Solid-liquid separation system and process for tail salt liquid generated in production of potash fertilizer from carnallite

A solid-liquid separation, carnallite technology, applied in separation methods, filtration separation, chemical instruments and methods, etc., can solve the hidden dangers of potash fertilizer production, high cost, high site requirements, and achieve high production significance and environmental protection significance. Controllable use and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

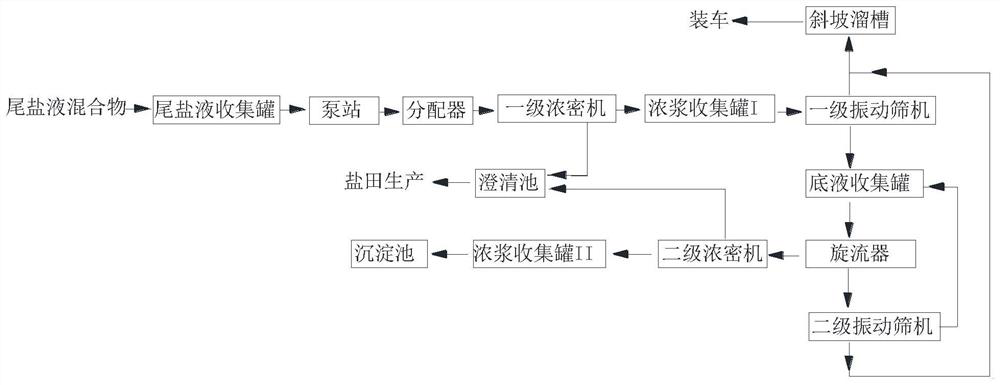

[0040] A liquid-solid-liquid separation process of tail salt produced by carnallite production of potash fertilizer, and its process flow chart is as follows: figure 1 shown, including the following steps:

[0041] The tail salt liquid mixture (a mixture of solid and liquid) in the potash fertilizer production workshop is flowed into and concentrated in the tail salt liquid collection tank through one or more pipes, stirred to make the solid and liquid phases as uniform as possible, and then pumped and piped to It is sent to the distributor with a higher geographical location, and the distributor transports the tailings liquid mixture through pipelines and valves to multiple parallel primary thickeners for gravity sedimentation; due to the height difference between the distributor and the primary thickener, so The flow of this step does not require an electric pump, but rather the self-flow is controlled by a valve. In order to ensure that the tail salt liquid can be continuo...

Embodiment 2

[0049] The present embodiment proposes a liquid-solid-liquid separation process of tail salt produced by the production of potash fertilizer from carnallite, which is basically the same as that in Example 1, and the similarities will not be repeated. The difference is that the overflow water in the cyclone directly enters the main chute , and then discharged into the clarifier for precipitation. The treatment process in this embodiment requires a dredger with a larger processing capacity for treatment.

Embodiment 3

[0051] The present embodiment proposes a liquid-solid-liquid separation process of tail salt produced by carnallite to produce potash fertilizer, which is basically the same as that in Example 1, and the similarities will not be repeated, the difference is that the overflow water in the cyclone is discharged into the secondary Concentrate again in the thickener, collect the secondary thickener underflow (slurry with higher concentration) into the thick slurry collection tank II and stir it as evenly as possible, pump it into the centrifuge with a water pump of the corresponding specification and model, and use the centrifuge The slurry with higher concentration after passing through the secondary thickener is subjected to the third active separation. During the separation process, the top overflow water of the thickener is collected through the top inclined chute around the thickener itself, and then enters the main chute through the pipe or small chute from the collection port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com