Water-based two-component fluorosilicone acrylic anticorrosive paint and preparation method thereof

A technology of fluorosilicone acrylic polyurethane and hydroxyfluorosilicone acrylic acid is applied in the field of waterborne two-component polyurethane anti-corrosion coating and its preparation, and can solve the problems of low solid content, low cross-linking density, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] A. Preparation of water-based hydroxyfluorosilicone acrylic resin:

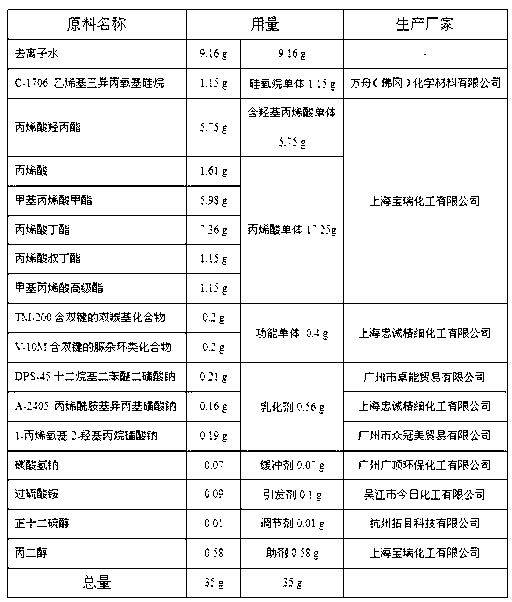

[0080] a. Nuclear raw materials:

[0081]

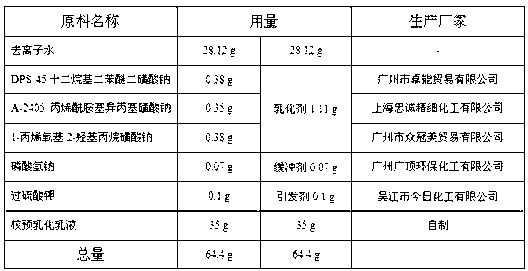

[0082] Among them, the nuclear pre-emulsion emulsion includes:

[0083]

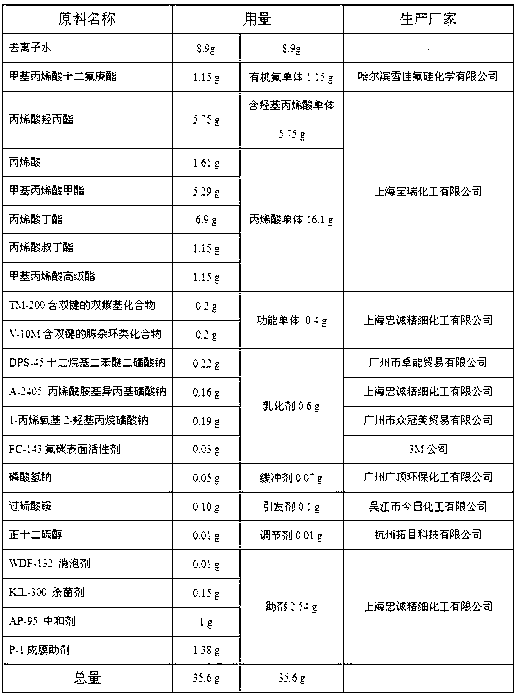

[0084] b. Shell raw materials:

[0085]

[0086] Preparation:

[0087] The first step: mixing the raw materials of the nuclear pre-emulsified emulsion to prepare the nuclear pre-emulsified emulsion;

[0088] Step 2: Add deionized water, emulsifier, buffer, and initiator in the raw materials of the nuclear part into the reactor, add 1.5 g of nuclear pre-emulsified emulsion under the stirring condition of 80 rpm, and react at a constant temperature of 80-85 °C for 15 minutes to form Seed emulsion, then add the remaining 33.5 g of nuclear pre-emulsified emulsion dropwise, the dropping time is 2-3 hours, the temperature is 80-85 °C, after the addition of nuclear pre-emulsified emulsion, 80-87 °C constant temperature reaction for 1-1.5 hours, Prepare a nuclear partial em...

Embodiment 2

[0097] A. Preparation of water-based hydroxyfluorosilicone acrylic resin:

[0098] Same as Example 1

[0099] B. Preparation of water-based two-component fluorosilicone acrylic polyurethane anticorrosion coating:

[0100]

[0101] The preparation steps of waterborne two-component fluorosilicone acrylic polyurethane anticorrosion coating are as follows:

[0102] Add deionized water, other additives except thickening and leveling agent into the stirring tank, add rutile titanium dioxide, ultra-fine mica powder, ultra-fine talc powder and precipitated barium sulfate under stirring, and disperse at a high speed of 900-1400rpm for 30 minutes , and then ground to a fineness of not more than 30 μm, then transported to the paint tank, adding water-based hydroxyfluorosilicone acrylic resin and thickening and leveling agent under the stirring condition of 80-90rpm, stirring evenly, discharging, filtering, and making into a finished product Membrane material composition;

[0103...

Embodiment 3

[0106] A. Preparation of water-based hydroxyfluorosilicone acrylic resin:

[0107] Same as Example 1

[0108] B. Preparation of water-based two-component fluorosilicone acrylic polyurethane anticorrosion coating:

[0109]

[0110] The preparation steps of waterborne two-component fluorosilicone acrylic polyurethane anticorrosion coating are as follows:

[0111] Add deionized water, other additives except thickening and leveling agent into the stirring tank, add rutile titanium dioxide, ultra-fine mica powder, ultra-fine talc powder and precipitated barium sulfate under stirring, and disperse at a high speed of 900-1400rpm for 30 minutes , and then ground to a fineness of not more than 30 μm, then transported to the paint tank, adding water-based hydroxyfluorosilicone acrylic resin and thickening and leveling agent under the stirring condition of 80-90rpm, stirring evenly, discharging, filtering, and making into a finished product Membrane material composition;

[01...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com