Patents

Literature

83results about How to "Efficient extrusion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

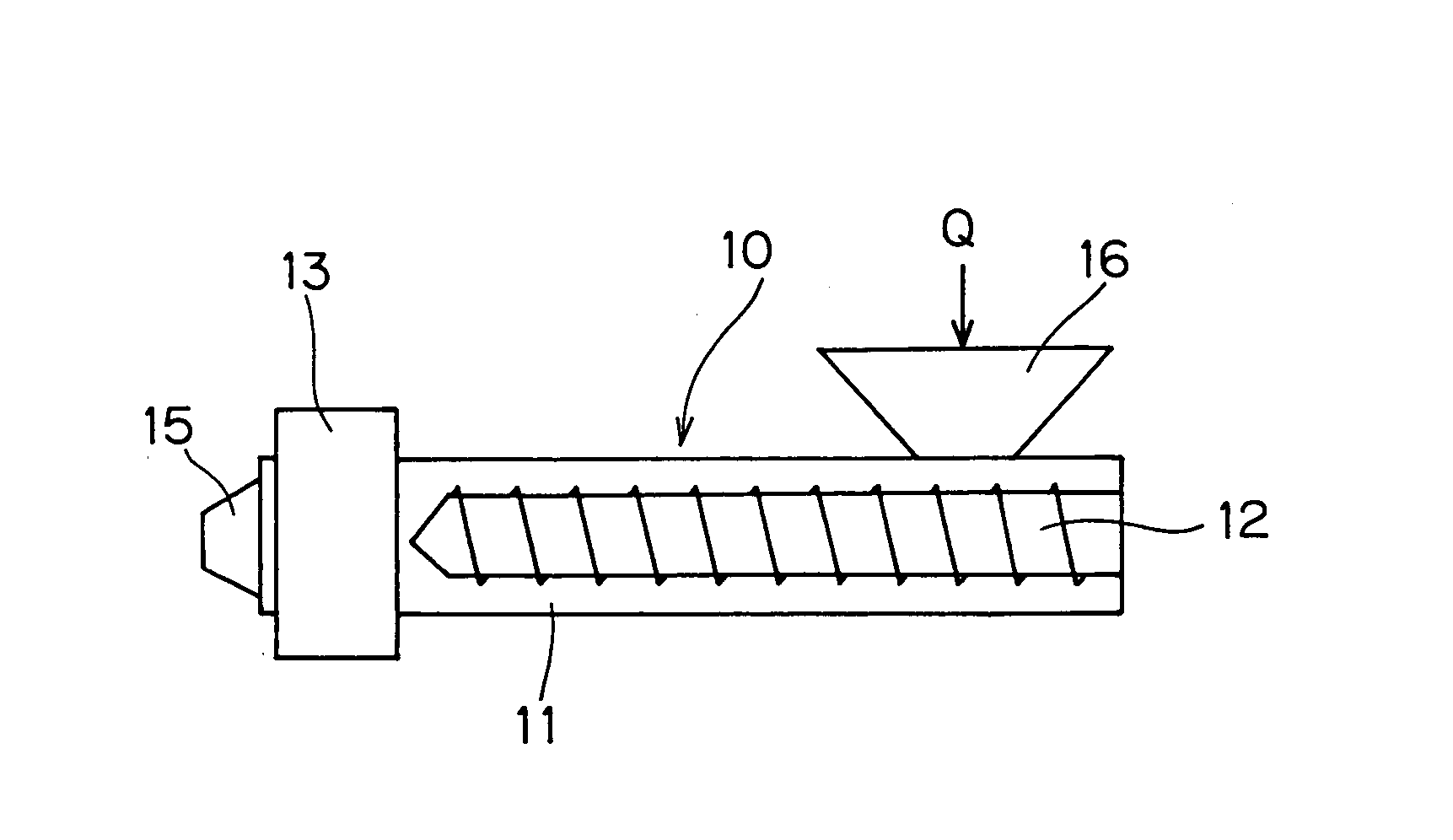

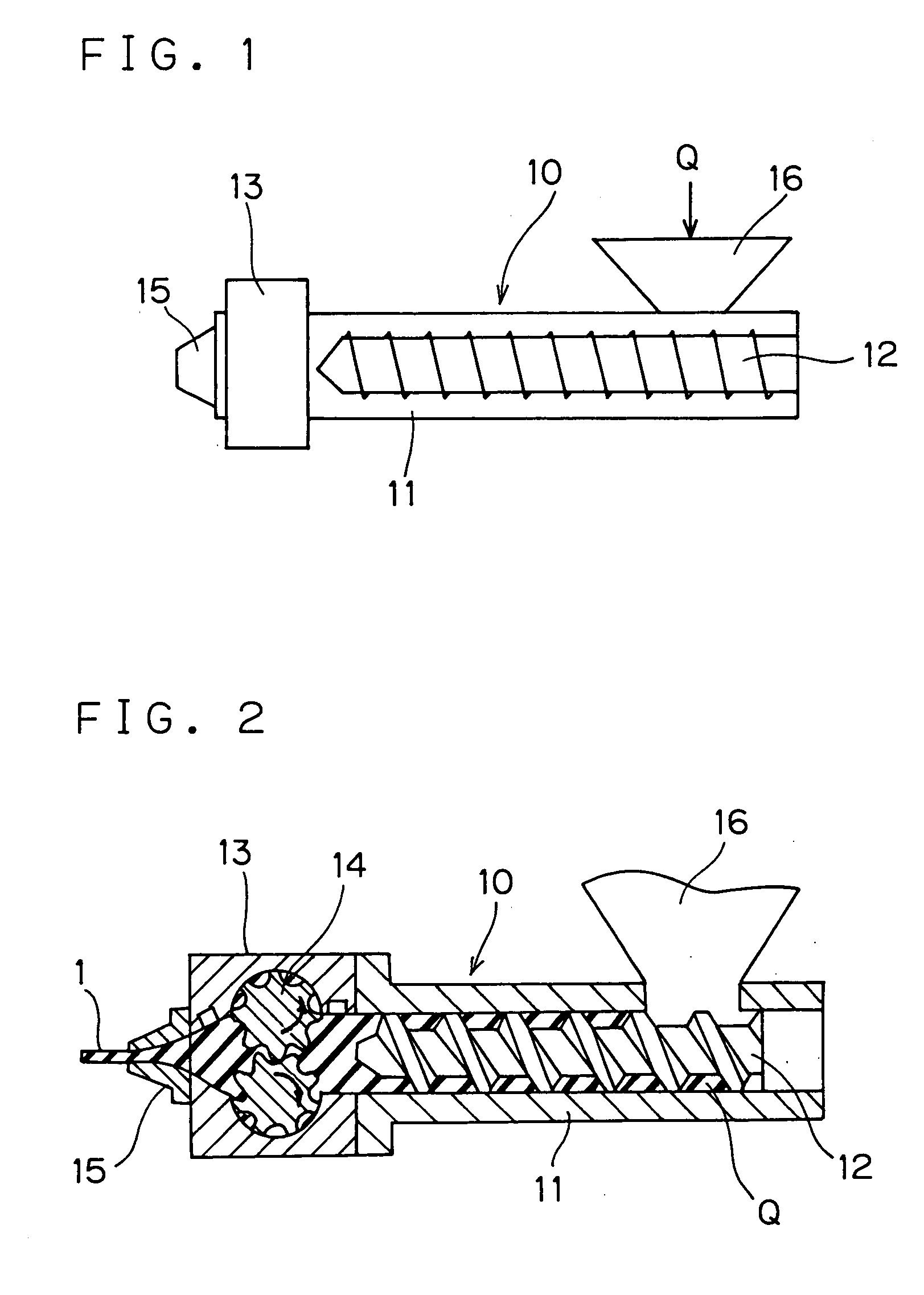

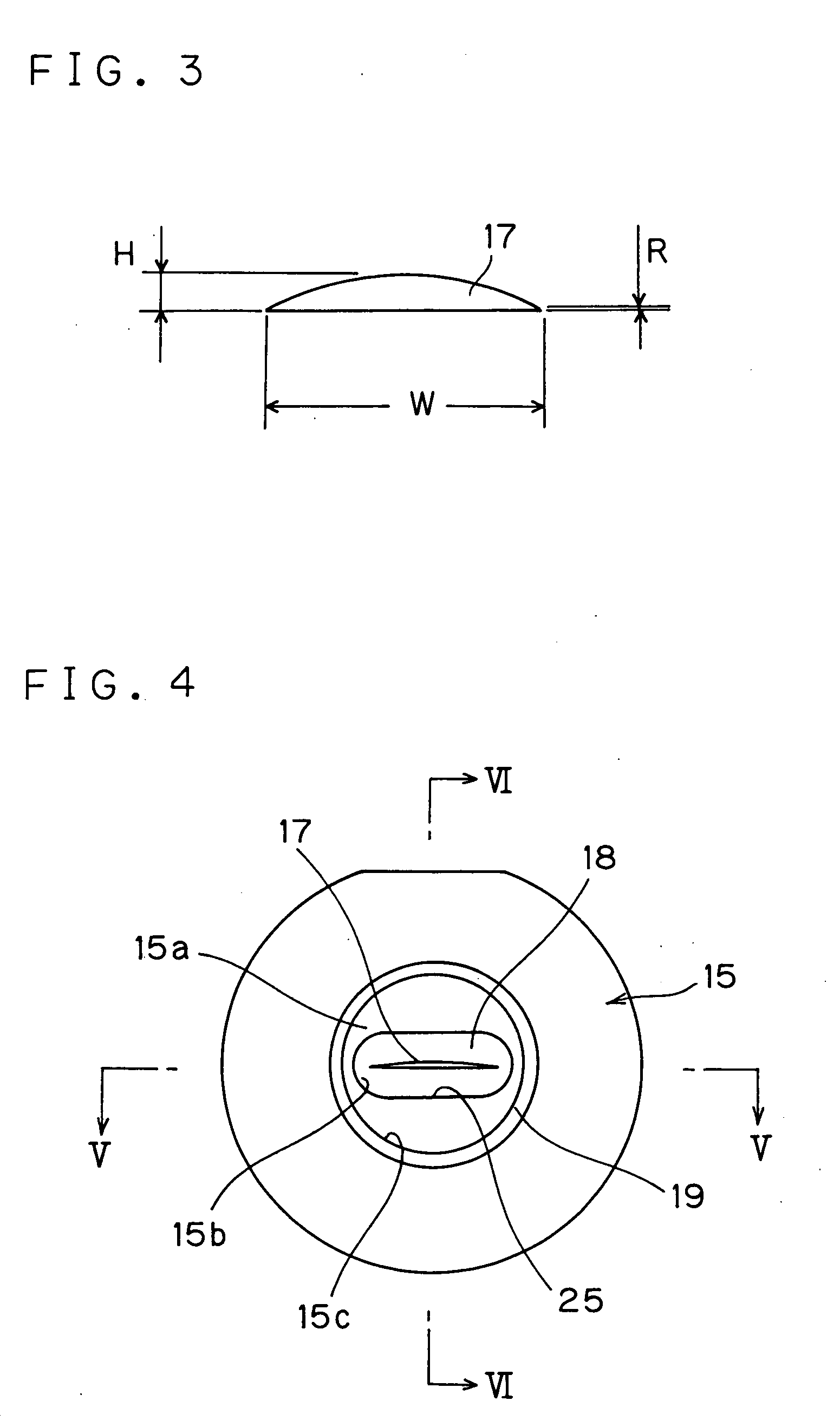

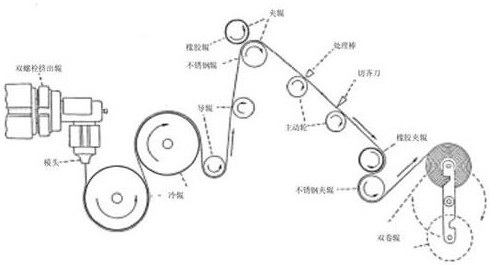

Method of and apparatus for forming rubber strip materials for building tires and method of building tires

ActiveUS20050189061A1Shorten cycle timeEfficient preparationTyresAuxillary shaping apparatusRubber materialBand shape

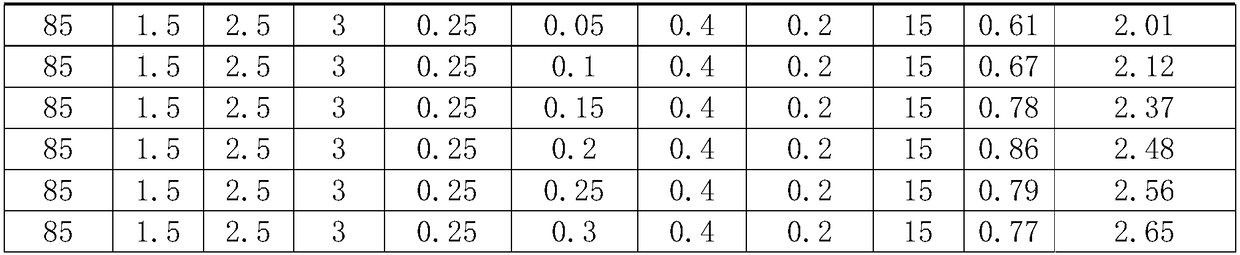

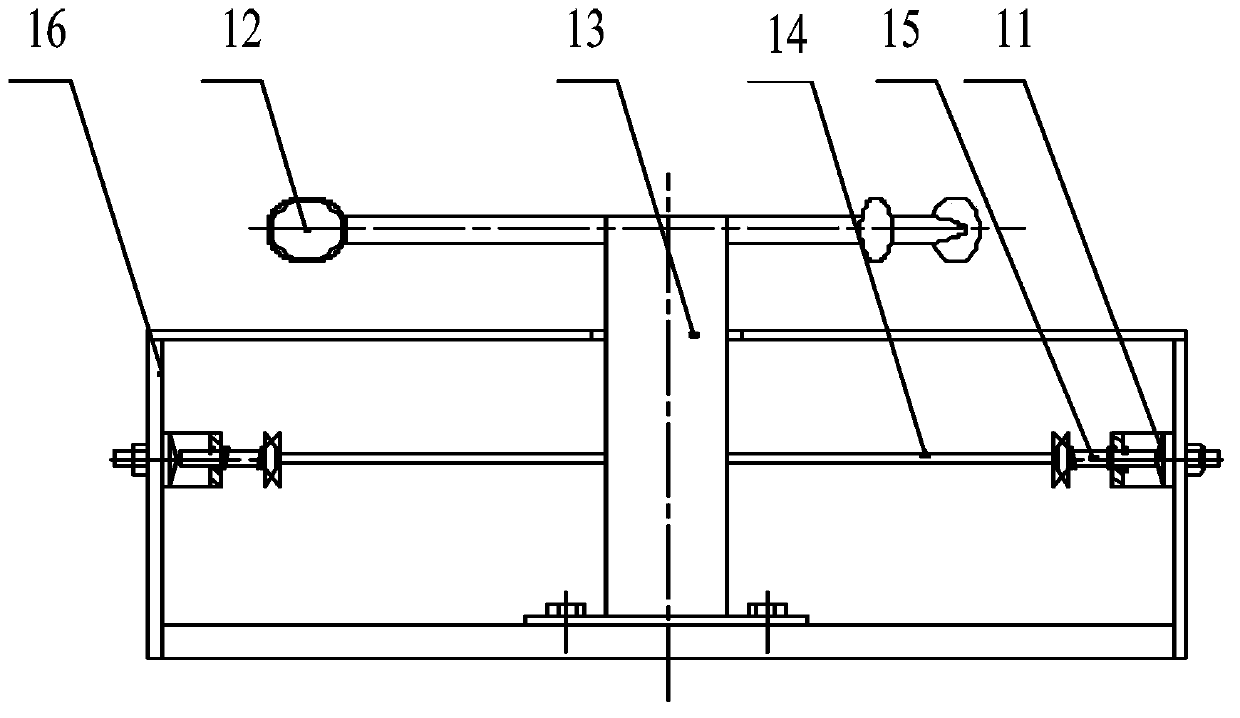

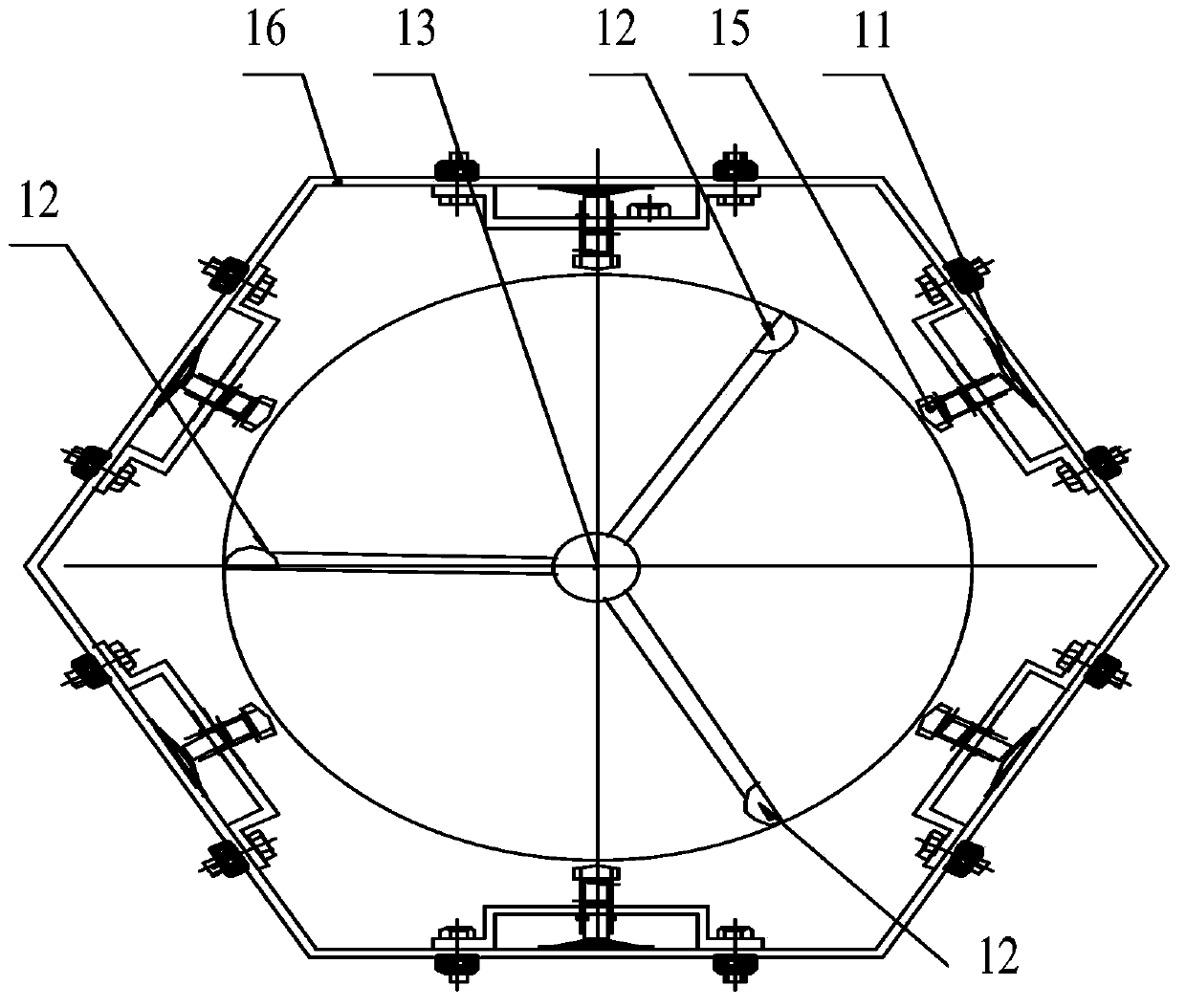

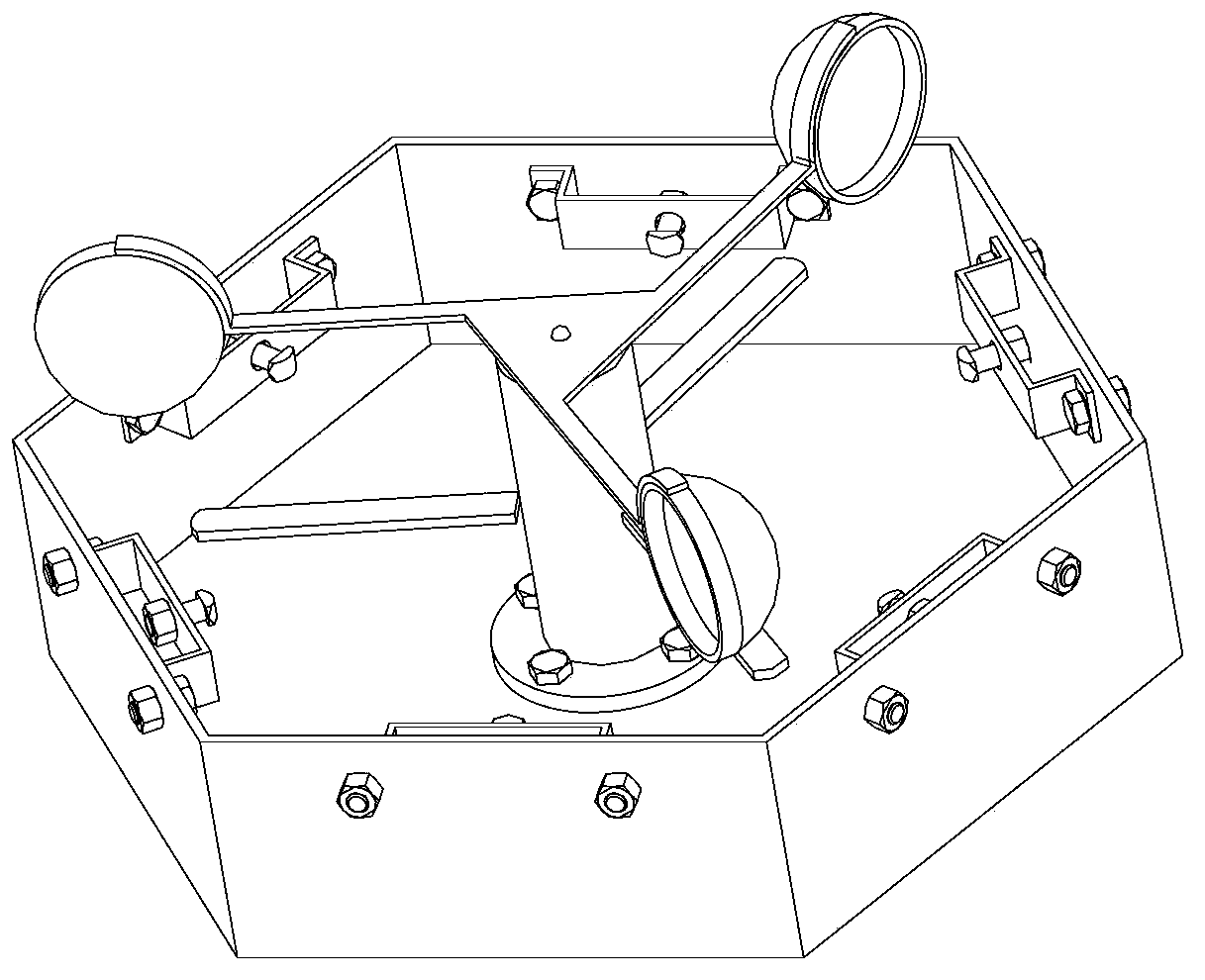

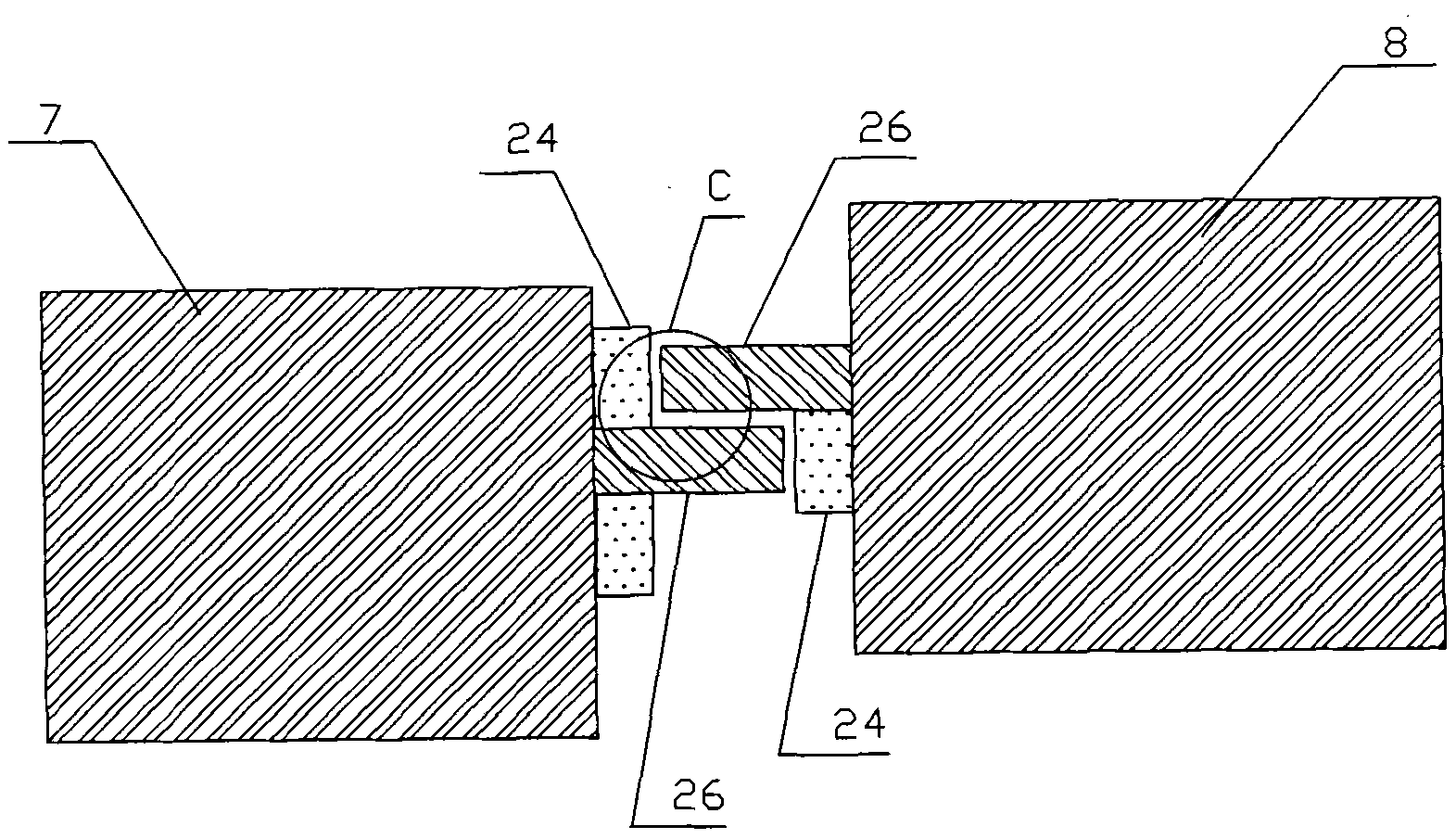

[Problems to be solved] It is to provide a method for forming a rubber strip which enables a wider rubber of small thickness without lowering an extruding speed and enables to reduce a building cycle time, thereby increasing the efficiency of tire manufacturing. [Means for Solving the Problems] Temperatures at a main-part casing 11, a screw shaft 12 and a head region included with the die 13 are controlled to be different from each other in a manner that: the temperature as controlled in the main-part casing 11 is higher than that in the screw shaft 12; and the temperature as controlled in the head region is higher than that in the main-part casing 11, when continuously extruding a rubber material in a form of a ribbon in forming a rubber strip 1.

