Patents

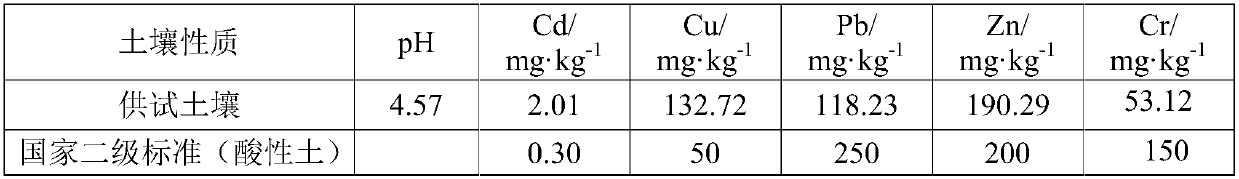

Literature

70 results about "Thermopotash" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

ThermoPotash is a slow-release, multi-nutrient fertilizer product made from a silicate-based potash resource. It contains on average 4%-14% K₂O. It is derived by performing a pyrometallurgical process on Verdete (green) slate rock and limestone.

Saline-alkali soil modifier and preparation method thereof

ActiveCN102212370AReduce salinityReduce concentrationOrganic fertilisersSoil conditioning compositionsEcological environmentAlkali soil

The invention relates to a saline-alkali soil modifier and a preparation method thereof. The preparation method comprises the following steps: mixing 5-20 parts of humic acid, 15-30 parts of heavy calcium carbonate, 5-10 parts of solid sulphuric acid, 8-15 parts of farmyard manure, 3-7 parts of trace element compound and 1-3 parts of bone meal to pelletize; using 0.3-1 part of biological bacterium to pelletize; and mixing the obtained particles, adding 10-20 parts of nitrogen fertilizer, 5-14 parts of phosphatic fertilizer and 3-8 parts of potassic fertilizer to mix evenly and prepare the saline-alkali soil modifier. Pig manure and chicken manure are used as carrier to be combined with the saline-alkali soil modifier and prepare granule, the granule is applied 3cm and 10cm below seeds, thus the saline-alkali concentration around the root systems of the seeds can be reduced, the circular damage of the return of saline-alkali in deep underground on the root systems of crop can be suppressed, a good ecological environment can be created for the root systems of crop and the aims of strong root systems, more and stronger roots, luxuriant branches and leaves, high and stable yield can be realized. The technology can be used in the sustainable development of Chinese agriculture, thus the farmer with a limited land can have higher income.

Owner:张志辉

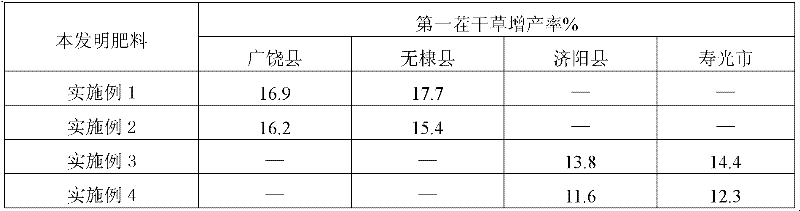

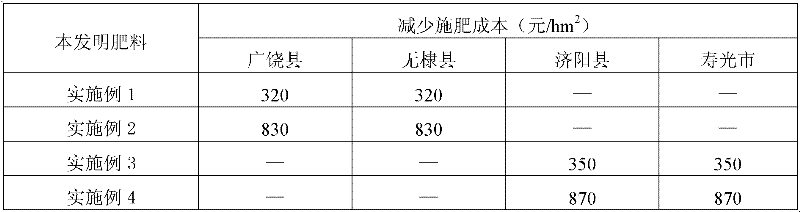

Mid-low yield field alfalfa special-purposed fertilizer, preparation method thereof, and application method thereof

InactiveCN102515950AReasonable ratio of nutrientsIncrease profitFertilising methodsFertilizer mixturesMass ratioOrganic matter

The invention discloses a mid-low yield field alfalfa special-purposed fertilizer, a preparation method thereof, and an application method thereof. The special-purposed fertilizer comprises raw materials of nitrogen fertilizer, phosphate fertilizer, potash fertilizer, and organic matters. The fertilizer is prepared through pan granulation. A mass ratio of the nutrients in the special-purposed fertilizer is represented by that N:P2O5:K2O=5-7:15-20:3-4. The alfalfa special-purposed fertilizer provided by the invention can be applied as a basal fertilizer or a top dressing. The fertilizer is advantaged in simple production technology, low cost, environment-friendliness, high utilization rate, and substantial yield-increasing effect. The fertilizer satisfies requirements of high yield and high-quality production of alfalfa plantation in saline-alkali lands or non-saline-alkali lands with middle or low land capabilities.

Owner:SHANDONG AGRI SUSTAINABLE DEV INST

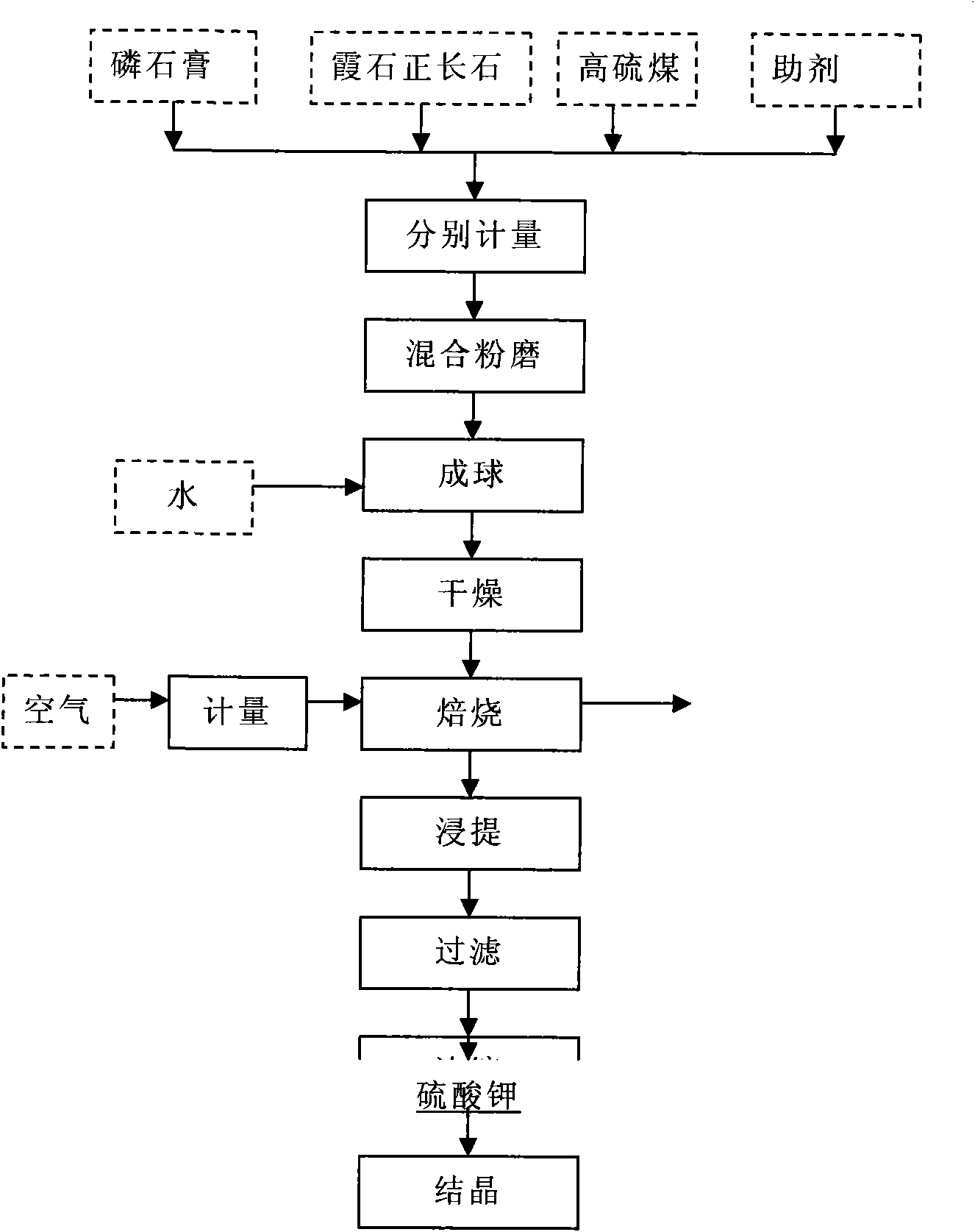

Preparation method for preparing potash fertilizer and producing sulfuric acid simultaneously employing mineral with potassium, ardealite and high-sulphur coal

InactiveCN101607834AAvoid the requirement of high sulfur conversion rateLess investmentSolid waste disposalSulfur compoundsBall millSolid phases

The invention relates to a preparation method for preparing potash fertilizer and producing sulfuric acid simultaneously employing mineral with potassium, ardealite and high-sulphur coal, comprising the following steps: mixing the mineral with potassium, ardealite and high-sulphur coal in a mass percent of 32-65:31-61:4-7 with assistant, then adding the mixture in a ball mill for grinding, adding water to form balls, drying the balls, performing roasting reaction at 950-1250 DEG C in a tube furnace with a controllable reaction atmosphere which uses reducing atmosphere firstly and later weakly oxidizing atmosphere in the reaction process, finally separating the products into gaseous phase and solid phase and preparing soluble potassium sulfate fertilizer and the feed gas for making acid, namely SO2 simultaneously; wherein, the content of assistant is 1-3wt% of KAlSi3O8 contained in the mineral with potassium. The invention makes full use of the characteristic that China has rich resource of insoluble patassium-bearing rocks, combines the actual situation that usage of ardealite in high analysis phosphate fertilizer industry is large and the utilization rate is low, realizes the recycling of sulfur resources for the phosphate fertilizer industry and expands the product structure of the phosphate fertilizer industry.

