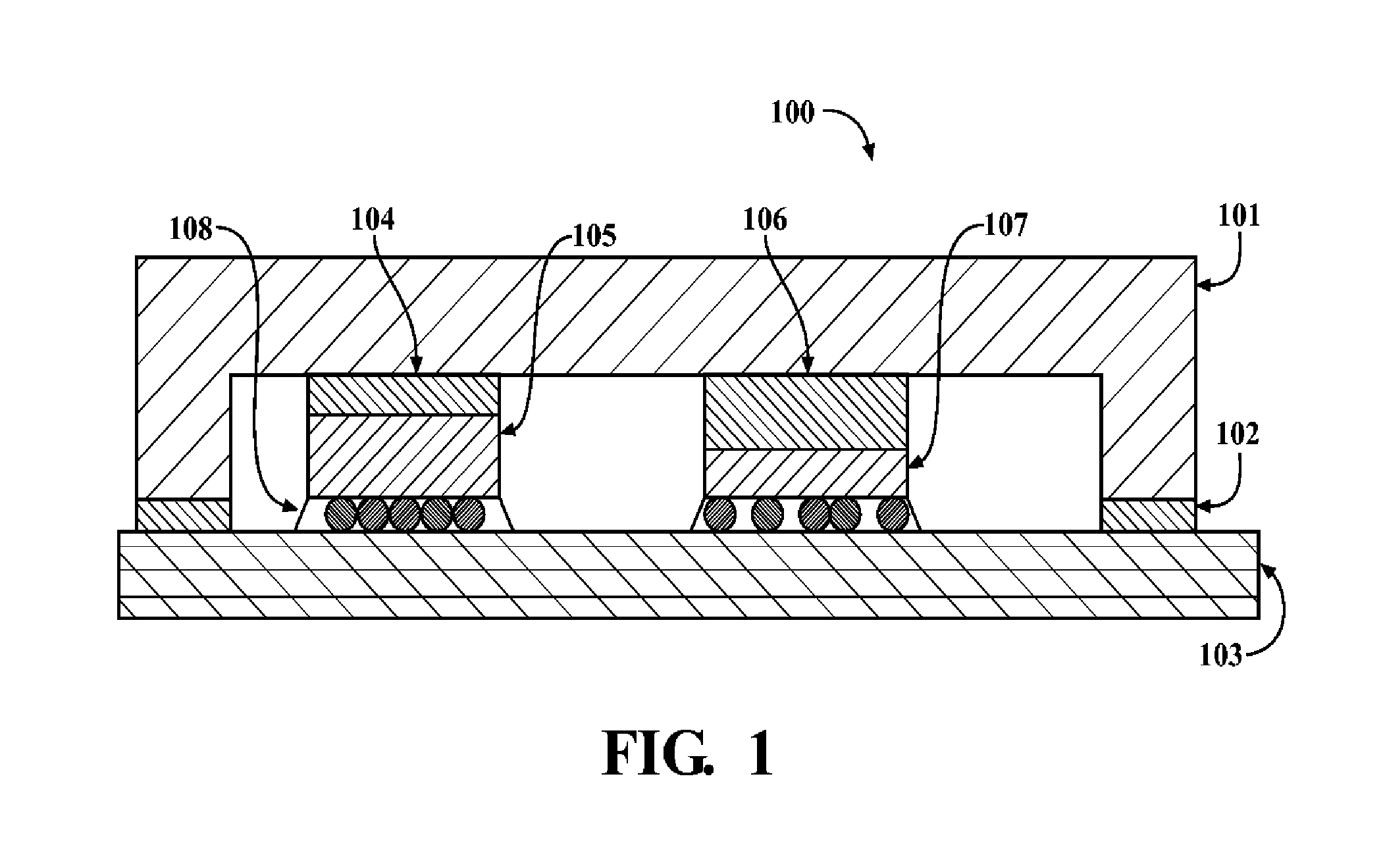

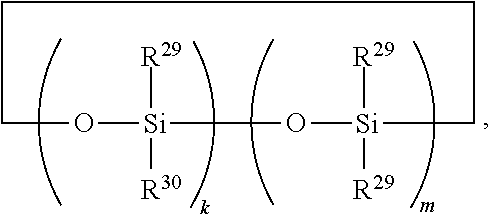

Method of Fabricating an Electronic Device

InactiveUS20160197025A1Avoid heat dissipationEfficient heat transferSemiconductor/solid-state device detailsSolid-state devicesPolymer scienceElectric devices

A silicone composition contains I) a shrink additive and II) a curable polyorganosiloxane composition. A method for fabricating an electronic device includes the steps of: 1) interposing the silicone composition between an IHS and a substrate, 2) curing the curable polyorganosiloxane composition to form a cured silicone product, and 3) removing the shrink additive during and / or after step 2), thereby compressing the IHS to the substrate. Compressing occurs as thickness of the cured silicone product decreases, as compared to thickness of the silicone composition interposed in step 1).

Owner:DOW CORNING CORP

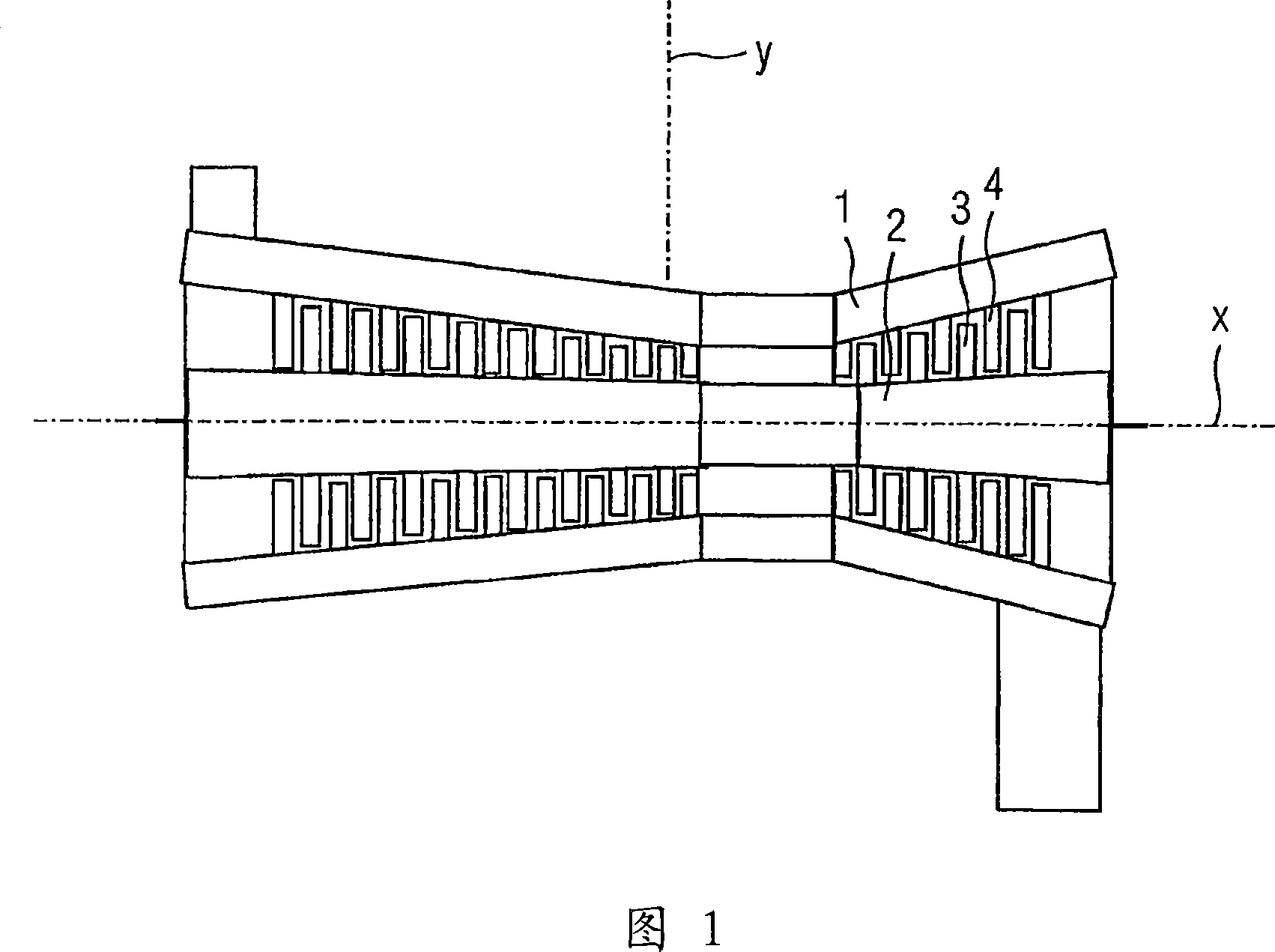

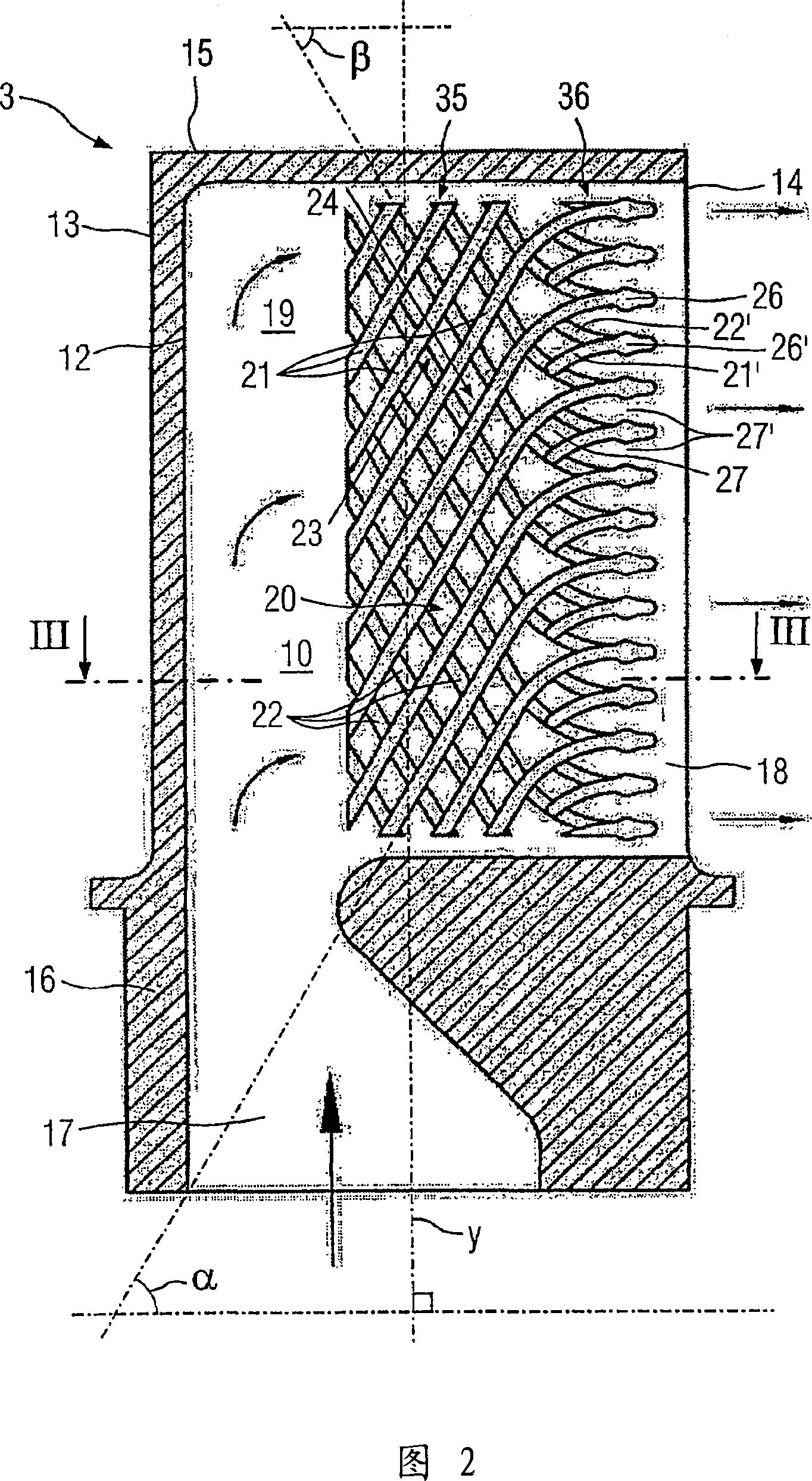

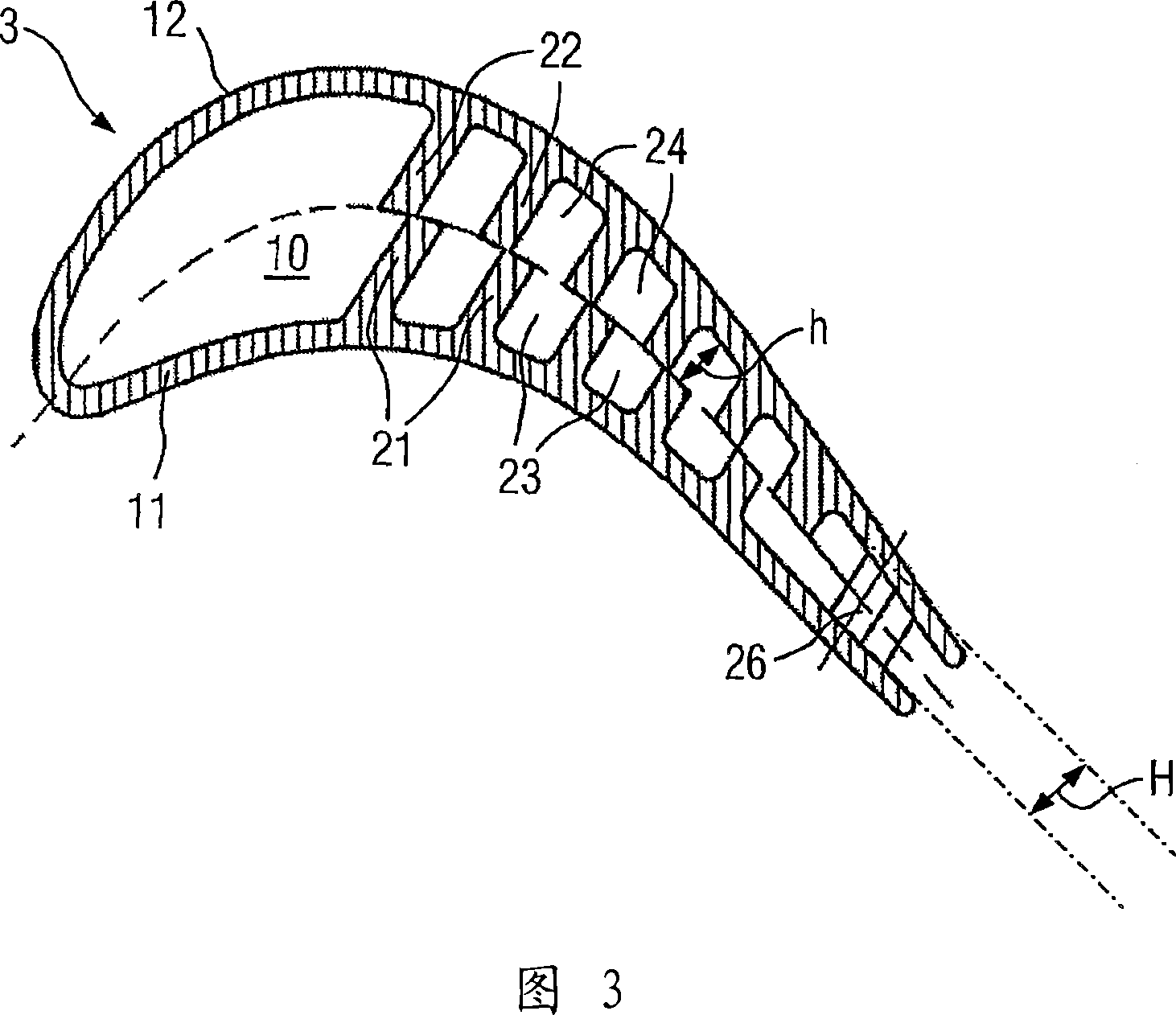

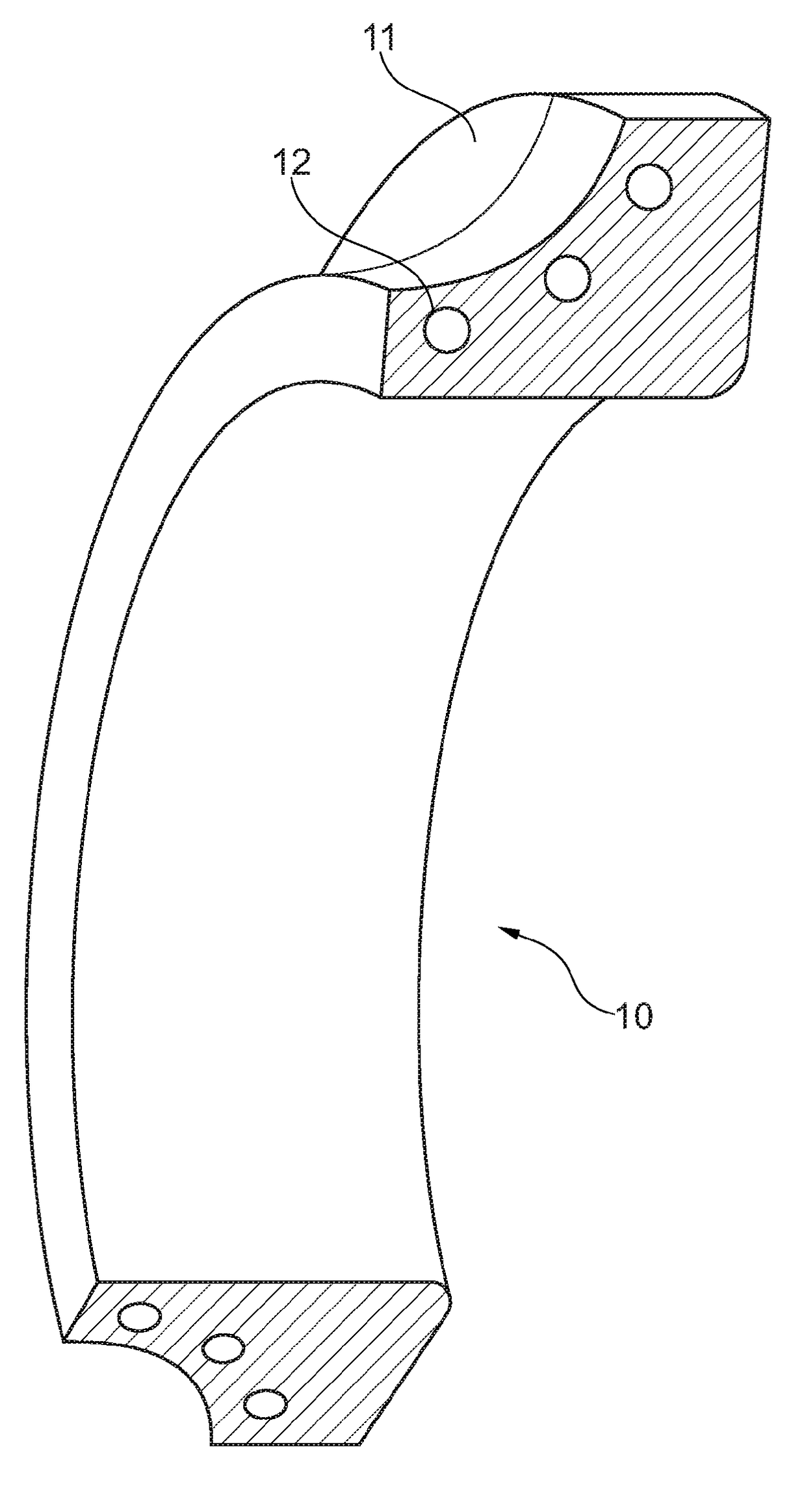

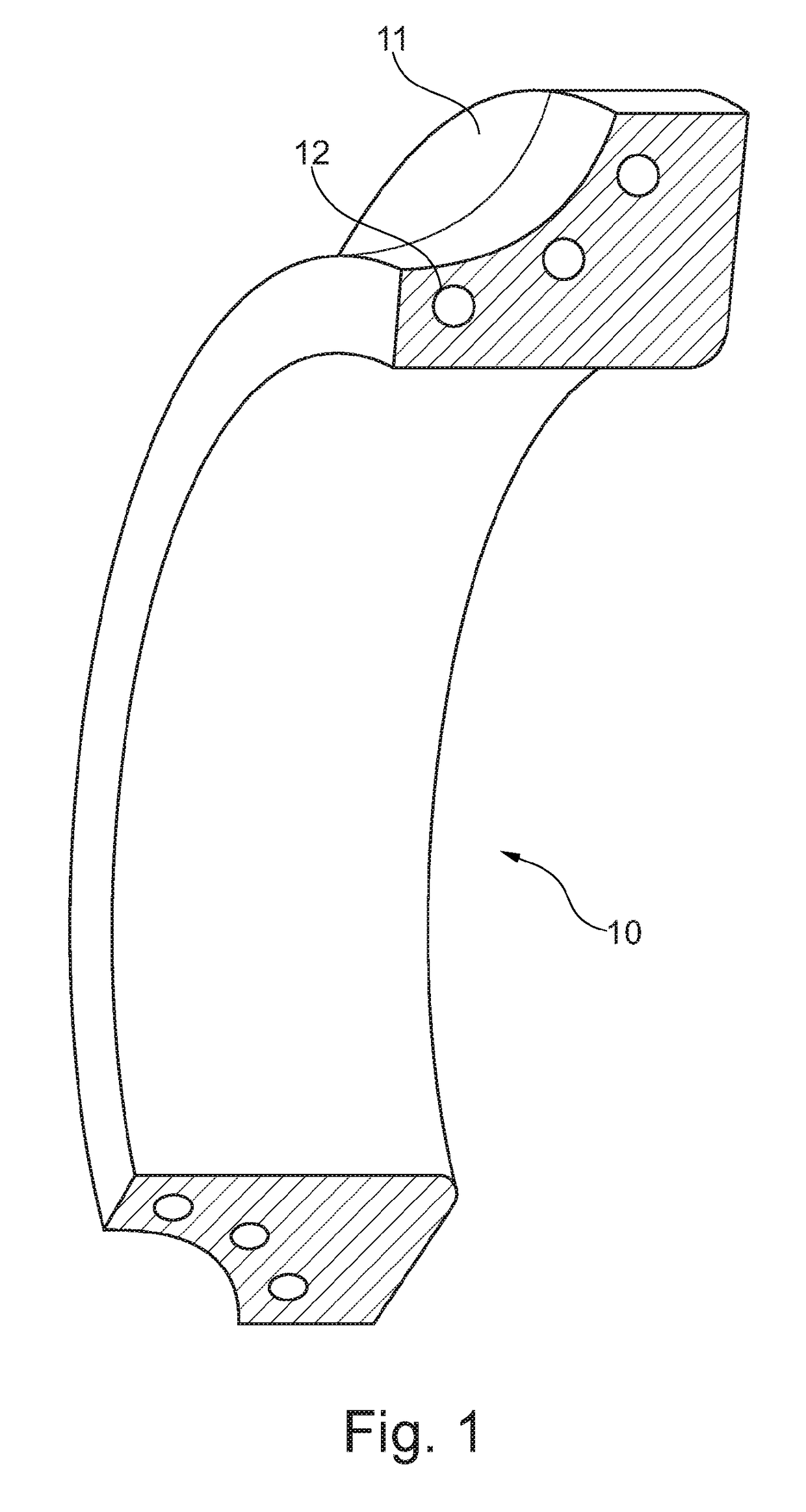

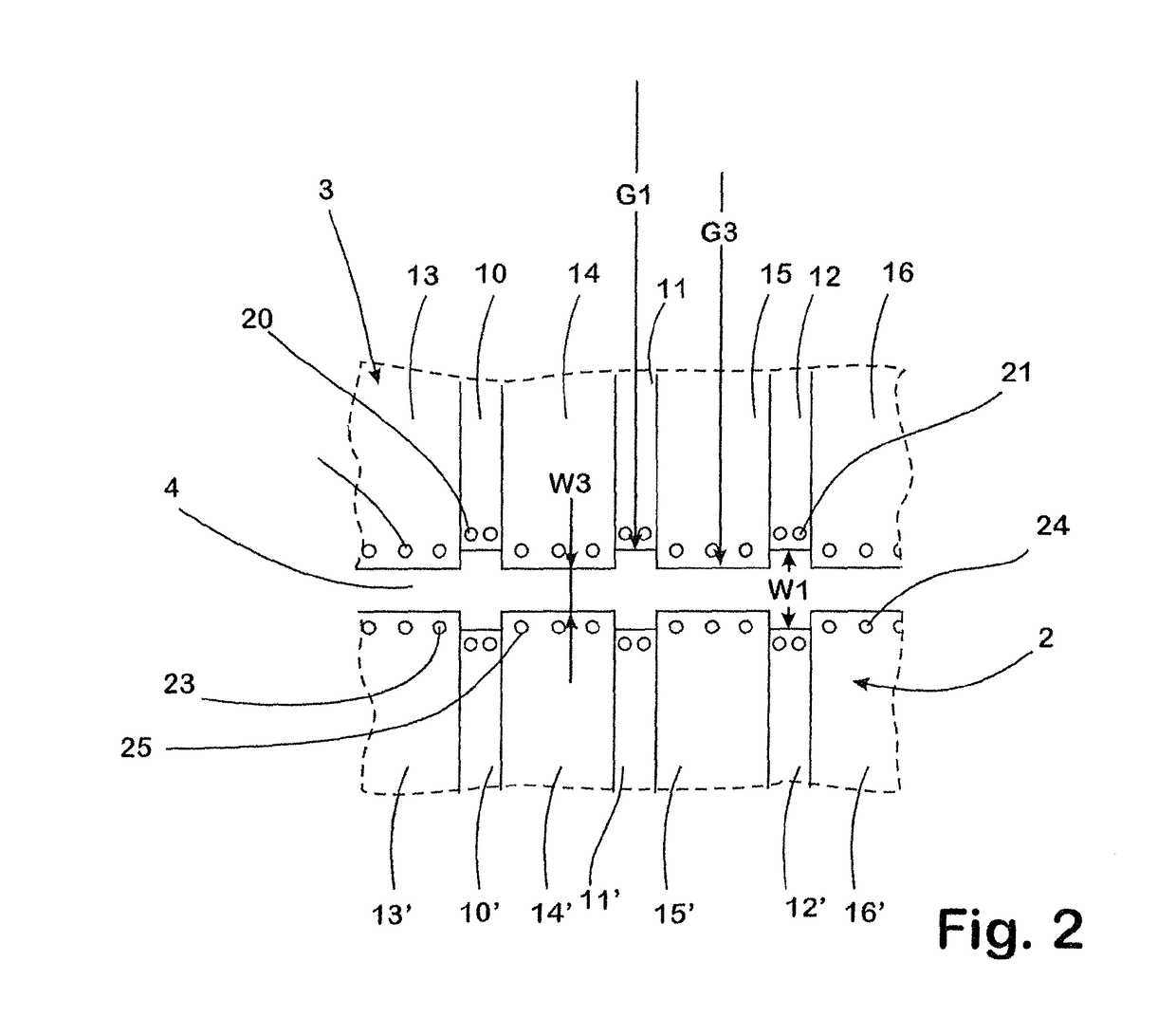

Blade or vane for a rotary machine

InactiveCN1997810AReduce cloggingIncrease contact areaEngine fuctionsBlade accessoriesInterior spaceEngineering

