Patents

Literature

108results about How to "Promote the development of circular economy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

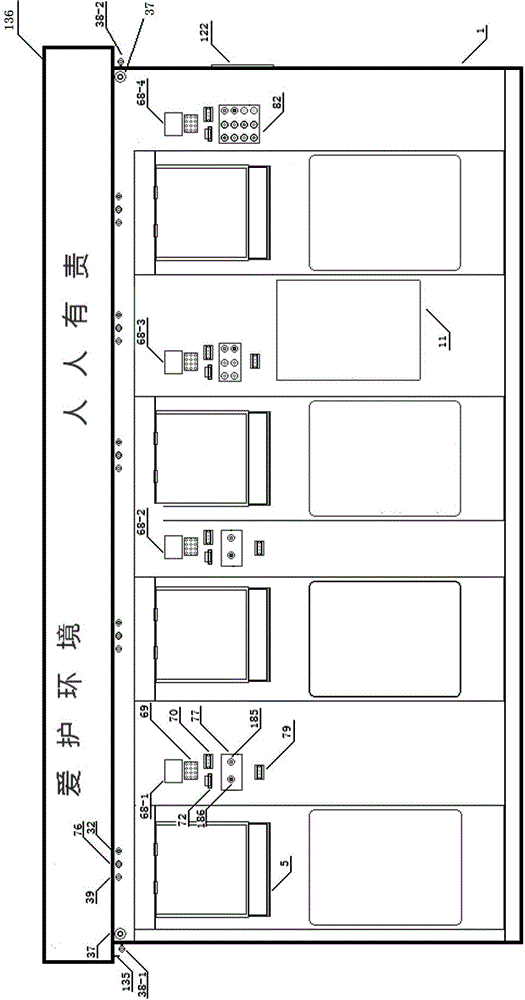

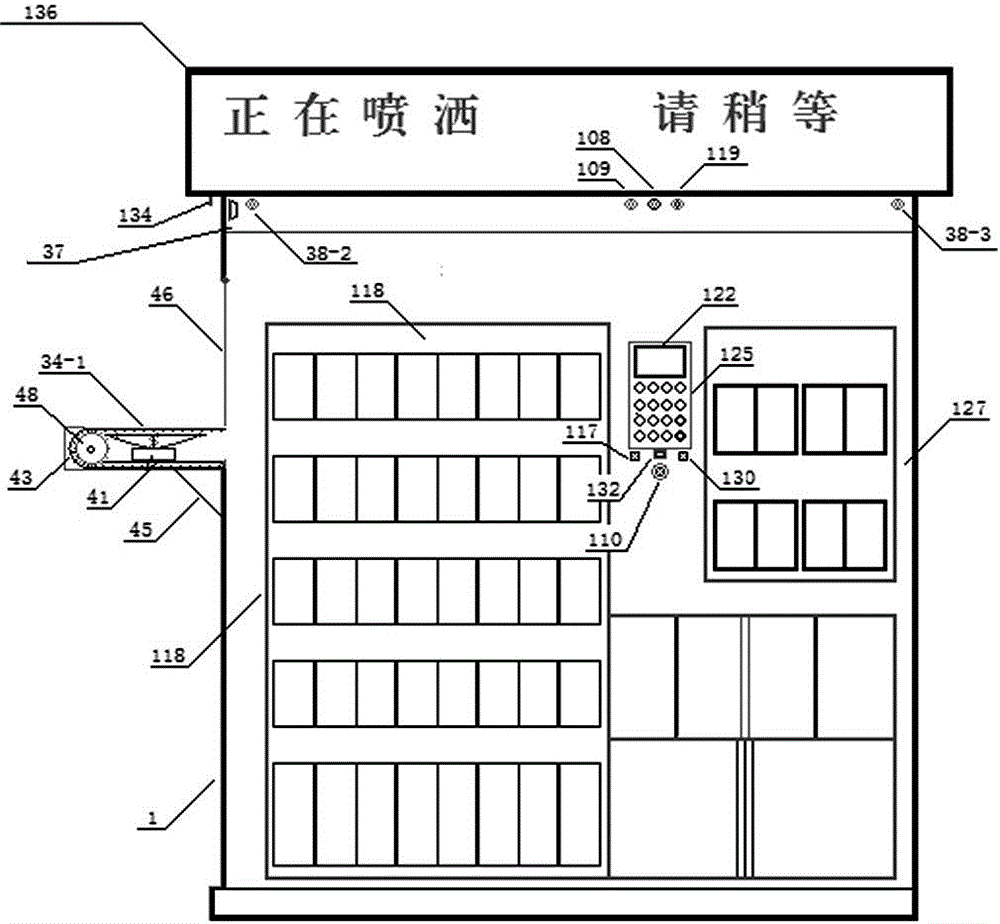

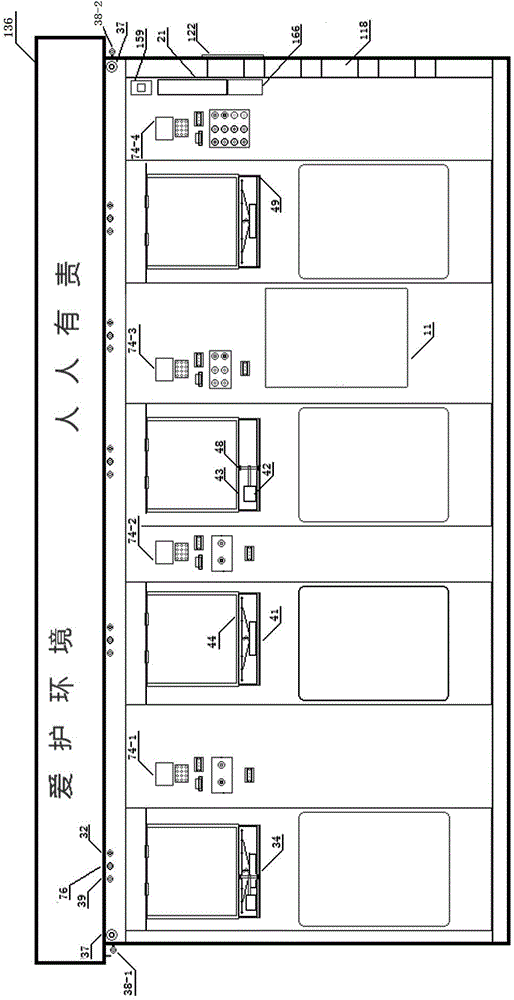

Multi-functional household garbage classified putting device

ActiveCN105775531AClassified collection works flexiblyClassification and collection work is simple and easyWaste collection and transferRefuse receptaclesDistribution systemMultiple function

The invention relates to a multi-functional household garbage classified putting device which comprises putting collection rooms, an inductive control system, a language broadcasting system, a camera shooting acquisition system, a classified collection transportation device, a classified material push unloading device, classified collection storage garbage cans, an overflow alarm and automatic box changing can adjusting system, an environment-friendly scorecard account management system, an accumulated score scanning and code printing system, a bulk object recycling device, an automatic fly eradication and deodorization device, a reserved door-to-door service system, a delivery deposit device, a lost object storing and finding device, an emergency help seeking and calling system, an advertisement circulating playing system, an electronic screen turn-on and turn-off control system, a free wireless network (Wifi), an automatic solar power generation and power distribution system, a microcomputer center control system, a back-stage management operating system, and other ancillary facilities and devices. According to the multi-functional household garbage classified putting device, the classified collection of household garbage is completely achieved, and a plurality of people-oriented services are provided for community residents.

