Patents

Literature

45results about How to "Improved scorch resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-temperature-resistant rubber sealing ring for automobiles

The invention discloses a high-temperature-resistant rubber sealing ring for automobiles. The high-temperature-resistant rubber sealing ring comprises the following raw materials in parts by weight: 70-90 parts of ethylene-propylene-diene-terpolymer rubber, 10-30 parts of chloroprene rubber, 1-4 parts of an anti-aging agent, 0.8-1.5 parts of active zinc oxide, 0.2-0.4 part of magnesium oxide, 0.5-1.0 part of calcium oxide, 0.6-1.5 parts of butyltin mercaptide, 30-40 parts of modified kaolin, 10-15 parts of magnesium methacrylate, 1-3 parts of a promoter, 6-10 parts of soybean oil, 1-2 parts of ethyl methacrylate, 40-80 parts of paraffin oil, 0.2-0.5 part of triallyl phosphate, 1.0-1.5 parts of a crosslinking agent BIBP, 0.5-1.2 parts of an assistant crosslinking agent TAIC, 0.3-0.5 part of microcrystalline wax, 2-3 parts of a vulcanizing agent and 0.5-1 part of phthalic anhydride. The sealing ring disclosed by the invention has strong weather resistance, corrosion resistance and ozone resistance, and can be suitable for being used as the high-temperature-resistant rubber sealing ring for the automobiles.

Owner:TONGLING SANSHENG ELECTRONICS

Preparation method of nitrile butadiene rubber for preparing seal ring of floating oil seal with high wear resistance

The invention relates to a preparation method of nitrile butadiene rubber for preparing a seal ring of a floating oil seal with high wear resistance. The preparation method comprises a formula and a preparation process, wherein the formula comprises the following components: nitrile butadiene rubber, N-550 carbon black, high-wear resistant carbon black, semi-reinforced carbon black, calcium carbonate, polyvinyl chloride, stearic acid, dibutyl ester, sulfur, accelerant, accelerant TE, accelerant TMTD, anti-aging agent RD, anti-aging agent 4010 and zinc oxide; the preparation process comprises the following steps: adjusting the temperature of a mixing machine to 100 DEG C, keeping the rotational speed at 32 revolutions / min, putting rubber raw material, a filling agent, a softening agent, an acidifying agent, the anti-aging agents and an activator into the mixing machine to mix for 20min, controlling the rubber temperature below 130 DEG C to discharge the rubber, then transferring to an open mill, and cooling extruded sheets to obtain a master batch; and putting the master batch into the mixing machine, adding a vulcanizing agent, blending, mixing, controlling the rubber temperature below 100 DEG C to discharge the rubber to the open mill, then cooling the extruded sheets, standing and curing to obtain the nitrile butadiene rubber for preparing the seal ring of the floating oil seal with high wear resistance.

Owner:ZHEJIANG GUANGLI ENG MACHINERY

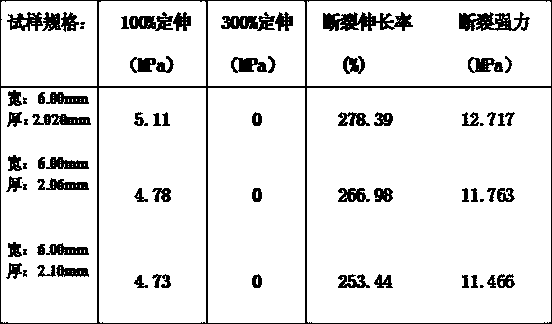

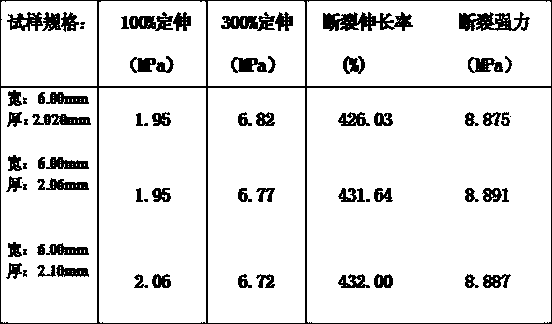

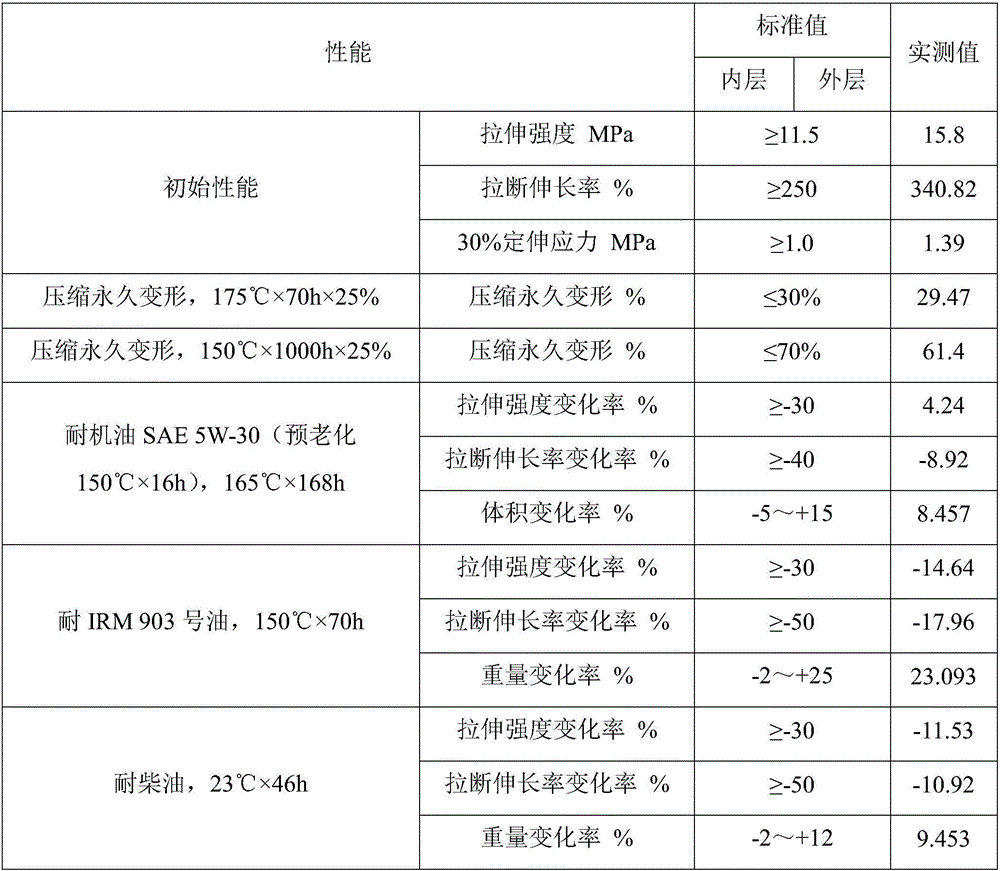

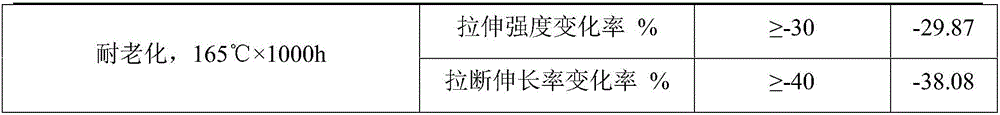

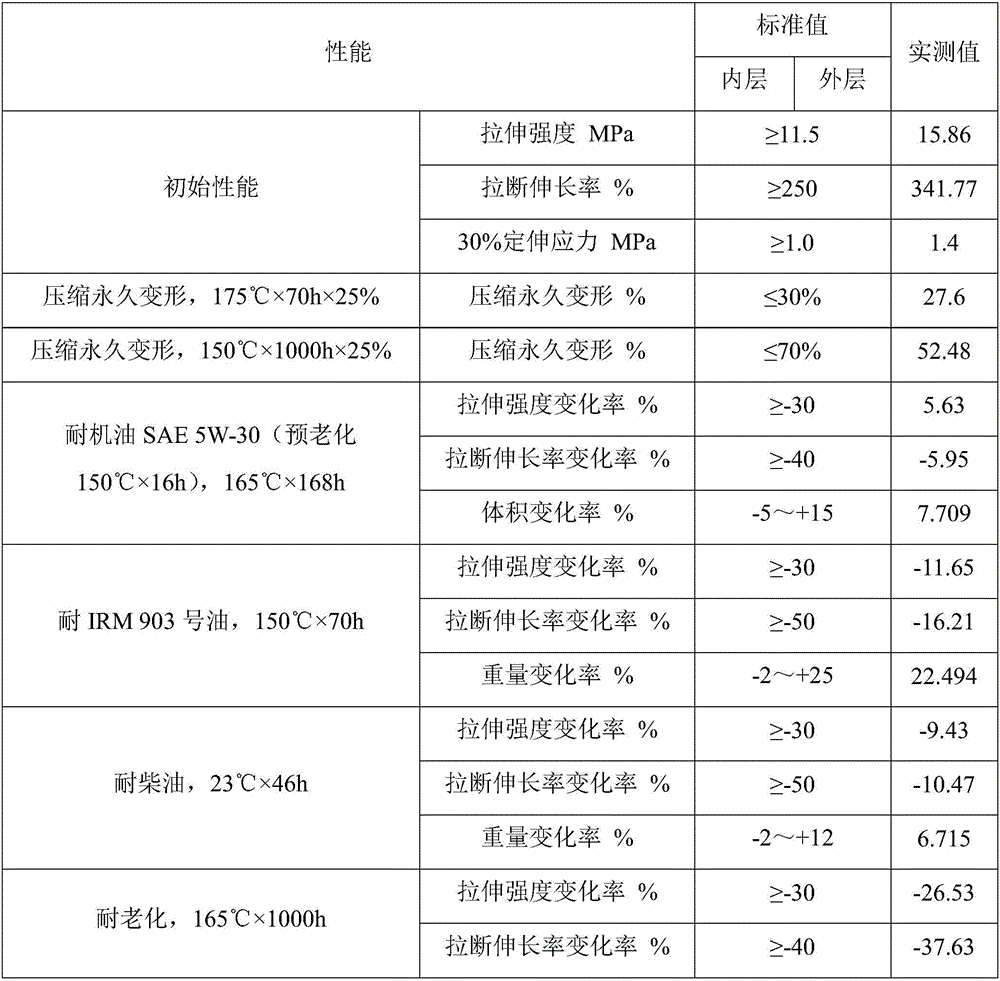

Rubber composition for preparing external and internal layers of automotive turbocharged hose and production method thereof

The invention relates to a rubber composition for preparing external and internal layers of an automotive turbocharged hose. The rubber composition comprises 100 parts of ethylene acrylate rubber, 1.0-3.0 parts of anti-aging agent, 1.0-3.0 parts of processing agent, 10.0-20.0 parts of plasticiser, 50.0-70.0 parts of carbon black, 0.5-1.5 parts of internal releasing agent, 2.0-3.0 parts of vulcanization activator and accelerator and 1.0-2.0 parts of vulcanizing agent. The invention further provides a preparation method for the rubber composition. The rubber composition improves high temperature resistance and oil resistance, reduce compression permanent sets, and is not prone to scorching, good in processing characteristics, and can serve as the external layer and the internal layer of the automotive turbocharged hose.

Owner:QINGDAO SUNSONG CO LTD

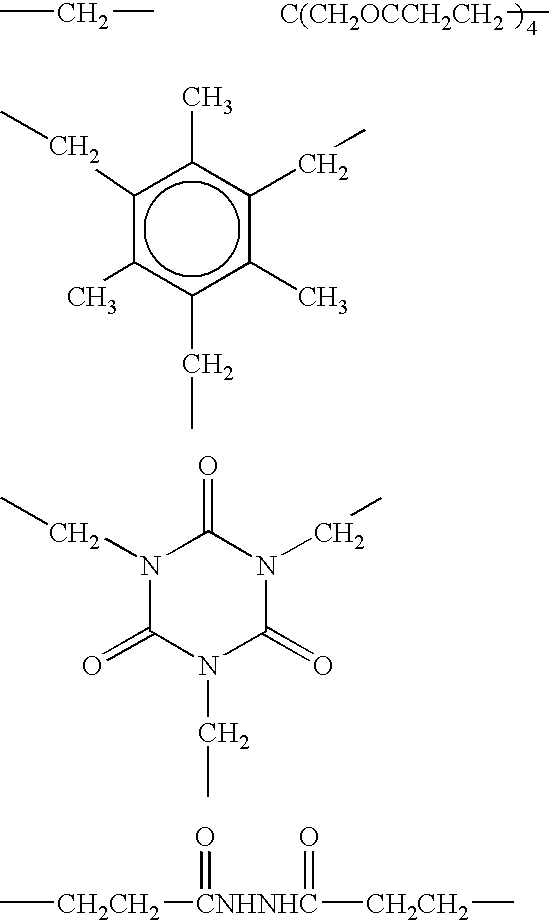

Sulfur free, low color generating scorch time extending compositions for use in compounding and cure of free radical initiator curable polymers

InactiveUS6555019B2Improved scorch resistanceOther chemical processesDrilling compositionSulfurPolymer

Sulfur free, crosslinking, scorch-retarding compositions for compounding and cure of polymers susceptible to cure by free radical initiators are disclosed.

Owner:ARKEMA INC

High-performance rubber for generator shock pad and preparation process thereof

ActiveCN103627043AIncreased shear strengthImprove anti-aging propertiesRubber materialPolymer science

The invention discloses high-performance rubber for a generator shock pad and a preparation process thereof. Raw materials of the rubber comprise: natural rubber, DBD (Dibromodulcitol), 100-mesh zinc oxide, stearic acid, CTP (Cytidine Triphosphate), spraying carbon black, DCP (Dicalcium Phosphate), BMI (Bismaleimide Resin), TMTD (Thiram), CZ (Citrazinic Acid), m-phenylenediamine and bisphenol A type epoxy resin; and the preparation process comprises: premixing, mixing and vulcanizing. A rubber material is fully activated by mixing to improve the heat resistance, aging resistance and deformation resistance of the rubber material, the m-phenylenediamine and the BMI are pre-mixed before the vulcanizing procedure to improve the toughness of the BMI, the bisphenol A type epoxy resin is added with the m-phenylenediamine, the three components are compatible and perforative to improve the shearing strength and the aging resistance of the rubber, the CZ and the TMTD are added to further improve the curing speed and the scorch resistance, and the finally obtained rubber has good breaking strength and breaking elongation, proper hardness, excellent high temperature resistance and good damping effect.

