Soya-bean milk making device

The technology of a soymilk machine and a barrel body is applied in the field of soymilk machines heated by superheat-conducting pipes, which can solve the problems affecting the quality of the slurry and the health of users, and achieve the effects of simple and reasonable structure, high-efficiency thermal conductivity, and large heat flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

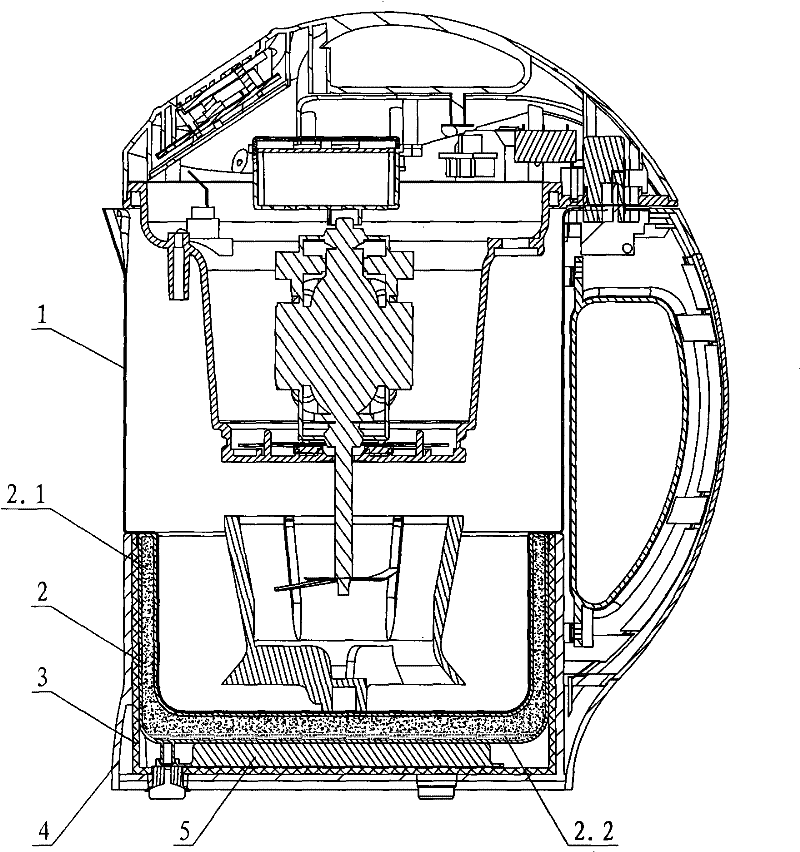

[0020] see figure 1 , The soymilk machine comprises a barrel body 1, a heating plate 5, a superheater and a base 4, the base is arranged at the bottom of the barrel, the inner wall is provided with a heat insulating layer 3, and the superheater and the heating plate are arranged in the base.

[0021] The superheater includes a groove-shaped casing 2, a vacuum chamber is arranged inside the casing, a working medium is arranged in the vacuum chamber, the lower section is the evaporation section 2.2, which is connected to the heating surface of the heating plate 5, and the upper section is the condensation section, wrapped On the outer wall and outer bottom surface of the barrel body 1 bottom. The lower wall of the bucket body 1 is recessed inward corresponding to the wall of the superheater housing 2 and the wall of the base 4 .

[0022] The above-mentioned working medium is potassium, sodium, ethanol or a combination thereof. The bottom surface of the barrel can be opened, bu...

no. 2 example

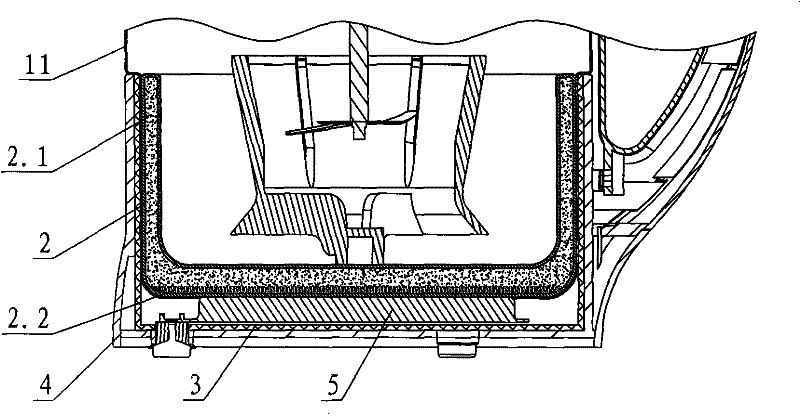

[0025] see figure 2 , the bottom of the barrel body 11 is open, the superheater is sealed and arranged in the barrel body, and the lower evaporation section 2.2 is connected to the heating plate. Other unmentioned parts are the same as the first embodiment.

[0026] When the bottom of the barrel body is closed, the evaporation section of the lower section of the superconducting heat body is connected to the heating plate through the bottom surface of the barrel body, which does not affect the use effect.

no. 3 example

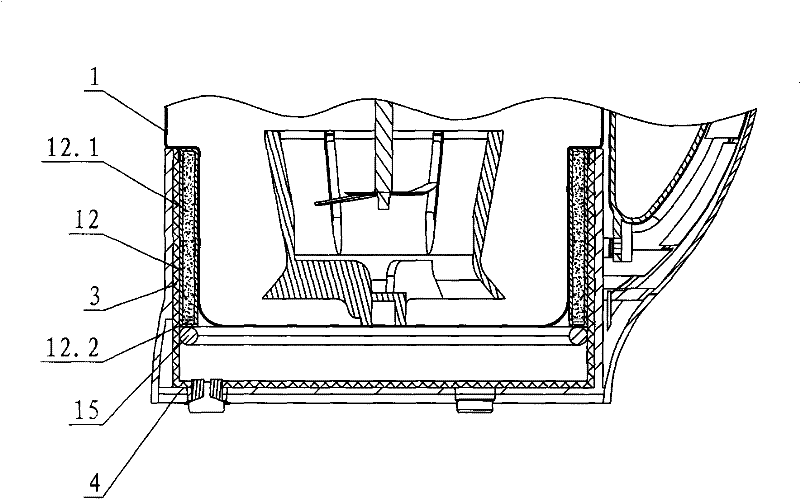

[0028] see image 3 , the superheater includes a ring-shaped shell 12, a vacuum chamber is arranged inside the shell, a working medium is arranged in the vacuum chamber, the evaporation section 12.2 is connected to the annular heating plate 15, and the condensation section 12.1 is wrapped on the outer wall of the lower part of the barrel body 1 . Other unmentioned parts are the same as the first embodiment.

[0029] The above-mentioned annular heating plate 15 can be applied to the heating plate 5 of the first embodiment. The central part of the heating plate directly heats the bottom surface of the barrel, and the outer periphery transmits heat to the side of the barrel through a ring-shaped superconducting heat body, thereby producing a three-dimensional surround. The effect of heating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com