Insulating resin composition for direct-current power cable, crosslinked resin, direct-current power cable, member for forming insulating reinforcement layer of direct-current power cable junction, and direct-current power cable junction

一种绝缘性树脂、树脂组合物的技术,应用在绝缘电缆、绝缘体、电力电缆等方向,能够解决绝缘油环境的影响等问题,达到耐焦烧性良好、扭矩适当、圆度高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

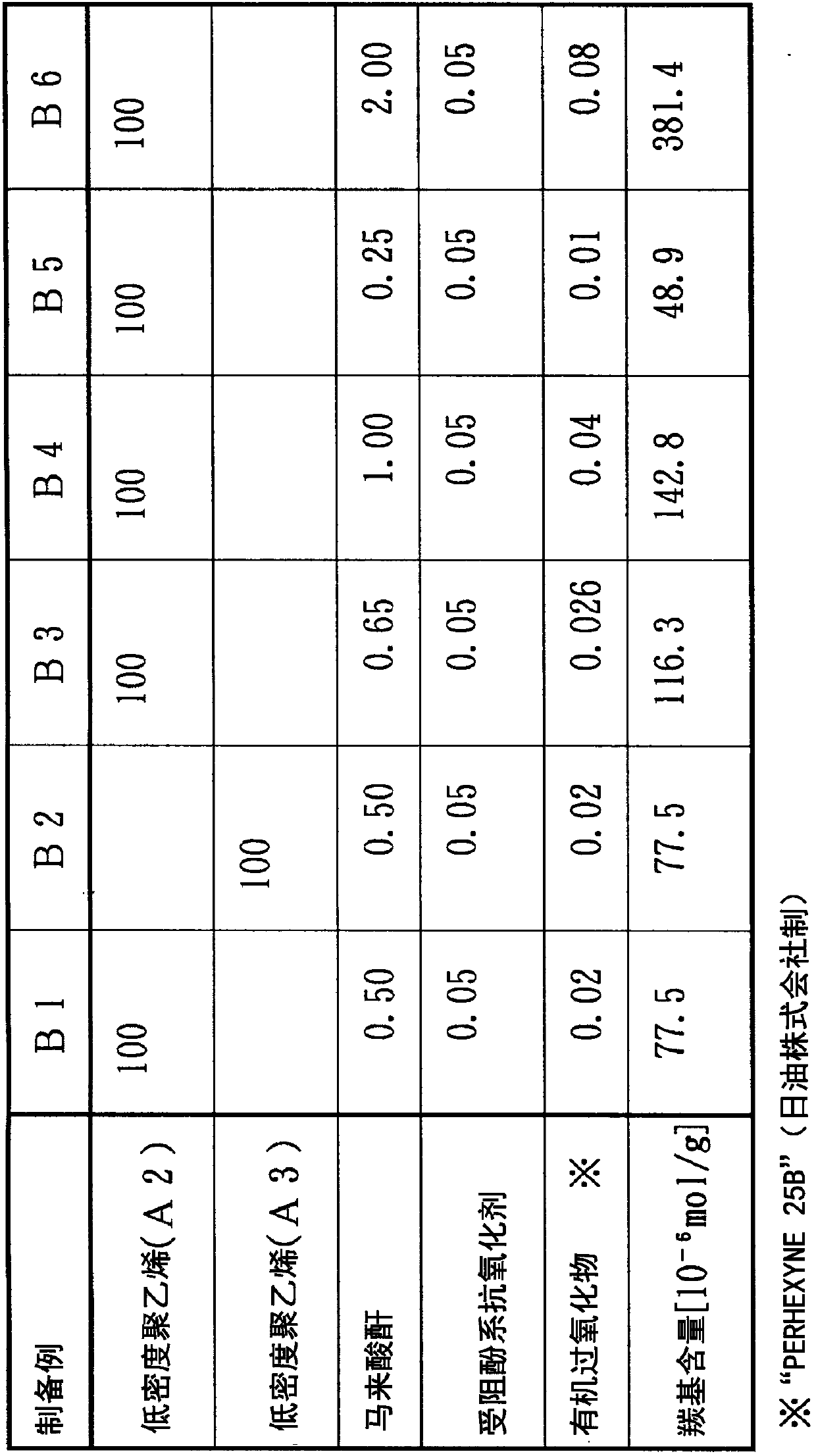

[0078] As the preparation method of (B) component, low-density polyethylene, antioxidant, modified monomer, and organic peroxide are mixed in an extruder, heated, reacted, and granulated into granules. Feed or granular method.

[0079] It should be noted that the antioxidant used in the preparation of the (B) component is inactivated along with the synthesis of the (B) component, and does not constitute the (C) component in the resin composition.

[0080]

[0081] (C)component which comprises the resin composition of this invention is a stabilizer containing the mixture of 40 to 60 weight% of hindered phenolic antioxidants, and 60 to 40 weight% of thioether antioxidants.

[0082] The resin composition of this invention has favorable scorch resistance by containing the stabilizer which contains a thioether type antioxidant by the ratio mentioned later in the ratio of 40 mass % or more.

[0083] In addition, by setting the ratio of the thioether-based antioxidant in the stabi...

Embodiment

[0142] Hereinafter, the present invention will be described by way of examples.

[0143]

[0144] (1) MFR: Based on JIS K 7210, it was measured under the conditions of a measurement temperature of 190° C. and a load of 21.18 N.

[0145] (2) Density: Measured in accordance with JIS K 7112.

[0146] (3) Carbonyl content:

[0147] (3-1) Production of samples

[0148] The resin composition preheated at 120° C. and 1 MPa for 5 minutes was heated with a press machine at 180° C. and 15 MPa for 15 minutes to produce a crosslinked sheet (sheet-shaped crosslinked resin) with a thickness of about 0.2 mm. The thickness of the obtained crosslinked sheet was accurately measured with a micrometer.

[0149] (3-2) Determination of infrared absorption spectrum:

[0150] Infrared spectrophotometer "FT / IR-4200" (manufactured by JASCO Co., Ltd.) with 16 accumulation times and a resolution of 4cm -1 Under the condition of measuring 1790cm -1 Absorbance (baseline 1760 ~ 1840cm -1 ).

[0151]...

preparation example B1

[0177] According to the recipe shown in Table 1 below, 0.5 parts by mass of maleic anhydride and 0.05 parts by mass of hindered phenolic antioxidant were added to 100 parts by mass of low-density polyethylene (A2), and 2,5 - 0.02 parts by mass of dimethyl-2,5-bis(tert-butylperoxy) 3-hexyne "PERHEXYNE 25B" (manufactured by NOF Co., Ltd.), mixed in an extruder and heated to react, thereby A carbonyl content of 7.75×10 was obtained -5 mol / g of the modified polyethylene (B1) formed by the graft copolymer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| complex viscosity | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com