Owner:KUNMING UNIV OF SCI & TECH

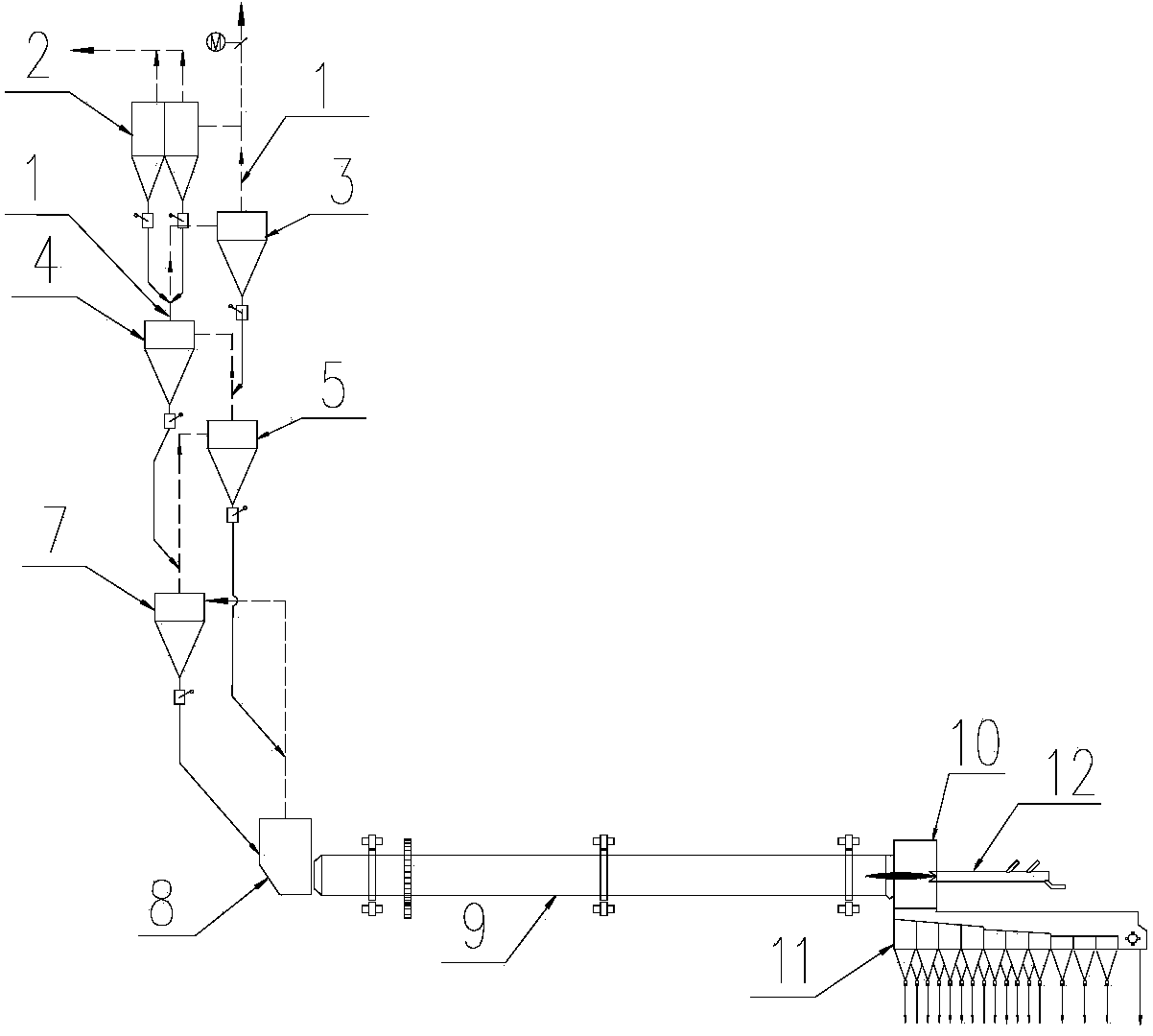

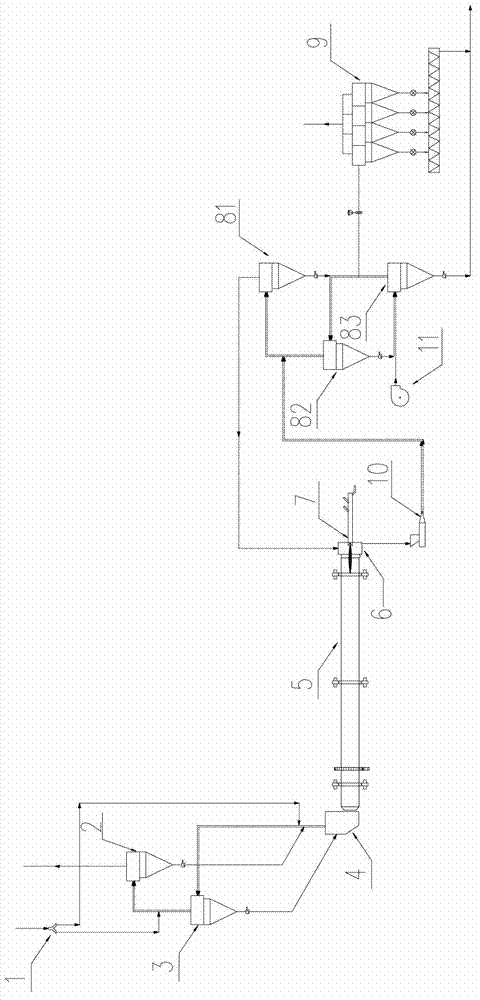

Production process and equipment of silicon-calcium-potassium fertilizer

ActiveCN103739341ASimple processReduce energy consumptionFertilizer mixturesTunnel kilnProduction line

The invention discloses a production process of a silicon-calcium-potassium fertilizer. The process comprises the following steps: with water insoluble potassium ore and limestone or dolomite serving as raw materials, sequentially smashing, grinding, calcining by using a rotary kiln, cooling by using a cooling machine, smashing and grinding to obtain the silicon-calcium-potassium fertilizer, wherein in the step of calcining in the rotary kiln, the burning zone temperature is between 1150 DEG C and 1400 DEG C and the retention time of the raw materials in the kiln is between 20 minutes and 60 minutes. The invention also discloses equipment adopting the process. Compared with a process of sintering the silicon-calcium-potassium fertilizer in a grinding and block making tunnel kiln, the process disclosed by the invention has the advantages that a preheater system is adopted to preheat, a decomposing furnace is adopted to decompose, the rotary kiln is adopted to calcine and the cooling machine is adopted to cool, so that the production line heat loss and the production cost are greatly reduced, the environmental protection performance is greatly improved and the single line production capacity is increased; water adding and briquetting steps in the sintering process in the tunnel kiln are not required, so that the process is simplified; pulverized coal serves as a fuel, so that the fuel cost is reduced; the labour intensity is greatly reduced, the automation degree is high and the system parameters are measurable and controllable.

Owner:TIANJIN CEMENT IND DESIGN & RES INST

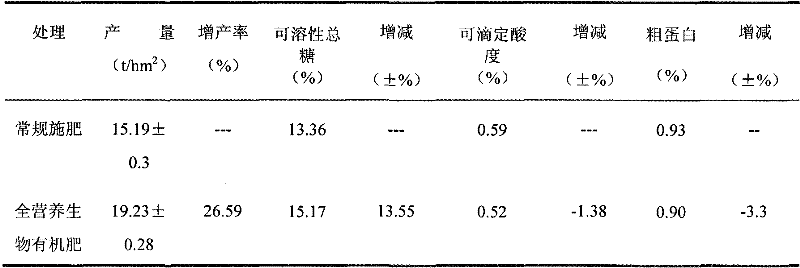

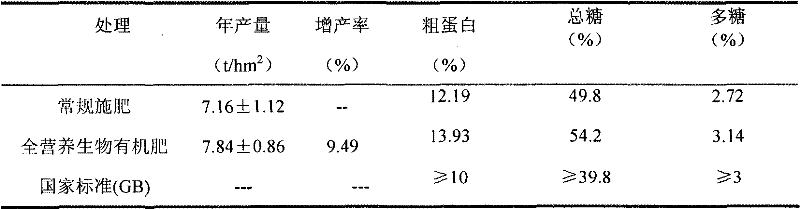

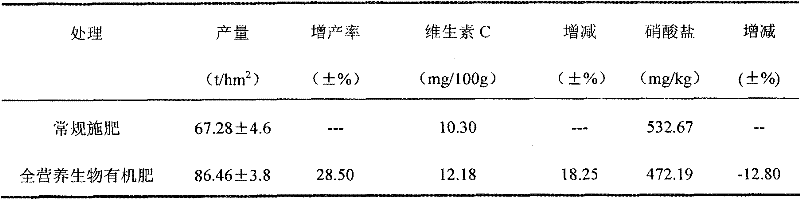

Method for preparing complete nutrient bioorganic fertilizer from wastes of biological environment-friendly pig-raising industry and product

InactiveCN102234207AAddress effectivenessStructural solutionBio-organic fraction processingClimate change adaptationDry weightManganese

The invention discloses a method for preparing a complete nutrient bioorganic fertilizer from wastes of the biological environment-friendly pig-raising industry and a product, belongs to the technologies of innocent treatment and recycling of agricultural solid wastes, and effectively solves the problem that the wastes of the biological environment-friendly pig-raising industry cannot be treated. The method comprises the following steps of: mixing the wastes of the biological environment-friendly pig-raising industry and inorganic nitrogen fertilizer, phosphate fertilizer and potassic fertilizer in a ratio of (150-180):(10-15):(3-5):(9-12), and performing primary fermentation; and performing secondary fermentation with medium and micro elements (magnesium, iron, boron, molybdenum and manganese) in a ratio of 0.5-1.5 percent (based on dry weight), fully composting, and granulating to obtain the complete nutrient bioorganic fertilizer. The product has the total nitrogen content of 3.62 percent, the total NPK nutrient content of over 9.0 percent and the total medium and micro element content of 2.43 percent. Experimental results show that: after the fertilizer is applied to crops such as wine grapes, Chinese wolfberries, protected cucumbers and protected tomatoes, the yield is increased by 5 to 10 percent compared with that obtained by using simple-substance fertilizers in the same nutrient using amount; moreover, the product quality is obviously improved.