Owner:STATE GRID CORP OF CHINA +1

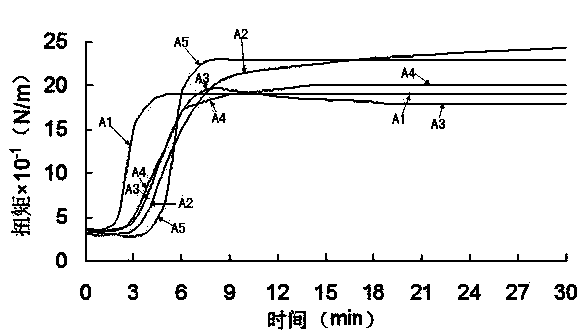

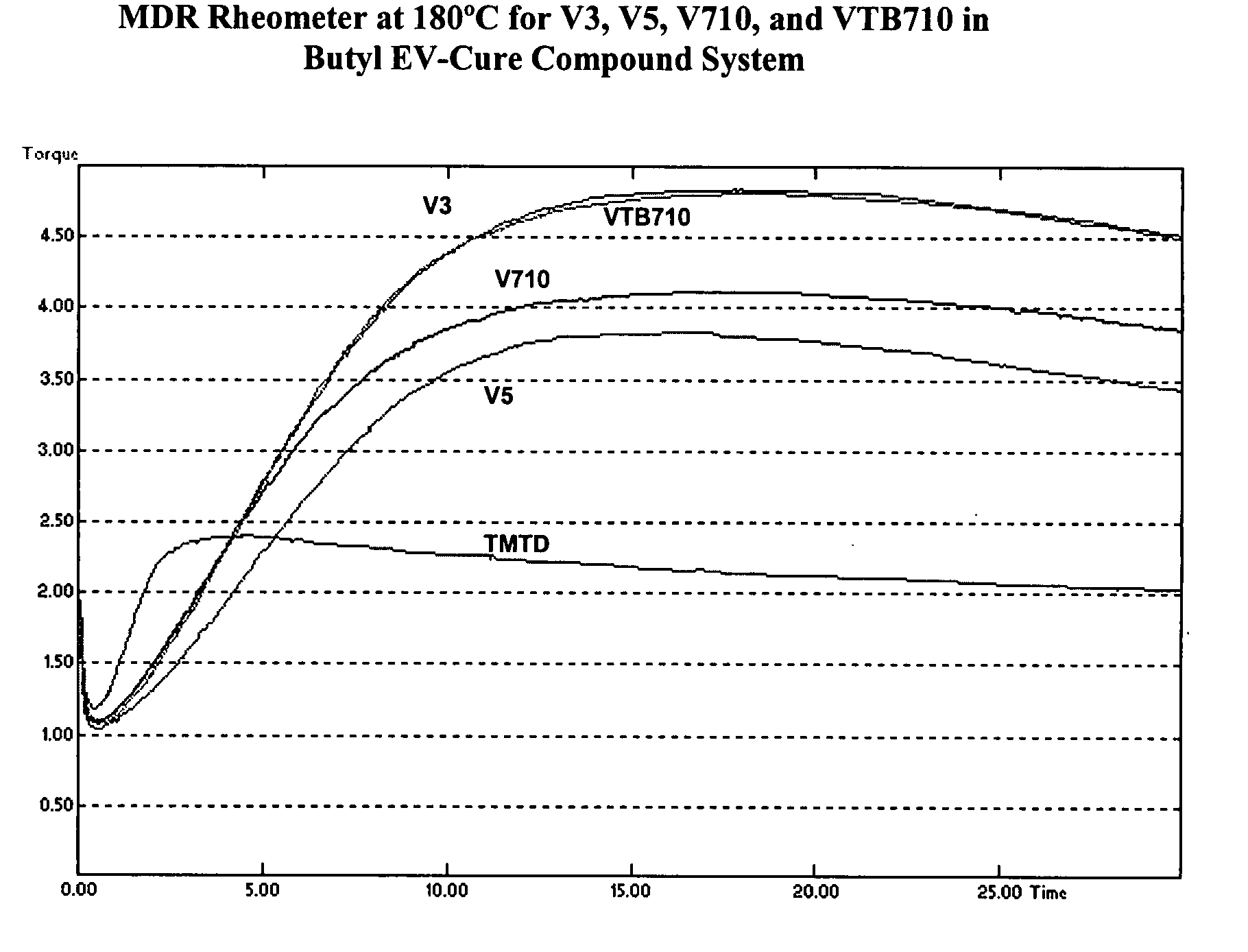

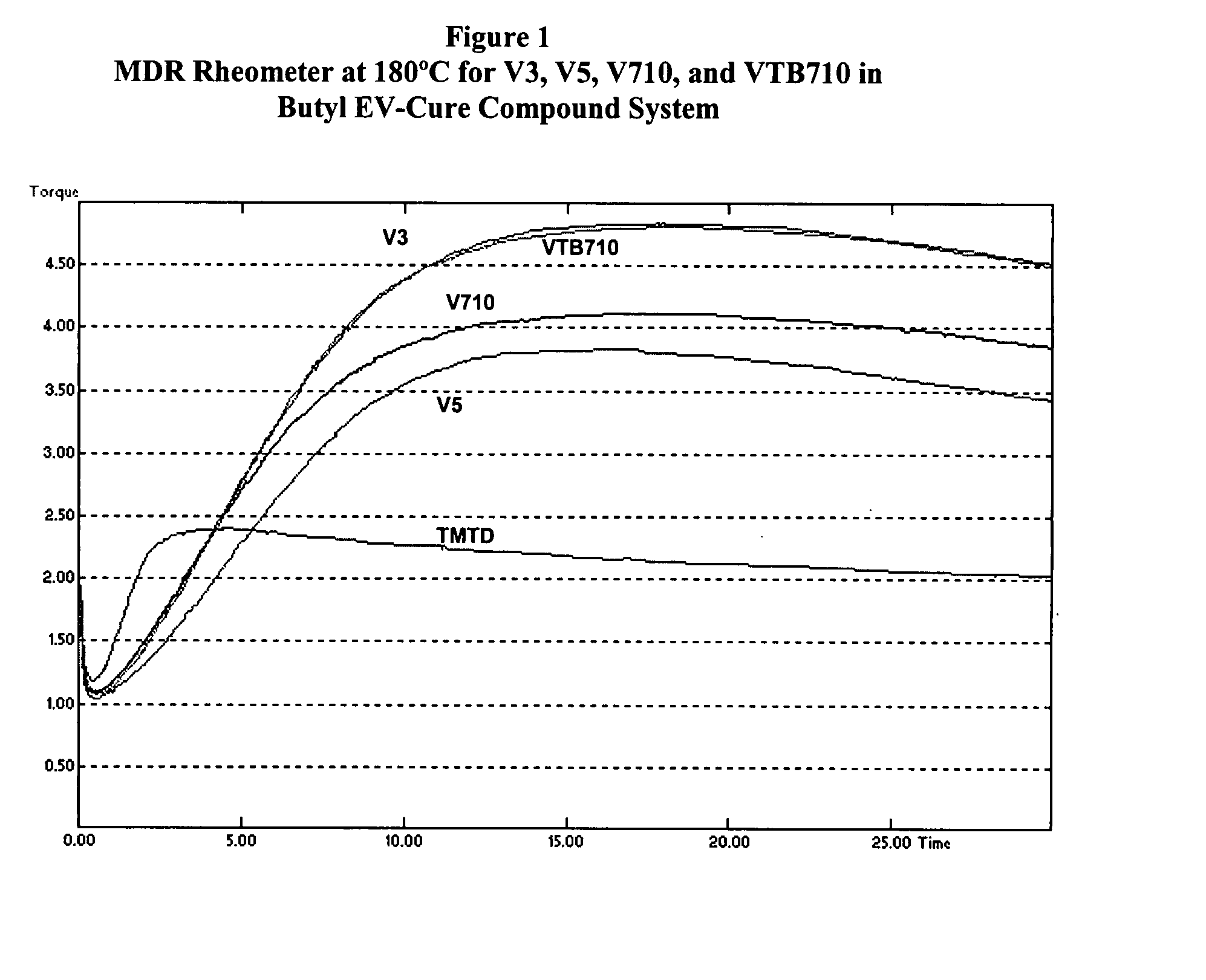

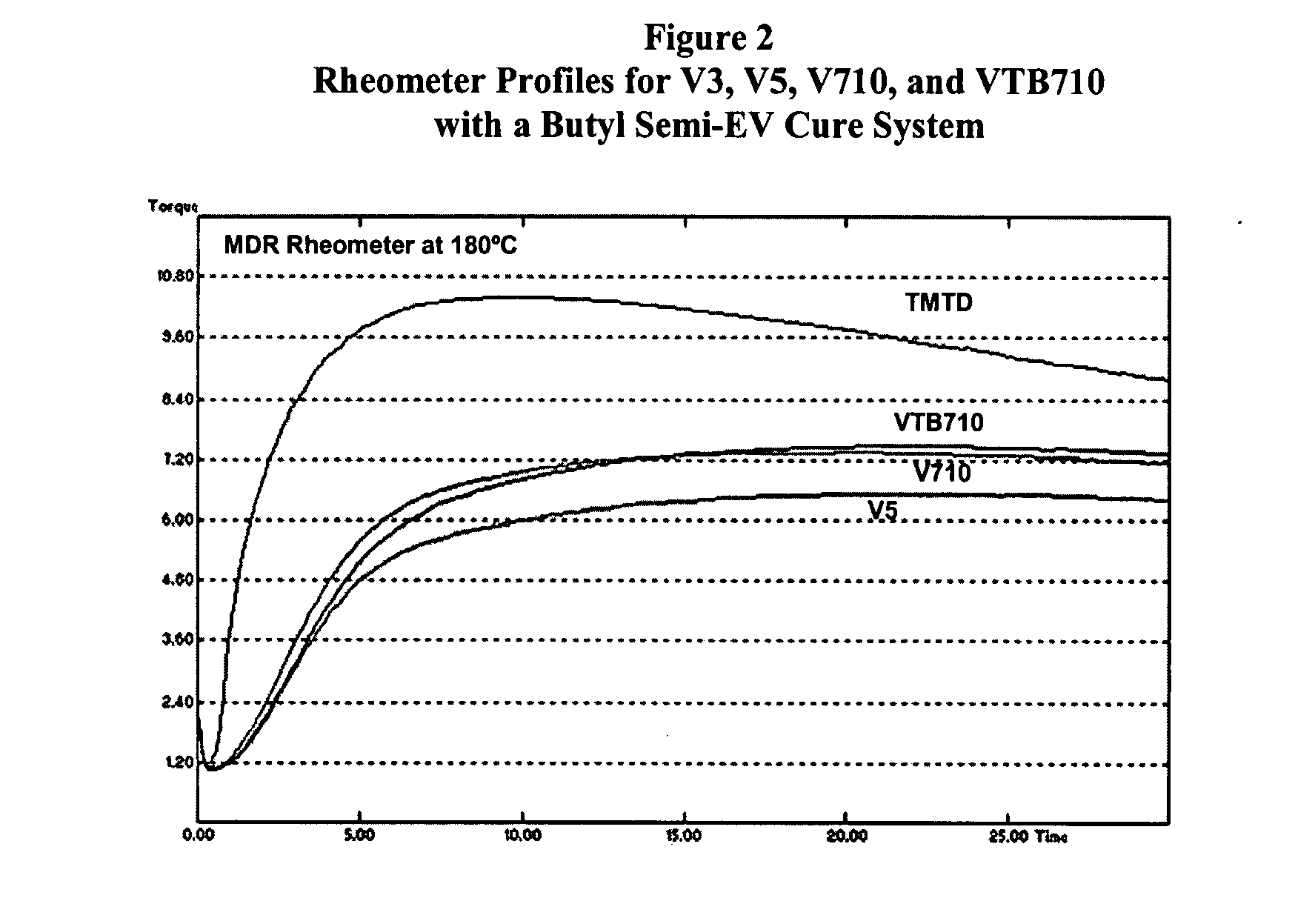

Cure systems for rubber compounds

The invention relates to the use of alkylphenol disulfide accelerators in butyl and halobutyl compounds.

Owner:EXXONMOBIL CHEM PAT INC

Formula of rubber piston and preparation method thereof

The invention discloses a formula of a rubber piston. According to parts by weight, the formula comprises 288-352 parts of nitrile butadiene rubber, 14.4-17.6 parts of a reinforcing agent, 3.6-4.4 parts of a stearic acid, 117-143 parts of phenolic resin, 117-143 parts of white carbon black, 6.3-7.7 parts of an adhesive agent, 5.58-6.82 parts of a promoting agent, 28.8-35.2 parts of dibutyl ester, 10.8-13.2 parts of sulfur and 0-0.3 part of epoxy resin. The rubber piston has good sealing performance; and the sealing performance and deformation thereof achieve the operating requirements.

Owner:TAIZHOU GAOGANG ZONE SHENGYUAN RUBBER CO LTD

Novel rubber seal ring for explosion-proof motor and production technology for rubber seal ring for

InactiveCN104592603AExcellent ozone resistanceImprove low temperature resistanceSulfidationEngineering

The invention discloses a novel rubber seal ring for an explosion-proof motor, and belongs to the technical field of sealing rings. The rubber seal ring is characterized by comprising the following raw materials in parts by weight: 45-55 parts of neoprene, 10-20 parts of EPDM rubber, 4-6 parts of sulfidation system, 5-10 parts of a coldproof soften flux, 12-18 parts of a reinforcing agent, 5-10 parts of a coldproof assistant, and 2-5 parts of an ozone proof assistant. The rubber seal ring has the advantages that the rubber seal ring is high in ozone resistance, good in low temperature resistant performance, and reliable in sealing; the abrasion resistant capability is reinforced greatly; the product quality is more stable; the service life is prolonged by 200% to rubber seal rings for explosion-proof motors in the prior art.

