Patents

Literature

86results about "Thomas phosphate fertilisers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

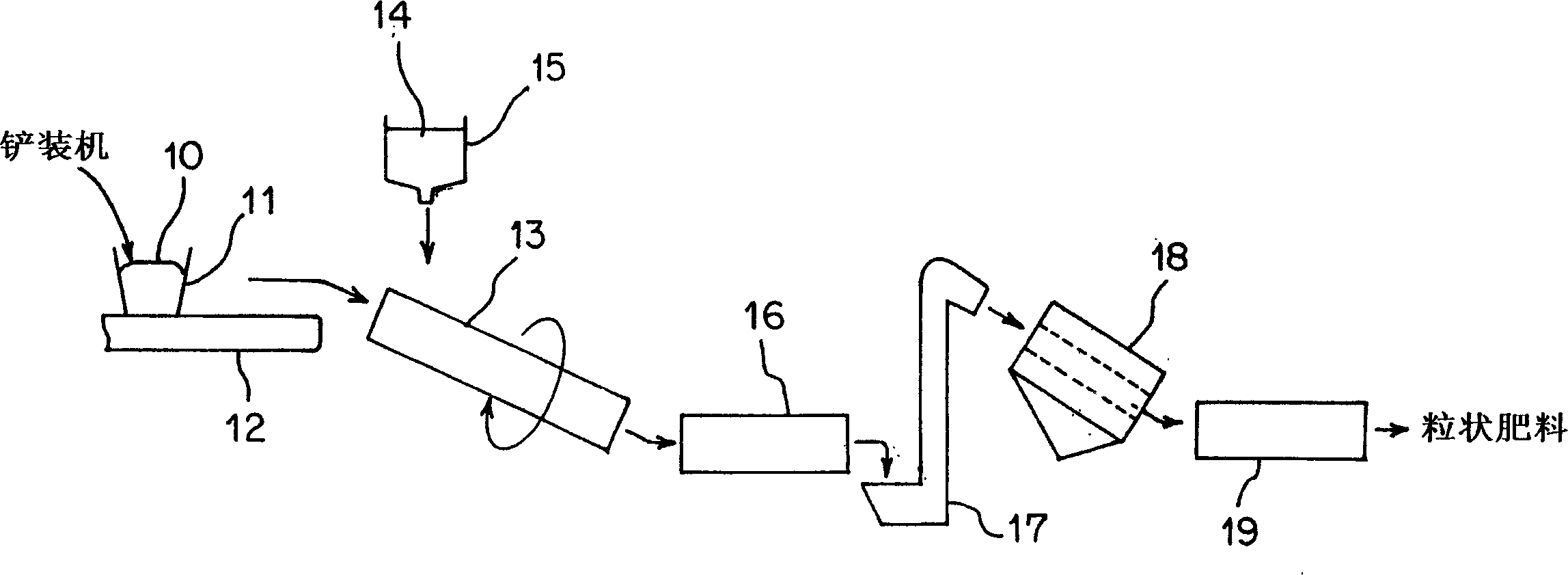

Environmentally-friendly efficient microbial compound fertilizer and preparation method thereof

InactiveCN105566012AEasy to useAvoid destructionThomas phosphate fertilisersExcrement fertilisersBacillus licheniformisBacillus thuringiensis

The invention discloses an environmentally-friendly efficient microbial compound fertilizer and a preparation method thereof. The environmentally-friendly efficient microbial compound fertilizer is prepared from chicken manure, cow dung, dried pond sludge powder, ground phosphate rock, edible fungi residues, furfural residues, a microbial agent, wheat bran, bean cakes, urea, ammonium nitrate, potassium humate, wheat straws, charcoal powder and traditional Chinese medicine residues, wherein the microbial agent is prepared from bacillus licheniformis, bacillus subtilis, bacillus mucilaginosus, bacillus megatherium, pseudomonas, bacillus thuringiensis, bacillus amyloliquefaciens and nitrogen-fixing bacteria. The edible fungi residues and the furfural residues are smashed and mixed with water, the microbial agent is added for fermentation, the Chinese traditional medicine residues are added to perform fermentation, then the rest of the raw materials are added, and the microbial compound fertilizer can be obtained by performing full mixing, granulation and drying. The raw materials used for the microbial compound fertilizer are all natural fertilizers and contain rich mineral substances, the damage of a soil acid-base structure and a nutritional ingredient structure caused by inorganic fertilizer application is avoided, and the environmentally-friendly efficient microbial compound fertilizer is greener and more environmentally-friendly.

Owner:范洲卫

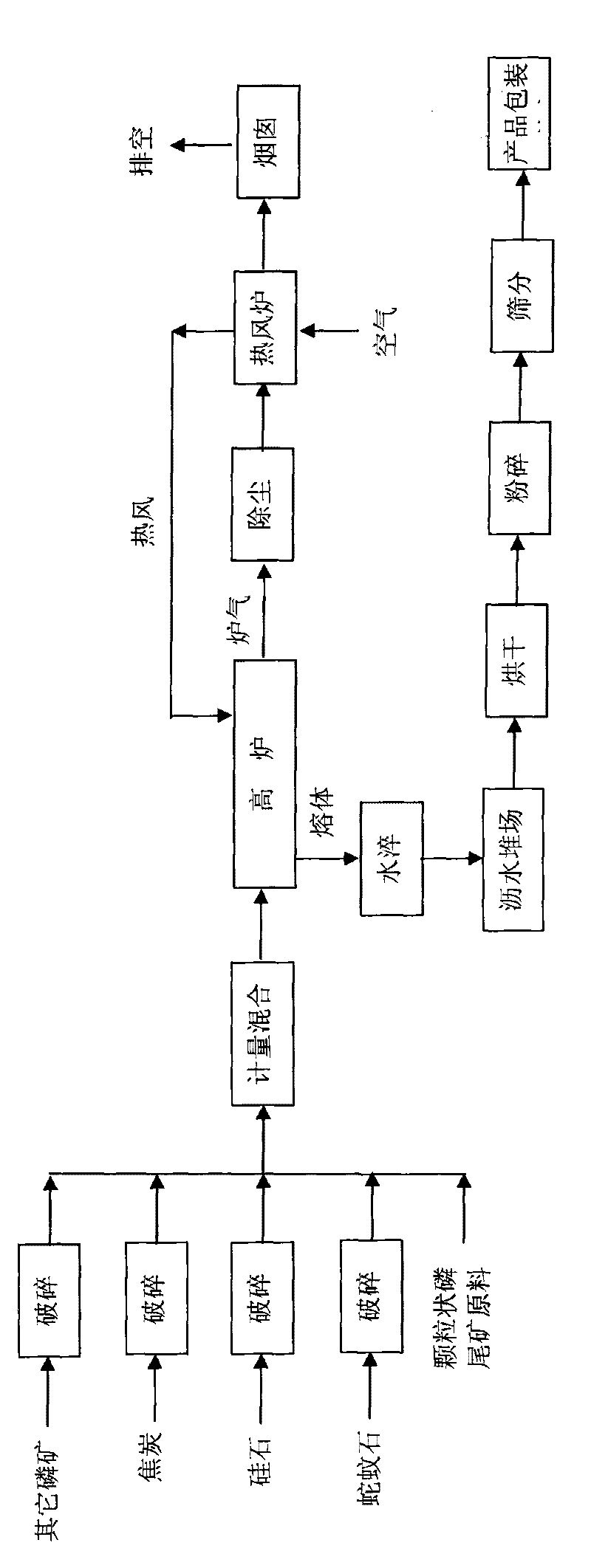

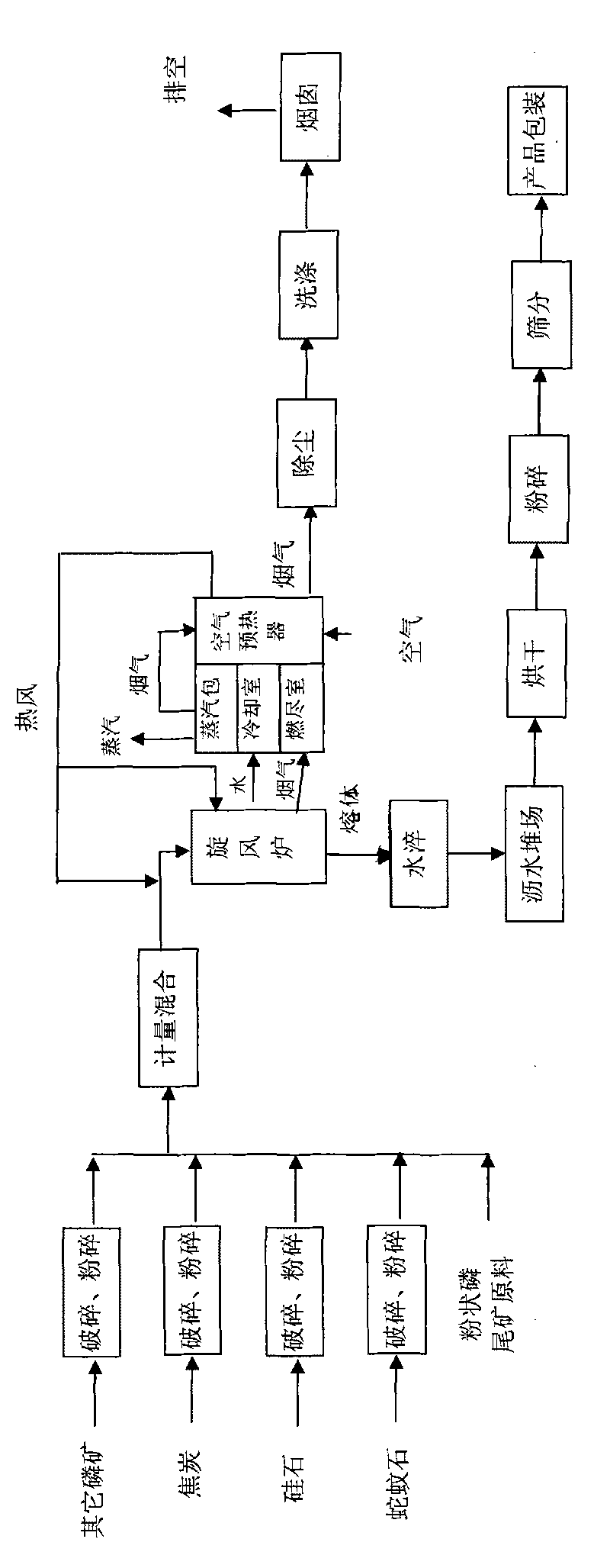

Method for preparing calcium magnesium phosphate fertilizer by utilizing phosphorite flotation tailing blast furnace method

InactiveCN101747090ALow costWide variety of sourcesThomas phosphate fertilisersWater contentPhosphoric acid

Owner:YUNNAN CHEM RES INST

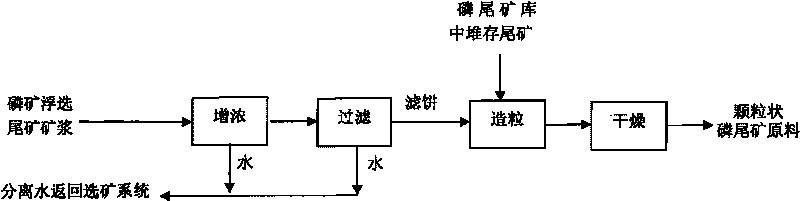

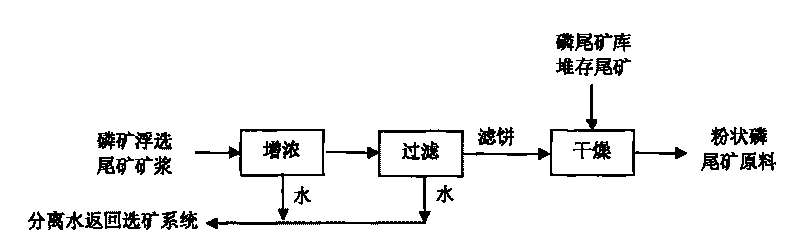

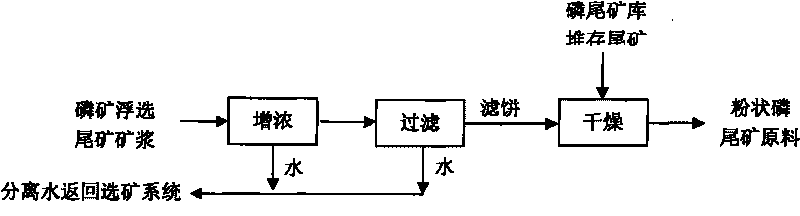

Method for preparing calcium magnesium phosphate fertilizer by using phosphorite floatation tailing as raw material

ActiveCN101747091AReduce manufacturing costPromote the development of circular economyThomas phosphate fertilisersChemical industryPhosphoric acid

The invention relates to a method for preparing calcium magnesium phosphate fertilizer through cyclone furnace process by using phosphorite floatation tailings as raw materials, in particular to a method for preparing calcium magnesium phosphate fertilizer through adopting a cyclone furnace by using phosphorite floatation tailings as main raw materials, belonging to the technical field of phosphate fertilizer chemical industry. The method uses the phosphorite floatation tailings as the main raw materials and adopts the cyclone furnace to prepare calcium magnesium phosphate fertilizer, and comprises the following steps: (1) the phosphorite floatation tailings are used as the raw materials, pulp dry basis contains 8-12 percent of P2O5 by weight percent, tailing filter cakes are obtained through treatment and the tailing filter cakes contain 20-40 percent of water; (2) the tailing filter cakes obtained through the step (1) are dried to tailing power containing water less than 2 percent by using a dryer, and the required grain size of tailing powder is that more than 80 percent of particles can pass through a 100-mesh sieve; (3) other primary phosphorite, coal, serpentine stone and silica to be jointly calcined are metered, mixed, cracked and crushed into joint-calcination mixed powder with fineness that more than 80 percent of particles can pass through the 100-mesh sieve; (4) 100 parts of phosphorite raw material, 190-280 parts of pulverized coal, 0-10 parts of silica and 0-20 parts of serpentine stone powder are added in the cyclone furnace by weight; and (5) the calcined powder raw material obtained through the step (4) is used to prepare calcium magnesium phosphate fertilizer by adopting the cyclone furnace. The invention has the advantages that the source of the raw materials is wide and the cost is low; sulfuric acid and phosphoric acid are not consumed, the product quality is reliable, the use is economic and feasible, and the social benefit is remarkable.