Owner:周涛 +2

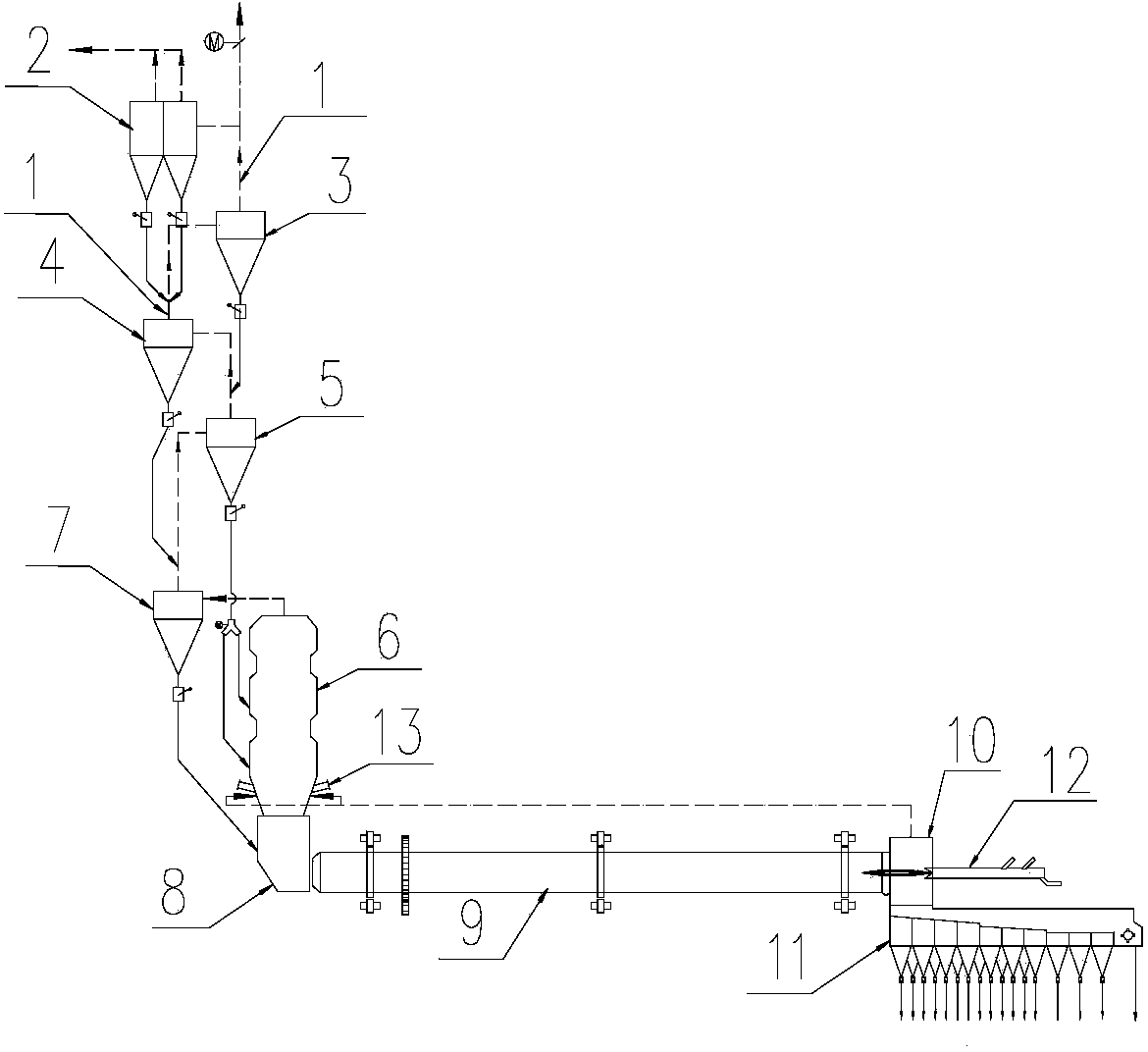

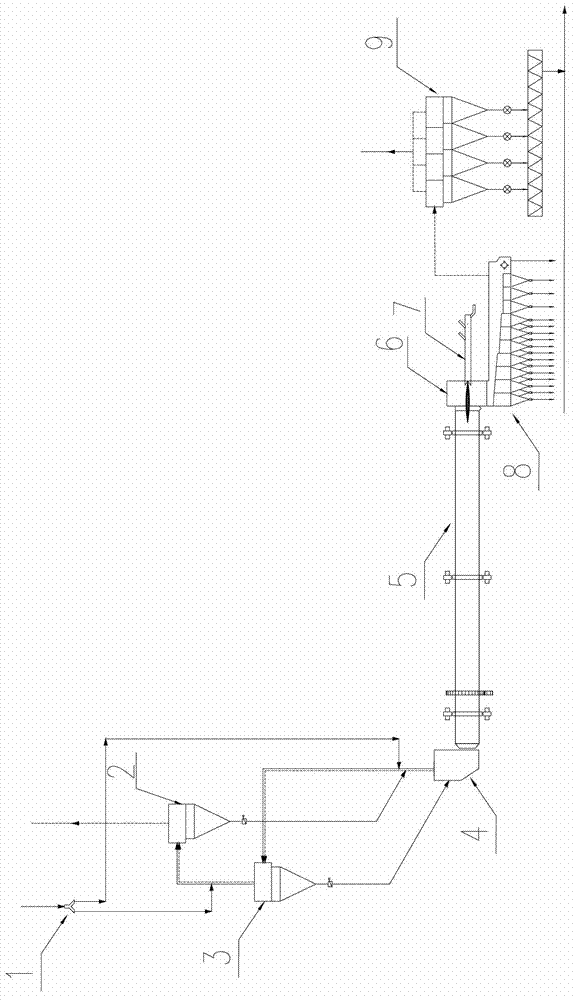

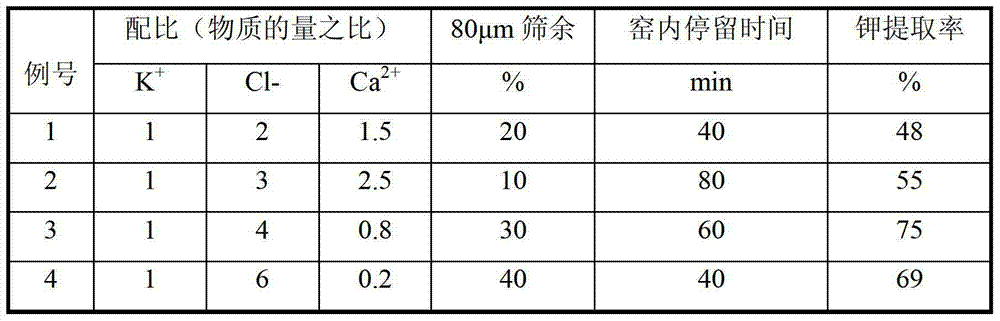

Method and device for roasting water insoluble potassium ore to extract potassium chloride to produce potash fertilizer

ActiveCN103288102AHigh extraction rateReduce manufacturing costProcess efficiency improvementAlkali metal chloridesCalcium in biologyWater insoluble

The invention discloses a method for roasting water insoluble potassium ore to extract potassium chloride to produce potash fertilizer. The method comprises the following steps of: 1) respectively crushing chloride and calcium raw materials used as accessory ingredients of the water insoluble potassium ore, and distributing the materials to obtain a raw material; 2) grinding the obtained raw material until the residue on sieve of a square hole sieve of 80 microns is 10-40%; 3) conveying the obtained raw material into a rotary kiln for roasting, wherein the temperature of a burning zone is 750-1000 DEG C, and the standing time of the material in the kiln is 40-80 minutes; 4) cooling a roasted product; 5) dissolving and soaking the cooled roasted product in water, performing evaporating and crystallization separating on the solution to obtain a potassium chloride product with purity larger than 95%. The invention further discloses a device adopting the method. The method disclosed by the invention is simple in technological process, low in energy consumption and low in production cost.

Owner:TIANJIN CEMENT IND DESIGN & RES INST

Method for preparing potassic fertilizer by using high temperature steel slag or high temperature blast furnace slag and potash feldspar

The invention relates to a method for preparing potassic fertilizer by using high temperature steel slag or high temperature blast furnace slag and potash feldspar. The method comprises the followingsteps of: using high temperature steel slag or high temperature blast furnace slag as heat source, processing potash feldspar by using CaO and MaO therein and extra assistant, destroying lattice structure of the potash feldspar, causing potassium ions therein to be extracted by a leaching method, thus obtaining the potassic fertilizer. As silicon oxide and aluminium oxide in potash feldspar reactwith calcium elements in the assistant to generate matters such calcium silicate, calcium aluminate and the like, solid slag can be used for generating cement, steel slag micro powder, serves as roadengineering material or refilling material, asphalt concrete aggregate or is used for producing microcrystalline glass after the potassium is extracted.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

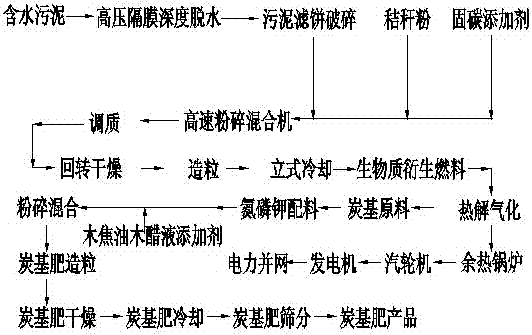

Carbon-based compound fertilizer and biomass gas co-production technology based on municipal sludge

InactiveCN107324941AImprove adsorption capacityLight weightAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersCropTar

The invention discloses a carbon-based compound fertilizer and biomass gas co-production technology based on municipal sludge. The technology comprises the following steps: 1) dehydration; 2) crushing; 3) mixing: 53%-92% by mass of sludge particles, 1%-40% by mass of straw powder and 3%-8% by mass of a carbon sequestration additive are mixed, wherein the carbon sequestration additive contains diatomite, calcium oxide and magnesium ore powder; 4) drying; 5) granulation; 6) pyrolysis and gasification: biomass derived fuel particles are fed into a gasifier and subjected to pyrolysis and gasification under the micro-oxygen condition of air equivalent ratio being 0.18-0.25 at 600-800 DEG C, biomass mixed fuel containing part of purities is obtained, and carbon residues in the gasifier are discharged; 7) gas separation: wood tar and wood vinegar are removed from the biomass mixed fuel through purification, and the purified biomass mixed fuel is taken as gas fuel; 8), carbon-based compound fertilizer preparation: 40%-60% of the carbon residues, 12%-20% of a wood tar and wood vinegar mixed liquid, 20%-35% of inorganic nitrogen phosphorus and potassium fertilizer and 2%-5% of diatomite are mixed. Biomass in the municipal sludge and residues obtained after energy conservation treatment can be used efficiently, by means of the obtained compound fertilizer, soil granulation can be increased, the rate of utilization of the fertilizer by crops is increased, heavy metal components are solidified, secondary pollution to the environment is avoided, few resources are consumed, and the comprehensive economic benefits are increased.

