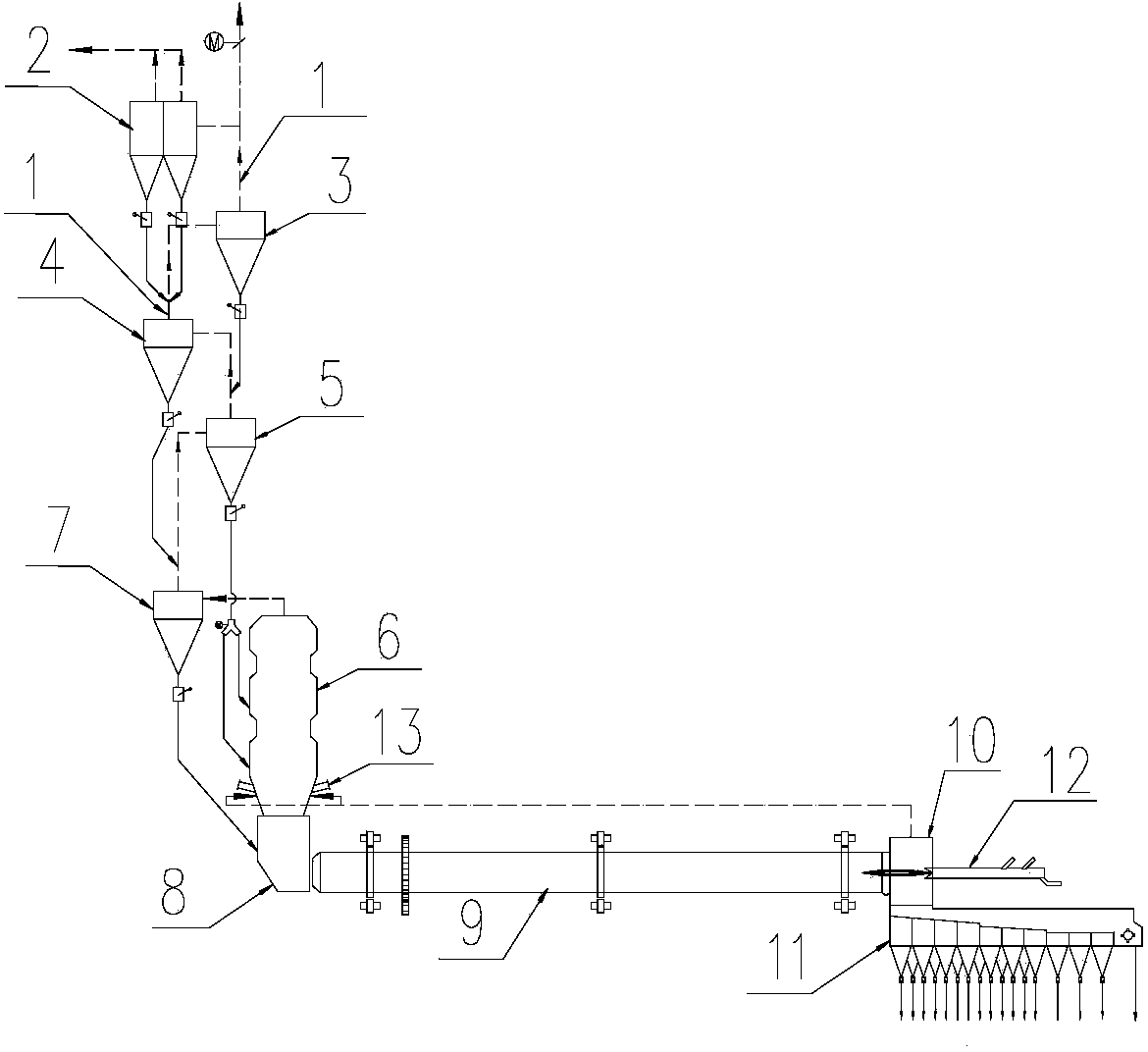

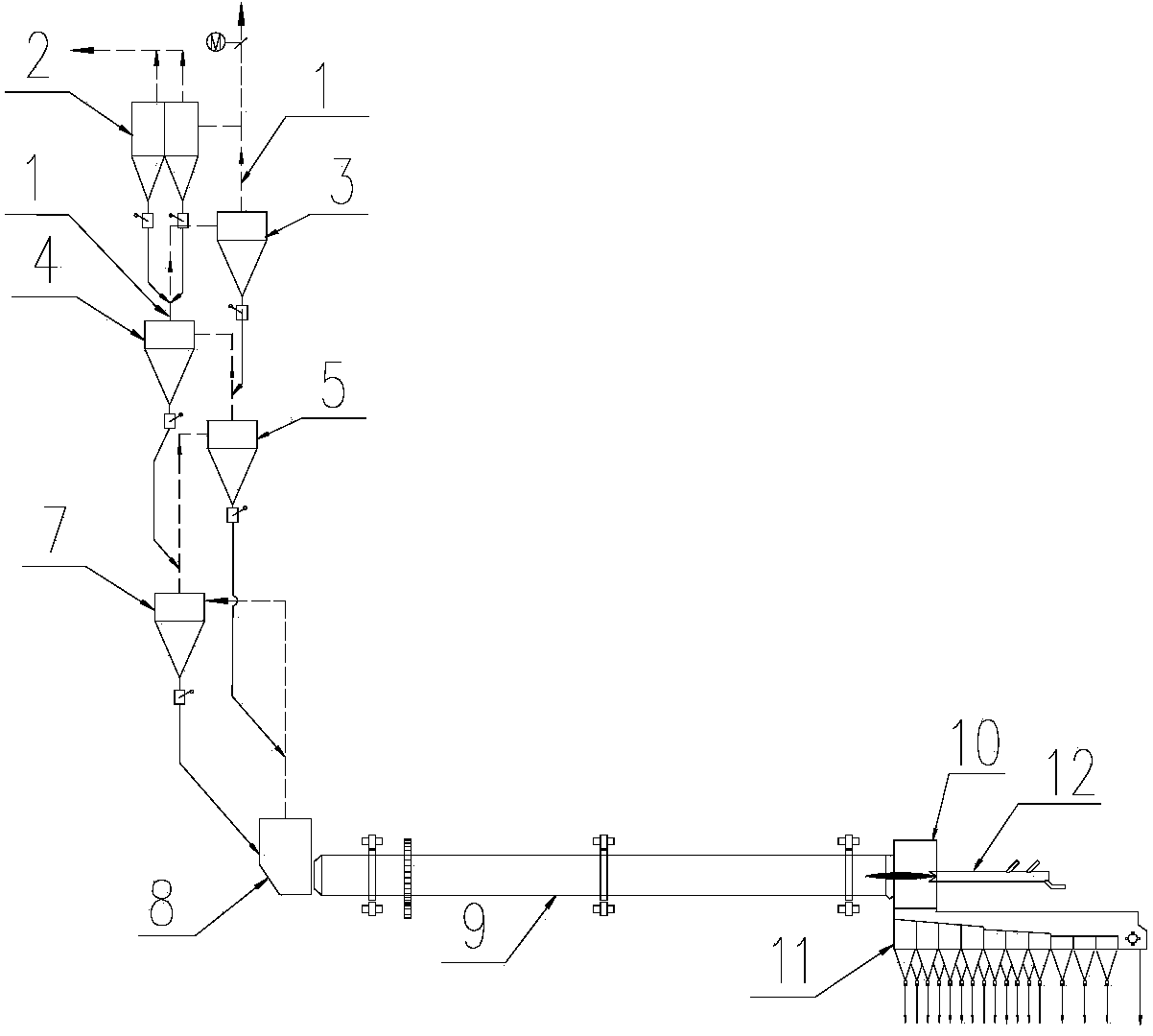

Production process and equipment of silicon-calcium-potassium fertilizer

A production process and production equipment technology, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve the problems of low utilization rate of chemical fertilizers, lack of understanding of the important role of silicon fertilizers, etc., and achieve fuel cost reduction, high degree of automation, and measurable parameters controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: take water-insoluble potassium ore-potassium-containing silicate rock and limestone as raw materials, and sequentially pass through crushing, grinding, rotary kiln calcination, cooling by cooler, crushing and grinding to obtain silicon calcium potassium fertilizer; wherein, rotary In the kiln calcination process, the temperature of the firing zone is 1150-1250°C, and the material residence time in the kiln is 20-60 minutes.

[0026] In this embodiment, in order to reduce heat consumption and production cost, the material is preheated after the grinding process and before the calcining process in the rotary kiln. Further, in the preheating process, the material is decomposed.

Embodiment 2

[0027] Example 2: Different from Example 1, the temperature of the firing zone in the calcination process of the rotary kiln is 1250-1350°C, and the residence time of the material in the kiln is 30-50 minutes.

Embodiment 3

[0028] Example 3: Different from Example 1, the temperature of the firing zone in the calcination process of the rotary kiln is 1200-1400°C, and the residence time of the material in the kiln is 20-40 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com