Rubber composition for preparing external and internal layers of automotive turbocharged hose and production method thereof

A rubber composition and turbocharging technology are applied in the field of rubber compositions for manufacturing the inner and outer rubber layers of automobile turbocharged hoses, which can solve the problems of poor permanent deformation performance, poor resistance to low aniline oil polar solvents, etc. The effect of improved scorch resistance, good stiffness and improved thermal oxygen resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

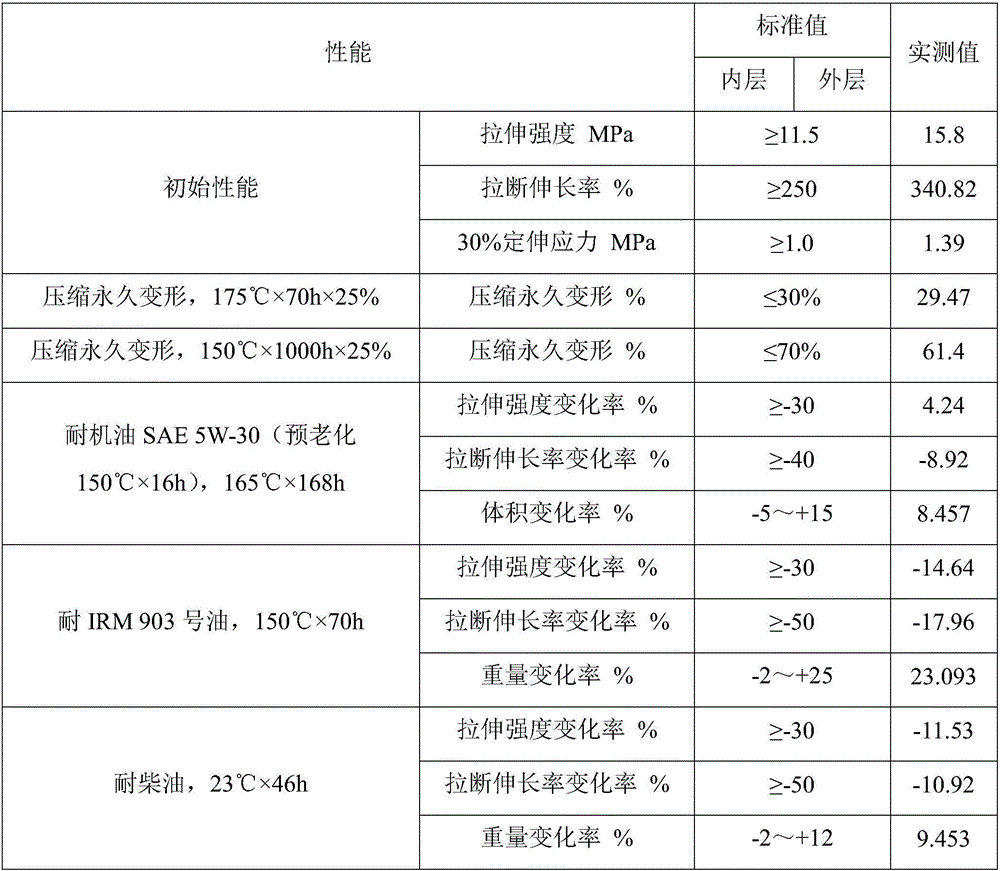

[0030] The ethylene acrylate rubber composition used to manufacture the inner and outer rubber layers of automobile turbocharger hoses, see Table 1 for its components and parts by mass.

[0031] The composition of the rubber composition of table 1 embodiment 1 and consumption table thereof

[0032] raw material Dosage Ethylene acrylate rubber 100 stearic acid 1.0 Vanfre VAM 1.0 Naugard 445 2.0 Fast pressing furnace black N550 55 RS-WT 10 ACT55 2.0 DK-1 1.1 Artmix 18D 0.5

[0033] With above-mentioned rubber composition, carry out according to the following steps:

[0034] One-stage mixing: use a fully automatic mixing production line for production, add ethylene acrylate rubber to the internal mixer, then add processing aids and anti-aging agents, then add carbon black and plasticizer, press pressure 0.35MPa, mix Refining for 4 minutes, debinding at 100°C;

[0035] Two-stage mixing: put the discharge materi...