Owner:四川雷鸣环保装备有限公司

Preparation for slow release glass potassic fertilizer by smelting iron and steel fag-end

A slow-releasing glass potassium fertilizer is prepared from the slag generated by smelting iron and steel through mixing it with KOH or K2CO3, smelting to become glass-state molten material, solidifying, and slow cooling.

Owner:上海维安新材料研究中心有限公司

Preparation method of mixed nutrient soil for flowers

The invention relates to a preparation method of mixed nutrient soil for flowers. The preparation method comprises the following steps of 1, for preparation of mixed nutrient soil for flower, mixing raw material components according to a ratio to obtain a uniform raw material, 2, putting the uniform raw material into a sealed tank at a temperature of 50-60 DEG C and carrying out fermentation to obtain a fermentation raw material, 3, gradually adding a small amount of rice chaff ash into the fermentation raw material to obtain a PH raw material, 4, adding phosphate fertilizer and potash fertilizer into the PH raw material and carrying out stirring to obtain a uniform mineral raw material, 5, carrying out disinfection on the mineral raw material to obtain a disinfected raw material, and 6, crushing the disinfected raw material, and carrying out sieving to obtain a product with the particle sizes of 2-3cm, wherein the product is the flower mixed nutrient soil. The preparation method has simple processes and saves time and labor. Flower can be directly planted and grow in the prepared flower mixed nutrient soil.

Owner:NANJING XINGZHI LANDSCAPE DESIGN

Manufacturing method of puffed particle compound fertilizer and product thereof

ActiveCN101993317AImprove solubilityFertiliser formsFertilizer mixturesPhosphate fertilizerChemistry

The invention discloses a manufacturing method of a puffed particle compound fertilizer, which comprises the following steps of: uniformly mixing nitrogenous fertilizer, phosphate fertilizer, potassic fertilizer, stuff and other raw materials used in production of the compound fertilizer into a mixer according to a certain proportion to prepare a compound fertilizer mixture; and manufacturing the puffed particle compound fertilizer through the procedures of puffed granulation, drying, cooling, screening and the like. The invention belongs to a novel manufacturing process of the novel compound fertilizer.

Owner:SHENZHEN BATIAN ECOTYPIC ENG +1

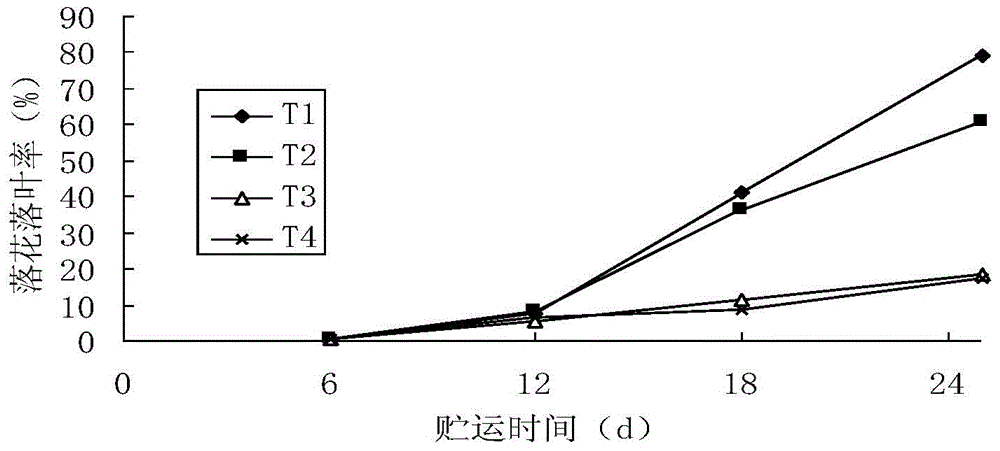

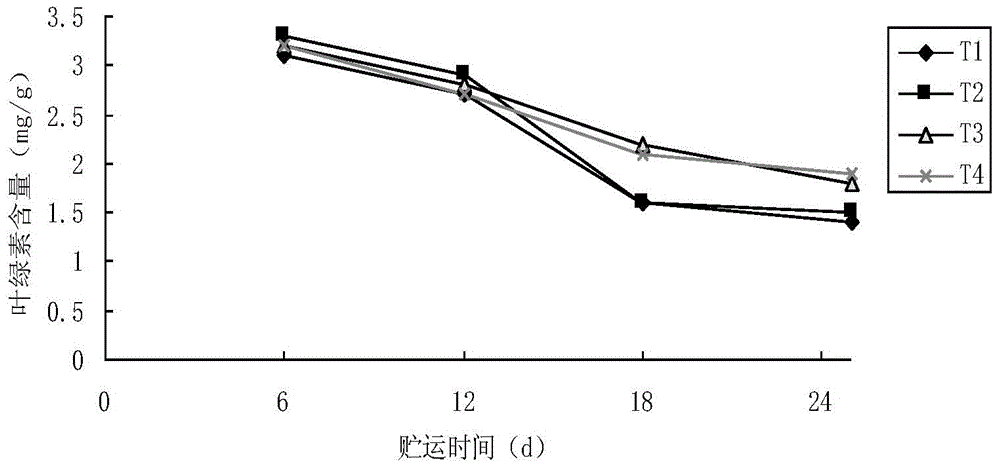

Processing method of improving preservation and storage tolerance of bougainvillea glabra

The invention provides a processing method of improving preservation and storage tolerance of bougainvillea glabra. The processing method comprises pre-storage domestication and post-storage flowering phase regulation and is characterized in that the best pre-storage domestication condition is that imported coco coir, imported turf and perlite are used as soilless culturing substrate with the size ratio being 8:1:1, the water-retaining agent is crystal soil, the mass ratio of the water-retaining agent and the substrate is 1:100, 100 parts of nutrient fertilizer of mixed nitrogen and potash fertilizer with the ratio being 1:1 and a plant growing conditioning agent, naphthylacetic acid, with the spraying concentration being 400 microgram per liter are added under the temperature of 15 plus or minus 1 DEC G and with the shading degree being 50%, and the post-storage flowering phase regulation is the naphthylacetic acid with the spraying concentration being 50 mg / L, paclobutrazol with the spraying concentration being 50 mg / L or the naphthylacetic acid with the spraying concentration being 25 mg / L.

Owner:福建省亚热带园艺植物研究中心

Red mud-silico-calcium-potash fertilizer and preparation method thereof

ActiveCN109134154ALow costLow fine grinding abilityCalcareous fertilisersPotassium fertilisersSolventChemistry

The invention discloses a red mud-silico-calcium-potash fertilizer and a preparation method thereof. The preparation method comprises the following steps: 1) weighing 20-50wt% of red mud, 30-60wt% offly ash and 5-30wt% of desulfurization slag, and mixing uniformly to obtain a mixed material; 2) weighing potassium hydroxide equivalent to 2-30% of the mass of the mixed material, preparing to a solution with water as a solvent, adding the solution to the mixed material, mixing uniformly, and granulating to obtain a granulated material; 3) placing the obtained granulated material in dry powder tofully contact, and wrapping the surface of the granulated material with a layer of dry powder to obtain powder-coated powder material; and 4) calcining the obtained powder-coated powder material at 450 DEG C or above, and cooling after calcining, so as to obtain the fertilizer. The method disclosed in the invention is simple, easy to control, and low in cost, and the obtained fertilizer is low incontent of free sodium and high in content of insoluble or slightly soluble silicon.

Owner:中国有色桂林矿产地质研究院有限公司

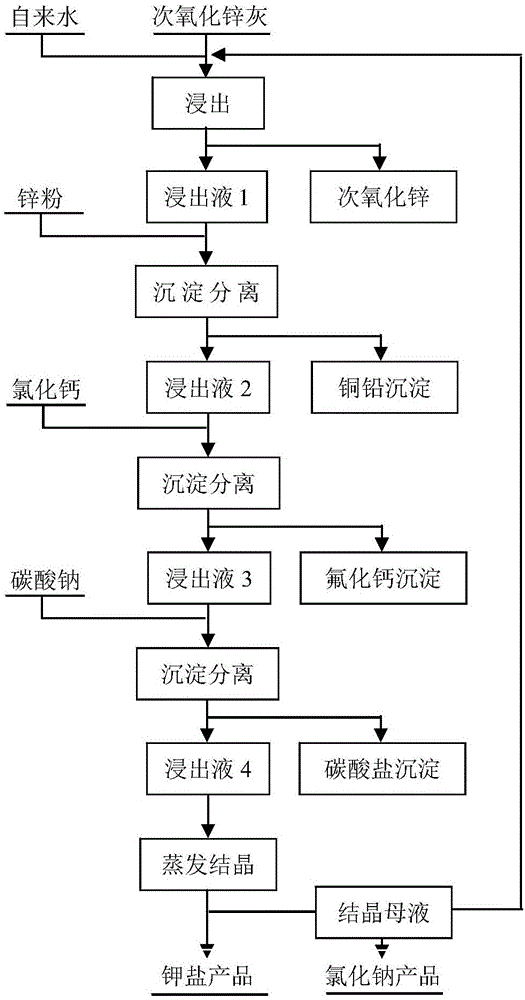

Method for extracting potassium chloride and sodium chloride from secondary zinc oxide ash and application

ActiveCN106745075AFull recoveryEmission reductionOther chemical processesAlkali metal chloridesSludgeMagnesium ion

The invention discloses a method for extracting potassium chloride and sodium chloride from secondary zinc oxide ash and application. The method is particularly suitable for a treatment process for secondary zinc oxide ash obtained by taking zinc-bearing dust and sludge produced by rotary kilns, rotary hearth furnaces and the like in steel plants as a raw material. The method comprises the following steps: separating potassium in the secondary zinc oxide from other soluble salts and insoluble substances by a water washing way; concentrating and purifying an obtained solution to separate heavy metal ions such as zinc and lead dissolved in water and a part of calcium and magnesium ions; obtaining potassium chloride by means of evaporative crystallization separation to serve as a potassium fertilizer, wherein the sodium chloride is taken as a snow removing agent. By adopting the method, the problem of sewage discharge in a process of utilizing the high additional value of the secondary zinc oxide is solved; process waste water is used for preparing a potassium chloride fertilizer; the treatment process has the advantages of simple flow, high efficiency and extremely high environmental protection and economic benefits.