Owner:TOYO TIRE & RUBBER CO LTD

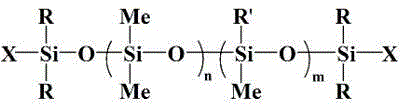

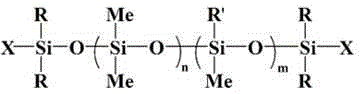

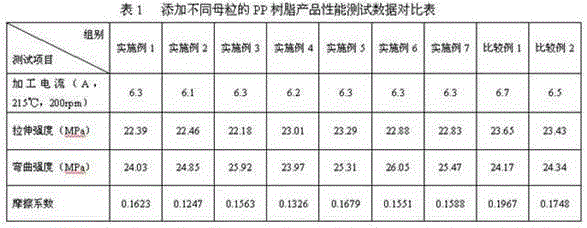

Silicone master batch with high silicone content and preparation method of silicone master batch

The invention relates to silicone master batch with a high silicone content and a preparation method of the silicone master batch and belongs to the technical field of macromolecular materials. The silicone master batch with the high silicone content is prepared from the following raw materials which are mixed through a mixer and extruded and granulated through a twin-screw extruder in percentage by weight: 50-65% of silicone, 5-40% of carrier resin, 5-30% of a compatilizer, 0-10% of filler and 0-5% of auxiliaries, wherein the content of silicone can be higher than 50%. By adding the silicone master batch with the high silicone content provided by the invention, the basic mechanical properties of a material can be maintained well while the rub resistance and processability of the material can be further effectively improved. The production efficiency can be improved to a great extent, and the demand on the processability and rub resistance of materials in industries such as automobiles, electronics and the like can be satisfied.

Owner:CHINA BLUESTAR CHENGRAND CO LTD

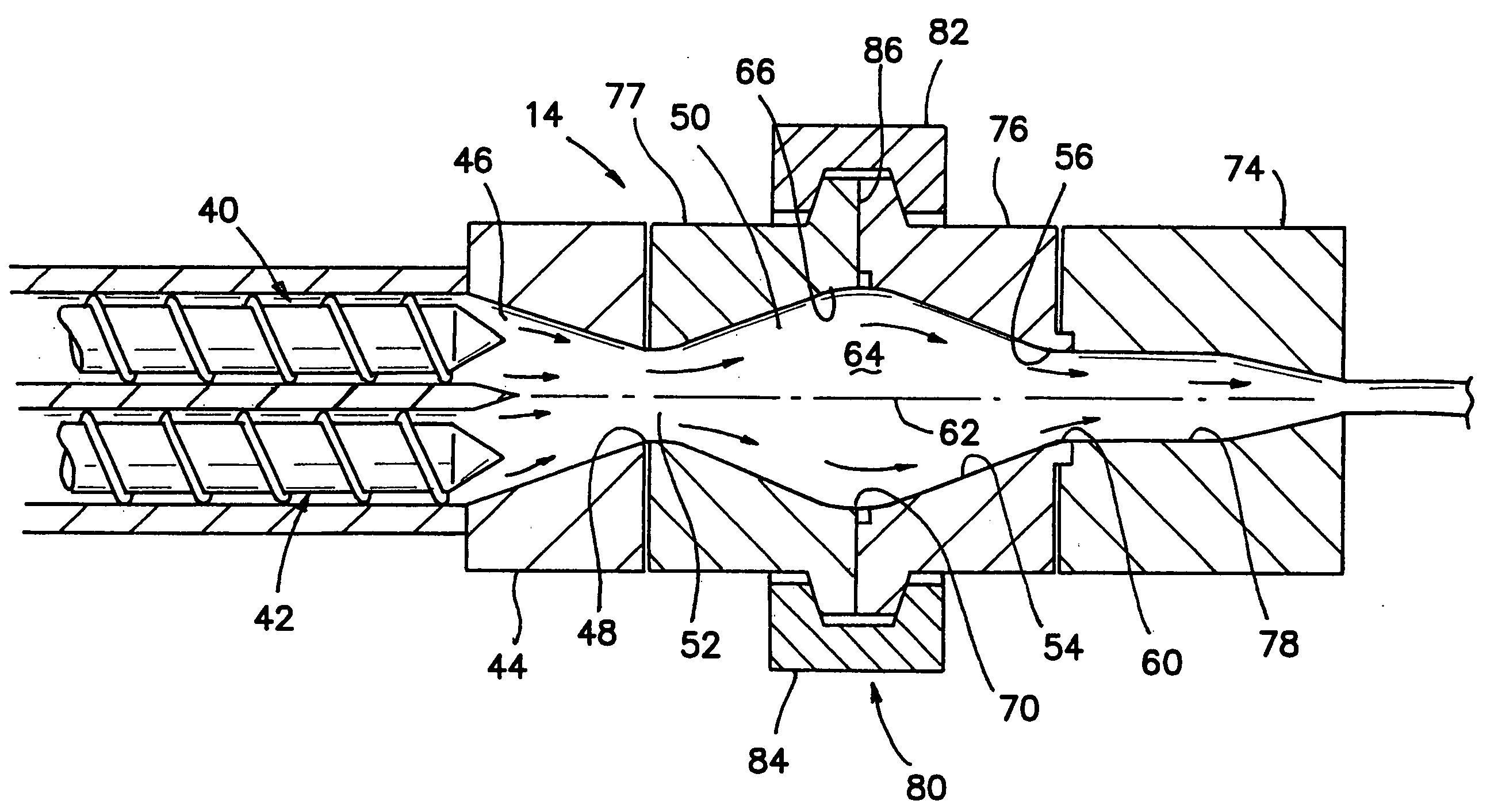

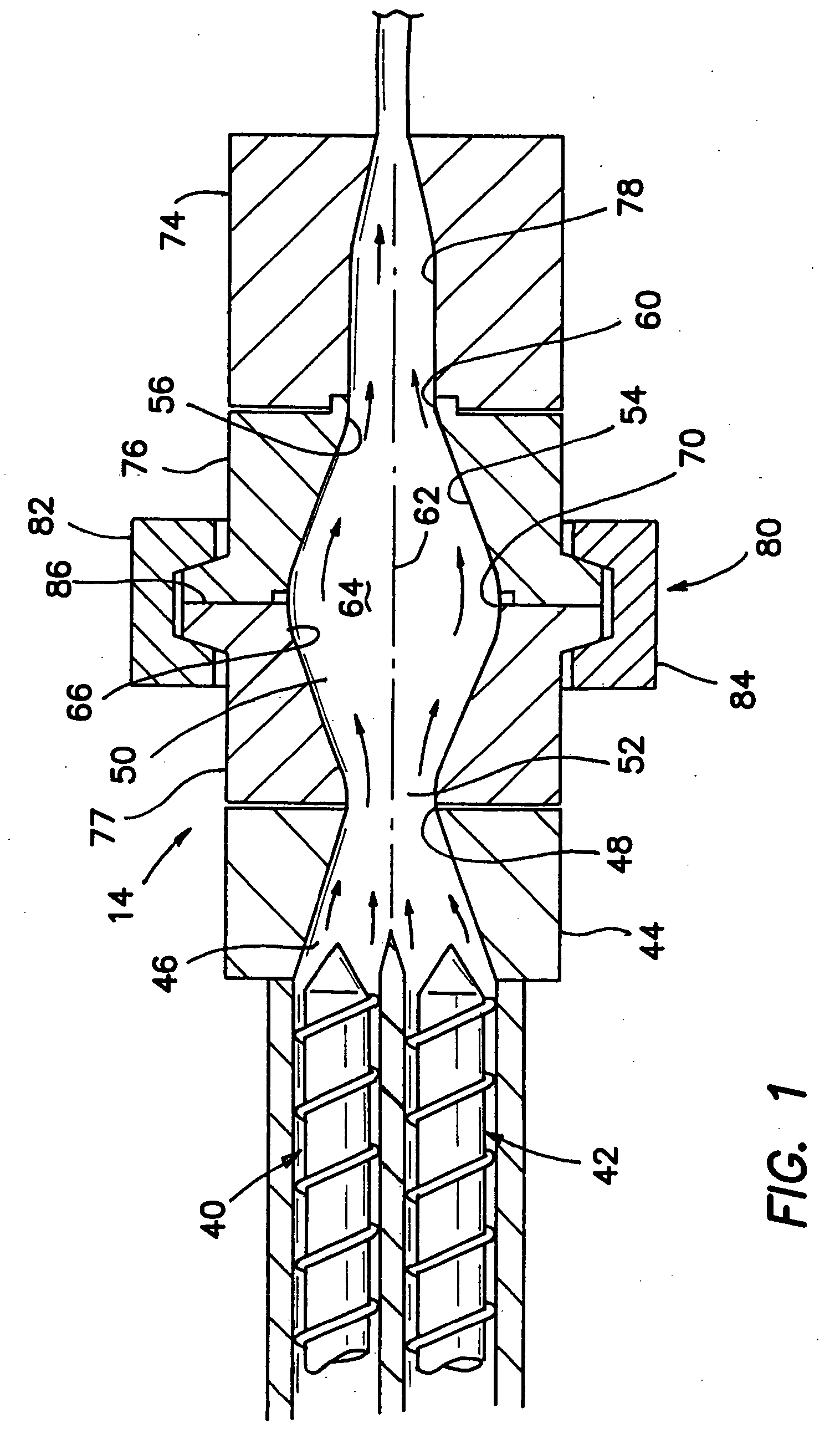

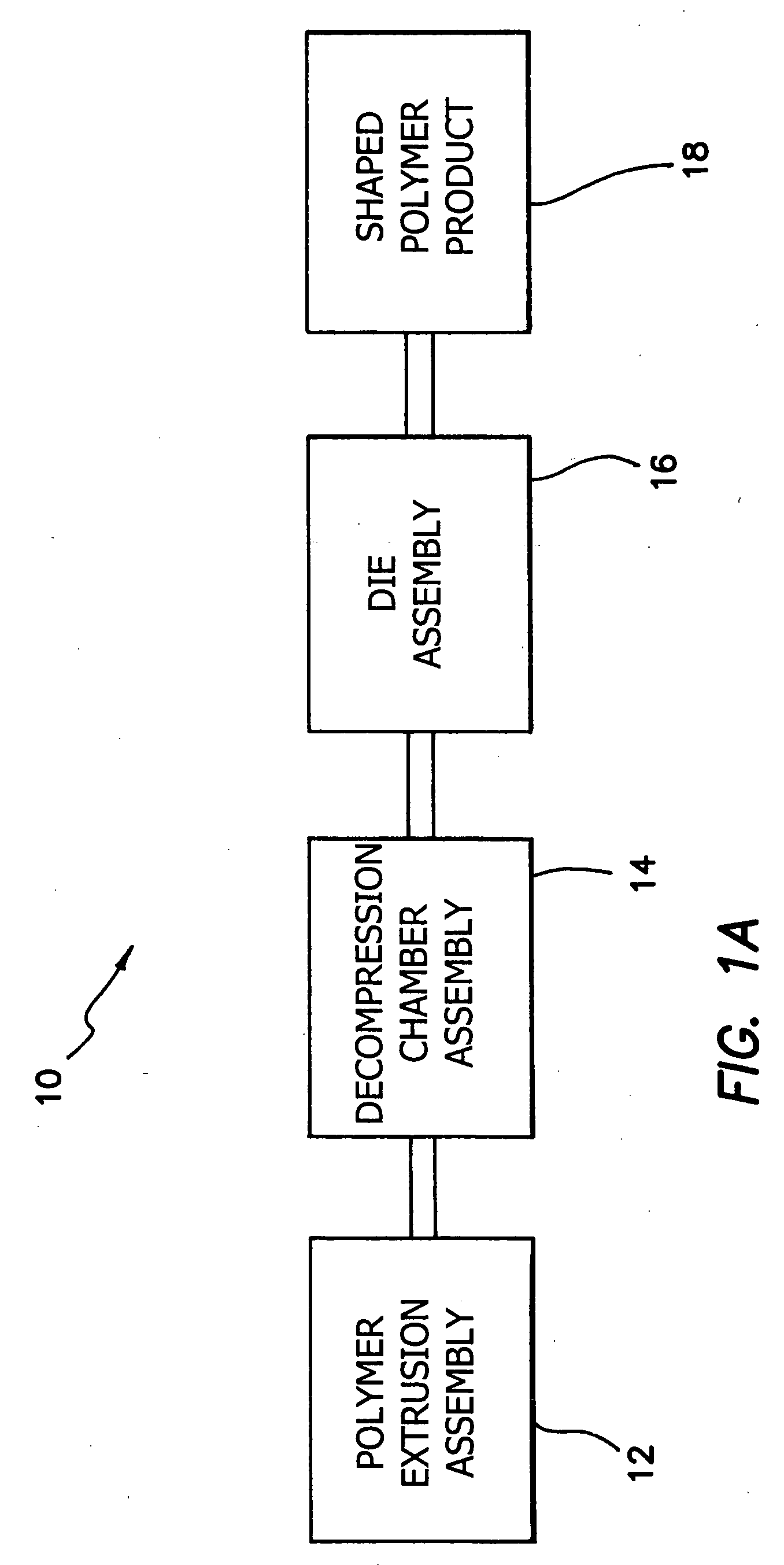

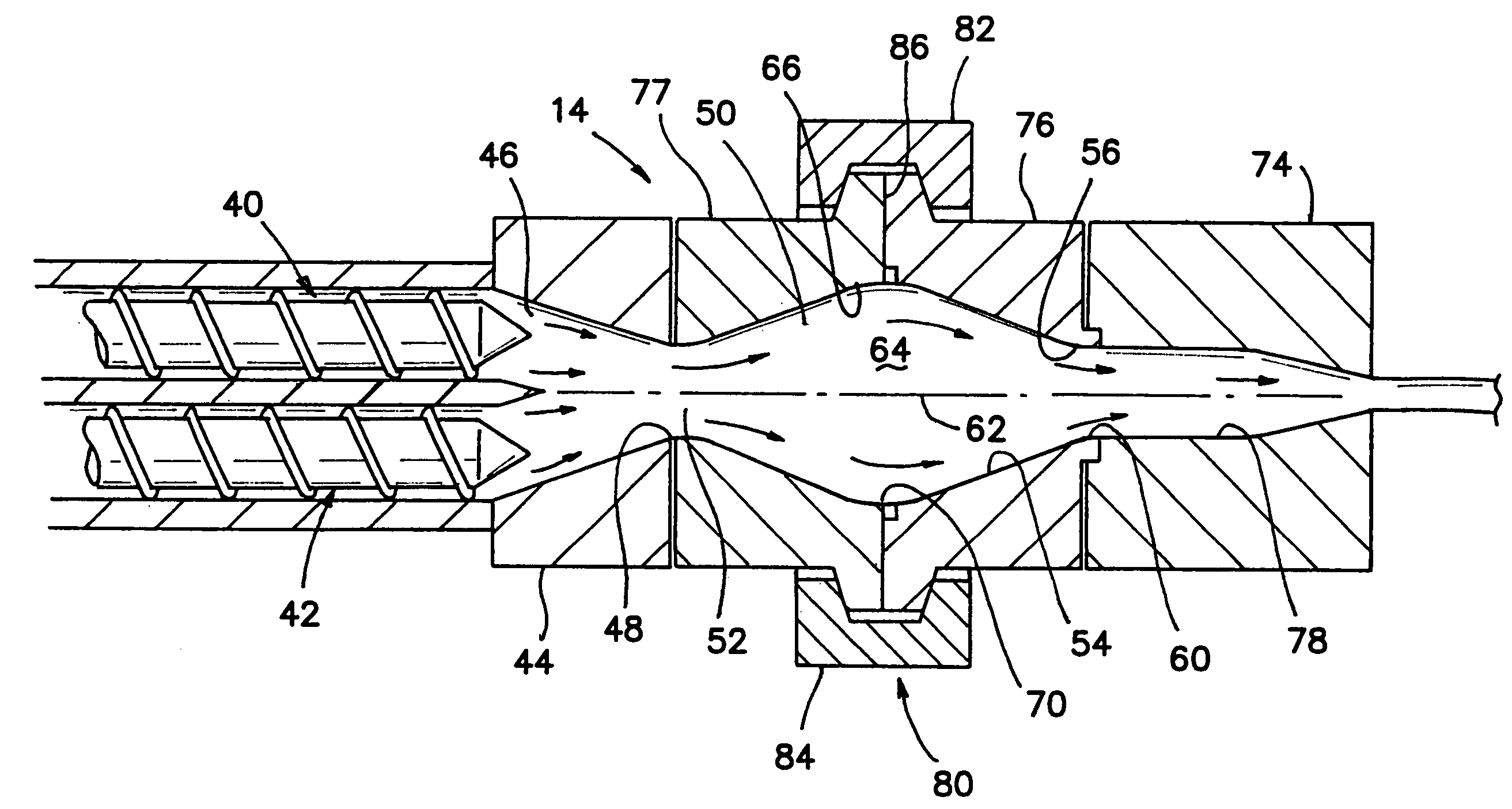

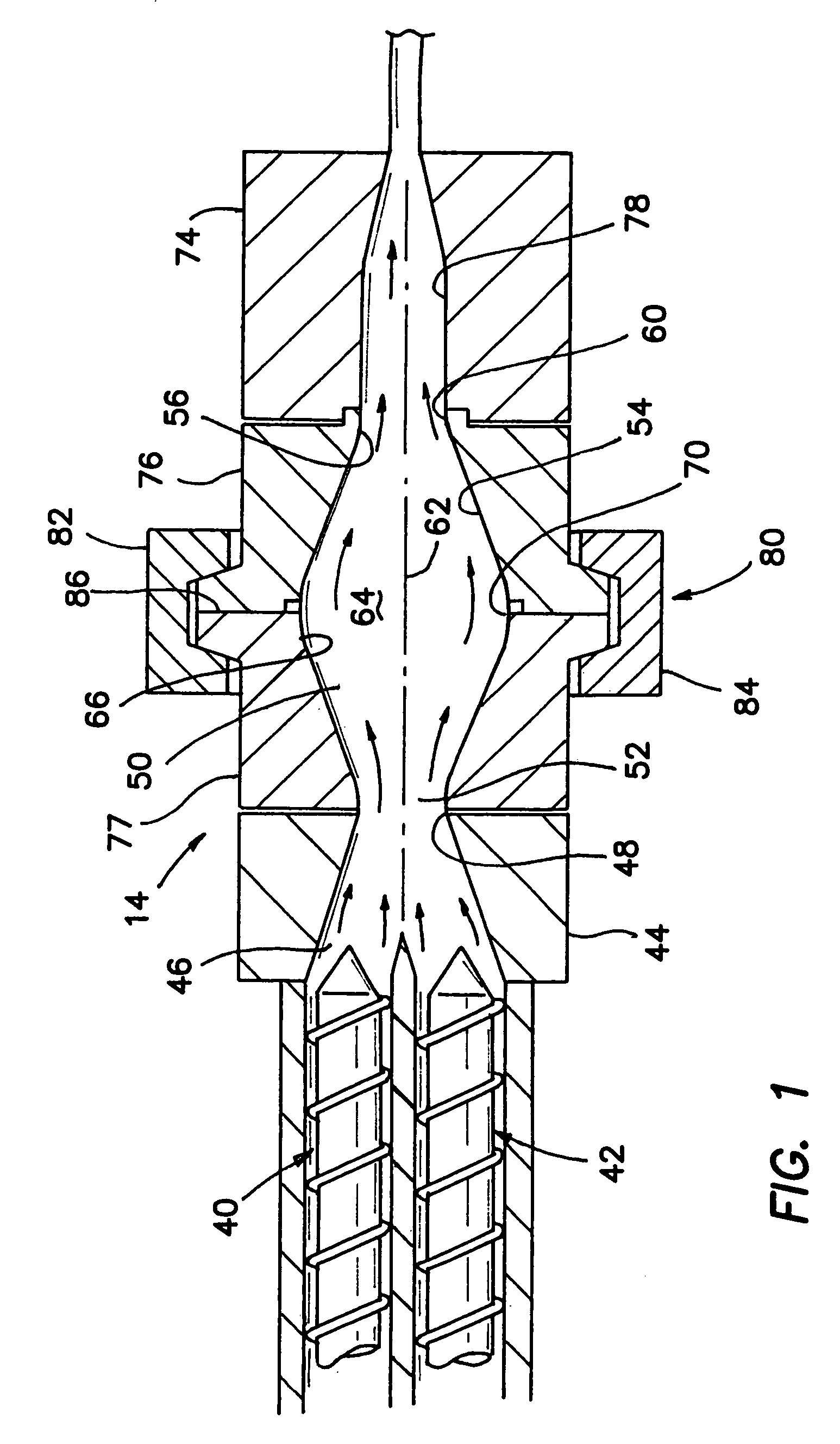

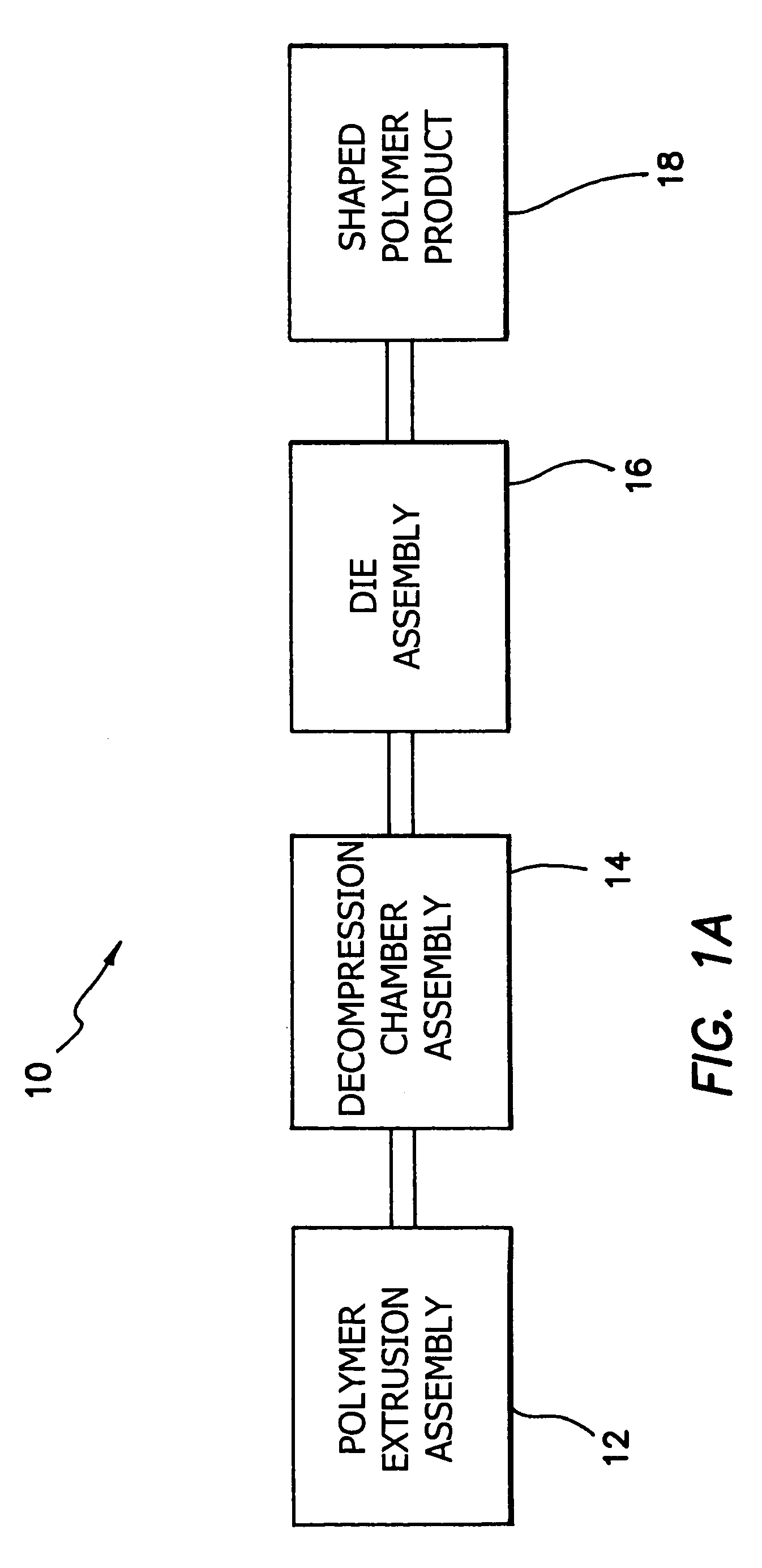

Polymer processing system including compression chamber and method for using same

InactiveUS20060105072A1Efficient extrusionReduce productivityConfectionerySweetmeatsDecompression chamberEngineering

Polymer processing systems are provided including an extrusion assembly, a specially configured decompression chamber assembly, and a die assembly. Such systems are effective to provide shaped polymer products having reduced extrusion markings. Methods of using such systems are also provided.

