Crushing and compressing device for waste plastic

A technology of compression device and waste plastic, applied in the field of compression device, can solve the problems of poor compression effect and low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

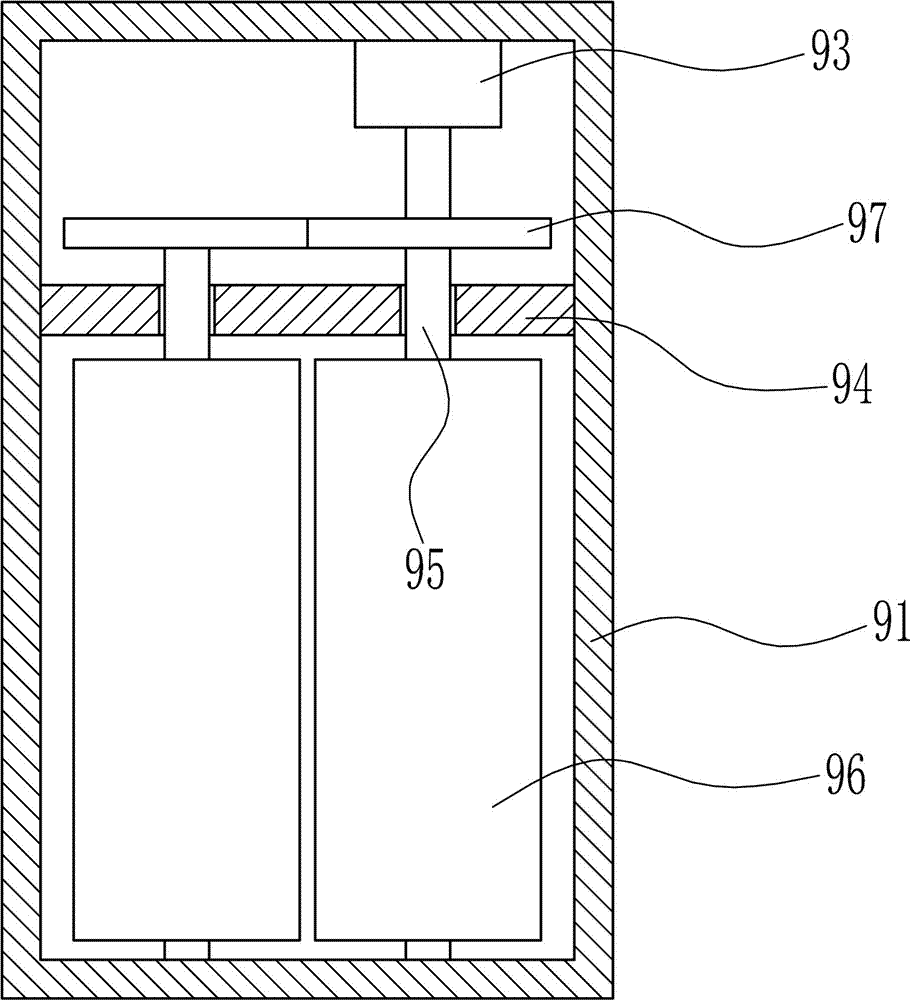

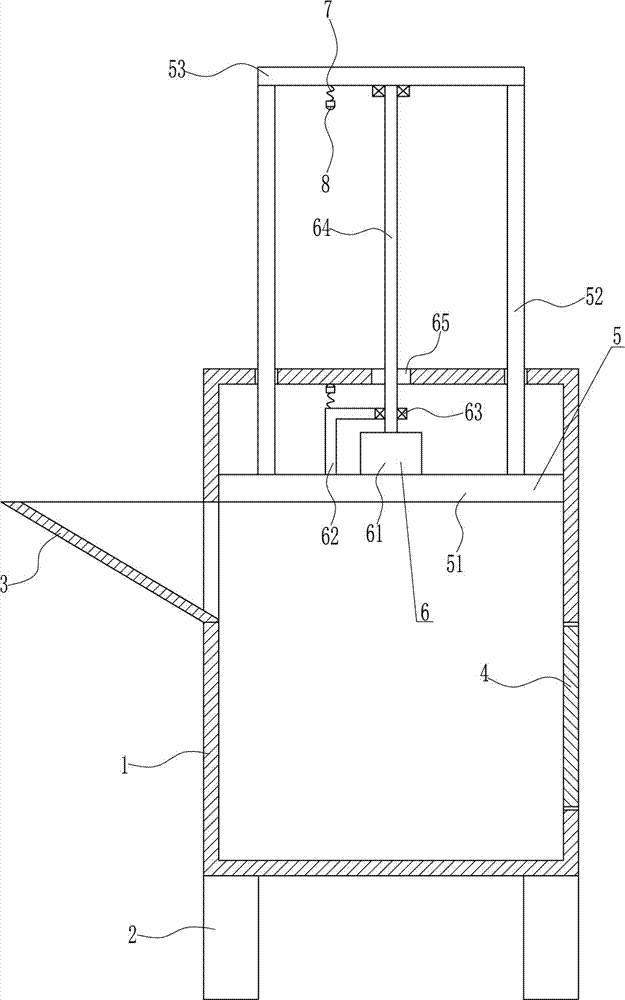

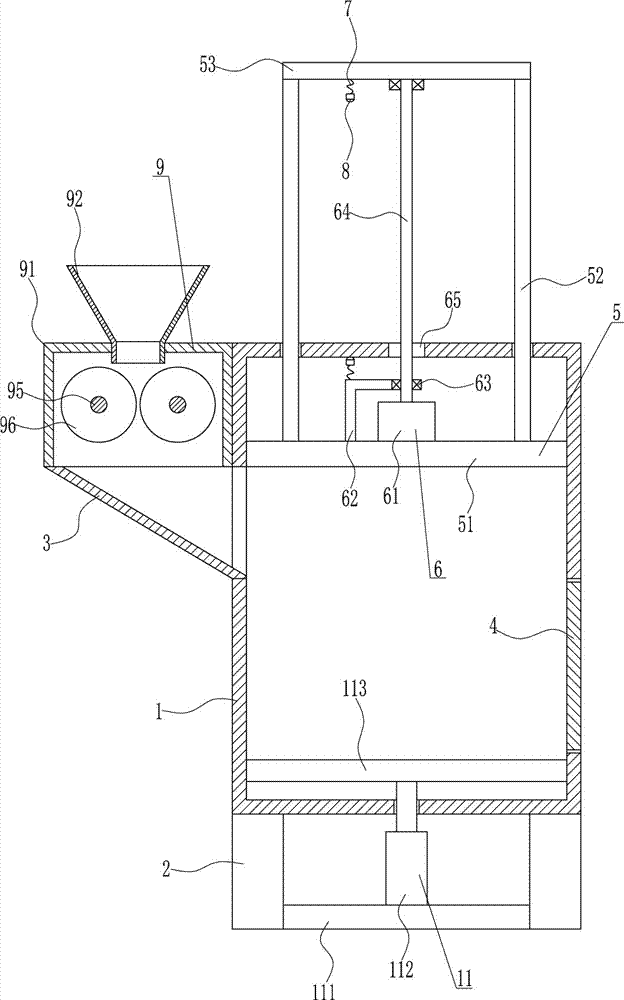

[0035] A waste plastic crushing and compressing device, such as Figure 1-7 As shown, it includes a box body 1, a leg 2, a lower hopper 3, a box door 4, a first extruding device 5 and a driving device 6, and the four corners of the bottom of the box body 1 are connected with the legs 2 by bolts. The middle part on the left side of the box body 1 is connected with the lower hopper 3 by means of bolt connection, the lower hopper 3 is connected with the box body 1, and the lower part of the right side of the box body 1 has a material opening, and a box door 4 is provided at the material opening, and the box door 4 passes through the The hinge is connected with the box body 1 , and a first extruding device 5 is arranged on the inner upper part of the box body 1 , and a driving device 6 is arranged on the first extruding device 5 .

Embodiment 2

[0037] A waste plastic crushing and compressing device, such as Figure 1-7 As shown, it includes a box body 1, a leg 2, a lower hopper 3, a box door 4, a first extruding device 5 and a driving device 6, and the four corners of the bottom of the box body 1 are connected with the legs 2 by bolts. The middle part on the left side of the box body 1 is connected with the lower hopper 3 by means of bolt