Method for preparing calcium magnesium phosphate fertilizer by utilizing phosphorite flotation tailing blast furnace method

A calcium-magnesium-phosphate fertilizer and blast furnace technology, applied in phosphate fertilizers, Thomas phosphate fertilizers, applications, etc., can solve problems such as hidden safety hazards, environmental pollution, occupation of land resources, etc., and achieve economic feasibility, reduce production costs, and save phosphorus resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

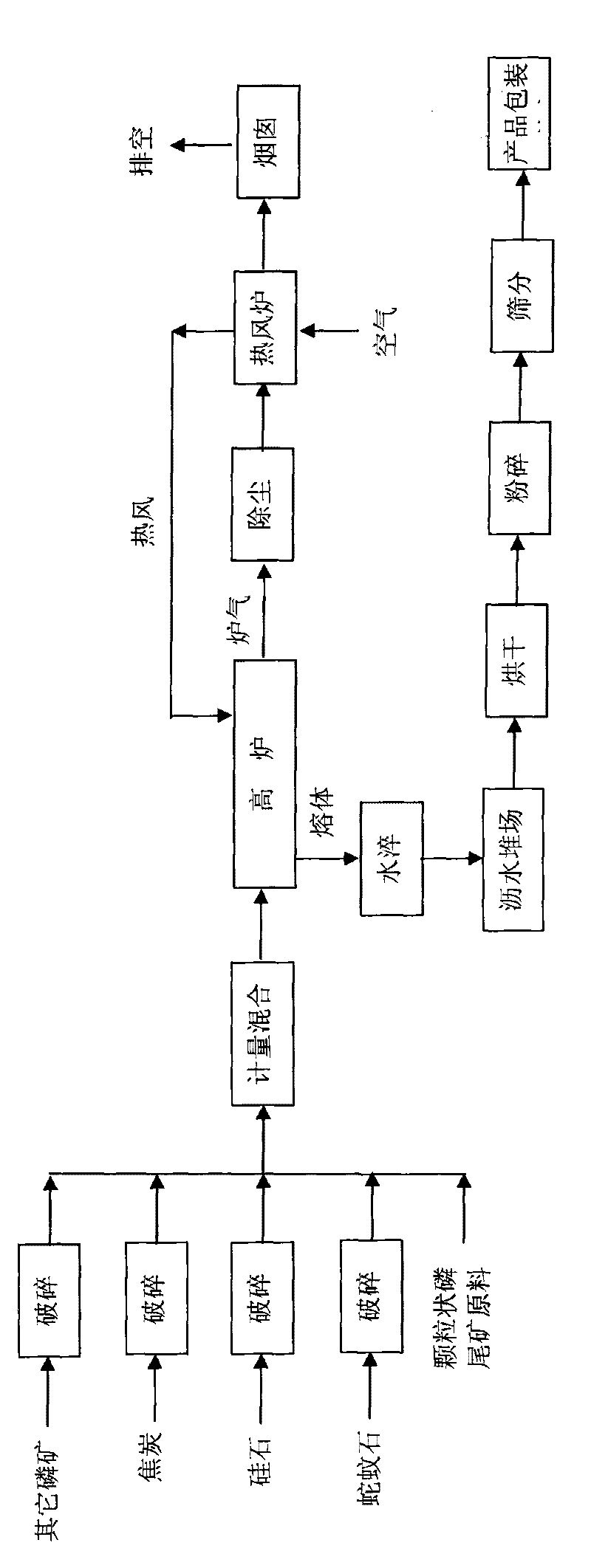

[0021] In this example, using phosphate rock flotation tailings as the main raw material, the production process and operation control steps of preparing calcium magnesium phosphate fertilizer by blast furnace are as follows:

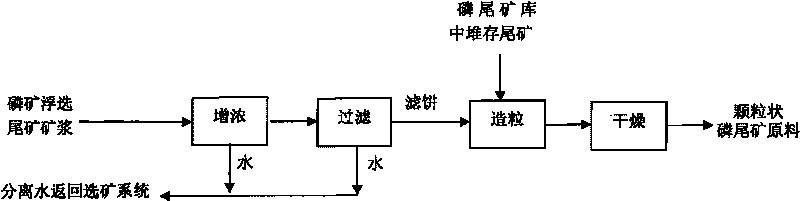

[0022] (1) Preparation of phosphorous tailings raw materials

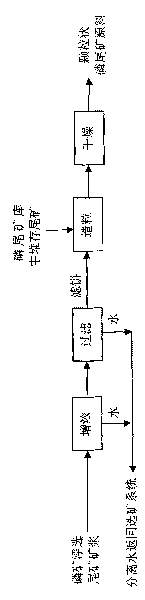

[0023] Use flotation phosphorus tailings slurry as raw material, dehydrate through thickener and filter to obtain flotation tailings filter cake with water content of 20-40%; use the filter cake or wet tailings stockpiled in tailings pond Granulator granulation (material particle size is 10 ~ 50mm); it is dried and dehydrated with a drier to obtain phosphorous tailings granules with a water content of 2 o 5 ) is 8 to 12%,). The production process is attached figure 1 .

[0024] (2) Preparation of raw materials for furnace melting

[0025] Primary phosphate rock W(P 2 o 5 ≥23%), coal, snakebite, and silica are crushed into lumps with a particle size of 30-60mm. The various minerals and...

Embodiment 2

[0036] (1) Chemical composition of flotation phosphorus tailings and phosphate rock raw materials

[0037] Typical chemical composition (mass %) of flotation phosphorus tailings and furnace phosphate rock raw materials used in this example

[0038] chemical composition

P 2 o 5

MgO

CaO

SiO 2

Flotation tailings

9.20

12.10

29.60

8.10

Phosphate Rock Raw Materials

15.50

10.80

32.80

12.35

[0039] (2) The production process and operation steps of calcium magnesium phosphate fertilizer prepared by cyclone furnace

[0040] Production flow and operation control step are identical with embodiment 1, and process flow chart is as figure 1 , figure 2 .

[0041] (3) Typical process conditions of this example

[0042] Typical process conditions for this example

[0043] Melting temperature (℃)

1370

Melting time (min)

38

Quenching temperature (℃)

30

...

Embodiment 3

[0048] (1) Chemical composition of flotation phosphorus tailings and phosphate rock raw materials

[0049]Typical chemical composition (mass %) of flotation phosphorus tailings and furnace phosphate rock raw materials used in this example

[0050] chemical composition

P 2 o 5

MgO

CaO

SiO 2

Flotation tailings

9.60

11.30

30.86

9.15

Phosphate Rock Raw Materials

15.90

10.76

32.26

12.85

[0051] (2) The production process and operation steps of calcium magnesium phosphate fertilizer prepared by cyclone furnace

[0052] Production flow and operation control step are identical with embodiment 1, and process flow chart is as figure 1 , figure 2 .

[0053] (3) Typical process conditions of this example

[0054] Typical process conditions for this example

[0055] Melting temperature (℃)

1380

Melting time (min)

40

Quenching temperature (℃)

35

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com