Owner:李恩霞

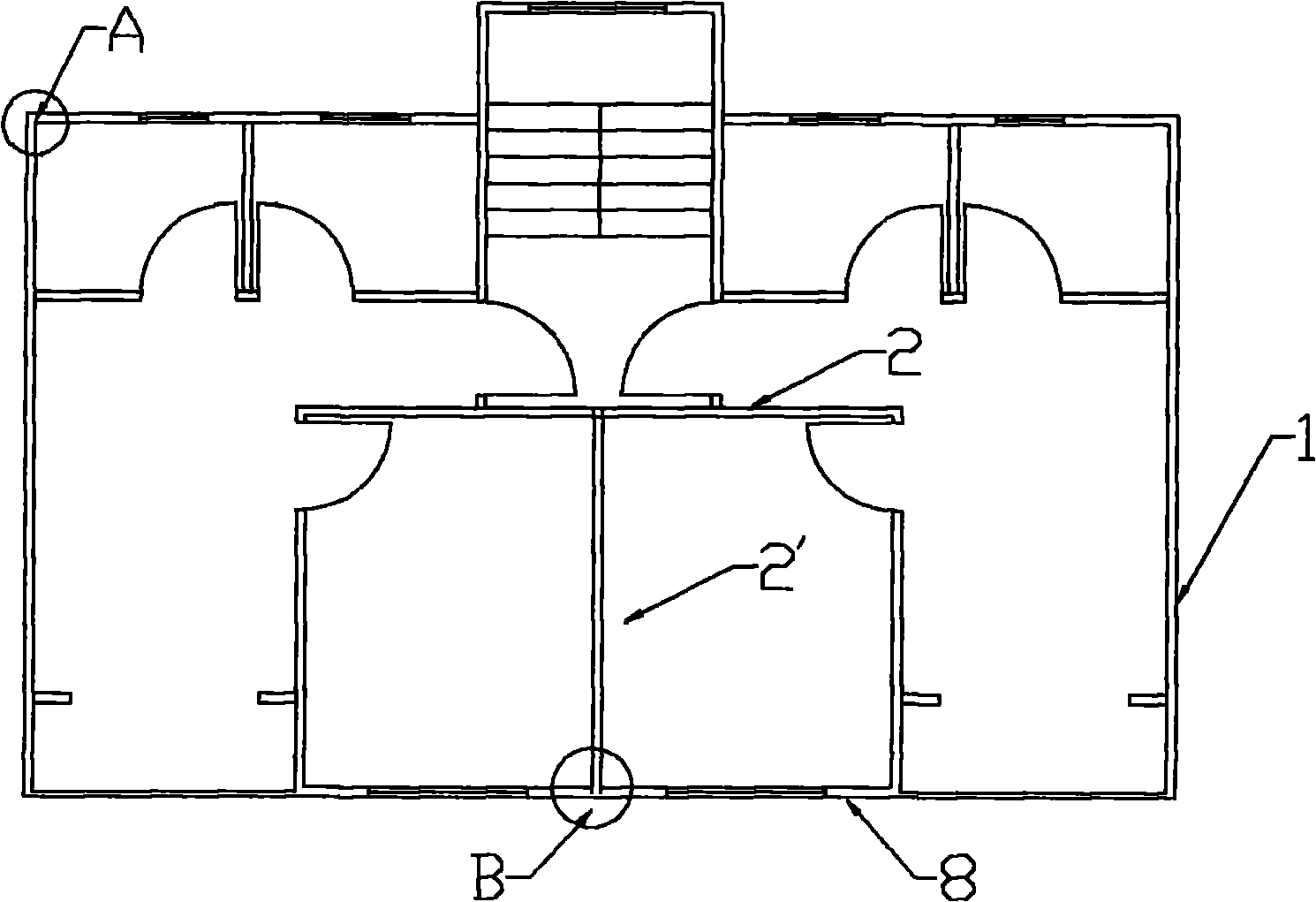

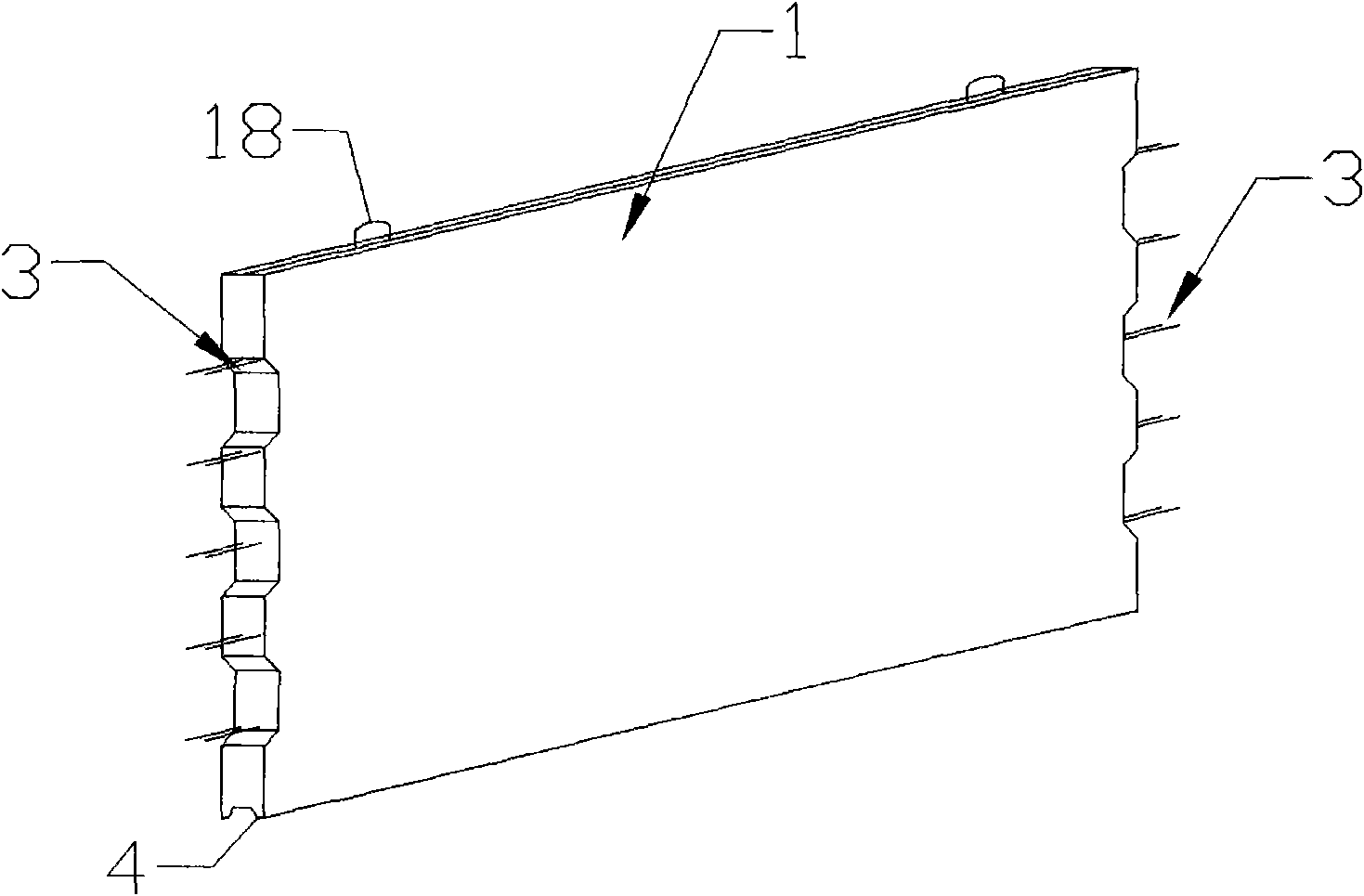

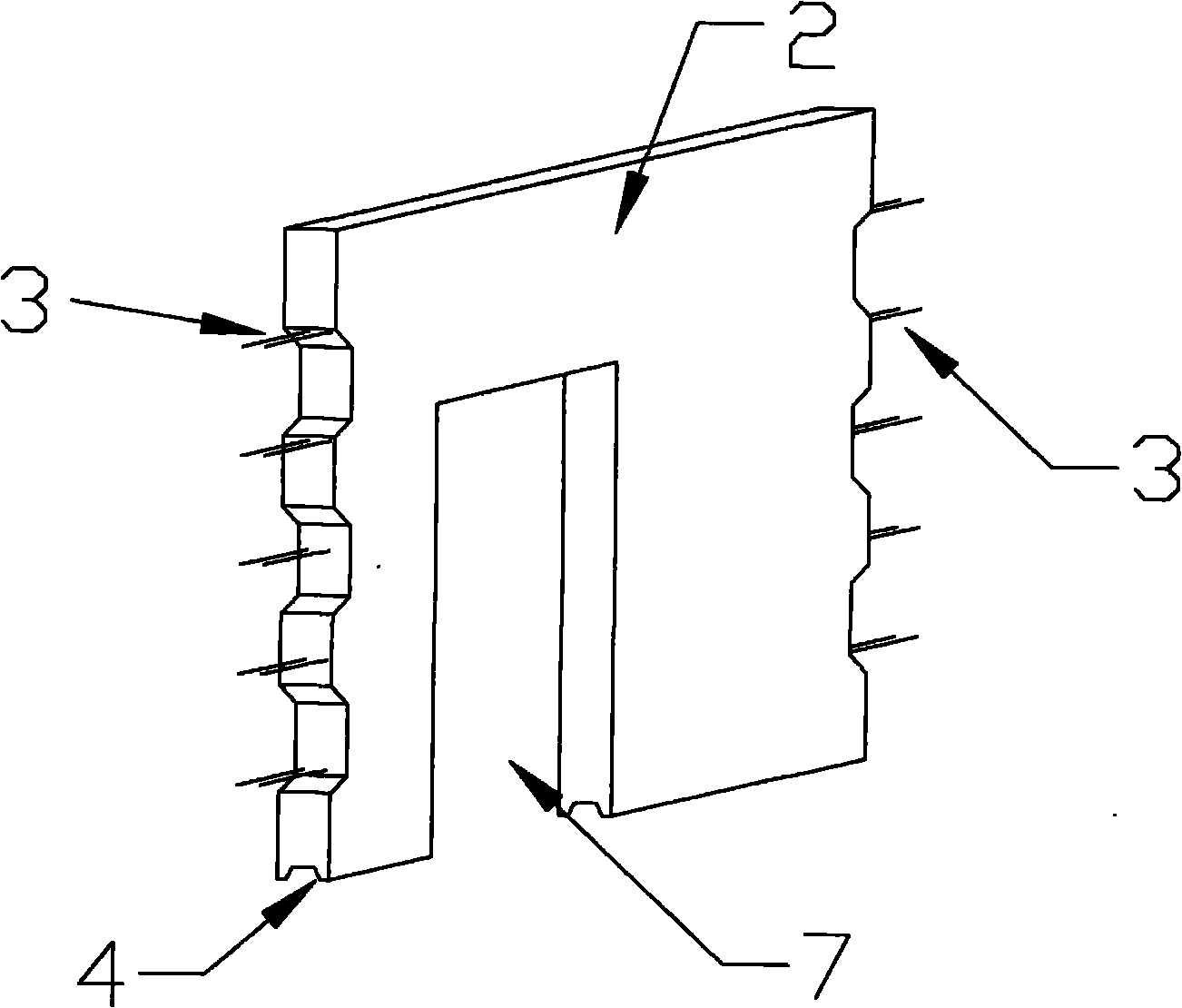

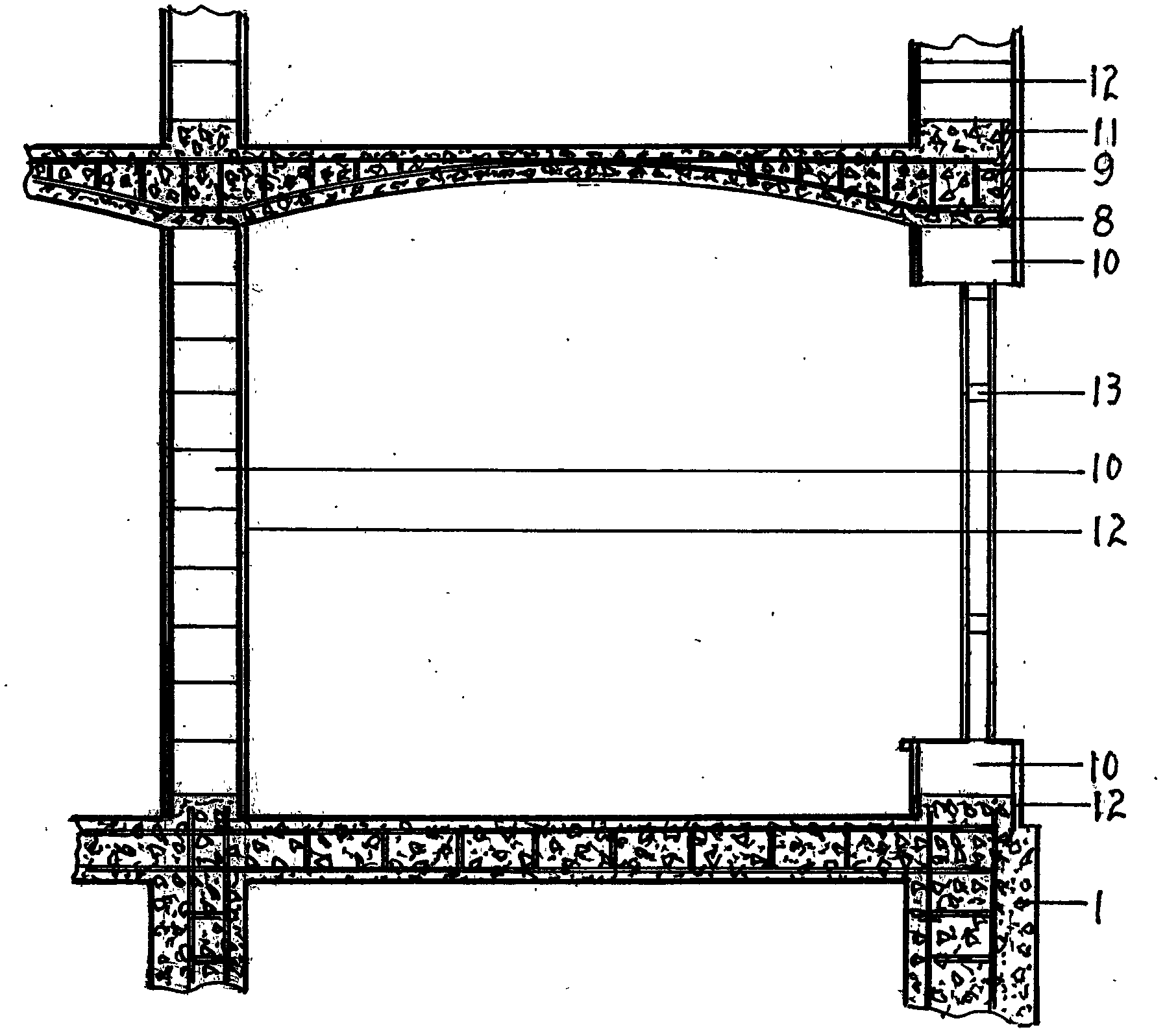

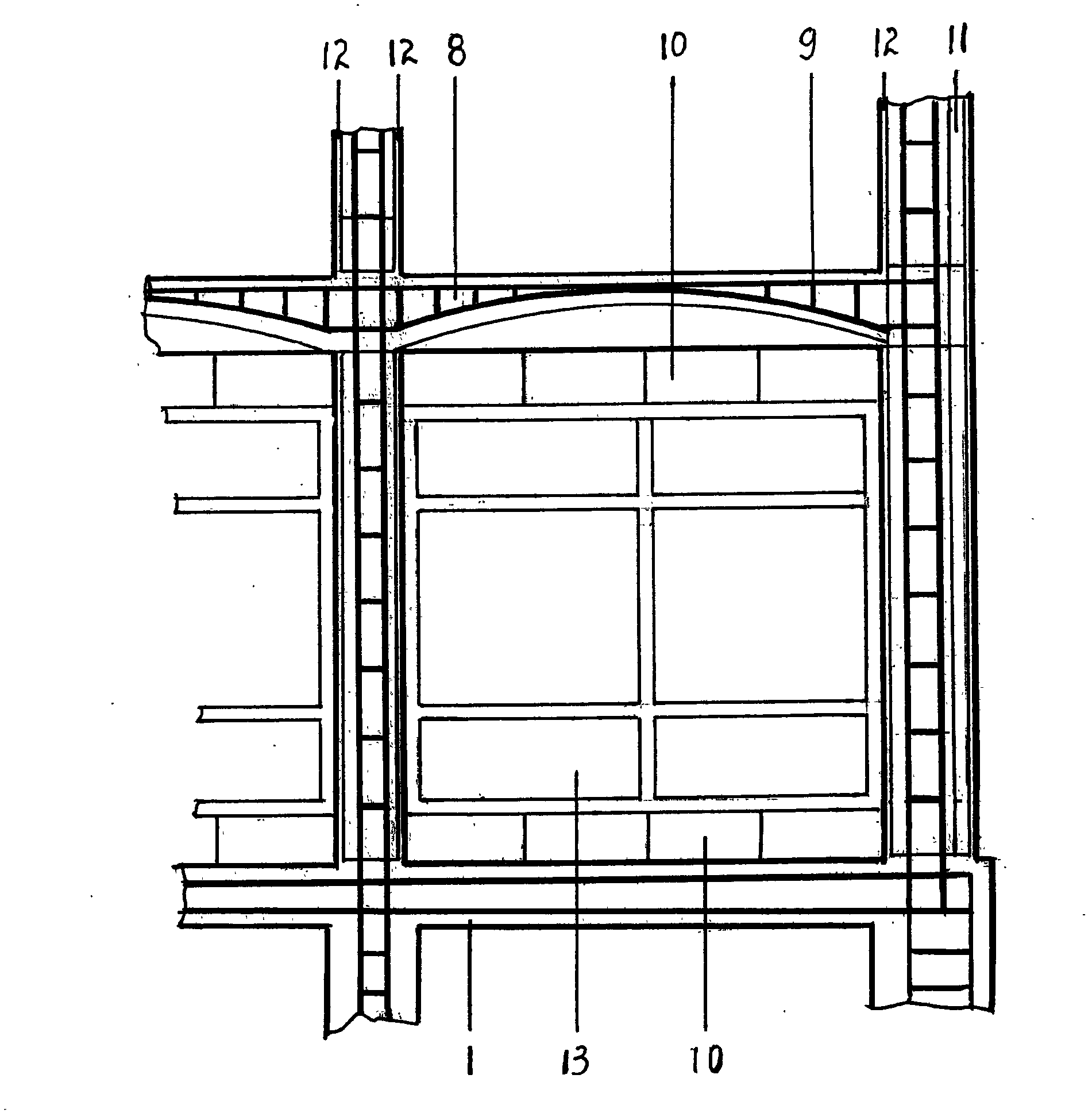

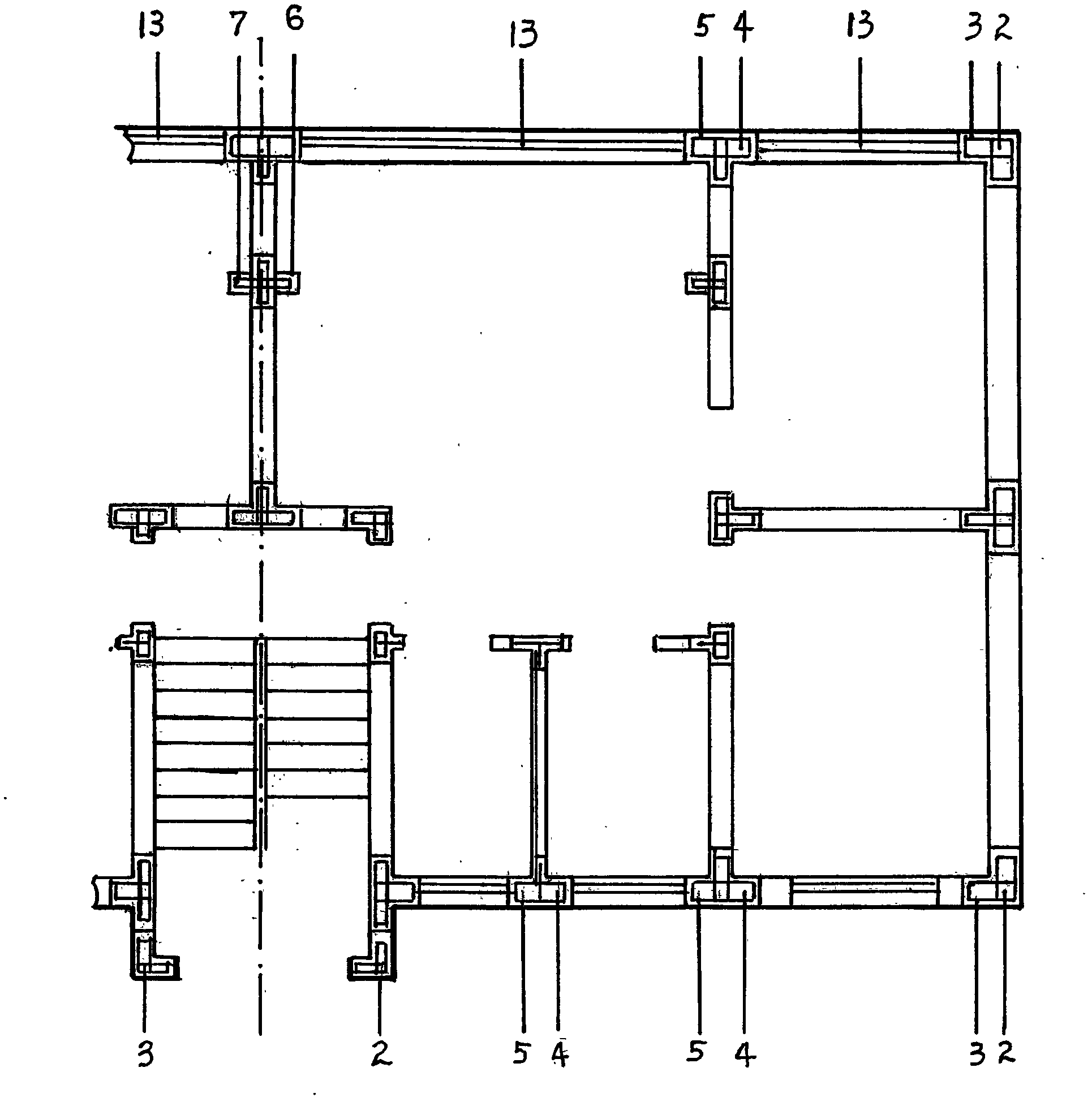

Board-mixing structure assembly type house and building method thereof

InactiveCN101967851APromote the development of circular economyImprove the level of industrializationBuilding constructionsThermal insulationWall plate

The invention discloses a board-mixing structure assembly type house and a building method thereof. The house is characterized in that an inner wall board, an outer wall board and superimposed floor boards which are prefabricated are connected with constructional columns and floors which are cast in site so as to form a whole; and the inner wall board, the outer wall board, the superimposed floor boards and the constructional columns are prefabricated or cast by adopting green concrete. The house can improve the industrial level of house construction and the whole level of house buildings greatly and reduce the construction difficulty and cost, is beneficial to solving the node waterproofing problem, improving the thermal insulation level and durability of thermal insulating materials and reducing the laying of reinforcing steel bars on the floors and laying of templates, and is beneficial to realizing standardized production and greatly shortening the construction period.