connection, the lower hopper 3 is connected with the box body 1, and the lower part of the right side of the box body 1 has a material opening, and a box door 4 is provided at the material opening, and the box door 4 passes through the The hinge is connected with the box body 1 , and a first extruding device 5 is arranged on the inner upper part of the box body 1 , and a driving device 6 is arranged on the first extruding device 5 .

[0038] The first pressing device 5 includes a first pressing plate 51, a first guide rod 52 and a top plate 53. The upper part of the box body 1 is sl...

Embodiment 3

[0040] A waste plastic crushing and compressing device, such as Figure 1-7 As shown, it includes a box body 1, a leg 2, a lower hopper 3, a box door 4, a first extruding device 5 and a driving device 6, and the four corners of the bottom of the box body 1 are connected with the legs 2 by bolts. The middle part on the left side of the box body 1 is connected with the lower hopper 3 by means of bolt connection, the lower hopper 3 is connected with the box body 1, and the lower part of the right side of the box body 1 has a material opening, and a box door 4 is provided at the material opening, and the box door 4 passes through the The hinge is connected with the box body 1 , and a first extruding device 5 is arranged on the inner upper part of the box body 1 , and a driving device 6 is arranged on the first extruding device 5 .

[0041] The first pressing device 5 includes a first pressing plate 51, a first guide rod 52 and a top plate 53. The upper part of the box body 1 is sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com