Owner:南阳天一密封股份有限公司

Acrylic rubber, crosslinkable acrylic rubber composition and moldings

An acrylic rubber comprised of a copolymer comprising 0.1 to 20% by weight of (A) units of a butenedioic acid monoester monomer having an alicyclic structure and 50 to 99.9% by weight of (B) units of at least one kind of monomer selected from acrylic acid ester monomers and methacrylic acid ester monomers. A crosslinkable acrylic rubber composition comprising the acrylic rubber and a crosslinking agent, especially a polyamine crosslinking agent, has good process-stability and good shapability and gives a shaped article having high heat resistance and exhibiting reduced permanent set.

Owner:ZEON CORP

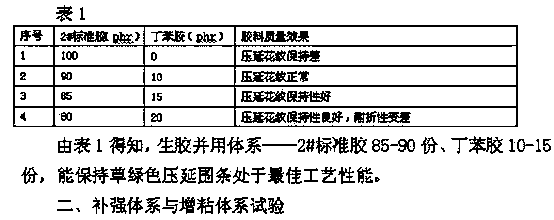

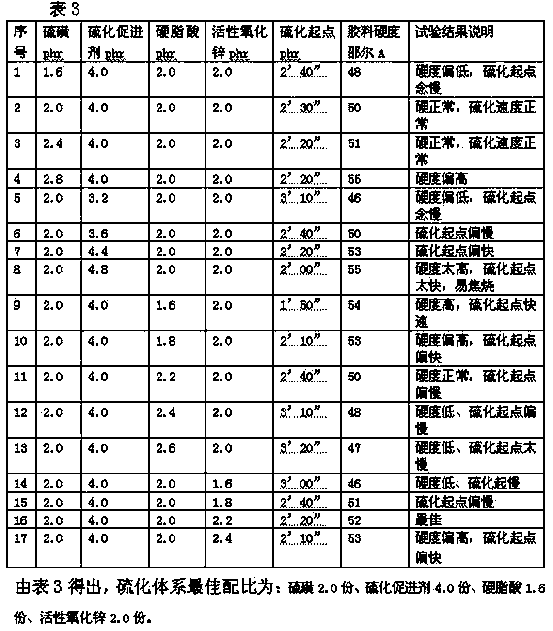

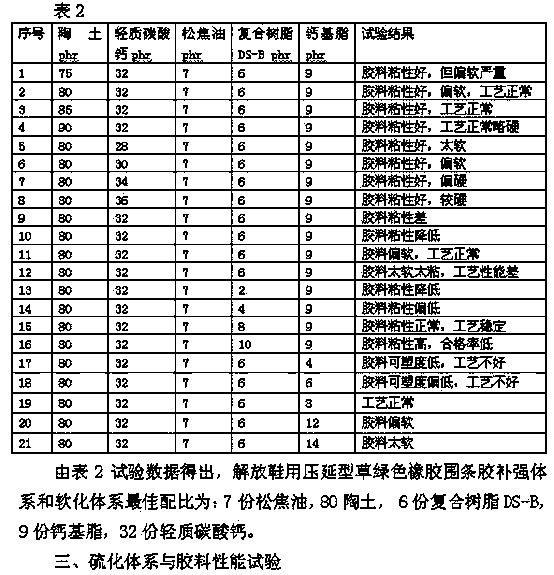

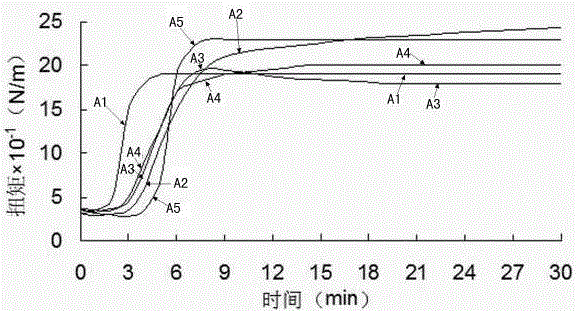

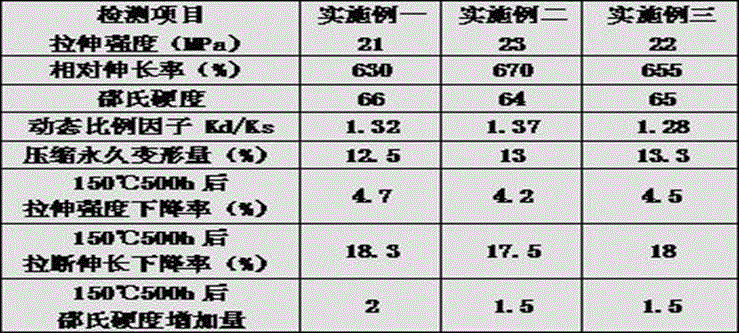

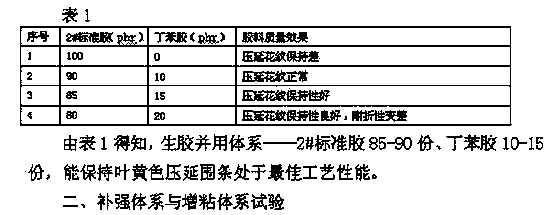

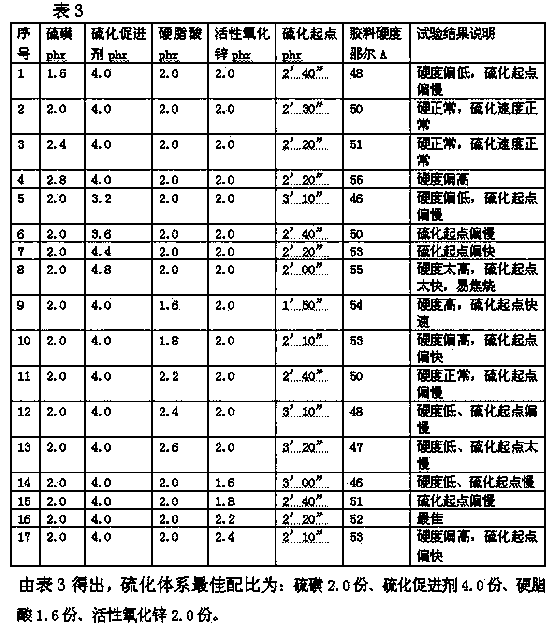

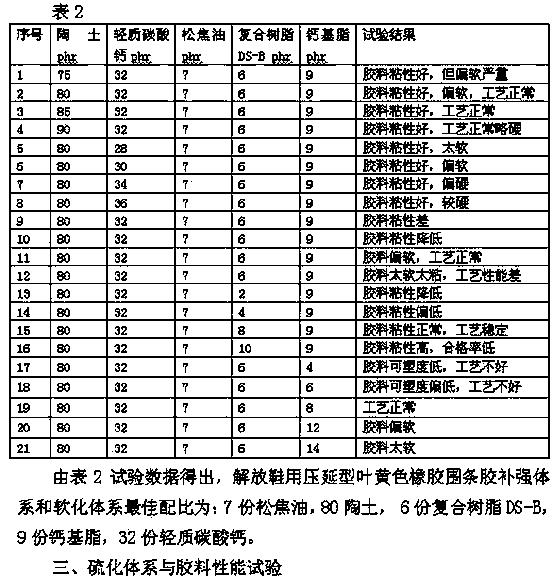

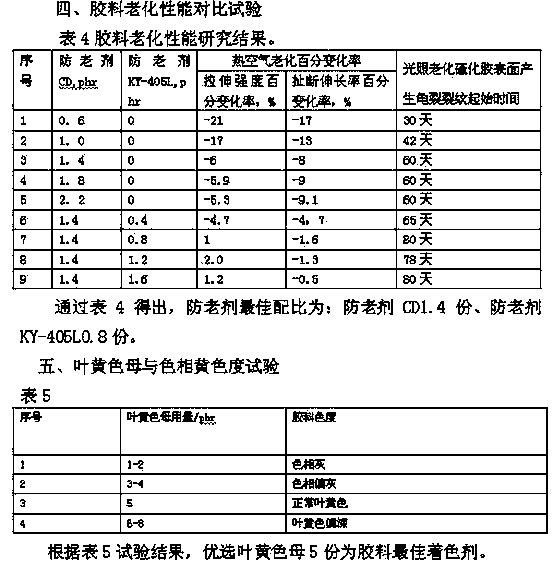

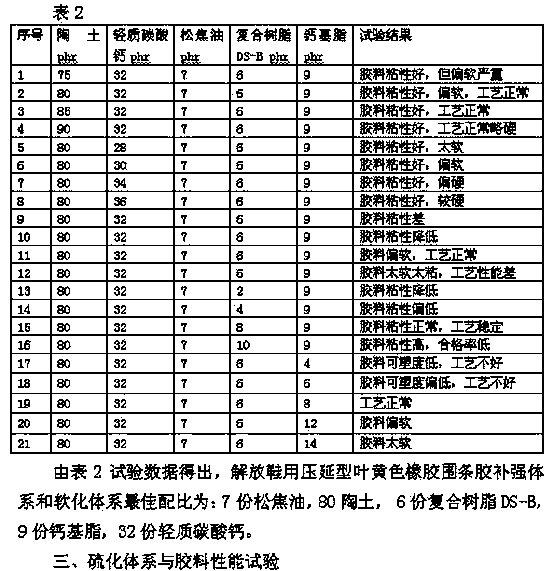

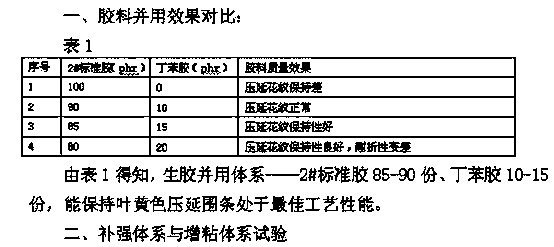

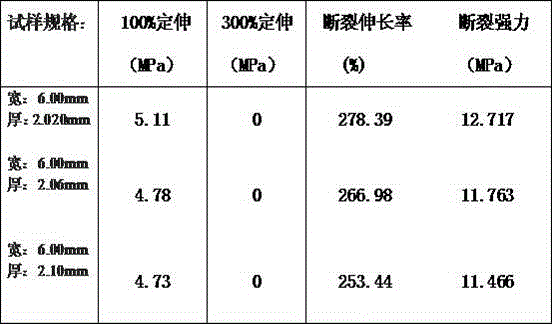

Calendering grass green rubber foxing adhesive for wear-resistant liberation shoes as well as preparation method and application thereof

InactiveCN104311900AImprove process stabilityImproved scorch resistance and flex resistanceFootwearTarChemistry

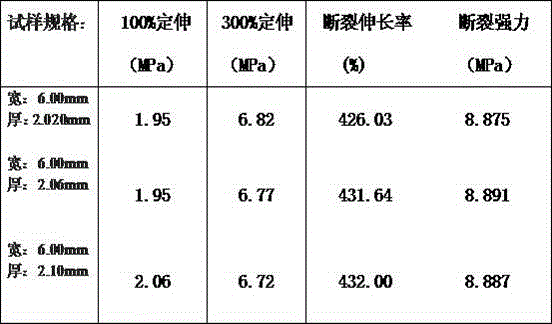

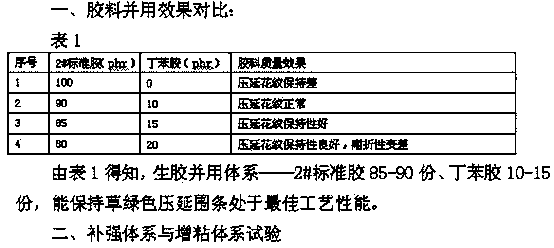

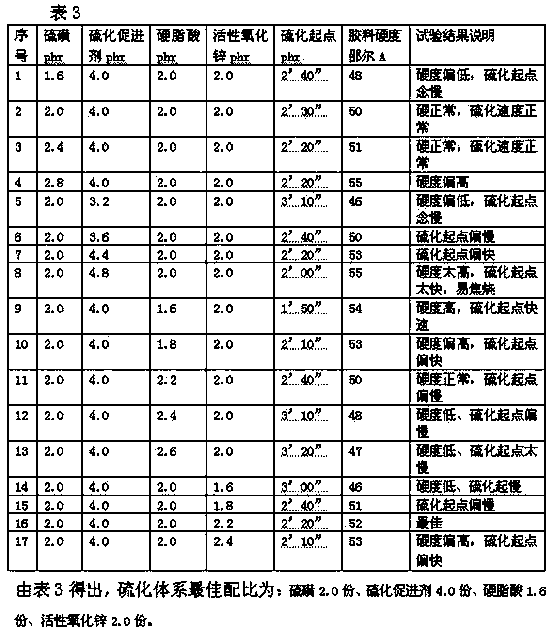

The invention discloses a calendering grass green rubber foxing adhesive for wear-resistant liberation shoes. The adhesive is prepared from the following components in parts by weight: 85-90 parts of standard rubber, 10-15 parts of butadiene-styrene rubber, 15 parts of high styrene, 2.0-2.4 parts of sulfur, 3.6-4.0 parts of a vulcanization accelerator, 1.8-2.2 parts of stearic acid, 1.8-2.2 parts of activated zinc oxide, 6-8 parts of pine tar, 75-85 parts of argil, 2.0-2.4 parts of an anti-aging agent, 4-8 parts of composite resin DS-B, 8-10 parts of calcium grease, 30-36 parts of light calcium carbonate and 4-6 parts of grass green masterbatch.

Owner:JIHUA 3537 SHOE MAKING

Medical rubber gloves with antibacterial function and preparation method thereof

The invention provides medical rubber gloves with an antibacterial function and a preparation method thereof and relates to the field of medical products. The medical rubber gloves are prepared from natural rubber, modified carbon black, modified white carbon black, dialdehyde pullulan, sericin, sulfur, dibutyl adipate, zinc oxide, stearic acid, dioctyl phthalate, light calcium carbonate, diatomaceous earth, silver nitrate, rosin, potassium hydroxide, calcium chloride, zinc N-ethyl-N-phenyldithiocarbamate, micro-silica gel, didecyldimethylammonium bromide, bamboo fibers, saponin extract, an antiager, a vulcanization accelerator and an appropriate of water. The medical rubber gloves have a strong antibacterial function and excellent comprehensive performances, prevent the transfer of poisonous and harmful substances among patients and medical personnel, improve the safety and well protect the medical personnel and patients.