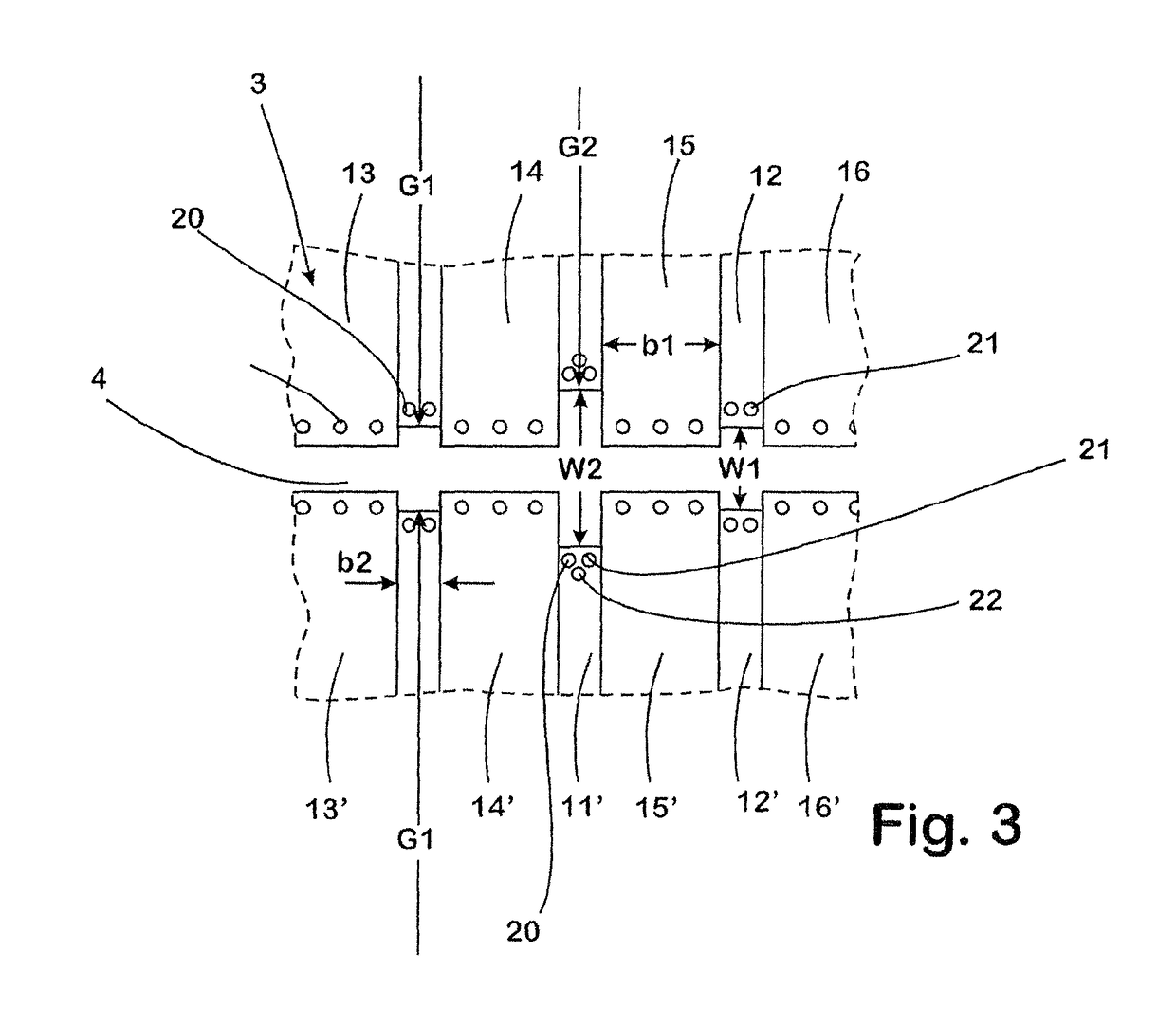

A component defines a blade or a vane for a rotor rotatable about a rotary axis (x). An inner space (10) of the component is limited by first and second walls (12), and forms a passage for a cooling fluid. First and second ribs (21, 22) project form the first and second walls, respectively, and extend in parallel to each other to form channels for the fluid from a leading end to a trailing end of the ribs. The ribs extend along a first and a third direction, respectively, in the proximity of the leading end and along a second direction and fourth direction, respectively, in the proximity of the trailing end. The first direction is inclined in relation to the second direction. The third direction is inclined in relation to the fourth direction. The first direction intersects with the third direction. The ribs extend from the leading end to the trailing end along a continuously curved path.

Owner:SIEMENS AG

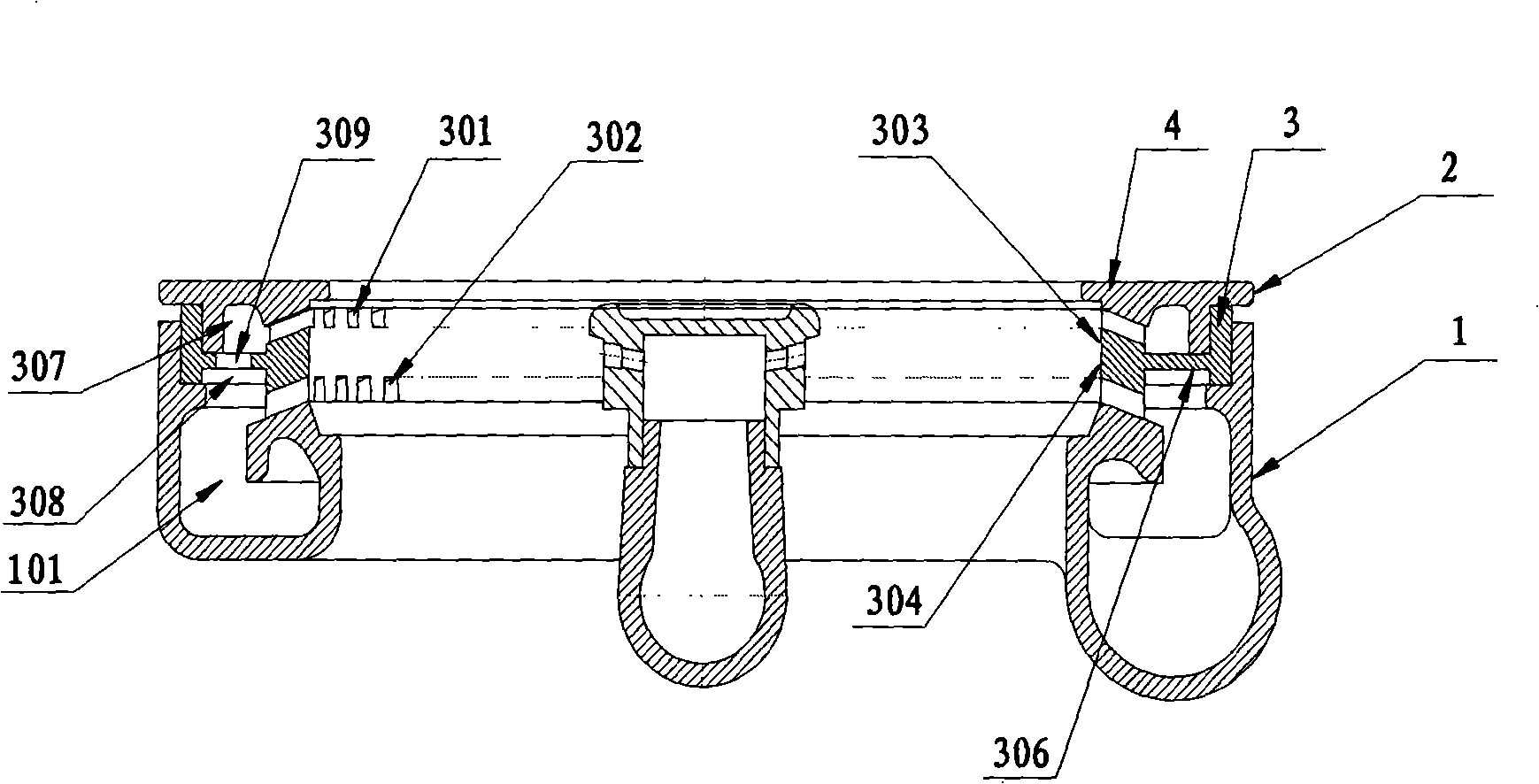

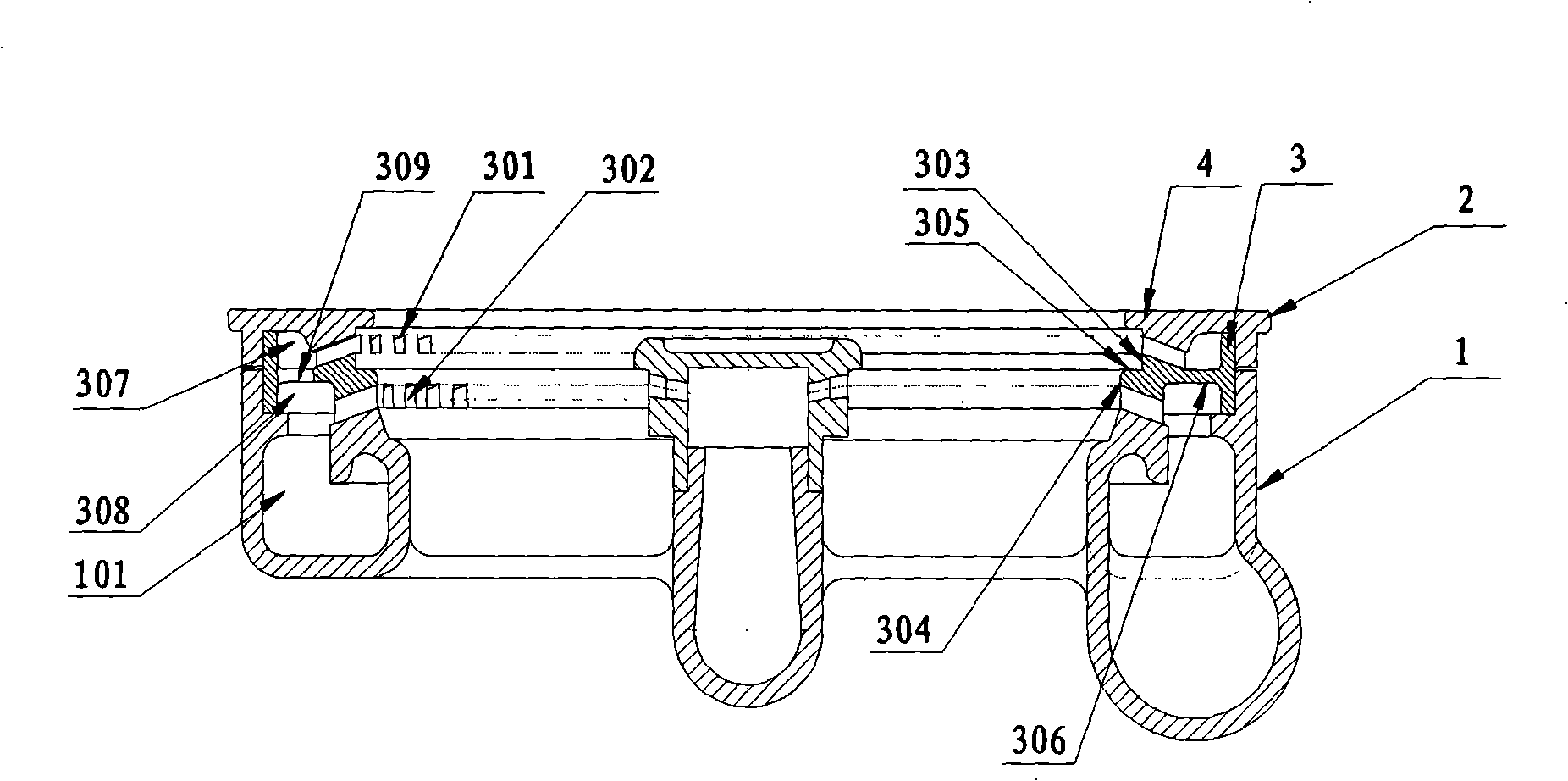

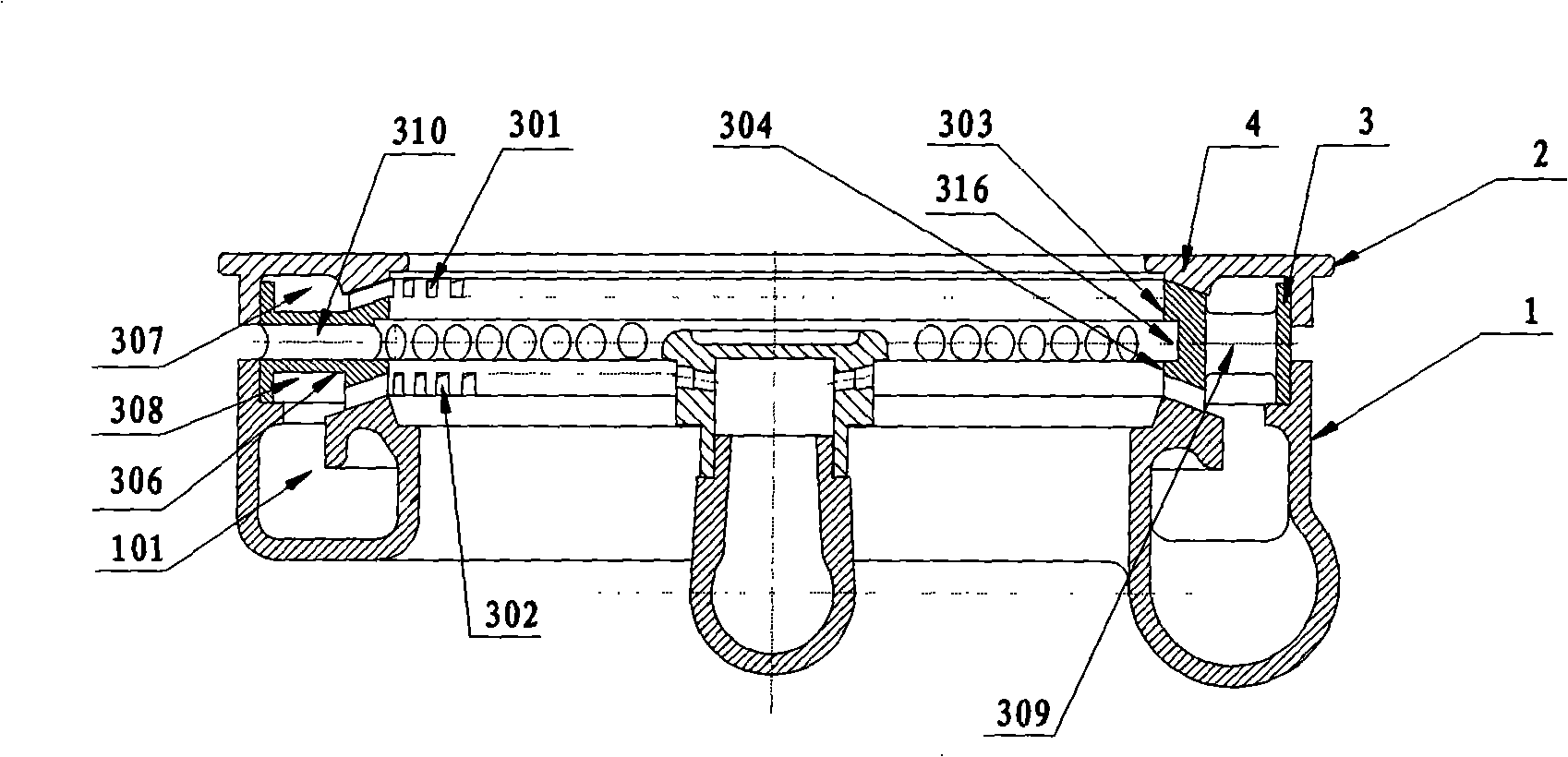

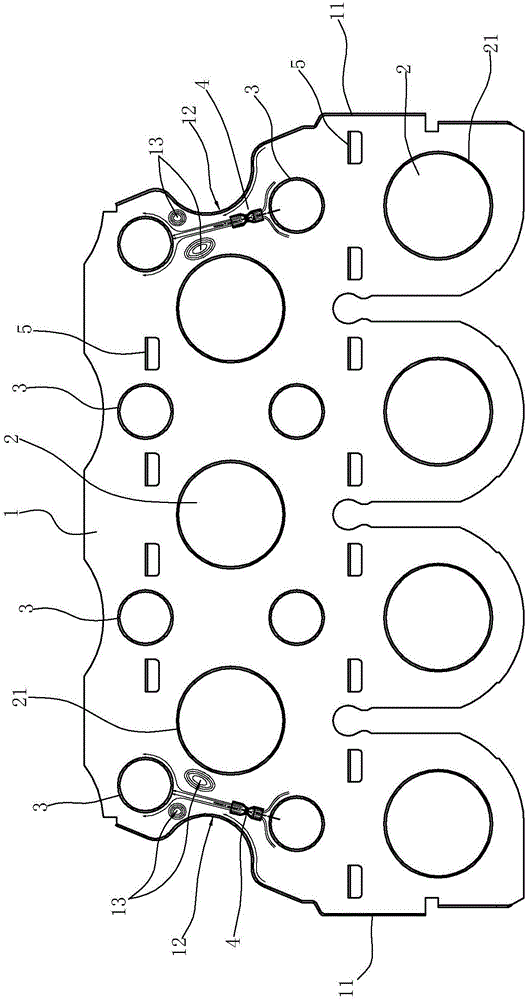

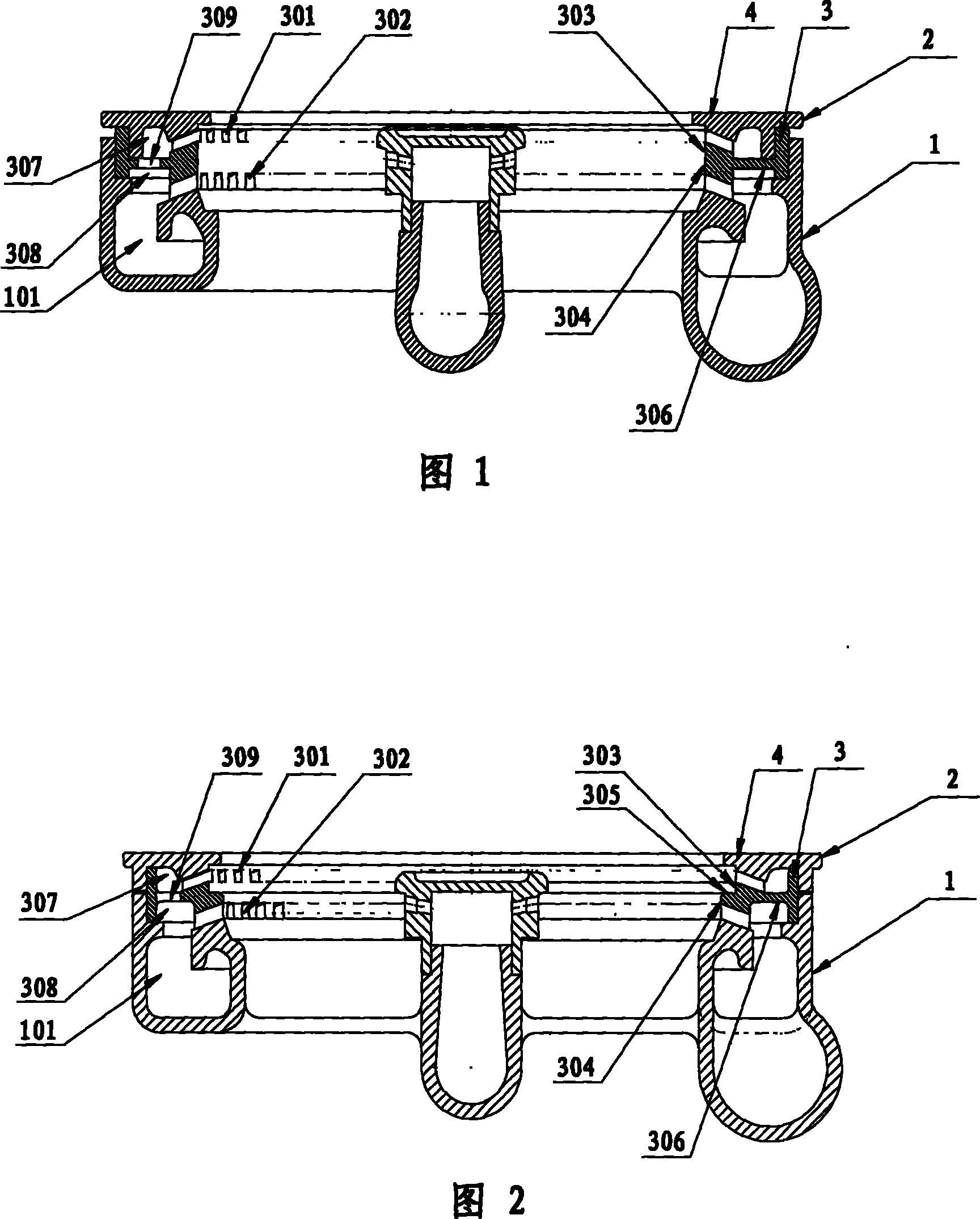

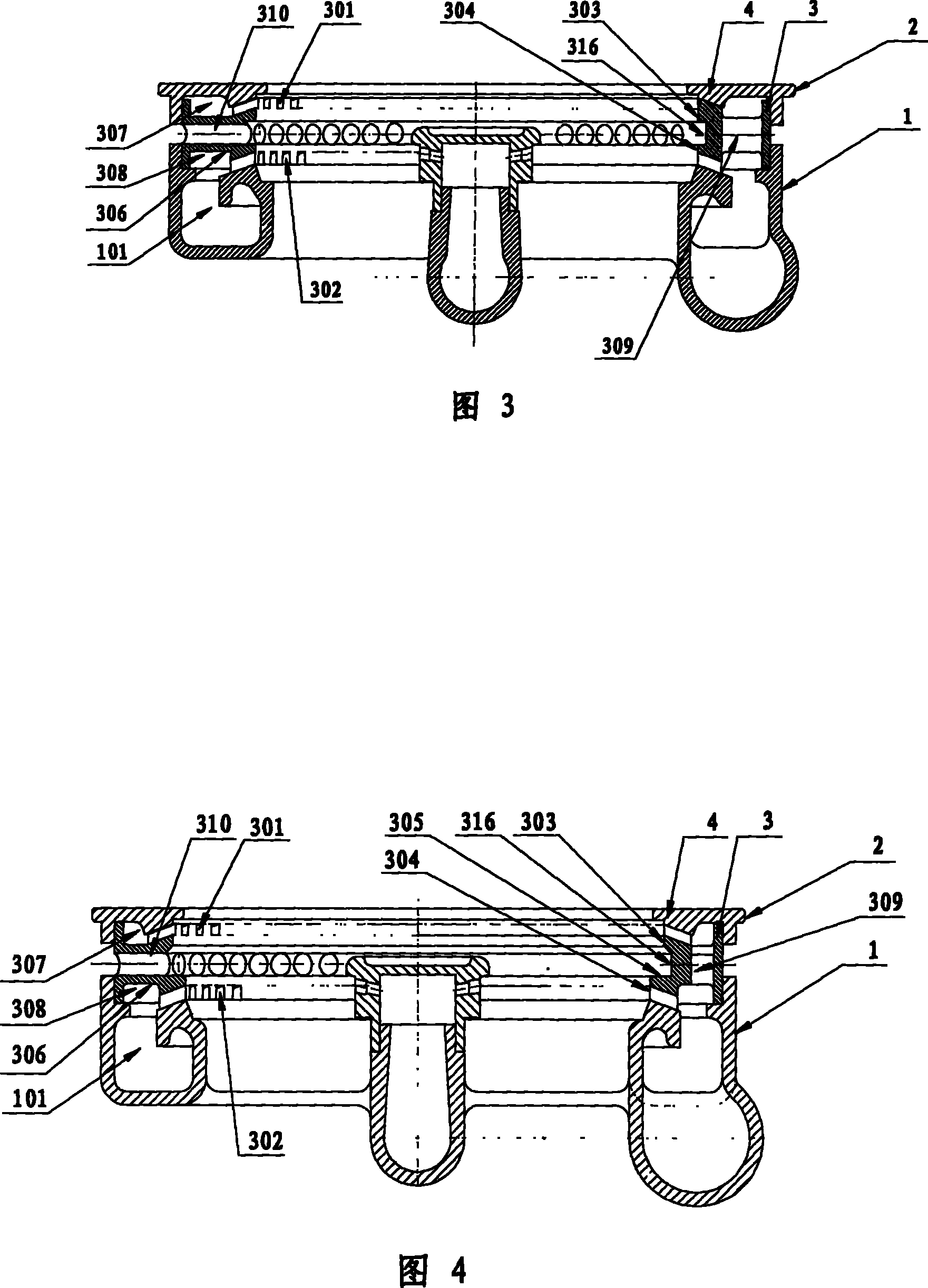

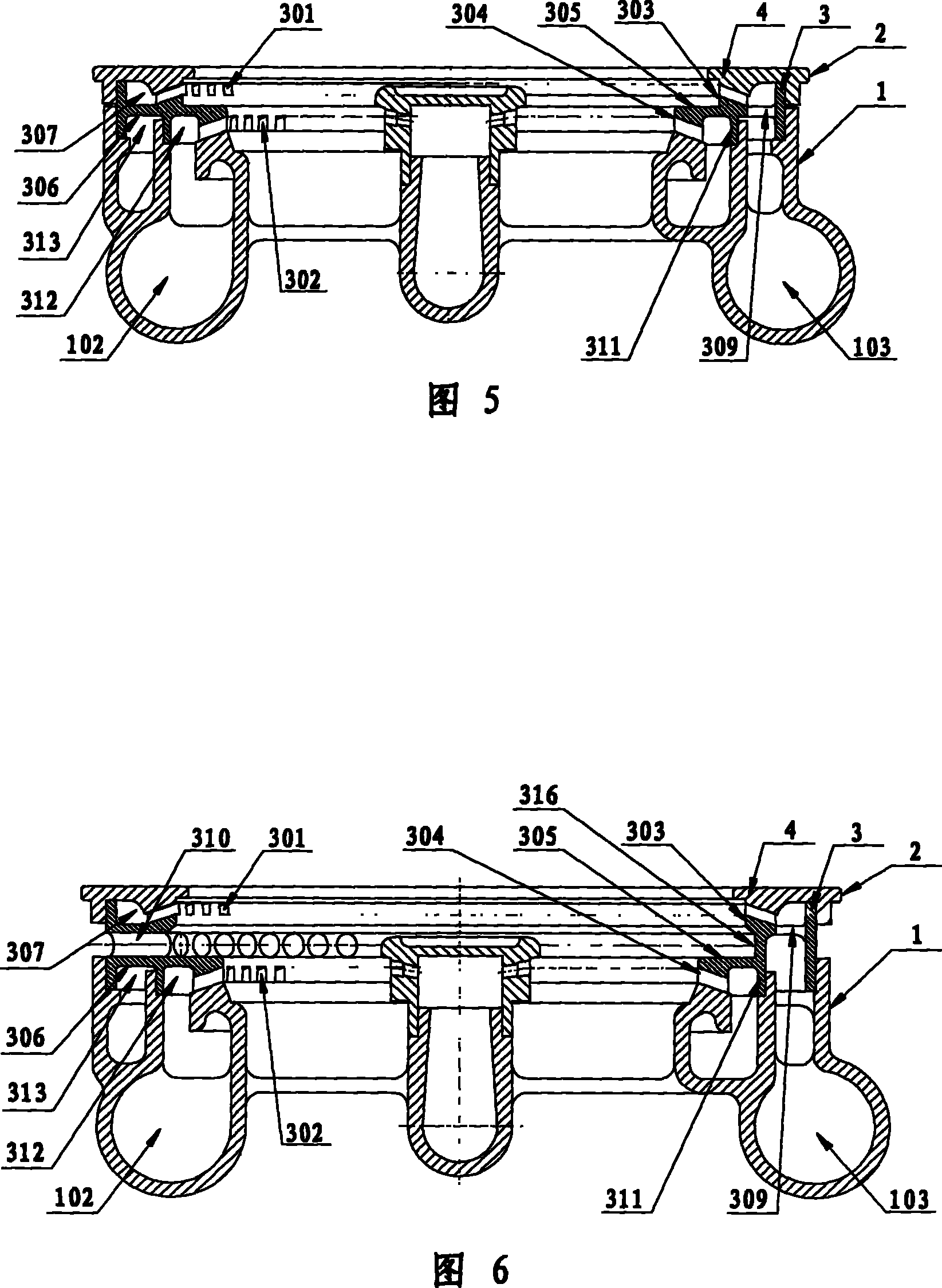

Combustor of inner flame gas range

The invention discloses a burner of an inner flame gas stove, which consists of a burner body and a fire distributer device; an upper layer fire hole and a lower layer fire hole are arranged on the fire distributer device and the direction of the outlets of the fire holes is inward, and an air channel is arranged or not arranged between the upper layer fire hole and the lower layer fire hole; a single inner cavity or two independent inner cavities is or are arranged; the two independent inner cavities are arranged so that the flame at the upper layer and the lower layer can be regulated independently; while the air channel is arranged so that the air supplementation can be more abundant. The burner utilizes multiple-layer fire holes, stratified combustion and multiple-layer cyclonic flame, and has the advantages of large heat flow, fierce fire power, high heat efficiency, low-CO and low-NOx in smoke gas, no fire hole blocking and the like.