Embodiment 2

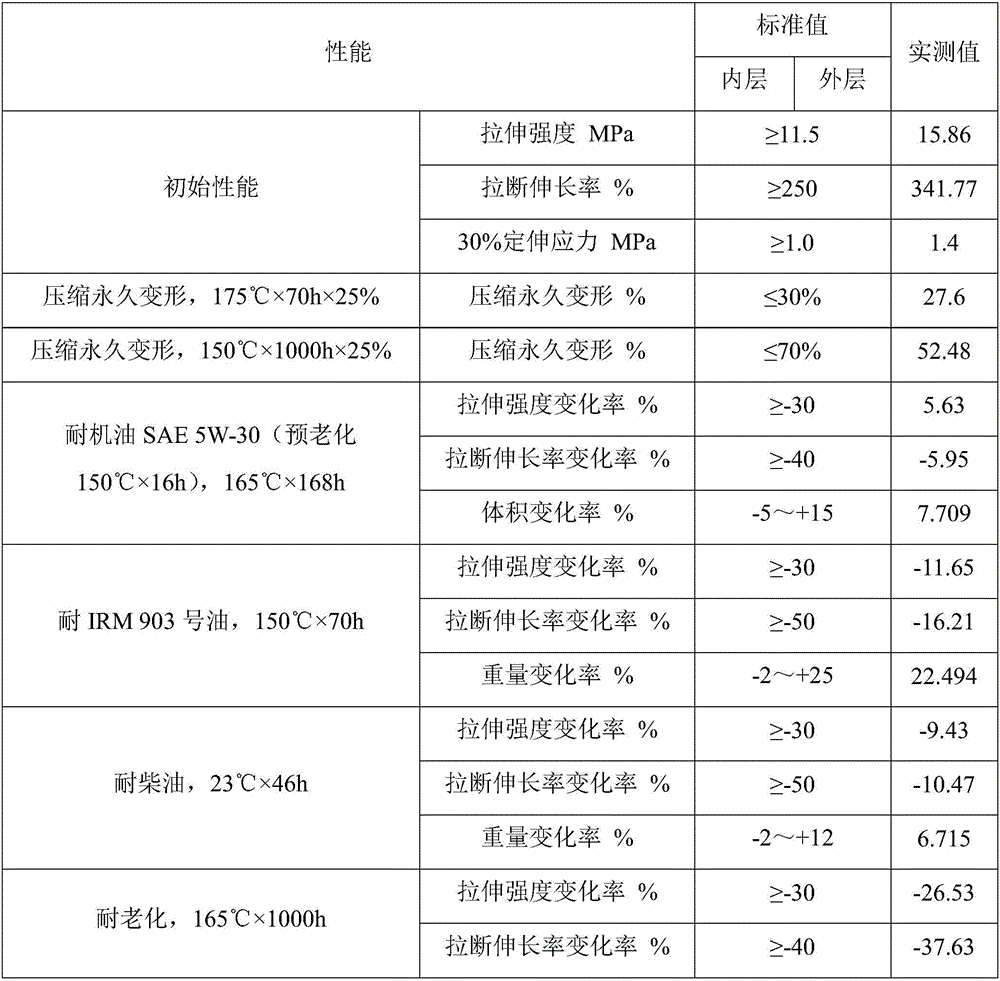

[0041] The ethylene acrylate rubber composition used to manufacture the inner and outer rubber layers of automobile turbocharger hoses, see Table 3 for its components and parts by mass.

[0042] The composition of the rubber composition of table 3 embodiment 2 and consumption table thereof

[0043] raw material Dosage Ethylene acrylate rubber 100 stearic acid 1.0 Vanfre VAM 1.0 Naugard 445 2.0 Fast pressing furnace black N550 58 RS-WT 10 ACT55 2.5 DK-1 1.1 Artmix 18D 1.0

[0044] With above-mentioned rubber composition, carry out according to the following steps:

[0045] One-stage mixing: use a fully automatic mixing production line for production, add ethylene acrylate rubber to the internal mixer, then add processing aids and anti-aging agents, then add carbon black and plasticizer, press pressure 0.37MPa, mix Refining for 5 minutes, debinding at 110°C;

[0046] Two-stage mixing: Put the material dischar...

Embodiment 3

[0051] The ethylene acrylate rubber composition used to manufacture the inner and outer rubber layers of automobile turbocharger hoses, see Table 5 for its components and parts by mass.

[0052] The composition of the rubber composition of table 5 embodiment 3 and consumption table thereof

[0053]

[0054]

[0055] With above-mentioned rubber composition, carry out according to the following steps:

[0056] One-stage mixing: use a fully automatic mixing production line for production, add ethylene acrylate rubber to the internal mixer, then add processing aids and anti-aging agents, then add carbon black and plasticizer, press pressure 0.33MPa, mix Refining for 4 minutes, debinding at 105°C;

[0057] Two-stage mixing: Put the material discharged from the internal mixer into the pull tab of the open mixer to cool, and when the rubber material is cooled below 60°C, put it back into the internal mixer for mixing, and then add the vulcanizing agent, accelerator and interna...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| compression set | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com