Method for preparing organic multi-microelement fermented potash fertilizer by fermenting insoluble potassic rock at high temperature

A high-temperature fermentation and organic technology, applied in organic fertilizers, potash fertilizers, inorganic fertilizers, etc., can solve the problems of insufficient utilization of potassium resources, no mention of high-temperature fermentation, no multi-element fertilizers, etc., to improve environmental conditions and taste. Fresh and pollution-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

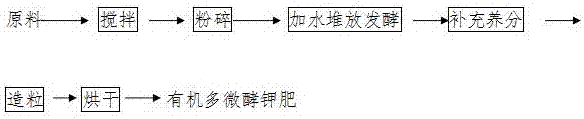

Method used

Image

Examples

Embodiment

[0029] The potassium-bearing rocks in Tongren, Guizhou Province were used as raw materials, and the K 2 O grade is 9.0%.

[0030] Take peat as A-type auxiliary materials, take oily waste and slaughtered livestock and poultry waste as B-type auxiliary materials, and take phosphate rock powder, yellow phosphorus slag and iron-making chimney ash as C-type auxiliary materials.

[0031] Grinding the potassium-containing rock raw material, A-type auxiliary materials, solid auxiliary materials in B-type auxiliary materials and C-type auxiliary materials to below 120 mesh;

[0032] Mix 100kg of crushed potassium-containing rock powder, 20kg of A-type auxiliary material powder, 20kg of B-type auxiliary material powder and 10kg of C-type auxiliary material powder, add 10L of water to mix, stir well, introduce 10kg into the enzyme system, stack and ferment until the temperature reaches 35°C ~65°C;

[0033] After stacking and fermenting, add 20 kg of enzyme system and 20 L of water to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com