Owner:吴成年 +1

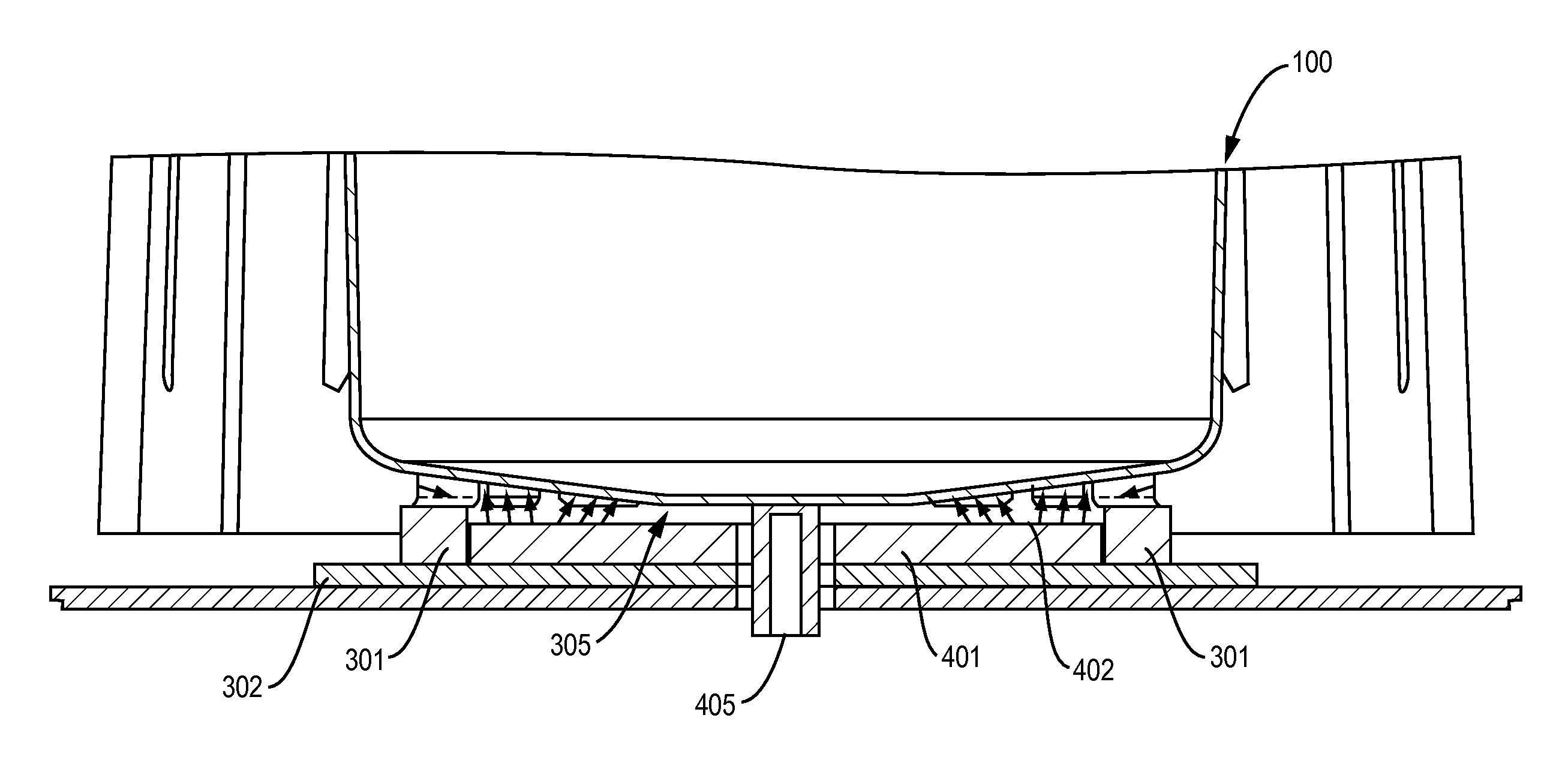

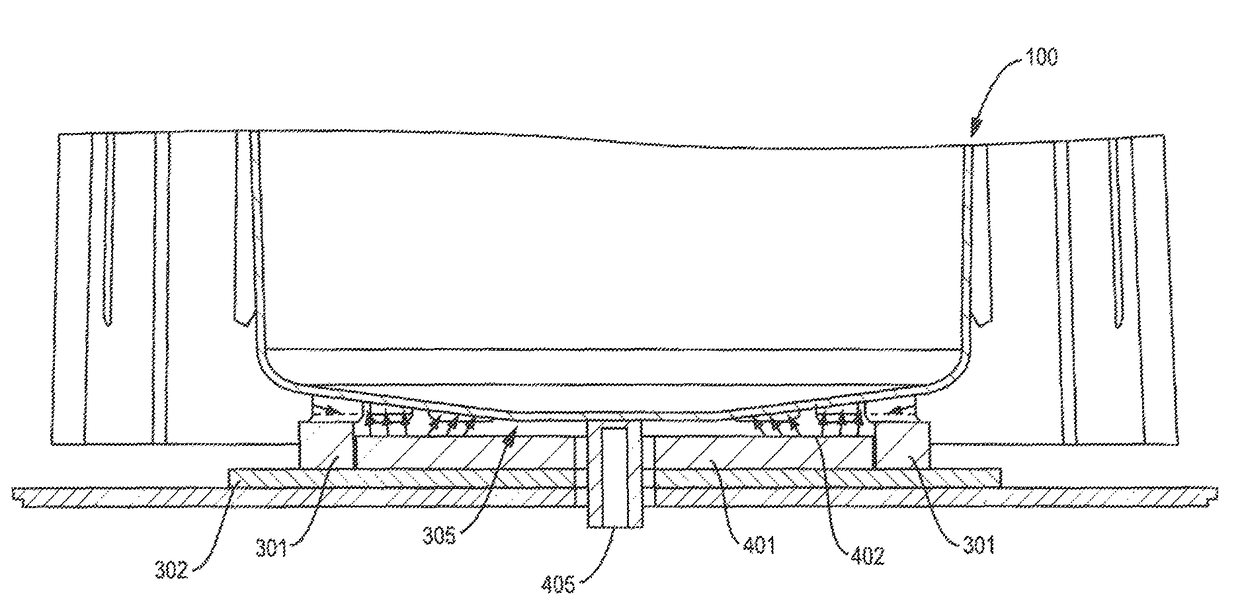

Advanced crucible support and thermal distribution management

ActiveUS20150176150A1Large heat flowAvoid overall overheatingAfter-treatment apparatusPolycrystalline material growthSupporting systemPlate heat exchanger

According to the disclosed embodiments, an advanced crucible support system is described that allows for greater heat flow to and from the bottom of a crucible, preferably while also preventing excessive heat from reaching a heat exchanger. In particular, a support base is described that includes one or more vents enabling improved heat flow throughout the system. Also, according to one or more additional embodiments, the functionality of the crucible support is adapted to be leveraged by a crucible manipulating device. For example, the support plate may have a plurality of slots for insertion of a “lifting arm”, such that the entire support plate assembly, as well as the crucible itself while on the support assembly, may be lifted and transported as a single unit.

Owner:GTAT CORPORATION

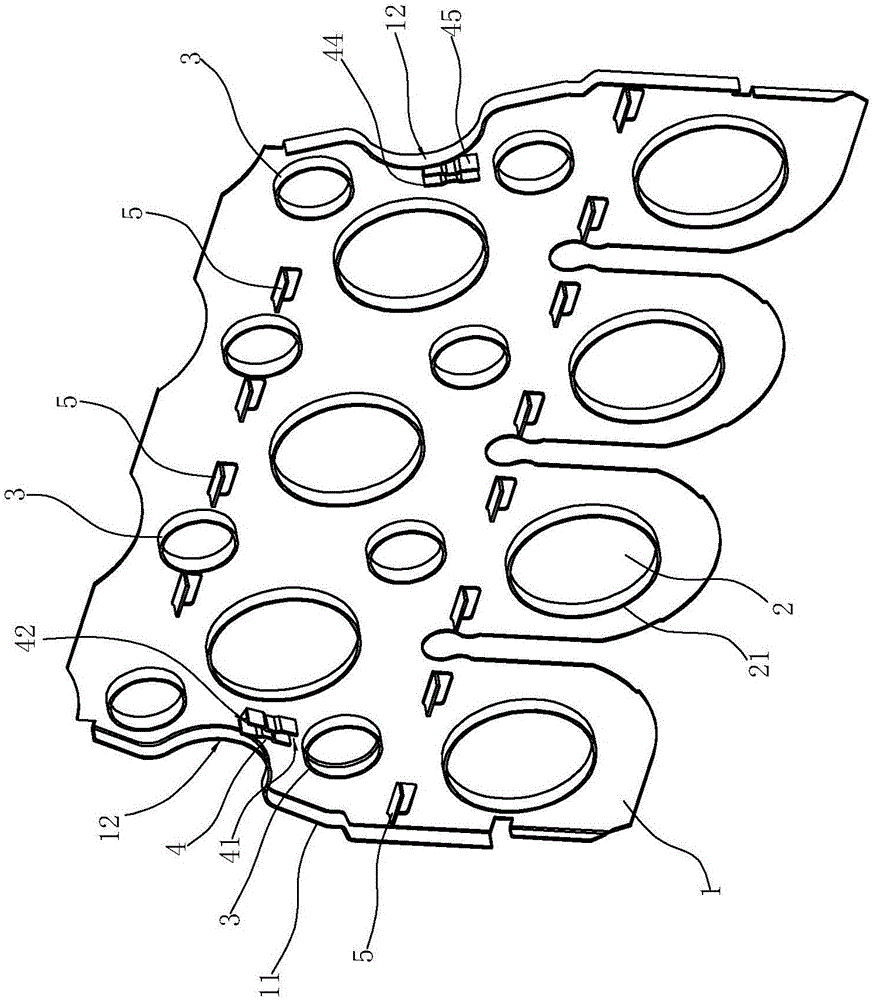

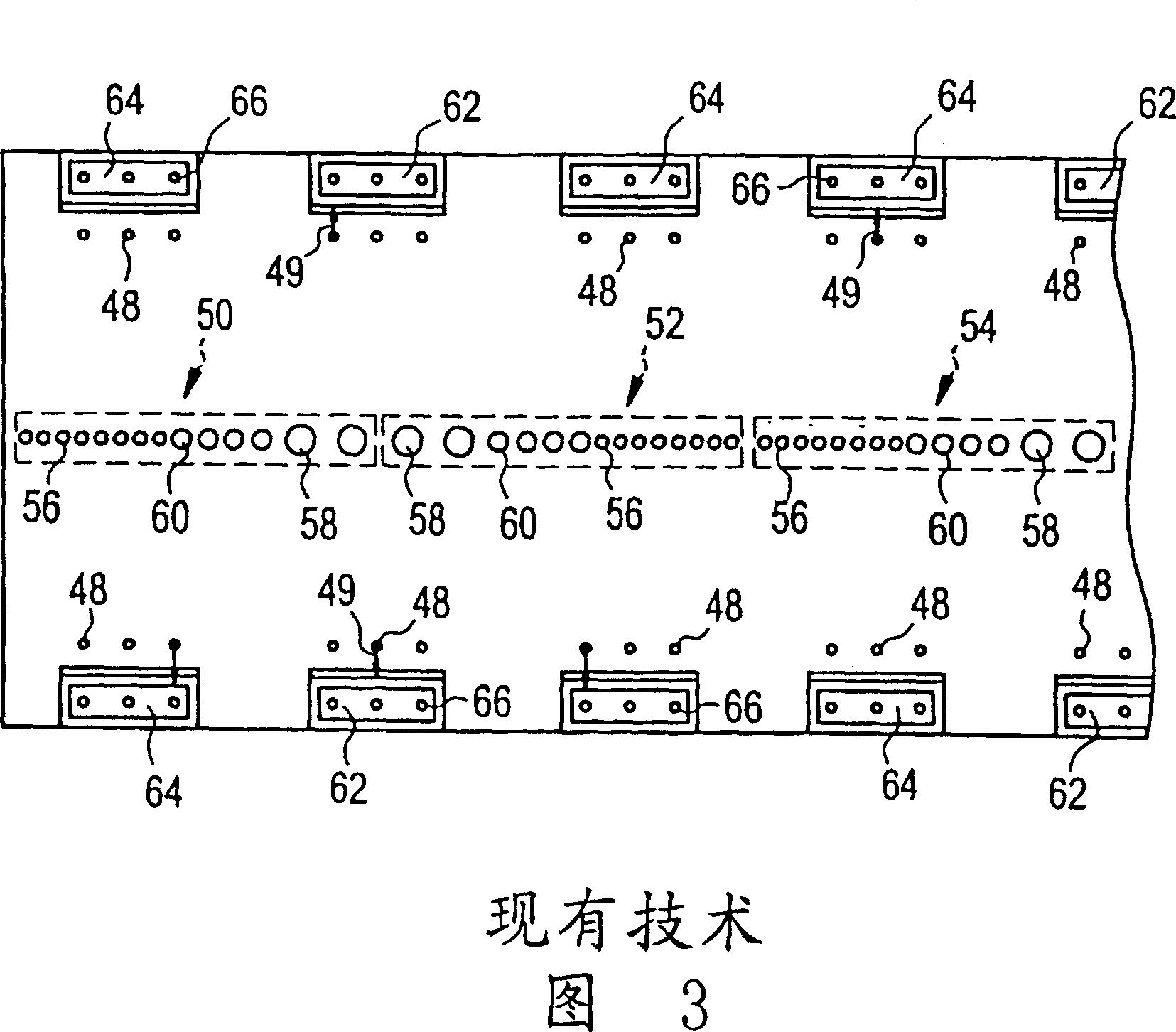

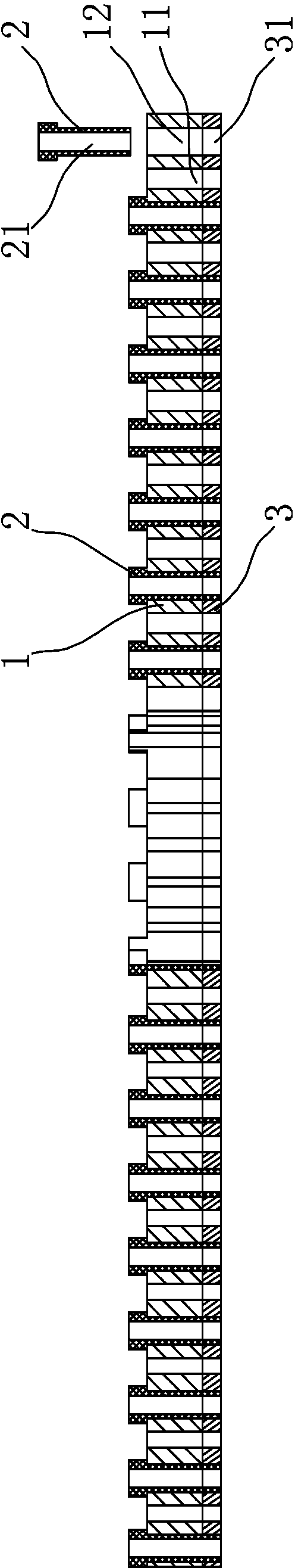

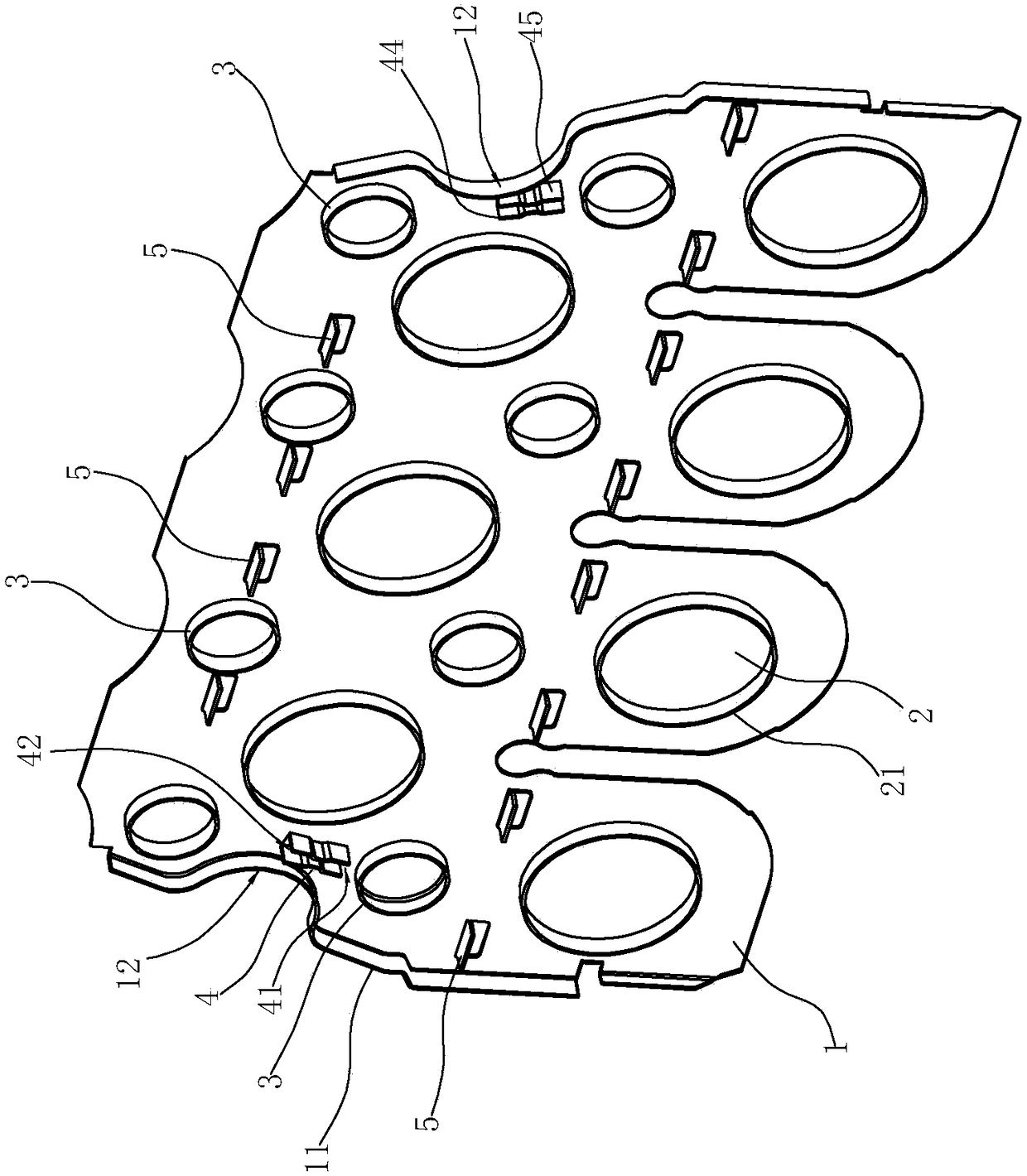

Efficient heat exchange fin

The invention relates to an efficient heat exchange fin. The efficient heat exchange fin comprises a base plate. The surface of the base plate is provided with at least two heat exchange pipe holes at intervals and provided with at least two flow disturbing rings at intervals. The efficient heat exchange fin is characterized in that the heat exchange pipe holes are arranged in two rows, the upper row of heat exchange pipe holes and the lower row of heat exchange pipe holes are staggered, the flow disturbing rings are also arranged in two rows, the upper row of flow disturbing rings and the lower row of flow disturbing rings are staggered, each flow disturbing ring is located above the corresponding heat exchange pipe hole, the two side edges of the base plate are each provided with a turnup protruding outwards, the portion, located between the two rows of flow disturbing rings, of each turnup is recessed inwards, so that an energy gathering arc is formed, the portions, corresponding to the energy gathering arcs, of the surface of the base plate are provided with flow guide channels, the flow guide channels are located between the upper flow disturbing rings and the lower flow disturbing rings, a first end opening of each flow guide channel faces the lower row of flow disturbing rings, and a second end opening of each flow guide channel faces the upper row of flow disturbing rings. The efficient heat exchange fin can greatly improve the heat exchange intensity and the heat exchange efficiency.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