Owner:YUNNAN CHEM RES INST

Method for preparing fertilizer from cane sugar factory filter mud

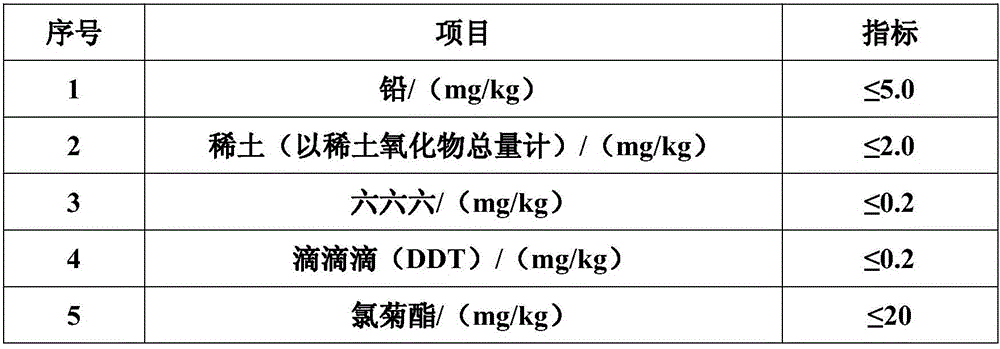

InactiveCN104341177AGood physical propertiesOdorlessCalcareous fertilisersBio-organic fraction processingRare-earth elementPotassium

The invention relates to a cane sugar factory waste filter mud recycling technology. According to the invention, a conditioning agent is added into filter mud that is not subjected to a drying treatment; the mixture is mixed by stirring, and is subjected to a reaction, such that a powdery or granular mixed fertilizer with excellent physical properties is prepared; proper amounts of nitrogen, phosphorus, potassium and rare earth elements, and a plant growth regulator are further added, such that various binary and ternary composite fertilizers comprising the rare earth element or growth regulator can be obtained. Therefore, mud-like smelly filter mud is turned into the odorless powdery or granular fertilizer, such that an environment pollution problem caused by the filter mud is solved. The method is in accordance with the principles of local material, local processing, local use, and turning waste into treasure. The method has significant economic and social benefits.

Owner:陈亮亮

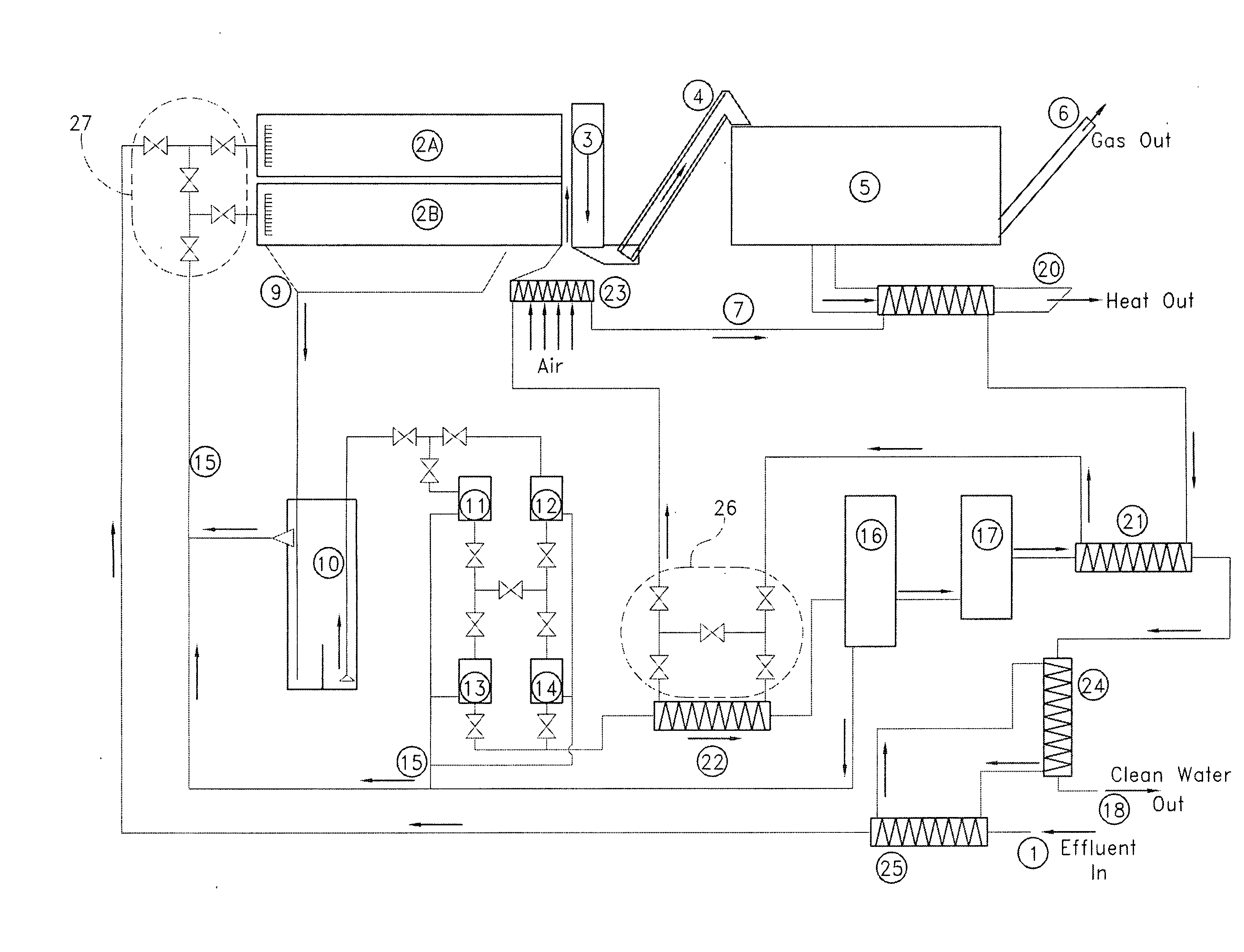

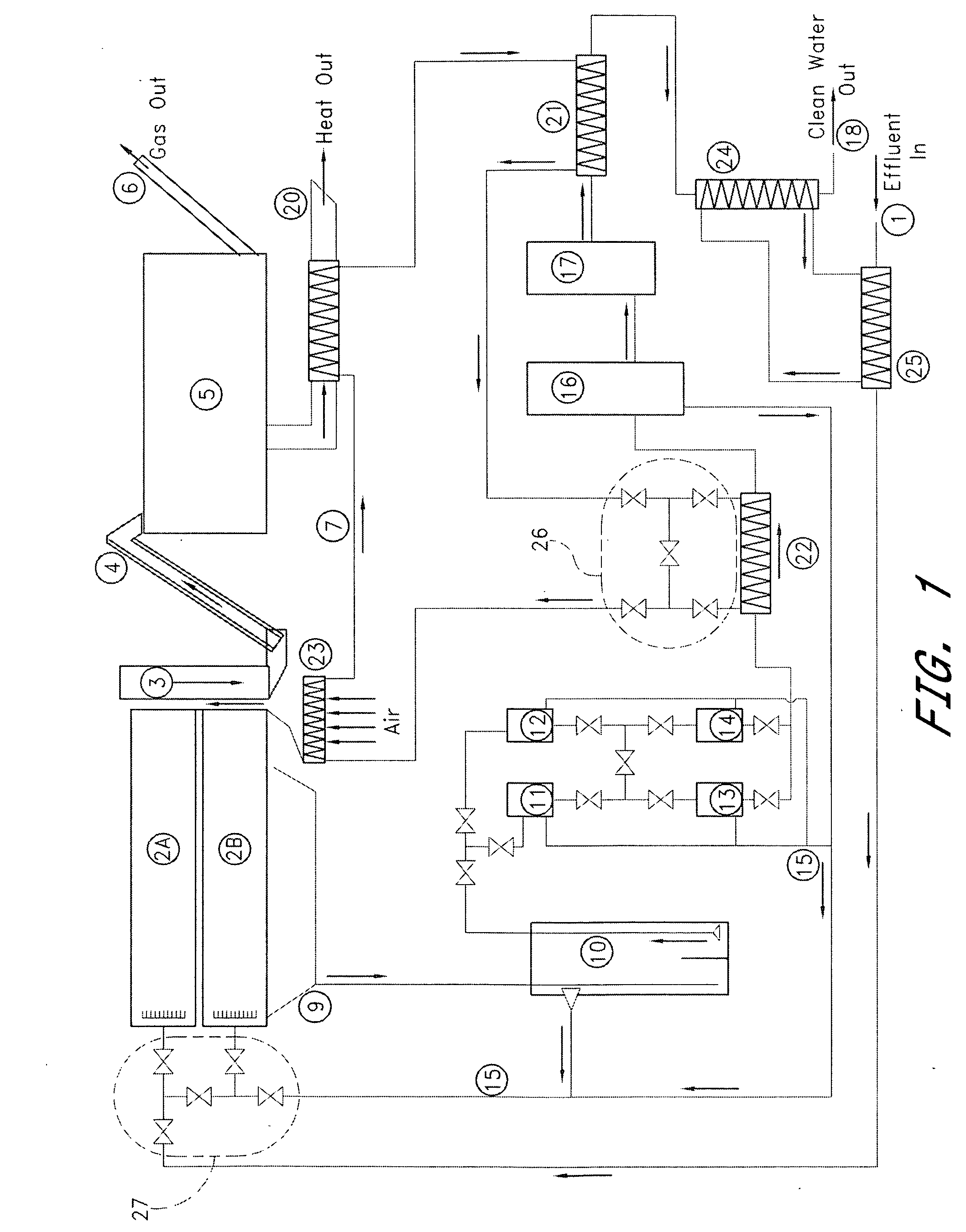

Methods and systems for dewatering and gasification

InactiveUS20050279711A1Efficient removalEasy to cleanWaste water treatment from animal husbandryTreatment involving filtrationReverse osmosisAnimal waste

Methods and systems for processing animal waste are disclosed. Effluent, including waste solids and water, is received. The effluent is at least partly separated into solids and water. The separated water is processed using a dissolved air flotation device and / or a reverse osmosis system to clarify the separated water. The separated solids are transferred to a gasifier, which processed the separated solids to form a least a first gas.

