Passive radiation refrigeration composite material layer and preparation method thereof

A technology of composite material layer and radiative refrigeration, which is applied in the field of solar radiation-blocking coatings, solar radiation-blocking composite materials and their preparation, can solve the problems of increasing preparation and application costs, unfavorable application of passive radiative refrigeration materials, etc., and achieves The preparation method is simple, easy to realize, and the effect of optimizing comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

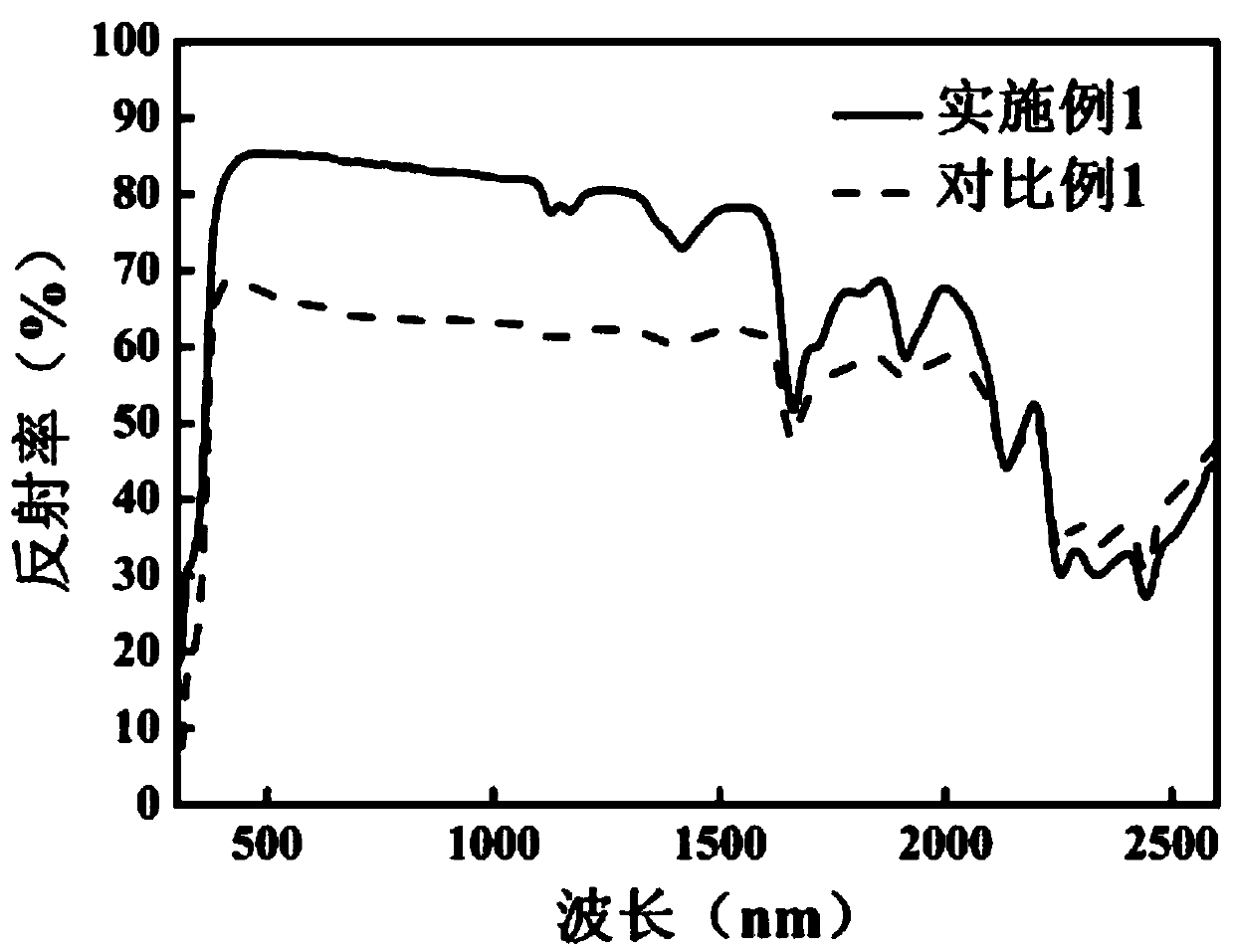

Embodiment 1

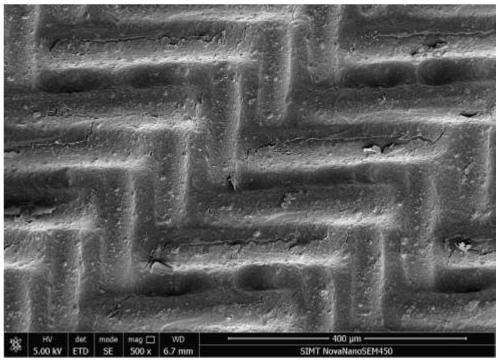

[0048] In this embodiment, a passive radiative cooling composite material layer, when the acetate fiber fabric with a size of 50 cm × 50 cm purchased from Mitsubishi Corporation of Japan is used as the base, the passive radiative cooling composite material layer is coated and arranged on the base , forming a composite layer structure of a substrate and a passive radiative cooling layer, the passive radiative cooling layer reflects visible light and near-infrared light in sunlight, and dissipates heat through an atmospheric window in the form of infrared radiation. The material components of the passive radiative cooling composite layer include functional inorganic nanoparticles α-Al that can reflect and scatter sunlight 2 o 3 1. A functional polymer acetate fiber with a radiation-enhancing effect, wherein the functional inorganic nanoparticles are evenly distributed in the functional polymer.

[0049] A preparation method of the passive radiative cooling composite material la...

Embodiment 2

[0062] This embodiment is basically the same as Embodiment 1, and the special features are:

[0063]In this embodiment, a passive radiation cooling composite material layer, when an organza fabric with a size of 50cm×50cm is used as the base, the passive radiation cooling composite material layer is coated on the base to form the base and the passive base. The passive radiation cooling layer reflects visible light and near-infrared light in sunlight, and dissipates heat through the atmospheric window in the form of infrared radiation. The material components of the passive radiative cooling composite layer include functional inorganic nanoparticles α-Al that can reflect and scatter sunlight 2 o 3 1. A functional polymer acetate fiber with a radiation-enhancing effect, wherein the functional inorganic nanoparticles are evenly distributed in the functional polymer.

[0064] A preparation method of the passive radiative cooling composite material layer of this embodiment, compr...

Embodiment 3

[0085] This embodiment is basically the same as the previous embodiment, and the special features are:

[0086] In this embodiment, a passive radiation refrigeration composite material layer, when an aluminum plate with a size of 15cm×7.5cm×0.05cm is used as the substrate, the passive radiation refrigeration composite material layer is coated on the substrate to form the substrate and The composite layer structure of the passive radiative cooling layer, the passive radiative cooling layer reflects visible light and near-infrared light in sunlight, and dissipates heat through the atmospheric window in the form of infrared radiation. The material components of the passive radiative cooling composite layer include functional inorganic nanoparticles α-Al that can reflect and scatter sunlight 2 o 3 , functional polymer acetate fiber for radiation enhancement and epoxy resin that can improve coating adhesion, the functional inorganic nanoparticles are uniformly distributed in the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com