Owner:EXTRUTECH INT

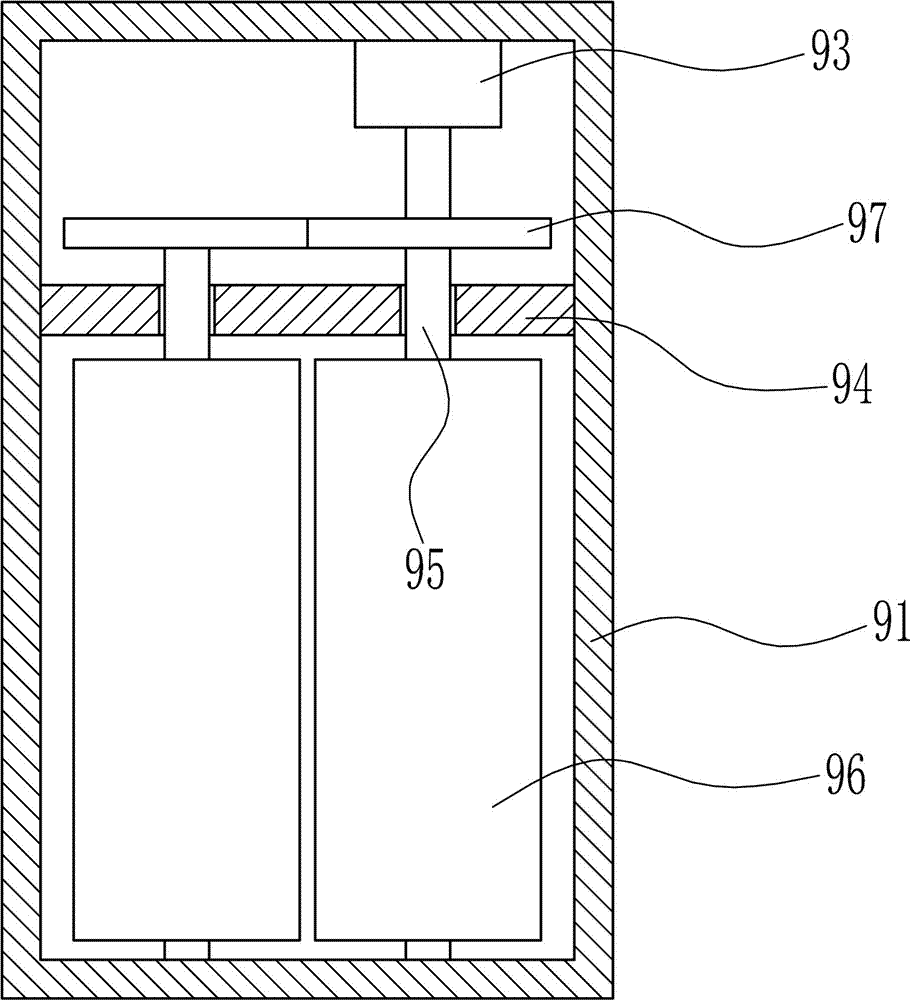

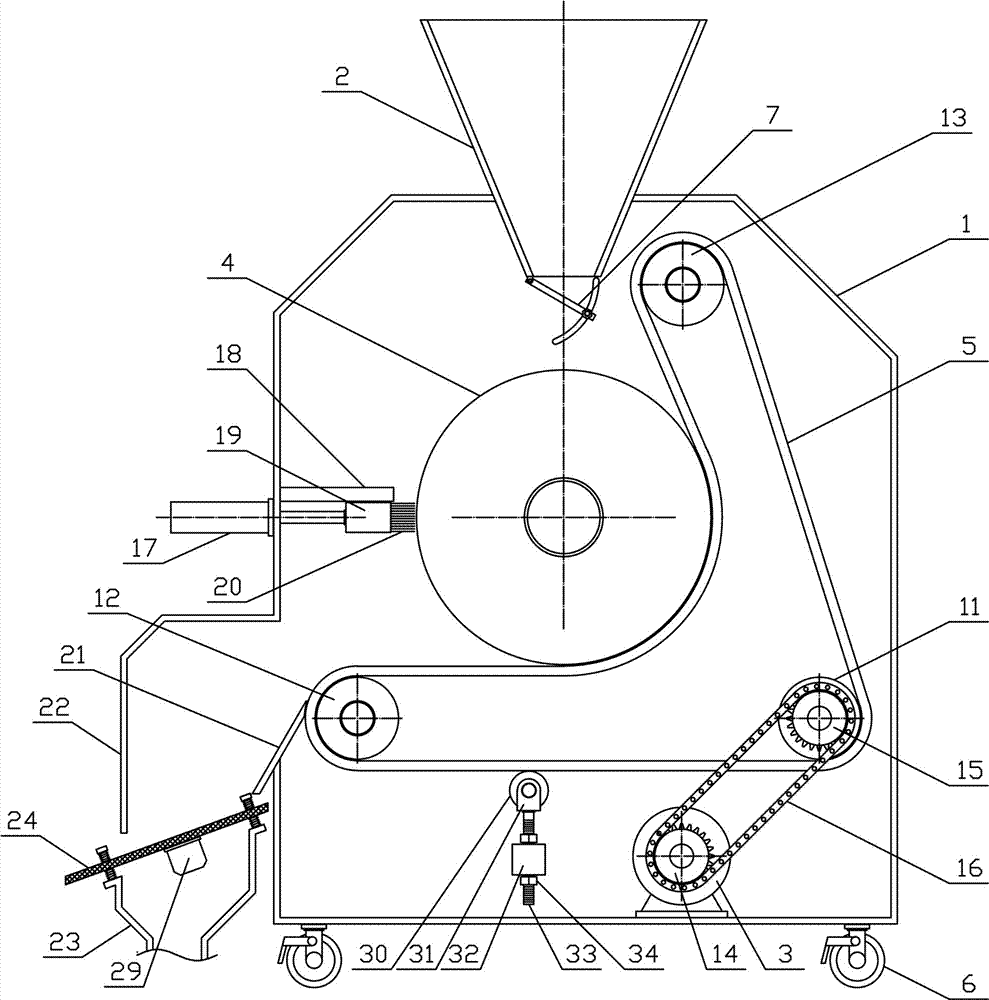

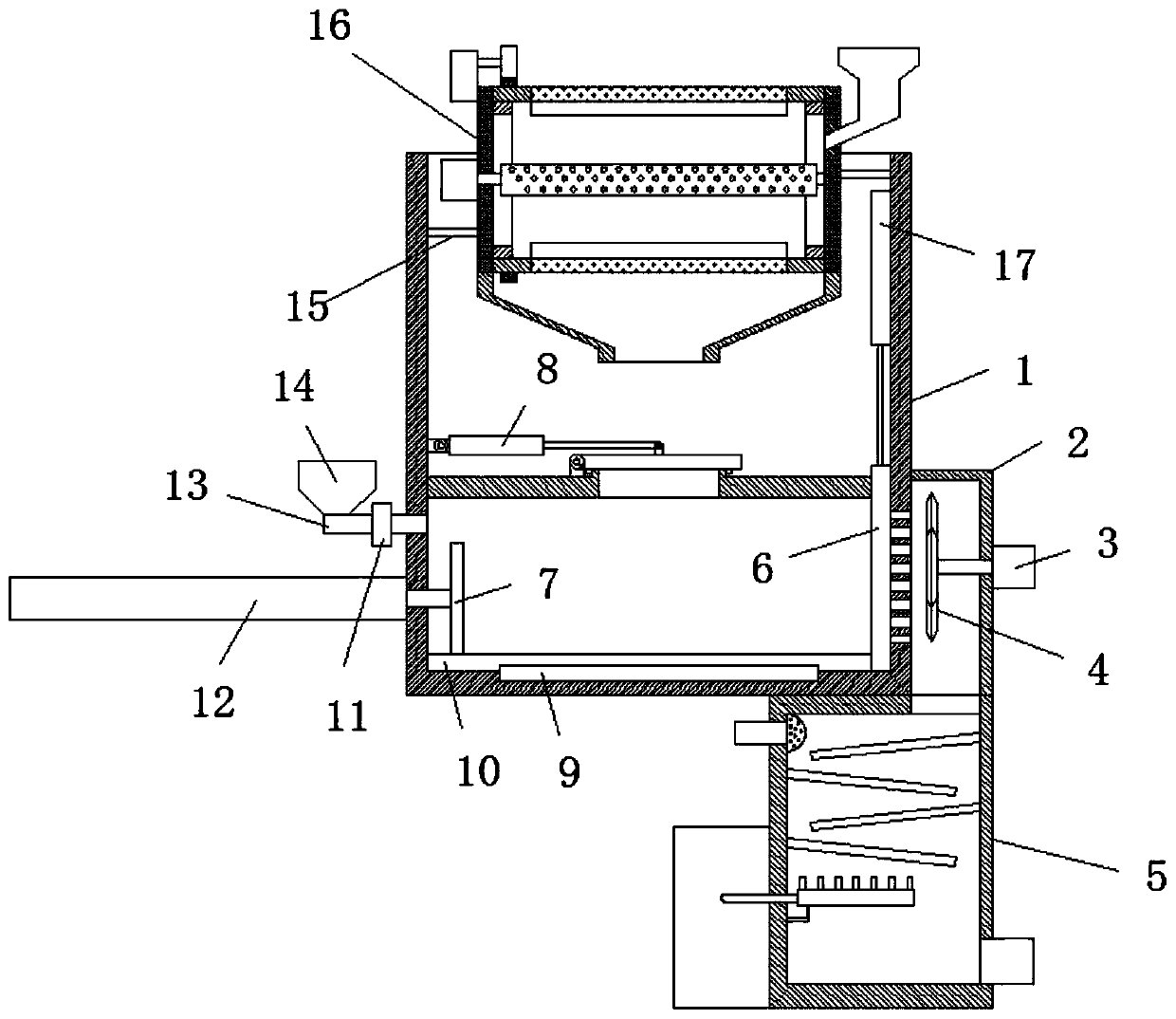

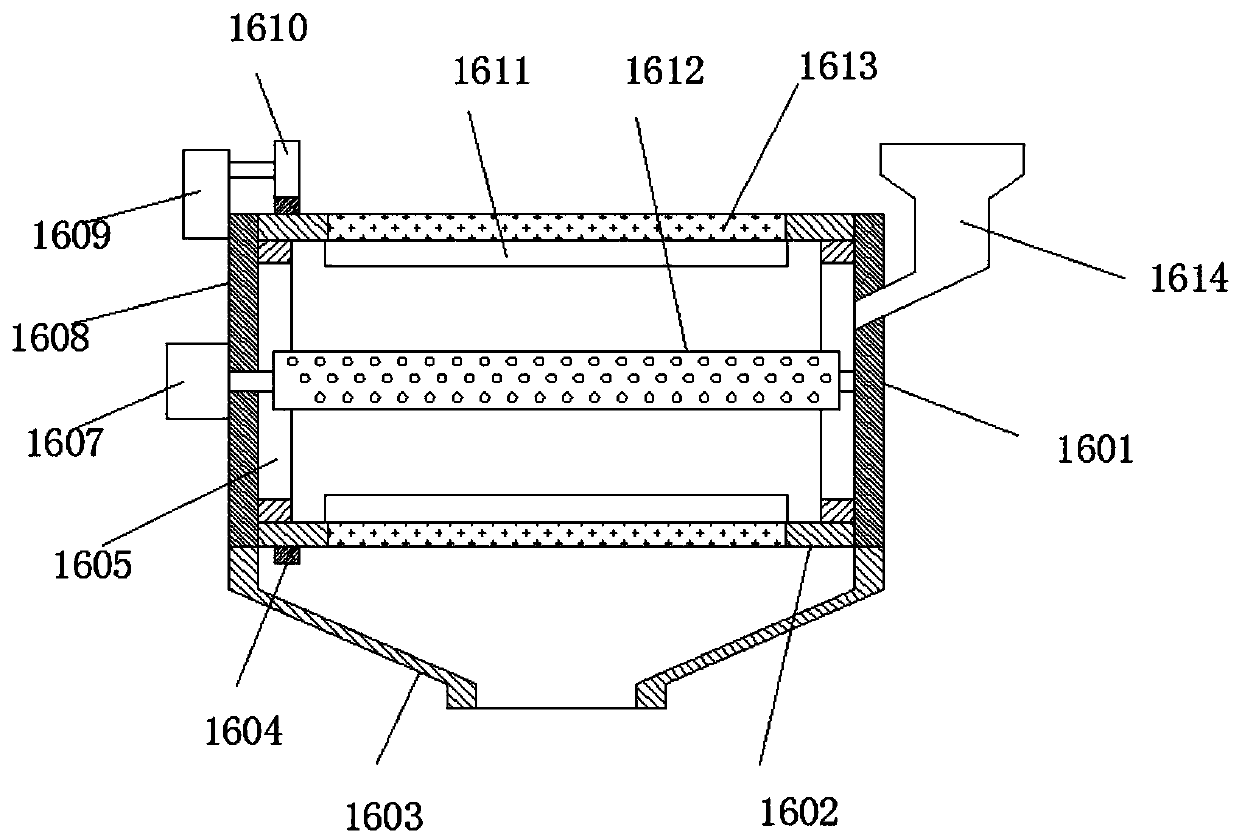

Crushing and compressing device for waste plastic

InactiveCN107379324AEfficient extrusionImprove efficiencyPlastic recyclingGrain treatmentsEngineeringBolt connection

The invention relates to a compressing device, in particular to a crushing and compressing device for waste plastic, and aims at providing the crushing and compressing device with a good compression effect and high efficiency for the waste plastic. In order to achieve the technical purposes above, the crushing and compressing device for the waste plastic comprises a box body and the like, wherein the four corners of the bottom of the box body are connected with supporting legs through bolts, the middle of the left side of the box body is connected with a feeding hopper through bolts, and the feeding hopper is communicated with the box body; the lower portion of the right side of the box body is provided with a material port where a box door is positioned, and the box door is connected to the box body through hinges; the inner upper portion of the box body is provided with a first extrusion device provided with a driving device. According to the crushing and compressing device for the waste plastic, by using the driving device to drive the first extrusion device to run, the waste plastic is crushed by a crushing device, and the first extrusion device and a second extrusion device conduct efficient extrusion on the plastic, so that a great compression effect and high efficiency can be achieved.

Owner:谢思媛

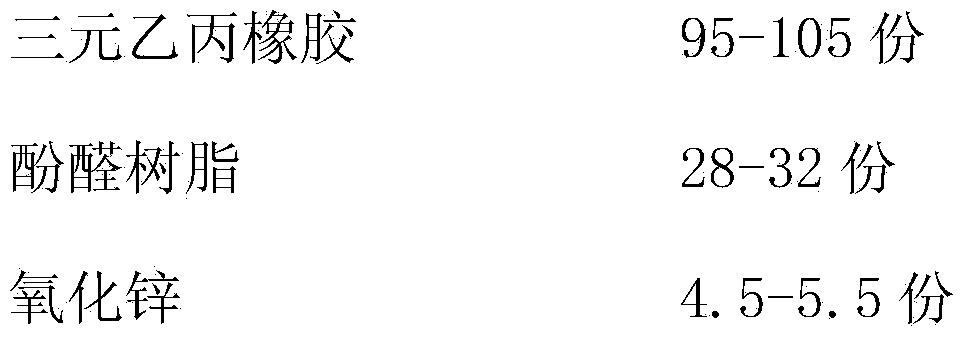

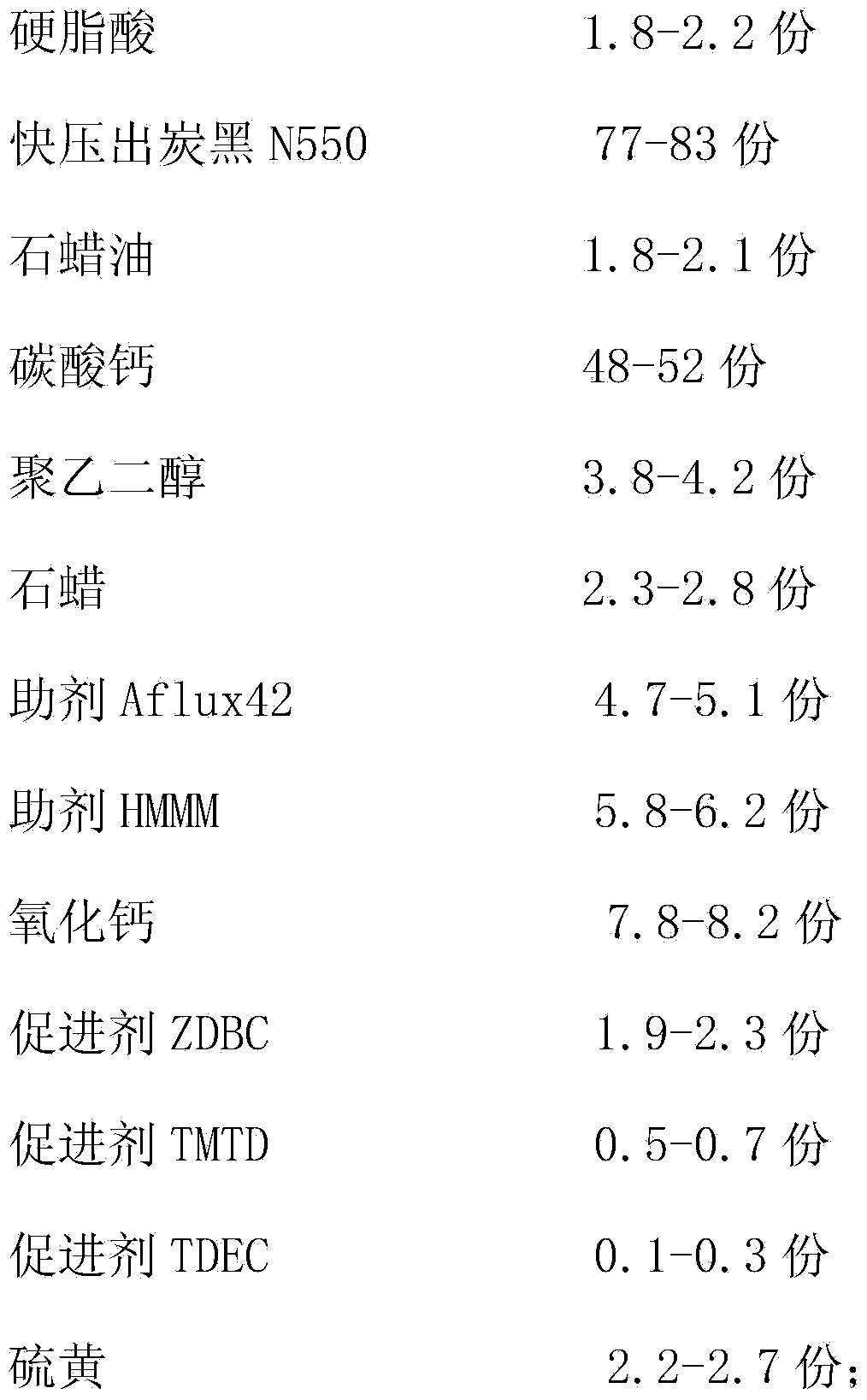

Rubber fastener for automobile air conditioner pipe and manufacturing method of rubber fastener

The invention relates to a rubber fastener for an automobile air conditioner pipe. The rubber fastener comprises a fastener main body and a fastening component, wherein the fastener main body consists of ethylene-propylene-diene-terpolymer rubber, phenolic resin, zinc oxide, stearic acid, fast extruding furnace black N550, paraffin oil, calcium carbonate, polyethylene glycol, paraffin, an aid Aflux42, an aid HMMM (Hexakis (methoxymethyl) melamine), calcium oxide, an accelerant ZDBC, an accelerant TMTD, an accelerant TDEC and sulfur; the fastening component consists of ethylene-propylene-diene-terpolymer rubber, zinc oxide, stearic acid, fast extruding furnace black N550, super-fine calcium carbonate, paraffin oil, calcium oxide, an accelerant EZ, an accelerant CZ, an accelerant Na-22, an accelerant TMTD, an accelerant TDEDC and sulfur. Each part is moderate in hardness, very high in cold resistance, tensile strength and the like and excellent in bonding performance, the situations of cracking, facture and the like are avoided, the service life of a product is prolonged, and the cost is reduced.

Owner:YANGZHONG HONGHUI RUBBER PROD

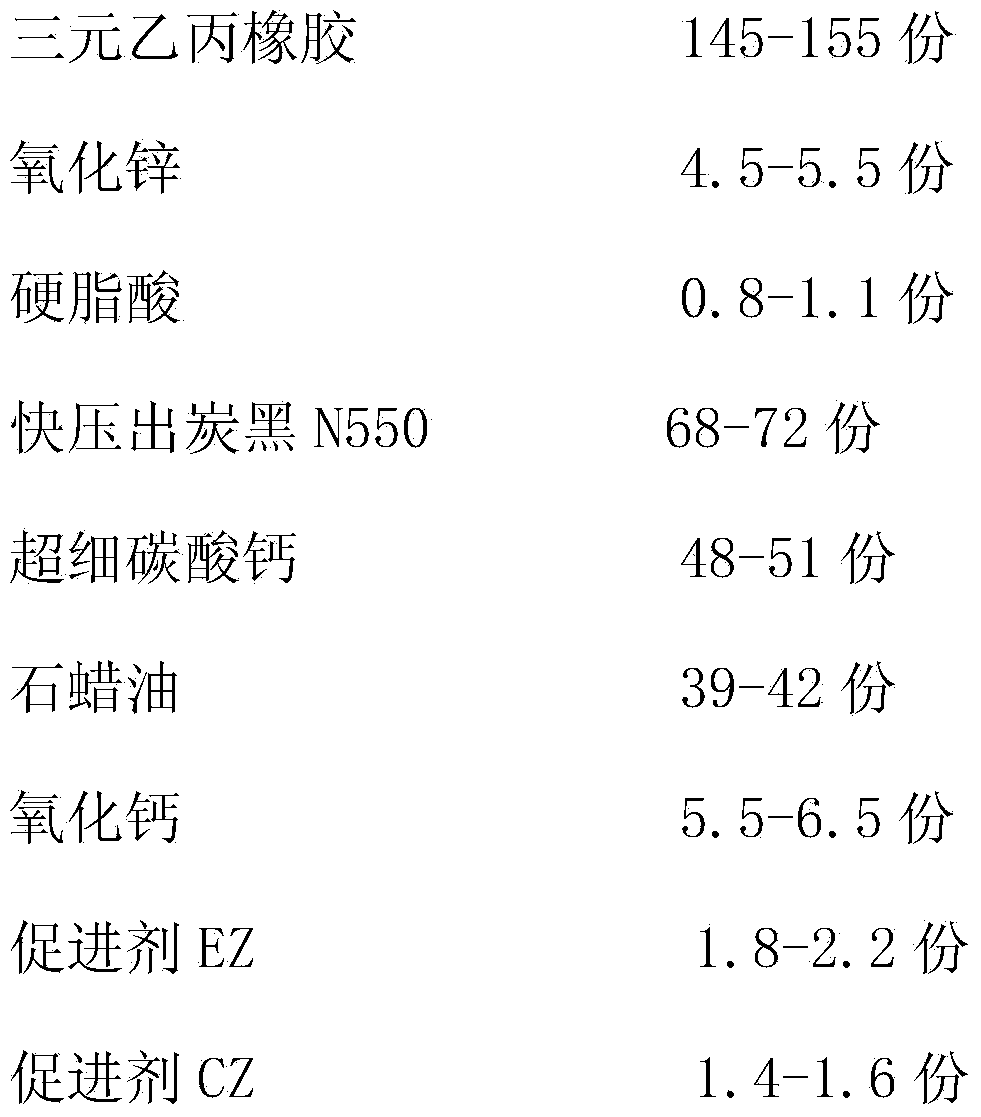

Ultra-low temperature-resistant toughening material for injection molding-grade nylon and preparation method of toughening material

ActiveCN108129757AImprove low temperature resistanceImprove notched impact strengthNylon 6-10Antioxidant

The invention belongs to the field of polymer materials, and particularly relates to an ultra-low temperature-resistant toughening material for injection molding-grade nylon and a preparation method of the toughening material. Raw materials of the ultra-low temperature-resistant toughening material comprise: in parts by weight, 70-80 parts of ethylene-propylene-diene monomer rubber, 20-30 parts ofethylene-octene copolymer, 5-10 parts of dibenzoyl peroxide, 0.5-2 parts of maleic anhydride, 1-5 parts of KT-1, 1-5 parts of carbon nanotubes, 0.05-0.3 part of solid initiator, 0.05-0.3 part of liquid initiator, 0.1-0.5 part of thermal stabilizer, 0.1-0.3 part of antioxidant and 10-20 parts of nylon 6. The prepared nylon toughening agent belongs to injection molding-grade toughening agents, anda step of reaction-extrusion of nylon toughened by a toughening agent is omitted, so that the production cost is saved effectively; secondly, the toughening material can be used in an environment withan ambient temperature of 50 DEG C below zero, so that low-temperature resistance of the toughened nylon is improved effectively, and the notched impact strength of the toughened nylon is improved.