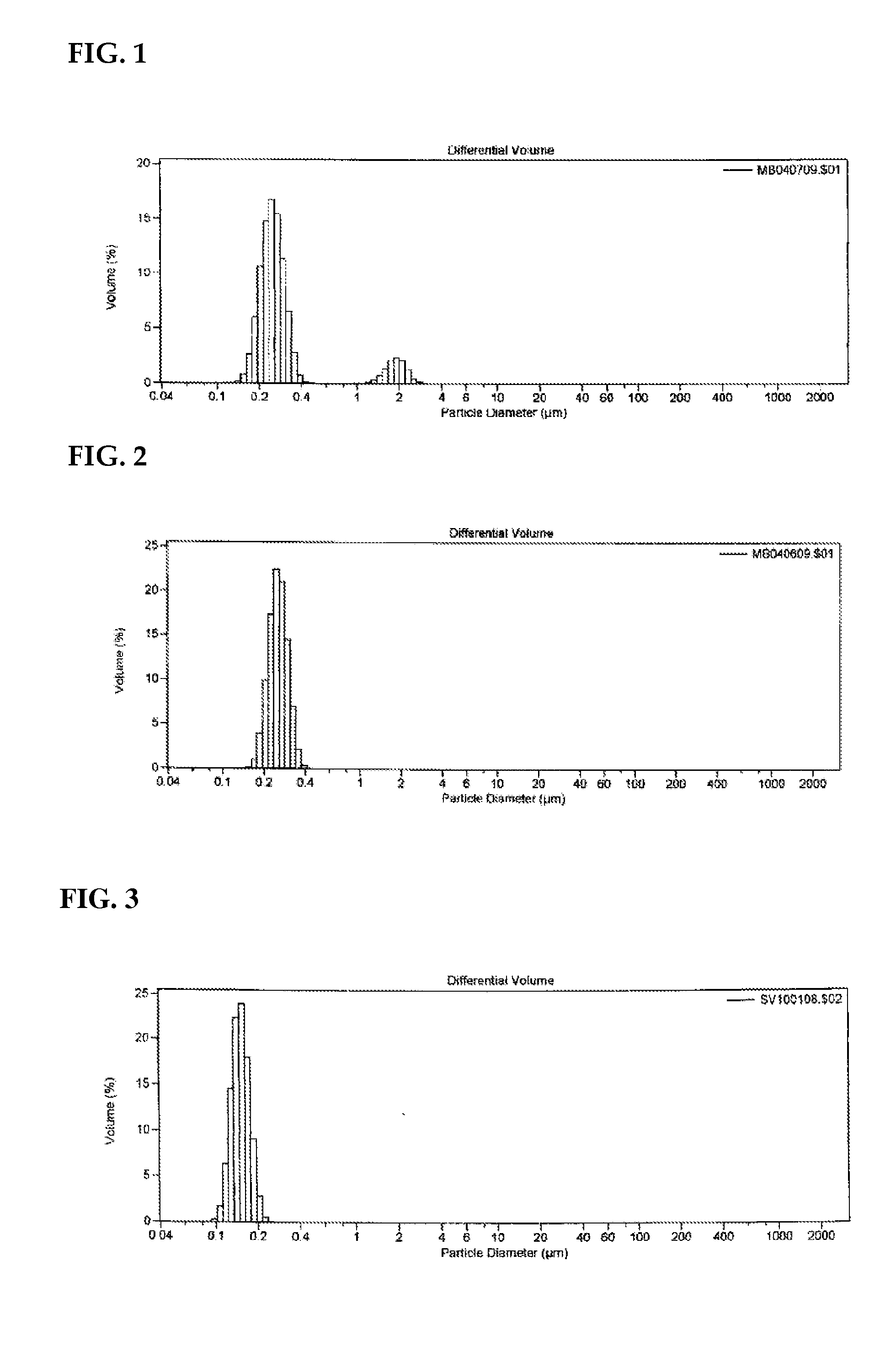

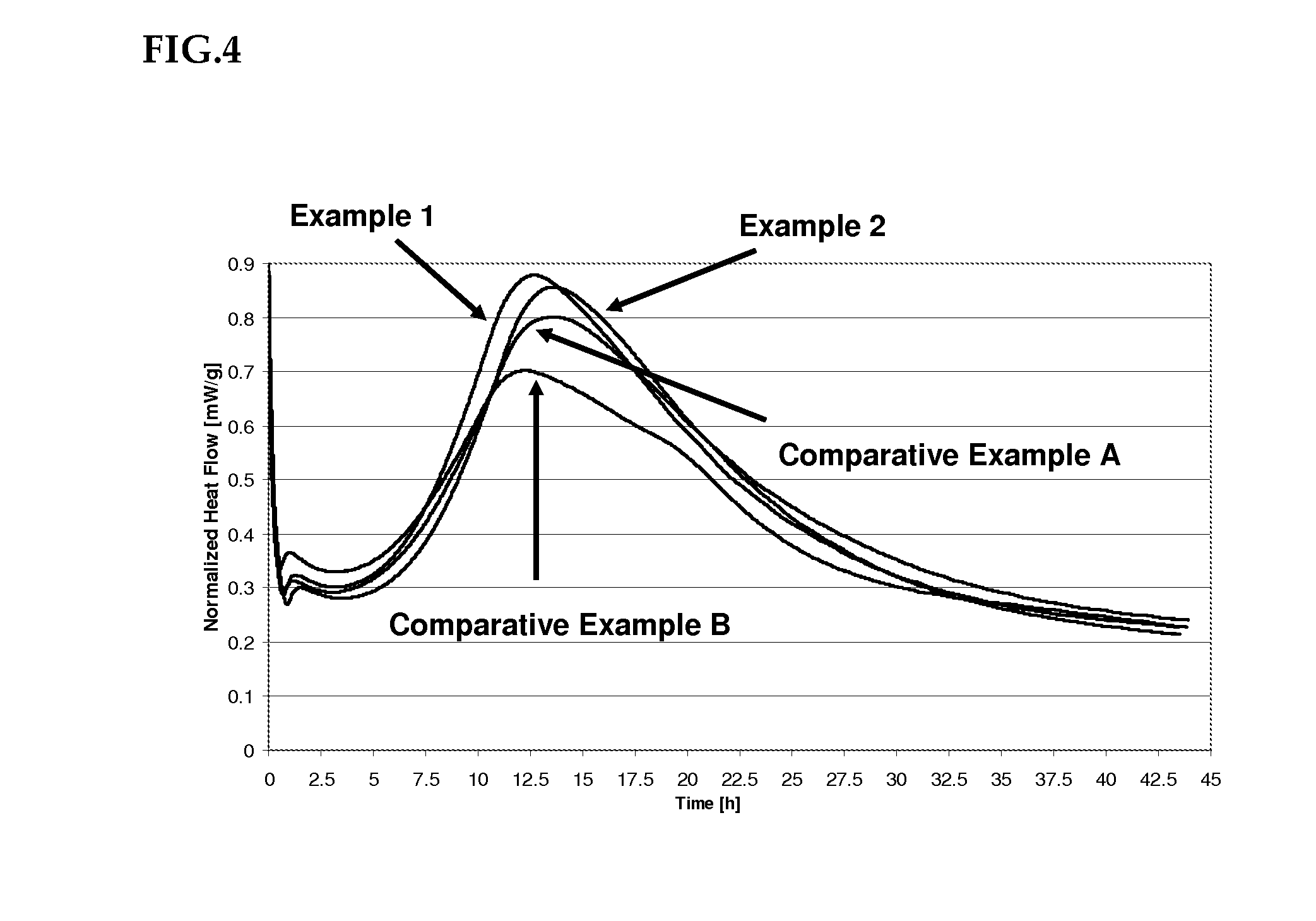

Redispersible polymer powders prepared from low carboxylation styrene butadiene-based latex

InactiveUS20110257305A1Low viscosityFacilitates spray dryingSpecial tyresPolymer adhesivePolymer science

A water redispersible polymer powder is produced by drying an aqueous mixture of a low carboxylation, low Tg, large average particle size water insoluble film-forming polymer latex or emulsion and a colloidal stabilizer. The latex polymer may have an average particle size of 2000 Å to 5,000 Å, and an amount of carboxylation of 0.1% to 2.75% by weight of at least one ethylenically unsaturated dicarboxylic acid, salts or mixtures thereof, based upon the weight of the polymer. Dispersions containing the polymer and a polyvinyl alcohol as a colloidal stabilizer exhibit an unexpectedly low viscosity which facilitates spray drying and permits use of high solids content dispersions with low pressure spray drying to increase production efficiency. Cement compositions such as mortars, which contain the redispersible polymer powder exhibit unexpectedly lower rates of viscosity buildup for better workability or troweling, faster set time, and superior heat flow characteristics.

Owner:KIM HABERMEHL LINDA H +2

Combustor of inner flame gas range

The invention discloses a burner of an inner flame gas stove, which consists of a burner body and a fire distributer device; an upper layer fire hole and a lower layer fire hole are arranged on the fire distributer device and the direction of the outlets of the fire holes is inward, and an air channel is arranged or not arranged between the upper layer fire hole and the lower layer fire hole; a single inner cavity or two independent inner cavities is or are arranged; the two independent inner cavities are arranged so that the flame at the upper layer and the lower layer can be regulated independently; while the air channel is arranged so that the air supplementation can be more abundant. The burner utilizes multiple-layer fire holes, stratified combustion and multiple-layer cyclonic flame, and has the advantages of large heat flow, fierce fire power, high heat efficiency, low-CO and low-NOx in smoke gas, no fire hole blocking and the like.

Owner:吴成年 +1

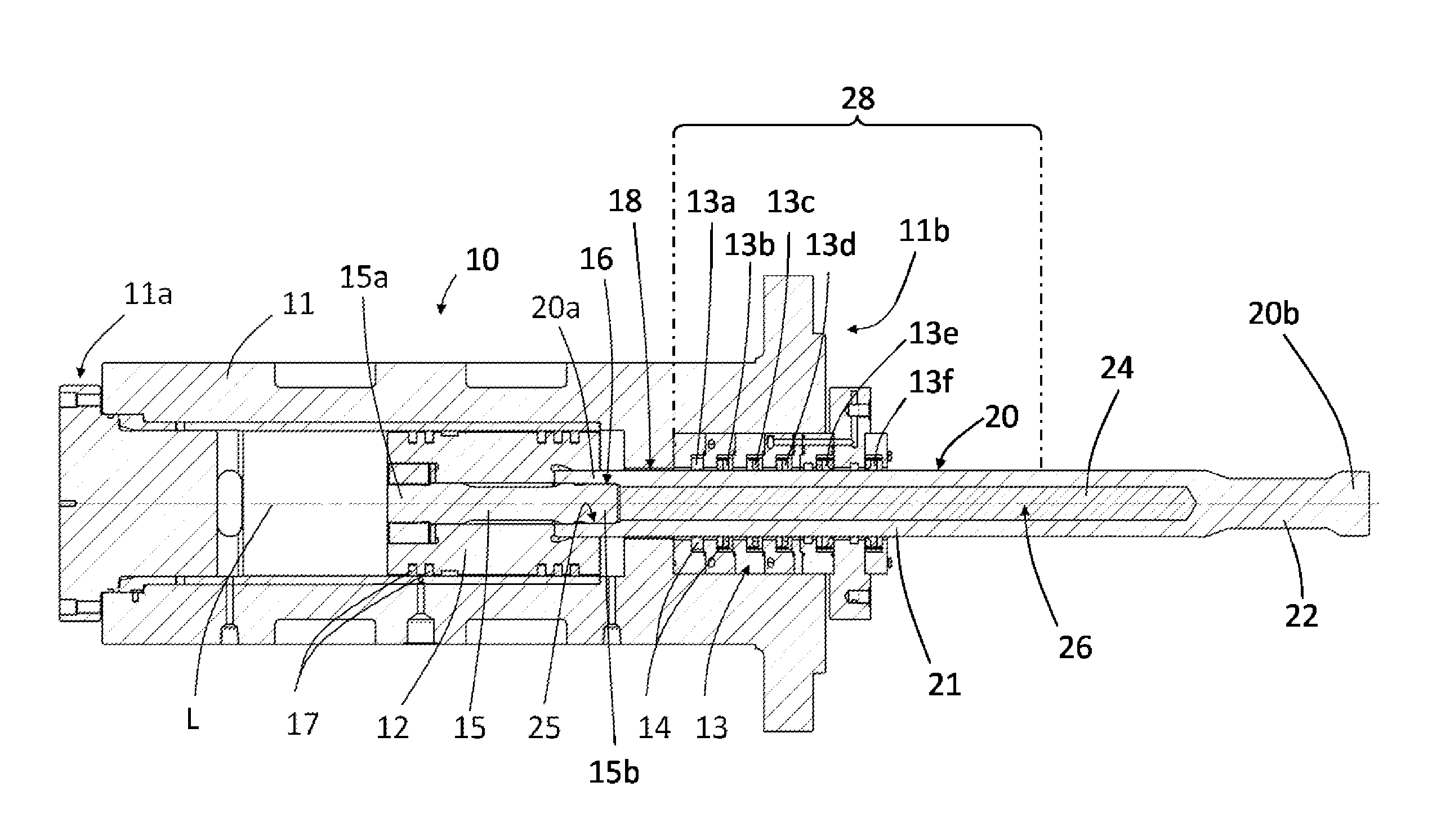

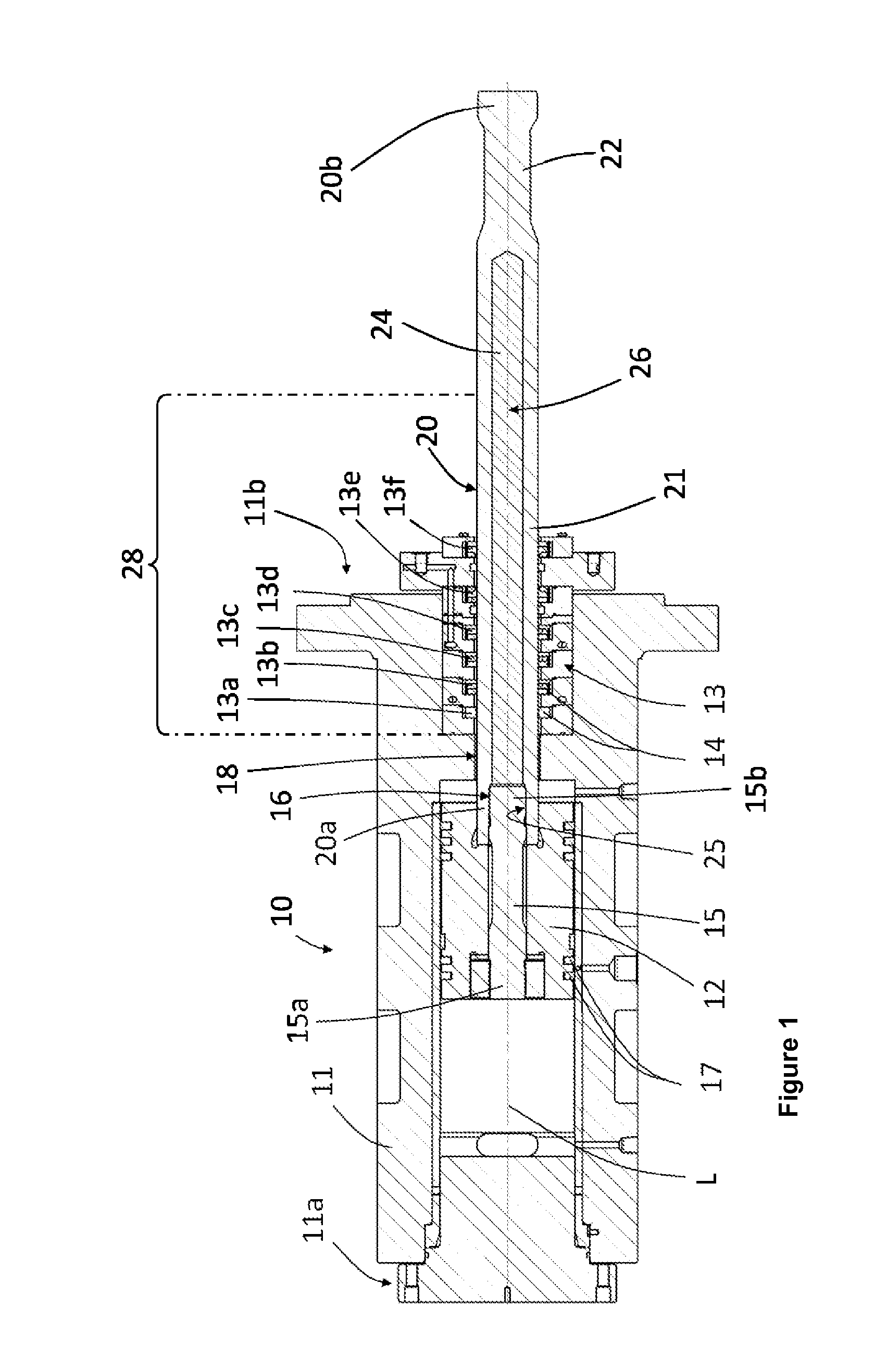

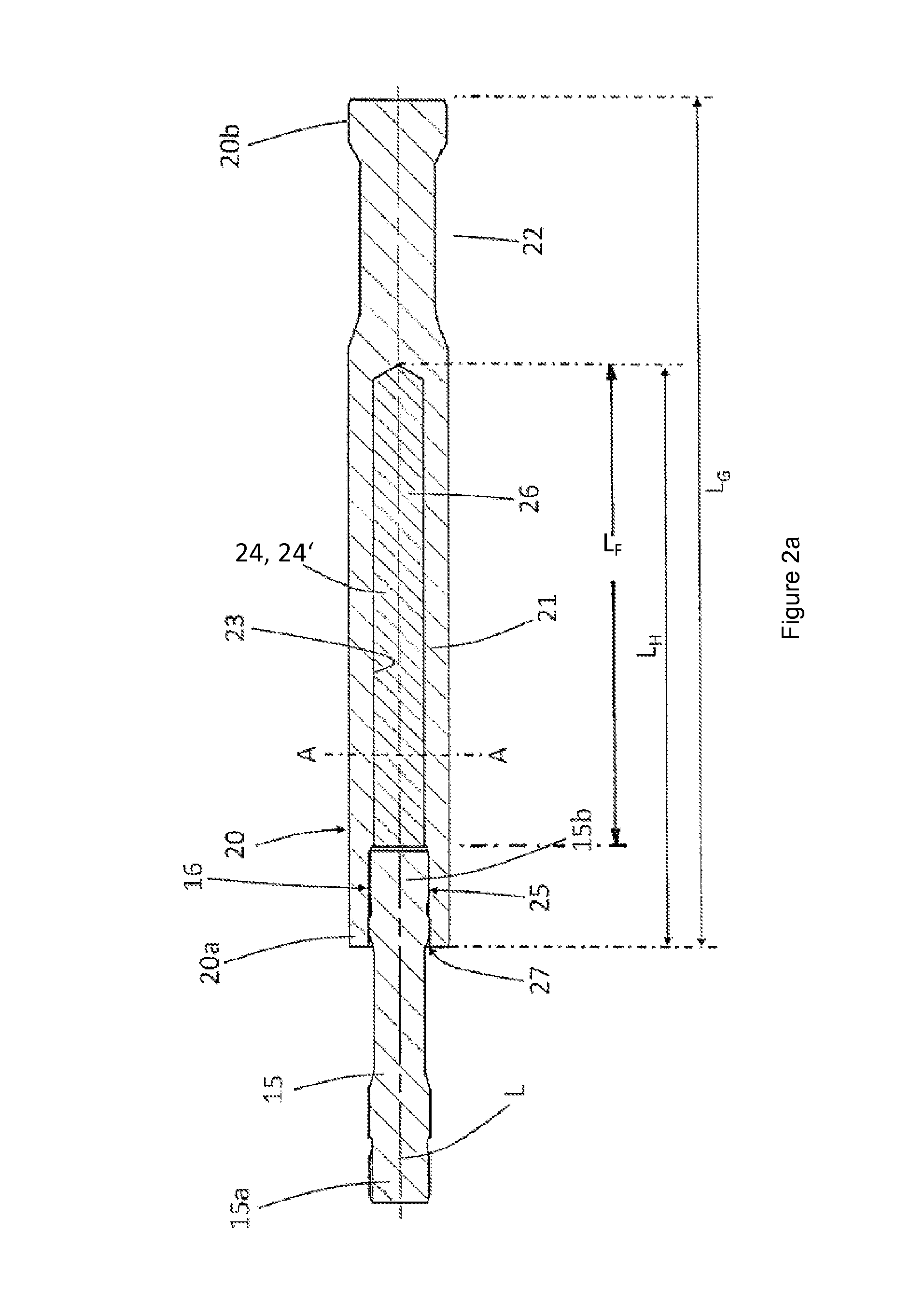

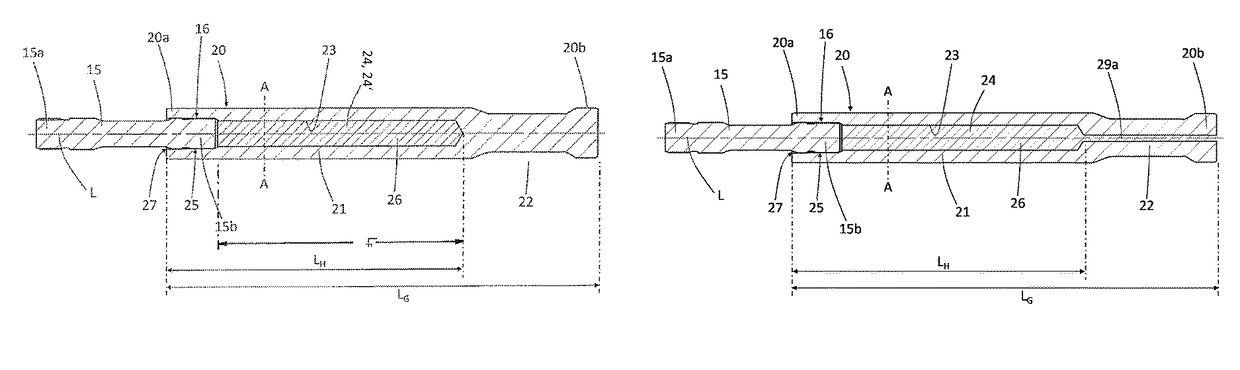

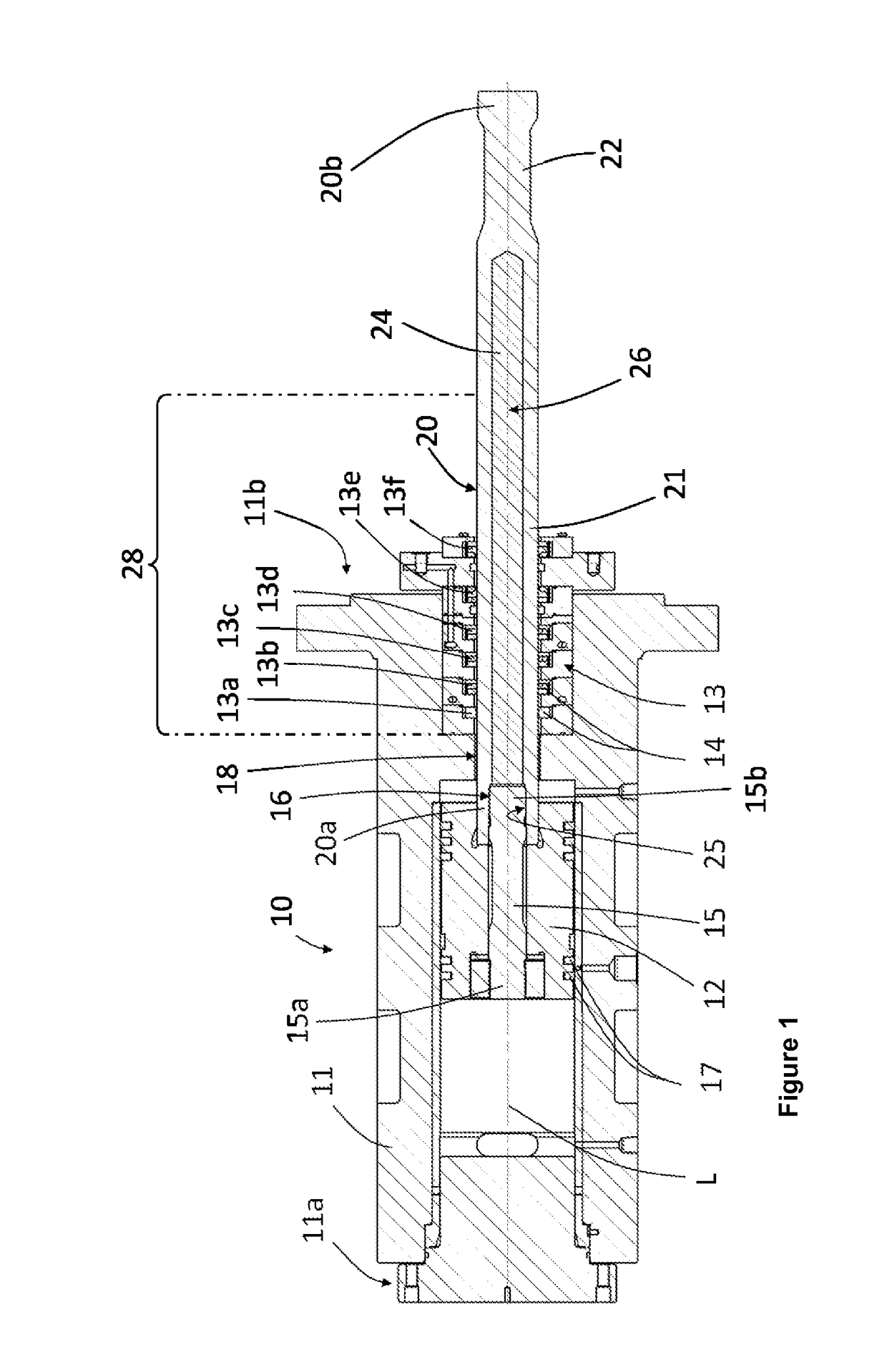

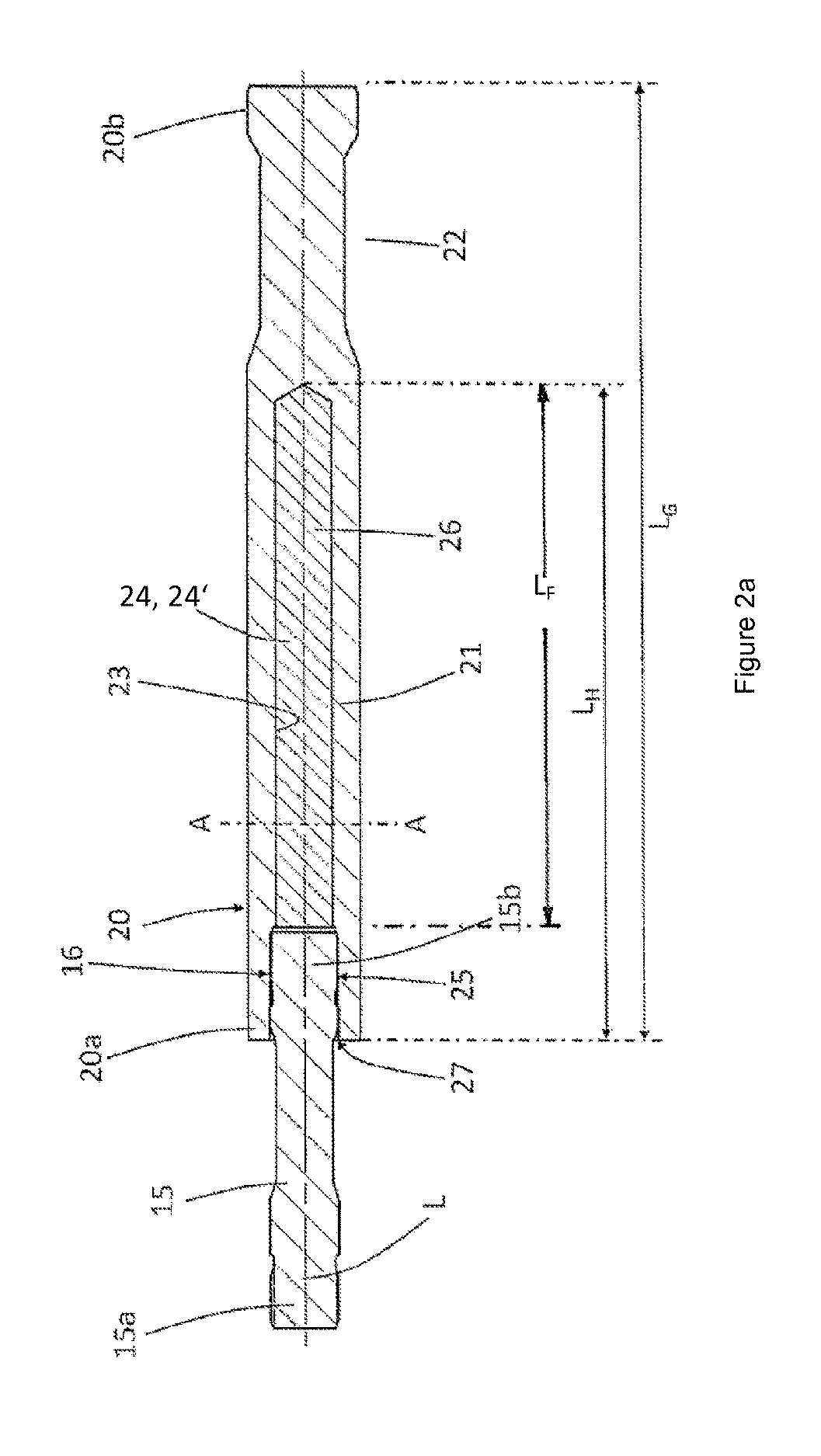

Piston rod for a piston compressor, and the piston compressor

InactiveUS20150211514A1Reliable coolingLess maintenance-demandingPositive displacement pump componentsPlungersEngineeringMechanical engineering

A piston rod for piston compressors, wherein the piston rod has a base body with one end facing the piston, one end away from the piston, and at least one cavity. The cavity is filled with a solid, whose specific thermal conductivity is greater than that of the base body.Furthermore, the invention concerns a piston compressor with a piston and a nonlubricated piston rod seal, wherein the piston is connected to the described piston rod.