Owner:王维维

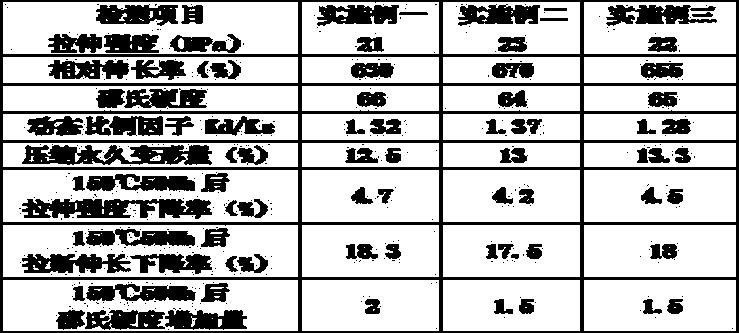

A kind of high-performance rubber for generator shock absorber and its preparation process

ActiveCN103627043BIncreased shear strengthImprove anti-aging propertiesRubber materialPolymer science

The invention discloses high-performance rubber for a generator shock pad and a preparation process thereof. Raw materials of the rubber comprise: natural rubber, DBD (Dibromodulcitol), 100-mesh zinc oxide, stearic acid, CTP (Cytidine Triphosphate), spraying carbon black, DCP (Dicalcium Phosphate), BMI (Bismaleimide Resin), TMTD (Thiram), CZ (Citrazinic Acid), m-phenylenediamine and bisphenol A type epoxy resin; and the preparation process comprises: premixing, mixing and vulcanizing. A rubber material is fully activated by mixing to improve the heat resistance, aging resistance and deformation resistance of the rubber material, the m-phenylenediamine and the BMI are pre-mixed before the vulcanizing procedure to improve the toughness of the BMI, the bisphenol A type epoxy resin is added with the m-phenylenediamine, the three components are compatible and perforative to improve the shearing strength and the aging resistance of the rubber, the CZ and the TMTD are added to further improve the curing speed and the scorch resistance, and the finally obtained rubber has good breaking strength and breaking elongation, proper hardness, excellent high temperature resistance and good damping effect.

Owner:STATE GRID CORP OF CHINA +1

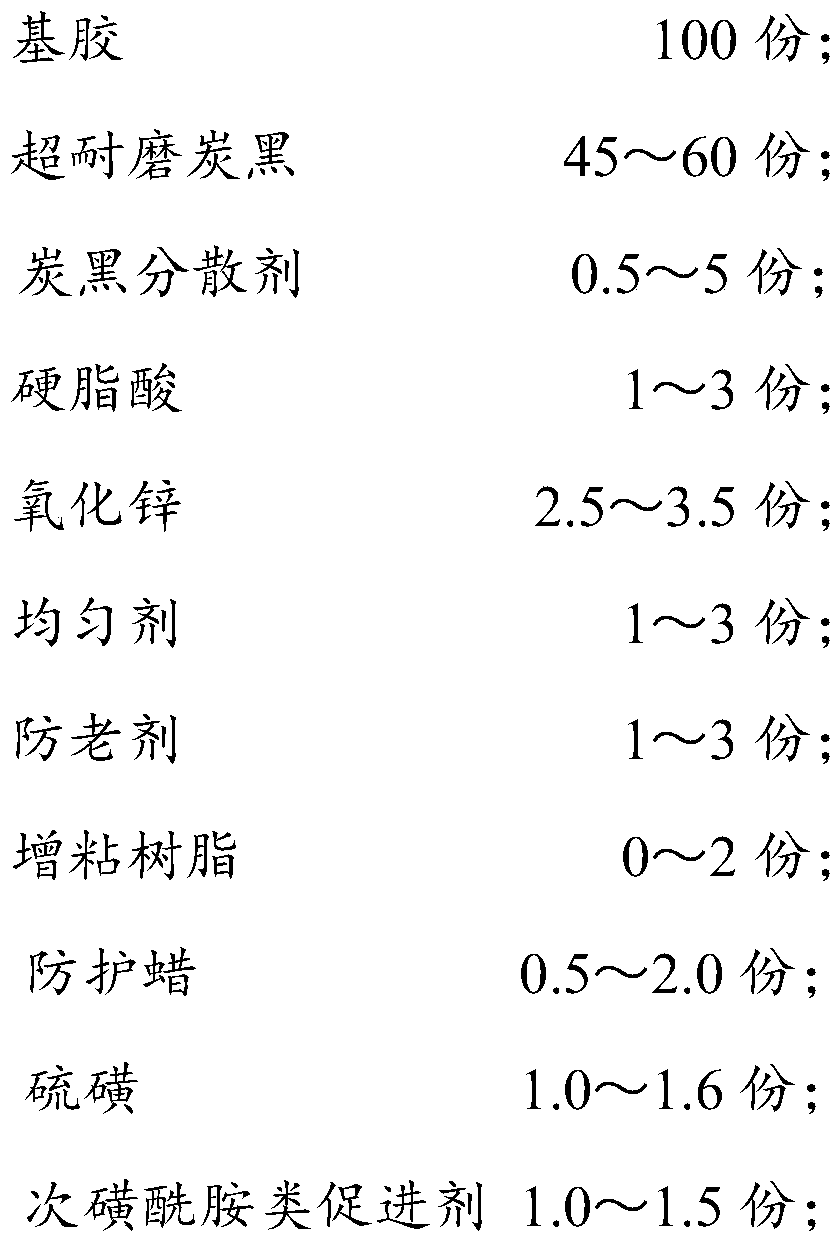

All-steel tread formula with high wear resistance and long mileage and preparation process of all-steel tread formula

The invention relates to an all-steel tread formula with high wear resistance and long mileage and a preparation process of the all-steel tread formula. The all-steel tread formula comprises the following components: 100 parts of base rubber; 45 to 60 parts of super wear-resistant carbon black; 0.5-5 parts of a carbon black dispersant; 1-3 parts of stearic acid; 2.5 to 3.5 parts of zinc oxide; 1-3parts of a homogenizing agent; 1-3 parts of an anti-aging agent; 0-2 parts of tackifying resin; 0.5 to 2.0 parts of protective wax; 1.0 to 1.6 parts of sulfur; 0.6 to 1.5 parts of a sulfenamide accelerator. According to the invention, the carbon black with low heat generation and high wear resistance is adopted; meanwhile, an NR / BR / SBR (natural rubber / polyisoprene rubber / styrene butadiene rubber)three-gel combined system is adopted; the carbon black dispersant capable of participating in the reaction of rubber and carbon black is used, the interaction between rubber and carbon black is enhanced, the aggregation of the filler and the heat generation of the rubber material are reduced, the adverse effect of hysteresis on aging is reduced, and the friction coefficient of the rubber materialis reduced, so that the wear resistance and durability of a tread can be effectively improved.