Owner:山东星苑锌业科技有限公司

Repairing method for electric migration of surface layer soil heavy metal Cd to deep layer for fixation

InactiveCN107695092AReduce absorptionEnhancing Electric Restoration EffectsContaminated soil reclamationSoil heavy metalsEngineering

The invention discloses a restoration method for electromotively transferring heavy metal cadmium in surface soil to deep fixation. The restoration method of the present invention is a vertical electrodynamic restoration. After the soil is saturated with water, the battery provides a DC power supply. The positive electrode graphite plate is placed directly on the top surface of the soil column, and the negative electrode aluminum plate is placed on the bottom of the soil column at a depth of 40 cm, and is supplemented by adding potassium fertilizer KCl. The electrodynamic repair effect can make more than 80% of Cd migrate to below 15cm, reduce the absorption of heavy metal Cd by crops, and form high pH soil in the 35-40cm soil layer, which can fix heavy metals without polluting groundwater. The method is simple to operate, does not need complex equipment, is easy to operate in the field, and is easy to apply and popularize. And it does not add non-agricultural chemicals to the soil, which is more friendly to the environment.

Owner:SOUTH CHINA AGRI UNIV

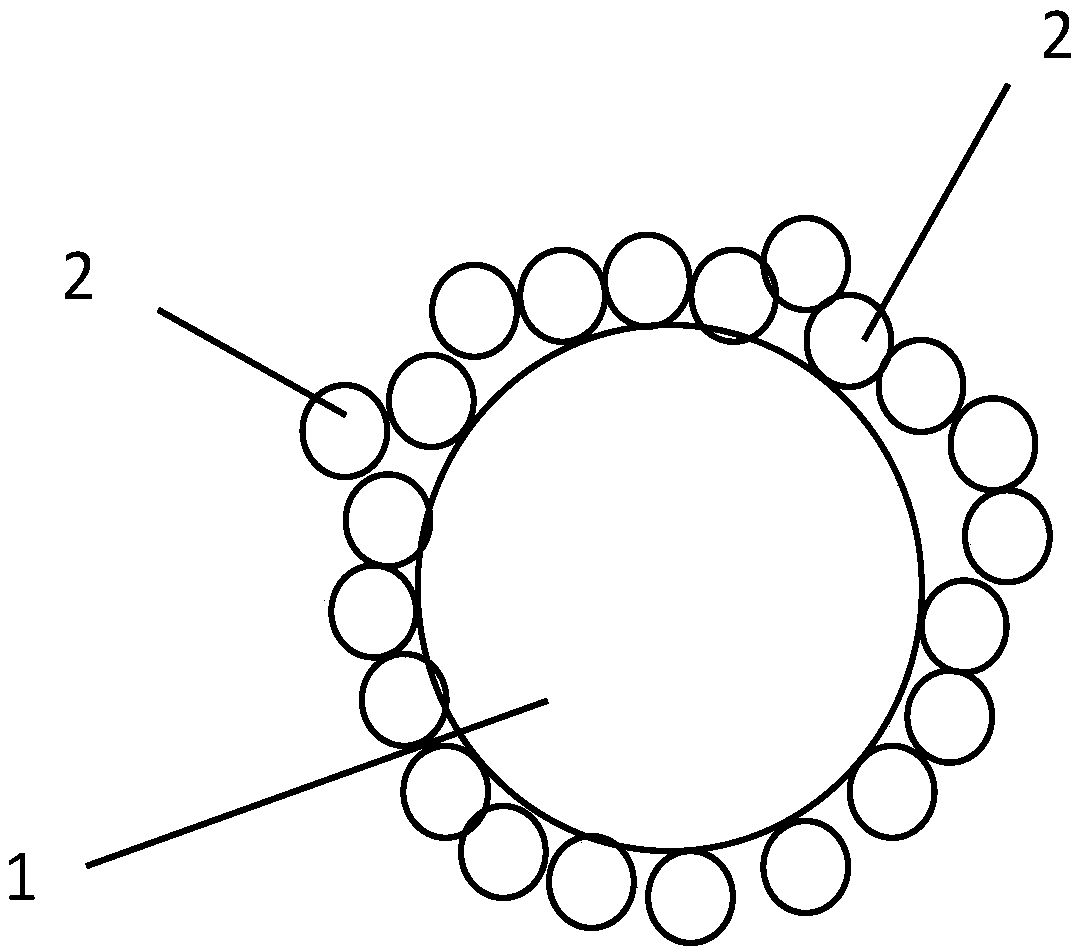

Core-shell solid fertilizer rich in mineral substance and preparation method thereof

InactiveCN108658659ANo need for manual compoundingEfficient separationAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersAdhesiveMineral particles

The invention discloses core-shell solid fertilizer rich in mineral substance. The core-shell solid fertilizer comprises the following raw materials in percentage by weight: A, 35 to 98.5 percent of at least one of chemical fertilizer particles in nitrogen fertilizer, phosphate fertilizer and potash fertilizer; B, 1 to 40 percent of coal or separated mineral particles from gangue before the gangueis burnt or subjected to chemical conversion; C, 0.5 to 25 percent of an adhesive, wherein the outer surface of the chemical fertilizer particles is coated with a plurality of mineral particles through the adhesive. The mineral particles are rich in medium trace elements, such as at least one of B, Ca, Cl, Cu, Fe, Mg, Mn, Mo, S and Zn, which are necessary for plant growth. The core-shell solid fertilizer can realize cost-optimal and high-efficiency utilization of mineral substance waste in coal chemical industry. The core-shell solid fertilizer can control the release rate of chemical fertilizer particles through the concentration of porous mineral substance particles and the thickness of a coating layer. The invention further discloses a preparation method of the core-shell solid fertilizer rich in mineral substance.

Owner:SHENZHEN REVELATION TECH CO LTD

Nitro-compound fertilizer and preparation method thereof

InactiveCN110981583ARaw materials are easy to obtainHigh nutrient contentAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersAgricultural engineeringThermopotash

The intention discloses a nitro-compound fertilizer and a preparation method thereof, and relates to the technical field of agricultural fertilizers, the raw material of the nitro-compound fertilizercomprises 35-65 parts of molten ammonium nitrate, 10-35 parts of a phosphate fertilizer, 10-50 parts of a potash fertilizer and 1-10 parts of a fertilizer stabilizer. The raw materials of the compoundfertilizer are simple and easy to obtain, the nutrient content is high, the stability and uniformity are high, and after granulation, the compound fertilizer has the advantages of being smooth in particle shape, few in broken particles and / or balanced in particles.