Owner:ECOLOGY ENERGY

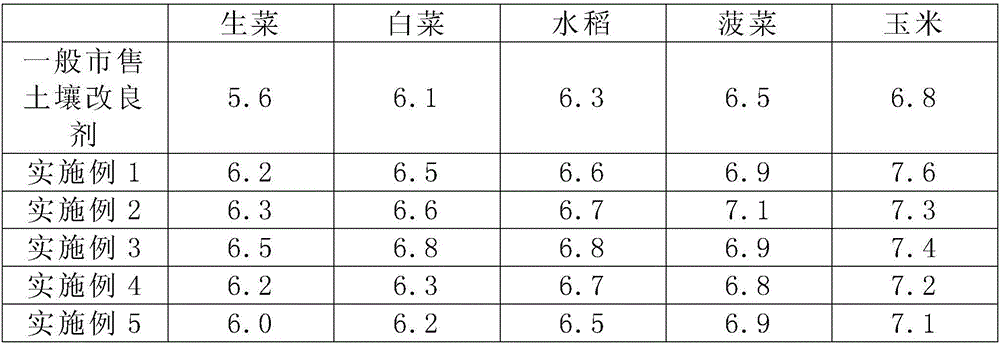

Anti-disease synergistic Guizhou sterile acidified yellow soil conditioner and preparation and use method thereof

InactiveCN106220421AEasy to prepareEasy to getSoil lifting machinesThomas phosphate fertilisersDiseaseContinuous cropping

The invention discloses an anti-disease synergistic Guizhou sterile acidified yellow soil conditioner and a use method thereof. The conditioner is prepared from, by weight, 25-35 parts of vinasse-based biochar, 10-20 parts of yellow phosphorus slag, 5-10 parts of calcium magnesium phosphate, 10-20 parts of potassium humate, 10-20 parts of rapeseed cake powder, 1-5 parts of alkali lignin, 1-5 parts of wood vinegar and 5-10 parts of microelement. Different amounts of Guizhou sterile acidified soil conditioners are applied according to different pH values. The conditioner is simple in preparation method, raw materials can be obtained locally and are easy to obtain, and cost and price are low. Soil hardening caused when a single conditioner is used is prevented. The granular structure of soil is increased, and soil quality is improved. The C / N ratio of the soil can also be adjusted, the problems of continuous cropping obstacles, soil fertility reduction and the like caused when people get much from the soil but give little to soil for a long time are solved, the activity of beneficial microorganisms of the soil is improved, and the virtuous cycle of the soil is benefited.

Owner:GUIZHOU INST OF SOIL & FERTILIZER

Nutrient sustained-release acid soil conditioner and preparation method thereof

InactiveCN107226762AImprove textureTrace element balanceCalcareous fertilisersThomas phosphate fertilisersSodium BentonitePotassium

The invention discloses a nutrient sustained-release acid soil conditioner. The nutrient sustained-release acid soil conditioner is prepared from the following substances in parts by weight: 20 to 30 parts of phosphate tailings, 28 to 31 parts of dolomite, 18 to 25 parts of quick lime, 15 to 20 parts of phosphatic fertilizer, 4 to 6 parts of bentonite and 0 to 10 parts of potassium humate. The nutrient sustained-release acid soil conditioner is suitable for acid soil areas in the south, which are large in rainfall amount and large in leaching amount, and supplements part of nutrients. Meanwhile, the aluminum toxicity risk can be reduced, and nutrient elements such as calcium, magnesium and the like are provided.

Owner:CHINA AGRI UNIV

Tree planting method at magnesite flour dust polluted area hillside fields and tree pit filler

InactiveCN101366354ASufficient raw materialsLow priceThomas phosphate fertilisersFertilising methodsPhosphogypsumPollution

The invention relates to a plant cultivation method, in particular to a tree planting method and a tree pit filling for magnesite dust polluted area slope land, which solves the problems that the magnesite dust polluted area slope land is low in forest coverage rate and serious in water and soil loss phenomenon. The filling per pit comprises 50 to 80 portions of organic material, 5 to 10 portions of phosphogypsum, 0.5 to 1.0 portion of industrial sulphur and 0.5 to 1 portion of slow-release urea or slow-release compound fertilizer, and the weight of the filling accounts for 5 to 15 percent of the sum of tree pit soil and the filling. The method adopts scale-pit reverse-slope stepped soil preparation, wherein each planting pit is 40 to 60 cm long, 40 to 60 cm wide and 50 to 70 cm deep; and in-situ soil or foreign soil is utilized and mixed with the filling for planting trees in the slope land. In the invention, the tree pit filling is low in price and free from pollution, and the tree planting method is simple and easy to apply and has the effects of improving the survival rate and growth rate of tree seedlings, restoring soil and vegetation and reducing water and soil loss.

Owner:SHENYANG INST OF APPLIED ECOLOGY - CHINESE ACAD OF SCI

Soil conditioner and preparation method thereof

InactiveCN106966780AGuaranteed oxygen contentGuaranteed moisture contentCalcareous fertilisersAgriculture tools and machinesPorosityMicrobial agent

The invention provides a soil conditioner and a preparation method thereof. The soil conditioner comprises, by weight, 12 to 20 parts of plant ash, 5 to 10 parts of phosphorous slag, 5 to 9 parts of quicklime, 2 to 5 parts of zeolite, 2 to 5 parts of attapulgite, 1 to 3 parts of Yilong seaweed ooze, 2 to 5 parts of Chinese magnoliavine residues, 2 to 5 parts of large-flowered skullcap root residues, 20 to 30 parts of straw, 8 to 13 parts of hickory nut shells, 0.02 to 0.04 part of rotenone, 10 to 15 parts of mangosteen shells, 3 to 5 parts of an EM microbial agent, 7 to 20 parts of urea phosphate, 8 to 14 parts of urea, 10 to 15 parts of biochemical potassium fulvate and 9 to 12 parts of gamma-polyglutamic acid. The invention has the beneficial effects that the soil conditioner has high porosity and has specific adsorption effect on heavy metal ions; the soil conditioner can adjust the pH value of soil, is rich in trace elements and can elemental N, elemental P and elemental K at the same time; and the soil conditioner allows soil to maintain high porosity and to be long in fertility maintenance time and good in water retention performance.

Owner:嵊州市派特普科技开发有限公司

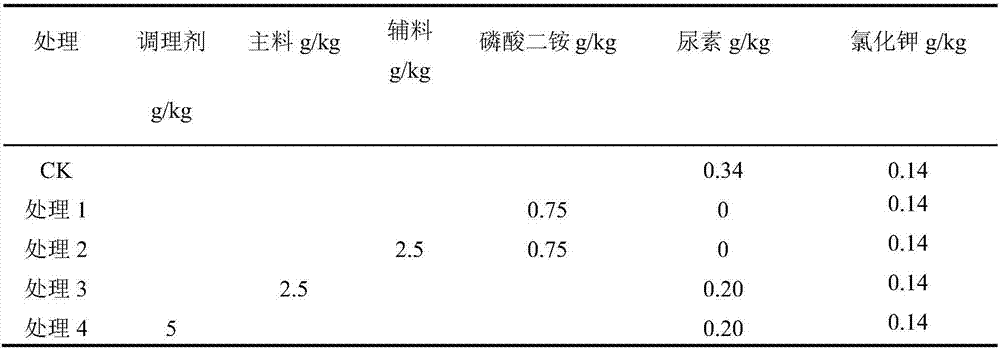

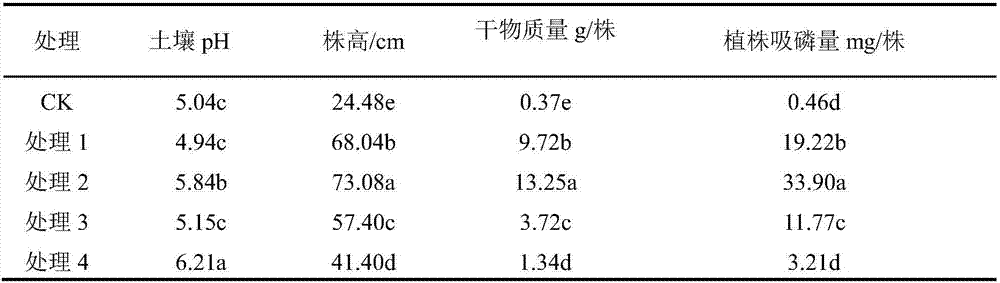

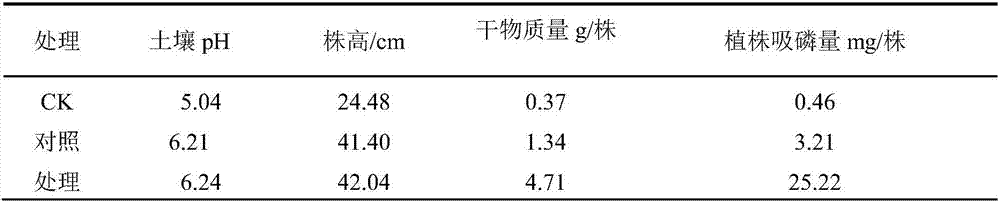

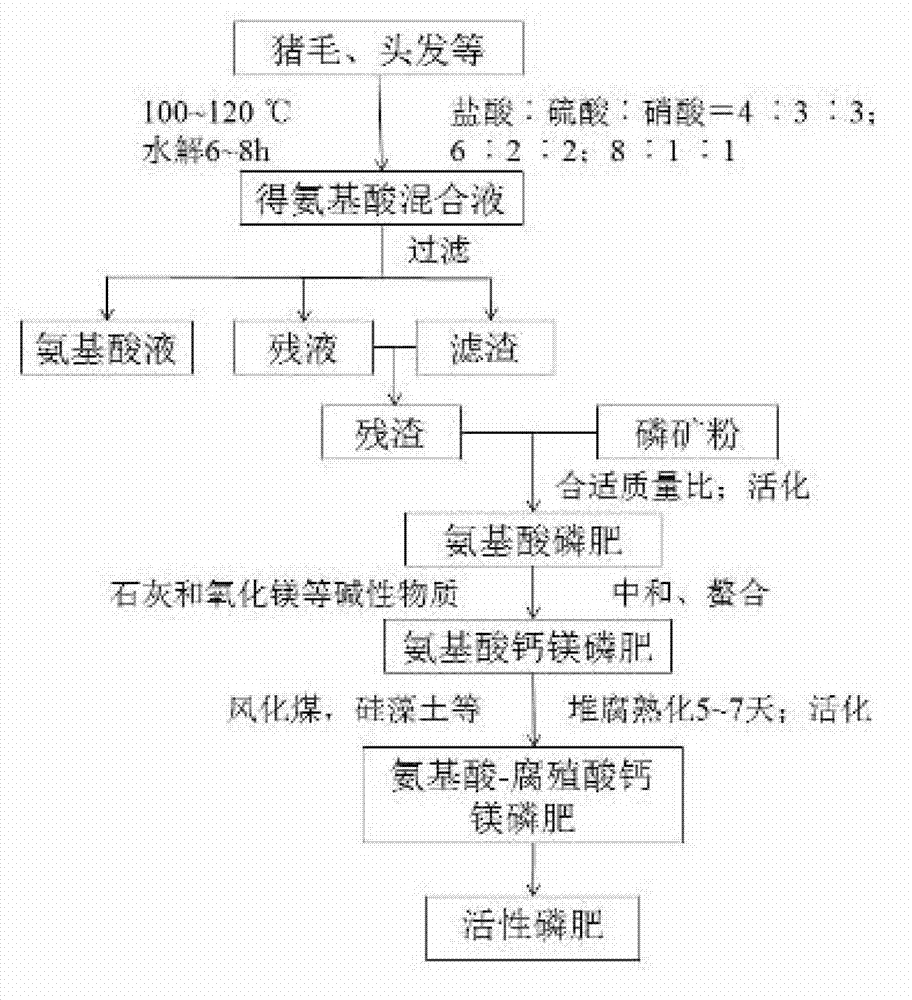

Active phosphate fertilizer as well as preparation method and application thereof