Owner:SAILUN GRP CO LTD

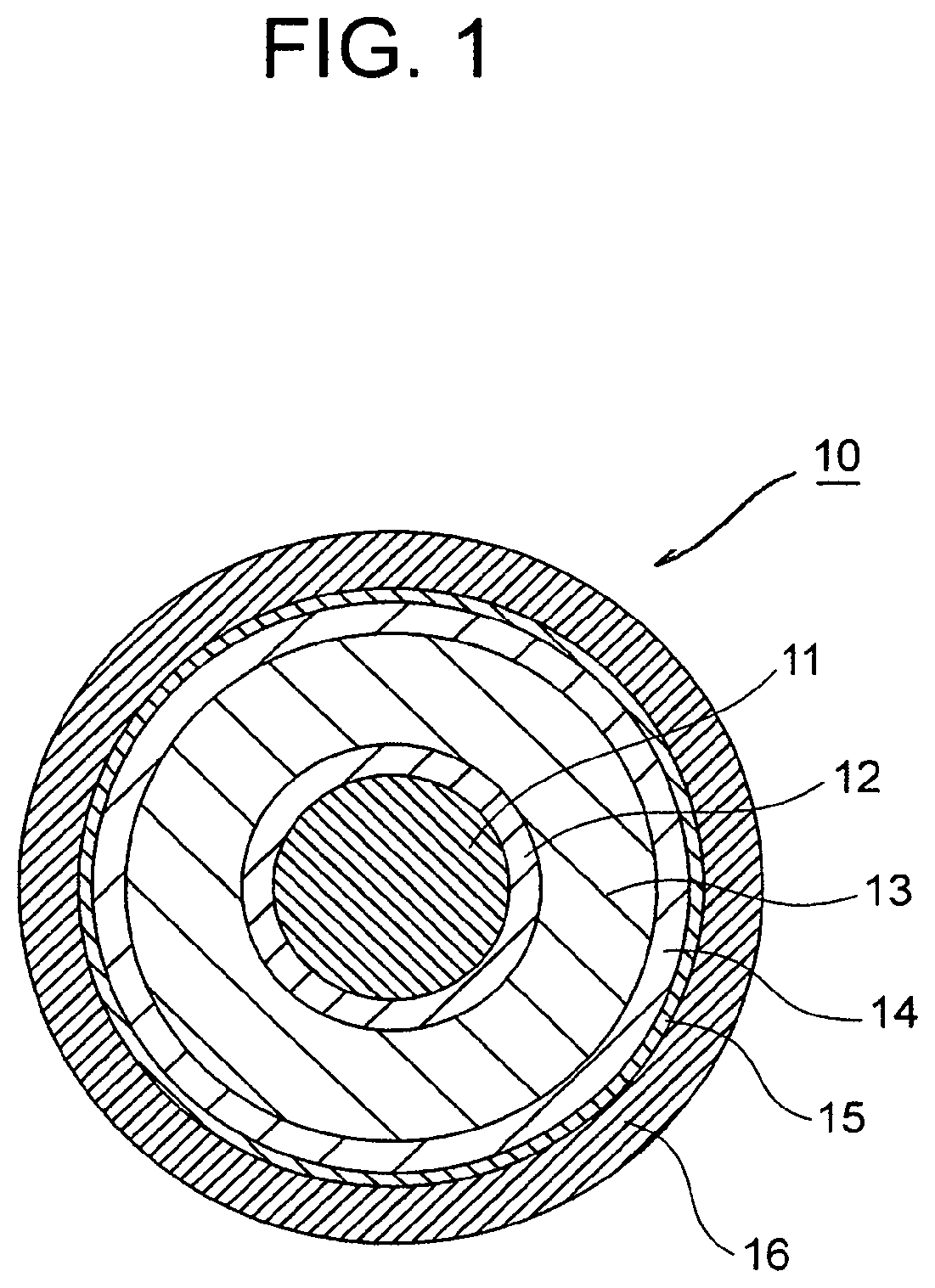

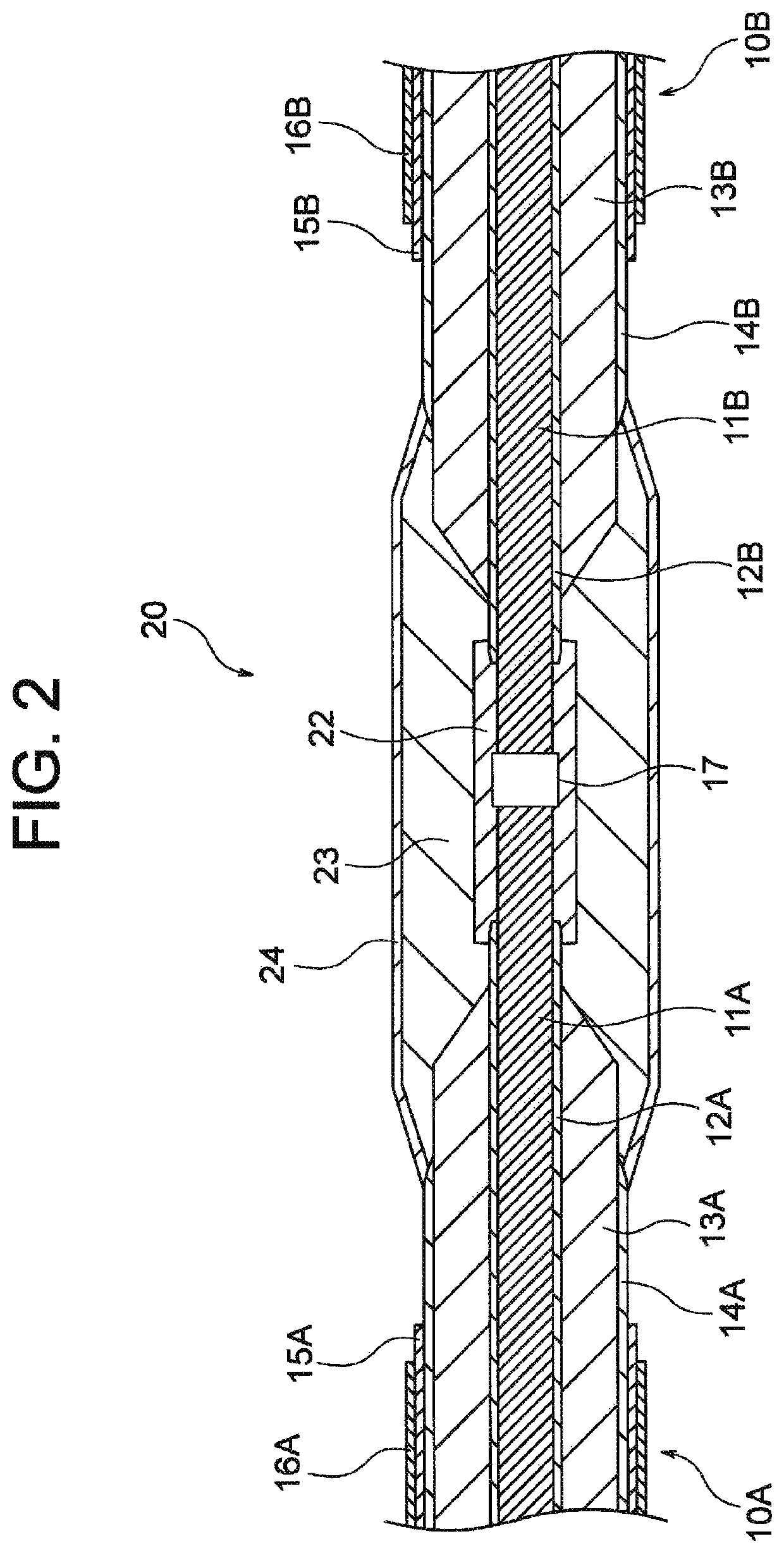

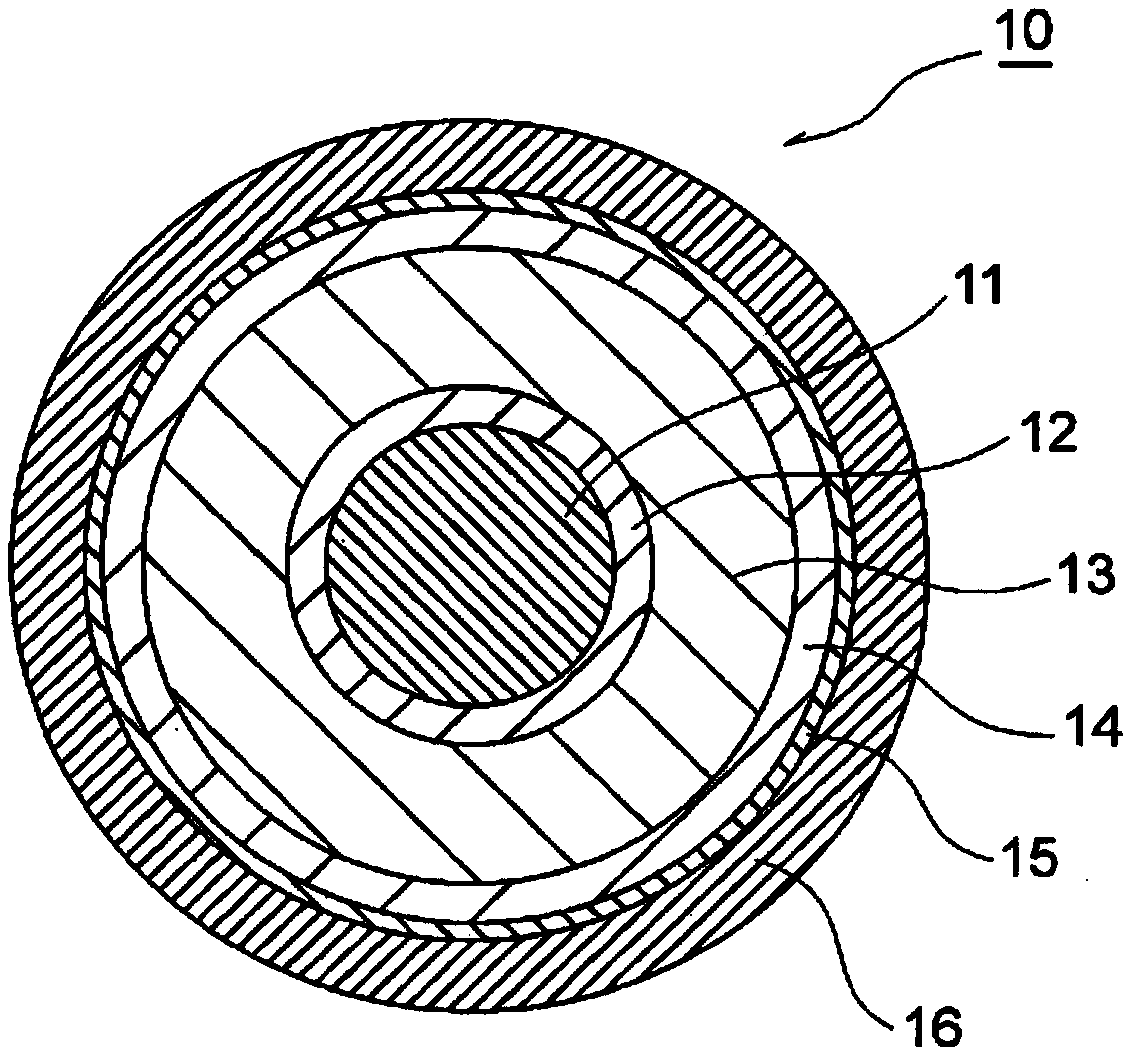

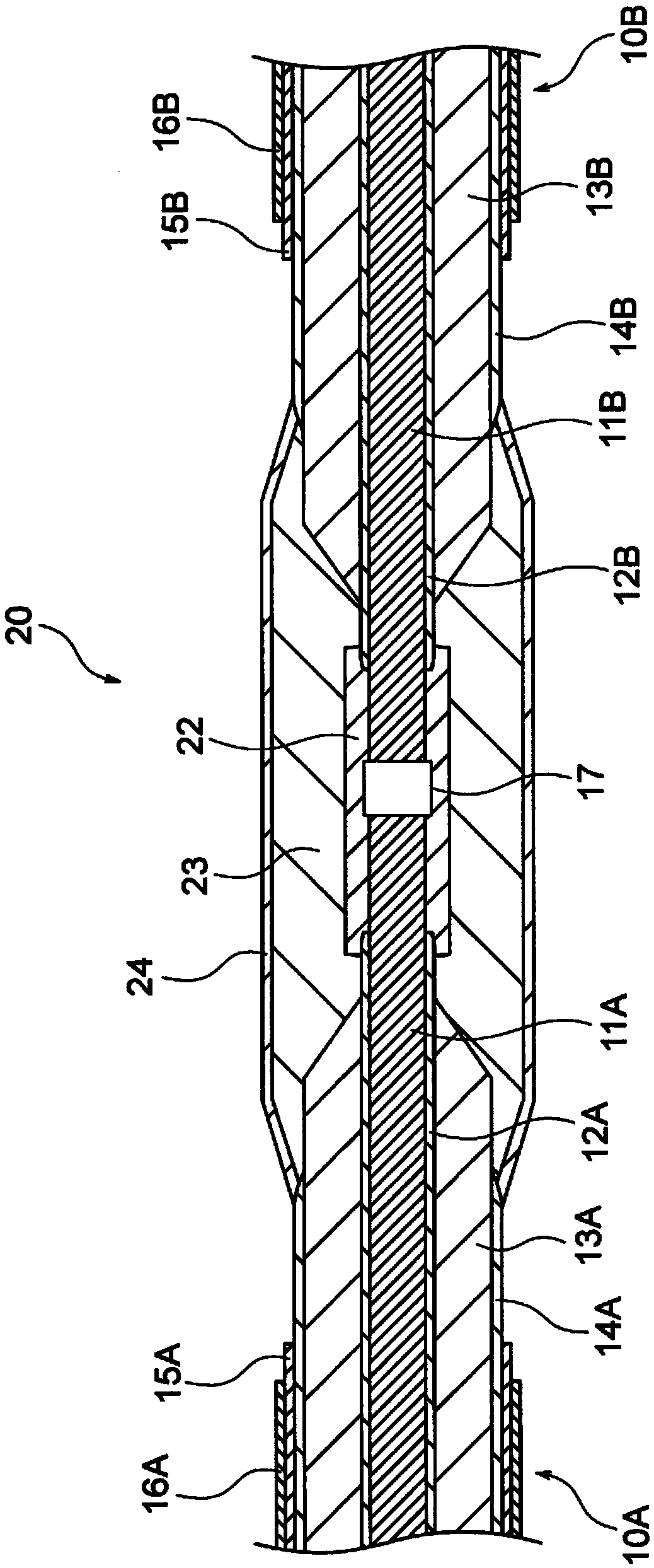

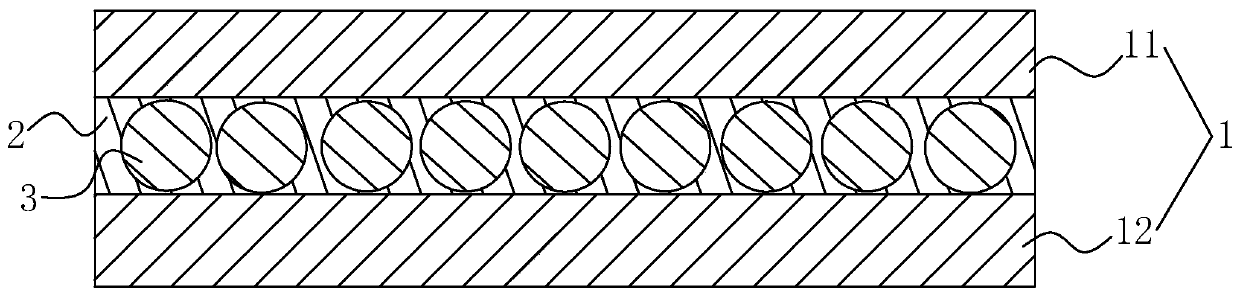

Process for Degassing Crosslinked Power Cables

ActiveUS20160225490A1Low volume resistivityIncrease resistancePlastic/resin/waxes insulatorsApparatus for heat treatmentElectric forcePower cable

A power cable comprising: (A) a conductor, (B) an insulation layer, and (C) a semiconductor layer comprising in weight percent based on the weight of the semiconductor layer: (1) 49-98% of a crosslinked olefin block copolymer (OBC) having a density less than (<) 0.9 grams per cubic centimeter (g / cm3), a melt index greater than (>) 1, and comprising in weight percent based on the weight of the OBC: (a) 35-80% soft segment that comprises 5-50 mole percent (mol %) of units derived from a monomer comprising 3 to 30 carbon atoms; and (b) 20-65% hard segment that comprises 0.2-3.5 mol % of units derived from a monomer comprising 3 to 30 carbon atoms; (2) 2-51% conductive filler, the insulation layer and semiconductor layer in contact with one another, is degassed by a process comprising the step of exposing the cable to a temperature of at least 80° C. for a period of time of at least 24 hours.

Owner:DOW GLOBAL TECH LLC

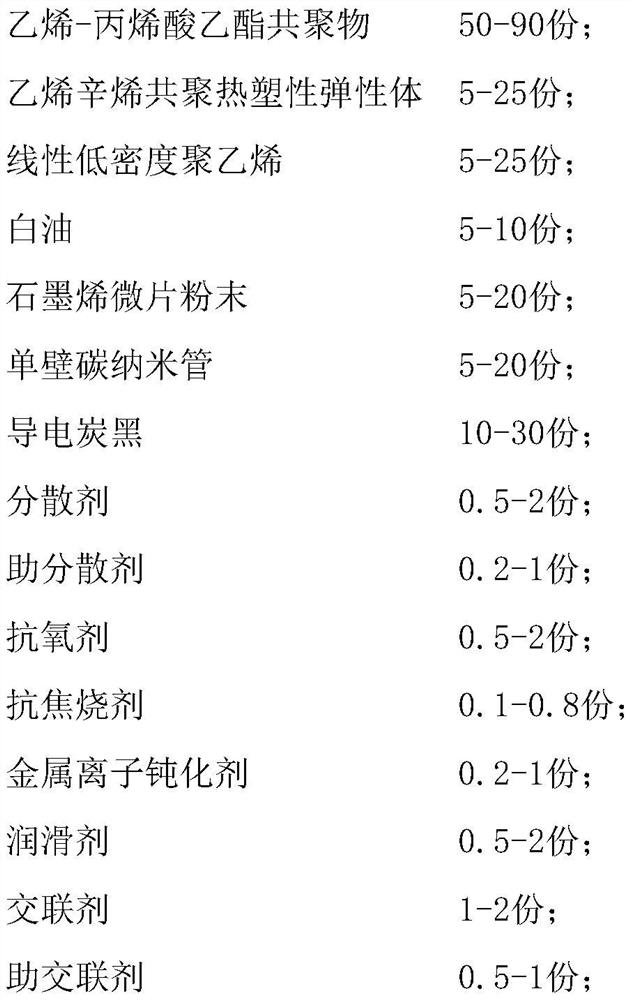

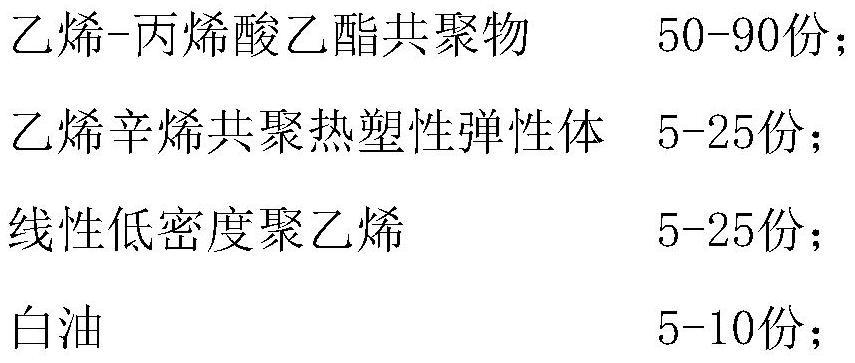

Graphene-carbon nanotube synergistic high-electrical-property semiconductive shielding material and preparation method thereof

PendingCN113943454AReduce usageEasy to processMagnetic/electric field screeningLinear low-density polyethyleneElastomer

The invention discloses a graphene-carbon nanotube synergistic high-electrical-property semiconductive shielding material and a preparation method thereof. The graphene-carbon nanotube synergistic high-electrical-property semiconductive shielding material is used for a semiconductive shielding layer of a middle-and-high-voltage power cable. The electrical shielding material comprises the following raw materials in parts by mass: 50-90 parts of an ethylene-ethyl acrylate copolymer, 5-25 parts of an ethylene-octene copolymer thermoplastic elastomer, 5-25 parts of linear low-density polyethylene, 5-10 parts of white oil, 5-20 parts of graphene microchip powder, 5-20 parts of a single-walled carbon nanotube, 15-50 parts of conductive carbon black, 0.5-2 parts of a dispersant, 0.2-1 part of a dispersing aid, 0.5-2 parts of an antioxidant, 0.1-0.8 part of an anti-scorching agent, 0.2-1 part of a metal ion passivator, 0.5-2 parts of a lubricant, 1-2 parts of a cross-linking agent, and 0.5-1 part of an assistant cross-linking agent. According to the graphene-carbon nanotube synergistic high-electrical-property semiconductive shielding material, the graphene and the carbon nanotube are compounded for use, so the use amount of a conductive filler can be effectively reduced, the processability of the material is improved, and the graphene-carbon nanotube synergistic high-electrical-property semiconductive shielding material has excellent conductivity, volume resistivity temperature stability, thermal stability, scorch resistance, surface smoothness and mechanical properties.