Owner:SICHUAN GOLDEN ELEPHANT SINCERITY CHEM CO LTD

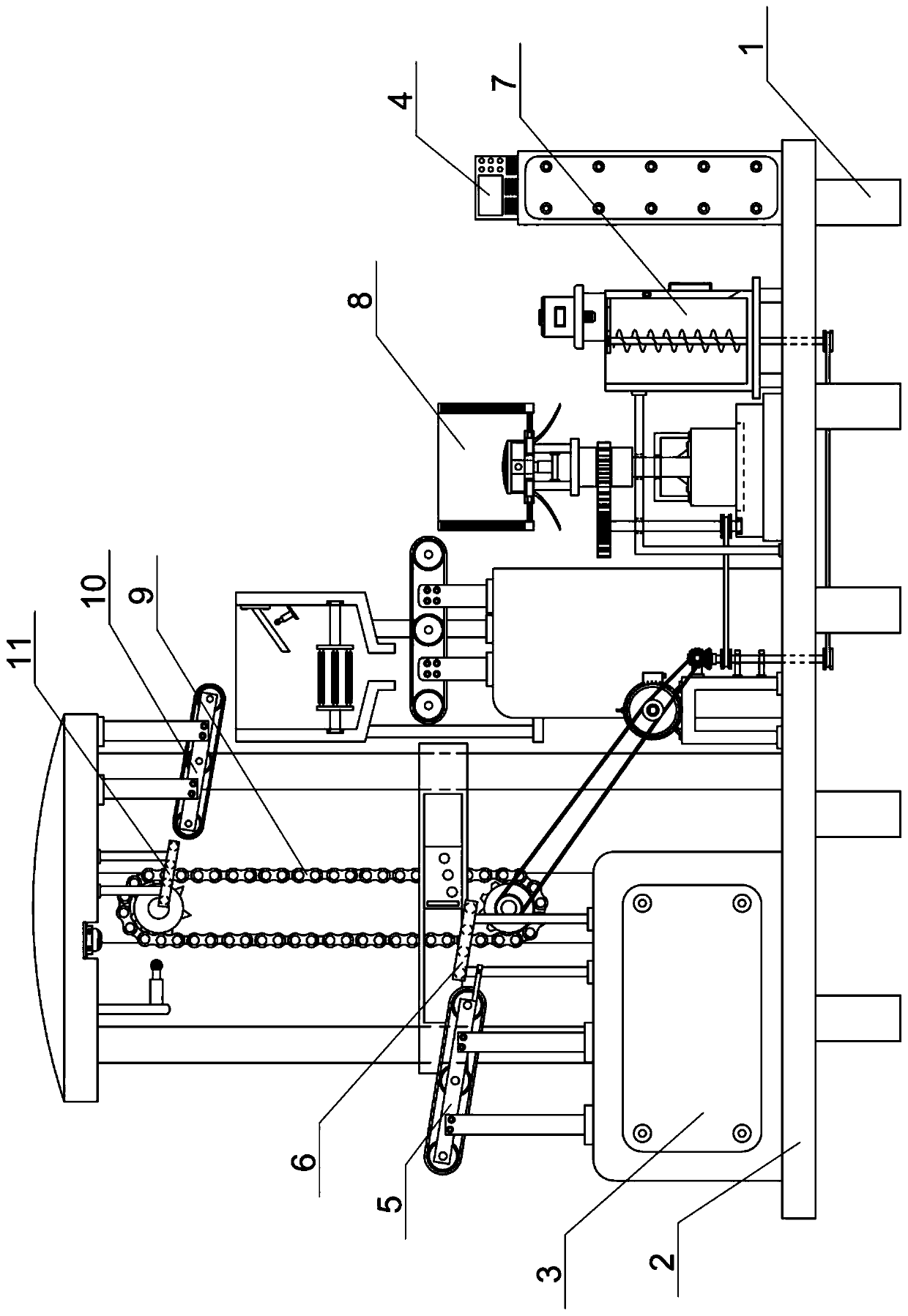

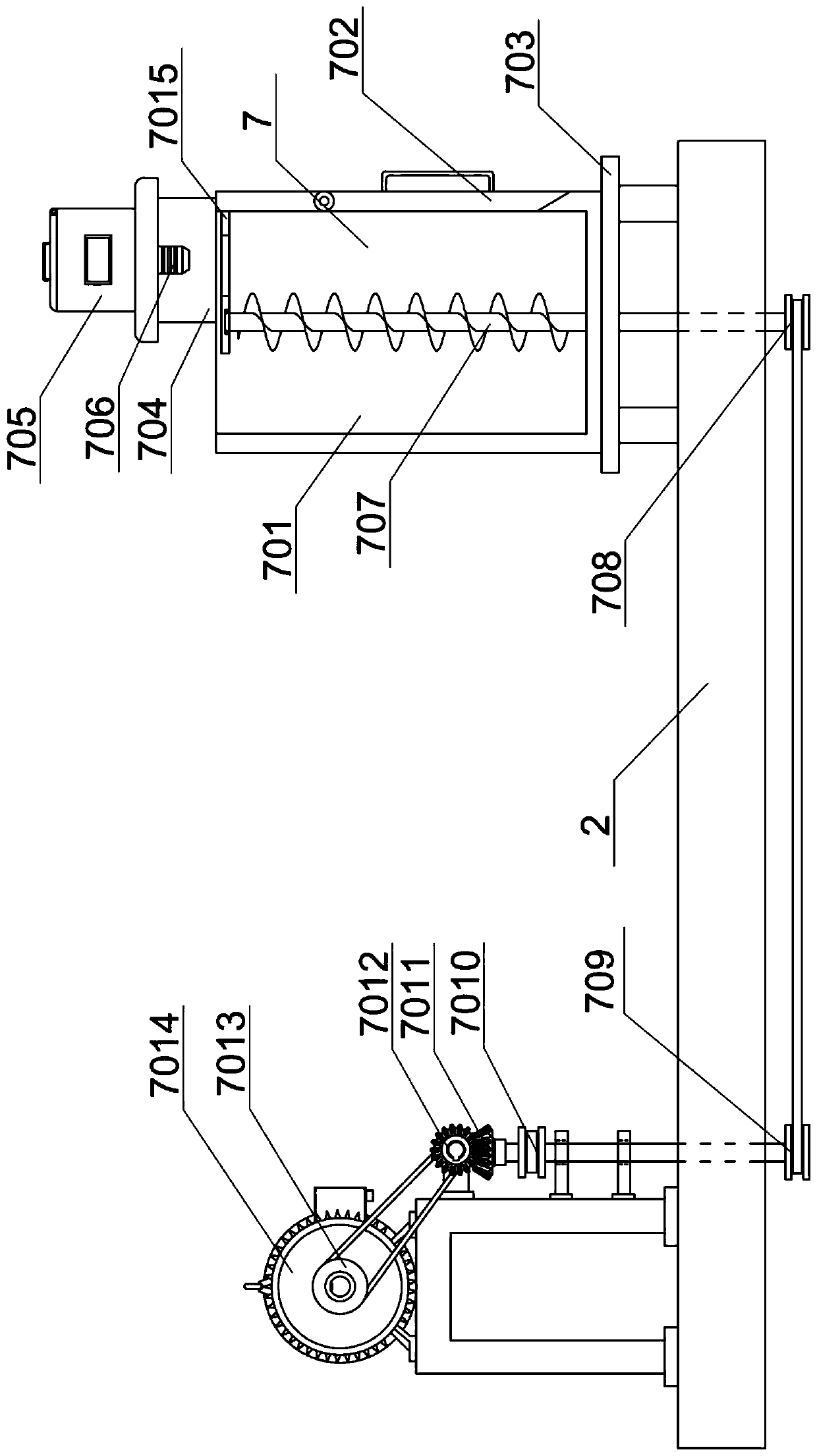

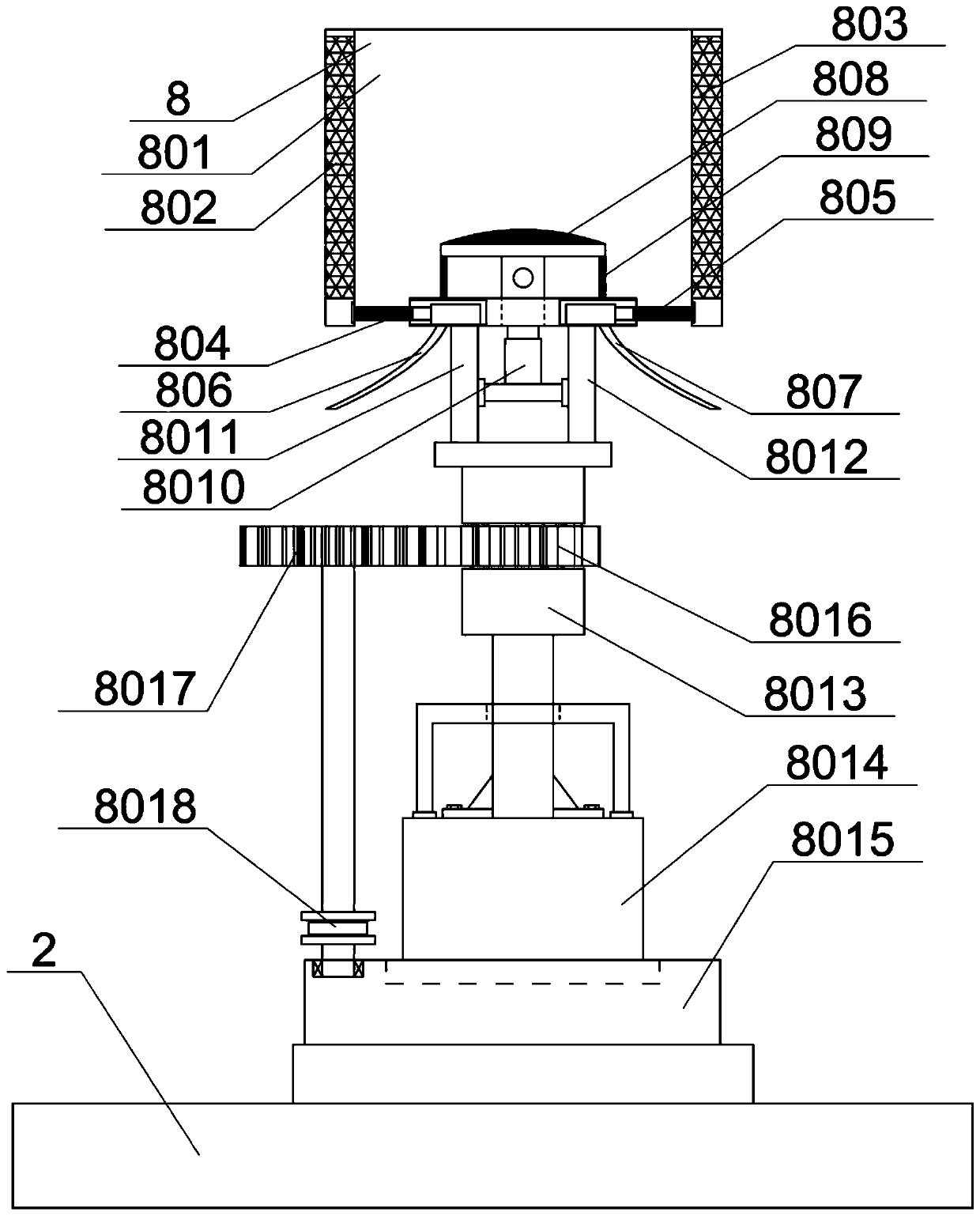

Ore fertilizer soil manufacture device

ActiveCN111570045AImprove breathabilityFully absorbedTransportation and packagingRotary stirring mixersSoil scienceAgricultural engineering

The invention relates to the field of ores and particularly relates to an ore fertilizer soil manufacture device. The technical problem to be solved by the invention is to provide the ore fertilizer soil manufacture device. The ore fertilizer soil manufacture device comprises a first four-roller grid plate, a fertilizer manufacture device, a potash fertilizer outward leading device, a block cracking device, a second conveying belt and a second four-roller grid plate, wherein the fertilizer manufacture device is disposed on the right side of the middle of the top of a baseplate; and the potashfertilizer outward leading device is disposed on the rear middle right side of the middle of the top of the baseplate. The device provided by the invention has the beneficial effects that ores are fully mixed with soil, plant rooting is promoted, and soil hardening is prevented; the ores on the outer layer of a whole airing box can be heated uniformly, contact architecture among the ores is prevented through ascending and descending of a mushroom plate, and mutual jam of the ores is prevented; and mica blocks are crushed through automatic striking, effects and the speed of crushing are increased, raw material waste is avoided, and personal injury events caused by outward bursting of fragments do not take place.