Owner:董杨

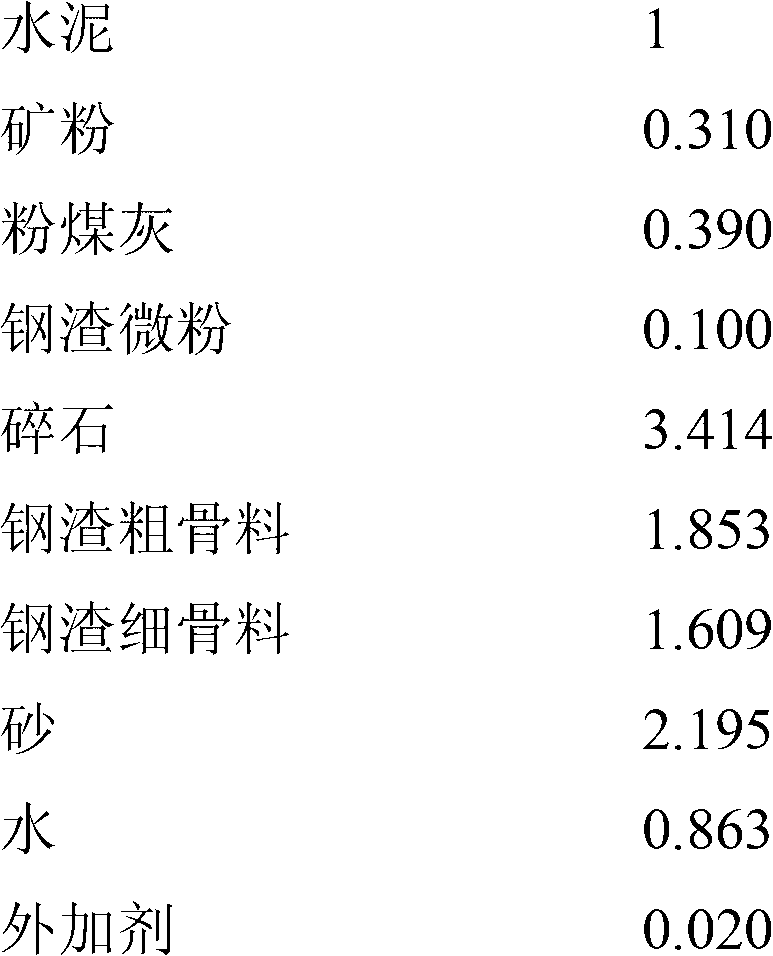

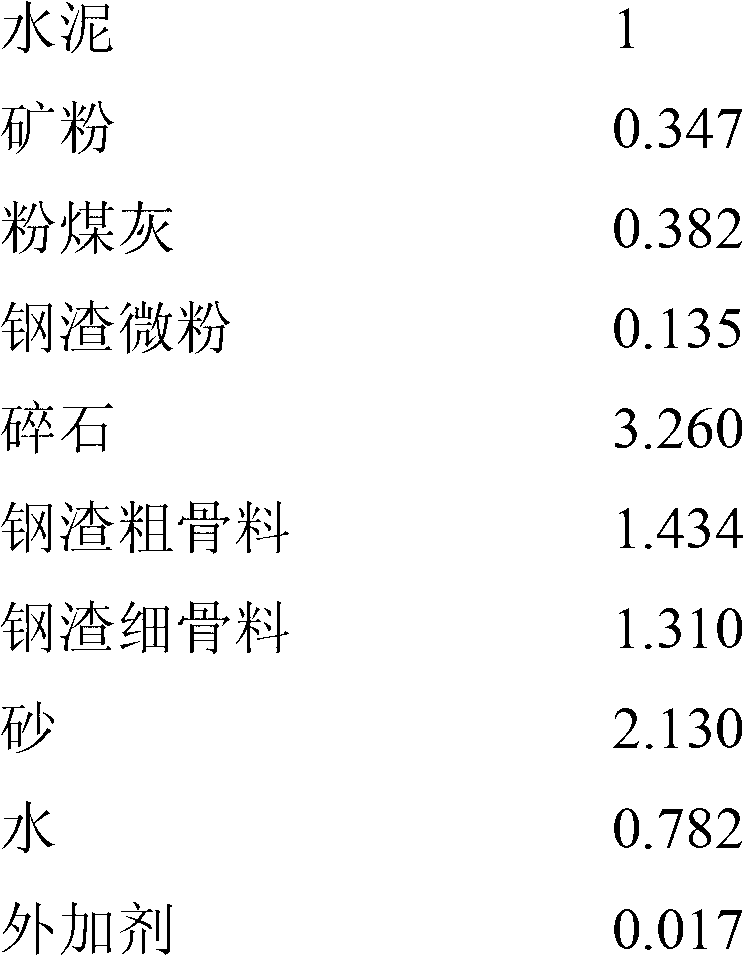

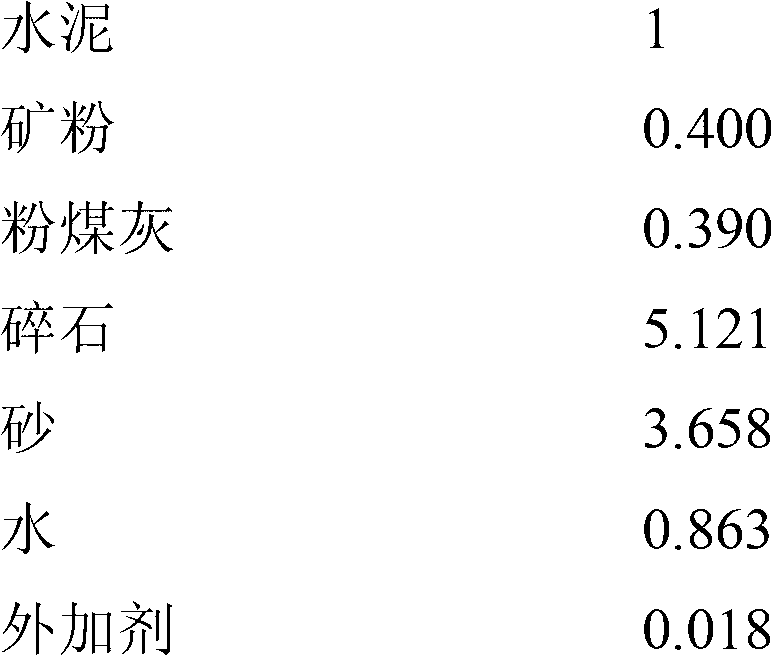

Resource utilization type steel-slag concrete

The invention discloses a resource utilization type steel-slag concrete. The resource utilization type steel-slag concrete is characterized in that the volume weight is 2400 -2600kg / m3, and the raw material components and the weight part of each component based on the mass percentage of cement are as follows: 1.000 parts of cement, 0.300-0.350 parts of mineral powder, 0.350-0.400 parts of coal ash, 0.100-0.150 parts of steel-slag fine powder, 1.300-1.650 parts of steel-slag fine aggregate, 1.400-1.900 parts of steel-slag rough aggregate, 2.000-2.200 parts of sand, 3.200-3.450 parts of broken stone, 0.700-0.900 parts of water, and 0.015-0.025 parts of additive. In comparison with the normal concrete, the resource utilization type steel-slag concrete provided by the invention has the advantages that the total content of solid wastes such as steel-slag and coal ash is higher than 30%; with the adoption of the industrial solid slag, the additional value is enhanced, the production cost is reduced, and meanwhile, the environmental problem is solved; the prepared concrete has good compactness and excellent mechanical property.

Owner:SHANGHAI BAOTIAN NOVEL BUILDING MATERIALS +1

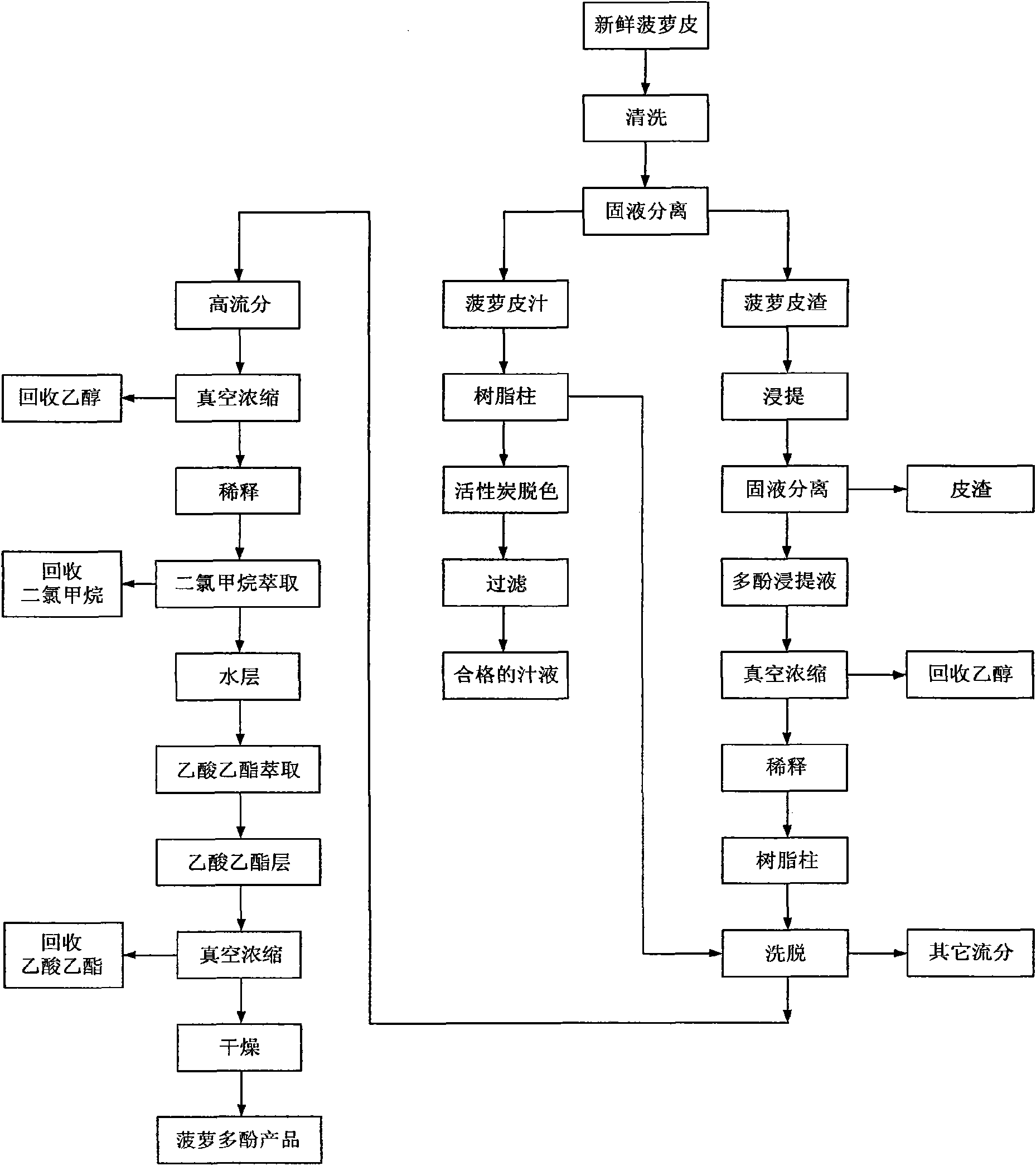

Method for combined preparation of pineapple polyphenol and juice by taking pineapple peel as main material and application thereof

ActiveCN101648980AReduce browningGood economic benefitsOrganic chemistryFood preparationSlagActivated carbon

The invention discloses a method for combined preparation of pineapple polyphenol and juice by taking pineapple peel as main material and application thereof. The method includes that pineapple peel is cleaned, pressed and separated, so as to respectively obtain pineapple peel slag and pineapple peel juice; the pineapple peel juice is subject to macroporous resin column absorption, powered activated carbon absorption, filtering and the like, so as to obtain clear juice with extremely low clear and brown stain degree; the pineapple peel slag is subject to alcohol digestion, vacuum concentration, dilution, macroporous resin column absorption and the like, so that pineapple polyphenol can be absorbed into the macroporous resin; the macroporous resin column used for absorbing polyphenol substance in the pineapple peel juice and pineapple peel slag digestion solution is eluted by alcohol solution, the elution is subject to methylene dichloride extraction, ethyl acetate extraction, concentrated drying and the like, so that pineapple polyphenol with purity more than 90% can be obtained and extraction ratio is more than 2.5g / kg. The invention has the characteristics of easy industrializedproduction, high yield, high production purity, obvious co-production economic benefit and has important significance on promoting recycling economy development.

Owner:蔡施平 +1

Cultivating method of poria cocos bag material

The invention provides a cultivating method of a poria cocos bag material and relates to a method for cultivating poria cocos without using pine-wood. The method comprises the following steps: grinding the plant straws or branches, mixing evenly with pine wood chips, rice bran, sucrose, calcined gypsum and the like, and manufacturing into a bacteria bag; inoculating the poria cocos strain after the bacteria bag is sterilized and then is placed in a greenhouse to cultivate poria cocos hypha; embedding into a cultivation cellar when the poria cocos bacteria hypha grows and the bacteria bag is filled with the poria cocos bacteria hypha; selecting the intensive part of the hypha body in the bacteria bag to inoculate a small block of tender fresh poria cocos sclerotium block; then earthing and encapsulating the cellar; leading the poria cocos hypha in the fresh sclerotium block to recover the vitality, and fusing with the hypha body in the cultivating bacteria bag to form sclerotium primordium, then growing to form newly born sclerotium. The invention utilizes plant straws or branches rich in cellulose and hemicellulose, pine wood chips, rice bran, sucrose and the like to manufacture into the cultivation bacteria bag to substitute pine wood, thus not only turning waste into wealth, effectively protecting pinery resources, but also needing only 3 to 4 months for the picking time, thereby being beneficial for the circulating and comprehensive utilization of the cultivation site and enlarging the production of poria cocos.

Owner:王克勤 +1

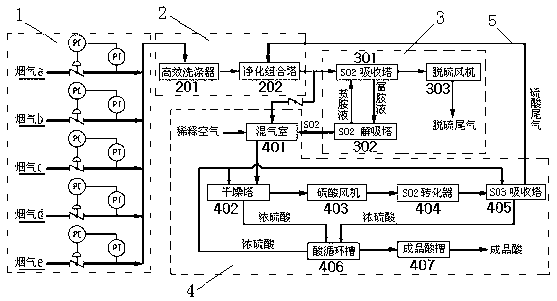

Comprehensive multi-gas source low-concentration SO2 fume recycling acid-making technological process

ActiveCN103303877AImprove sulfur recoveryOptimization of equipment and investmentDispersed particle separationSulfur compoundsScrubberCircular economy

The invention discloses a comprehensive multi-gas source low-concentration SO2 fume recycling acid-making technological process. The fume is mixed in a pressure adjusting gas distribution mode, is subjected to washing by using a high-efficiency washer and deep purification by using a combined purification tower, and is subsequently fed into a fume desulfurization system, and the tail gas is fed into a chimney to discharge out. The high-concentration SO2 which is produced from desulfuration and desorption is diluted by air or a part of pre-washed wet fume and is fed into an acid-making system, a finished product sulfuric acid is produced, the sulfuric acid tail gas is fed back to the combined purification tower and the fume desulfurization system, and the tail gas is discharged out when being subjected to up-to-standard desulfurization. The process is a comprehensive sulfur resource recycling technique that a multi-gas source mixed conveying technique, an SO2 recycling technique which employs an absorption-desorption method and a conversion-absorption acid-making technique are combined together, has the characteristics of high sulfur recycling rate, optimization in equipment and investment and low operation expense, can realize clean production and comprehensive recycling of SO2, prompts the development of circular economy of companies, and can be widely applied to comprehensive treatment on fume with low-concentration SO2 in industries of colored metal, steel and iron, thermal power, chemistry and the like.

Owner:CHINA NERIN ENG

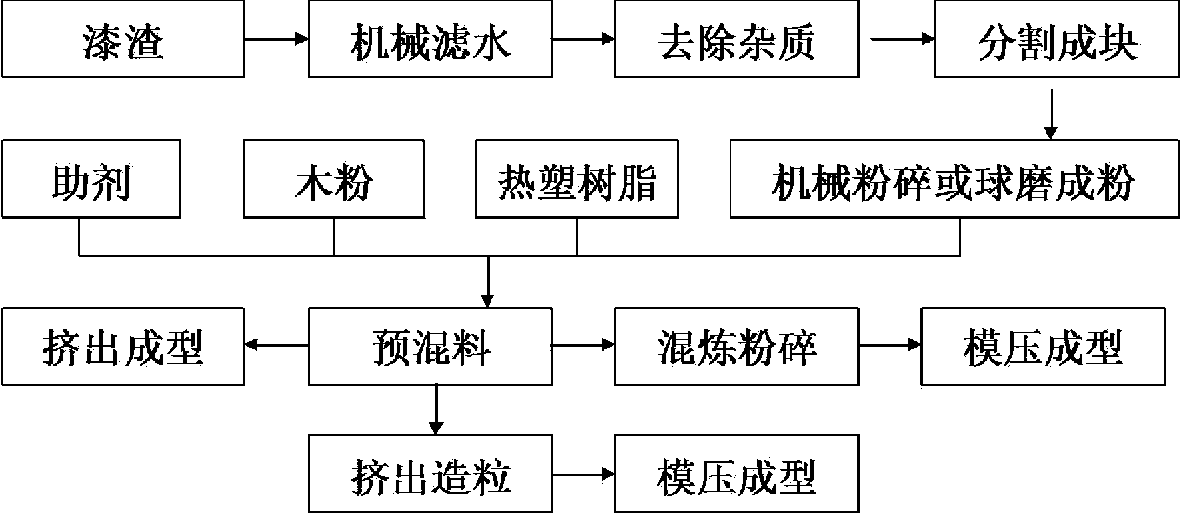

Preparation method of waste paint slag compatibilized wood-plastic composite material

ActiveCN103665902AReduce manufacturing costImprove interface compatibilityPlasticizerFilm-forming agent

The invention relates to a preparation method of a waste paint slag compatibilized wood-plastic composite material, which comprises the following steps: mixing waste paint slag with thermoplastic resin and wood flour, compounding, and performing die pressing or extrusion to produce the wood-plastic composite material, wherein the paint slag is mainly composed of film forming matter, pigment, solvent and additive; the film former component in the paint slag contains multiple active functional groups such as hydroxyl groups, carboxyl groups, ester groups, amido groups and the like, and can be bonded with active groups on the surfaces of the wood flour and resin, such as hydroxyl groups, carboxyl groups, ester groups or the like; alkyl plastic chain segments in the film former or plasticizer in the paint slag are attached to soft chain segments of the resin, thereby increasing the interface bonding force and compatibility between the wood flour and the resin and improving the mechanical property of the wood-plastic composite material; and the pigment in the paint slag is used instead of master batches and added into the wood-plastic composite material, so that the decoration effect of a wood-plastic product is enhanced, and the production cost is lowered. Thus, the problems that waste paint slag pollutes environment and the waste paint slag treatment cost of an automobile manufacturer is high are effectively solved, and the unification of environmental benefits, social benefits and economic benefits is realized.