Owner:SHENYANG KETONG PLASTIC

Wind power generation system

ActiveCN104179637AEfficient extrusionImprove power generation efficiencyMachines/enginesWind motor combinationsWind forceAutomotive engineering

The invention discloses a wind power generation system. The problem of the current power generation system that the power generation efficiency is low because an electric generator cannot by effectively extruded and rubbed by wind energy is solved. The wind power generation system comprises a power generation device and an energy-storing device, wherein the power generation device comprises a machine body, a rotating shaft, a wind power driving component, a driving component, a friction electric generator and a suppressing component; the machine body is of semi-closed cylindrical body and comprises a bottom wall and a side wall; the friction electric generator and the suppressing component corresponding to the friction electric generator are fixed to the side wall of the machine body; the friction electric generator and the side wall of the machine body are fixed through a first side surface; the suppressing component extrudes or releases the second side surface of the friction electric generator under the action force of the driving component; the bottom wall of the machine body is moveably connected with the bottom end of the rotating shaft; the top end of the rotating shaft extends from the interior of the machine body; the wind power driving component is fixedly arranged at the top end of the rotating shaft; a first end of the driving component is a fixed end fixedly arranged on the middle part of the rotating shaft; a second end of the driving component is a free end.

Owner:NEWNAGY TANGSHAN

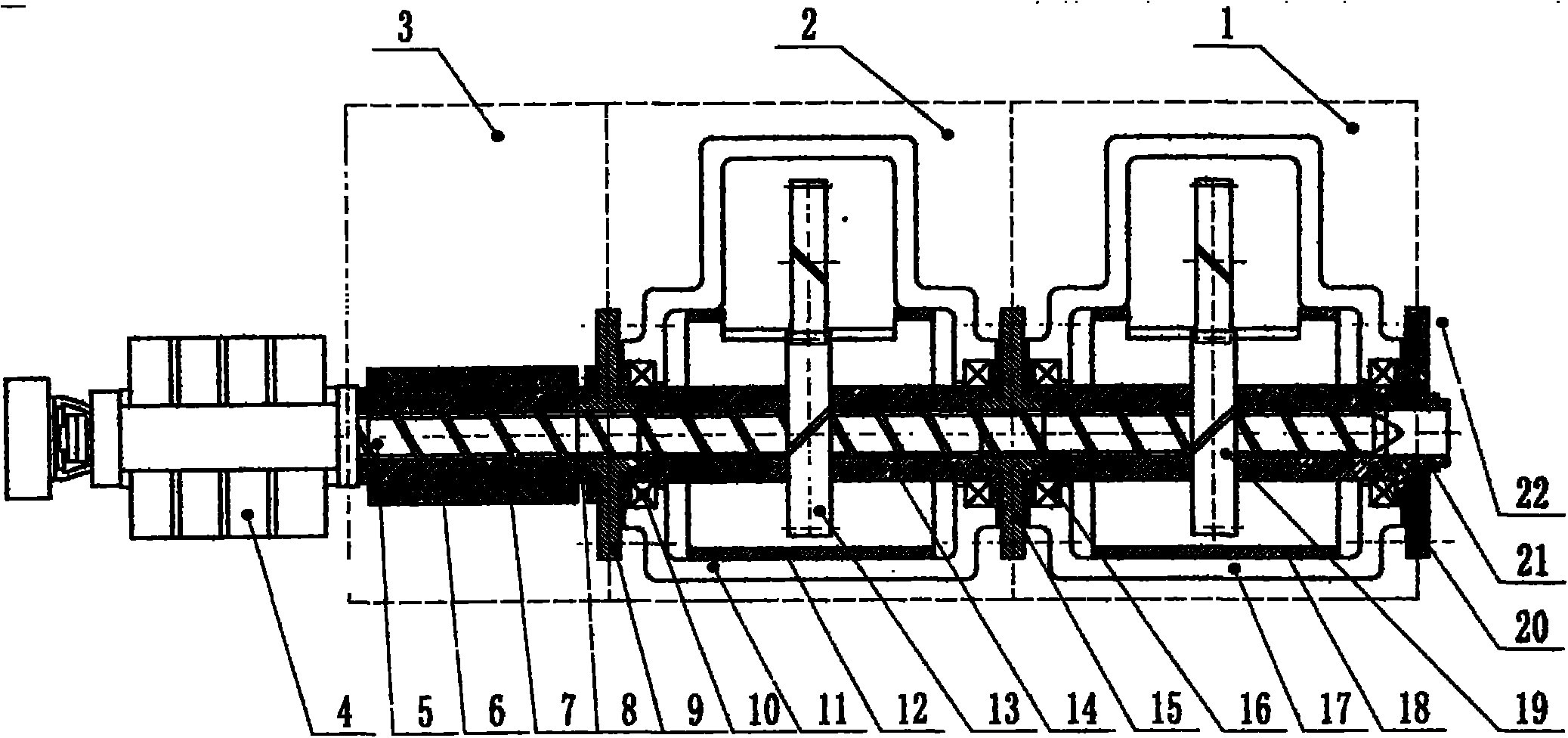

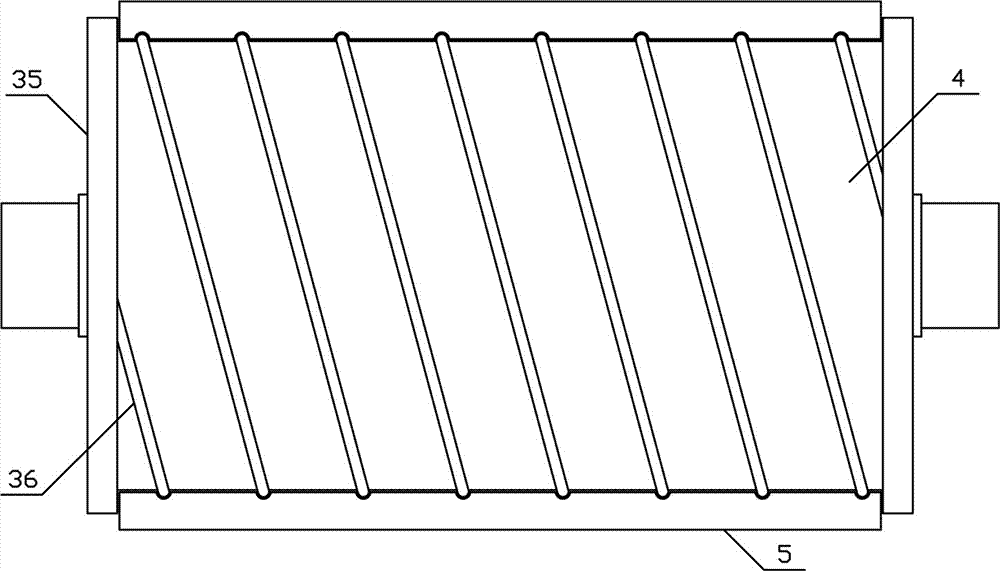

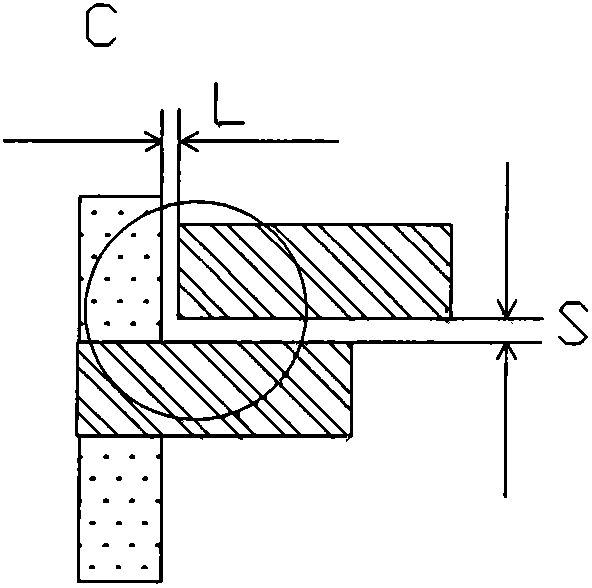

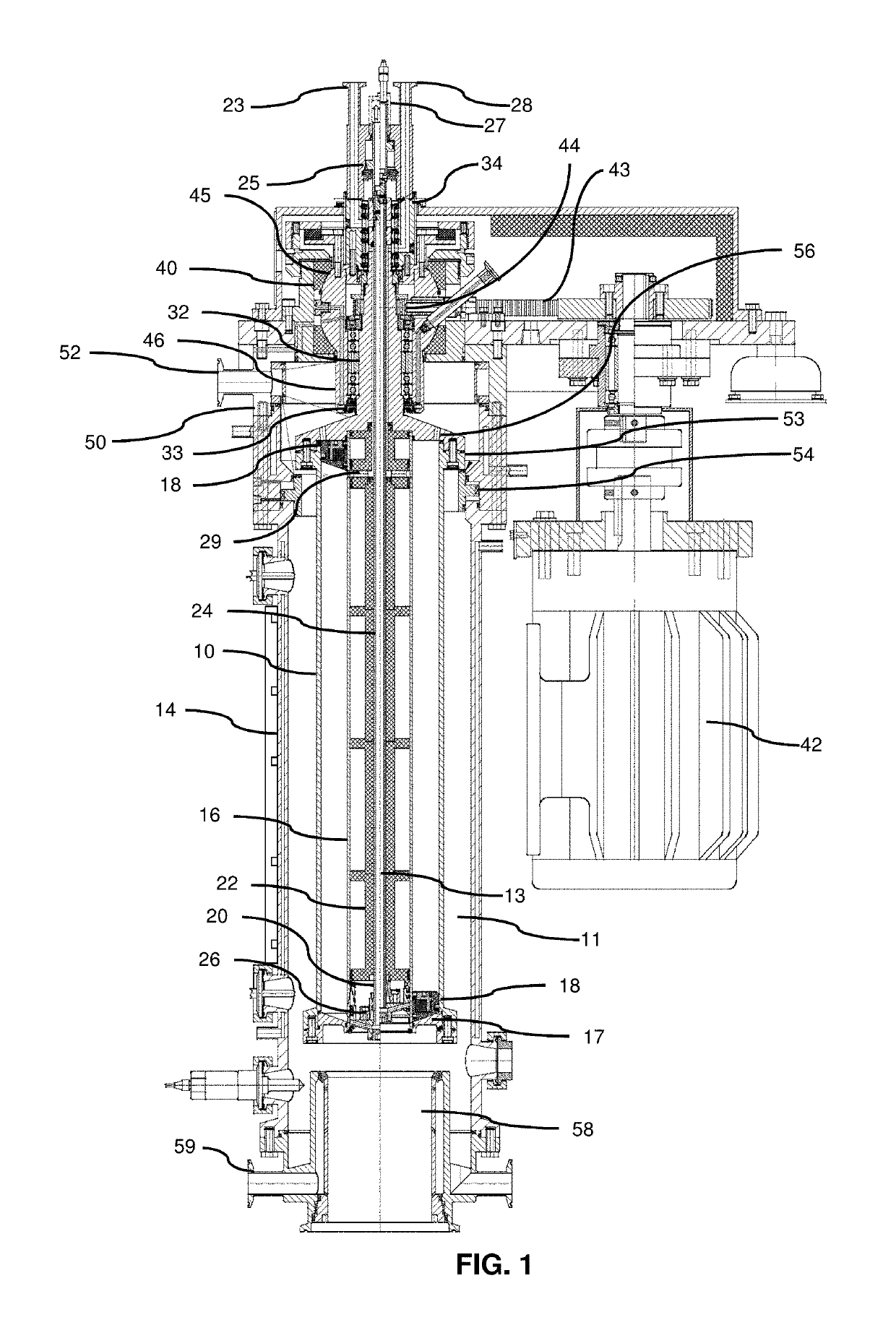

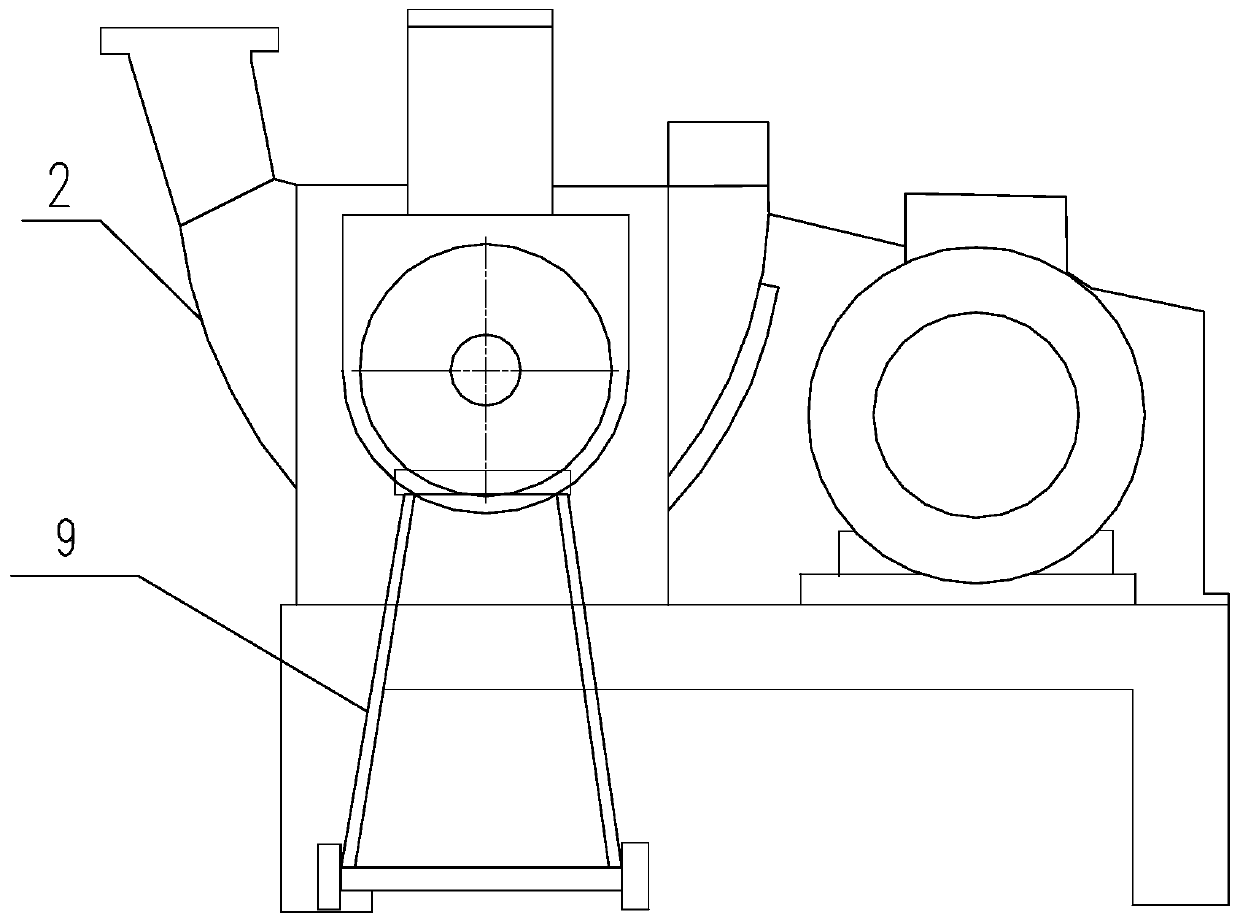

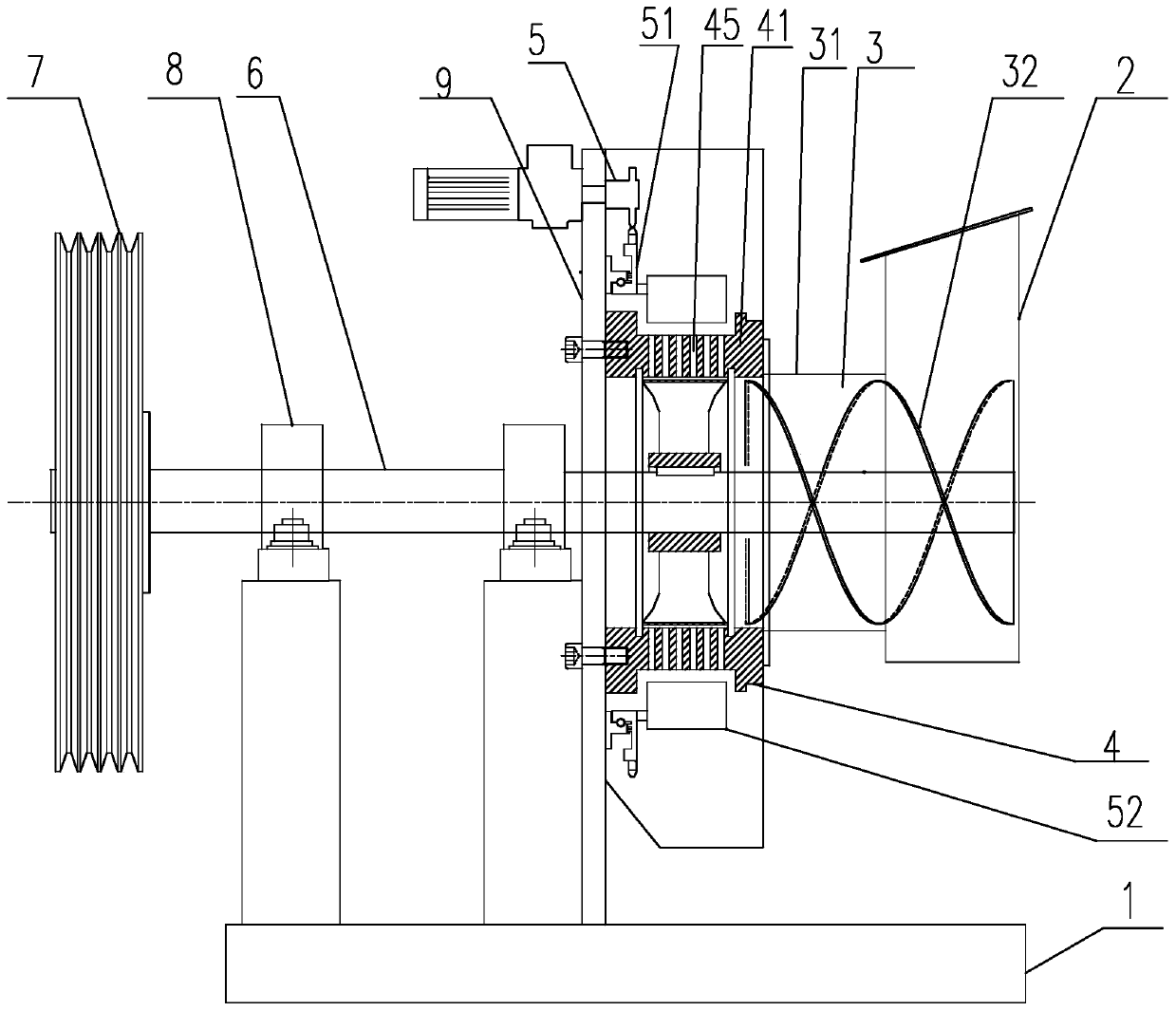

Efficient plasticizing single-screw extruder

The invention discloses an efficient plasticizing single-screw extruder, which is composed of a solid conveying section cylinder (6), a rotatable melting section cylinder (14), a rotatable melt conveying section cylinder (20), a screw (5), a screw transmission system (4), a melting section cylinder transmission system (13), a melt conveying section cylinder transmission system (19), a solid conveying section heating and temperature measuring device (7), a melting section heating and temperature measuring device (12) and a melt conveying section heating and temperature measuring device (18). At a certain screw rotating speed, the shearing speed of the material at the melting section is increased by adjusting the rotating speed of the rotatable melting section cylinder so as to adjust the material melting efficiency; the shearing speed of the material at the melt conveying section is increased by adjusting the rotating speed of the rotatable melt conveying section cylinder so as to adjust the material mixing efficiency, thus realizing coordination and unification of the solid conveying efficiency, the melting efficiency and the melt mixing conveying efficiency and further realizing high speed and efficient plasticization of polymers.