Owner:嘉兴鼎尚信息科技有限公司

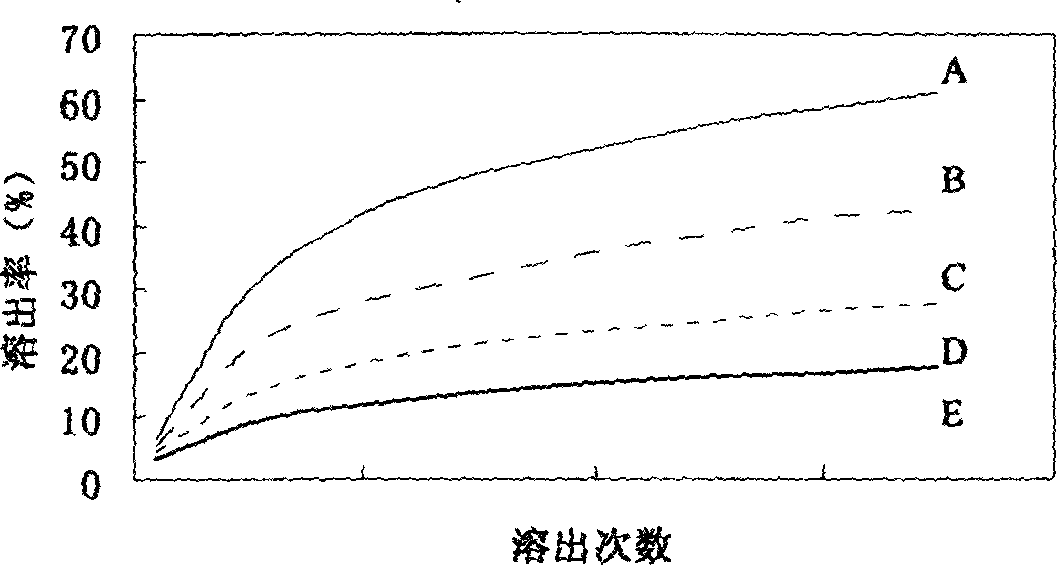

Preparation method for potash fertilizer particles

ActiveCN104311258AHigh strengthReduce intensitySolid/semi-solid fertilisersPotassium fertilisersThermopotashPotash

The invention relates to a preparation method for potash fertilizer particles. The preparation method is characterized in that the potash fertilizer particles are pelletized by a two-stage mixing extruder, potash fertilizer powder and additives are rapidly refined, scattered and mixed due to the strong shear force of the high rotation speed screw of a first-stage twin screw mixing mill, and then enter a second-stage single screw extruder through exhaust, the output end can conduct high pressure stable extrusion at a low rotation speed, and finally, pelleting is carried out by a die surface pelletizer to obtain the potash fertilizer particles. The potash fertilizer particles have high nutrient concentration, are regular in shape and uniform in diameter, and have high strength and good slow release performance. The preparation method is simple to operate, has strong technological adaptability, consumes little energy, has high granulation rate and high yield, and has market application value.

Owner:山东亿田生物肥料科技有限公司

Anti-hardening drip irrigation fertilizer suitable for improving salinized and hardened soil and preparation method thereof

InactiveCN112279735ASolve the problem of salt hardeningImprove physical and chemical propertiesAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersSoil scienceNutrition

The invention discloses an anti-hardening drip irrigation fertilizer suitable for improving salinized and hardened soil and a preparation method thereof. The anti-hardening drip irrigation fertilizeris prepared from the following raw materials in parts by weight: 10 to 20 parts of nitrogen fertilizer, 15 to 25 parts of phosphate fertilizer, 15 to 25 parts of potash fertilizer, 10 to 20 parts of humic acid powder, 0.5 to 2 parts of trace elements and 5 to 10 parts of an anti-hardening agent, and all the raw materials are crushed and mixed to obtain the anti-hardening drip irrigation fertilizer. The product is suitable for salinized and hardened soil, the anti-hardening agent in the product enters a salinized layer of soil after fertilization, the binding force between salting-out crystalsis destroyed, the soil structure is adjusted, nutrient elements needed by growth and development are provided for crops, and therefore the dual effects of improving soil and providing nutrition are achieved.

Owner:新疆德福优品生物科技有限公司

Biological potassic fertilizer produced by using low-grade potassium-bearing rocks and production method thereof

InactiveCN101229984BImprove conversion rateImprove effectivenessBio-organic fraction processingClimate change adaptationPotassiumDrug biotransformation

The invention provides biological potassium fertilizer produced by using low taste rock containing potassium and a production method for the fertilizer. The biological potassium fertilizer is prepared through the following steps of solid state fermentation treatment of the low taste rock containing potassium, processing waste of agricultural byproducts, water, earthworm and complex bacteria, biotransformation under the effect of the earthworm and housefly larvae as well as the bioleaching. On the basis of the two-step transformation method (the solid state fermentation and the bioleaching) for producing biological potassium fertilizer, the biotransformation step is added in the invention. After the solid state fermentation, biology with biotransformation function is inoculated. The conversion of the potassium in the low taste rock containing potassium is improved; therefore, the rock powder containing the potassium and agriculture waste are turned into good organic fertilizer through a plurality of transmission ways. The contents of other trace elements in the potassium fertilizer are increased. Therefore, the invention has a good market promotion prospect with an economical and practical advantage and good fertility of the potassium fertilizer.

Owner:INST OF GEOCHEM CHINESE ACADEMY OF SCI

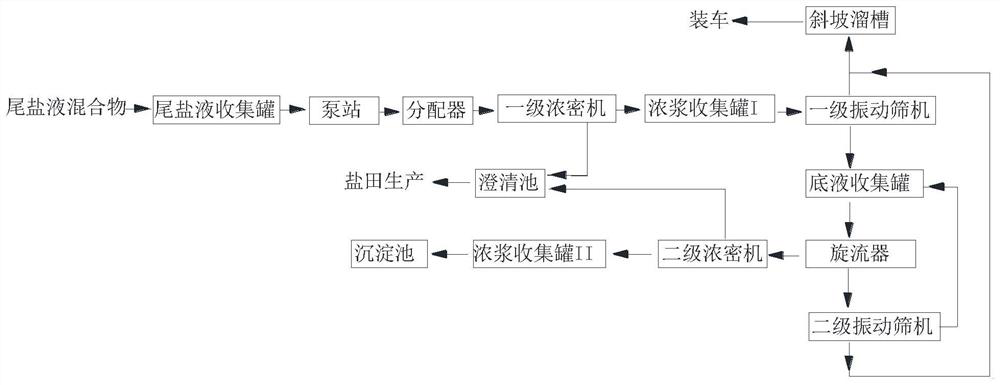

Solid-liquid separation system and process for tail salt liquid generated in production of potash fertilizer from carnallite

PendingCN114642919AQuality improvementControllable stackingFiltration circuitsAgricultural engineeringEnvironmental engineering

The invention provides a solid-liquid separation system and a solid-liquid separation process for tail salt liquid generated in production of a potash fertilizer from carnallite, and relates to the technical field of chemical production. The solid-liquid separation system comprises a tail salt liquid collection tank, a pump station, a first-stage thickener, a first-stage vibrating screen machine, a cyclone, a second-stage thickener and a sedimentation tank which are sequentially connected through a conveying pipeline; the cyclone is also connected with a secondary vibrating screen machine; and the first-stage thickener and the second-stage thickener are connected to the clarification tank through pipelines or water tanks. The system is used for treating the tail salt liquid generated during potassium fertilizer production from carnallite, solid and liquid in the tail salt liquid can be separated to the maximum extent finally, and the solid and the liquid which are separated again can enter a production system to be reused. The separated liquid (brine) is high in quality, the solid (tail salt) is controllable in transportation and stacking use, the site use is small, the cost is low, the tail salt liquid generated in a potash fertilizer production workshop can be continuously treated without shutdown, and the production efficiency is high.

Owner:蔡静

Fertilizer special for amomum tsao-ko

InactiveCN103483048ASimple recipeReduced amount of fertilizer per muFertilizer mixturesAgricultural scienceAmomum tsaoko

The invention discloses a fertilizer special for amomum tsao-ko. The fertilizer comprises a compound fertilizer, a nitrogen fertilizer, a phosphate fertilizer and a potash fertilizer that are in a proportion of 4-5:1-1.6:2-3:2-3. The fertilizer special for amomum tsao-ko has the advantages of simple formula, high efficiency and no toxicity, a fertilizer dosage decreased by 5%-10% for per 667 square meters, a yield increased by 20%-25%, effective components improved by 10%-15%, and simple application process, as well as easy operation.

Owner:黄振忠

Winter jujube cultivation method

InactiveCN111084041ABreeding method is simpleReduce cost investmentFertilising methodsCultivating equipmentsFarmyard manurePest control

The invention relates to a winter jujube cultivation method. The cultivation method comprises the following steps: S1, land selection: selecting sandy loam or clay loam which is convenient to drain and irrigate and has a thick soil layer; S2, field planting: carrying out soaking in clear water for 15-20 hours before field planting, applying farmyard manure before planting, then conducting field planting, wherein a field planting depth does not exceed an in-situ plane by 3-4 cm, performing sufficient watering in time after field planting, and then covering the tree disks with plastic films; S3,soil management: carrying out grass covering and grass growing in a winter jujube orchard; S4, fertilization: applying fertilizer 1-3 times every year, wherein the applied fertilizer comprises farmyard manure, urea, phosphate fertilizer and potash fertilizer; and S5, pest control. Winter jujubes obtained by using the method are natural and pollution-free, the cultivation method is simple, cost investment is low, and the yield of the winter jujubes is relatively high.

Owner:刘凯

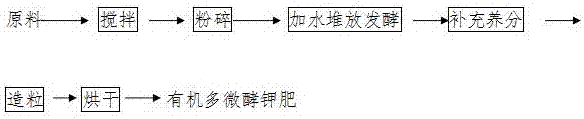

Method for preparing organic multi-microelement fermented potash fertilizer by fermenting insoluble potassic rock at high temperature

InactiveCN107244964ASimple structureImprove qualityBio-organic fraction processingThomas phosphate fertilisersFarmyard manureToxic industrial waste

The invention discloses a method for preparing an organic multi-microelement fermented potash fertilizer by fermenting an insoluble potassic rock at the high temperature. The method comprises the following steps: (1) choosing the raw material: choosing the insoluble potassic rock as the main material; (2) pulverizing the main material and an auxiliary material; (3) stacking and fermenting; (4) fermenting at the high temperature; (5) complementing nutrients; and (6) pelleting and drying. Through adoption of the method, the natural resources are effectively utilized, particularly the insoluble potash rock; a large quantity of industrial waste residues is used, so that the harmful is turned into the beneficia; the produced organic multi-microelement fermented potash fertilizer improves the fertilizer structure in the agricultural production; the fertilizer efficiency of the organic multi-microelement fermented potash fertilizer is equivalent to that of the traditional farmyard manure; the organic multi-microelement fermented potash fertilizer is used for planting vegetables and grains; and the flavors of the vegetables and grains are fresh, and the tastes of the vegetables and grains are good. The pollution caused by urban and rural wastes is reduced, the environment condition is improved, the qualities of the vegetables and the grain crops are also improved, and the method not only has economic benefits, but also has higher social benefits, and is suitable for all urban and rural areas.