Owner:NEUMAN & ESSER

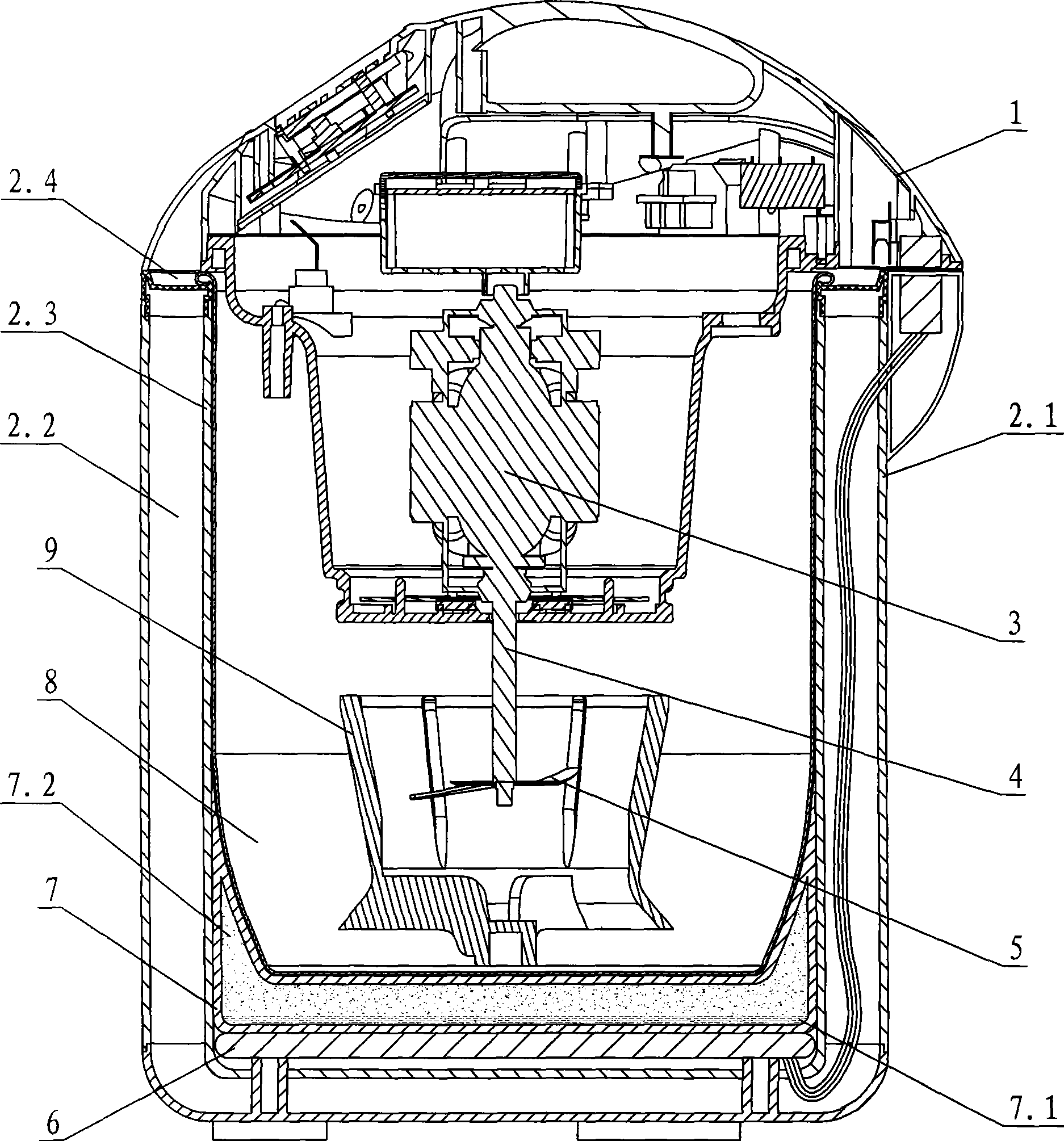

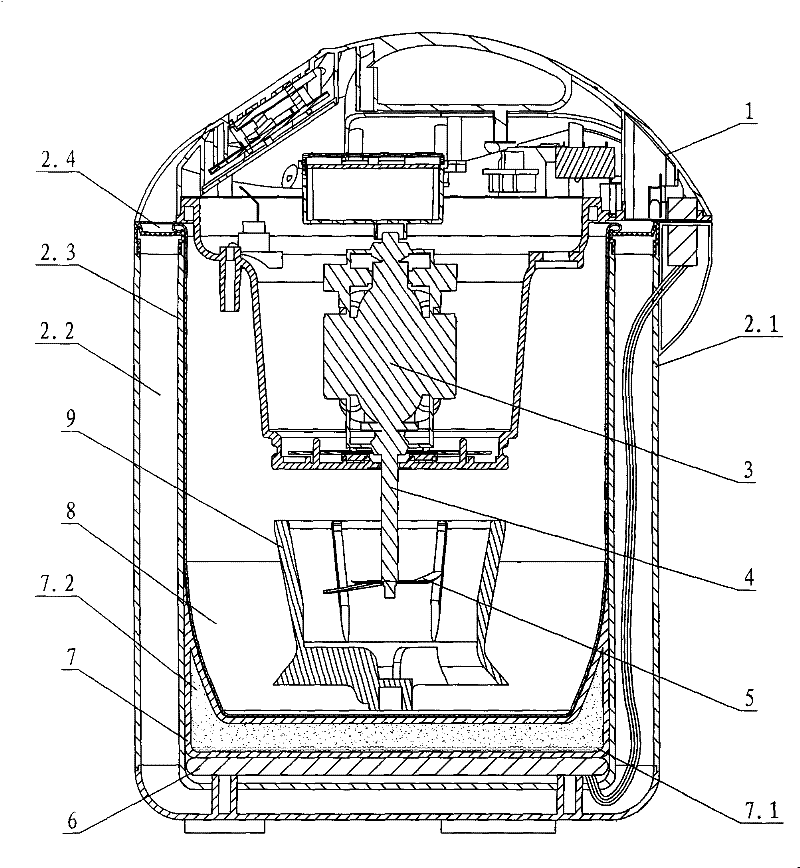

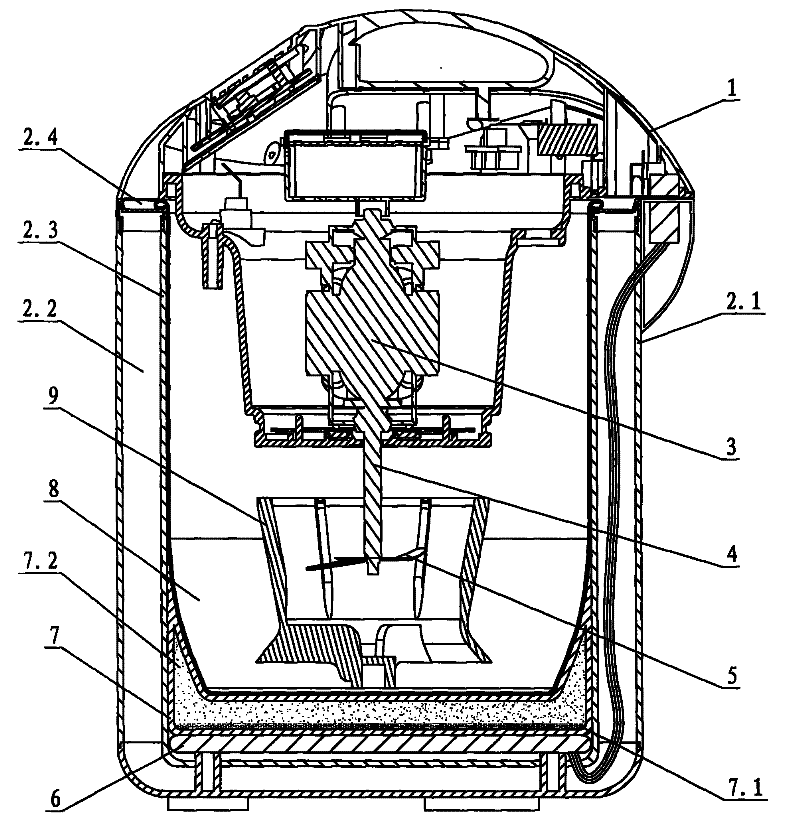

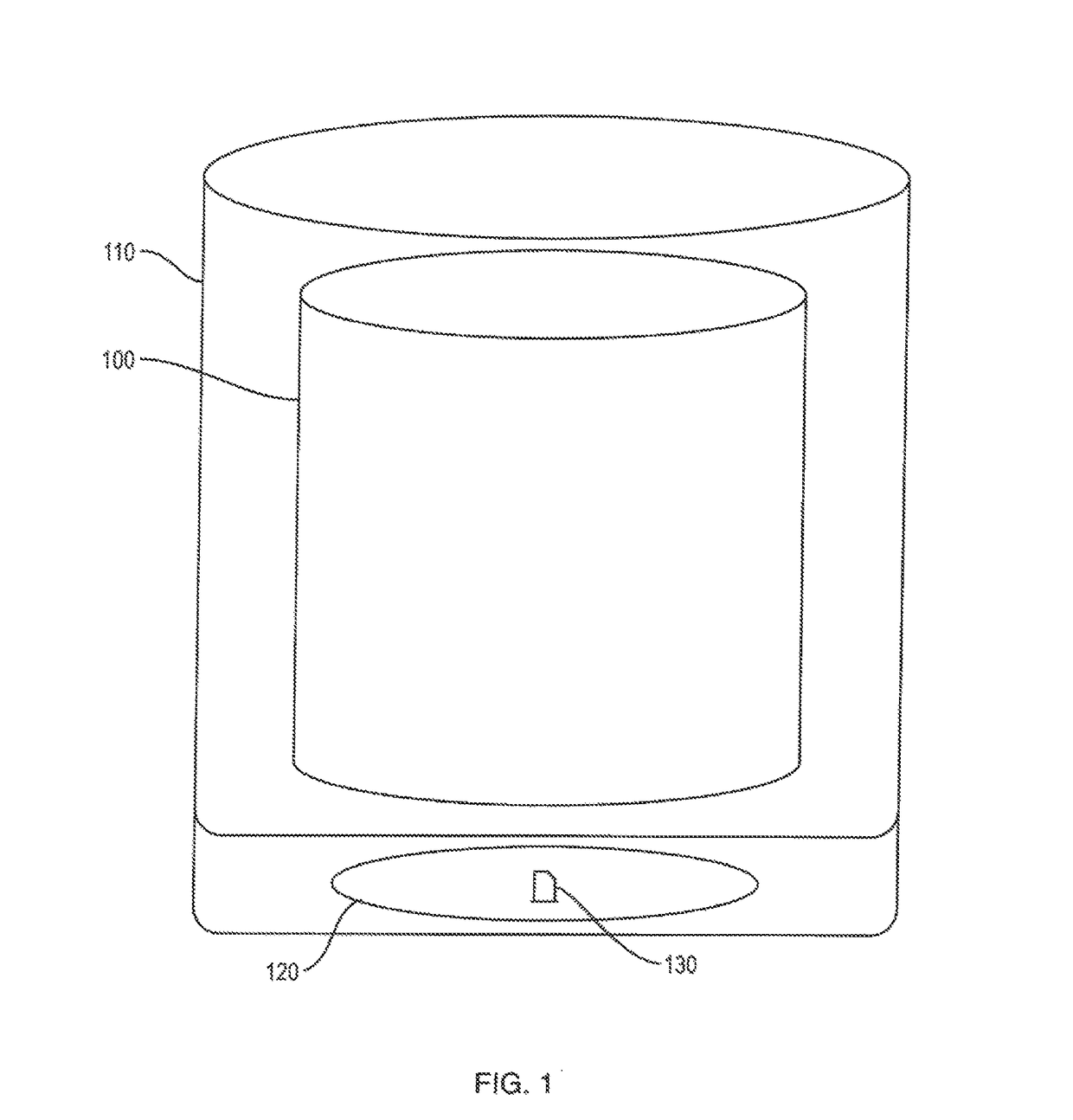

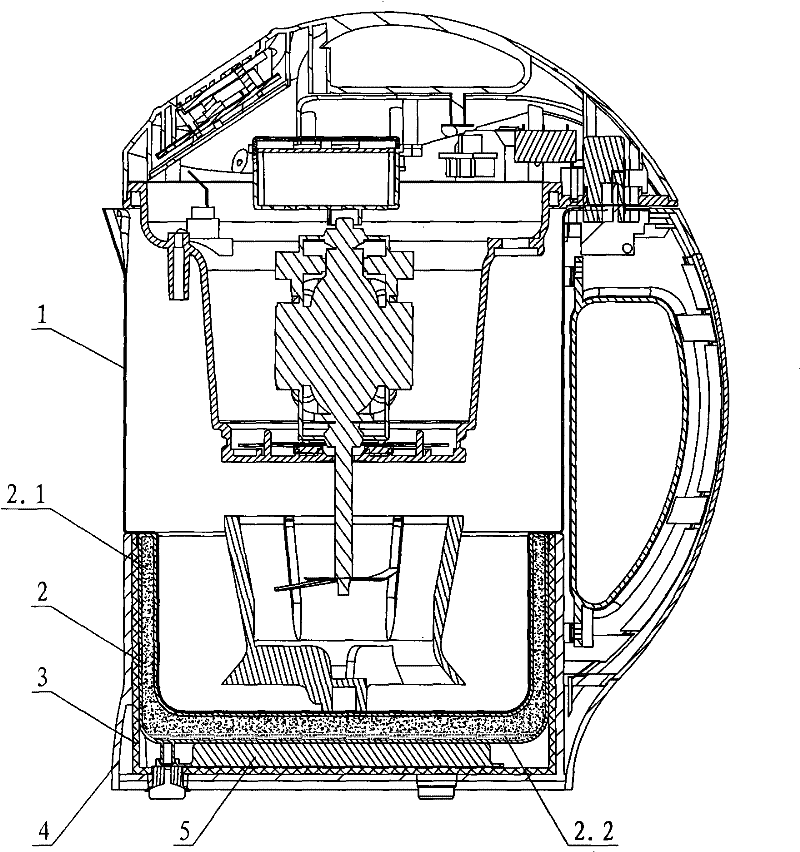

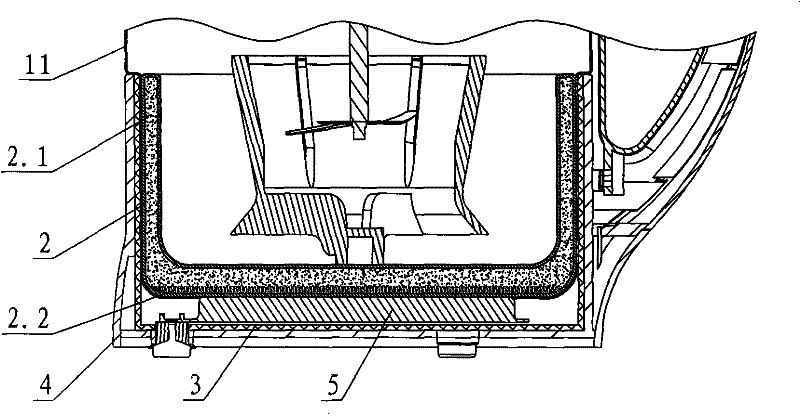

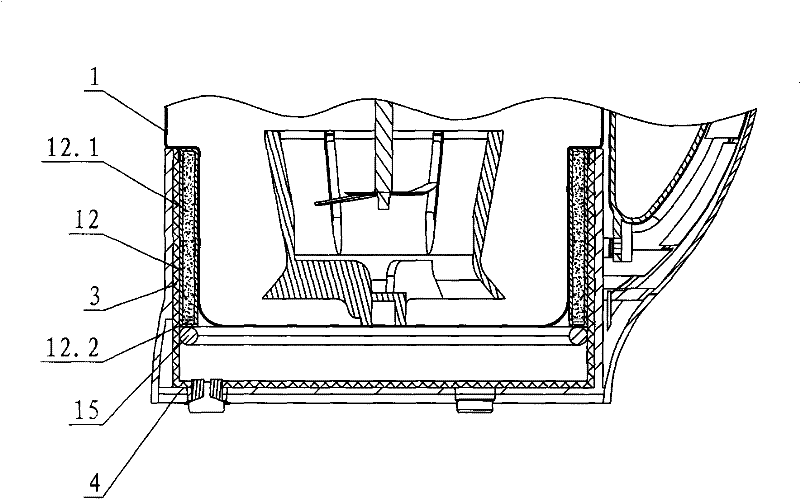

Soya-bean milk making device

InactiveCN101449785AImprove insulation effectSimple structureBeverage vesselsFood preparationHeat flowThermal insulation

A soya-bean milk machine includes a container and a heating element, an outer barrel is arranged outside the container in a split way, and the heating element is arranged on an inner bottom and / or inner side part of the outer barrel. In the outer barrel, a super heat conductor is arranged on a heating surface of the heating element or close to the heating element and is used for heating slurries in the container. The outer barrel has a double-layer structure, a outer layer is a outer casing, a inner layer is a reflecting layer, and a heat insulation cavity is formed between the outer casing and the reflecting layer. The container is connected with the outer barrel in a split way and can be individually fetched out for cleaning, and the outer barrel has better thermal insulation effect. In addition, when the heating element is heating, the soya-bean milk machine forms a real stereo encircling constant-temperature heating for the bottom of the container by utilizing efficient heat-conducting characteristic (thermal resistance is close to zero) and isothermal performance of the super heat conductor. The soya-bean milk machine has advantages of simple and reasonable structure, large heat flow, large heating area, convenient cleaning, energy conservation and environmental protection.

Owner:ZHANGZHOU WANLIDA ZHONGHUAN TECH INC

Piston rod for a piston compressor, and the piston compressor

InactiveUS9869312B2Reliable coolingLess maintenance-demandingPositive displacement pump componentsPositive-displacement liquid enginesEngineeringMechanical engineering