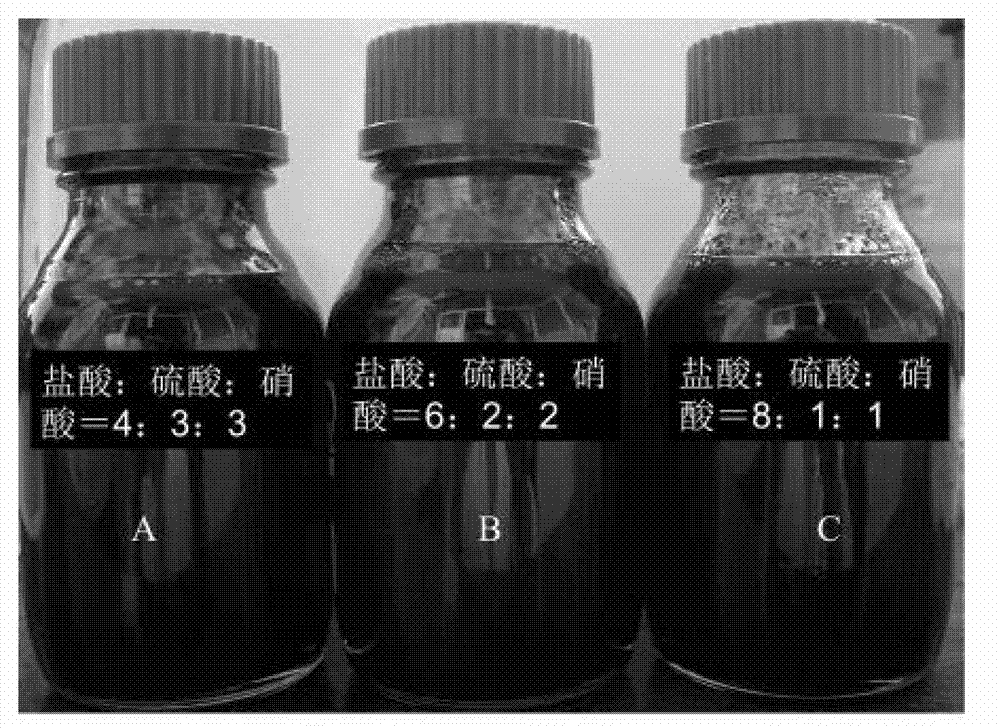

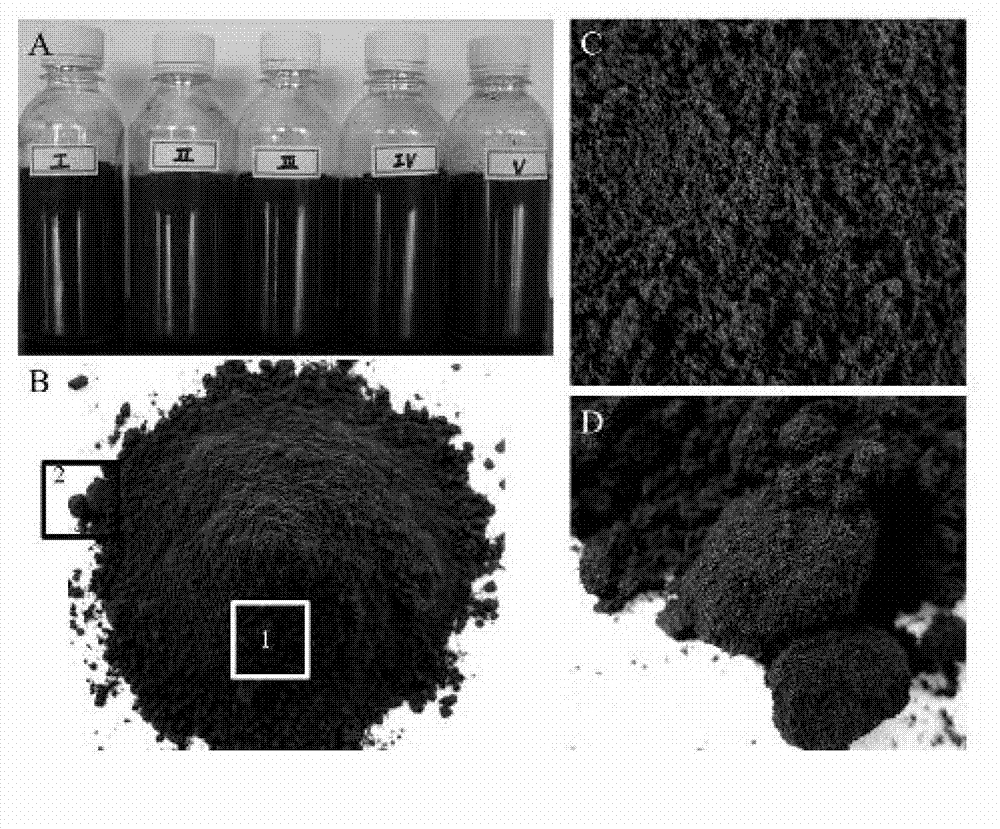

The invention discloses an active phosphate fertilizer as well as a preparation method and application thereof, and belongs to the fertilizer industrial field. The active phosphate fertilizer adopts waste animal protein (furs, hairs, skins or horns and the like) as a raw material; the animal protein is hydrolyzed by using mixed acid to obtain amino acid residues, wherein the mixed acid comprises hydrochloric acid, nitric acid and sulfuric acid; the residues are mixed with ground phosphate rock; alkali substances, such as lime, magnesium oxide and the like are added; and materials, such as decomposed coal, kieselguhr and the like are added for modifying; then the materials are turned, composted for several days, dried and smashed to obtain the active phosphate fertilizer. The active phosphate fertilizer has rich contents of organic matters, N, P, Ca and Mg, high contents of water-soluble phosphorus and available phosphorus and reasonable moisture and pH value, and brings convenience to crop absorption and utilization; the preparation technique is simple, has low production cost, and is easy to exert; and the active phosphate fertilizer has the characteristics of soil looseness, increment of granular structures and fertility improvement, and is the high-quality fertilizer in the non-hazardous agriculture.

Owner:深圳市杜高生物新技术有限公司

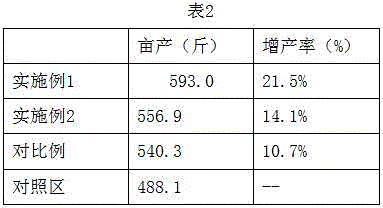

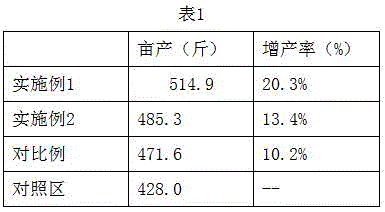

Method for planting high-yield organic rice by rice-duck integrated farming

ActiveCN105284512ASimple structureStrong nitrogen fixation abilityThomas phosphate fertilisersAlkali orthophosphate fertiliserAstragalus sinicusIntegrated farming

The invention discloses a method for planting high-yield organic rice by rice-duck integrated farming. The method comprises the steps of: planting astragalus sinicus in a rice field, carrying out green manuring and adding water for retting, and applying a base fertilizer in 10-25 days according to the amount of 800-1000 kg / mu; exposing the rice field to the sun, rotatably tilling the rice field, separating ridges and carrying out rice transplanting after irrigation; when the roots of the rice seedlings survive, applying a composite fertilizer according to the amount of 20-35 kg / mu; in 12-20 days after rice transplanting, putting in 10-15-day old ducks according to the amount of 5-10 ducks / mu; carrying out field draining in 10-15 days, and additionally applying the base fertilizer in A according to the amount of 100-300 kg / mu; then putting 7-10-day old ducks in the rice field when water is irrigated to 8-10 cm, wherein the inputting amount is 8-15 ducks / mu, taking the ducks back 10-15 days before the rice is mature, and drying the rice field after water-break. The method for planting high-yield organic rice by rice-duck integrated farming disclosed by the invention is high in yield, and the obtained rice is good in organic property, and meanwhile, high quality duck meat can be obtained, so that the economical benefit is improved.

Owner:ANHUI MUMAHU AGRI DEV GRP

Planting method of camphor trees with high survival rate and high quality

InactiveCN106857135ASimple structurePrevent compactionCalcareous fertilisersMagnesium fertilisersMain branchFarmyard manure

The invention discloses a planting method of camphor trees with a high survival rate and a high quality. The method comprises the following steps: S1, digging holes to plant camphor tree seedlings, applying a base fertilizer into each of the planting holes, then filling the planting holes with nutritional soil and planting soil of an original nursery stock planting land, and sufficiently watering rooting water; S2, applying an organic compound fertilizer in March to April for maiden trees which are planted 1-2 years ago, fertilizing the maiden trees in the first ten days and middle ten days of May separately with 45% potassium sulphate compound fertilizer every time, applying urea in the middle ten days of June and July, applying the 45% potassium sulphate compound fertilizer in the last ten days of August, digging deep holes in October to fertilize farmyard manure and calcium magnesium phosphate fertilizer; applying a germinating fertilizer before germination for adult trees in the middle ten days of February, and applying an organic release control fertilizer; and S3, leaving four main branches for every adult tree which is 2-3m high, carving sprouts on the tops of the branches in spring, primarily pinching in summer if being branched at 4cm, and pinching for the second time if being branched at 10cm, and starting to stretch the branches in June. According to the planting method of camphor trees, disclosed by the invention, the quality and the survival rate of the camphor trees can be effectively improved.

Owner:洪兵

Method for directly producing compound fertilizer by using phosphate tailings

InactiveCN106365747AEfficient use ofAchieve reductionThomas phosphate fertilisersAlkali orthophosphate fertiliserSludgeDecomposition

The invention relates to a method for directly producing a compound fertilizer by using phosphate tailings. The method comprises the steps of pretreatment, sulfuric acid decomposition, compound fertilizer preparation and the like. The problem of comprehensive utilization of tailings produced after phosphorite raw ore concentration and phosphoric acid sludge acid produced in a wet process phosphoric acid process is effectively solved, elements in the phosphate tailings and the phosphoric acid sludge acid are recovered and utilized, and the method is in conformity with the comprehensive utilization principle 'reduction, reutilization and recycling'.

Owner:ZHENGZHOU UNIV

Material for phosphate fertilizer and for producing thereof

InactiveCN1509261AReduce fluorine contentLow costCalcareous fertilisersThomas phosphate fertilisersSlagPhosphoric acid