Owner:SHANDONG UNIV OF TECH

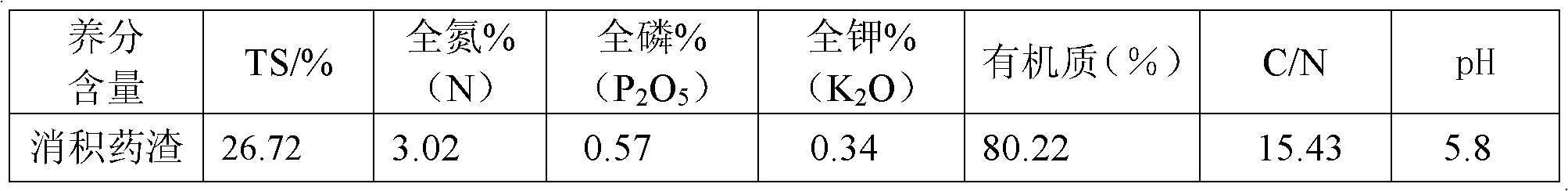

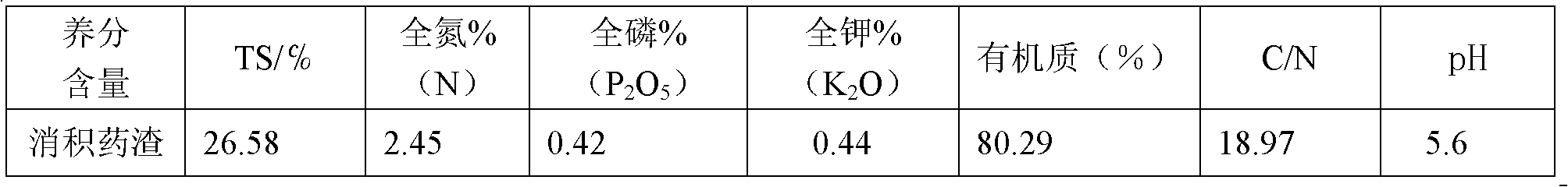

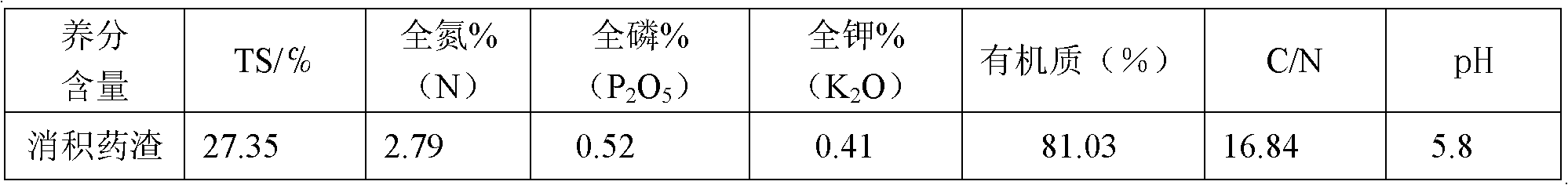

Method for generating biogas through anaerobic fermentation by taking traditional Chinese medicine dregs as raw materials

ActiveCN102382859AEasy to operateSuitable for useWaste based fuelFermentationProduction effectMedicine

The invention relates to a method for generating biogas through anaerobic fermentation by taking traditional Chinese medicine dregs as raw materials. Medicine dregs produced in a pharmaceutical factory of traditional Chinese medicine are used as fermentation raw materials, are united with waste water of the pharmaceutical factory for anaerobic fermentation, and are properly proportioned with biogas slurry and water for composting pretreatment, a proper amount of NaOH is added after the mixture enters a pool, the TS (total solid) concentration of the fermentation raw materials is 7-9%, 10-15% of biogas slurry is added as an inoculum so as to realize quick start, and the biogas production efficiency is high. Partial biogas slurry flows back after normal operation so as to ensure the concentration of microorganisms in an anaerobic tank. The traditional Chinese medicine dregs are taken as main raw materials for fermentation to produce the biogas, cow dung and other fermentation raw materials do not need to be added, the operation is simple, the gas production effect is good, the utilization ratio of the raw materials is high, the problem of environment pollution caused by the medicinedregs and the waste water can be solved, and simultaneously biogas energy sources can be recycled.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT SHANDONG ACADEMY OF AGRI SCI

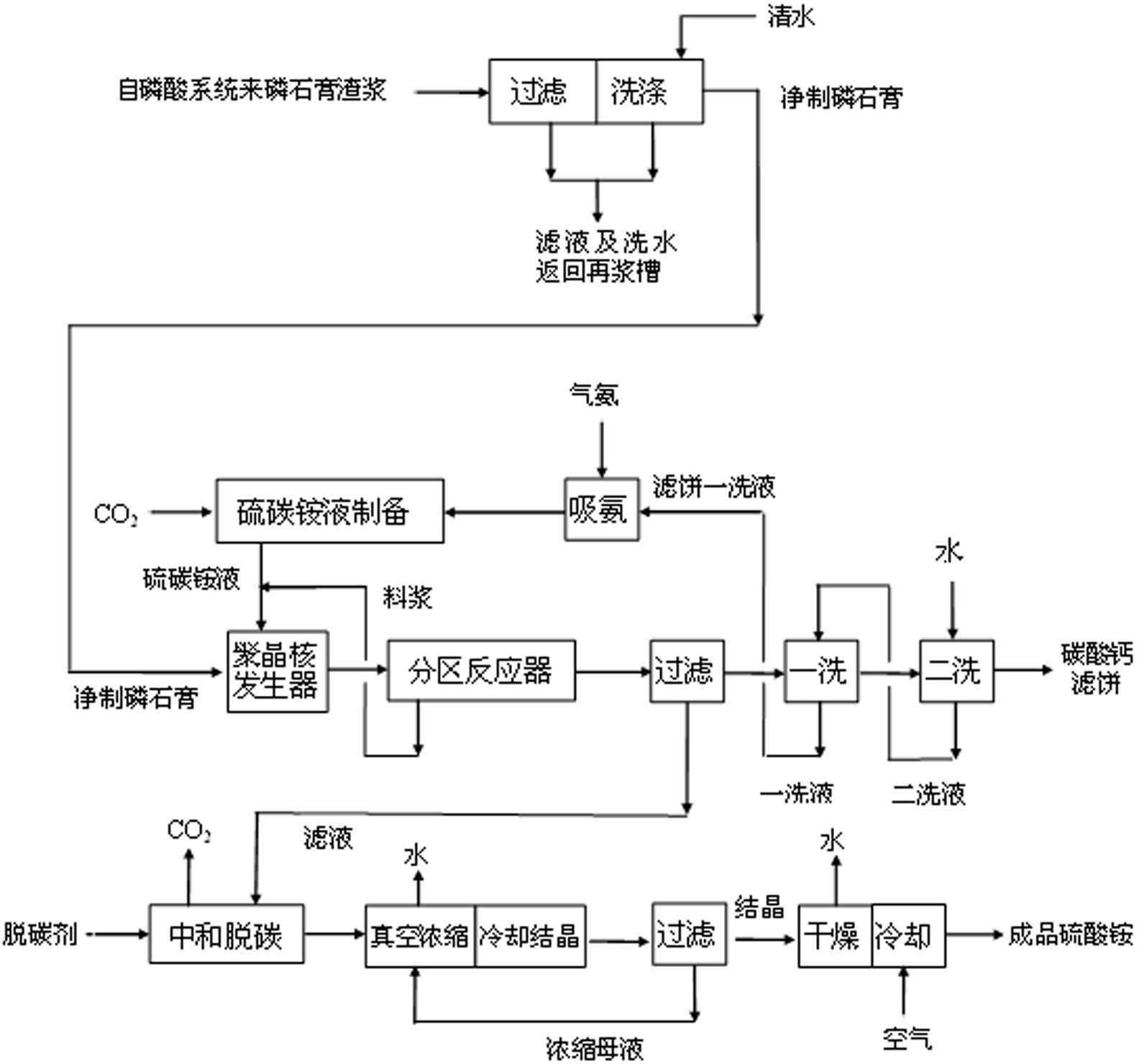

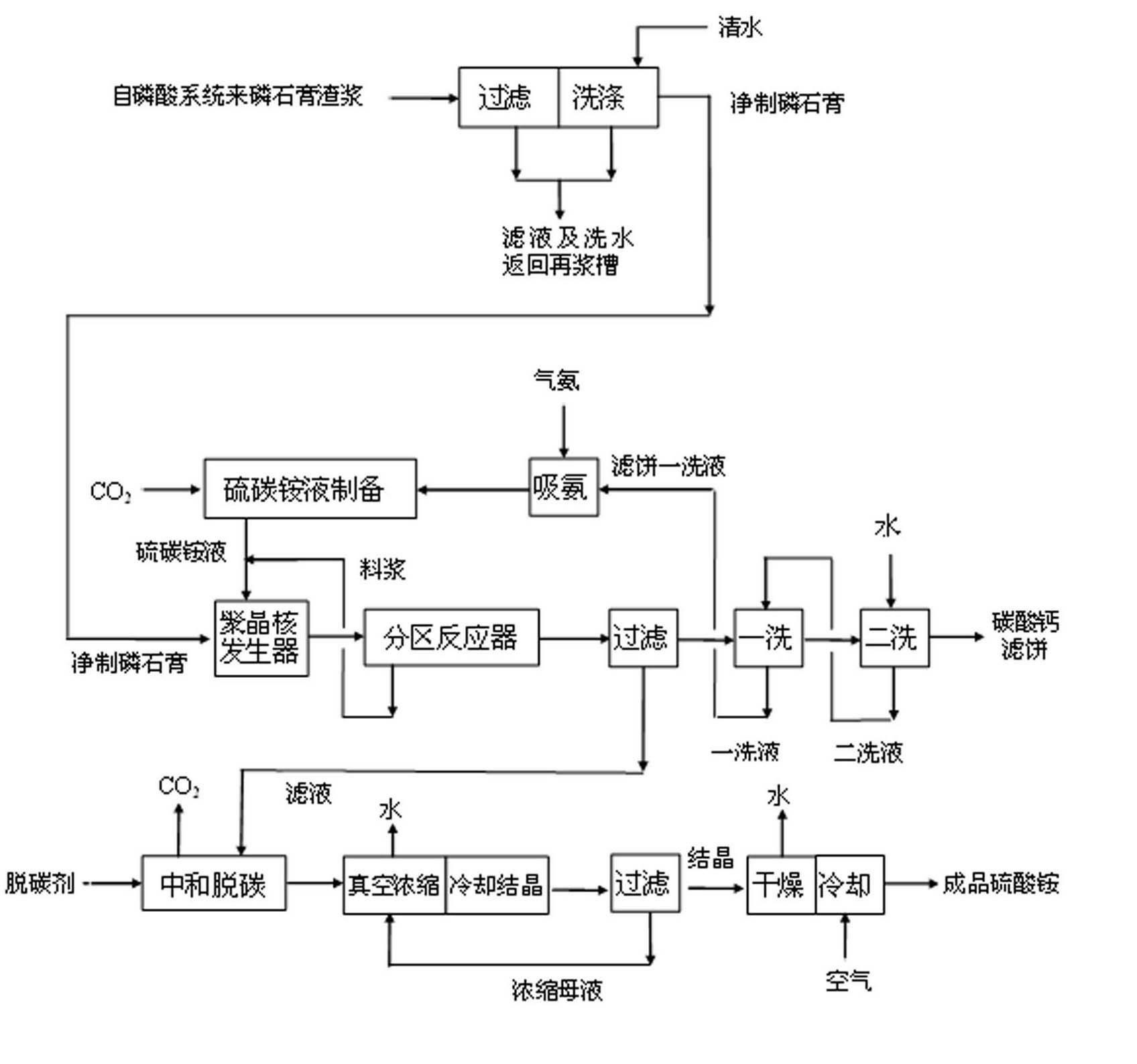

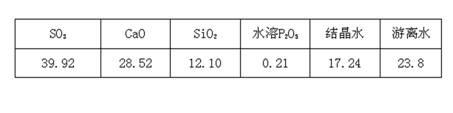

Method for preparing ammonium sulfate by conversion of phosphogyspum with polycrystalline method

ActiveCN102303874AImprove filter strengthEmission reductionAmmonium sulfatesChemical industryO-Phosphoric Acid

The invention relates to a method for preparing ammonium sulfate by continuous conversion of phosphogyspum with a polycrystalline method, belonging to the technical fields of resource comprehensive utilization and chemical industry, and relates to a method for producing ammonium sulfate by conversion of phosphogyspum with a polycrystalline method based on a byproduct phosphogyspum in a (sulfuric acid) wet phosphoric acid industry as a main raw material. The production process comprises the following steps: (1) pretreating the raw material of phosphogyspum discharged in the wet phosphoric acidindustry so as to obtain purified phosphogyspum; (2) absorbing ammonia and carbon dioxide with a ammonia-sulfate-containing primary lotion which is produced by washing a calcium carbonate filter cakewith water in a filtration process in a carbonation tower so as to produce an ammonia sulfate and carbonate solution; (3) connecting a calcium carbonate polycrystalline nucleus generator with a multiple-tank or multiple-partition groove type reactor with a stirrer in series to constitute a conversion crystallizer; (4) filtering a reaction material slurry discharged from the conversion crystallizer so as to obtain a filter cake and filtrate containing 38-40% by weight of ammonium sulfate; (5) carrying out secondary countercurrent washing on the filter cake obtained in the step (4) with clear water, and feeding the ammonia-sulfate-containing primary lotion to the carbonation tower for absorbing gas ammonia and carbon dioxide so as to produce an ammonia sulfate and carbonate liquid; and (6) neutralizing and decarburizing the filtrate containing ammonium sulfate from the step (4) with sulfuric acid, then centrifugally separating so as to obtain a crystal containing wet ammonium sulfate, separating out a mother liquid, carrying out cycle concentration on the mother liquid, and drying the crystal containing wet ammonium sulfate so as to obtain a finished product ammonium sulfate.

Owner:YUNNAN CHEM RES INST

Electroplating sludge resource utilization method

ActiveCN106007423ASolve pollutionPromote the development of circular economySpecific water treatment objectivesCalcium/strontium/barium sulfatesHeavy metalsPolymetal

An electroplating sludge resource utilization method comprises the following steps: (1) pretreatment: separating heavy metal elements from electroplating sludge by a wet process, and neutralizing the electroplating sludge with lime or limestone, to obtain an electroplating sludge waste residue with calcium sulphate dihydrate as a main component; (2) preparation of raw material: replacing all gypsum and all iron raw materials in raw material ingredients with the electroplating sludge waste residue, or replacing a part of gypsum and a part of iron raw materials with the electroplating sludge waste residue, then blending with gypsum and vanadine, and powder-grinding to prepare the raw material for producing a calcium sulphoaluminate or calcium sulphoferrate clinker; and (3) baking for 0.5-1 h at the temperature of 1250-1400 DEG C. The electroplating sludge is used as the raw material containing polymetal and is subjected to resource utilization to produce two kinds of materials, namely a corresponding metal and / or metal salt material and a gypsum-based building material, so the problem of pollution in electroplating industry is facilitated to be solved, and the implementation of circular economy development is facilitated.

Owner:湖南省小尹无忌环境能源科技开发有限公司 +1

Method for fertilizer granulation through molasses alcohol fermentation liquor

InactiveCN104030768ATurn waste into fertilizerSave waterFertilizer mixturesAlcoholCleaner production

The invention provides a method for fertilizer granulation through molasses alcohol fermentation liquor. Before granulation, the molasses alcohol fermentation liquor is mixed with a macro-element chemical fertilizer raw material, a medium-element chemical fertilizer raw material, a microelement chemical fertilizer raw material and organic raw materials so that crystal nuclei of particles can be formed, and then granulation is conducted in a granulation device. According to the method, the granulation efficiency of fertilizer is improved to a great extent, the production efficiency of the fertilizer is improved, the production cost is reduced, and clean production through comprehensive use of the molasses alcohol fermentation liquor is achieved.

Owner:GUANGXI LIYUANBAO SCI & TECH

Method for quickly fermenting silkworm excrement organic fertilizer

ActiveCN104230420AImprove breathabilityIncrease temperatureBio-organic fraction processingClimate change adaptationEllipseOrganic fertilizer

The invention discloses a method for quickly fermenting a silkworm excrement organic fertilizer. The method comprises the following steps: inputting 10-20kg of compound bacteria per 1000kg of silkworm excrements within 4 hours after mounting silkworm cocoons on a cocooning frame; uniformly scattering the compound bacteria on the surface of silkworm excrements; then, stacking the silkworm excrements with the compound bacteria next to a wall or on a flat ground within four hours, wherein during stacking, an ellipse or a circle is formed on the surface, the stacking height is over 100cm, the silkworm excrements cannot be compacted during stacking and cannot be covered by a film, are kept loose and ventilating, water is prevented from entering during fermentation and rain proofing and sun proofing are needed; and when the stacking fermentation time reaches 10-20 hours, overturning and stirring the silk excrements when the temperature of the silkworm excrements automatically raises to 60-70 DEG C, and then fermenting again 10-14 hours till the silkworm excrements are completely fermented to obtain the silkworm excrement organic fertilizer. The method disclosed by the invention is simple to operate and feasible, short in fermentation time and high in production efficiency. The silkworm excrement organic fertilizer is granular, is high in quality and good in application effect and has relatively good economic, social and ecological benefits.

Owner:GUANGXI SANBAO AGRI SCI & TECH

Iron tailing sand PVA fiber-reinforced-cement-based composite

InactiveCN105777020ARealize bulk resourcesReduce pollutionSolid waste managementLand resourcesProcessing cost

The invention discloses an iron tailing sand PVA fiber-reinforced-cement-based composite.The composite is composed of, by mass, 26.1-27.6% of cement, 31.3-33.2% of coal ash, 20.9-22.1% of iron tailing sand, 15.2-20% of water, 1.24-1.25% of fibers, 0.34-0.66% of an efficient water reducing agent, 0.03% of an antifoaming agent and 0.03% of a thickening agent.According to the composite, fine aggregate is used as the iron tailing sand and replaces all natural sand, massive recycling of iron tailings can be achieved, the problems of environmental pollution and ecological hazards caused by the iron tailings are reduced, land resources and natural sand resources are saved, circular economy development of a city and saving type city construction are promoted, and certain social benefits and economic benefits are created; processing cost of the composite is greatly lowered; in addition, the composite can meet the strength requirement in engineering and has excellent tensile strain hardening performance, deformation performance, energy-dissipating capacity and excellent endurance performance.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

Material utilization method for electroplating sludge

ActiveCN105923658AGood gelling and curing propertiesImprove water resistanceFerric oxidesIron sulfatesSludgePre treatment

The invention provides a material utilization method for electroplating sludge. The method comprises the following steps: (1) pretreatment; (2) preparation of a gypsum material; (3) preparation of a clinker; and (4) preparation of an ultrafine gypsum filling material or anhydrite gelling material. According to the invention, a sulfuric acid leaching method and a biological leaching method belonging to mature wet processes are employed for pretreatment and separation of heavy metals in electroplating sludge, and lime or limestone is used for neutralization, so most valuable metals or heavy metals can be recovered at low cost for preparation of corresponding metal or metal salt materials, high-purity metal or metal salt materials or raw materials can be easily obtained, and waste sludge residues with dihydrate gypsum as a main mineral, i.e., a usable gypsum-based resource, can be easily obtained; and waste residues of electroplating sludge are not discharged, so environmental pollution and hidden troubles caused by the waste residues are thoroughly eliminated and environmental protection is benefited.