Owner:NEUMAN & ESSER GMBH & CO KG

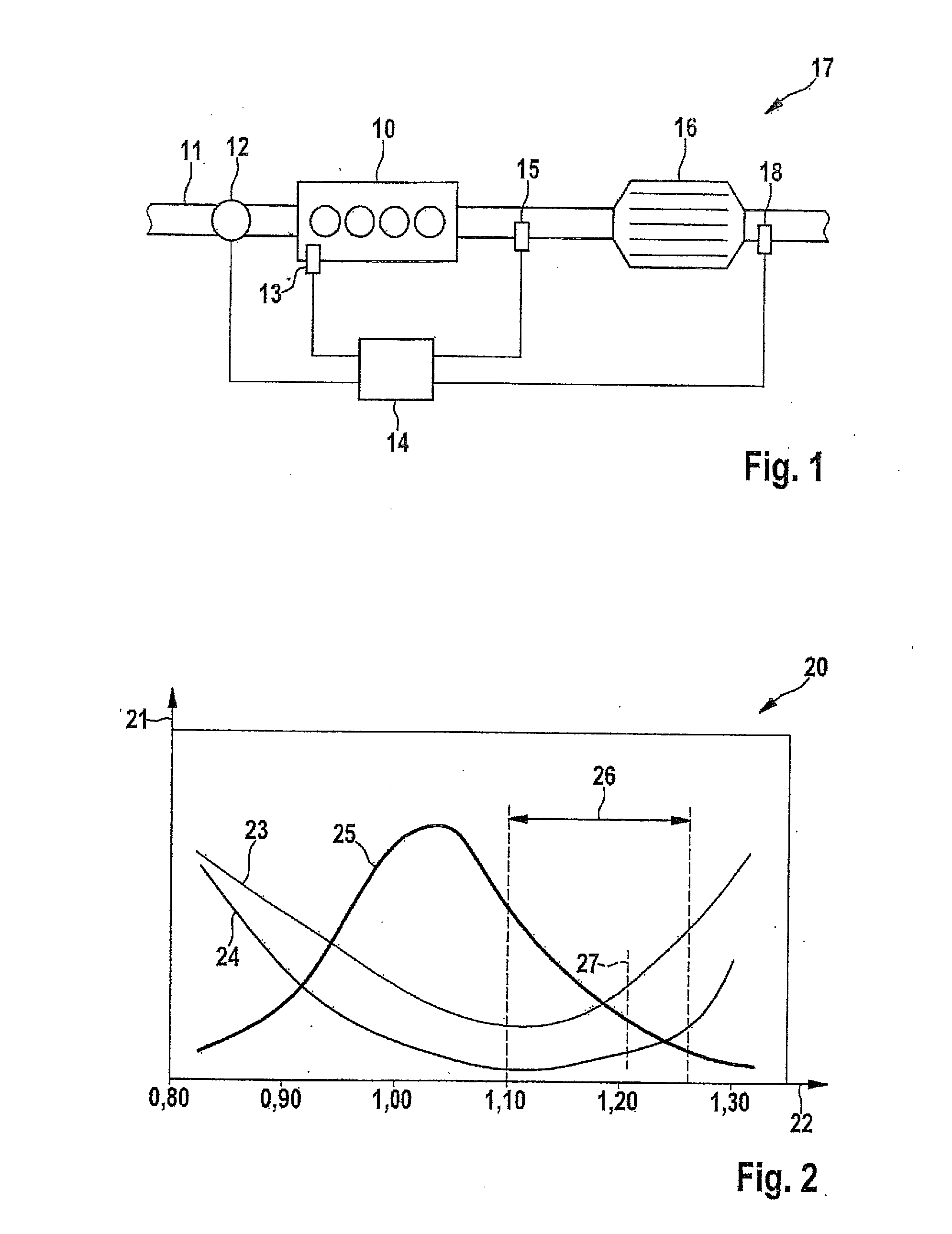

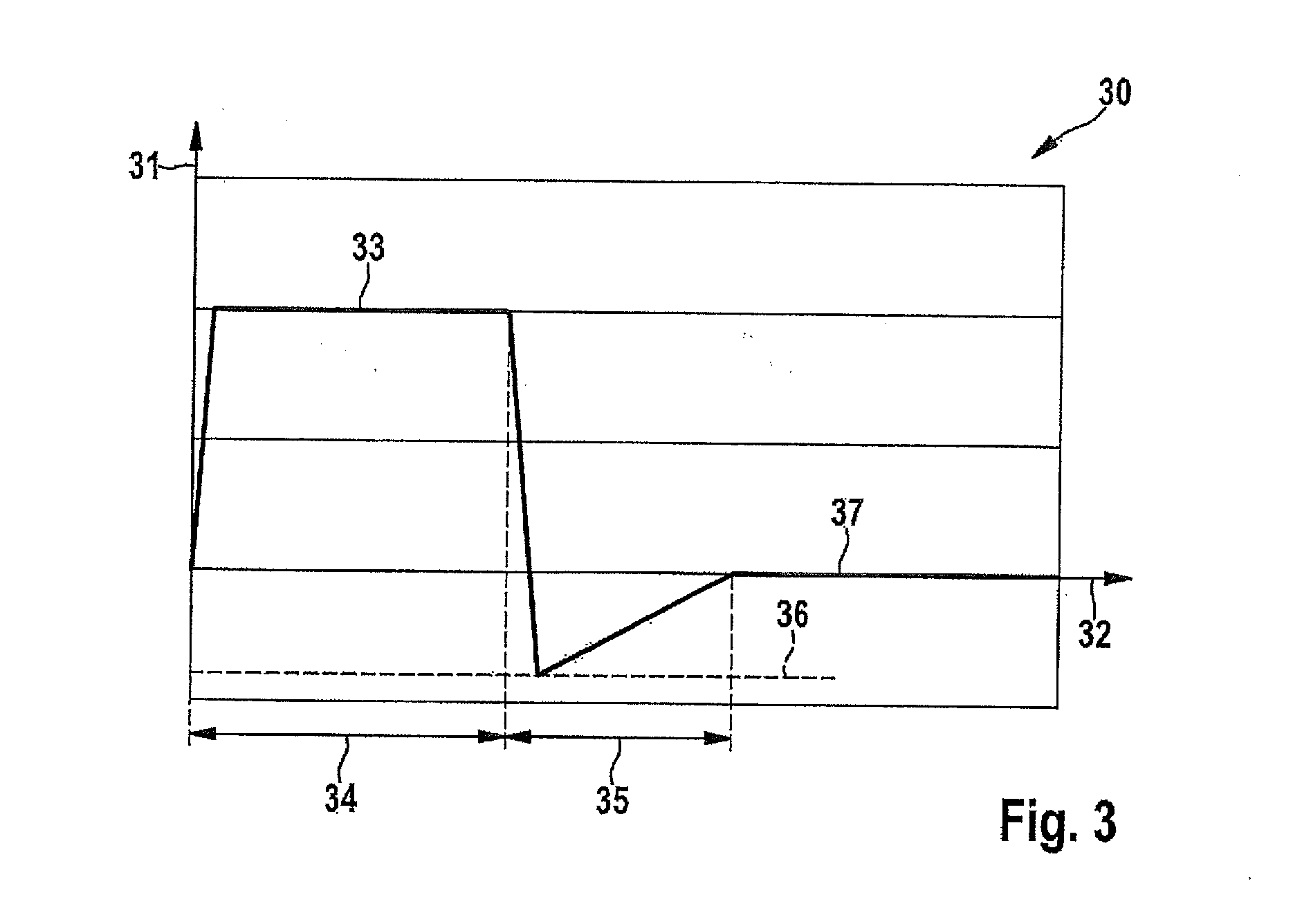

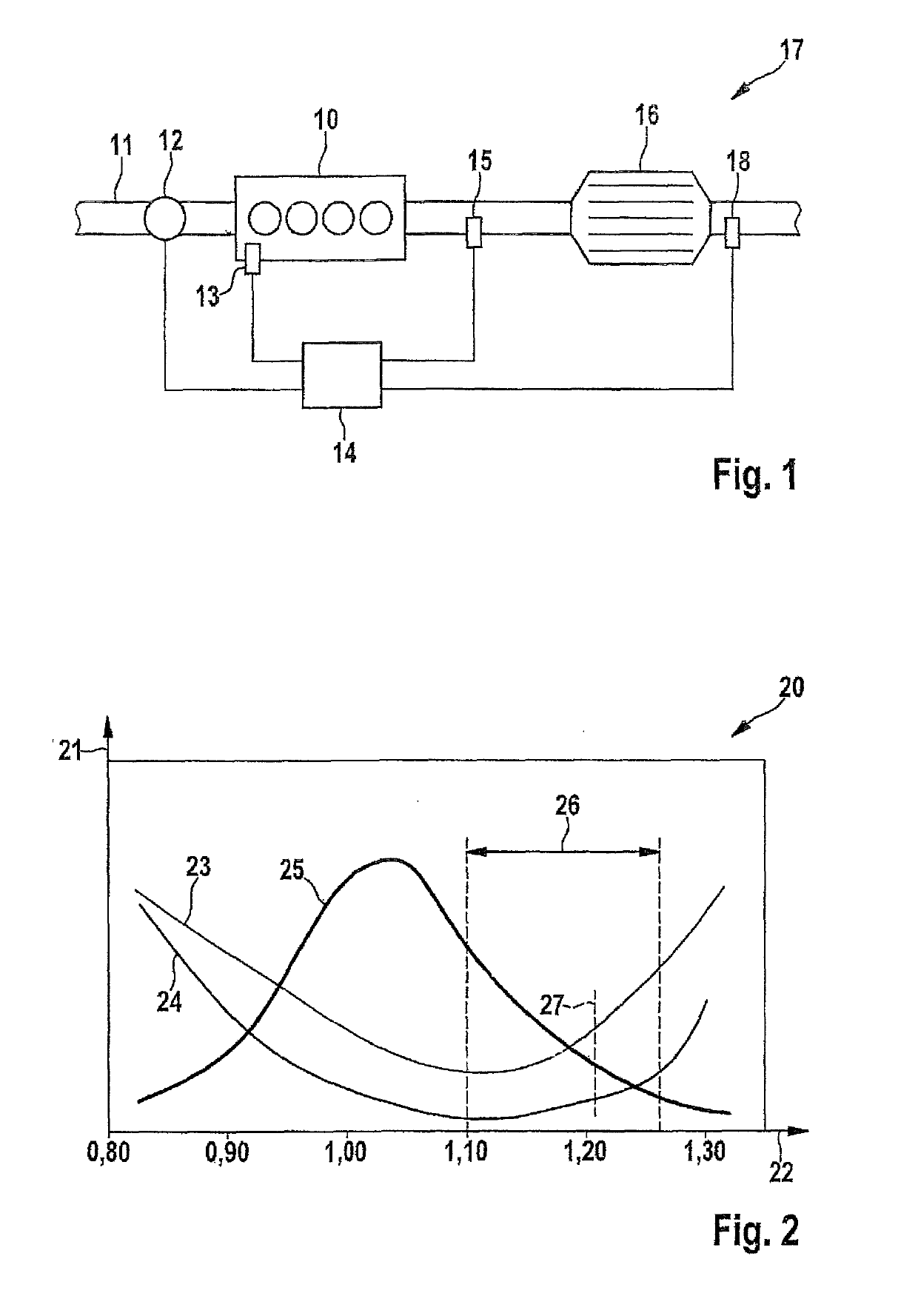

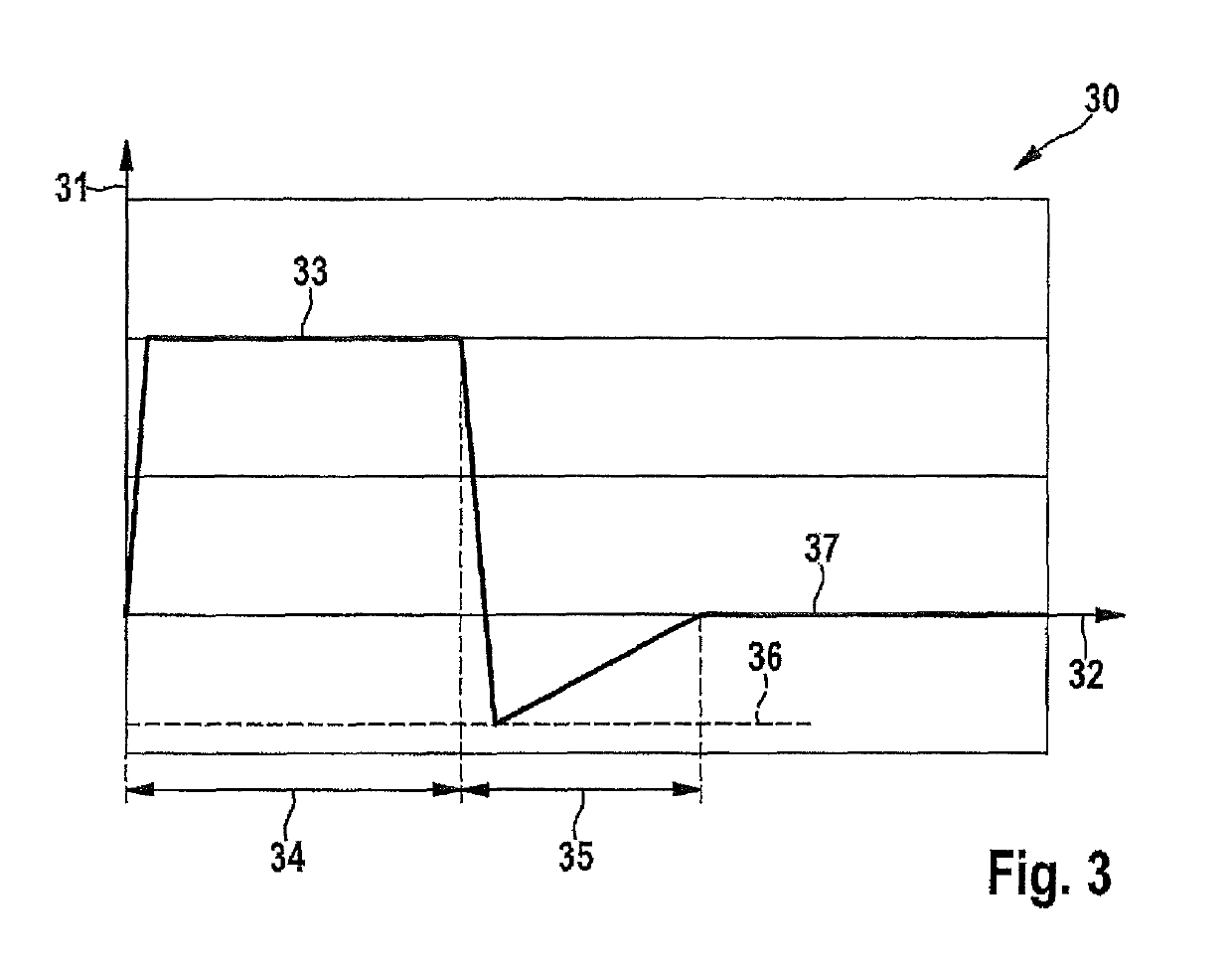

Method and device for reducing the emissions of an internal combustion engine

ActiveUS20150113955A1Emission reductionReduce raw emission of hydrocarbonElectrical controlInternal combustion piston enginesState variableExternal combustion engine

A method for reducing the pollutant emissions in the exhaust gas in a start / catalytic converter heating phase of an internal combustion engine featuring externally supplied ignition and having at least one catalytic converter in an exhaust gas tract of the internal combustion engine, and for adapting a catalytic converter heating strategy to suitable state variables of the internal combustion engine and the catalytic converter as well as to the fuel quantity, the aging state and ambient conditions. The internal combustion engine is operated in a first phase of the start / catalytic converter heating phase using a lean air-fuel mixture in a range between a lambda value of 1.05 and at a lean misfire limit of the internal combustion engine that lies at a higher lambda value, and / or in a second phase of the start / catalytic converter heating phase, initially using a rich air-fuel mixture.

Owner:ROBERT BOSCH GMBH

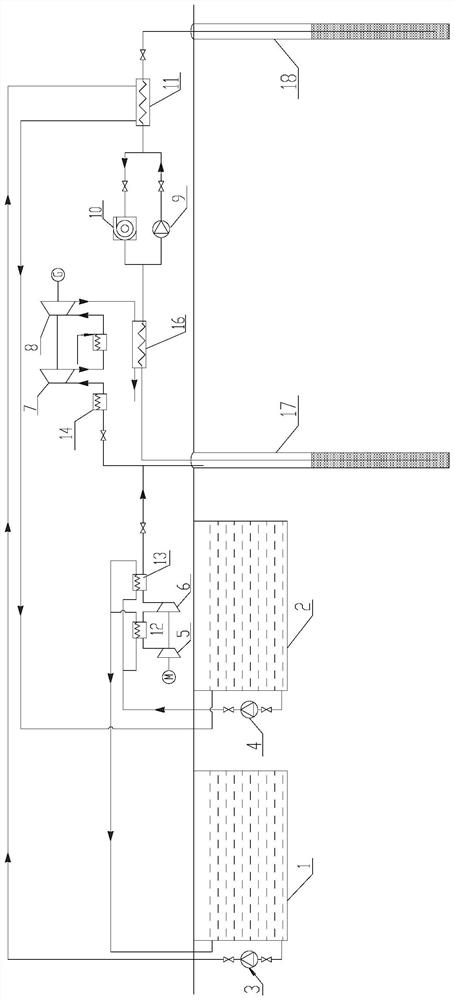

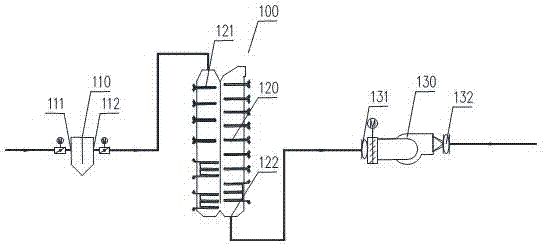

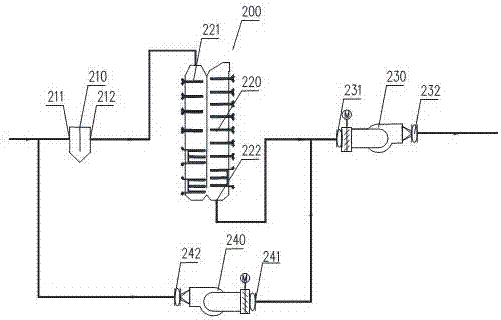

Water pumping and compressed air energy storage system and method for storing energy and heat by utilizing geothermal well

ActiveCN114754519ARun fastGuaranteed uptimeHeat pumpsGeothermal energy generationWater storageCombustion chamber

The invention discloses a water pumping compressed air energy storage system and method for storing energy and heat through a geothermal well. The water pumping compressed air energy storage system comprises a compressor unit, a heat exchanger, a combustion chamber unit and an expansion unit. An outlet of each stage of compressor is connected with a heat exchanger, the heat exchanger is connected with a cold water storage pool and a hot water storage pool, the heat exchanger is further connected with a combustion chamber unit and a first geothermal well, and a combustion chamber is arranged in the combustion chamber unit. An outlet of the first geothermal well is sequentially connected with a third heat exchanger, a variable frequency water pump, a fourth heat exchanger and a second geothermal well, the fourth heat exchanger is further connected with an under-pressure water turbine, and the under-pressure water turbine is connected with the third heat exchanger. The compressor air energy storage system, the underground geothermal well, the variable frequency water pump and the pressurized water turbine are mutually coupled, low-grade compression heat and exhaust waste heat of the expansion machine during energy storage are utilized, the energy utilization efficiency is improved, and meanwhile the effect of improving the geothermal recovery function is achieved.

Owner:XI AN JIAOTONG UNIV

Method and device for reducing the emissions of an internal combustion engine

ActiveUS10400692B2Emission reductionReduce raw emission of hydrocarbonElectrical controlInternal combustion piston enginesState variableExternal combustion engine

A method for reducing the pollutant emissions in the exhaust gas in a start / catalytic converter heating phase of an internal combustion engine featuring externally supplied ignition and having at least one catalytic converter in an exhaust gas tract of the internal combustion engine, and for adapting a catalytic converter heating strategy to suitable state variables of the internal combustion engine and the catalytic converter as well as to the fuel quantity, the aging state and ambient conditions. The internal combustion engine is operated in a first phase of the start / catalytic converter heating phase using a lean air-fuel mixture in a range between a lambda value of 1.05 and at a lean misfire limit of the internal combustion engine that lies at a higher lambda value, and / or in a second phase of the start / catalytic converter heating phase, initially using a rich air-fuel mixture.

Owner:ROBERT BOSCH GMBH

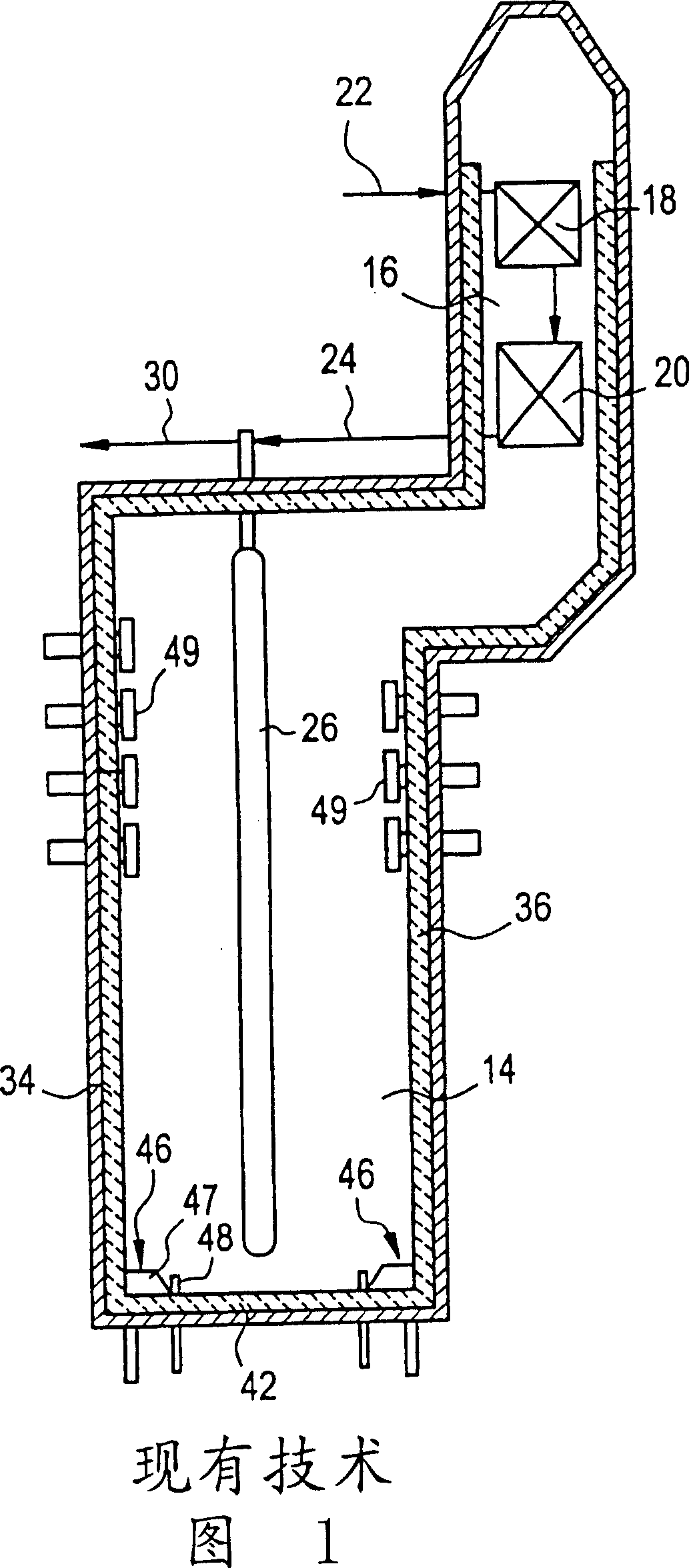

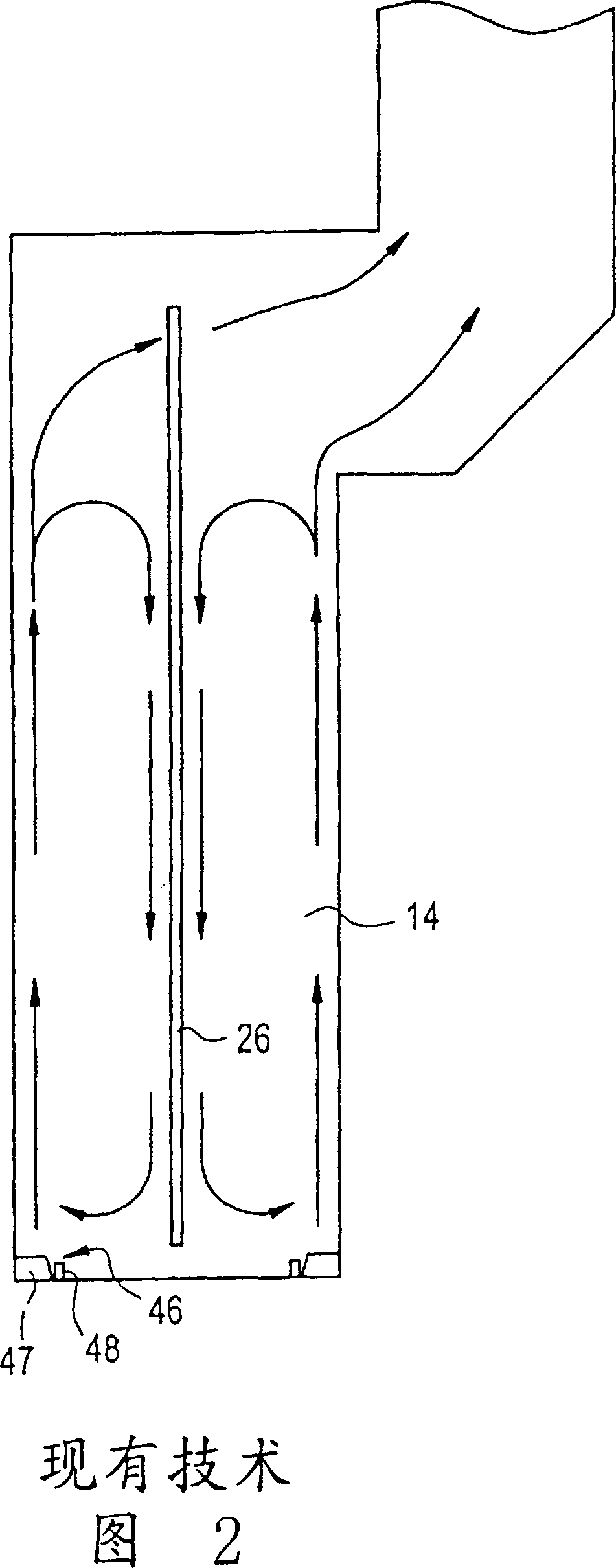

Pyrolysis heater with paired burner zoned firing system

A pyrolysis heater has the inlet sections of the process coils grouped together and the outlet sections of these same process coils also grouped together. High heat liberation hearth burners are located adjacent to the inlet sections of the coils and lower heat liberation burners are located adjacent to the outlet sections. The secondary fuel tips of the burners are inclined toward the adjacent, heater wall. The high heat liberation hearth burners adjacent to the inlet coils are arranged in spaced apart pairs with the secondary burner tips of each of the pair being inclined toward the other burner of the pair.

Owner:ABB LUMMUS GLOBAL INC

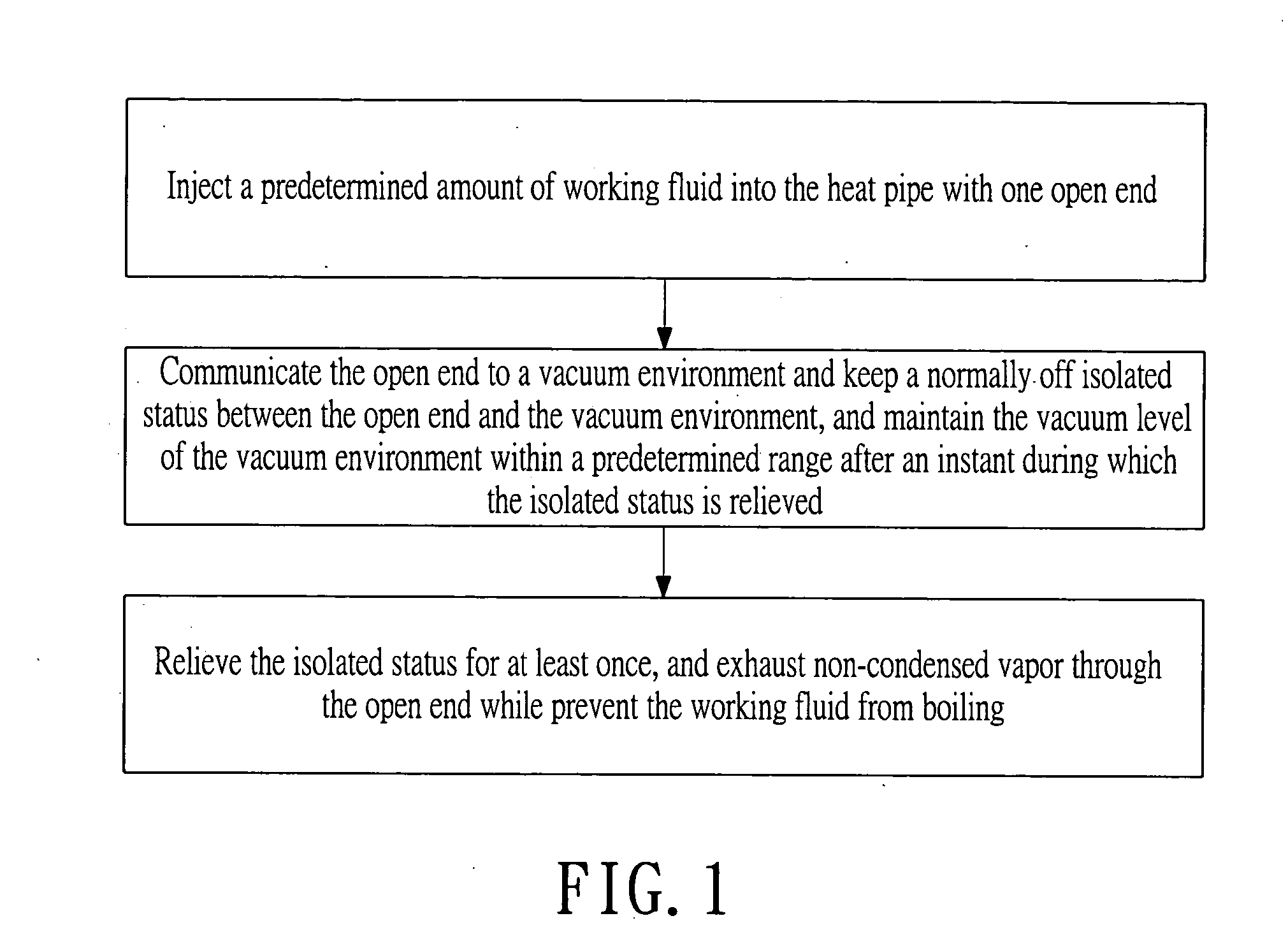

Method for removing vapor within heat pipe

InactiveUS7650915B2Stable quantityQuality improvementMotor/generator/converter stoppersStarter detailsWorking fluidVacuum level

A method for removing vapor within a heat pipe includes providing a predetermined amount of working fluid injected into the heat pipe. An opening is reserved at one end of the heat pipe. The opening is communicated with a vacuum environment. The communication between the opening and the vacuum environment is normally disconnected, such that at the instant the communication is connected ,the vacuum level of the vacuum environment is maintained at a certain range. The communication between the opening of the heat pipe and the vacuum environment is intermittently connected for several times. Within the duration while the communication between the opening and the vacuum environment is connected, the working fluid is evaporated without being boiled and vapor is exhausted from the opening.

