Method and device for roasting water insoluble potassium ore to extract potassium chloride to produce potash fertilizer

A water-insoluble potassium chloride technology, applied in fertilization equipment, potassium fertilizer, alkali metal chloride, etc., can solve the problems of staying in the laboratory stage, etc., and achieve the effect of low production cost, high potassium extraction rate, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

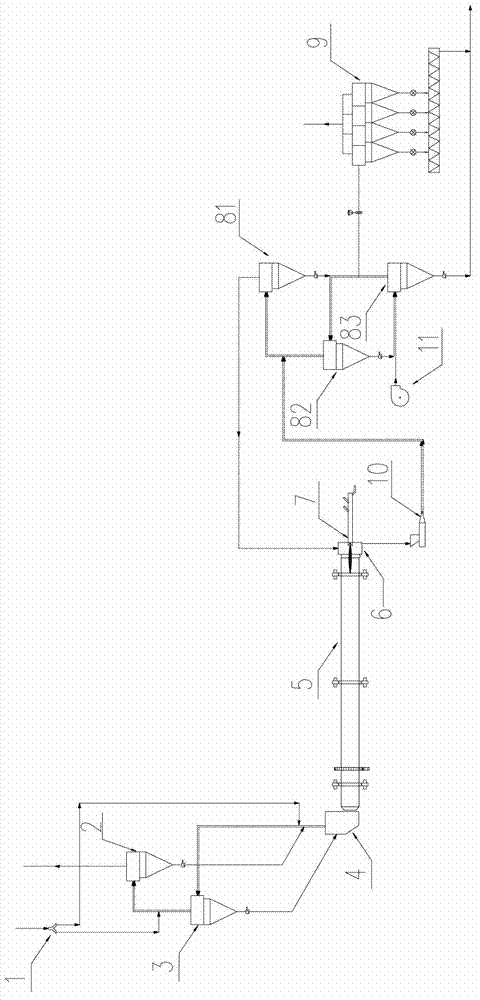

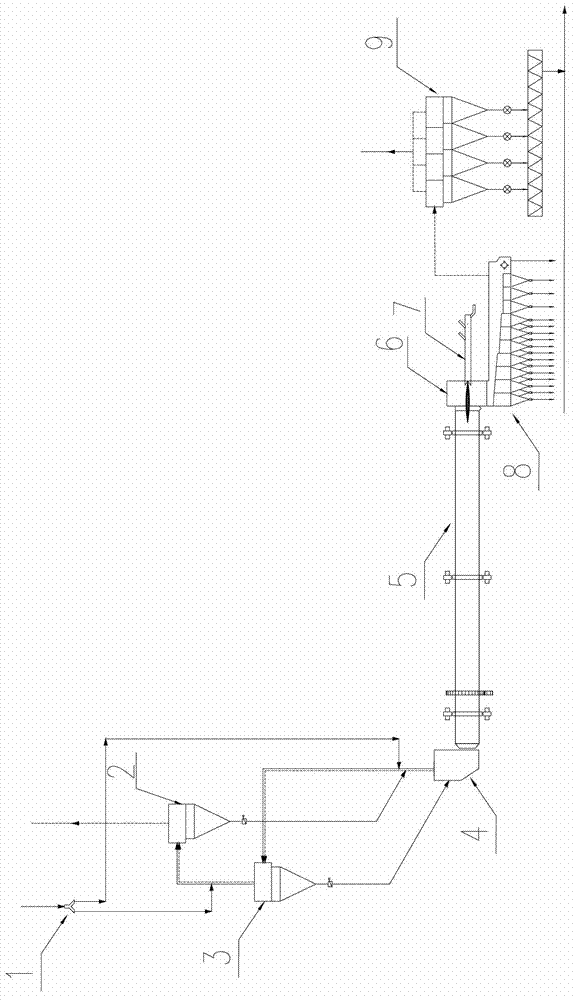

Method used

Image

Examples

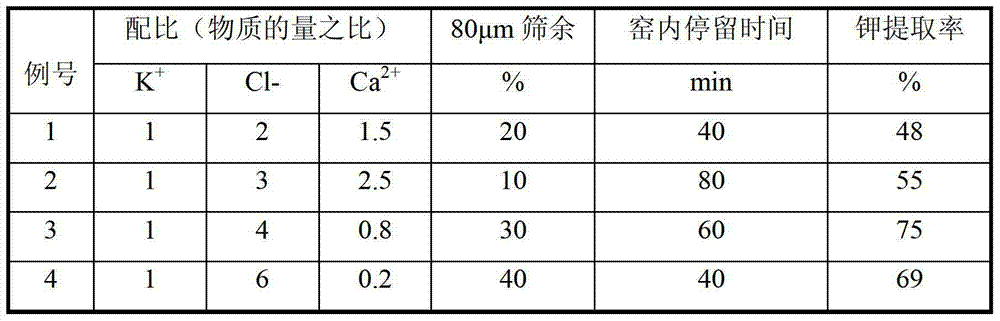

Embodiment 1-4

[0035] 1) Selection of raw materials

[0036] Potassium aluminosilicate minerals having the chemical composition shown in Table 1 were used.

[0037] Chemical composition (%) of table 1 raw material

[0038]

LOSS

SiO 2

Al 2 o 3

Fe 2 o 3

CaO

MgO

K 2 o

Na 2 o

Cl

potash ore

3.89

56.88

16.62

7.51

0.14

2.10

9.47

0.18

0.008

rock salt

N / A

0.21

0.14

0

0.04

0.06

0.04

48.00

52.625

limestone

43.02

1.70

0.20

0.10

54.28

0.32

0.04

0.04

0.009

[0039] 2) Preparation of raw meal

[0040] Separately crush potassium ore, halite and limestone, press certain (K + : Cl - : Ca 2+ ) The ratio of the amount of substances is compounded to obtain raw meal, and the raw meal is ground to 80μm sieve with 10-40% remaining by using a vertical mill.

[0041] 3) Roasting of raw materials

[0042] Feed the raw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com