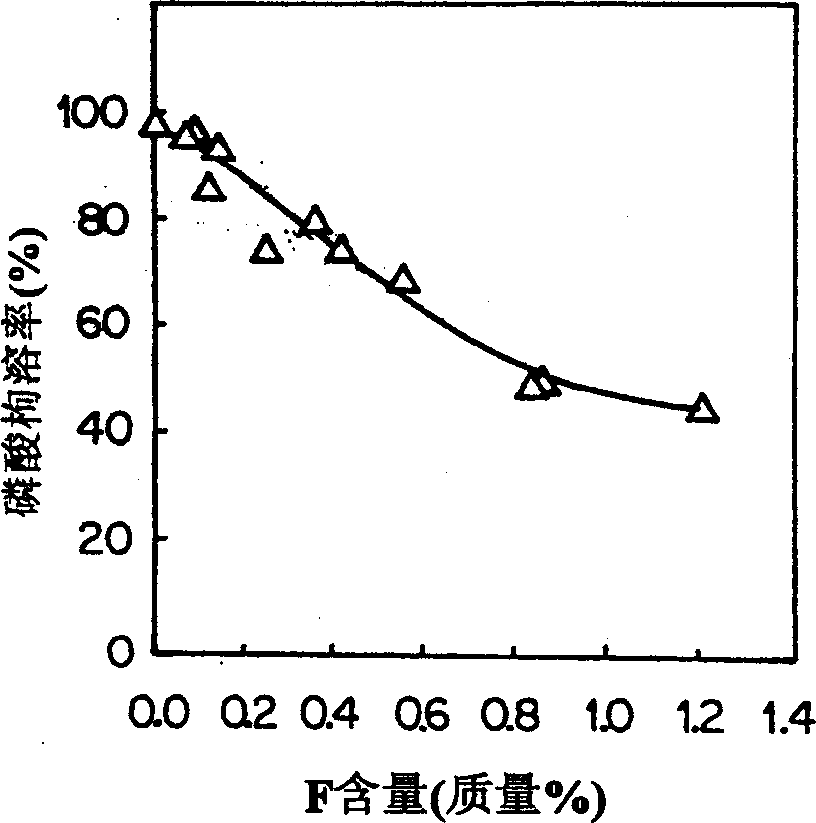

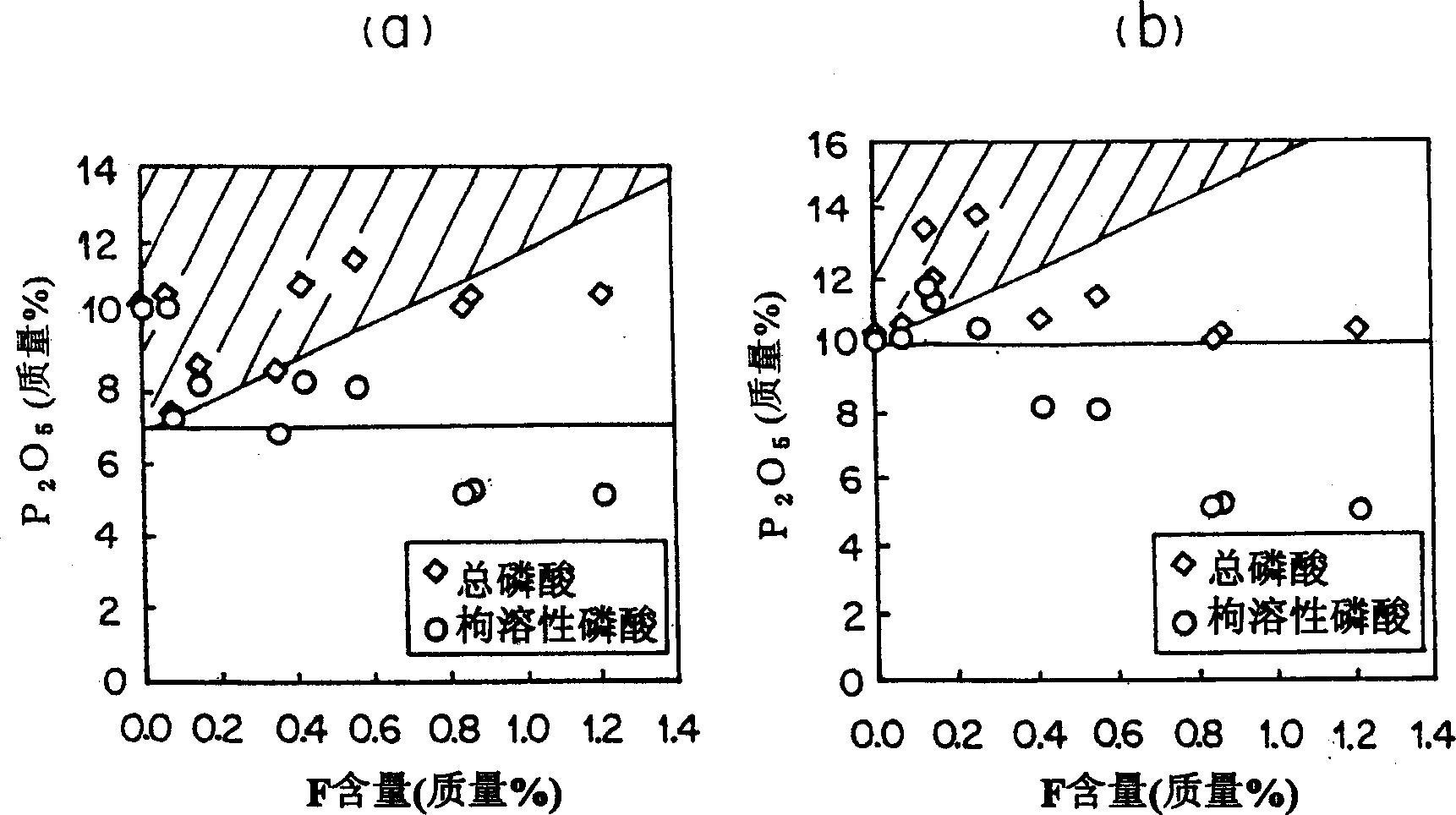

Provided is a raw material for phosphate fertilizer having excellent fertilizer characteristics, which raw material consists essentially of a slag containing phosphate generated from dephosphorization reaction in molten iron, and is a method for manufacturing the raw material suitable for manufacturing the phosphate fertilizer. The raw material for phosphate fertilizer consists essentially of a slag containing phosphate generated from dephosphorization reaction in molten iron. As for the slag composition, the phosphate content satisfies the formula (1), and preferably the formula (2): [P2O5]>=5.6x[F]+7 (1) [P2O5]>=5.6x[F]+10 (2) where, [P2O5] is the phosphate content in slag, (mass %) and [F] is the fluorine content in slag, (mass %). The method for manufacturing the raw material thereof is a method of charging an oxygen source and a CaO source to a molten iron which decreases the Si concentration therein to a sufficient level, thus inducing the dephosphorization reaction in the molten iron, or a method of charging a CaO source and a gas oxygen in respective specified configurations and conditions to the molten iron, thus inducing the dephosphorization reaction in the molten iron.

Owner:JFE STEEL CORP

Soil remediation fertilizer for strawberry in greenhouse and preparation method thereof

InactiveCN106883023AReduce leachingReduce releaseSuperphosphatesThomas phosphate fertilisersContinuous croppingNatural mineral

The invention discloses a soil remediation fertilizer for strawberry in a greenhouse and a preparation method thereof. The soil remediation fertilizer is characterized by being prepared from the following components in parts by mass: 20-30 parts of biological carbon, 2-4 parts of EM bactericide, 30-40 parts of organic fertilizer, 10-15 parts of crop stalks, 4-6 parts of calcium superphosphate, 4-6 parts of potassium chloride, 1-2 parts of zinc sulfate, 1-2 parts of ferrous sulfate, 6-8 parts of natural mineral powder and a moderate amount of water. The invention provides the soil remediation fertilizer which can solve the problem on continuous cropping soil for the strawberry in the greenhouse; and problems on salt accumulation, acidification, soil hardening, nutrient imbalance, microecology dysbiosis and the like present in the continuous cropping soil for the strawberry are solved effectively.

Owner:SUZHOU DINGYU BIOLOGICAL TECH CO LTD

Organic-inorganic compound fertilizer and preparation method thereof

InactiveCN105367357AReasonable nutritional structureEasy to loseThomas phosphate fertilisersExcrement fertilisersSlagPotassium

The invention belongs to the field of biochemical fertilizers, and particularly relates to an organic-inorganic compound fertilizer and a preparation method thereof. The preparation method comprises the following steps: uniformly mixing organic matters and bacillus subtilis at the room temperature, stacking into a fertilizer heap I with the height of 60-70 cm, conducting primary stage fermentation treatment, then adding enzyme microorganism, and stacking into a fertilizer heap II with the height of 1-1.5 m, and conducting secondary stage fermentation treatment to obtain a fermented fertilizer; calcining kalium-containing rock and phosphate rock slag together at 500-800 DEG C for 1-2 h, cooling to 70-80 DEG C, adding humic acid, and unceasingly stirring until the temperature is equal to the room temperature to obtain a mixed material; uniformly mixing the fermented fertilizer, the mixed material and urea formaldehyde, heating to 50-60 DEG C, feeding into a granulating machine, spraying a starch solution into the granulating machine, and drying particles obtained through granulation so as to obtain the organic-inorganic compound fertilizer. The organic-inorganic compound fertilizer and the preparation method are short in process flow, simple in process, free of pollution, low in cost, and good and stable in fertilizer effect.

Owner:GUIZHOU RES INST OF CHEM IND +1

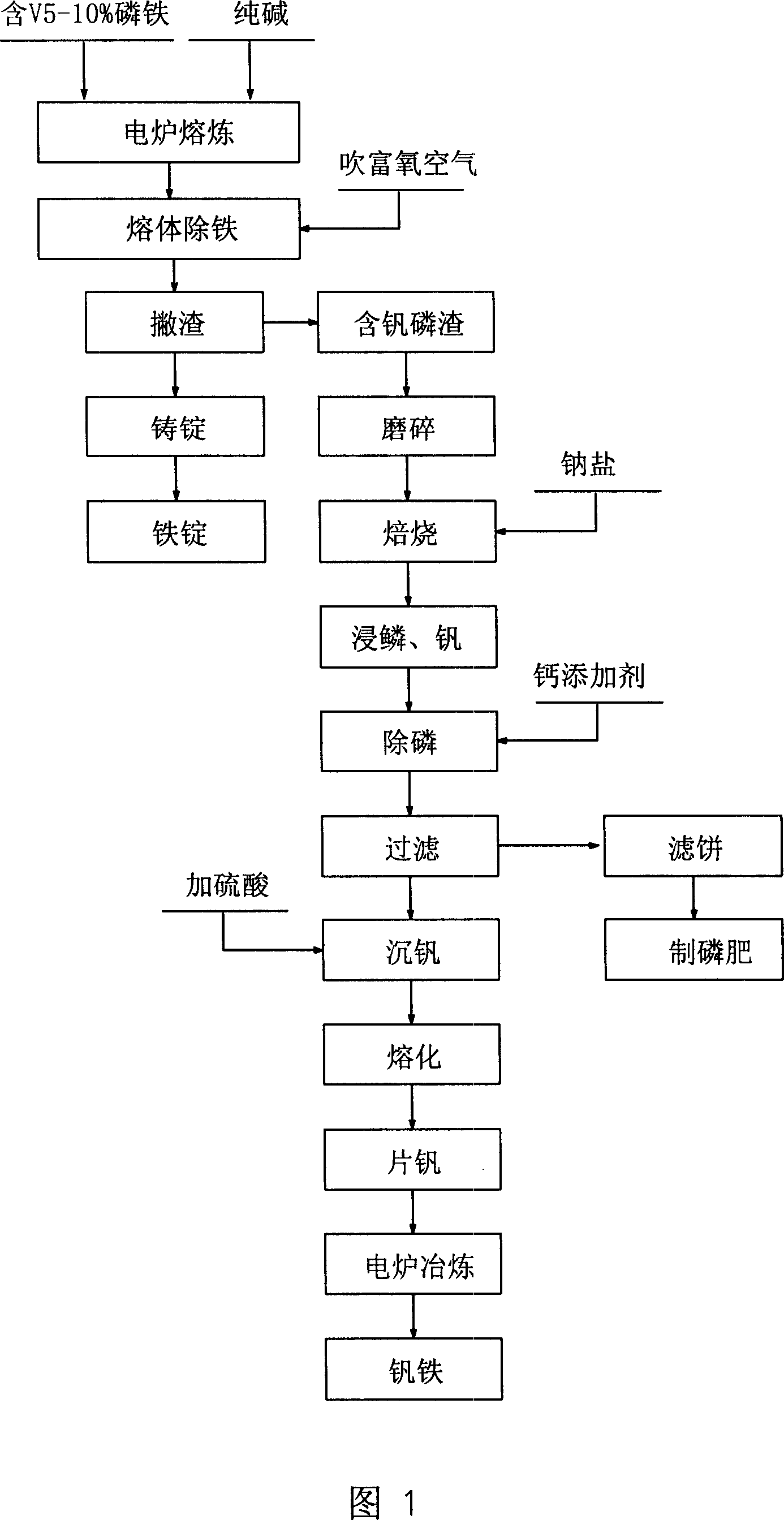

Process for smelting ferrovanadium by extraction of vanadium from vanadium-containing errophosphorus

InactiveCN1970803ASimple processLess investmentThomas phosphate fertilisersProcess efficiency improvementFertilizerSmelting process

The invention discloses an extracting and smelting method of vanadium through vanadophosphoric ferric, which is characterized by the following: adopting vanadophosphoric ferric and steel-smelting high-vanadophosphoric slag as raw material; extracting vanadium through water immersing method; removing ferric through electric furnace smelting method; recycling vanadium and ferric; smelting the vanadium ferric; recycling further; ripening phosphor slag pie; making phosphorous fertilizer; simplifying manufacturing technique; improving receiving rate at 82-65%; making smelting product satisfy national standard GB4139-87FeV50A.B and GB4139-87 FeV70A.B with eligible rate over 95%.

Owner:郴州市金龙铁合金有限公司

Cultivation method of maple tree saplings

InactiveCN106234120AImprove survival rateShorten the breeding cycleBiocideSeed and root treatmentDiseasePotassium permanganate

The invention provides a cultivation method of maple tree saplings. The cultivation method comprises the following steps: A, pretreating seeds: firstly, adding the maple tree seeds into a potassium permanganate solution with the temperature of 35 to 40DEG C and the concentration of 0.3 to 0.8 percent, soaking for 3 to 5 hours, then fishing out, mixing into wet river sand, and storing in a room for 15 days; B, sowing: selecting weak acid and wet sandy loam soil with good water permeability and good irrigation conditions, spreading organic fertilizer in each mu of land, furrowing afterwards, then spreading a herbal disease and insect resisting agent in formed furrows, sowing the maple tree seeds treated in the step A in the formed furrows, paving a layer of fine grained soil on the seeds, wetting surface soil by spraying, and keeping water in the furrows; C, growing seedlings: after the seeds sown in the step B are sprouted and unearthed to grow into seedlings, starting to fertilize the maple tree saplings, and promoting quick growth of the saplings to obtain the maple tree saplings. According to the method, by specifically combining specified seed pretreatment, sowing and seedling growing processes, the growing-seedling period is shortened, and the survival rate of the maple tree saplings is improved.

Owner:遂宁育宁农业开发有限公司

Planting method of heart cone chrysanthemum

InactiveCN106588205AImprove growth efficiencyImprove growth qualityCalcareous fertilisersMagnesium fertilisersOrganic fertilizerObserved Survival

The invention discloses a planting method of heart cone chrysanthemum. The planting method comprises the following steps: S1, soil preparation: selecting a land which is loose in soil, good in ventilation and moist and does not accumulate water as a planting land and then scattering a base fertilizer to the planting land; S2, fixed planting: digging fixed planting holes in the planting land, putting blueberry seedlings in the fixed planting holes, then filling the holes with nutrient soil and then scattering a fixed planting fertilizer; and S3, fertilizer application: after fixed planting the young seedlings, spraying a decomposed organic fertilizer to the planting land; before accelerating germination, topdressing a germination-accelerating fertilizer; and in pre-flowering 10 days, topdressing an organic slow release fertilizer. The planting method of heart cone chrysanthemum disclosed by the invention can effectively improve the planting efficiency and the survival rate of heart cone chrysanthemum.