Owner:HSU HUL CHUN

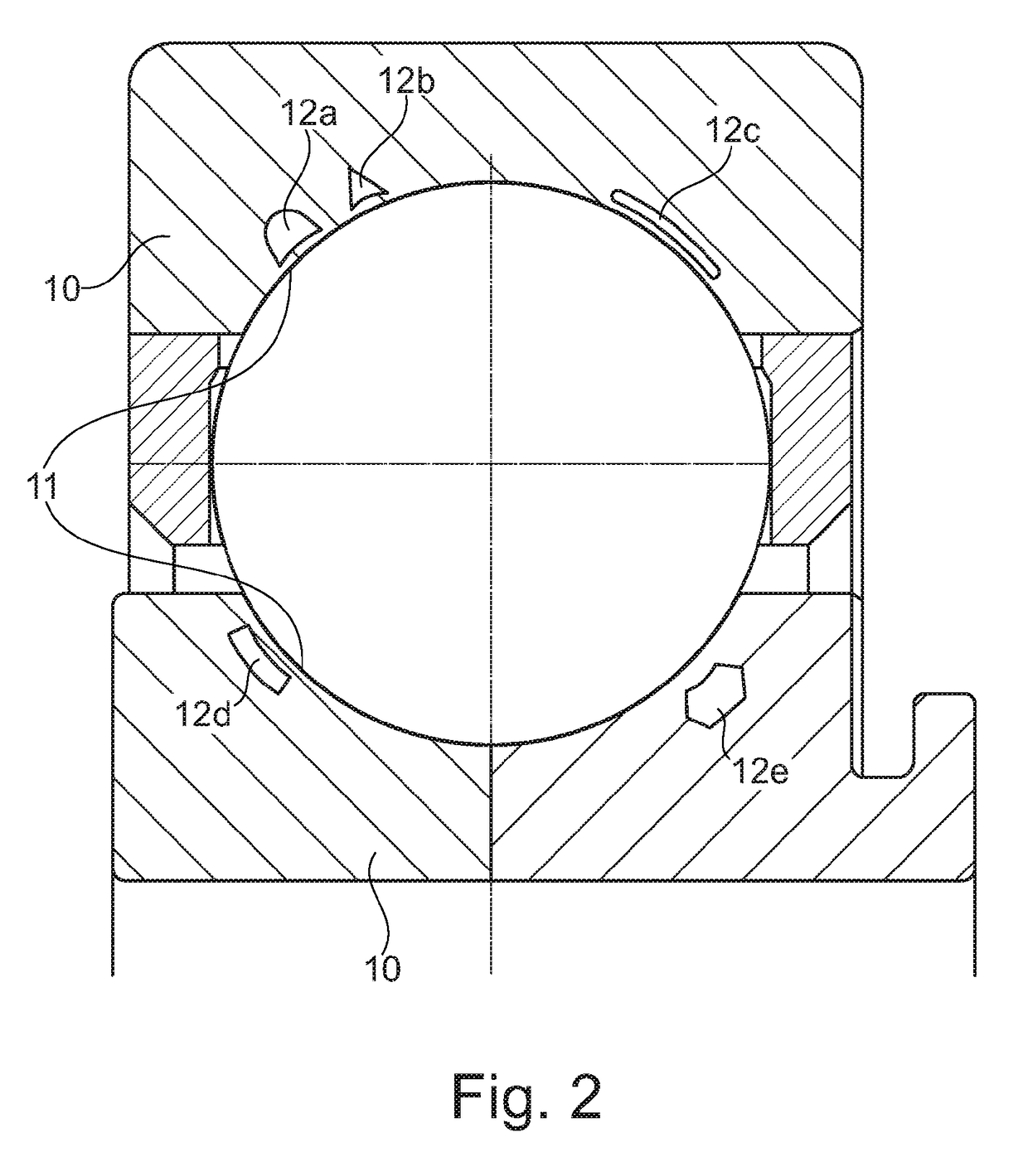

Bearing ring and layer by layer method for manufacturing a bearing ring

InactiveUS20170276022A1Effective coolingHeat transferAdditive manufacturingShaftsEngineeringCooling channel

Owner:SCHAEFFLER TECH AG & CO KG

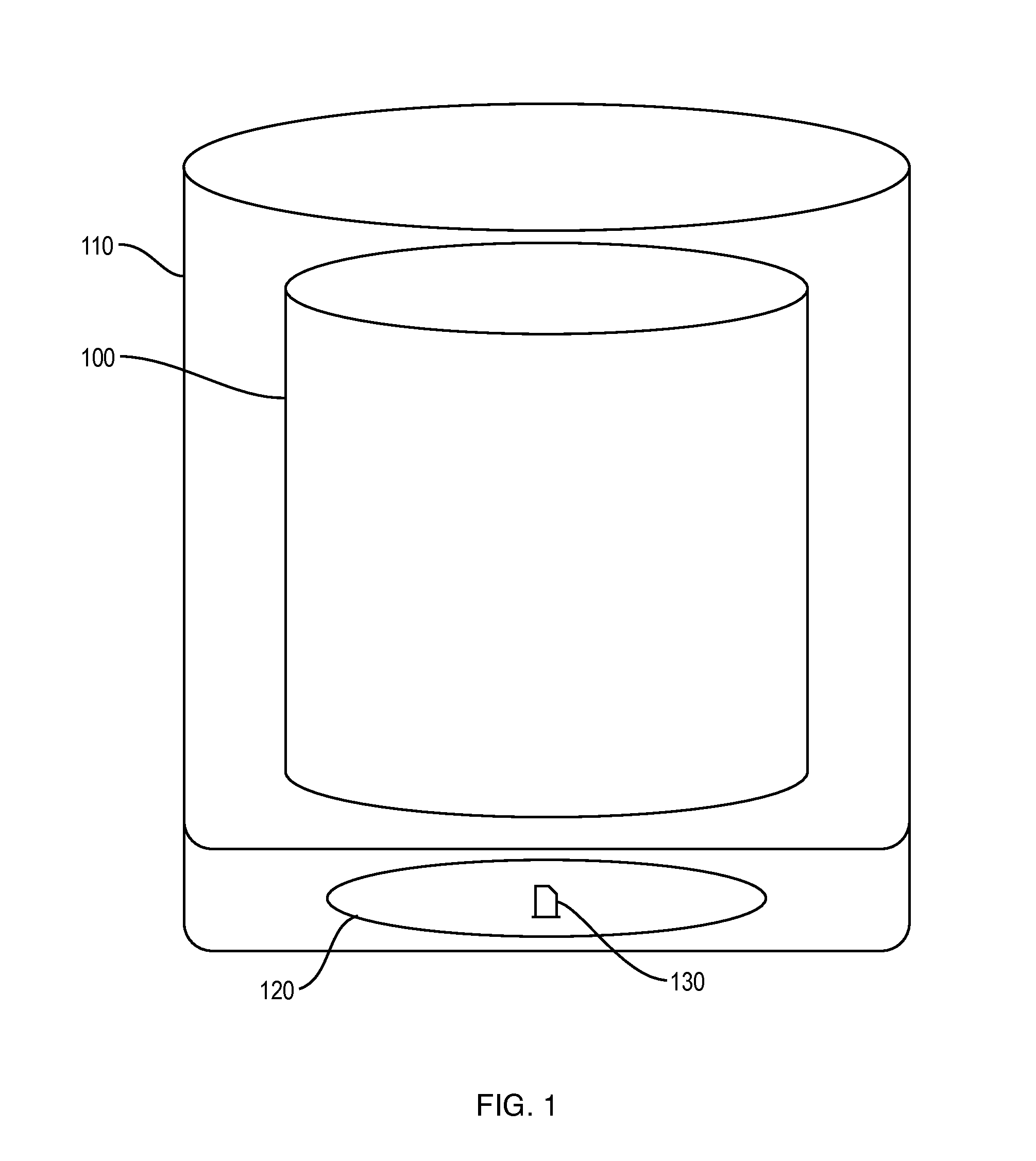

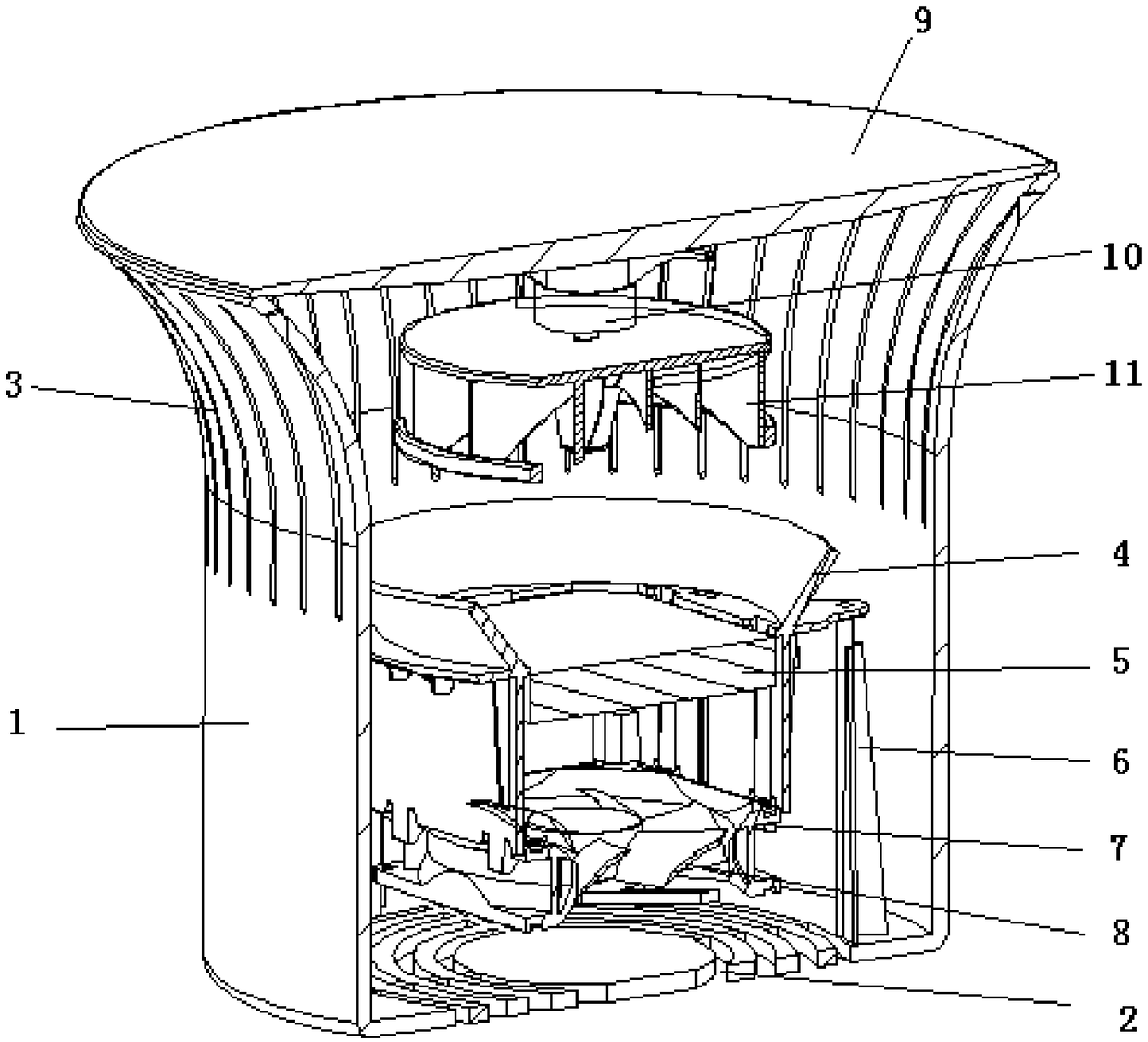

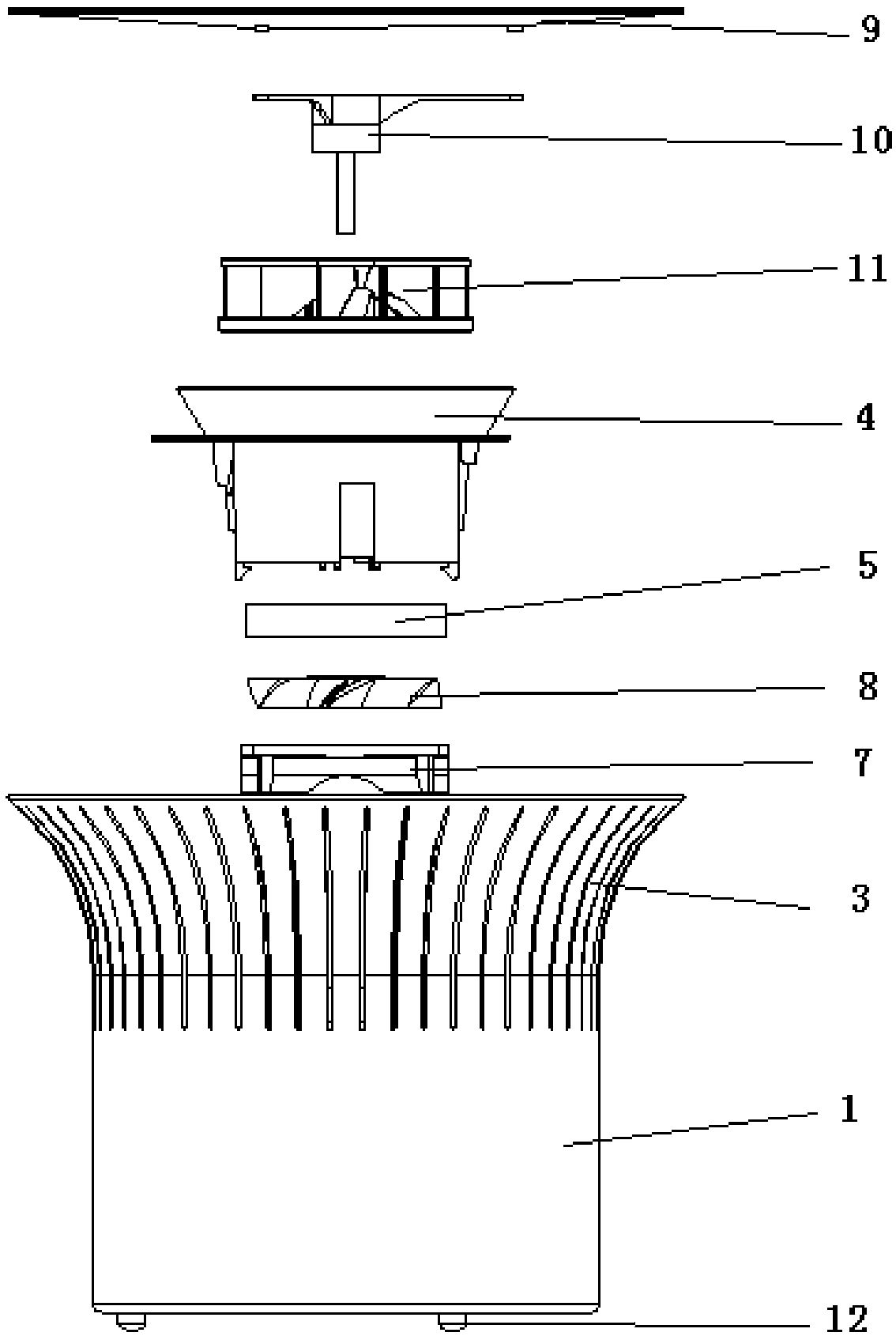

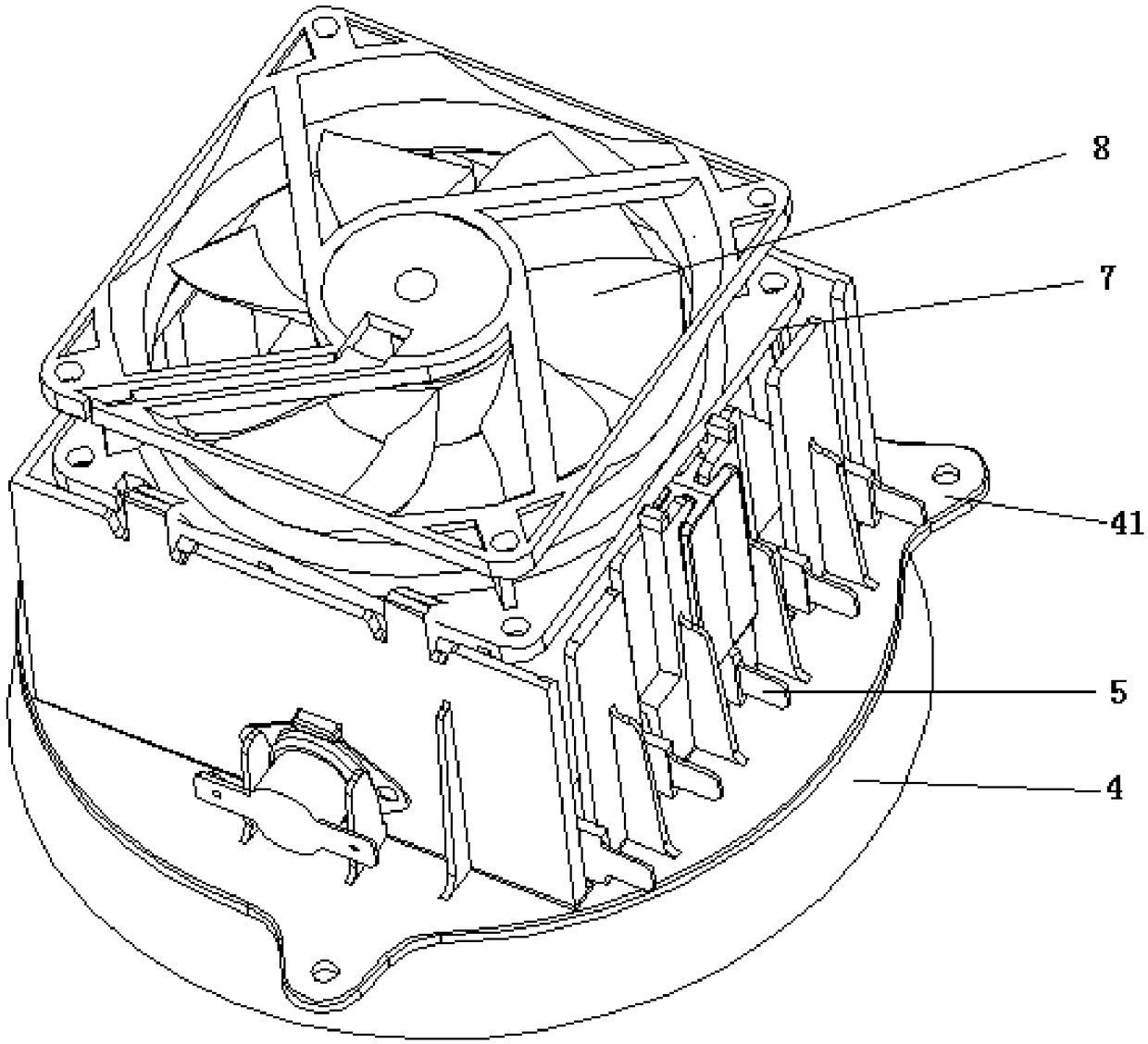

Heater

PendingCN109237777AEnhanced waterproof functionImprove the scope of use and use safety performanceAir heatersHeat flowEngineering

The invention provides a heater. The heater comprises a housing, a heating body, a first fan and a second fan. An air inlet and an air outlet are formed in the housing, and the air outlet is formed around the circumference of the housing; the heating body is disposed in the housing, located between the air inlet and the air outlet and used for heating air in the housing; the first fan is disposedbetween the air inlet and the heating body and used for blowing the air entering from the air inlet to the heating body; the second fan is disposed between the heating body and the air outlet and usedfor blowing the air heated by the heating body to the air outlet. The air enters the housing from the air inlet, the first fan blows the air entering from the air inlet to the heating body, the heating body heats the air, and the second fan blows the air heated by the heating body to the air outlet. Since the air outlet is formed around the circumference of the housing, the heat flow rate of theair outlet is large, heating can be performed around the circumference of the housing, and the heating range is wide.

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

Smelting electric furnace waste heat recovery and recirculation system and method

InactiveCN106969640ALarge heat flowImprove recycling efficiencyEnergy industryIncreasing energy efficiencyHeat flowStreamflow

The invention discloses a smelting electric furnace waste heat recycling and recirculation system. The smelting electric furnace waste heat recycling system comprises a dust remover, a waste heat boiler, an induced draft fan and a recirculation draft fan. A smoke outlet of the dust remover is connected with a smoke inlet of the waste heat boiler through a smoke-air pipeline. A smoke outlet of the waste heat boiler, a smoke inlet of the induced draft fan and a smoke inlet of the recirculation draft fan are connected through the smoke-air pipeline. The smoke outlet of the recirculation draft fan is connected with a smoke inlet of the dust remover through the smoke-air pipeline. The invention discloses a smelting electric furnace waste heat recycling and recirculation method simultaneously. The recirculation draft fan with appropriate parameters is selected by calculating; and part of low-temperature smoke is extracted from the smoke outlet of the waste heat boiler and led in the smoke inlet of the dust remover. The heat flow of smoke at the smoke inlet of the waste heat boiler is increased, the recovery efficiency of the waste heat boiler is improved, the material heat resistant class is lowered, and the engineering cost is reduced.

Owner:中国船舶重工集团公司第七〇三研究所无锡分部

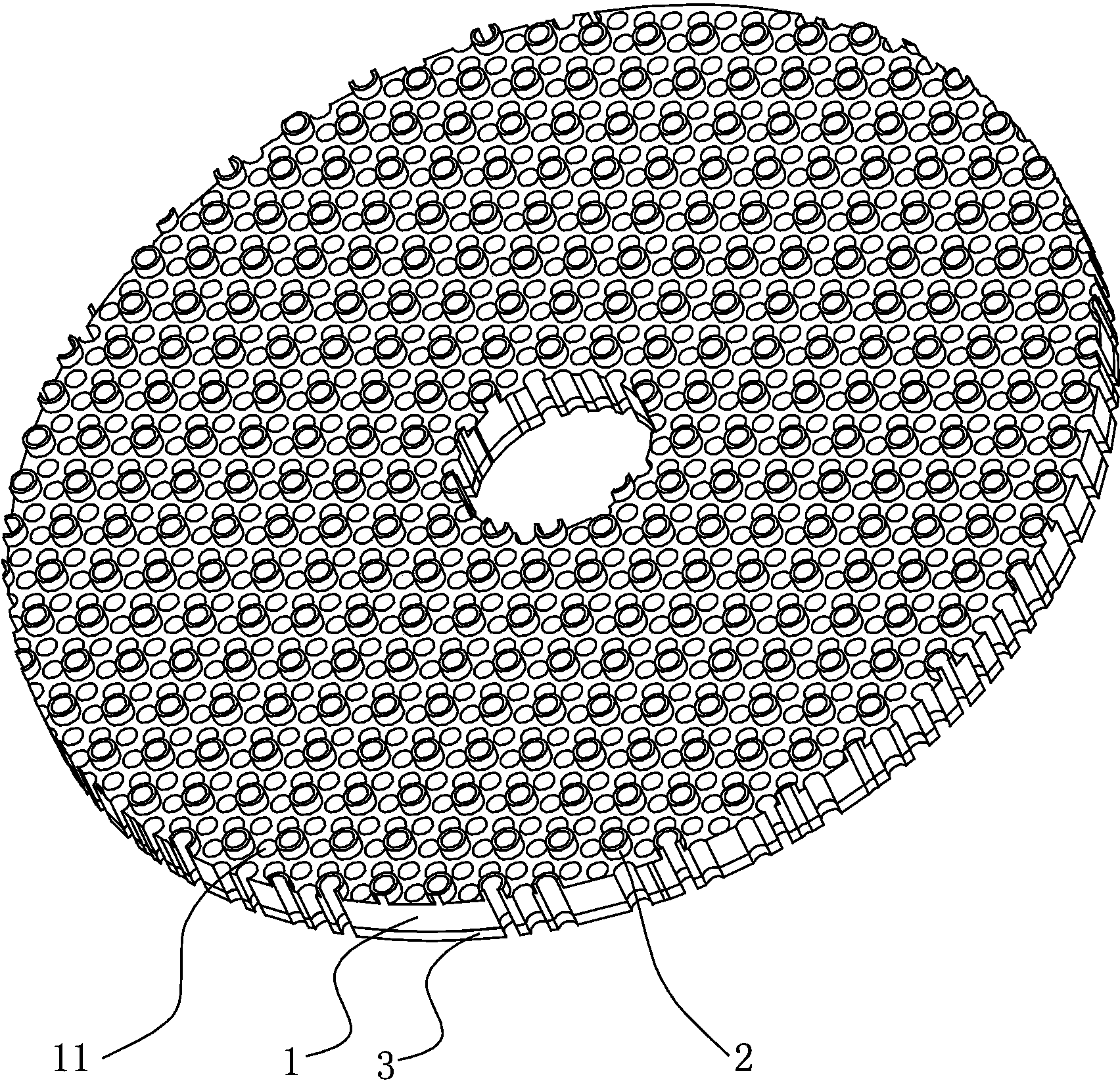

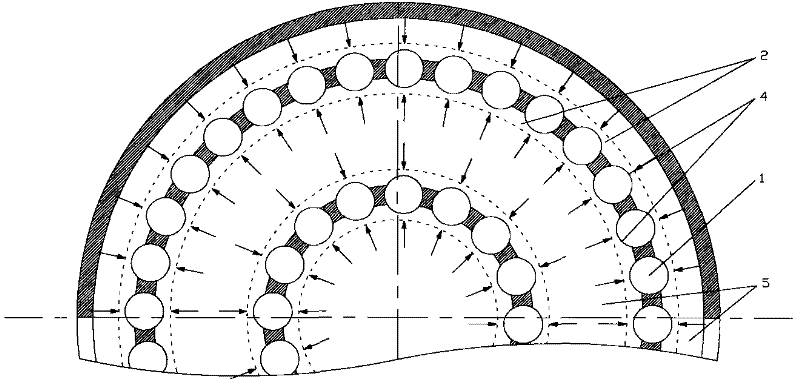

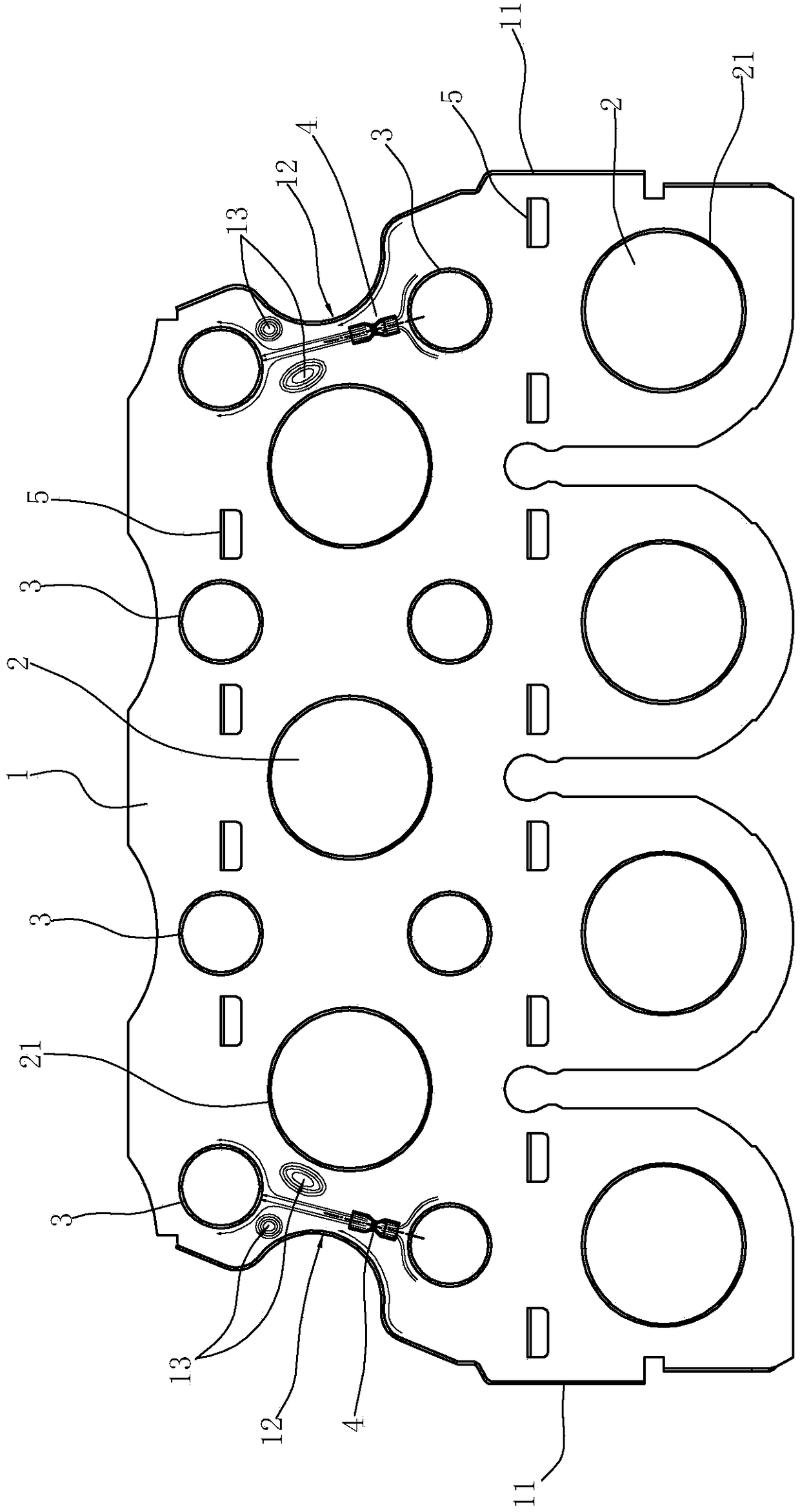

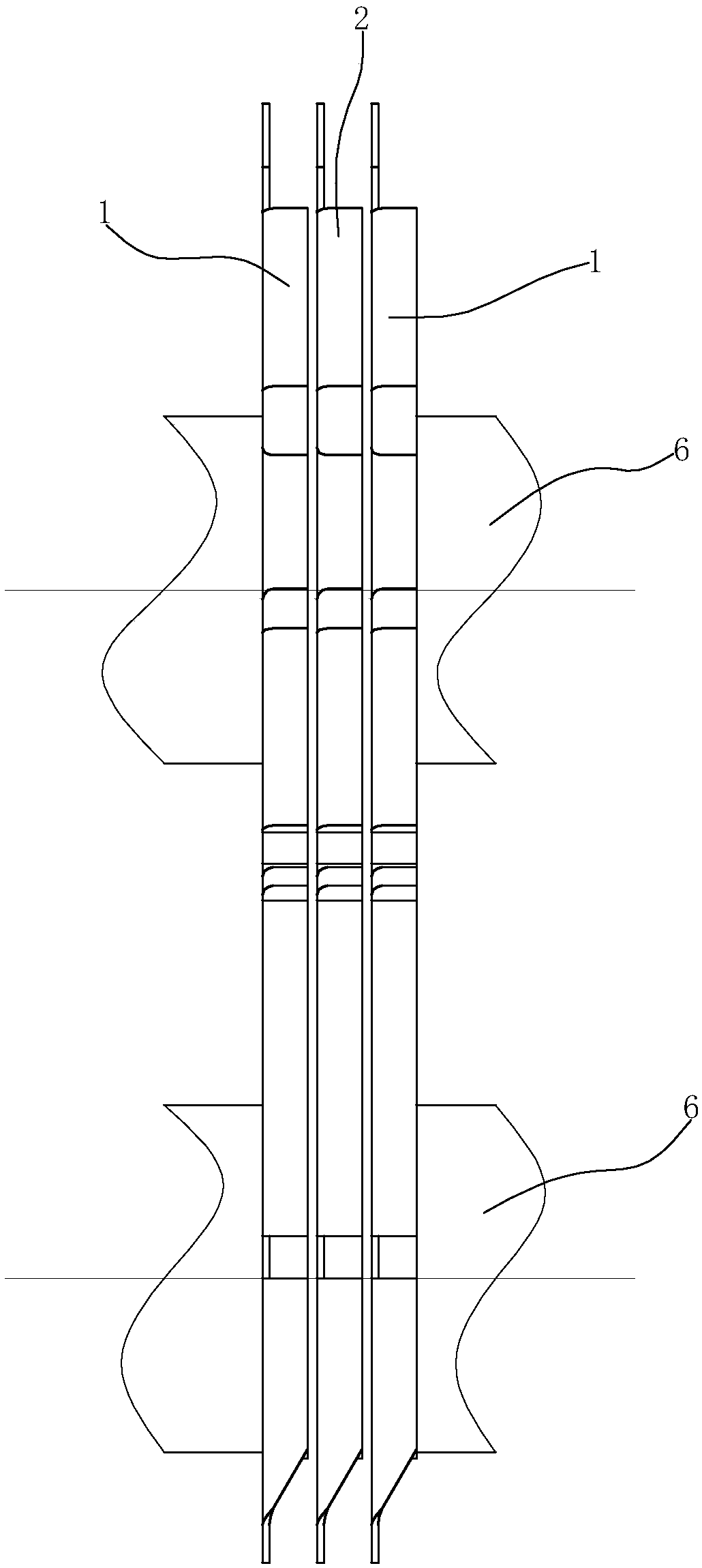

Radiator of infrared radiation gas stove

ActiveCN104110715AImprove Radiation PerformanceIncrease the effective areaDomestic stoves or rangesLighting and heating apparatusInfraredConvex structure