Owner:湖南省小尹无忌环境能源科技开发有限公司 +1

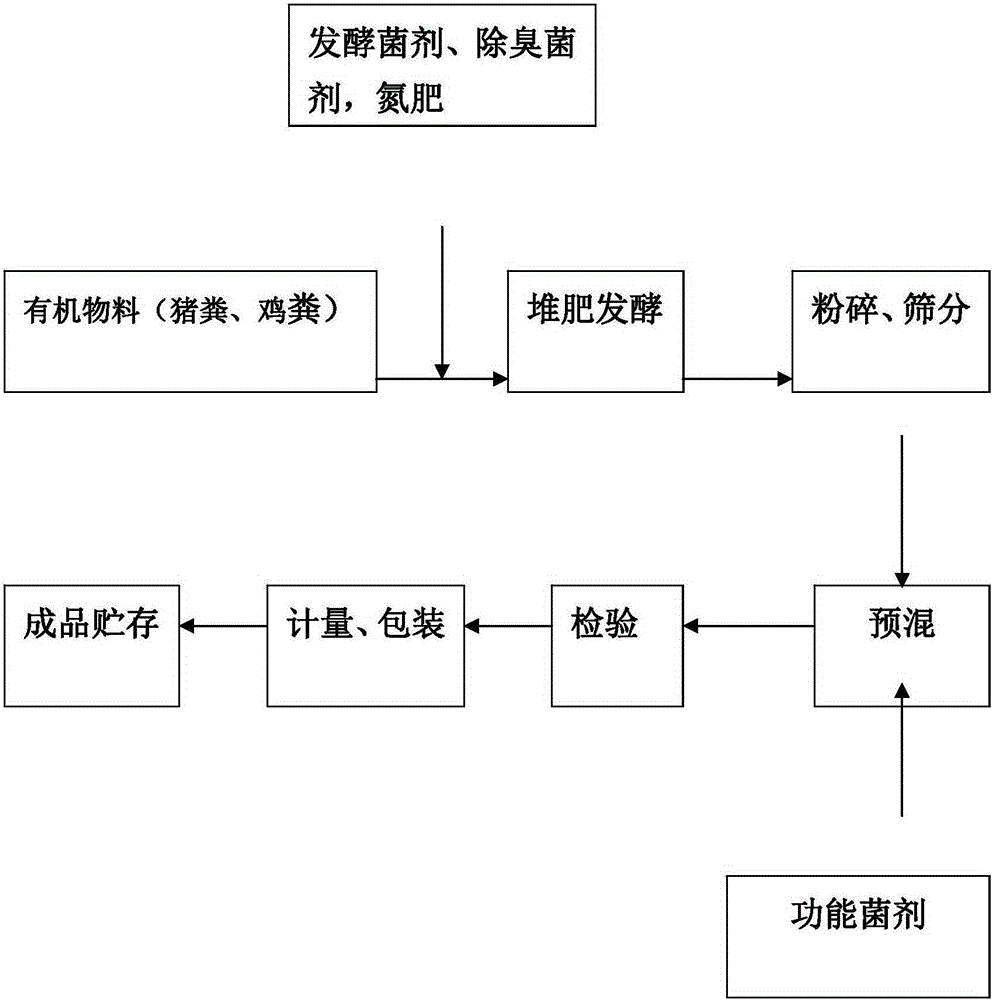

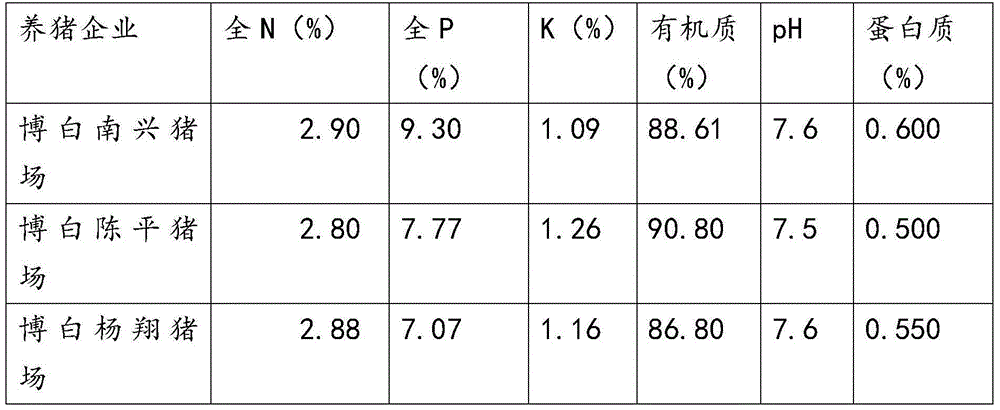

Bio-organic fertilizer employing pig dung as raw material and preparation method therefor

InactiveCN105175051AImprove qualityImprove physical and chemicalBio-organic fraction processingClimate change adaptationMicrobial agentDecomposition

The invention provides a bio-organic fertilizer employing pig dung as a raw material and a preparation method therefor. The bio-organic fertilizer comprises the following steps: firstly, pig dung is pretreated, and then chicken manure, fermentation agents and deodorizing fungicides are added; the C / N ratio is adjusted to 25-30:1 by utilization of urea or ammonium sulfate, the pH value is adjusted to 5.5-8.5 by utilization of calcium superphosphate the moisture content is kept at 50-60%, the materials are subjected to fermentation decomposition and then are crushed and sieved and then functional microbial agents are added; secondly, fermentation is carried out by utilization of compost fermentation. The beneficial effects are that firstly, the prepared bio-organic fertilizer raises output and economic benefits of crops of watermelons, bananas and the like greatly; the prepared bio-organic fertilizer improves physical, chemical and biologic properties of soil effectively; the agricultural product quality is raised; fourthly, development of agriculture and animal husbandry circular economy is promoted.

Owner:AGRI RESOURCE & ENVIRONMENT RES INST GUANGXI ACADEMY OF AGRI SCI

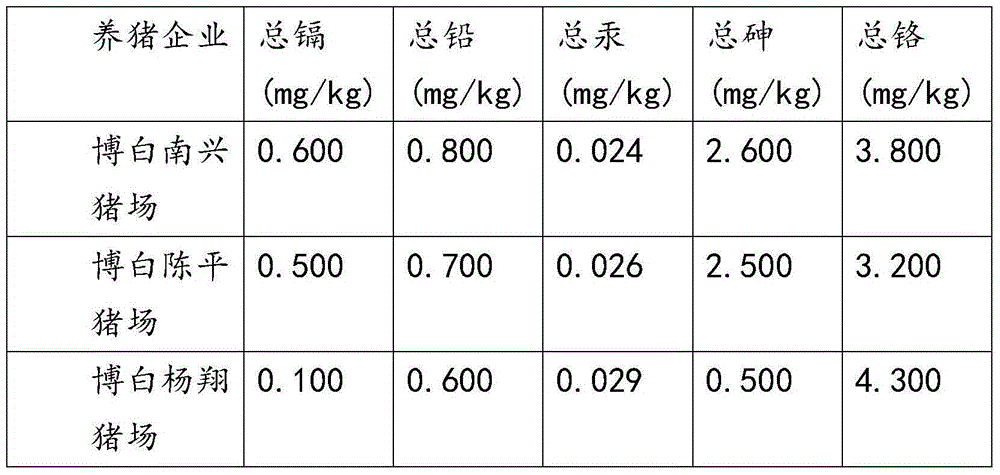

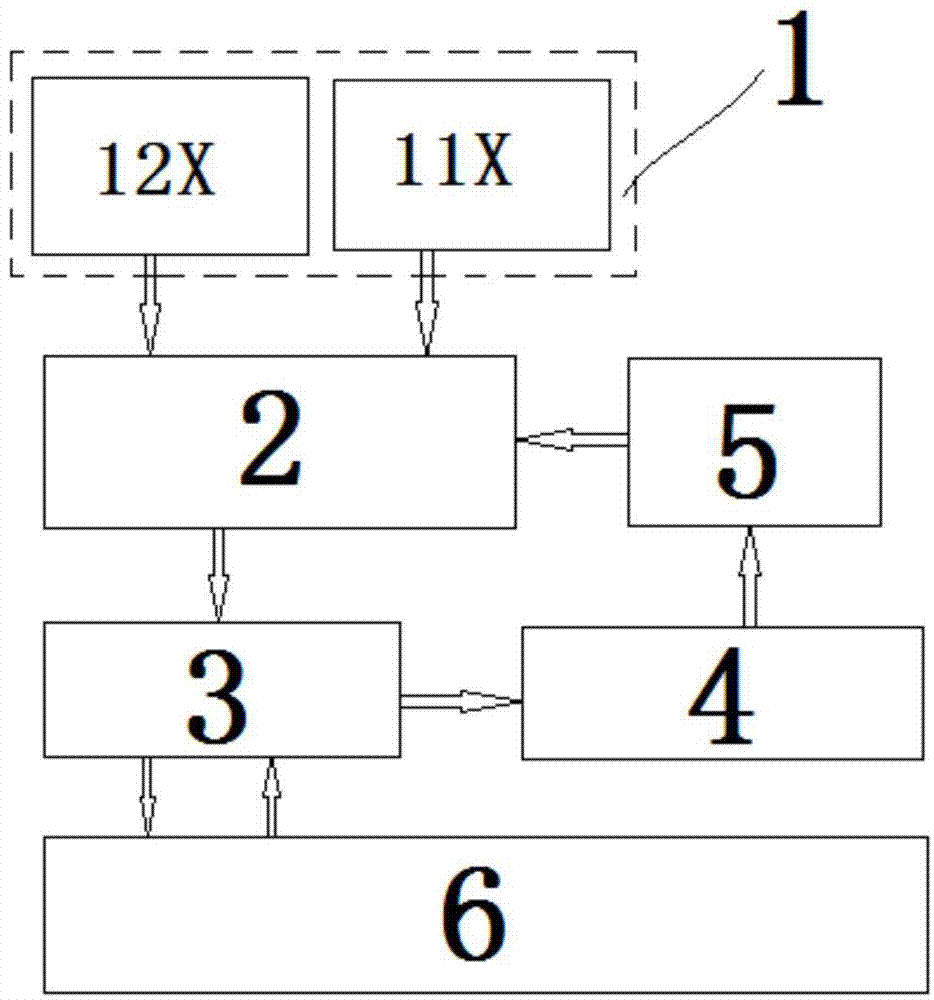

High-quality efficient double-forming-machine parallel closed-loop full-automatic building block production line

ActiveCN104118044ASimplified Crafting ModeSmall footprintCeramic shaping plantsStacking articlesProduction lineDual core

The invention relates to a high-quality efficient double-forming-machine parallel closed-loop full-automatic building block production line. The production line comprises a material distributing and stirring system, two sets of forming machine plate ascending systems, a program-controlled transferring main and auxiliary kiln car, a plate descending and stacking system and a plate returning and transferring system. According to the production line, two high-strength and high-quality building block main engines are adopted, and a heavy-load coordinate type stacking robot is adopted in the plate descending and stacking system, two independent single forming machine production lines in traditional significance are designed into the efficient double-forming-machine parallel dicaryon closed-loop full-automatic building block line saving energy. Compared with the prior art, the production line optimizes the process mode of the stacking system, the production efficiency is high, equipment investment, capital construction investment, personnel investment and energy consumption are greatly reduced under the circumstance that the productivity is equal to that of the independent double lines, and the human resource cost is saved.

Owner:XIAN SILVER HORSE IND DEV CO LTDRIAL DEV CO LTD

Apparatus for preparing ecological fertilizer using animal-bird feces

InactiveCN101024589AProcess matching is reasonableReasonable processBio-organic fraction processingClimate change adaptationSludgeAnimal feces

The invention relates to a device to make biology fertilizer from livestock dejection. It includes material intake, material outlet, gate valve, marsh gas control valve and jar. The main technology is that: the identity cavity is separated into anaerobic cavity and aerobic cavity, the outlet pipe end of returning pump extending into anaerobic cavity and connecting to gas nozzle, the output end of sludge pump extending into identity anaerobic cavity and connecting to spray pipe, top part of identity aerobic cavity is set light-passing board, and the output end of burst device connects to burst pipe of aerobic pipe. The invention has the advantages of high intention, super thin, electric energy saving, low running cost, and could effectively improve producing efficiency and quality of biology fertilizer.