Owner:JIANGSU SHANGSHANG CABLE GRP NEW MATERIAL CO LTD +1

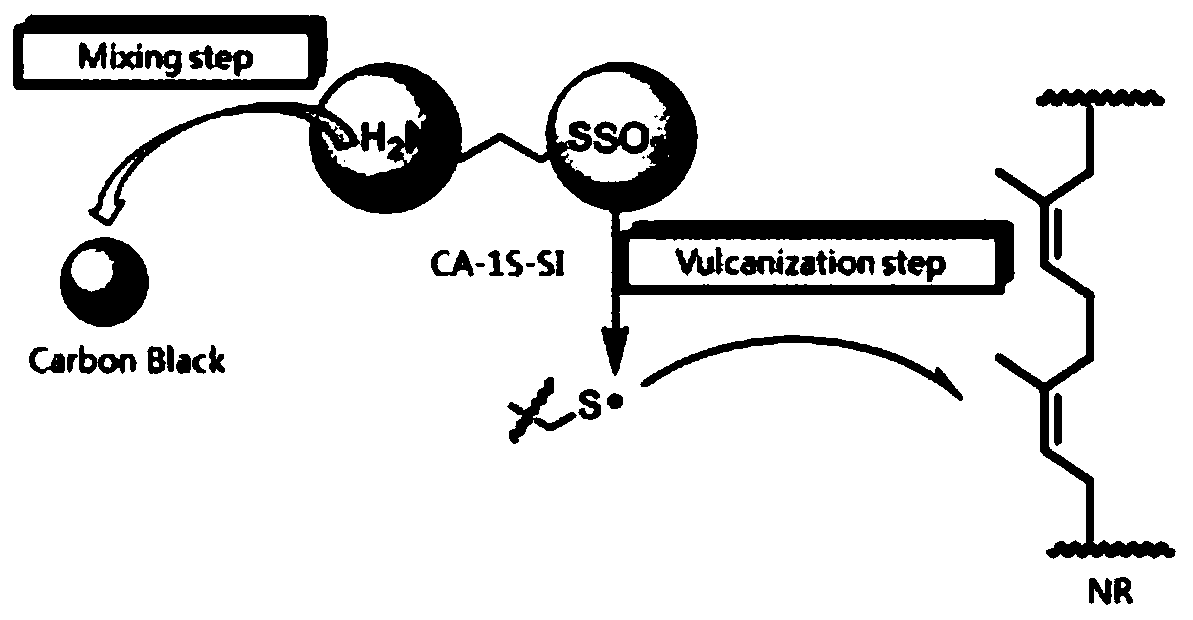

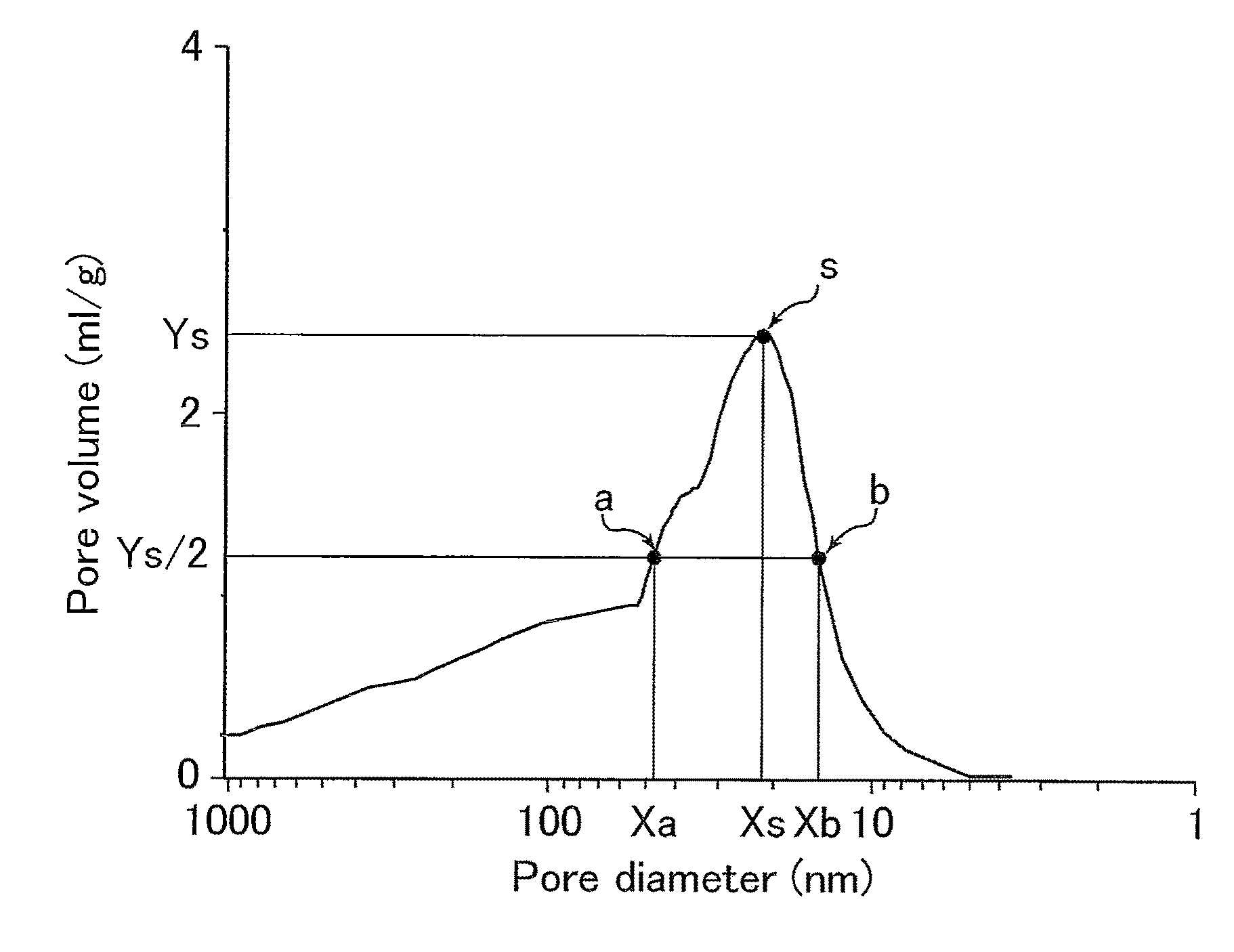

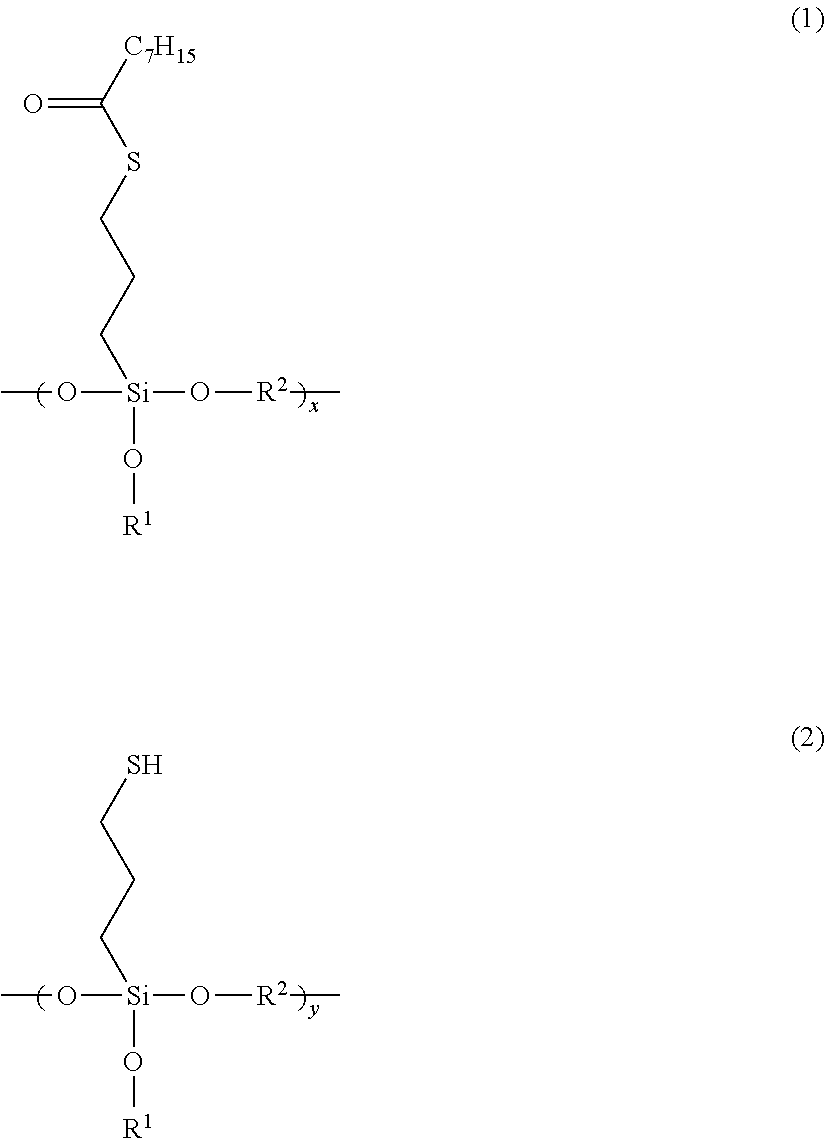

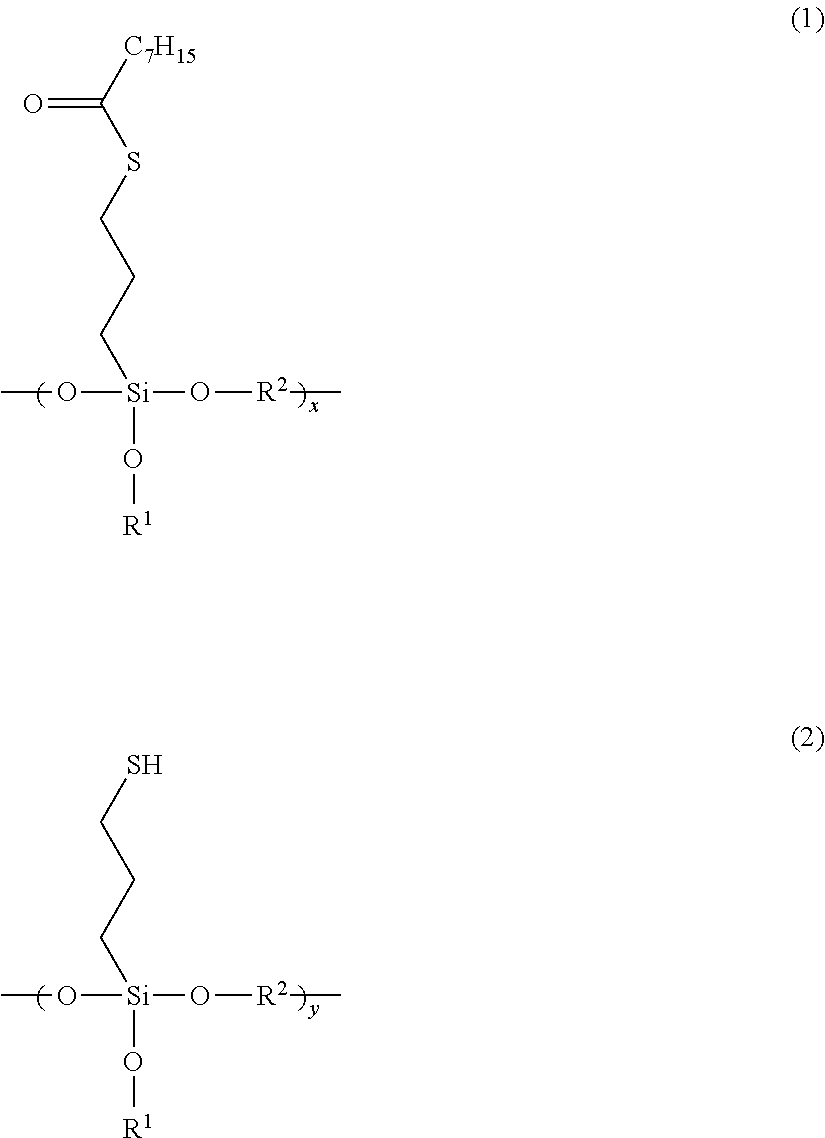

Tire rubber composition and pneumatic tire

InactiveUS8455582B2Improve performanceImprove rolling resistanceSilicon organic compoundsSpecial tyresPolymer scienceSilicon dioxide

It is an object of the present invention to provide a tire rubber composition excellent in performances such as silica dispersibility and processability. The present invention relates to a tire rubber composition, comprising: a rubber component; silica; and a silane coupling agent, wherein the silica has a CTAB specific surface area of 180 m2 / g or more and a BET specific surface area of 185 m2 / g or more, and the silane coupling agent is a copolymer comprising units A represented by formula (1) and units B represented by formula (2), and the proportion of the units B is 1 to 70 mol % of the total molar amount of the units A and the units B.

Owner:SUMITOMO RUBBER IND LTD

Non-slip EVA shoe sole and preparation method thereof

The invention relates to a non-slip EVA shoe sole. The EVA shoe sole includes an A material and a B material, the A material comprises the following components, in parts by weight: 8-12 parts of standard natural rubber, 6-10 parts of styrene-butadiene rubber, 12-16 parts of cis-polybutadiene, 12-16 parts of white carbon black, 18-22 parts of EVA, and 3-7 parts of white rubber powder; and the B material includes the following components, in parts by weight: 5-9 parts of white oil, 0.1-1 part of diethylene glycol, 4-8 parts of titanium dioxide, 0.1-0.3 part of stearic acid, 1.2-1.6 parts of PEG4000, 0.8-1 part of an anti-aging agent, 0.1-0.3 part of anti-fog wax, 1.3-1.7 parts of an anti-frost agent, 2-6 parts of active zinc oxide, 0.3-0.7 part of wear-resistant oil, 0.1-0.3 part of tetramethyl thiuram monosulfide, 1.1-1.5 parts of sulfur, 0.1-0.3 part of NS powder, and 1.1-1.5 parts of an anti-yellowing accelerant. The EVA shoe sole has the advantage of lightness on the basis of slip resistance.