Owner:XINJIANG INST OF ENG +1

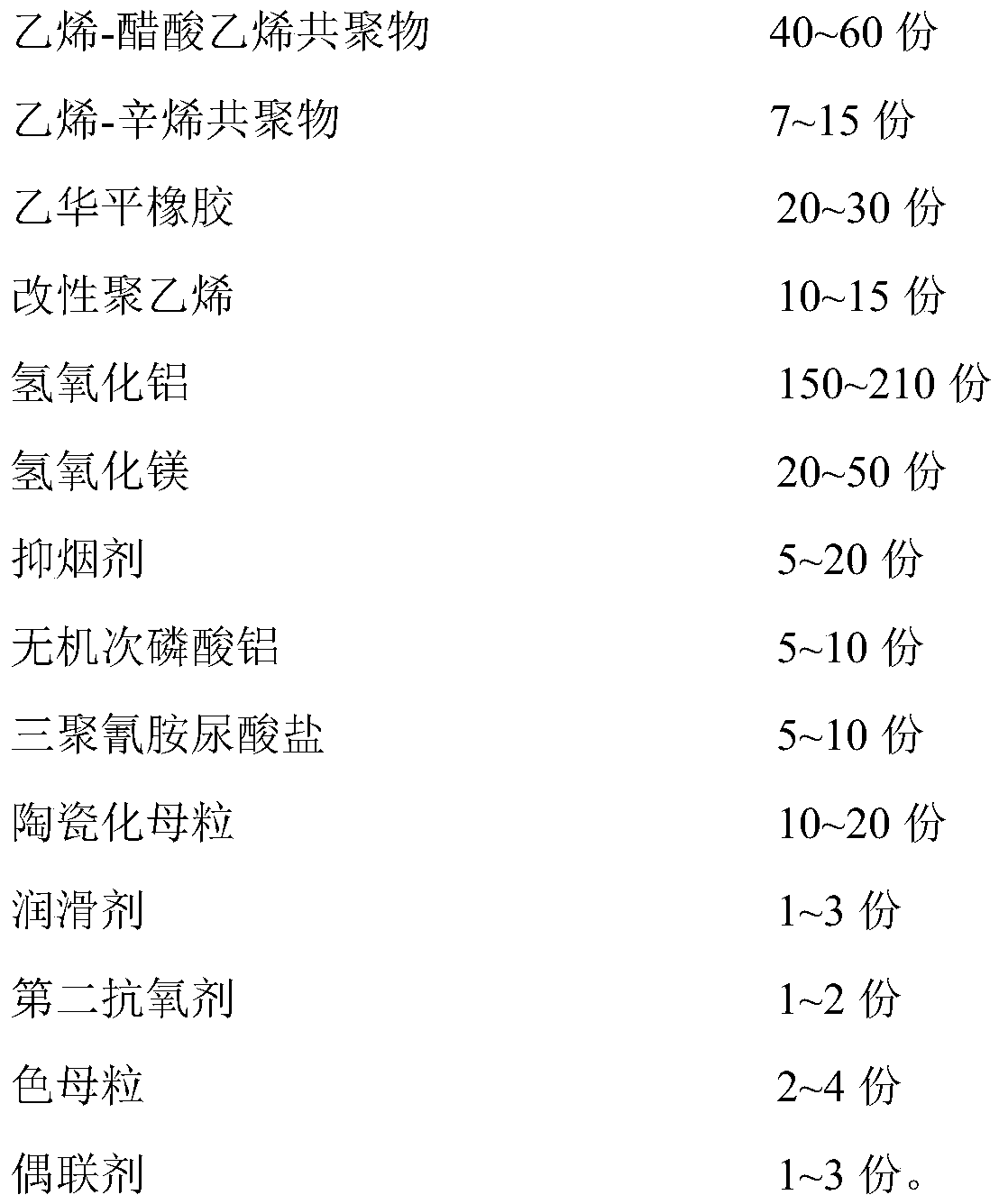

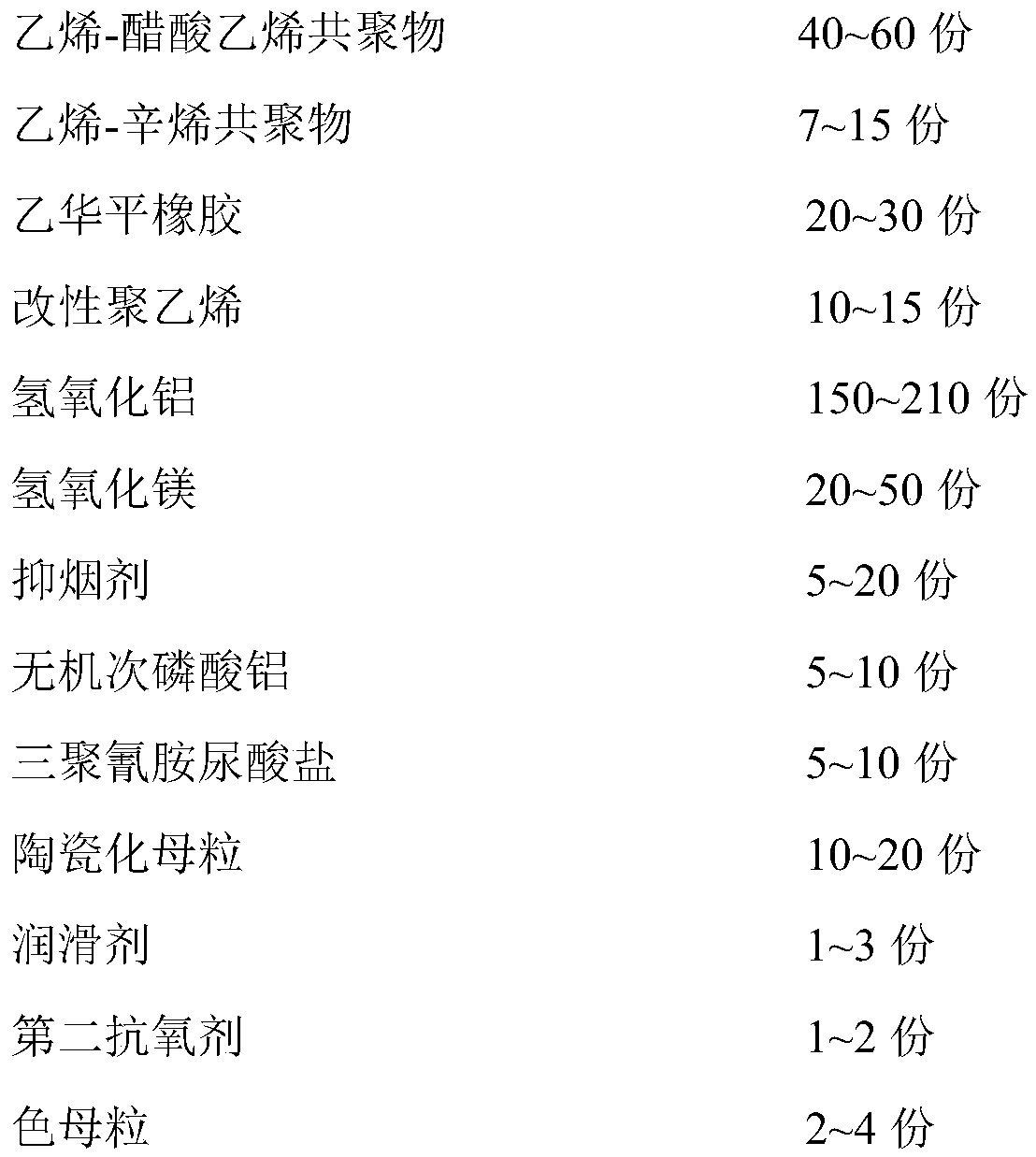

Low-smoke zero-halogen flame-retardant polyolefin oxygen barrier material

The invention relates to a low-smoke zero-halogen flame-retardant polyolefin oxygen barrier material with low heat release and high coking property, which comprises Levapren rubber and a ceramic master batch. The VA content of the Levapren rubber is greater than or equal to 50%, and at 100 DEG C, the mooney viscosity of the Levapren rubber is 20-30; based on the total weight of the ceramic masterbatch, the ceramic master batch comprises the following components in percentage by mass: 40-60% of ceramic powder, 40-60% of polyethylene resin, 0.1-0.3% of first antioxidant, 0.1-0.5% of polyethylene wax and 0.2-0.6% of silicone powder. The polyolefin oxygen barrier material disclosed in the invention has low heat release property, high coking property and excellent extrusion machinability.

Owner:中广核高新核材科技(苏州)有限公司

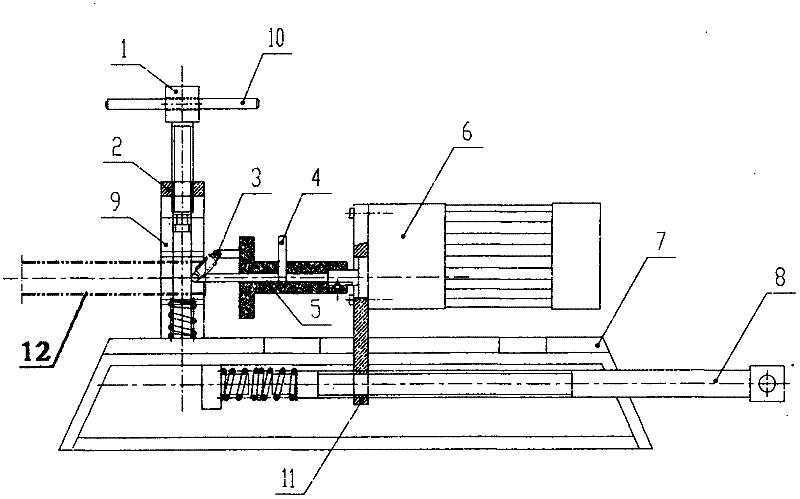

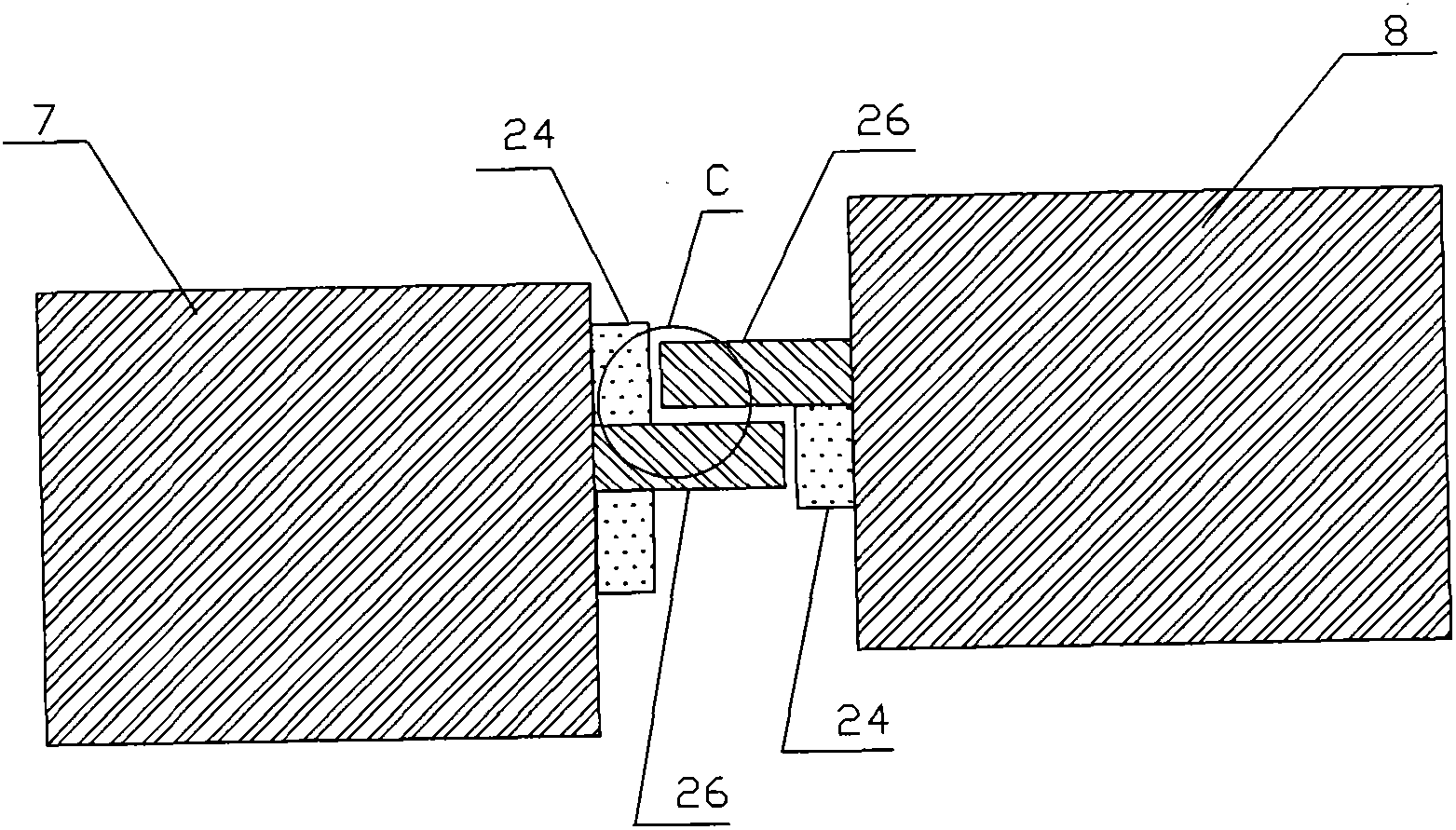

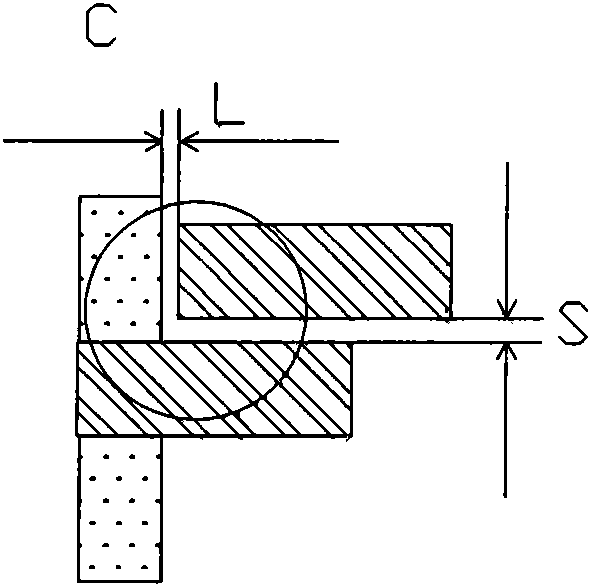

Electric flanging machine for steel pipes

The invention discloses an electric flanging machine for steel pipes. The invention aims to provide the electric flanging machine for the steel pipes for replacing manual flanging operation. The electric flanging machine comprises a lead screw, an adjusting rod with a roller and a base. The electric flanging machine is characterized in that: A, one end of the lead screw passes through a lead screw rack and is connected with a clamping block, and the other end of the lead screw is connected with a lead screw spanner; B, one end of the adjusting rod with the roller is connected with a motor, and the other end of the adjusting rod is positioned on the lateral surface of the lead screw; and C, a motor lead screw is arranged in the base, the motor lead screw is in threaded connection with a sliding seat, and the edge of the sliding seat is arranged in a chute of the base and can move along the chute. The electric flanging machine is mainly applied to steel pipe flanging.

Owner:汪涛

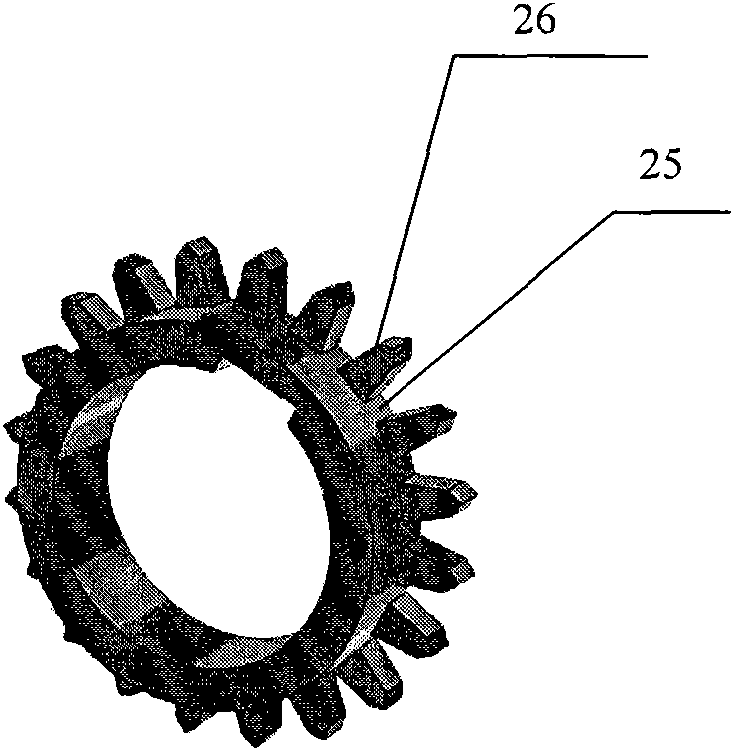

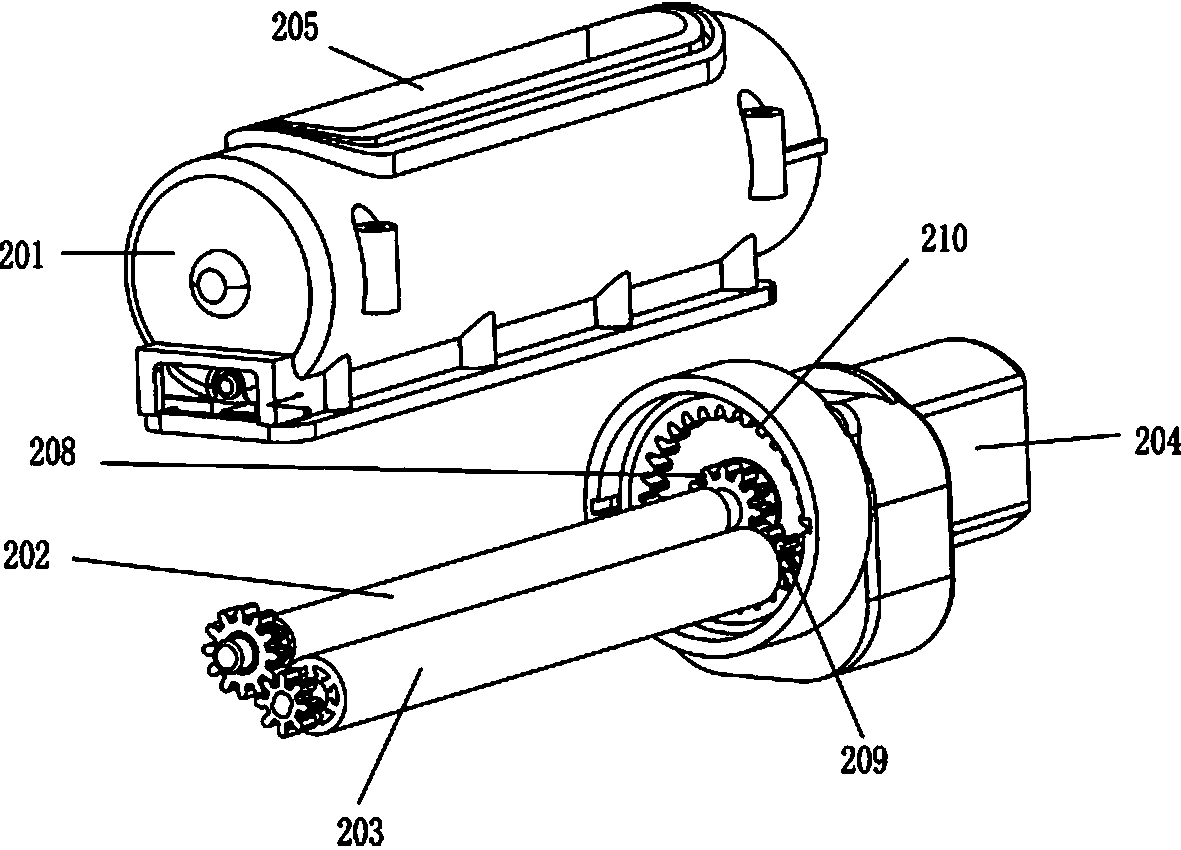

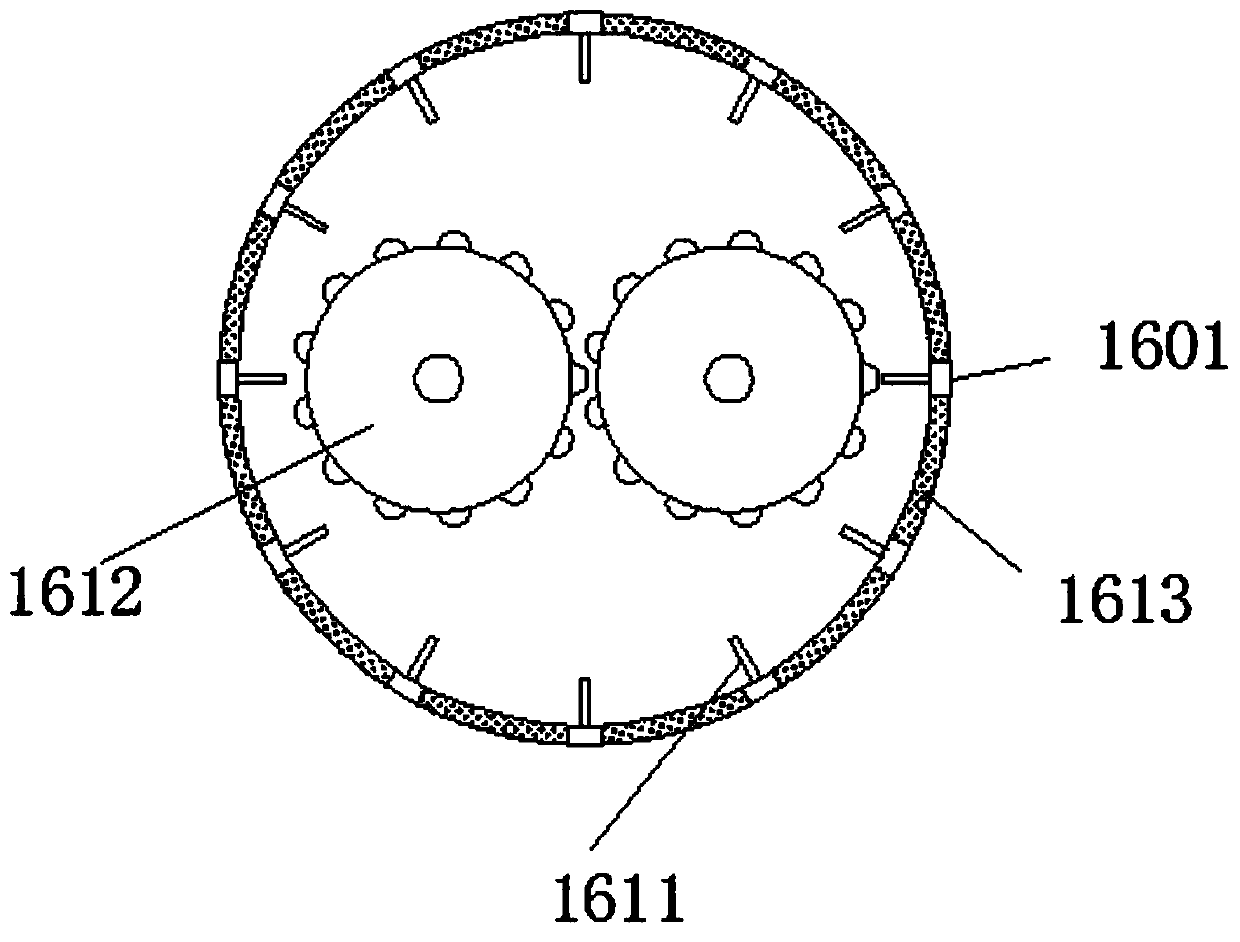

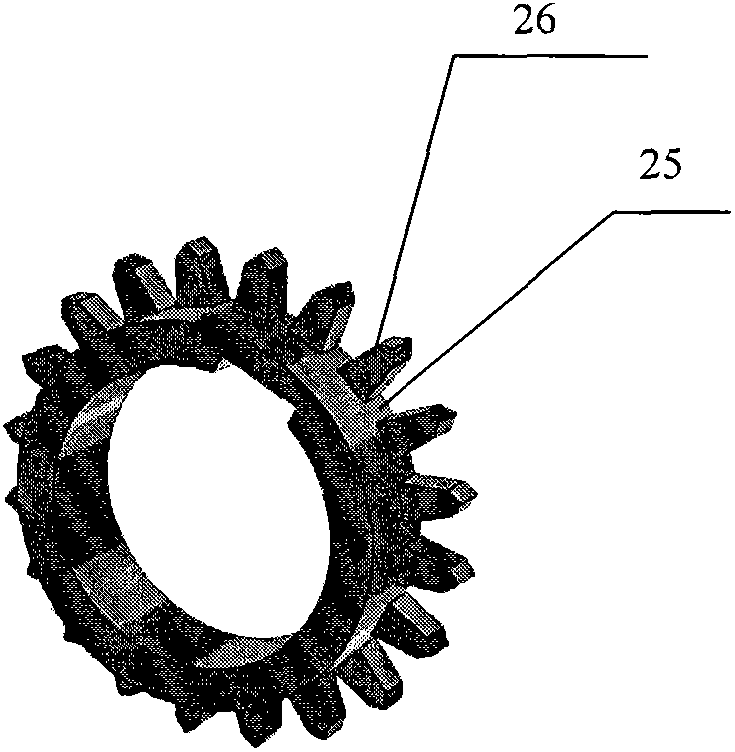

Grinding gear, grinding device and grinder

The invention belongs to the mechanical field and relates to a grinding or crushing device, in particular to a grinding gear, a grinding device and a grinder. The end part of the teeth on the existing grinding gear is generally a plane or cambered surface which is not good for grinding materials. In order to solve the defect of the prior art, the invention provides a grinding gear which comprises a gear ring, wherein gear teeth are arranged on the gear ring, and the top end of each gear tooth is of a sharp blade shape. The grinding gear can effectively stab or puncture and shear materials. The invention also provides a grinding device which comprises the grinding gear. The invention also provides a grinder which comprises the grinding device. Through the grinding gear, grinding device and grinder provided by the invention, the materials can be effectively ground.

