Radiator for gas stoves with infrared radiation

An infrared radiation, gas stove technology, applied in the field of radiators, can solve problems such as energy loss, limited radiation capacity, and inability to satisfy consumers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

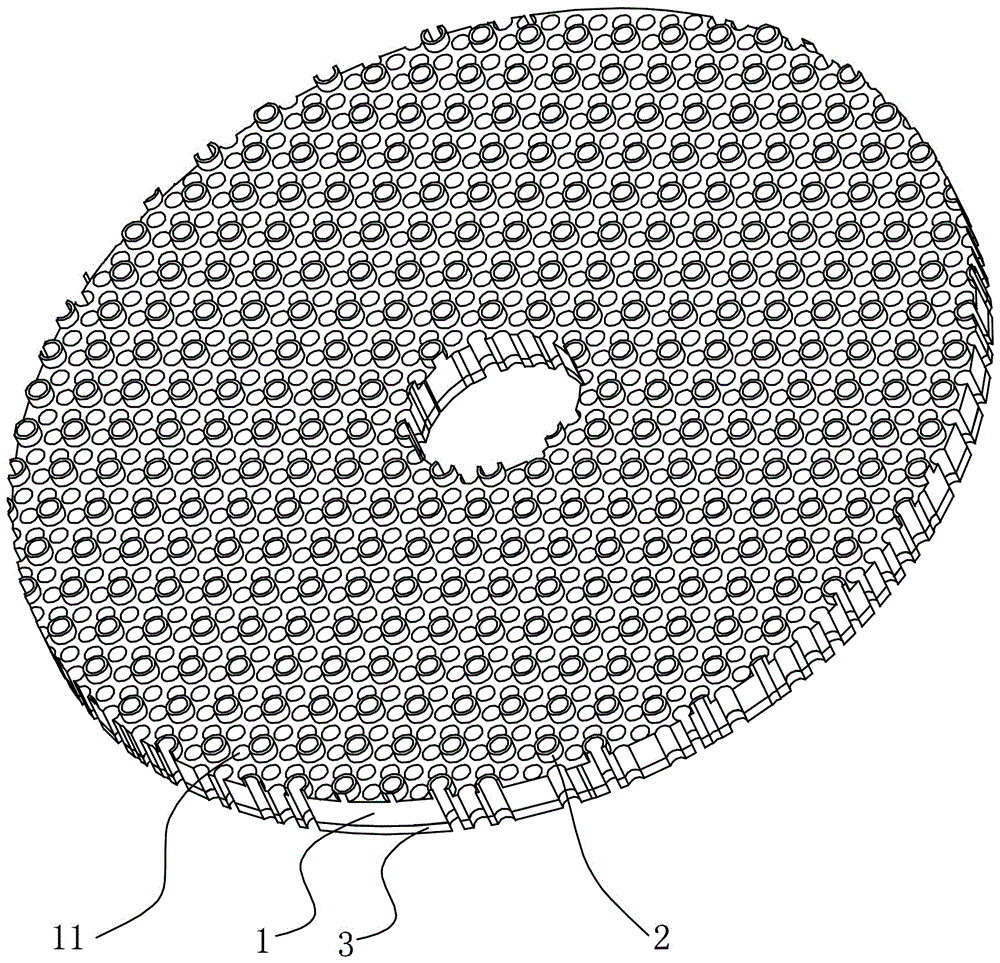

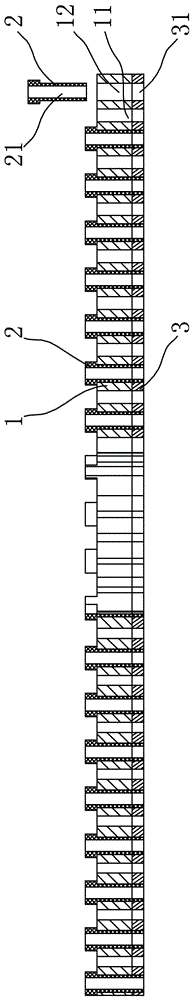

[0016] Specific implementation method: see figure 1 and figure 2 As shown, this embodiment includes a ceramic substrate 1 made of cordierite and a burner 2 made of mullite. Several fire holes 11 and connection holes 12 are distributed on the substrate 1, and the connection holes 12 and the fire holes 11 are interlaced. Arranged at intervals, the entire substrate 1 is in a honeycomb-like shape. A reinforcing plate 3 made of mullite is adhered to the bottom of the base plate 1 , and the reinforcing plate 3 is provided with through holes 31 coaxially arranged in one-to-one correspondence with the connecting holes 12 . The burner 2 is inserted in the connection hole 12 at intervals and protrudes from the upper surface of the substrate 1. The outer contour of the cut surface of the burner 2 and the substrate 1 in the side view direction of the ceramic substrate is a square waveform, and the bottom of the burner 2 extends into the connection. The hole 12 is in interference fit wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com