Owner:温州市添荣鞋材有限公司

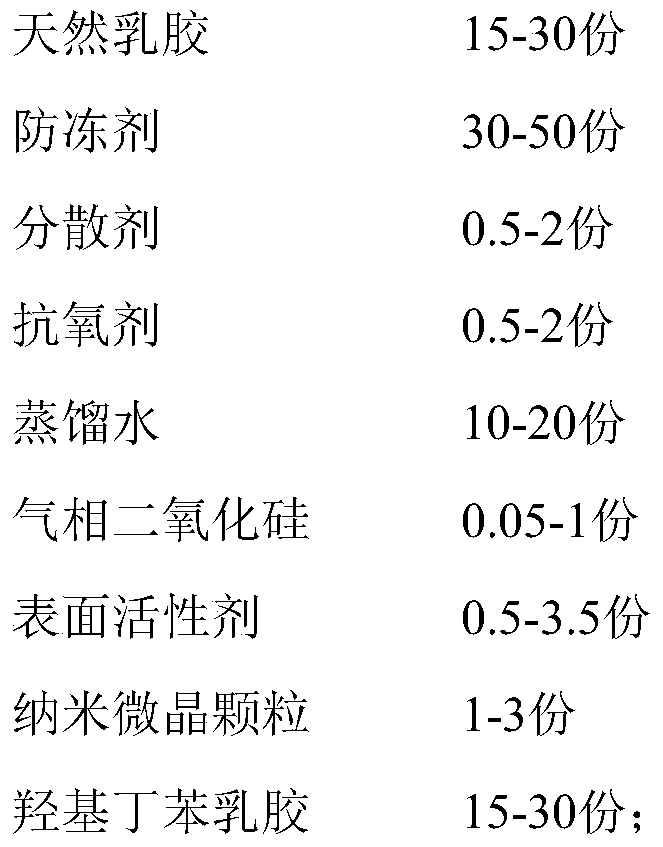

Auto-inflatable tire repairing liquid and preparation method thereof

PendingCN110358473AImprove sealingImprove anti-seepage performanceNatural rubber adhesivesNon-macromolecular adhesive additivesAdhesiveAntioxidant

The invention specifically relates to an auto-inflatable tire repairing liquid and a preparation method thereof, belonging to the technical field of chemical adhesives. The auto-inflatable tire repairing liquid comprises the following raw materials by weight: 15-30 parts of natural latex, 30-50 parts of an antifreezing agent, 0.5-2 parts of a dispersing agent, 0.5-2 parts of an antioxidant, 10-20parts of distilled water, 0.05-1 part of fumed silica, 0.5-3.5 parts of a surfactant, 10-20 parts of nanocrystalline particles and 15-30 parts of hydroxyl butylbenzene latex, wherein the natural latexhas a solid content of 50-70%. According to the tire repairing liquid of the invention, the hydroxyl butylbenzene latex, the natural latex and the nanocrystalline particles are reacted to instantly form a three-dimensional structural network which instantly blocks a punctured tire; the hydroxyl butylbenzene latex and the natural latex are activated by the surfactant and then filled with the fumedsilica so as to form a network structure which inhibits the flowing of colloids, accelerates a curing speed, improves bonding effect and enhances the sealing performance and impermeability of the tire repairing liquid; and the antifreezing agent further enhances the anti-icing ability of the tire repairing liquid.

Owner:东莞市宝临塑胶有限公司

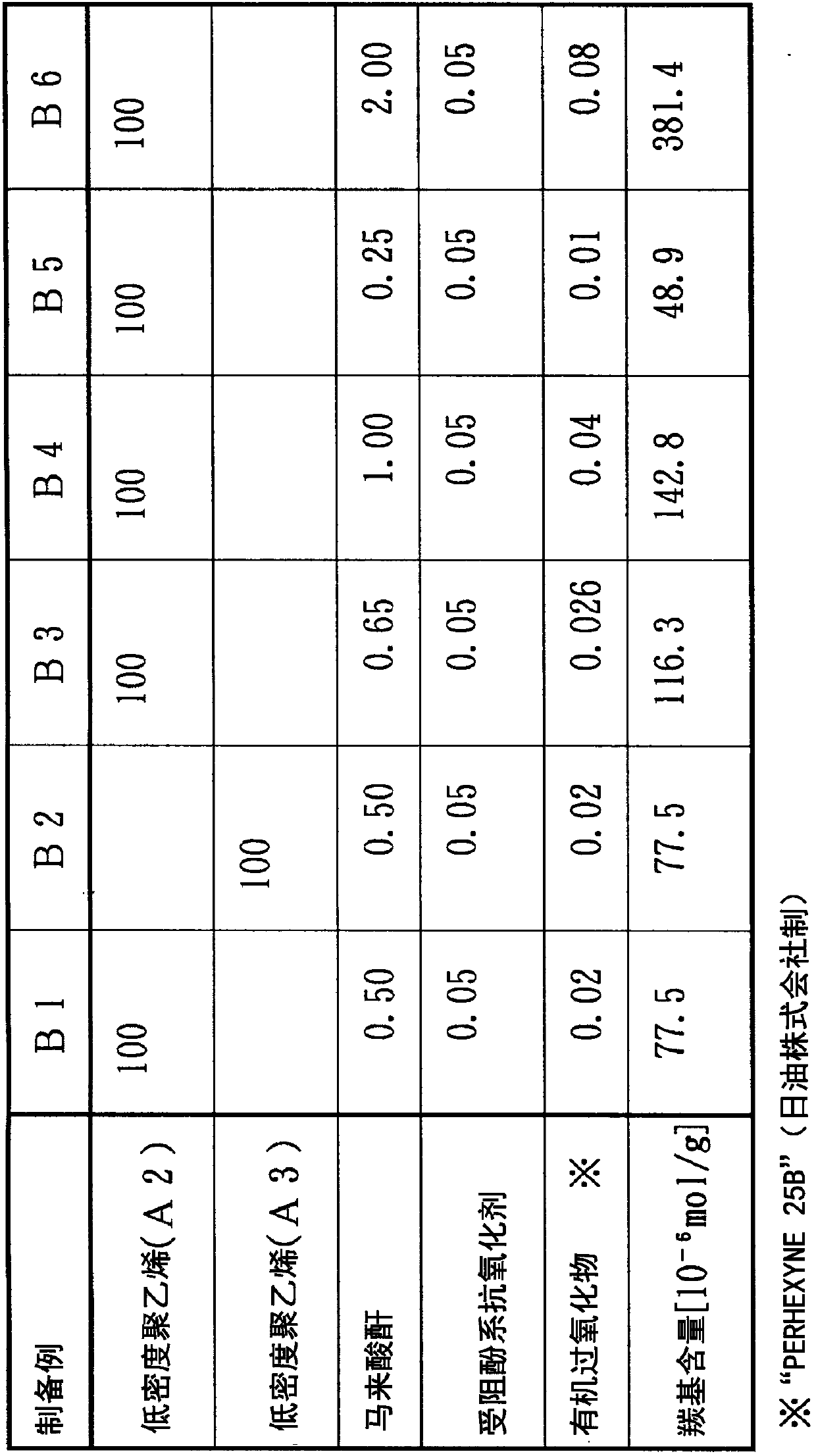

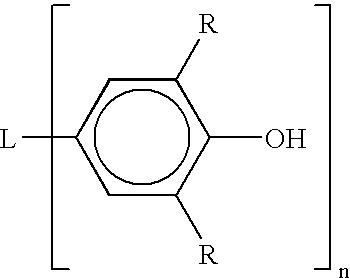

Insulating resin composition for DC power cable, crosslinked resin body, DC power cable, member for forming reinforcing insulating layer of DC power joint, and DC power cable joint

ActiveUS10752758B2Improve the extrusion effectImproved scorch resistancePlastic/resin/waxes insulatorsPower cables with screens/conductive layersLow-density polyethylenePower cable

An insulating resin composition for a DC power cable improves DC electrical properties and extrusion stability, and includes (A) a low-density polyethylene having a complex viscosity η*100, which is measured at 130° C. and a frequency of 100 rad / s, of 600 to 1,300 Pa·s, wherein a ratio (η*0.1 / η*100) of a complex viscosity η*0.1, which is measured at 130° C. and a frequency of 0.1 rad / s, to the complex viscosity η*100 is 4 or more; (B) a modified polyethylene; and (C) a stabilizer including a mixture of a hindered phenol antioxidant and a thioether antioxidant. The amount of carbonyl groups introduced into the resin composition through the component (B) is 7×10−6 to 1.3×10−5 mol / g relative to the total mass of the component (A), the component (B), and the component (C).

Owner:NUC +1

Ultrathin water storage device

The invention relates to an ultrathin water storage device, which belongs to the technical field of water storage devices. The ultrathin water storage device is prepared from the following components by weight percent: 10 to 18 percent of ordinary butyl rubber, 30 to 50 percent of halogenated butyl rubber, 30 to 48 percent of carbon black, 2 to 3 percent of resin, 0.1 to 1 percent of internal releasing agent, and 1.5 to 3.5 percent of flow promoter. The ultrathin water storage device is high in scorching resistance and good in mobility; when in injection production, rubber materials are unlikely to vulcanize early in a short time, a whole mold cavity can be fully filled, and an inferior product is avoided.

Owner:浙江华和塑胶科技有限公司

Calendering type leaf-yellow rubber foxing glue for liberation shoes, and preparation method and application thereof

InactiveCN104356437AImprove the stability of the calendering processImproved scorch resistanceFootwearVulcanizationResin-Based Composite

The invention discloses calendering type leaf-yellow rubber foxing glue for liberation shoes. The glue comprises the following components in parts by weight: 75-85 parts of standard glue, 20-25 parts of butylbenzene glue, 2.0-2.4 parts of sulphur, 3.6-4.0 parts of a vulcanization accelerator, 1.4-1.8 parts of stearic acid, 1.8-2.2 parts of activated zinc oxide, 8-10 parts of pine tar, 80-90 parts of pottery clay, 2.0-2.4 parts of an anti-aging agent, 4-8 parts of composite resin DS-B, 8-10 parts of calcium-based grease, 26-34 parts of light-weight calcium carbonate and 7-9 parts of leaf yellow female glue, wherein every 108.7 parts of the leaf-yellow female glue consist of 50 parts of colophony butylbenzene glue, 4 parts of paraffine, 0.8 part of N330 carbon black, 0.9 part of phthalocyanine green G and 53 parts of medium chrome yellow.

Owner:JIHUA 3537 SHOE MAKING

Bending-resistant calendered leaf-yellow rubber edge strip rubber for liberation shoes, and preparation method and application thereof

InactiveCN104371150AImprove the stability of the calendering processImproved scorch resistanceFootwearVulcanizationStearic acid

The invention discloses a bending-resistant calendered leaf-yellow rubber edge strip rubber for liberation shoes, which comprises the following components in parts by weight: 75-85 parts of standard rubber, 20-25 parts of butadiene styrene rubber, 15-25 parts of silica white, 2.0-2.4 parts of sulfur, 3.6-4.0 parts of vulcanization accelerator, 1.4-1.8 parts of stearic acid, 1.8-2.2 parts of activated zinc oxide, 8-10 parts of pine tar, 60-70 parts of argil, 2.0-2.4 parts of anti-aging agent, 4-8 parts of compound resin DS-B, 8-10 parts of calcium grease, 26-34 parts of light calcium carbonate and 7-9 parts of leaf-yellow master batch. Every 108.7 parts of leaf-yellow master batch is composed of 50 parts of rosin butadiene styrene rubber, 4 parts of paraffin, 0.8 part of N330 carbon black, 0.9 part of phthalocyanine green G and 53 parts of medium chrome yellow.

Owner:JIHUA 3537 SHOE MAKING

A kind of preparation method of the nitrile rubber that is used to prepare high wear-resisting floating oil seal sealing ring

The preparation method of the nitrile rubber used to prepare the high wear-resistant floating oil seal sealing ring, including formula and preparation process, the formula includes the following components: nitrile rubber, N-550 carbon black, high wear-resistant carbon black, semi-reinforced carbon Black, calcium carbonate, polyvinyl chloride, stearic acid, dibutyl ester, sulfur, accelerator, accelerator TE, accelerator TMTD, antioxidant RD, antioxidant 4010, zinc oxide; preparation process: adjust the temperature of the internal mixer to 100°C, speed 32 rpm, put rubber raw materials, fillers, softeners, acidifiers, anti-aging agents and active agents into the internal mixer and mix for 20 minutes, control the glue temperature below 130°C to discharge the glue, then move to Open the mixer, discharge the sheet to cool down, and obtain the masterbatch; put the masterbatch into the internal mixer, add a vulcanizing agent to mix, banbury, control the temperature of the glue below 100°C, discharge the glue to the open mixer, and then discharge the sheet Cooling, standing and aging to obtain the nitrile rubber used to prepare high wear-resistant floating oil seal rings.

Owner:ZHEJIANG GUANGLI ENG MACHINERY

Rolling type grass green foxing glue for folding-resistant liberation shoes as well as preparation method and application thereof

InactiveCN104356438AImprove process stabilityImproved scorch resistance and flex resistanceFootwearTarChemistry

The invention discloses a rolling type grass green foxing glue for folding-resistant liberation shoes. The rolling type grass green foxing glue comprises the following components in parts by weight: 85-90 parts of standard glue, 10-15 parts of butadiene-styrene rubber, 15 parts of white carbon black, 2.0-2.4 parts of sulphur, 3.6-4.0 parts of a vulcanization accelerator, 1.8-2.2 parts of stearic acid, 1.8-2.2 parts of activated zinc oxide, 6-8 parts of pine tar, 75-85 parts of argil, 2.0-2.4 parts of an anti-aging agent, 4-8 parts of composite resin DS-B, 8-10 parts of calcium-based grease, 30-36 parts of light calcium carbonate and 4-6 parts of grass green rubber master batch.

Owner:JIHUA 3537 SHOE MAKING

Insulating resin composition for direct-current power cable, crosslinked resin, direct-current power cable, member for forming insulating reinforcement layer of direct-current power cable junction, and direct-current power cable junction

ActiveCN109642059AExcellent DC characteristicsImproved scorch resistanceInsulated cablesPower cablesLow-density polyethylenePower cable

Owner:ENEOS NUC CORP +1

Special anti-ageing and low-temperature-resistant modified fluoride rubber sheath material for ship cable

InactiveCN105860373AImprove low temperature resistanceEasy to processRubber insulatorsCalcium silicateCarbon nanotube

The invention discloses a special anti-ageing and low-temperature-resistant modified fluoride rubber sheath material for a ship cable. The material is prepared from fluoride rubber, fluorine-containing acrylate rubber, epoxy acrylate rubber, HNBR, maleic anhydride grafted polyethylene, stearic acid, active magnesium oxide, bisphenol AF, benzyl triphenyl phosphorus chloride, trimethylolpropane trimethacrylate, phenolic resin, carbon nanotubes, stearic acid modified diatomite, calcium silicate, polyaniline nanofiber, magnesium hydroxide, calcium hydroxide, inositol hexaphosphate, epoxidation triglyceride fatty acid, epoxy linseed oil, 2,6-ditert-butyl-p-aminophenol, 2,5-di-tert-butylhydroquinone, nitrosodiphenylamine, butylmercaptooxo stannane and accelerant. The special anti-ageing and low-temperature-resistant modified fluoride rubber sheath material for the ship cable is high in strength, good in anti-ageing performance, excellent in oil resistance and low temperature resistance and capable of meeting use requirements of ship cable sheaths.