Owner:辽宁中田干燥设备制造有限公司

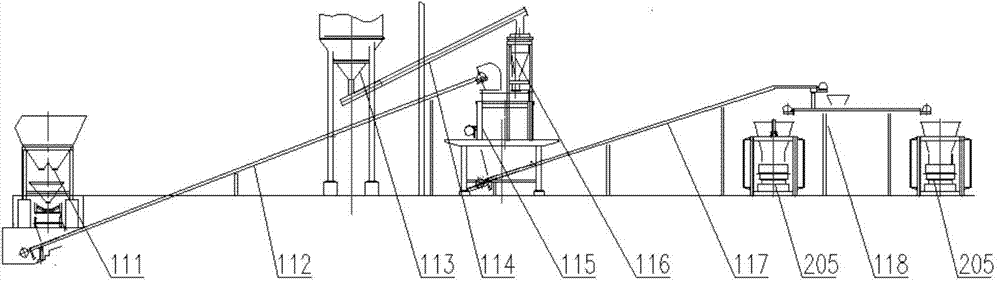

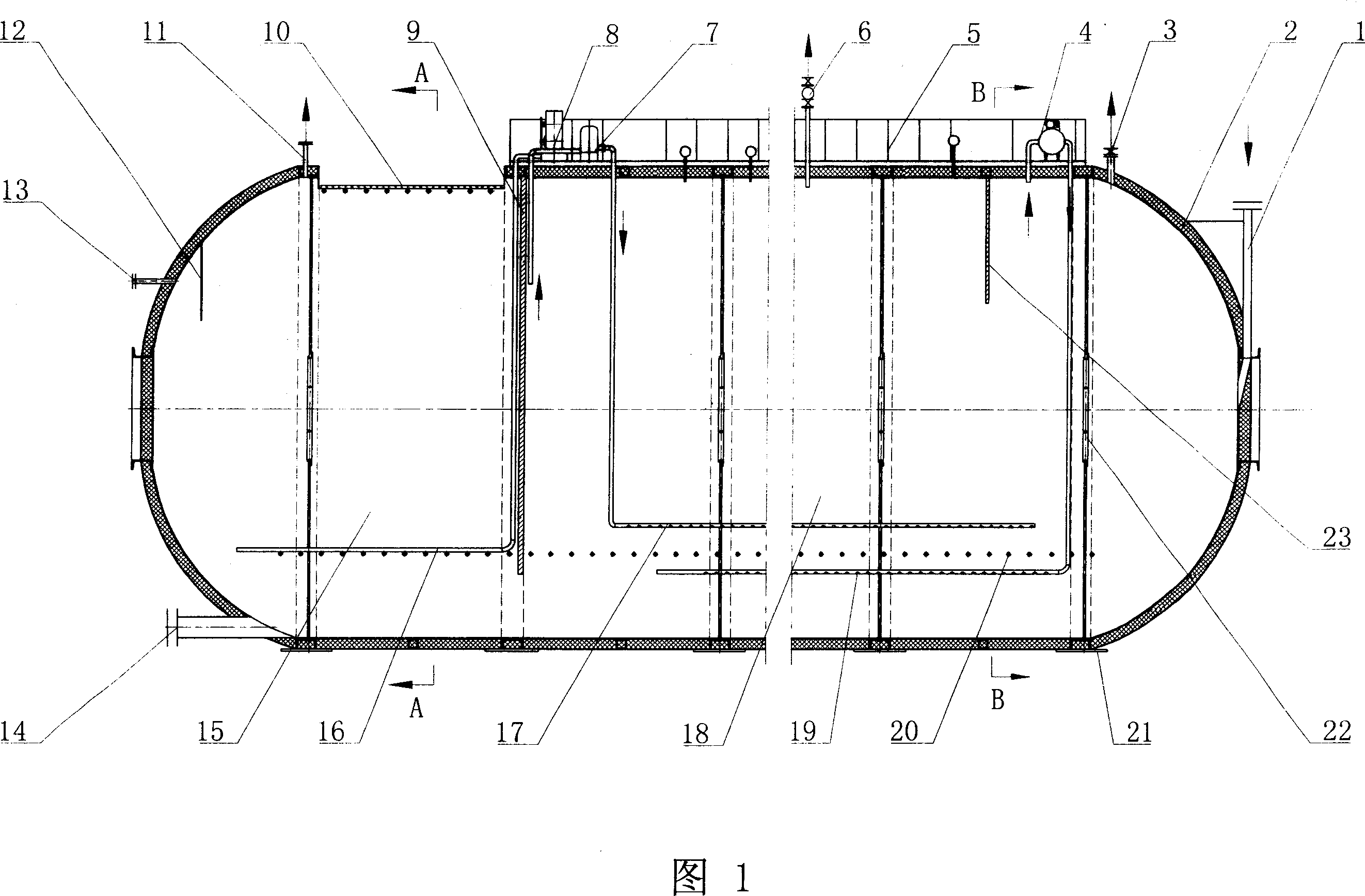

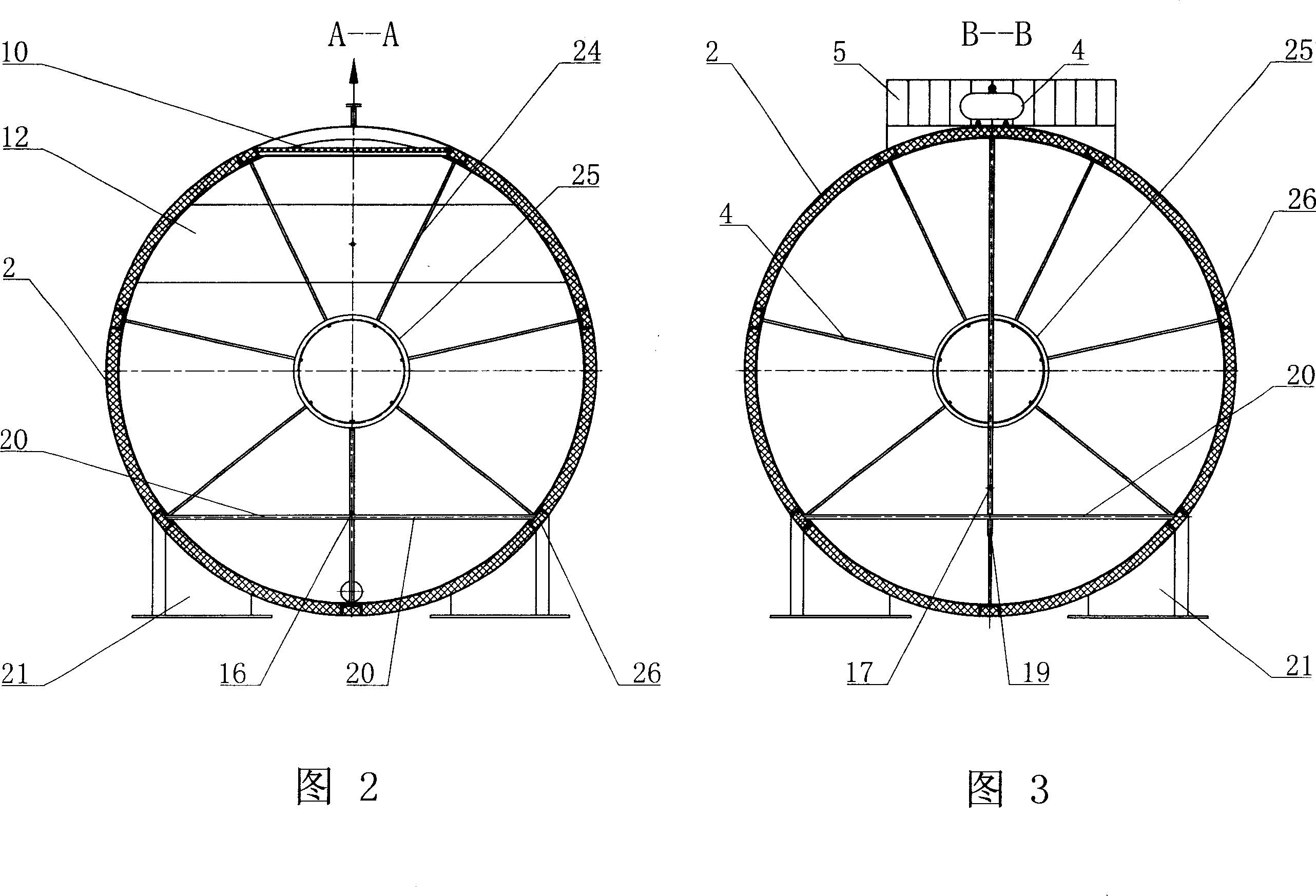

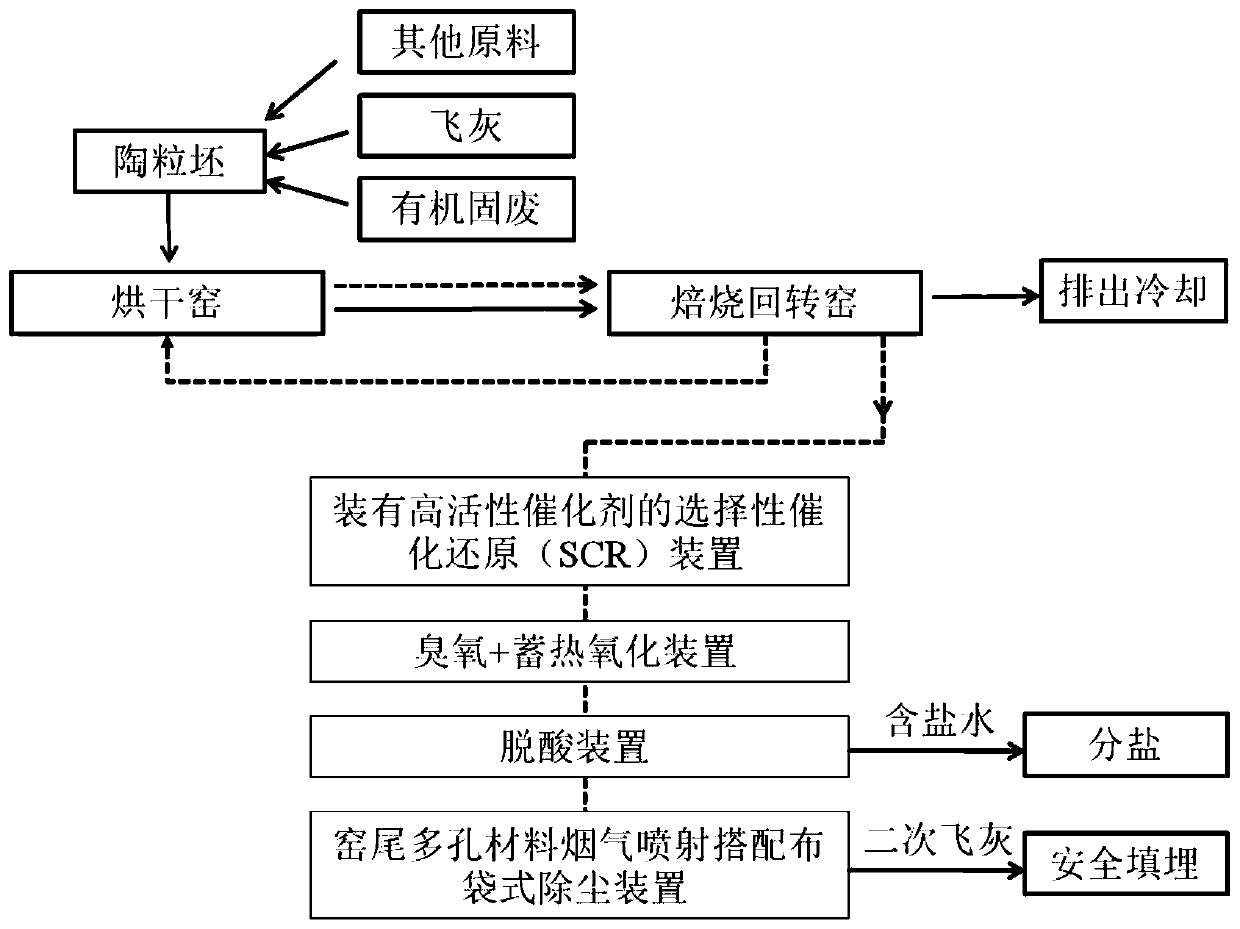

Method for disposal of solid waste by ceramsite kiln and ceramsite kiln for disposal of solid waste

InactiveCN110357578AExpand the usable rangePromote the development of circular economyDispersed particle filtrationDrying gas arrangementsSludgeExpanded clay aggregate

The invention provides a method for disposal of solid waste by a ceramsite kiln and a ceramsite kiln for disposal of solid waste. The ceramsite kiln includes a drying kiln and a calcination rotary kiln. The method includes: preparing ceramsite raw materials, which include solid waste; drying and calcining ceramsite, and enabling circulation flow of the generated flue gas along the drying kiln-calcination rotary kiln-drying kiln; cooling and discharging ceramsite; and disposing flue gas and tail gas. Specifically, the solid waste includes at least one of fly ash or organic solid waste; fly ashis selected from the incineration ash of at least one of domestic garbage, industrial waste or medical waste; the organic solid waste is selected from at least one of polluted soil, oily sludge, sludge obtained by chemical plant sewage treatment, medical solid waste or industrial waste residue. The method adopts fly ash and organic solid waste as the ceramsite raw materials, consumes fly ash and organic solid waste in the ceramsite manufacturing process, not only solves the hidden trouble of pollution caused by fly ash and organic solid waste, but also solves the cost problem caused by the limitation of ceramsite raw materials.

Owner:CHINA BUILDING MATERIALS ACAD

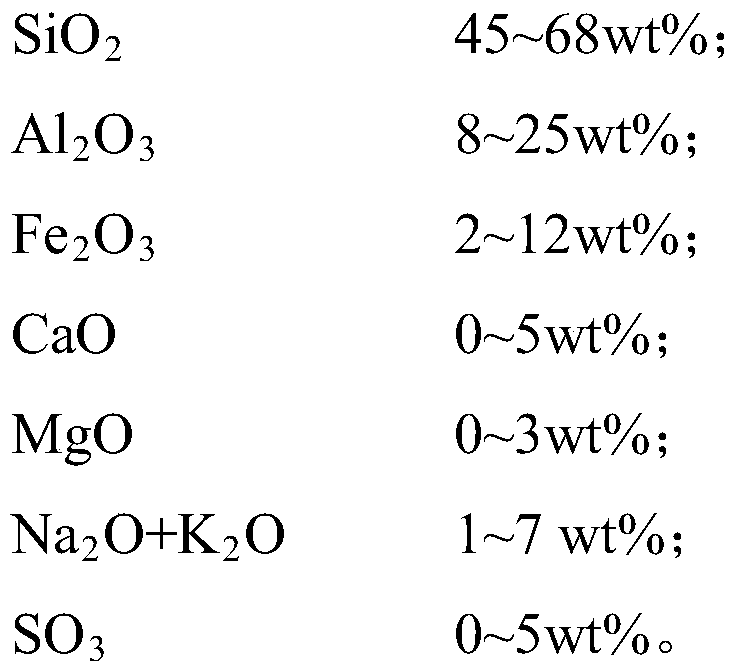

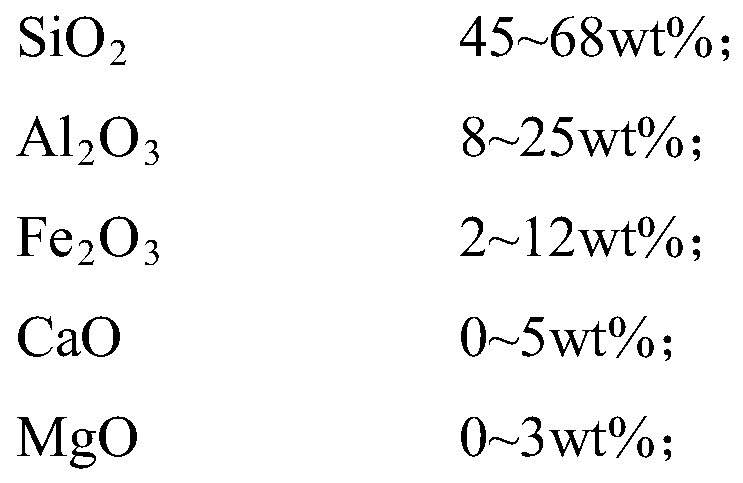

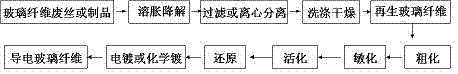

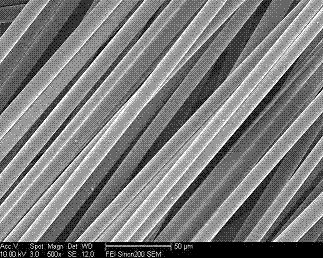

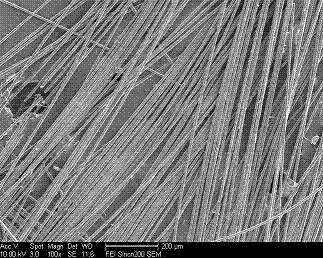

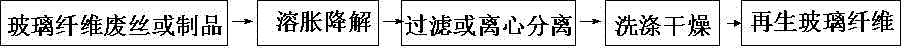

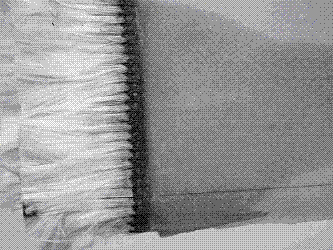

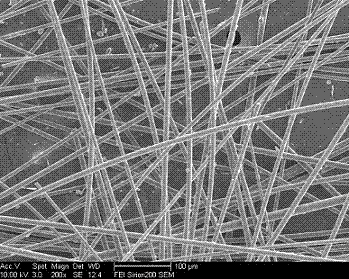

Method for preparing conductive glass fibers from waste glass fibers

The invention relates to a method for regenerating glass fibers from waste glass fibers. The method realizes comprehensive utilization of waste glass fibers and preparation of low-cost conductive glass fibers. The method comprises soaking glass fibers through a highly permeable degradation liquid, removing a glass fiber surface impregnating compound at the normal temperature under normal pressure to obtain regenerated glass fibers, and carrying out sensitization, activation, reduction and chemical plating, metal electroplating or conductive polymer coating to obtain conductive glass fibers. The method has simple processes, is free of preprocessing, saves crushing and smashing costs, is free of heating and has almost zero energy consumption. The regenerated glass fiber or filler is not corroded so that fiber damage is small, the surface is treated cleanly and completely, and high value-added glass fibers are prepared.

Owner:SHANDONG UNIV OF TECH

Method for preparing harmless rock fragments by using well drilling waste liquid and application of rock fragments

ActiveCN103240261AReduce manufacturing costSimple processSolid waste managementSolid waste disposalWell drillingEconomic benefits

The invention discloses a method for preparing harmless rock fragments by using well drilling waste liquid and an application of the rock fragments. The method comprises four steps of separation, oil removal sedimentation, oxidation sedimentation and oxidation adsorption to ensure that the well drilling waste liquid is subjected to harmless treatment, the harmless rock fragments can be separated from the well drilling waste liquid, and the rest is water which can reach an industrial water standard. The harmless rock fragments treated by a harmless technology are used as main materials for preparing dry-mixed mortar. By adopting the method, the phenomena that the petroleum drilling enterprises in the past dig pits for landfill of harmful mixed wastes, the soil is destroyed, the environment is polluted and resources are wasted are avoided; and moreover, a precedent for carrying out harmless comprehensive treatment, recycling waste mixed resources, and promoting the development of cyclic economy for the petroleum drilling enterprises to make money is opened up for the petroleum drilling enterprises, and the method meets the requirements of the strategic planning of energy saving and emission reduction comprehensive utilization during the twelfth five-year of the country. The method has considerable economic benefits and wide market application prospects.

Owner:薛西伟

Method for regenerating glass fibers from waste glass fibers or products at normal temperature under normal pressure

The invention relates to a method for regenerating glass fibers from waste glass fibers or products at the normal temperature under normal pressure. The method realizes comprehensive utilization of waste glass fibers and regeneration and use of glass fibers. The method comprises soaking glass fibers through a highly permeable degradation liquid so that glass fibers and a resin base are separated at the normal temperature under normal pressure and carrying out regeneration to obtain glass fibers and fillers in the waste glass fibers. The method can treat waste glass fibers at the normal temperature under normal pressure, realizes glass fiber regeneration and glass fiber eco-friendly use, has simple processes, is free of preprocessing, saves crushing and smashing costs, is free of heating and reduces energy consumption. The regenerated glass fiber or filler is not corroded so that fiber damage is small, the surface is treated cleanly and completely, and high energy consumption and high value-added glass fiber regeneration and glass fiber recycling are realized.

Owner:SHANDONG UNIV OF TECH

Process technology for producing seedling-growing medium by using tobacco wastes

InactiveCN103570447AEfficient killingLight weightBio-organic fraction processingOrganic fertiliser preparationCircular economyProcess engineering

The invention discloses a process technology for producing a seedling-growing medium by using tobacco wastes; the process technology comprises the following steps: collecting and crushing the tobacco wastes, separating under high temperature and high pressure, fermenting, fumigating, and disinfecting, so as to obtain a thoroughly decomposed material; uniformly mixing a thoroughly decomposed material, perlite and vermiculite according to a mass ratio of (60-70):(10-30):(10-30), so as to obtain the seedling-growing medium; as turf is replaced by the tobacco waste thoroughly decomposed material, and the perlite and the vermiculite are added according to a certain ratio, the seedling-growing medium provides an excellent nutrition resource, the production cost is reduced, and the deficiency of the non-renewable resource, namely the turf is reduced, the comprehensive utilization of the resource is realized, and the development of the local recycling economy is improved.