Owner:崔克昌

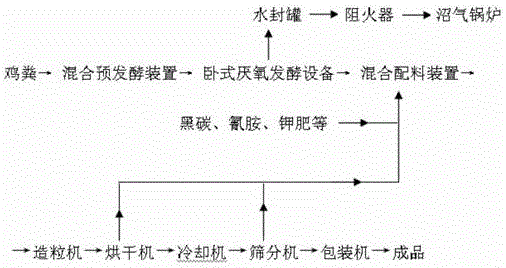

A kind of chicken manure organic fertilizer and preparation method thereof

The invention discloses a chicken manure organic fertilizer and a preparation method thereof. The chicken manure organic fertilizer comprises the following raw materials in parts by weight: 800-1,200 parts of chicken manure, 20-40 parts of black carbon, 80-120 parts of cyanamide and 70-80 parts of a potassium fertilizer. The method comprises the following steps: adding the chicken manure into a mixing and pre-fermenting device for pre-fermenting; adding auxiliary materials for compounding; and performing granulation, drying, cooling and sieving to obtain a finished product, wherein materials which do not satisfy certain conditions in the drying and sieving processes are mixed once again; and marsh gas obtained by means of horizontal anaerobic fermentation is utilized as energy through a marsh gas boiler. The chicken manure organic fertilizer provided by the invention has the advantages of comprehensive nutrition, high content, high benefit, input-output ratio of up to 1:(10-30) or more, and wide application, and is widely suitable for various soil properties and various crops, including various greenhouse vegetables, fruit trees, economical crops, grain crops, medicinal materials, flowers, lawns, garden plants and the like.

Owner:TAONAN FUXING BIO ORGANIC FERTILIZER CO LTD

Preparation and application methods of compound fertilizer matrix

InactiveCN112430158AIncrease profitSolve agglomerationCalcareous fertilisersOrganic fertilisersAgricultural engineeringThermopotash

The invention relates to the technical field of fertilizers, particularly to a preparation method and use method of a compound fertilizer matrix. The preparation method comprises the following steps:mixing a calcium source and a silicon source, performing hydrothermal reaction under an alkaline condition to obtain a substance A, and mixing the substance A with fly ash and coal gangue powder to obtain a compound fertilizer matrix. The use method comprises the step of mixing the obtained compound fertilizer matrix with a plant growth regulator, a nitrogen-phosphorus-potassium fertilizer, a trace element fertilizer and an organic fertilizer for use. After the compound fertilizer matrix is mixed with other fertilizers for use, the effects of regulating the plant growth, promoting the absorption of beneficial elements by plants, improving the fertilizer utilization rate, retaining water, resisting drought and improving the air permeability of soil can be achieved, and the caking problem inthe fertilizer compounding process can be effectively solved. The method has the characteristics of simple process, low energy consumption, sufficient raw material storage and the like.

Owner:XILINGOL VOCATIONAL COLLEGE +1

Potash fertilizer granulation method and granules thereof

ActiveCN104311232AIncreased crush strengthImprove water resistanceSolid/semi-solid fertilisersPotassium fertilisersAgricultural engineeringThermopotash

The invention relates to a potash fertilizer granulation method and granules thereof. The method is characterized by comprising the following steps: micronization is carried out on a potash fertilizer, and during the micronization process, a low molecular weight organic matter is used to process the surface of the potash fertilizer so as to endow the potash fertilizer with thermoplastic machinability; then, the potash fertilizer is sent into a screw extruder pelletizer to undergo compression, mixing and compaction extrusion; and finally, grain-sized dicing, cooling and screening are carried out successively, so as to obtain potash fertilizer granules. According to the method, the potash fertilizer accounts for more than 90% of the total weight of the granulation material and the concentration is high; the potash fertilizer granules are spheroidal; grain size is 2-5 mm; and average crushing strength is 40-60 N. The method has advantages of simple technology, low investment, continuous production, high yield and low energy consumption. The potash fertilizer granules obtained are regular, contain uniformly-dispersed nutrients, has high strength and has market application value.

Owner:GUANGDONG MIGAO CHEM

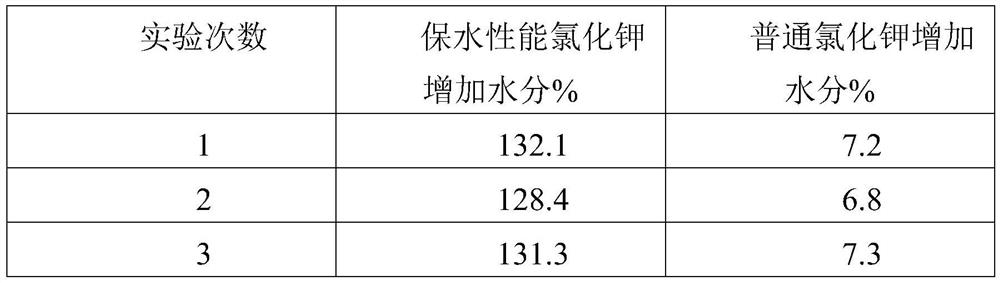

Potash fertilizer with high water retention capacity

InactiveCN113173819AImprove water retentionWith mass production capacityAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersAgricultural engineeringWater resources

The invention relates to a potash fertilizer with high water retention capacity. The potash fertilizer with high water retention capacity is formed by combining 1-20% by weight of a water-retaining agent, 0.1-5% by weight of a binder and 75-98.9% by weight of a potash fertilizer. The preparation method comprises the following steps: uniformly mixing the water-retaining agent and the potash fertilizer, conducting granulating in a granulation roller, dissolving the binder in water, spraying the binder in a mist form to enable the powder formed by mixing the water-retaining agent and the potash fertilizer to become particles, and then carrying out drying, screening and packaging. The potash fertilizer with high water retention capacity has the advantages that the potash fertilizer with high water retention capacity can be produced on a large scale, can be reserved according to customer requirements, can supplement water for crops in a water-deficient area, and provides a large amount of water resources for crops requiring a large amount of water.

Owner:HUBEI FORBON TECH

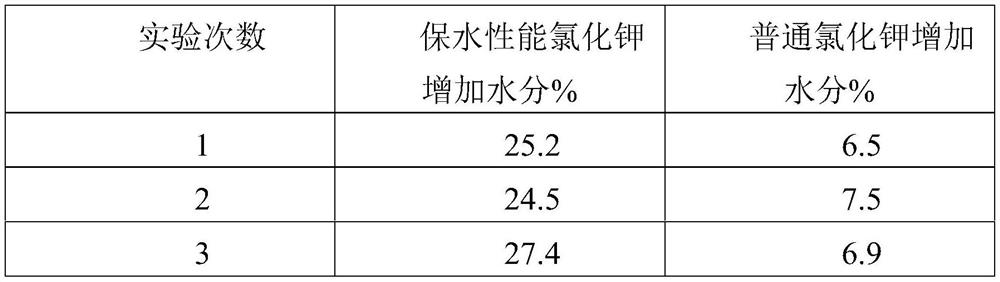

A system and method for drying carnallite

ActiveCN109336137BPromote precipitationShorten drying timeMagnesium chloridesEnergy inputPhysical chemistryPotassium ions

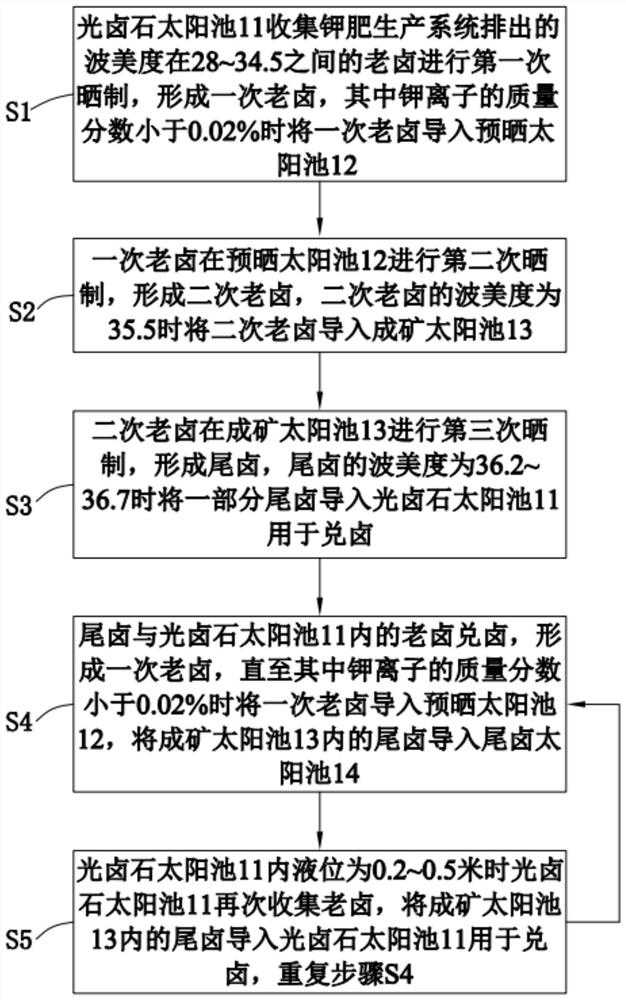

The invention discloses a carnallite sun-drying system. The carnallite sun-dried system includes a carnallite solar pool, a pre-sun solar pool, a mineralization solar pool, and a tailing brine solar pool connected in sequence. The carnallite solar pond is connected, and the carnallite solar pond collects the old brine discharged from the potassium fertilizer production system with a Baume degree between 28‑34.5 for the first drying to form a primary old brine. When the mass fraction of potassium ions is less than 0.02% The primary old brine is introduced into the pre-solarization solar pool for the second drying to form the second old brine. When the Baume degree of the second old brine is 35.5, the second old brine is introduced into the ore-forming solar pool for the third drying. Tail brine is formed, and when the Baumé degree of tail brine is 36.2 to 36.7, the tail brine is introduced into the carnallite solar pool. According to the carnallite sun-drying system and method provided by the present invention, the carnallite can be precipitated quickly through the joint brine of the tail brine and the old brine, and the sun-drying time is greatly shortened. Sulfate ions in the stone can reduce the cost for the subsequent production of magnesium metal.

Owner:QINGHAI SALT LAKE IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com