Owner:安徽剑春园林股份有限公司

Acidic soil improver

InactiveCN106083477AHigh bulk densityIncrease contentCalcareous fertilisersSuperphosphatesSlagOyster

The invention relates to the technical field of soil improvement, in particular to an acidic soil improver which is composed of 150-180 g / kg of humic acid, 150-180 g / kg of calcium oxide, 0.22-0.36 billion / g of composite microorganism flora powder, 20-30 g / kg of chitosan powder, 50 ml / kg of angiosperm extract, 20-40 g / kg of oyster shell powder, 4.8-8.2 g / kg of mixture of calcium superphosphate and steel slag phosphorus fertilizer, 3.6-7.2 g / kg of magnesium sulfate and 2.8-4.8 g / kg of zinc sulfate. Compared with existing common soil improvers, the acidic soil improver has the advantages that content of alkaline ingredients and calcium needed for soil improvement is obviously high; almost no heavy metal ingredients are detected in the soil improver; after the soil improver is applied, soil bulk density after treatment is remarkably improved and lowered from 1.31 g / m3 to 0.95 g / m3.

Owner:汤海涛

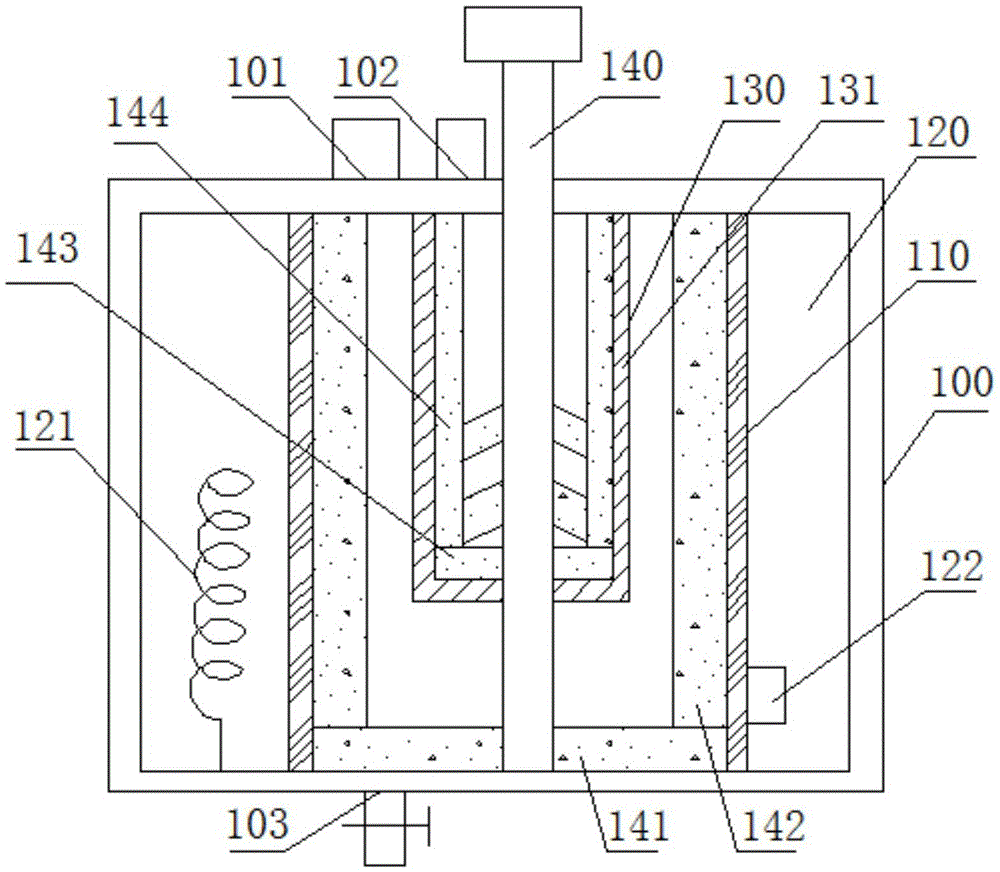

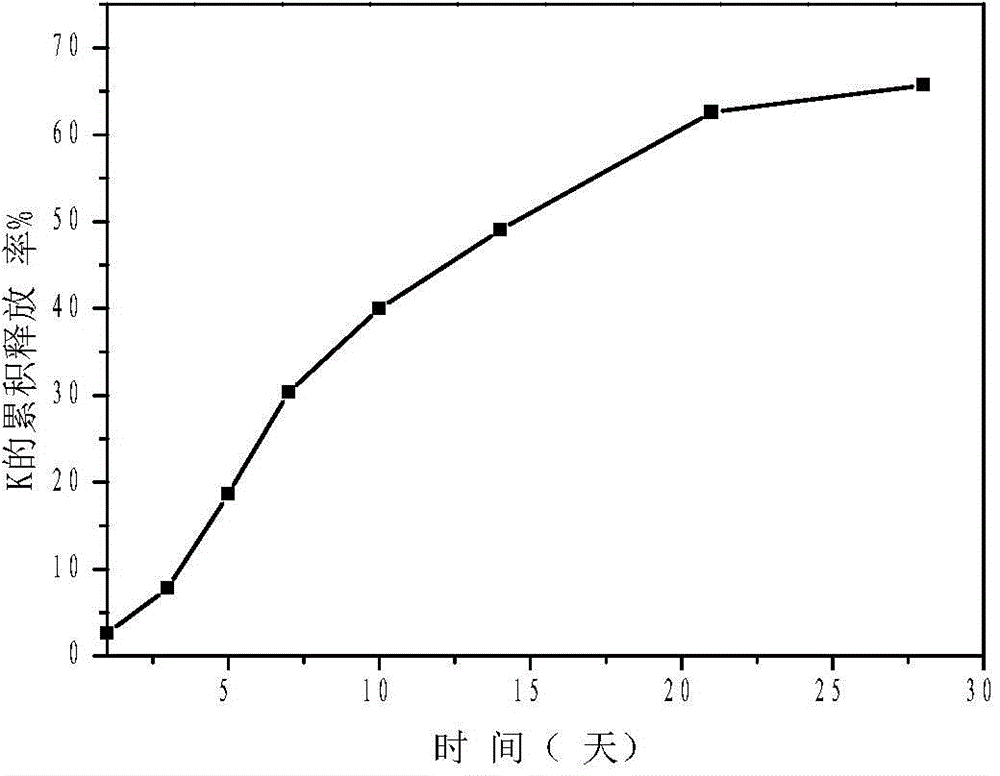

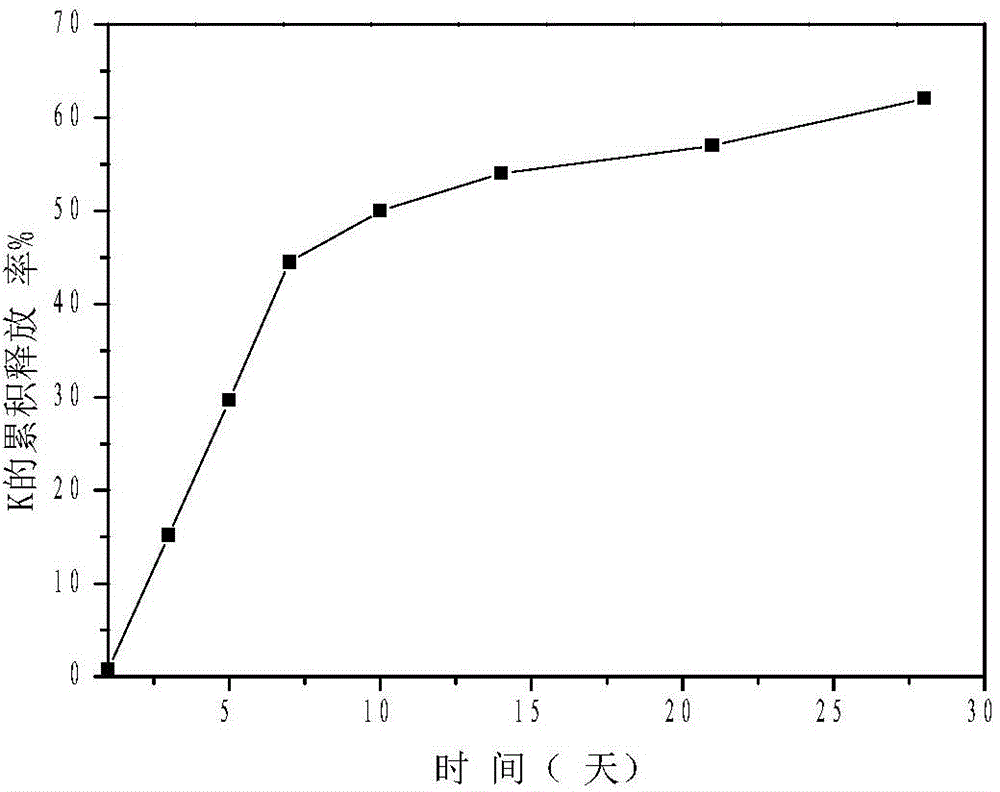

Controlled-released fertilizer preparation method and commercial crop controlled-released fertilizer prepared according to controlled-released fertilizer preparation method

InactiveCN105646107AFast growthIncrease productionSuperphosphatesBio-organic fraction processingMusa basjooGibberellin

The invention discloses a controlled-released fertilizer preparation method and a commercial crop controlled-released fertilizer prepared according to the controlled-released fertilizer preparation method. The method includes steps: adding papermaking black liquid into sodium tripolyphosphate caustic sludge, adding bagasse, fishpond sludge, gibberellin fungus residues, an overground part of Sophora Flavescens, Ilex Chinensis Sims, Artemisia Vulgaris and mixed bacteria to realize fermentation, adding seaweed gel residues, coal cinders, bamboo charcoal, diammonium phosphate and a binding agent into a fermentation product, and granulating to obtain particles 1; granulating triple superphosphate, urea and potassium chloride to obtain particles 2; adding leaves of musa basjoo, Radix glycyrrhizae, Fructus Psoraleae and Radix Tripterygii wilfordii into water, decocting, and adding ureaformaldehyde into decoction to obtain coating liquid; coating the particles 1 and the particles 2 with the coating liquid to obtain the controlled-released fertilizer. The controlled-released fertilizer is high in phosphorus content and can be used for various crops, vegetables, fruits and the like high in phosphorus demand. By separate granulation of the raw materials, nutritional ingredients can be released at different stages, the fertilizer is approximately released by 60% in an early stage and 40% in a later stage, and accordingly growth requirements of crops can be met in a whole growing period.

Owner:SHANDONG ZHIFENG NONGHUA GRP

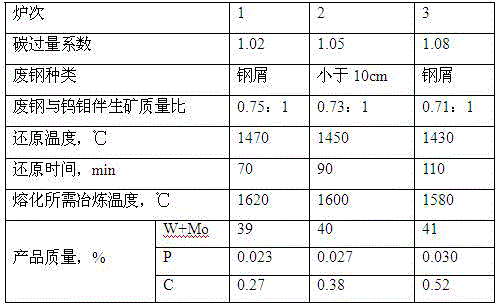

Method for smelting tungsten-molybdenum-iron alloy from tungsten-molybdenum associated mineral

InactiveCN106591566AReduce the amount addedLow costThomas phosphate fertilisersProcess efficiency improvementMixed materialsHeating furnace

The invention relates to the technical field of comprehensive utilization of a tungsten-molybdenum associated mineral, in particular to a method for smelting a tungsten-molybdenum-iron alloy from the tungsten-molybdenum associated mineral. The method includes the steps that firstly, the tungsten-molybdenum associated mineral, a carbonaceous reducing agent and a binding agent are evenly mixed and formed according to a certain ratio, the dried mixed material and waste steel are placed in an induction heating furnace according to a certain ratio to be subjected to high-temperature reduction, the tungsten-molybdenum-iron alloy is obtained, and P in the mineral continues to be left in the mineral. The method has the beneficial effects of being large in processing capacity, good in product quality, low in energy consumption, low in pollution, low in production cost, and the like.

Owner:SONGXIAN EXPLOITER MOLYBDENUM

Long-acting fertilizer special for sugarcane and preparation method thereof

InactiveCN105669317ASatisfy nitrogen nutrient needsMeet pre-growth needsSuperphosphatesMagnesium fertilisersAcrylic resinCoated urea

The invention discloses a long-acting fertilizer special for sugarcane and a preparation method thereof. The long-acting fertilizer special for sugarcane is prepared from, by weight, 12-14 parts of large granular urea, 36-42 parts of acrylic resin-coated urea, 22-24 parts of potash fertilizer, 5-7 parts of water soluble phosphate fertilizer, 15-21 parts of weak-acid-soluble phosphate fertilizer and 0.5-1.5 parts of chelation type medium trace element fertilizer. The prepared long-acting fertilizer special for sugarcane is used as a base fertilizer for application, the requirements for nutrients of various growing periods of sugarcane can be met, labor can be saved, and soil acidification and hardening can also be avoided.