Owner:河南省恒隆态生物工程股份有限公司

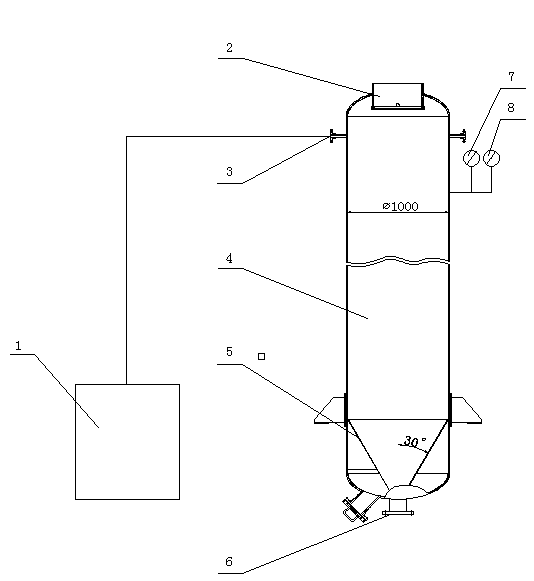

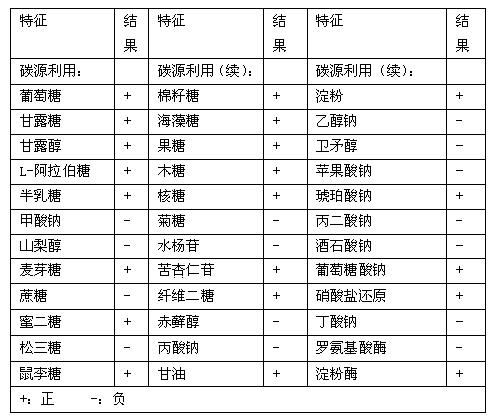

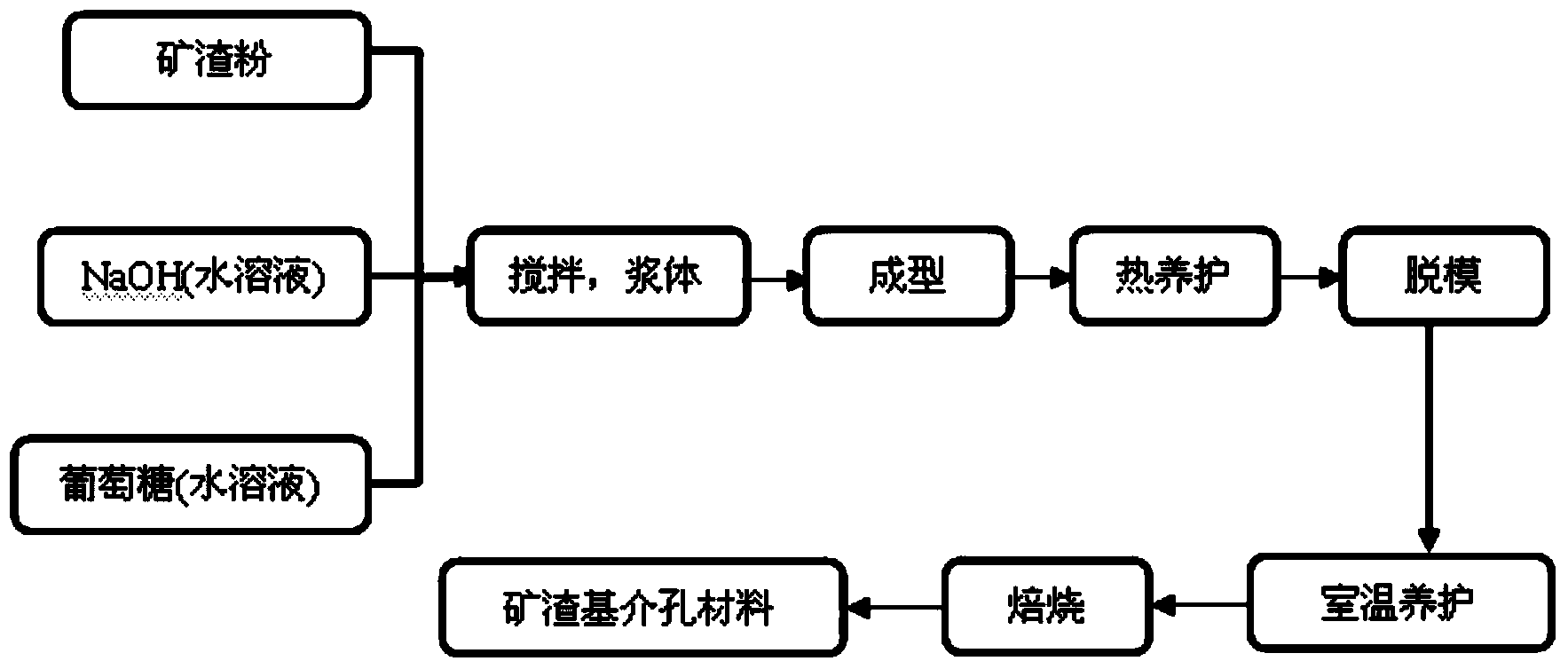

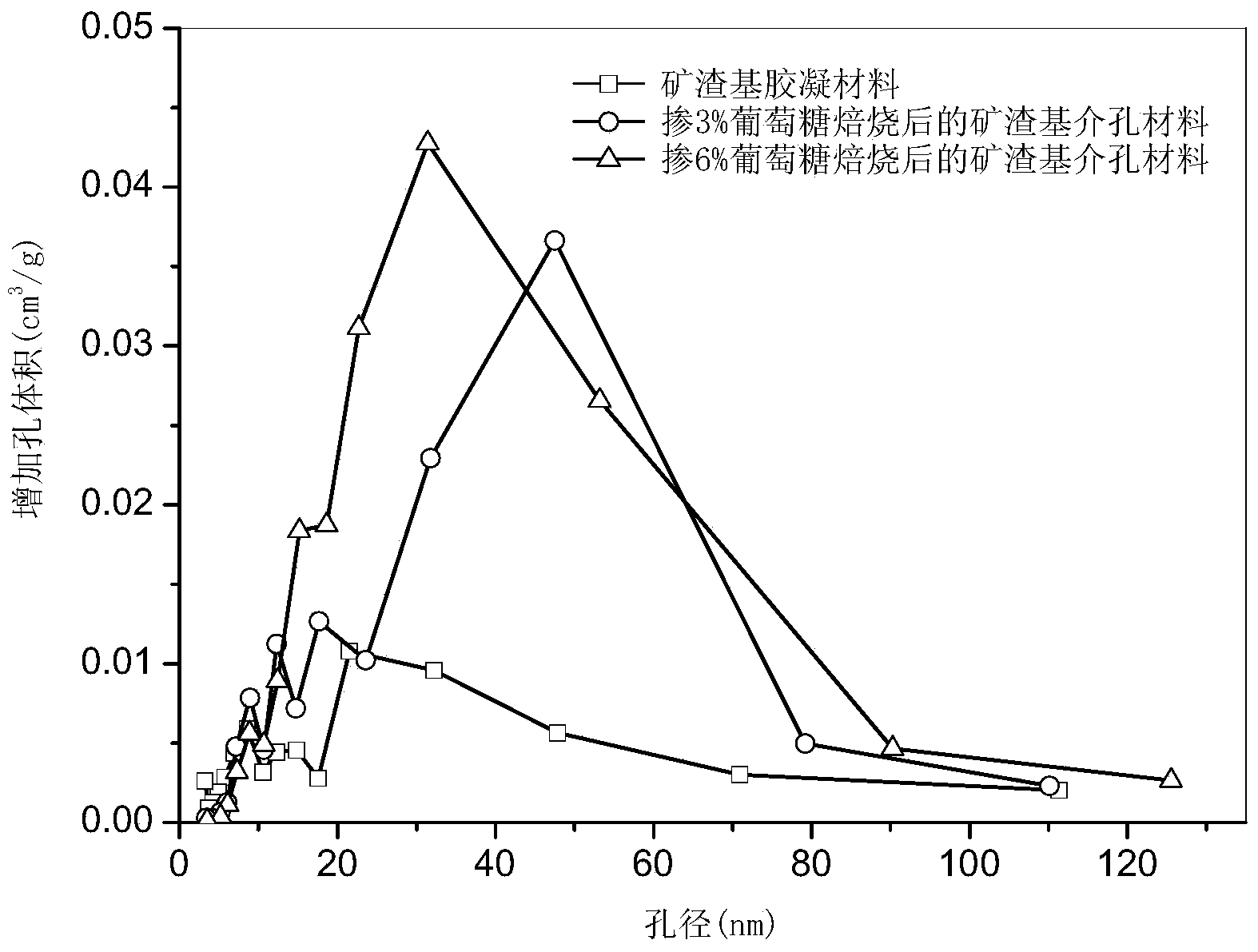

Slag based mesoporous material and preparation method thereof

InactiveCN104163615APromote the development of circular economyIncrease added valueCatalyst carriersSolid waste managementSlagMesoporous material

The invention discloses a slag based mesoporous material and a preparation method thereof; the slag based mesoporous material is prepared by putting raw material slag, sodium hydroxide water and pore increasing agent glucose into a mixing device for mixing, using a die for molding, curing, and burning; and taking the adding quantity of the slag mass as a basis, the adding quantity of the sodium hydroxide is 6% of the slag mass, the adding quantity of the pore increasing agent glucose is 3%-6% of the slag mass, and the ratio of water adding quantity to slag mass is 0.24-0.28. Compared with a sample free of the pore increasing agent, after addition of the pore increasing agent in an optimum adding amount, the mesopore volume of a sample is increased by 102.63%; slag can be completely used in one time, the slag based mesoporous material with high added value can be obtained, the whole process is simple, no slag treatment is needed, no three wastes is discharged, the slag based mesoporous material is green and environmentally-friendly, and controllable preparation of the slag based mesoporous material can be realized.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Agriculture and forestry organic solid waste static compost heat recycling system

PendingCN111393203AUniform oxygen concentrationUniform humidityBio-organic fraction processingRecuperative heat exchangersFresh airOrganic manure

The invention discloses an agriculture and forestry organic solid waste static compost heat recycling system, belongs to the technical field of agriculture and forestry organic solid waste resource utilization, and solves the problems that the existing agriculture and forestry organic solid waste compost heat recycling efficiency is low and static composting cannot be achieved. A leachate tank isarranged below a fermentation bin; the bottom ventilation space is communicated with the leachate tank through a pipeline; a spraying device is arranged above the material pile in the fermentation chamber; the fermentation bin is connected with a dividing wall type heat exchanger through an air supply pipe and an air return pipe; a circulating fan is arranged on the air return pipe, the air outletend of the air return pipe is located in the bottom ventilation space, a fresh air pipe is further arranged on the air return pipe between the dividing wall type heat exchanger and the circulating fan in a communicating mode, and the dividing wall type heat exchanger is connected with a heat using system through a pipeline to form a closed liquid or gas flowing loop. With application of the system, latent heat and sensible heat generated in the fermentation process can be recycled to the maximum extent while the organic fertilizer is obtained.

Owner:HARBIN INST OF TECH

Method of purifying and recycling heavy metals and fluorine, chlorine, sulfur and nitrates in industrial kiln flue gas

ActiveCN106178865ANothing producedNo emissionsGas treatmentDispersed particle separationOperational costsCorrosion

A method of purifying and recycling heavy metals and fluorine, chlorine, sulfur and nitrates in industrial kiln flue gas includes the steps of (1), preparing decontaminating oxidant powder or decontaminating oxidant solution; (2), decontaminating and oxidizing; the environment-friendly composite oxidant that is nontoxic, non-corrosive and free of chlorine is used as the process material, flue gas is treated by semi-dry or dry spraying, high oxidative action under neutral to alkaline conditions is utilized to purify sulfur, nitrate, fluorine, chlorine and heavy metal contaminants in the flue gas, incombustible hydrocarbons in the flue gas are oxidatively removed efficiently, decontamination products are recycled as chemical materials or agricultural fertilizers, the method is simple, low in investment and low in operational cost, no corrosion is caused to industrial kiln production line equipment, and the method has good economic and environmental benefits.

Owner:湖南省小尹无忌环境能源科技开发有限公司

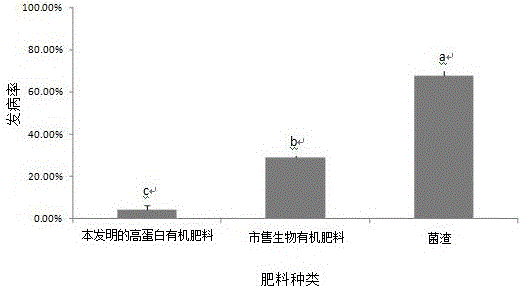

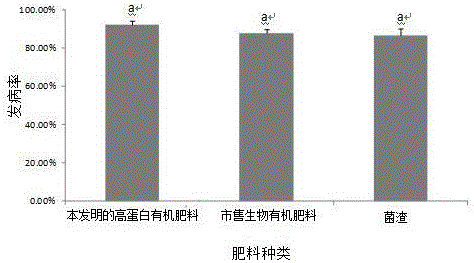

A method of producing a high-protein organic fertilizer by converting edible fungus dregs utilizing housefly larvae

InactiveCN106167423ASolve unhandled problemsSolve the problem of ecological treatmentBio-organic fraction processingFood processingBiotechnologyHousefly

A method of producing a high-protein organic fertilizer by converting edible fungus dregs utilizing housefly larvae is disclosed. The method includes (1) collecting the edible fungus dregs, drying in the sun, crushing and sieving with a sieve having a size of 20 meshes, (2) fully mixing the sieved edible fungus dregs with chicken manure and wheat bran in a ratio of 3-7:2-6:1, adding an EM bacterial stock liquid according to a ratio of 1% by weight and fish meal according to a ratio of 1%, adding water until the water content is 40-50%, and sealing and fermenting to prepare a housefly larva culture medium, and (3) adding the housefly larva culture medium into a converting pool, inoculating with fly blow, culturing at 25-30 DEG C with humidity being 60-75% for 4-5 days, drying the culture medium and the housefly larvae in the culture medium as a whole part, and crushing to prepare powder of the high-protein organic fertilizer or processing into particles. The method overcomes a problem that a large amount of waste in an edible fungus industry development process cannot be treated, produces the organic fertilizer having high quality, and generates ecological benefit and obvious economic benefit.

Owner:TAISHAN MEDICAL UNIV

'Copper/straw' electromagnetic wave shield composite material and preparation method thereof

InactiveCN102121100AHigh peel strengthImprove conductivityMagnetic/electric field screeningLayered productsScotch tapeCopper plating

The invention belongs to the technical field of electromagnetic wave shield materials, and relates to a 'copper / straw' electromagnetic wave shield composite material and a preparation method thereof. The composite material provided by the invention is prepared by plating copper membranes on the straws. The preparation method comprises the following steps: cleaning straws; immerging the cleaned straws in a silane coupling agent solution, and stoving; and carrying out silver nano particle activation, chemically copper plating and the like. The adhesivity between the copper membrane and straw substrate of the composite material is good, and can be tested through the Scotch tapes of a 3M (Minnesota Mining and Manufacturing) company; the electromagnetic wave shield efficiency of the 'copper / straw' composite material within the range of 0.15-1050MHz is more than 40dB, i.e., the electromagnetic wave anti-radiation rate is more than 99.99%. The composite material has the advantages of low cost, simple manufacturing process, great market prospect and favorable application value, can be widely applied to the electromagnetic wave shield of large-area building wall bodies, and is used for externally packaging the electromagnetic wave shield by precise instrument and the like.