The invention discloses a radiator of an infrared radiation gas stove. The radiator comprises a ceramic base plate (1), wherein a plurality of fire outlet holes (11) are formed in the base plate (1). The radiator is characterized by also comprising burners (2), wherein connecting holes (12) are formed in the base plate (1); the connecting holes (12) and the fire outlet holes (11) are formed at intervals in a staggered mode; the burners (2) are inserted into the connecting holes (12) and are protruded out of the upper surface of the base plate (1). The burners form an uneven concave-convex structure, so that the effective radiation area is increased, and the radiation strength is effectively improved.

Owner:GUANGDONG VANWARD ELECTRIC

Soya-bean milk making device

InactiveCN101449785BImprove insulation effectSimple structureKitchen equipmentFood scienceHeat flowThermal insulation

The invention relates to a soya-bean milk machine which includes a container and a heating element, an outer barrel is arranged outside the container in a split way, and the heating element is arranged on an inner bottom and / or inner side part of the outer barrel. In the outer barrel, a super heat conductor is arranged on a heating surface of the heating element or close to the heating element and is used for heating slurries in the container. The outer barrel has a double-layer structure, an outer layer is an outer casing, an inner layer is a reflecting layer, and a heat insulation cavity is formed between the outer casing and the reflecting layer. The container of the utility model is connected with the outer barrel in a split way and can be individually fetched out for cleaning, and the outer barrel has better thermal insulation effect. In addition, when the heating element is heating, the soya-bean milk machine forms a real stereo encircling constant-temperature heating for the bottom of the container by utilizing efficient heat-conducting characteristic (thermal resistance is close to zero) and isothermal performance of the super heat conductor. The soya-bean milk machine has advantages of simple and reasonable structure, large heat flow, large heating area, convenient cleaning, energy conservation and environmental protection.

Owner:ZHANGZHOU WANLIDA ZHONGHUAN TECH INC

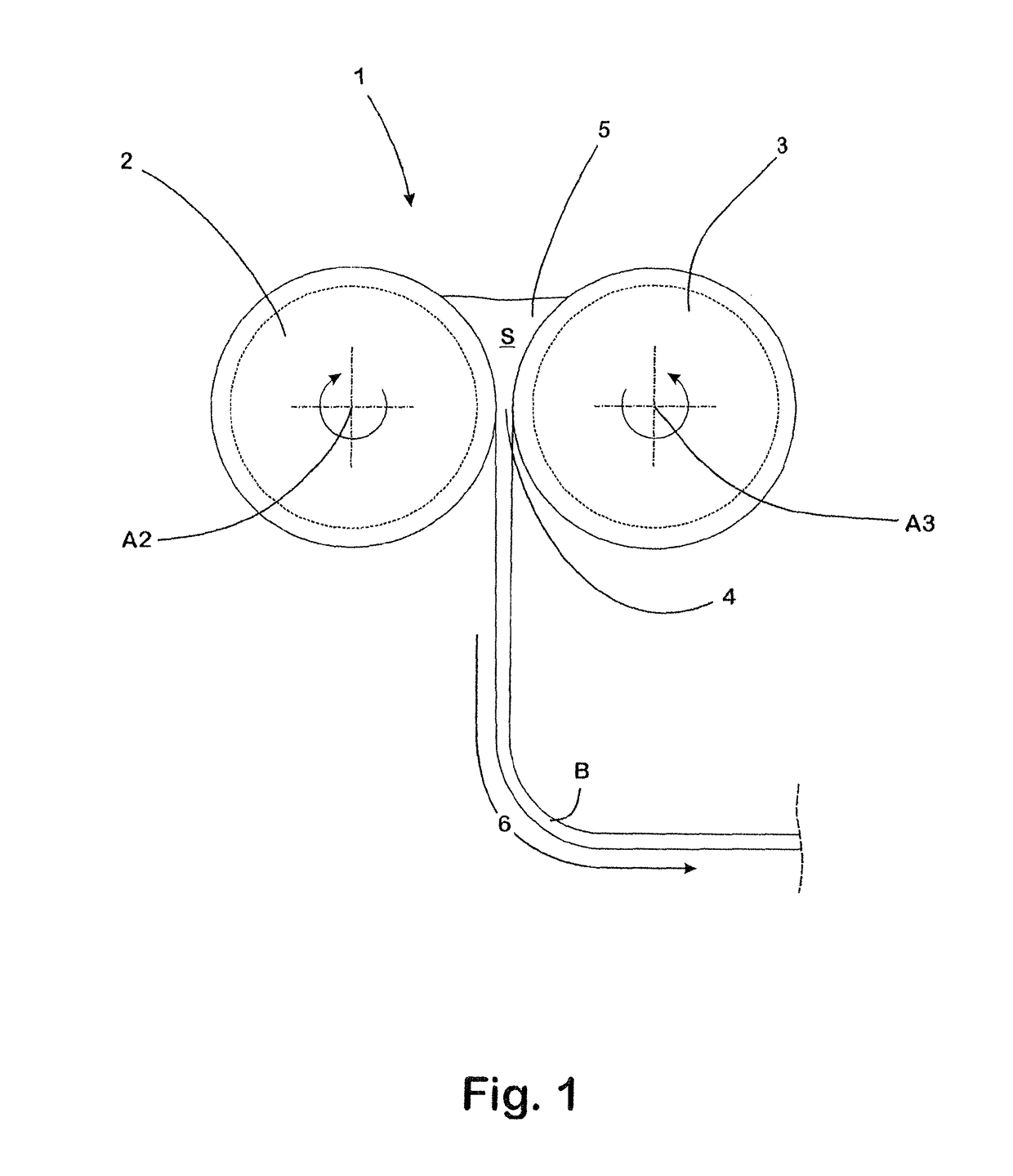

Method for producing a cast strip of molten metal and cast strip

A method for producing a cast strip of molten metal, in which the molten metal passes through a casting gap defined by two oppositely rotating casting rollers and is shaped into the cast strip, as well as the cast strip that is produced. By providing the cast strip in the casting gap with a different thickness in a first length section extending in the longitudinal direction of the cast strip than in a second length section bordering thereon, a metal strip is produced that has length sections with different thicknesses.

Owner:OUTOKUMPU NIROSTA

Advanced crucible support and thermal distribution management

ActiveUS9845548B2Avoid overall overheatingIncrease heat flowAfter-treatment apparatusPolycrystalline material growthSupporting systemHeat flow

According to the disclosed embodiments, an advanced crucible support system is described that allows for greater heat flow to and from the bottom of a crucible, preferably while also preventing excessive heat from reaching a heat exchanger. In particular, a support base is described that includes one or more vents enabling improved heat flow throughout the system. Also, according to one or more additional embodiments, the functionality of the crucible support is adapted to be leveraged by a crucible manipulating device. For example, the support plate may have a plurality of slots for insertion of a “lifting arm”, such that the entire support plate assembly, as well as the crucible itself while on the support assembly, may be lifted and transported as a single unit.

Owner:GTAT CORPORATION

Radiator for gas stoves with infrared radiation

ActiveCN104110715BImprove Radiation PerformanceIncrease the effective areaDomestic stoves or rangesLighting and heating apparatusConvex structureEngineering

The invention discloses a radiator of an infrared radiation gas stove. The radiator comprises a ceramic base plate (1), wherein a plurality of fire outlet holes (11) are formed in the base plate (1). The radiator is characterized by also comprising burners (2), wherein connecting holes (12) are formed in the base plate (1); the connecting holes (12) and the fire outlet holes (11) are formed at intervals in a staggered mode; the burners (2) are inserted into the connecting holes (12) and are protruded out of the upper surface of the base plate (1). The burners form an uneven concave-convex structure, so that the effective radiation area is increased, and the radiation strength is effectively improved.

Owner:GUANGDONG VANWARD ELECTRIC

Air vent manufactured in mode of forming branch air passages on side wall of main air passage

The invention discloses air vents manufactured in a mode of forming branch air passages on the side wall of a main air passage. The geometric characteristics and quantity of inlets and outlets of the air vents are completely different, but the circulation capability of the inlets and outlets are approximately same. The air vent is characterized in that a plurality of branch air passages are formed on the side wall of the main air passage, thus the air vent taking the plurality of branch air passages as the inlets, taking the main air passage as a transfer passage, and taking openings at the upper end of the main air passage as the outlets are formed, the air vent has the characteristics of high heat flow rate and use safety, can be used for producing a combustor with high heat flow rate, high combustion intensity and centralized flame, and is good for improvement of the combustion reaction temperature and heat transfer intensity.

Owner:李芳春

Soya-bean milk making device

InactiveCN101449784BNot easy to burnEvenly heatedBeverage vesselsFood preparationHeat flowHeat conducting

Owner:ZHANGZHOU WANLIDA ZHONGHUAN TECH INC

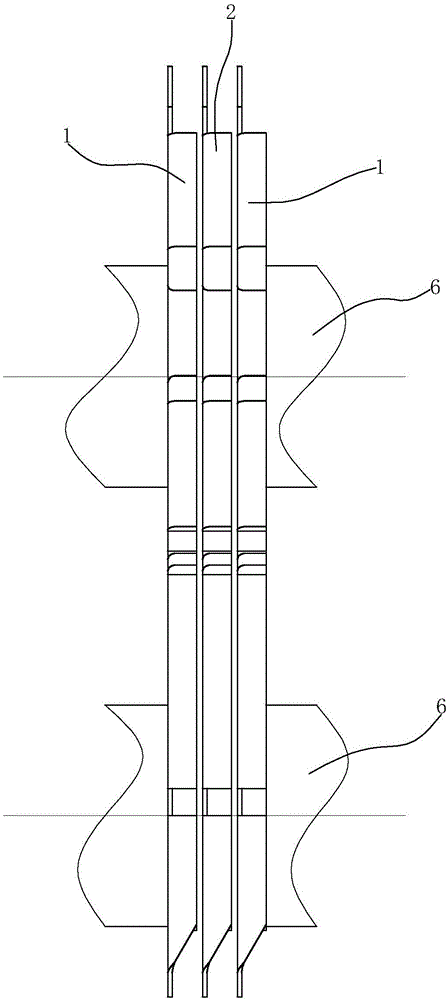

Heating coil welding fitting

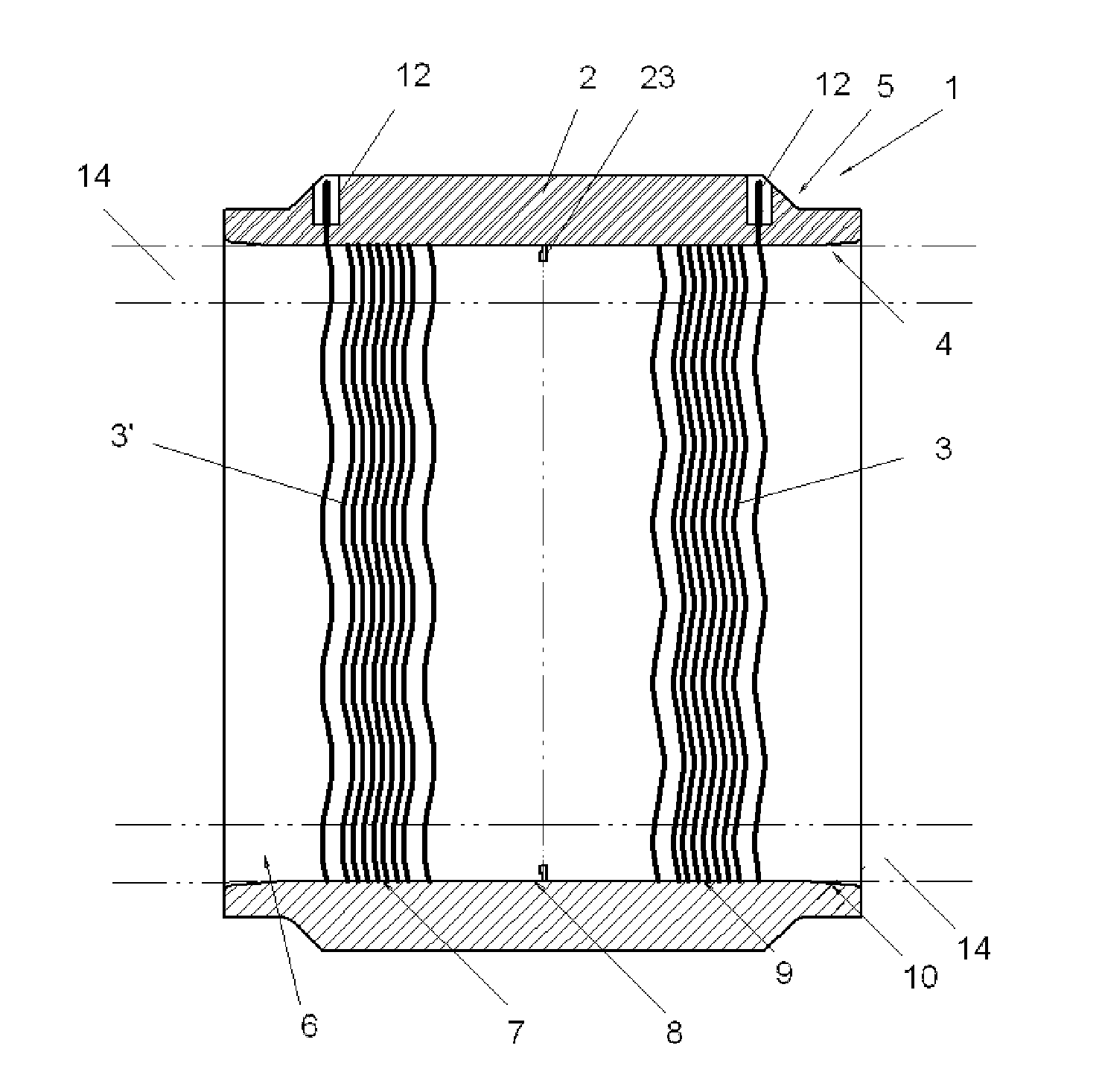

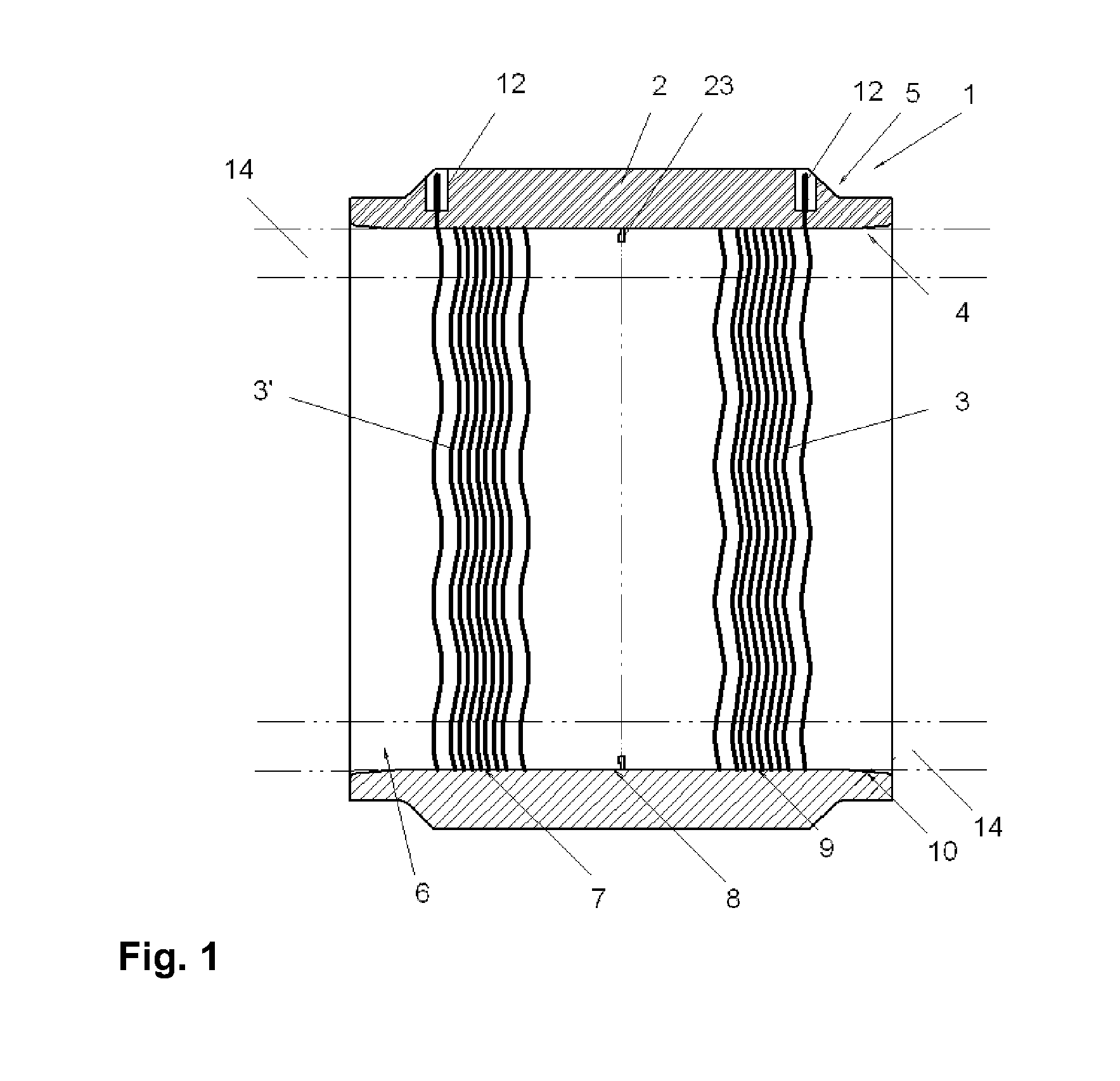

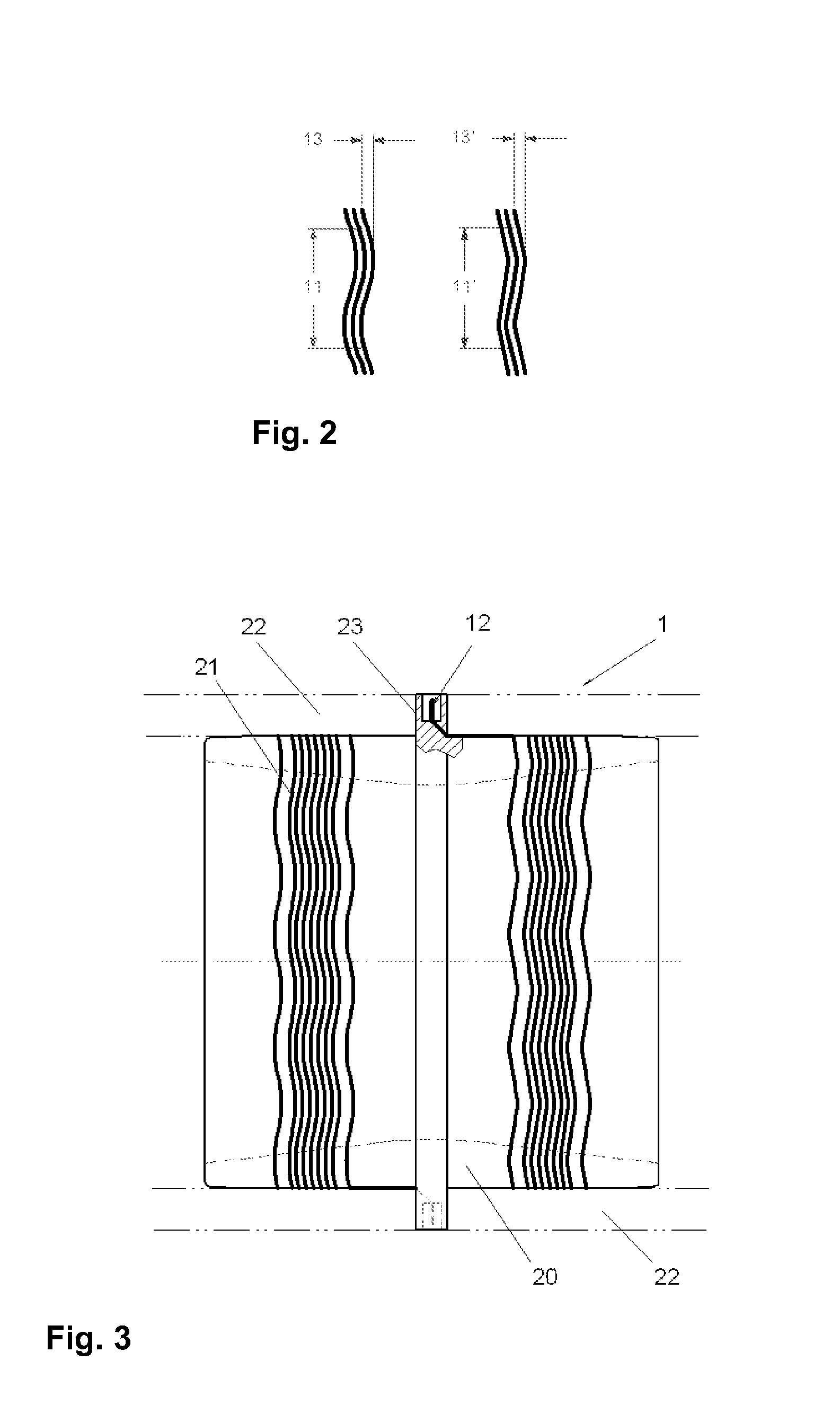

InactiveUS20120111503A1Shorten heating timeWeaken energyMechanical working/deformationLaminationThermoplasticCoupling

A heating coil welding fitting comprising a cylindrical coupling body for welding pipelines made of thermoplastics or other weldable plastics, containing at least two heating wire windings, each with a plurality of turns which are at any desired distance from one another, and contacts for feeding the electric current, wherein the heating wire winding is wavy, preferably sinusoidal, and the coupling can be deformed as a result.

Owner:GEORG FISCHER ROHRLEITUNGSSYST

a heat exchange fin

ActiveCN106643255BEvenly distributedExtended stayFluid heatersHeat exhanger finsEngineeringUltimate tensile strength

The invention relates to an efficient heat exchange fin. The efficient heat exchange fin comprises a base plate. The surface of the base plate is provided with at least two heat exchange pipe holes at intervals and provided with at least two flow disturbing rings at intervals. The efficient heat exchange fin is characterized in that the heat exchange pipe holes are arranged in two rows, the upper row of heat exchange pipe holes and the lower row of heat exchange pipe holes are staggered, the flow disturbing rings are also arranged in two rows, the upper row of flow disturbing rings and the lower row of flow disturbing rings are staggered, each flow disturbing ring is located above the corresponding heat exchange pipe hole, the two side edges of the base plate are each provided with a turnup protruding outwards, the portion, located between the two rows of flow disturbing rings, of each turnup is recessed inwards, so that an energy gathering arc is formed, the portions, corresponding to the energy gathering arcs, of the surface of the base plate are provided with flow guide channels, the flow guide channels are located between the upper flow disturbing rings and the lower flow disturbing rings, a first end opening of each flow guide channel faces the lower row of flow disturbing rings, and a second end opening of each flow guide channel faces the upper row of flow disturbing rings. The efficient heat exchange fin can greatly improve the heat exchange intensity and the heat exchange efficiency.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com