Owner:广西新方向现代农业发展有限公司

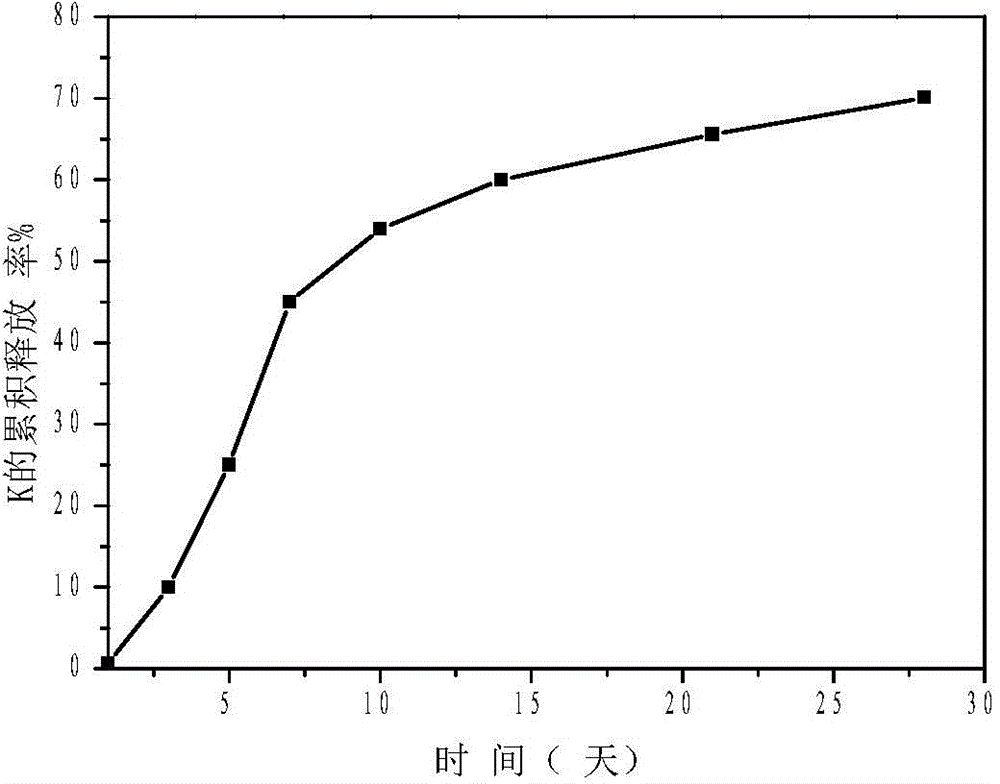

Method for preparing controlled release compound fertilizer through magnesium slag phosphorus acid passivation

InactiveCN104628479APromote growthLow costThomas phosphate fertilisersUrea compound fertilisersPhosphateSlag

The invention provides a method for preparing a controlled release compound fertilizer through magnesium slag phosphorus acid passivation, and relates to magnesium slag comprehensive utilization and preparation of a controlled release compound fertilizer. According to the method, magnesium slags, phosphorus acid, urea and potassium sulphate are used as basic materials, magnesium slag phosphorus acid passivation, quantitative dosing, stirring and mixing, prilling, drying and other processing methods are performed, and the controlled release compound fertilizer which can be used for crop growth is prepared. According to the invention, the characteristic that the magnesium slags are enriched in active magnesium oxide and active magnesium oxide and phosphoric acid are easily subjected to passivation reaction to generate magnesium calcium phosphate is fully utilized. The method not only has the advantages that the cost of raw materials is low, the processing process is relatively simple, and scale and industrial production is easy to realize, but also has the comprehensive advantages of no pollution, energy consumption reduction and high-efficient utilization of magnesium slags.

Owner:SHANXI UNIV

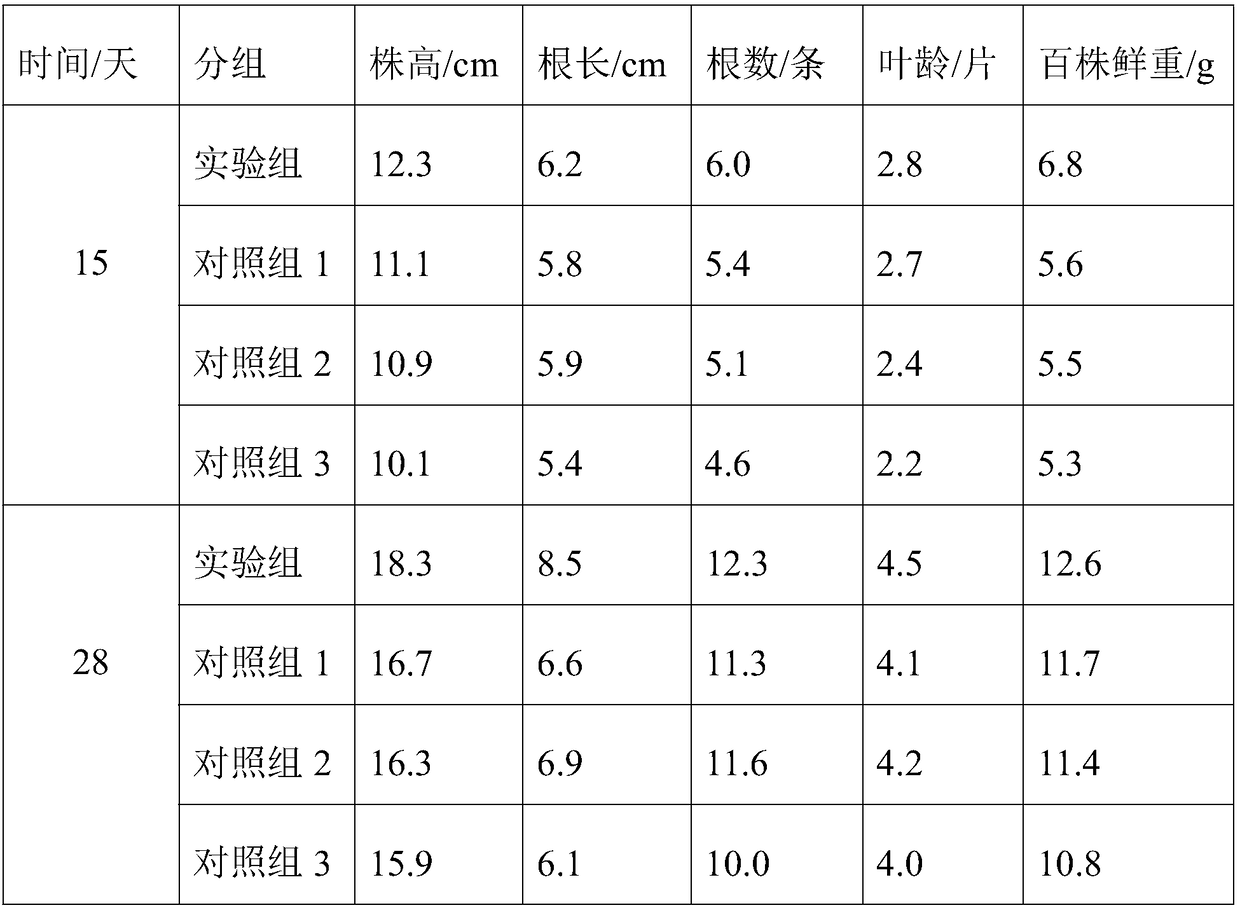

Seedling growing substrate, preparation method thereof and seedling growing tray containing same

InactiveCN108484257ALoose physical propertiesStrong water absorptionBio-organic fraction processingThomas phosphate fertilisersDry matterSlag

The invention provides a seedling growing substrate, a preparation method thereof and a seedling growing tray containing the same. The seedling growing substrate comprises the following raw materialsin parts by weight: 80-90 parts of straws, 10-20 parts of straw carbon, 5-15 parts of animal wastes, 5-15 parts of furnace slag, 0.04-0.05 part of fermentation strain and 0.8-72 parts of water. The seedling growing substrate provided by the invention is loose in physical behavior, moderate in pH value, strong in hygroscopic property, good in permeability and high in nutrient content, can make riceseedlings grow rapidly, take roots well and have more roots, developed root systems and high fresh weight of 100 plants compared with a commercially-available ordinary seedling growing substrate andcan achieve the best seedling quality required for rice production in aspects of plant shape formation and dry matter accumulation.