Owner:ANHUI HUAYU CABLE GRP

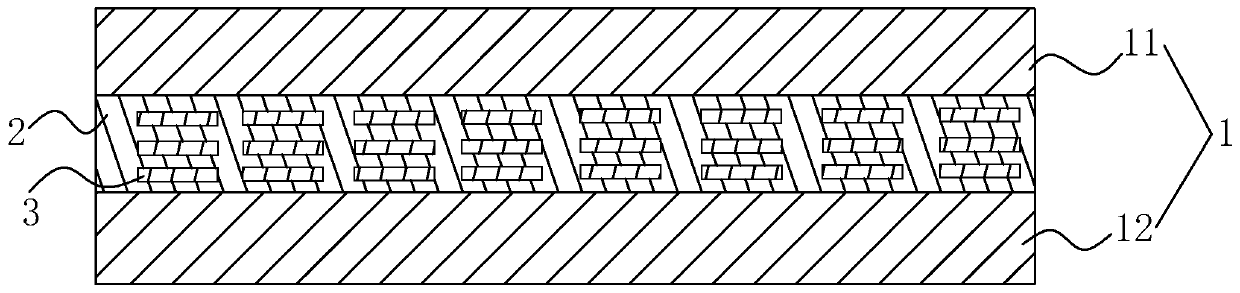

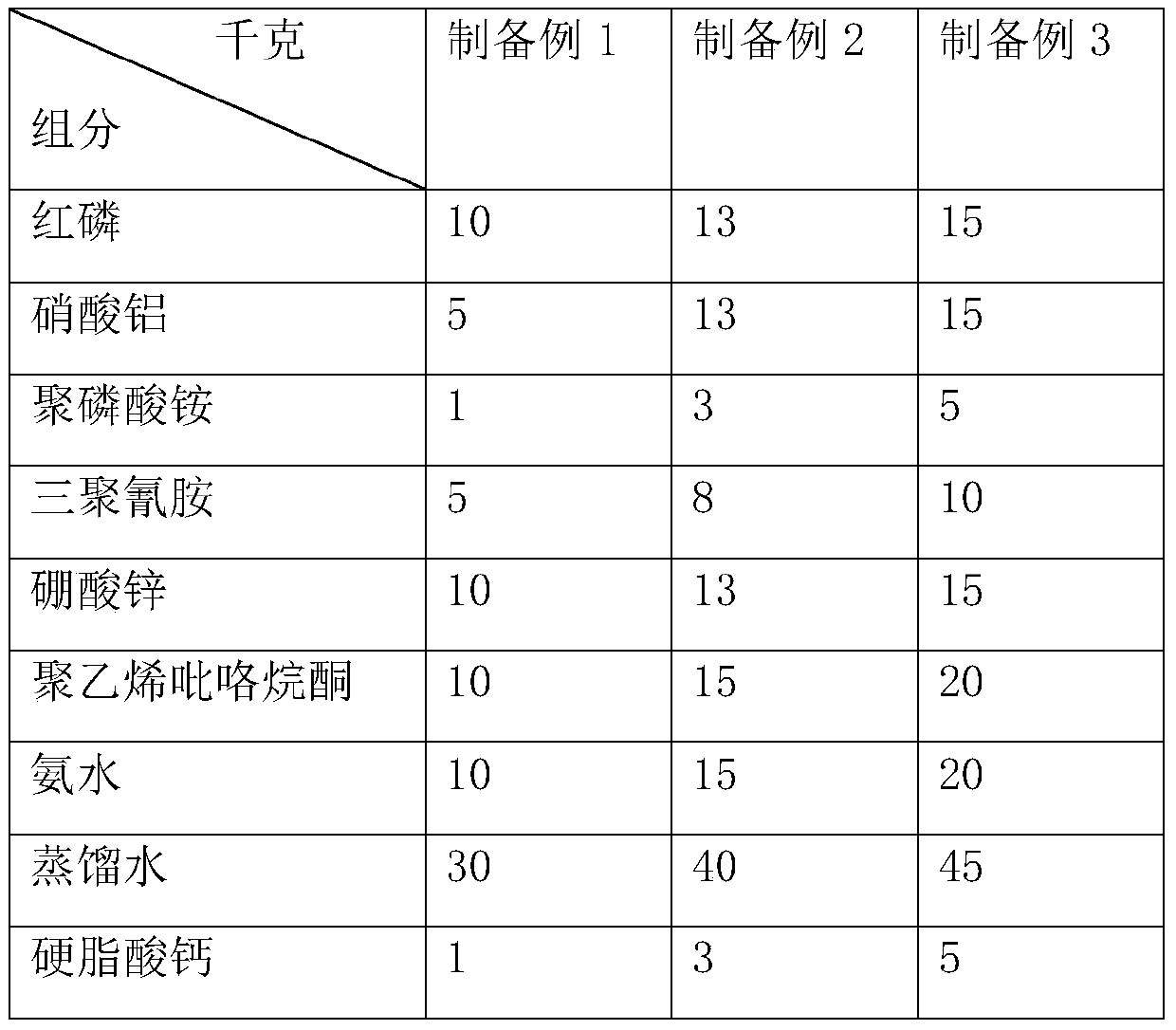

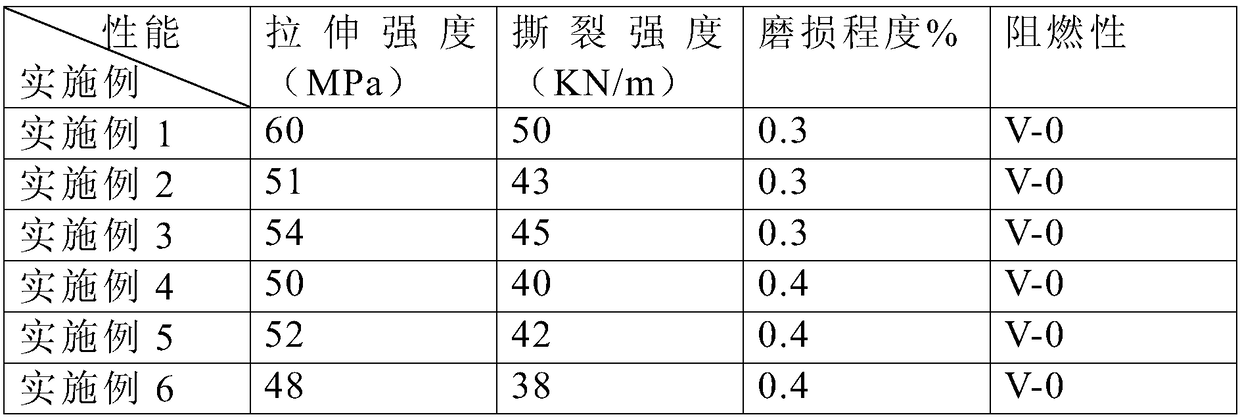

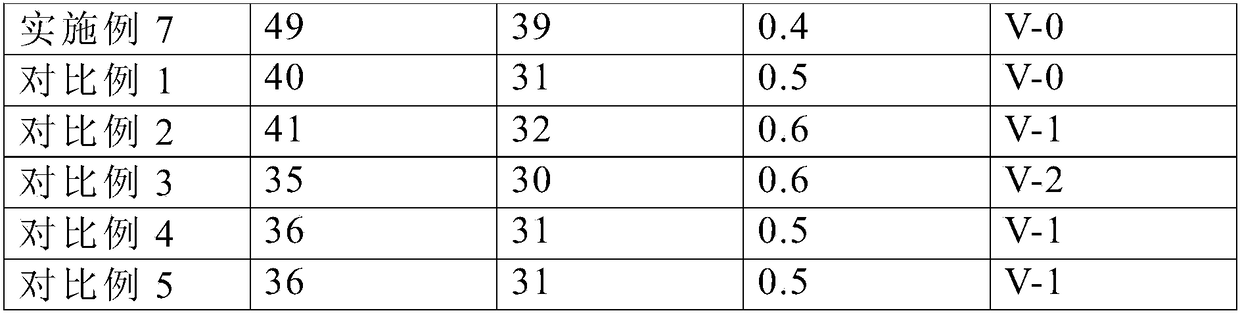

Flame-retardant conveyor belt and manufacturing process thereof

The invention discloses a flame-retardant conveyor belt and a manufacturing process thereof. The flame-retardant conveyor belt comprises a cover rubber, an intermediate adhesive and a skeleton material, wherein the cover rubber comprises an upper cover rubber and a lower cover rubber, and the skeleton material is a steel wire rope or a flame-retardant polyester fabric. The manufacturing process comprises the following steps: S1, the preparation of the cover rubber: I, the preparation of a composite flame retardant; II, pre-plasticization; III, cold mixing; IV, granulation; S2, the preparationof the intermediate adhesive: (1) stirring and mixing; (2) grinding; (3) de-aeration; S3, impregnation of the skeleton material and plasticization; and S4 extrusion and lamination of the cover rubber.The flame-retardant conveyor belt has the advantages of good flame-retarding effect, low smoke, low toxicity, safety and environmental protection; in addition, the manufacturing process has the advantages of simple process, easy manufacturing, low production cost and high production efficiency.

Owner:青岛环球输送带有限公司

Tire high-temperature adhesive

ActiveCN108148527AImproved scorch resistanceIncreased process safetyNon-macromolecular adhesive additivesMacromolecular adhesive additivesAdhesiveMaterials science

The invention discloses a tire high-temperature adhesive, and belongs to the technical field of high polymer materials. The adhesive is prepared from the following components of, in parts by weight:,140-160 parts of xylene, 5-7 parts of dioctyl ester, 25-35 parts of chloroprene rubber adhesive, 15-25 parts of powder butyronitrile, 3-5 parts of carbon black, 18-26 parts of petroleum resin, 4-8 parts of activating agents, 6-10 parts of enhancers, 10-14 parts of fillers, 30-50 parts of complex, 5-7 parts of essence, and 4-6 parts of coloring matter. The formula of the adhesive is mainly composedof liquid organisms, combined with powder butyronitrile and macromolecular resin, and meanwhile comprises complex which is specially prepared, so that the tire high-temperature adhesive has excellentperformance on both mixing complexity of the raw materials and the compatibility of the finished product on different rubber. The abrasion resistance, the elasticity and the flexural property of thesizing material are improved as well, and the adhesive has the advantages of heat resistance, aging resistance, flex and fatigue resistance, low compression deformation and good transverse rigidity due to changing of the fillers.

Owner:浙江美亿佳新科技有限公司

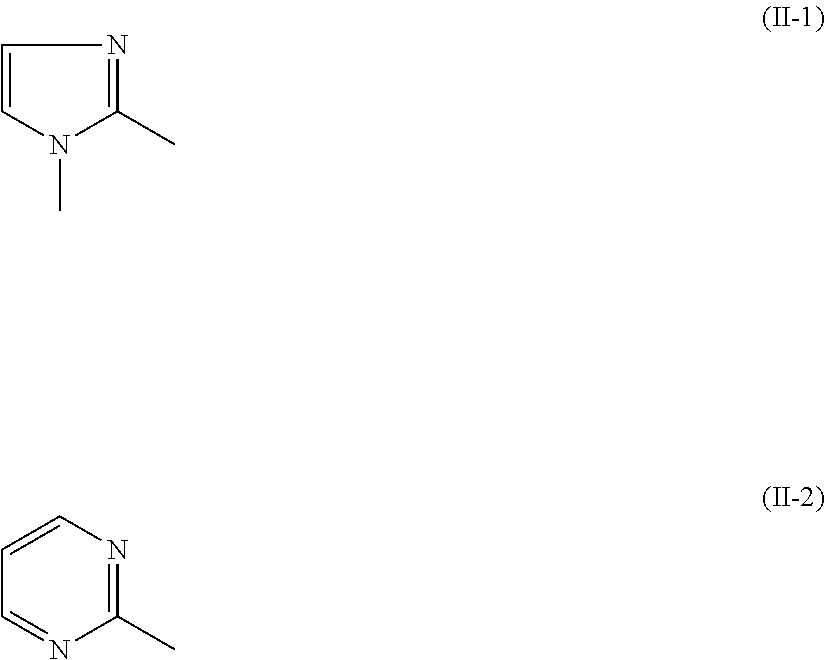

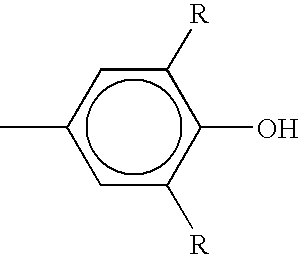

Rubber composition, and pneumatic tire using same

ActiveUS20150353657A1Enhance chemical interactionImprove performanceSpecial tyresCompound aPolymer science

The invention provides a rubber composition prepared by mixing, per 100 parts by mass of the rubber component comprising at least 50% by mass of a diene-based rubber, from 20 to 150 parts by mass of a filler, and from 0.05 to 30 parts by mass of a compound A which has a specific amidine structure and has a functional group reactive with the diene-based rubber. The rubber composition improves both a high elastic modulus and a low tan δ. The invention also provides a pneumatic tire using the rubber composition.

Owner:BRIDGESTONE CORP +1

Flame retardant insulation composition having improved scorch resistance

InactiveUS6984677B2Good processing characteristicsImprove curing efficiencyOrganic chemistryPlastic/resin/waxes insulators4-Methyl-1-pentenePolymer chemistry

Crosslinkable, flame retardant insulation compositions having improved resistance to scorch are provided. The compositions are comprised of a base resin, hydrated inorganic filler, coupling agent and stabilizer and formulated with a peroxide / scorch retardant combination, specifically, a combination of α,α′-bis(t-butylperoxy)diisopropyl benzene and 2,4-diphenyl-4-methyl-1-pentene.

Owner:EQUSR CHEM LP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com