Owner:邢征

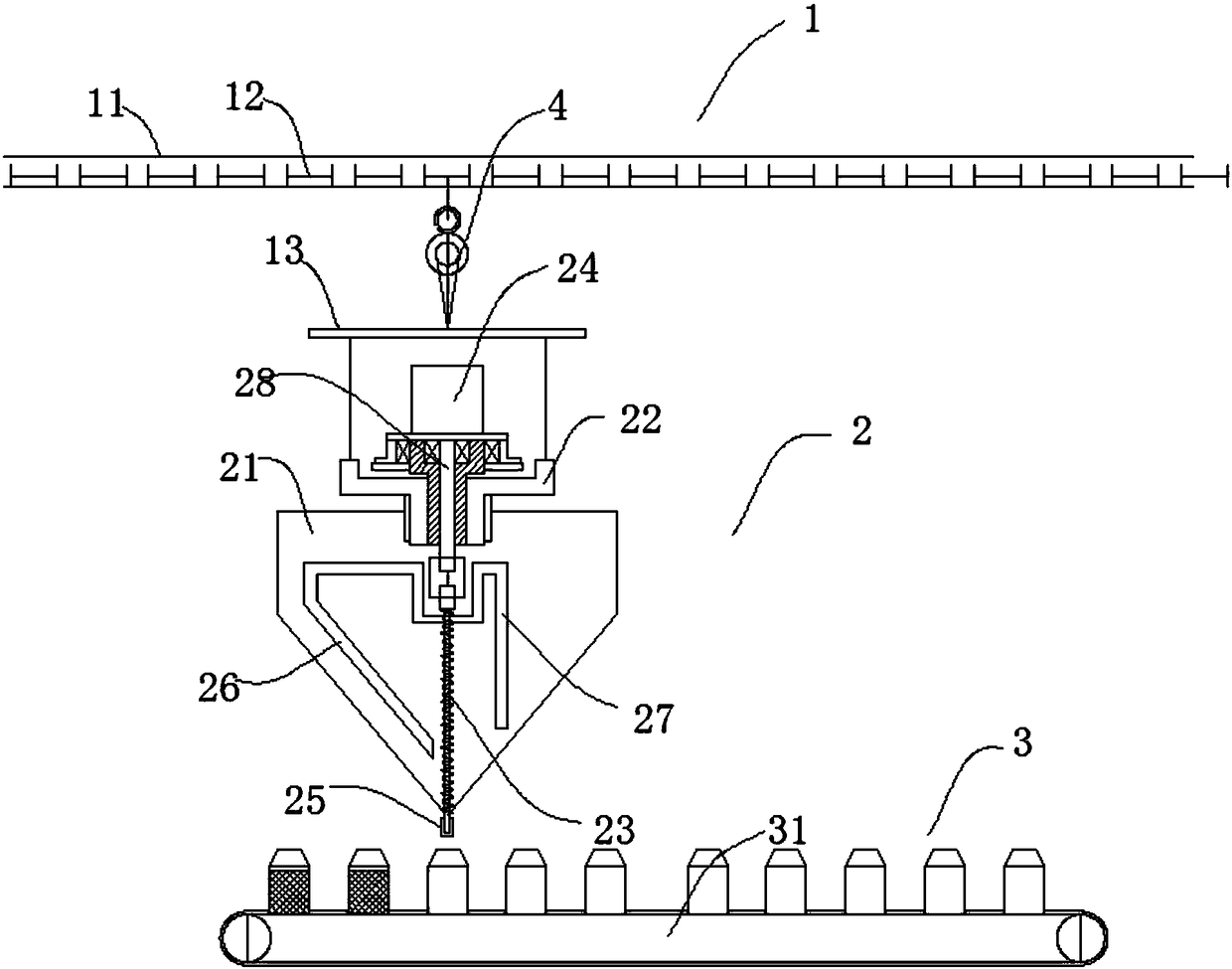

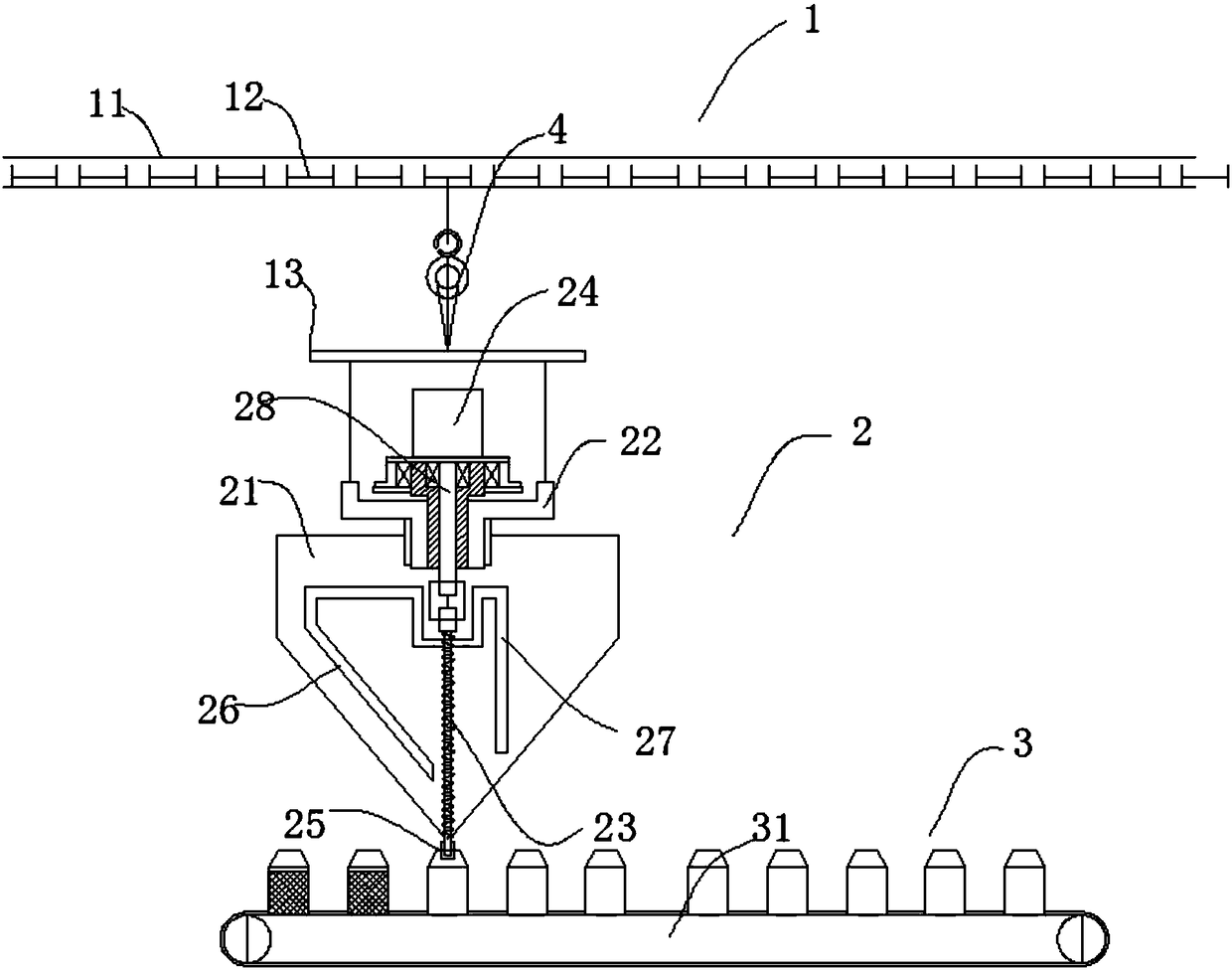

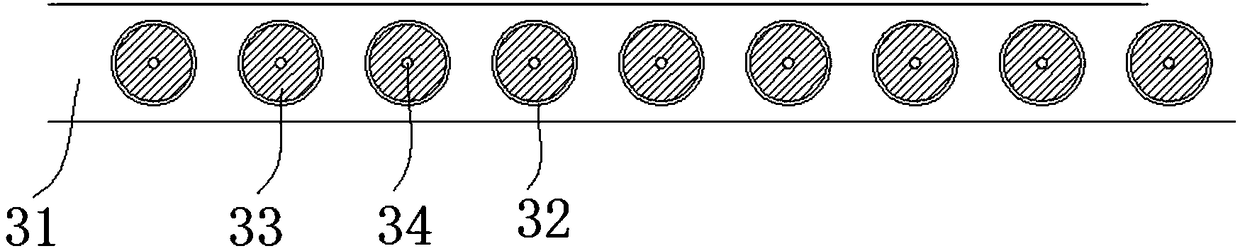

Filling device for chilli sauce

PendingCN108190067AEfficient mixing and extrusionEfficient mixingLiquid materialEngineeringAssembly line

The invention provides a filling device for a chilli sauce, and relates to the field of filling equipment. The filling device comprises a support, a filling device body and an assembly line, wherein the filling device body is arranged on the support, and the assembly line is located below the filling device body; the support comprises a support body, a chain and a plurality of hangers, wherein thechain is arranged on the support and is driven by a driving mechanism, and the hangers are hung on the chain; the filling device body comprises a funnel-shaped material barrel, a sleeve, a discharging screw and a first motor, wherein the first motor is used for driving the discharging screw to rotate; and the assembly line comprises a conveyor belt and an external motor, wherein the conveyor beltis driven by the external motor to rotate and is located below the filling device body. The filling device has the advantages that the structural design is reasonable, the efficiency of the filling assembly line can be greatly improved, and the chilli sauce can be prevented from being contaminated in the filling process.

Owner:淮北顶大调味品有限公司

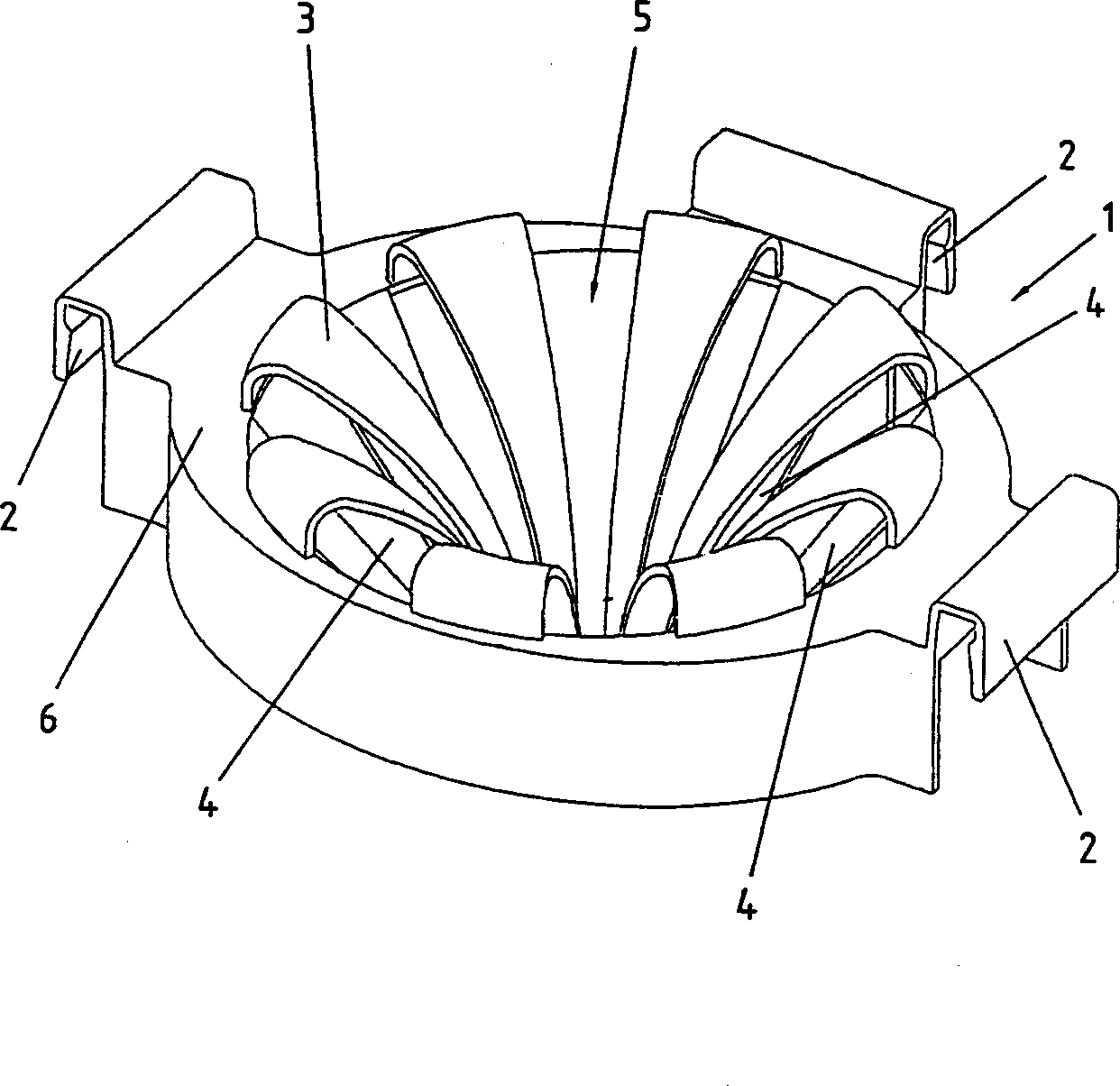

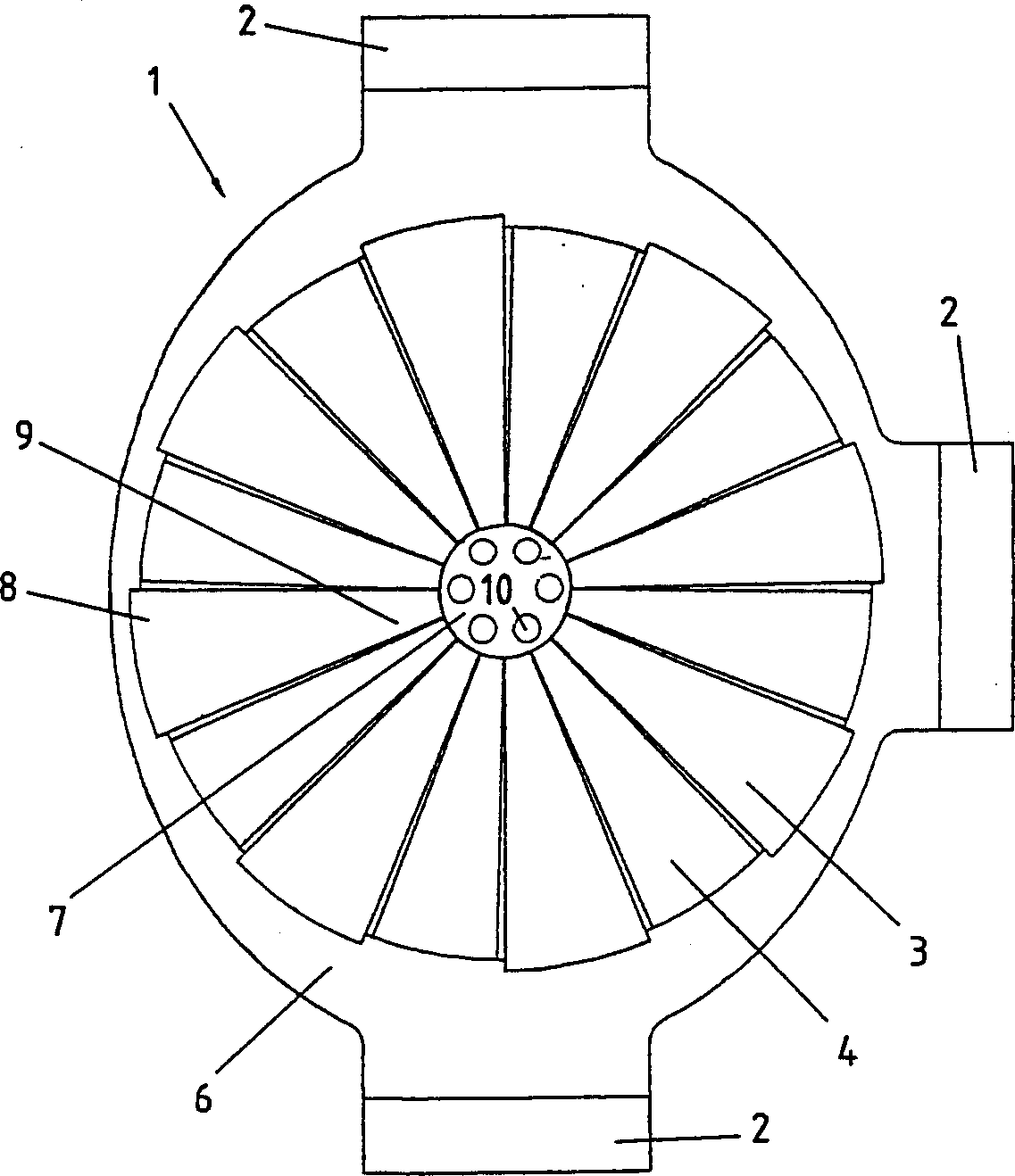

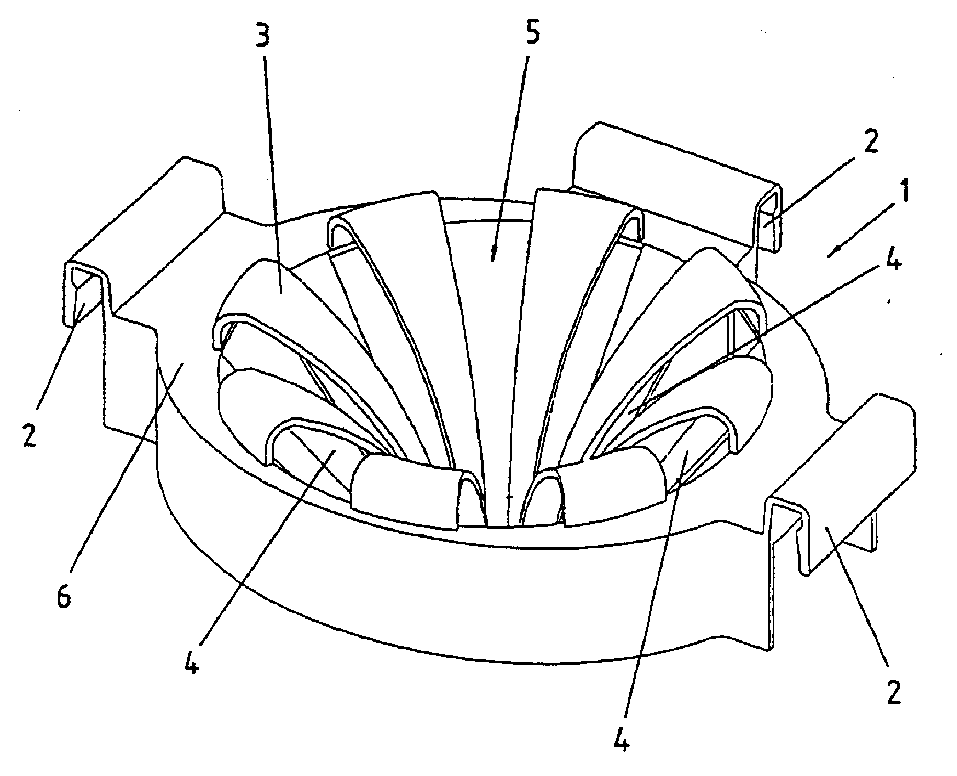

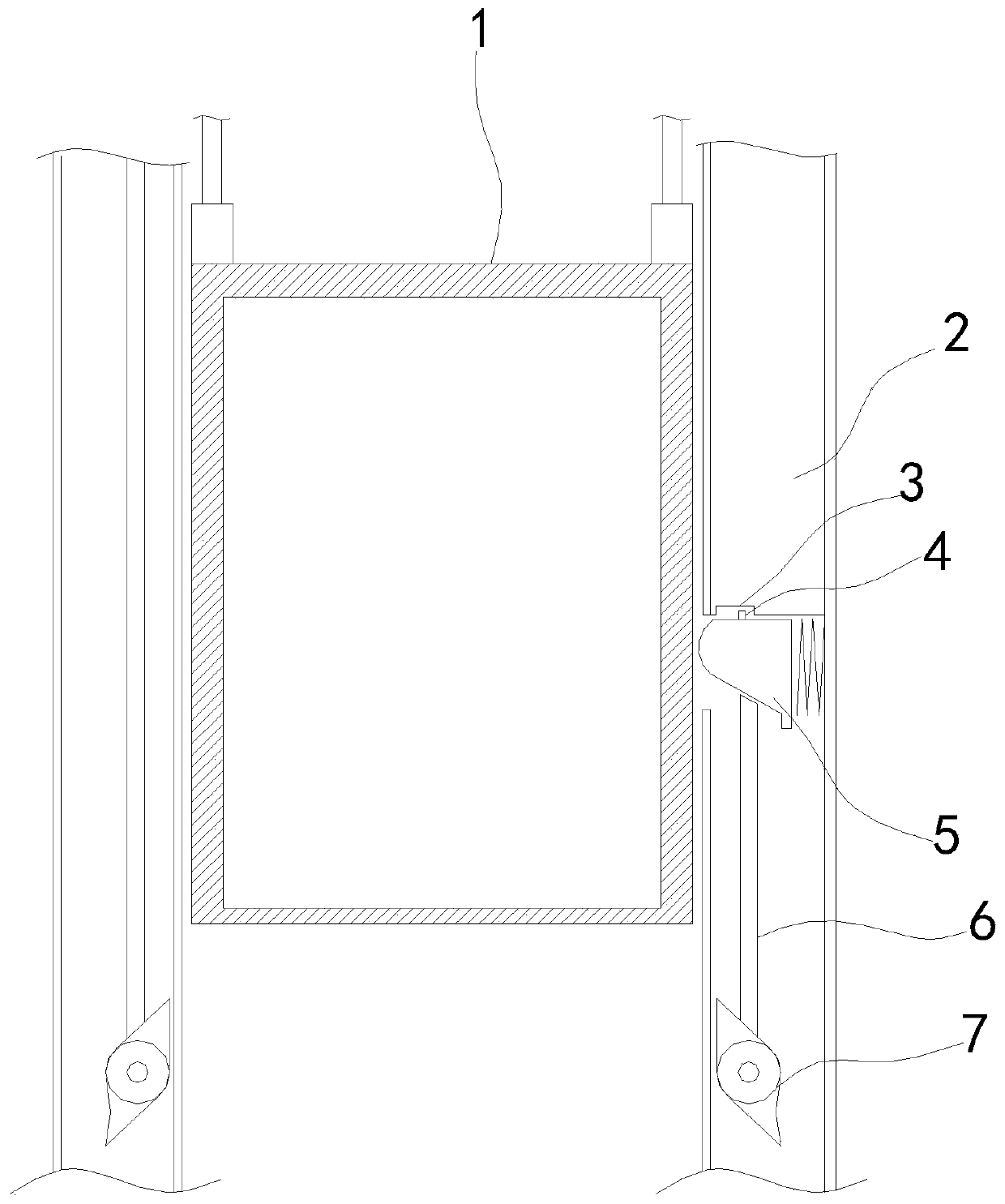

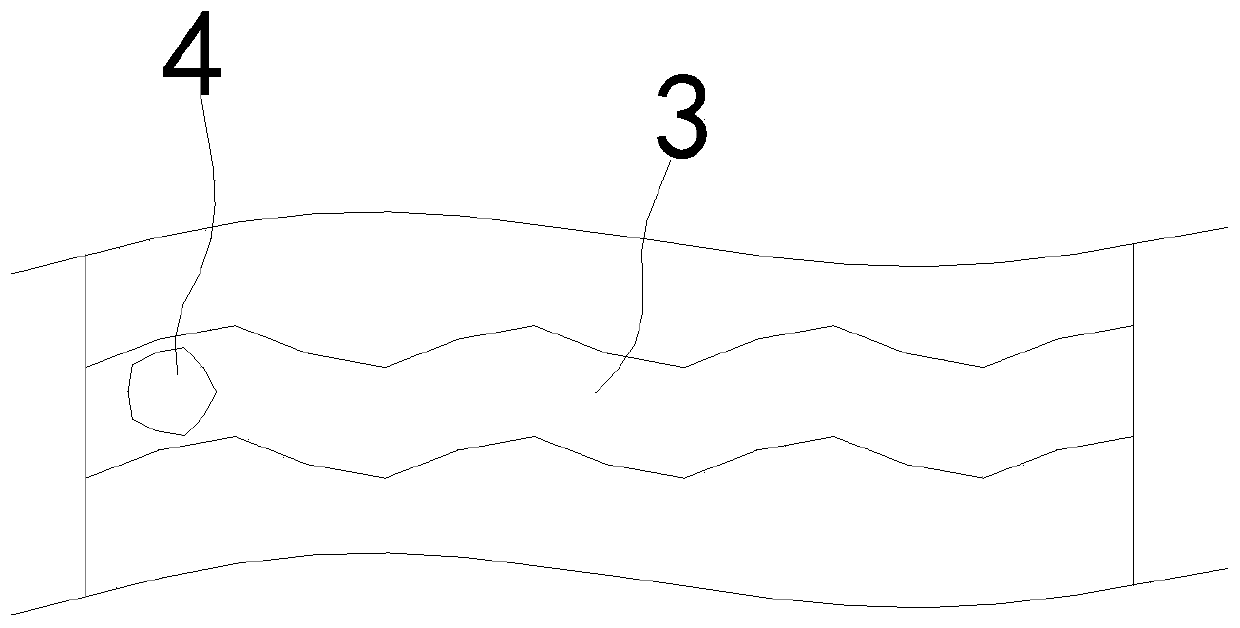

Wring-out device for cleaning element for wetting and moisting cleaning tool

InactiveCN1343478AEffective wring resultEasy to wringCarpet cleanersFloor cleanersConvex sideEngineering

A wringing device for cleaning elements of wet and moist mops, the wringing device having a liquid-permeable receptacle (1) which can be affixed to a container, and in which a cleaning element can be wrung out by the exertion of pressure, the receptacle having deformable wall parts (3) and the inside width of the receptacle changing when the cleaning element is pressed in due to the effective force of pressure, wall parts being formed from spring elements (3) with convex curvature, which can be deformed by exertion of pressure for the purpose of enlarging the inside width.

Owner:CARL FREUDENBERG KG

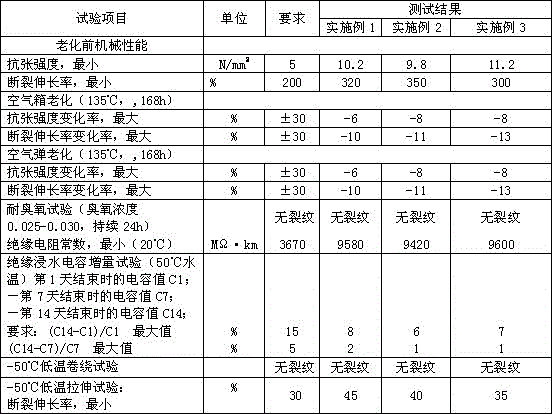

Ethylene propylene rubber insulation material for charging pile cables and preparation method of ethylene propylene rubber insulation material for charging pile cables

ActiveCN106317654AIncrease elasticityImprove low temperature resistanceRubber insulatorsInsulated cablesHigh resistanceMicrocrystalline wax

The invention discloses an ethylene propylene rubber insulation material for charging pile cables. The ethylene propylene rubber insulation material comprises 100 parts of ethylene-propylene-diene monomer, 2.8-3.5 parts of dicumyl peroxide, 1-1.5 parts of triallyl isocyanurate, 5-8 parts of zinc oxide, 80-120 parts of surface-modified calcined potter's clay, 30-50 parts of talcum powder, 1.2-2 parts of 2-mercaptobenzimidazole, 0.5-1 part of poly(1,2-dihydro-2,2,4-trimethylquinoline), 0.3-0.5 part of pentaerythritol-tetra-[beta-(3,5-di-tert-butyl-4-hydroxyphenyl)-propionate], 5-8 parts of microcrystalline wax, 8-12 parts of paraffin oil, 0.5-0.8 part of stearic acid and 1-2 parts of vinyl-tris(b-methoxyethoxy)silane. The invention further discloses a preparation method of the ethylene propylene rubber insulation material for the charging pile cables. The ethylene propylene rubber insulation material has the advantages of high insulation resistance, excellent physical mechanical performance and high resistance to ozone aging, thermo-oxidative aging, high temperature and low temperature and conforms to the 2PGF 1908 / 05.12 standards.