Owner:BEIJING SANJU GREEN ENERGY TECH CO LTD

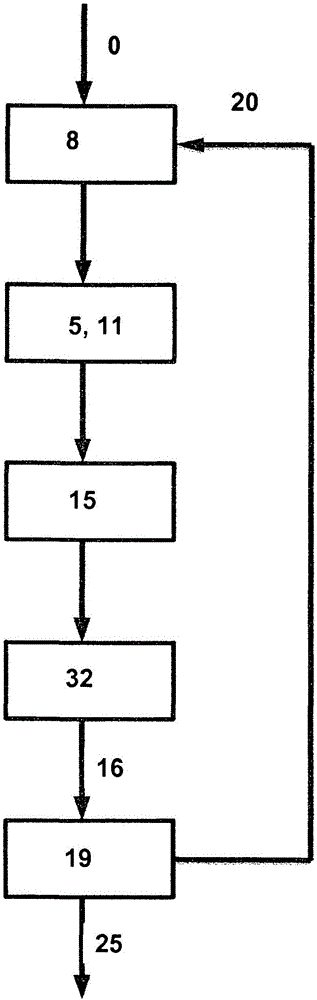

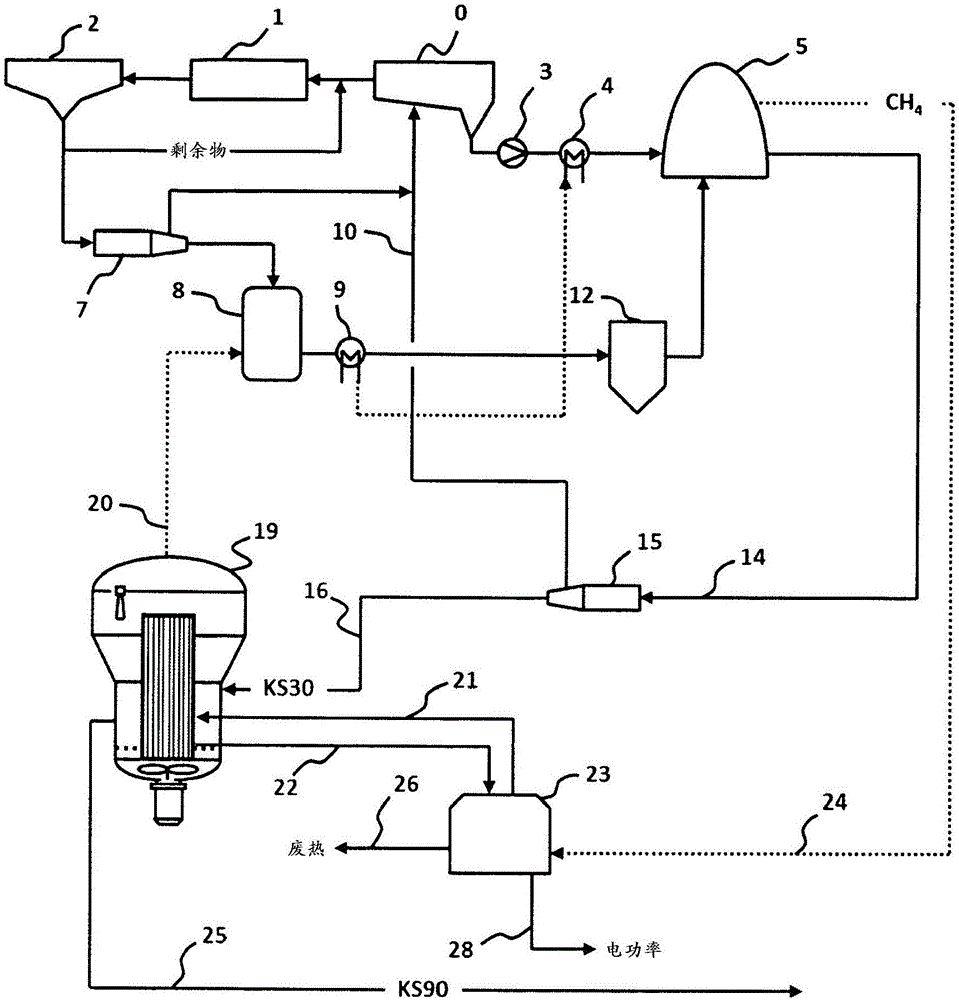

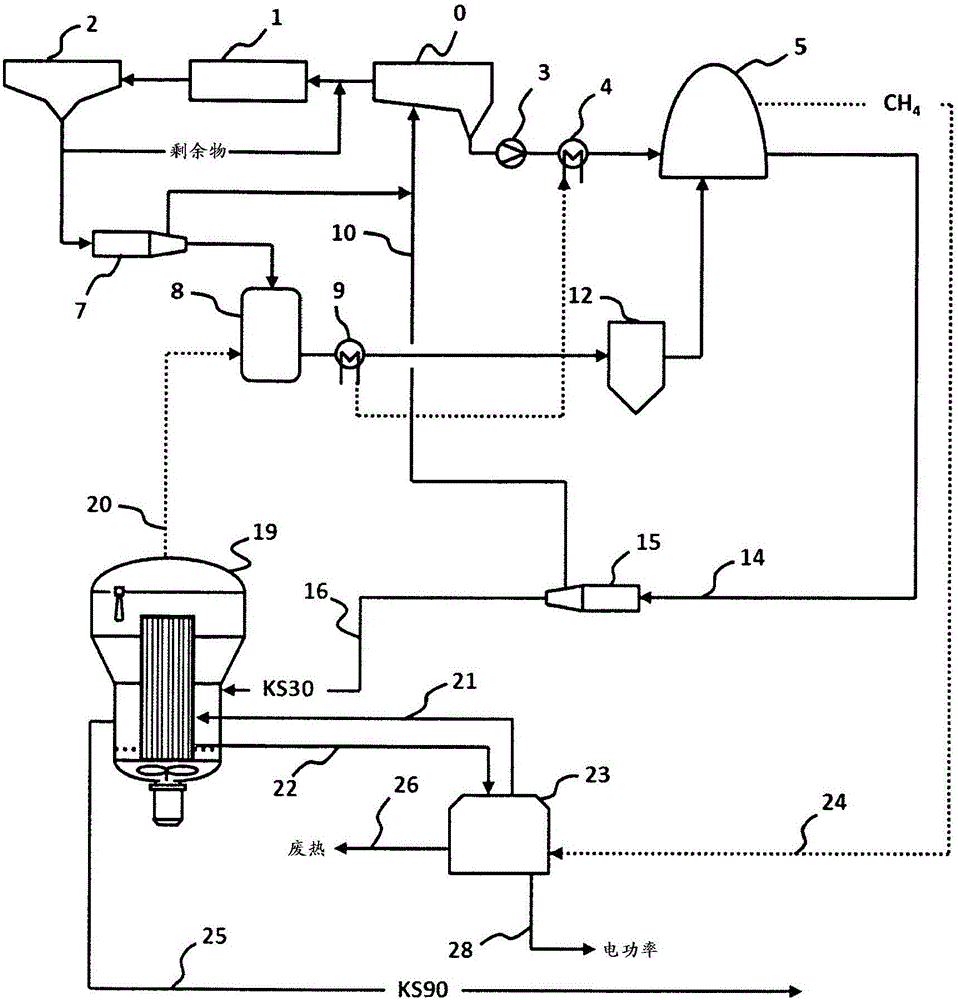

Method and arrangement for wastewater treatment

PendingCN106795023AReduce consumptionLow costByproduct vaporizationWaste based fuelSludgePositive pressure

The invention relates to a method and an arrangement for wastewater treatment, in which at least portions of the sewage sludge contained in the wastewater (0) are subjected to a hydrolysis (8). The hydrolysis (8) is carried out as a thermal hydrolysis. After the hydrolysis step (8), a drying process is (19) carried out. The drying process (19) is a process operating with positive pressure in the steam region. At least parts of the steam resulting from the drying process (19), which operates with positive pressure, are fed (20) to the portions of the sewage sludge in the thermal hydrolysis (8).

Owner:AWAMA

Silicon-calcium capsule fertilizer and preparation method thereof

InactiveCN106187598AIncrease organic matterOrganic matter improvementMagnesium fertilisersThomas phosphate fertilisersSodium BentoniteSlag

The invention belongs to the field of agriculture, and discloses a silicon-calcium capsule fertilizer suitable for the modern agriculture and a preparation method thereof. The silicon-calcium capsule fertilizer comprises the following components: tailing slag, ammonium sulfate, agricultural magnesium sulfate, agricultural zinc sulfate, agricultural ferrous sulfate, agricultural borax, silicon dioxide, soluble starch, trace elements, bentonite, a hydrophilic polymer material, a surfactant, citric acid powder, amino acid, cortex meliae, fructus quisqualis, Chinese gall, pubescent holly root, soapberry episperm, rhizoma atractylodis, and cellulase. The silicon-calcium capsule fertilizer is practical and is capable of effectively solving the problems of insects, diseases, nutritional imbalance, low fertilizer utilization rate, and soil salinization.

Owner:河南金地宝生态肥业有限公司

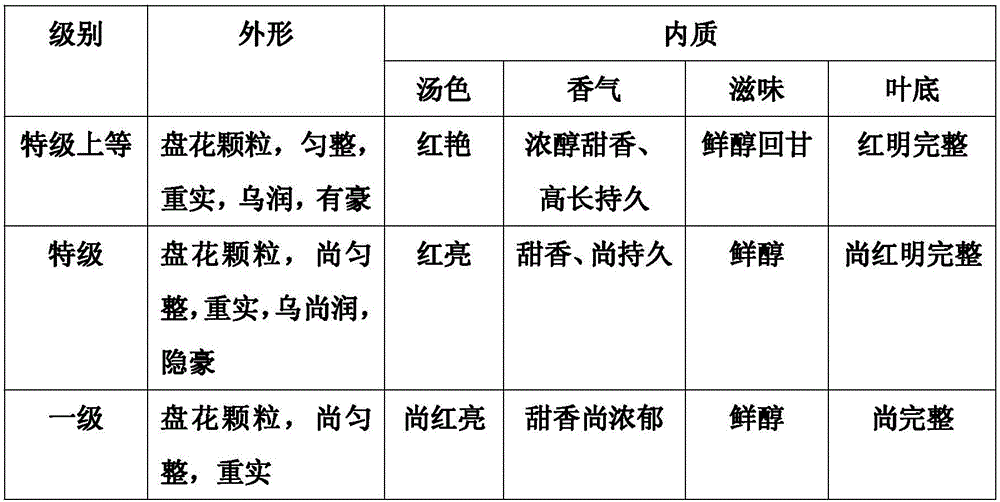

Black tea processing technology

InactiveCN106070772AImprove qualityIncrease the content of amino acidsSuperphosphatesPre-extraction tea treatmentBitter tastesAmino acid content

The invention discloses a black tea processing technology. The black tea processing technology comprises the steps of pretreatment, fresh leaf selection, leaf spreading, leaf cooling, rocking of green leaves, rolling, fermenting, incipient drying, drying, fragrance increasing and packing. The tea processed through the technology is good in quality, the content of amino acids is increased, the content of tea polyphenols and caffeine is reduced, and the black tea is free of the bitter taste.

Owner:贵州贵茶(集团)有限公司

Method for preparing free cutting steels and slag phosphate fertilizers using phosphorus-rich sulfur-rich iron powder

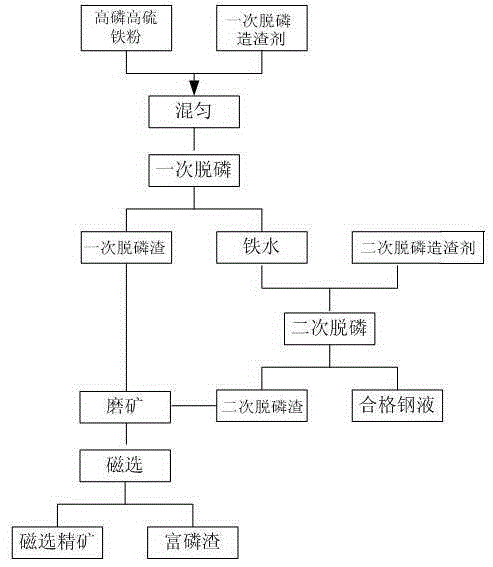

ActiveCN105400930APromote rapid formationMeets requirements for free-machining steelsThomas phosphate fertilisersIron powderSeparation technology

The invention belongs to the field of ferrous metallurgy, and particularly relates to a method for preparing free cutting steels and steel slag phosphate fertilizers using phosphorus-rich sulfur-rich iron powder. According to the method disclosed by the invention, a special slagging agent is prepared based on fully utilization of the oxide impurities in the iron powder; a melting separation technique is adopted, so that the migration of phosphorus from an iron phase to a slag phase is realized, and sulfur is reserved in the iron phase; dephosphorization is performed through a double slag process, so that molten steel and slags rich in phosphorus, which conform to the requirements of the free cutting steels are obtained at the same time; the slags rich in phosphorus can be directly used as the steel slag phosphate fertilizers after being separated magnetically, and finally the comprehensive utilization of the phosphorus-rich sulfur-rich iron powder is realized.

Owner:上海逢石科技有限公司

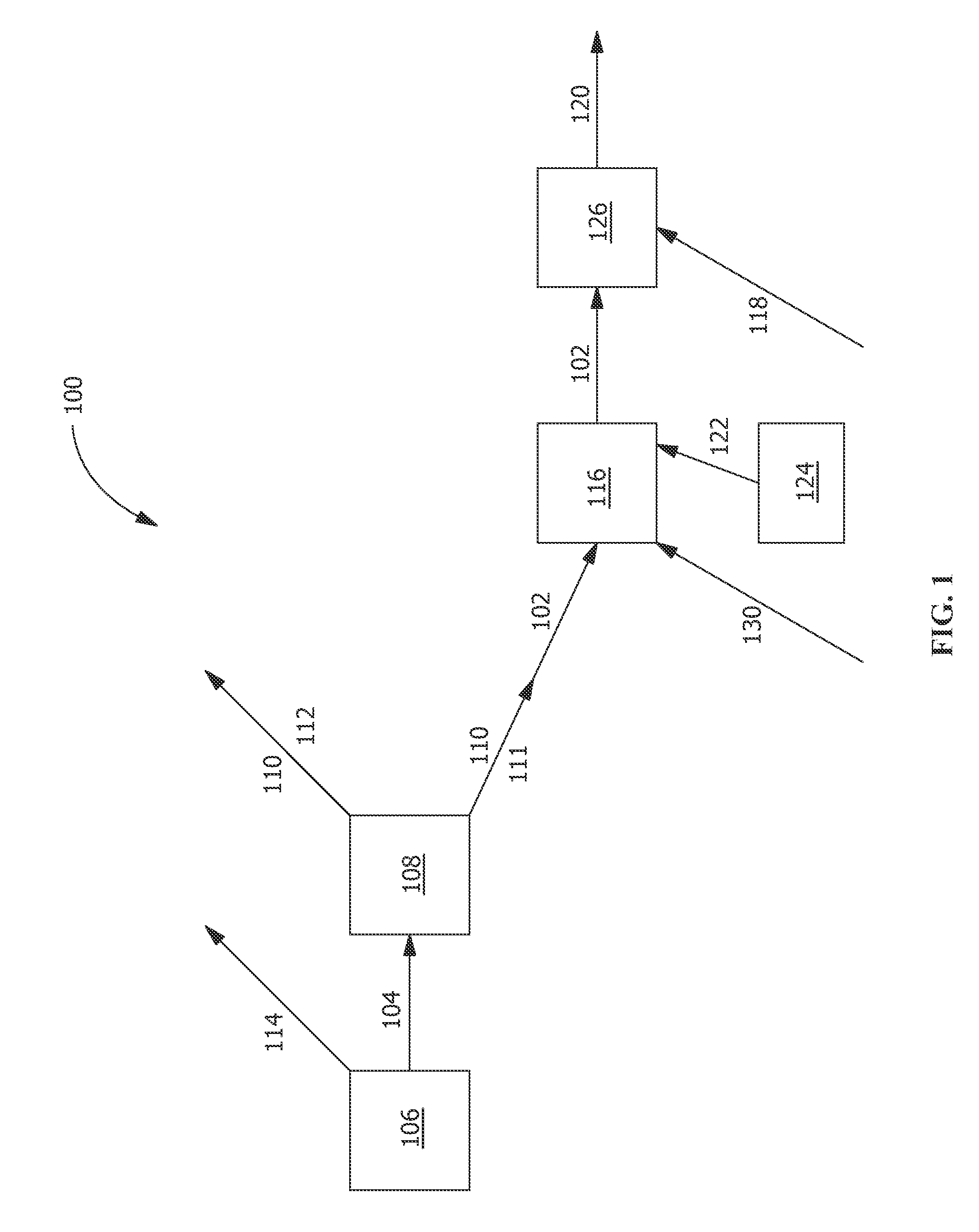

Agricultural blend and process of forming an agricultural blend

The present disclosure describes an agricultural blend and a process of forming an agricultural blend. The agricultural blend includes a slag by-product from a process having a slag other than stainless steel slag or includes 11 atomic % silicon from a soluble compound and total silicon of less than about 30 atomic % silicon or greater than about 39 atomic % silicon. The process includes producing a slag by-product and blending the slag by-product with a liquid binder system to form the agricultural blend, the slag not being stainless steel slag.

Owner:HARSCO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com