Owner:FUDAN UNIV

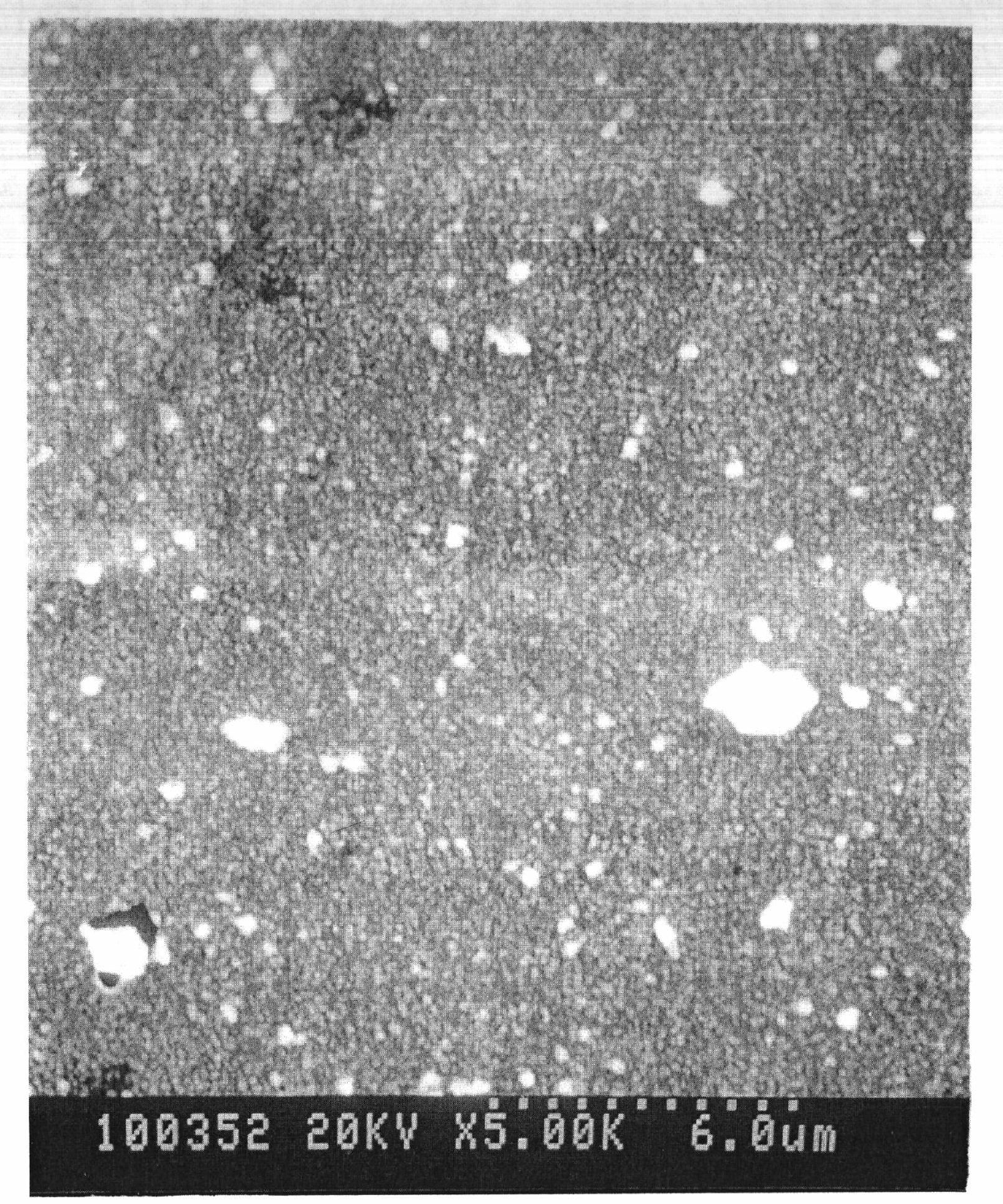

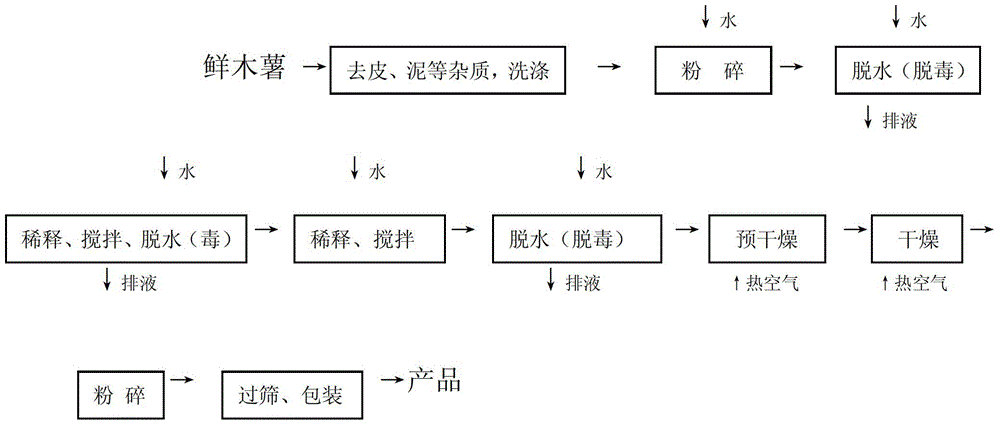

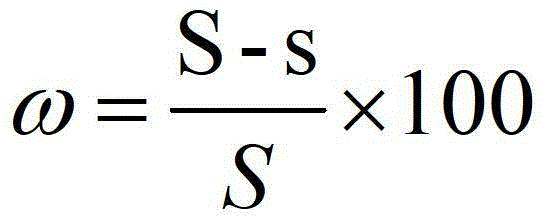

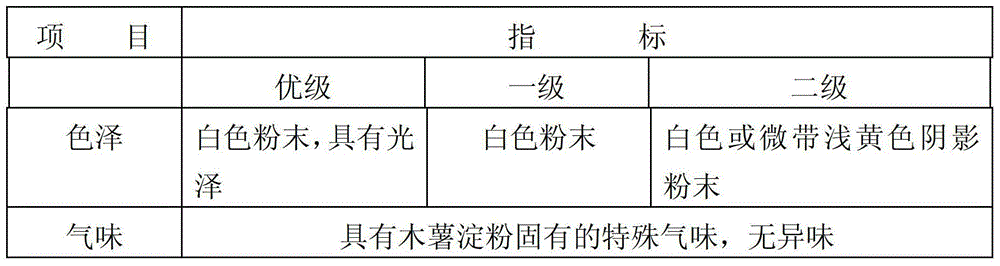

Rapid tapioca flour detoxification method

InactiveCN103330111AStorage and transportation safetyLow costAnimal feeding stuffFood preparationMagmaSlurry

The invention discloses a rapid tapioca flour detoxification method which comprises the following steps: (1) collecting, shelling and washing fresh tapiocas under the hydraulic pressure of 0.0389 Mpa-0.387 Mpa while washing; (2) smashing the fresh tapiocas processed in step (1), and adding water to prepare magma; (3) performing dehydration on the magma to enable the moisture content of the magma to be less than 45% by using a plate-and-frame filter press; (4) performing dilution on the dehydrated material processed in step (3) to enable the dehydrated material to become seriflux with solid content of 45% to 60% by using water, and after stirring the seriflux, using the plate-and-frame filter press to perform dehydration to enable the moisture content of the seriflux to be less than 45%; (5) performing dilution on the dehydrated material processed in step (4) to enable the dehydrated material to become seriflux with solid content as 45% to 60% by using water; (6) pre-drying and drying the dehydrated material processed in step (5), and smashing to realize rapid detoxification on the tapioca flour. The method provided by the invention only takes less than four hours from the raw material to the disinfectant product, and the product is completely in conformity with related national standard request. The invention discloses a 'safe, high efficient and rapid' tapioca flour detoxification production method.

Owner:GUANGXI UNIV +1

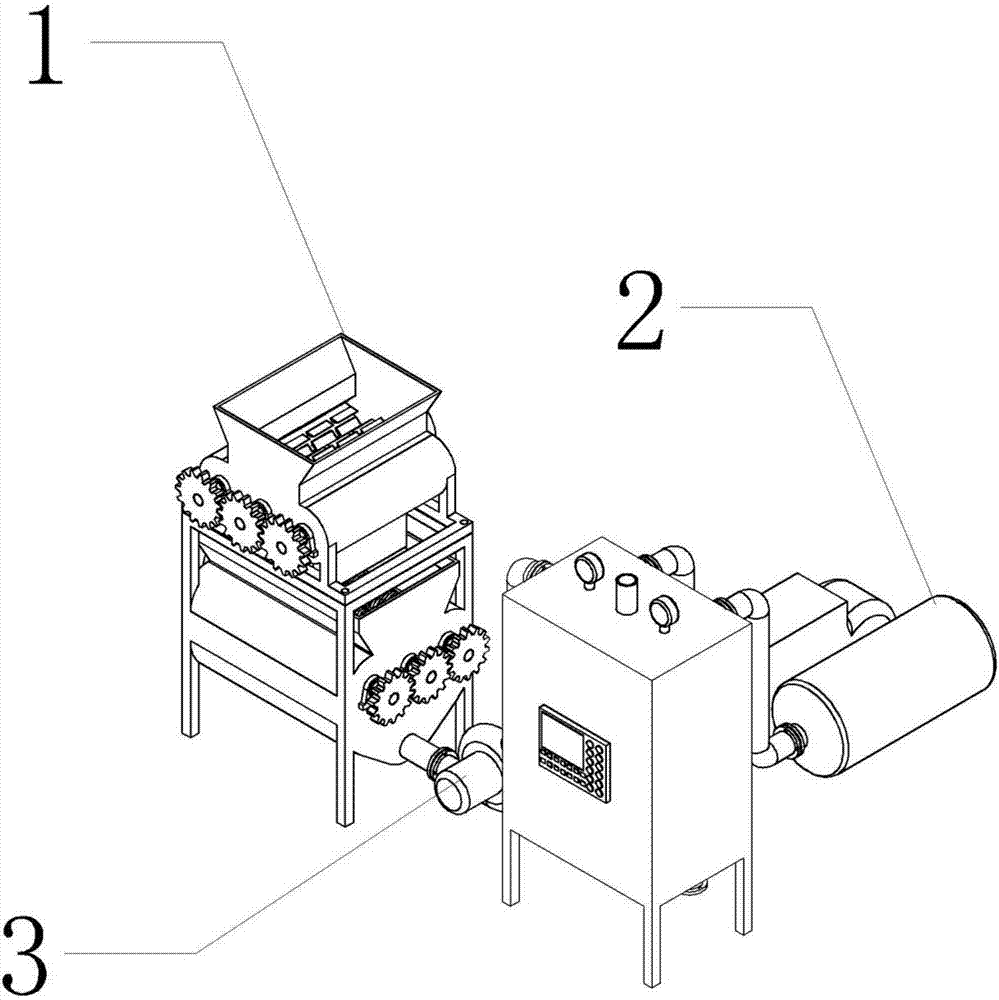

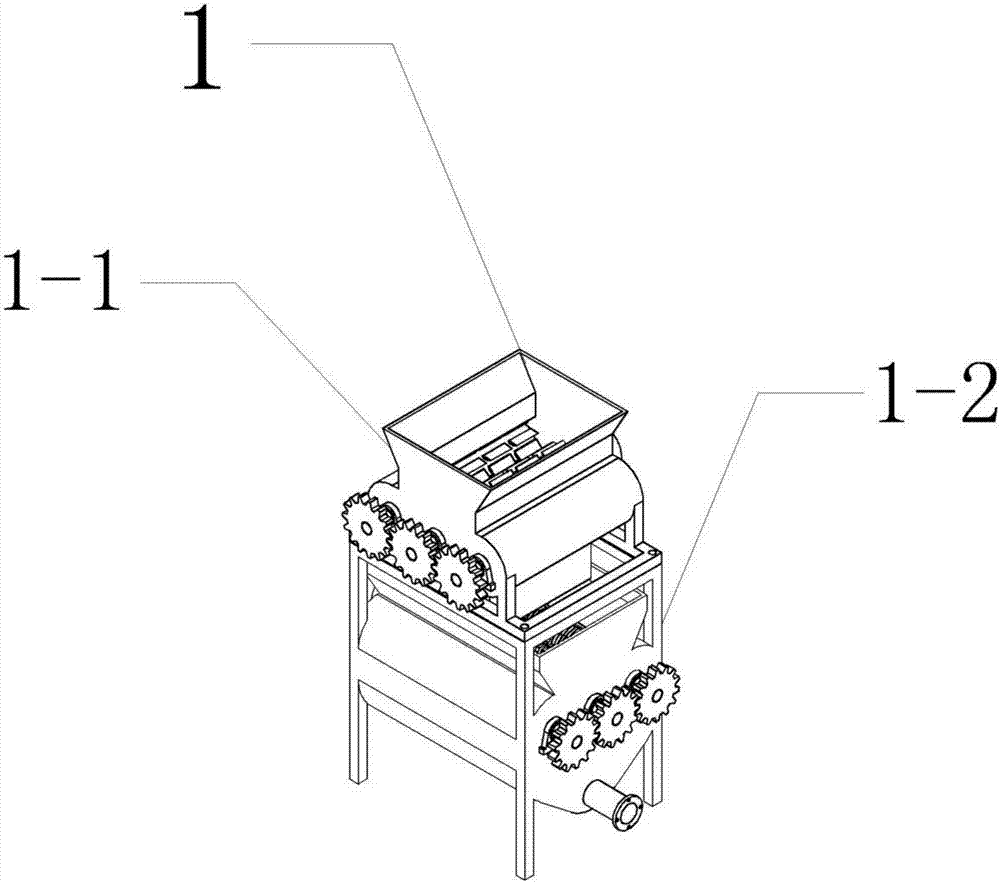

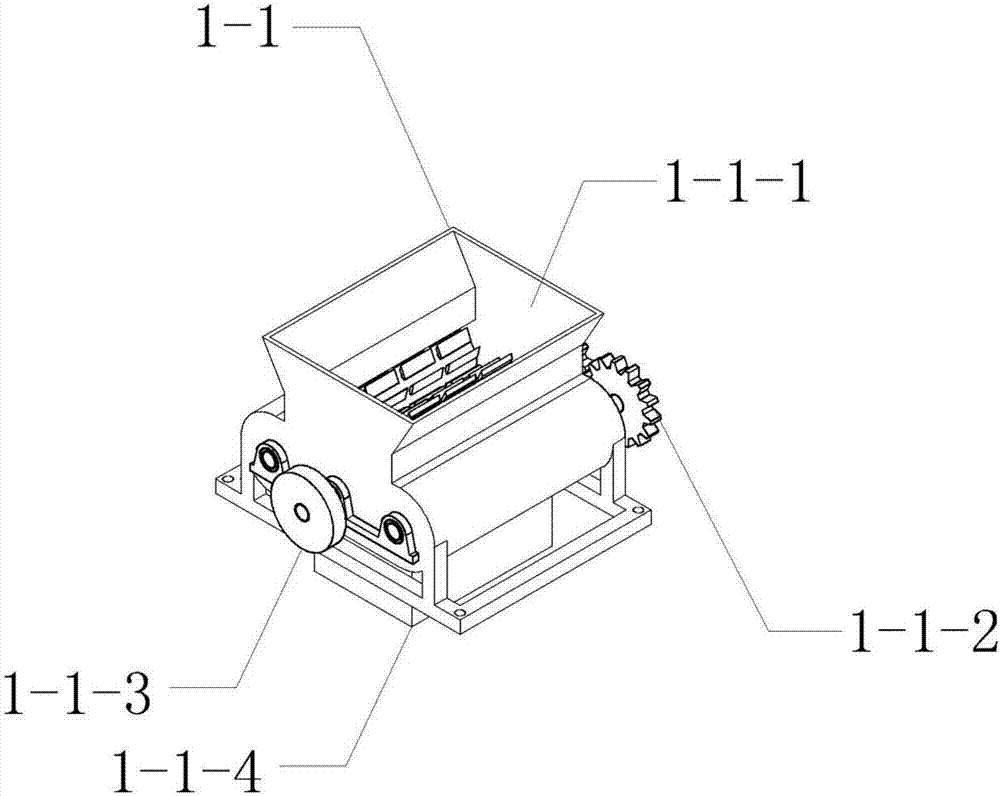

Special pulverizing and softening device for primary shaping of fungi blank

ActiveCN107185635AReduce duplication of effortLow pollution rateGrain treatmentsHorticultureNitrogenPulp and paper industry

The invention belongs to the technical field of processing device of edible fungi, and discloses a special pulverizing and softening device for primary shaping of fungi blank. The device consists of a pulverizing device, a softening device and a draught fan. By using the special pulverizing and softening device for primary shaping of fungi blank, integrated production equipment can be moved to a farmland, straw is pulverized and softened to be made into best raw materials for the fungi blank, so that repeated operations of transportation, pulverization, fermentation, turning and the like of the straw can be reduced; because the raw materials are not repeatedly transported and stored for a long time, the raw materials are fresh, impure fungi radix is few, and the quality of the product is high; the production can be completed in an enclosed tunnel so that the production is safe and reliable; by further completing automation of the equipment, the pollution rate of the raw materials can be reduced, and the labor cost is reduced; due to a pulverizing machine, disposable pulverization of the crop straw can be realized; due to the arrangement of the softening device, the pulverized pulverizing material is softened, so that the pulverizing material can be turned into feed with good palatability or a raw material of a fertilizer with high nitrogen content.

Owner:HUNAN AGRICULTURAL UNIV

High-cost-performance building technology with double-curvature-arch floors and energy-saving walls

InactiveCN103046769AObvious beneficial effectReduce indoor and outdoor heat exchange areaStrutsWallsReinforced concreteSteel bar

The invention provides high-cost-performance building technology with double-curvature-arch floors and energy-saving walls. The high-cost-performance building technology is characterized in that aerated concrete building block non-bearing heat preservation walls and right angular reinforced concrete load-bearing columns, T-shaped reinforced concrete load-bearing columns, cross-shaped reinforced concrete load-bearing columns and beam slabs with flat upper portions, double-curvature-arch lower portions, thin middle portions and thick peripheries form whole floors, wherein the aerated concrete building block non-bearing heat preservation walls are connected through the right angular reinforced concrete load-bearing columns, the T-shaped reinforced concrete load-bearing columns, the cross-shaped reinforced concrete load-bearing columns and the beam slabs. The high-cost-performance building technology is applicable to all light and livable units. Buildings built through the technology has the advantages of being energy-saving, environment-friendly, strong in structure, low in cost and large in effective use area.

Owner:丁文斗

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com