Owner:FUJIAN NANPING SUN CABLE

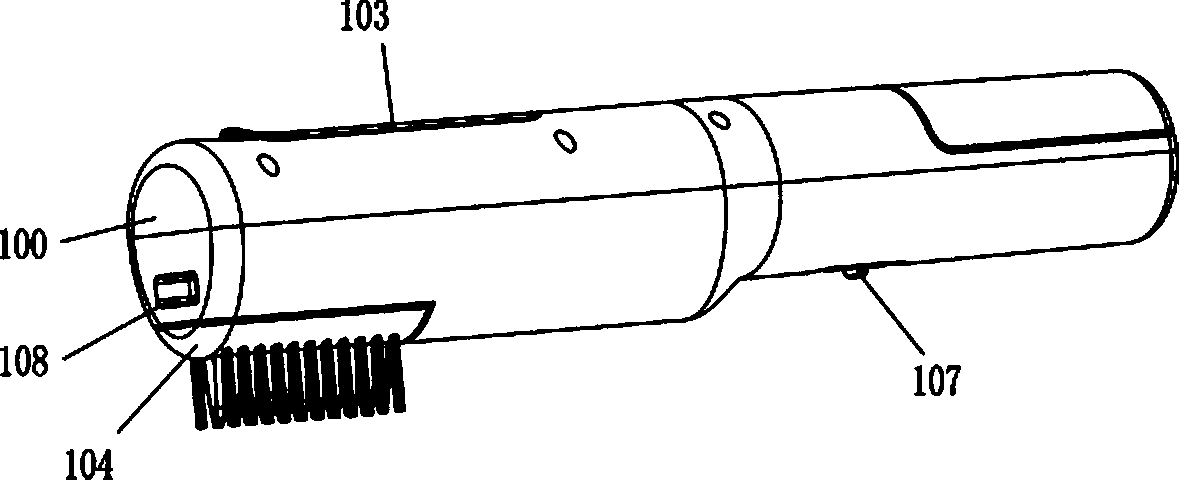

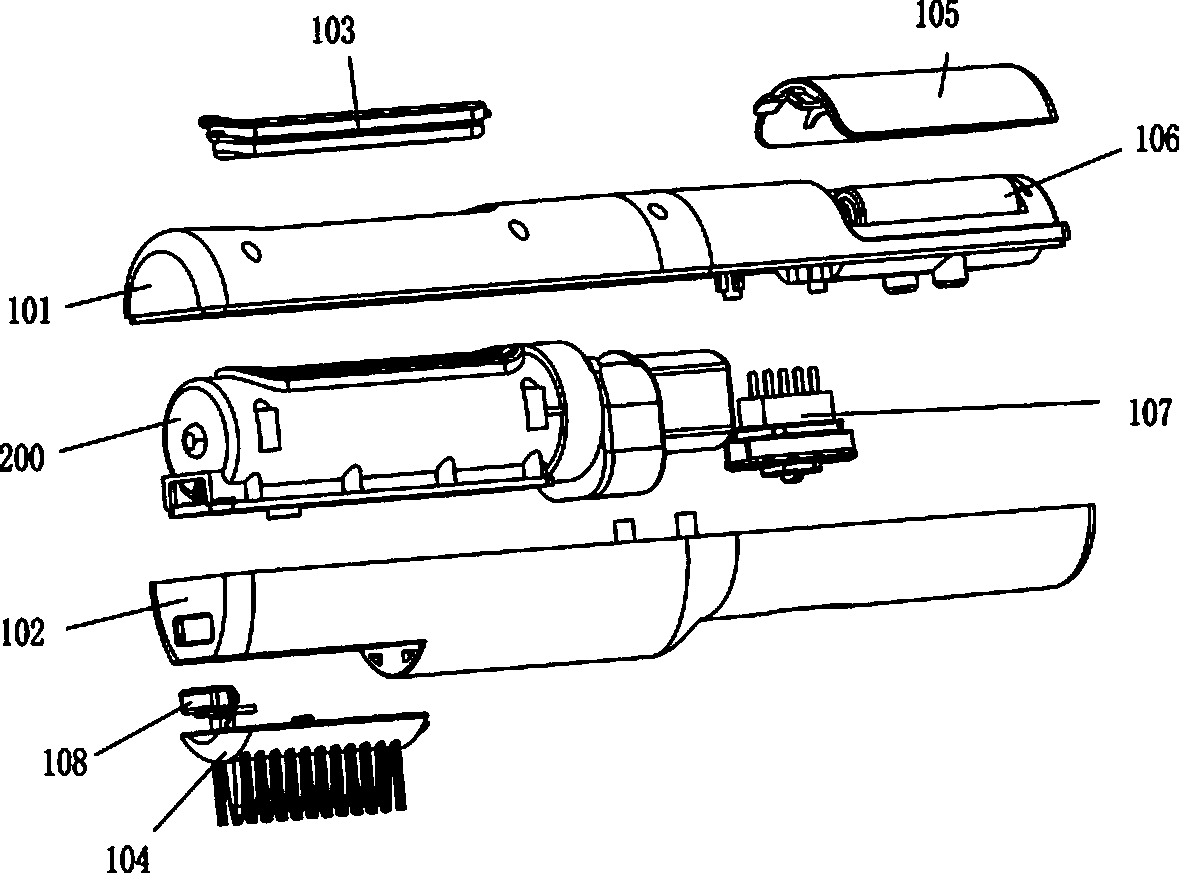

Stirring extrusion type hair dyeing comb

PendingCN111513447ASufficient stockQuantitative extrusionTransportation and packagingMixersPolymer scienceHair Colorants

Owner:DONG GUAN KONG ELECTRIC ELECTRICAL APPLIANCES CO LTD

Cedarwood fiber-based bio-composite material and preparation method thereof

The invention discloses a cedarwood fiber-based bio-composite material and a preparation method thereof. According to the preparation method, the advantages of good toughness, corrosion resistance, moth resistance, low cost and the like of abandoned cedarwood fibers are fully utilized, the cedarwood fibers are processed through a high temperature extrusion process in an earlier stage, then the cedarwood fibers are mixed with polyvinyl chloride (PVC), and matched with other additives, and proper processing steps and parameters are adopted, so as to obtain the bio-composite material which is high in strength, high in toughness and low in cost by squeezing granulation through a screw rod. The material can be processed to form various products through ways of injection molding, extrusion, mould pressing, machining and the like, is widely used in the fields of packaging, electronics, communication, furniture, decoration, automobiles, airplanes, war industry and the like, is capable of replacing the materials of plastic, logs and the like, and has very good social benefit and economic benefit.

Owner:湖南玥昇杰科技有限责任公司

Fall-prevention safe fire-fighting equipment for high-rise elevator

The invention relates to the field of elevator fire protection, in particular to fall-prevention safe fire-fighting equipment for a high-rise elevator. The fall-prevention safe fire-fighting equipmentcomprises an elevator lift car and an elevator shaft, a trigger block is movably installed in the elevator shaft, a limit device is movably installed below the trigger block, the two ends of the limit device are arranged to be in diamond shapes, and the two ends of the limit device and a fixing device are arranged to be in an oblique acute angle triangle shape, so that when the limit device rotates to limit the elevator lift car, the fixing device can be triggered to move upwards through a slope, and the two sides of the elevator lift car are accordingly clamped and fixed; then the right sideof the rhombic lower end of the limit device is arranged in an inwards-sinking manner, and a meshing groove where a meshing protrusion block arranged below the fixing device is embedded is arranged,so that the efficiency that the limit device drives the fixing device to move upwards is improved; and through fixing protrusion blocks, opposite to wholly-wavy zigzag grooves fixedly connected to oneside of the elevator lift car, of the fixing device, and the fixing efficiency of the elevator lift car is improved after contact with the elevator lift car.

Owner:北京实创电梯工程有限公司

Beanpod shelling device

PendingCN107397240AReasonable structural designEfficient extrusionFood treatmentMechanical equipmentEngineering

The invention discloses a beanpod shelling device, and belongs to the field of agricultural processing mechanical equipment. The beanpod shelling device comprises a translation bearer, a blanking hopper, a rotating motor, a beanpod pressing roll, a beanpod pressing belt, a brush roll mechanism, a tensioning mechanism and a discharging mechanism; the blanking hopper is vertically and downwardly disposed at an upper side of the translation bearer; the beanpod pressing belt is successively wound and connected to a first driving roll, a second driving roll and a third driving roll; the brush roll mechanism is horizontally disposed on the translation bearer at the beanpod pressing roll side; the tensioning mechanism is vertically and upwardly disposed on the translation bearer disposed between the first driving roll and the second driving roll; the discharging mechanism comprises a blanking guide plate, a discharging baffle plate, a discharging hopper and a discharging separating screen mesh; and the middle of a lower side of the discharging separating screen mesh is provided with a discharging vibrator. The beanpod shelling device is reasonable in structure design, beanpods can be shelled continuously, rapidly and efficiently, beanpod shelling efficiency and quality are improved, and processing and using requirements are satisfied.

Owner:浙江绿康农产品配送有限公司

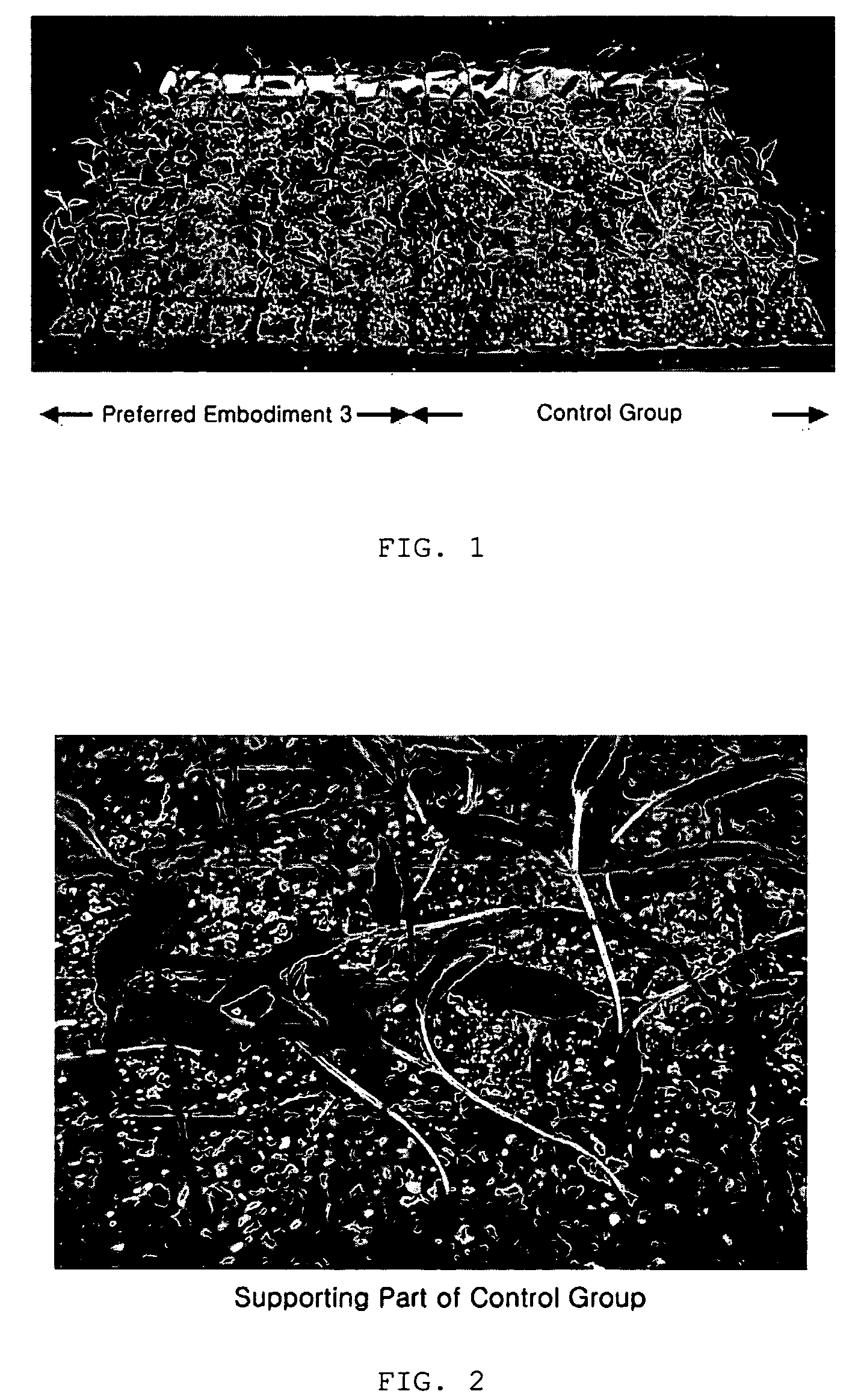

Method for producing the sustained-releasing agricultural chemicals

InactiveUS20040116296A1Good curative effectLow costBiocideAnimal repellantsAdditive ingredientAgricultural engineering

The invention relates to a method for producing sustained-releasing agricultural chemicals. The effective ingredients of the agricultural chemicals are absorbed into a carrier and are released sustainedly. The effect of a injection last about 30 to 40 days, and the concentration of the agricultural chemicals is enough to have an effect. The agricultural chemicals of this invention may save the farmers' labor, reduce costs caused by continuous injections, and decline environmental contamination as an environmentalfriendly agricultural chemicals.

Owner:BIO DREAMS

Composite fertilizer production device

InactiveCN110357694ARealize grinding and crushingRealize the drying operationFertilizer mixturesHydraulic cylinderHeat conducting

The invention discloses a composite fertilizer production device. The composite fertilizer production device comprises a first casing; a pulverizing device is arranged in the first casing; a sealing cover device is arranged in the first casing and positioned below the pulverizing device; a heating plate is fixed at the bottom of the first casing; a heat-conducting plate is fixed at the top of theheating plate; a third hydraulic cylinder is arranged on the inner wall of the first casing; a first baffle is fixed on a piston rod of the third hydraulic cylinder; a second hydraulic cylinder is arranged on the side of the first casing; a piston rod of the second hydraulic cylinder is inserted into the first casing and fixed with a pressing plate; the side of the first casing is communicated with a water adding pipe; the tail end of the water adding pipe is communicated with a first funnel; and a shut-off valve is arranged on a pipe section of the water adding pipe. The efficient pulverizing, curing, extrusion pelleting and drying process of materials can be realized; processing continuity and high efficiency are unified; and the composite fertilizer production device is convenient to operate and suitable for promotion.

Owner:扬州市耕地质量保护站

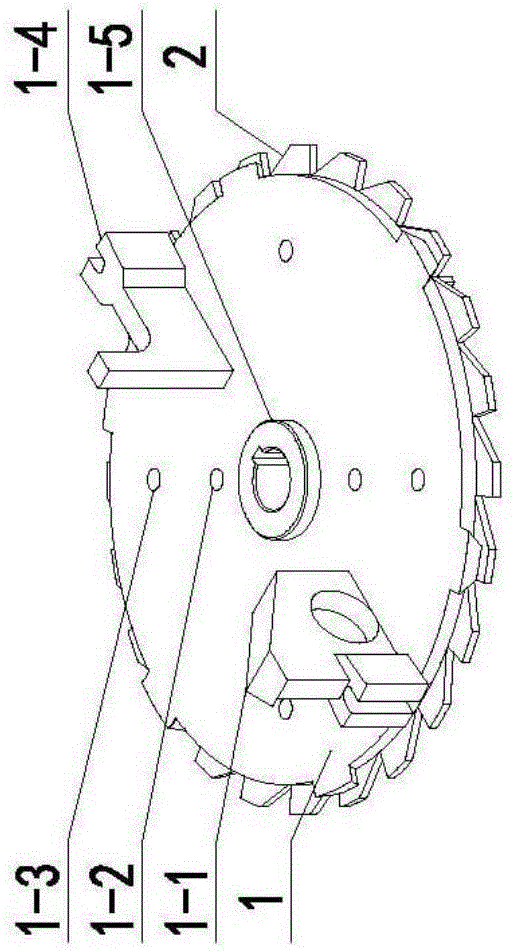

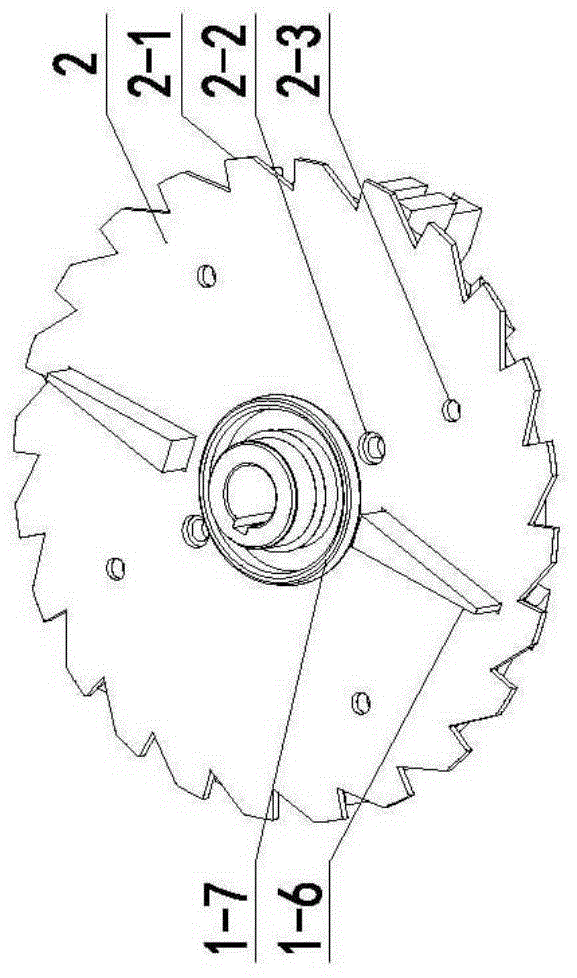

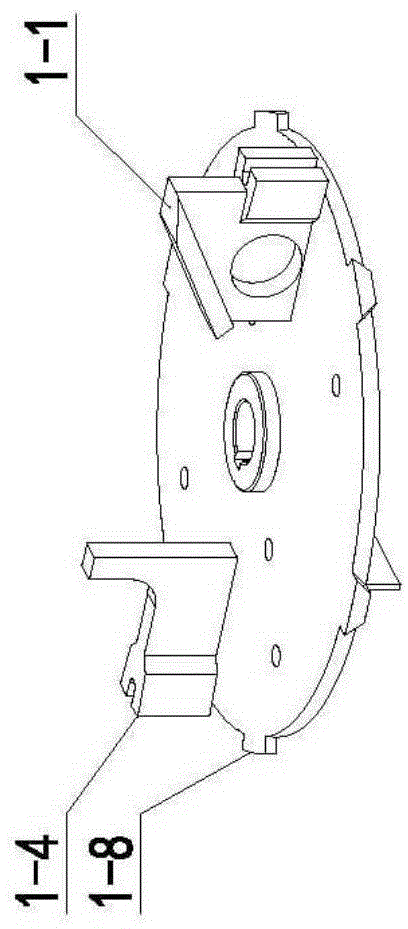

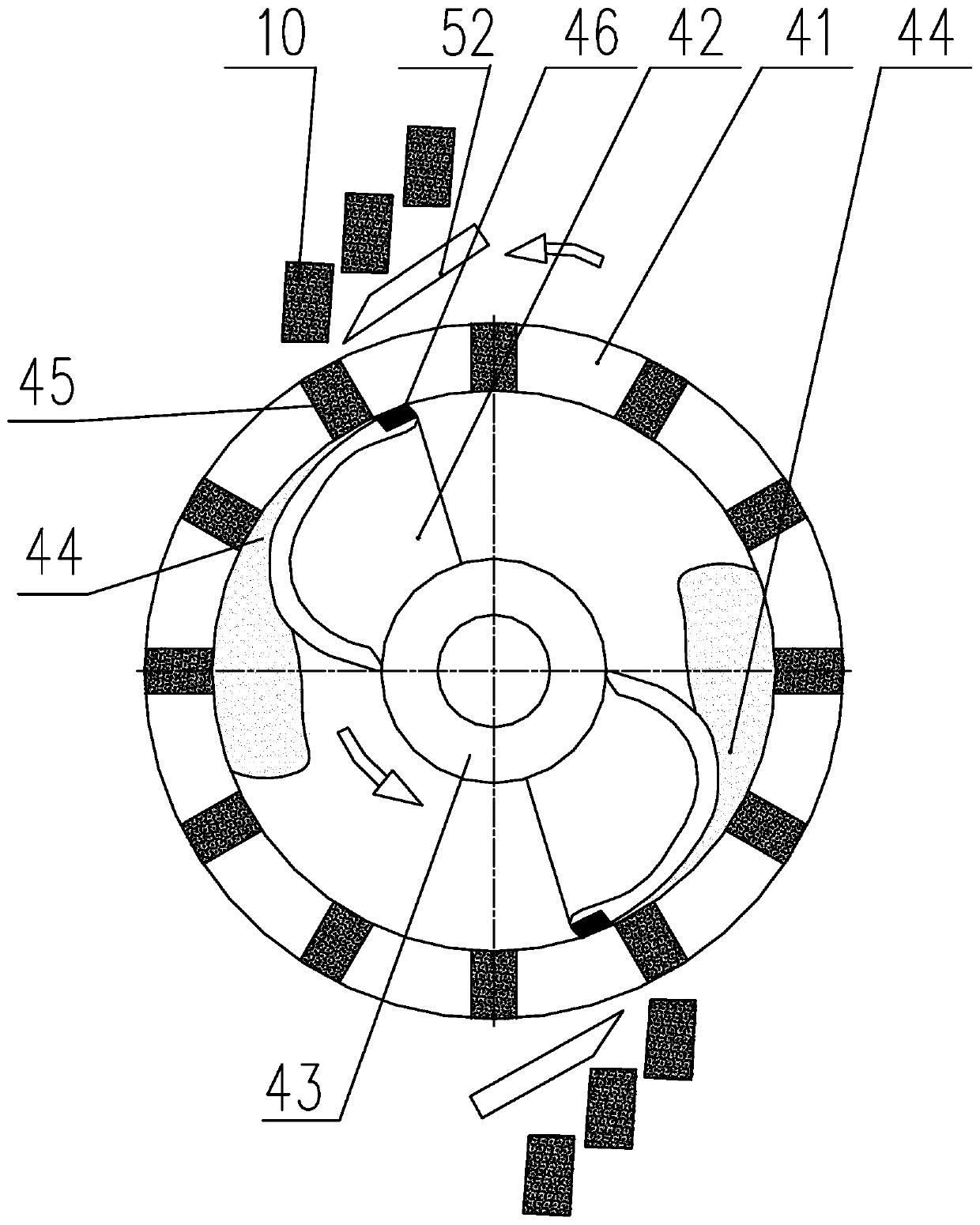

Composite cutter disc of food rubbish processor

ActiveCN106311423AEfficient crushingEfficient extrusionDomestic plumbingGrain treatmentsEngineeringMechanical engineering

Disclosed is a composite cutter disc of a food rubbish processor. The cutter disc is formed by fixing of a first cutter disc and a second cutter disc below the first cutter disc; the first cutter disc is provided with four cutter blocks, the first cutter block is a fork-shaped block, an integrated cutter bit combined body is formed by the first cutter block and the upper portion of the first cutter block, a fork tip is located on the disc side, a fork rod points to a disc center, and an extruding hole is formed; the second cutter block on the opposite side is also a fork-shaped block, and a cutter rod combined body is formed by the second cutter block and the upper portion of the tail; the third cutter blocks are four to six inverted trapezoidal blocks on the disc side; the fourth cutter blocks are in a wedge shape and located on the disc back face; the first cutter disc is further provided with an upper shaft table, a lower shaft table, a retention ring located outside the lower shaft table and a process hole; one-way flat top teeth which are densely and regularly distributed are arranged on the side of the second cutter disc, wedge holes matched with the fourth cutter blocks are formed in the disc face, and the disc enter is provided with a retention ring hole. The trial proves that the cutter disc arranged on the food rubbish processor has the highest speed and is most effective at present.

Owner:嘉兴溢联环保科技股份有限公司

Grinding gear, grinding device and grinder

The invention belongs to the mechanical field and relates to a grinding or crushing device, in particular to a grinding gear, a grinding device and a grinder. The end part of the teeth on the existing grinding gear is generally a plane or cambered surface which is not good for grinding materials. In order to solve the defect of the prior art, the invention provides a grinding gear which comprises a gear ring, wherein gear teeth are arranged on the gear ring, and the top end of each gear tooth is of a sharp blade shape. The grinding gear can effectively stab or puncture and shear materials. The invention also provides a grinding device which comprises the grinding gear. The invention also provides a grinder which comprises the grinding device. Through the grinding gear, grinding device and grinder provided by the invention, the materials can be effectively ground.

Owner:邢征

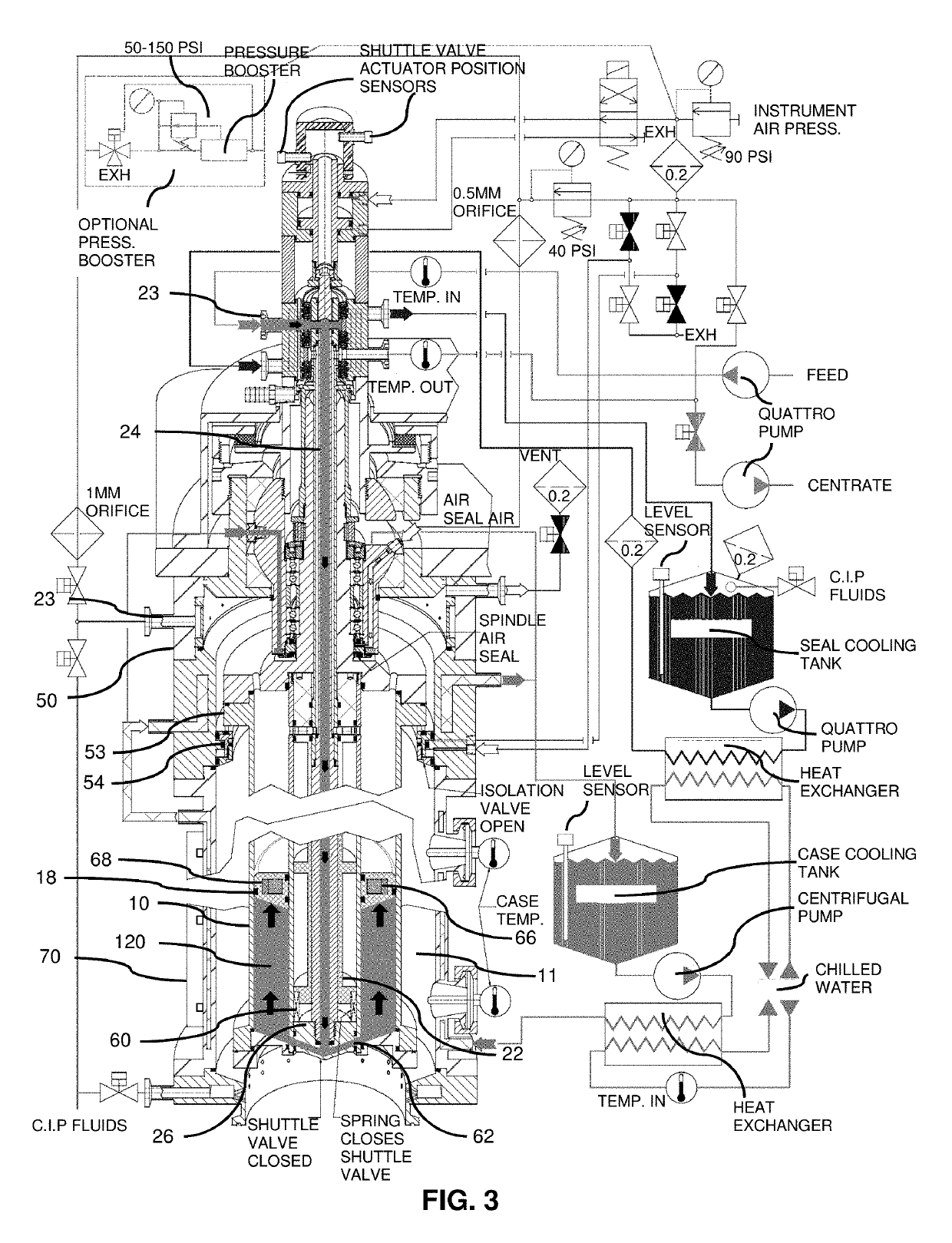

Centrifugal separator with annular piston for solids extrusion

A centrifugal separator includes a cylindrical bowl, a core tube assembly, and an annular piston disposed around the core tube assembly and inside the inner surface of the bowl. Feed liquid is injected down the core tube assembly into the lower portion of the bowl, raising the annular piston. During a separation mode, the bowl rotates at high speed, separating solids from the feed liquid to accumulate along the inner surface of the bowl, while collecting clarified centrate as it exits the top of the bowl and through the core tube assembly. Following solids accumulation, bowl rotation is stopped and residual liquid is pumped from the bowl. In a solids discharge mode, the annular piston is urged downward along a vertical axis in response to compressed gas. The downward movement of the piston forces accumulated solids from the bowl via an opening in the lower end thereof.

Owner:CARR ROBERT BRET

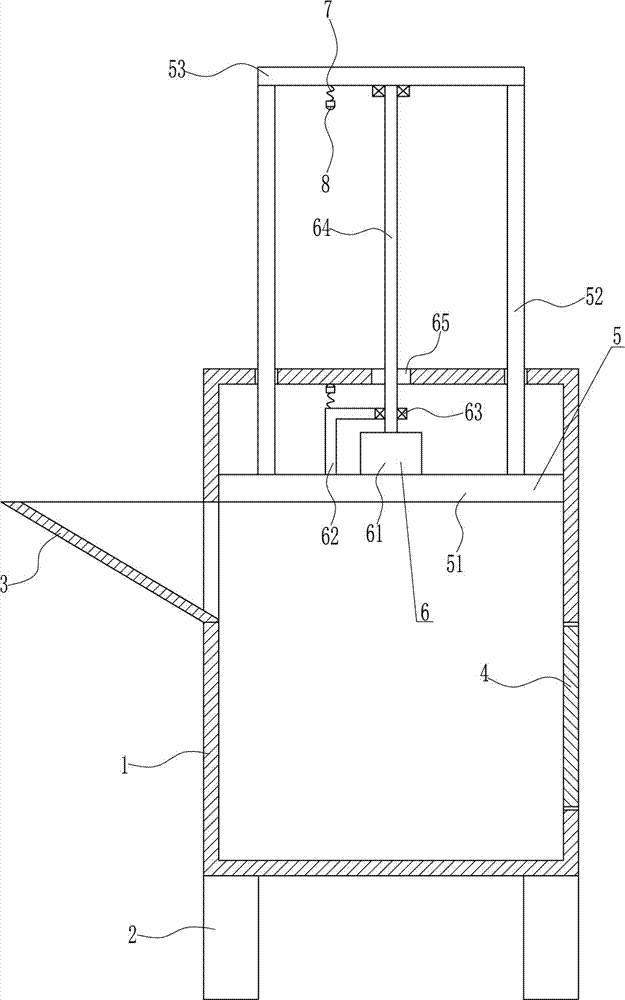

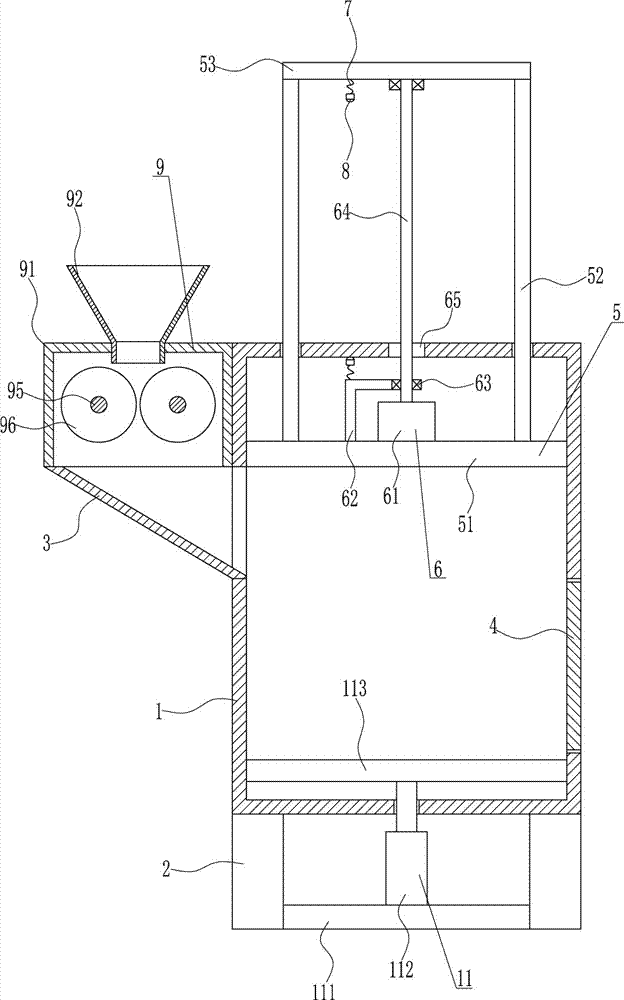

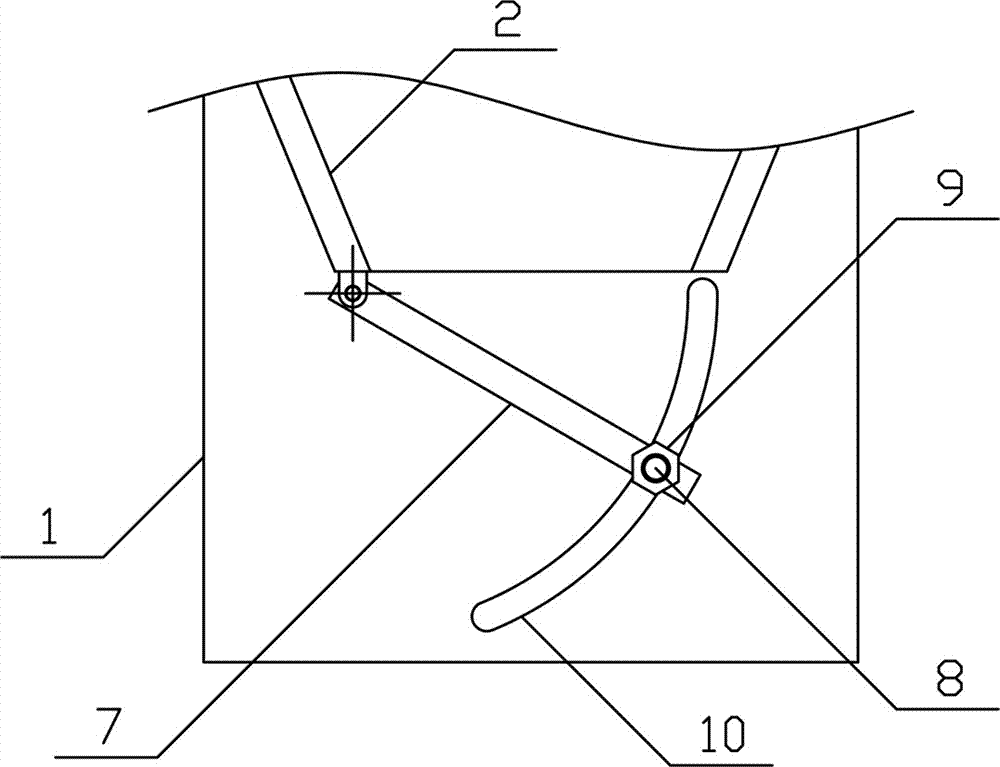

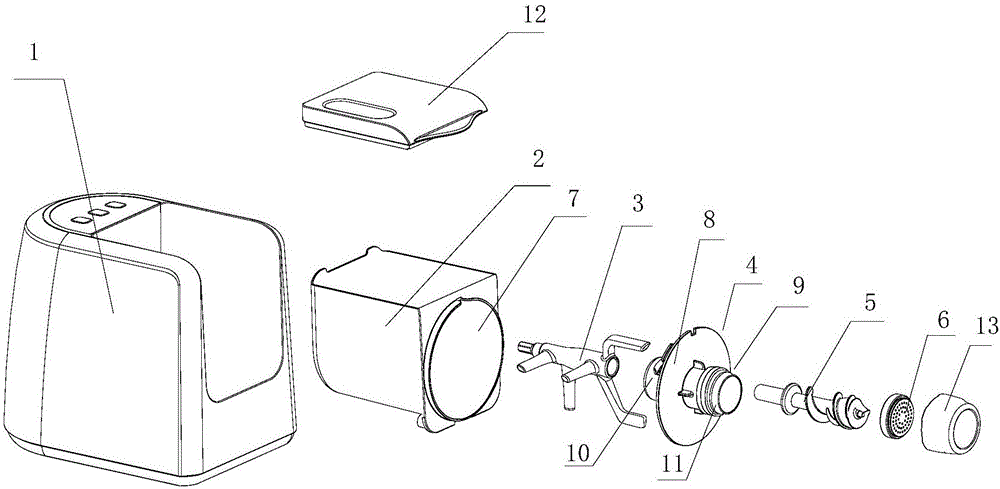

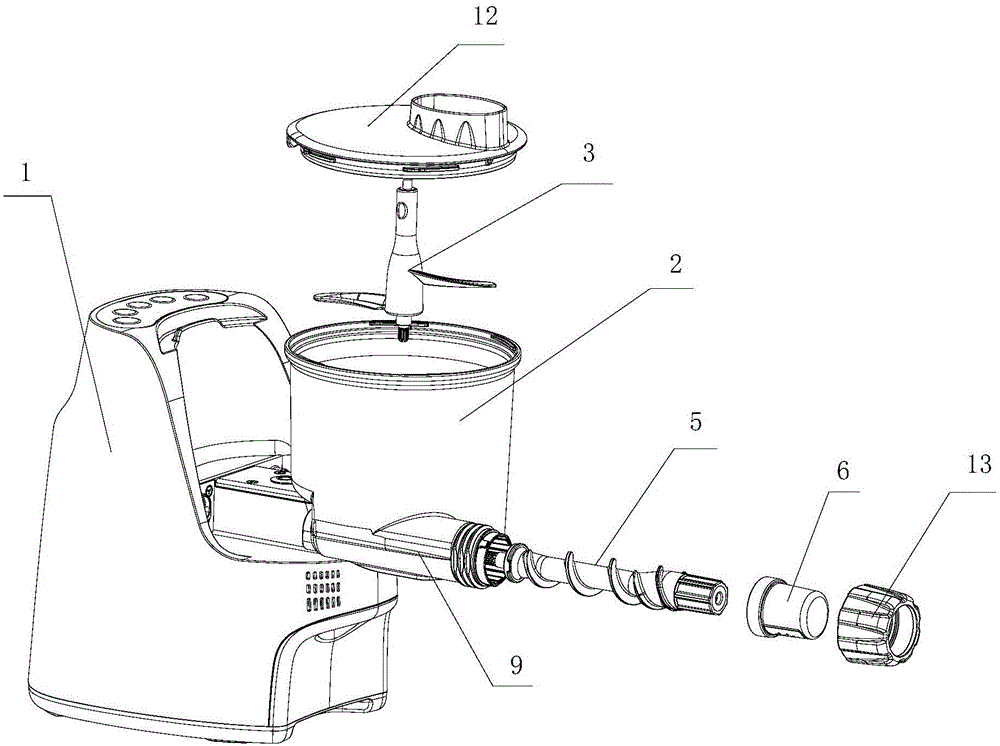

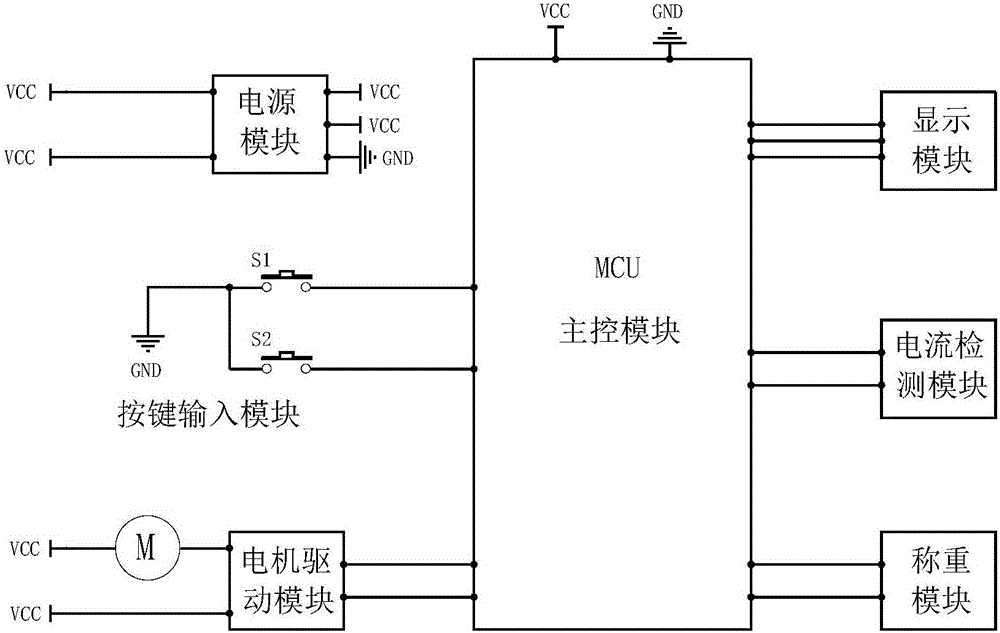

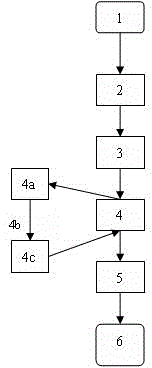

Intelligent and efficient noodle making method of noodle maker, and noodle maker

ActiveCN106818979AEfficient extrusionSqueeze fullyMixing/kneading structural elementsMixing/kneading with vertically-mounted toolsControl systemEngineering

The invention relates to an intelligent and efficient noodle making method of a noodle maker, and the noodle maker. The noodle maker comprises a machine base with a motor, and a stirring cup, a stirring rod, a noodle extruding cylinder, a screw rod, a mold head and a control system which are connected with the machine base; the stirring rod is arranged in the stirring cup; the screw rod is arranged in the noodle extruding cylinder; the mold head is detachably arranged at the end part of the noodle extruding cylinder; the motor drives the stirring rod and the screw rod to rotate. The noodle making method at least comprises the dough kneading step and the extrusion forming step; the extrusion forming step is provided with an intermittent noodle extruding process; in the intermittent noodle extruding process, the screw rod rotate positively for a period of time, stops for a period of time and continuously rotate positively. By the noodle making method provided by the invention, dough residues can be reduced and the noodle yield can be increased.

Owner:JOYOUNG CO LTD

Polymer processing system including decompression chamber and method for using same

InactiveUS7052260B1Reduce productivityEasy to operateConfectioneryMeat processingDecompression chamberEngineering

Owner:EXTRUTECH INT

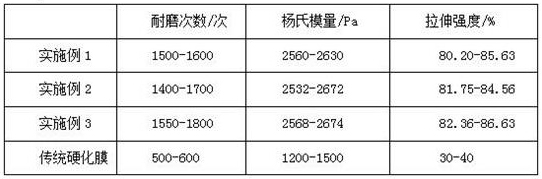

Preparation method of thermoplastic polyurethane film

PendingCN112708259ALower glass transition temperatureImprove carrying capacityFlat articlesPolymer scienceAntioxidant

The invention relates to the technical field of protective films, in particular to a preparation method of a thermoplastic polyurethane film, which comprises the following raw materials: polyurethane, dimethylformamide, an antioxidant, an ultraviolet light absorber, an antibacterial agent, a lubricant and a filler. Polyurethane and dimethylformamide are adopted as main materials to improve polyurethane material molecules so as to achieve a strong stretching effect, a slit trial extrusion type coating high-temperature baking thermosetting mode is adopted in the preparation process, products with different hardness can be obtained by changing the proportion of all reaction components of polyurethane, along with the increase of the hardness, the product still maintains good elasticity and wear resistance, the bearing capacity, impact resistance and shock absorption performance of a polyurethane product are outstanding, the glass transition temperature of polyurethane is relatively low, and good elasticity, flexibility and other physical properties are still maintained at the temperature of -35 DEG C.

Owner:揭西鑫昌顺电子科技有限公司

Preparation method for potash fertilizer particles

ActiveCN104311258AHigh strengthReduce intensitySolid/semi-solid fertilisersPotassium fertilisersThermopotashPotash

The invention relates to a preparation method for potash fertilizer particles. The preparation method is characterized in that the potash fertilizer particles are pelletized by a two-stage mixing extruder, potash fertilizer powder and additives are rapidly refined, scattered and mixed due to the strong shear force of the high rotation speed screw of a first-stage twin screw mixing mill, and then enter a second-stage single screw extruder through exhaust, the output end can conduct high pressure stable extrusion at a low rotation speed, and finally, pelleting is carried out by a die surface pelletizer to obtain the potash fertilizer particles. The potash fertilizer particles have high nutrient concentration, are regular in shape and uniform in diameter, and have high strength and good slow release performance. The preparation method is simple to operate, has strong technological adaptability, consumes little energy, has high granulation rate and high yield, and has market application value.

Owner:山东亿田生物肥料科技有限公司

Efficient ring die granulator

PendingCN110394121AAvoid slipping and stallingEfficient intakeGranulation by pressingPolymer scienceMoisture

The invention relates to the technical field of granulators, in particular to an efficient ring die granulator. Compared with a traditional ring die granulator, the extrusion device is the extrusion block, the extrusion block replaces a compression roller of the traditional granulator, the compression roller is prevented from slipping and stalling due to excessive moisture of materials, and granulation of the high-moisture materials can be completed. When the extrusion block rotates, the circular mold is static, and the extrusion block and the circular mold form a wedge-shaped extrusion area,so that materials are efficiently fed into the extrusion area without overflowing, and the extrusion efficiency is improved. The granulator can be used for treating materials with the moisture contentof 20%-40%, and is suitable for market requirements. Due to a dual-spiral forced feeding mode, materials are evenly pushed into the two wedge-shaped extrusion areas respectively, and therefore the materials cannot block the machine. A wedge-shaped extrusion area is formed by the extrusion block and the inner wall of the ring die, and materials are efficiently extruded out of the ring die hole along with rotation of the extrusion block. In addition, the unique rotary cutter device adopts a speed regulation design, so that particles with different lengths can be formed according to requirements.

Owner:江苏思贝德机械有限公司

A fir fiber-based biomass composite material and preparation method thereof

The invention discloses a cedarwood fiber-based bio-composite material and a preparation method thereof. According to the preparation method, the advantages of good toughness, corrosion resistance, moth resistance, low cost and the like of abandoned cedarwood fibers are fully utilized, the cedarwood fibers are processed through a high temperature extrusion process in an earlier stage, then the cedarwood fibers are mixed with polyvinyl chloride (PVC), and matched with other additives, and proper processing steps and parameters are adopted, so as to obtain the bio-composite material which is high in strength, high in toughness and low in cost by squeezing granulation through a screw rod. The material can be processed to form various products through ways of injection molding, extrusion, mould pressing, machining and the like, is widely used in the fields of packaging, electronics, communication, furniture, decoration, automobiles, airplanes, war industry and the like, is capable of replacing the materials of plastic, logs and the like, and has very good social benefit and economic benefit.

Owner:湖南玥昇杰科技有限责任公司

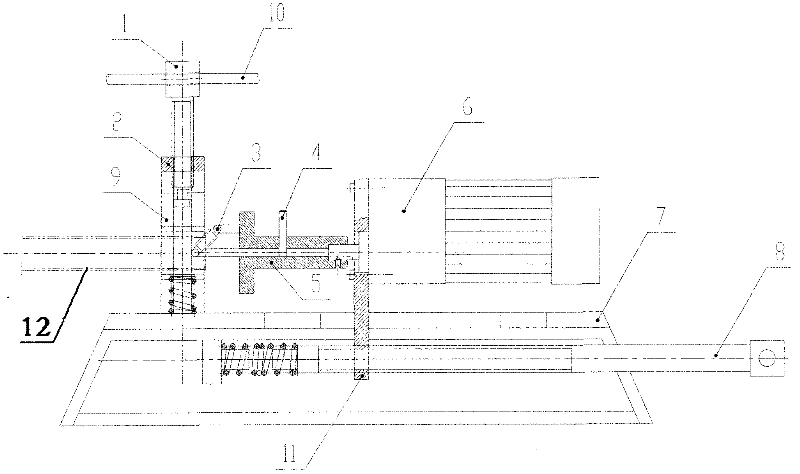

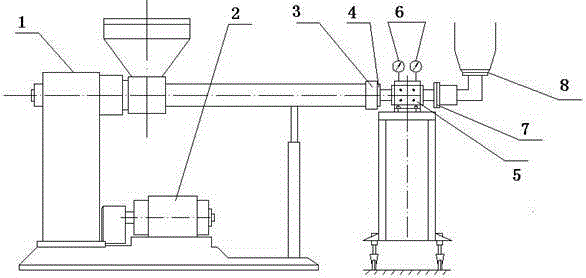

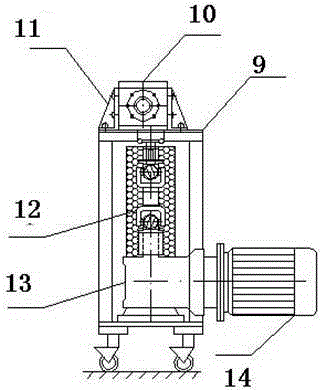

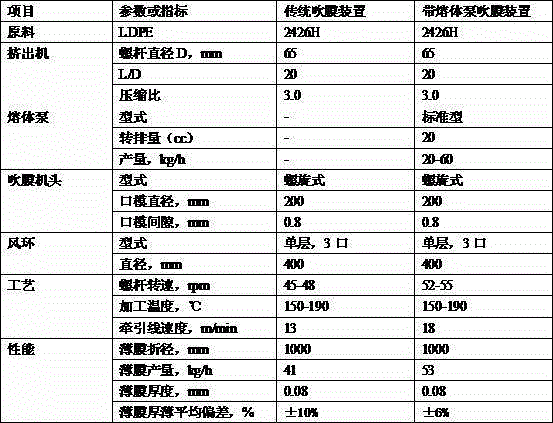

Blown film device with melt pump

The invention discloses a blown film device with a melt pump. The device comprises an extruder, a motor, a splitter plate, an extruder connecting body, a melt pump assembly, a pressure sensor, a machine head connecting body and a film blowing machine head, wherein the melt pump assembly serves as the core of the blown film device provided by the invention, the blown film device comprises a support, a gear pump, a mounting plate, a universal coupling, a speed reducer and a motor. The melt pump assembly is connected with the extruder through the extruder connecting body, and is connected with the film blowing machine head through the machine head connecting body, the pressure sensor is mounted at the top of the melt pump assembly, the splitter plate is mounted at the outlet of the extruder and connected with the extruder connecting body, the motor is connected with the extruder, and power is provided for the entire device. The device can stable a plasticizing process, lower the melting temperature, improve product yield and quality, and further prolong the service life of the extruder.

Owner:YIXING GUANGHUI PACKAGE +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com